Patents

Literature

89results about How to "Low oxygen transmission rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High barrier film and manufacturing method thereof

InactiveCN102837474AImprove barrier propertiesLow oxygen transmission rateSynthetic resin layered productsSurface layerLow oxygen

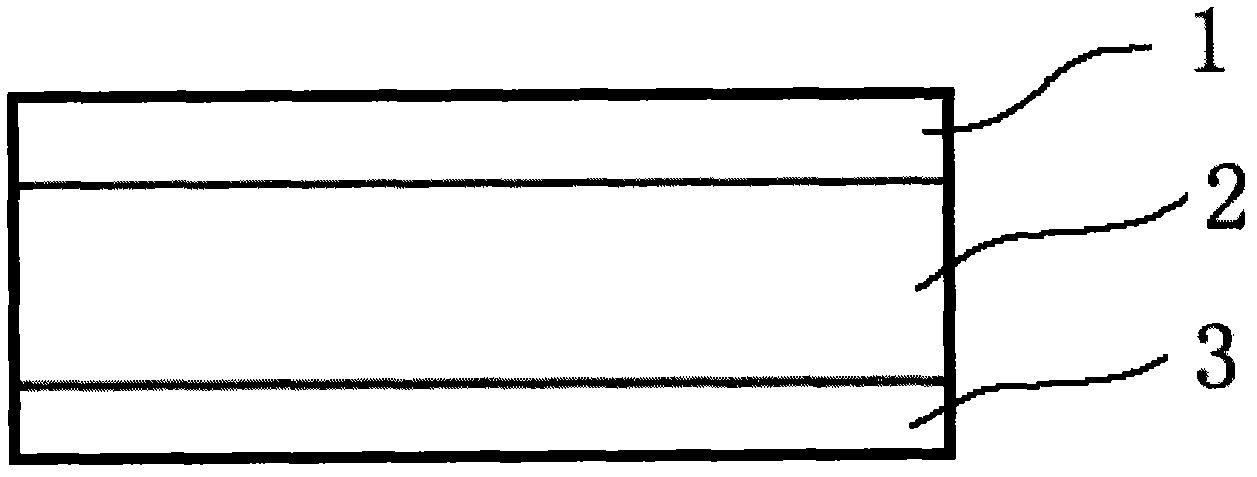

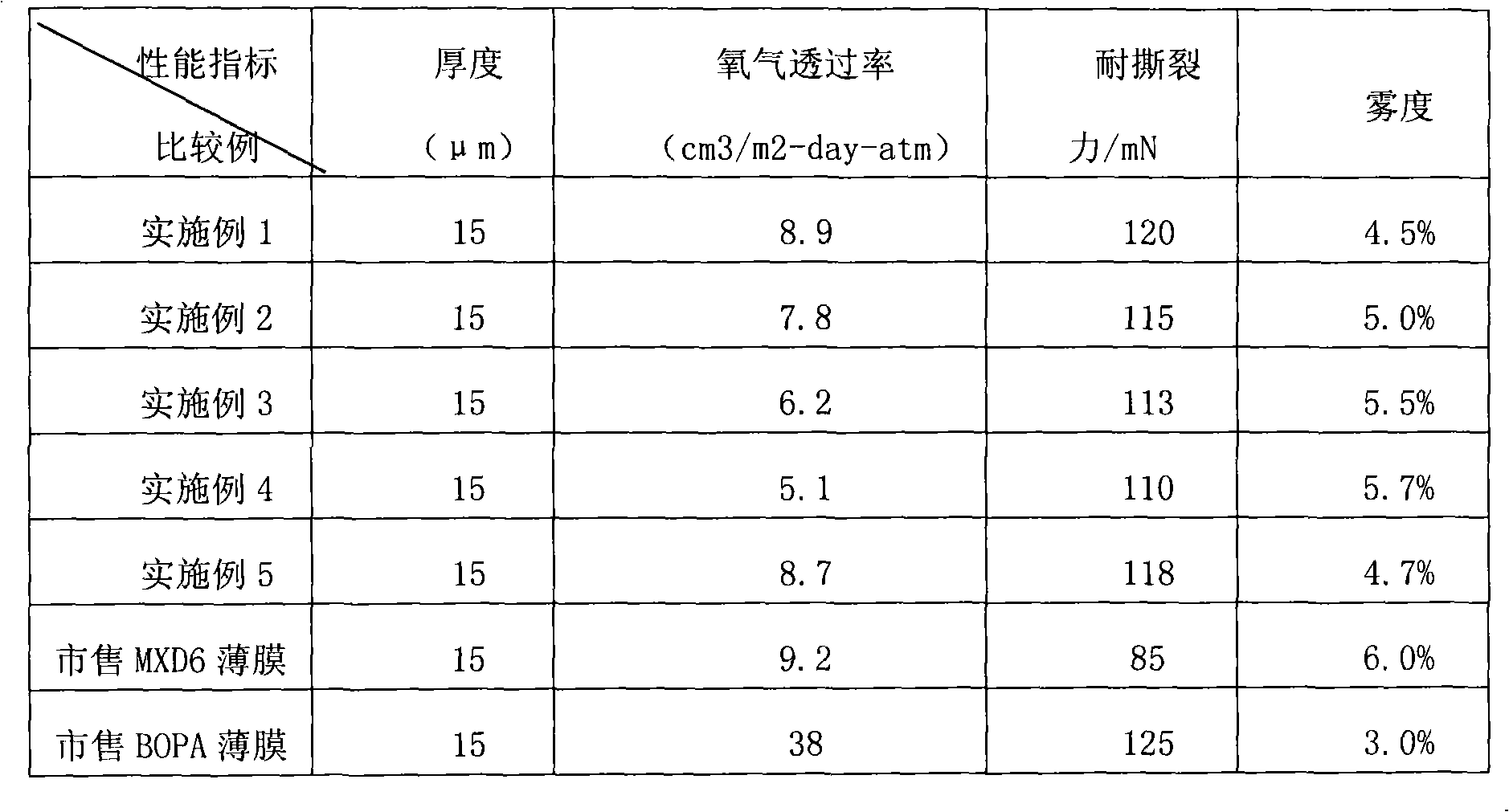

The invention provides a high barrier film and a manufacturing method thereof. The high barrier film is a three-layer structure composed of a first surface layer, a core layer, and a second surface layer. The first surface layer is composed of 0-0.3wt% of a slipping agent, 0-0.5wt% of an anti-block agent, 10-40 wt% of MXD6, and 59.2-90 wt% of PA6 