Method for preparing ITQ-2 molecular sieve

A technology of ITQ-2 and molecular sieve, applied in the field of preparation of ITQ-2 molecular sieve, can solve the problems of high cost, unfavorable industrial application, poor effect, etc., and achieve the effect of rationalized yield, simple and feasible method, and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

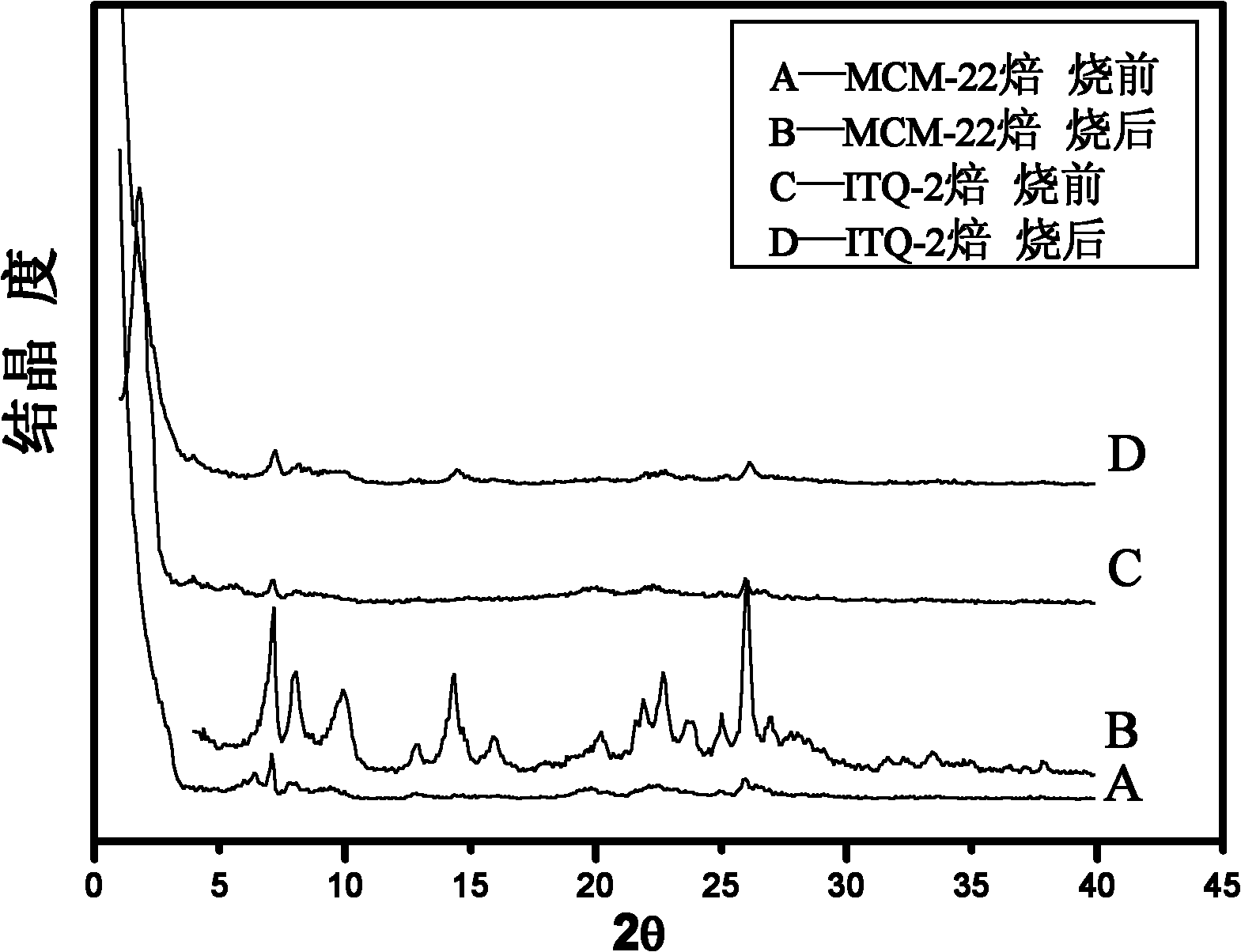

Embodiment 1

[0041]First prepare 80ml of 0.2mol / L NaOH solution, then add 0.8g of white carbon black into the lye to obtain A solution, then add the solution containing 12.5g of cetyltrimethylammonium bromide to A solution, stir The B solution was obtained uniformly, and then the obtained mixture was transferred to a three-neck flask for heating in a water bath, and 5 g of MCM-22 molecular sieves were added under constant stirring, and then expanded at 80° C. for 24 h. After the mixed liquid is cooled, it is treated with 50KHz ultrasonic waves for 1 hour, and the pH value is quickly adjusted to be less than 2 with 6mol / L HCl. The solid is collected by centrifugation, washed, dried, and calcined at 540°C for 6 hours. The yield is calculated as 87%. XRD crystal phase analysis of the samples showed that the prepared samples were pure phase ITQ-2 molecular sieves. Spectrum see attached image 3 .

