Patents

Literature

131results about How to "Play a lubricating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based lubricant and preparing method of the same based on nanometer tungsten disulfide

The invention discloses a water-based lubricant based on nanometer tungsten disulfide, which comprises the following components and contents, by weight, 1% to 15% of nanometer tungsten disulfide, 1% to 10% of solid lubricant, 0.2% to 3% of antirust agent, 10% to 40% of aqueous stearic acid, 10% to 20% of waterborne zinc stearate, 0.4% to 4% of emulsifying stabilizer, 0.01% to 0.05% of defoaming agent, and 8% to 77% of water. The constituent content of the components sums up to 100%. The preparing method of the water-based lubricant and a usage method thereof are disclosed. The water-based lubricant based on the nanometer tungsten disulfide has the advantages of being good in the lubrication effect of the water-based lubricant, large in elongation coefficient, environment-friendly and unpolluted, and wide in applying scope. In addition, the preparing method of the water-based lubricant and the use method and process steps thereof are simple and fast so as to improve the production efficiency and benefit the environmental protection.

Owner:HENAN HUIER NANO TECH

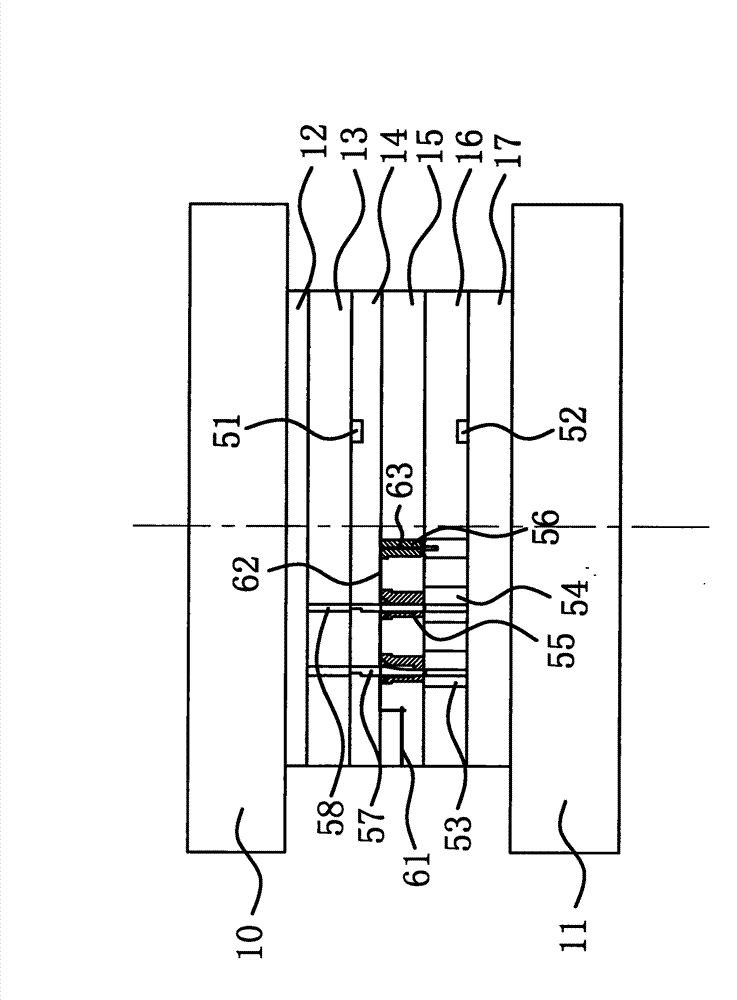

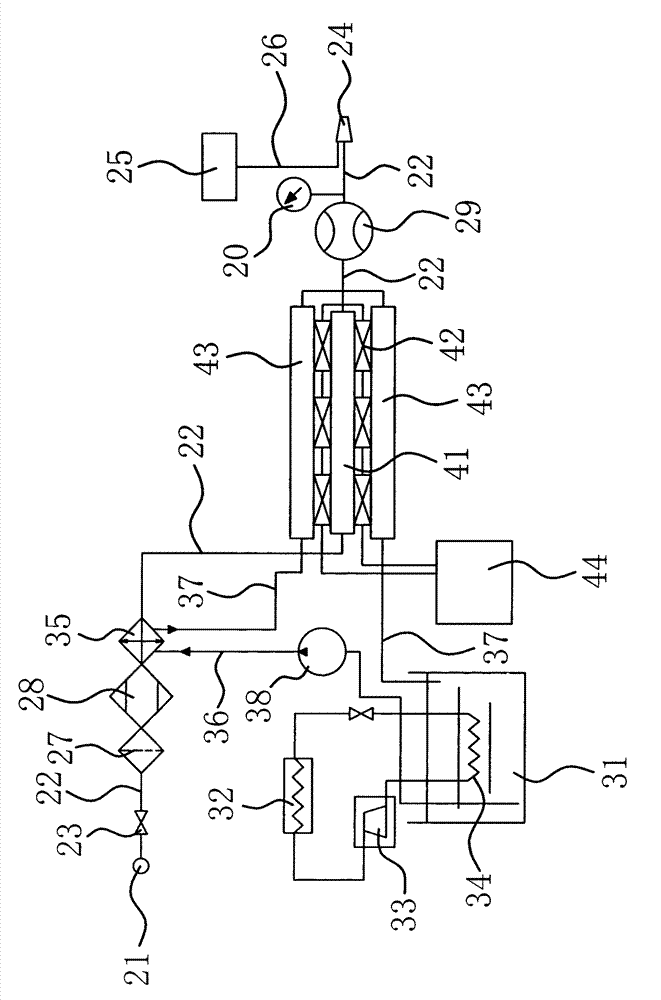

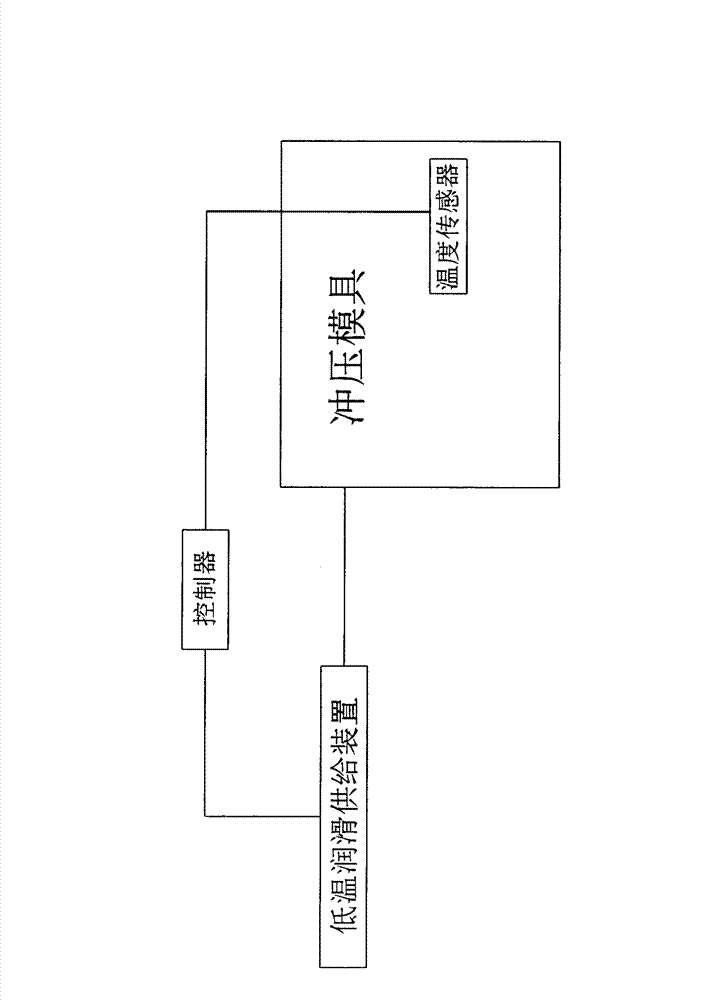

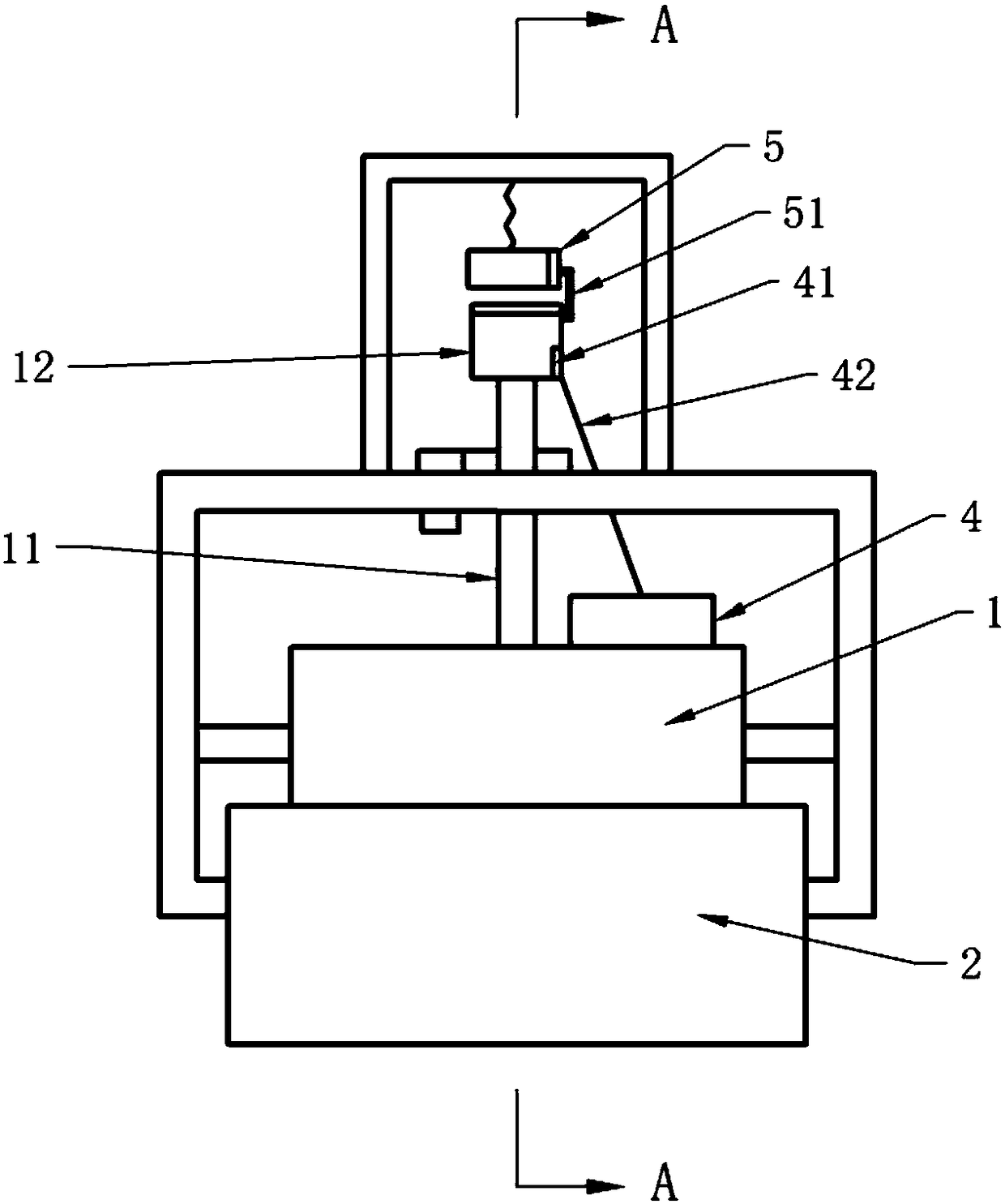

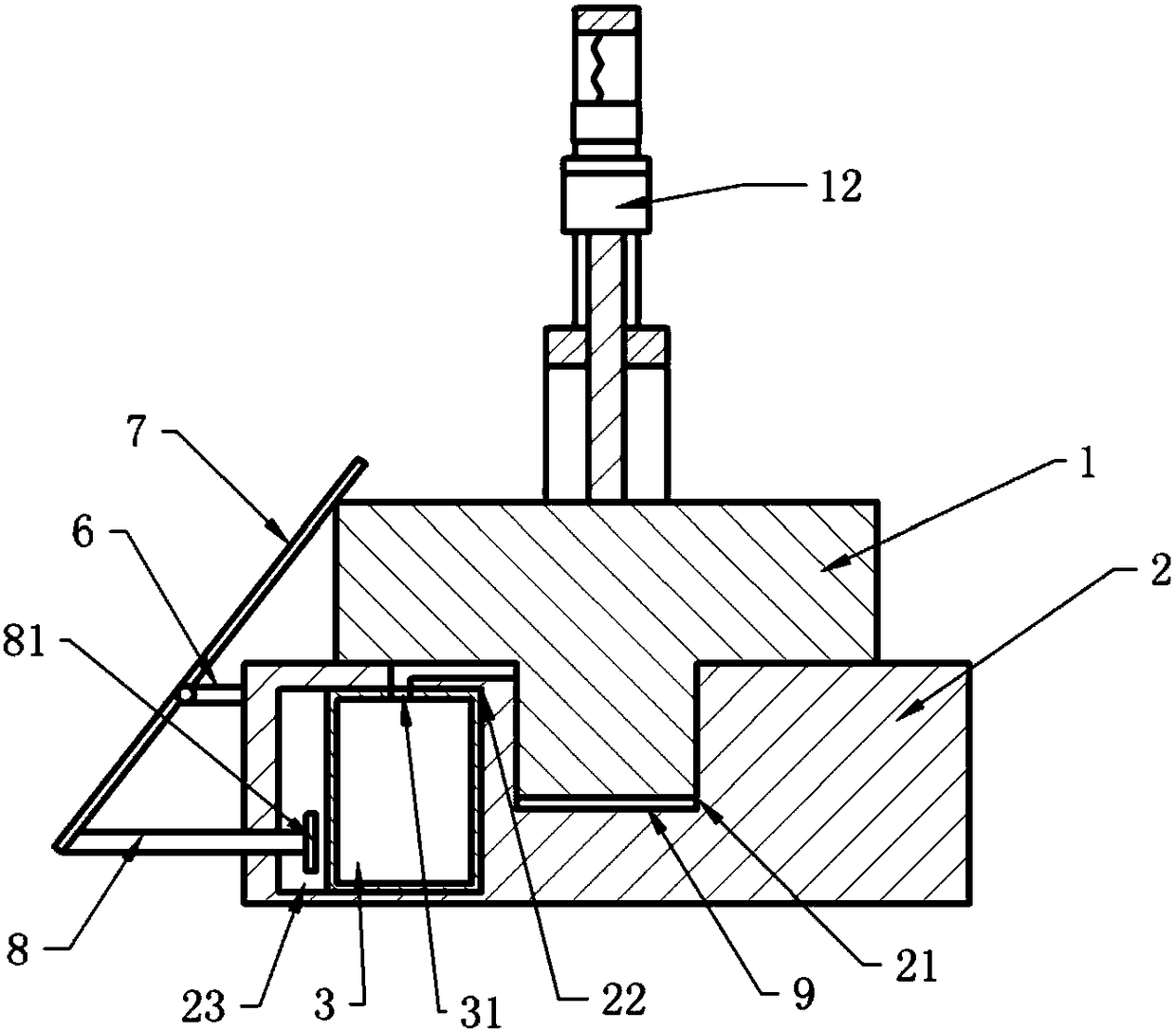

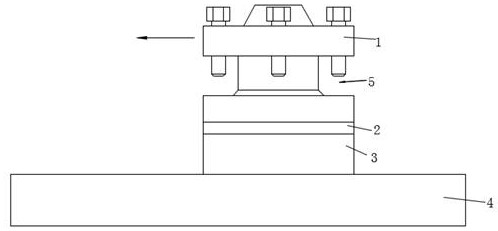

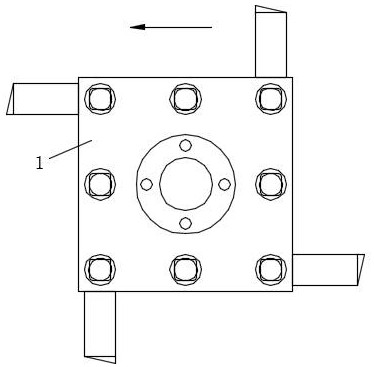

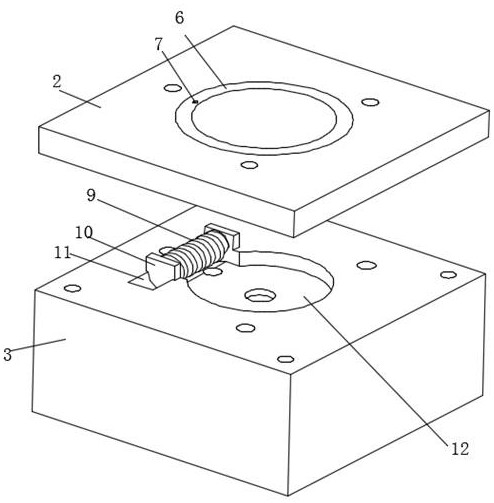

High speed stamping die with low temperature lubricating structure

InactiveCN102921818AReduce deformation or damageExtended service lifeShaping toolsStamping processLubrication

The invention provides a high speed stamping die with a low temperature lubricating structure and belongs to the technical field of dies. The invention solves the problems of bad cooling effect, bad lubricating effect and short service life of the current stamping die. The high speed stamping die with the low temperature lubricating structure comprises an upper die holder and a lower die holder, wherein a forming plate group composed of an upper die lining plate, a punch fixing plate, a discharge lining plate, a discharging plate, a lower template and a lower die lining plate is arranged between the upper die holder and the lower die holder, a forming assembly is arranged in the forming plate group, an oil gas path communicated with the forming assembly is arranged between the forming plate groups, and the inlet of the oil gas path is connected with a low temperature lubrication feeding device. The low temperature lubrication feeding device mixes and atomizes low temperature compressed air and micro-lubricating oil to form low temperature gas-liquid two-phase stream, and the low temperature gas-liquid two-phase stream is jetted to a stamping processing region through a gas channel so as to permeate the low temperature cold air to a stamping processing contact interface with oil particles atomized by the micro-lubricating oil to play a lubricating effect and effectively take away the heat generated during the stamping process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

