Patents

Literature

537results about How to "Reduce join" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricity coatings preparation method on the medical catheter polymers surface

InactiveCN101455861AImprove surface physicochemical propertiesChange adsorption stateCatheterCoatingsPolymer scienceGraft reaction

The invention discloses a method for preparing a lubricant coating on the surface of polymer materials of a medical catheter, which comprises the following steps: (A), pretreating the surface of the polymer materials of the medical catheter, so as to obtain hydrophilic adsorption active sites; (B), soaking the pretreated polymer materials of the medical catheter in step (A) into a prepared precursor solution of the lubricant coating for adsorption; and (C), performing grafting reaction on the soaked polymer materials of the medical catheter in step (B), and washing and drying the polymer materials of the medical catheter. The method can be widely used for preparing medical polymer materials and coating materials on the surface of a medical apparatus.

Owner:SOUTHEAST UNIV

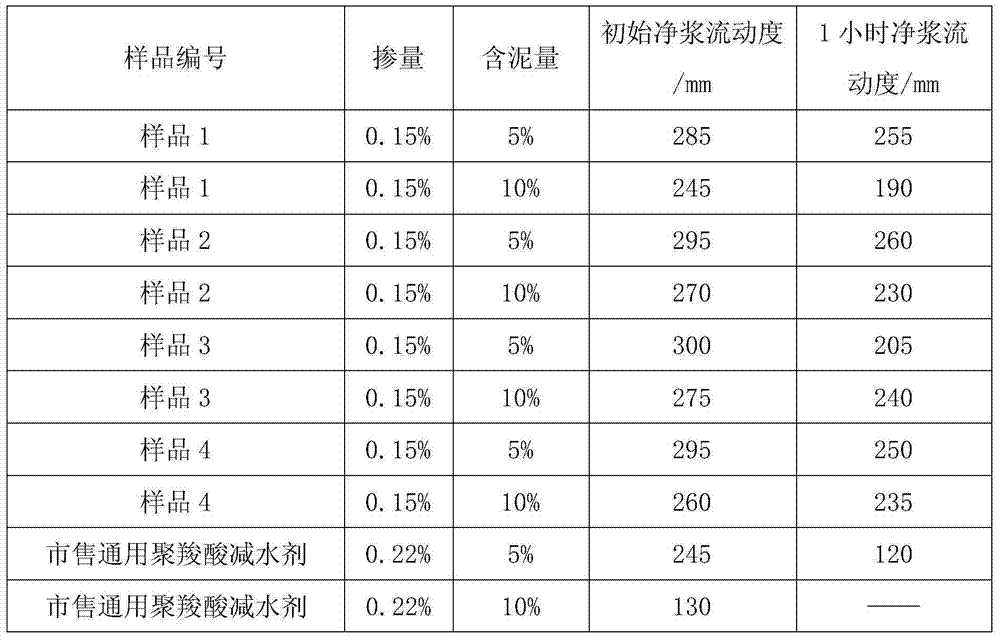

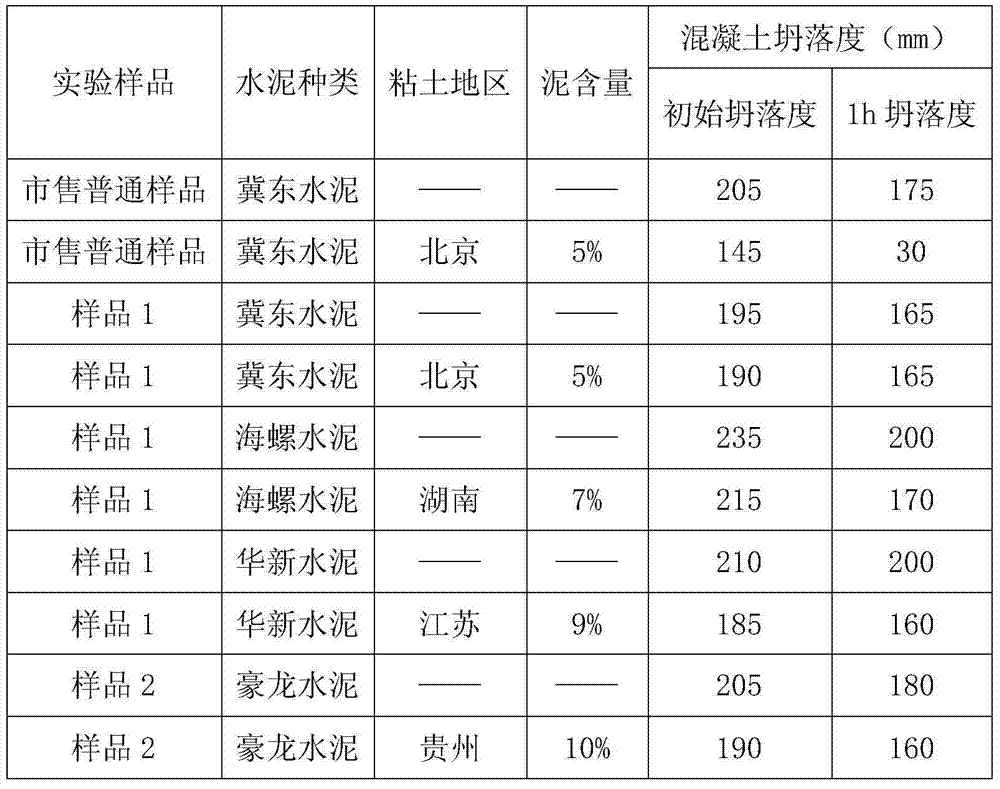

Mud-resistant polycarboxylic acid water reducer and preparation method thereof

The invention discloses a mud-resistant polycarboxylic acid water reducer. The mud-resistant polycarboxylic acid water reducer is prepared from the following components: vinyl polyoxyethylene ether, sodium p-styrenesulfonate, an acrylic acid and acrylamide compounds as monomers as well as an alkaline neutralizer, an initiator and a molecule modulator as auxiliary materials through copolymerization. The mud-resistant polycarboxylic acid water reducer disclosed by the invention is high in water-reducing rate, small in slump loss, good in mud-resistant effect, free of formaldehyde pollution in a production process, and especially adapts to sand concrete with relatively high mud content.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Zeolite-like lightweight heat preservation and sound insulation board and production method thereof

ActiveCN102167546ADelayed clotting timeStrong sound absorption effectCement productionPolystyreneZeolite

The invention provides a zeolite-like lightweight heat preservation and sound insulation board applied to a building outer wall, or wall filling of a nonbearing wall or a building top layer. The board comprises dry powder slurry and lightweight aggregate, wherein the dry powder slurry is a zeolite-like geopolymer formed by the excitation of a composite alkali excitant and comprises the following components in percentage by weight: 70-85 percent of coal ash, 5-15 percent of phosphorus slag, 8-20 percent of composite alkali excitant and 0.1-0.3 percent of anticracking fiber; the lightweight aggregate is EPS (Expandable Polystyrene) granules; and the charge ratio of the dry powder slurry to the lightweight aggregate is (89-95): (5-15). The zeolite-like lightweight heat preservation and soundinsulation board has low volume weight, high compression strength, favorable heat preservation and heat insulation properties and good sound absorption effect on various frequency bands of sound waves. The invention also provides a production method of the zeolite-like lightweight heat preservation and sound insulation board. The method has simple process conditions and is easy to realize.

Owner:广骏新材料科技股份有限公司

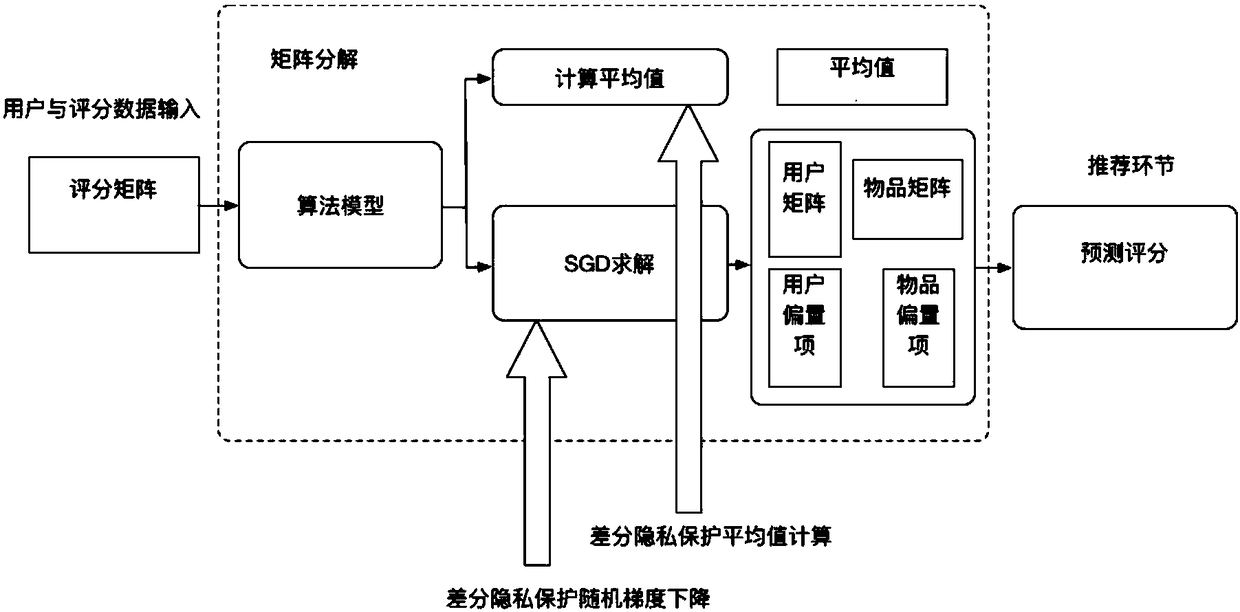

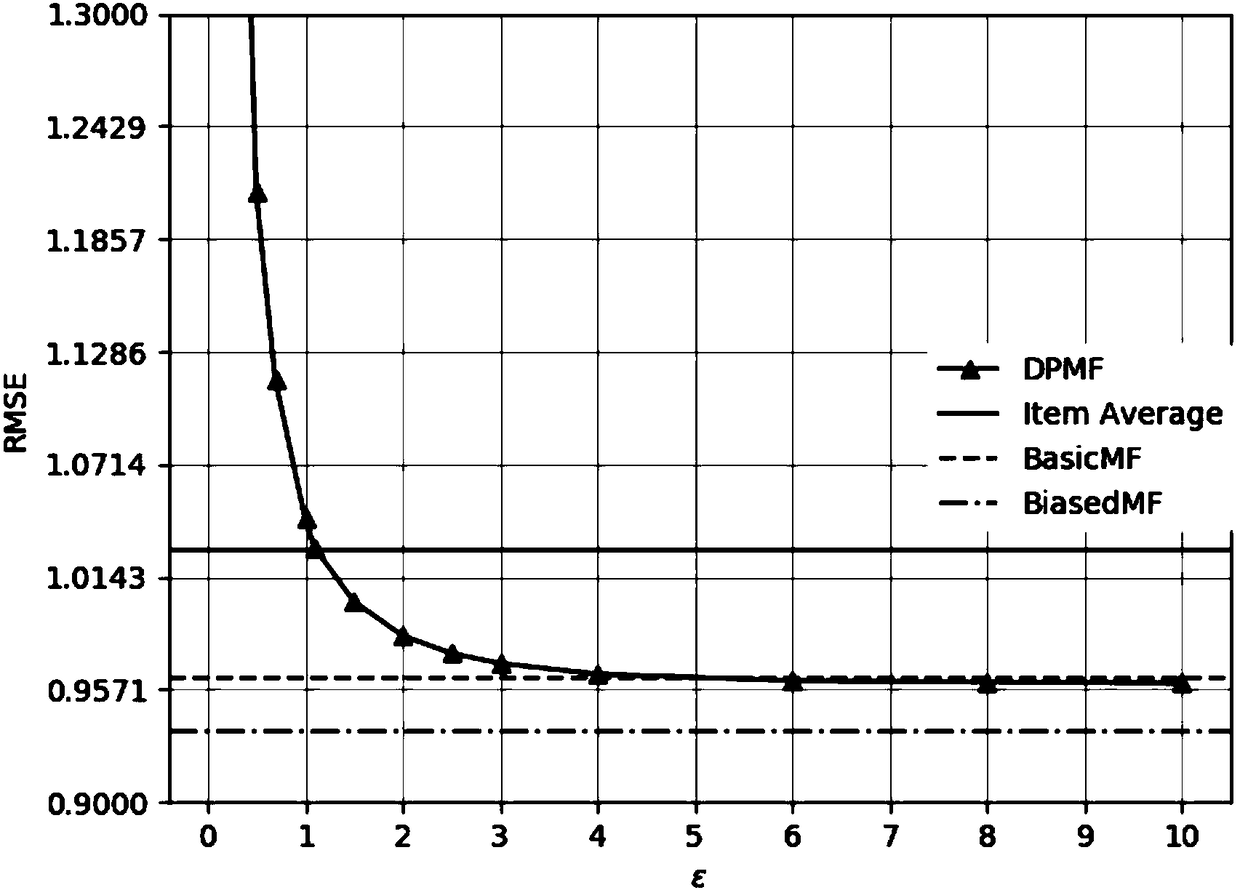

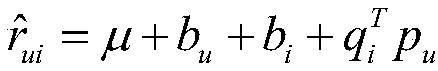

Matrix decomposition recommending method based on difference privacy protection

InactiveCN108280217AEffective protectionReduce joinDigital data protectionComplex mathematical operationsFactor matrixRating matrix

The invention discloses a matrix decomposition recommending method based on difference privacy protection. The method comprises the steps of converting the collected evaluation or preference of usersfor an object into a user-score matrix as a training set of a recommending method model; utilizing a score average value, a user factor matrix, an object factor matrix, a user bias item and an objectbias item to predict score conditions for the object by the users; through a difference privacy average value calculation method, calculating an average value of the user scores under difference privacy protection; according to a score prediction model, building a minimum square error function; through a difference privacy random gradient lowering method, training the score prediction model, adding difference privacy noise in the training process and achieving the difference privacy protection of parameters; through the score prediction model and trained difference privacy protection model parameters, predicting scores for the object by the users. When a recommending result is provided, information of the users can be subjected to the difference privacy protection, and the recommending accuracy is high.