Embodiment 2

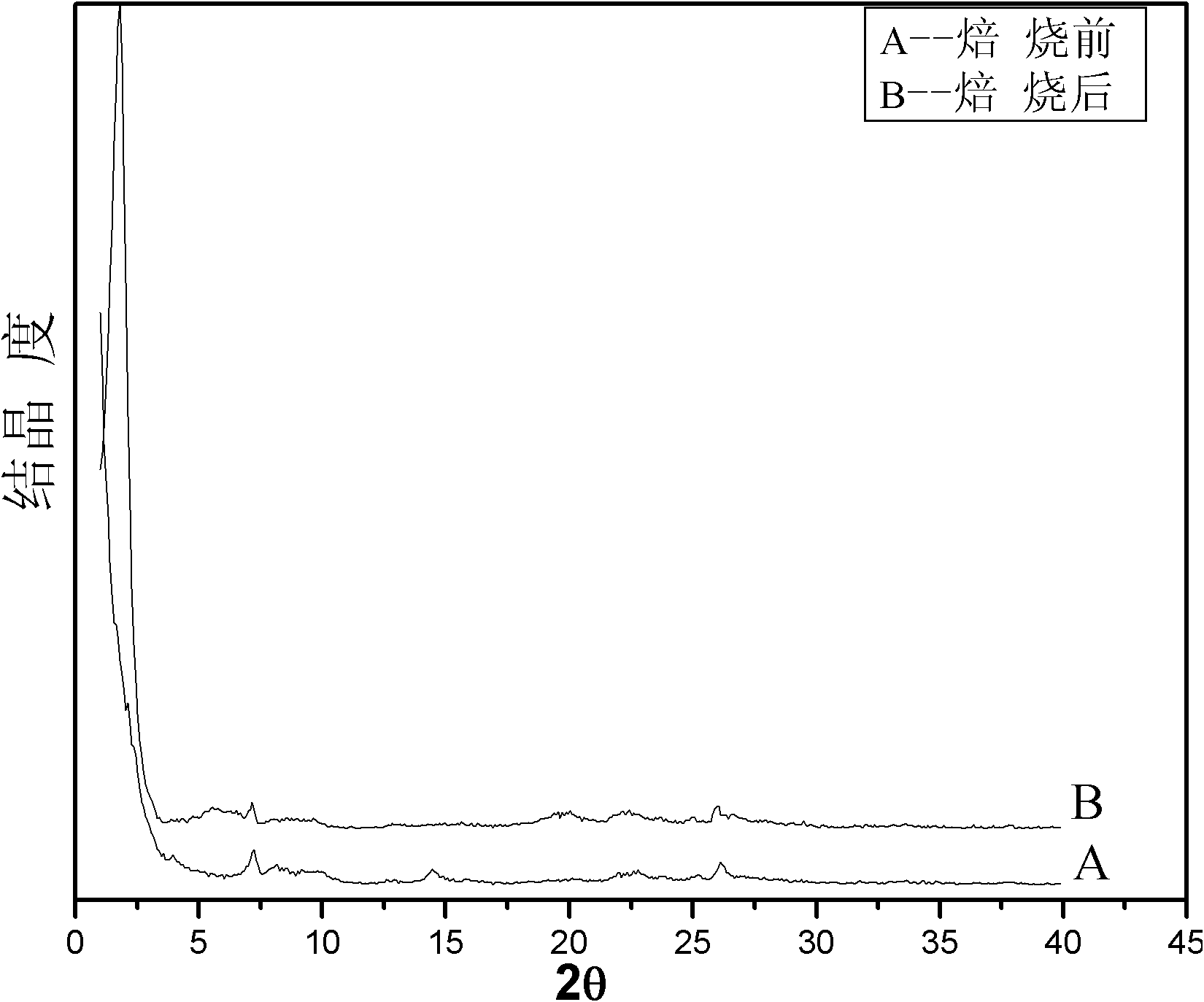

[0043] Repeat Example 1, but change the NaOH solution concentration into 0.05mol / L, 0.1mol / L, 0.5mol / L, 0.8mol / L, 1.0mol / L respectively, and the yield of the solid product obtained as a result is respectively 103%, 95%, 60%, 56%, 50%. XRD crystal phase analysis was carried out on the sample, and the results showed that the product distribution of the prepared sample was a mixture of MCM-22 and a small amount of amorphous substance, a mixture of a small amount of MCM-22 and a large amount of ITQ-2, a small amount of amorphous substance and a large amount of ITQ-2 A mixture of a small amount of ITQ-2 and a large amount of amorphous material, amorphous material. Wherein the yield obtained by the NaOH solution of 0.05mol / L is greater than 100%, the main reason is that the low alkalinity cannot completely dissolve the white carbon black, and the amount of the remaining white carbon black is greater than the amount lost by the MCM-22 molecular sieve.

