Multifunctional softener and preparation method for same

A multi-functional, fabric softener technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of high parameter control ability, complex configuration process, difficult production and application, etc., and achieve good washing durability, preparation process Simple process, good bioactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

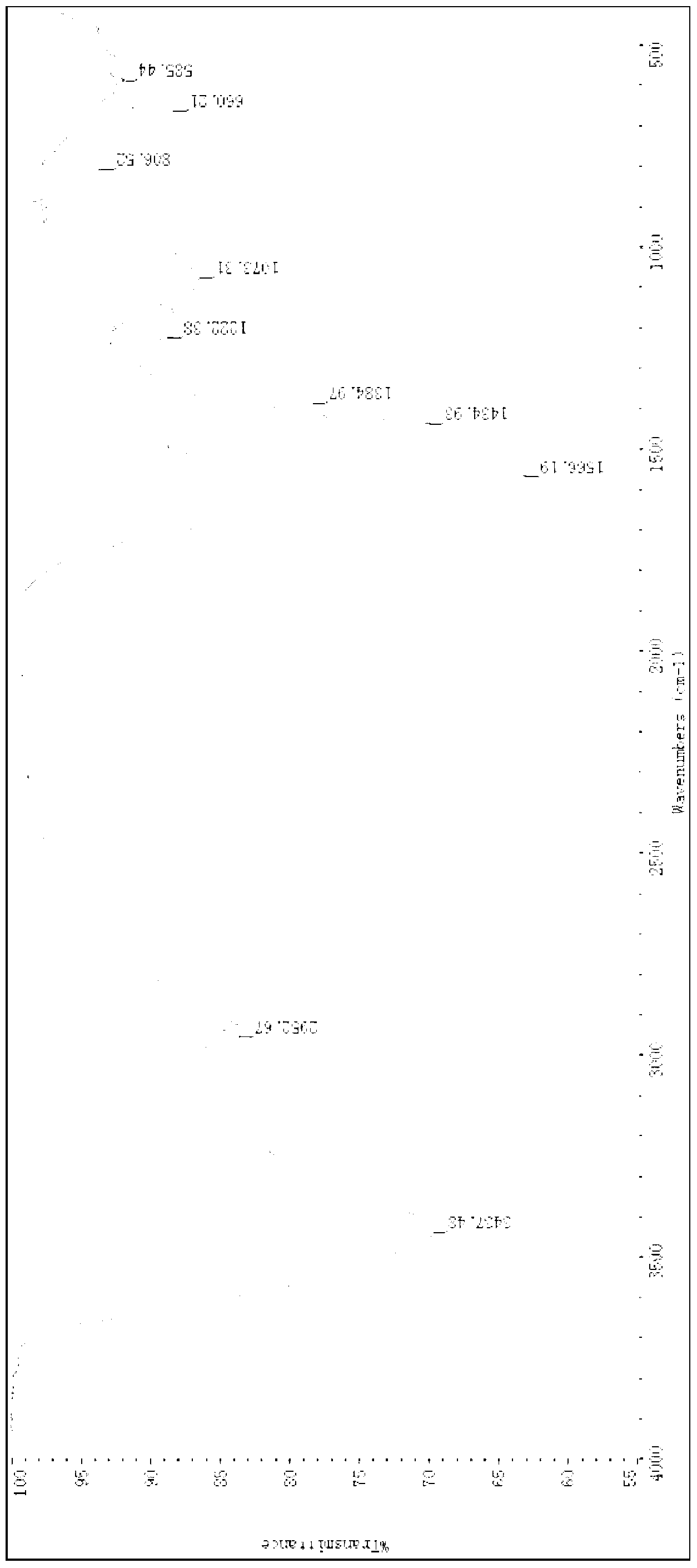

Image

Examples

Embodiment 1

[0037] A preparation method for a multifunctional fabric softener, comprising the steps of:

[0038] One, the preparation of water-soluble chitosan

[0039] Stir chitosan and isopropanol to reflux, heat in a water bath, raise the temperature to 30°C, slowly add the modifier dimethyl sulfate dropwise; after stirring evenly, raise the temperature to 70°C, and react for 12 hours; after the reaction is completed, stop heating And the solution was cooled, filtered with suction, and distilled under reduced pressure to obtain rough water-soluble chitosan. Wash with ethanol-acetone solution, filter with suction, and dry to obtain refined water-soluble chitosan.

