Organic waste water treatment process

A technology for organic wastewater treatment and organic wastewater, applied in the treatment process of water, sewage or sludge, and the field of wastewater, can solve the problems of difficult oxidation reaction, can not effectively destroy the dispersion system, can not produce precipitation effect, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

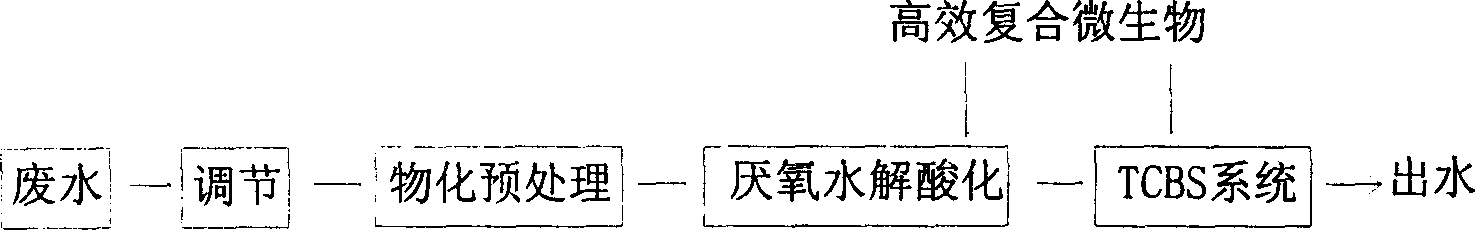

Method used

Image

Examples

Embodiment 1

[0018] The experimental wastewater is taken from the chemical reagent wastewater discharged from a chemical plant, COD cr About 4000~5000mg / L, BOD 5 About 300~600mg / L, NH 3 -N is about 100mg / L or so. The volume ratio of iron shavings and carbon powder in the iron-carbon micro-electrolytic cell is 1:1, and the aeration volume is 1.5m 3 Gas / m 3 Water.min, the action time is 2-3 hours, the dosage of hydrogen peroxide is 1mL / L wastewater, and the dosage of PAM is 5mg / L. The rejuvenated Type A complex microorganisms were added to the anaerobic acidification hydrolysis system, the hydraulic retention time was 48 hours, and the supernatant was taken out for SBR aerobic treatment. Add rejuvenated B-type complex microorganisms into the aerobic treatment tank, aerate for 16-18 hours, stir for 2 hours, settle for about 2 hours and then discharge. The physical and chemical pretreatment process combining iron-carbon micro-electrolysis, Fenton oxidation, and coagulation-sedimentation h...

