Patents

Literature

110 results about "Pore system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

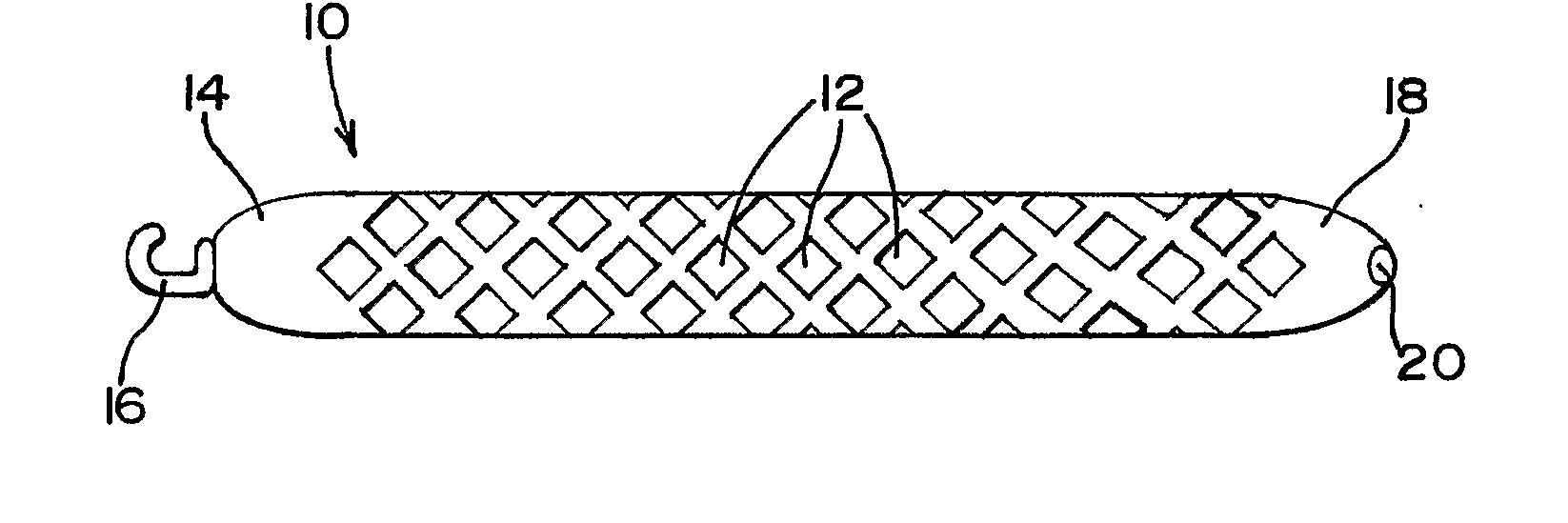

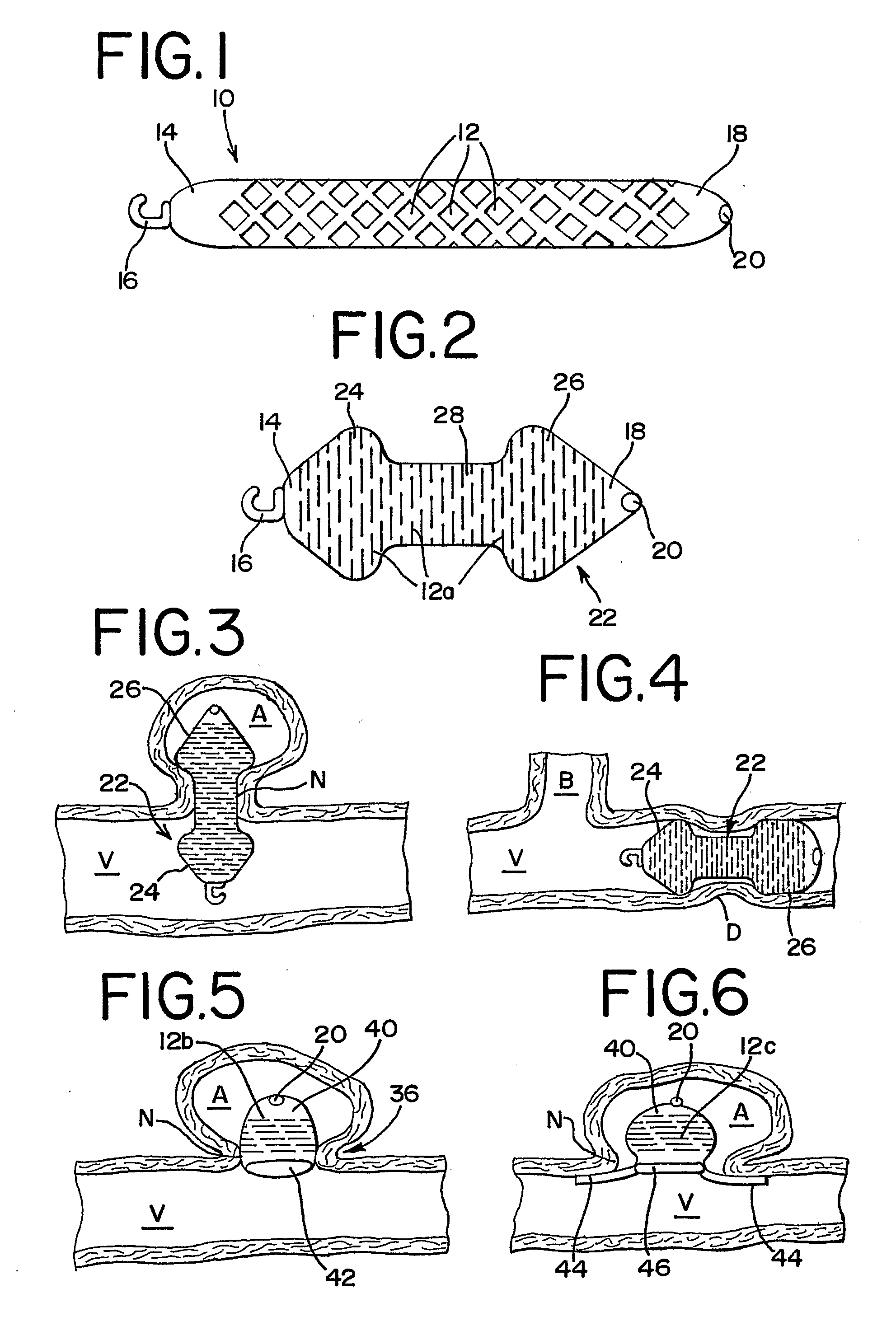

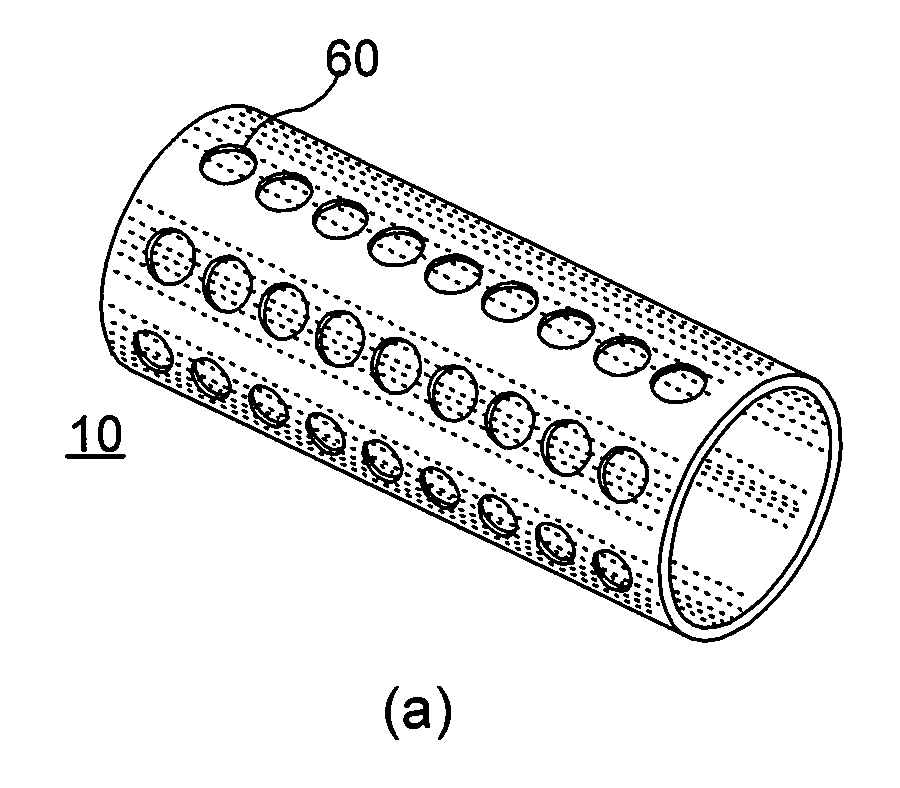

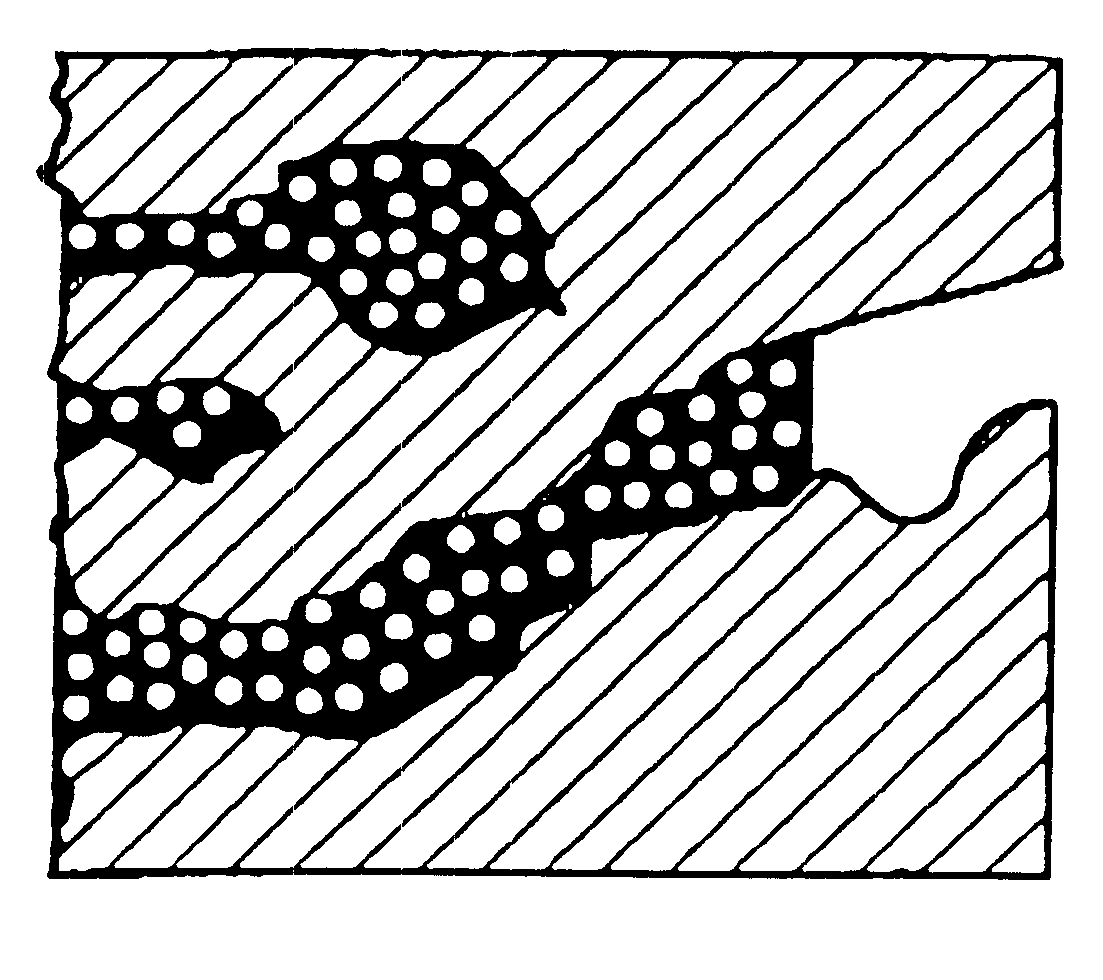

Thin Film Metallic Device for Plugging Aneurysms or Vessels

ActiveUS20080097495A1Small shapeSolve Porosity InsufficiencyDilatorsOcculdersBlood vesselBiomedical engineering

