Patents

Literature

443results about How to "Easy compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

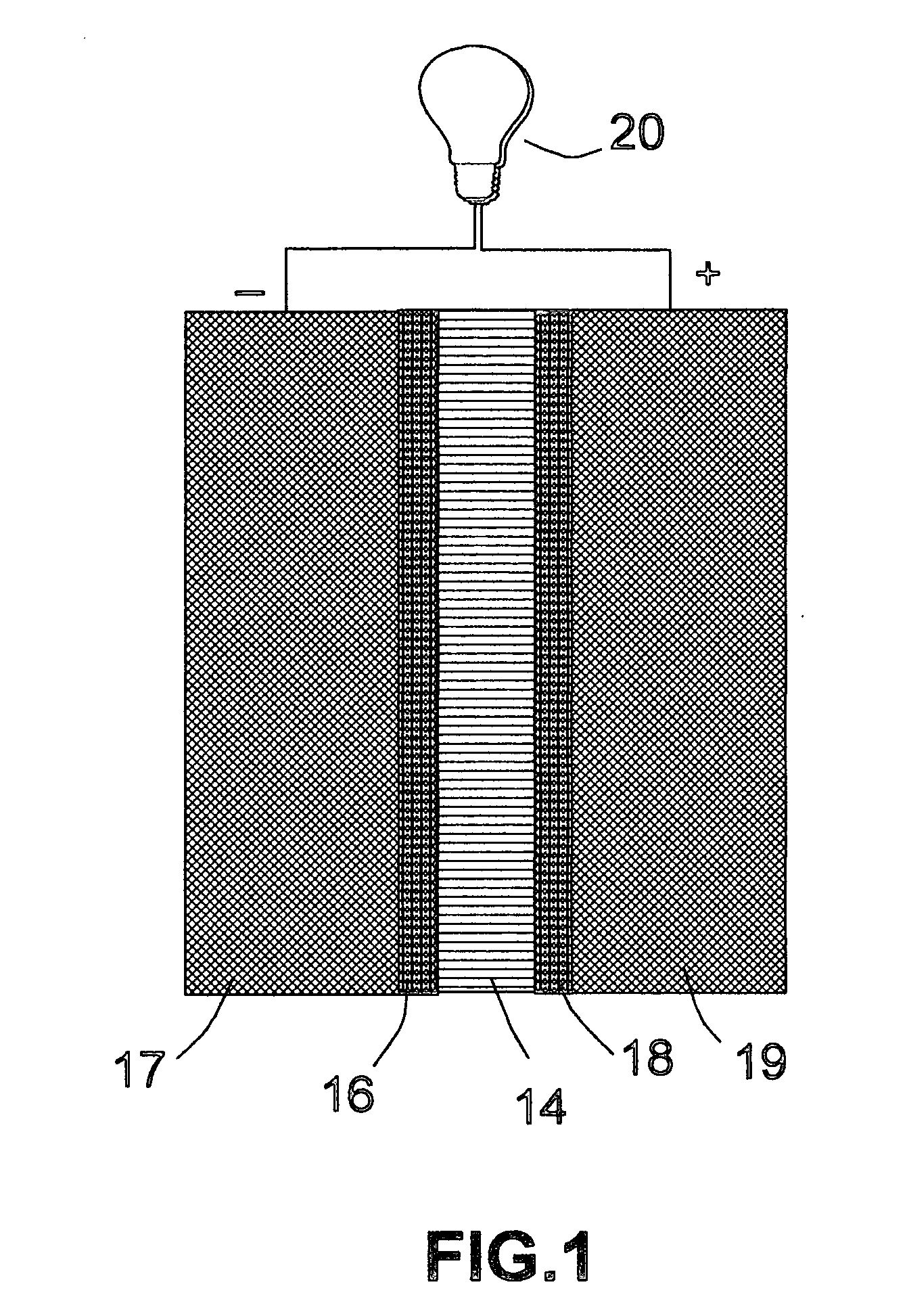

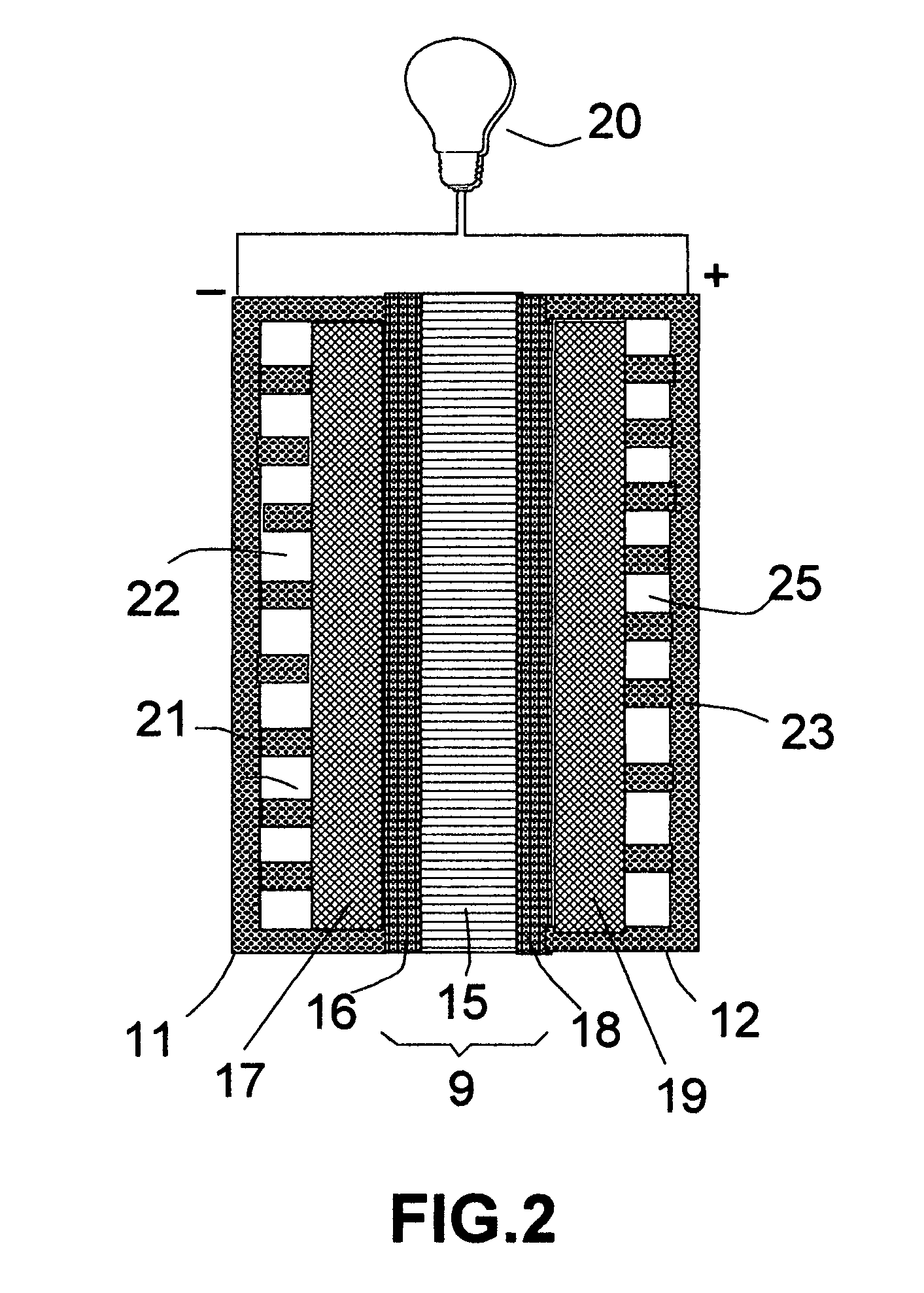

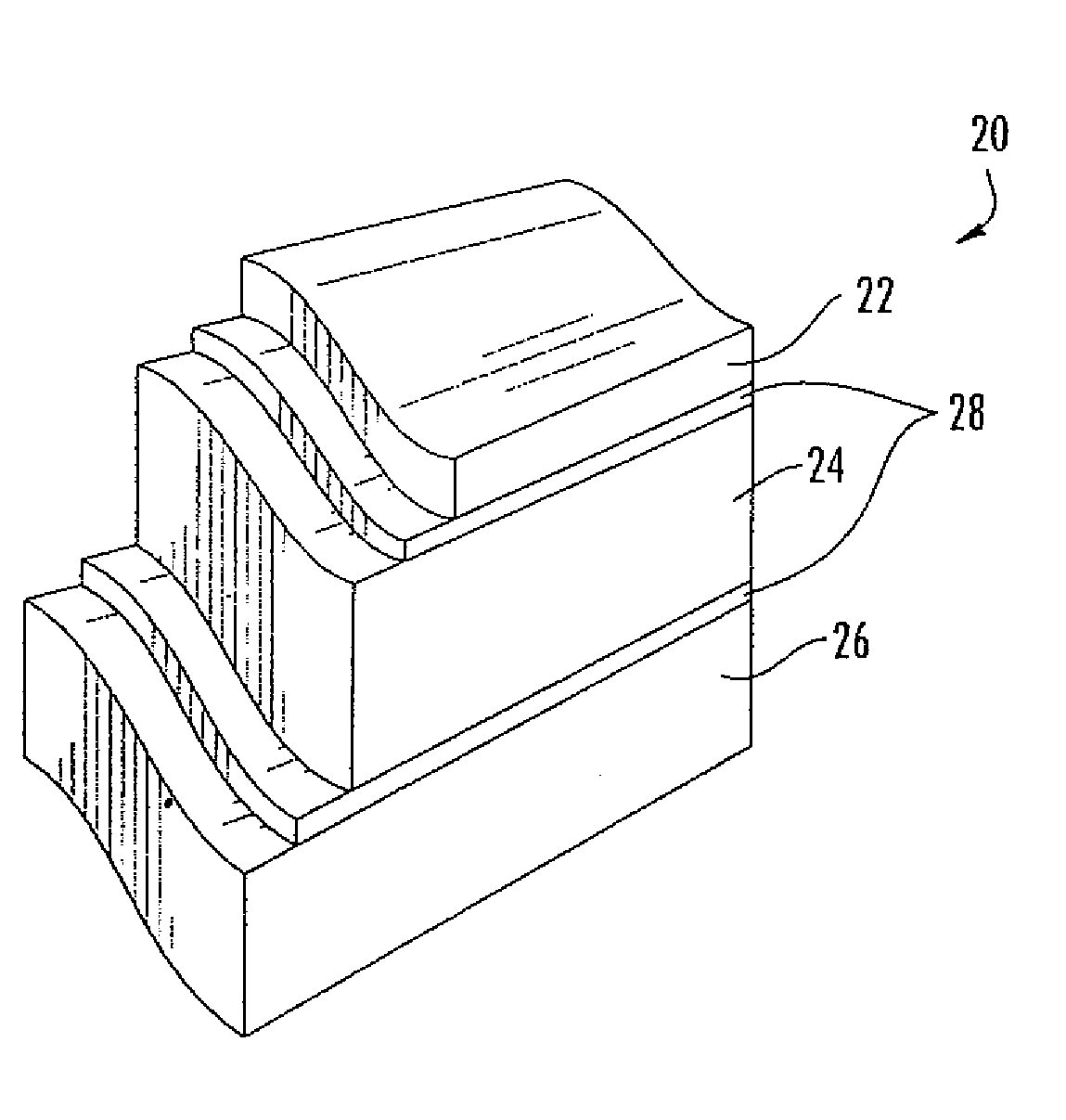

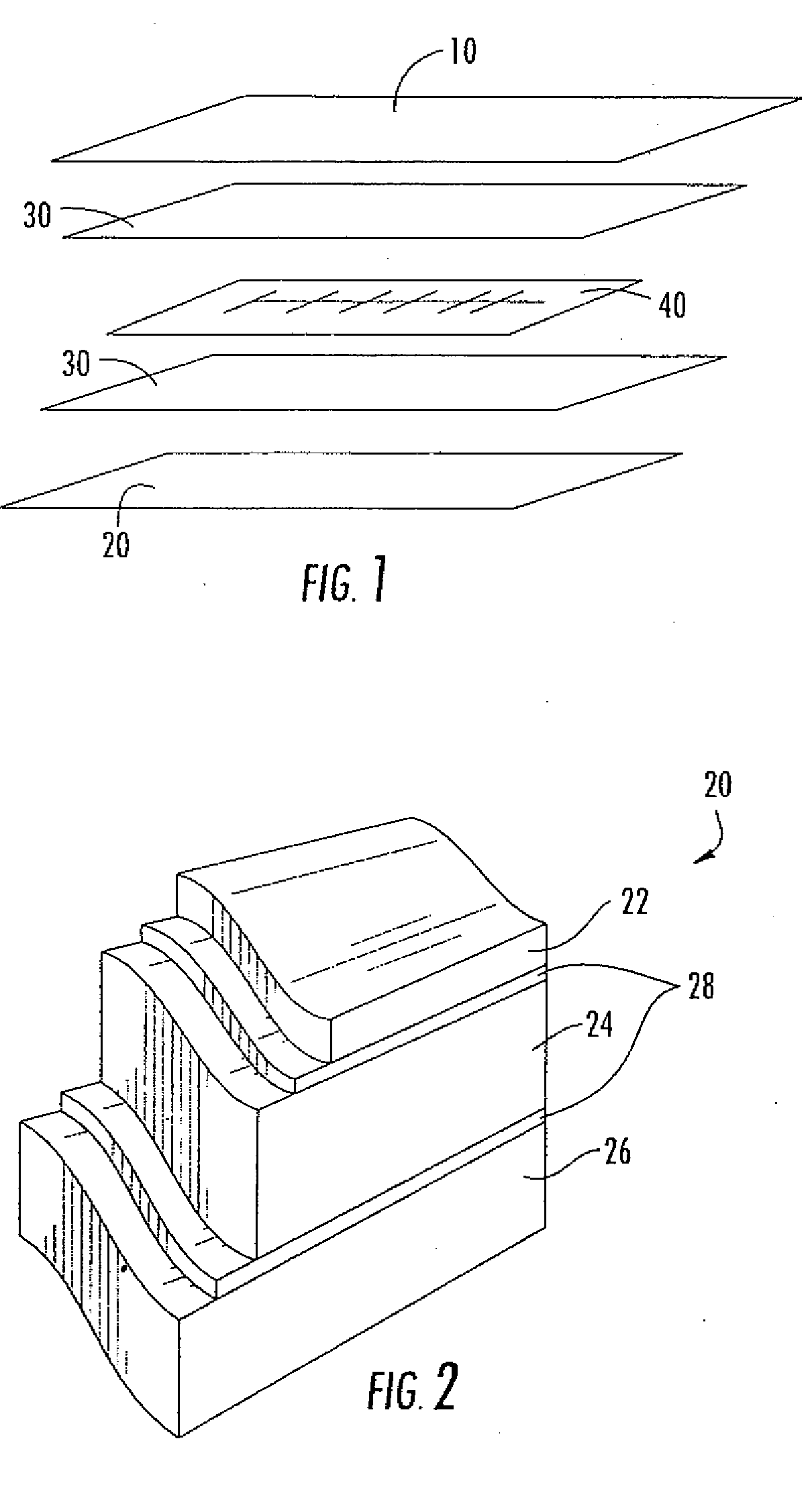

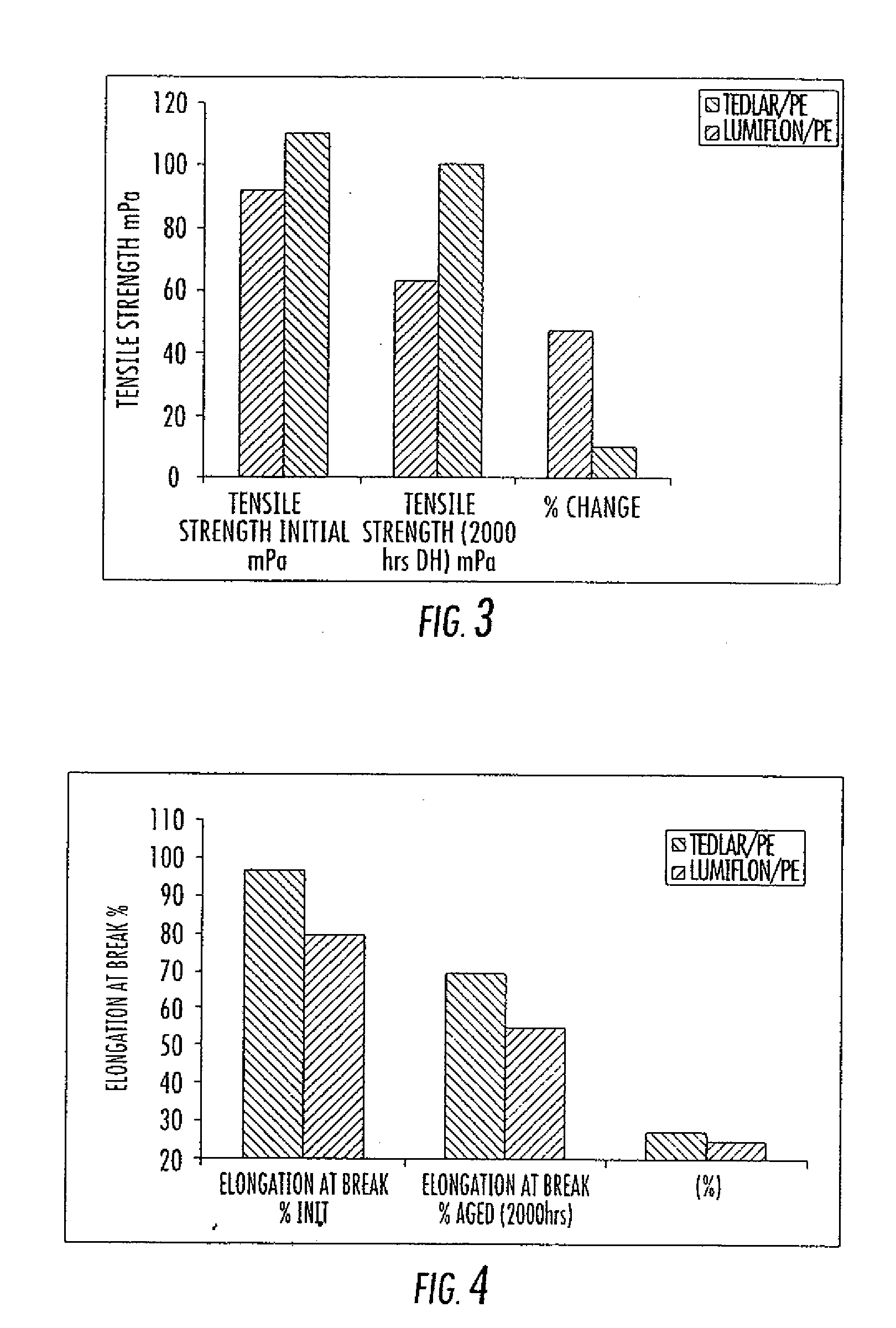

Backing sheet for photovoltaic modules and method for repairing same

InactiveUS20080264484A1Improve adhesionGood color retentionSynthetic resin layered productsCoatingsWeather resistanceHeat resistance