Owner:NANJING UNIV OF SCI & TECH

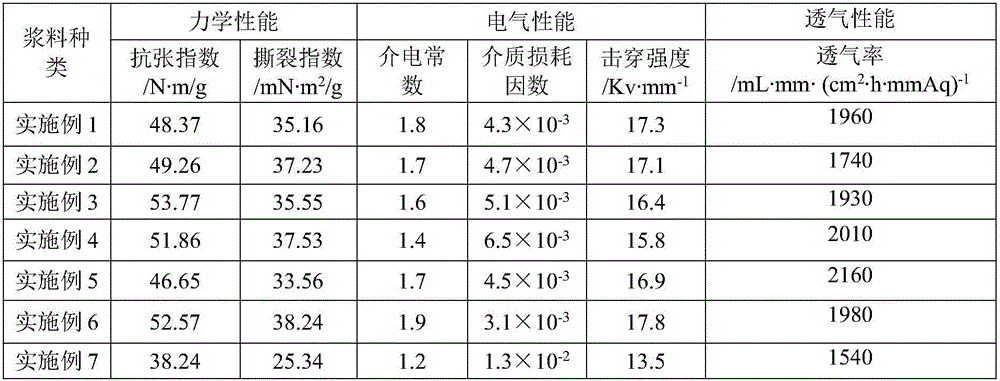

Preparation method of polyimide fiber paper

ActiveCN106436441AHigh surface energyIncrease roughnessDefoamers additionPaper/cardboardFiberPapermaking

The invention discloses a preparation method of polyimide fiber paper, and belongs to the field of paper-making industries and materials. The method comprises the steps that polyimide chopped fiber is treated by a chemical reagent, the treated fiber is washed to be neutral, then, the fiber, a binder and a dispersing agent M are mixed according to a certain mass ratio, the fiber raw materials are dispersed into a pulp suspension, papermaking is performed through a paper making machine to obtain raw polyimide fiber paper, and finally hot pressing is performed through a hot press to obtain the polyimide fiber paper. According to the preparation method, the fiber is subjected to modification treatment, fiber surface active groups are added, the fiber surface energy and roughness are improved, the binding force of components in paper pages can be improved, the binder flows in the paper pages to achieve the effect of viscose fiber through hot pressing and melting, the preparation method can remarkably reduce chemical auxiliaries added in the polyimide fiber raw paper making process, environmental pollution caused in the paper making process can be reduced, and the mechanical performance, the electrical performance and the gas permeability of the polyimide fiber paper can be effectively improved.

Owner:JIANGNAN UNIV +2

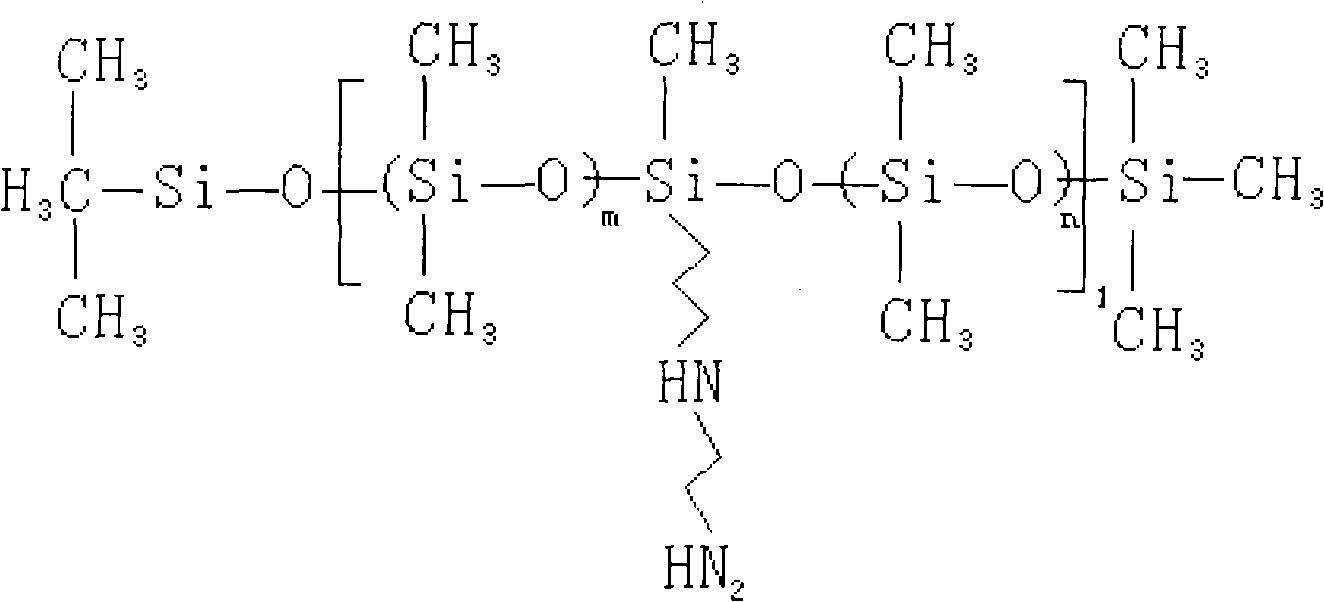

Amino silicone modified waterborne polyurethane and preparation method thereof

InactiveCN102167795AReduce joinLower surface energyPolyurea/polyurethane coatingsPropanoic acidSide chain

The invention discloses amino silicone modified waterborne polyurethane. The waterborne polyurethane is prepared from the following raw materials in parts by weight: 150-220 parts of polyether, 100-150 parts of isophorone diisocyanate, 15-20 parts of dimethylol propionic acid, 0.5-0.8 part of catalyst, 0-5 parts of trimethylolpropane, 15-30 parts of 1,4-butanediol, 4-5 parts of acetone, 10-15 parts of triethylamine, 5-10 parts of side chain amino silicone oil and 620-630 parts of deionized water. The preparation method of the amino silicone modified waterborne polyurethane is that side chain amino silicone oil is introduced in the aqueous phase chain extending process for modification; and the waterborne polyurethane has low preparation cost and good water resistance and adhesive force, is environmentally friendly and has no security threat.

Owner:王奇

Meat chicken feed and preparation method thereof

InactiveCN102210409ALow water soluble proteinReduce joinFood processingAnimal feeding stuffAdditive ingredientWater quality

The invention discloses a meat chicken feed. The formula of the feed consists of corn, enzymolysis bean pulp, corn albumen powder, dry corn distilled grain, edible oil and fat, calcium hydrogen phosphate, salt, composite vitamin, composite trace element, composite amino acid and composite enzyme preparation serving as main components. The feed is prepared by the following steps of: crushing the corn, the corn albumen powder, the dry corn distilled grain and the prepared enzymolysis bean pulp until granularity reaches 0.5 to 0.8 millimeters, mixing the components uniformly, adding the rest feed components, and mixing all the components uniformly to obtain the product. Aiming at the characteristics of incomplete digestive physiology and the like of the meat chicken, the enzymolysis bean pulp, a bacillus subtilis preparation and an enzyme preparation are added in the formula of the feed, so that the survival rate and the production performance of the chicken are improved, the digestive utilization efficiency of organic substances and mineral substances is improved at the same time, the emission of nitrogen and phosphorus in the manure is reduced, and pollution of the nitrogen and the phosphorus in the chicken manure to the soil and the water is effectively controlled.

Owner:HENAN UNIV OF SCI & TECH

Method for preparing high-moisture fermented granular feed for poultry

InactiveCN102178092AHigh densityHigh nutrient concentrationAnimal feeding stuffWorking-up animal fodderDiseaseBiotechnology

The invention relates to a method for preparing high-moisture fermented granular feed for poultry. The feed is composed of 60-70wt% of corn and 30-40wt% of fermented protein feed, firstly the fermented protein feed is prepared by utilizing composite bacterium liquid to ferment soybean meal, cottonseed meal and vinasse, and then the fermented protein feed is mixed with the corn to finally obtain the high-moisture fermented granular feed. The granular feed prepared by the method provided by the invention is convenient to store, package and transport; since the density of the granular feed is high, the volume is reduced, and the nutrient concentration is high, the feed intake of animals is correspondingly increased; and the composite flora is used for fermenting soybean meal and cottonseed meal to increase the content of crude protein and promote generation of the beneficial flora, thereby improving the beneficial flora in an intestinal canal, reducing the incidence of disease, improving the physicochemical properties of certain nutrient components in the feed, and enhancing the digestion absorption rate and the utilization rate of nutrient substances to a certain degree.

Owner:河南宏翔生物科技有限公司

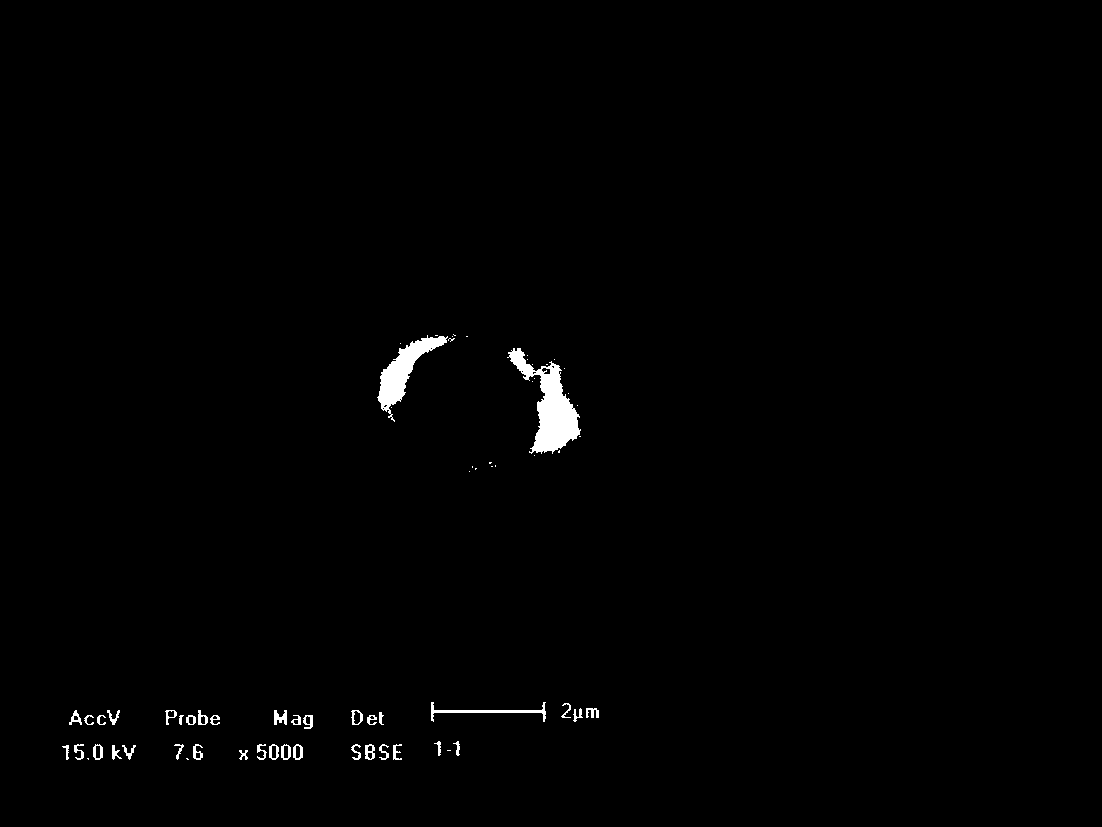

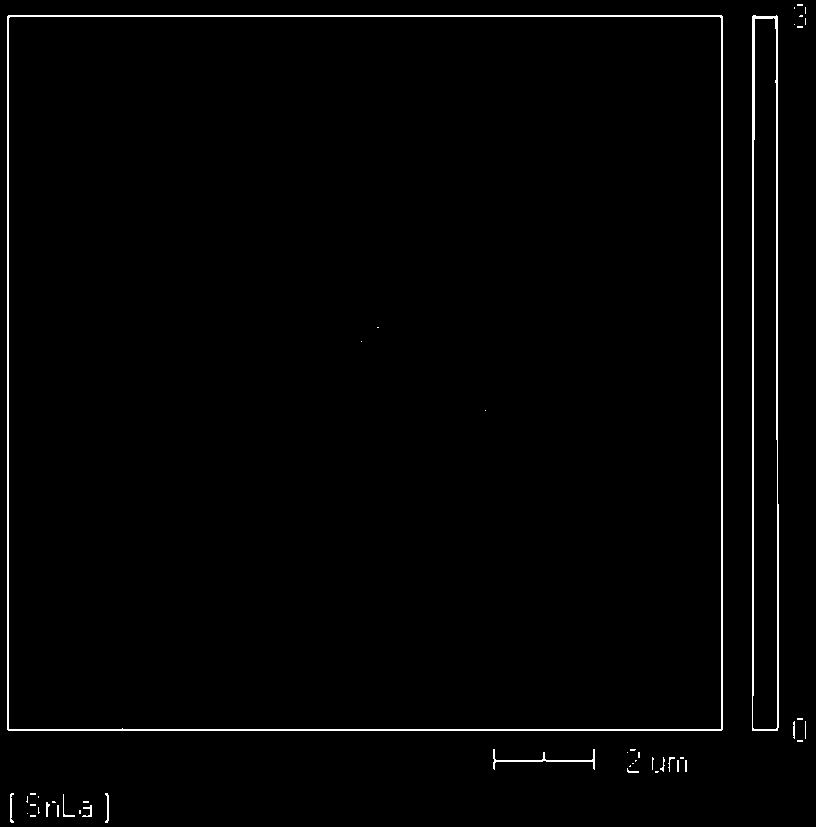

Abnormally segregated stanniferous low-clearance ferritic stainless steel and preparation method thereof

The invention discloses abnormally segregated stanniferous low-clearance ferritic stainless steel and a preparation method thereof, and belongs to the technical field of metallurgy. The stainless steel comprises the following components in percentage by weight: 0.005-0.03% of C, 0.2-0.4% of Si, 0.2-0.5% of Mn, less than or equal to 0.03% of P, less than or equal to 0.02% of S, 14-16% of Cr, less than or equal to 0.01% of N, 0.1-0.4% of Sn, Nb, Ti and / or V and the balance of iron and inevitable impurities; the tensile strength is 445-451MPa; the pitting potential is 202-240mV. The preparation method comprises the following steps: (1) smelting and casting a blank according to set components; (2) heating to be 1150+ / -10 DEG C, carrying out heat preservation for 1-3 hours, and subsequently hot-rolling to make a hot-rolled steel plate; (3) annealing at 900+ / -10 DEG C for 2-3 hours, cooling to room temperature, pickling and then cold-rolling to make a cold-rolled steel plate; (4) heating to 800+ / -10 DEG C and carrying out normalizing treatment to obtain the abnormally segregated stanniferous low-clearance ferritic stainless steel. By adopting the method disclosed by the invention, the production cost of the stainless steel can be greatly lowered, the process is simple, and a product is high in strength, hardness and corrosion resistance.