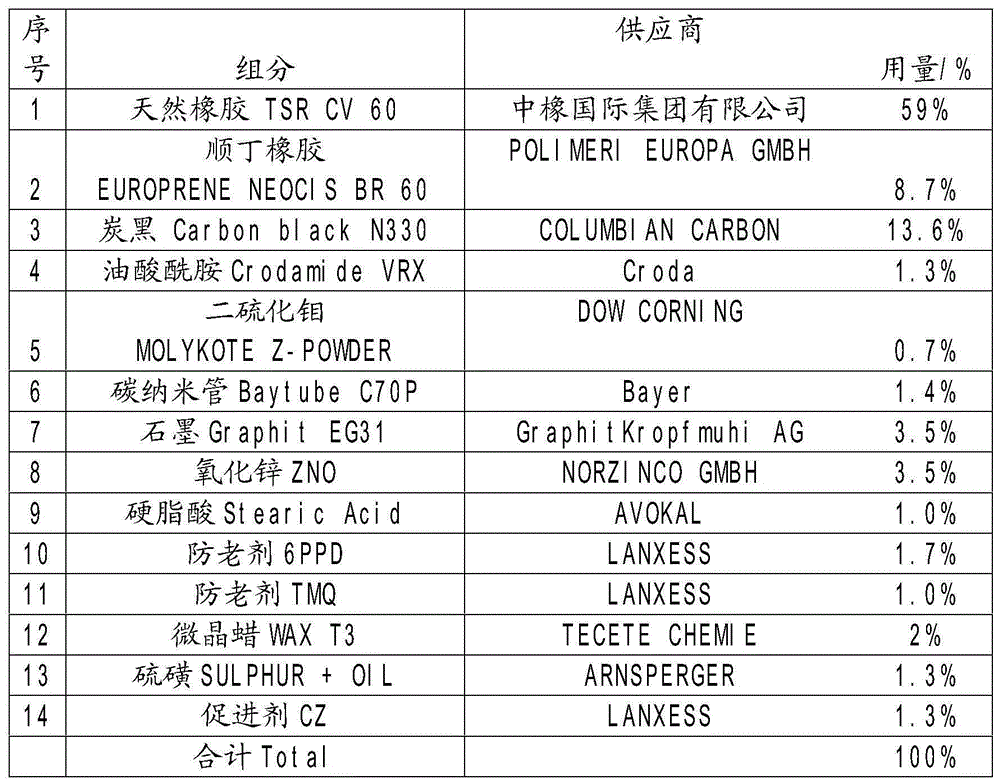

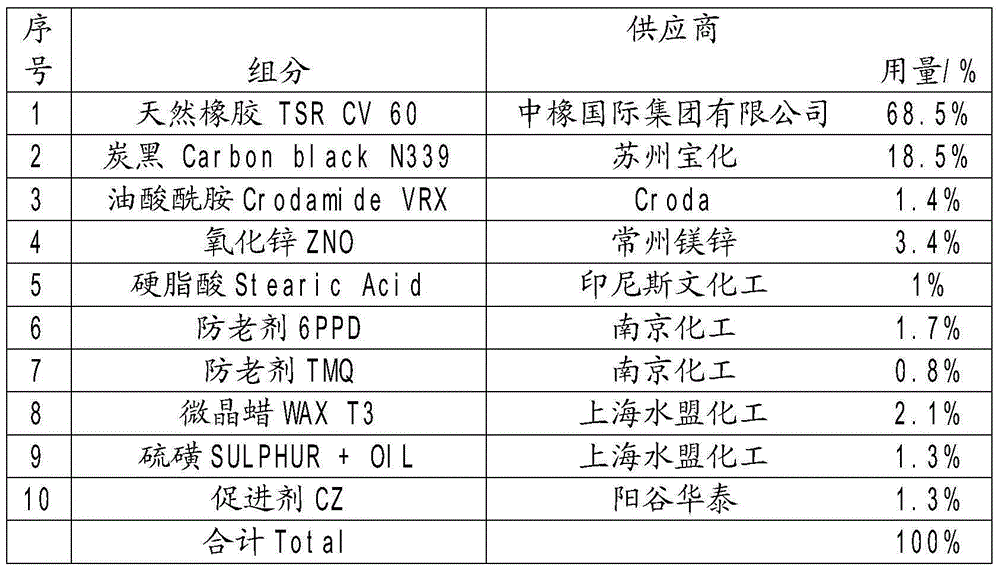

Rubber with self-lubricating effect for lining and preparation method of rubber

ActiveCN105295120AExcellent abrasion resistancePlay a lubricating effectVegetable oilMicrocrystalline wax

The invention discloses rubber with a self-lubricating effect for a lining. The rubber is prepared from the following components in percentage by weight: 55 to 59 percent of natural rubber, 7 to 14 percent of butadiene rubber, 0.7 to 2 percent of refined vegetable oil oleamide, 0.7 to 2 percent of molybdenum disulfide, 0.7 to 2 percent of carbon nano tubes, 3.5 to 4.1 percent of graphite, 3.2 to 3.5 percent of zinc oxide, 1 percent of stearic acid, 1 to 1.7 percent of antioxidant 6PPD, 1 percent of antioxidant TMQ, 2 percent of microcrystalline wax, 13.1 to 13.8 percent of carbon black N 330, 1.3 to 1.4 percent of sulfur grundum and 1.0 to 1.3 percent of accelerant CZ. The rubber for the lining, disclosed by the invention, has quadruple sustained releasing functions and is suitable for the lining of a self-lubricating high-end car; the problem that common self-lubricating rubber easily fails in lubricating can be solved, and the abrasion resistance of the rubber is increased; by combining specific situations of rubber abrasion at different stages, the service life of rubber and lining products can be prolonged. Meanwhile, the invention provides a preparation method of the rubber with the self-lubricating effect for the lining.

Owner:BOGE ELASTMETALL SHANGHAI CO LTD

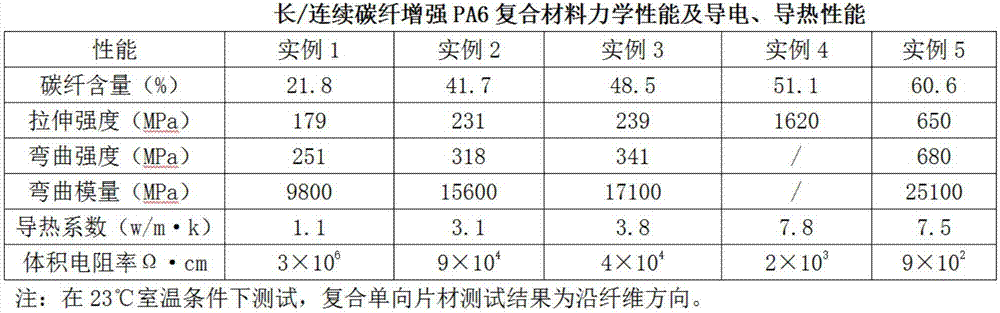

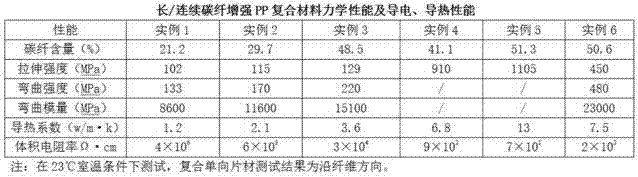

Continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity, and preparation method thereof

InactiveCN106939124AImprove conductivityHigh thermal conductivityHeat-exchange elementsFiberCarbon fibers

The invention relates to a continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity, and a preparation method thereof. The composite comprises, by weight, (1) 100 parts of PA6 resin, (2) 0.2 to 1 part of an anti-oxidant, (3) 0.2 to 1.2 parts of a flow promoter, (4) 2 to 10 parts of a flexibilizer and (5) 1 to 5 parts of a compatilizer. The preparation method comprises the following steps: premixing the above components according to a certain ratio, carrying out melting and mixing via a double / single-screw set and then extruding the obtained mixture into a die head for flow splitting and impregnation so as to prepare the continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity. Compared with conventional staple carbon fiber-reinforced PA6 composites, the continuous carbon fiber-reinforced PA6 composite prepared by using a special impregnation process in the invention has greatly improved mechanical properties since the length retention rate of carbon fibers in a PA6 carrier is high or continuous and has substantially improved electrical conductivity and thermal conductivity due to a continuous network structure, so the application range of the composite is greatly broadened.

Owner:浙江胜钢新材料有限公司

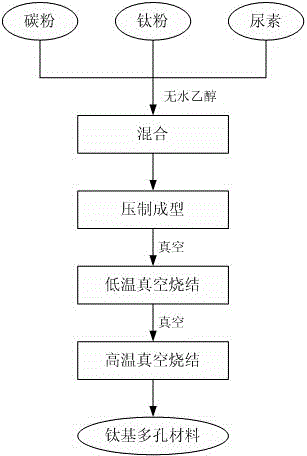

Preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials

The invention discloses a preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials. A powder metallurgy pore forming substance technology is used, and urea, carbon powder and titanium powder are used for being subjected to mixing, pressing forming and sintering to prepare the titanium-based multi-hole composite materials. The urea is used as a pore forming substance. Absolute ethyl alcohol is used as binding agents. Components of the titanium-based multi-hole materials are easy to control. Meanwhile, the advantage that raw material cost is low is achieved. A two-stage type sintering process is used for reducing energy consumption, equipment cost is lowered, and benefit is improved. In addition, the titanium-based multi-hole composite materials prepared with the preparing method of the in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials are high in intensity, good in comprehensive mechanical property and high in anti-corrosion performance, the durability of the titanium-based multi-hole composite materials is improved, a new technology path is provided for sewage purification, biology implant materials and the like, and great application prospect is achieved.

Owner:CHONGQING UNIV

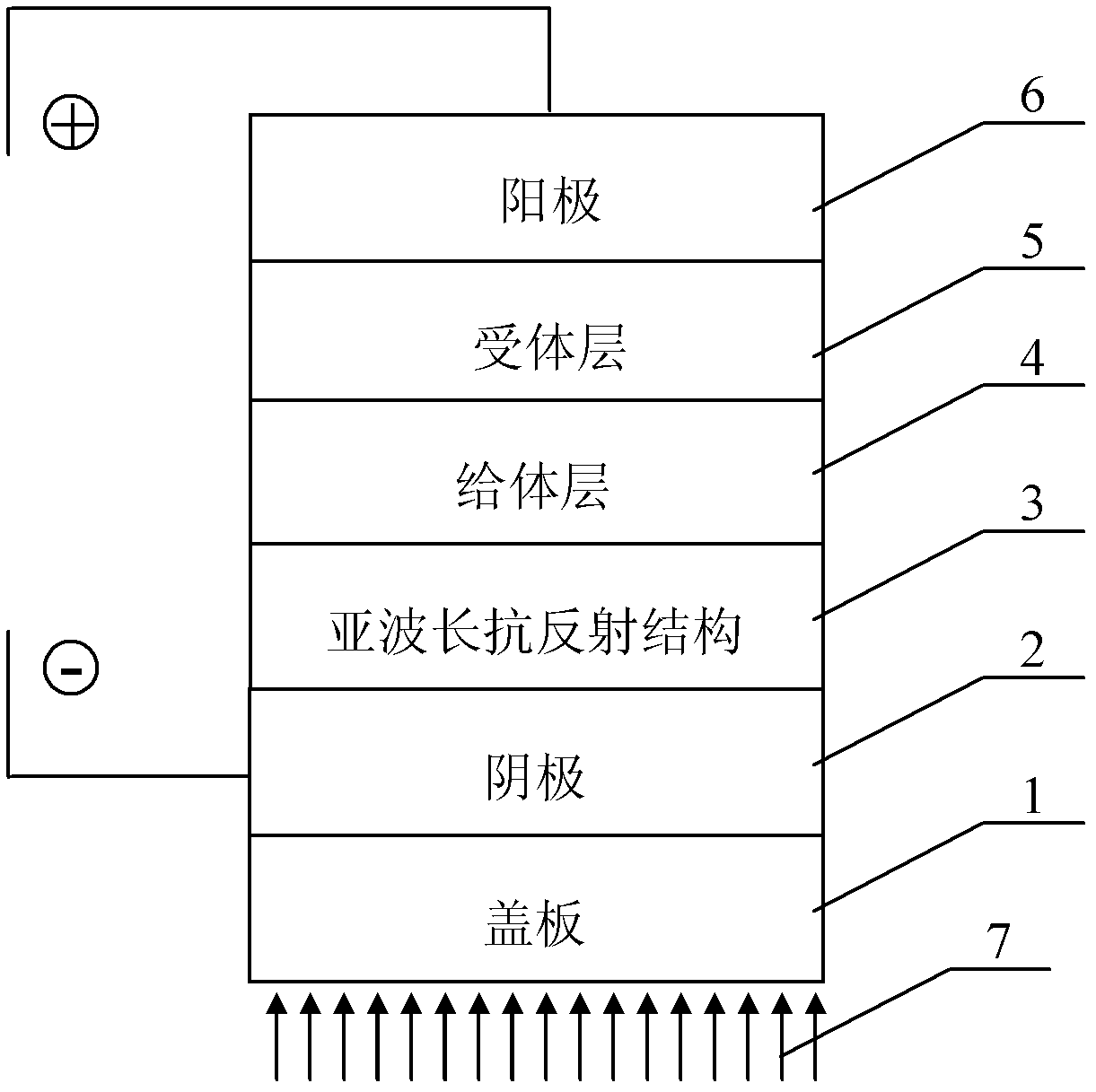

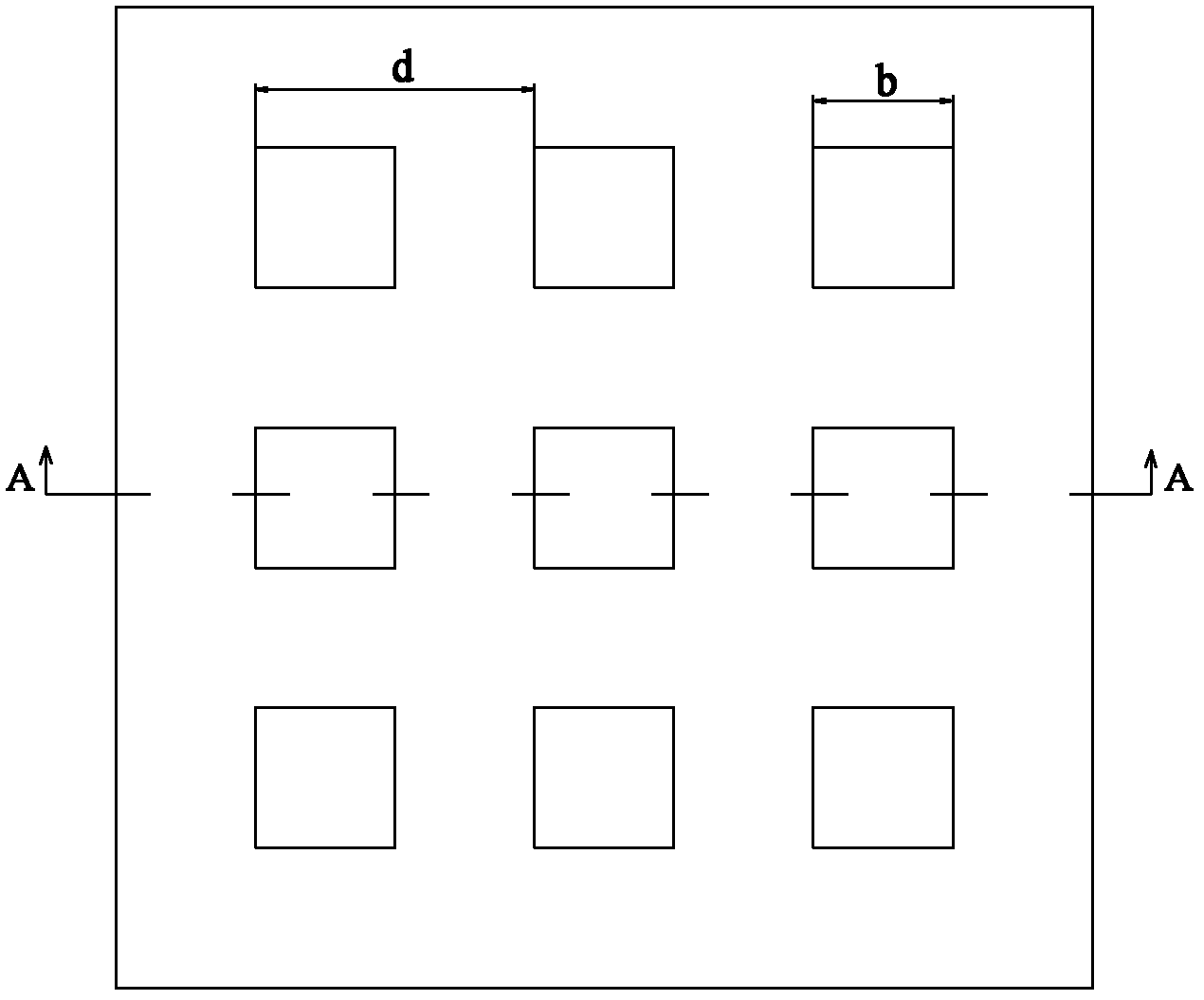

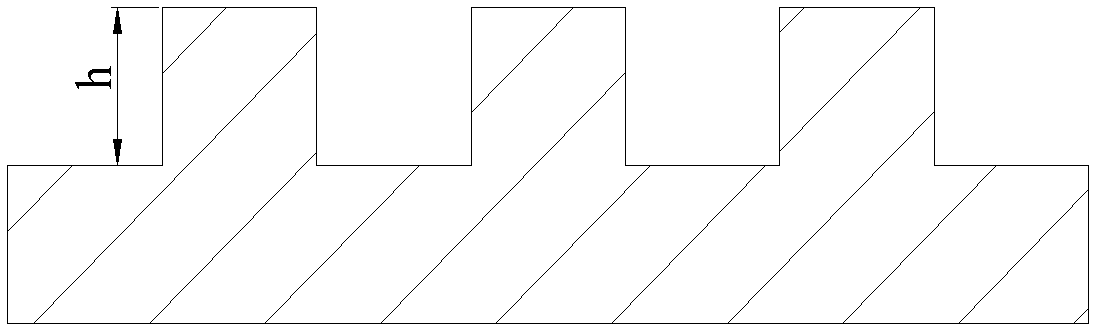

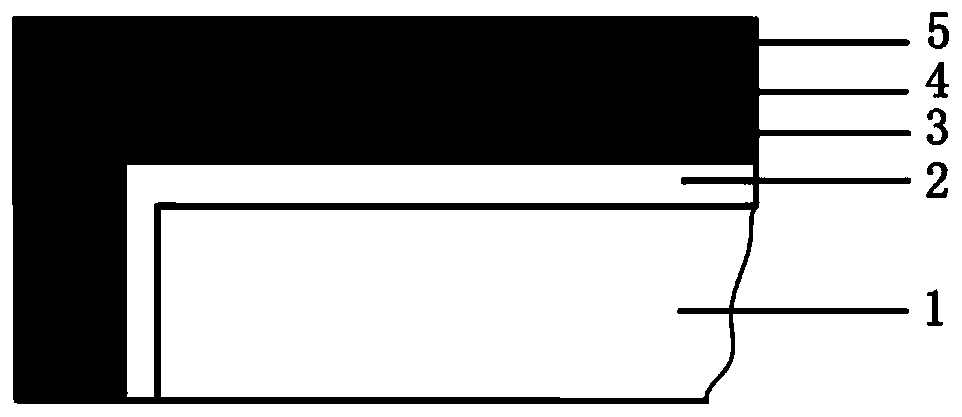

Polymer solar cell with subwavelength anti-reflective structure and manufacturing method for polymer solar cell

InactiveCN102544376AHigh light conversion efficiencyReduce reflexesFinal product manufactureSolid-state devicesConductive polymerLight beam

The invention discloses a polymer solar cell with a subwavelength anti-reflective structure. The polymer solar cell comprises a cover plate, a cathode, a donor layer, an acceptor layer and an anode, wherein the donor layer is a conducting polymer layer; the subwavelength anti-reflective structure is arranged on one side of the conducting polymer layer which is close to the cathode and comprises a plurality of bulges of which the structure sizes are less than or equal to 400 nanometers*400 nanometers*400 nanometers; and by the subwavelength anti-reflective structure, the reflective action of light is weakened greatly, and light beams are constrained effectively, so that the light conversion efficiency of the polymer solar cell is improved. The invention also discloses a method for preparing the polymer solar cell with the subwavelength anti-reflective structure. High rigidity among conjugated molecular chains in a conducting polymer is reduced and the flow characteristic of the conducting polymer is improved by an ultrasound field by a processing method for ultrasound composite thermal transfer print, so that the impressing quality is higher. The method is low in processing cost and efficient in processing and has a bright application prospect, and the polymer solar cell is easy to produce industrially.