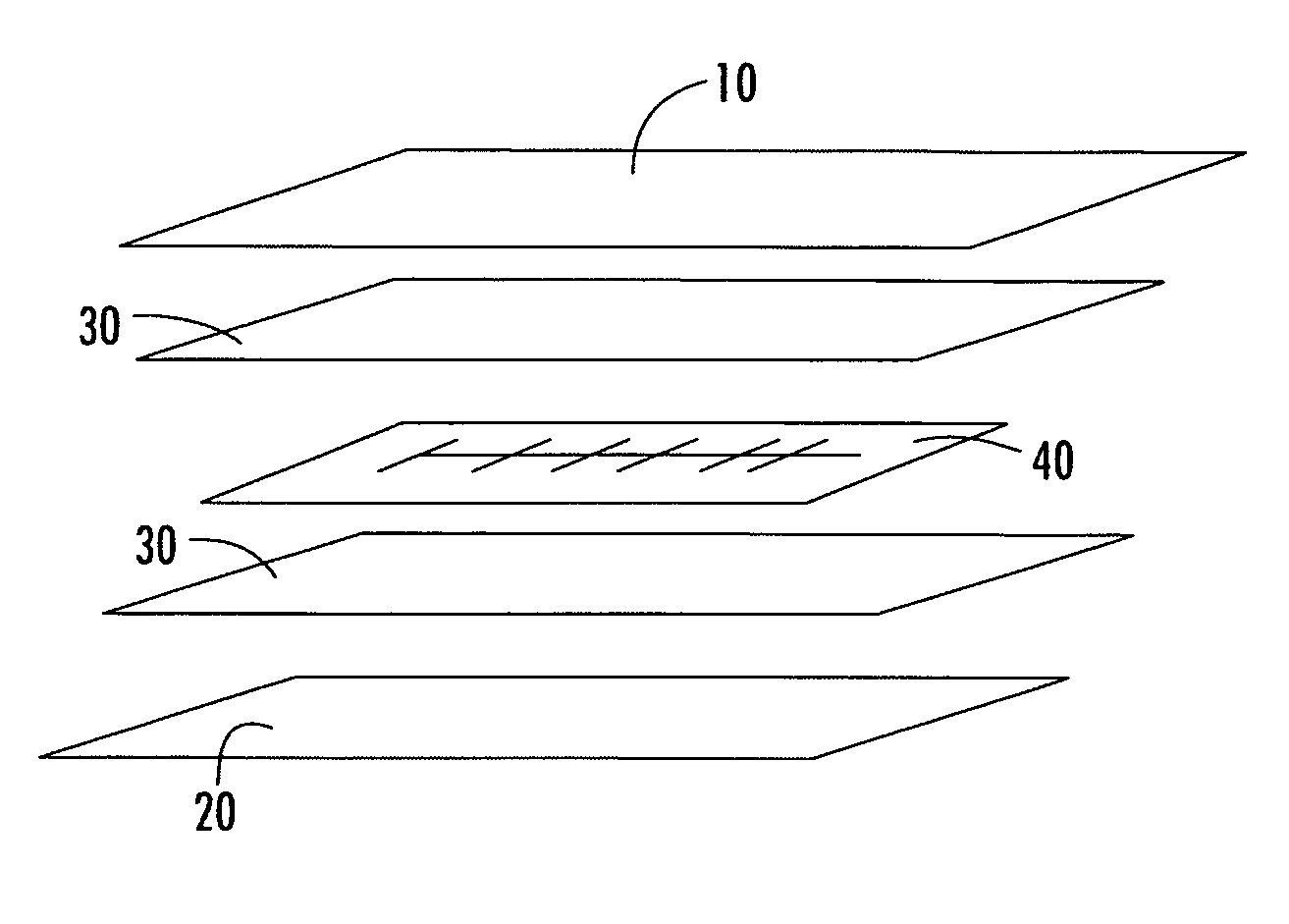

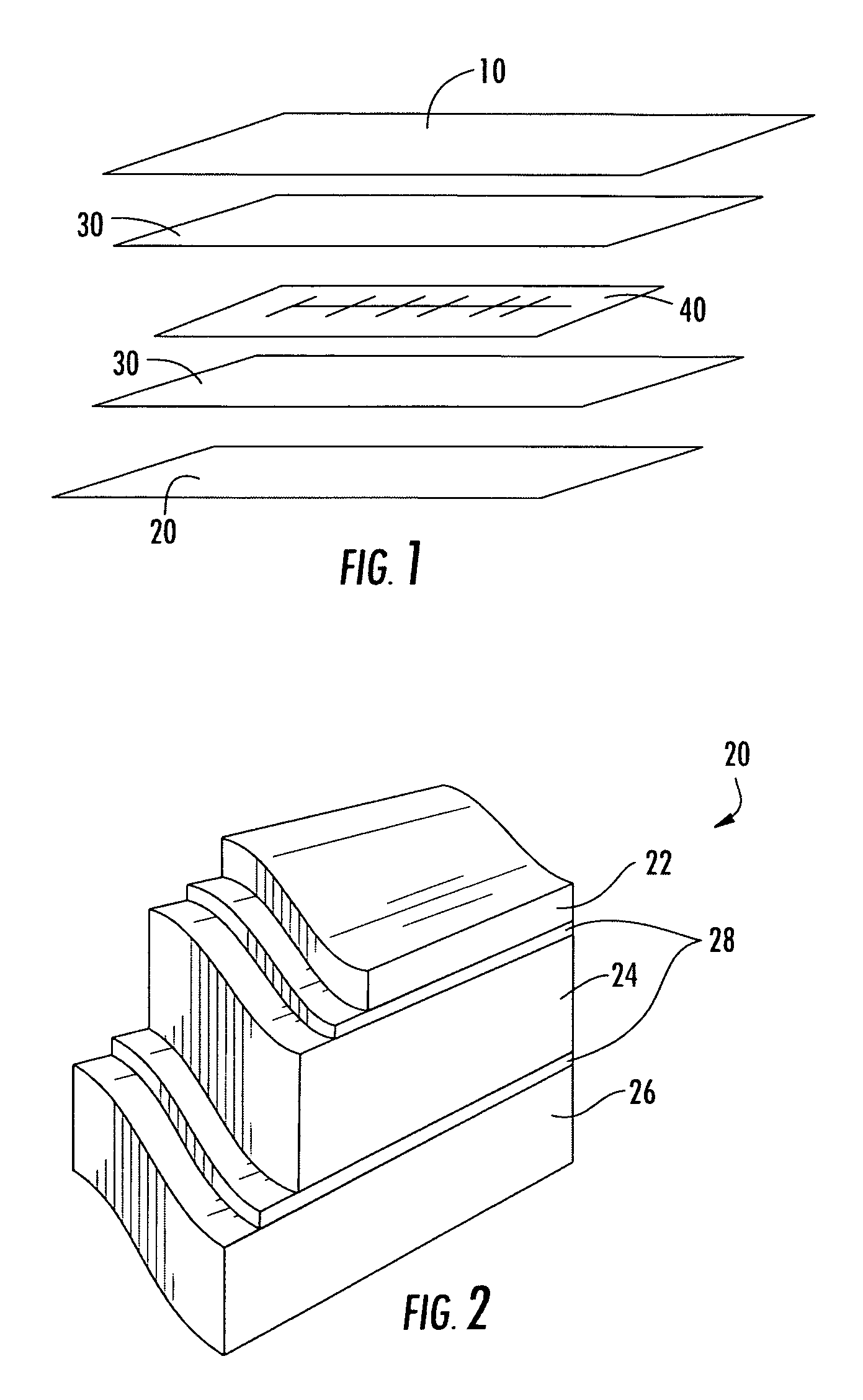

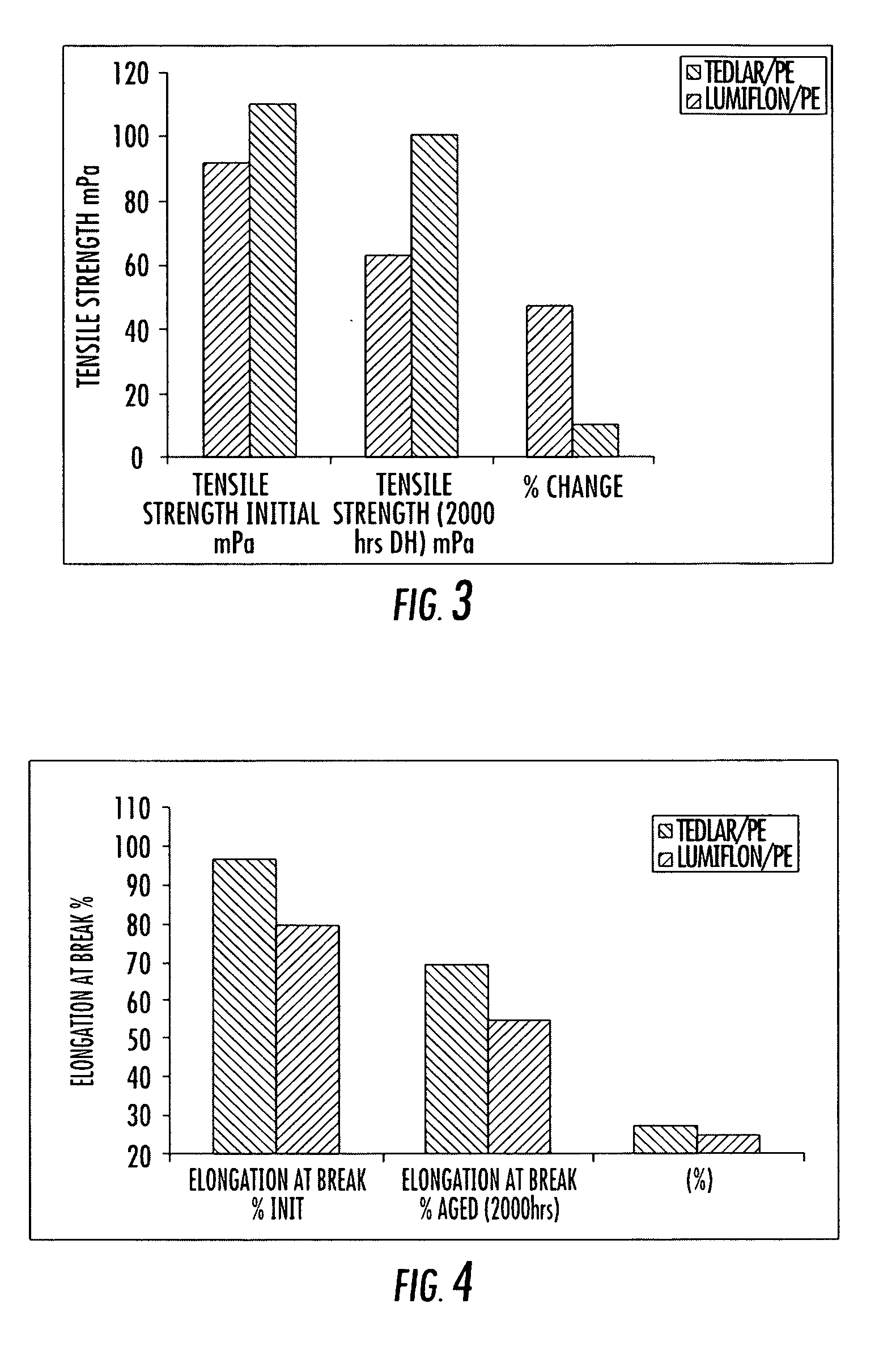

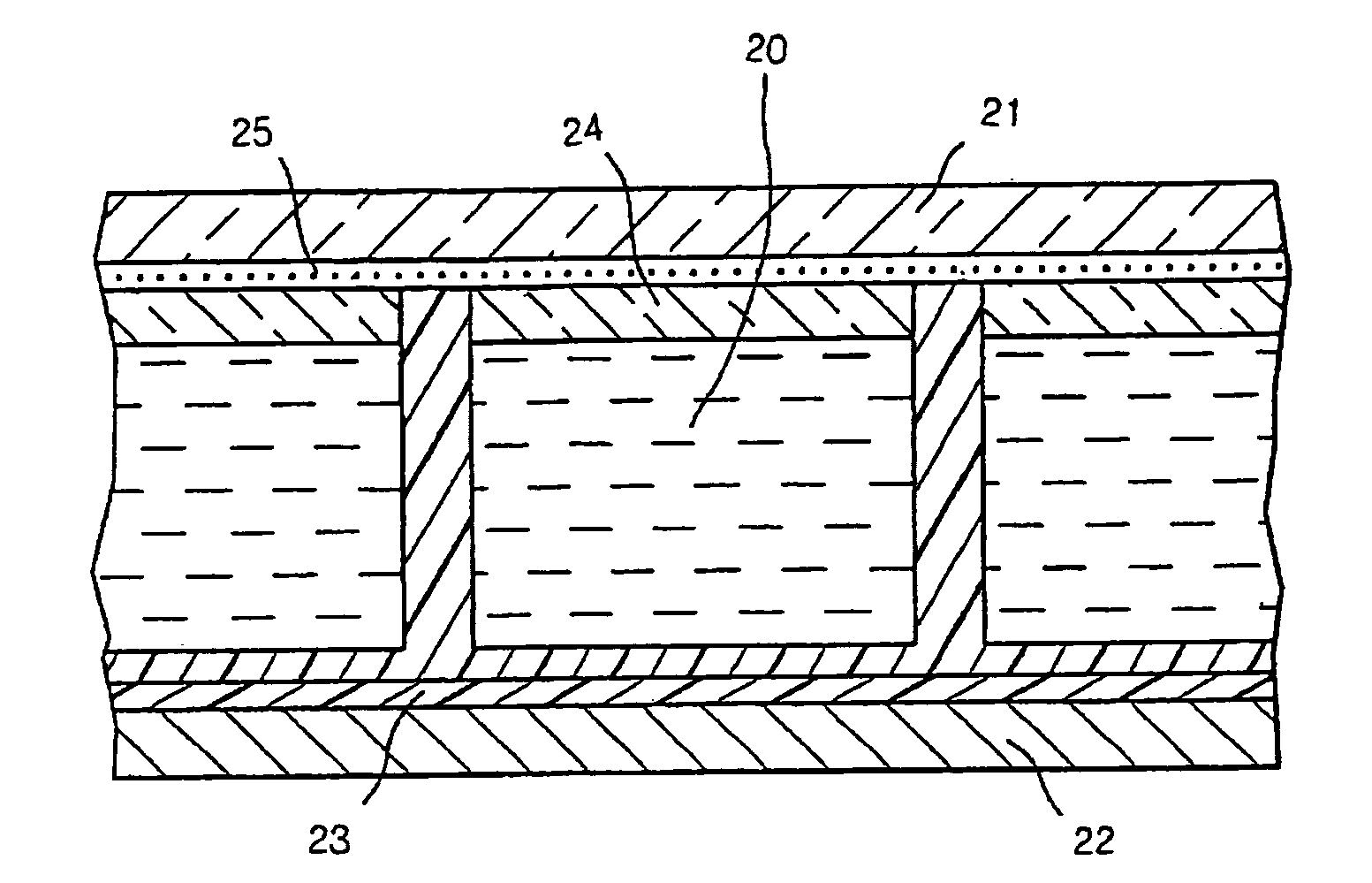

The present invention provides a protective backing sheet for photovoltaic modules. The backing sheets of the current invention possess excellent weather resistance, heat resistance, color retention, adhesion between layers and encapsulant, and scratch resistance. The backing sheet can minimize the deterioration in the performance of the solar module due to moisture permeation. It also can achieve desirable photoelectric conversion efficiency over a long period of time. Additionally the described backing sheet, or alternately referred to backskin, can be made in an aesthetically pleasing form.

Owner:MADICO INC

Display cell structure and electrode protecting layer compositions

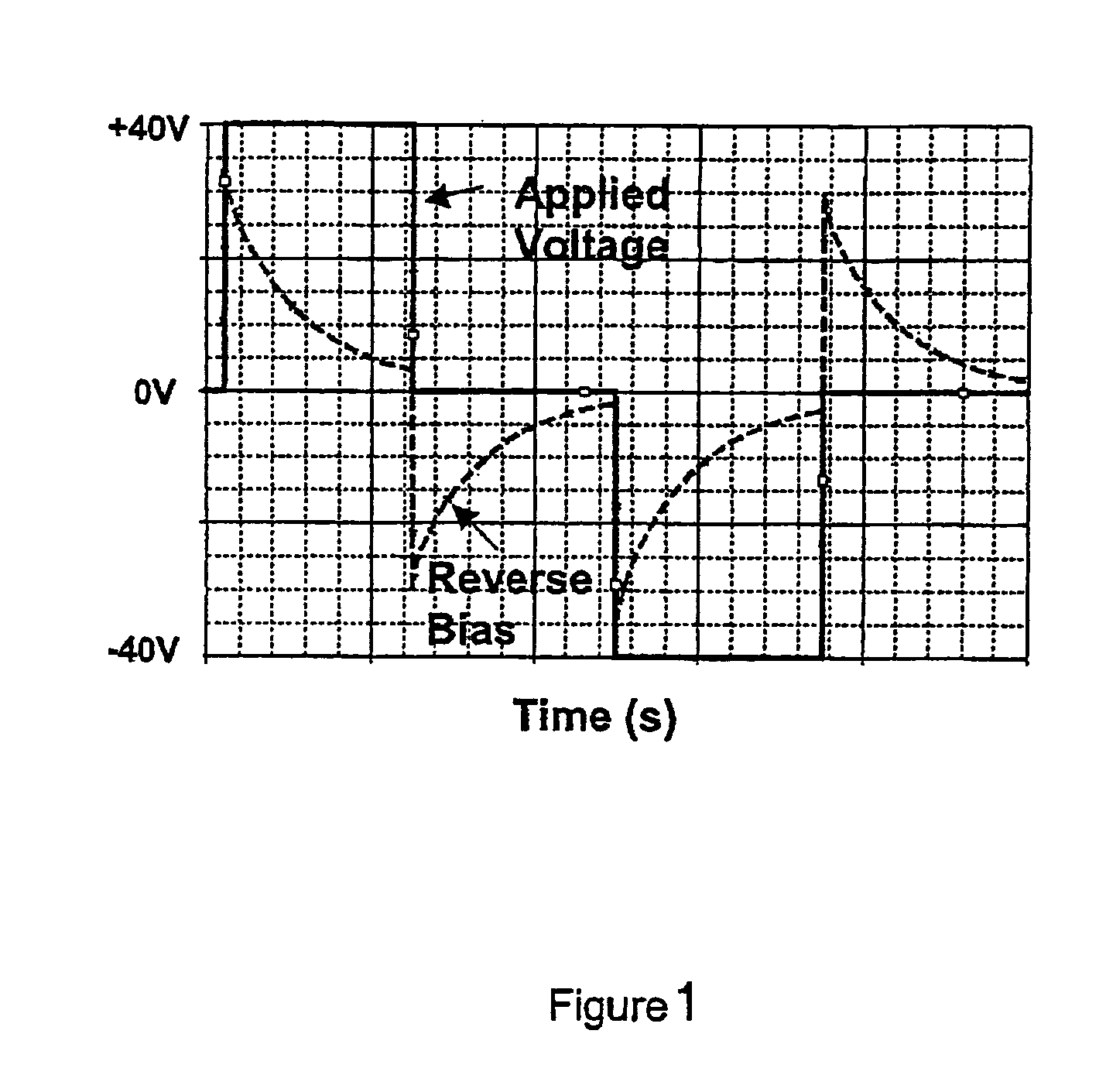

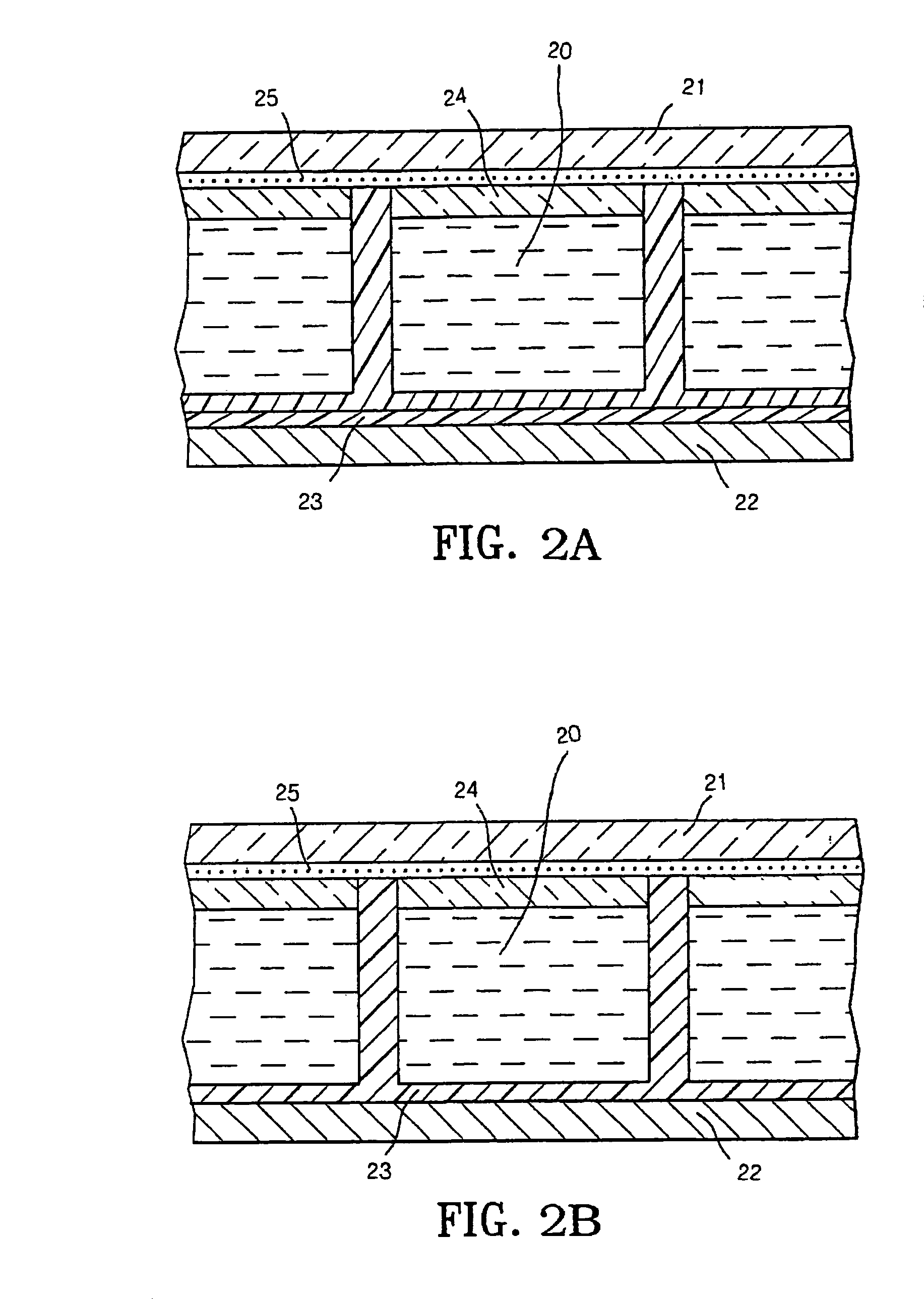

ActiveUS7880958B2Improve the display effectImprove performanceLiquid crystal compositionsStatic indicating devicesVitrificationElectrical battery