Owner:NORTHEASTERN UNIV

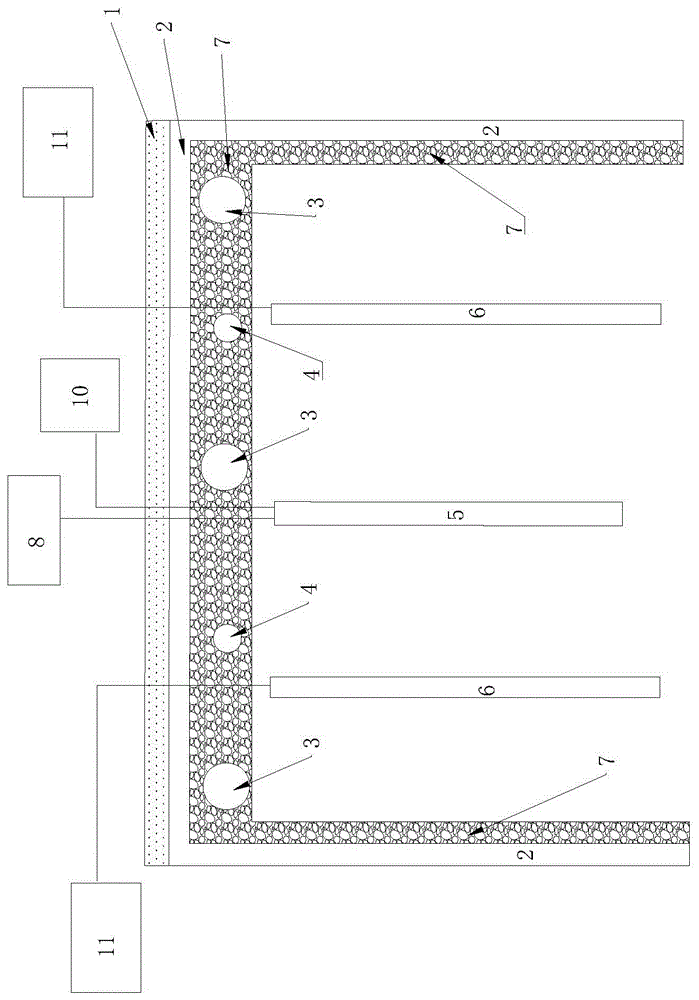

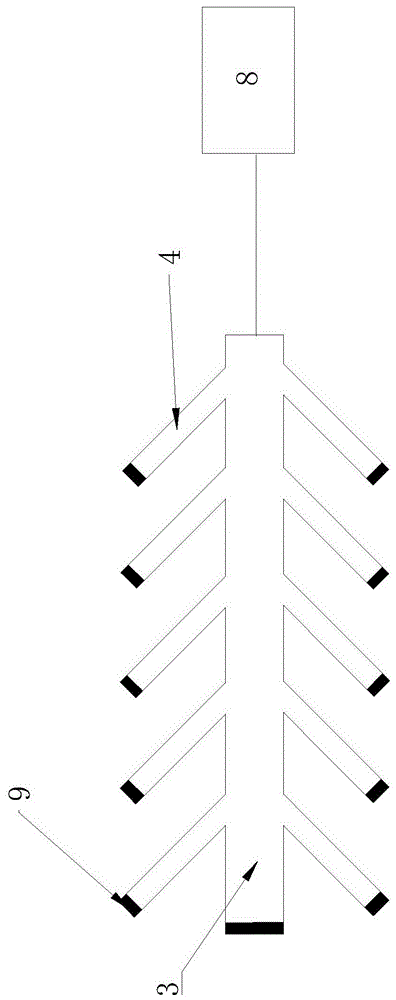

Organic contaminated site reinforced repair system and process

PendingCN106734167AFacilitated DiffusionGood for volatilizationContaminated soil reclamationSulfate radicalsCompound (substance)

The invention discloses an organic contaminated site reinforced repair system which comprises an extraction system, a medicament injection system, a heating system and a blocking repair layer. According to the organic contaminated site reinforced repair system, the in-situ thermal desorption technology and the chemical oxidization technology are combined, meanwhile, a repair material layer is added, the repair material layer is prepared from slow release oxidization materials and mainly prepared from persulfate, natural clay materials, nonmetallic mineral, cement and the like, and sulfate radical produced after persulphate reaction can be fixed. By means of the repair system, on one hand, the organic contaminated site in-situ thermal desorption repair cost can be reduced; on the other hand, the in-situ chemical oxidation repair efficiency can be improved, secondary pollution can be reduced, accordingly, the repair cost is reduced, and the repair efficiency is improved.

Owner:BEIJING GEOENVIRON ENG & TECH

Process for dispersing hot-melt adhesive fillers

InactiveCN101289599AReduce joinImprove product added valueNon-macromolecular adhesive additivesGranulation by material expressionLight whiteTalc

The invention relates to a method for dispersing hot-melt adhesive filler. The method comprises the following steps that: filler and other components of hot-melt adhesive are evenly mixed by granulation equipment; or part of the filler and other components of the hot-melt adhesive are evenly mixed and granulated by granulation equipment, and then the left over filler is evenly mixed with the granulated mixture. Other components of the hot-melt adhesive comprise main body resin, tackifying resin and a diluent agent; the filler comprises toner, flash powder, calcium carbonate, micro silicon powder, talc powder, white carbon black, light white carbon black, metal nitride, metal oxide and metal nitride or metal oxide; moreover, extruding granulation adopts a single screw extruder or a double screw extruder. The method has the advantages that: the addition of a poisonous and harmful dispersing agent is reduced to protect the environment; the filler is evenly mixed through a physical method, and manufacturing technique is simplified to reduce cost; and because a granular material contains less air volatile matter, the product is not easy to generate air bubbles, thereby ensuring product quality.

Owner:金尔升

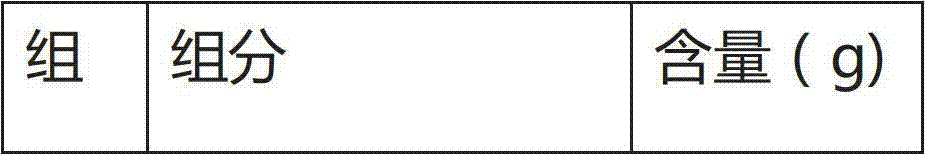

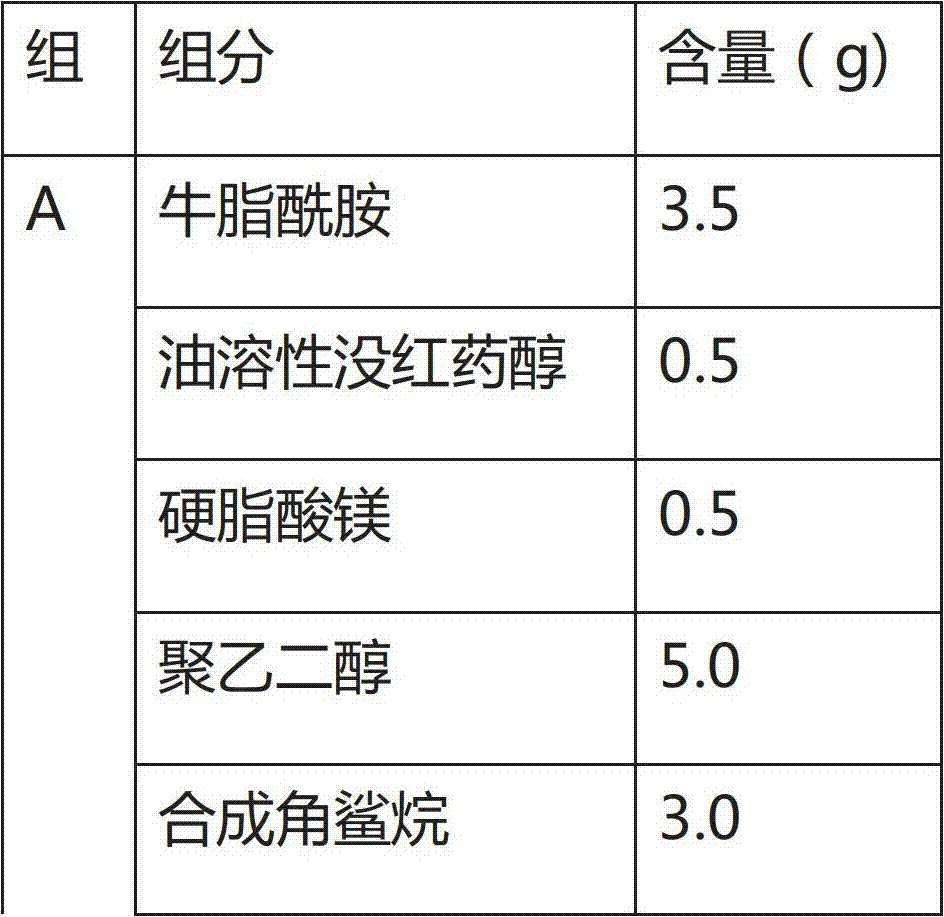

Chlorophyll sun-screening repair cosmetic

InactiveCN102846485AReduce joinReduce inflammationCosmetic preparationsToilet preparationsPreservativeMedicine

The invention discloses a chlorophyll sun-screening repair cosmetic, which comprises the following components, by weight, 0.005-0.105 part of a pigment, 0.1-1 part of oil soluble bisabolol, 5-40 parts of an emulsifier, 1-10 parts of a moisturizing agent, 0.01-0.5 part of a preservative, 0.005-0.1 part of an essence, and 60-85 parts of deionized water, wherein the effect components comprise the chlorophyll and the oil soluble bisabolol. The chlorophyll sun-screening repair cosmetic disclosed by the present invention is a cosmetic with effects of skin nourishing, skin sunscreen and repair, and can be used for skin care and after-sun repair in summer.

Owner:GUANGDONG COOWAY BIOTECH CO LTD

Method for preparing high-moisture fermented granulated feed for pigs

InactiveCN102178093AEasy storageAvoid moisture cakingFood processingAnimal feeding stuffNutrientChemistry

The invention discloses a method for preparing a high-moisture fermented granulated feed for pigs. The feed is prepared from the following raw materials in percentage by weight: 65-70% of corn and 30-35% of fermented protein feed; and the method comprises the following steps: firstly, fermenting bean pulp, bran and a vinasse protein feed by using compound microbial liquid so as to obtain a fermented protein feed; and then, mixing the fermented protein feed with the corns. The feed prepared by using the method is a granulated feed which is easy to store, package and transport; because the density of the granulated feed is large, the volume thereof is reduced, and the nutrient concentration thereof is high, so that the feed intake of animals is correspondingly increased; and the crude protein content of the feed and the generation of beneficial microorganisms can be increased by simply fermenting the bean pulp and bran by using complex microorganisms, thereby improving the beneficial microorganisms in intestinal canals, reducing the occurrence of diseases, improving the physicochemical properties of some nutrients in the feed, and enhancing the digestibility of the feed and the utilization rate of nutrients in the feed to some extent.