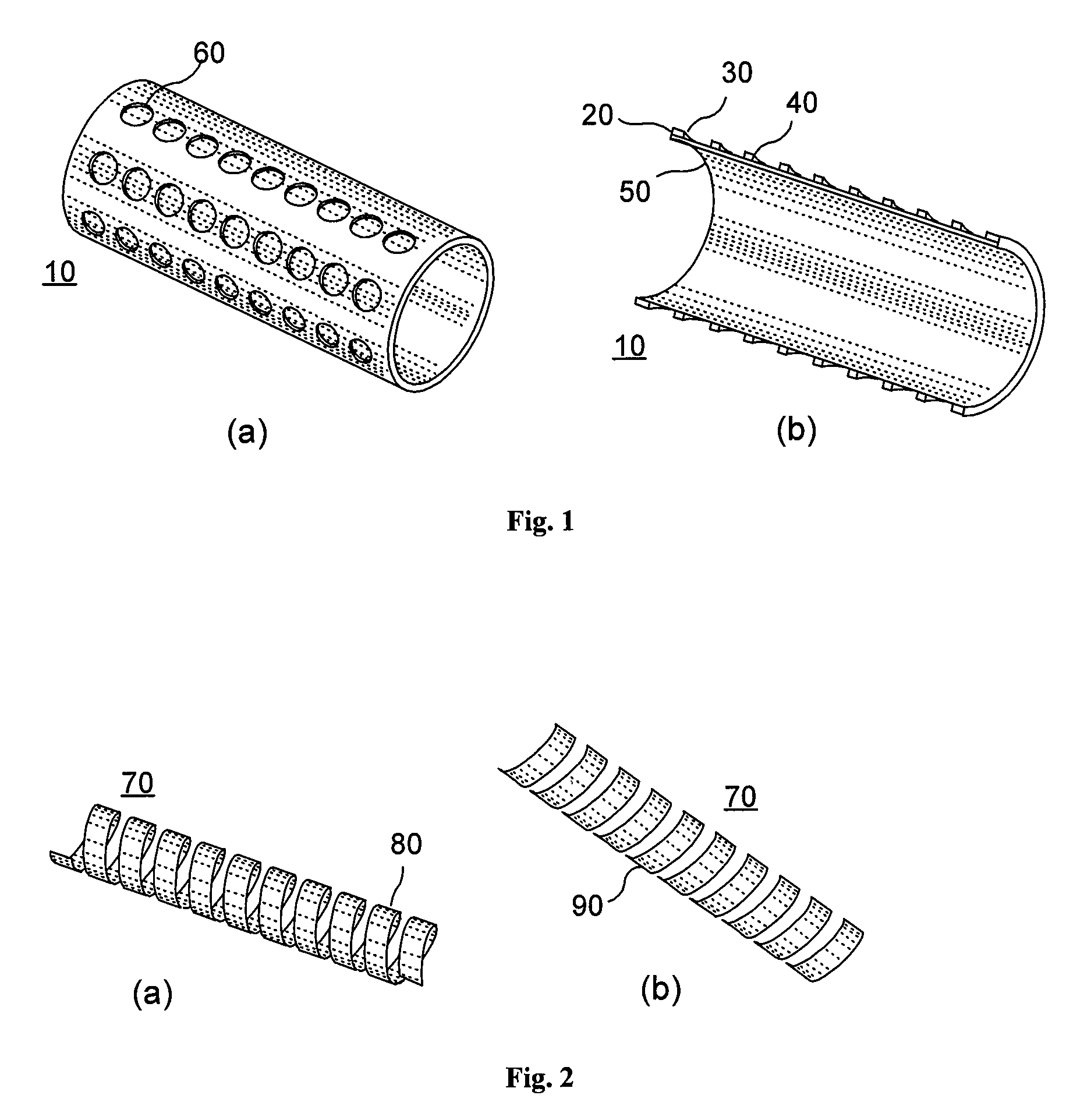

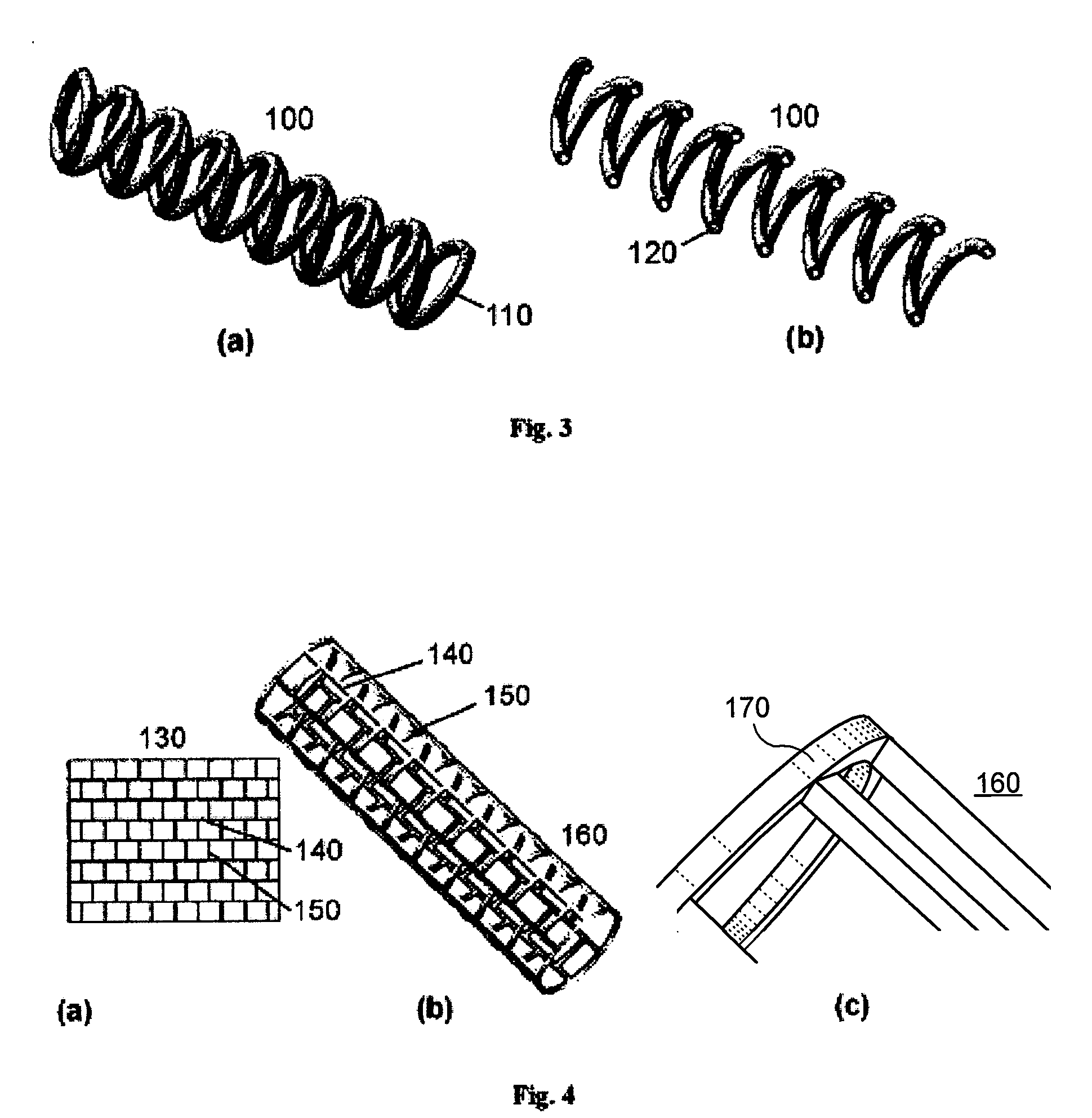

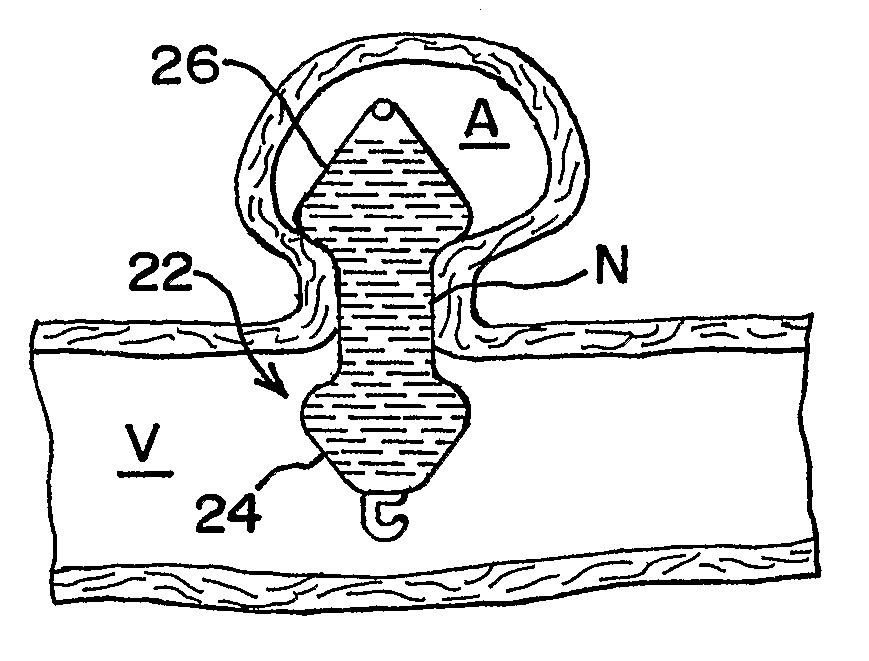

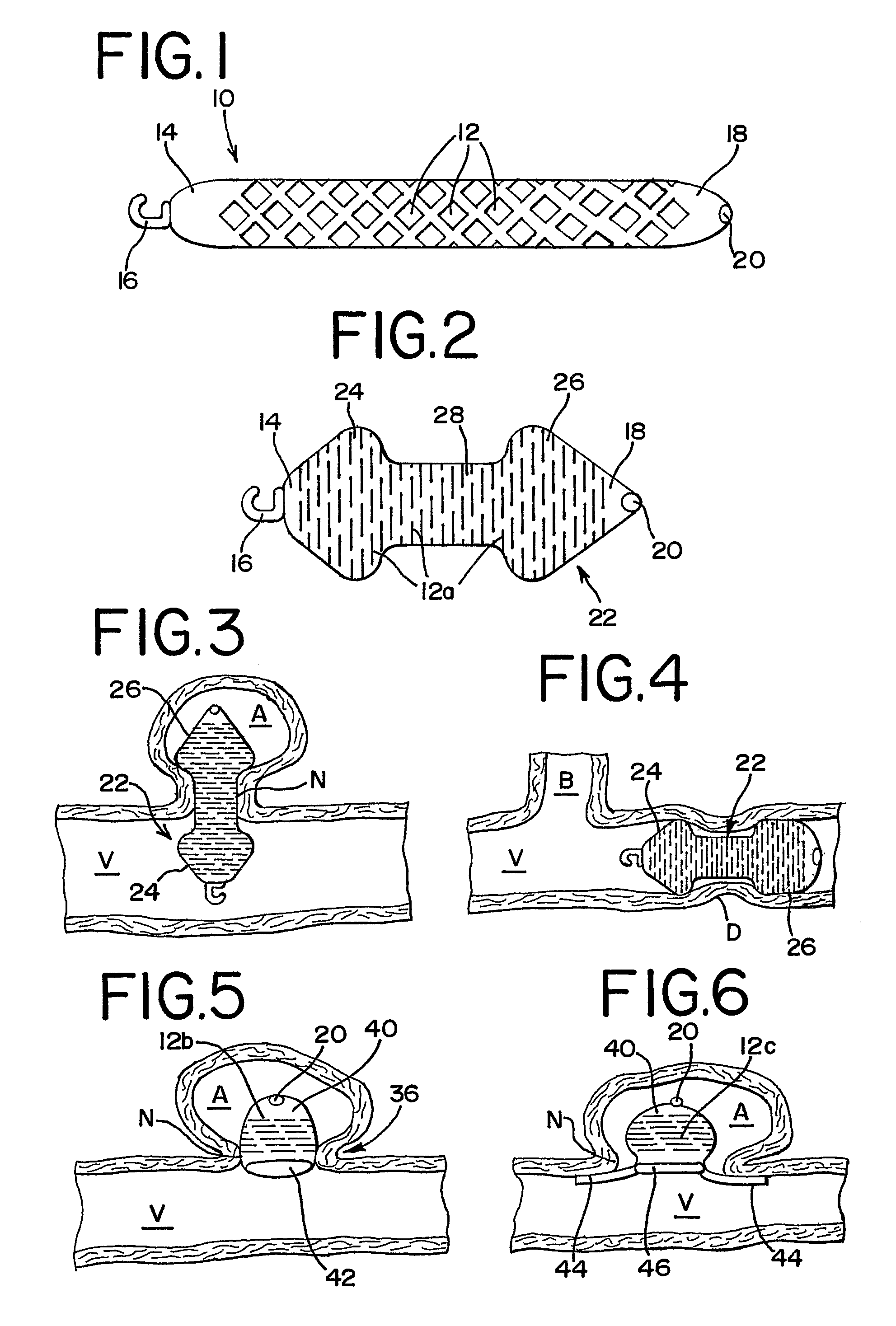

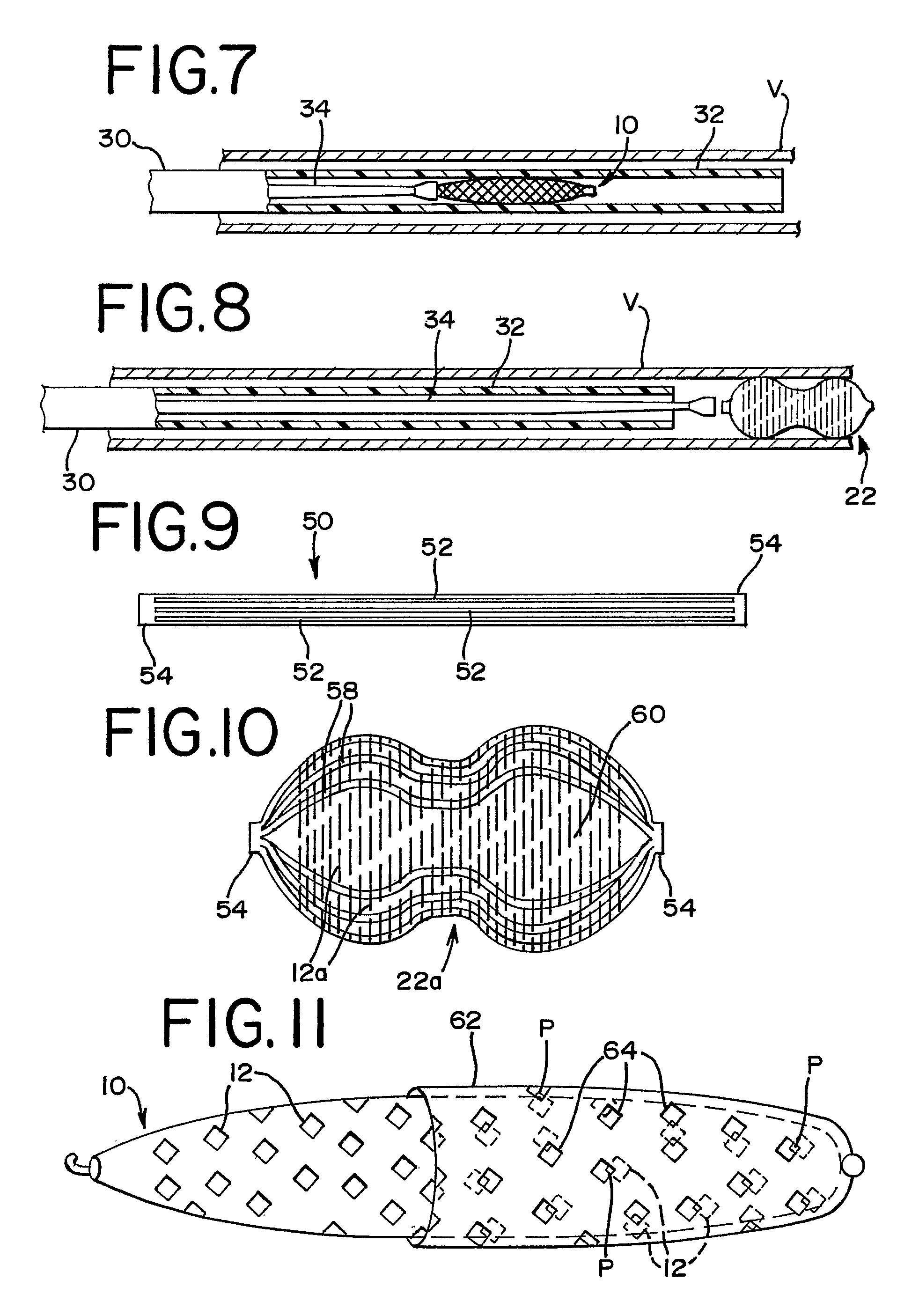

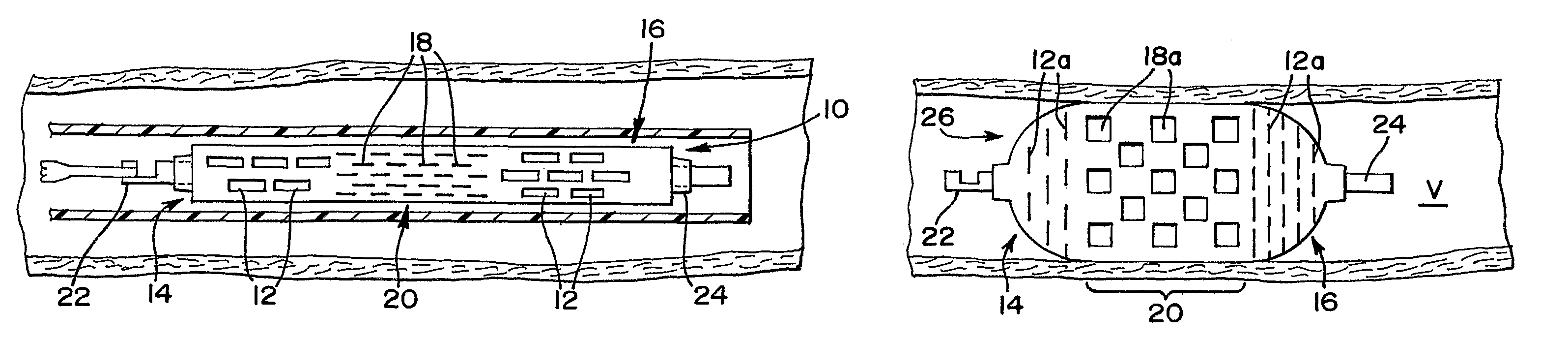

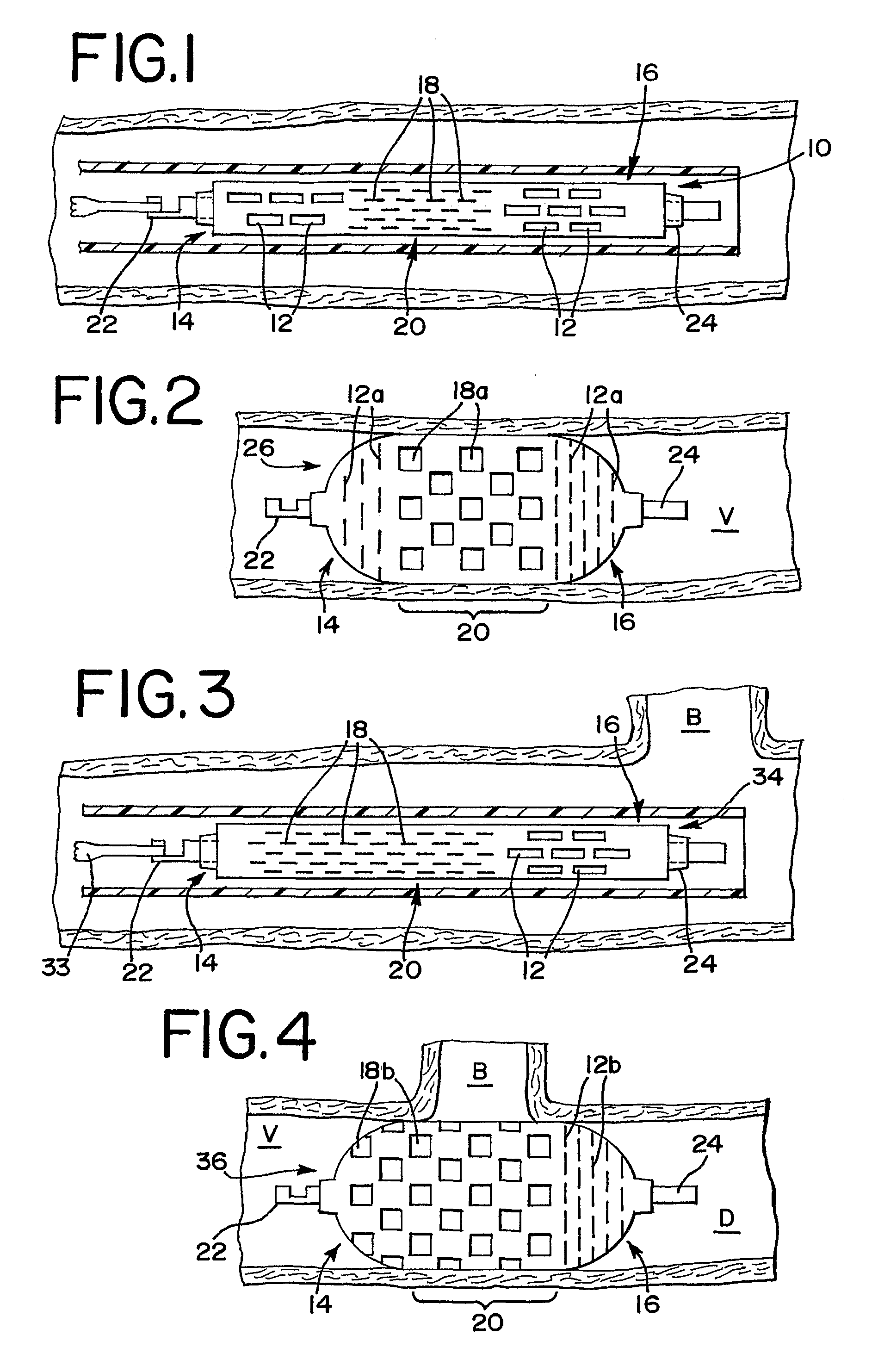

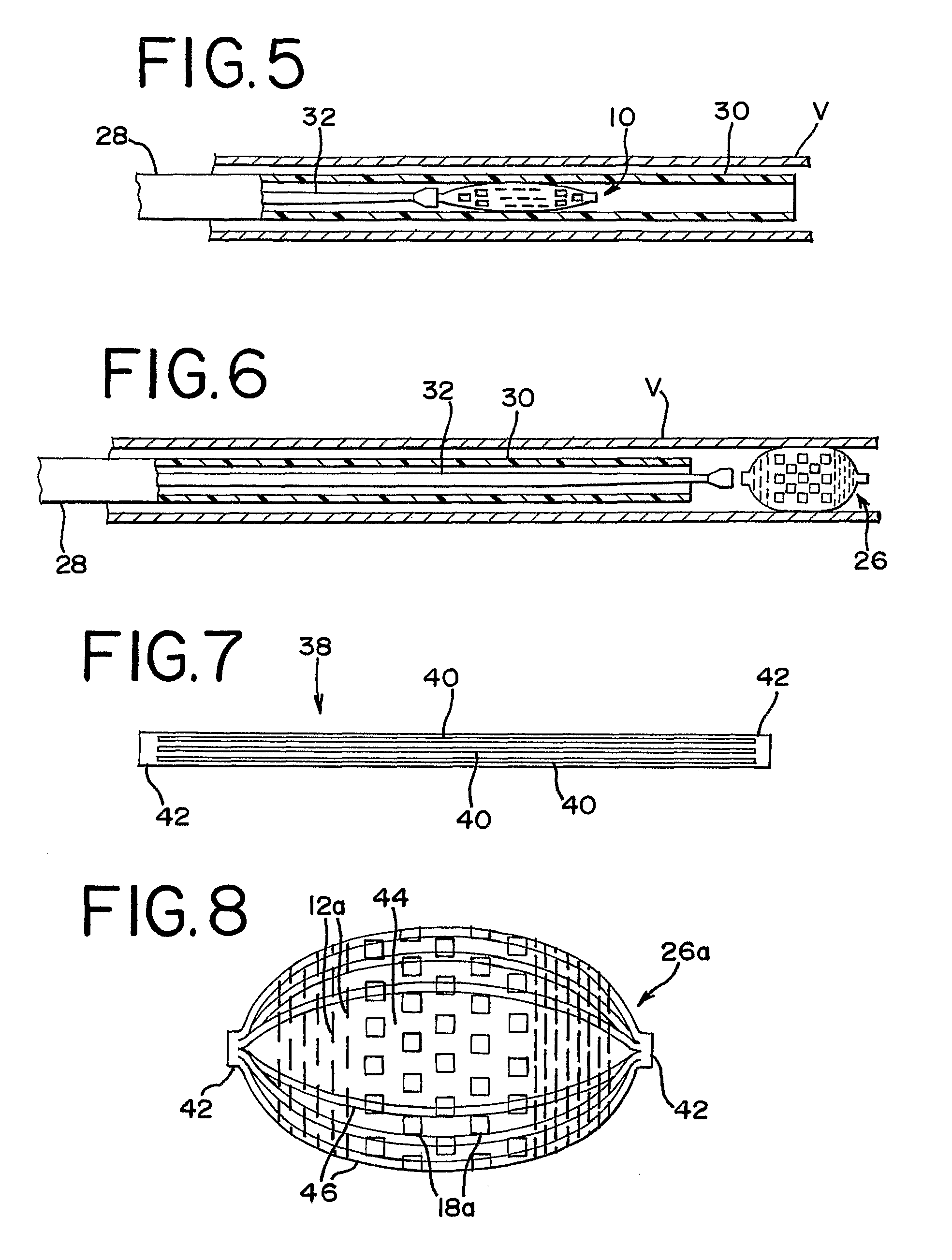

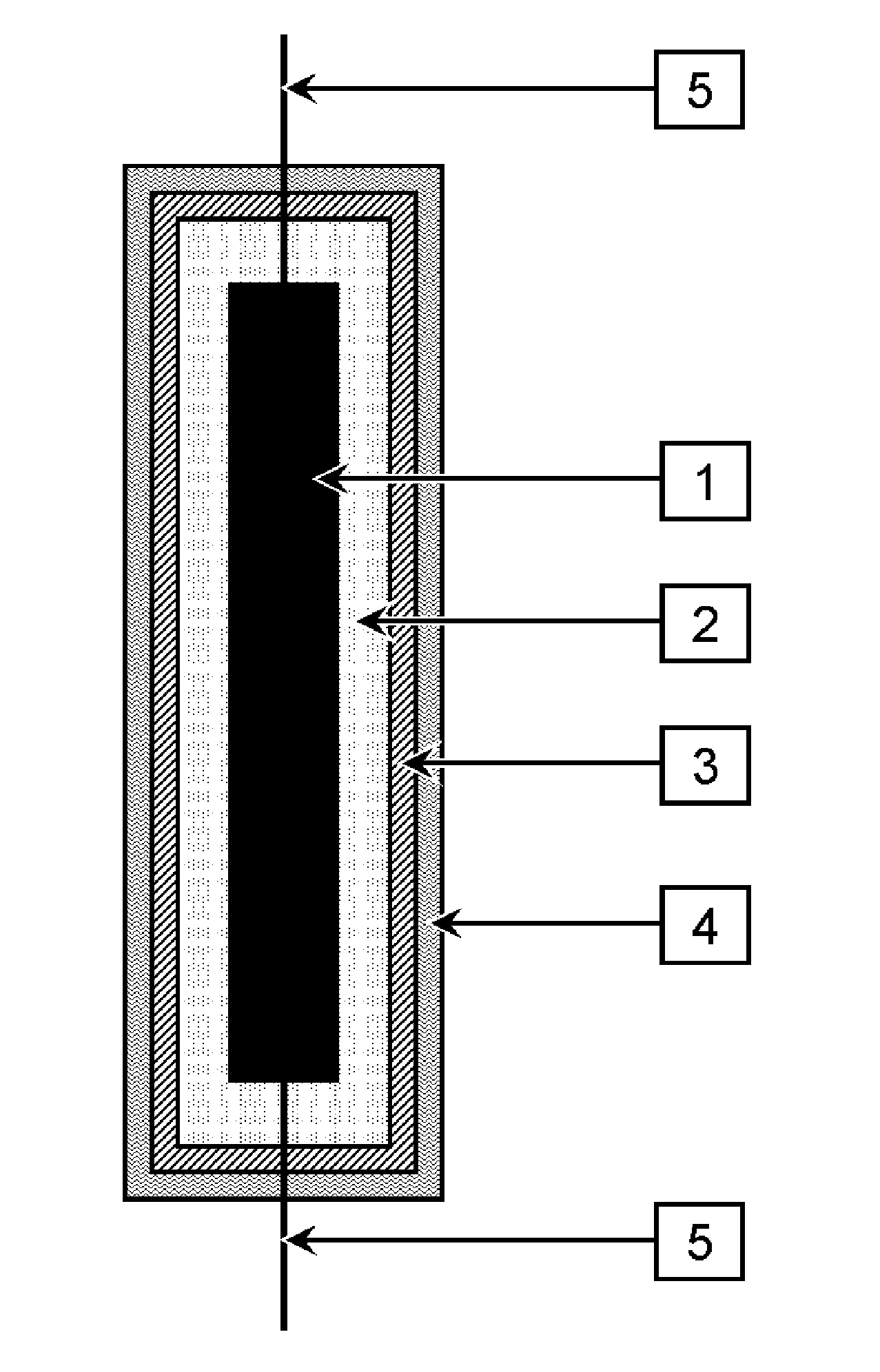

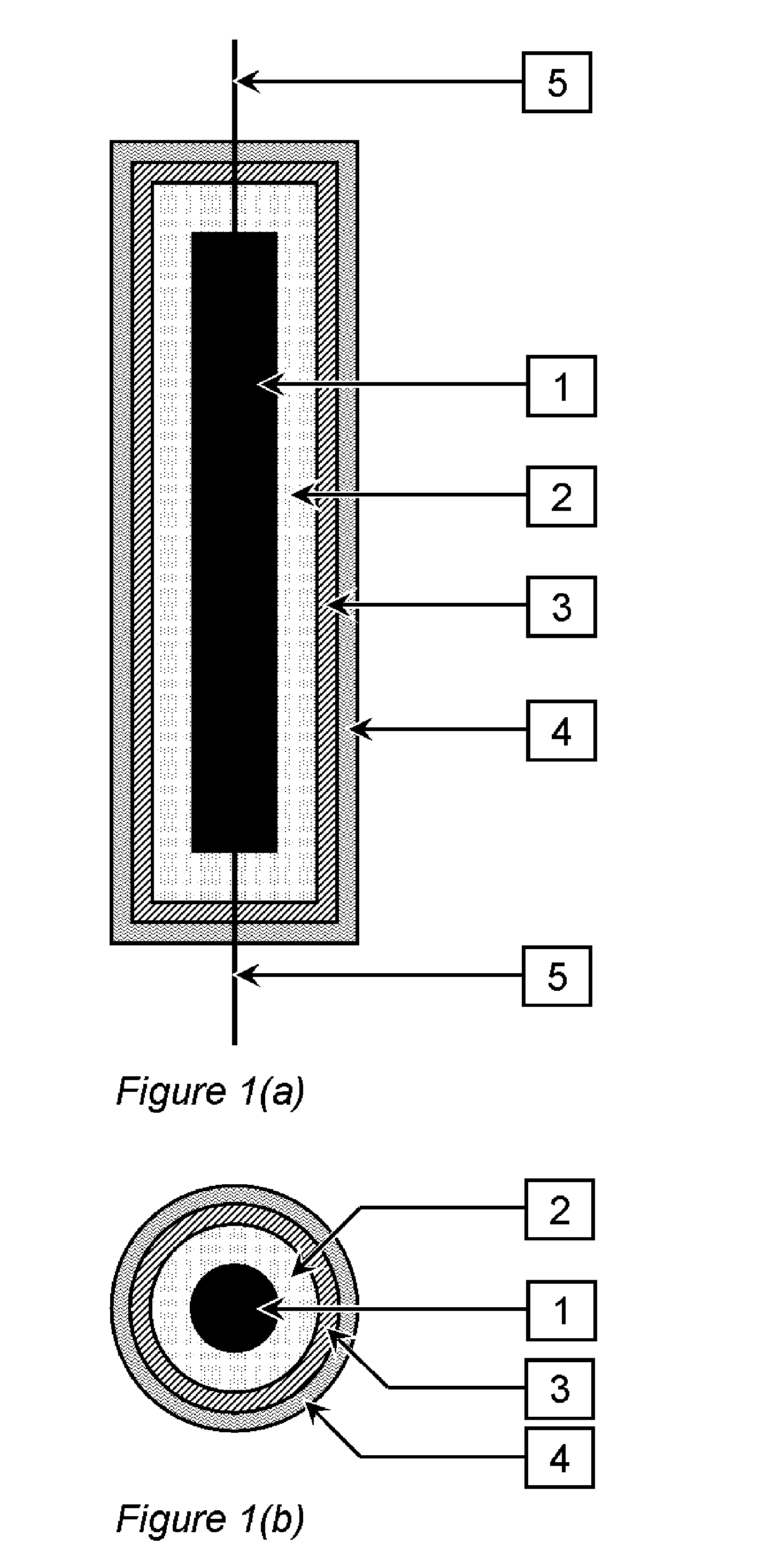

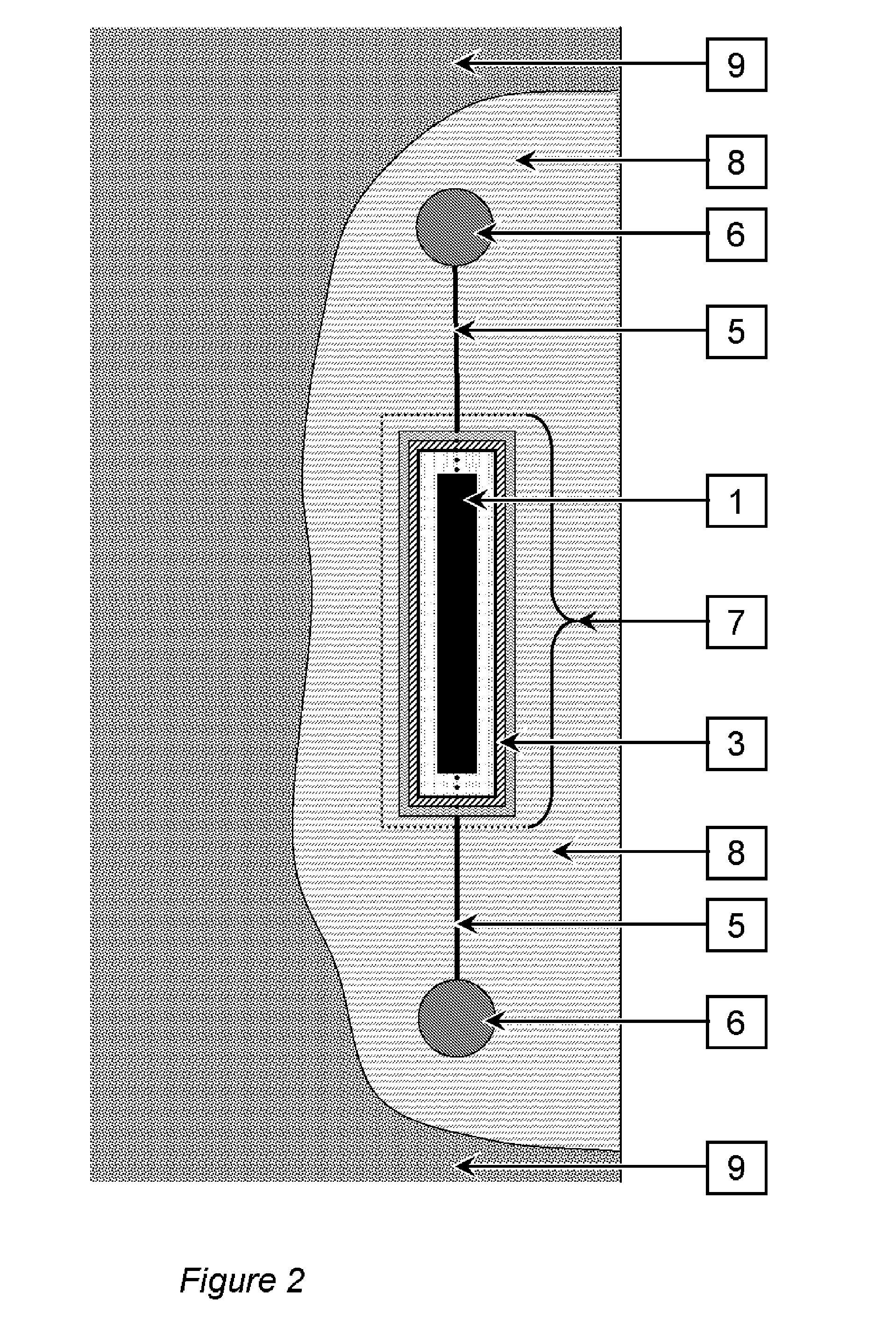

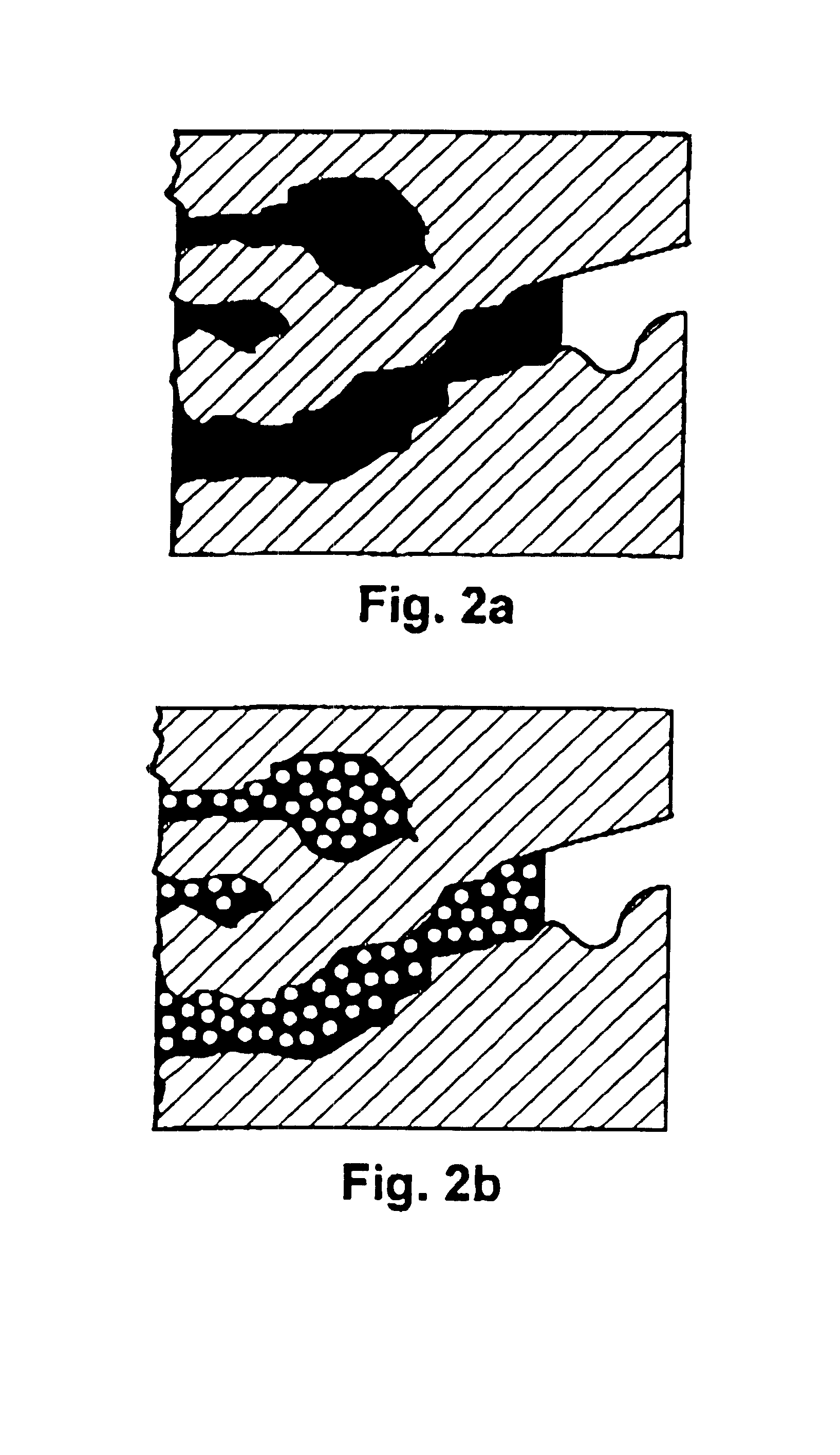

Thin film metallic devices implantable within a human subject for occlusion of an aneurysm or blood vessel are provided. The devices are movable from a porous, elongated, collapsed configuration for delivery to a deployed configuration within the body. The pores telescope as the device moves to its deployed configuration, which causes the device to longitudinally foreshorten and radially expand, while also decreasing in porosity for preventing blood flow. The occlusion devices may be either self-supporting or supported by a strut structure. Additionally, the occlusion devices may comprise a plurality of layers having unaligned pore systems which further reduce porosity in the deployed configuration.

