High barrier film and manufacturing method thereof

A technology with high barrier properties and production methods, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of poor toughness, brittle film, poor barrier properties, etc., and achieve less decrease in barrier properties and higher Barrier performance, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

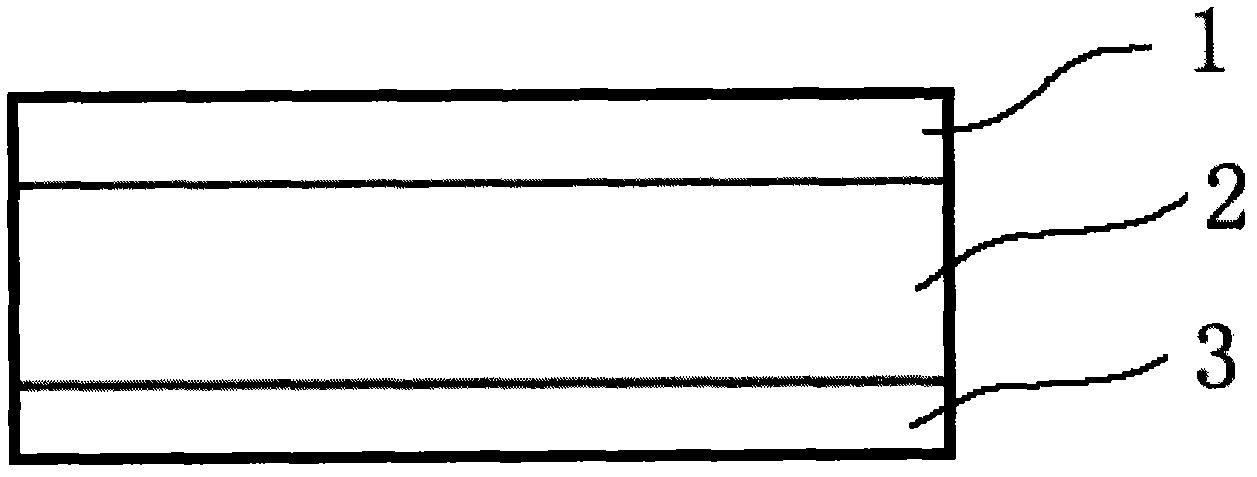

[0037] Such as figure 1 Shown is a high barrier film with a three-layer structure consisting of the first surface layer 1, the core layer 2, and the second surface layer 3. The components of the first surface layer 1 are 10wt% of MXD6, 89.6wt% of PA6, 0.2wt% % anti-blocking agent and 0.2wt% slip agent; the above-mentioned core layer 2 consists of 60wt% MXD6, 40wt% PA6; the above-mentioned second surface layer 3 consists of 10wt% MXD6, 89.6wt% PA6, 0.2wt% anti-blocking agent and 0.2wt% slip agent.

Embodiment 2

[0039] Such as figure 1 Shown is a high barrier film with a three-layer structure consisting of the first surface layer 1, the core layer 2, and the second surface layer 3. The components of the first surface layer 1 are 20wt% of MXD6, 79.4wt% of PA6, 0.3wt% % anti-blocking agent and 0.3wt% slip agent; the above-mentioned core layer 2 consists of 65wt% MXD6, 35wt% PA6; the above-mentioned second surface layer 3 consists of 20wt% MXD6, 79.4wt% PA6, 0.3wt% anti-blocking agent and 0.3wt% slip agent.

Embodiment 3

[0041] Such as figure 1 The shown three-layer high barrier film composed of the first surface layer 1, the core layer 2 and the second surface layer 3, the components of the first surface layer 1 are 30wt% of MXD6, 69.5wt% of PA6, 0.3wt% % anti-blocking agent and 0.2wt% slippery agent; the above-mentioned core layer 2 consists of 80wt% MXD6, 20wt% PA6; the above-mentioned second surface layer 3 consists of 30wt% MXD6, 69.5wt% PA6, 0.3wt% anti-blocking agent and 0.2wt% slip agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com