Grinding tool for glass finishing

A grinding tool and glass technology, applied in the field of glass processing abrasive tools, can solve problems such as lung injury, debris easily blocking the line of sight, and affecting the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

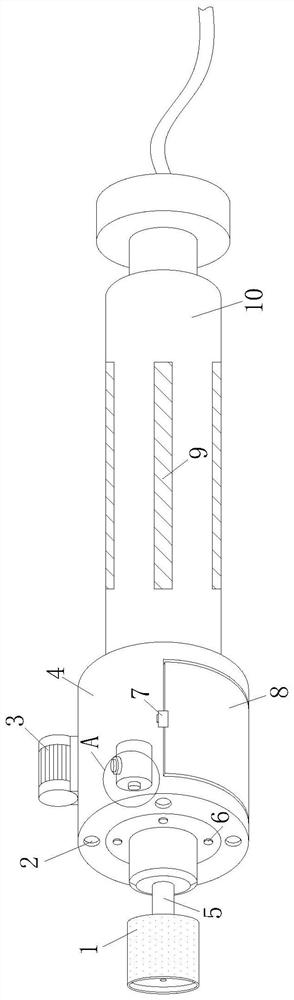

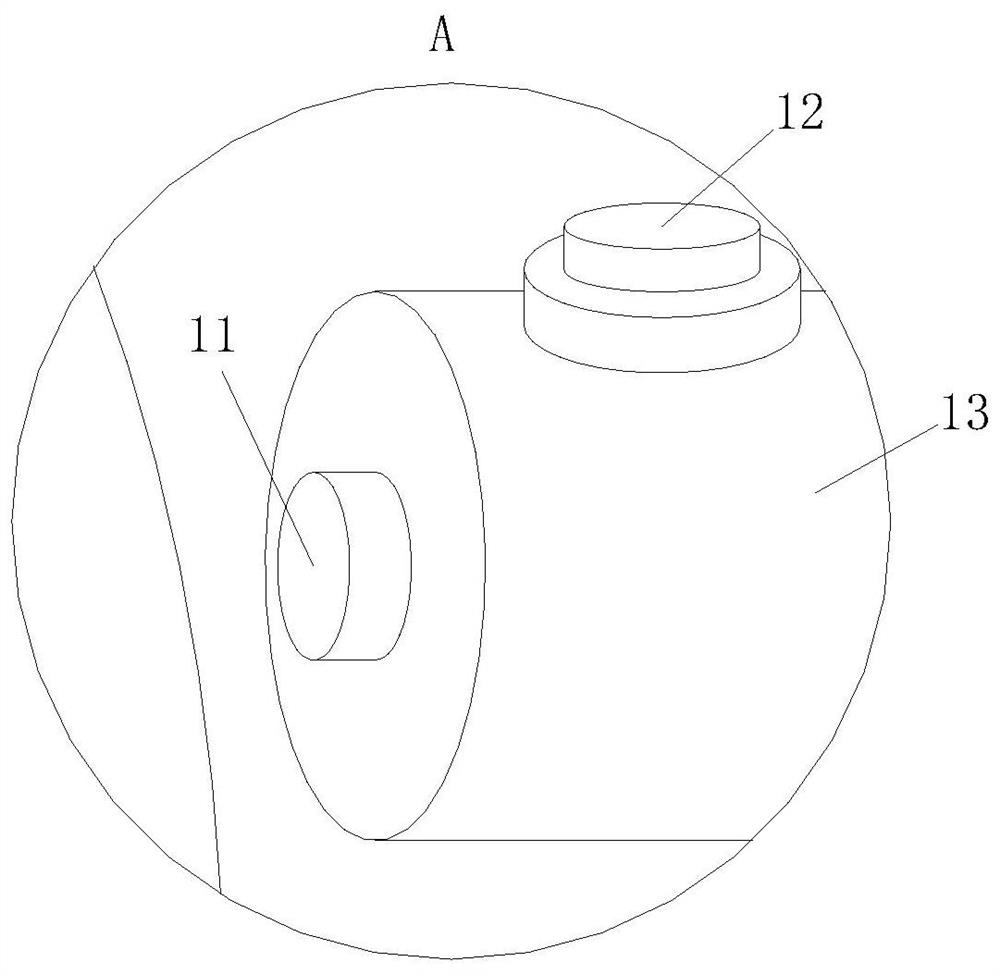

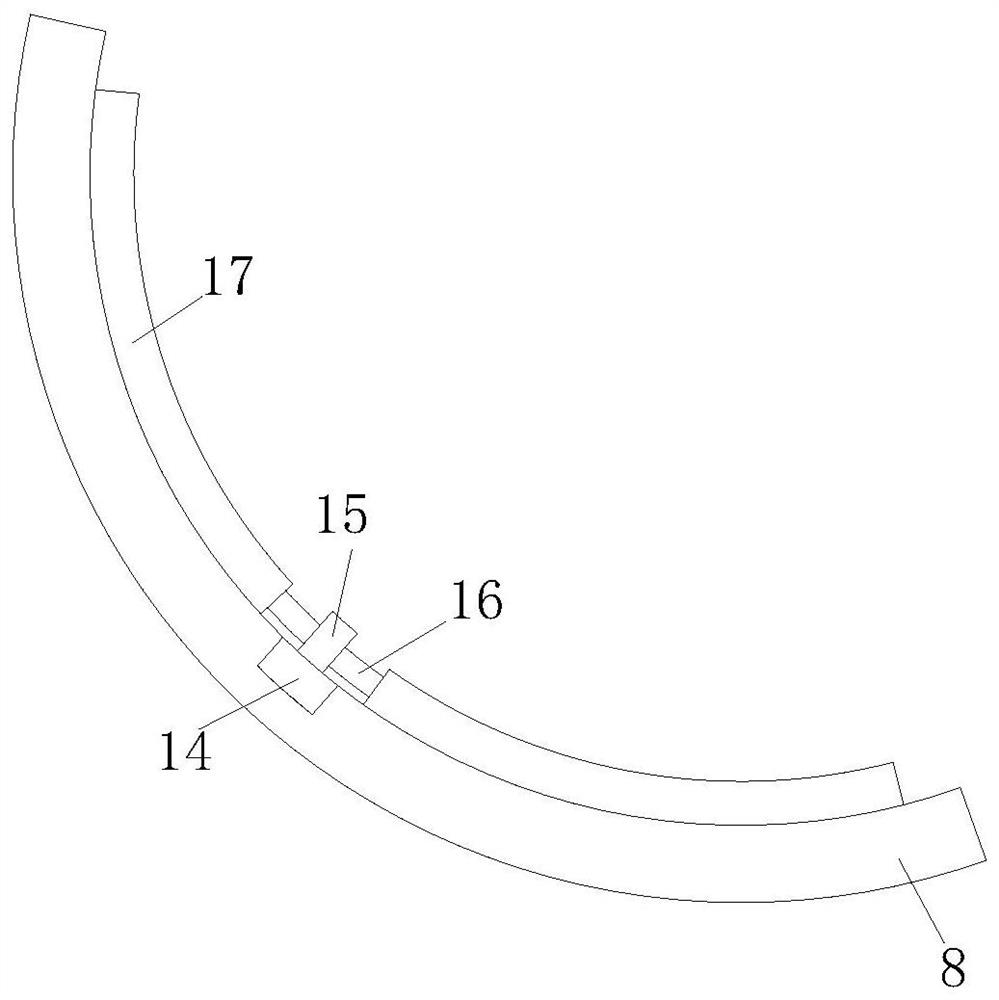

[0029] As a specific embodiment of the present invention, a number of uniformly distributed lighting lamps 6 are installed on the front end of the grinding machine body 10, and anti-skid lines 9 are provided on the outside of the grinding machine body 10; It is suitable for a dark environment and can be adapted to a bright environment, which is convenient for operators to observe the situation; at the same time, anti-skid lines 9 are set to prevent the polishing workers from dropping their hands in the process of polishing the glass rough edge, resulting in failure of the glass rough edge grinding, and more What's more, it causes the breakage of the glass.

[0030] Working principle: The turning handle 5 drives the grinding head 1 to rotate, thereby grinding the rough edge of the glass, and under the operation of the micro air pump 3, the waste generated during grinding is sucked through the adsorption hole 2, thereby reducing the damage to people's health , when cleaning, by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com