Owner:河南宏翔生物科技有限公司

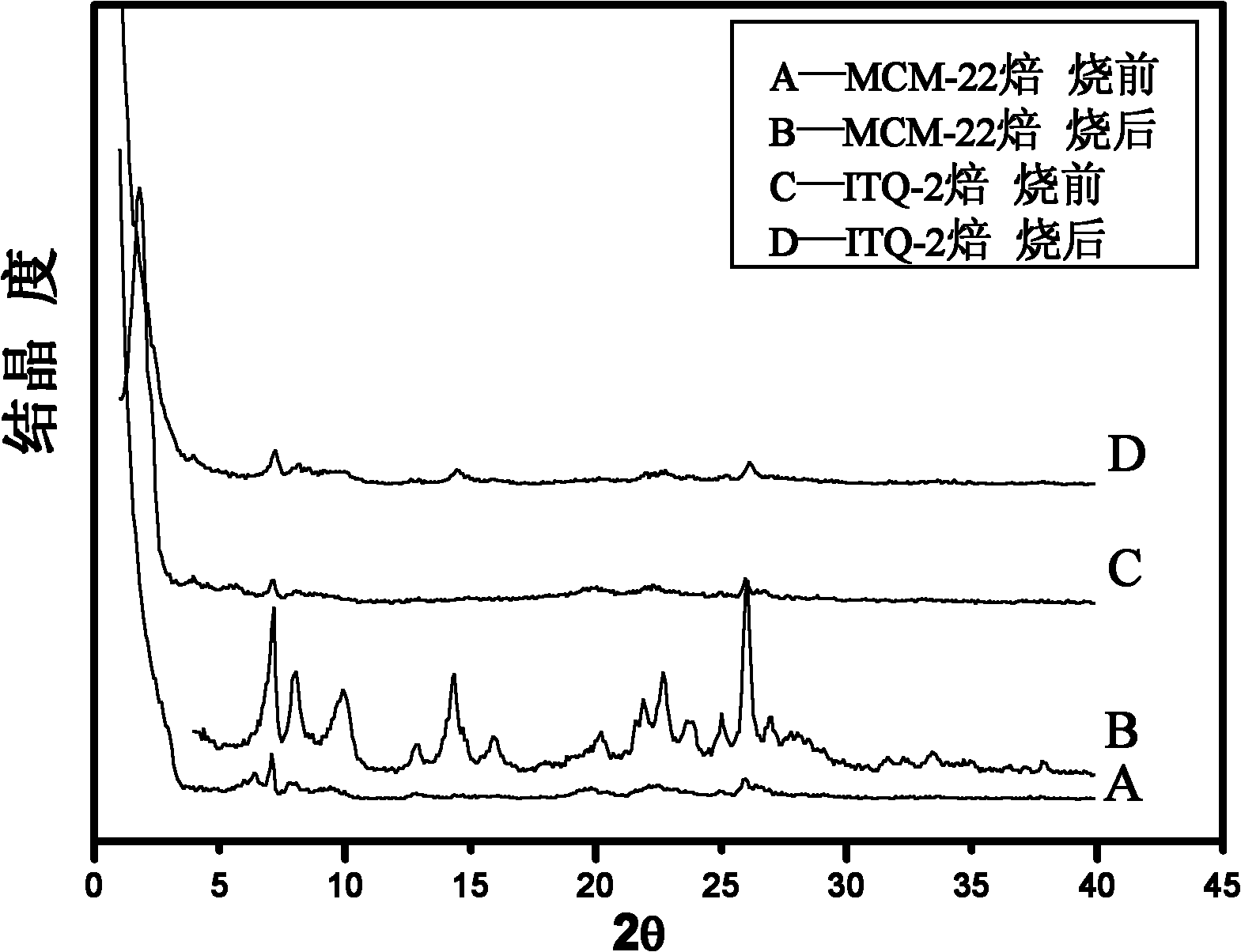

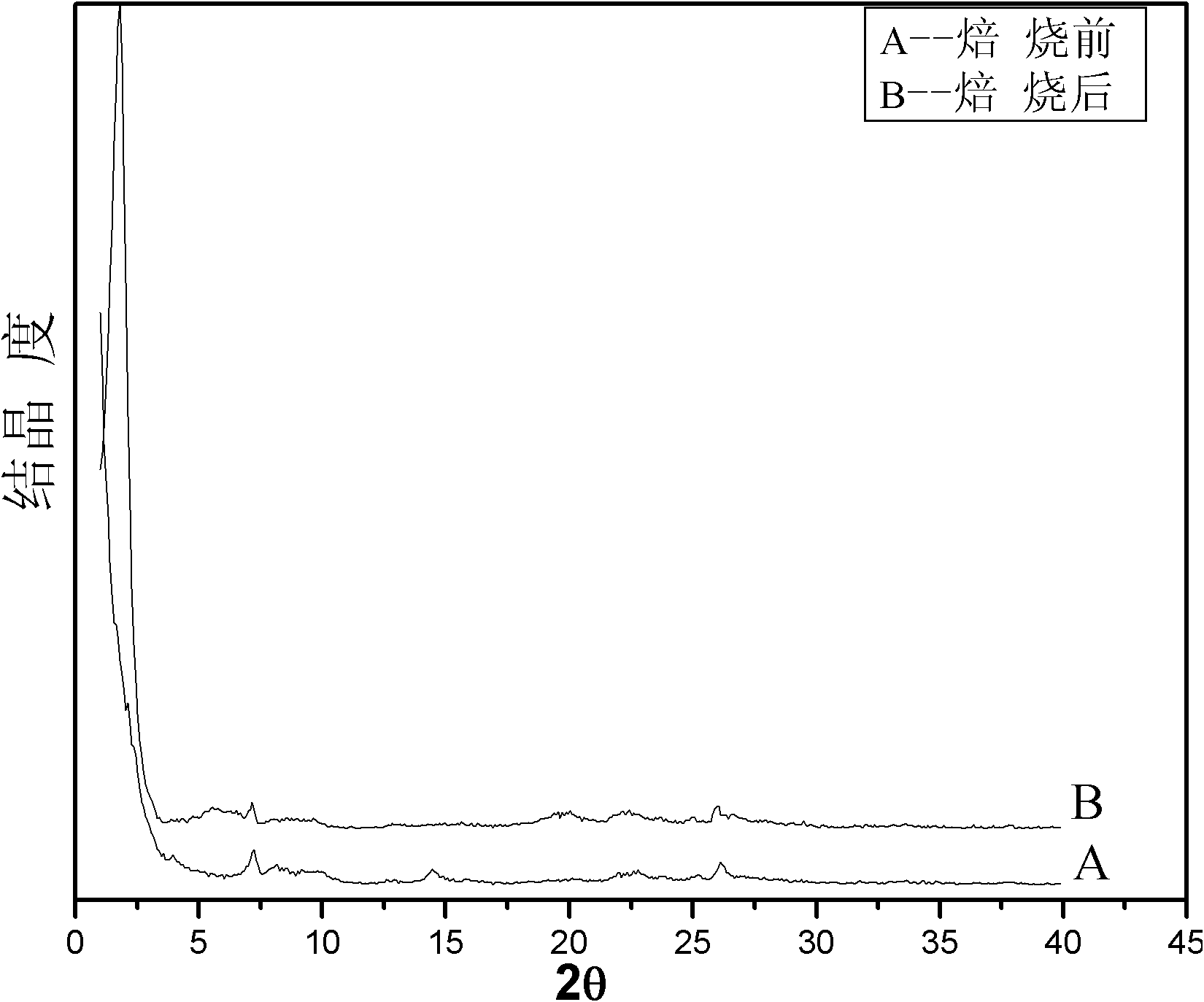

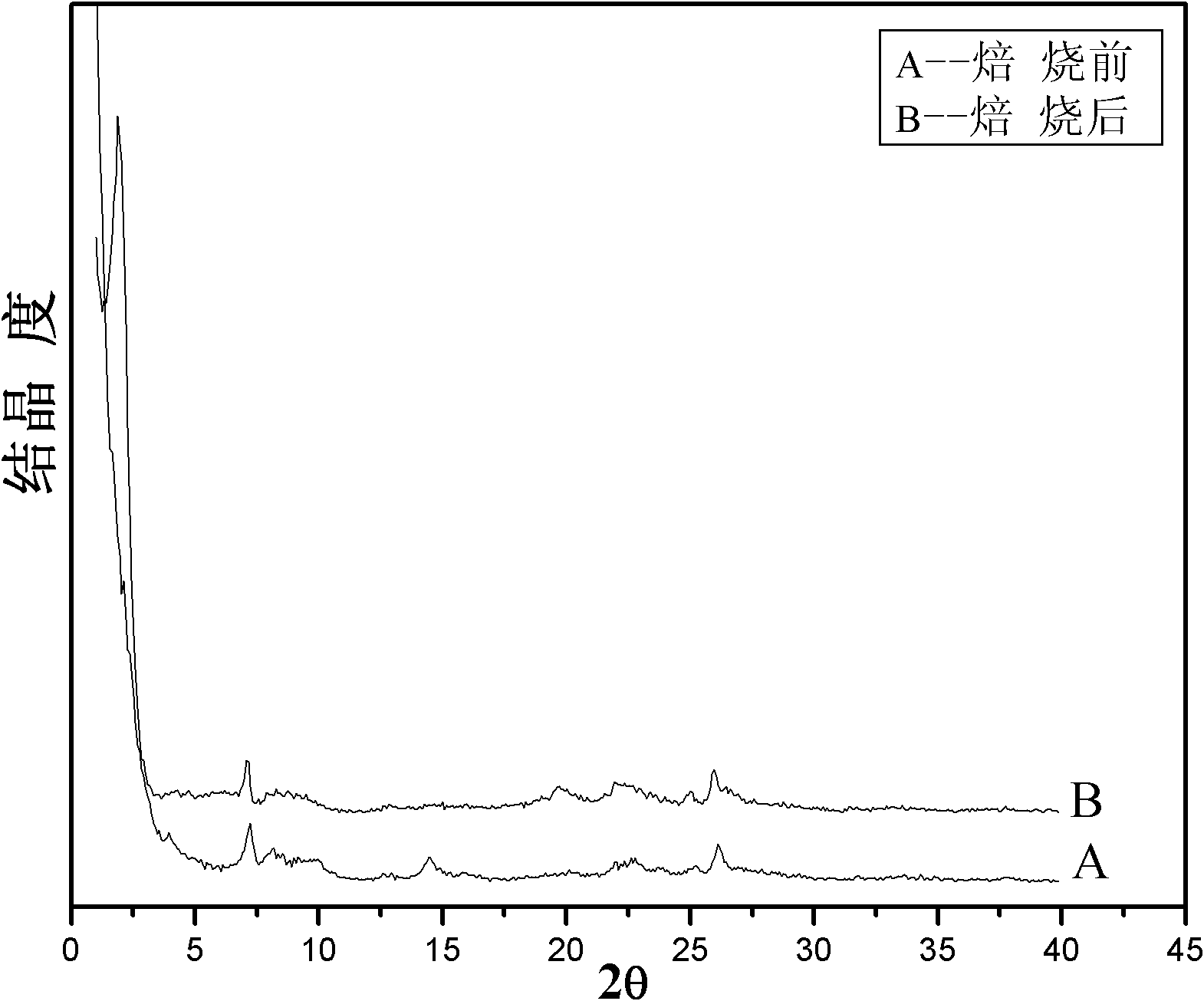

Method for preparing ITQ-2 molecular sieve

InactiveCN101973560AReduce joinGuaranteed yield rationalizationCrystalline aluminosilicate zeolitesMolecular sieveDecomposition

The invention provides a method for preparing an ITQ-2 molecular sieve, which is characterized in that an MCM-22 molecular sieve is prepared, NaOH, KOH or mixture of NaOH and KOH or silicate containing NaOH and KOH is taken as an alkali source to prepare alkali solution; a silicon source is added in the obtained alkali solution and stirred to obtain solution A; an expanding agent is added into the solution A to obtain solution B; the solution B is heated and stirred continuously, then the MCM-22 molecular sieve is added in the solution B for expanding treatment, the expanded pulp is treated by ultrasonic wave, and the pH value of the solution after ultrasonic treatment is adjusted by acid solution. In the method, quaternary ammonium base for synthesizing the ITQ-2 molecular sieve is completely replaced by inorganic base, the production cost is low, desilicication by adding the silicon source is restrained, and the rationalization of the yield of target products is guaranteed. The method is simple and available and does not require the addition of organic base, thus reducing the pollution to the environment due to decomposition of the organic matters in the process of subsequent processing.

Owner:DALIAN UNIV OF TECH

Drunken tilapia snack food and processing method thereof

The invention discloses a drunken tilapia snack food and a processing method thereof. Tilapia fillets are prepared into semi-dried drunken fillets through the steps of picking, inebriating, vacuum microwave drying and the like. By controlling the drying conditions, the flavoring material and original chewiness of the drunken fish are well maintained while the water content of the drunken fish is improved, and thus the drunken fish is good in flavor and taste. The process is capable of shortening the production period, reducing the production cost, and facilitating production. The drunken tilapia snack food processed by the method disclosed by the invention is natural in flesh color, compact, fresh and tender in meat, proper in salt taste, hardness and moisture, free from intermuscular fishbone, and suitable for people of all ages. The method is further suitable for small and medium freshwater fish, such as colussoma brachypomum, without or with less intermuscular fishbone.

Owner:GUANGDONG YUJIA AQUATIC FOOD

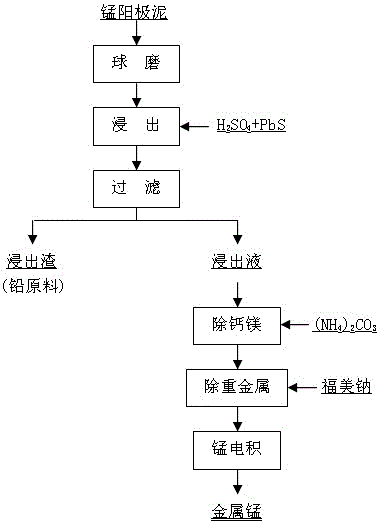

Method for comprehensively recycling manganese, lead, silver and selenium from manganese anode slime

ActiveCN106544511AWide variety of sourcesLow costPhotography auxillary processesProcess efficiency improvementLead smeltingElectrolysis

The invention provides a method for comprehensively recycling manganese, lead, silver and selenium from manganese anode slime. The method comprises the steps that firstly, the manganese anode slime, lead sulfide concentrate and ball milling liquid are mixed and subjected to wet-type ball milling; secondly, leaching of valuable metals such as manganese and selenium is conducted, leachate is reserved, and leached residues serve as lead smelting raw materials for recycling lead and silver; thirdly, a calcium-magnesium removing agent is added for impurity removing; and fourthly, a neutralizer, namely, ammonium hydroxide, and ammonium sulfate are added, a cleaning agent, namely, sodium dimethyl dithiocarbamate is dropwise added, and after stewing is conducted, activated carbon is added for adsorption, filter pressing is conducted, an electrolyzing additive is dropwise added into filtrate, and electrolytic manganese metal is prepared through electrolyzation. The method is small in investment, simple in technology, low in cost and capable of effectively increasing the comprehensive recovery rate.

Owner:ZHUZHOU SMELTER GRP

Large-strain X80 dual-phase steel plate produced by virtue of process at low temperature and under high pressure

The invention belongs to the field of the low-alloy high-strength pipeline steel and more specifically relates to a large-strain X80 dual-phase steel plate produced by virtue of a process at a low temperature and under a high pressure. The large-strain X80 dual-phase steel plate is composed of the following components in percentage by weight: 0.05-0.07% of C, 0.25-0.35% of Si, 1.40-1.80% of Mn, less than or equal to 0.01% of P, less than or equal to 0.003% of S, 0.01-0.04% of Nb, 0.01-0.02% of Ti, less than or equal to 0.035% of Mo, less than or equal to 0.30% of Cu, less than or equal to 0.035% of Cr, less than or equal to 0.030% of Ni, less than or equal to 40ppm of N, less than or equal to 20ppm of O, less than or equal to 1.2ppm of H and the balance of Fe and inevitable impurities. The large-strain X80 dual-phase steel plate has the beneficial effects that the steel plate is subjected to accelerated cooling by virtue of high-pressure water in the adopted rolling process so that the crystalline grain are effectively refined and the production efficiency is improved, and multi-pass cooling and rolling at a low temperature and under high pressure are not carried out in a non-recrystallization zone, and finally, a proeutectoid ferrite-lath bainite structure is obtained, the obtained steel plate has the yield strength Rt0.5 of 480-560MPa, the tensile strength Rm of 770-800MPa, the yield ratio Rt0.5 / Rm being less than or equal to 0.75, the Charpy impact energy at -20 DEG C being greater than or equal to 350J, the drop shear area at -15 DEG C being greater than or equal to 95% and the Uniform elongation UEL being greater than or equal to 12, and the steel plate is high in anti-deforming capability, and furthermore, the stress ratios of the steel plate are as follows: Rt2.0 / Rt1.0 is greater than or equal to 1.09 and Rt1.5 / Rt0.5 is greater than or equal to 1.15.

