Fireproof decorative board base material

A decorative board and base material technology, applied in the field of building materials, can solve the problems of poor fire performance, fading, growth, etc., and achieve the effect of high strength, high fire rating, and small density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

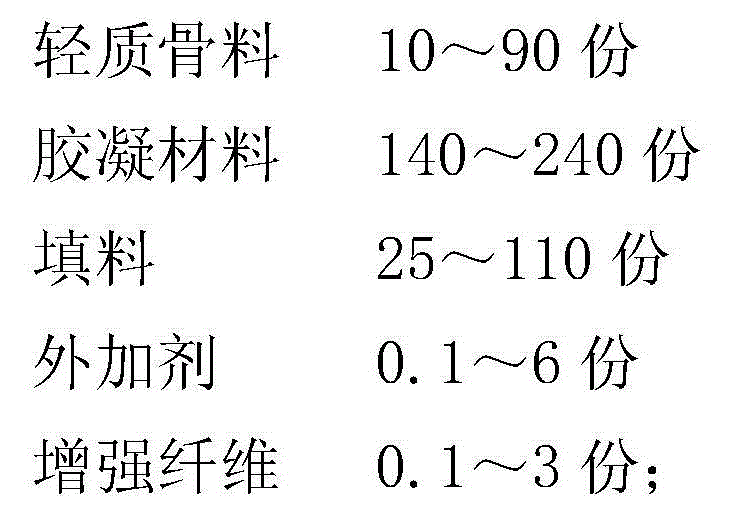

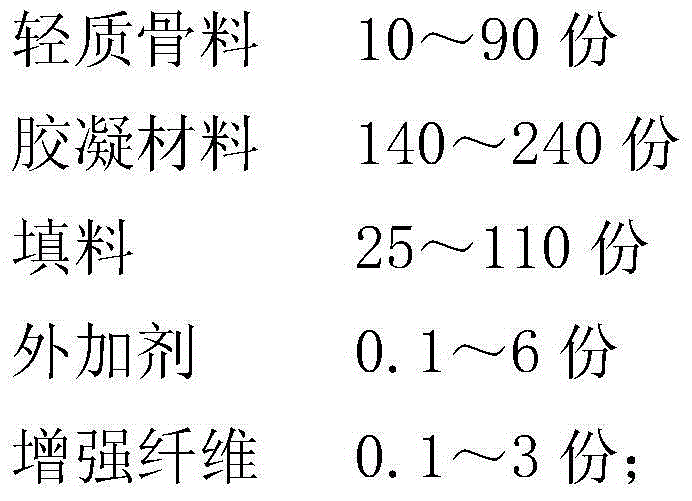

Method used

Image

Examples

Embodiment 1

[0021] A base material for a fireproof decorative board, consisting of the following components: 17g of perlite, 100g of acrylic acid, 40g of gypsum, 10g of fly ash, 27g of acicular powder, 10g of magnesium hydroxide, 3g of melamine, 7g of kaolin, and 0.1g of fluororesin fiber , defoamer 2g, dispersant 0.5g.

[0022] The above components are stirred and pulped, pressed and formed, maintained and cut to obtain the base material of the fireproof decorative board. The detection performance is as follows: Density = 1.26g / cm 3 , Flexural strength = 12.9Mpa, combustion grade is A grade.

Embodiment 2

[0024] A base material for a fireproof decorative board, which consists of the following components: 10g of perlite, 30g of hollow glass beads, 135g of styrene-acrylic emulsion, 50g of white cement, 15g of fly ash, 35g of needle powder, 20g of aluminum hydroxide, water reducing Dose 0.5g.

[0025] The above components are stirred and pulped, pressed and formed, maintained and cut to obtain the base material of the fireproof decorative board. The detection performance is as follows: Density = 1.12g / cm 3 , Flexural strength = 14.3Mpa, combustion grade is A grade.

Embodiment 3

[0027] A base material for a fireproof decorative board, consisting of the following components: 35g of perlite, 10g of hollow glass beads, 138g of acrylic acid, 56g of gypsum, 25g of fly ash, 31g of acicular powder, 5g of melamine, 5g of kaolin, and 3g of fluororesin fiber , water reducer 0.1g, dispersant 2g.

[0028] The above components are stirred and pulped, pressed and formed, maintained and cut to obtain the base material of the fireproof decorative board. The detection performance is as follows: Density = 0.86g / cm 3 , Flexural strength = 16.3Mpa, combustion grade is A grade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com