Deep groove ball bearing outer ring and alloy material for manufacturing same

A technology of deep groove ball bearings and alloy materials, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., and can solve the problems of relatively high strength of bearing inner and outer rings and firm stress points, bearing heating, cage burns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

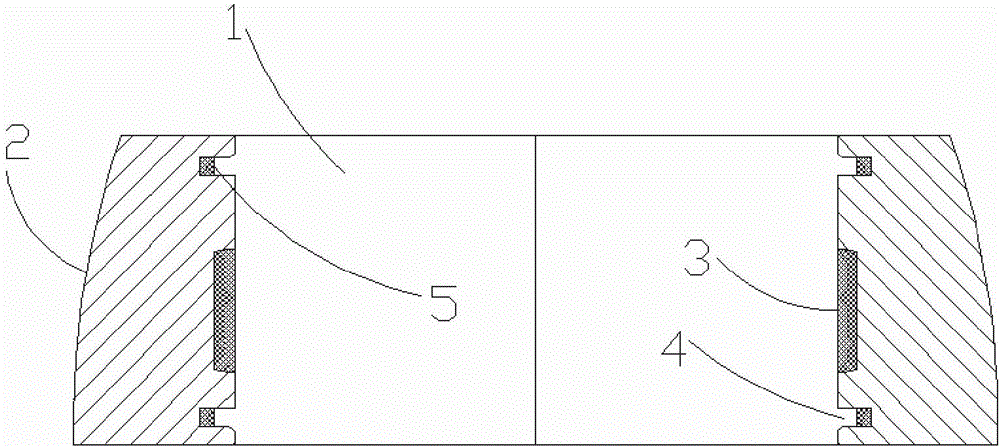

Image

Examples

Embodiment 1

[0063] An alloy material for manufacturing the outer ring of a deep groove ball bearing, characterized in that it includes the following components according to the weight ratio:

[0064] Iron content at 73%;

[0065] Manganese content at 5%;

[0066] Copper content is 3%;

[0067] Magnesium content at 5%;

[0068] Aluminum content is 4.2%;

[0069] Cadmium content is 0.3%;

[0070] Lithium content is 6.5%;

[0071] The content of nano graphite is 3%.

[0072] In the present invention, with the rational allocation and increase of manganese content, magnesium content, aluminum content and lithium content, the structural strength, oxidation resistance and corrosion resistance of the overall bearing outer ring are significantly improved, and the service life is prolonged. In addition, the content of nano graphite in the present invention is 3%, so that the alloy has a certain self-lubricating effect, increases lubricity, reduces the demand for lubricating oil, and obviously...

Embodiment 2

[0074] An alloy material for manufacturing the outer ring of a deep groove ball bearing, characterized in that it includes the following components according to the weight ratio:

[0075] Iron content at 78%;

[0076] Manganese content at 7%;

[0077] Copper content is 4.7%;

[0078] Magnesium content at 5%;

[0079] Aluminum content is 0.5%;

[0080] Cadmium content is 1.3%;

[0081] Lithium content at 1.5%;

[0082] The content of nano graphite is 2%.

[0083]In the present invention, with the rational configuration of iron content, manganese content, magnesium content, aluminum content and lithium content, the structural strength, oxidation resistance and corrosion resistance of the overall bearing outer ring are improved, and the service life is prolonged. In addition, the content of nano graphite in the present invention is 2%, so that the alloy has a certain self-lubricating effect, increases lubricity, reduces the demand for lubricating oil, and reduces the number...

Embodiment 3

[0085] An alloy material for manufacturing the outer ring of a deep groove ball bearing, characterized in that it includes the following components according to the weight ratio:

[0086] Iron content at 80%;

[0087] Manganese content at 5%;

[0088] Copper content is 4.7%;

[0089] Magnesium content at 6%;

[0090] Aluminum content is 0.5%;

[0091] Cadmium content is 1.3%;

[0092] Lithium content is 1%;

[0093] The content of nanometer graphite is 1.5%.

[0094] In the present invention, with the increase of iron content, the reduction of manganese content, magnesium content, aluminum content and lithium content, the oxidation resistance and corrosion resistance of the overall bearing outer ring are somewhat improved, and the service life is prolonged. In addition, the content of nano-graphite in the present invention is relatively low, so that the alloy has a certain self-lubricating effect, but a certain amount of lubricating oil needs to be added during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com