Owner:JIGANG GRP

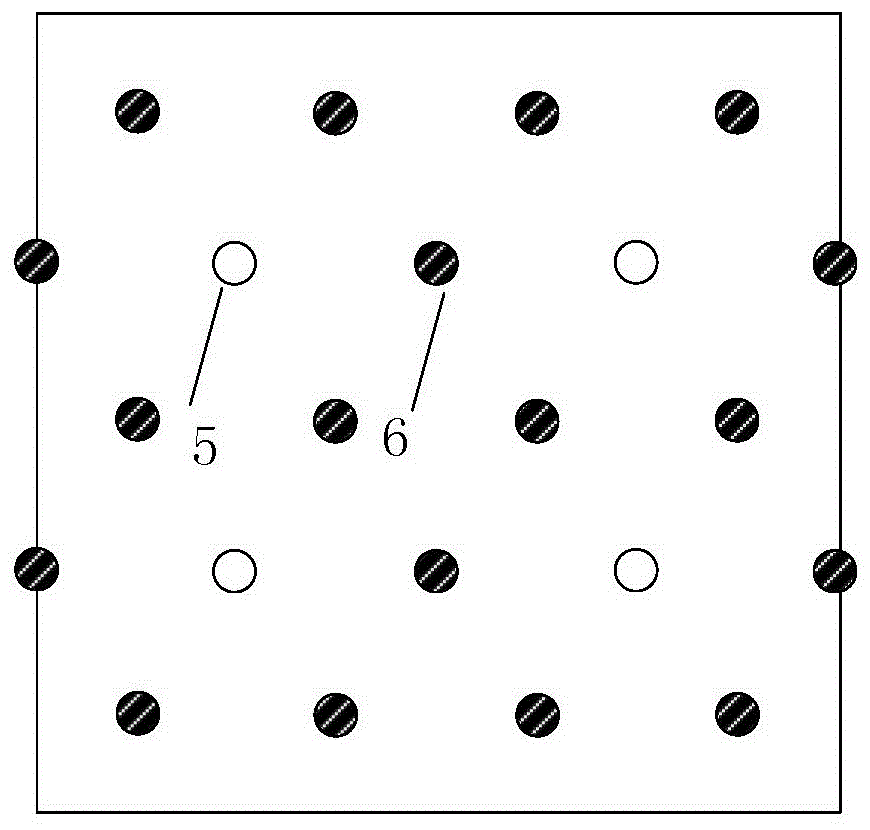

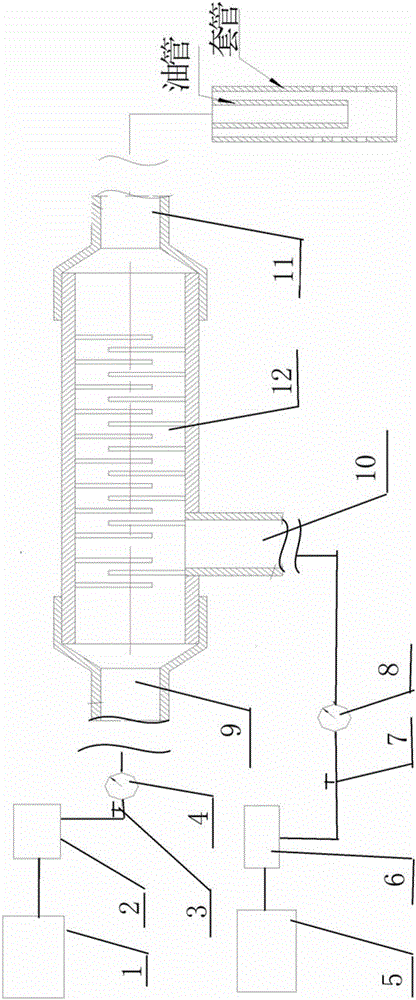

Biotrickling filter for treating volatile organic waste gas

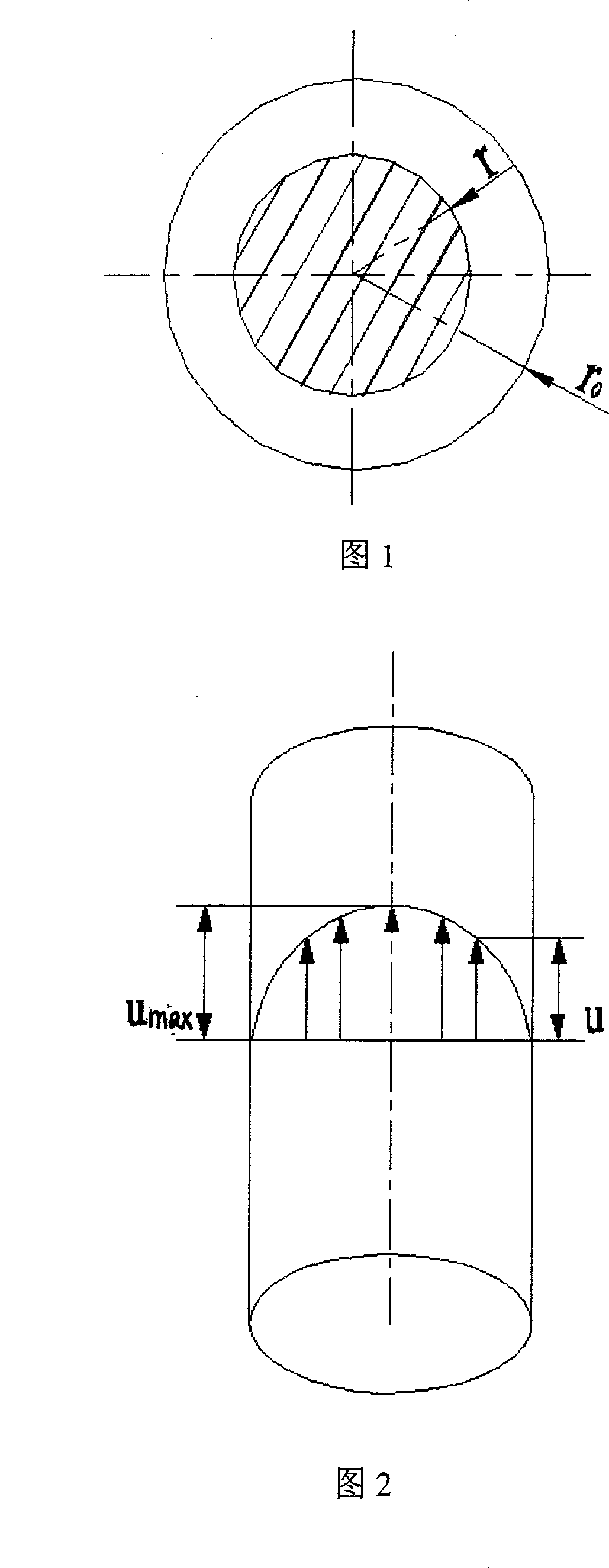

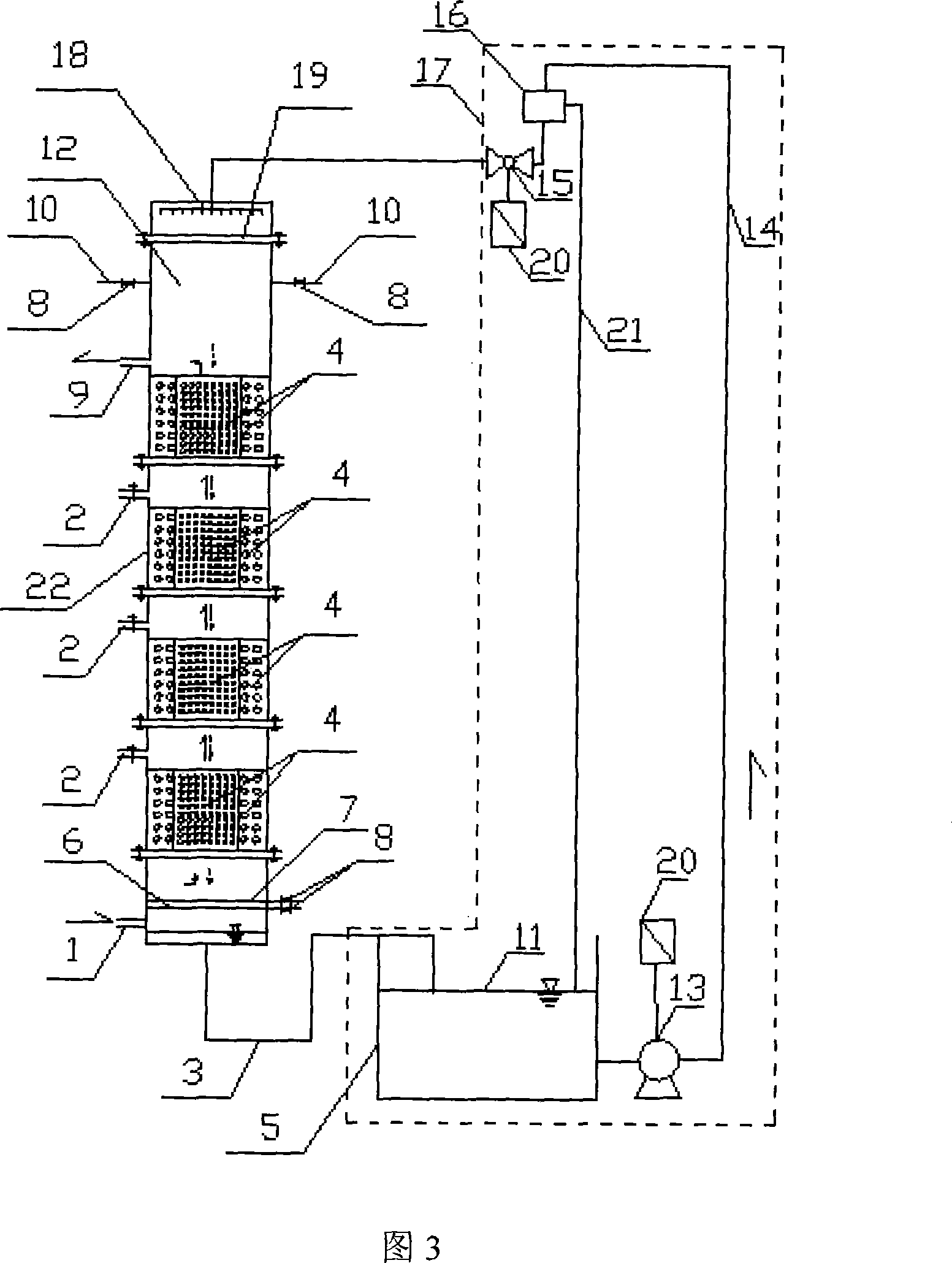

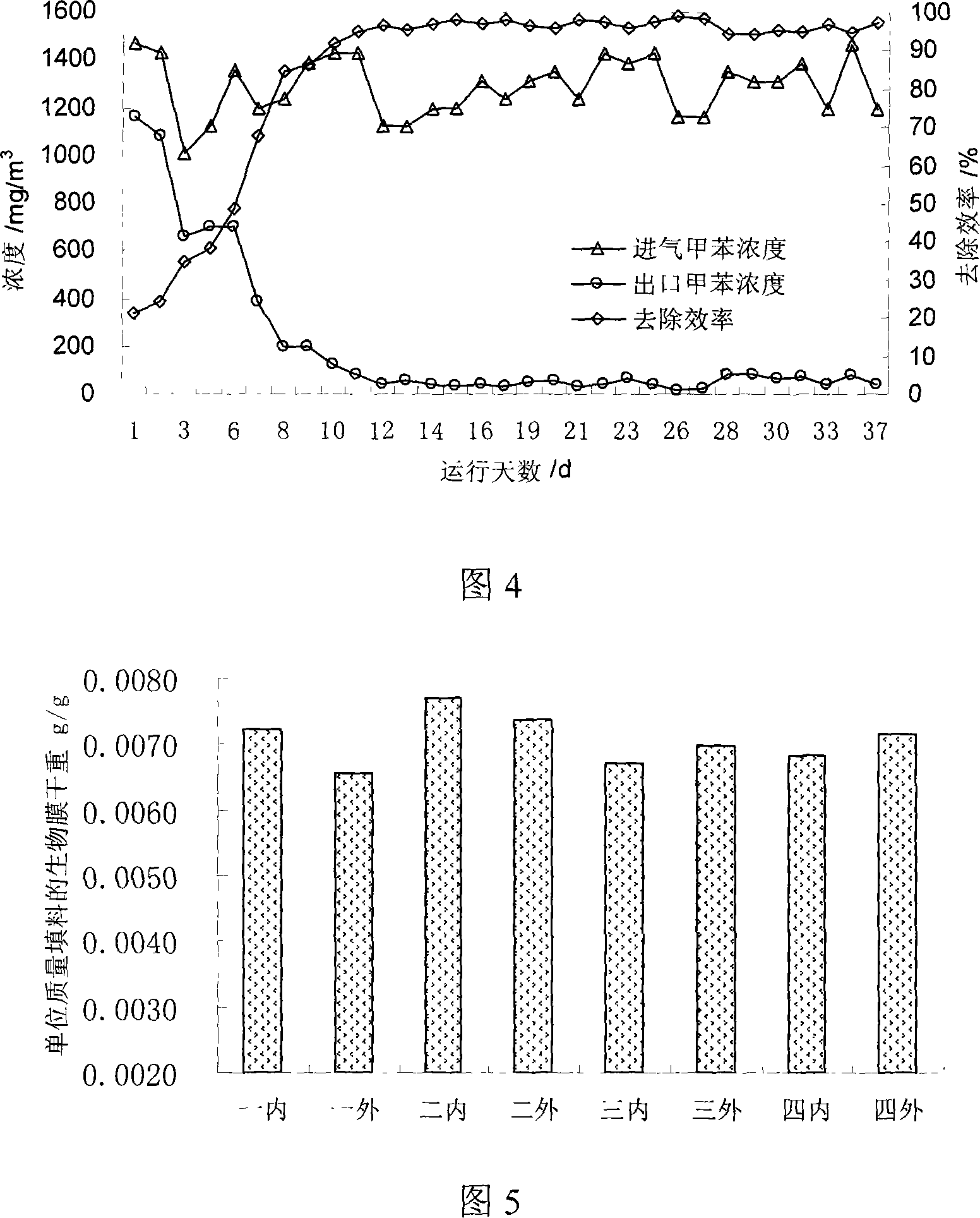

InactiveCN101125280AEvenly distributedAvoid wall flowDispersed particle separationAir quality improvementVoltage dropEngineering

The present invention relates to a BTF used for dealing with the volatile waste gas, belonging to the field of treatment of the volatile waste gas, which aims at solving the problems that the prior BTF has uneven air flow distribution and biomass distribution, high center gas speed and voltage drop, and the prior BTF is easy to be blocked. The technic proposal is that: the volatile waste gas passes through an intake pipe (1) and then comes into a biofilter (22), and then being drained away by an exhaust pipe (9) after having the processes of degradation and purification; a nutrient solution (11) comes into the biofilter (22) through a nutrient solution shower (18) and a dropwise adding distributor device (19) having fixed quantities at fixed time; the present invention is characterized in that adopting a light and cheap packing (4) with different grain diameters, the biofilter (22) takes a homocentric column shape sleeve structure , the grain diameters of the filled packing (4) from the center to the edge are distributed from small to big, the centre area is filled with the packing (4) with small grain diameters, the ring area of the around close walls is filled with the packing (4) of big grain diameters. The present invention makes the distribution of the biomass in the biofilter even, thereby fully utilizing the useful space of the biofilter.