Owner:ZHEJIANG UNIV

High-strength antistatic alloy and preparation method thereof

The invention discloses a high-strength antistatic alloy and a preparation method thereof. a PC (Polycarbonate) / PBT (Polybutylece Terephthalate) alloy is prepared from the following raw materials in parts by weight: 50 to 80 parts of PC, 20 to 40 parts of PBT, 8 to 18 parts of antistatic filler, 3 to 11 parts of compatibilizer, 0.05 to 0.3 part of ester exchange inhibitor, 0.2 to 0.6 part of antioxidant, 0.2 to 0.6 part of lubricating agent and 0.1 to 0.5 part of ultraviolet absorbent. According to the high-strength antistatic alloy disclosed by the invention, the PC / PBT alloy is subjected to blending modification by adopting assistants such as the compatibilizer, the ester exchange inhibitor and the antistatic filler, so that a prepared alloy system has the advantages of respective excellent properties of the PC and the PBT baste materials, excellent antistatic property, high strength, small warp, good dimensional stability, good processing fluidity and excellent chemical solvent resistance, and further the high-strength antistatic alloy can be widely applied to the fields of automobiles, household appliances, illumination, electronic communication and the like.

Owner:DONGGUAN HONOUR E P

Die for car interior part

ActiveCN108188274ARealize automatic demouldingImprove demoulding efficiencyShaping toolsEngineeringMechanical engineering

The invention belongs to the technical field of die for car parts processing, and discloses a die for a car interior part. The die for the car interior part comprises an upper male die and a lower female die; the lower female die is provided with a support formed by a cross plate and two vertical plates; the upper male die is provided with an electromagnet and a sliding rod penetrating through thecross plate; the cross plate is provided with a drive piece; the top portion of a sliding rod is provided with a support block; the lower portion of the side wall of the support block is provided with a conducting strip; an electric lead is arranged between the conducting strip and the electromagnet; the cross plate is provided with a support frame; a communicating block is arranged between the support frame and the cross plate; an elastic piece is arranged between the top potion of the communicating block and the bottom of the support frame; the communicating block is provided with a power source; the power source is provided with a conductive needle; one end, away from the power source, of the conductive needle is connected with the side wall provided with the conducting strip of the support frame in a sliding mode; the lower female die is internally provided with a cavity; and the cavity is internally connected with an iron block in a sliding mode. The die for the car interior partsolves the problem that the interior parts are tightly attached with the lower die after impact molding to the interior parts in the prior art, leading to the difficulty of removing the car interiorparts.

Owner:CHONGQING YINSHENG MOLD

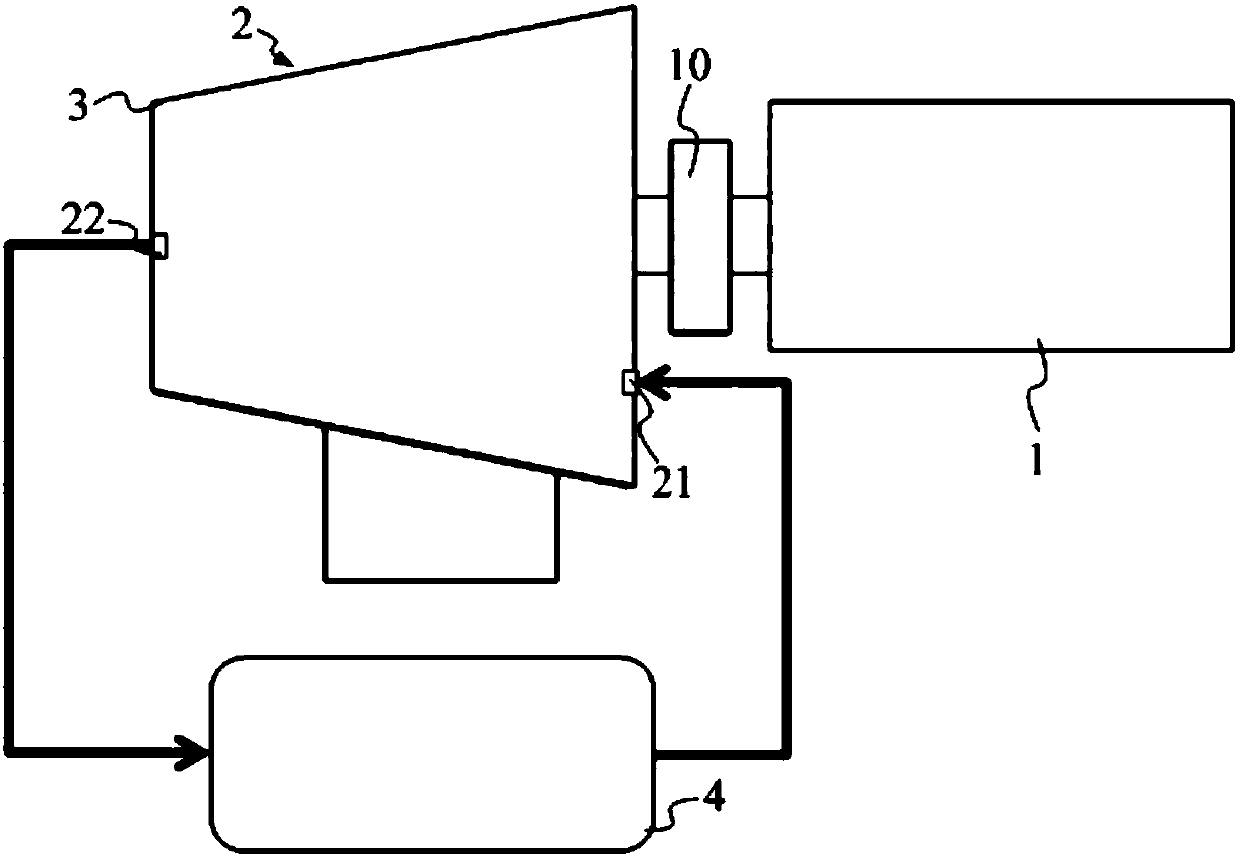

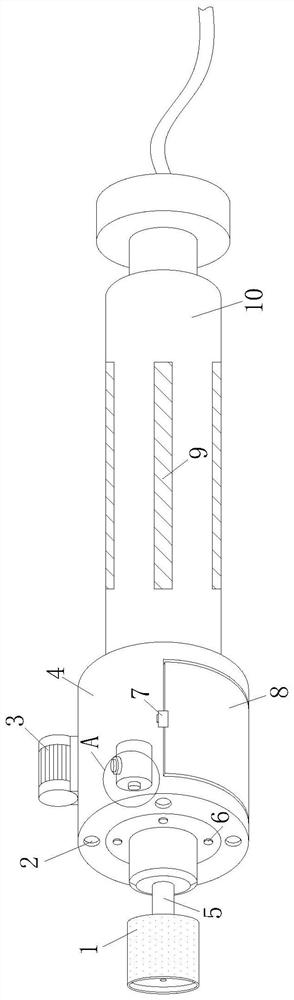

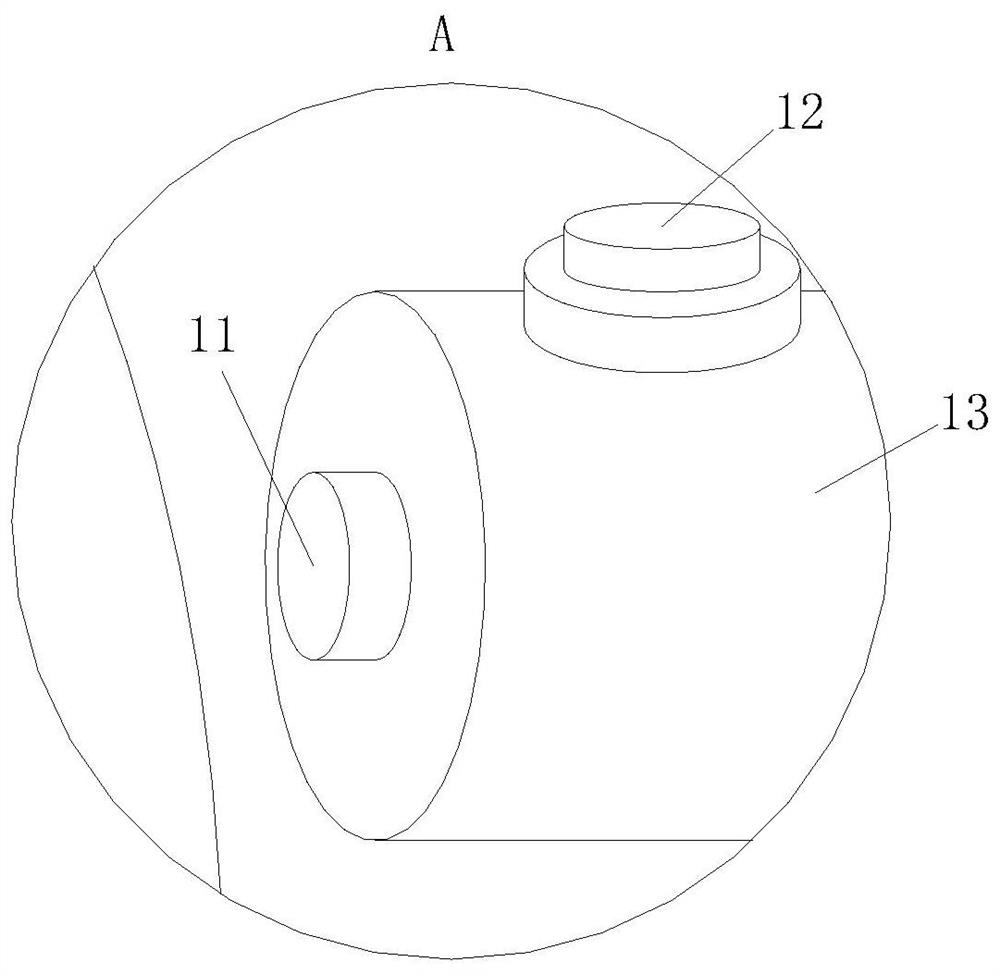

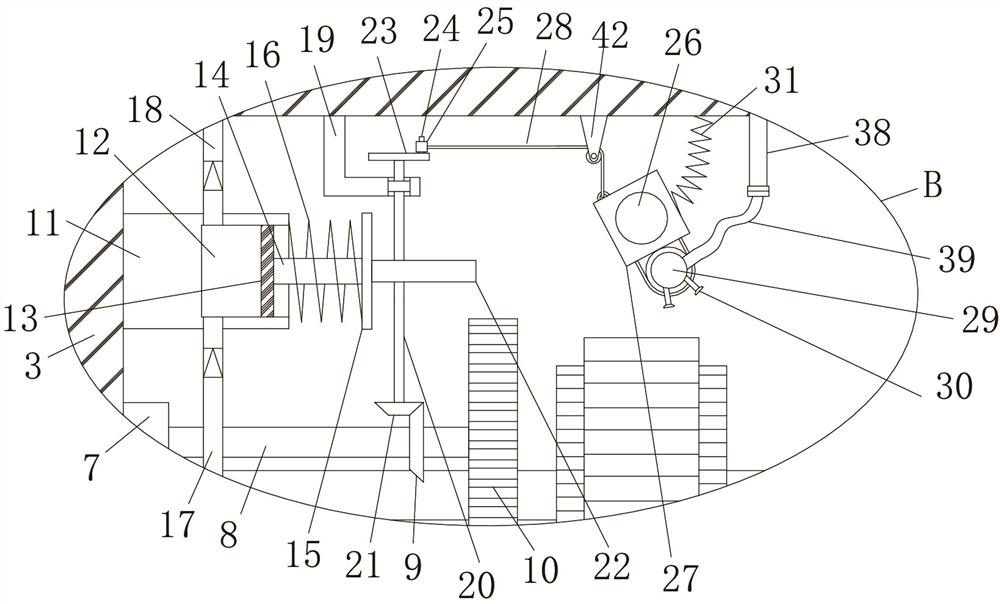

Gearbox lubricating test device and measuring device for lubricating oil injection quantity

InactiveCN107687946APlay a lubricating effectOptimal Solution for Filling VolumeMachine gearing/transmission testingCapacity measurement calibrationPetroleum engineeringVariator