Owner:CODMAN & SHURTLEFF INC

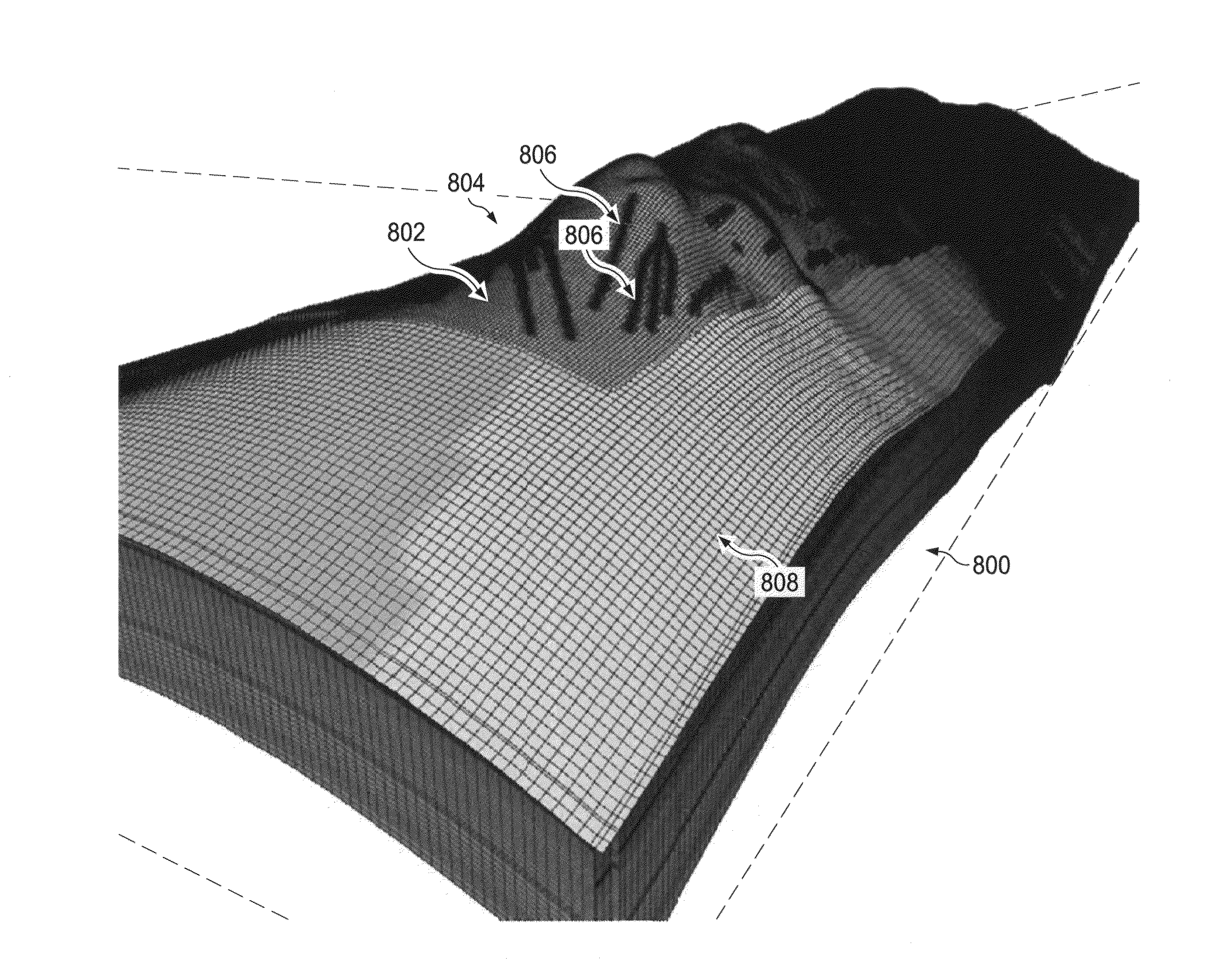

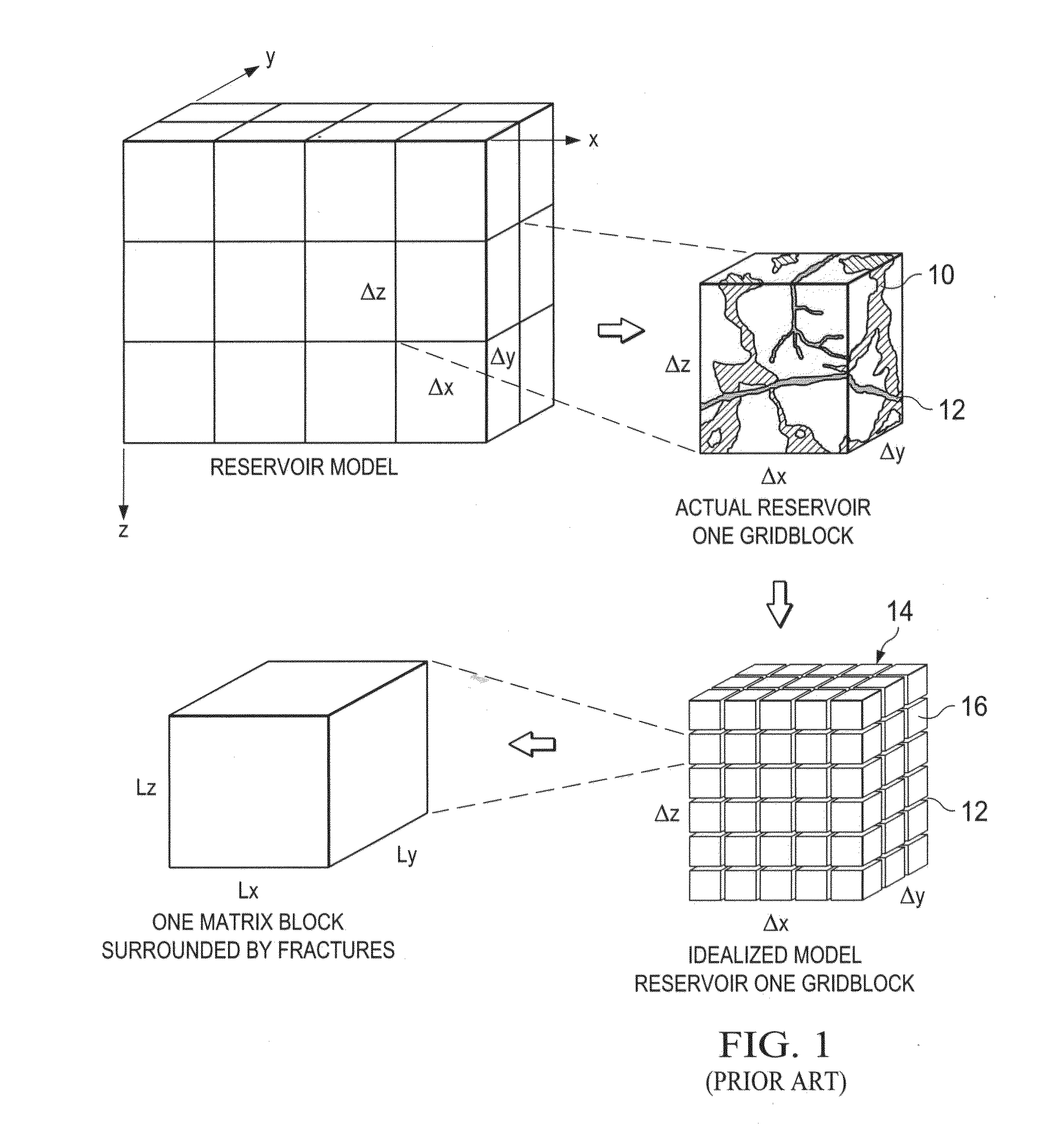

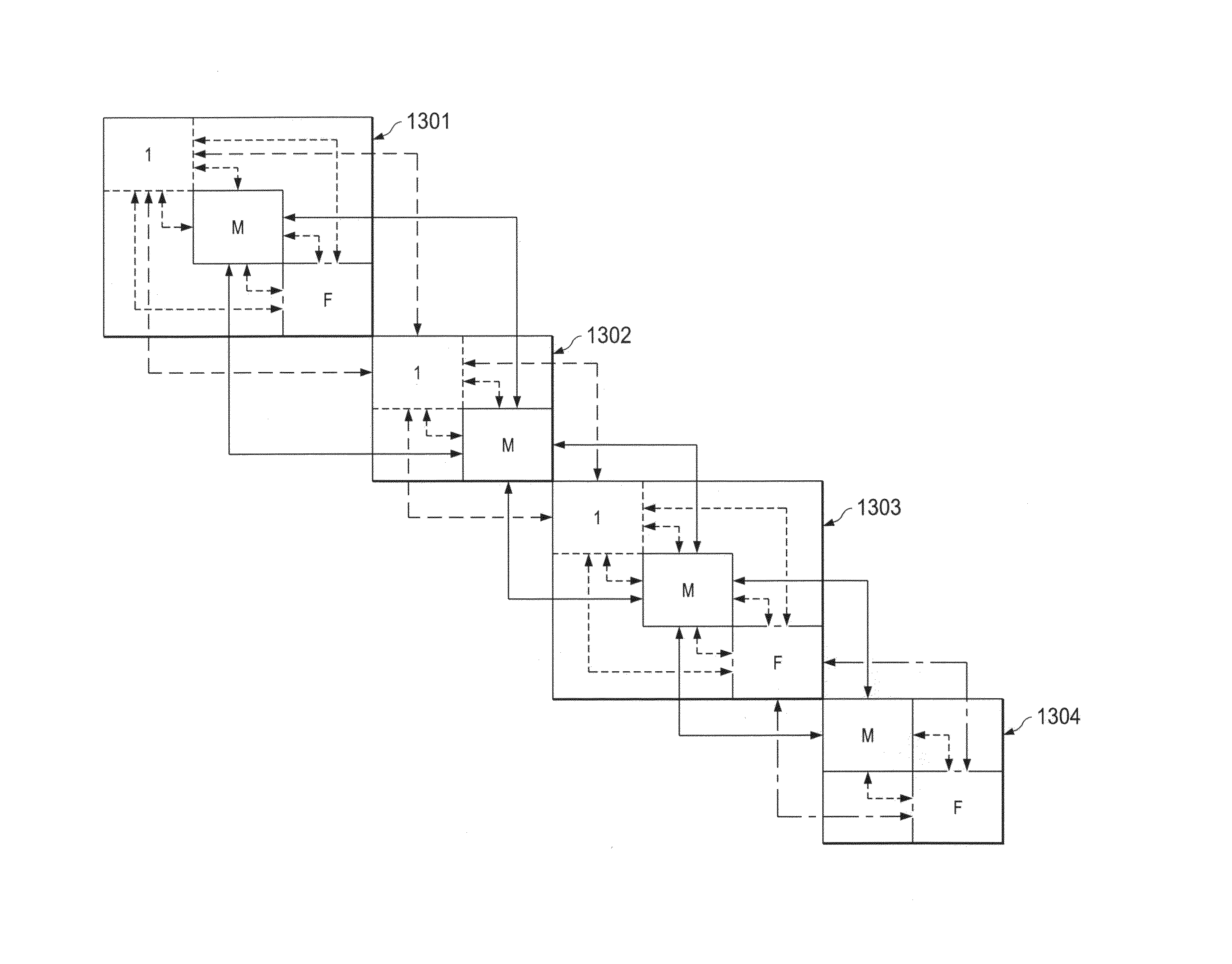

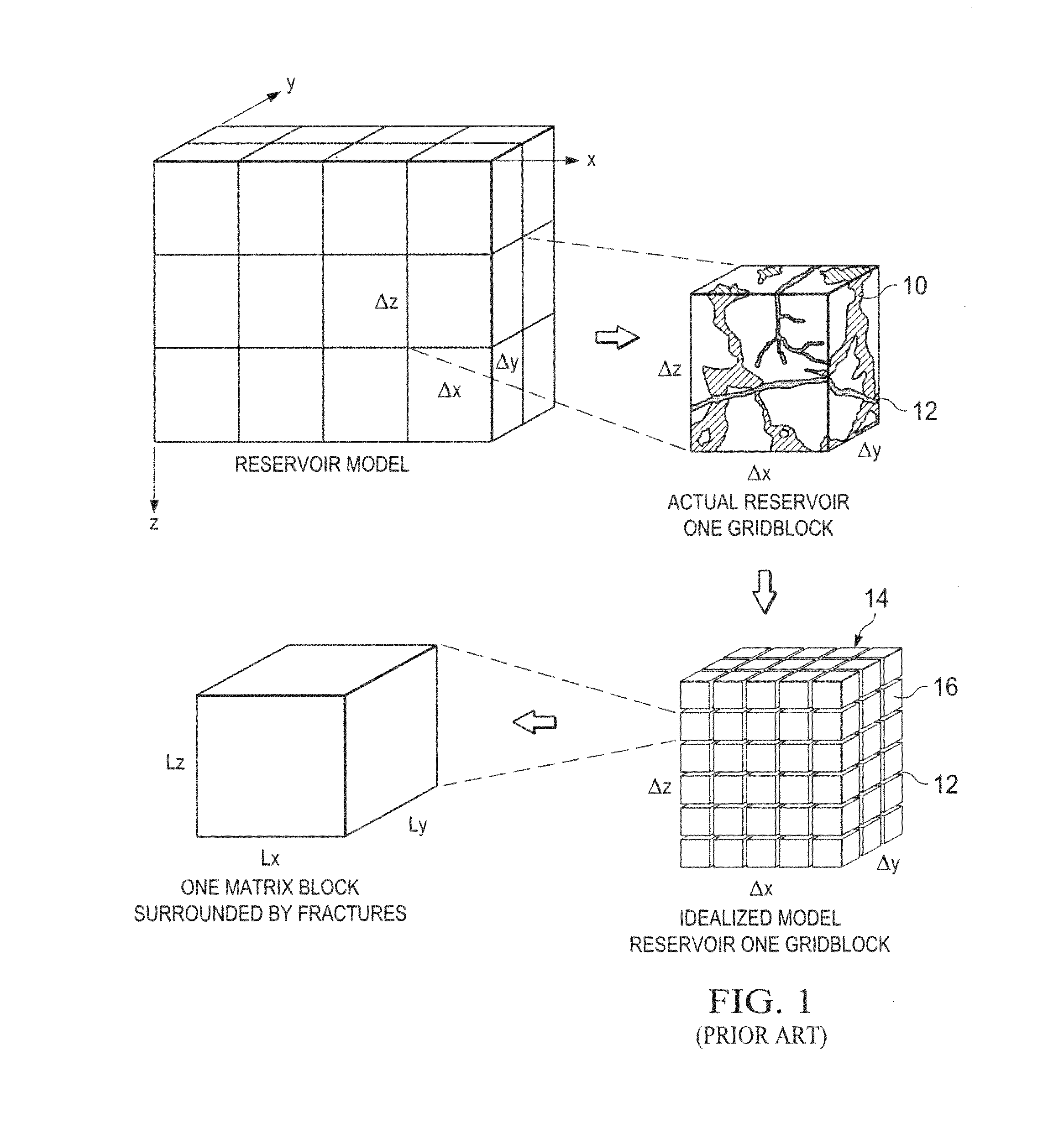

Scalable Simulation of Multiphase Flow in a Fractured Subterranean Reservoir as Multiple Interacting Continua

ActiveUS20120179436A1GeomodellingComputation using non-denominational number representationPore systemCounter current

A subterranean reservoir where the pore space of media or formation rock is multimodal, and the media may have imbedded multiple scales of fracture networks, is simulated. The modes of the pore system and the scale of fracture networks are each represented as a separate, but interactive continuum with the other. The simulation allows multiple continua to be co-located and multi-interacting, in that each continuum may have current and counter-current multiple multiphase exchanges with other continua.

Owner:SAUDI ARABIAN OIL CO

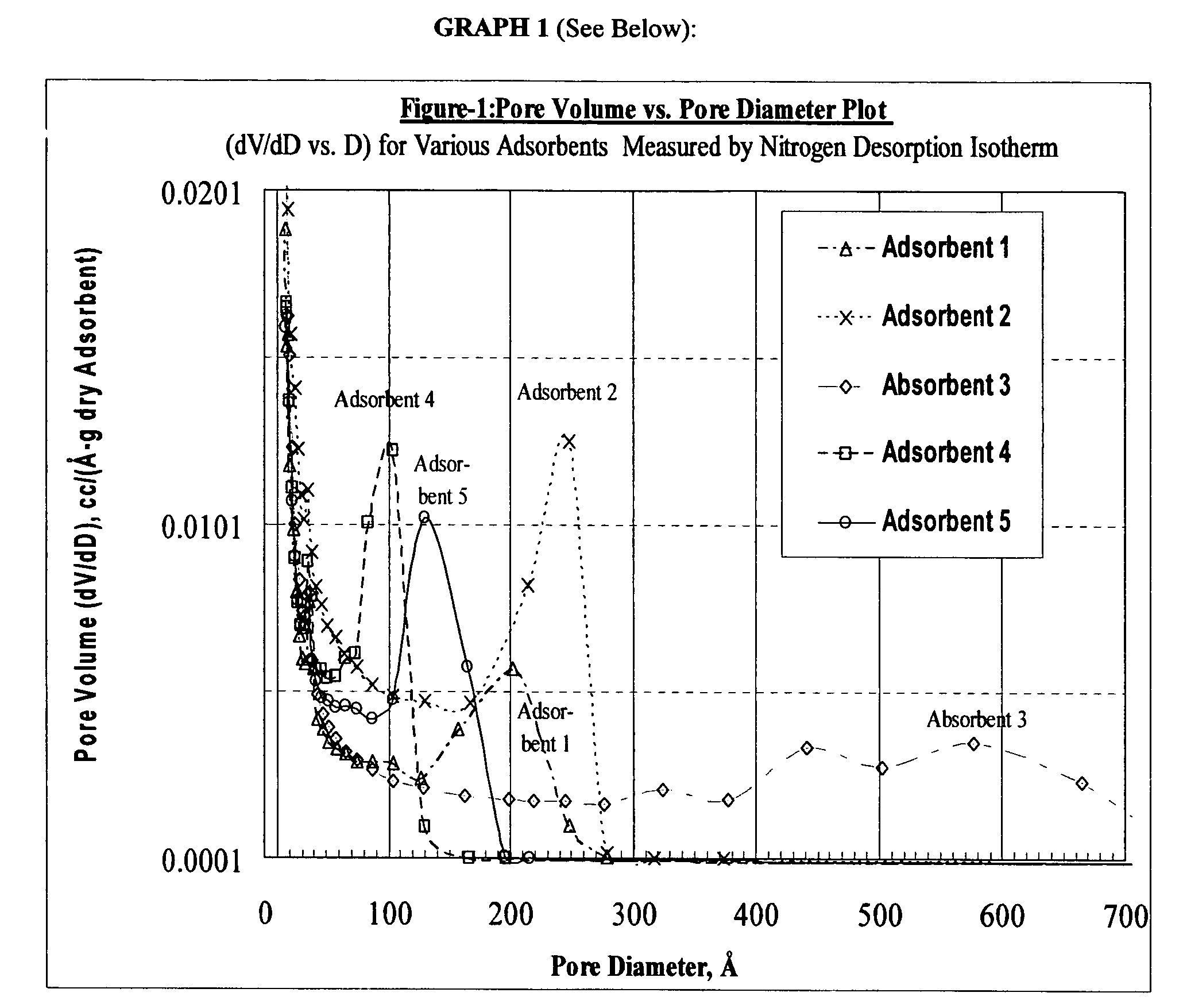

Size-selective hemoperfusion polymeric adsorbents

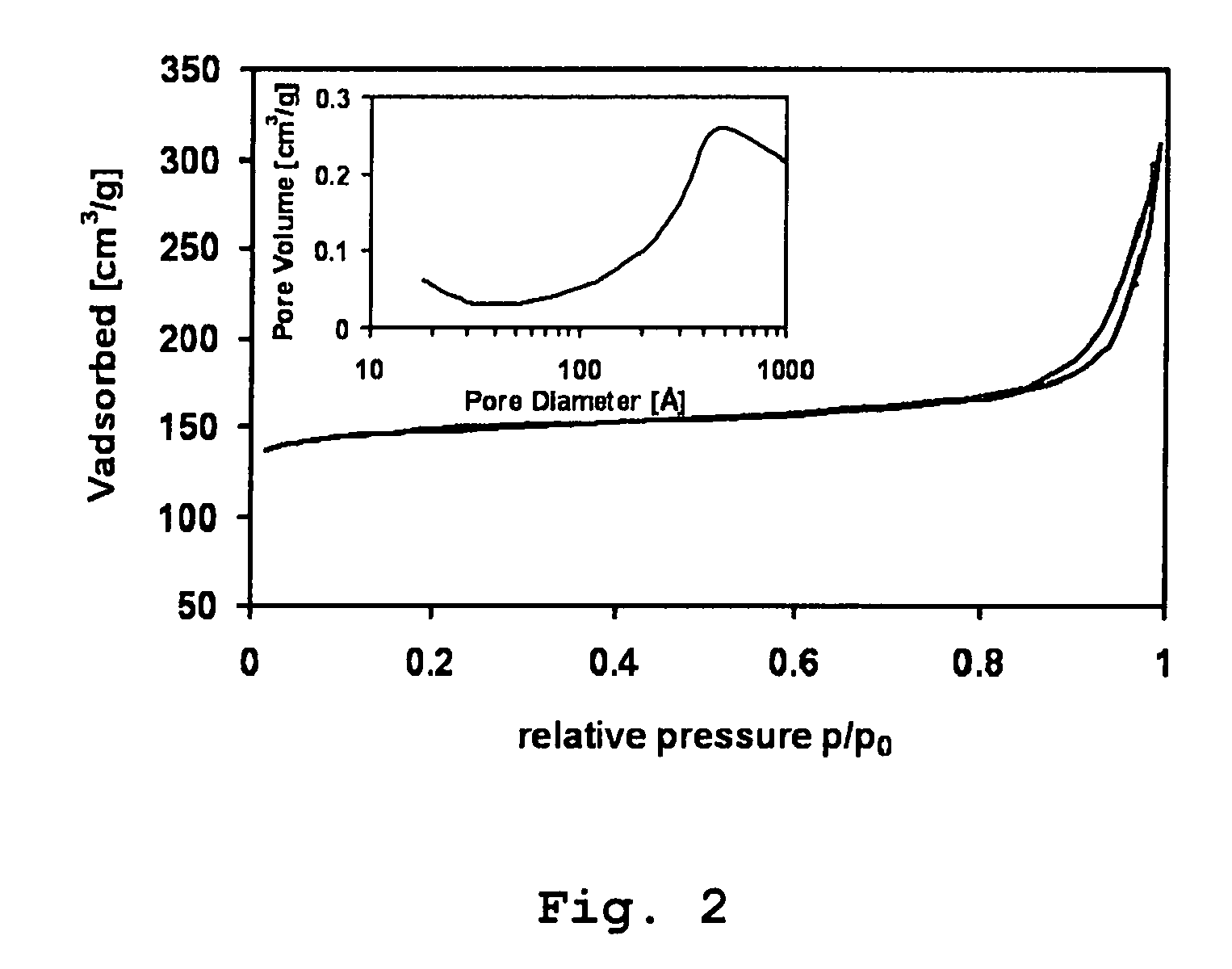

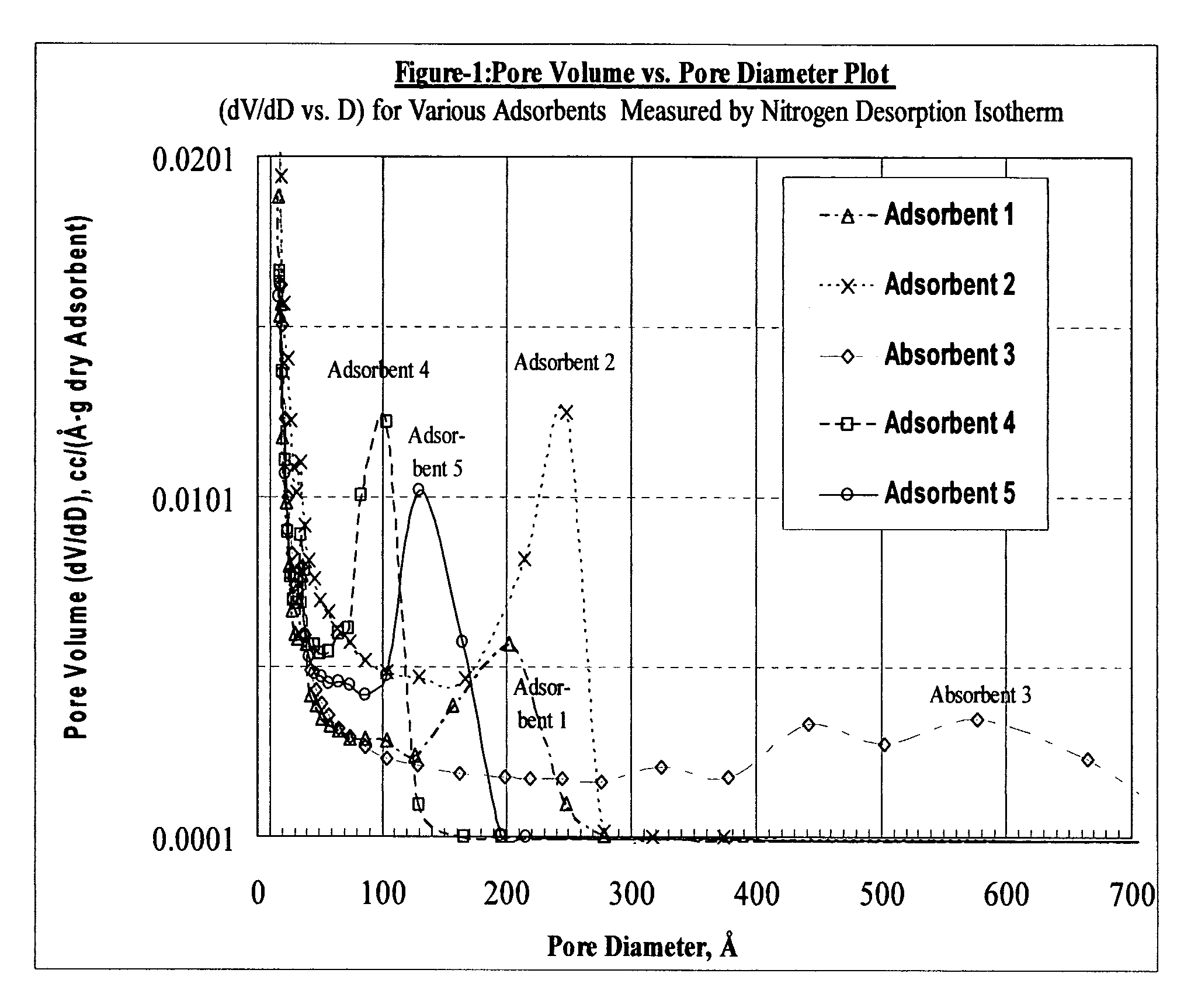

Size-selective hemocompatible porous polymeric adsorbents are provided with a pore structure capable of excluding molecules larger than 50,000 Daltons, but with a pore system that allows good ingress and egress of molecules smaller than 35,000 Daltons. The pore system in these porous polymeric adsorbents is controlled by the method of synthesis so that 98% of the total pore volume is located in pores smaller than 300 Angstroms (Å) in diameter with a working pore size range within 100 to 300 Å in diameter. The porous polymeric adsorbents of this invention are very selective for extracting midsize proteins, such as cytokines and β2-microglobulin, from blood and other physiologic fluids while keeping the components required for good health such as cells, platelets, albumin, hemoglobin, fibrinogen, and other serum proteins intact.

Owner:CYTOSORBENTS CORP

Reservoir implants and stents

InactiveUS20080195196A1Increase effective volumeStentsBlood vesselsInsertion stentBULK ACTIVE INGREDIENT

Exemplary embodiments of the present invention related to medical implants, such as e.g. stents are provided. For example, the implant can comprise at least one hollow space or lumen within the structural material or structure of the device, other than a pore or pore system, which may be used as a reservoir for a specific amount of active ingredient to be released after implantation into the body.

