Synthesis method and application of molecularly imprinted mesoporous material

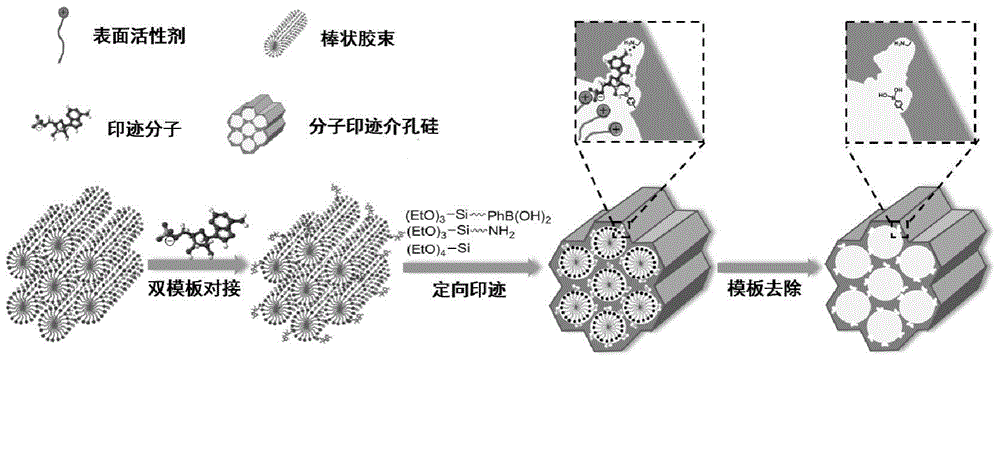

A mesoporous material and molecular imprinting technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of cumbersome steps and limited applicability, and achieve the effects of wide application prospects, excellent performance, and high imprinting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

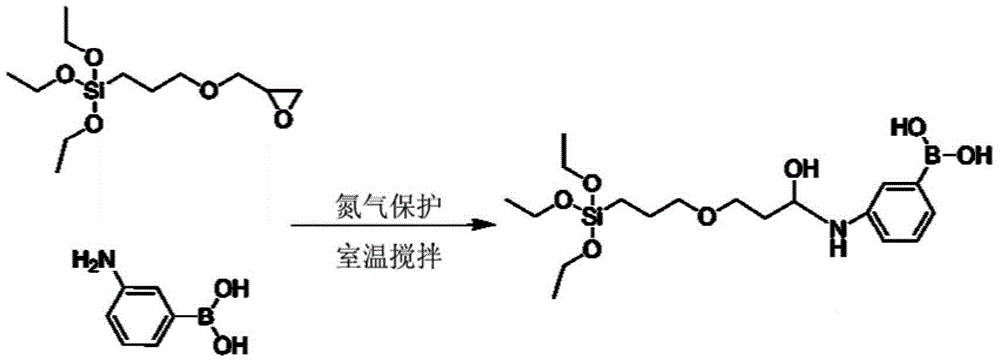

[0029] Example 1: Synthesis of triethoxysilane modified with aminophenylboronic acid

[0030] Synthetic steps see figure 2 , specifically: add 10mmol glycidyl etheroxypropyltriethoxyoxysilane and 10mmol m-aminophenylboronic acid to a 25mL round bottom flask, vacuumize the flask and fill it with nitrogen, inject 15mL tetrahydrofuran, and then Stir at room temperature under protection for 12 hours. After evaporating the solvent, the obtained oily liquid was redissolved with 10 mL of methanol to obtain a 1 mmol / mL solution S-1, namely a solution of triethoxysilane modified with aminophenylboronic acid.

Embodiment 2

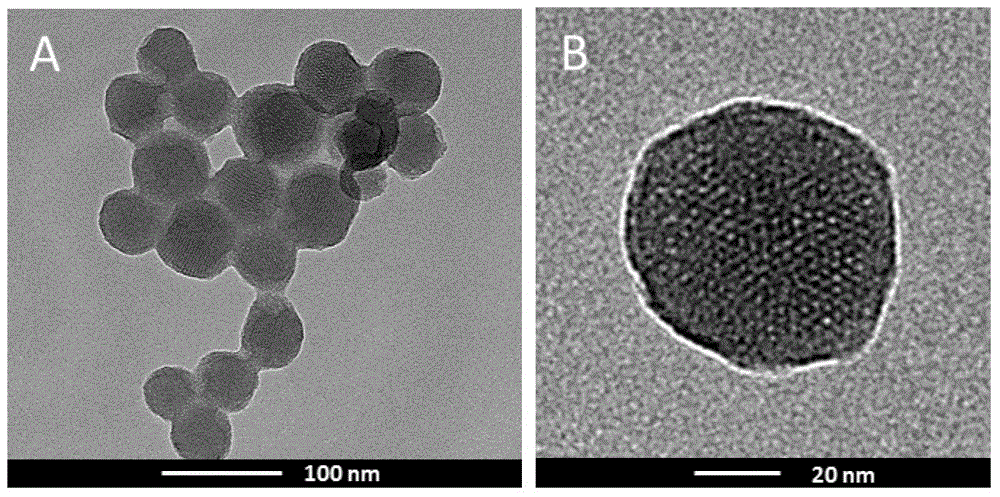

[0031] Example 2: Preparation of crude product of molecularly imprinted mesoporous material

[0032] First, add 0.6g of cetyltrimethylammonium bromide, 168mg of sodium hydroxide, and 288mL of water into a 500mL round bottom flask to obtain a mixture, then heat the above mixture to 80°C with stirring, then add 69.4mg of monophosphoric acid Adenosine (AMP) was stirred for 15 minutes until the solution was clear. Then, under vigorous stirring, the prepolymer solution was added dropwise to the above clear solution, kept at 80° C. for 2 hours, and then filtered to obtain the crude product. The above-mentioned pre-polymerization liquid is prepared by mixing 9.8 mmol orthoethyl silicate, 0.2 mmol 3-aminopropyltriethoxysilane, and 0.2 mmol solution S-1.

[0033] The above-mentioned anionic surfactant cetyltrimethylammonium bromide can be replaced by sodium lauryl sulfate (0.57g) of an equimolar amount, and all the other steps remain unchanged.

[0034] The above imprinting template ...

Embodiment 3

[0037] Embodiment 3: the removal of template

[0038] The removal of the template in this embodiment includes both the removal of the mesoporous template and the removal of the imprinted template. The removal of the above two template molecules is simultaneous. Specifically, the Soxhlet extraction method is used to remove the template under acidic conditions. The acidic condition is the acidic extraction solution. The acidic extraction solution is prepared by dissolving 1.5mL of hydrochloric acid with a mass concentration of 37.2% in 150mL of methanol solution, and the extraction time is 24 hours. . After the extraction, the obtained material was vacuum-dried at 60° C. for 12 hours; the molecularly imprinted mesoporous material was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com