Owner:SAIC MOTOR

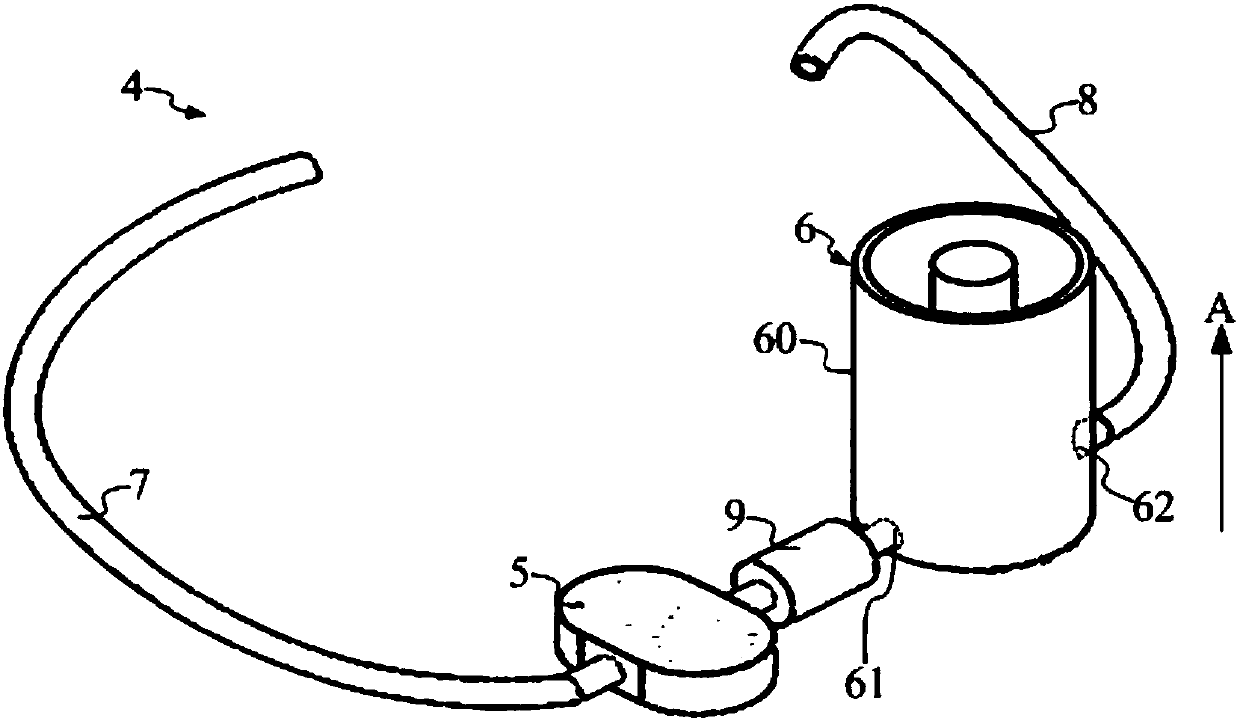

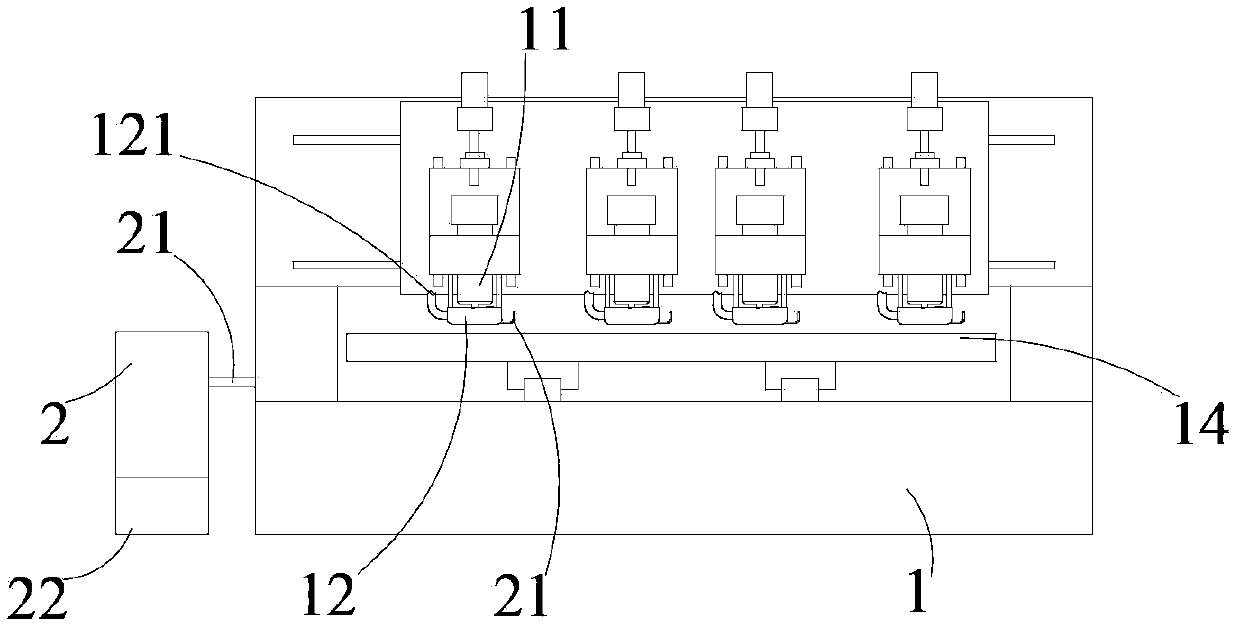

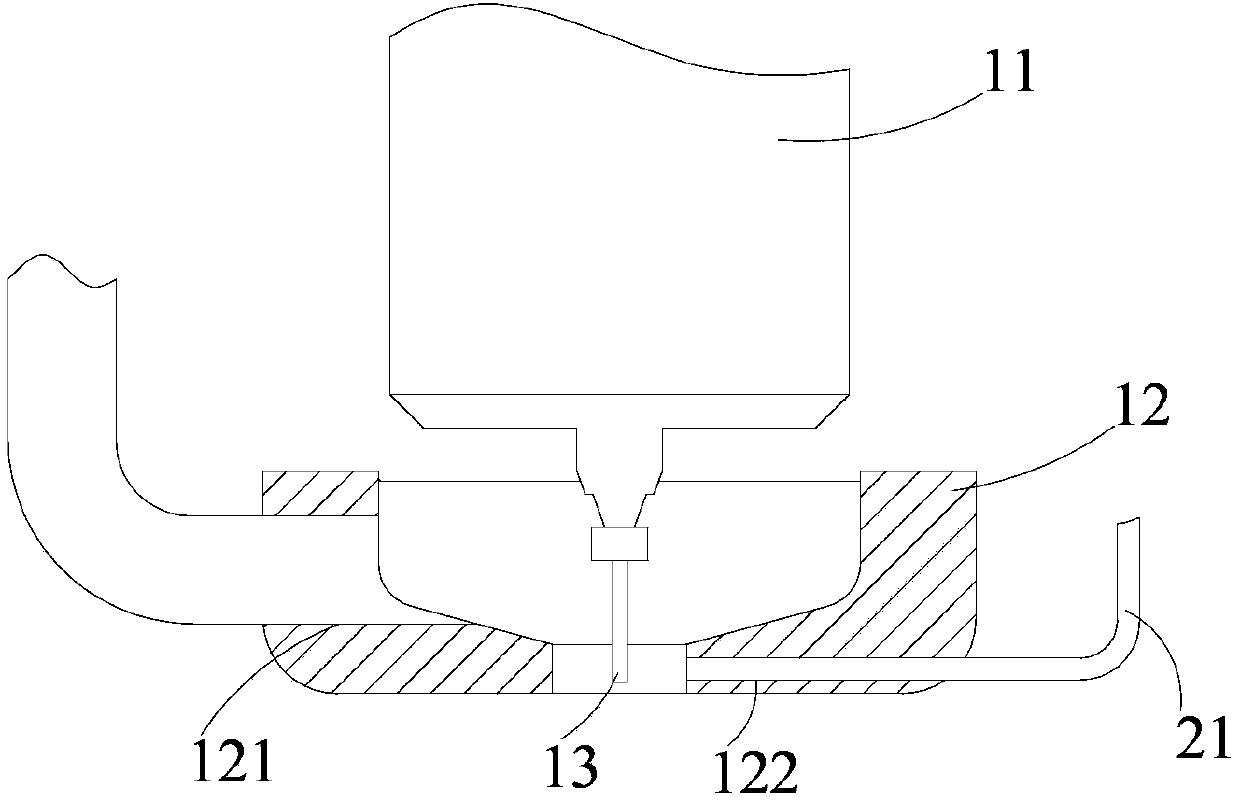

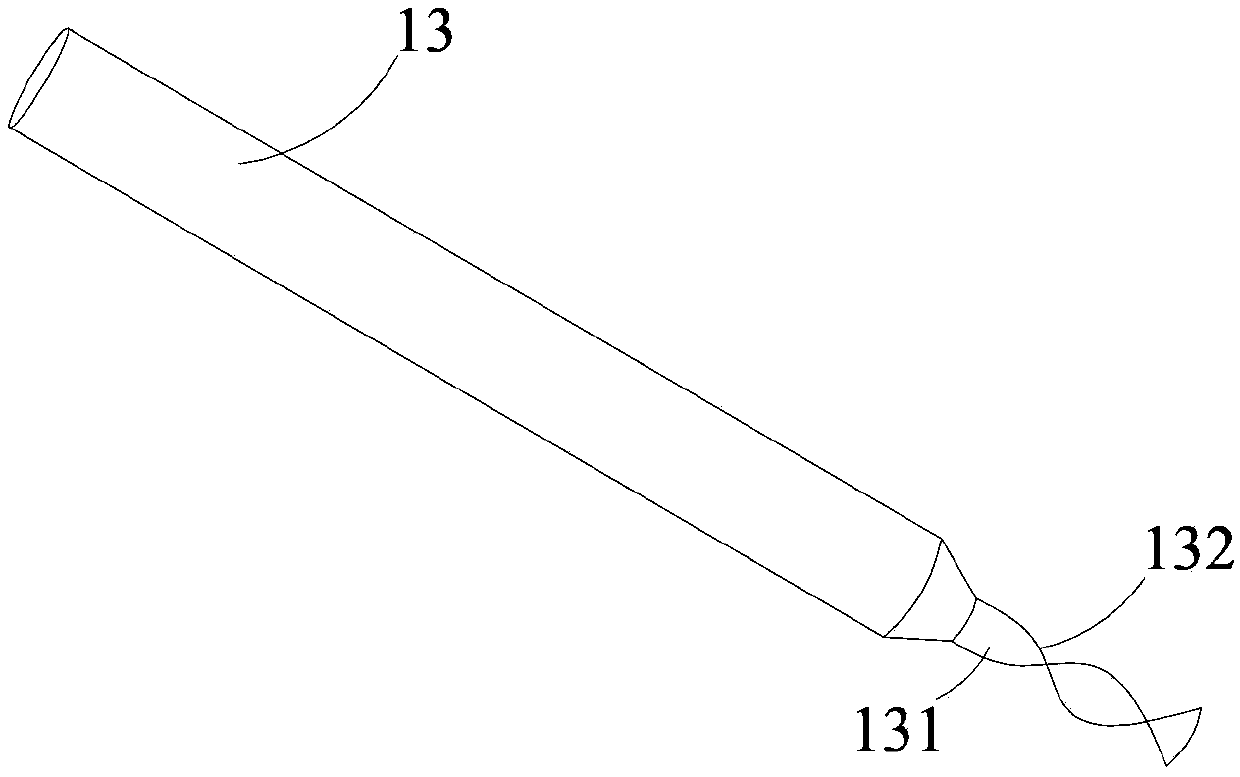

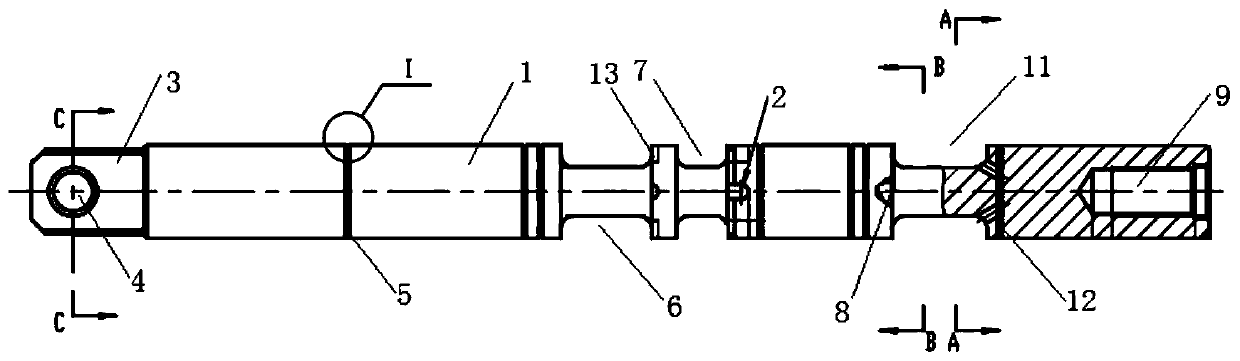

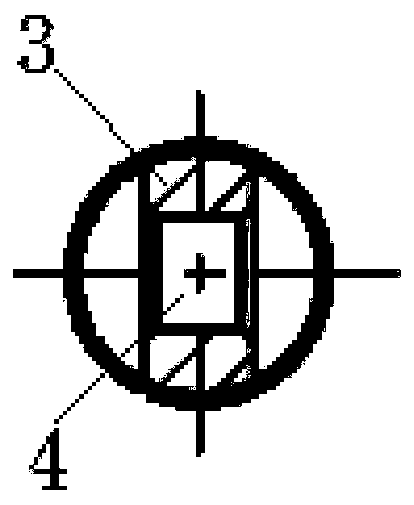

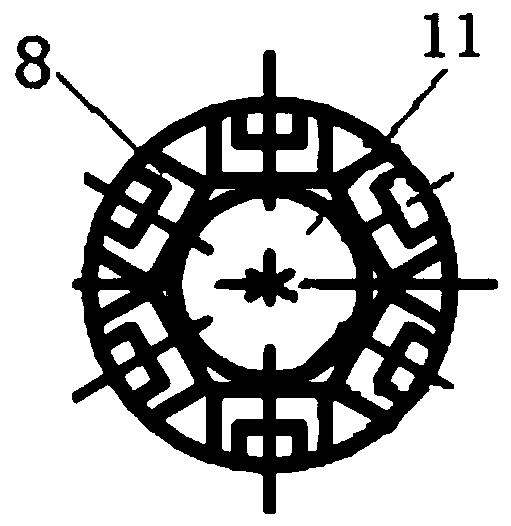

Micro hole processing device and micro hole processing method

ActiveCN104174898AMeet speed requirementsPlay a lubricating effectTransportation and packagingWorkpiecesElectric controlDrill

The invention relates to drilling processing, and provides a micro hole processing device. The micro hole processing device comprises a high speed drill, wherein the high speed drill comprises a plurality of main shafts, a plurality of chipping suction covers, an electric control system and a cooling device, each chipping suction cover is provided with a dust collection pipeline, the cooling device is provided with a plurality of liquid guiding pipes, each chipping suction cover is provided with a liquid guiding pipeline, and each liquid guiding pipe stretches into the corresponding chipping suction cover along the corresponding liquid guiding pipeline. The invention also provides a micro hole processing method. The micro hole processing device is adopted by the micro hole processing method, and the rotating speed of a drilling tool is 15-120 Krpmin, and the feed amount of the drilling tool is 0.01-0.4 m / min. According to the micro hole processing device and the micro hole processing method, provided by the invention, the high speed drill is additionally provided with the cooling device, cooling liquid is guided into the chipping suction covers through the liquid guiding pipes, cooling and lubricating effects on the drilling tool can be formed, the broken rate of the drilling tool is greatly reduced, liquid accumulation is unlikely formed on a working platform, the rotating speed and the range of the feed amount of the drilling tool are limited when a micro hole is further processed, the drilling requirement can be met, and the broken rate of the drilling tool can be further reduced.

Owner:HANS CNC SCI & TECH

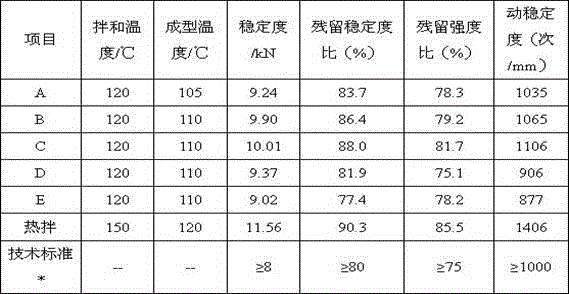

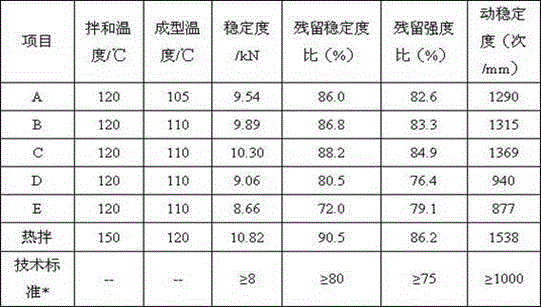

Zwitter-ion and nonionic composite asphalt warm-mixing agent and preparation method thereof

ActiveCN104559251AReduce high temperature viscosityImprove performanceClimate change adaptationBuilding insulationsHydrogenAsphalt

The invention discloses a zwitter-ion and nonionic composite asphalt warm-mixing agent and a preparation method thereof. The zwitter-ion and nonionic composite asphalt warm-mixing agent comprises in percentage by weight: 0.1-20% of zwitter-ion components, 0.1-20% of macromolecule nonionic components, 0.1-15% of low-molecular-weight nonionic components, 0.1-3% of acid catalysts and 42-99.6% of water. The preparation method comprises the following steps: the water is added into a container in the proportion, the temperature is controlled to range from 40 DEG C to 60 DEG C, the macromolecule nonionic components are added, a mixture is stirred for 0.5-2 hours at a constant temperature and then heated to 60-80 DEG C, the low-molecular-weight nonionic components and the zwitter-ion components are added in the proportion and are respectively stirred for 0.5-1 hours, the acid catalysts are added so that a pH (potential of hydrogen) can be adjusted to be 5-7, and the composite asphalt warm-mixing agent is obtained. The zwitter-ion and nonionic composite asphalt warm-mixing agent can effectively reduce high-temperature viscosity of the asphalt, improves the anti-peeling performance of the asphalt and stone and has the advantages of good compounding performance, stable performance, easiness of collection of the raw materials, low production cost, simple and convenient preparation method, wide application range and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Expelling water type automobile windscreen cleaning agent

InactiveCN101041792AReduce frictionDelay agingInorganic/elemental detergent compounding agentsSurface-active detergent compositionsAlcoholCleansing Agents

The invention discloses an expelling water type windscreen cleaning agent, which is characterized by the following: allocating alcohol, non-ionic surface activator with dewatering function, inhibitor, de-icing film former and water; producing the product. This invention is designed for rain, lacca, oily soil and dust, which possesses a finite antistatic property.

Owner:BEIJING JIAOTONG UNIV

Continuous carbon fiber reinforced polypropylene high-performance electricity-conductive and heat-conductive composite material and preparation thereof

The invention relates to a continuous carbon fiber reinforced polypropylene high-performance electricity-conductive and heat-conductive composite material and a preparation thereof. The continuous carbon fiber reinforced polypropylene high-performance electricity-conductive and heat-conductive composite material comprises the components in parts by weight: (1) 100 parts of polypropylene, (2) 0.1-1 parts of an antioxidant, (3) 0.2-2 parts of a flow promoter, and (5) 1-5 parts of a compatilizer; after being premixed according to a certain proportion, the components are melted, mixed and extruded into a hanger-shaped mold head by a double / single-screw machine unit to be shunted; finally, the components enter an S-shaped mold head to sufficiently soak carbon fibers so as to prepare the continuous carbon fiber reinforced polypropylene high-performance electricity-conductive and heat-conductive composite material. Compared with the traditional carbon fiber reinforced PP composite material, the continuous carbon fiber reinforced polypropylene high-performance electricity-conductive and heat-conductive composite material provided by the invention has the advantages that the mechanical property of the continuous carbon fiber reinforced composite material prepared by using a special soaking process is greatly improved because the length retention rate of carbon fibers in a PP carrier is very high or the carbon fibers are continuous in the PP carrier; on the basis of a continuous network structure, the electricity-conductive and heat-conductive performances of the continuous carbon fiber reinforced composite material are also greatly improved.