Owner:CINVENTION AG

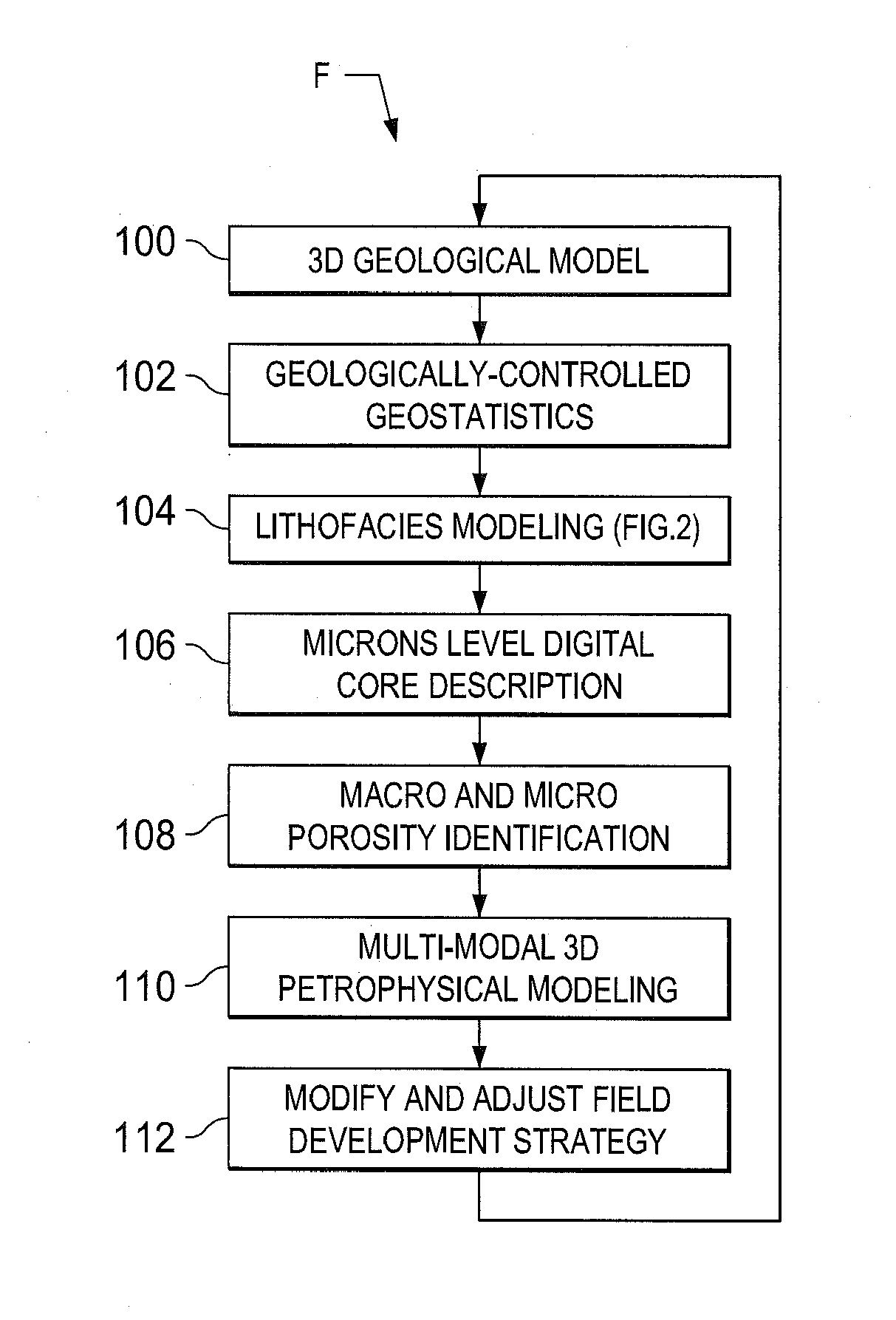

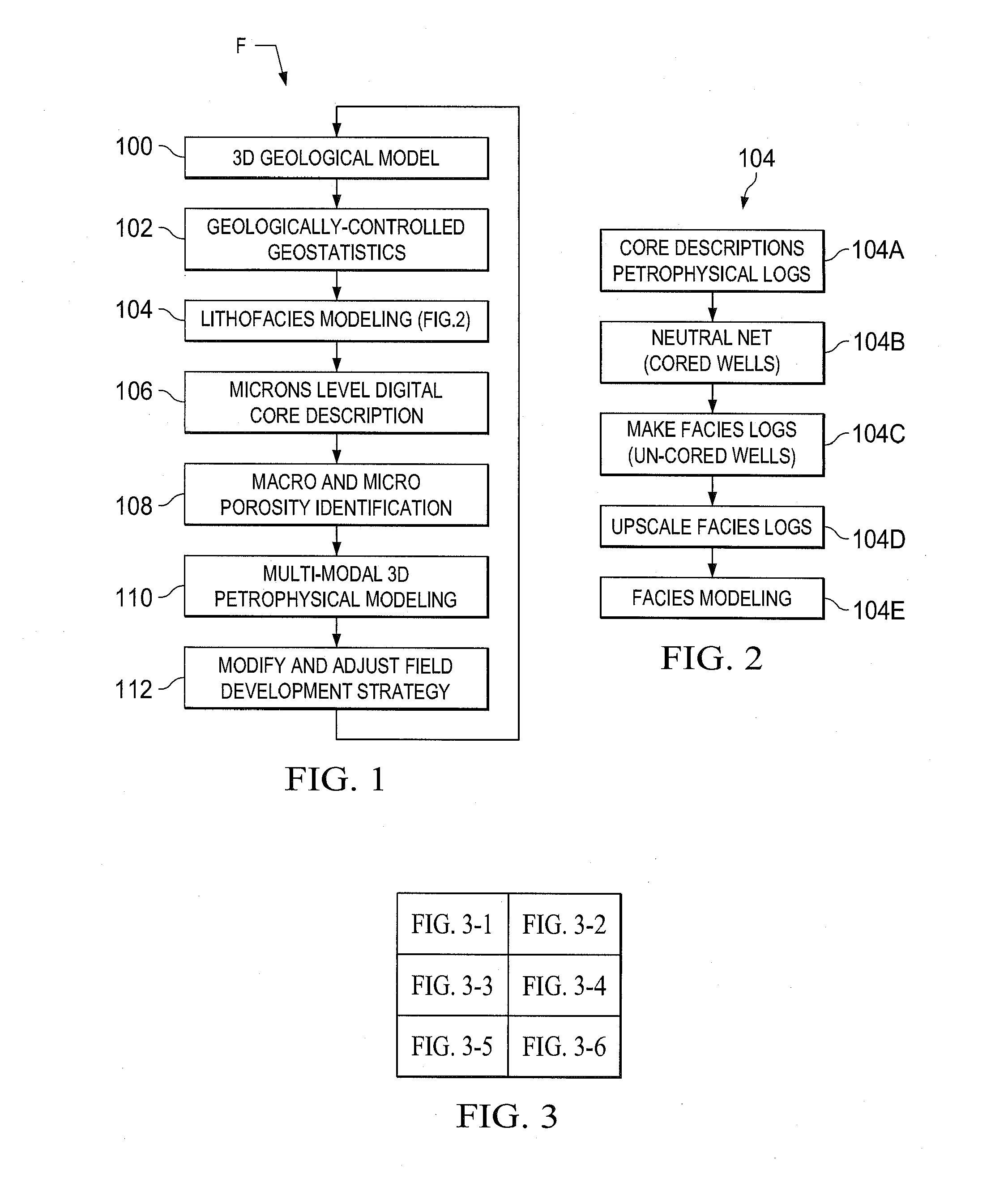

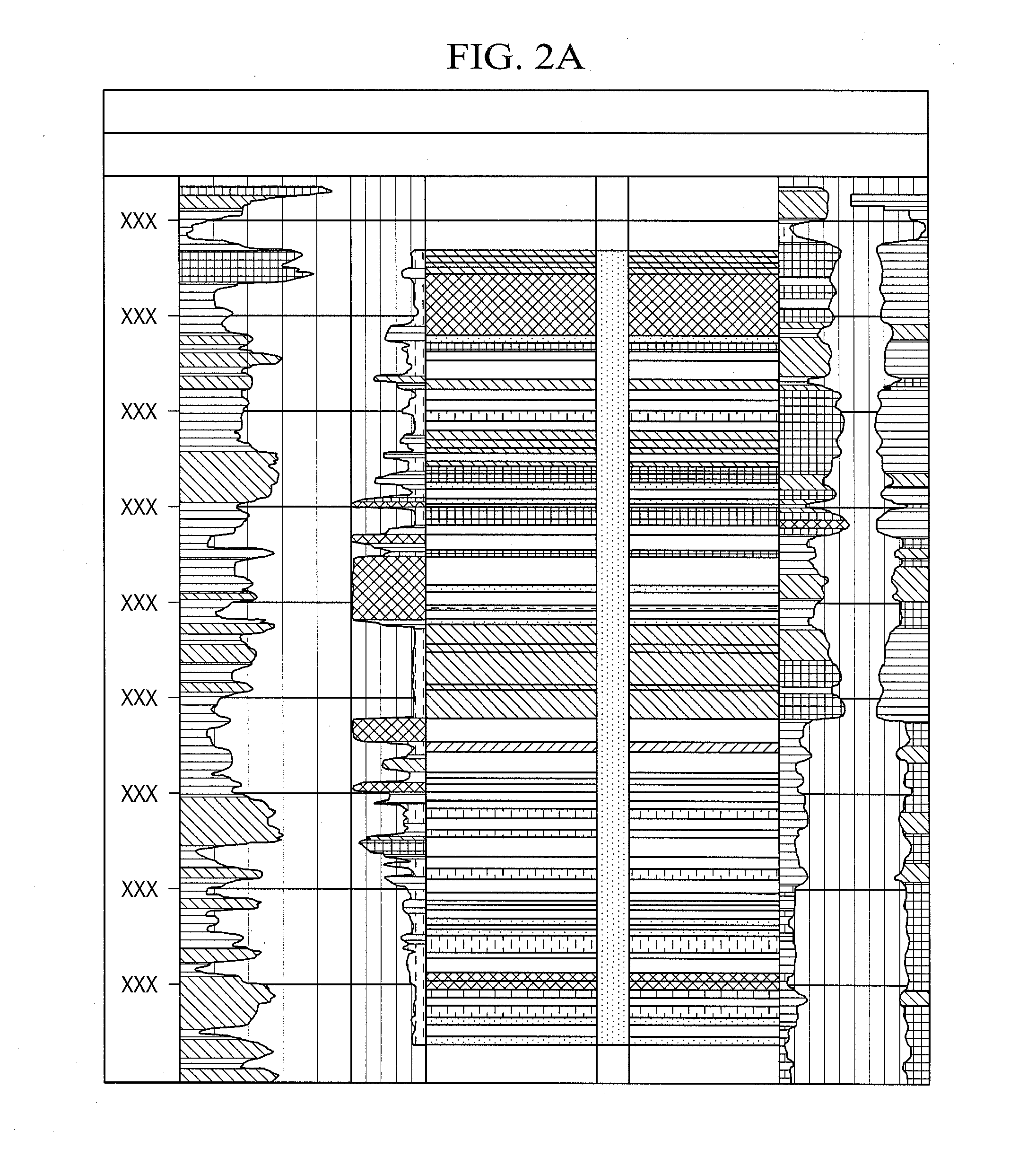

Three-dimensional multi-modal core and geological modeling for optimal field development

A roadmap for a field development strategy for optimal recovery is provided in a high quality 3D geological model. This geological model combines geological attributes, pore and rock properties for an optimum 3D representation of the reservoir thousands feet beneath the surface. The model is based on the pertinent geological facies, derived from well core description and detailed studies of rock, as well as fluid and pore properties (Full Pore System) obtained from laboratory analyses of core material and well log data. These data differentiate various important pore throat and pore body regions and relationships, i.e., macroporosity and microporosity. Understanding hydrocarbon volumes in the various pore type groups and then establishing proper recovery techniques through focused laboratory studies yields a field development strategy that can significantly increase hydrocarbon recovery from a reservoir.

Owner:SAUDI ARABIAN OIL CO

Scalable simulation of multiphase flow in a fractured subterranean reservoir as multiple interacting continua

ActiveUS8583411B2GeomodellingComputation using non-denominational number representationPore systemCounter current

A subterranean reservoir where the pore space of media or formation rock is multimodal, and the media may have imbedded multiple scales of fracture networks, is simulated. The modes of the pore system and the scale of fracture networks are each represented as a separate, but interactive continuum with the other. The simulation allows multiple continua to be co-located and multi-interacting, in that each continuum may have current and counter-current multiple multiphase exchanges with other continua.

Owner:SAUDI ARABIAN OIL CO

Thin film metallic device for plugging aneurysms or vessels

ActiveUS8357180B2Small shapeSolve Porosity InsufficiencyDilatorsOcculdersThree vesselsBiomedical engineering

Thin film metallic devices implantable within a human subject for occlusion of an aneurysm or blood vessel are provided. The devices are movable from a porous, elongated, collapsed configuration for delivery to a deployed configuration within the body. The pores telescope as the device moves to its deployed configuration, which causes the device to longitudinally foreshorten and radially expand, while also decreasing in porosity for preventing blood flow. The occlusion devices may be either self-supporting or supported by a strut structure. Additionally, the occlusion devices may comprise a plurality of layers having unaligned pore systems which further reduce porosity in the deployed configuration.

Owner:CODMAN & SHURTLEFF INC

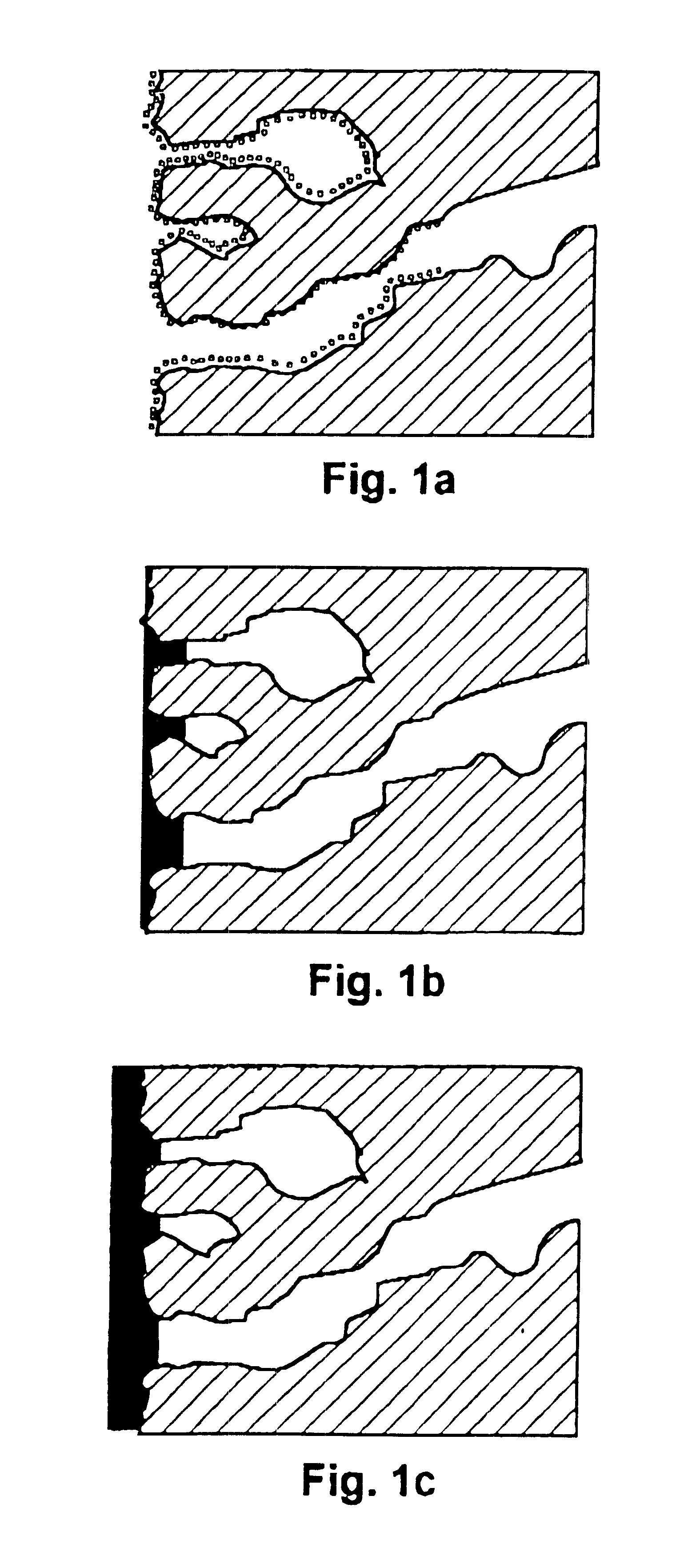

Thin film devices for temporary or permanent occlusion of a vessel

ActiveUS7811300B2Facilitates endoluminal deploymentReduced cross-sectional extentDilatorsOcculdersTelescopeBlood vessel

Thin film devices implantable within a human subject for occlusion of an aneurysm or body vessel are provided. The devices are movable from an elongated, collapsed configuration for delivery to a deployed configuration within the body. Open slots in selected portions of the device telescope as the device moves to its deployed configuration, which causes the associated portions to longitudinally foreshorten and radially expand, while also decreasing in porosity for preventing blood flow. Closed slits in other portions of the device open as the device moves to its deployed configuration, which causes the associated portions to longitudinally foreshorten and radially expand, while remaining open for fluid flow or endothelialization. The occlusion devices may be either self-supporting or supported by a strut structure. Additionally, the occlusion devices may comprise a plurality of mesh layers having unaligned pore systems which further reduce porosity in desired portions of the deployed configuration.

Owner:CODMAN & SHURTLEFF INC

Bone Implant, and Set for the Production of Bone Implants

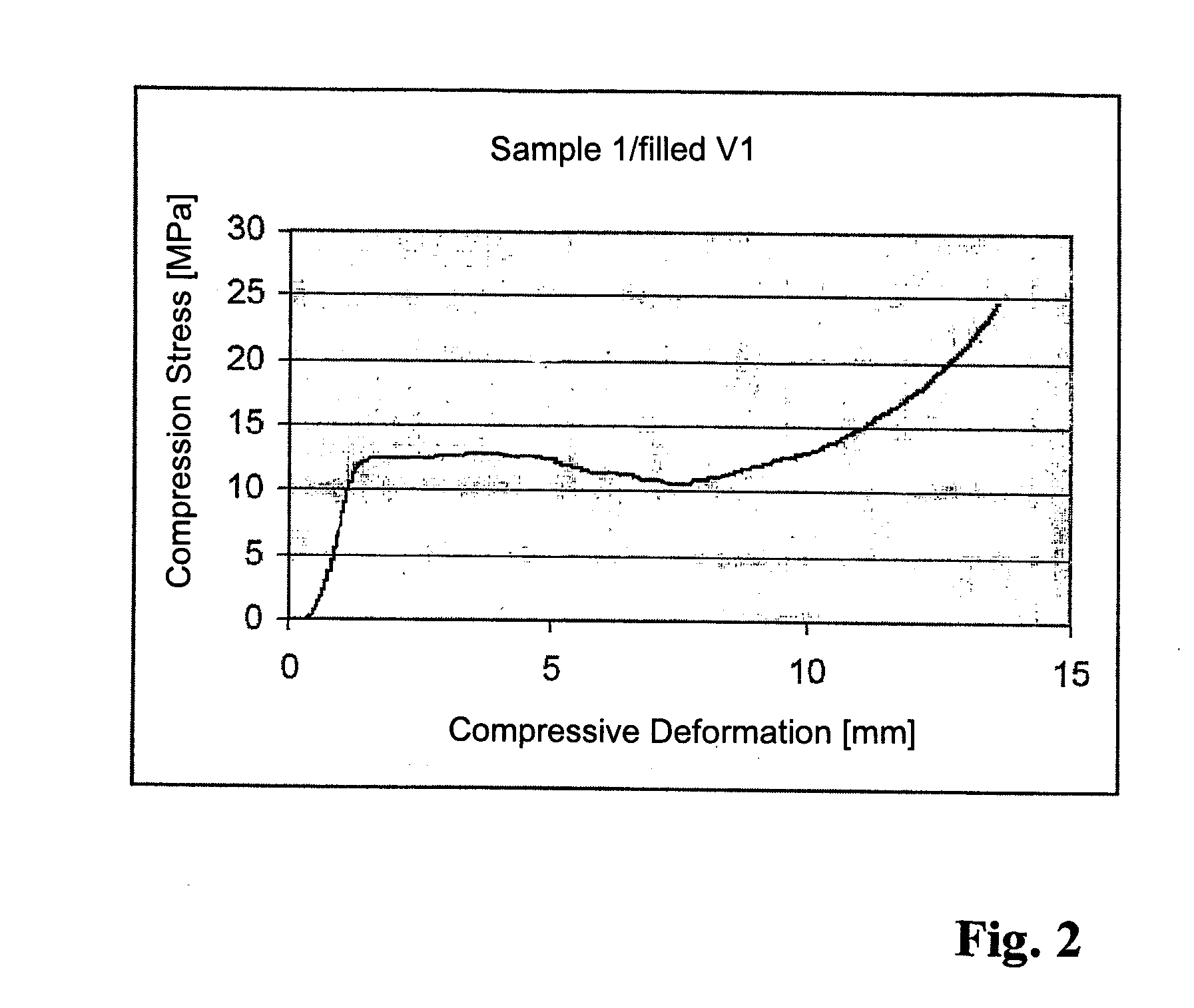

InactiveUS20100185299A1Great mechanical adaptabilityMechanical performanceBone implantTissue regenerationBiological conditionBone implant

The invention relates to bone implants and sets for producing bone implants. Said bone implants are made from pasty or cementitious preparations which are introduced into open-cell metal structures comprising an interconnected pore system as solid or porous materials and are optionally allowed to set, the metal structure per se being biocompatible in biological conditions and being stable or corrodible. The bone implant according to the invention contains at least one open-cell metal structure that has an interconnected pore system which is at least partially filled with a preparation made of at least one bone replacement material. The open-cell metal structure is significantly less rigid than the solid material made of the same metal.

