g-CNQDs/GO composite photocatalysis material preparation method

A composite photocatalysis and protonization technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unsolved secondary pollution of metal composite materials, low composite efficiency, and long time consumption , to achieve excellent photocatalytic effect, increase recombination efficiency, and solve the effect that is not easy to recombine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

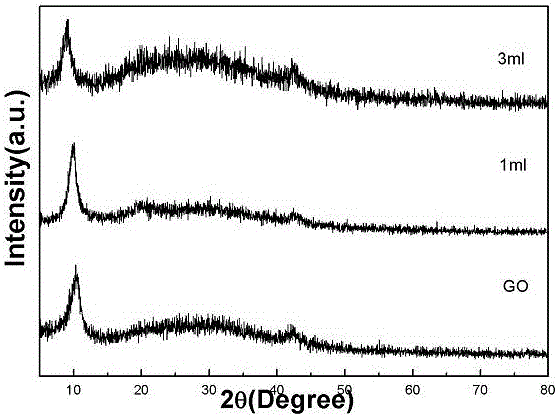

[0027] Step 1: Preparation of Graphene Oxide

[0028] (1) In a 150ml beaker, add 18ml of concentrated sulfuric acid, 500mg of 8000 mesh graphite powder, and 2g of sodium nitrate, place the beaker in an ice-water bath, stir and react on a magnetic stirrer for 1 hour, then slowly add 3g of ground Potassium permanganate solid powder.

[0029] (2) After adding potassium permanganate, keep stirring in an ice-water bath for 2 hours, then raise the temperature to 35°C, and keep it for 1 hour. At this time, a large amount of purple smoke is generated, and then slowly add 40ml of deionized water to the reaction In the system, it takes about half an hour to complete the addition by controlling the rate of addition;

[0030] (3) After adding deionized water, transfer the beaker to an oil bath at 100°C, keep it for 15 minutes, take it out, wait for the reaction system to cool down to room temperature, add 70ml of deionized water, and then add 12ml of 30% hydrogen peroxide solution, At t...

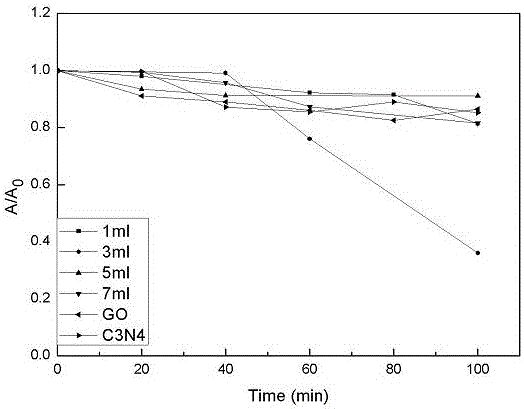

Embodiment 2

[0042] The first step to the third step are the same as in Example 1. In the fourth step, the prepared graphene oxide powder is dispersed into 10ml of deionized water, and after stirring for 10min, 3ml of protonated g-CNQDs solution is added. Ultrasonic treatment at 40kHz and 140W power for 15min. Then, the mixture was taken out and left to stand for about 48 hours, and the final solution was dried in a vacuum oven at 60 degrees for 24 hours, and the product was collected and ground into powder. The obtained product was 3ml C3N4 / GO. Weighed 10mg of this product and used it to degrade 50ml of methyl orange solution with a concentration of 10PPm under visible light (λ>420nm). The degradation rate reached 64% after 100min.

Embodiment 3

[0044] The first step to the third step are the same as in Example 1. In the fourth step, the prepared graphene oxide powder is dispersed into 10ml of deionized water. After stirring for 10min, 5ml of protonated g-CNQDs solution is added. Ultrasonic treatment at 40kHz and 140W power for 15min. Then, the mixture was taken out and left to stand for about 48 hours, and the final solution was dried in a vacuum oven at 60 degrees for 24 hours, and the product was collected and ground into powder. The obtained product was 5ml C3N4 / GO. Weighed 10mg of this product and used it to degrade 50ml of methyl orange solution with a concentration of 10PPm under visible light (λ>420nm). The degradation rate reached 9.3% after 100min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com