Owner:浙江胜钢新材料有限公司

Non-ionic asphalt warm mixing agent and preparation method thereof

The invention discloses a non-ionic asphalt warm mixing agent and a preparation method thereof. The non-ionic asphalt warm mixing agent comprises the following components in percentage by weight: 0.1-10 percent of a macromolecular component, 0.1-20 percent of a low-molecular component, 1-15 percent of inorganic micro powder and 55-98.8 percent of water. The preparation method comprises the following steps: adding water into a container according to the ratio, adding the macromolecular component, stirring for 0.5-2 hours at constant temperature, controlling the temperature to be 40-60 DEG C, then adding the low-molecular component and the inorganic micro powder according to the ratio, heating to 60-80 DEG C, and continuously stirring for 0.5-1 hour to obtain the non-ionic asphalt warm mixing agent. The non-ionic asphalt warm mixing agent disclosed by the invention can effectively reduce the high-temperature viscosity of asphalt and has the advantages of high dispersion property, stable performance, available raw material, low production cost, simple and convenient preparation method, wide application range and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

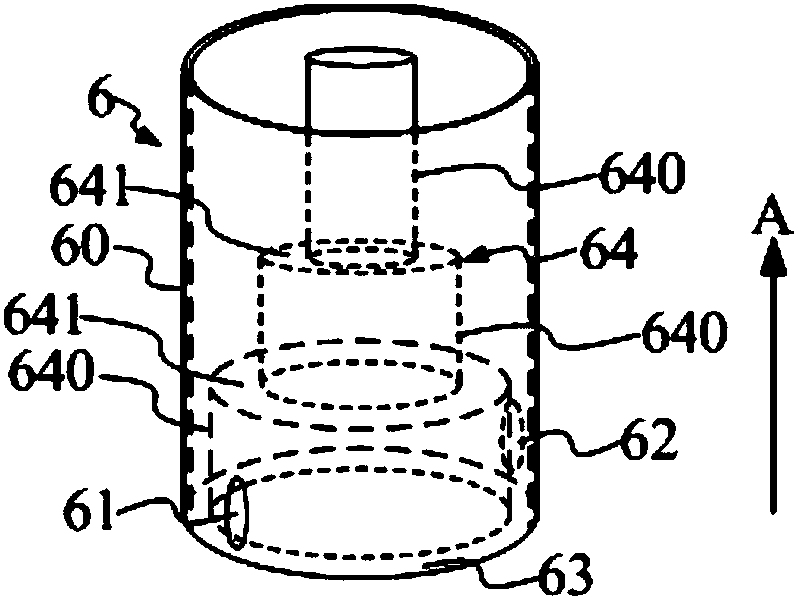

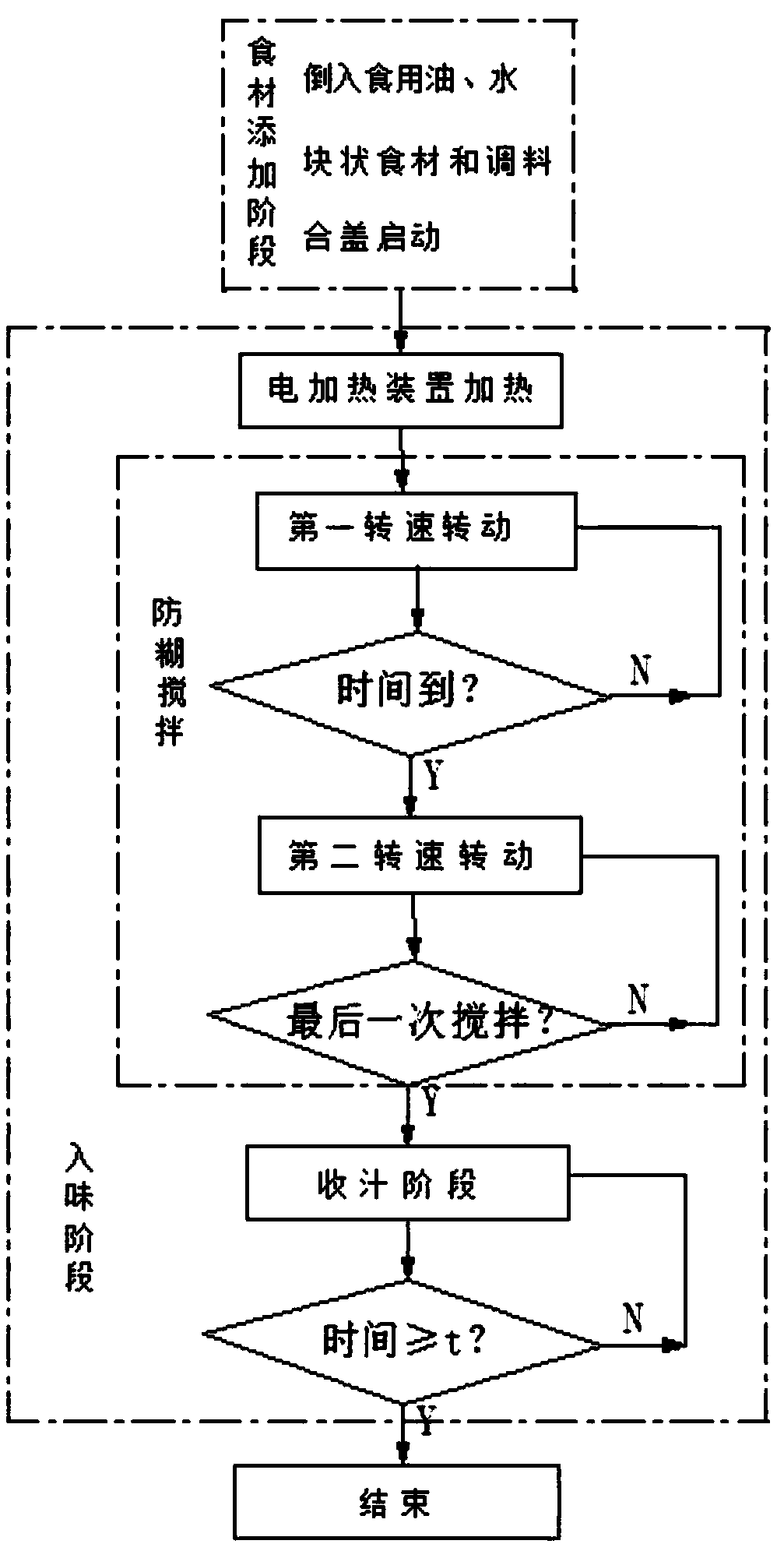

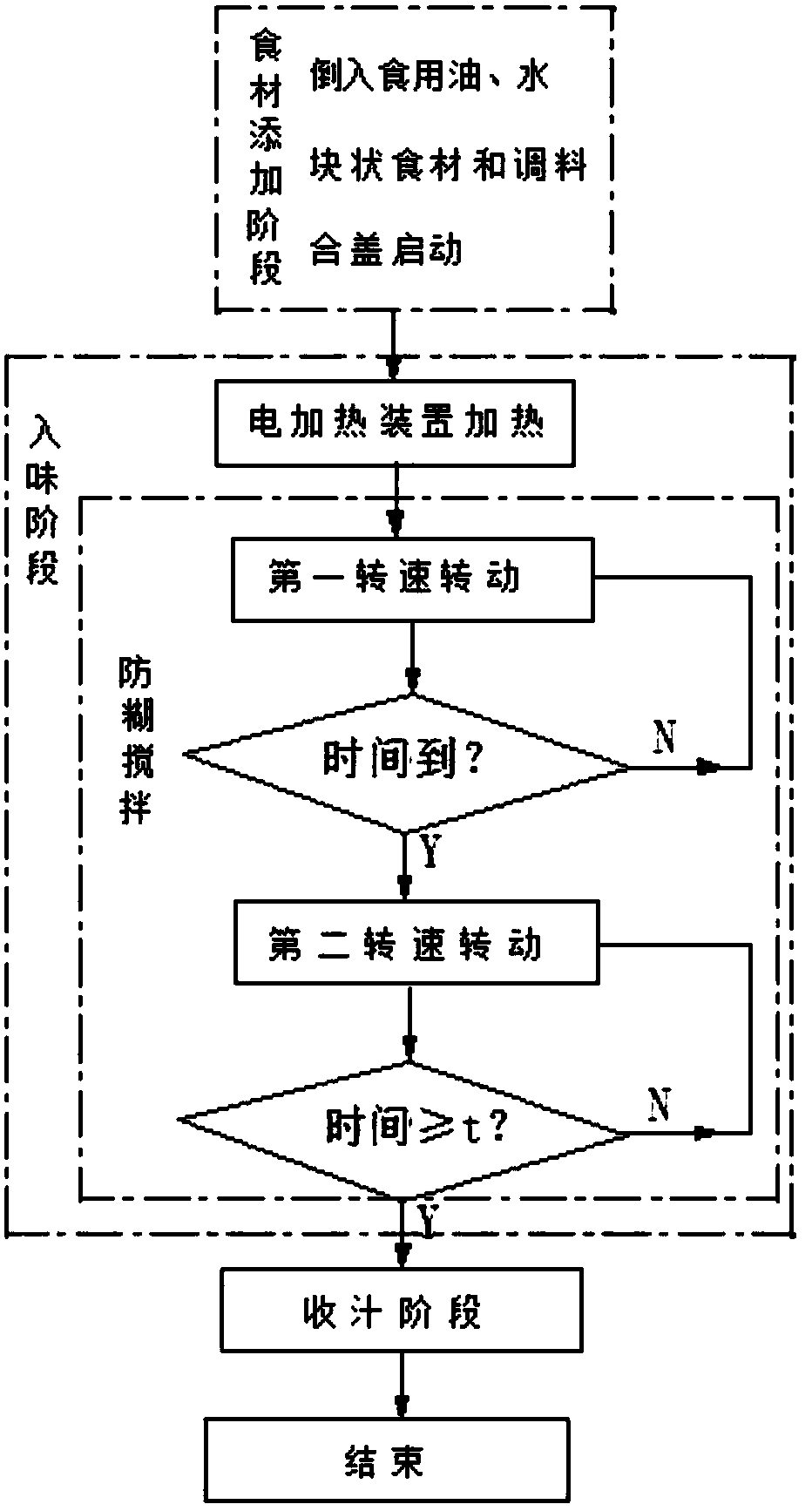

Cooking method of automatic cooker

The invention relates to a cooking method of an automatic cooker. The method includes: in a food material adding stage, adding oil and water first to make the oil and water positioned below food materials, and then adding blocky food materials and seasonings to achieve a lubricating effect and prevent stickiness; in a flavoring stage, setting anti-burning stirring, and controlling rotating frequency to guarantee complete heating, wherein a ratio of the rotating frequency n to cooking time t is 1:4-2:1 times / minute, namely at least once stirring rotation is set in 4 minutes, and at most twice stirring rotation is set in 1 minute, so that stickiness to a wok can be prevented. Since the automatic cooker is covered with a cover, low moisture evaporation is realized, and added water is low in quantity; if stirring at a time interval over four minutes, the portion, contacting with the wall of the wok, of the blocky food materials is sticky to the wok due to heating of an electric heating device; if stirring for more than 2 times in one minute, the blocky food materials are damaged while heating is incomplete, and risks of long cooking time or undercooked food materials are caused.

Owner:JOYOUNG CO LTD

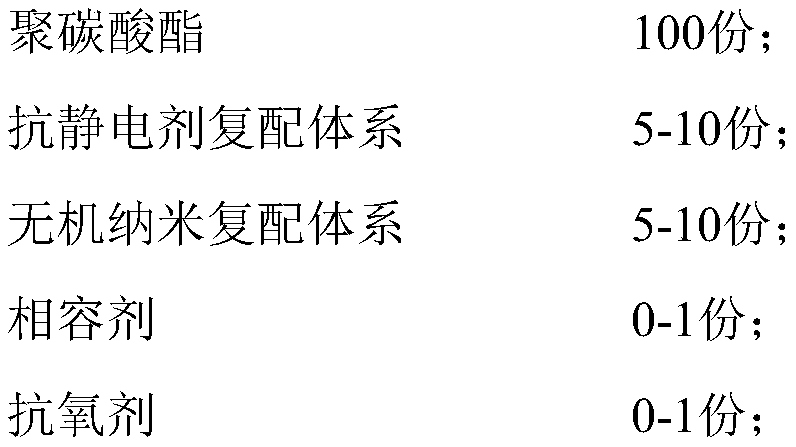

High-strength antistatic transparent polycarbonate film and preparing method thereof

The invention belongs to the technical field of materials, and particularly discloses a high-strength antistatic transparent polycarbonate film and a preparing method thereof. The high-strength antistatic transparent polycarbonate film is prepared from, by weight, 100 parts of polycarbonate, 5-10 parts of antistatic agent compounded system, 5-10 parts of inorganic nanometer compounded system, 0-1 part of compatilizer and 0-1 part of antioxidant. The prepared polycarbonate film has high anti-static function and transparency, and light transmittance can be over 90%. Meanwhile, the film has excellent mechanical property, and the surface of the film is resistant to scraping. The film is especially suitable for static sensitive transparent polycarbonate film products such as mobile phone screens, precise instruments and electronic products.

Owner:JINGMEN TIANHUA PACKING

Scratch-resistant PP plastic and preparation method thereof

The invention discloses a scratch-resistant PP plastic and a preparation method thereof, the scratch-resistant PP plastic is obtained by co-extrusion granulation of a composite filler and polypropylene resin, and the composite filler is obtained by mixing a modified filler and carboxylated polypropylene micro wax powder according to a weight ratio, ball milling and drying. Carboxylated polypropylene micro wax powder is grafted on the surface of the modified filler, so that the dispersion effect of the modified filler in polypropylene and the combination effect of the modified filler and a polypropylene material are improved. In the preparation process of the modified filler, a compound of nano hydrotalcite and nano silicon dioxide is mixed with a nano graphene dispersion liquid, and then heating and ultrasonic reaction are performed, so that a layer of graphene is grafted and fixed on the surface of the compound of nano hydrotalcite and nano silicon dioxide, on one hand, the surface friction coefficient of the plastic is reduced, and on the other hand, hydrotalcite sheet layers and nano silicon dioxide exposed when the surface of the plastic is scratched can be reduced, and obviousscratches are avoided.

Owner:蔡美英

Continuous carbon nano tube fiber-reinforced PA6 thermoplastic composite material and preparation method thereof

InactiveCN106987118AImprove conductivityImprove thermal conductivityCarbon nanotubeNetwork structure

The invention relates to the technology of carbon nano tube fiber, in particular to a continuous carbon nano tube fiber-reinforced PA6 thermoplastic composite material and a preparation method thereof. The preparation method comprises the following steps: firstly mixing 100 parts of PA6 resin, 0.1 to 0.5 part of an antioxygen, 0.2 to 1 part of a flowing accelerant, 1 to 5 parts of a compatibilizer and 2 to 10 parts of a flexibilizer, extruding the mixture into a hanger type die head for shunting through fusion mixing of a double / single screw unit, entering into an S-shaped die head for carrying out sufficient impregnation on active carbon nanot tube fiber, carrying out cooling water cooling pelleting, and finally preparing the continuous carbon nano tube fiber-reinforced PA6 thermoplastic composite material. According to the composite material disclosed by the invention, the mechanical property is greatly promoted, and based on a continuous network structure, the electric conduction and heat conduction performances of the composite material are also greatly improved.

Owner:JIANGXI UNIV OF SCI & TECH

Superhard self-lubricating coating tool and preparation method thereof

The invention discloses a superhard self-lubricating coating tool and a preparation method thereof, and can be widely applied to cutting machining of dry cutting and refractory materials. A tool base material is high-speed steel, and a laminated superhard coating composed of a hard alloy layer, an aluminum oxide ceramic layer, a silicon nitride ceramic layer and a cubic boron nitride layer is arranged on the surface of a base body in sequence, a laminated coating has the self-lubricating effect; the laminated coating has the function of self-lubrication, and is prepared by adopting a plasma spraying method. The tool integrates high-speed steel, hard alloy, alumina ceramic and silicon nitride ceramic, cubic boron nitride and the laminated coating, the adding of a carbon nano pipe (CNTs) and a boron nitride nanopipe (BNHTs) improves the hardness, the wear resistance and the toughness of the coating, the whole tool not only has good toughness, but also has very high hardness and wear resistance; and in the cutting process, when the temperature is low, the graphene can have a lubricating effect, when the temperature is high, PbO, Mo and TiB2 can generate in-situ reaction to generate PbMoO4, TiO2 and B2O3 with a lubricating effect, so that the friction and abrasion of the tool in the cutting process can be reduced, and the service life of the tool is prolonged.

Owner:SOUTHEAST UNIV

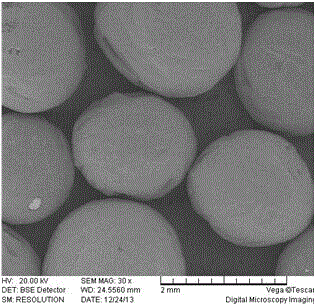

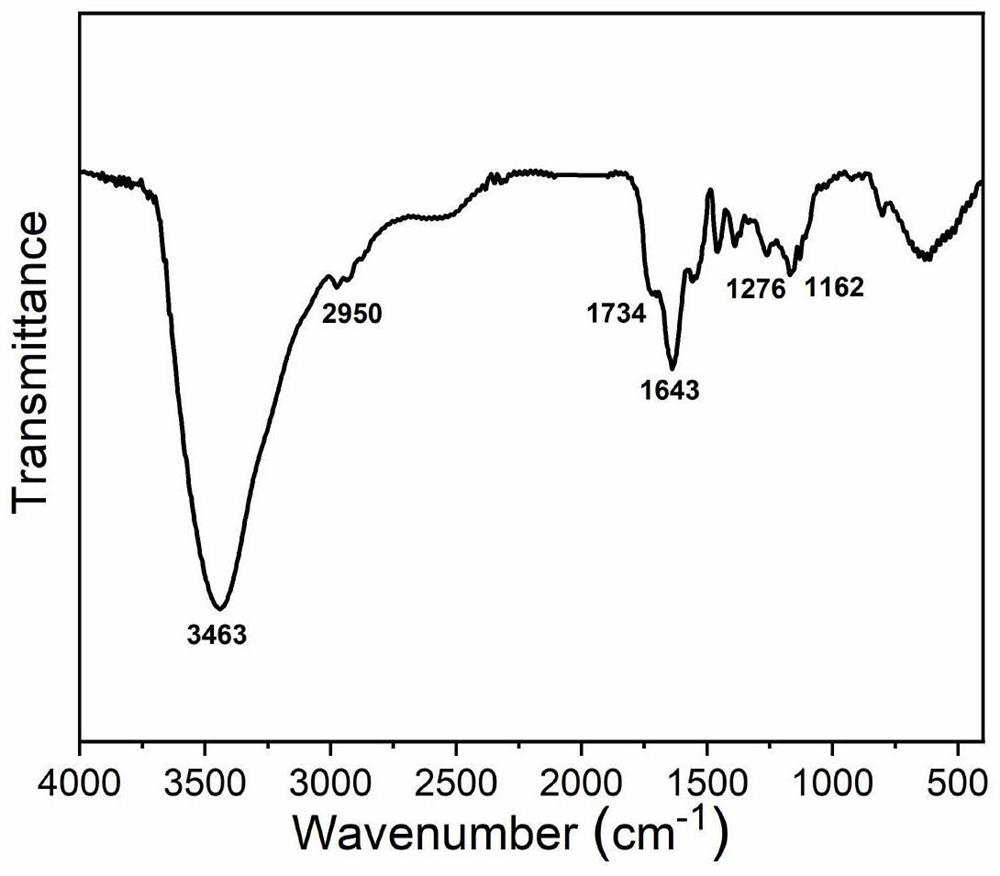

Nano lubricating additive for regulating and controlling interface friction as well as preparation method and application of nano lubricating additive