Owner:E INK CORPORATION

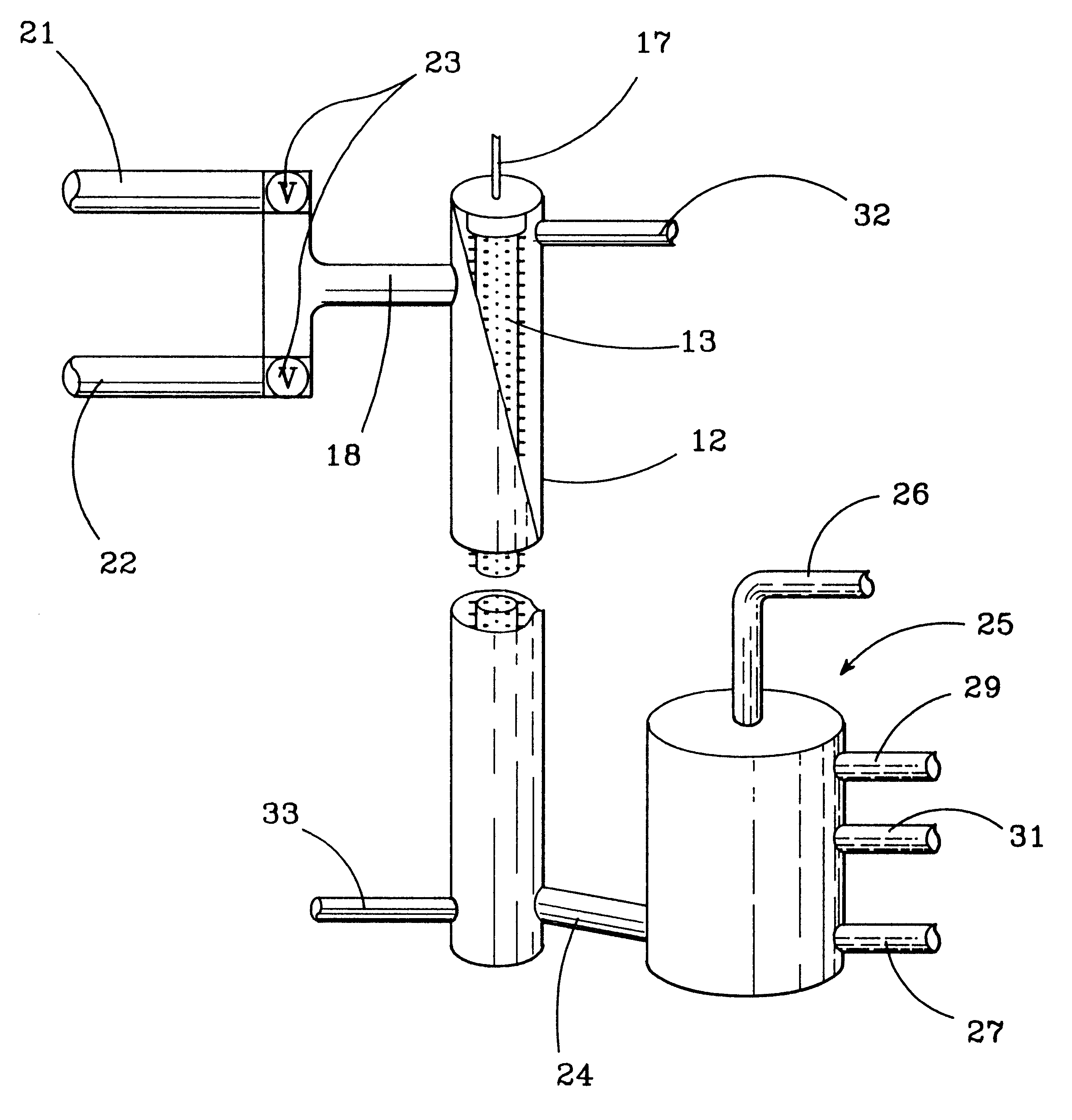

Electrostatic method and means for removing contaminants from gases

InactiveUS6224653B1Easy to operateHigh voltageGas treatmentDispersed particle separationHigh concentrationCorona discharge

An electrical apparatus includes a reaction chamber. A stream of contaminated gasses flows through the chamber. An elongated coronating electrode is positioned in the reaction chamber for producing a corona discharge within the chamber. A multi-stage Fitch generator connected to the electrode produces a high level, rapidly pulsating voltage in the electrode. Controlled amounts of an inert gas or inert gas-air mixture are combined with the contaminated gases to provide a high concentration of inert gas in the reaction chamber. In the inert gas-enriched atmosphere, the pulsating corona discharge produces a high concentration of metastable intermediates that greatly increase the rate of chemical conversion of the contaminants. Switching circuitry allows the pulsating voltage output of the Fitch generator to be superimposed on a constant direct current voltage in the electrode, setting up an electrostatic field in the reaction chamber for removing conversion byproducts from the gas stream.

Owner:PULSATRON TECH CORP

Elastomer Composite and Method for Producing It

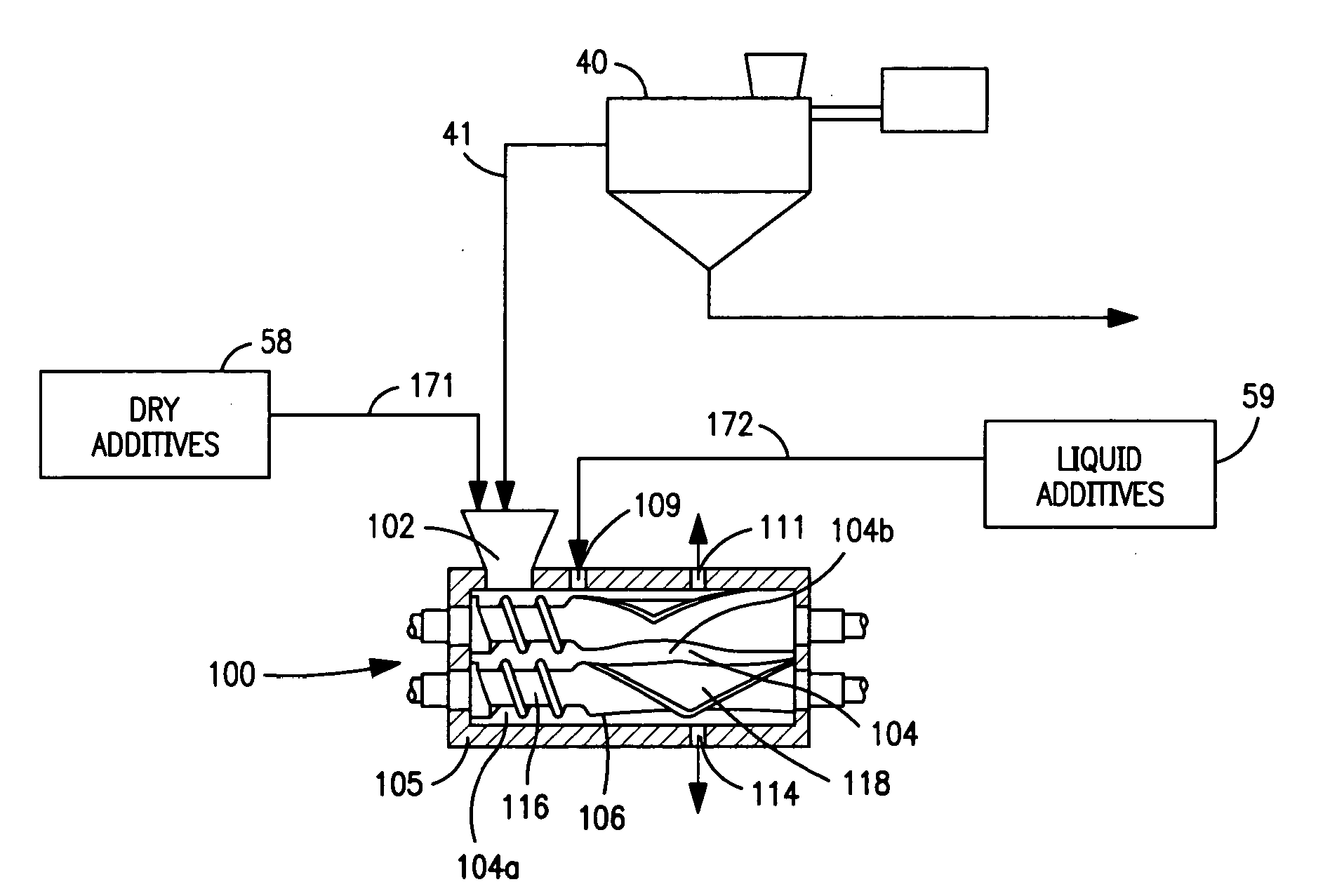

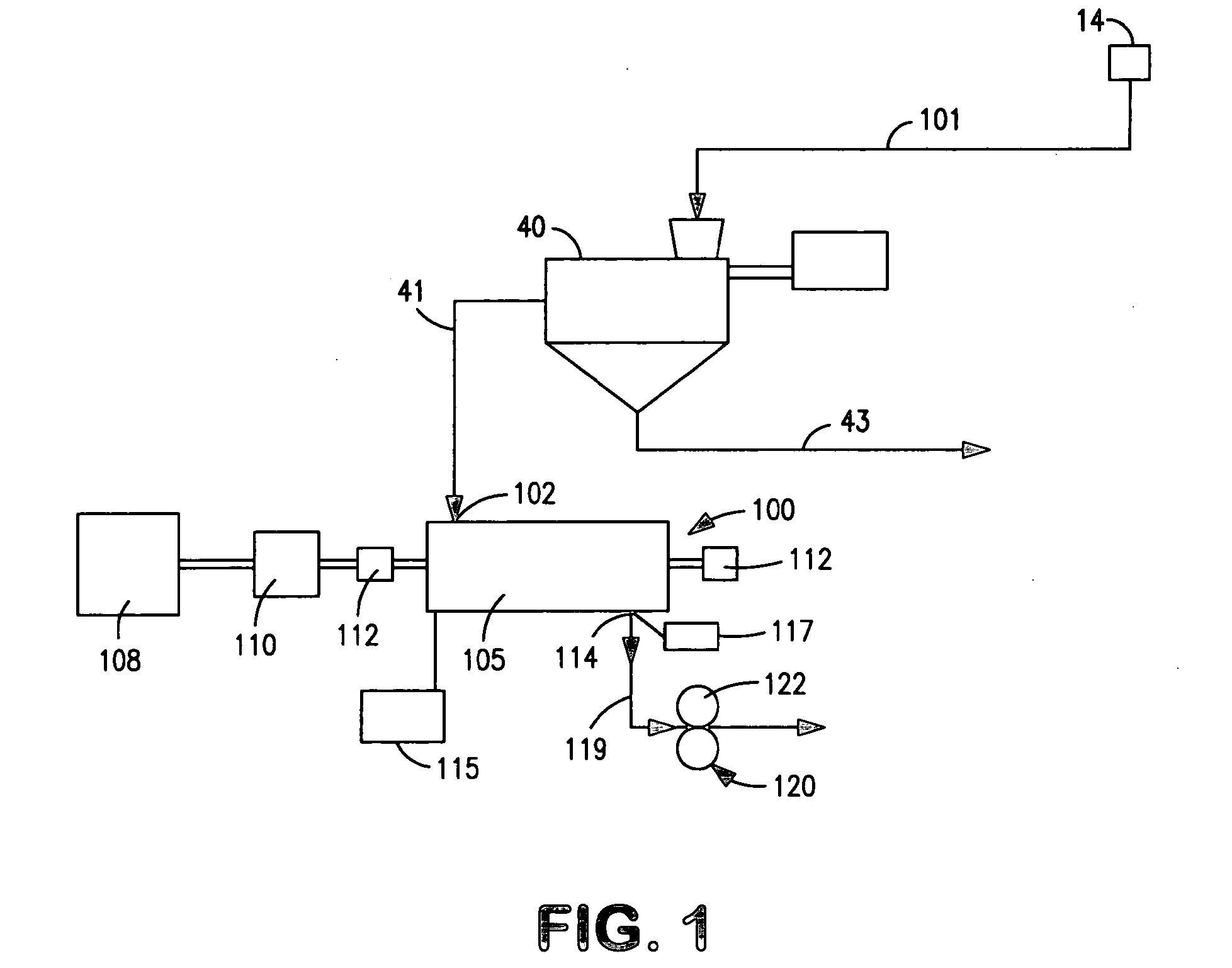

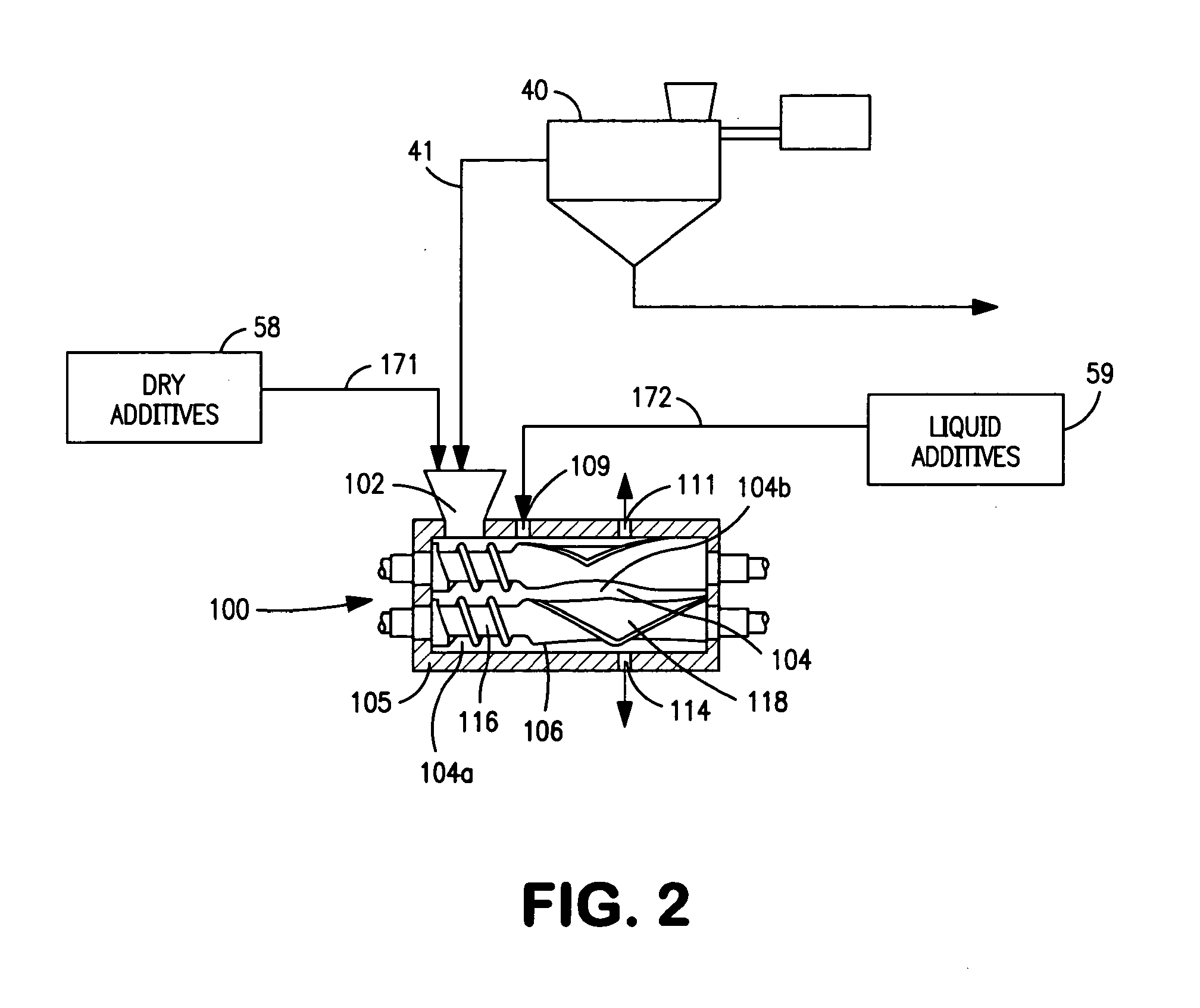

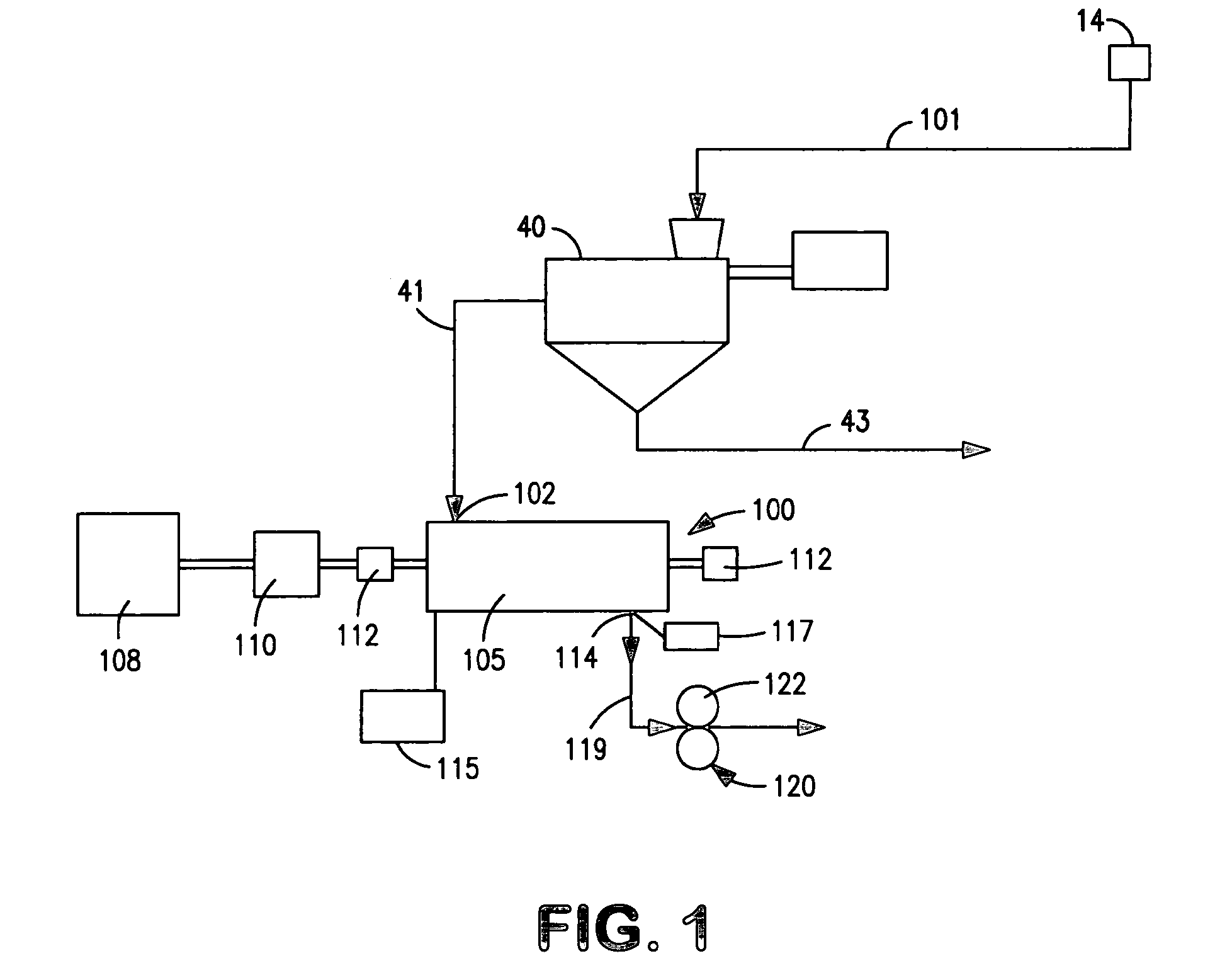

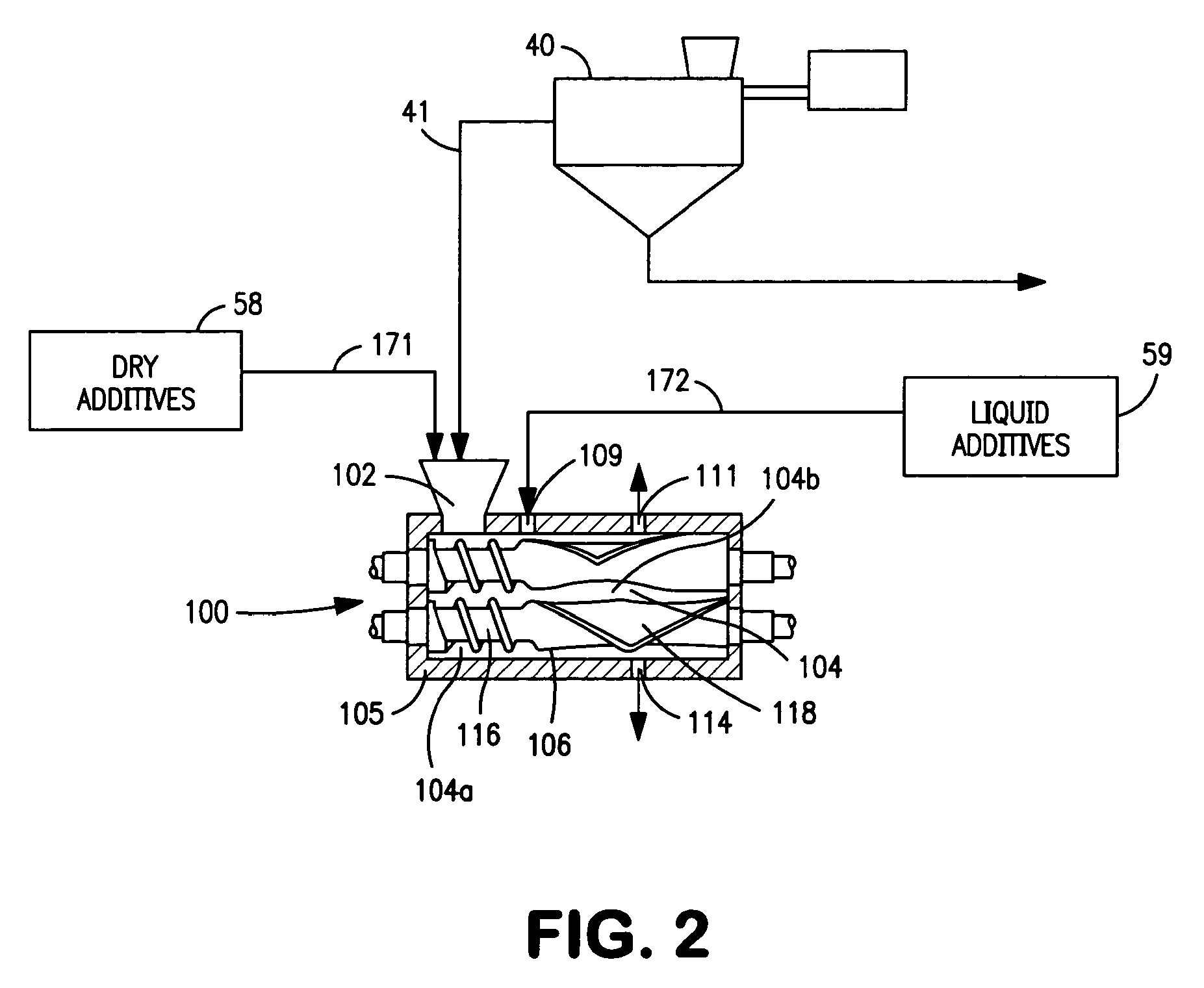

A method of producing an elastomer composite. The method includes A) combining a first fluid comprising elastomer latex with a second fluid comprising particulate filler; B) causing the elastomer latex to coagulate, thereby forming masterbatch crumb; C) bringing the masterbatch crumb to a water content of about 1 weight percent to about 20 weight percent, thereby forming a dewatered coagulum; D) removing water from the dewatered coagulum by subjecting the dewatered coagulum to mechanical energy, thereby causing the dewatered coagulum to heat as a result of friction, while allowing the dewatered coagulum to achieve a temperature of about 130° C. to about 190° C., wherein water content is reduced to about 0.5% to about 3% and wherein substantially all of the decrease in water content is accomplished by evaporation, thereby producing a masticated masterbatch; and E) subjecting the masticated masterbatch to at least an additional 0.3 MJ / kg of mechanical energy while further reducing the water content.