[0040] Among them, the particle size of chitosan is 80 mesh, the degree of deacetylation is 85%; the mass ratio of chitosan to isopropanol is 1:10; the molar ratio of chitosan to modifier is 1:3; The volume ratio of ethanol to acetone is 0.4:1.

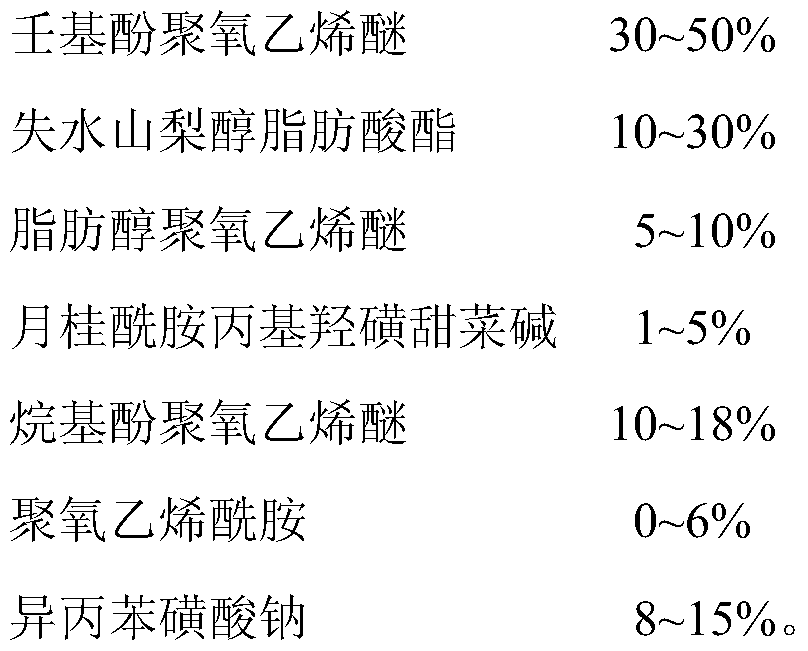

[0041] 2. Compounding of compound emulsifier

[0042] Highly purified surfac...

Embodiment 2

[0056] One, the preparation of water-soluble chitosan

[0057] Chitosan and isopropanol were stirred and refluxed, heated in a water bath, and the temperature was raised to 50°C, and the modifier 3-epoxypropyltrimethylammonium chloride was slowly added dropwise; after stirring evenly, the temperature was raised to 80°C, and the reaction was carried out for 10 hour; after the reaction was completed, stop heating and cool the solution, filter it with suction, and carry out distillation under reduced pressure to obtain the rough body of water-soluble chitosan. Wash with ethanol-acetone solution, filter with suction, and dry to obtain refined water-soluble chitosan.

[0058] Among them, the particle size of chitosan is 90 mesh, the degree of deacetylation is 90%; the mass ratio of chitosan to isopropanol is 1:30; the molar ratio of chitosan to modifier is 1:5; The volume ratio of ethanol to acetone is 1:1.

[0059] 2. Compounding of compound emulsifier

[0060] The mass fractio...

Embodiment 3

[0072] One, the preparation of water-soluble chitosan

[0073] Mix chitosan and isopropanol, stir and reflux, heat in a water bath, raise the temperature to 60°C, slowly add the modifier 3-chloro-2-hydroxypropyltrimethylammonium chloride dropwise; after stirring evenly, raise the temperature to 90°C , reacted for 8 hours; after the reaction was completed, the heating was stopped and the solution was cooled, suction filtered, and vacuum distillation was carried out to obtain the rough water-soluble chitosan. Wash with ethanol-acetone solution, filter with suction, and dry to obtain refined water-soluble chitosan.

[0074] Among them, the particle size of chitosan is 100 mesh, and the degree of deacetylation is 95%; the mass ratio of chitosan to isopropanol is 1:20; the molar ratio of chitosan to modifier is 1:8; The volume ratio of ethanol to acetone is 1.8:1.

[0075] 2. Compounding of compound emulsifier

[0076] Highly purified surfactants usually form loose interfacial f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com