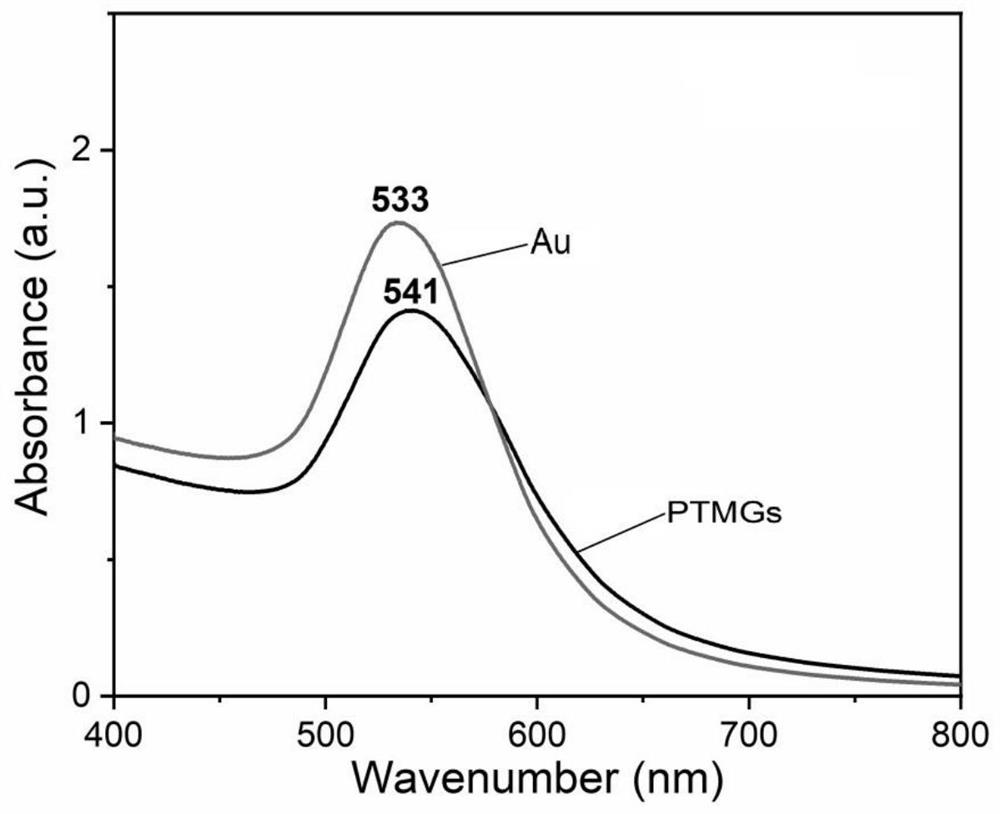

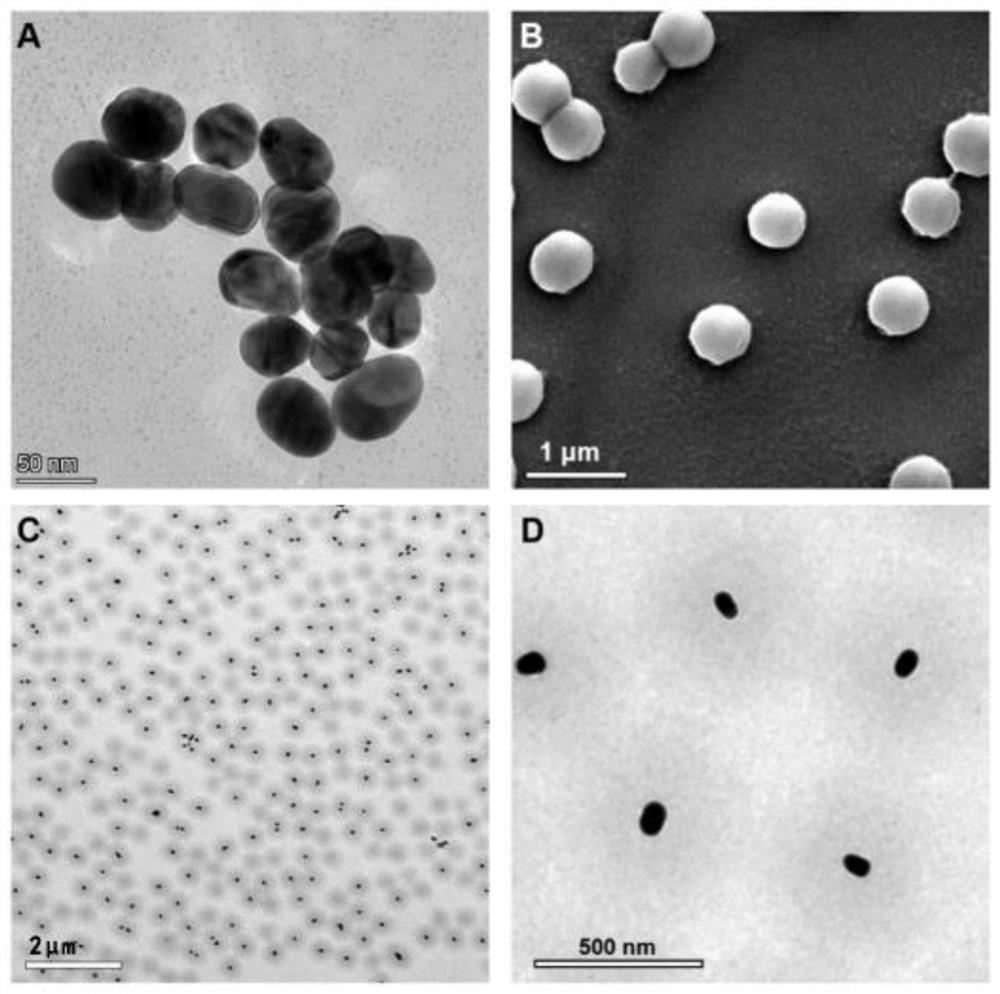

The invention belongs to the technical field of functional materials and preparation thereof, and provides a nano lubricating additive for regulating and controlling interface friction, a preparation method and application, the nano lubricating additive comprises core-shell structure nanospheres formed by taking gold nanoparticles as a core and taking a temperature-sensitive polymer cross-linked network as a shell; the manufacturing method comprises the following steps that s1, reducing gold ions into gold nanoparticles, and preparing a gold nanoparticle solution; s2, synthesizing a composite microgel ball dispersion liquid by adopting a soap-free emulsion polymerization method; s3, purifying the composite microgel ball dispersion liquid synthesized in the step S2; wherein composite microgel balls are dispersed in water, are used as a hydrated lubricating additive, can respond to near-infrared light stimulation, and are used for preparing a friction force switching agent for realizing rapid switching between low friction and high friction. The nano lubricating additive prepared by adopting soap-free emulsion polymerization can respond to near-infrared light stimulation, so that rapid switching between low friction and high friction is realized, and the friction performance of microgel is remotely regulated and controlled.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

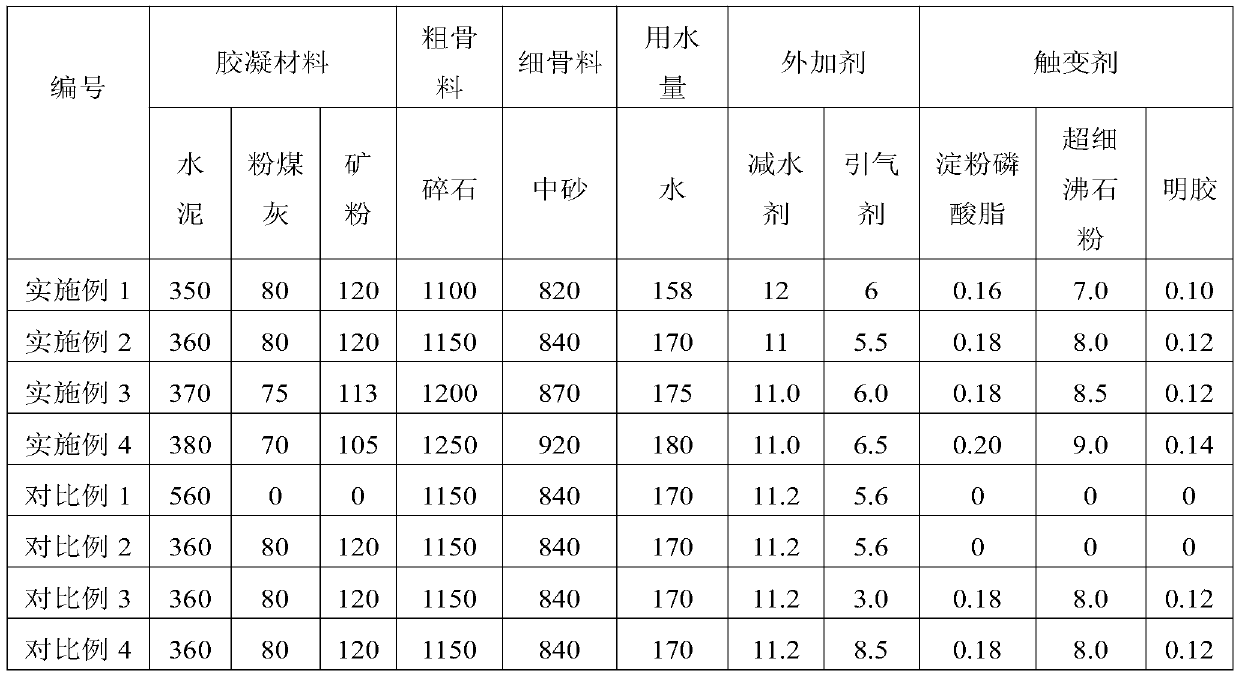

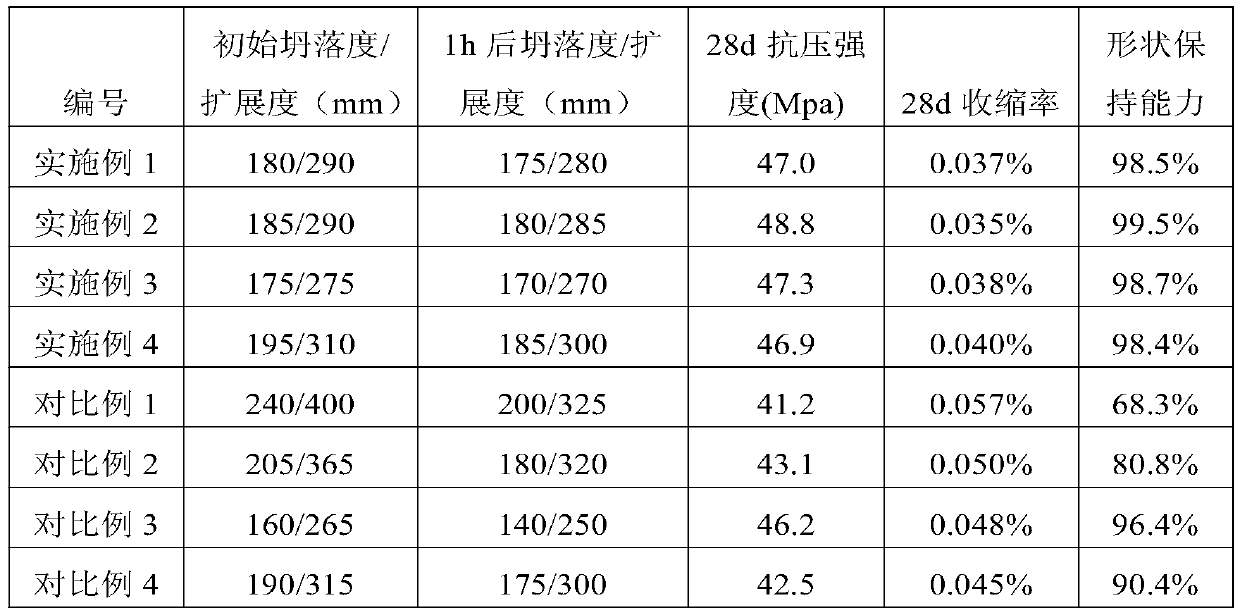

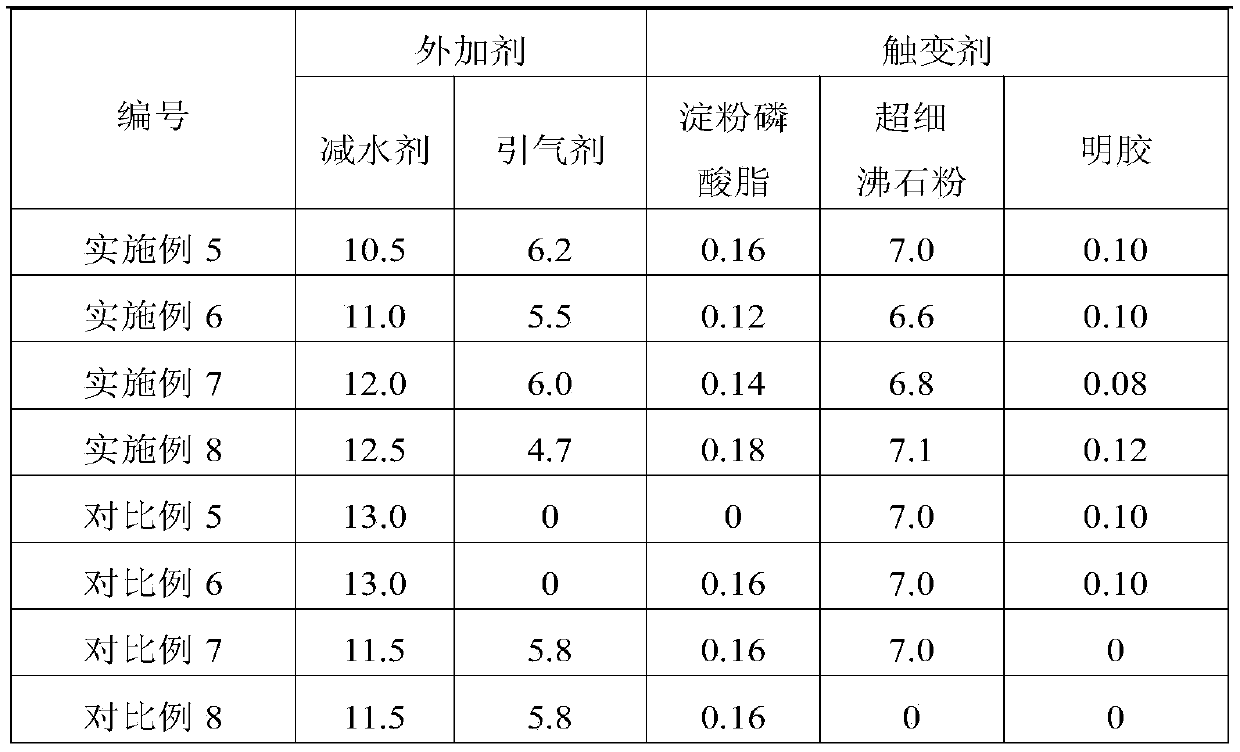

Large-fluidity spread concrete and preparation method thereof

The invention provides large-fluidity spread concrete and a preparation method thereof. The concrete includes 34-39 parts of cement, 17-20 parts of a mineral additive, 110-131 parts of coarse aggregate, 82-95 parts of fine aggregate, 15-19 parts of tap water, 1.6-2 parts of an admixture, and 0.7-1 part of a compound thixotropic agent, wherein the admixture is a polycarboxylic acid high-efficiencywater reducer and an air entraining agent, and the compound thixotropic agent is starch phosphate ester, ultra-fine zeolite powder and gelatin. The starch phosphate ester, the ultra-fine zeolite powder, the gelatin, the polycarboxylic acid high-efficiency water reducer and the air entraining agent are mixed with other raw materials to make the concrete endowed with large fluidity and excellent shape retention ability. The contradiction between the fluidity and the shape retention ability of the concrete is solved, and such problems are solved that at present, concrete over-vibration is causedby the adoption of high-frequency vibration to compact the low-fluidity concrete, aggregate settlement and segregation occur and the gas content is reduced. The construction performance of the concrete is greatly improved, the service life of the concrete is greatly prolonged in engineering, the spread quality is ensured, and the concrete can be spread more smoothly and uniformly.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST +2