Owner:NIES BERTHOLD

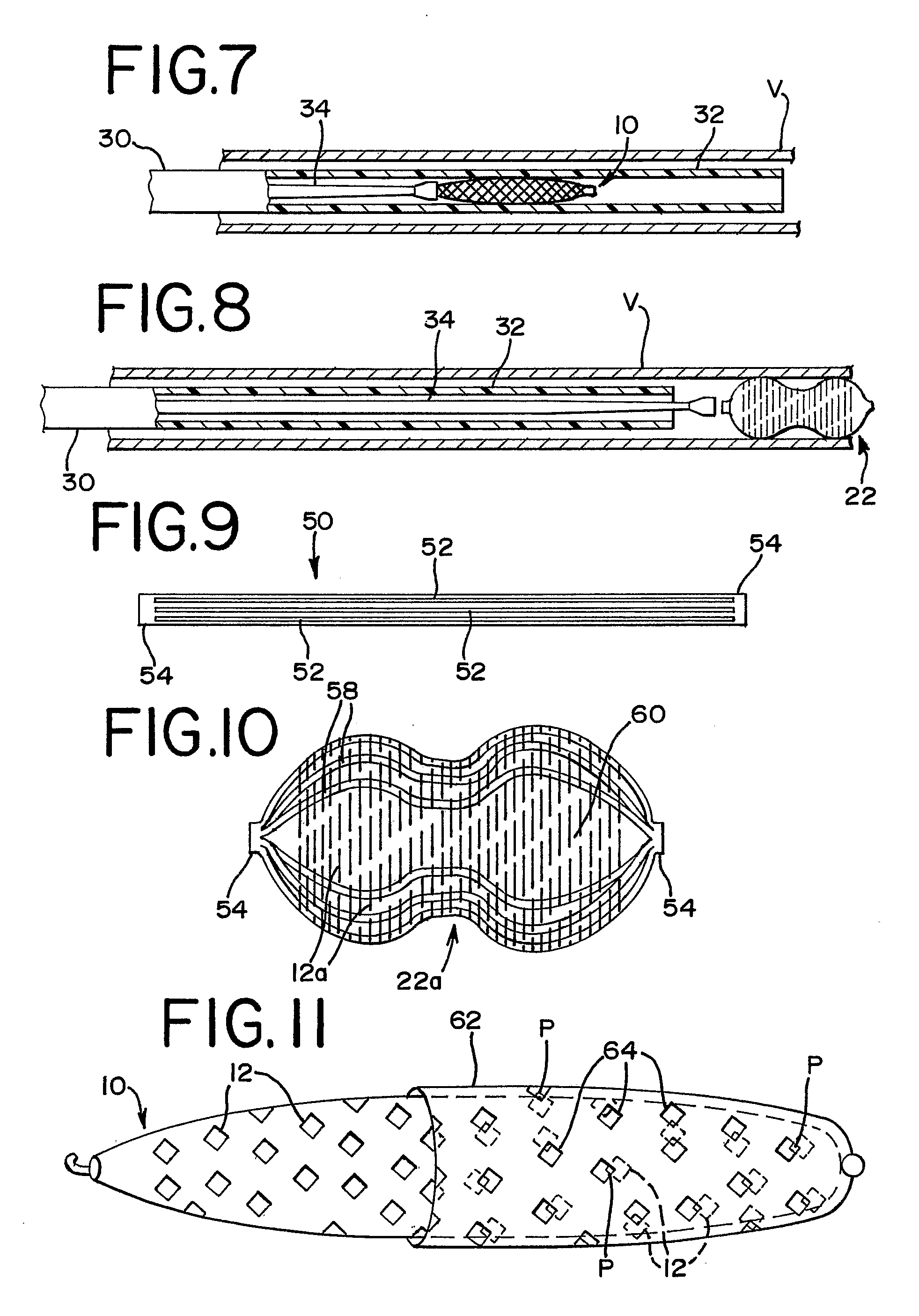

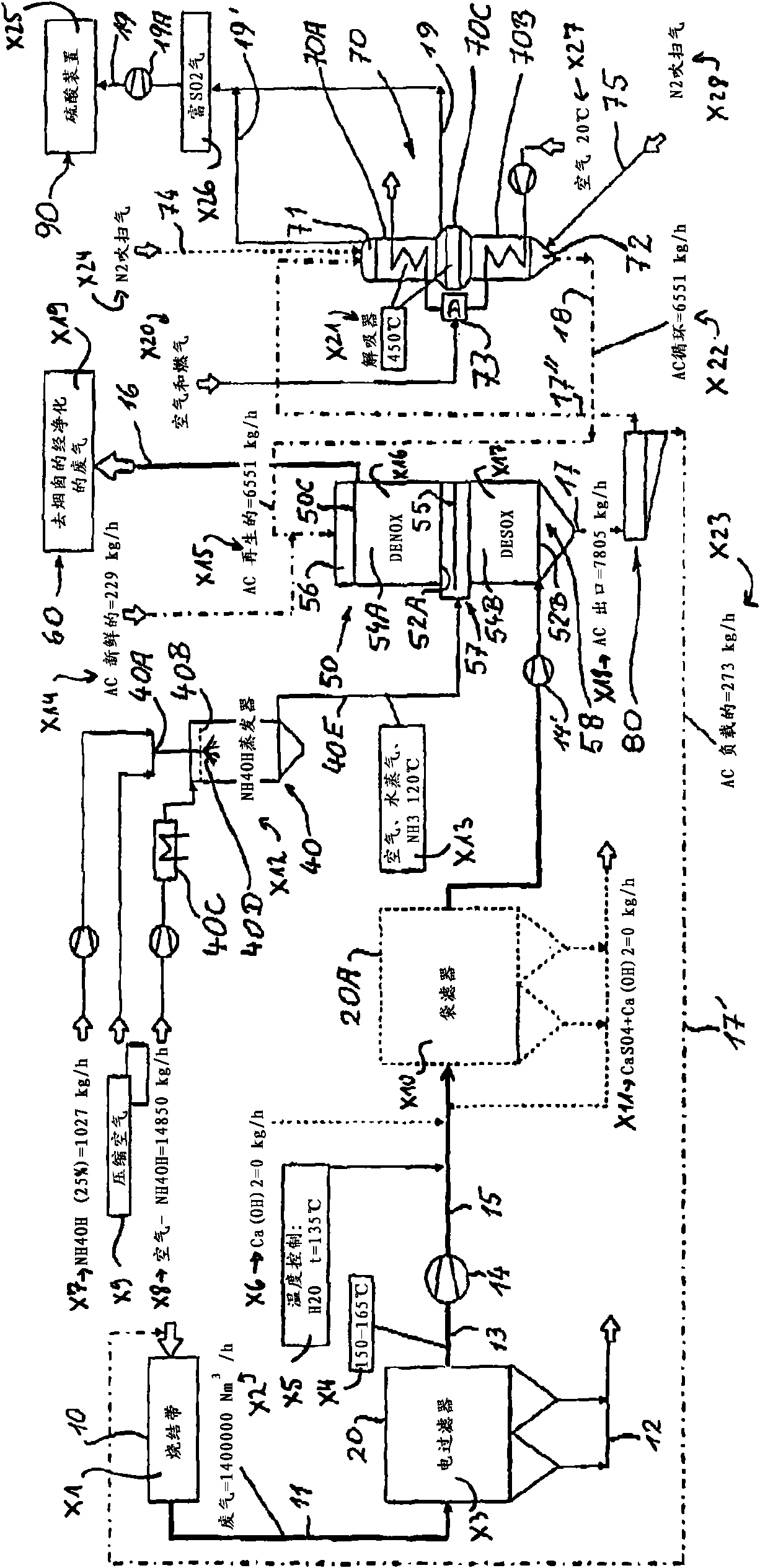

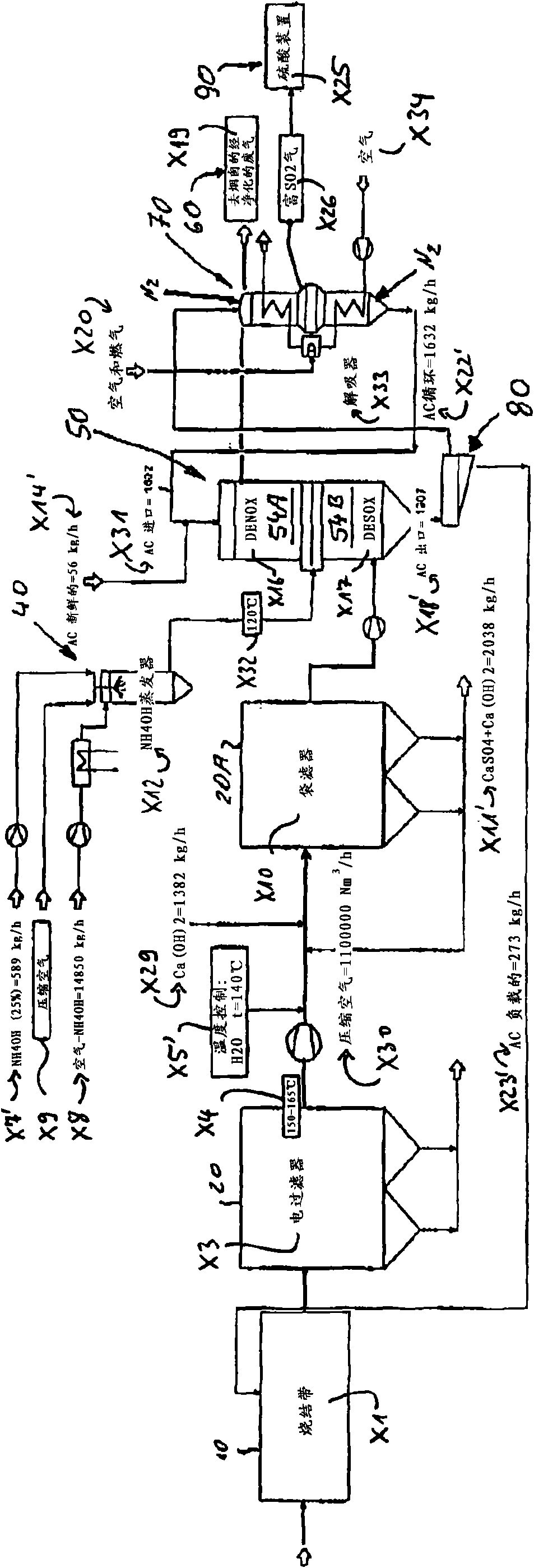

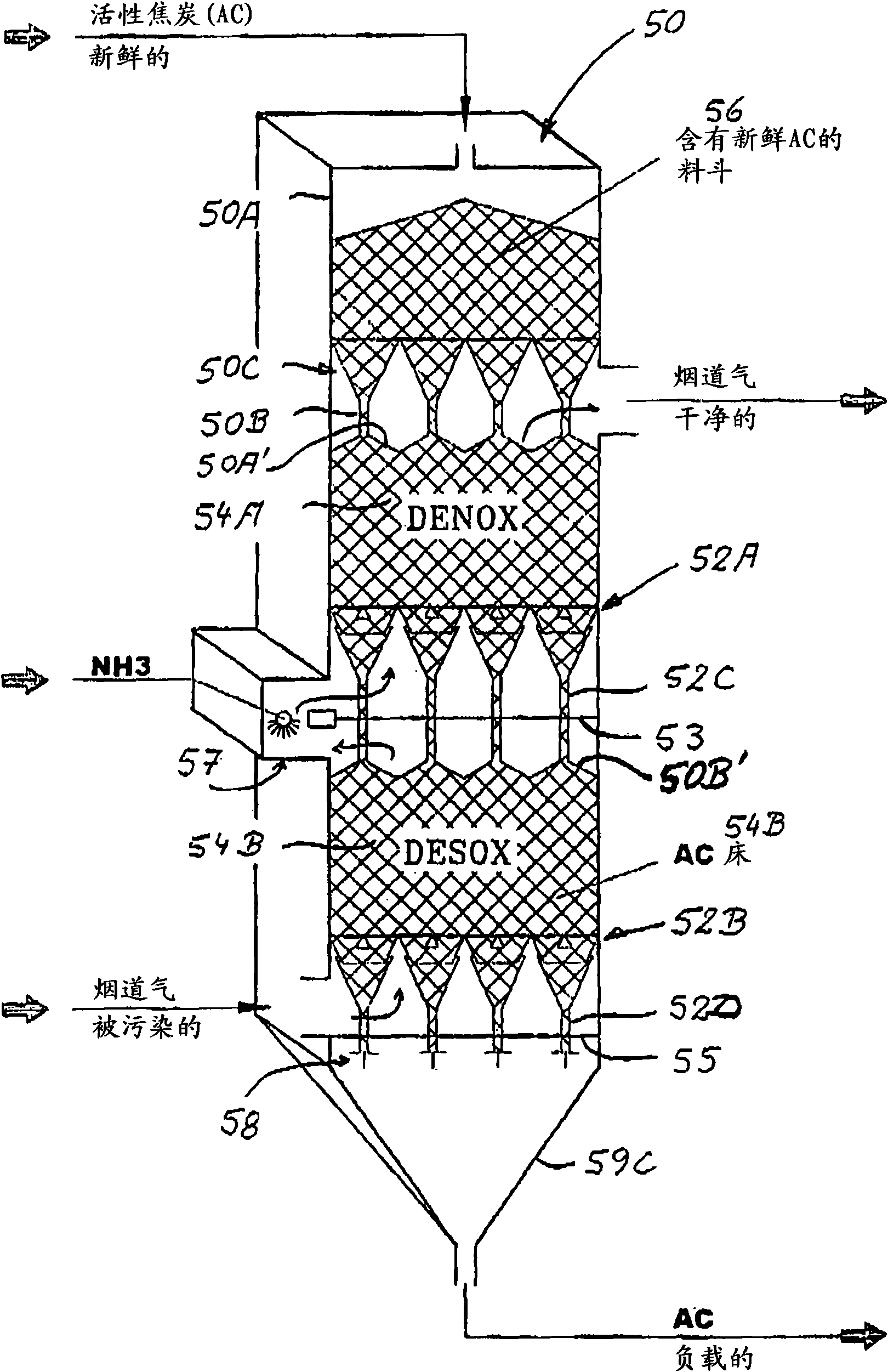

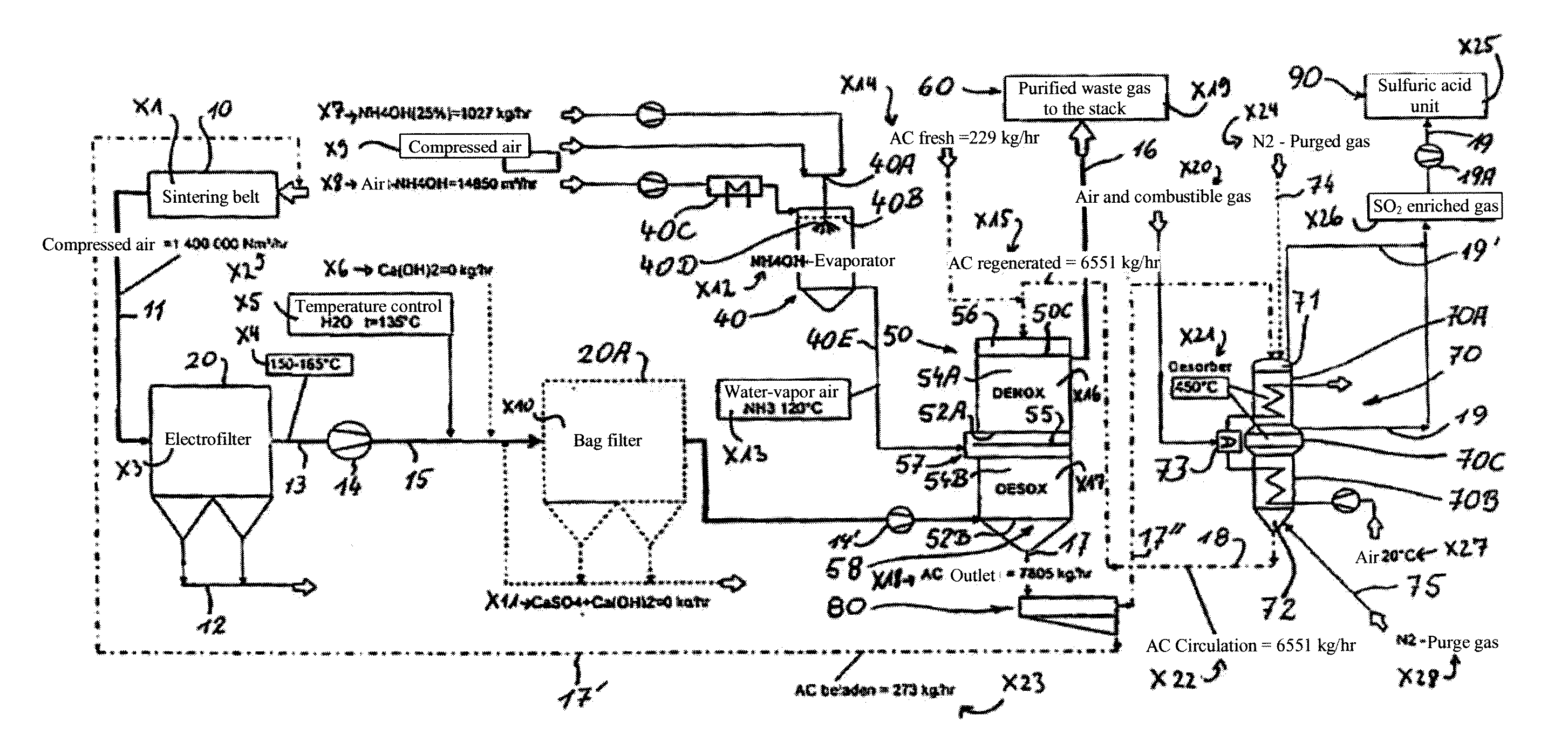

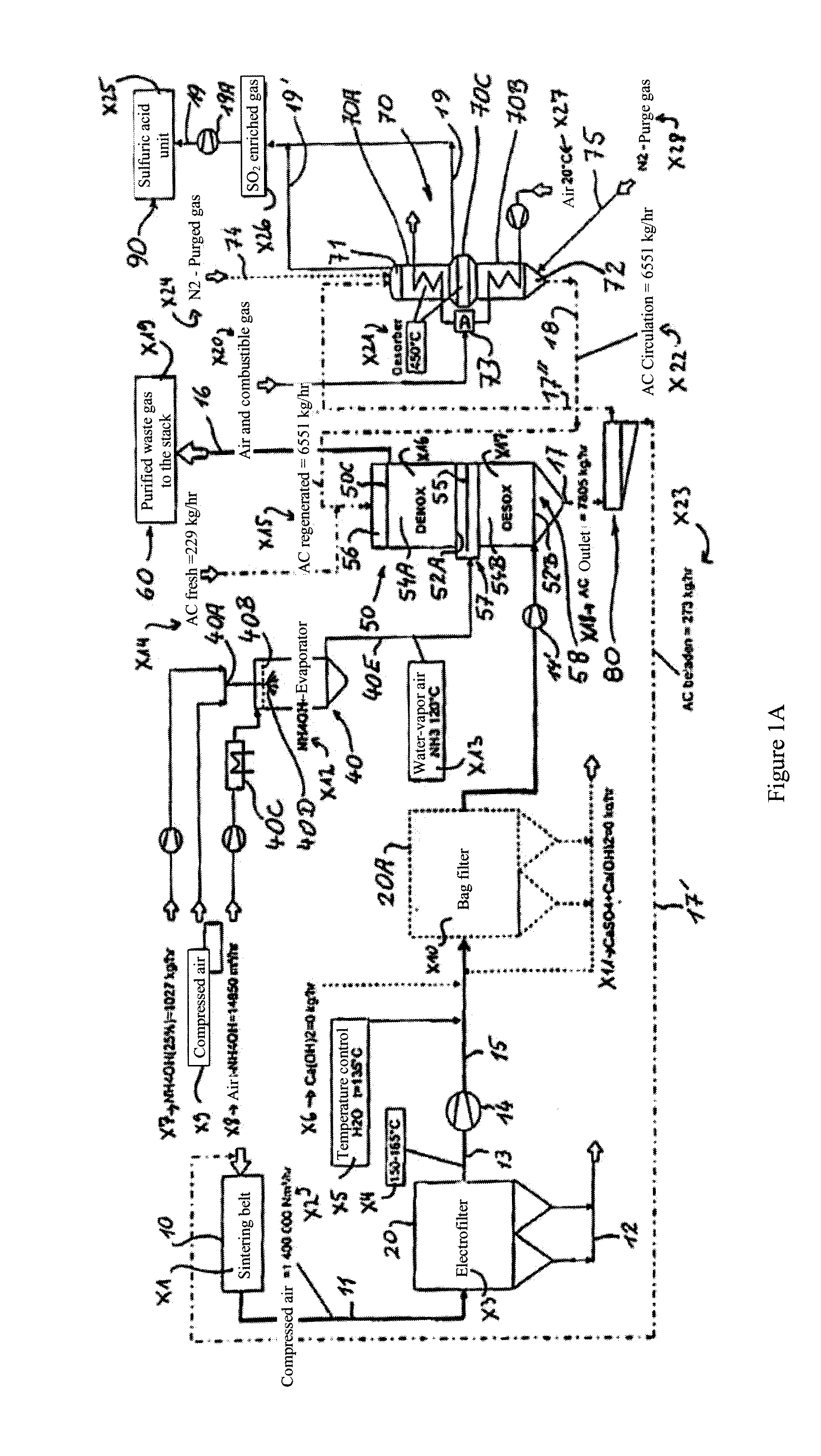

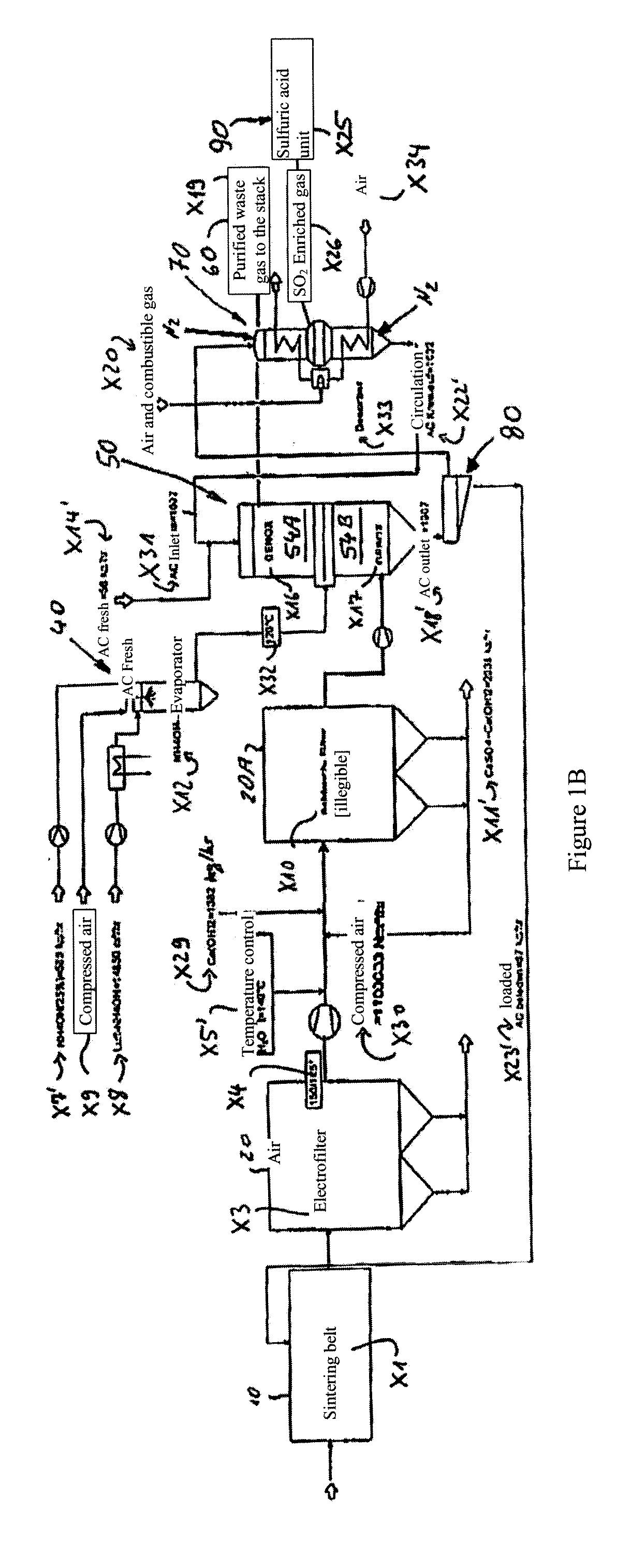

Method and device for purifying the flue gases of a sintering process of ores and/or other material-containing materials in metal production

ActiveCN101605589AReduce consumptionGas treatmentDispersed particle separationAmmonium compoundsSorbent

The invention relates to a method for scrubbing effluent gases from a sintering process for ores in metal production, in which ore material is sintered with a solid fuel by combustion of the solid and passing through a carbonisation process, wherein at least the pollutants SOx and / or HCl and NOx are reduced or essentially removed. The sinter effluent gas is introduced into a moving bed reactor (50) from below through a lower and an upper layer (54B; 54A) of adsorption and / or absorption agent which is already charged with NOx and SOx and / or HCl, wherein at least the majority of the SOx and / or HCI components from the sinter effluent gas are absorbed in the pore system of the adsorption and / or absorption agent charged with NOx. The sinter effluent gas purified of the majority of the SOx and / or HCI components is homogeneously mixed with an ammoniacal compound such as ammonia or urea and admitted from below into the upper layer of adsorption and / or absorption agent already charged with NOx and small amounts of SOx and / or HCl from below through an upper horizontal gas influx and bulk material outlet floor (52A) of the moving bed reactor. On flowing through the upper layer (54A) at least the majority of NOx components from the sinter effluent gas is absorbed on the surface of the absorption / adsorption agent charged with NOx or N2 and small amounts of SOx and / or HCl. Fresh and / or regenerated adsorption / absorption agent is introduced via a bulk material distribution floor (50C) at the upper end of the moving bed reactor and continuously moves through the upper and lower layer of the whole moving bed reactor wherein firstly Nox and N2 and steam are absorbed on the surface thereof and then SOx and / or HCl are absorbed in the pore system thereof.

Owner:霍斯特·格罗霍夫斯基

Activated carbon with a special finishing, production and use thereof

ActiveUS20160038924A1High wearing comfortImprove filtration efficiencyChemical protectionGas treatmentActivated carbonChemical compound

The invention relates to a method for producing activated carbon provided and / or impregnated with a metal-organic framework substance (MOF material), the activated carbon being in particular in the form of discrete activated carbon particles, and preferably for producing an activated carbon with a reactive and / or catalytic action. The metal-organic framework substance is produced in situ in the pores and / or in the pore system of the activated carbon, starting from at least one metal precursor compound(MP) containing a metal and at least one ligand precursor (LP).

Owner:BLUCHER GMBH +1

Method and device for purifying the flue gases of a sintering process of ores and/or other material-containing materials in metal production

ActiveUS20100296991A1Simple methodHigh burning of the carbonCombination devicesOrganic chemistrySorbentWater vapor

In a method for the purifying of the waste gases of a sintering process of ores in the production of metals, in which ore material is sintered with a solid fuel, with the combustion of the solids and passage through a smoldering process, at least the pollutants SOx and / or HCl and NOx are reduced or extensively eliminated. To this end, the sintering waste gas is guided into a moving bed reactor (50) from below through a lower and upper layer (54B; 54A) of an adsorption and / or absorption agent already polluted with NOx and SOx and / or HCl, wherein at least the main quantity of SOx and / or HCl components is adsorbed from the sintering waste gas into the pore system of the NOx-loaded adsorption and / or absorption agent. The sintering waste gas, purified of the main quantity of SOx and / or HCl components, is intimately mixed with an ammonium-containing compound, such as ammonia or urea, and flows in below through an upper horizontal gas inflow and bulk material removal tray (52A) of the moving bed reactor into the upper layer of the adsorption and / or absorption agent already polluted with NOx and small quantities of SOx and / or HCl. In the throughflow of the upper layer (54A), at least the main quantity of NOx components is adsorbed from the sintering waste gas onto the surface of the adsorption / absorption agent, loaded with NOx or N2 and small quantities of SOx and / or HCl.Fresh and / or regenerated adsorption / absorption agent is delivered, via a bulk material-distributing tray (50C), at the upper end of the moving bed reactor and subsequently migrates, without interruption, through the upper and lower layers of the entire moving bed reactor, wherein initially, NOx and N2 and water vapor is adsorbed onto its surface, and subsequently, with SOx, and / or HCl, in its pore system.

Owner:GROCHOWSKI HORST

High-energy-density Li-air battery air electrode, and battery and making method thereof

ActiveCN103280586AEffective protectionImprove catalytic reaction efficiencyCell electrodesMetallic lithiumHigh energy

The invention belongs to the chemical power supply field, and concretely relates to a high-energy-density Li-air battery air electrode, and a battery and a making method thereof. The air battery is a non-aqueous chargeable Li-air (or Li / O2) battery concretely, and comprises a lithium metal negative electrode, a non-aqueous electrolyte, a diaphragm and the air electrode, the air electrode comprises a catalyst, a carrier and a binder, and the carrier is a composite double pore system material composed of nano-graphene having a two-dimensional nanostructure, a high heat conduction coefficient (-5000W / m.k), a high specific surface area (-2630m<2> / g) and a high electrical conductivity (10<3>-10<4>Sm<-1> and an SiO2 aerogel, provides a circulation channel and a storage space for O2 and discharge reaction products respectively, and adopts a double-surface electrode structure; and the non-aqueous electrolyte adopts a lithium salt and organic solvent mixed electrolyte, and has the advantages of high electrical conduction, low volatility, good chemical stability and the like. The oxygen-selective diaphragm is added to the air battery to increase the pressure of O2 in a reaction area and prevent water in air from entering the battery, so the metallic lithium is effectively protected, and the safety of the battery is increased.

Owner:深圳市集创云天新材料有限公司

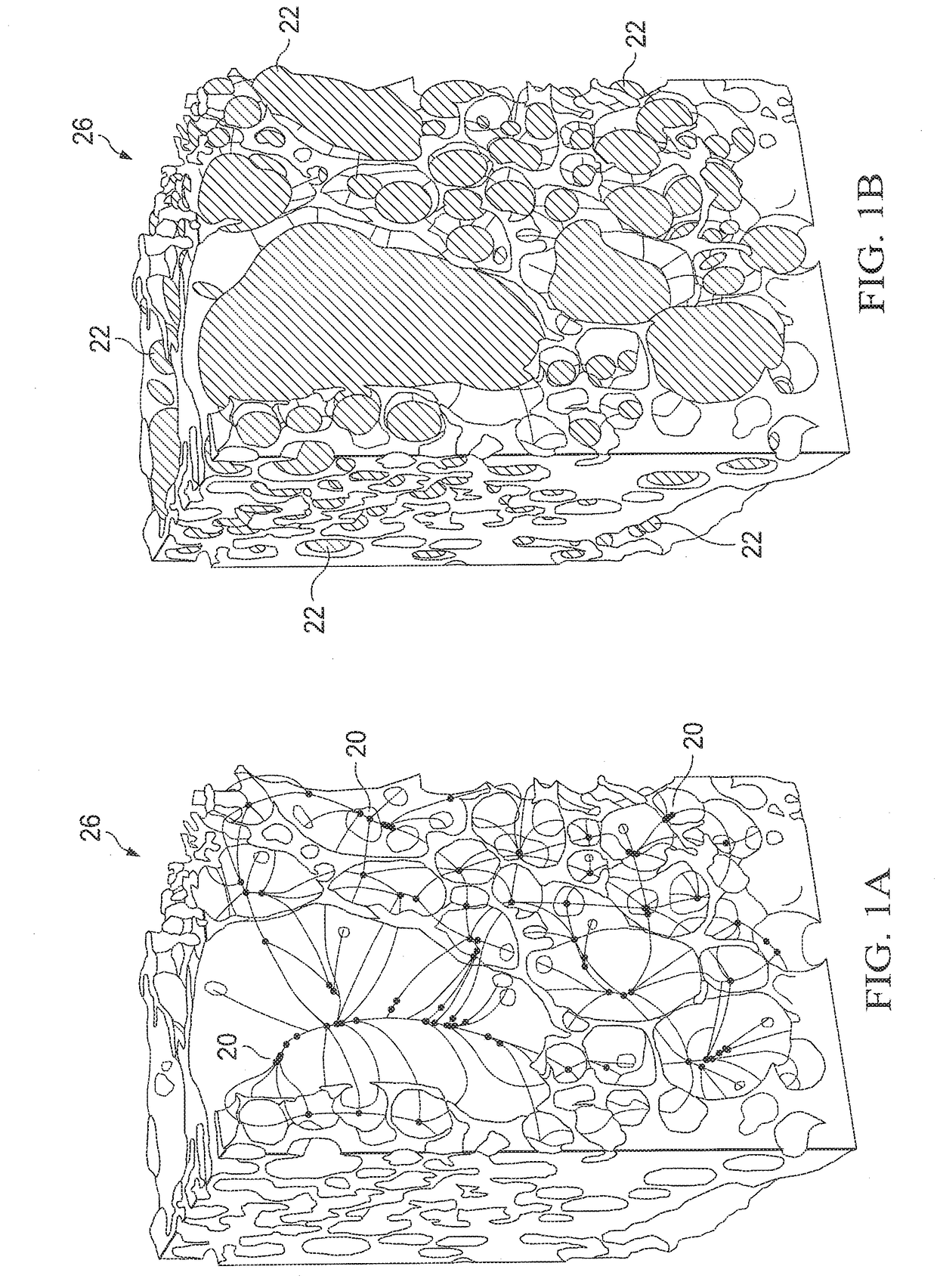

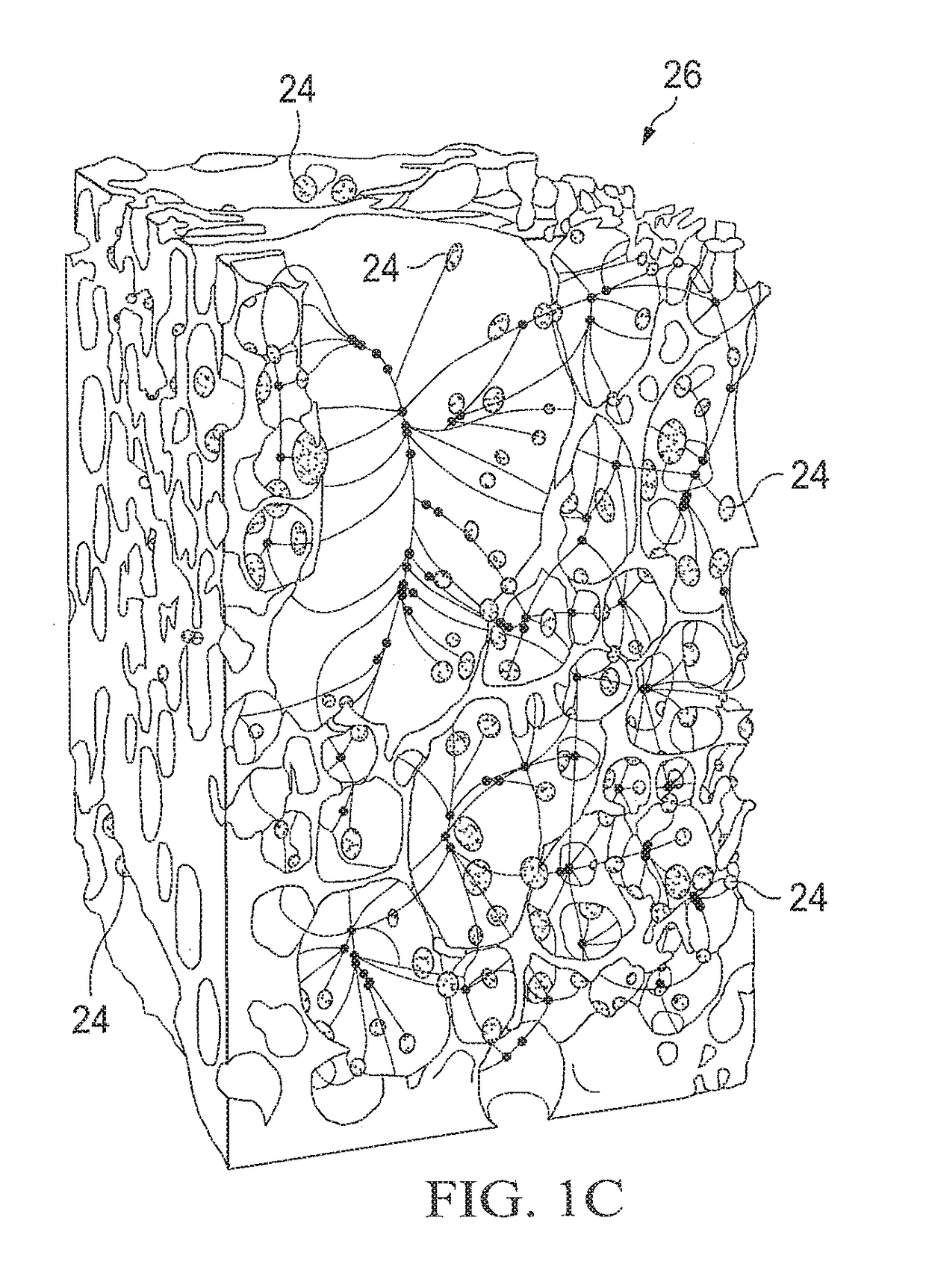

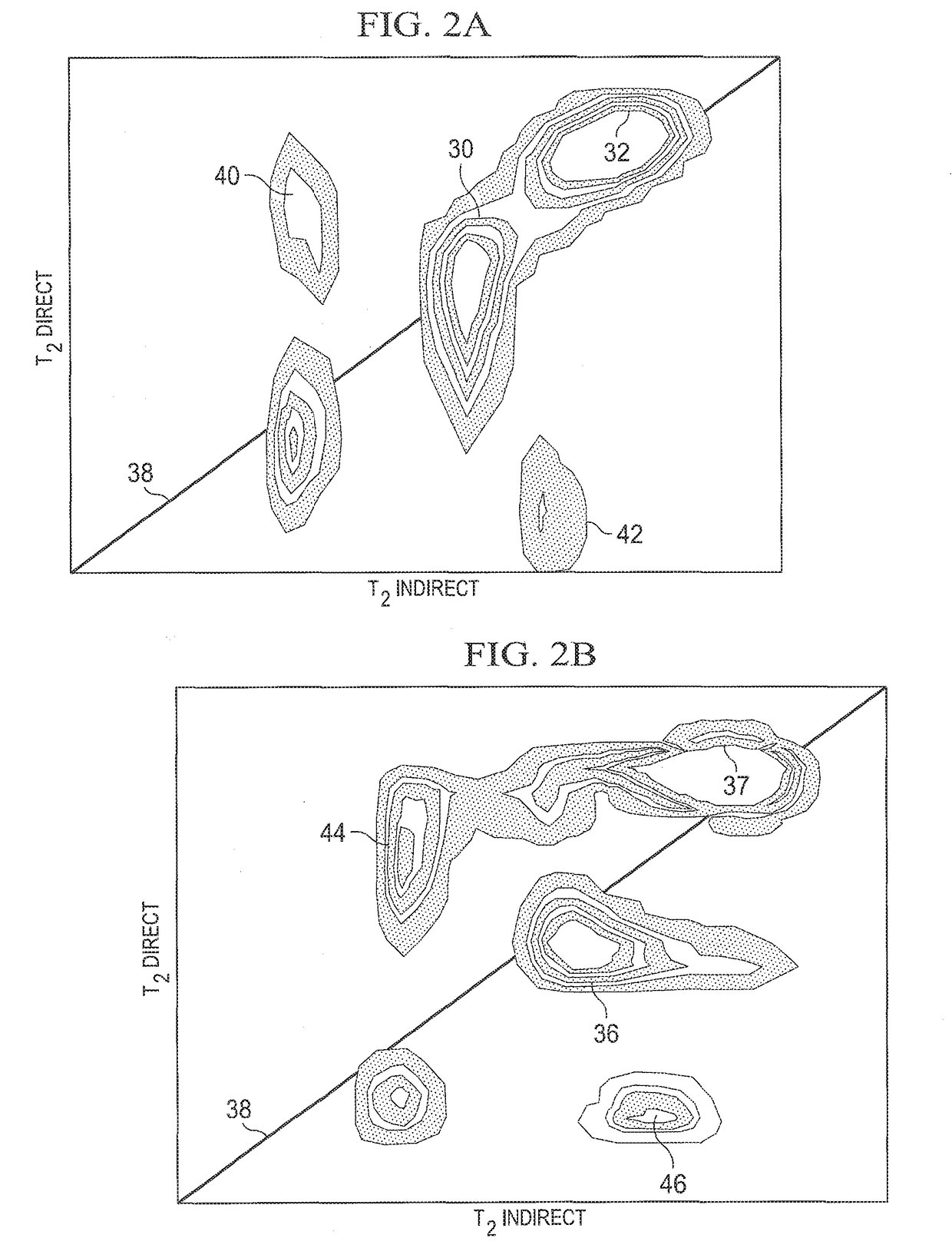

Measuring connectivity between different pore types in porous media

InactiveUS20170115242A1Measurements using NMR spectroscopyAnalysis using nuclear magnetic resonancePorous mediumProton

The connectivity between different pore types in porous media is measured by using low-field nuclear magnetic (NMR) and fast field cycling NMR techniques. Due to the fluid exchange between connected pores, T1(T2) NMR relaxation times of proton nuclei of fluids in the different pore types are shifted. By comparing the T1(T2) NMR relaxation times of porous media samples which are 100% brine saturated with relaxation times for the samples containing brine and hydrocarbon in the different pore systems of the samples, the connectivity between the pores can be measured.

Owner:SAUDI ARABIAN OIL CO

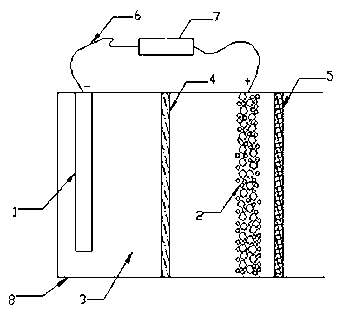

Protection of reinforcement

InactiveUS7749362B2Low healthImprove securityLaminationLamination apparatusHigh concentrationPorous layer

A method of protecting steel in concrete is disclosed. It consists of connecting the steel (6) to a discrete sacrificial anode assembly (7) comprising a base metal (1), a relatively small quantity of catalytic activating agent in contact with the base metal and a substantially inert porous layer (3) that surrounds the base metal and catalytic activating agent. The inert porous layer efficiently maintains a sustainable concentration gradient of the catalytic activating agent between the base metal and the surrounding environment as a result of the electric field across this layer. The preferred porous layer comprises a material that exhibits a net repulsion of negative ions from its pore system and the preferred catalytic activating agent comprises doubly charged sulphate ions as small electric fields maintain very high concentration gradients of these ions resulting in high concentrations at the base metal surface and insignificant concentrations at the assembly periphery.