chips; the core layer is composed of 60-95 wt% of MXD6, and 5-40 wt% of PA6 chips; and the second surface layer is composed of 0-0.3wt% of a slipping agent, 0-0.5wt% of an anti-block agent, 10-40 wt% of MXD6, and 59.2-90 wt% of PA6 chips. The high barrier film above has greatly improved barrier performance, and has the characteristics of excellent barrier property, low oxygen transmission rate of the film, and good transparency and flexibility.

Owner:厦门长塑实业有限公司

High-resistance antibacterial PE (polyethylene) film and preparation method thereof

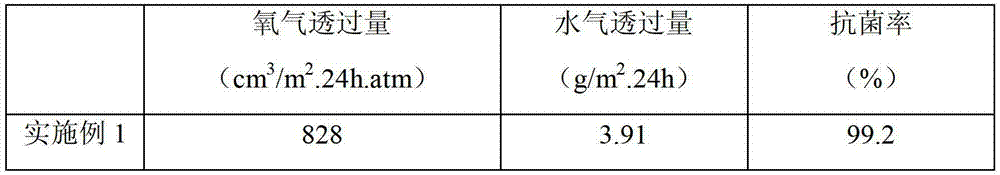

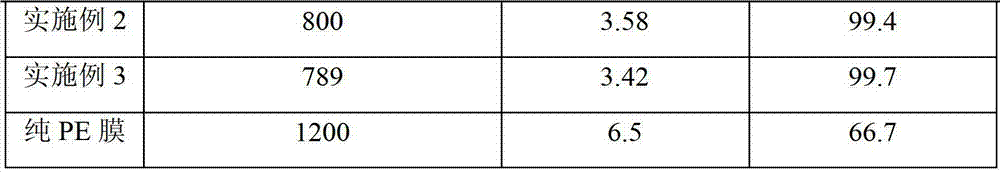

ActiveCN103205049AImprove barrier propertiesLow oxygen transmission rateLow-density polyethyleneHigh resistance