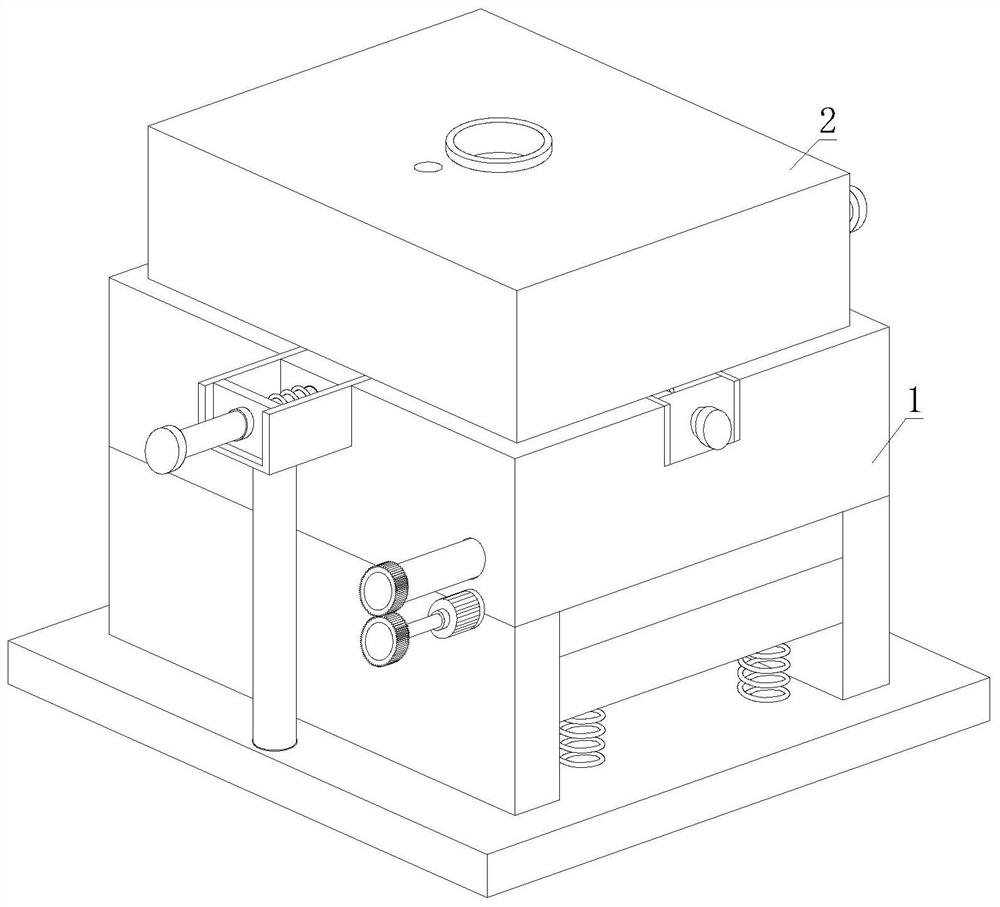

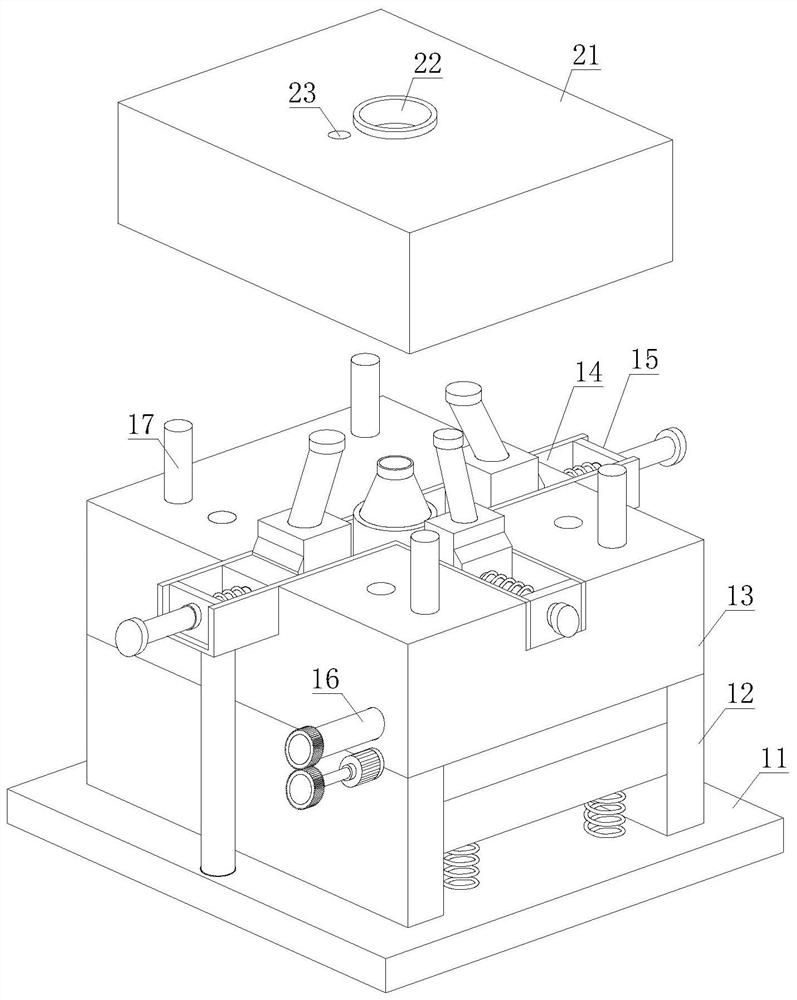

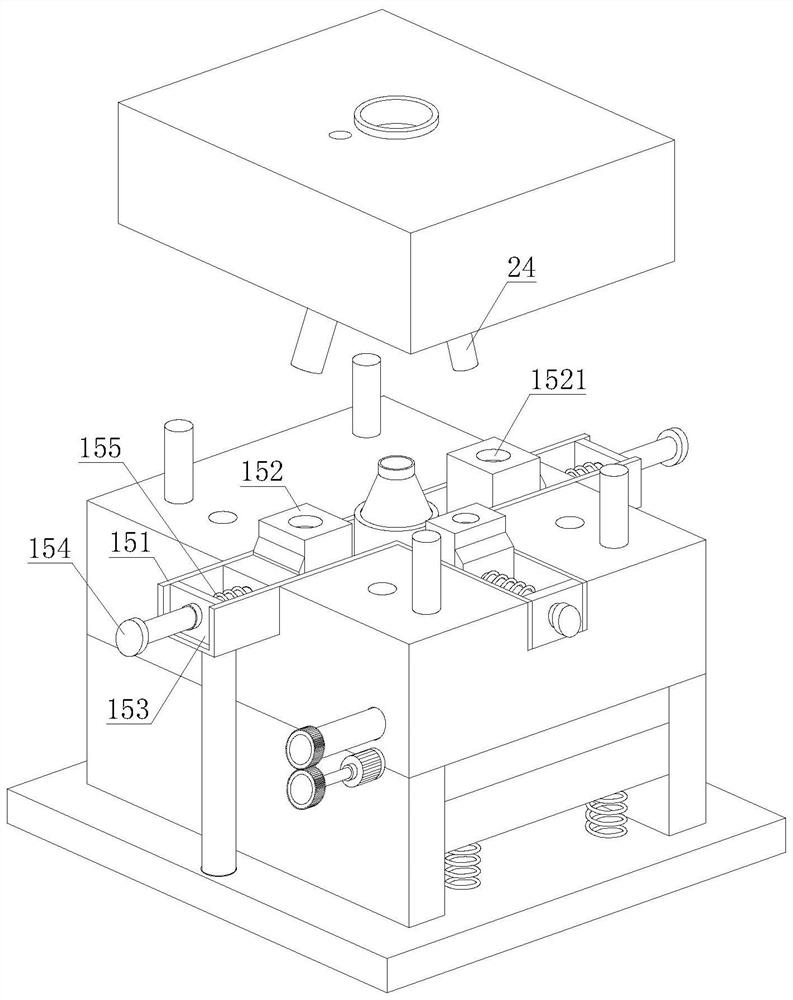

Shirt collar type mold machine with multi-directional core pulling mechanism and implementation method thereof

The invention discloses a shirt collar type mold machine with a multi-directional core pulling mechanism. The shirt collar type mold machine comprises a lower mold and an upper mold, wherein a slidingsleeve is a component made of stainless steel materials and is arranged inside a groove, so that sliding of a sliding block is facilitated; the sliding block is arranged inside the sliding sleeve, afixing block is fixedly arranged inside the sliding sleeve, a pull rod penetrates through the fixing block and is fixedly connected with the sliding block, a spring is fixedly arranged on the outer surface of the pull rod, and the two ends of the spring are connected with the sliding block and the fixing block respectively; and a pressing plate is lifted after forming, a first mold core drives thesliding block to move towards the two sides along the sliding sleeve in the upward moving process, the spring is compressed, a clamping ring is fixedly arranged on the inner wall of a core pulling hole, and a scraper is fixedly connected with the inner wall of the clamping ring. According to the shirt collar type mold machine, the lower end of the first mold core is wrapped by lubricating oil ofa sponge layer, then the first mold core is brought into the core pulling hole, when the first mold core passes through the scraper, the lubricating oil and burrs are scraped off by the scraper, the deburring effect is good, the lubricating oil is left in the core pulling hole, and the effect of lubricating the first mold core can be achieved conveniently.

Owner:河北万发服装纺织集团有限公司

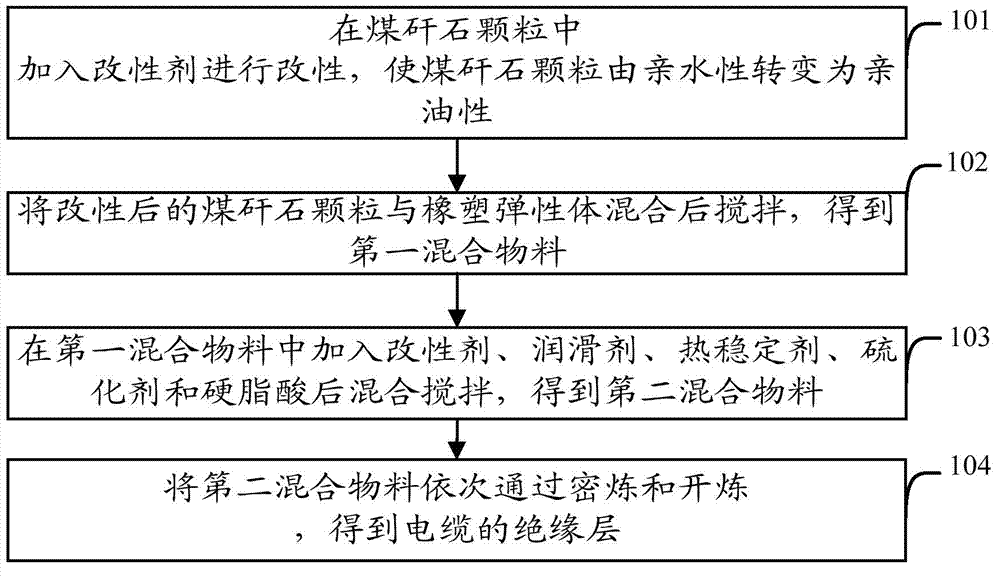

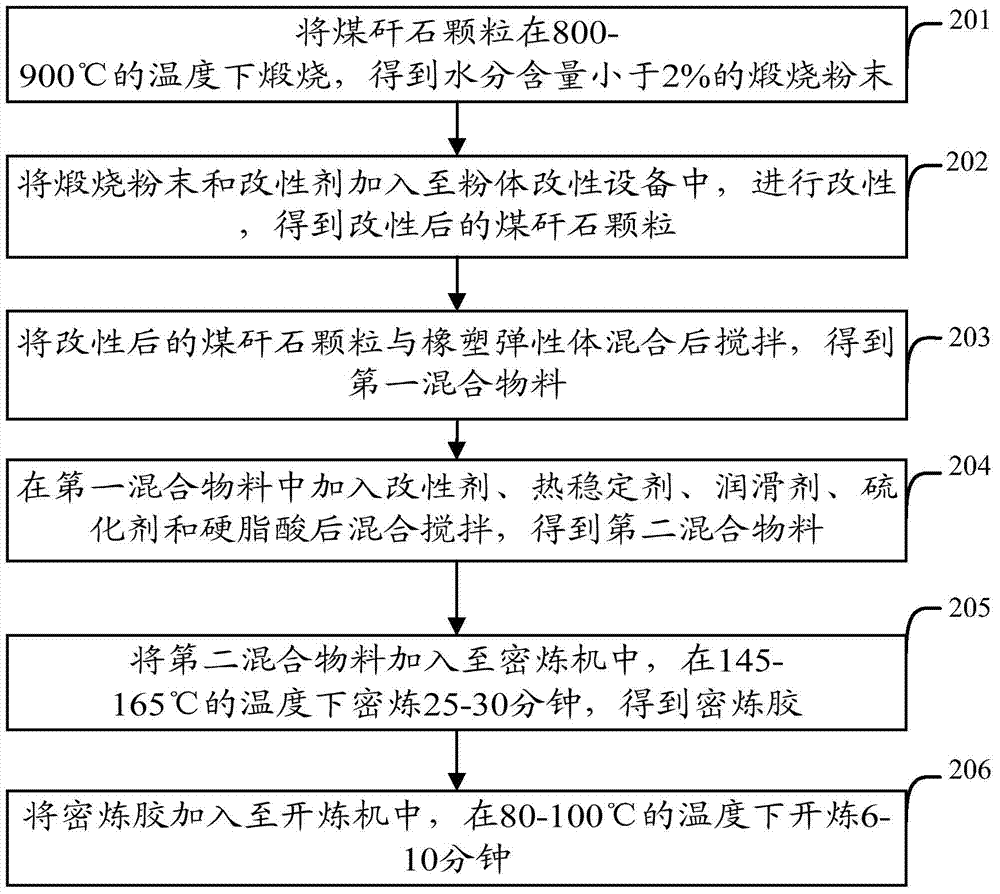

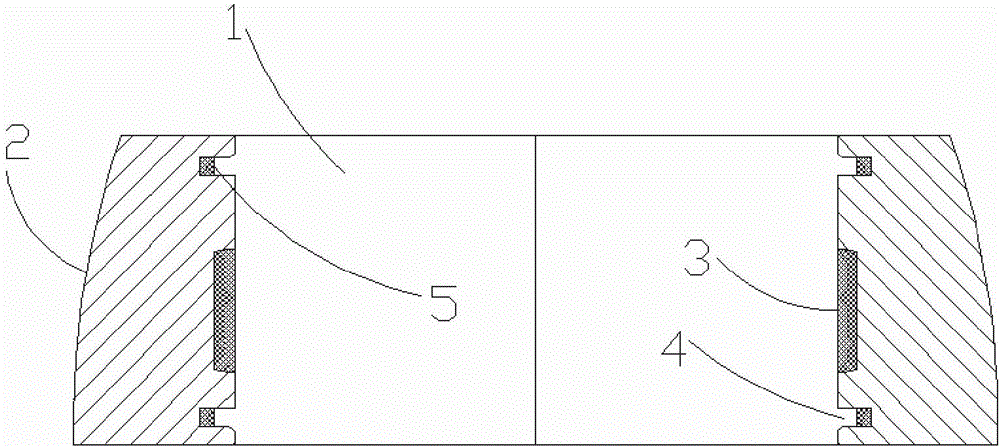

Cable insulation layer and making method thereof

InactiveCN103483852ALow costIncreased internal surface areaRubber insulatorsPlastic/resin/waxes insulatorsElastomerInsulation layer

The invention relates to the cable field, and especially relates to a cable insulation layer and a making method thereof. The making method of the cable insulation layer comprises the following steps: adding a modifier to gangue particles to modify the gangue particles in order to change the hydrophilicity of the gangue particles to lipophilicity; mixing the modified gangue particles with a rubber-plastic elastomer, and stirring to obtain a first mixed material; adding the modifier, a lubricant, a heat stabilizer, a vulcanizing agent and stearic acid to the first mixed material to obtain a second mixed material; and sequentially carrying out internal mixing and open milling of the second mixture to obtain the cable insulation layer. The main components comprising the gangue particles and the rubber-plastic elastomer of the cable insulation layer have low prices, so the cost of the made cable insulation layer is low, thereby the cable insulation layer has the advantages of guaranteed insulation performance and low material cost.

Owner:HYDRAULIC MACHINERY PLANT SHANXI PROV

Deep groove ball bearing outer ring and alloy material for manufacturing same

InactiveCN104088909AImprove structural strengthImprove structural firmnessBearing componentsLithiumBall bearing

The invention discloses a deep groove ball bearing outer ring, which comprises an outer ring body, wherein the outer end surface of the outer ring body is conical; an annular graphite layer is embedded in the inner surface of the outer ring body and is close to one end of the outer ring body with a larger outer diameter; slots are formed in two sides of the graphite layer; a graphite bar is embedded in the bottom of the slot. The invention further relates to an alloy material for manufacturing the deep groove ball bearing outer ring. The alloy material comprises the following material in percentage by weight: 60-80% of iron, 6-8% of manganese, 3-5% of copper, 3-5% of magnesium, 0.5-10% of aluminum, 0.3-2% of cadmium, 1-8% of lithium and 1.5-5% of nano graphite. According to the deep groove ball bearing outer ring, the structural strength and lubricating performance are improved; the product load is alleviated and the service life is prolonged.

Owner:胡海旺

Grinding tool for glass finishing

InactiveCN111805344AAvoid damageImprove cleanlinessEdge grinding machinesPortable grinding machinesAir pumpEngineering

The invention relates to the technical field of glass finishing, specifically to a grinding tool for glass finishing. The grinding tool for glass finishing comprises a grinding machine body; a rotating handle is fixedly connected to an output end of the grinding machine body; a grinding head is fixedly connected to the front end of the rotating handle; a dust collection mechanism is connected to the external side of the grinding machine body; and the dust collection mechanism comprises a storage box, a micro air pump and an arc plate. According to the grinding tool for glass finishing, under the working of the micro air pump, scraps generated during grinding are adsorbed through an adsorbing hole so as to reduce the damage to the health of people; during cleaning, a sweeping roll can be driven by pulling a connecting plate to sweep the internal wall of the arc plate so as to improve the sweeping effect of the grinding tool; meanwhile, by pressing a hand pump, water in a water tank canbe sprayed through a nozzle to spray the scraps so that a lubricating effect is realized and a certain dust suppression effect is realized; and therefore, the grinding effect is improved.