Embodiment 2

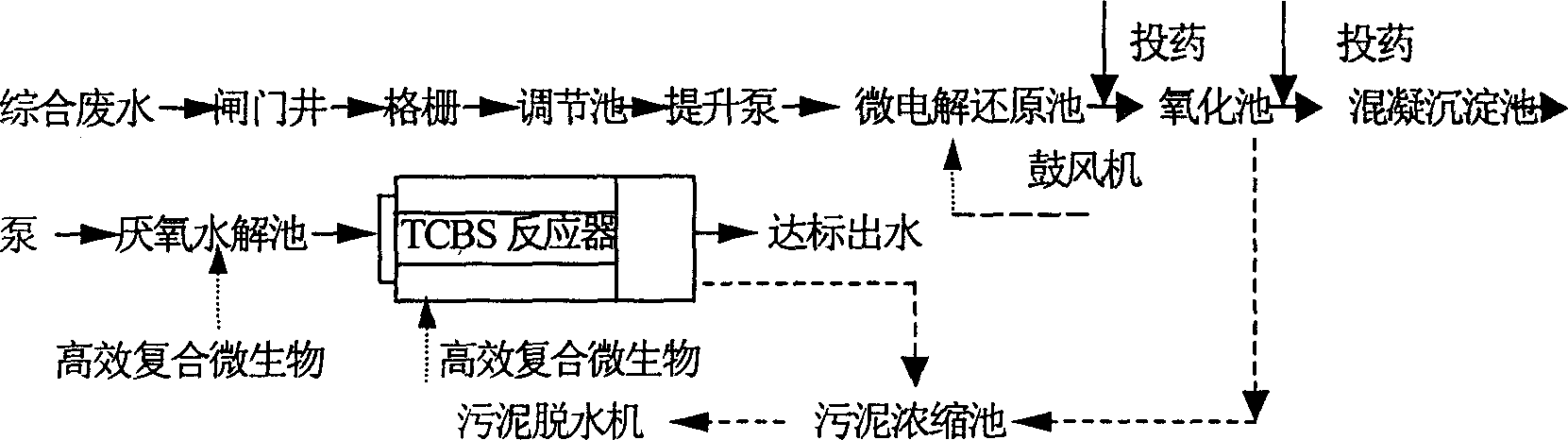

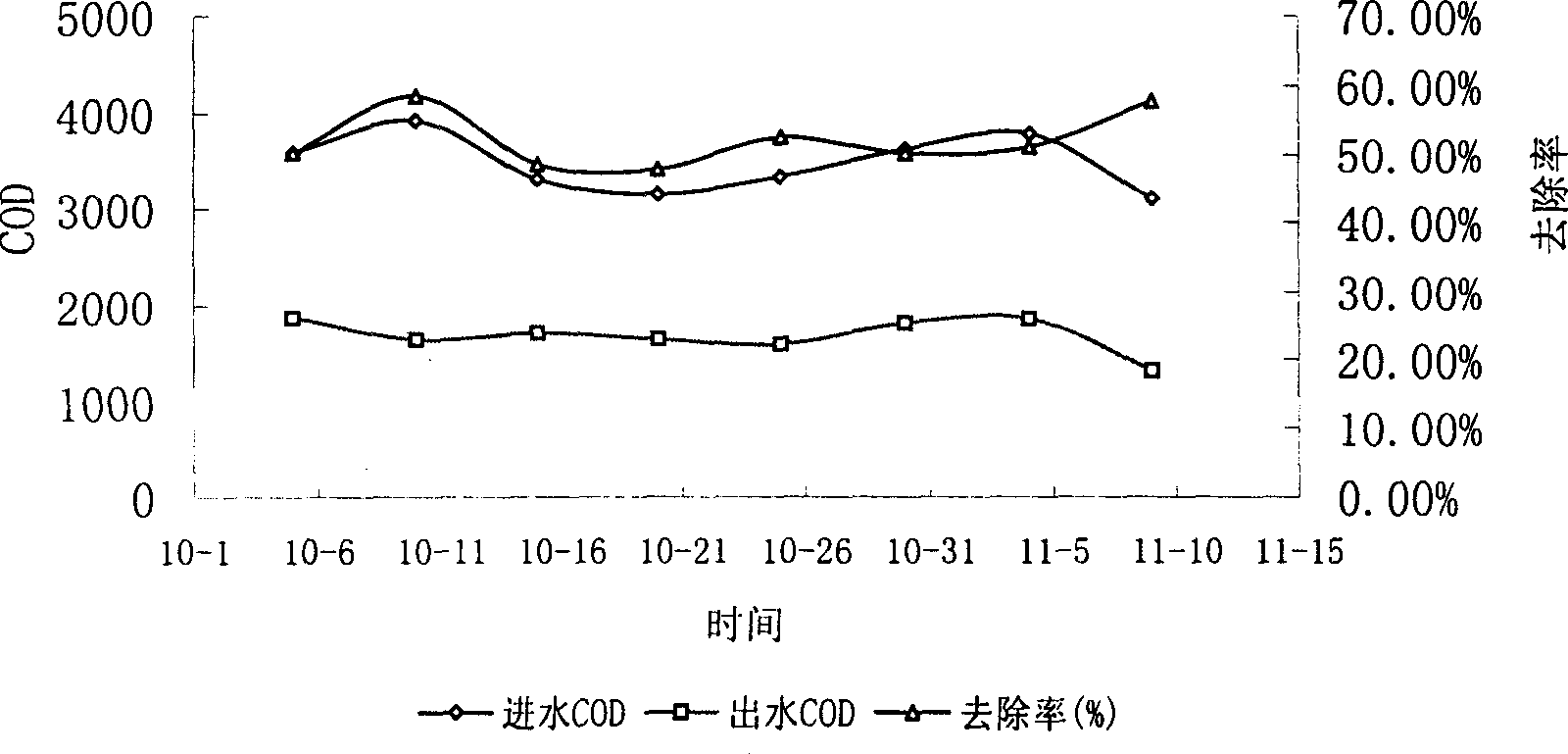

[0025] Shanghai Shisihewei Chemical Co., Ltd. is located at No. 1004, Wusong Taihe Road, Baoshan District, Shanghai. It mainly produces various chemical products, including azobisisobutyronitrile, azobisisoheptanonitrile, OBPA and TAN. The produced industrial wastewater contains not only a large amount of suspended solids and organic matter, but also ammonia nitrogen, cyanide, fluoride and various metal ions. Water volume 1200m 3 / d, the influent COD is as high as 4000-6000mg / L, and the B / C is only 0.15. At the same time, due to the discharge of a large amount of acid in the production process, the wastewater is acidic and highly corrosive. The organic wastewater treatment process designed by the present invention is applied See figure 2 . Figure 6 and Figure 7 Respectively COD and NH after stable operation of the present invention 3 - Schematic diagram of the removal effect of N. From the running results, it can be seen that the COD in the final effluent is below 100mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com