Owner:BEIJING UNIV OF TECH

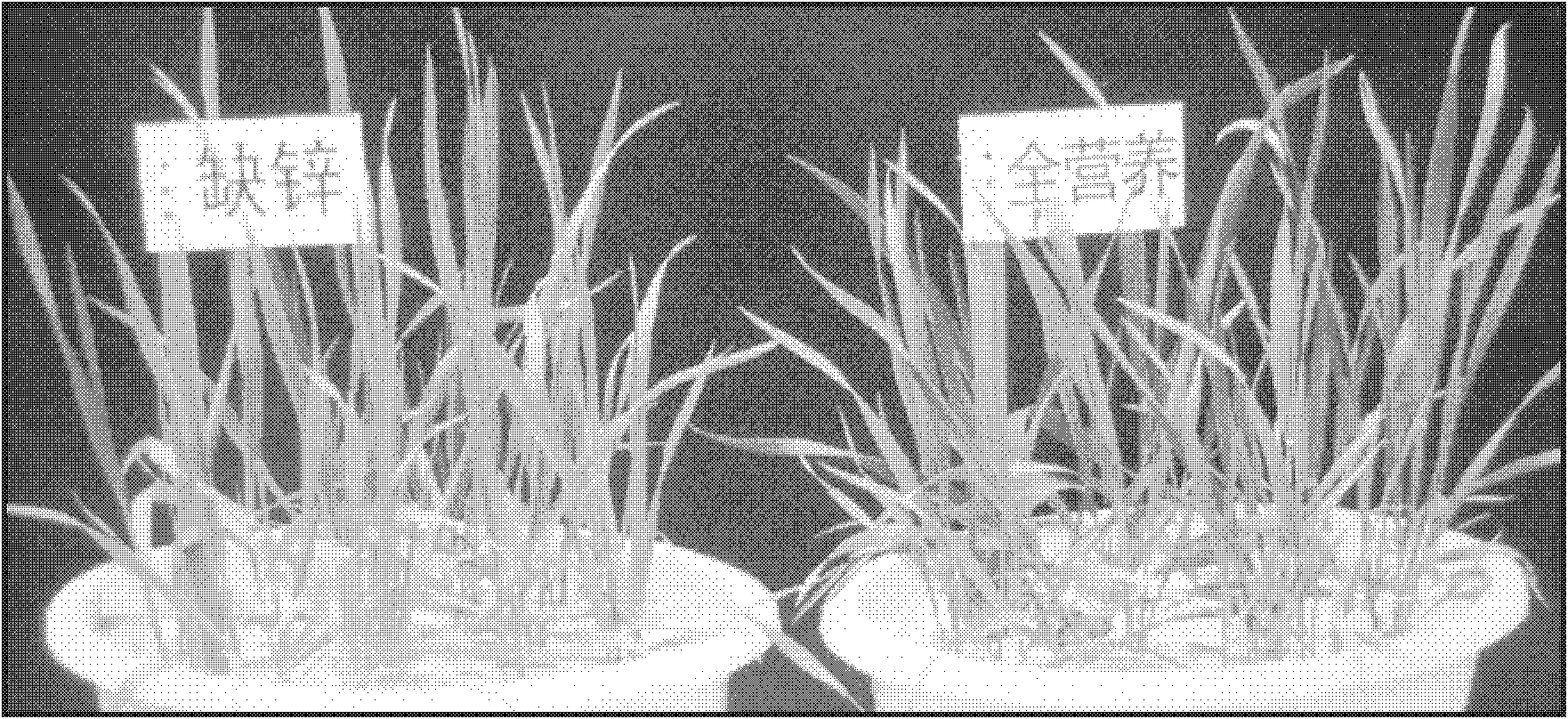

Preparation method of nutrient solution for culturing nutrient-deficient wheat seedling

ActiveCN102126882AReduce joinIncrease productionFertilizer mixturesNutrient solutionComparison standard

The invention relates to a preparation method of a nutrient solution for culturing a nutrient-deficient wheat seedling. The nutrient-deficient nutrient solution for culturing at a wheat seedling stage is prepared from the following nutrition elements of a total nutrient solution, NO<3->, NH<4+>, H2PO<4->, K<+>, Ca<2+>, Mg<2+>, SO4<2->, Cu<2+>, Fe<2+>, Mn<2+>, Zn<2+>, H3BO3, Mo7O24<6-> and Cl<-> in the molar ratio of (3.5-5):2:(0.5-1):(2.5-4.5):(1-2):(0.25-0.5):(1.78-2):0.003:0.025:0.003:0.002:0.01:0.0001:0.016, wherein when one of the nutrition elements is omitted, the molar ratio of other nutrition elements is kept unchanged. Judgment on soil nutrient deficiency in a wheat seedling growing process is guided by taking the nutrient-deficient wheat seedling cultured by using the obtained nutrient-deficient nutrient solution as a comparison standard, a fertilizer is effectively supplemented and scientific fertilizer application is performed, so that the yield and quality of wheat are enhanced.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

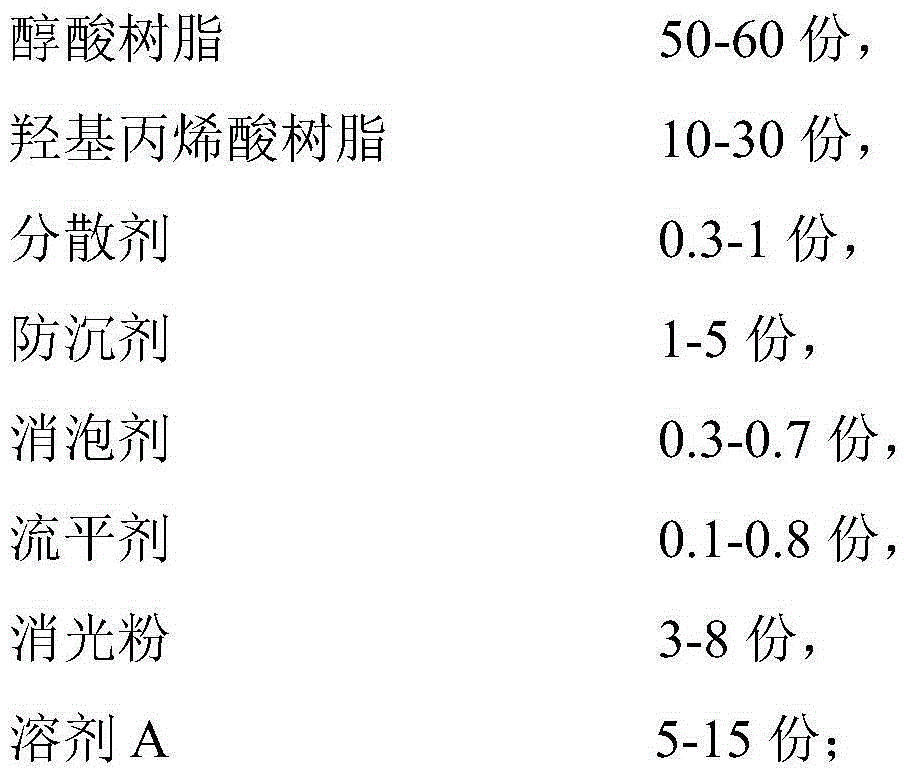

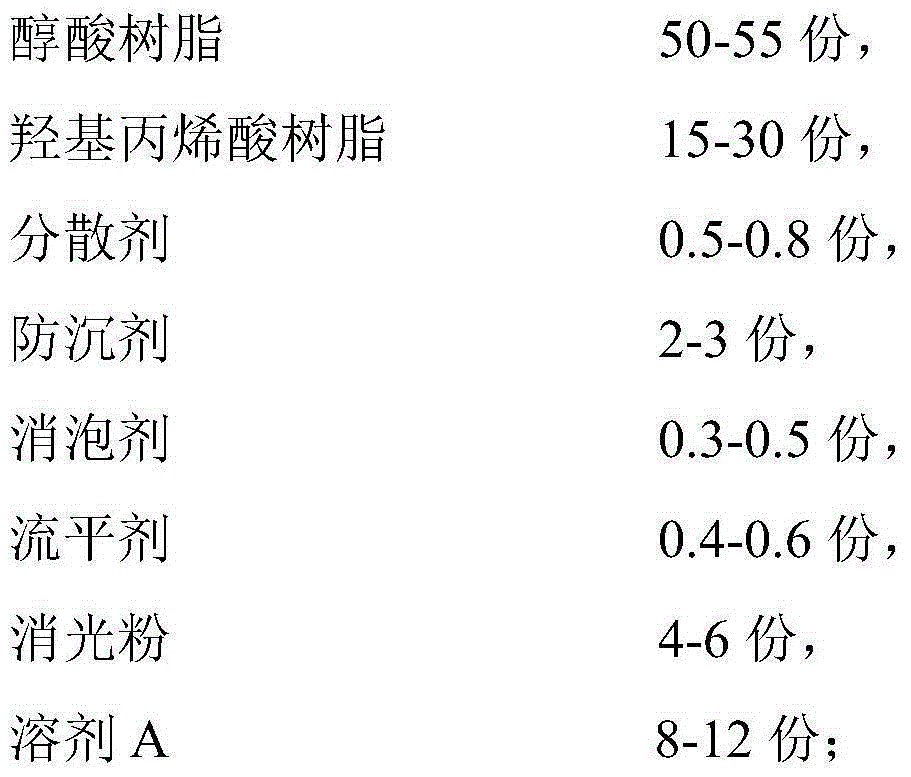

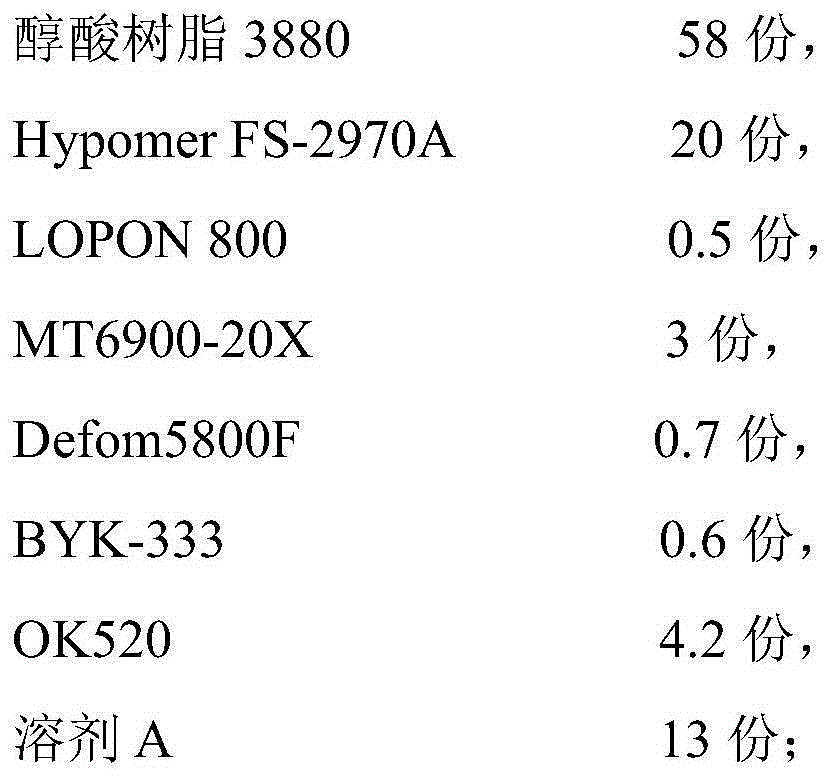

Low-VOC (volatile organic compounds) anti-scratch transparent matte varnish and preparation method thereof

InactiveCN105153923ASmall particle sizeHigh transparencyPolyurea/polyurethane coatingsAcrylic resinLacquer

The invention relates to low-VOC (volatile organic compounds) anti-scratch transparent matte varnish and a preparation method thereof. The matte varnish is made by combining a component A resin paint and a component B solidifying agent according to a weight ratio: 2:1, wherein the component A resin paint comprises 50-60 parts of alkyd resin, 10-30 parts of carboxyl acrylic resin, 0.3-1 part of a dispersant, 1-5 parts of an anti-settling agent, 0.3-0.7 part of a defoaming agent, 0.1-0.8 part of a leveling agent, 3-8 parts of matting powder, and 5-15 parts of a solvent A. The component B solidifying agent comprises 55-70 parts of a solidifying agent and 20-35 parts of a solvent. Compared with the prior art, the matte varnish and the preparation method thereof have the advantages that the preparation method is simple, a selection range of materials is wide, and the matte varnish prepared provides smooth surface, has high hardness, good scratch resistance, high transparency, good clarity and interlayer adhesion and features good hardness, good impact resistance and the like.