The invention discloses a high-resistance antibacterial PE (polyethylene) film and a preparation method thereof, wherein the high-resistance antibacterial PE film is prepared in the way that nanometer composite modified master batch is added to LDPE (low density polyethylene) matrix resin and finally extrusion blown molding is carried out; the mass of the nanometer composite modified master batch is 3-8% of the mass of the LDPE matrix resin; and the nanometer composite modified master batch is prepared by carrying out blending extrusion on nanometer ZnO loaded organic montmorillonite, LDPE and maleic anhydride grafted polyethylene, the organic montmorillonite loading the nanometer ZnO is prepared by intercalation composition of nanometer ZnO loaded montmorillonite and an intercalation agent, and the nanometer ZnO loaded montmorillonite is prepared by loading the nanometer ZnO on montmorillonite. Compared with a pure PE film, the high-resistance antibacterial PE film disclosed by the invention has the advantages that the oxygen transmission rate is reduced by 31%, the water transmission rate is reduced by 40% and the antibacterial rate is up to 99.7%.

Owner:ANHUI SONGTAI PACKAGING MATERIALS

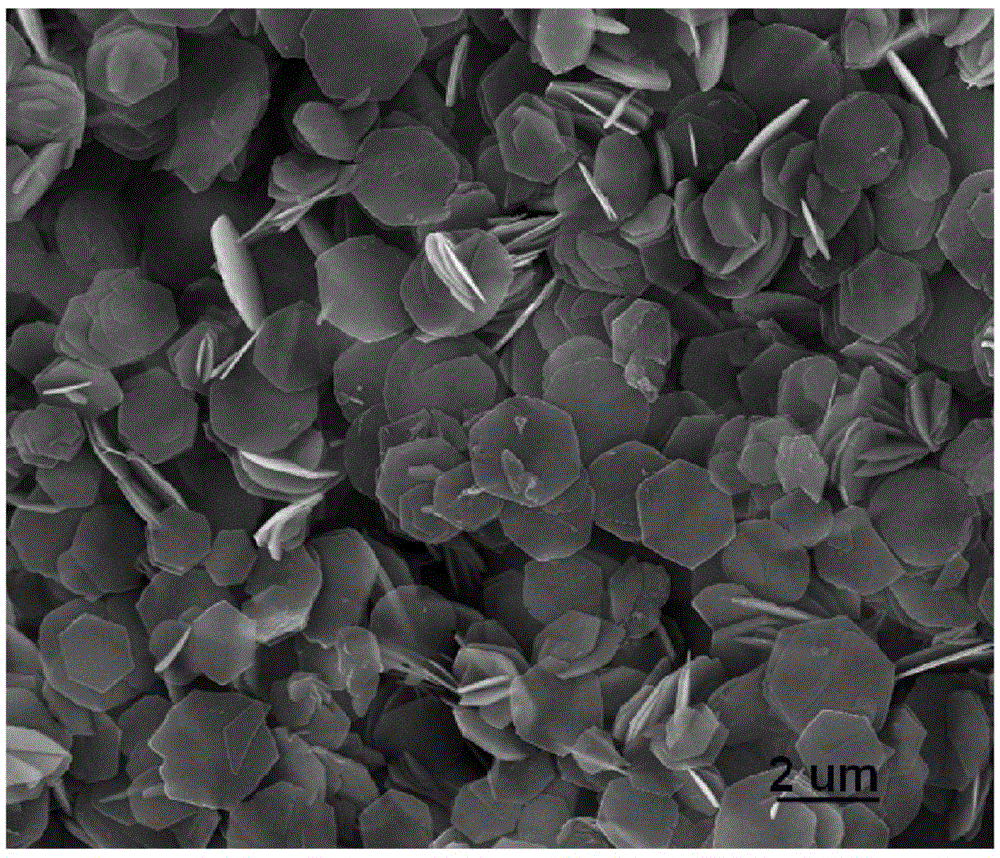

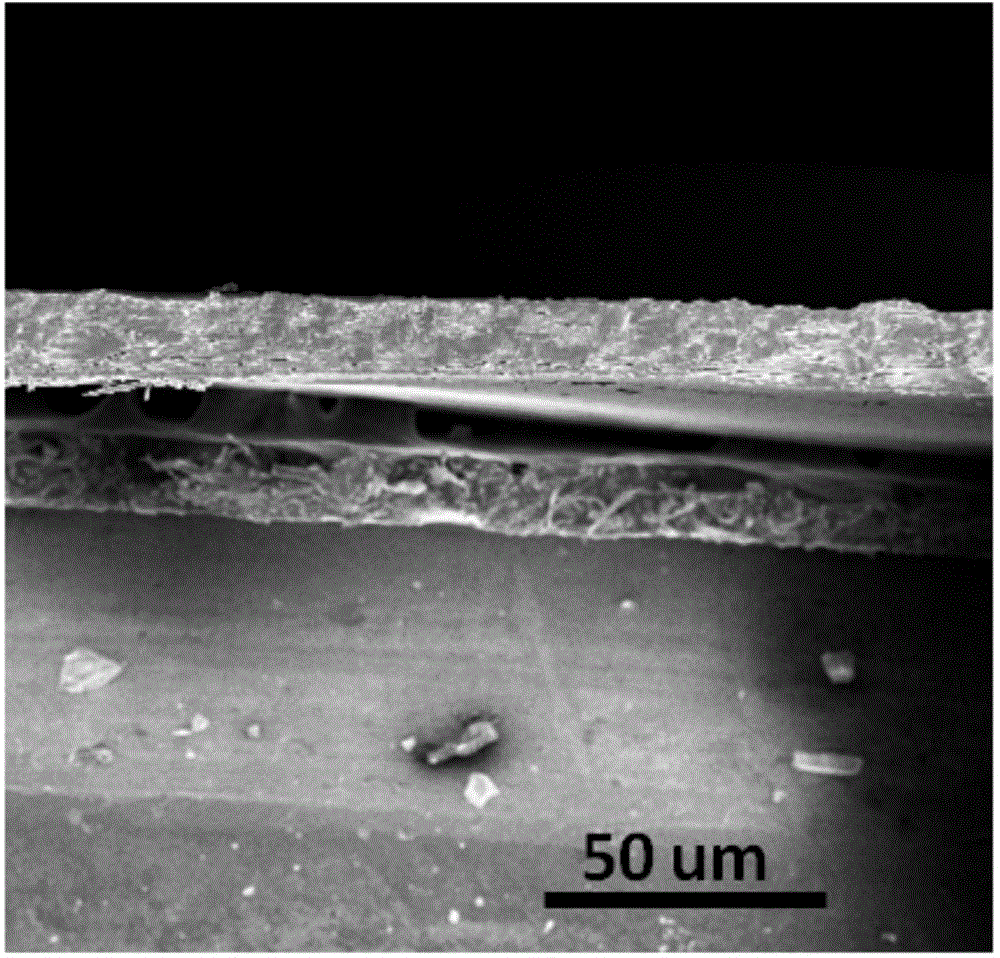

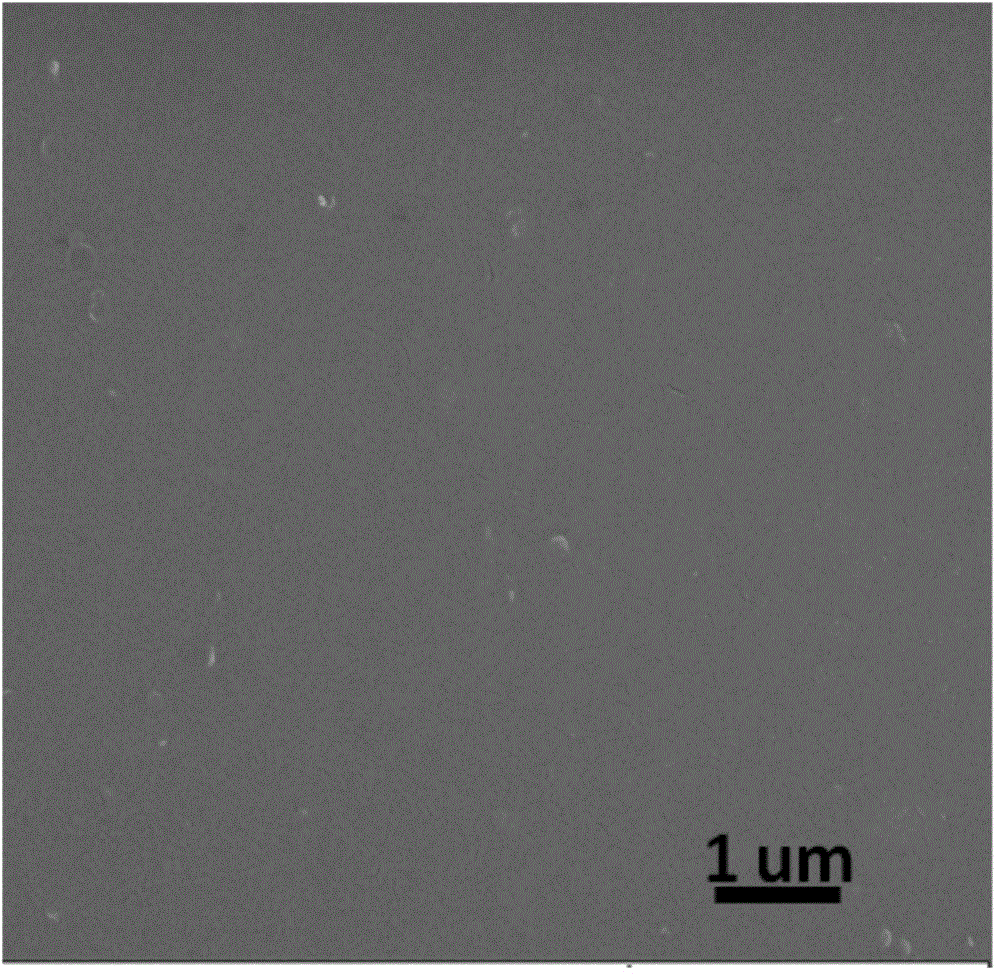

Transparent gas barrier film materials and production method thereof

The invention discloses transparent gas barrier film materials and a production method thereof. A large length-diameter ratio of hydrotalcite nano-sheet serves as a precursor, the hydrotalcite whish is of a two-dimensional layered structure and various commercial packaging polymer raw materials are composited into a film by a simple suction filter deposition film forming technology, a diffusion path of gas molecules in the composite film can be significantly extended due to the large length-diameter ratio and the two-dimensional ordered structure of the hydrotalcite, and accordingly the barrier performance