Preparation method and application of molecularly imprinted polymer microspheres

A molecularly imprinted polymer technology, applied in the chemical field, can solve the problems of low adsorption efficiency of molecularly imprinted polymer microspheres, and achieve the effect of increasing imprinting efficiency, high specific surface area, and rapid transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

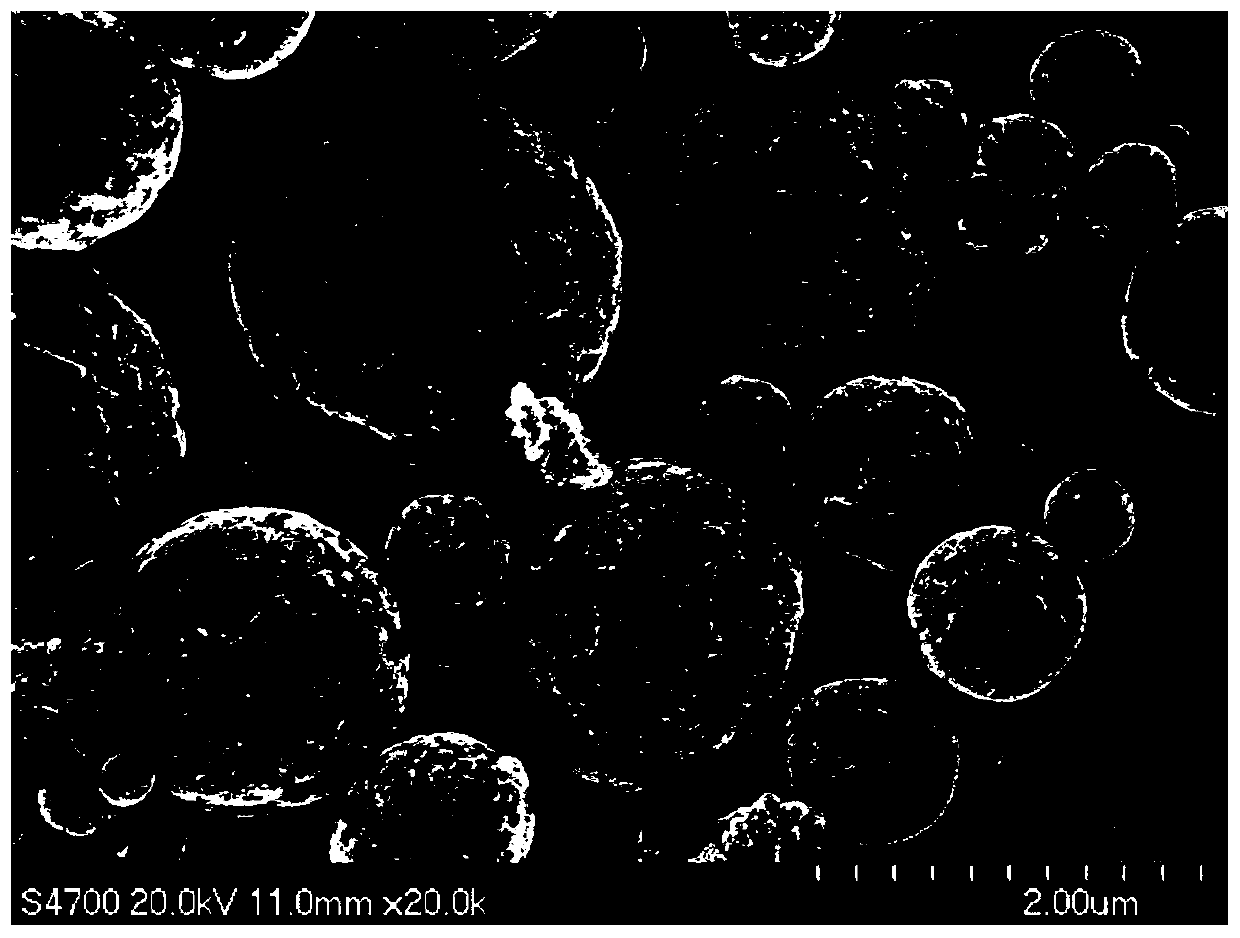

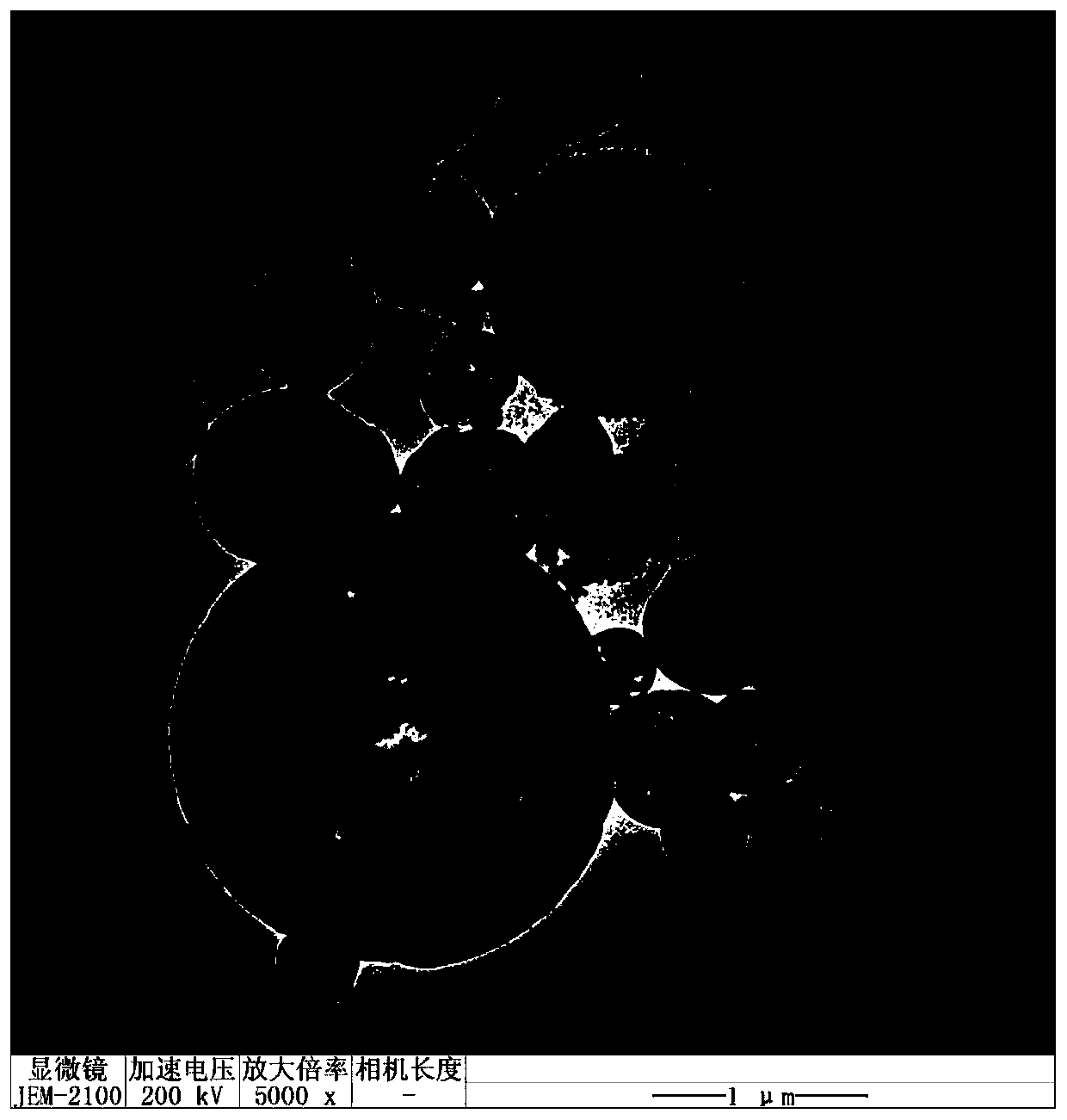

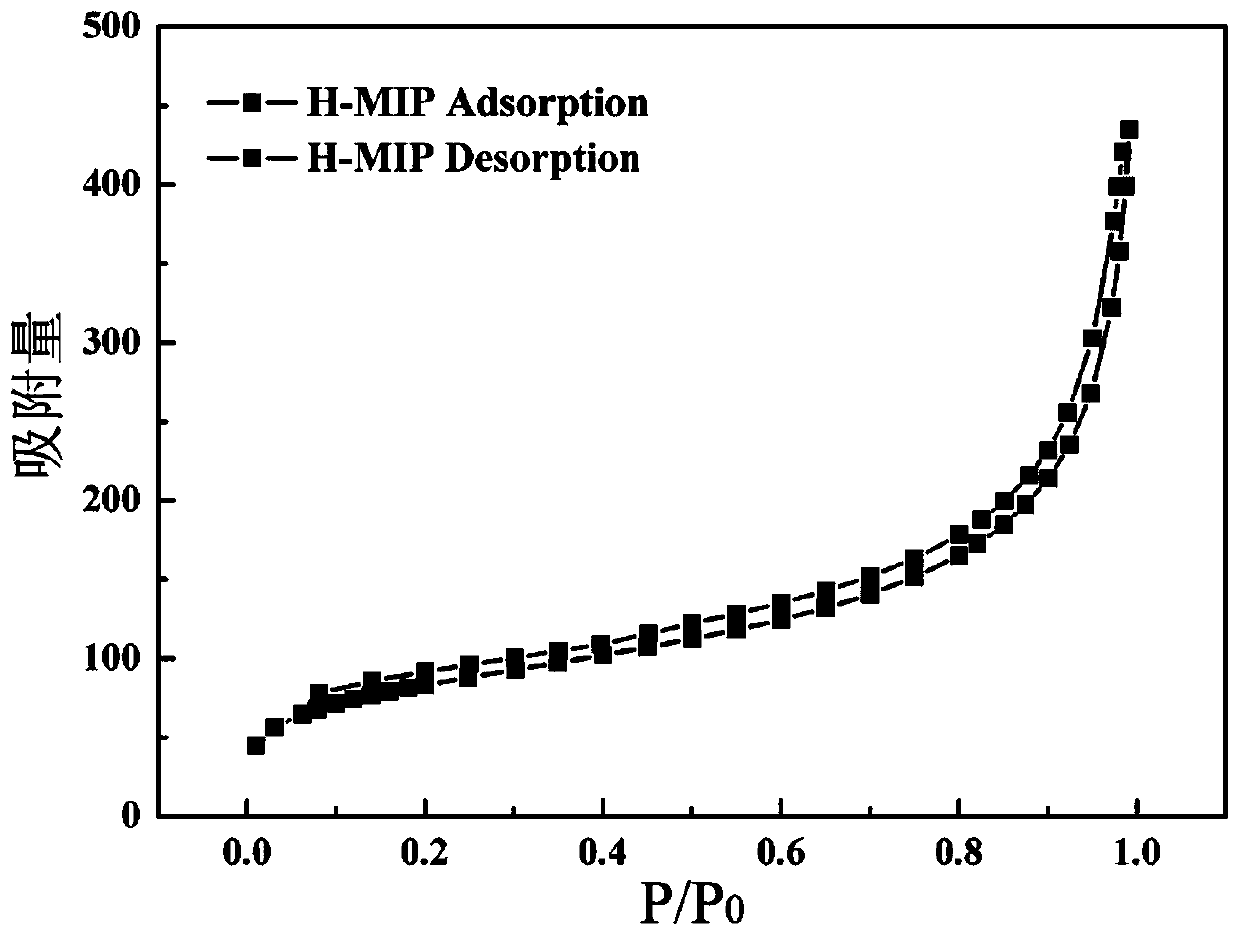

[0082] Weigh 2.5ml St, 0.045g AIBN, 0.045gNaSS, dissolve in 25ml methanol / water (v / v=9 / 1) solution, mix with ultrasonic wave, mechanically stir in water bath, and continue to pass nitrogen for 20min, then raise the temperature to 75 ℃, condensed and refluxed, reacted in a nitrogen atmosphere for 3 hours, slowly added 0.5ml DVB dropwise, and kept the drop rate at 2-4 drops per minute, and then continued to react for 5 hours. After the reaction was completed, it was cleaned by ultrasonic centrifugation with methanol for 3 times, and dried in a vacuum oven at 60° C. for 12 hours to obtain a dried spherical core sample.