Owner:DONGLAI COATING TECH SHANGHAI

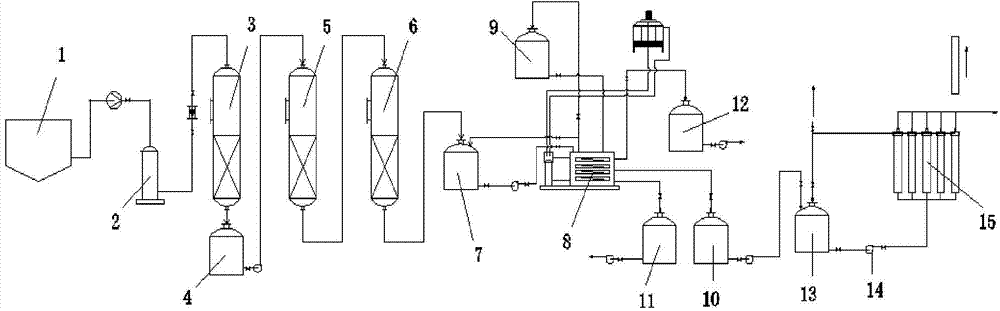

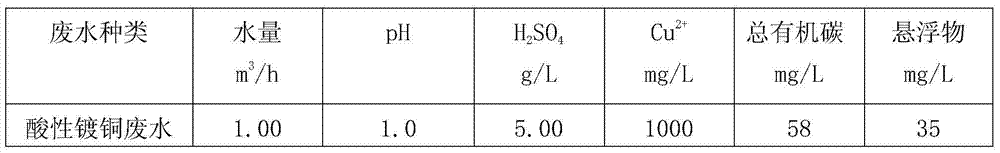

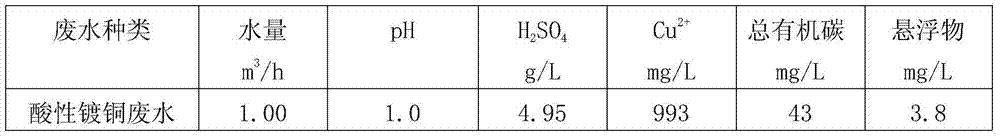

Process and device for recovering electrolytic copper from copper-containing wastewater

ActiveCN104773887AEnable direct recyclingReduce processing costsWater contaminantsWaste water treatment from metallurgical processElectrolysisAutomatic control

The invention relates to a process and device for recovering electrolytic copper from copper-containing wastewater. The electrolytic copper is produced by adopting the technological processes of removing suspended matters and part of organic matters through pretreatment, carrying out ultrafiltration treatment, retaining concentrated copper sulfate with a nanofiltration membrane, recovering wastewater and acids with a reverse osmosis membrane and carrying out cyclone electrolysis. The process and the device have the beneficial effects that the recovery rate of the electrolytic copper is 90% and the copper purity is more than 99.95%; meanwhile, the wastewater recovery rate is more than 90%; the recovery rate of free sulfuric acid in the wastewater is more than 90%; the resource recovery rate is high and the economic benefits are good; adopting the technological processes of combined adsorption resin, ultrafiltration membrane, acid stabilizing nanofiltration membrane and high desalting rate reverse osmosis membrane, compared with other membrane recovery systems, the process has the advantage that the properties and service lives of the membranes can be maintained for a long term; the process has the effects of achieving automatic control and ensuring stable operation of a wastewater treatment system and the quality of recovered matters; the process is suitable for recovering copper in the copper-containing wastewater in the electroplating industry, the electronic industry and the metallurgical industry and other copper-containing industrial wastewater and for wastewater treatment.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

Antiviral capsule

InactiveCN1401382ASignificant effectGood curative effectAntiviralsUnknown materialsCurative effectCoptis

An anti-viral capsule for suppressing viruses, especially for treating early cold or influenza is prepared from the concentrated extract of isatis root decoction and coarse powder of coptis root through proportioal mixing, baking, sieving and capsulizing. Its advantages are high curative effect, short course of treatment and low cost.

Owner:涂宏海

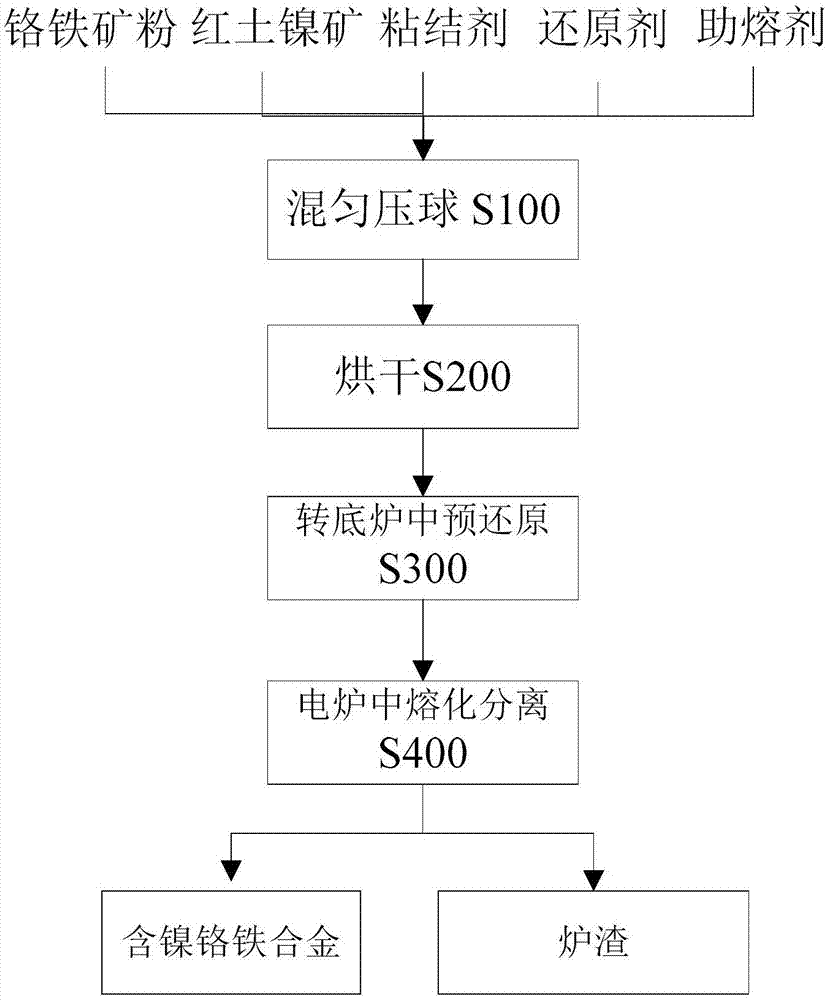

Method for smelting nickel-containing ferrochrome alloy

The invention relates to a method for smelting nickel-chromium ferroalloy, which comprises the following steps: uniformly mixing the ground laterite nickel ore with chromite powder, reducing agent, binder and fluxing agent to prepare balls The pellets are placed in a rotary hearth furnace for high-temperature reduction to obtain metallized pellets; the metallized pellets are sent to an electric furnace for high-temperature melting and separation to obtain nickel-chromium-iron alloys. The present invention uses the easy-to-form characteristics of laterite-nickel ore by mixing ingredients with chromite ore and high-magnesium laterite-nickel ore, reduces the addition of binders, and molds cheap and difficult-to-form chromite powder ore, reducing the Production cost; all raw materials are pre-mixed, the ingredients are relatively uniform, and the smelting time is shortened; the pellets are pre-reduced at high temperature in the rotary hearth furnace, which effectively reduces the power consumption of the electric furnace smelting; at the same time, due to the introduction of Ni in the laterite nickel ore, nickel-containing The ferrochrome alloy further obtained low-cost raw materials for smelting stainless steel.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

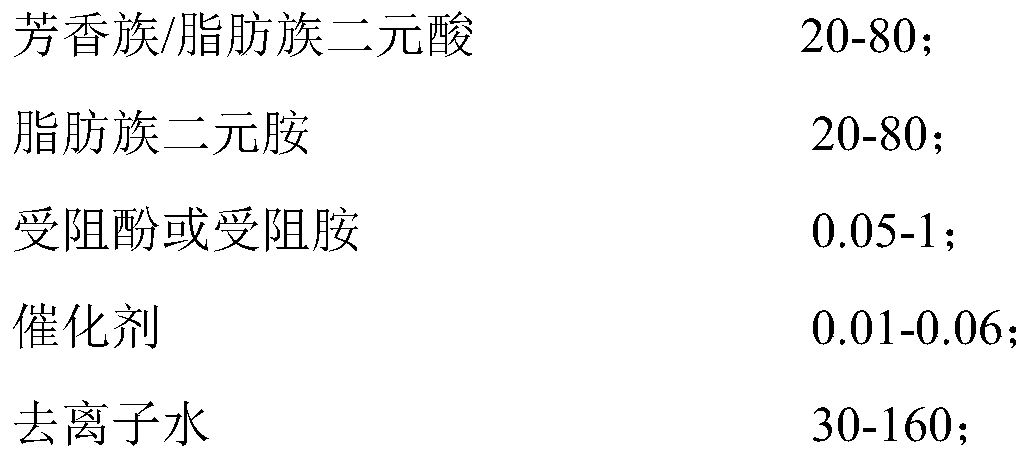

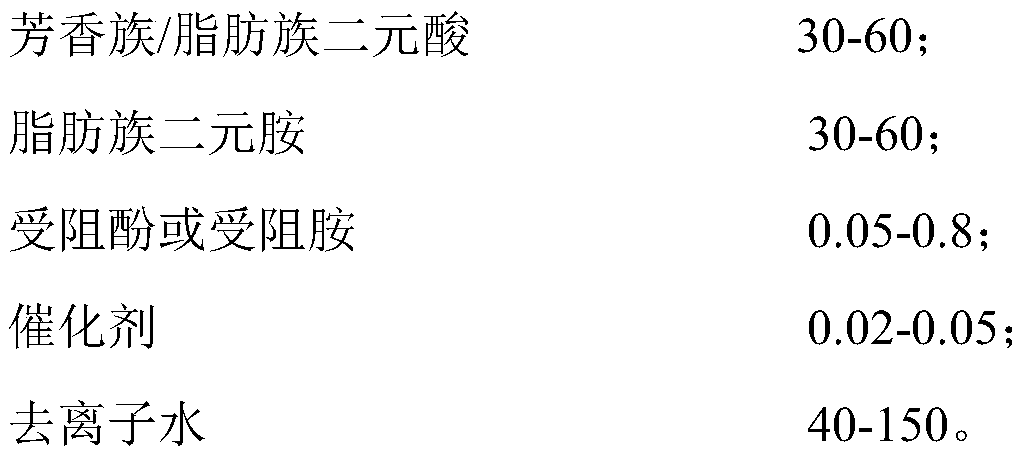

Semi-aromatic polyamide resin and preparation method thereof

The invention discloses semi-aromatic polyamide resin and a preparation method thereof. The semi-aromatic polyamide resin comprises, in parts by weight, 20 to 80 parts of aromatic / aliphatic dibasic acid, 20 to 80 parts of aliphatic diamine, 0.05 to 1 part of hindered phenol or hindered amine, 0.01 to 0.06 part of a catalyst, 30 to 160 parts of deionized water, wherein in the aromatic / aliphatic dibasic acid, the mass ratio of the aromatic dibasic acid to the aliphatic dibasic acid is 1:(0-9). A hindered phenol or hindered amine chemical group is connected to the tail end of a polyamide molecular chain through a chemical bond; the loss of the hindered phenol or hindered amine chemical group in a low-temperature environment is reduced; by adding a processing aid in the later-stage modification processing process, the phenomenon of heat stabilizer agglomeration or non-uniform dispersion during the modification does not exist, and the production cost is reduced, so that the product has goodthermal stability at the high temperature for a long time, and the mechanical property and the quality of the product are improved.

Owner:ZHONGLUN PLASTIC IND FUJIAN

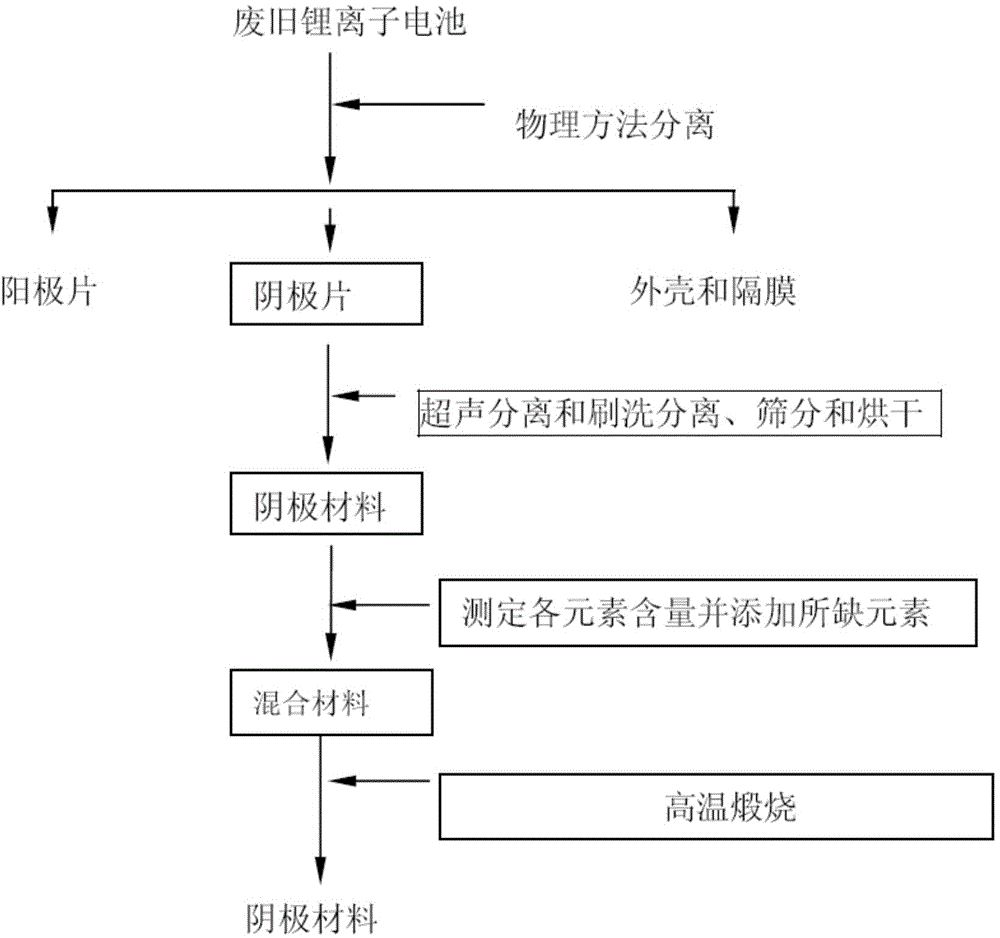

Method for preparing cathode material of lithium ion battery

InactiveCN103956533AImprove performanceReduce pollutionCell electrodesWaste accumulators reclaimingLithium-ion batteryCobalt

The invention discloses a method for preparing a cathode material of a lithium ion battery. The method comprises the following steps: 1, separating a cathode material on a cathode sheet of a waste and old lithium ion battery or a cathode material in lithium ion battery production scraps; and 2, determining the mass ratio of useful elements in the separated cathode material, calculating deficient elements of the separated cathode material according to the mass ratio of the elements of raw materials for preparing the cathode material of the lithium ion battery, adding compounds of the deficient elements in order to reach the stoichiometric ratio of a target product, and preparing the cathode material of the lithium ion battery. The method can recycle cathode materials comprising lithium cobaltate, nickel cobalt lithium manganate and lithium manganate used in waste and old lithium ions and cathode material scraps comprising lithium cobaltate, nickel cobalt lithium manganate and lithium manganate generated in the production of the lithium ion battery according to the waste recycling situation.