of the film materials is further improved. The finally produced transparent gas barrier film is ultra-low in oxygen transmissibility in comparison with a detection limit of an instrument and accordingly the problem that the requirement of the current barrier packaging field for the oxygen resistance performance of materials is high can be solved. According to the suction filter deposition film forming method, the production is simple, the raw material sources are wide, the material selection is convenient, the cost is low, and the environment-friendly and sustainable development requirements are met in comparison with the traditional method and accordingly the transparent gas barrier film materials comprise the potential application value in the fields of food, medicine packaging, electronic device packaging and the like.

Owner:BEIJING UNIV OF CHEM TECH

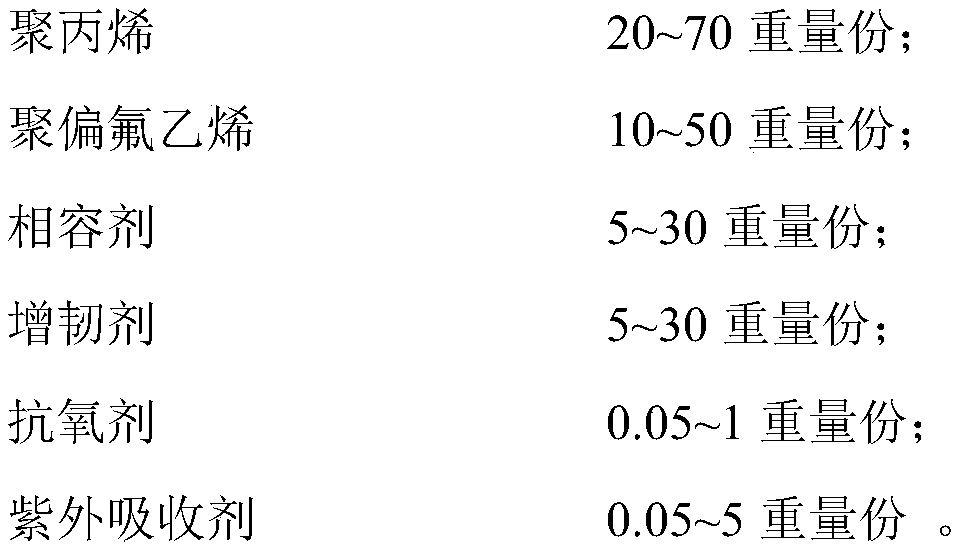

Polypropylene/polyvinylidene fluoride blended modified material and preparation method thereof