Owner:GLASS +1

Preparation of hydrodeoxygenation isomerization catalyst and application thereof in preparation of diesel oil from illegal cooking oil

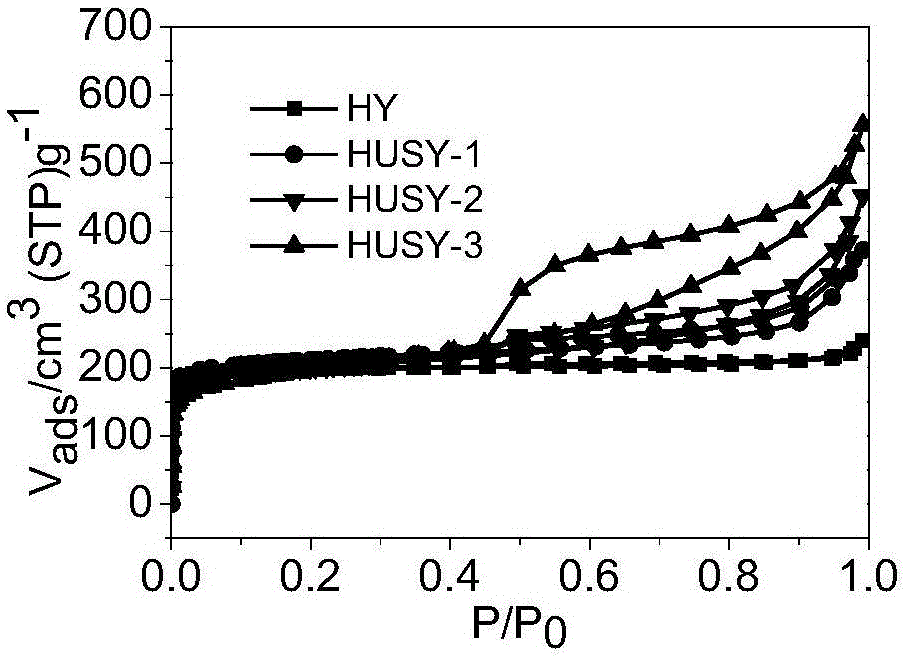

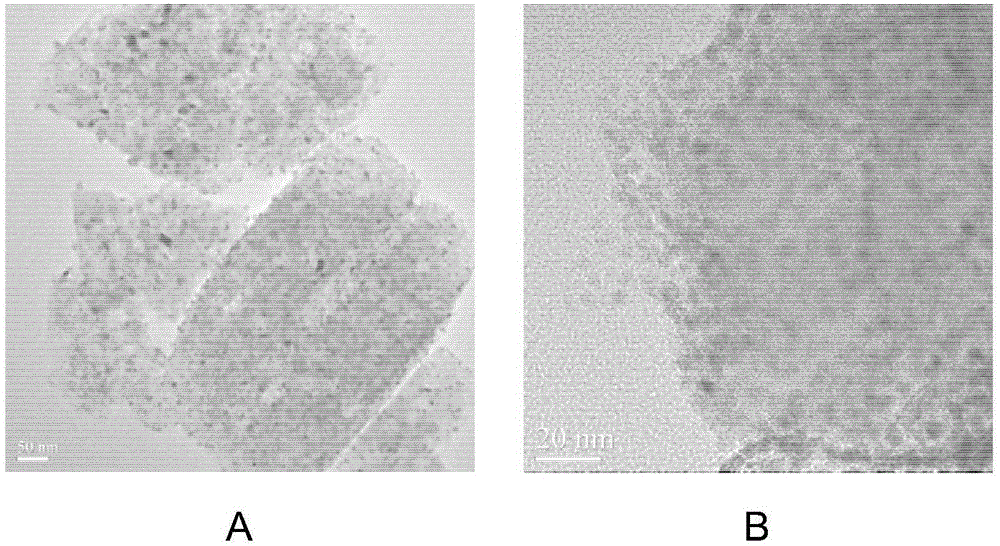

ActiveCN105126898AImprove anti-carbon performanceReduce manufacturing costMolecular sieve catalystsLiquid hydrocarbon mixture productionMolecular sieveDeposition precipitation

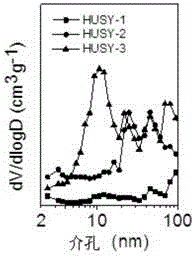

The invention discloses a hydrodeoxygenation isomerization catalyst, which includes a hydrodeoxygenation catalyst of an ultrastable Y molecular sieve loaded metal and a hydroisomerization catalyst of a molecular sieve loaded noble metal. The ultrastable Y molecular sieve has a microporous-mesoporous composite pore system, and the metal selected from Zn, Ni and Cu is loaded by means of deposition precipitation so as to obtain the hydrodeoxygenation catalyst. The hydroisomerization catalyst adopts the microporous molecular sieve SAOP-11, SAPO-31, SAPO-34, HZSM-5, HZSM-22 or HBEA as the carrier, and the noble metal selected from Pt, Pd and Ru are loaded on the molecular sieve through impregnation method, thus obtaining the hydroisomerization catalyst. The invention also puts forward application of the hydrodeoxygenation isomerization catalyst in preparation of high cetane number diesel oil from illegal cooking oil. The mixed catalyst has high activity and anti-carbon deposition capacity, and the obtained diesel oil product has the advantages of high cetane number and low freezing point.

Owner:EAST CHINA NORMAL UNIV

Fabrication of hierarchical zeolites

InactiveUS20080014140A1Possible to obtainReadily availableAluminium compoundsMolecular sieve catalystsCalcinationPhotochemistry

A method for producing zeolite or zeotype crystals with a hierarchical pore system having both pores with average diameter between 0.3-2 nm and pores with an average diameter size larger than 4 nm in diameter, comprising the steps of applying a carbohydrate or a carbohydrate solution onto a zeolite precursor material or into a zeolite precursor composition, partly or fully decomposing the carbohydrate, crystallizing the zeolite, removing the partly or fully decomposed carbohydrate by calcination or combustion.

Owner:HALDOR TOPSOE AS

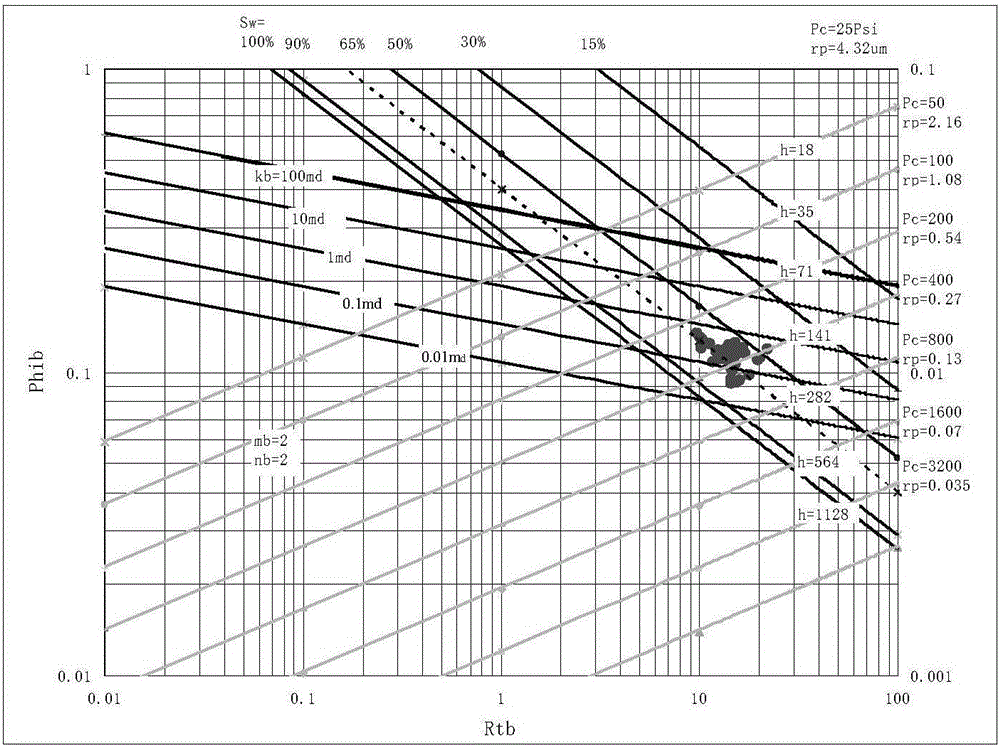

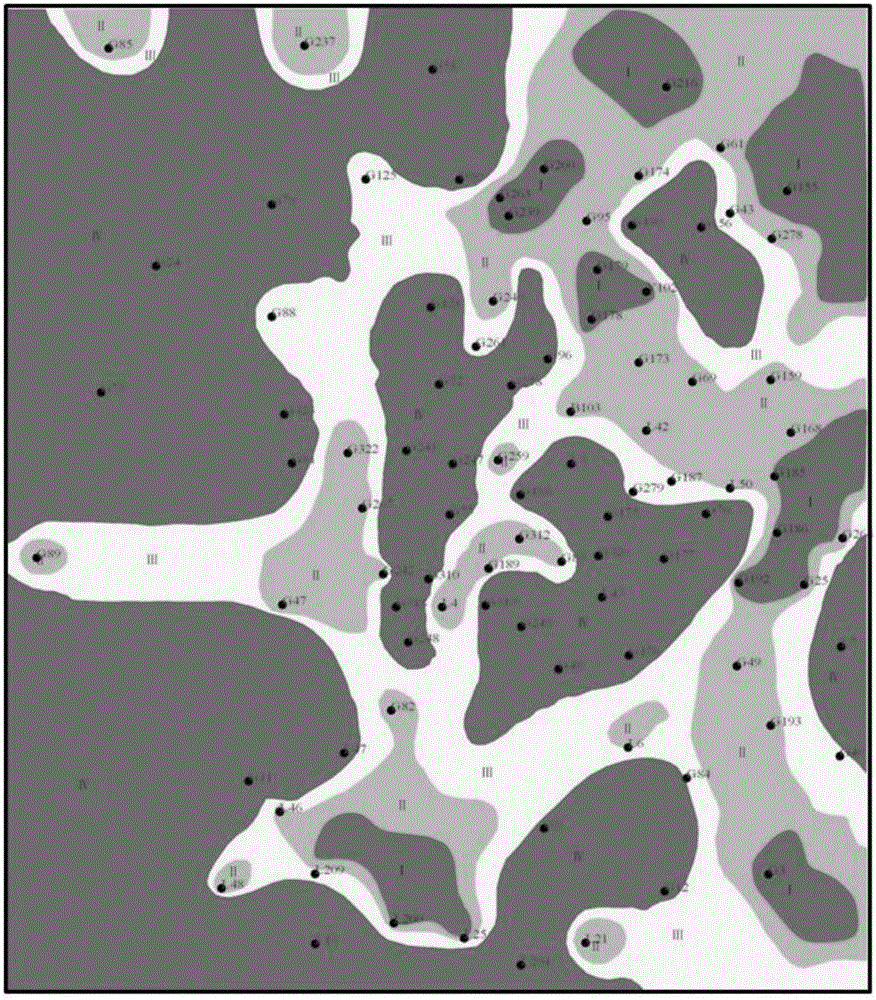

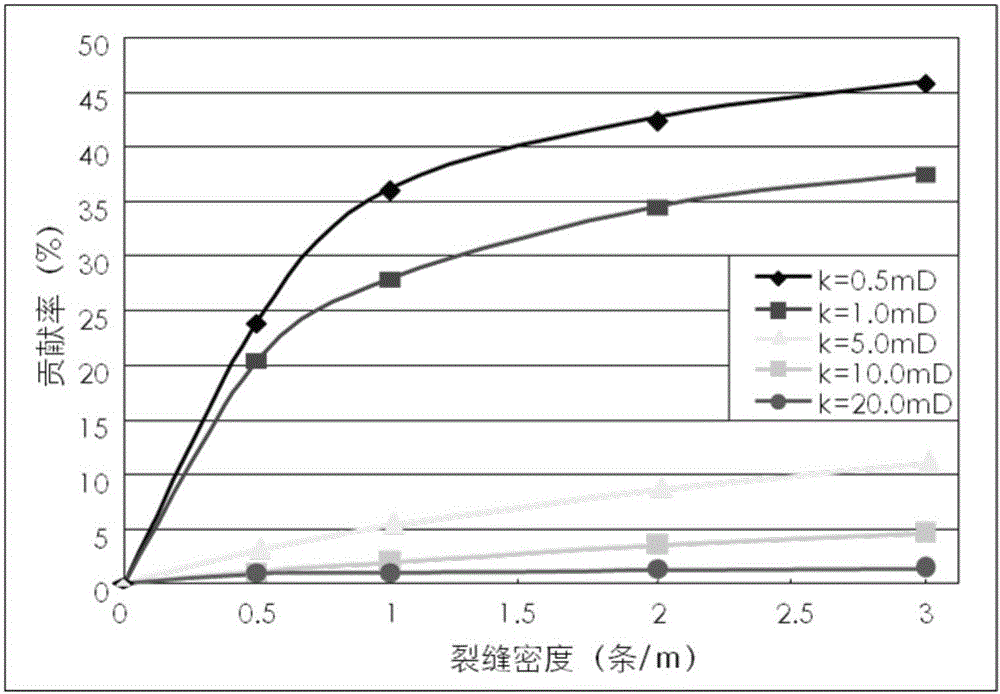

Fractured oil and gas reservoir quantitative evaluation method

InactiveCN106096249AImprove evaluation efficiencyGuide oil and gas exploration and developmentSpecial data processing applicationsInformaticsDistribution lawPore system

The invention relates to a fractured oil and gas reservoir quantitative evaluation method. The method comprises the following steps of (1) determining a matrix pore and oil gas enrichment law, analyzing the non-homogeneity of a reservoir, and dividing a reservoir unit; (2) predicting a fracture distribution law, evaluating fracture permeability anisotropy, and dividing a seepage flow unit; (3) evaluating a matrix pore and fracture matching relationship, and dividing a reservoir permeator unit; and (4) quantitatively evaluating a contribution rate of the fracture for the oil reservoir yield. According to the fractured oil and gas reservoir quantitative evaluation method, the non-homogeneity of a reservoir matrix pore system (a main reservoir space of oil gas), the non-homogeneity of a fracture system (a main seepage flow channel of the oil gas) and the matching relationship between the matrix pore system and the fracture system can be effectively reflected, the contribution of the fracture to the oil gas reservoir yield can be objectively evaluated, the evaluation efficiency of a complicated fractured reservoir is improved, the oil gas exploration and development of a complicated dual-porosity reservoir can be better guided, and the oil gas exploration and development risk cost of the reservoir is reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

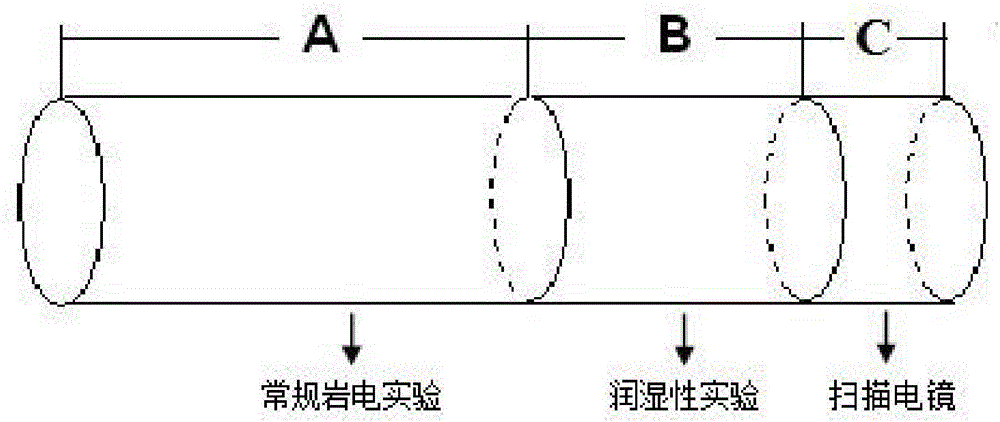

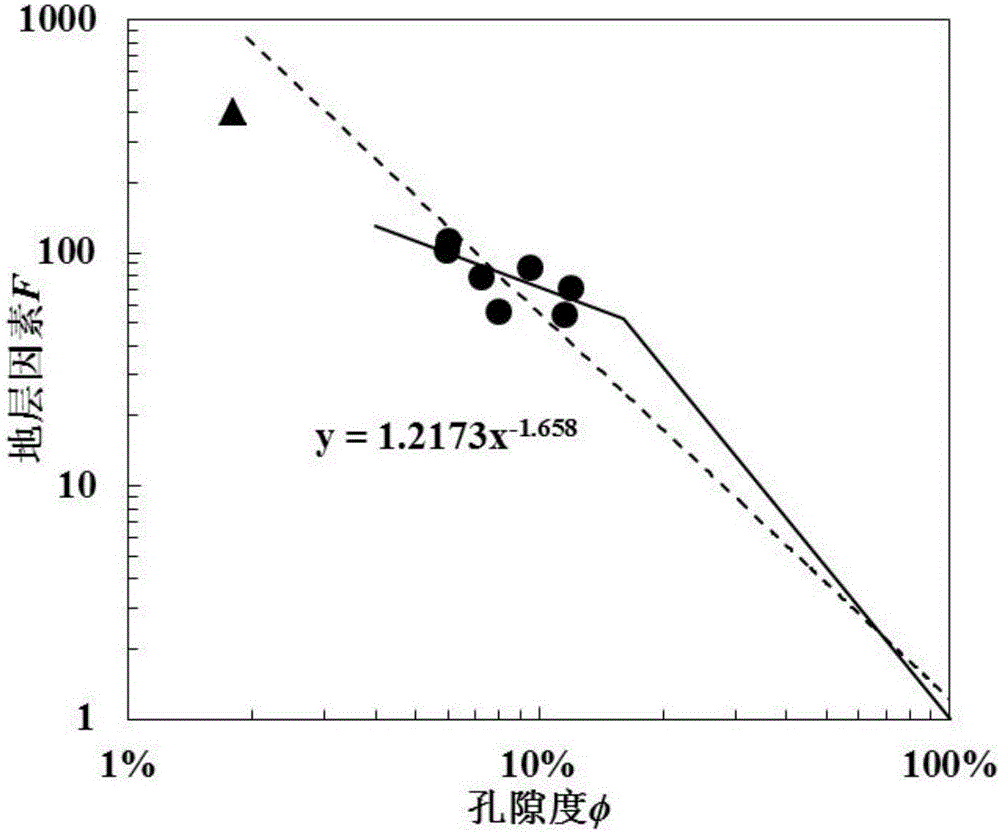

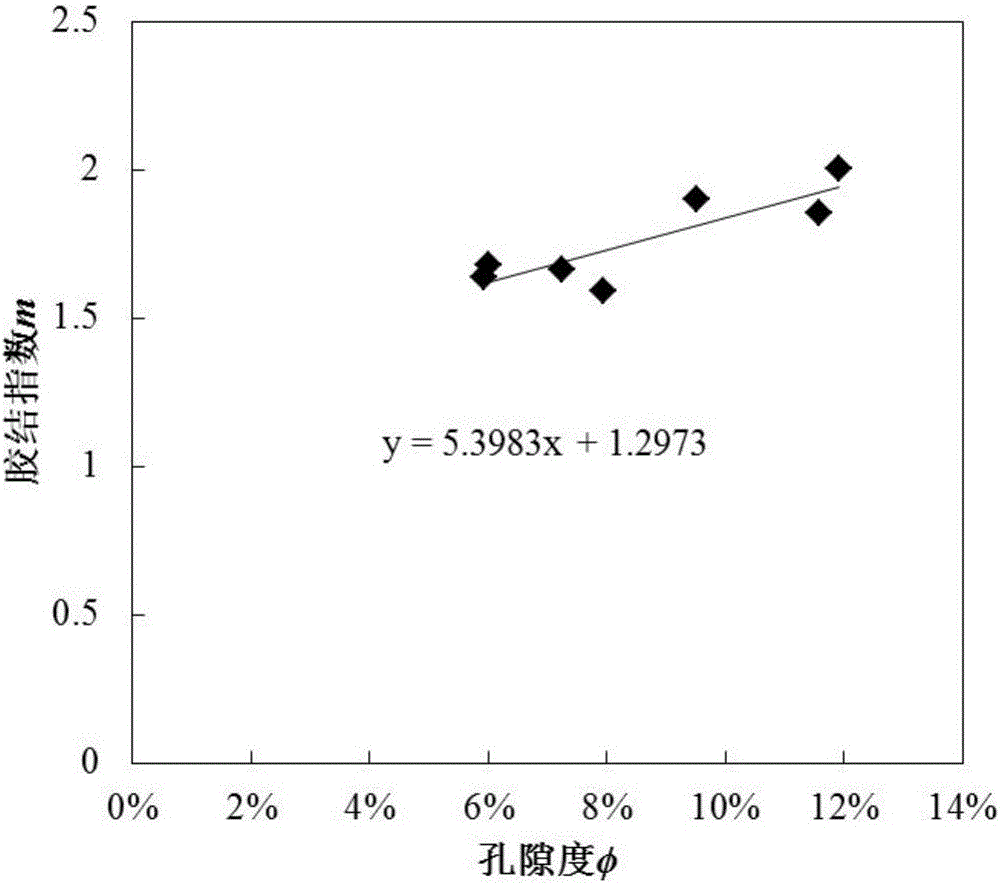

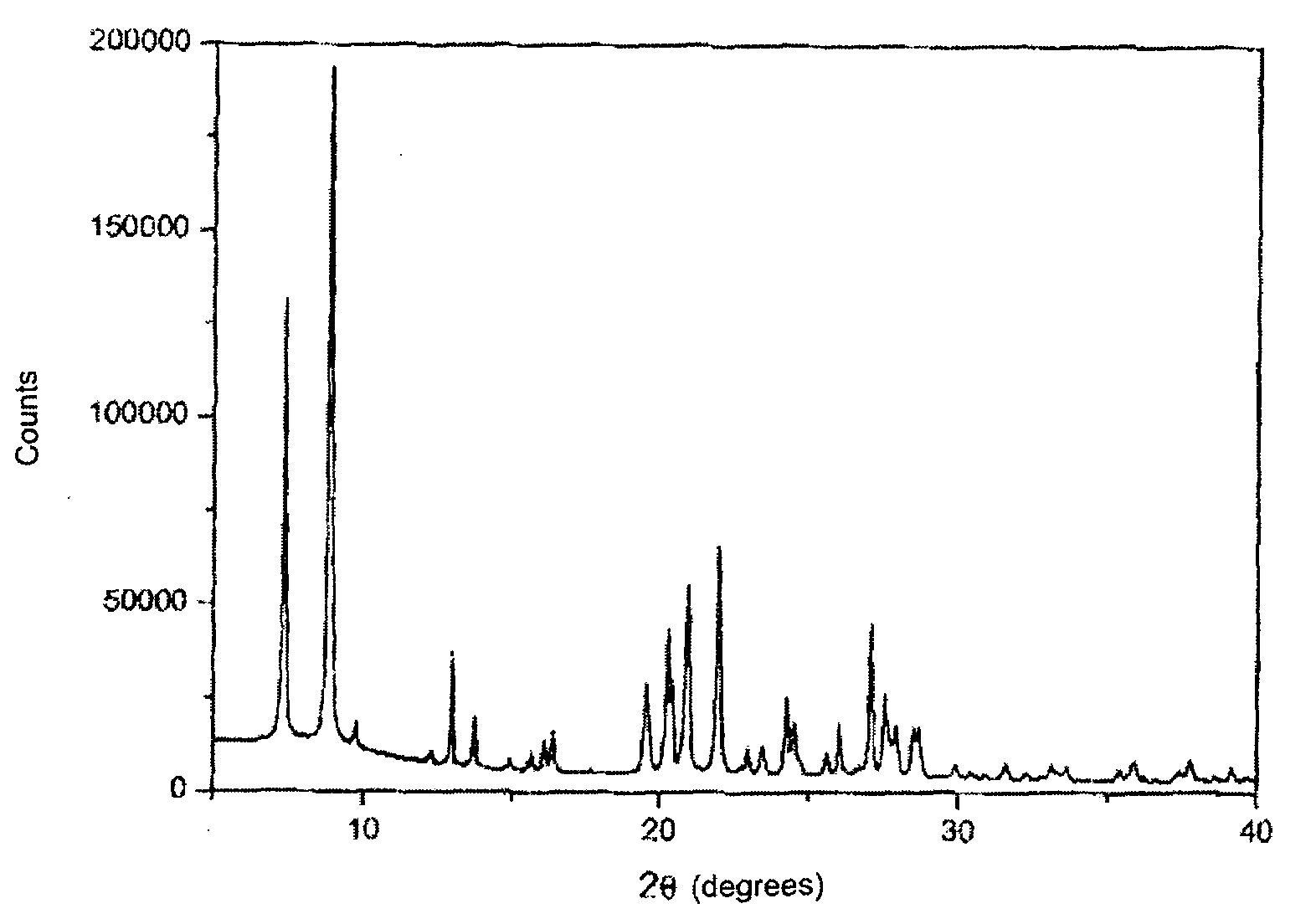

Dual-medium reservoir rock water saturation calculating method based on percolation network simulation

The invention discloses a dual-medium reservoir rock water saturation calculating method based on percolation network simulation. The method comprises the steps that (1) a rock sample is cut into a segment A, a segment B and a segment C, the segment A is subjected to a rock-electric test and a nuclear magnetic resonance test, the segment B is subjected to wettability measurement, and the segment C is subjected to a scanning electron microscope test; (2) the function relationship between the formation factor F and the porosity phi is fit; (3) constants C1 and C2 are calculated, and C1 and C2 reflect pore throat features and resistivity properties of dual-medium reservoir matrix pores; (4) the pore throat radius variable coefficient sigma of a rock dissolved pore system is worked out; (5) a dual-medium percolation network model is established, and by means of a trial-and-error method, the coordination number z of the dissolved pore system is determined through network simulation; and (6) the value of B' is determined, and the dual-medium reservoir rock water saturation S<w> is obtained. According to the method, an explanation method of logging through the electric field vector geophysical method is perfected, and the defects of theoretical knowledge of reservoir rock electrical properties and rock water saturation calculating methods are overcome.