Owner:SOUTH CHINA NORMAL UNIVERSITY

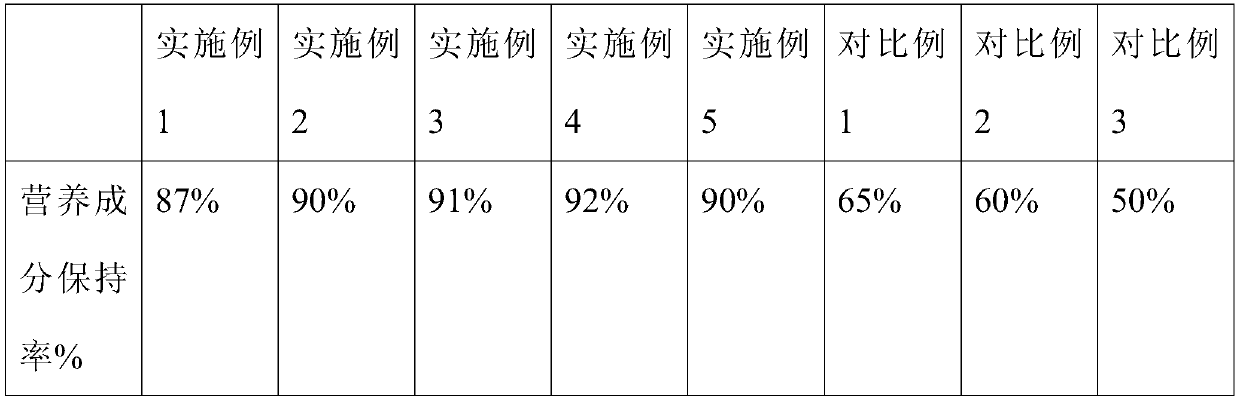

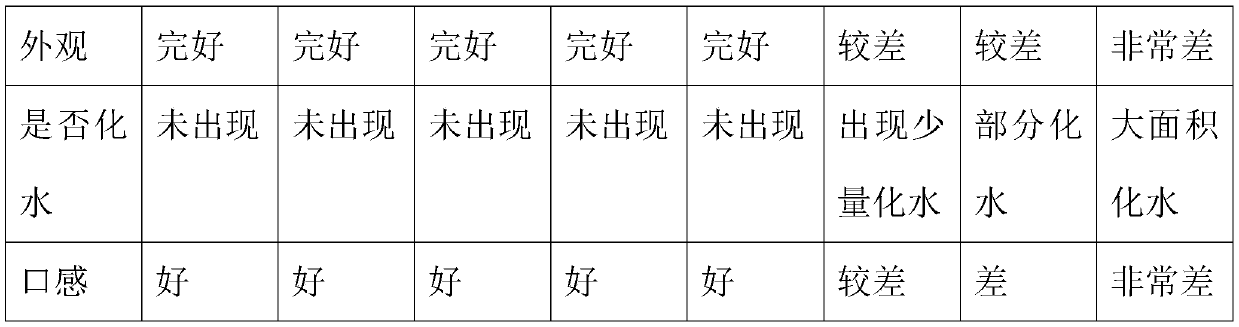

Sterilization method of instant canned edible bird's nest soup, instant canned edible bird's nest soup and preparation method of instant canned edible bird's nest soup

PendingCN110338331AReduced Possibility of HydrationReduce joinFood preservationCookerEnvironmentally friendly

The invention discloses a preparation method of an instant canned edible bird's nest soup. The method comprises the following steps of S1, soaking, wherein high-quality edible bird's nests are placedin pure water and soaked for 2-8 hours at 10 DEG C or below, after soaking, filtration is conducted, and soaking water is refrigerated for standby use; S2, feather picking-out, wherein swallow feathers in the soaked edible bird's nests are manually picked out, and the soaked edible bird's nests are obtained; S3, canning, wherein the soaked edible bird's nests with the certain weight are weighed and added into rock candy water, cap screwing and vacuum sealing are conducted, and semi-finished edible bird's nest soup products are obtained; S4, sterilization, wherein primary sterilization is conducted, that is, firstly, a sterilization cooker is heated to 70-80 DEG C, and then the semi-finished edible bird's nest soup products are put in the sterilization cooker for being cooked for 15-45 minutes; secondary sterilization is conducted, that is, after cooking, the temperature is increased to 121 DEG C, after sterilization is conducted for 3-10 minutes, the semi-finished products are cooled and fished out, and the instant canned edible bird's nest soup is obtained. According to the method, separate sterilization is conducted twice, by adopting the sterilization mode, the possibility of melting of the edible bird's nests in water is reduced, and therefore addition of food additives is reduced, the instant canned edible bird's nest soup presents an original egg white taste of the ediblebird's nests, and the greener, more environmentally friendly and more economical purpose is achieved.

Owner:遂宁市三丰食品有限公司

Steam-huff-and-puff oil production method assisted by injection of air and carbon dioxide

The invention provides a steam-huff-and-puff oil production method assisted by injection of air and carbon dioxide. The method includes the following steps that (1) an injection well and an adjacent well are arranged, and the oxygen content of casing pipes of the injection well and the adjacent well is measured online; (2) when the online measured oxygen content of the injection well casing pipe is higher than an explosion point, nitrogen and / or carbon dioxide are / is injected into the injection well, and the content of oxygen content of the injection well casing pipe, which is lower than the explosion point, is an injection finishing point; (3) the gas mixture of air and carbon dioxide is injected till the total reaches a design discharge, and after the injection is finished, a carbon dioxide slug killing well is used, and then steam is injected; or a gas mixture slug of air and carbon dioxide is injected, a steam slug is injected, then the gas mixture slug and the steam slug are injected continuously, circularly and alternately till the gas mixture slug injection total reaches the design discharge, and after the circular injection is finished, the carbon dioxide slug killing well is used; (4) the well is soaked till the pressure inside the well reaches a normal pressure, and blowout production is carried out.

Owner:PETROCHINA CO LTD

Preparation method of boron-modified alumina carrier

ActiveCN102728335ASuitable for acidityImprove pore structureCatalyst carriersRefining to eliminate hetero atomsSupersaturationSurface tension

The invention relates to a preparation method of a boron-modified alumina carrier. The method comprises the following steps of: firstly wetting an alumina precursor by the use of a low carbon alcoholic solution, adding a boron-containing solution formed by polyol and boric acid, and preparing the boron modified alumina carrier. By the adoption of the method, local supersaturation adsorption phenomenon caused by directly adding the boron-containing solution into the alumina precursor can be avoided, and the solution will not be over-absorbed into internal pores. Simultaneously, with the increase of the temperature during the kneading process, volatilization of low carbon alcohol and low surface tension help boron to uniformly disperse onto the surface of the alumina carrier. In addition, the method is beneficial to improving specific surface area and pore volume of the carrier. The boron modified alumina carrier provided by the invention is especially applicable to being used as a carrier for a hydrodenitrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oral rehydration salt effervescent tablet and application thereof

ActiveCN101732342AReduce joinComplete acid-base reactionOrganic active ingredientsMetabolism disorderSodium bicarbonateNuclear chemistry

The invention discloses an oral rehydration salt effervescent tablet which mainly contains sodium chloride, postassium chloride, anhydrous dextrose, citric acid, sodium bicarbonate and / or sodium carbonate and water-soluble lubricant. The invention also discloses the application of the oral rehydration salt effervescent tablet. The oral rehydration salt effervescent tablet is convenient to carry and use. The dosages of an acid source and an alkali source in the oral rehydration salt effervescent tablet can reflect the dosage of sodium citrate needed by the prescription for producing oral rehydration salt (ORSII), thereby reducing the addition of the raw material sodium citrate and lowering the production cost effectively.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

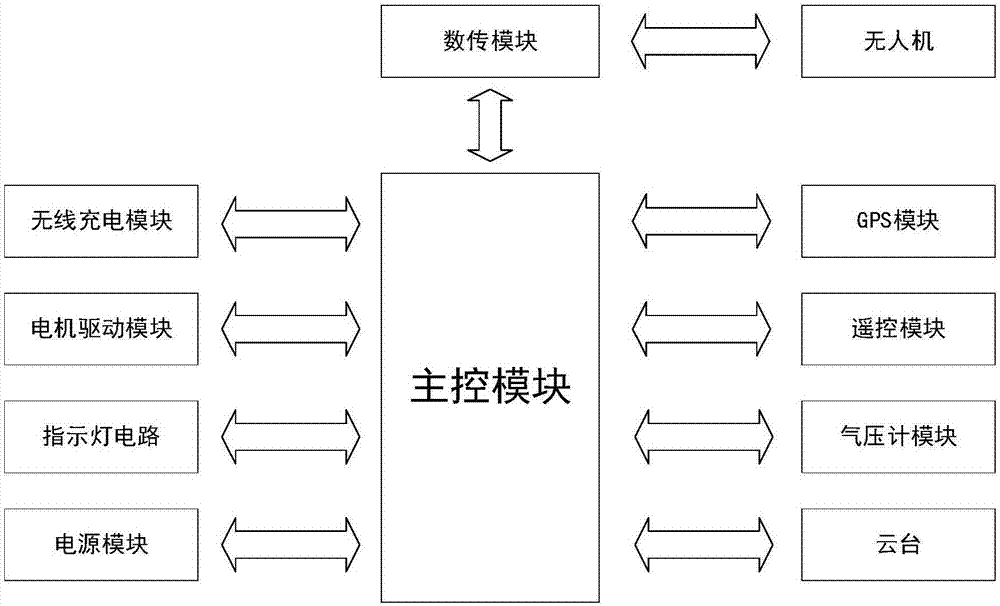

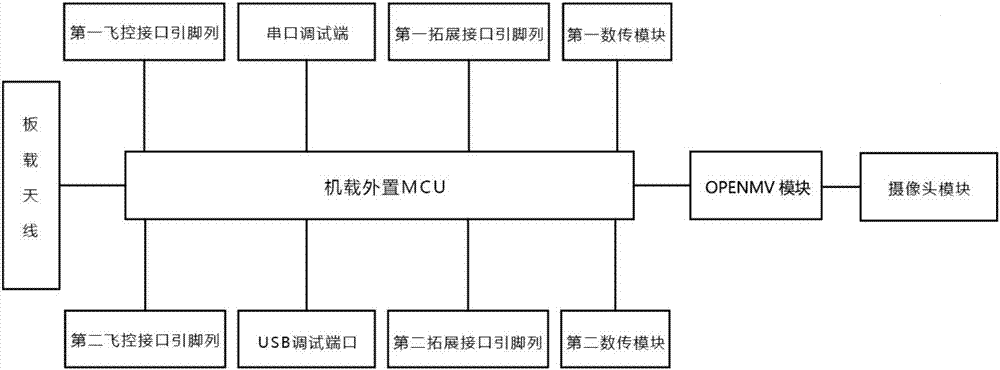

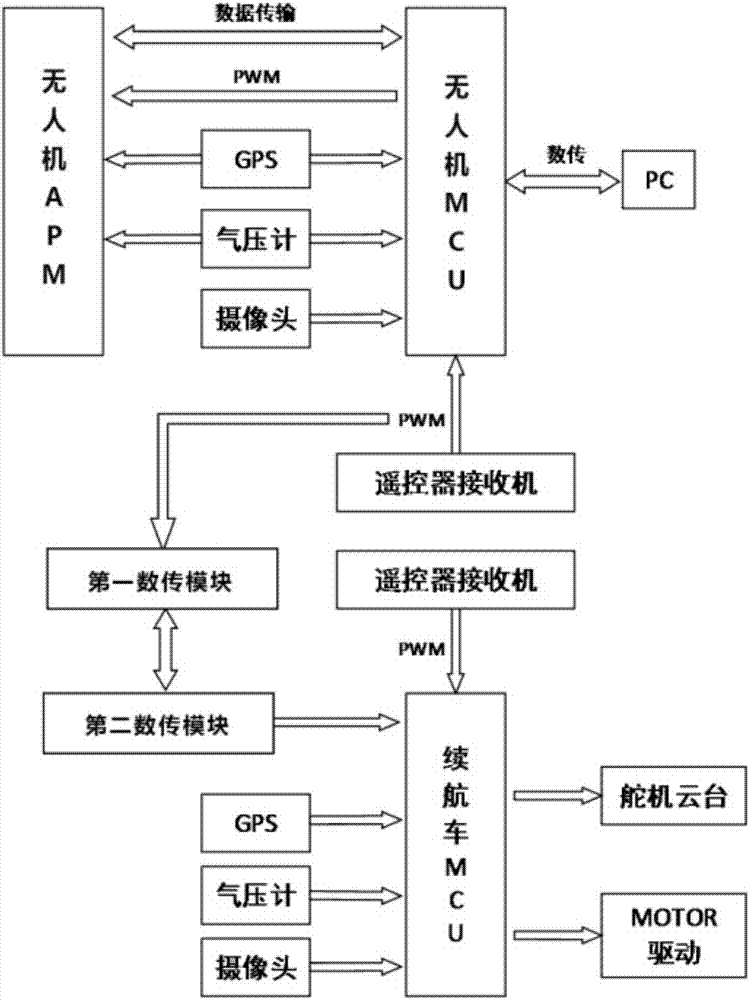

Automatic unmanned plane wireless charging control platform and method

InactiveCN106970649AReduce dependenceExtend battery lifeTarget-seeking controlElectricityAutomatic control

The invention relates to an automatic unmanned plane wireless charging control platform and method. The control platform comprises an endurance vehicle and an unmanned plane box, wherein the endurance vehicle comprises a main control module, and a GPS module, a remote control module, a wireless charging module and a data transmission module which are electrically connected with the main control module, the unmanned plane box comprises an airborne external MCU, a board-borne antenna, a first data transmission module, a second data transmission module, an OPENMV module and a camera module. The airborne external MCU is used for collecting data of a flight controller, the data transmission module and the remote control module, when an instruction returned to the wireless charging module is received, flight to an upper portion of the wireless charging module is carried out according to the position of the endurance vehicle, a control instruction is sent to the flight controller according to the relative position data transmitted by the OPENMV module and the latitude, longitude and height data transmitted by the flight controller, and the instruction is further returned to the wireless charging module. The automatic unmanned plane wireless charging control platform is advantaged in that dependence of an unmanned plane onto a standby cell or a charging cable is reduced, the endurance time and the maximum range of the unmanned plane are prolonged, and the unmanned plane is guaranteed to smoothly accomplish tasks in severe environments.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com