Owner:CABOT CORP

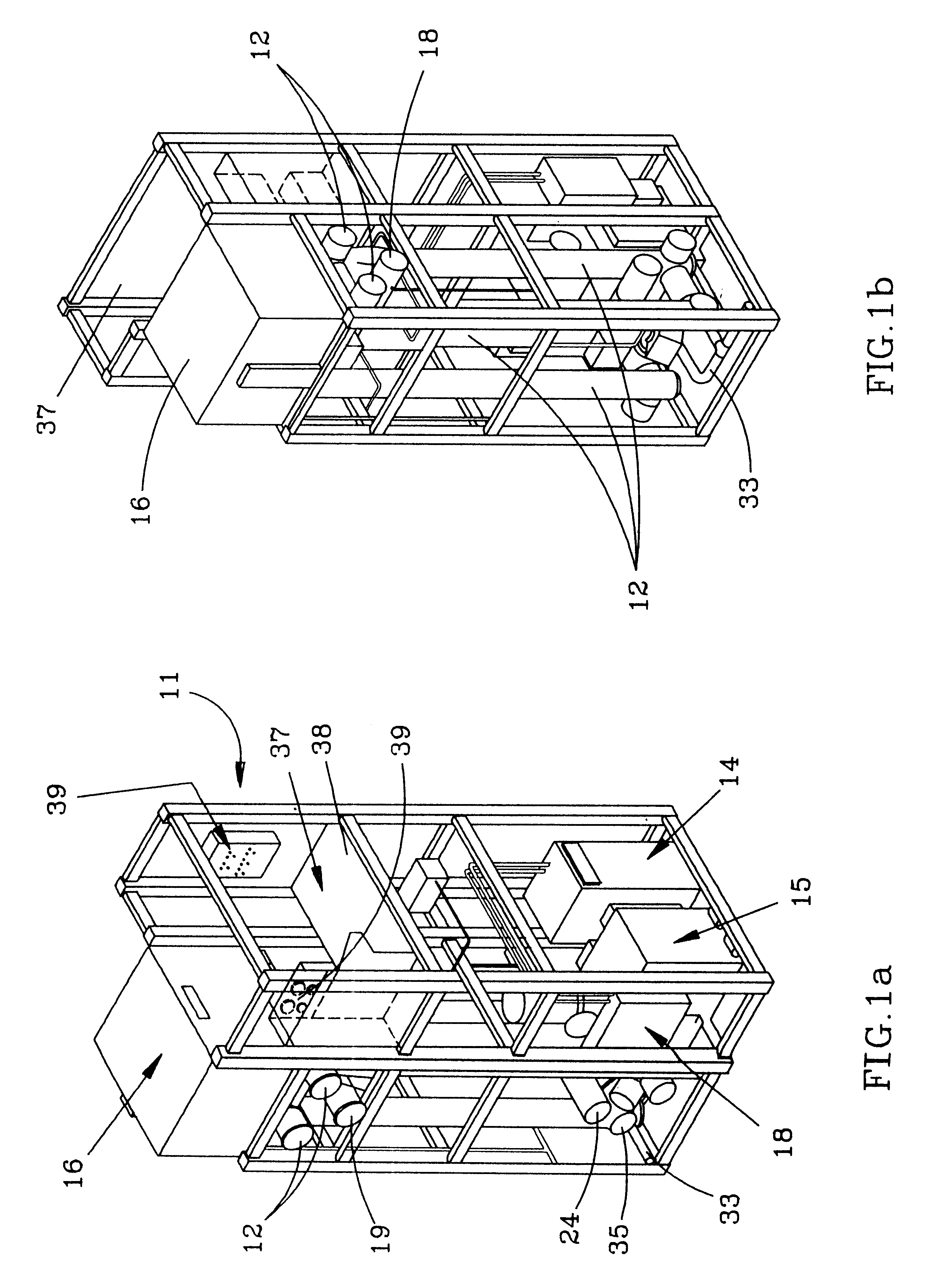

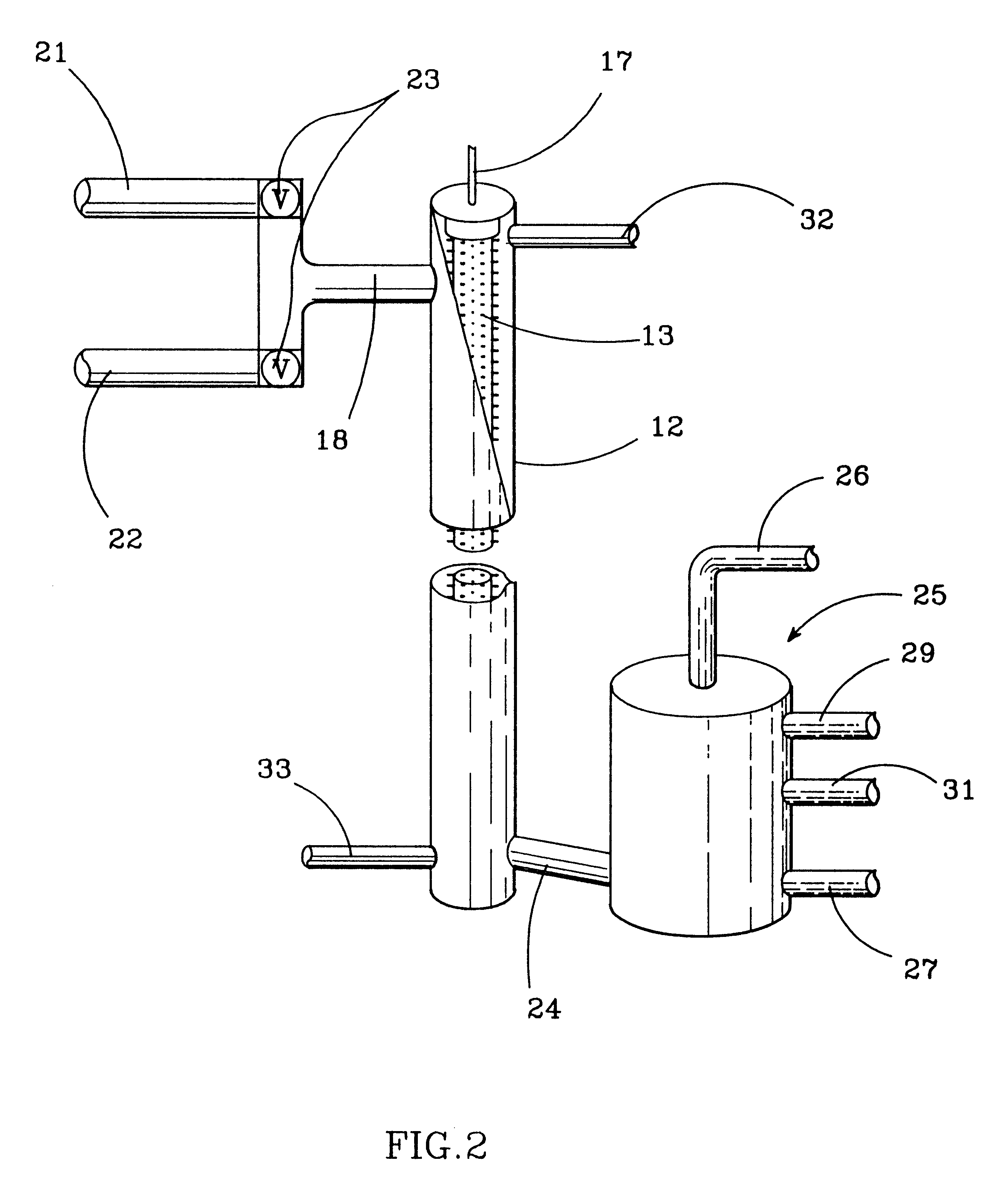

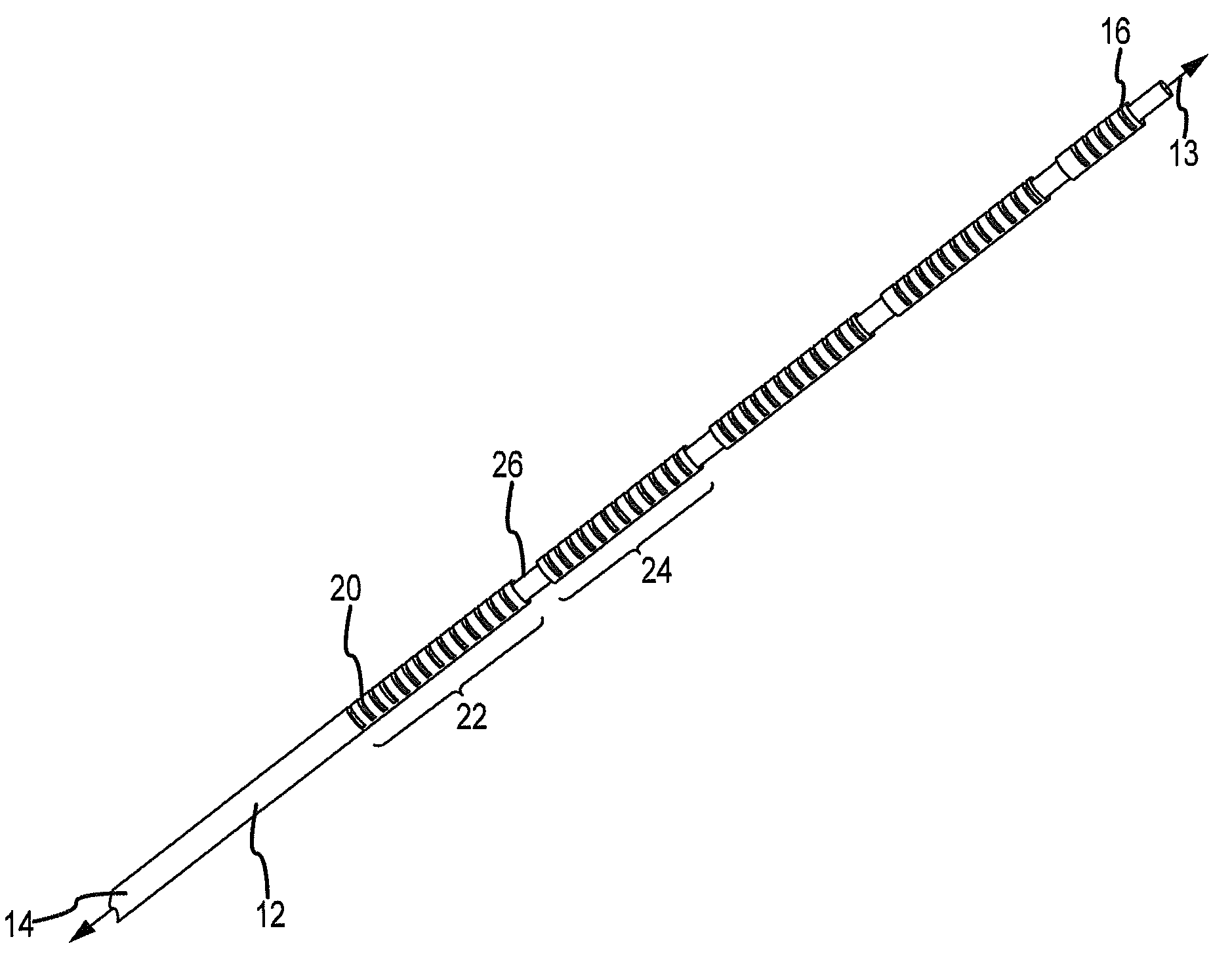

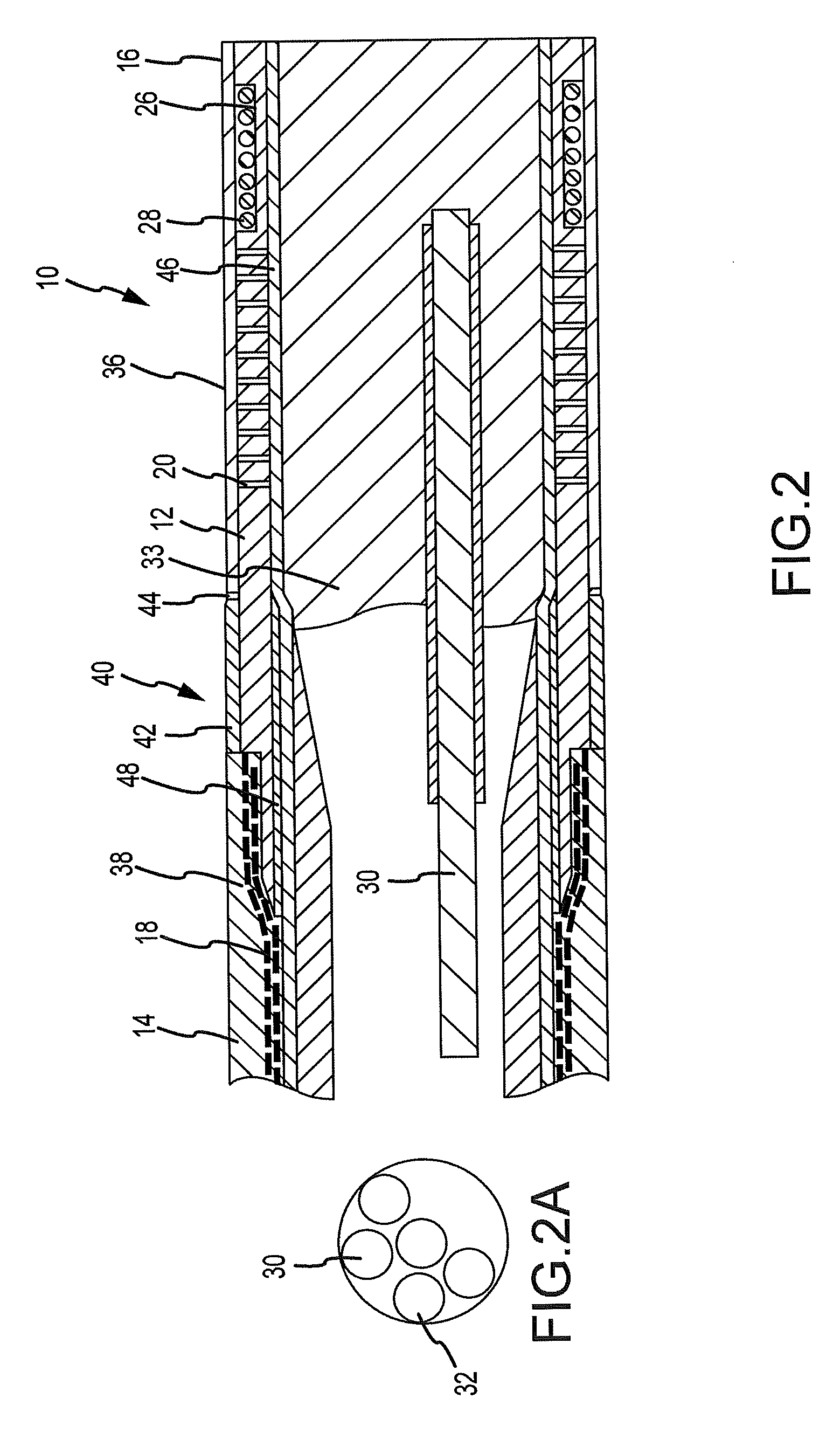

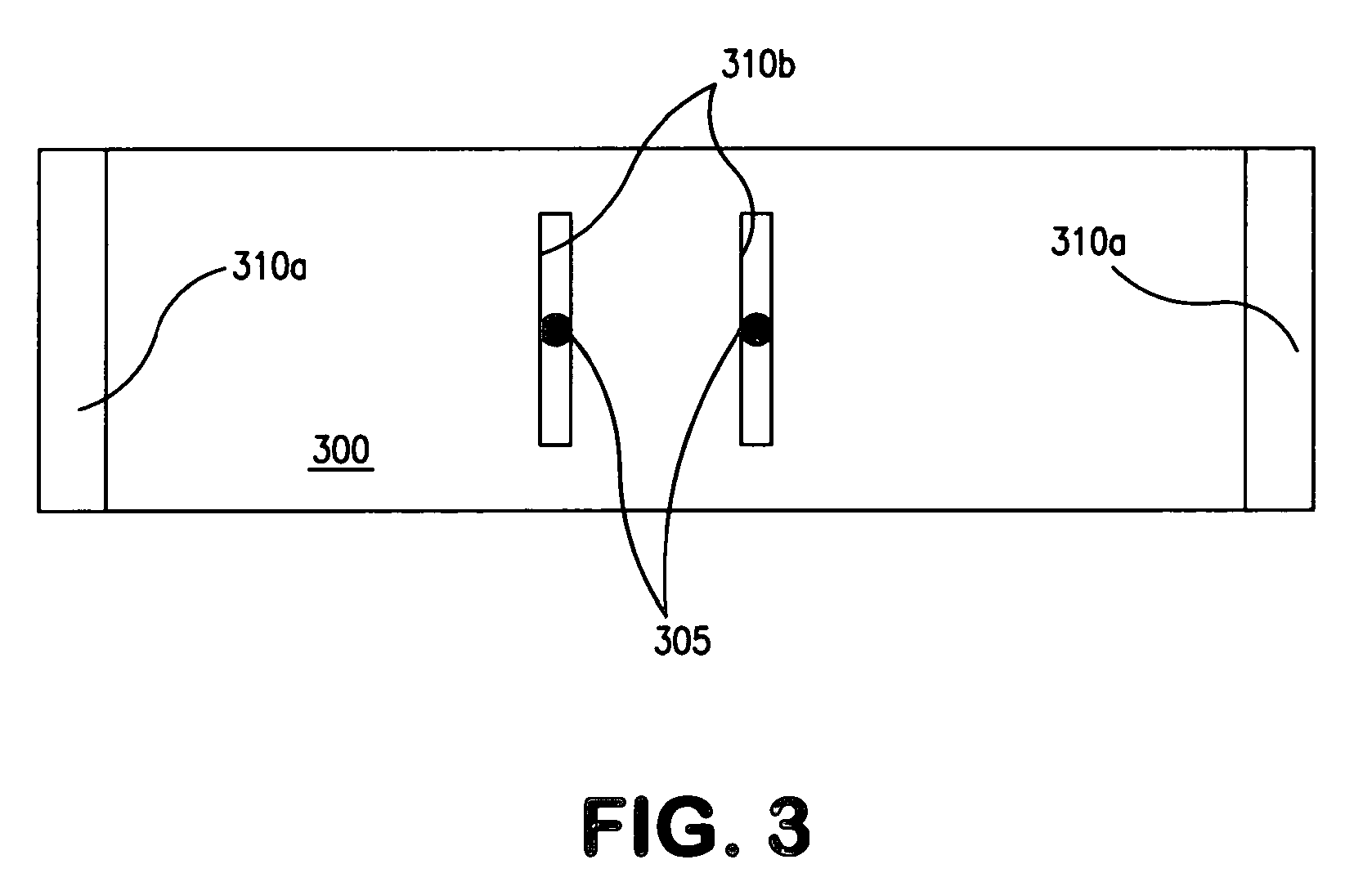

Longitudinally incompressible, laterally flexible interior shaft for catheter

InactiveUS20100286626A1Adequate torqueabilityAdequate pushabilityEndoscopesCatheterLateral bendingGuide tube

A catheter having a substantially longitudinally non-compressible non-metallic internal shaft or reinforcing member (12) is provided having proximal end, intermediate, and distal end portions. At least one of the portions of the shaft includes mechanical features that promote lateral bending of the shaft, and thus, the catheter. In one form, a plurality of spaced-apart cutouts (20,34) are formed within the shaft (12). A first of the plurality of cutouts (20) is disposed in a first plane. A second of the plurality of cutouts (34) is disposed in a second plane. The first plane and second plane can be substantially parallel. The cut-outs (20,34) can have diverse shape, size and cross-section and can be similar, identical and / or of varying dimension. In lieu of or in addition to one or more cut-outs, material removed from portions of the shaft provide relatively more or less flexibility in one or more lateral directions.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

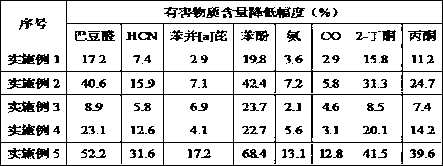

Grapheme type fiber cigarette filter and preparation method thereof

InactiveCN103005712ALarge surface atomic ratioUnique adsorptionTobacco smoke filtersFiberHazardous substance

The invention discloses a grapheme type fiber cigarette filter and a preparation method thereof. The filter comprises a fiber carrier, wherein the fiber carrier is provided with a grapheme type material for absorbing harmful components in smoke. The filter loads the grapheme type material on a carbon fiber or acetate fiber carrier; and the carrier is added in the filter by adopting the binary filter production mode in the existing industries to produce a compound filter for absorbing harmful substances in the smoke which is generated when cigarettes are smoked. The filter applies unique phi absorption characteristics and higher surface active atom ratio of novel two-dimensional nanometer materials to efficiently absorb benzo [a] pyrene, volatile aldehyde ketone type cancer promoting molecules, phenol and HCN (Hydrogen Cyanide) under the condition of smaller adding quantity, so that the filter is environment-friendly and has no additional poison; as the amount is small and the effect is high, the harm of the cigarettes to human bodies is reduced under the condition of not influencing the inherent sensory quality of the cigarettes. And at the same time, the method has the advantages of simple technique, large-scale production and low cost, and has wide application foreground in the cigarette field of harm reduction and tar reduction.