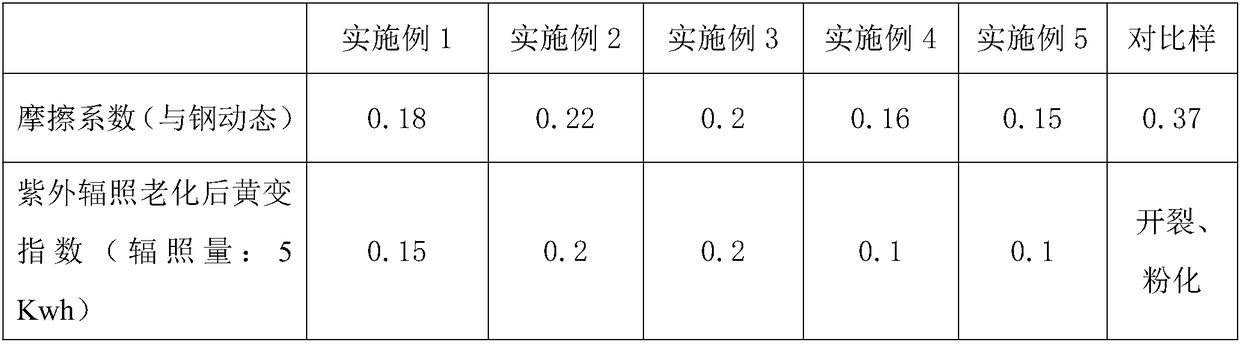

ActiveCN108164816AGood weather resistanceGood high and low temperature resistanceAntioxidantPolyvinylidene difluoride

The invention discloses a polypropylene / polyvinylidene fluoride blended modified material and a preparation method thereof. The polypropylene / polyvinylidene fluoride blended modified material includes, by weight, 20-70 parts of polypropylene, 10-50 parts of polyvinylidene fluoride, 5-30 parts compatibilizer, 5-30 parts of a toughener, 0.05-1 part of an antioxidant and 0.05-5 parts of an ultraviolet absorber. The preparation method comprises the following steps: the polypropylene, polyvinylidene fluoride, the compatibilizer, the toughener, the antioxidant and the ultraviolet absorber are weighed according to the above formula ratio, and are added into a twin-screw extruder, and the obtained mixture is plasticized, is dispersed, and then undergoes extrusion granulation to obtain the polypropylene / polyvinylidene fluoride blended modified material. The ultraviolet radiation resistance quantity of the polypropylene / polyvinylidene fluoride modified material prepared in the invention can be increased by 3 times, or more, the outdoor service life of a tube made from the polypropylene / polyvinylidene fluoride modified material is prolonged to 2 times or more of the original service life, theoxygen permeability is reduced by 80%, and the polypropylene / polyvinylidene fluoride modified material also can be used in a -20 to 100 DEG C environment, so the application range is expanded.