Embodiment 3

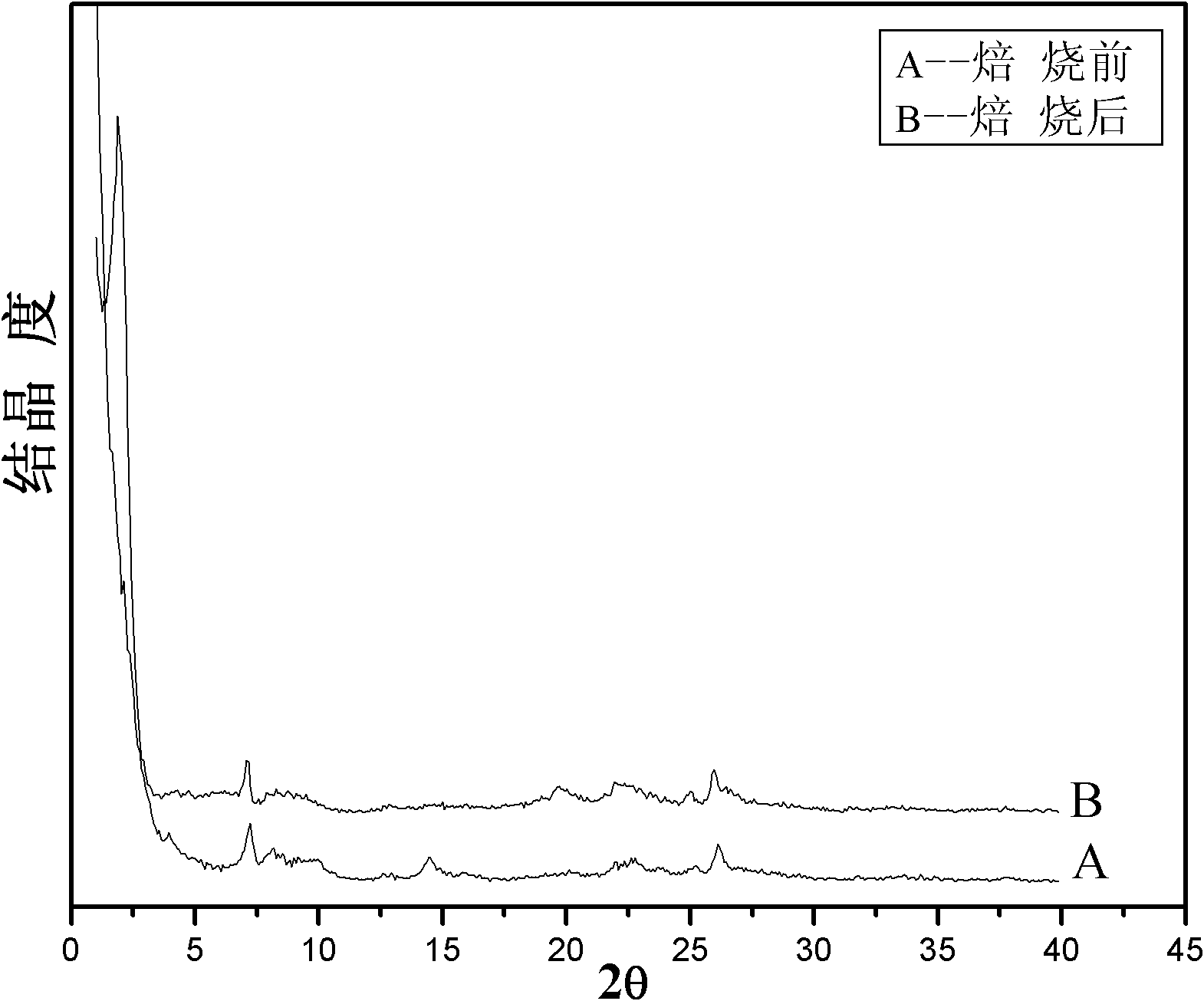

[0045] Repeat Example 1, but change the amount of white carbon black into 0.1g, 0.5g, 1.6g, 5g respectively, and the yield of the solid product obtained as a result is 64%, 84%, 95%, 190% respectively. XRD crystal phase analysis was carried out on the sample, and the results showed that the prepared samples were pure phase ITQ-2 molecular sieve, pure phase ITQ-2 molecular sieve, mixture of amorphous substance and a large amount of ITQ-2 molecular sieve, amorphous substance and ITQ-2 molecular sieve mixture. The yield obtained by adding 5g of white carbon black is greater than 100%, the main reason is that excessive white carbon black is mixed in the product in an amorphous form.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com