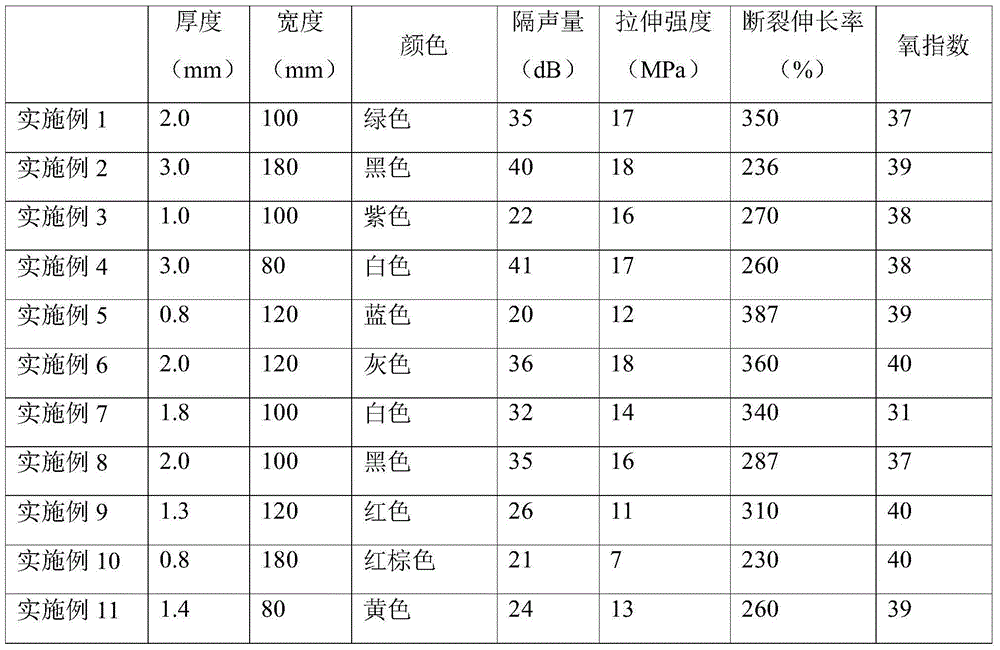

Sound insulating material and preparation method thereof

ActiveCN104629217ASimple production processReduce manufacturing costSound producing devicesChemistryPlasticizer

The invention belongs to the technical field of thermoplastic resin sound insulating material preparation and particularly relates to a thermoplastic resin sound insulating material and a preparation method thereof. The material comprises the following components: PVC resin (100 parts), a plasticizer (10-60 parts), a stabilizer (1-6 parts), sound insulating functional particles (30-90 parts) and filler (0-100 parts), and can also comprise a flame retardant and a smoke suppressant (5-20 parts), a lubricating agent (1-3 parts), an antioxidant (0.1-2 parts), an antistatic agent (0.1-2 parts) and a pigment (0.1-2 parts). The sound insulating functional particles include one or several of carbonate, sulfate, hydroxide, oxide and metal powder. The preparation method of the sound insulating material prepared from the components comprises the steps of raw material blending; extrusion granulating; and extrusion calendaring. The sound insulating material disclosed by the invention is prominent in sound insulating property, high in strength, flame-retardant, smoke-suppressant, nontoxic, environment-friendly as well as colorful and bright in color; and the preparation method is simple and convenient in production process and low in cost.

Owner:浙江兰溪金立达框业有限公司

High temperature and wear resistant graphene coating and preparation method thereof

The invention relates to a high temperature and wear resistant graphene coating, and the graphene coating is characterized by comprising the following components by weight percent: 35.0-60.0wt% of silicate, 0.01-20.0wt% of graphene, 0.1-25.0wt% of additive, and the balance of water as a solvent. The invention further provides a method for preparing the coating. The high temperature and wear resistant graphene coating disclosed by the invention can be used for well protecting matrixes by coating on pipelines, chemical equipment, storage, kiln furnace, medicine, aerospace and sewage, the service life of the matrix is prolonged, and the performance of the coating is much greater than that of a common material.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

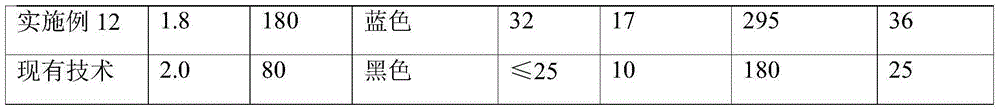

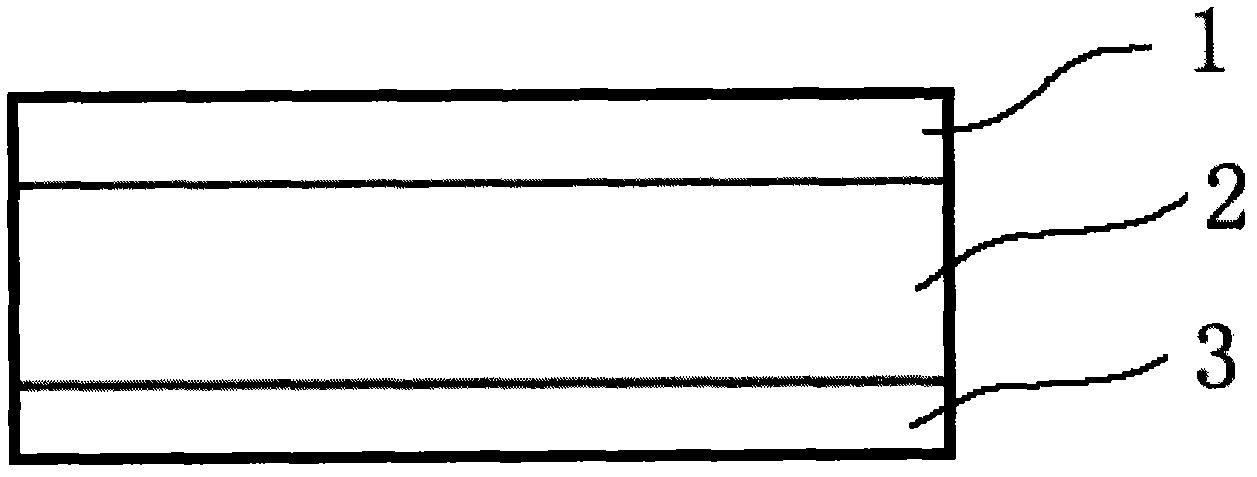

High barrier film and manufacturing method thereof

InactiveCN102837474AImprove barrier propertiesLow oxygen transmission rateSynthetic resin layered productsSurface layerLow oxygen

The invention provides a high barrier film and a manufacturing method thereof. The high barrier film is a three-layer structure composed of a first surface layer, a core layer, and a second surface layer. The first surface layer is composed of 0-0.3wt% of a slipping agent, 0-0.5wt% of an anti-block agent, 10-40 wt% of MXD6, and 59.2-90 wt% of PA6 chips; the core layer is composed of 60-95 wt% of MXD6, and 5-40 wt% of PA6 chips; and the second surface layer is composed of 0-0.3wt% of a slipping agent, 0-0.5wt% of an anti-block agent, 10-40 wt% of MXD6, and 59.2-90 wt% of PA6 chips. The high barrier film above has greatly improved barrier performance, and has the characteristics of excellent barrier property, low oxygen transmission rate of the film, and good transparency and flexibility.

Owner:厦门长塑实业有限公司

Elastomer composite and method for producing it

A method of producing an elastomer composite. The method includes A) combining a first fluid comprising elastomer latex with a second fluid comprising particulate filler; B) causing the elastomer latex to coagulate, thereby forming masterbatch crumb; C) bringing the masterbatch crumb to a water content of about 1 weight percent to about 20 weight percent, thereby forming a dewatered coagulum; D) removing water from the dewatered coagulum by subjecting the dewatered coagulum to mechanical energy, thereby causing the dewatered coagulum to heat as a result of friction, while allowing the dewatered coagulum to achieve a temperature of about 130° C. to about 190° C., wherein water content is reduced to about 0.5% to about 3% and wherein substantially all of the decrease in water content is accomplished by evaporation, thereby producing a masticated masterbatch; and E) subjecting the masticated masterbatch to at least an additional 0.3 MJ / kg of mechanical energy while further reducing the water content.

Owner:CABOT CORP

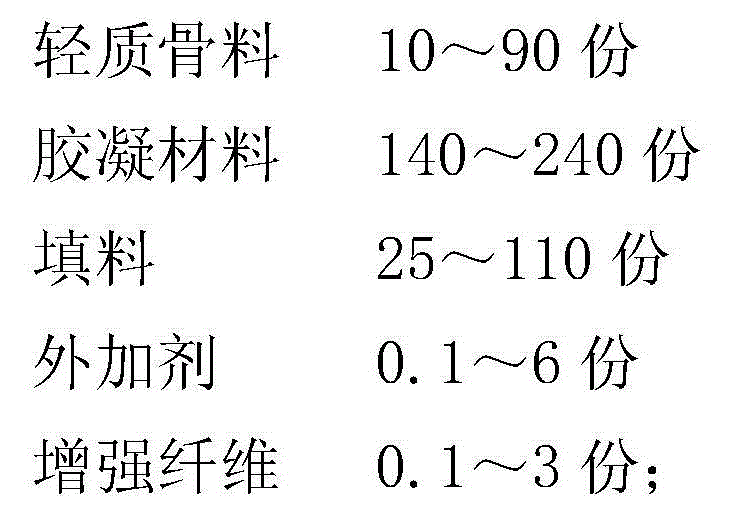

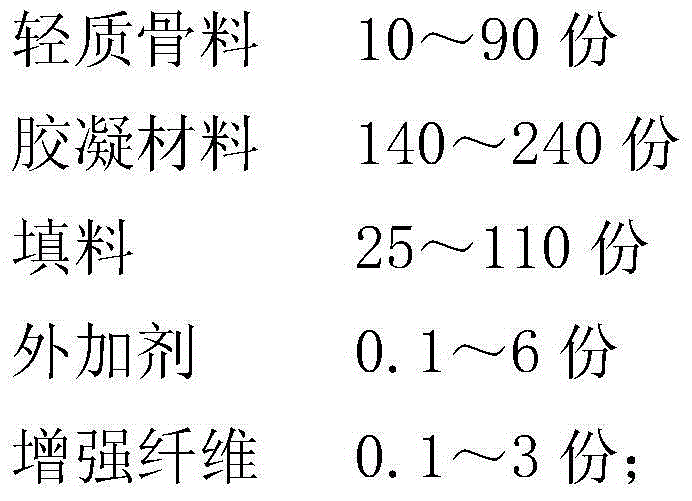

Fireproof decorative board base material

The invention provides a fireproof decorative board base material. The fireproof decorative board base material comprises 10 to 90 parts of lightweight aggregate, 140 to 240 parts of gel material, 25 to 110 parts of filler, 0.1 to 6 parts of additives and 0.1 to 3 parts of reinforced fibers; the lightweight aggregate comprises 10 to 60 parts of perlite; the gel material consists of an organic gel material and an inorganic gel material; additives are one or combination of more of water reducing agent, early strength agent, accelerating agent, defoaming agent, air entraining agent, water repellent, curing agent, dispersing agent, coupling agent, flame retardant and smoke inhibitor; the reinforced fibers are one of asbestos, paper pulp, polypropylene fibers, fluorine resin fibers and glass fibers. Compared with the prior art, the fireproof decorative board base material has the beneficial effects that the base material which is high in strength, high in fireproof grade, small in density and likely to composite with an aluminum foil is provided, the base material is composited with the aluminum foil to form a decorative board, and a novel solution is provided for the decoration of an outer wall.

Owner:SNTO TECH GRP

Sheet-form, curable pressure-sensitive adhesive

InactiveUS6376070B1Easy compoundMaintain good propertiesAdhesive processesFilm/foil adhesives without carriersPolymer scienceAdhesive

A sheet-form, curable pressure-sensitive adhesive is disclosed which includes a high molecular weight polymer (A) such as an acrylic polymer for constituting a pressure-sensitive adhesive component, a compound (B) containing an epoxy group, and a polymerization initiator (C) which is activated upon application of an activation energy such as a light to cause the compound (B) having an epoxy group to undergo a ring-opening polymerization.

Owner:SEKISUI CHEM CO LTD

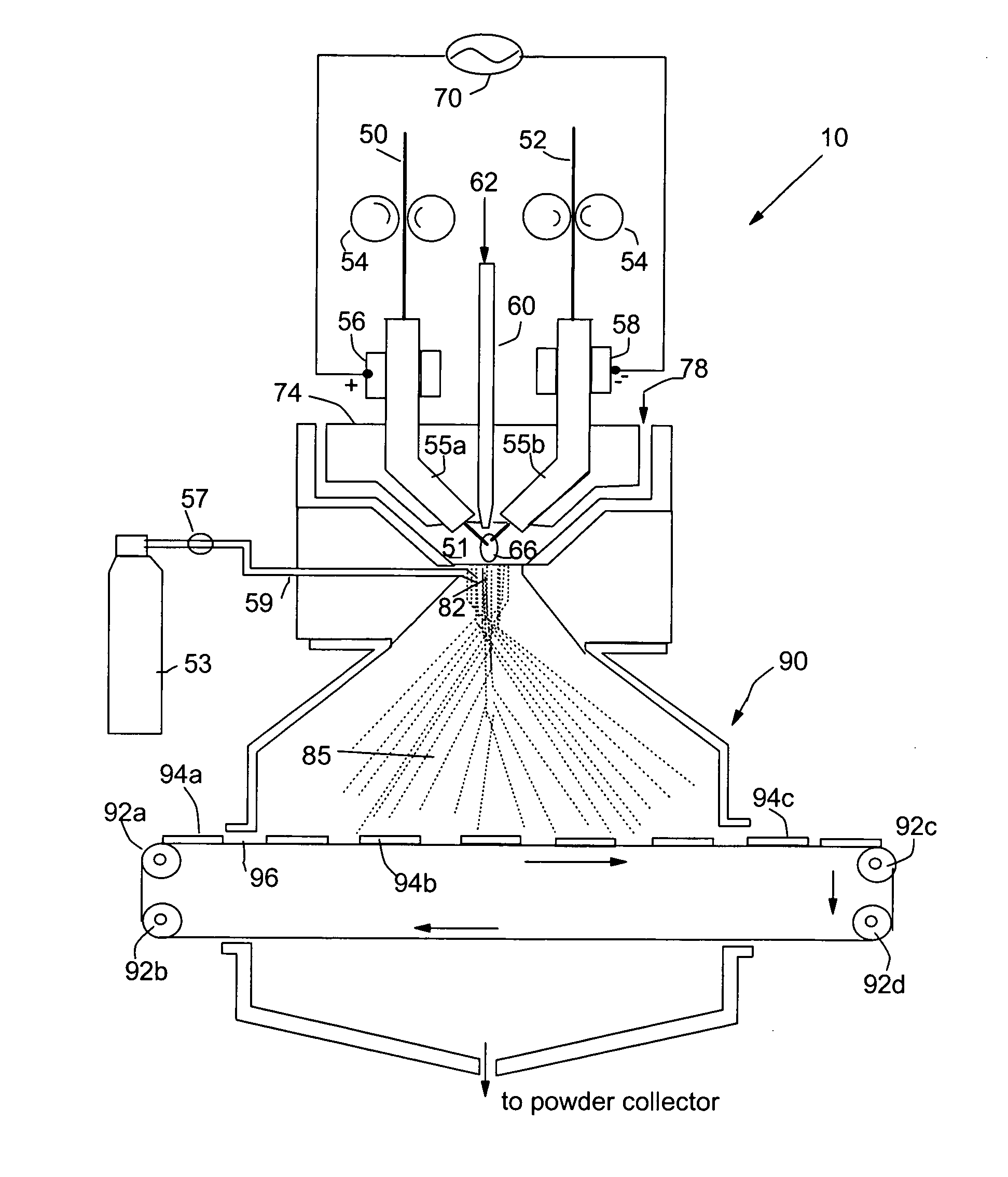

Twin-wire arc deposited electrode, solid electrolyte membrane, membrane electrode assembly and fuel cell

InactiveUS20050106435A1Easy to operateLow production costSolid electrolytesMolten spray coatingCoated membraneNanostructure

A twin-wire arc deposition method for depositing a nano-structured catalyst coating onto a solid electrolyte membrane or an electrode substrate from a precursor catalyst material selected from the group consisting of a metal, metal alloy, metal compound, and ceramic material. The method includes the steps of (a) providing an ionized arc nozzle comprising two consumable electrode and a working gas flow to form an ionized arc between the two electrodes, wherein the consumable electrodes provide the precursor catalyst material vaporizable therefrom by the ionized arc; (b) operating the arc nozzle to heat and at least partially vaporize the precursor catalyst material for providing a stream of nanometer-sized vapor clusters of the precursor catalyst material into a chamber in which the membrane or the electrode substrate has been placed; and (c) introducing a stream of a carrier gas into the chamber to impinge upon the stream of precursor vapor clusters to produce depositable nano clusters which are carried by the carrier gas to deposit onto a first side of the membrane or the electrode substrate for forming the nano-structured catalyst coating. Such a catalyst-coated membrane or electrode can be incorporated as a part of a fuel cell.

Owner:JANG BOR Z +2

Backing Sheet For Photovoltaic Modules

InactiveUS20090078314A1Improve adhesionGood color retentionSynthetic resin layered productsElectrical equipmentFluoropolymerHydrophobic silica

The present invention provides a protective backing sheet for photovoltaic modules. The backing sheet has a layer including fluoropolymer which is cured on a substrate, and the layer includes a hydrophobic silica. The amount of hydrophobic silica contained in the layer is within the range of 2.5 to 15.0% by weight, and preferably in the range of 7.5 to 12.5%. Also, the layer including fluoropolymer may further include a titanium dioxide.

Owner:MADICO INC

Heavy metal-contaminated soil remediation agent and preparation method thereof

InactiveCN105567247AHigh porosityHigh adsorption valueOther chemical processesOrganic fertilisersSodium BentoniteActivated Aluminum Oxide

The invention provides a heavy metal-contaminated soil remediation agent. The remediation agent is prepared from, by weight, 30%-45% of quick lime, 10%-25% of biomass charcoal, 10%-15% of kieselguhr, 10%-15% of sodium bentonite, 10%-15% of activated aluminum oxide, 5%-10% of nitrilotriacetic acid, 1%-5% of sodium lignin sulfonate and 1%-5% of sodium dodecyl sulfate. A preparation method comprises the steps that the quick lime, the biomass charcoal, the kieselguhr, the sodium bentonite, activated aluminum oxide, nitrilotriacetic acid, sodium lignin sulfonate and sodium dodecyl sulfate are stirred and mixed to be uniform according to the weight ratio, and then the soil remediation agent is prepared. The prepared soil remediation agent has the good effect when cadmium-lead-zinc-mercury compound contaminated soil is remedied.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Flaky nanometer molybdenum disulfide material, nanometer composite metal anticorrosive coating material and preparation method of flaky nanometer molybdenum disulfide material and nanometer composite metal anticorrosive coating material

InactiveCN104176781AEasy to prepareImprove efficiencyMaterial nanotechnologyAnti-corrosive paintsLamellar crystalsMetallic materials

The invention discloses a preparation method of a flaky nanometer molybdenum disulfide material. The preparation method comprises the steps of dispersing a raw material, namely molybdenum disulfide with a lamellar crystal structure, into a mixed solution of nitric acid and hydrochloric acid; carrying out liquid phase separation by using a heating or ultrasound method; and reacting to obtain the flaky nanometer molybdenum disulfide material. The invention also discloses a nanometer composite metal anticorrosive coating material and a preparation method thereof. The nanometer composite metal anticorrosive coating material is prepared by compounding flaky nanometer molybdenum disulfide and nanometer silicon dioxide sol. The preparation method disclosed by the invention is simple; the raw material is easily available; the flaky nanometer molybdenum disulfide material and the nanometer composite metal anticorrosive coating material are widely applied to the antirust treatment and performance improvement of metal materials; the service life of metal is prolonged; and the energy consumption is reduced.