Owner:SOUTHWEST PETROLEUM UNIV

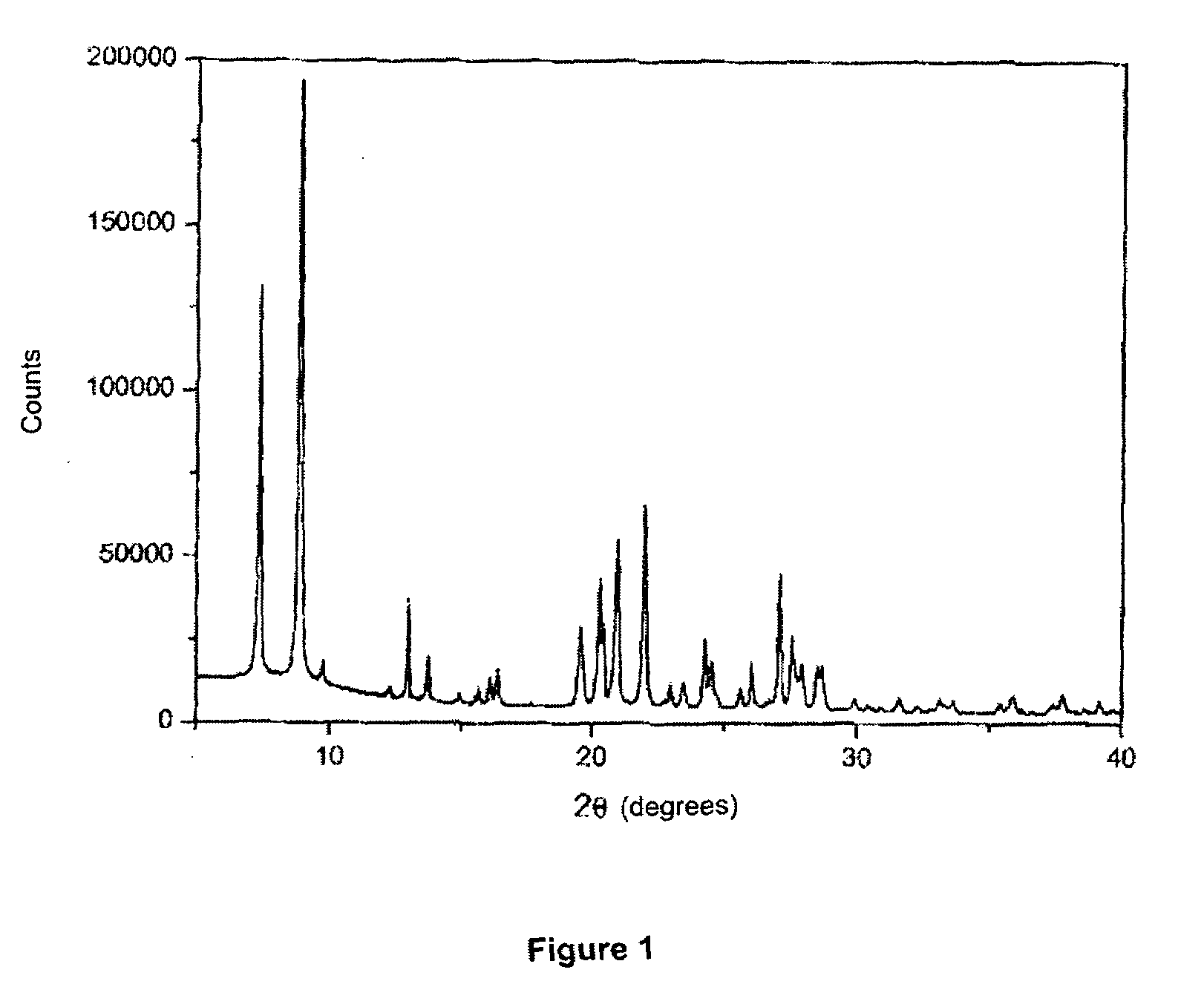

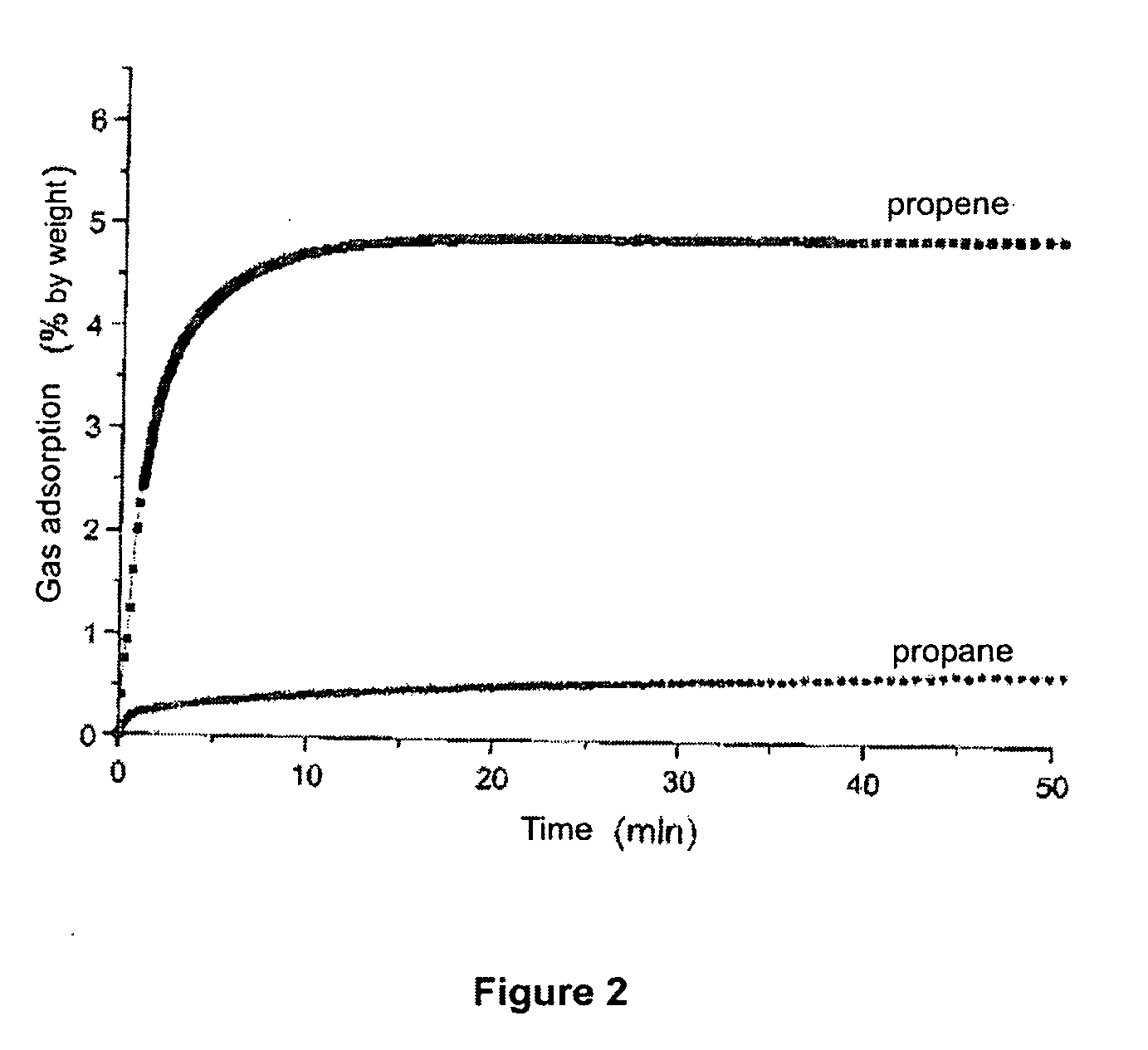

Separation of Fluids Using Zeolite Itq-32

InactiveUS20090202416A1Solid sorbent liquid separationIsotope separationOrganic chemistryTetrahedron

The invention relates to a method of separating fluids from mixtures using a zeolite known as ITQ-32 consisting of a two-dimensional pore system comprising channels with openings formed by 8 tetrahedra which are interconnected by channels with openings formed by 12 tetrahedra. The inventive method comprises at least the following steps: a) the zeolite ITQ-32 material is brought into contact with the mixture of fluids, b) one or more of the components are adsorbed in the zeolite ITQ-32 material, c) the non-adsorbed components are extracted, and d) one or more of the components adsorbed in the zeolite ITQ-32 material are recovered.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

Method for sealing porous building materials and building components

A method for sealing porous building materials, using a polyurethane and / or epoxy resin based sealing composition. The composition can include a substance / substance mixture with a viscosity of less than 100 mPa.s at 12° C. which can be added to a porous building material. This substance / substance mixture can be based on an epoxy resin. This resin can chemically react once inside of a porous region of the building material to substantially fill the pore system.

Owner:GERD PLEYERS

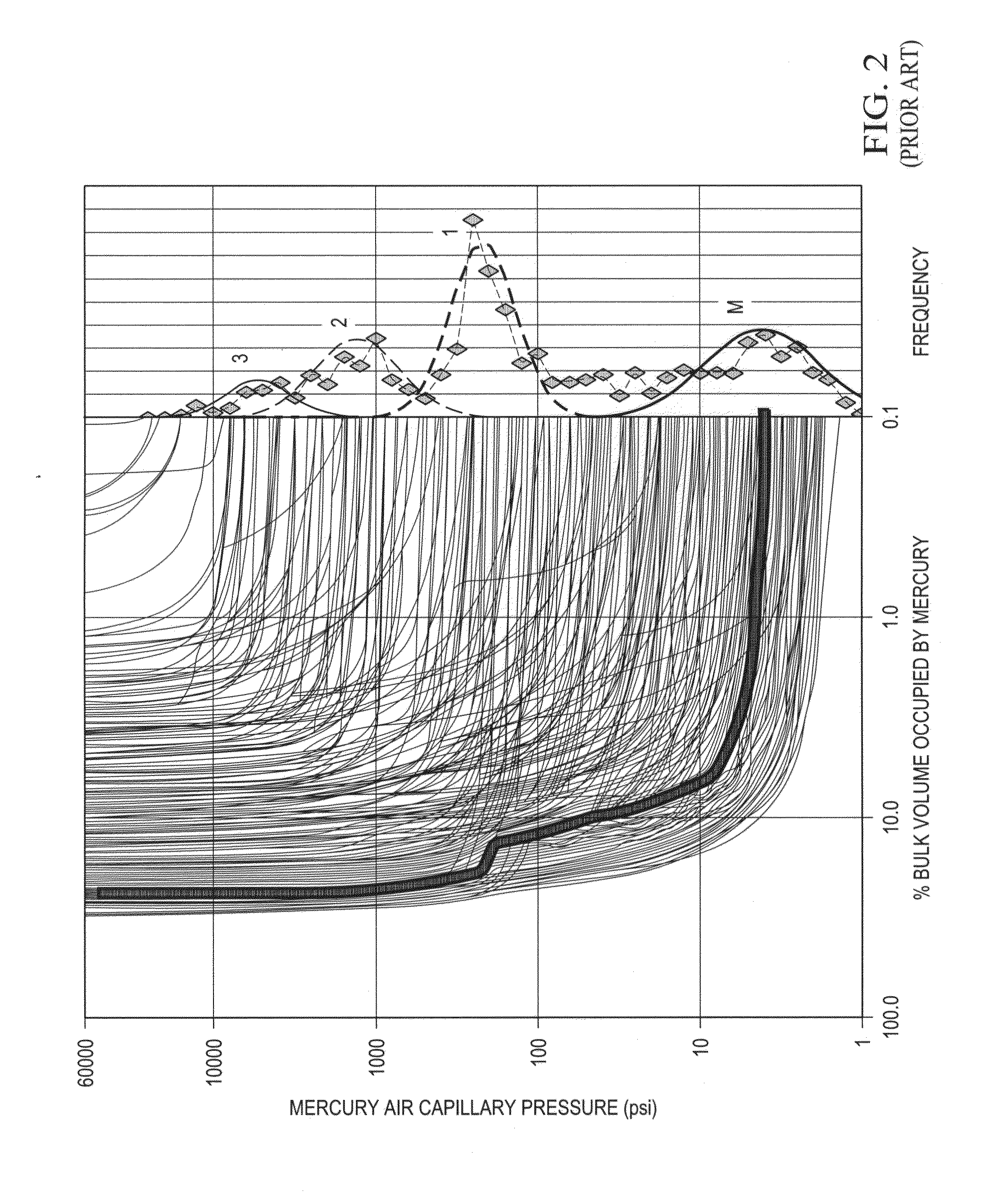

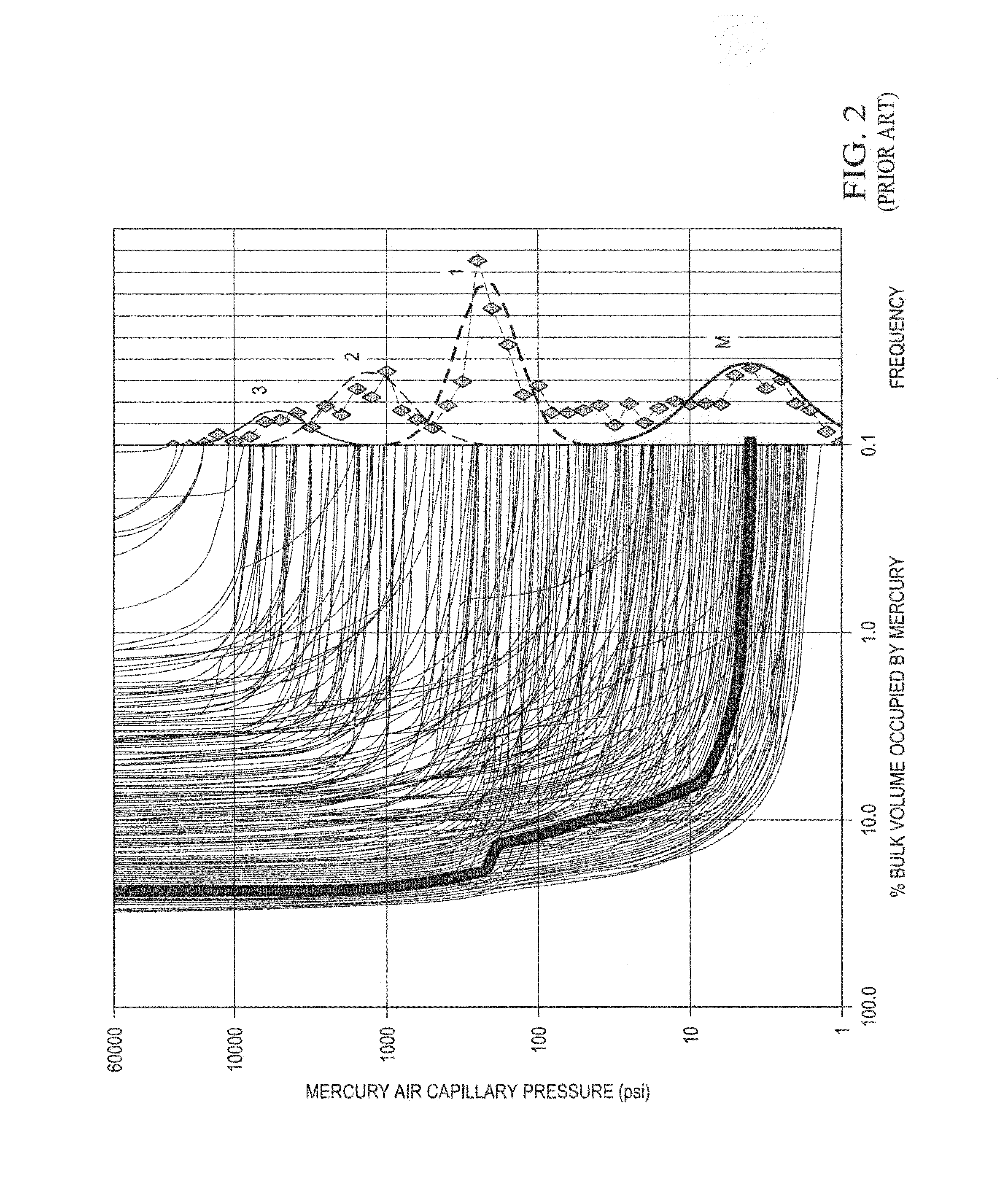

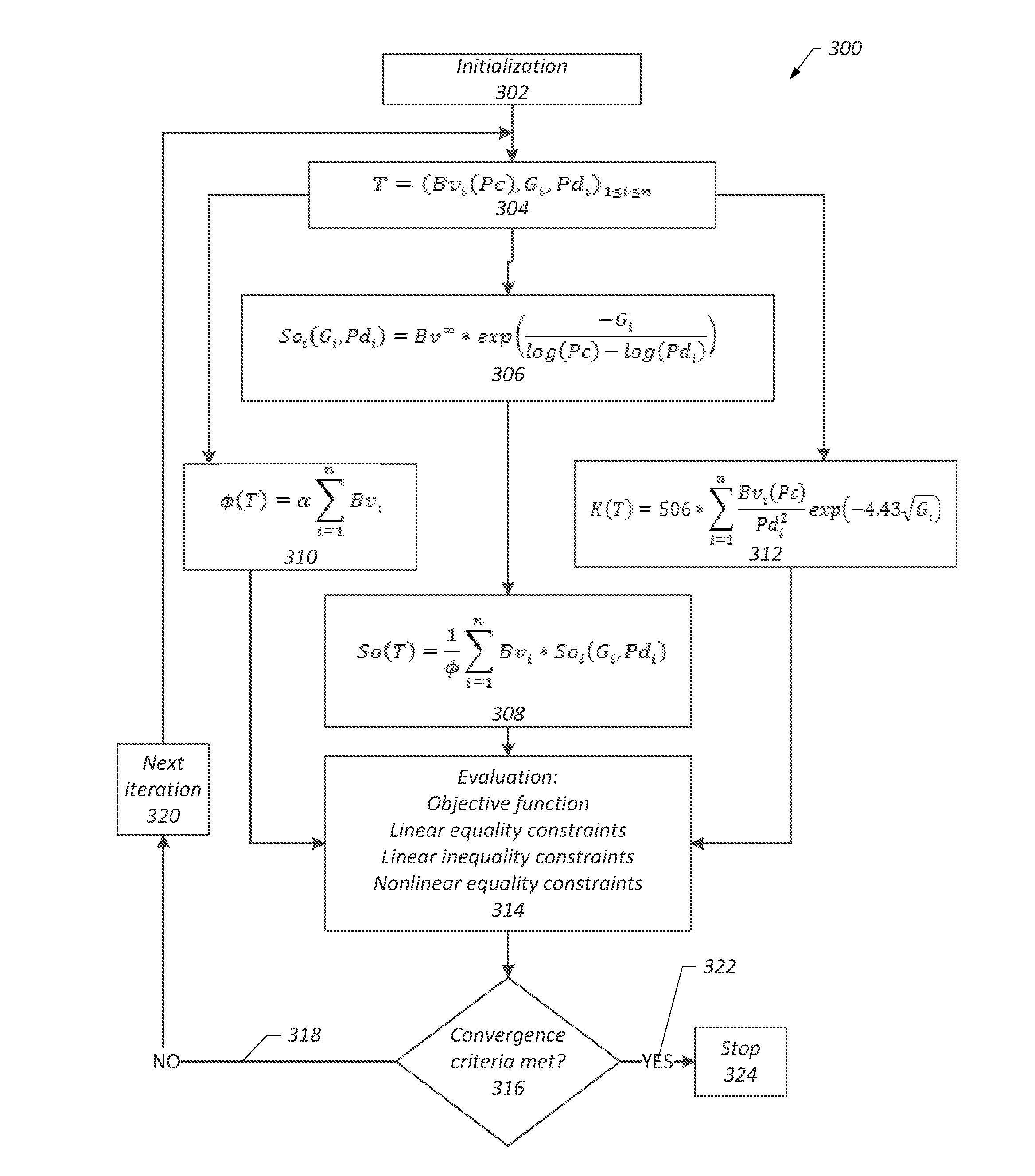

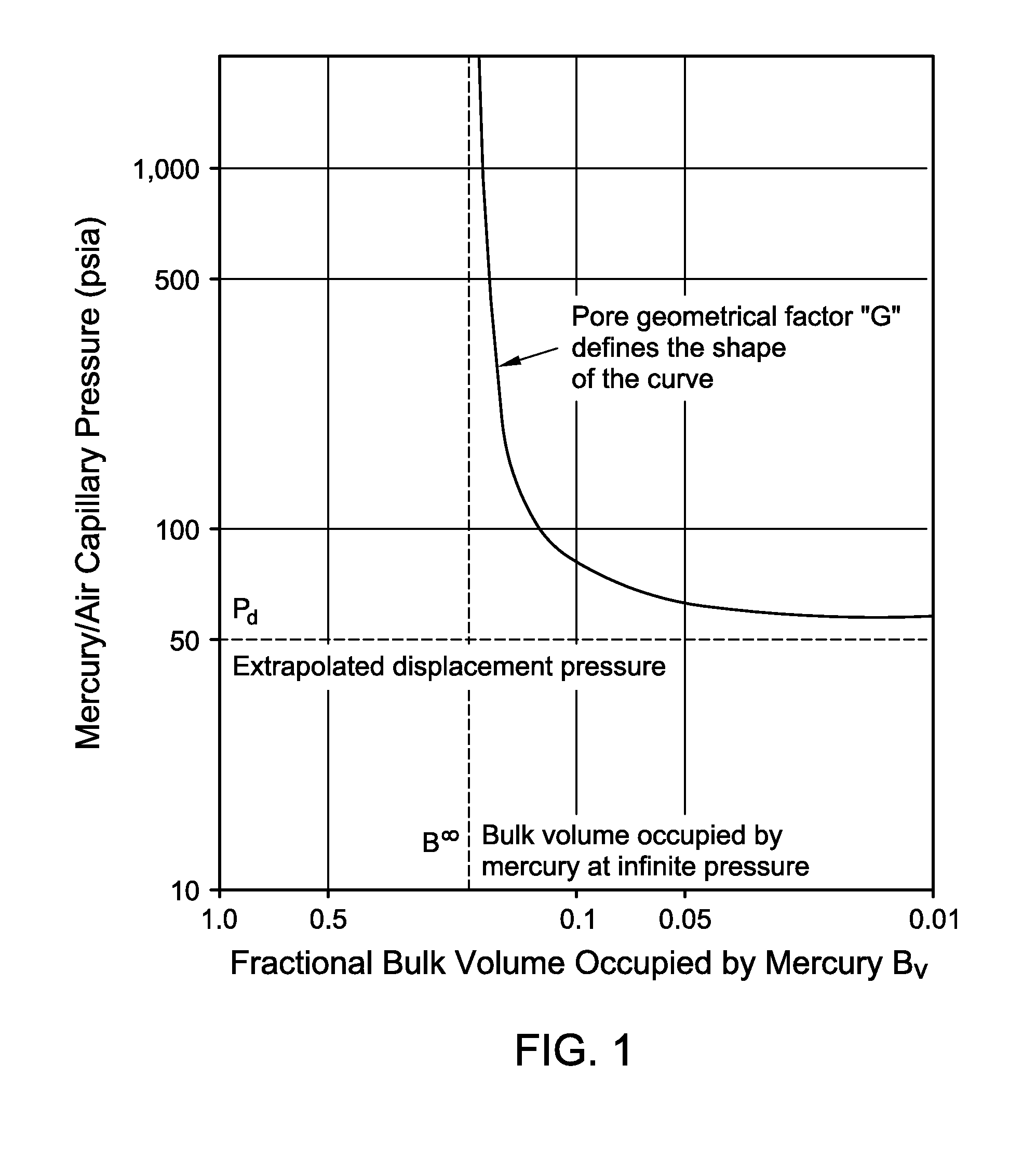

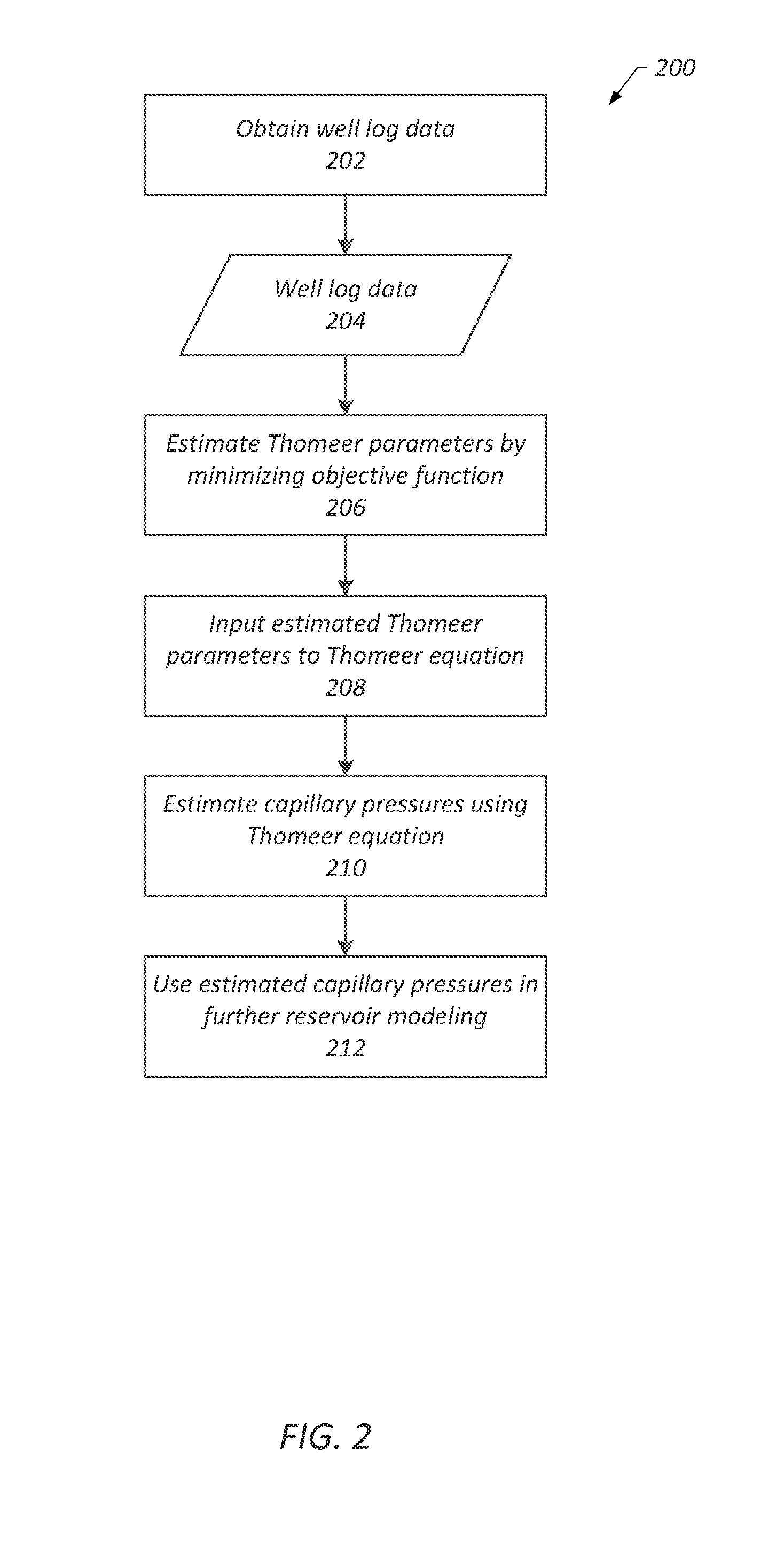

Systems, methods, and computer-readable media for continuous capillary pressure estimation

InactiveUS20140350860A1Electric/magnetic detection for well-loggingPermeability/surface area analysisContinuous capillaryWell logging

Provided are methods, systems, and computer-readable media for determining capillary pressure in a basin / reservoir. Well log data is obtained that includes permeability log data, porosity log data, water saturation log data, and oil saturation log data. Thomeer parameters for a multi-pore system of a Thomeer model are determined by evaluating an objective function that measures the mismatch between the well log data and modeled data having the Thomeer parameters as input. The objective function is iteratively evaluated using linear equality constraints, linear inequality constraints, and nonlinear equality constraints until convergence criteria are met.

Owner:SAUDI ARABIAN OIL CO

Preparation method of saturated hydrogenation Pd catalyst and method for catalyzing hydrogenation of polystyrene by virtue of saturated hydrogenation Pd catalyst

InactiveCN107213895AIncreased hydrogenation conversionSimple stepsCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPolystyrenePalladium

The invention relates to the technical field of catalytic hydrogenation and particularly discloses a preparation method of a saturated hydrogenation Pd catalyst and a method for catalyzing the hydrogenation of polystyrene by virtue of the saturated hydrogenation Pd catalyst. The preparation method is characterized by comprising the following steps: with P123 as a template, ethyl orthosilicate as a silicon source and 1,3,5-trimethylbenzene and ammonium fluoride as pore-enlarging agents, synthesizing by virtue of a hydrothermal method under an acidic condition, drying, and roasting, so as to obtain a powdery MCF material; calculating the mass of palladium metal salt according to a proportion that palladium is 1.0wt%-8.0wt% of the powdery MCF material, and dissolving the palladium metal salt, so as to prepare steeping liquid; and steeping the powdery MCF material into the steeping liquid, drying, roasting, and carrying out formation and sieving, so as to obtain a catalyst product. The preparation method has the beneficial effects that the steps are simple, and the catalyst is prepared from Pd as a main catalysis element as well as home-made MCF which has a relatively large specific surface, an adjustable super-large mesoporous and a three-dimensional penetrated pore system, so that the PS hydrogenation conversion rate is substantially increased.

Owner:SHANDONG YUHUANG CHEM CO LTD

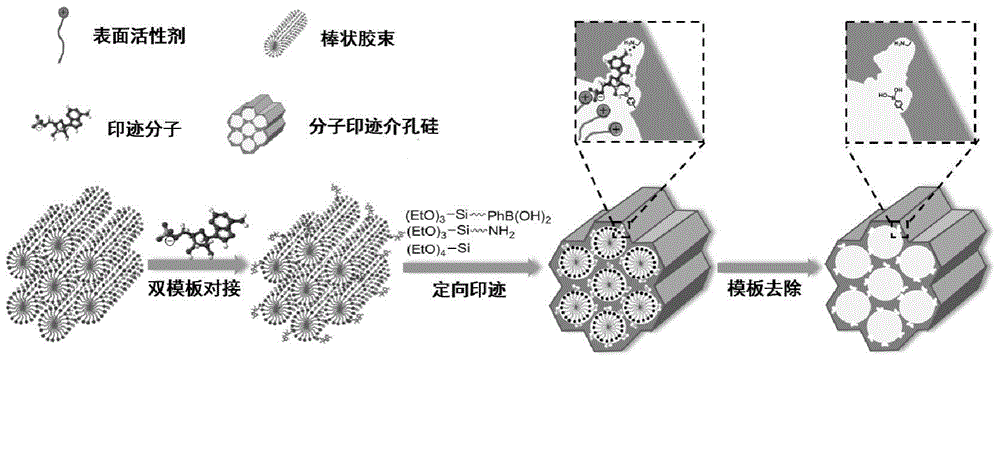

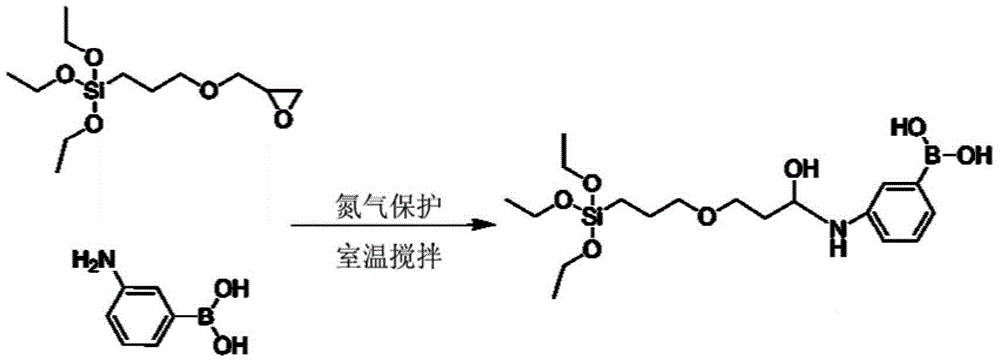

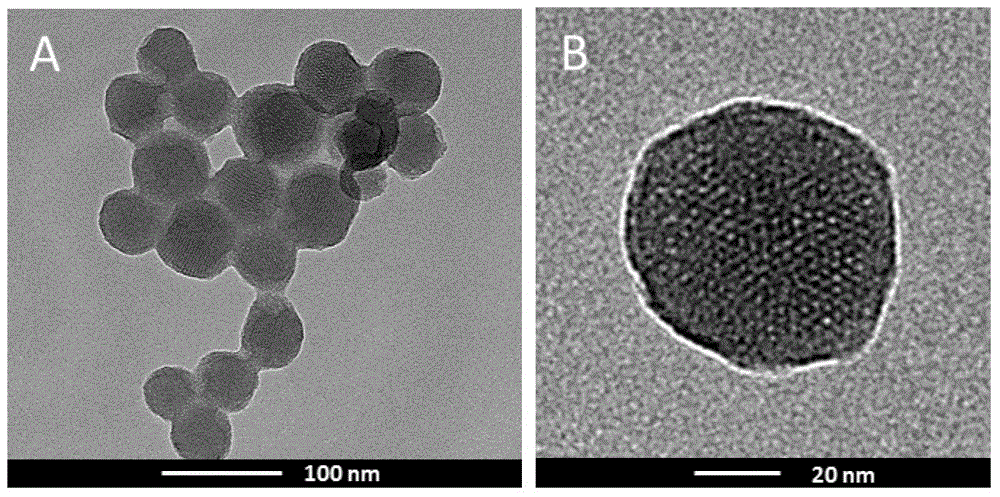

Synthesis method and application of molecularly imprinted mesoporous material

InactiveCN104945655AHigh blotting efficiencyExcellent specificity recognition abilityOther chemical processesSynthesis methodsMaterial synthesis

The invention discloses a synthesis method of a molecularly imprinted mesoporous material. The method comprises the following steps: assembling an imprinted template molecule onto the surface of a mesoporous template in a solution, polymerizing an auto-polymerizable compound in the solution to form a mesoporous material, and finally, removing the template under acidic conditions to form the mesoporous ducts and imprinted cavities, thereby obtaining the molecularly imprinted mesoporous material. The method can efficiently and conveniently remove the template in the imprinted material; and all the obtained imprinted cavities are distributed on the internal surface of the mesoporous ducts, and thus, the molecularly imprinted mesoporous material has excellent accessibility. The obtained material has favorable selectivity and excellent antijamming ability for the target molecule when being used in complex biological samples. The double-template docking technique in the invention is also applicable to synthesis of other pore-system-based porous imprinted materials, and has wide application prospects in the field of functional materials and preparation and synthesis thereof.