Owner:李大根

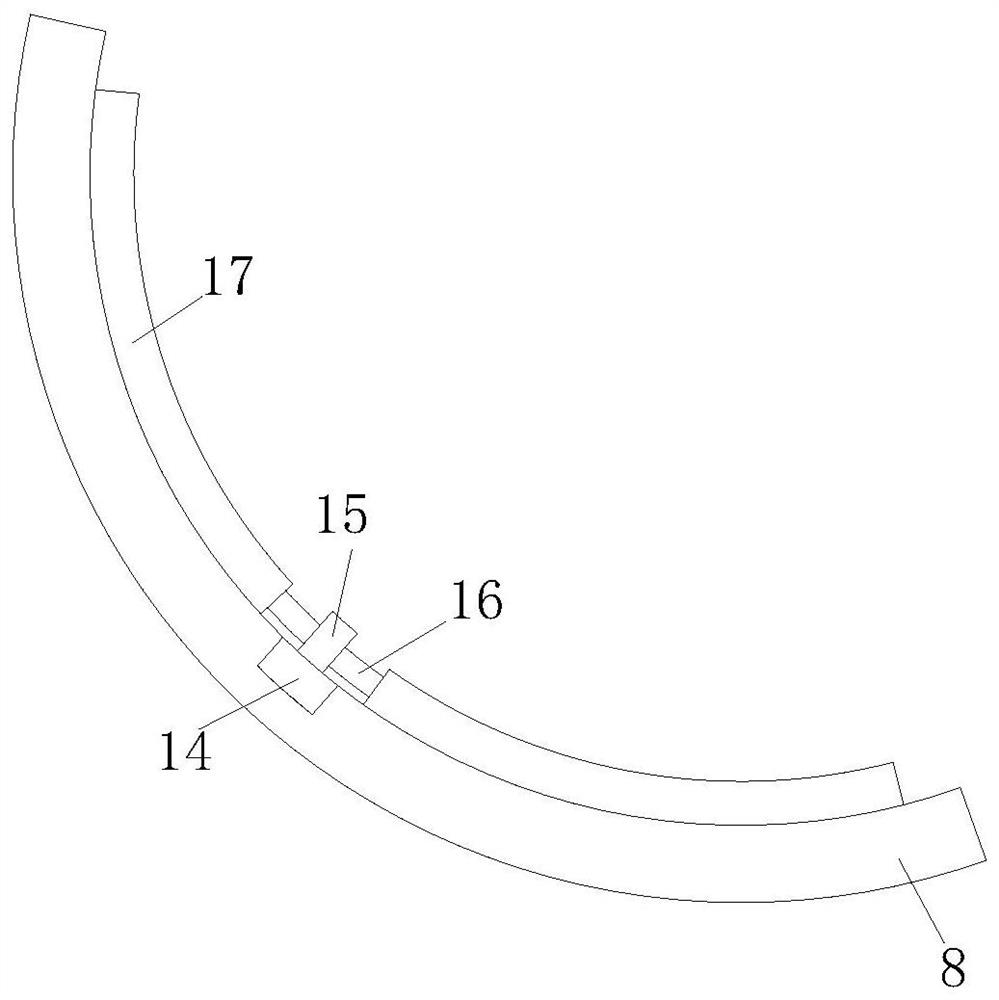

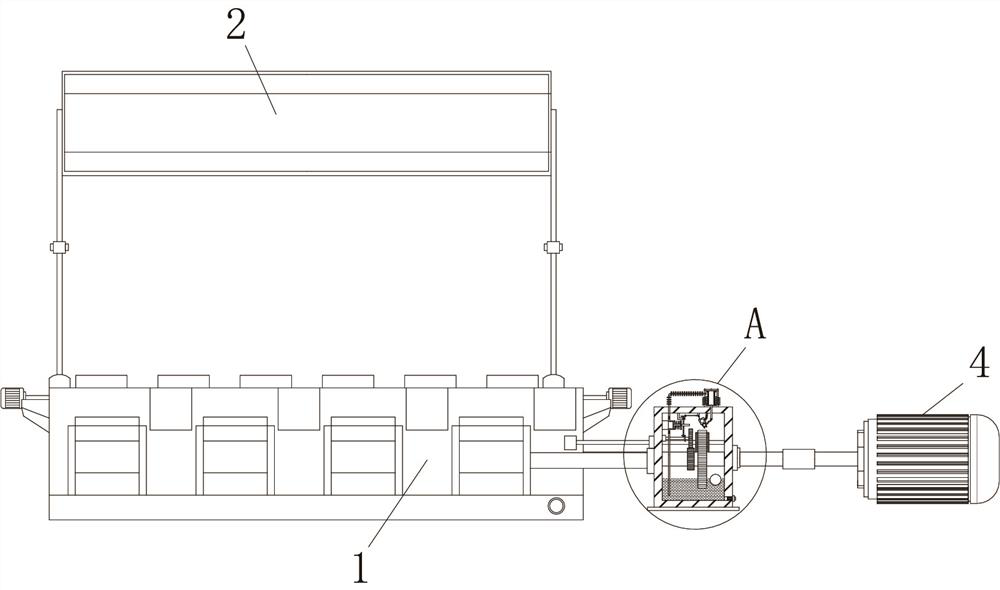

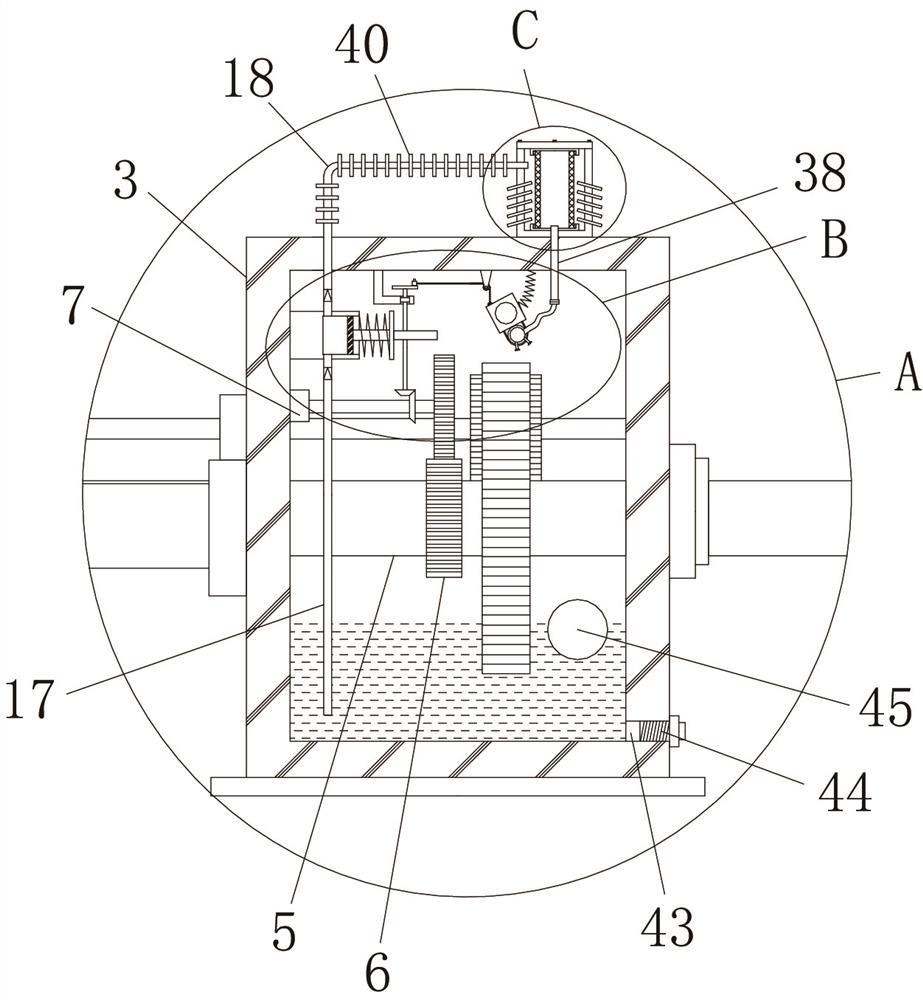

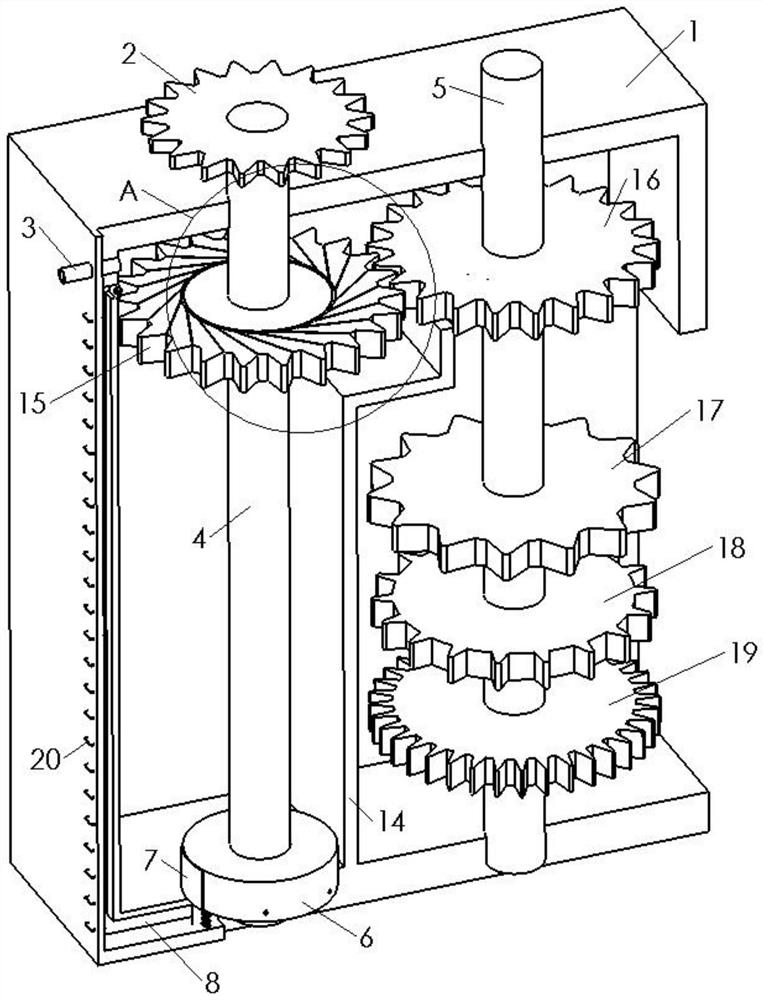

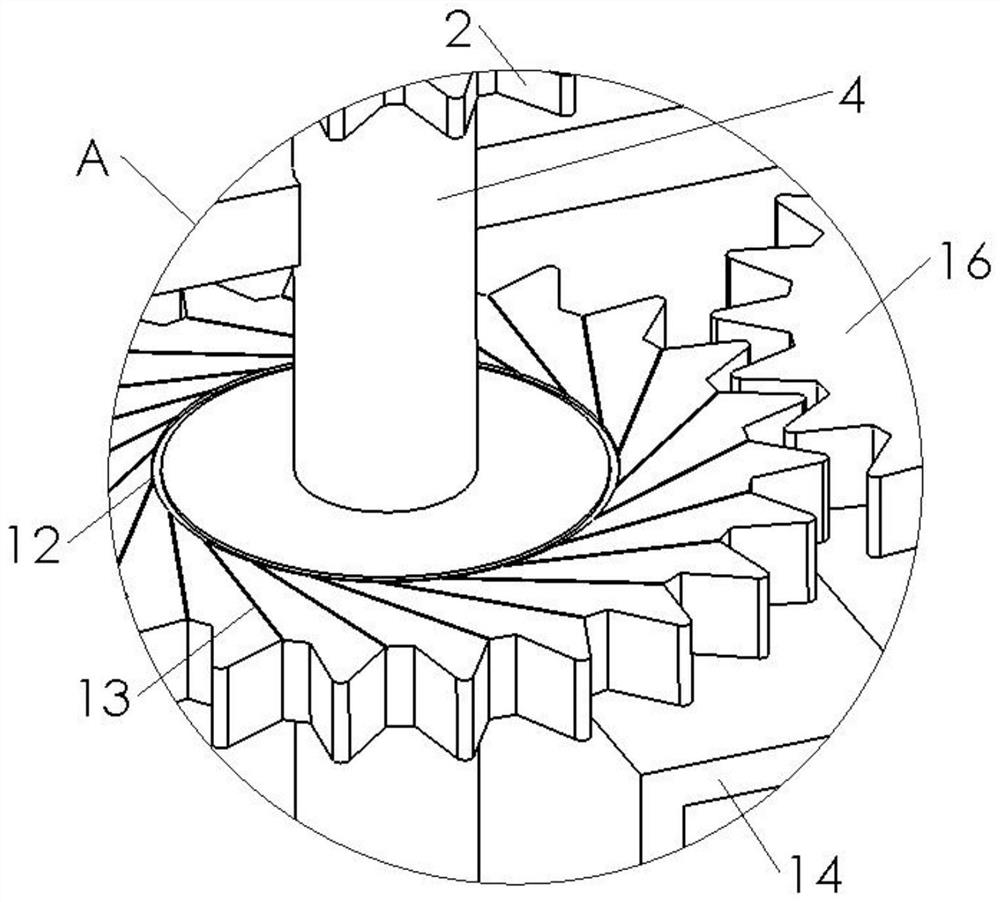

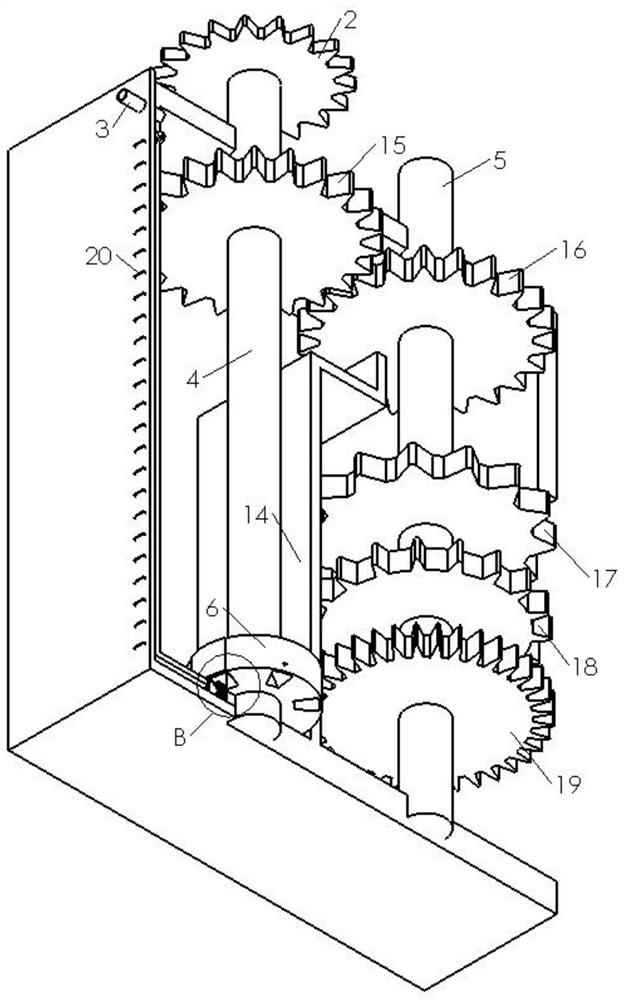

Centralized driving type multi-pass nonferrous metal rolling mill

InactiveCN112453063APlay a role in purificationEfficient cooling and coolingRollsMetal rolling arrangementsOil canNonferrous metal

The invention discloses a centralized driving type multi-pass nonferrous metal rolling mill. The centralized driving type multi-pass nonferrous metal rolling mill comprises a rolling mill body, a rolling mill safety hood, a gear box and a motor, a main rotating shaft is rotationally installed in the gear box, a first transmission straight gear is fixedly arranged on the main rotating shaft in a sleeving mode, a bearing seat is fixedly installed on the inner wall of one side of the gear box, a transverse shaft is rotationally installed on one side of the bearing seat, a first bevel gear is arranged on the transverse shaft in a sleeving mode, and one end, away from the bearing seat, of the transverse shaft is fixedly sleeved with a second transmission straight gear. The centralized driving type multi-pass nonferrous metal rolling mill is reasonable in design and good in practicability, effective purifying and cooling can be carried out on lubricating oil in the gear box, the lubricatingoil is evenly sprayed to the plurality of gears in the gear box by utilizing reciprocating left-right swing of a plurality of spray heads, and therefore the lubricating effect on the plurality of gears is improved, abrasion between the gears is reduced, the service life of the plurality of gears in the gear box can be prolonged, the replacement frequency of the lubricating oil can be reduced, theservice life of the lubricating oil can be prolonged, and the economic cost is reduced.

Owner:ZHEJIANG CHUANBOZHE METAL DECOUATION MATERIAL CO LTD

Gear variable-speed adjusting efficient lubricating and cooling device

PendingCN111878568AImprove lubrication efficiencyIncrease profitGear lubrication/coolingSpray nozzleInjector nozzle

The invention discloses a gear variable-speed adjusting efficient lubricating and cooling device which comprises a gearbox body, a baffle is arranged in the gearbox body, the section of the baffle isin a broken line shape, one end of the baffle is fixedly connected with the bottom of the gearbox body, and a driving shaft and a driven shaft are arranged at the left side and the right side of the baffle respectively. The driving shaft and the driven shaft are connected with the gearbox body in a rotating mode, the driving shaft is sleeved with a first transmission gear, and the end of the driving shaft is connected with a driving gear. An extrusion rotary disc is arranged at the bottom of the driving shaft at the bottom of the gearbox body, lubricating oil accumulated at the bottom of the gearbox body can be continuously extruded into an oil cavity formed in the side wall of the gearbox body through the extrusion rotary disc and then sprayed out through a spray head oil spray nozzle atthe end of the oil cavity, and the lubricating oil is sprayed to the first transmission gear; and therefore, the lubricating oil is recycled, and the utilization rate of the lubricating oil is improved.

Owner:陈祥柱

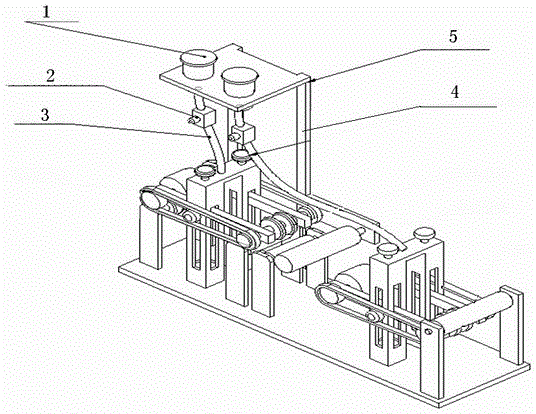

Simple grinding wheel lubricating and cooling device and beveling machine

InactiveCN105014542ASimple structureEasy to implementEdge grinding machinesGrinding/polishing safety devicesMetal stripsGrinding wheel

The invention relates to a simple grinding wheel lubricating and cooling device and a beveling machine with the same. The simple grinding wheel lubricating and cooling device mainly comprises cooling liquid cups, cooling liquid pipes and flow control switches. The cooling liquid cups are fixedly connected with the cooling liquid pipes. The wall of each cooling liquid pipe is connected with one flow control switch. The lubricating and cooling device can be installed beside the beveling machine. When the lubricating and cooling device is installed on the grinding wheel beveling machine, the tail ends of the cooling liquid pipes are fixed to the positions above a feeding belt of the beveling machine. The lubricating and cooling device is simple in structure and convenient to operate. When applied to beveling machines, the lubricating and cooling device can be flexibly installed and matched with beveling machines of various models. Through the flow control switches, cooling liquid is adjustably and evenly dripped, so that it is guaranteed that ground metal strip edges are smooth, clean, free of chippings, not sticky and free of high-temperature burns.

Owner:WUXI BAISHIJIE METAL PROD TECH

Hydraulic valve valve rod preventing clamping stagnation

InactiveCN111503079AHigh hardnessSolve stuckOperating means/releasing devices for valvesServomotor componentsStructural engineeringMechanical engineering

The invention discloses a hydraulic valve valve rod preventing clamping stagnation. The hydraulic valve valve rod preventing clamping stagnation comprises a valve rod. The left edge of the valve rod is fixedly provided with a flat connection body. An annular groove is arranged outside the valve rod. The valve rod is provided with a first through groove, a second through groove and a third throughgroove. A through hole located on the outer portion of the valve rod is arranged on the right side of the third through groove. An inclined hole is arranged on the right side face of the third throughgroove. A first throttling groove is arranged on the right side of the second through groove. The surface of the valve rod is plated with hard chromium, and then the hardness of the valve rod is improved. The inclined hole and the through hole formed on the valve rod enable lubricating oil to permeate the surface of the valve rod during movement, and a lubricating effect is achieved. A connectionhole and a connection hole A can conduct external connection. The arranged annular groove can store dirt in the motion process, and the first throttling groove, a second throttling groove and a thirdthrottling groove achieve the buffering function when the valve rod moves. The hydraulic valve valve rod preventing clamping stagnation can effectively solve the clamping stagnation problem of the valve rod and has the features of being convenient and practical.

Owner:唐万刚

Numerically controlled lathe tool changing frame

InactiveCN114523322APlay a lubricating effectSolve the problem of automatic oilingPositioning apparatusMaintainance and safety accessoriesStructural engineeringWaste oil

The invention discloses a tool changing frame of a numerically controlled lathe, which belongs to the technical field of machining and comprises a slide rail and a tool changing device capable of sliding along the length direction of the slide rail, and a driving mechanism for driving an output shaft to rotate is mounted in a driving groove; a plurality of balls used for supporting the tool frame to rotate are arranged at the joint of the tool frame and the connecting plate, a through hole is formed in the position, located below the balls, in the connecting plate and communicates with the driving groove, and an oil storage cavity is formed in the tool frame and extends to the surfaces of the balls. And in the rotating process of the ball body, lubricating oil in the oil storage cavity can be attached to the surface of the ball body, flows into the driving groove from the through hole along with the ball body and drips at the connecting position of the worm and the worm disc, the problems that automatic oil feeding cannot be achieved and waste oil always remains in the device can be solved, and the service life of the device is prolonged.

Owner:江苏恩格尔智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com