Owner:EAST CHINA NORMAL UNIV

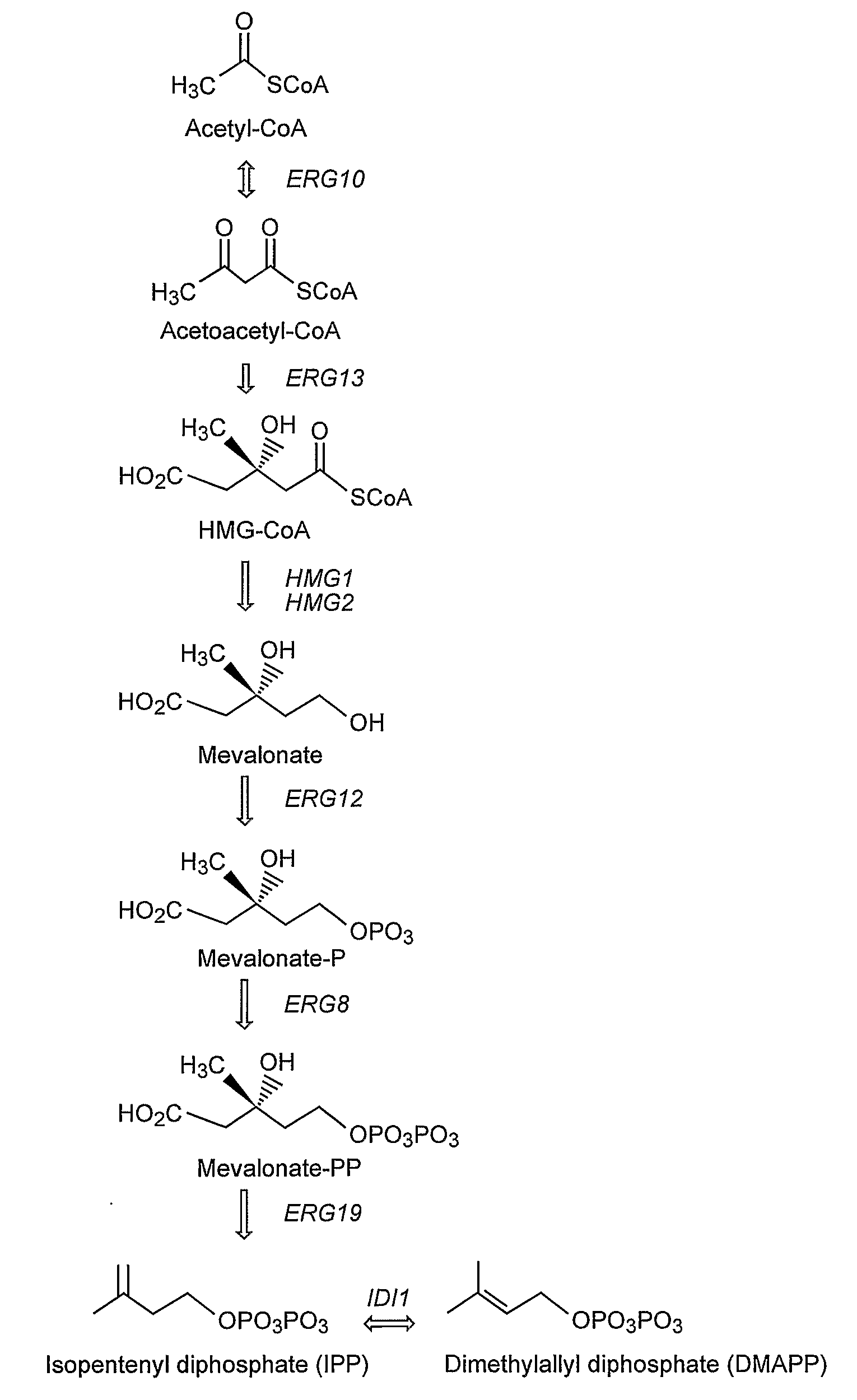

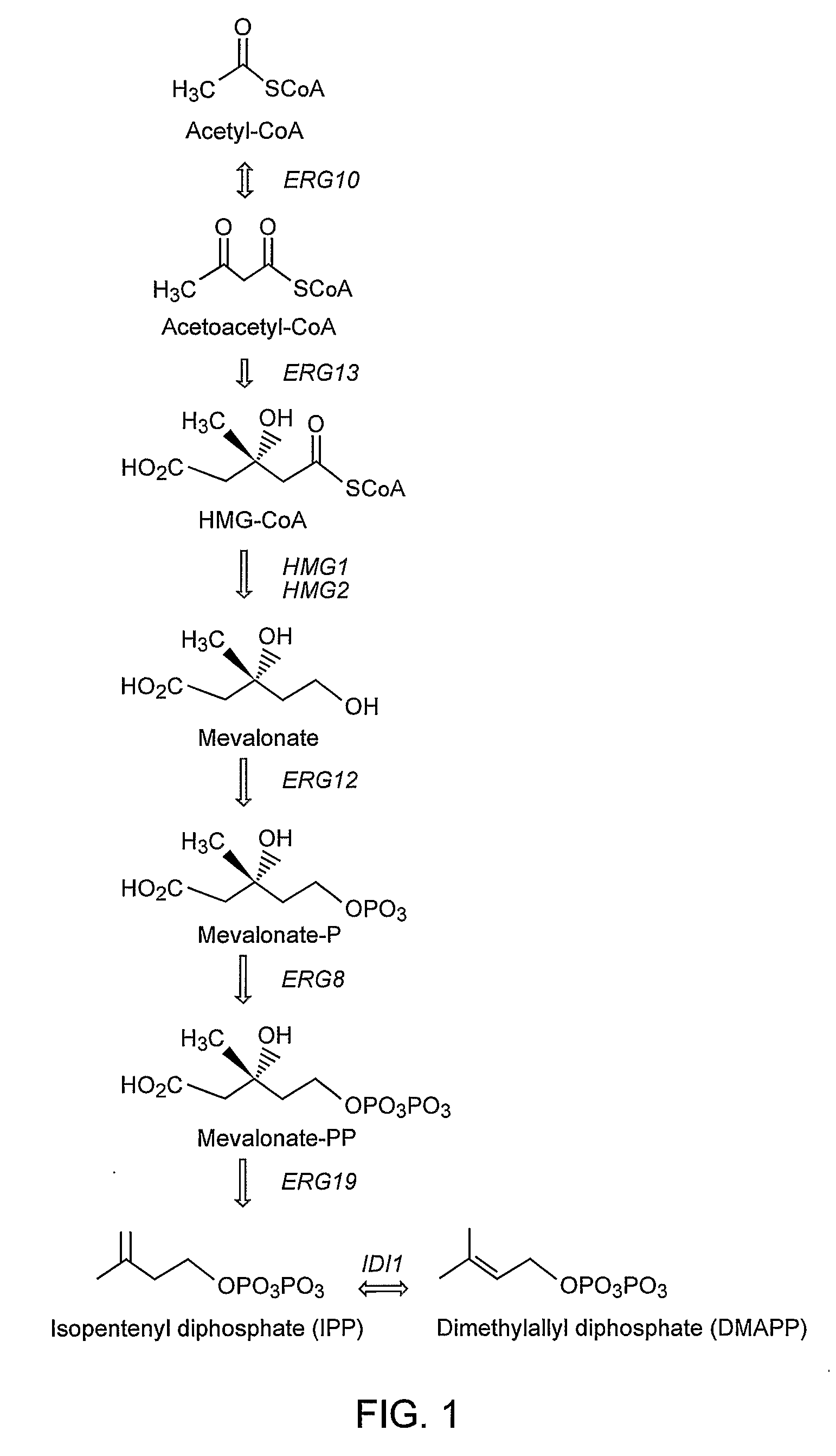

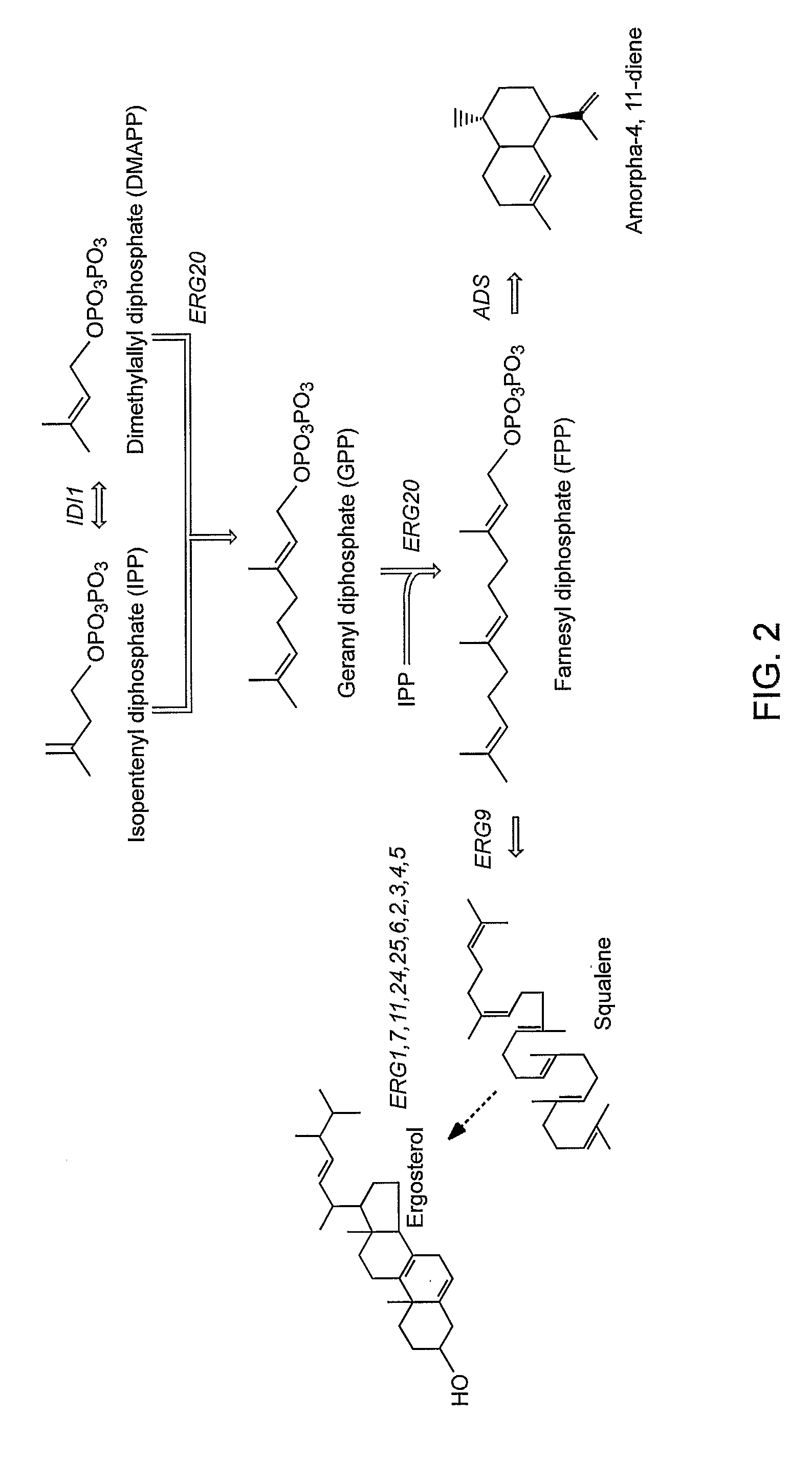

Genetically Modified Host Cells And Use Of Same For Producing Isoprenoid Compounds

ActiveUS20080171378A1Improve the level ofLower Level RequirementsMicroorganismsTransferasesPrenylationSqualene synthase activity

The present invention provides genetically modified eukaryotic host cells that produce isoprenoid precursors or isoprenoid compounds. A subject genetically modified host cell comprises increased activity levels of one or more of mevalonate pathway enzymes, increased levels of prenyltransferase activity, and decreased levels of squalene synthase activity. Methods are provided for the production of an isoprenoid compound or an isoprenoid precursor in a subject genetically modified eukaryotic host cell. The methods generally involve culturing a subject genetically modified host cell under conditions that promote production of high levels of an isoprenoid or isoprenoid precursor compound.

Owner:RGT UNIV OF CALIFORNIA

Formula of aquatic product composite preservative

InactiveCN106259830AStrong Broad Spectrum ResistanceEnhanced inhibitory effectNatural extract food ingredientsMeat/fish preservation using chemicalsPropolisAllium sativum

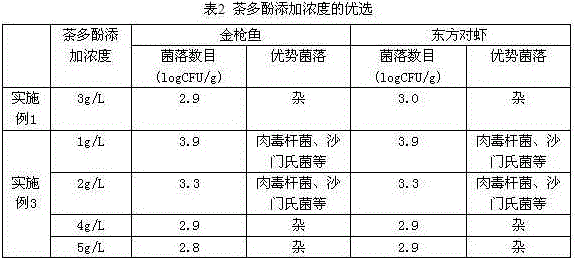

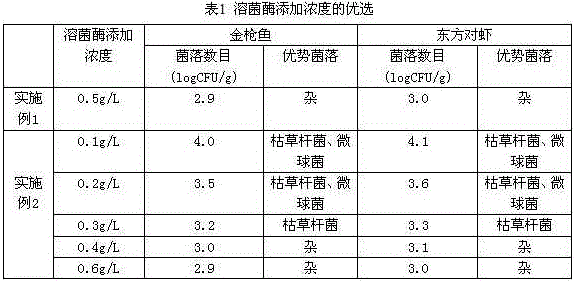

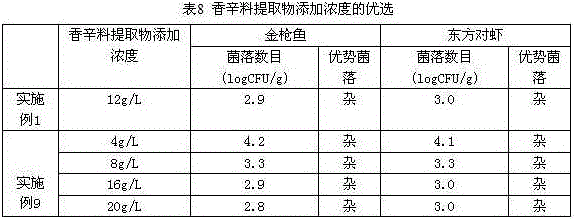

The invention relates to a formula of an aquatic product composite preservative. The formula of the aquatic product composite preservative is characterized in that the aquatic product composite preservative in each liter of distilled water comprises the following components: 0.4 to 0.6 g of muramidase, 2.5 to 3.5 g of tea polyphenol, 16 to 20 g of carboxymethyl chitosan, 10 to 14 g of nisin, 25 to 35 g of potassium sorbate, 17 to 23 g of sodium alginate, 20 to 30 g of lactobacillus, 1.5 to 2.5 g of propolis extracts and 10 to 14 g of spice extracts; and the spice extracting liquid comprises the raw materials: galangal, garlic, onion, cinnamon, clove and rosemary. The aquatic product composite preservative provided by the invention is prepared by compounding biological preservatives, is safe and non-toxic, has simple preparation and application methods, prominent microbial inhibition effect and good preservation effect, can greatly prolong the shelf life of frozen aquatic products, and has important industrial value.