[0083] Dissolve the dry sample in THF according to the ratio of 1g to 20ml THF, soak for 24h to dissolve the uncrosslinked part in the PS core, then wash twice with THF and once with methanol, and dry in a vacuum oven at 60°C for 12h , to get hollow bulb H-PS.

[0084] Take 0.4g of the prepared hollow bulb H-PS, add 10g of 0.2% SDS aqueous solution and sonicate ...

Embodiment 2

[0091] Weigh 2.5ml St, 0.034g AIBN, 0.04g NaSS, dissolve in 22.5ml methanol / water (v / v=9 / 1) solution, mechanically stir in a water bath after ultrasonication, and continue to blow nitrogen for 20min, then raise the temperature to 72°C , condensed and refluxed, reacted in a nitrogen atmosphere for 3.5 hours, slowly added 0.75ml DVB dropwise, controlled the dropping rate at 5-10 drops per minute, and continued to react for 6 hours. After the reaction was completed, it was cleaned by ultrasonic centrifugation with methanol three times, and dried in a vacuum oven at 55° C. for 14 hours.

[0092] Dissolve the dry sample in THF according to the ratio of 1g to 25ml THF, soak for 24h to dissolve the uncrosslinked part in the PS core, then wash twice with THF and once with methanol, and dry in a vacuum oven at 55°C for 14h , to get hollow bulb H-PS.

[0093] Take 0.4g of the prepared hollow bulb H-PS, add 12g of 0.2% SDS solution for ultrasonication, make H-PS and SDS aqueous solution...

Embodiment 3

[0100] Weigh 2.5ml St, 0.056g AIBN, 0.056g NaSS, dissolve in 30ml methanol / water (v / v=9 / 1) solution, mechanically stir in a water bath after ultrasonication, and continue argon for 30min, then heat up to 75°C , condensed and refluxed, reacted in an argon atmosphere for 3 hours, slowly added 0.6ml DVB dropwise, and kept the dropping rate at 2-4 drops per minute, and then continued to react for 5 hours. After the reaction was completed, it was cleaned by ultrasonic centrifugation with methanol for 3 times, and dried in a vacuum oven at 65° C. for 10 h.

[0101]Dissolve the dry sample in THF according to the ratio of 1g to 30ml THF, soak for 20h to dissolve the uncrosslinked part in the PS core, then wash twice with THF and once with methanol, and dry in a vacuum oven at 65°C for 10h , to get hollow bulb H-PS.

[0102] Take 0.4g of the prepared hollow bulb H-PS, add 15g of 0.3% SDS solution for ultrasonication, make H-PS and SDS aqueous solution form a uniform emulsion, and add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com