Owner:NANJING UNIV

High surface area activated carbon foam

InactiveUS20070155847A1Improved surface area and density and conductivityEasy to processCeramicwareActivated carbonHigh surface area

An activated carbon foam material with improved graphitizability is formed by including an oxidation promoting metal-containing additive into the carbon foam and subsequently heat treating the foam in a reactive atmosphere. The oxidation promoting metal-containing additive greatly improves the development of the carbon foam's ramified pore system resulting in a carbon foam with a much greater surface area. This inventive foam may be created by introducing the oxidation promoting metal by way of an oxidation catalyst during the polymerization of the phenolic resin or as a inorganic chemical activating agent to the formed phenolic resin. The foam is then heated in a reactive atmosphere to produce an activated foam with a surface area of from about 200 m2 / g to about 3000 m2 / g.

Owner:GRAFTECH INT HLDG INC

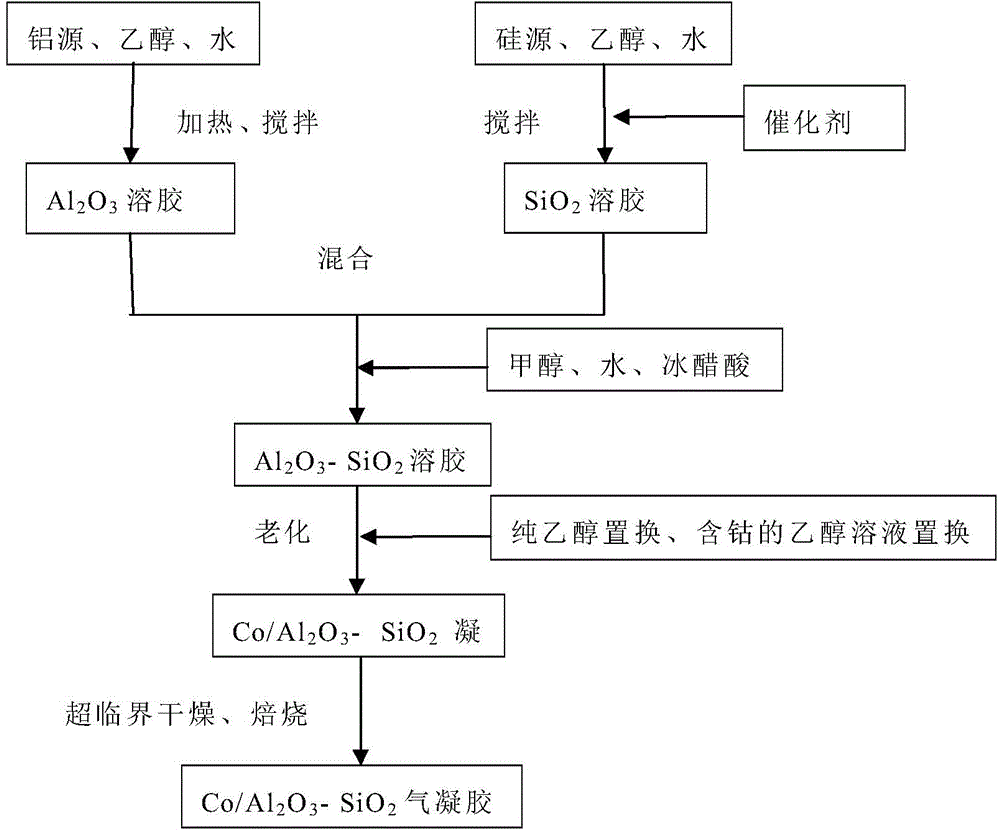

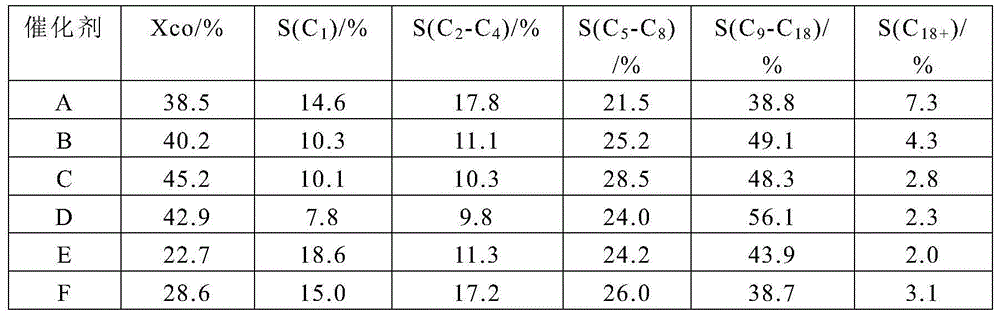

Cobalt-based fischer-tropsch synthesis catalyst and preparation method and application

ActiveCN104624192AAvoid reunionFacilitated DiffusionCatalyst activation/preparationLiquid hydrocarbon mixture productionActive componentMetal particle

The invention discloses a cobalt-based fischer-tropsch synthesis catalyst and a preparation method and application. The catalyst disclosed by the invention is prepared from 2wt%-10wt% of an active component Co and 90%-98% of a carrier Al2O3-SiO2 composite aerogel on the basis of the total weight of the catalyst, wherein the specific surface area of the catalyst is 250-750m<2> / g; the mean pore size is 9-28.6nm; and the pore volume is 2.75-4.23mL / s. The preparation method comprises the following steps: (1) preparing Al2O3 sol; (2) preparing SiO2 gel; and (3) preparing Co / Al2O3-SiO2 composite aerogel. The catalyst disclosed by the invention is high in specific surface area and large in aperture due to a three-dimensional pore system; the active components are evenly dispersed into pores; the agglomeration of metal particles is prevented; and the diffusion of a reactant and a product is facilitated, so that the cobalt-based fischer-tropsch synthesis catalyst can be relatively well applied to fischer-tropsch synthesis and the diesel selectivity is high.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

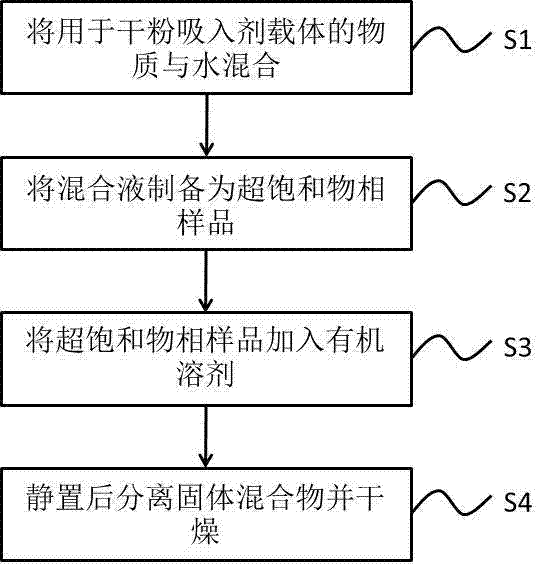

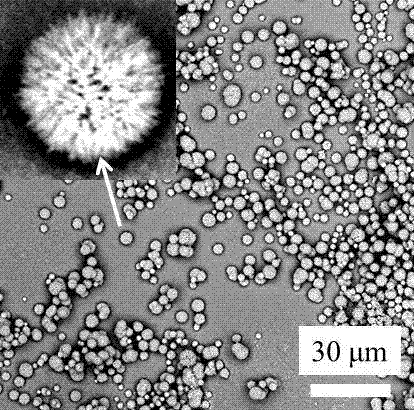

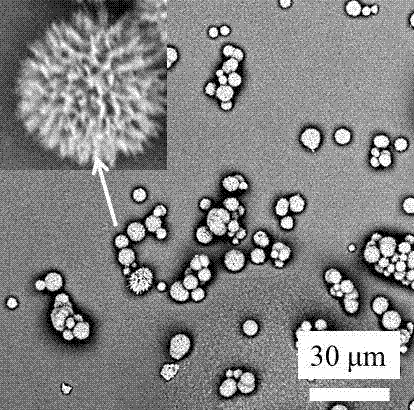

High-porosity dry powder inhaler carrier and supersaturated synthesis method and applications thereof

InactiveCN106924193AImprove uniformityImprove stabilityPowder deliveryOrganic active ingredientsParticulatesSynthesis methods

The invention relates to a high-porosity dry powder inhalant carrier and its supersaturated synthesis method and application. The carrier is a flower-shaped porous dry powder particle with a rough surface. The median diameter of a single particle under an electron microscope is 0.5-50 microns. The carrying capacity of drug molecules is 5-50% mass fraction, and the N2 adsorption specific surface area of the carrier is 10-100 square meters per gram, containing micro, medium and macro pores. For the first time, the present invention combines supersaturated synthesis technology and flower-shaped material preparation technology, and applies it to the field of dry powder inhalants. Using the synthesis method provided by the invention, the high-porosity dry powder inhalant carrier is prepared with controllable size and high performance. The porosity nanopore system is used for the adsorption, carrying and transportation of nano-level and molecular-level components, with good uniformity, stability and transmission efficiency. The invention realizes efficient, high-quality, cheap and practical mass production of nano- and micron-level high-porosity dry powder inhalant carrier materials.

Owner:谭淞文

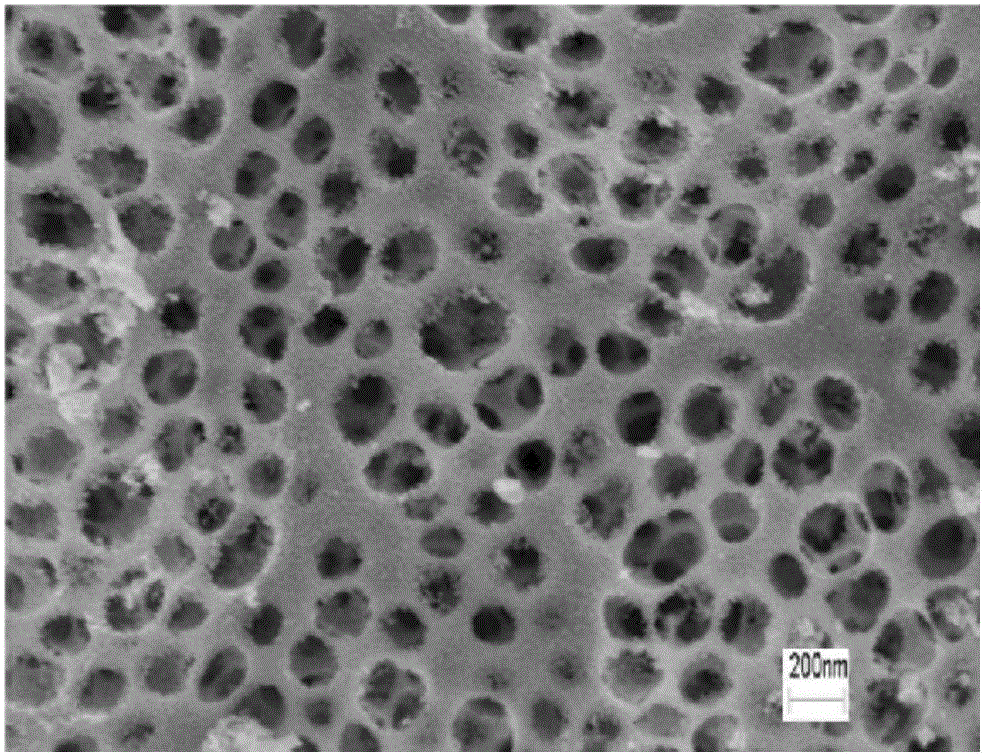

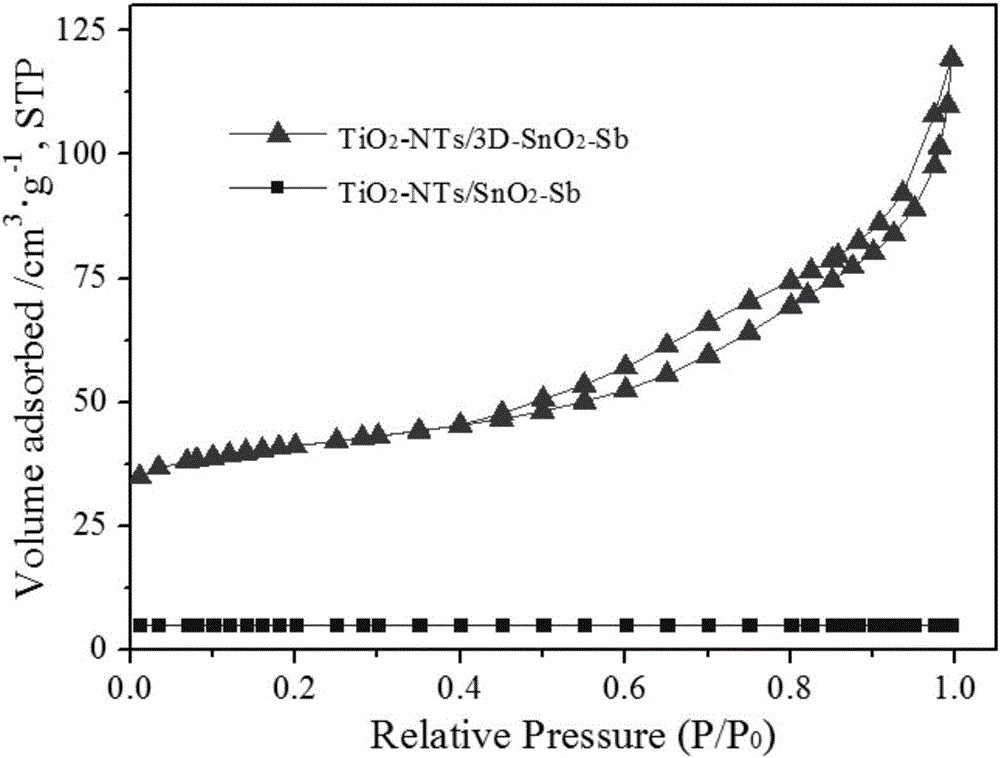

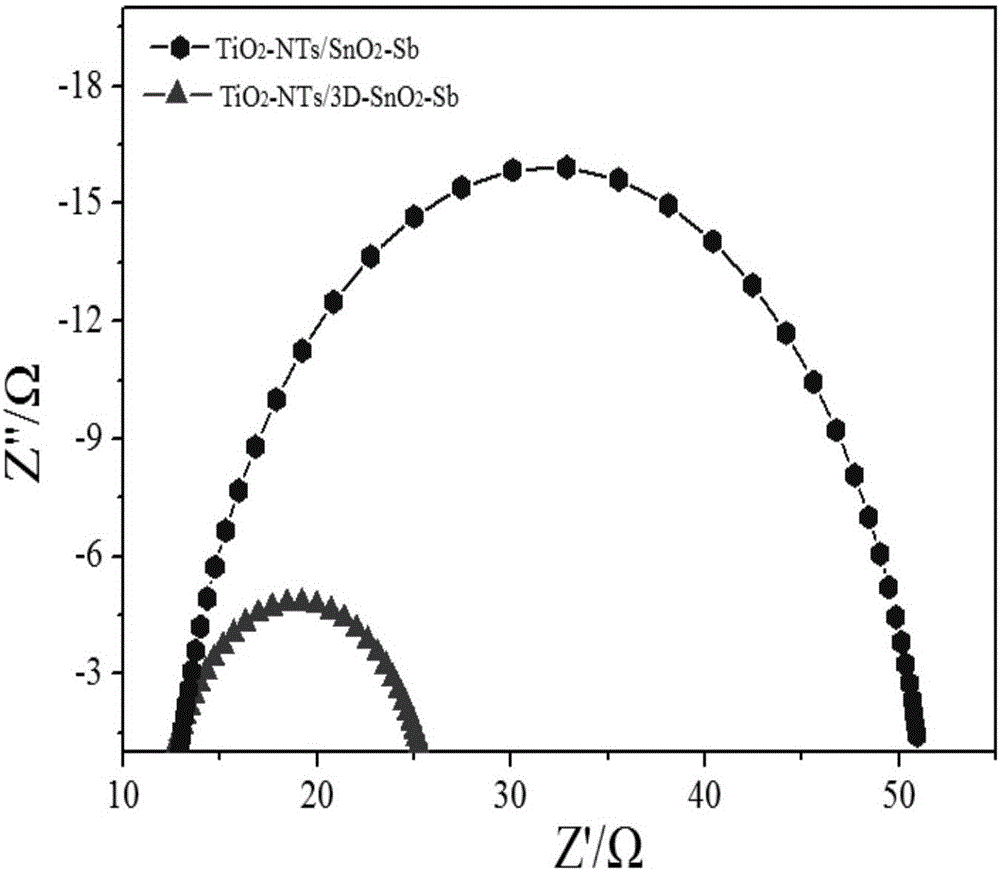

Three-dimensional combined-duct antimony-doped tin dioxide electrode and preparation method and application thereof

ActiveCN105776432ASave raw materialsEasy to prepareWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationTin dioxideMicrosphere

The invention discloses a three-dimensional combined-duct antimony-doped tin dioxide electrode and a preparation method and application thereof. In this electrode, a titanium base is used as a bottom layer, titanium dioxide nanotubes are then generated to form an intermediate layer, PMMA or PS microspheres are used as a hard template, precursor ethanol solution is formed with tin tetrachloride, antimony trichloride, citric acid and triblock copolymer, and three-dimensional macroporous antimony-doped tin dioxide with macroporous walls is made by calcining as a surface layer. The electrode prepared herein has an internally-communicated pore system, three-dimensional structure advantages of macropores and mesopores are given to full play, synergy will be created, this electrode has the advantages of low impedance, large specific surface area, high electrocatalytic activity and high electrocatalytic oxidative performance, and organic pollutants difficult to degrade can be degraded efficiently.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

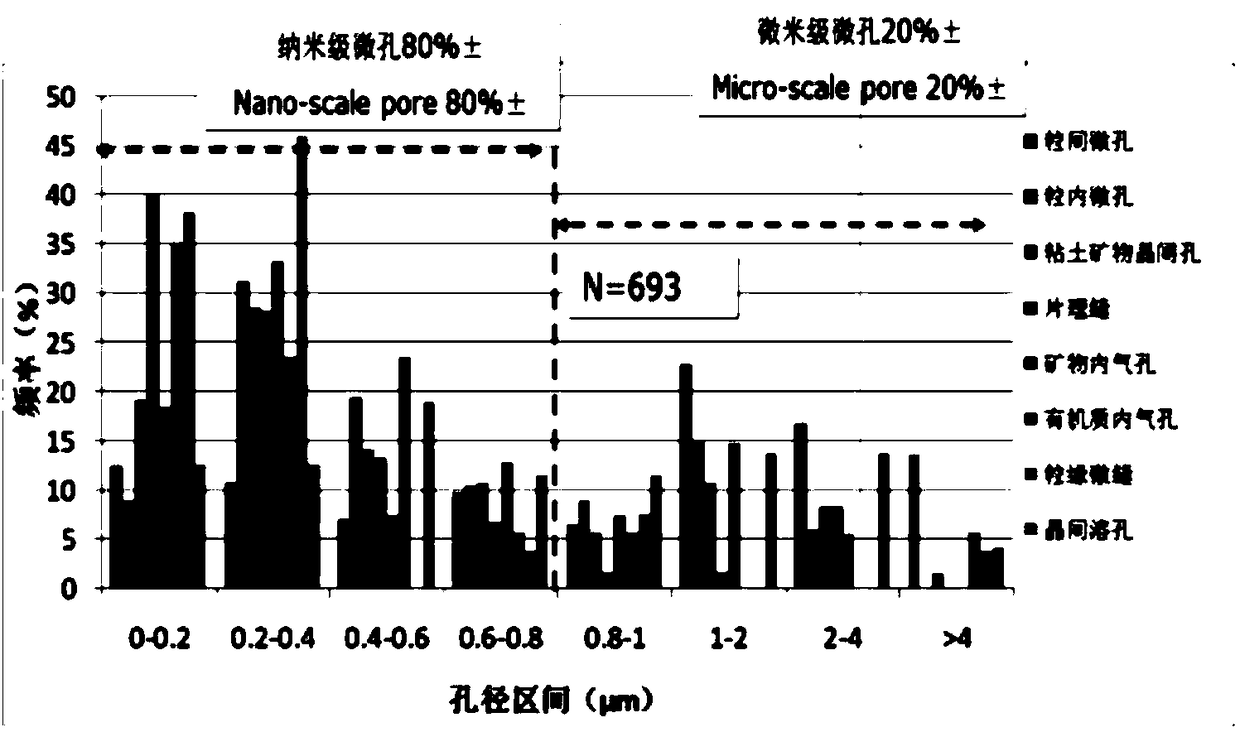

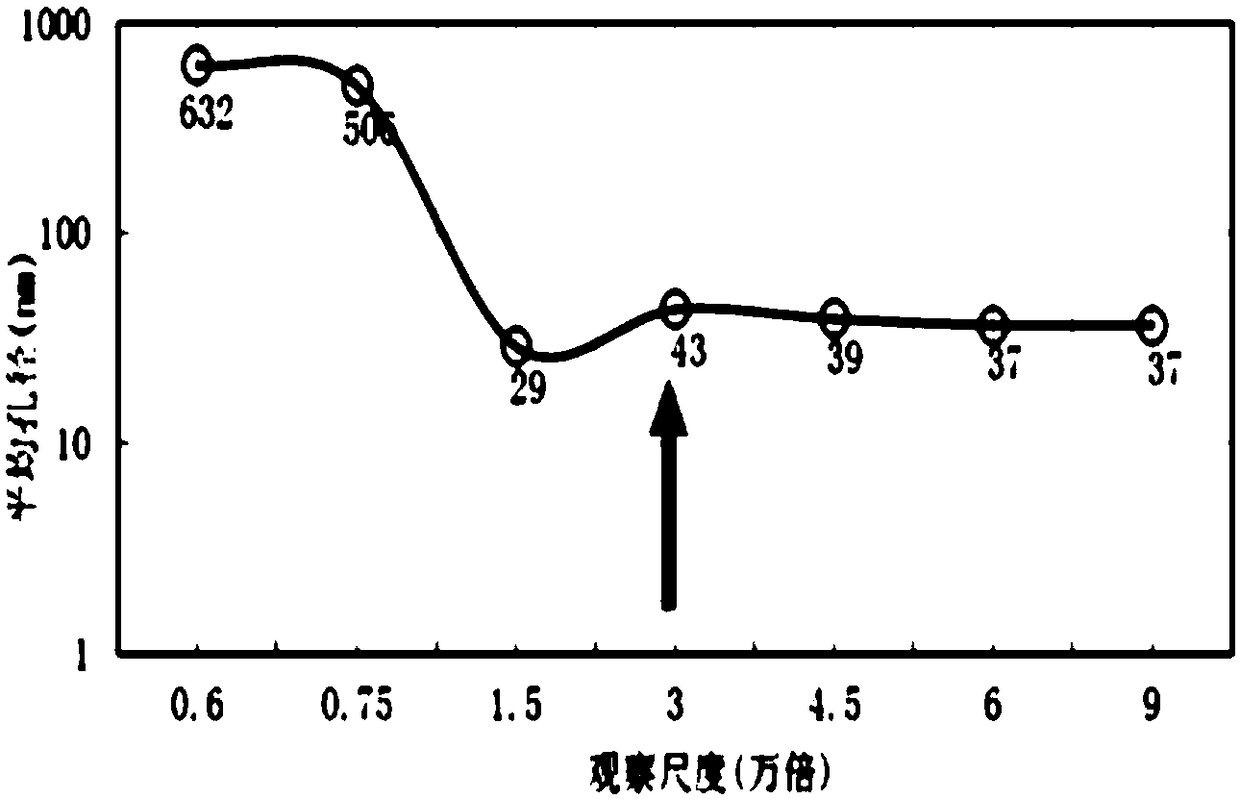

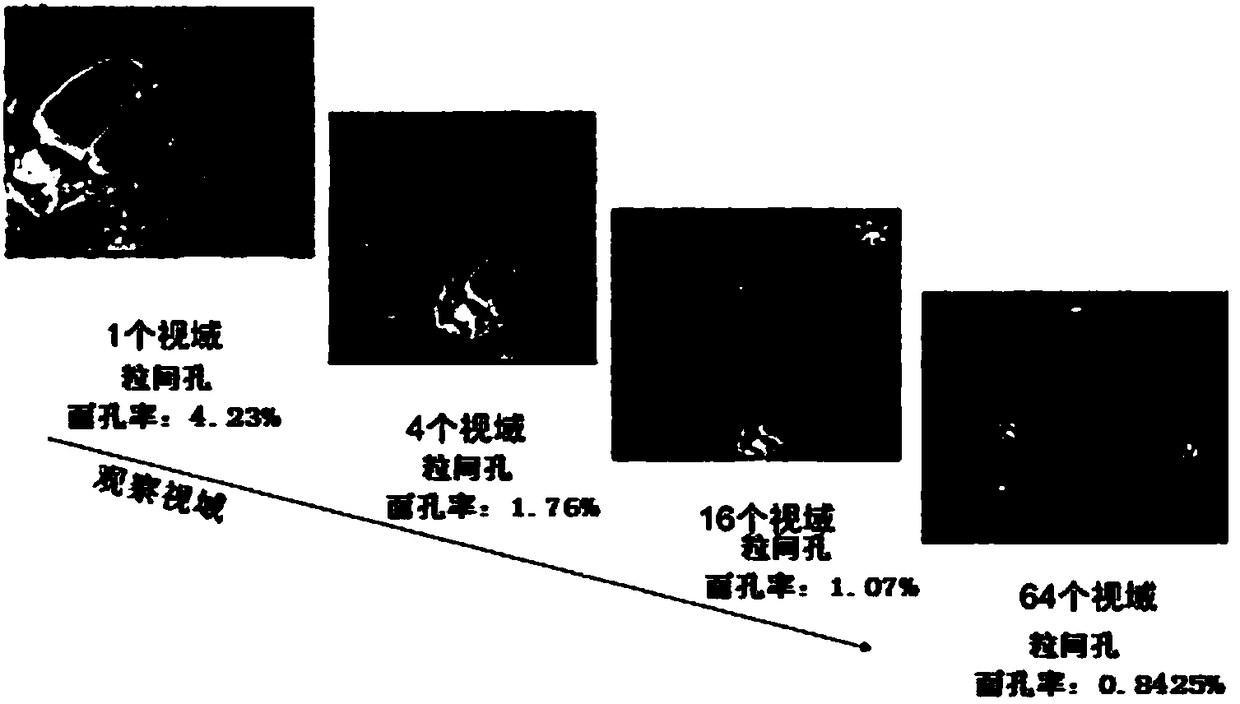

Quantitative characterization method of shale reservoir pore system and method for evaluating pore characteristics of shale reservoir

The invention discloses a quantitative characterization method of a shale reservoir pore system and a method for evaluating the pore characteristics of a shale reservoir, and relates to the technicalfield of pore characterization. The quantitative characterization method of the shale reservoir pore system comprises the following steps: determining the minimum magnification of organic pores can beobserved by an electron microscope; determining the number of observation vision fields of an electron microscope image when pore parameters tend to be stable; utilizing a software to perform quantitative statistics for the pore parameters of the number of observation vision fields; and establishing a mathematical distribution map of the pore parameters. The method can quantitatively characterizethe micro-nano-pore structure characteristics of the shale reservoir accurately. According to the method for evaluating the pore characteristics of the shale reservoir, the mathematical distributionmap obtained by the quantitative characterization method of the shale reservoir pore system is utilized to evaluate the pore characteristics. The evaluation results are relatively accurate.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Size-selective hemoperfusion polymeric adsorbents

Size-selective hemocompatible porous polymeric adsorbents are provided with a pore structure capable of excluding molecules larger than 50,000 Daltons, but with a pore system that allows good ingress and egress of molecules smaller than 35,000 Daltons. The pore system in these porous polymeric adsorbents is controlled by the method of synthesis so that 98% of the total pore volume is located in pores smaller than 300 Angstroms (Å) in diameter with a working pore size range within 100 to 300 Å in diameter. The porous polymeric adsorbents of this invention are very selective for extracting midsize proteins, such as cytokines and β2-microglobulin, from blood and other physiologic fluids while keeping the components required for good health such as cells, platelets, albumin, hemoglobin, fibrinogen, and other serum proteins intact.

Owner:CYTOSORBENTS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com