Owner:黎建波

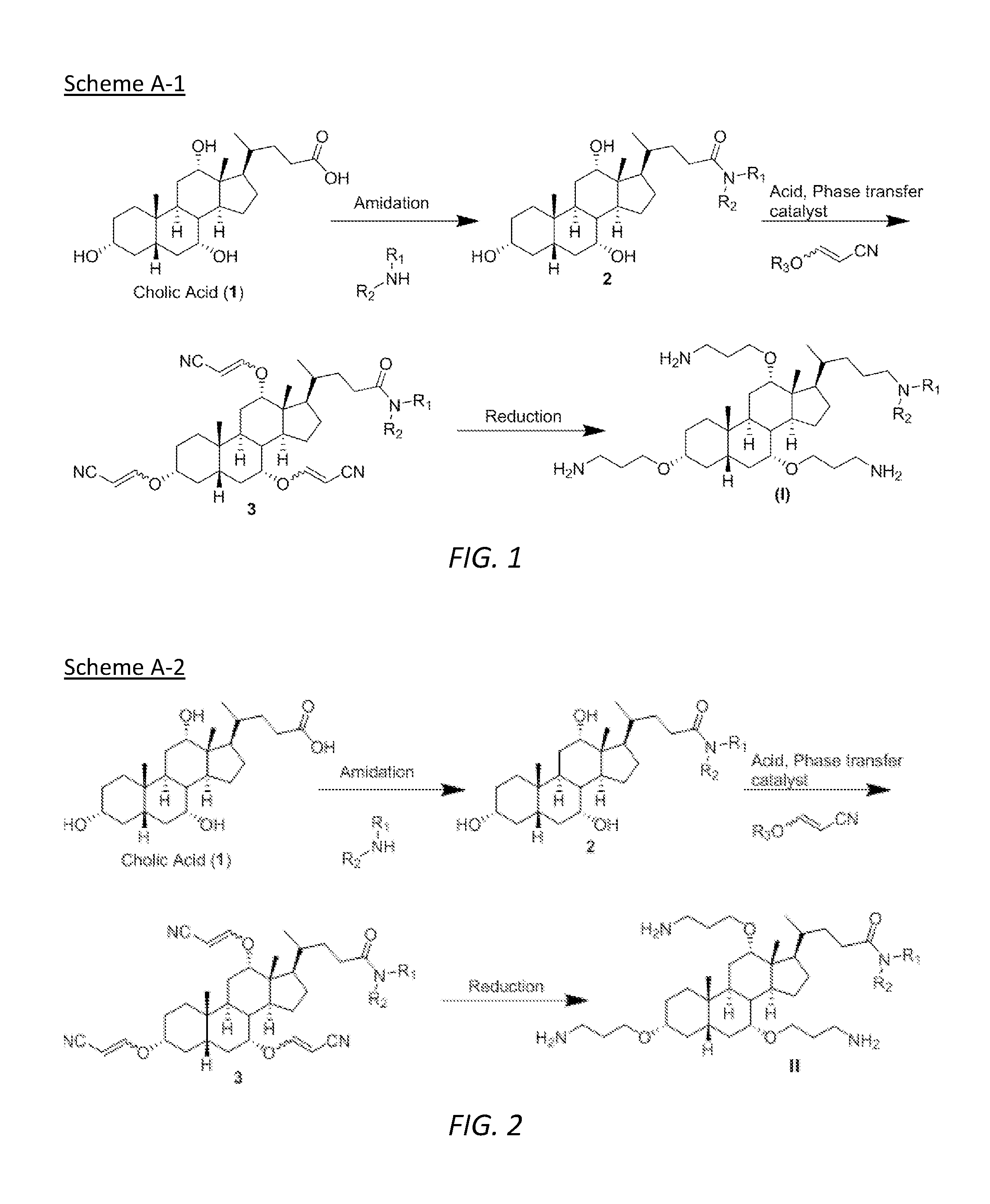

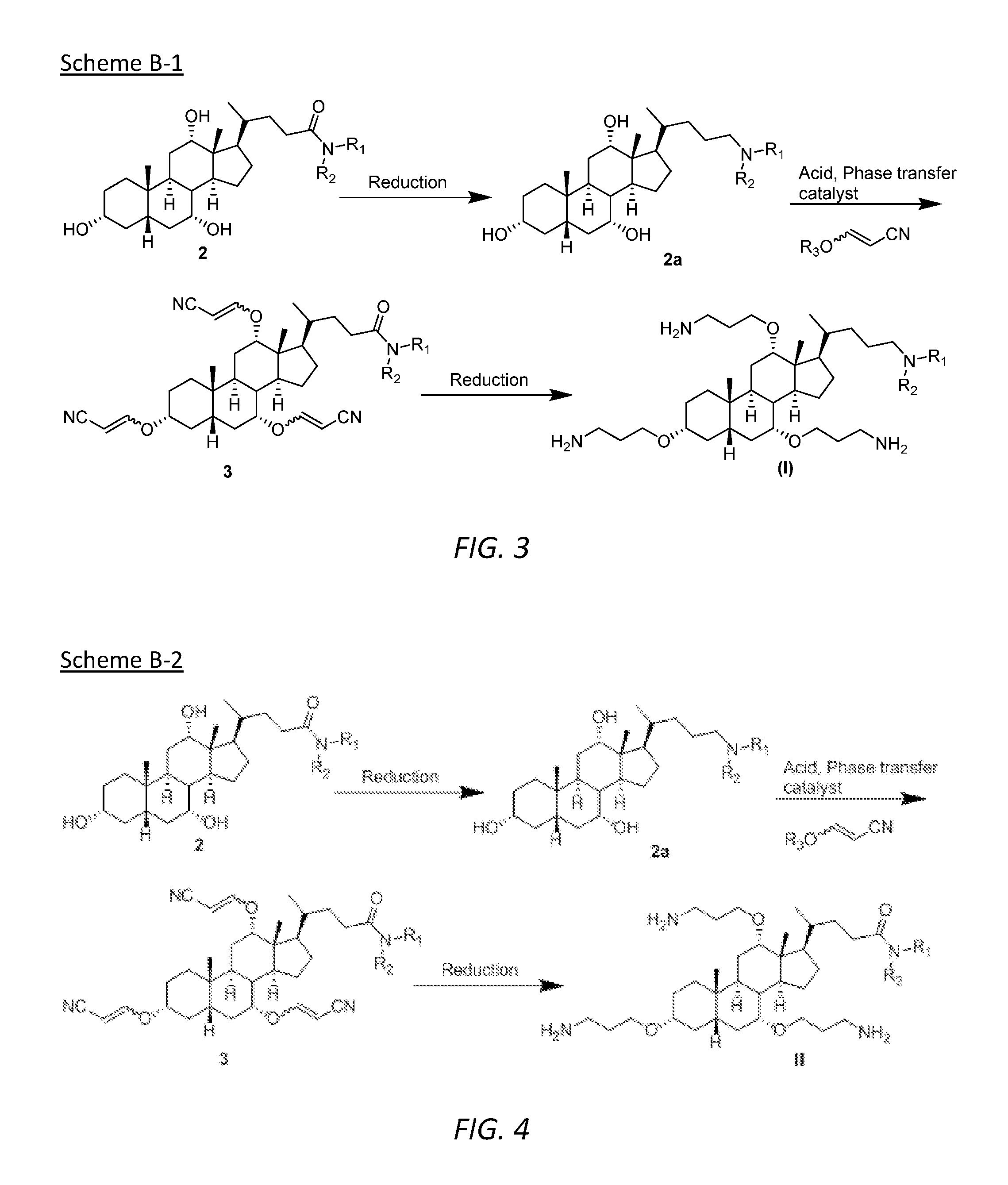

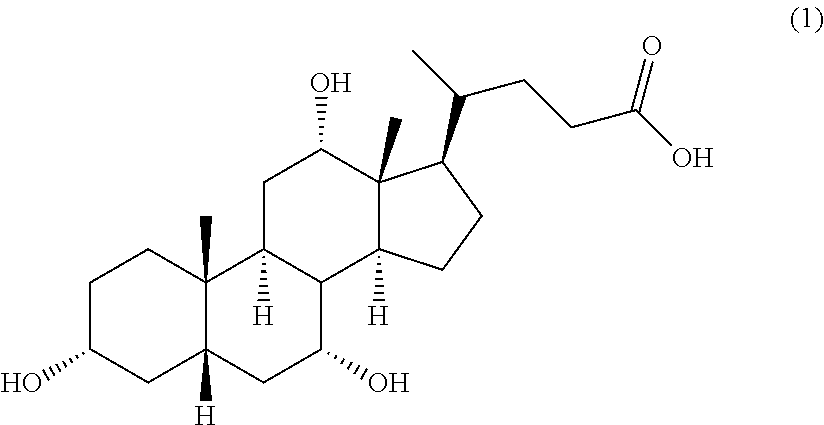

Methods for the synthesis of ceragenins

Disclosed herein are methods of making ceragenin compounds for treating, preventing, or diagnosing diseases, disorders, or conditions associated with bacterial or viral infections, cancer, inflammation, and osteogenesis. Ceragenin compounds display broad spectrum antibacterial activity utilizing a mode of action similar to antimicrobial peptides, but without the high synthesis costs and susceptibility to proteolytic degradation. Ceragenin compounds reproduce the amphiphilic morphology found in many antimicrobial peptides and display potent and diverse biological activities, including anti-bacterial, anti-cancer, anti -inflammatory, bone growth promotion, and wound healing promotion.

Owner:BRIGHAM YOUNG UNIV

Heavy metal cadmium, lead and arsenic compound contaminated soil restorative agent and preparation method thereof

InactiveCN105754610AHigh porosityHigh adsorption valueContaminated soil reclamationOrganic fertilisersSodium BentoniteActivated Aluminum Oxide

The invention provides a heavy metal cadmium, lead and arsenic compound contaminated soil restorative agent. The heavy metal cadmium, lead and arsenic compound contaminated soil restorative agent is prepared from the following components in percentage by weight: 30-50 percent of biomass charcoal, 5-10 percent of diatomite, 5-10 percent of sodium bentonite, 5-10 percent of activated aluminum oxide, 10-20 percent of dithiocar-bamate, 5-10 percent of ethylenediaminetetraacetic acid, 5-10 percent of tartaric acid, 5-10 percent of polyacrylamide and 5-10 percent of sodium dodecyl sulfate. A preparation method for the heavy metal cadmium, lead and arsenic compound contaminated soil restorative agent comprises the following steps: mixing the biomass charcoal, diatomite, sodium bentonite, activated aluminum oxide, ethylenediaminetetraacetic acid, tartaric acid, polyacrylamide and sodium dodecyl sulfate in mass proportion to obtain a mixture; and adding the dithiocar-bamate into the mixture in corresponding mass proportion to sufficiently mix uniformly, thereby obtaining the prepared soil restorative agent. The prepared soil restorative agent has good effect in restoring the cadmium, lead and arsenic compound contaminated soil.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

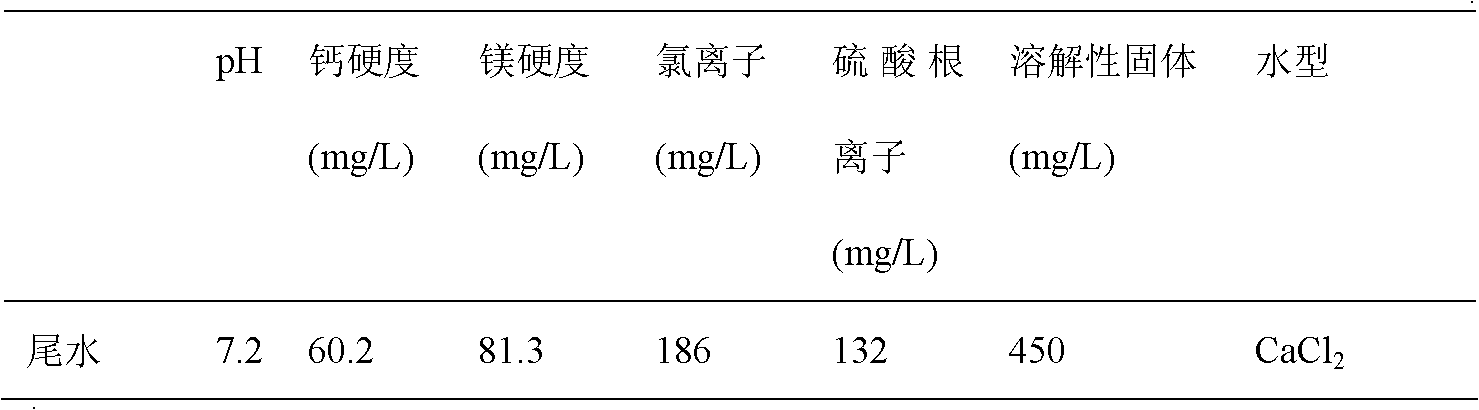

Scale and corrosion inhibitor

InactiveCN103319010AReduce eutrophication pollutionImprove protectionScale removal and water softeningEutrophicationFluorescence

The invention relates to a scale and corrosion inhibitor, comprising organic phosphonate, an inorganic scale and corrosion inhibition component, a carboxylic acid containing copolymer, zinc salt, a heterocyclic compound and a fluorescence tracing component. The scale and corrosion inhibitor is easy to compound, has good stability, and has good scale and corrosion inhibition performances for reusing tail water of a sewage plant into a circulating cooling system under a low addition amount; the scale and corrosion inhibitor can be directly added into a reclaimed water reusing pipeline, without needing to supplement calcium and alkali into the tail water in advance and regulating a pH value, and has a good treating effect; the scale and corrosion inhibitor does not contain a toxic compound and inorganic phosphatic, contains little phosphor, can reduce eutrophication pollution of a water body, and is in favor of environment protection.

Owner:常州市排水管理处 +1

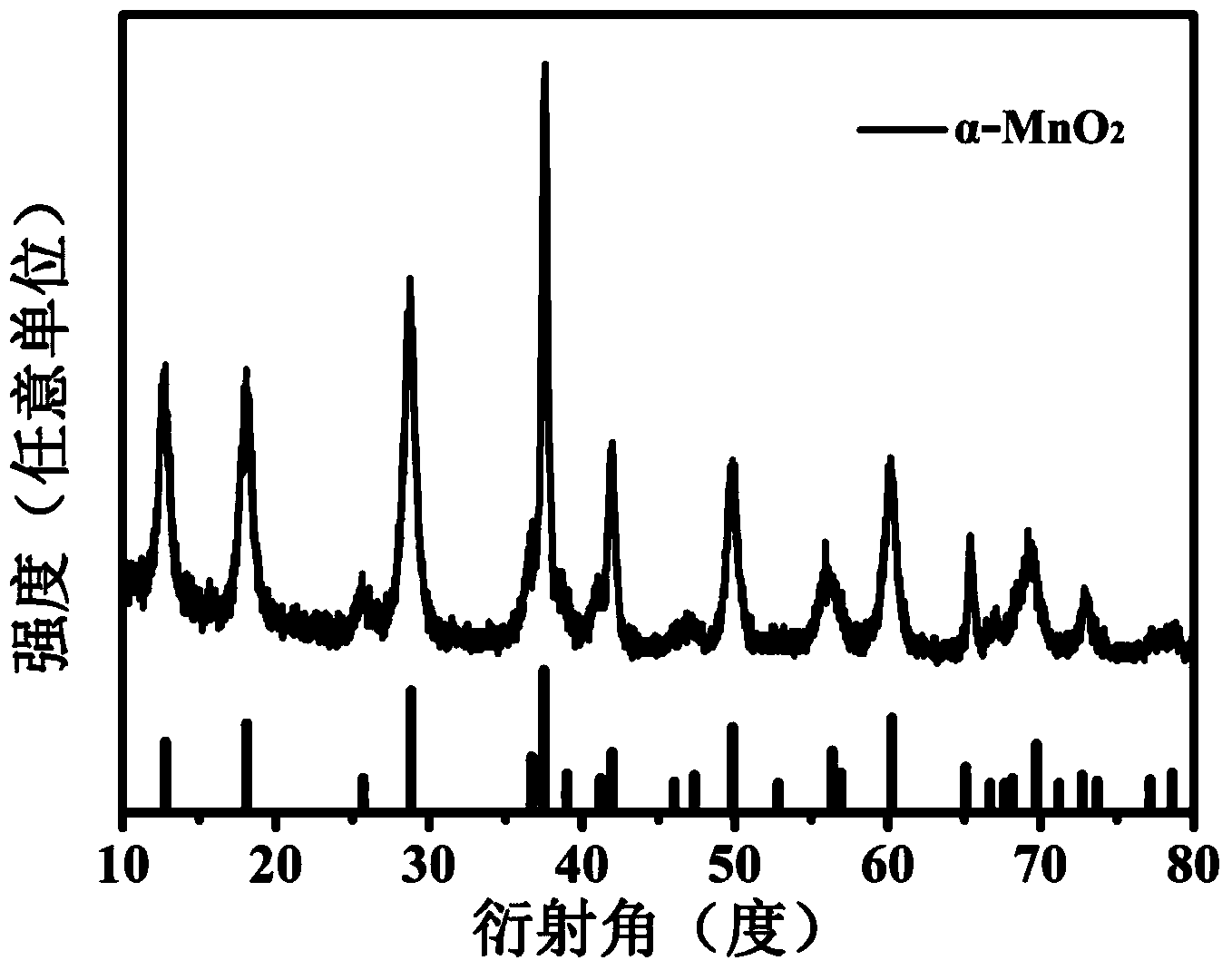

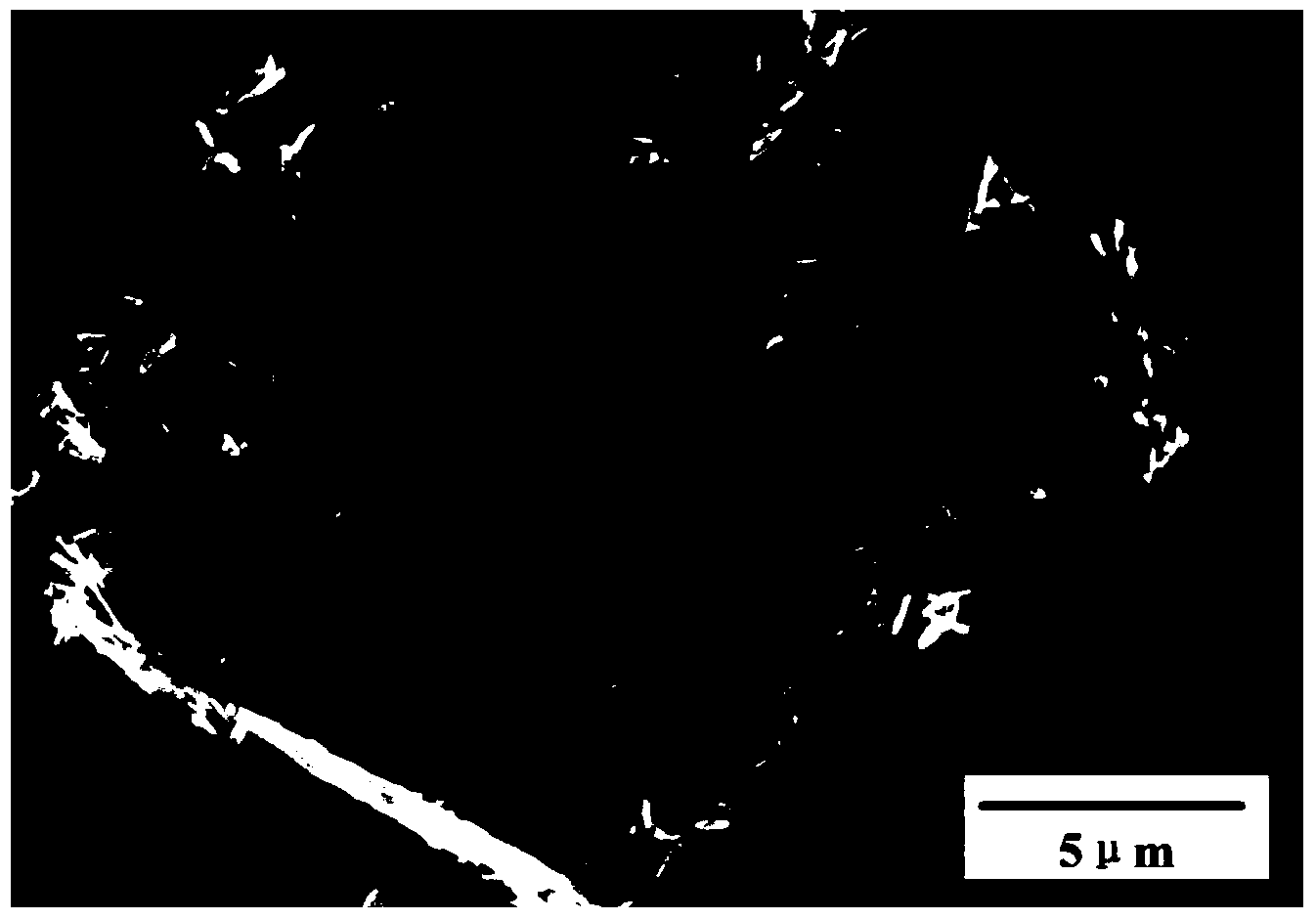

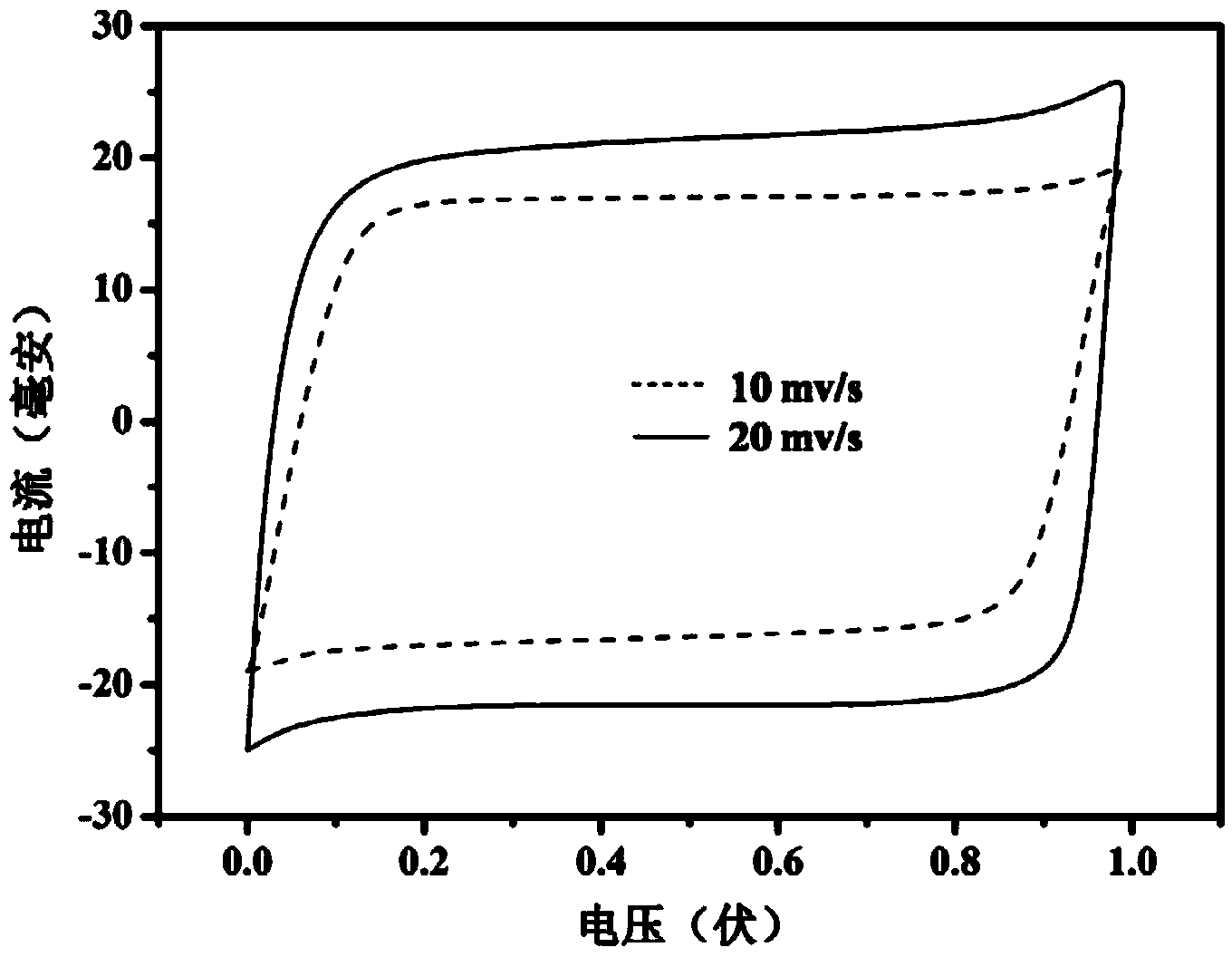

Manganese dioxide nanorod/graphene composite electrode material and preparation method thereof

InactiveCN103489660ALow costNo pollution in the processHybrid capacitor electrodesHybrid/EDL manufactureMaterials sciencePotassium permanganate

The invention belongs to the technical field of supercapacitor materials and provides a manganese dioxide nanorod / graphene composite electrode material and a preparation method thereof. The method comprises the following steps that graphite oxide is obtained through an improved Hummers method, the graphite oxide is reduced to be graphene by utilizing glucose and ammonium hydroxide, the graphene is dispersed into deionized water for ultrasonic processing and is mixed with equimolar manganese dioxide solution and potassium permanganate solution, and a precursor is obtained; hydrothermal reaction is conducted on the precursor for 8-24 hours at 120-180 DEG C; a reaction product is centrifuged, filtered, washed and dried for 24 hours at 180 DEG C, and the pure manganese dioxide nanorod / graphene composite electrode material is obtained. The preparation method of the manganese dioxide nanorod / graphene composite electrode material is simple in process and high in repeatability. The material has the good electrochemical property and is suitable for being used as an electrode material for a supercapacitor.

Owner:BEIJING UNIV OF TECH

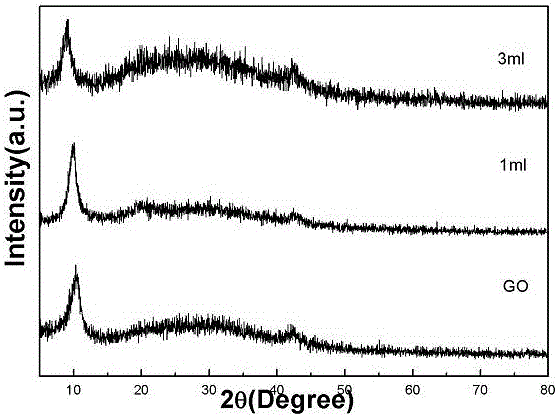

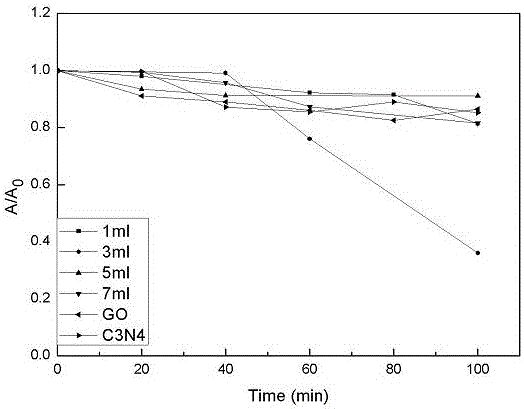

g-CNQDs/GO composite photocatalysis material preparation method

ActiveCN106111176ALarge specific surface areaEasy to separateWater/sewage treatment by irradiationWater treatment compoundsOrganic dyeOxide composite

The present invention provides a g-CNQDs / GO composite photocatalysis material preparation method. The concrete scheme of the method comprises that graphite powder, urea and concentrated nitric acid are used as main raw materials, an electrostatic coupling method is used, and four steps such as oxidation of graphene, oxidation of graphite phase carbon nitride quantum dots, oxidation of protonated graphite phase carbon nitride quantum dots, and g-CNQDs / GO compounding are performed to prepare the graphite phase carbon nitride quantum dot / graphene oxide composite photocatalysis material. According to the present invention, the photocatalytic property test on the prepared composite photocatalysis material is performed with visible light ([lambda] is more than 420 nm), and the results of the degradation on rhodamine B, methyl orange and other organic dyes show that the composite photocatalyis material has the excellent photocatalytic performance under the visible light.

Owner:NANCHANG HANGKONG UNIVERSITY

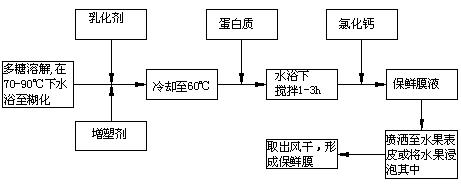

Method for preparing edible preservative film of fresh fruit

InactiveCN103583676AGood gas and moisture barrierEasy to operateFruits/vegetable preservation by coatingMoisture resistancePolysaccharide

The invention relates to a method for preparing an edible preservative film of a fresh fruit. The method comprises the steps as follows: (1) an edible preservative film solution is prepared as follows: Step 1: water is added to dissolve polysaccharide, and a water bath at 70-90 DEG C is performed till the polysaccharide is gelatinized completely; Step 2: an emulsifying agent and a plasticizing agent are added; Step 3: after the mixture is cooled to 60 DEG C, protein is added; Step 4: the mixture is stirred for 1-3h under the condition of the water bath; Step 5: calcium chloride is added; and Step 6: the mixture is cooled to the room temperature, and then the preservative film solution is obtained; and (2) the fresh fruit is soaked in the preservative film solution, taken out and air-dried quickly, or the preservative film solution is sprayed to the skin of the fresh fruit, and the preservative film is formed after quick air-drying. The preparation method is simple in technological operation and low in production cost, and the formed preservative film is good in gas and moisture resistance, transparent, glossy, high in safety and capable of remarkably prolonging the storage period of the fruit.

Owner:FUZHOU WEST FOOD LIMITED

Preparation method of graphene and ultrahigh-molecular-weight polyethylene composite fiber

ActiveCN108315833AHigh strengthImproves UV resistanceMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberPolymer science

The invention provides a preparation method of a graphene and ultrahigh-molecular-weight polyethylene composite fiber. The preparation method comprises the following steps: S1: dispersing ultrahigh-molecular-weight polyethylene resin and a filler into a solvent by adopting a blending method to form a uniform resin dispersion solution; S2: adding graphene powder into a dispersant, heating the mixture to certain temperature, adding an emulsifier for emulsification, and obtaining a graphene dispersion solution; S3: adding the graphene dispersion solution into the resin dispersion solution, and stirring and heating the mixed solution to obtain a spinning solution; S4: performing spinning, precursor fiber stewing and thermal stretching on the spinning solution, thus obtaining the graphene and ultrahigh-molecular-weight polyethylene composite fiber. According to the preparation method provided by the invention, the intensity of the ultrahigh-molecular-weight polyethylene fiber is enhanced byadding a filling material and graphene into ultrahigh-molecular-weight polyethylene fiber, so that the final intensity is up to 30 to 45 cN / dtex; in addition, the composite fiber further has excellent properties of ultraviolet resistance, cutting resistance and the like.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Efficient suspension liquid fertilizer containing fulvic acid for lettuce and preparation method thereof

InactiveCN106064983APromote absorptionImprove drought resistance and cold resistanceAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersTrace elementPotassium

The invention discloses a method applied to efficient suspension liquid fertilizer containing fulvic acid for lettuce. The suspension liquid fertilizer includes, by weight, 10-25 parts of fulvic acid, 35-50 parts of major element, 1-10 parts of medium element, 0.2-3 parts of trace element, 0-3 parts of functional substance, 3-5 parts of suspended aid, 2-12 parts of a composite chelating agent, 0-1 parts of a defoaming agent, 0-1 parts of solution stabilizer, and a thickener. The preparation method comprises the steps of: adding water, potassium humate, nitrogen fertilizer and potassium fertilizer into a reactor A, and conducting high-speed stirring to prepare a saturated mother liquor; adding water, phosphate fertilizer, trace element material, a dispersing agent, a filler and partial defoaming agent into a reactor B, conducting high-speed stirring and grinding for the formation of a solid-liquid mixture; mixing the saturated mother liquor and solid-liquid the mixture, adding a thickening agent, residual defoaming agent and an anti-freezer, and emulsifying to prepare a suspension liquid fertilizer. The invention has the advantages of high total nutrient content, no layering or deposition, and realization of long distance transportation.

Owner:GUANGDONG FENGKANG BIOTECH

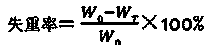

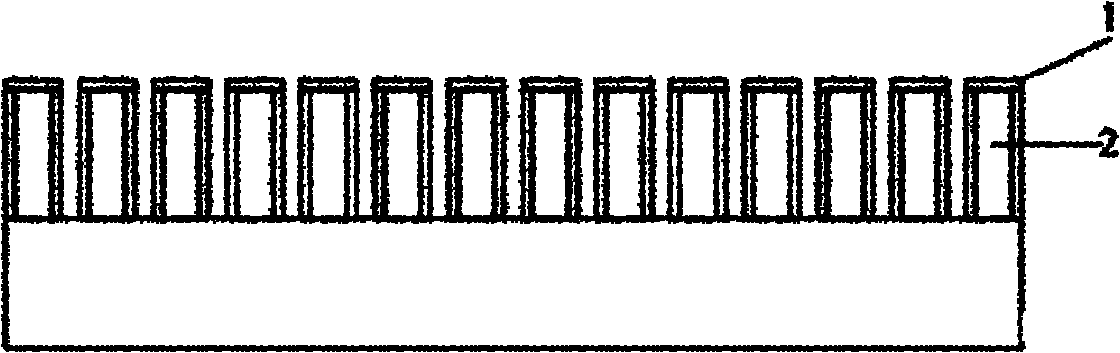

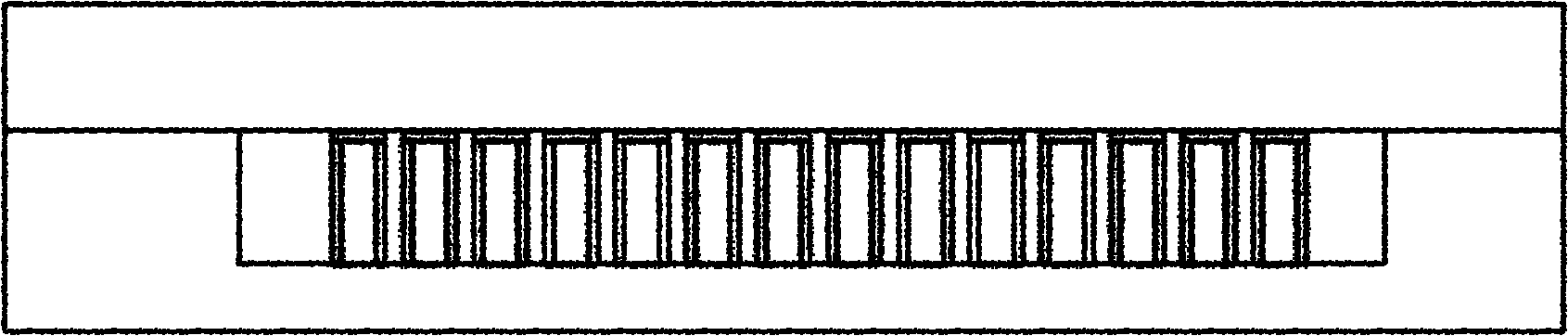

Preparation method for high-density interposer for microelectronic system-in-package

ActiveCN102070120AImprove reliabilitySmall coefficient of thermal expansionDecorative surface effectsChemical vapor deposition coatingThermal dilatationElectrical conductor

The invention discloses a preparation method for a high-density interposer for microelectronic system-in-package. The preparation method comprises the following steps of: 1, preparing a drectionally growing carbon nanotube bundle array, wherein the diameter of each carbon nanotube bundle is 0.5 to 30 microns, the gap of the carbon nanotube bundle is 0.8 to 100 microns, and the carbon nanotube bundle is 40 to 500 microns long; 2, depositing metal tungsten on the surface of the drectionally growing carbon nanotube bundle so as to form a conductor array; 3, melting borosilicate glass and compounding the melted borosilicate glass with the conductor array so as to form a compound body; and 4, grinding the upper surface and the lower surface of the formed compound body so as to expose the end of the carbon nanotube bundle deposited with the metal tungsten, and obtaining the high-density interposer for the system-in-package. The material adopted by the preparation method has low thermal expansivity and the process method is low in time consumption, so the prepared high-density interposer has the advantages of high density, high reliability and low cost.

Owner:SOUTHEAST UNIV

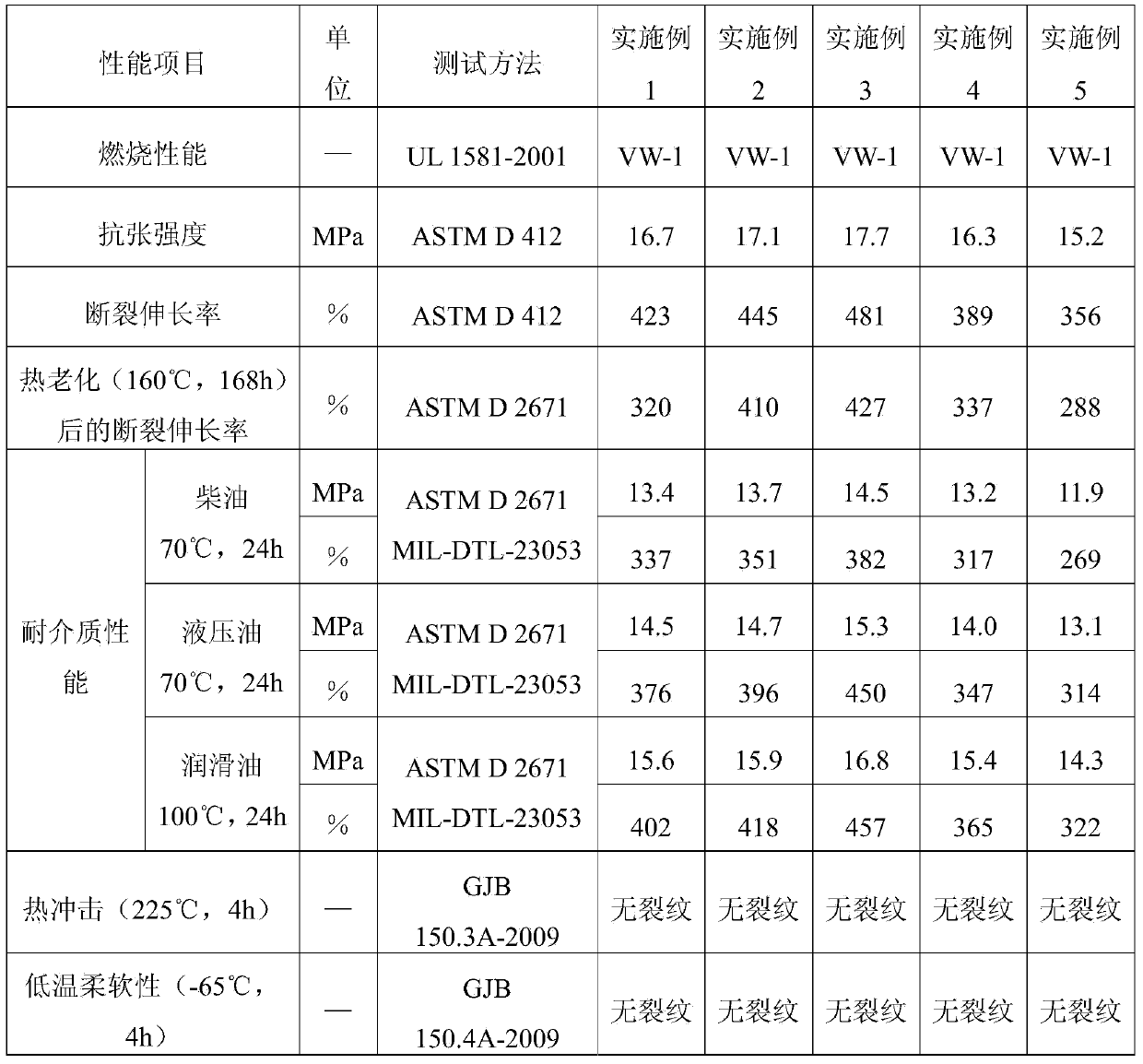

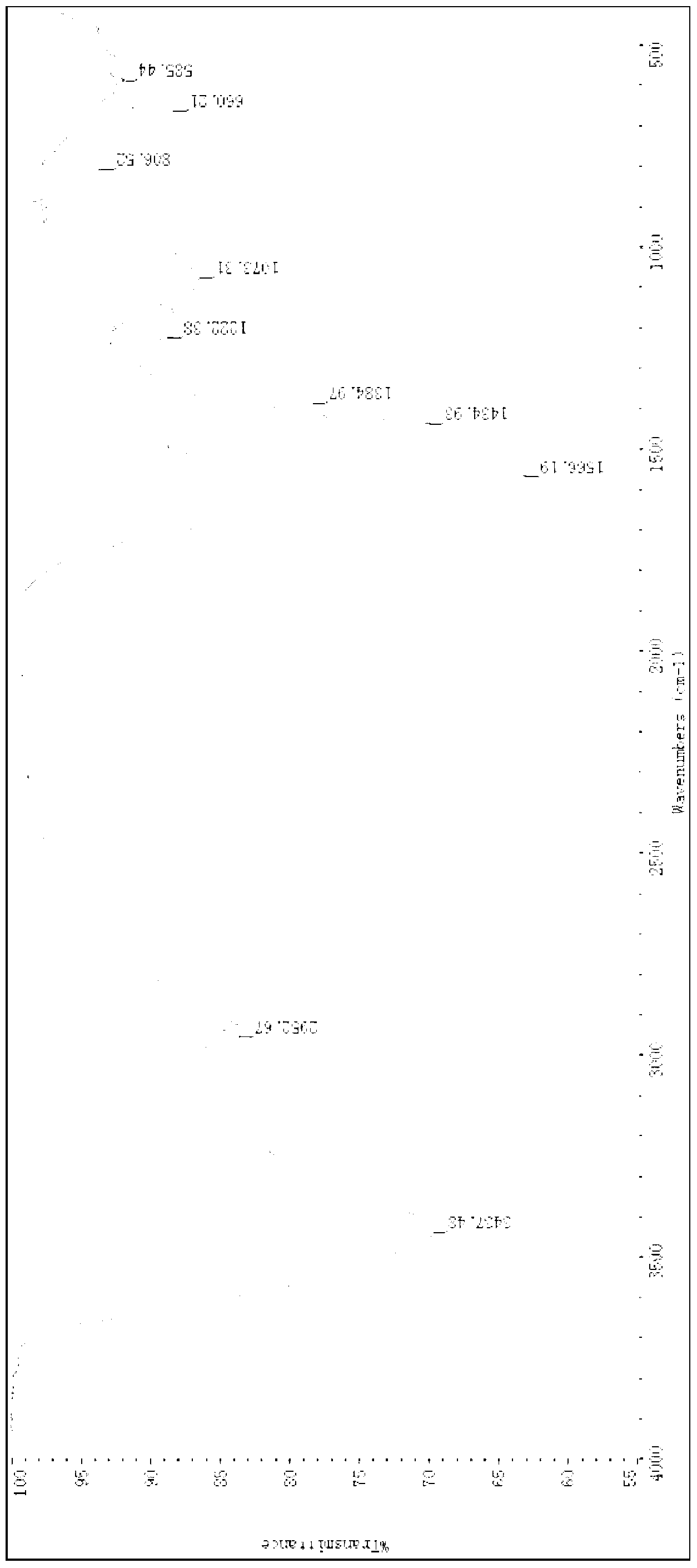

Thermoplastic polyester elastomer heat-shrinkable casing tube for automobile wire harness as well as preparation method and application of heat-shrinkable casing tube

The invention discloses a thermoplastic polyester elastomer heat-shrinkable casing tube for an automobile wire harness as well as a preparation method and an application of the heat-shrinkable casing tube. The heat-shrinkable casing tube comprises the following components in parts by weight: 50-80 parts of a thermoplastic polyester elastomer, 30-60 parts of halogen-containing resin, 5-15 parts of black masterbatch, 5-30 parts of diantimony trioxide, 0-100 parts of a flame retardant, 3-15 parts of a flame retardant synergist, 1-4 parts of a thermal stabilizer, 0.5-4 parts of an antioxidant, 0.5-2 parts of a silicone aid and 1-2.5 parts of a sensitizer. The preparation method comprises the following steps: mixing the thermoplastic polyester elastomer, the halogen-containing resin, the black masterbatch, diantimony trioxide, the flame retardant, the flame retardant synergist, the thermal stabilizer, the antioxidant and the silicone aid, adding the sensitizer, mixing, granulating, extruding to form a tube, performing irradiation crosslinking, stretching by expanding, shaping by cooling, flattening, and marking. The heat-shrinkable casing tube has the advantages of relatively low price, high-efficiency flame retardance, excellent mechanical property, low pollution, high-temperature oil resistance, acid-base corrosion resistance and capability of being applied in a severe working environment.

Owner:广州凯恒科塑有限公司

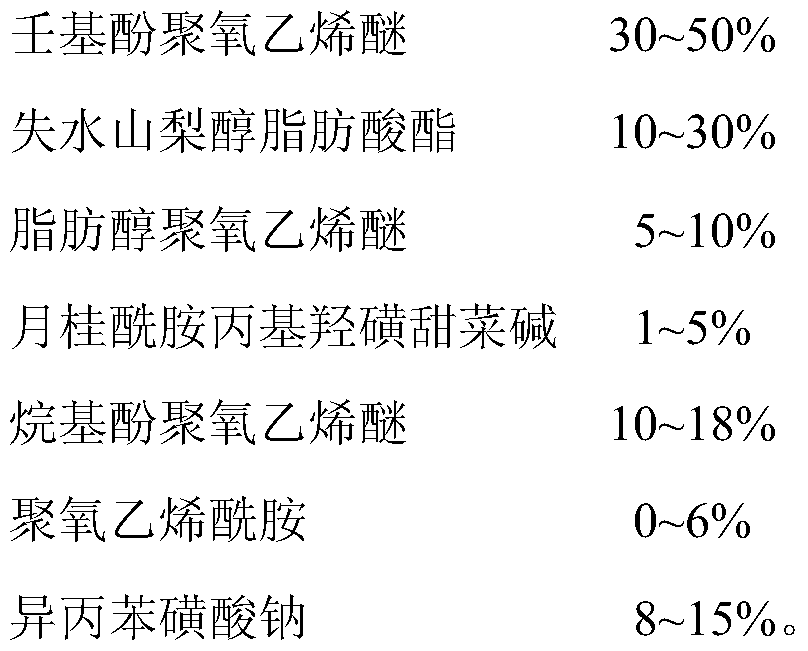

Multifunctional softener and preparation method for same

ActiveCN103321053AImprove biological activityPromote degradationFibre treatmentWater soluble chitosanAqueous solubility

The invention provides a multifunctional softener and a preparation method for the same. The multifunctional softener is composed of amino silicon oil, a compound emulsifier, water-soluble chitosan and water, wherein amino silicon oil is added in the compound emulsifier, and the mass ratio of the amino silicon oil to the compound emulsifier is 1:(0.2-0.8); then the water-soluble chitosan is added, and the added amount is 1-8% of the mass of the mixed solution of the amino silicon oil and the compound emulsifier; finally, water is added, and the mass of water is 10-50% of the total mass of the mixed solution aforementioned. The preparation method comprises the following steps of: preparation for the water-soluble chitosan, preparation for the compound emulsifier, and preparation for the multifunctional fabric softener. The multifunctional integrated softener obtained after compounding has all the excellent characteristics of modified chitosan on the basis of a soft function. Compared with the existing softener with an anti-bacterial function, the preparation process flow is simple, a complex configuration process is not required, and industrialized production is easy to realize.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Sheet-form, curable pressure-sensitive adhesive

InactiveUS20030026979A1Adequate initial cohesive strengthSufficiently tackyAdhesive processesFilm/foil adhesives without carriersActivation energyRing-opening polymerization

A sheet-form, curable pressure-sensitive adhesive is disclosed which includes a high molecular weight polymer (A) such as an acrylic polymer for constituting a pressure-sensitive adhesive component, a compound (B) containing an epoxy group, and a polymerization initiator (C) which is activated upon application of an activation energy such as a light to cause the compound (B) having an epoxy group to undergo a ring-opening polymerization.

Owner:SEKISUI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com