Owner:嘉兴高正新材料科技股份有限公司

High-barrier biodegradable free-standing bag and preparation method thereof

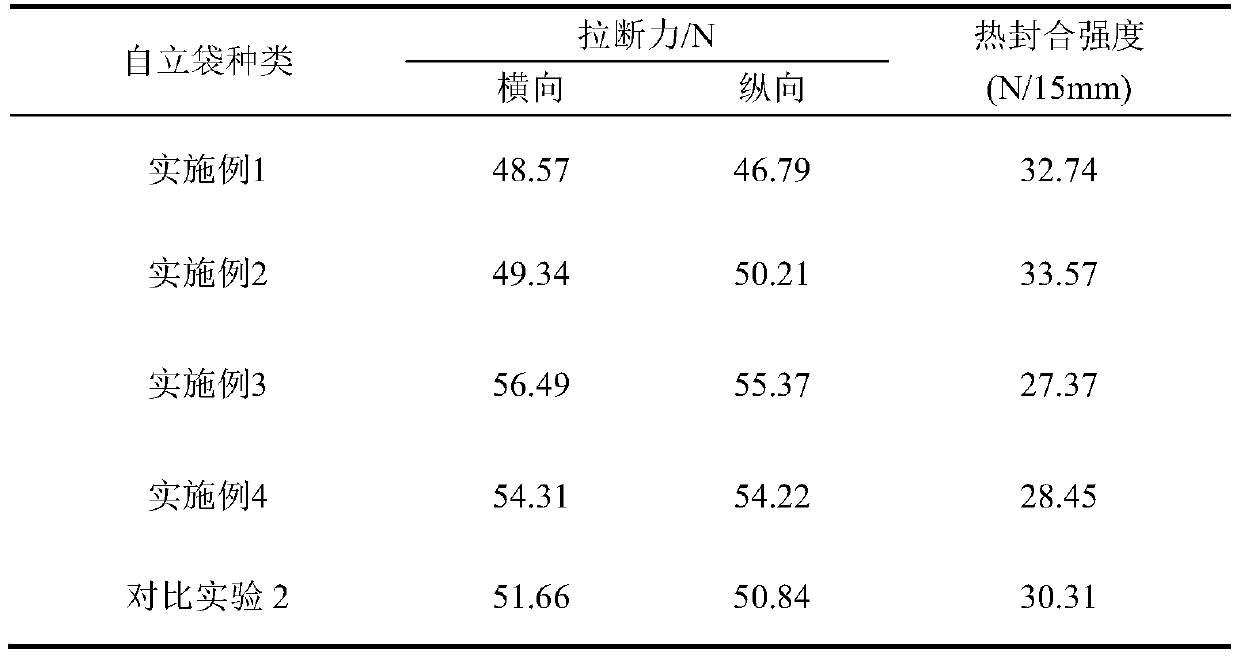

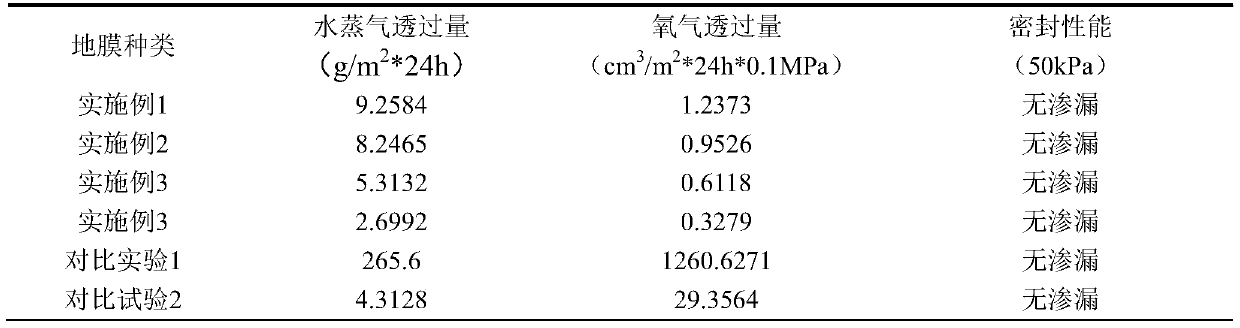

ActiveCN110921099ALow oxygen transmission rateLow water vapor transmission rateFlexible coversWrappersPolymer scienceBiodegradable bag

The invention discloses a high-barrier biodegradable free-standing bag and a preparation method thereof. The free-standing bag is composed of two parts of a high-barrier biodegradable self-sealing strip and a five-layer composite high-barrier biodegradable bag body, the main substrate of the high-barrier biodegradable self-sealing strip is PLGA and PPC with excellent barrier property, the five-layer composite high-barrier biodegradable bag body is composed of single-light white kraft paper, a bonding layer, a first barrier layer, a second barrier layer and a heat seal layer, and is integrallyformed by adopting the four-layer co-extrusion and film-coating combined process. Compared with a traditional non-degradable free-standing bag, the prepared high-barrier biodegradable free-standing bag has the advantages that the physical mechanical property and the heat sealing performance are substantially equivalent, the barrier property is more excellent, biodegradation can be achieved, the problem of "white pollution" caused by waste of traditional free-standing bags is solved, and the application of the biodegradable plastic in the field of high-barrier food packaging is expanded, so that the high-barrier biodegradable free-standing bag has very important significance.

Owner:JIANGSU GOLDEN RAINBOW NEW MATERIAL CO LTD

Tar-free epoxy resin coating and its preparation method

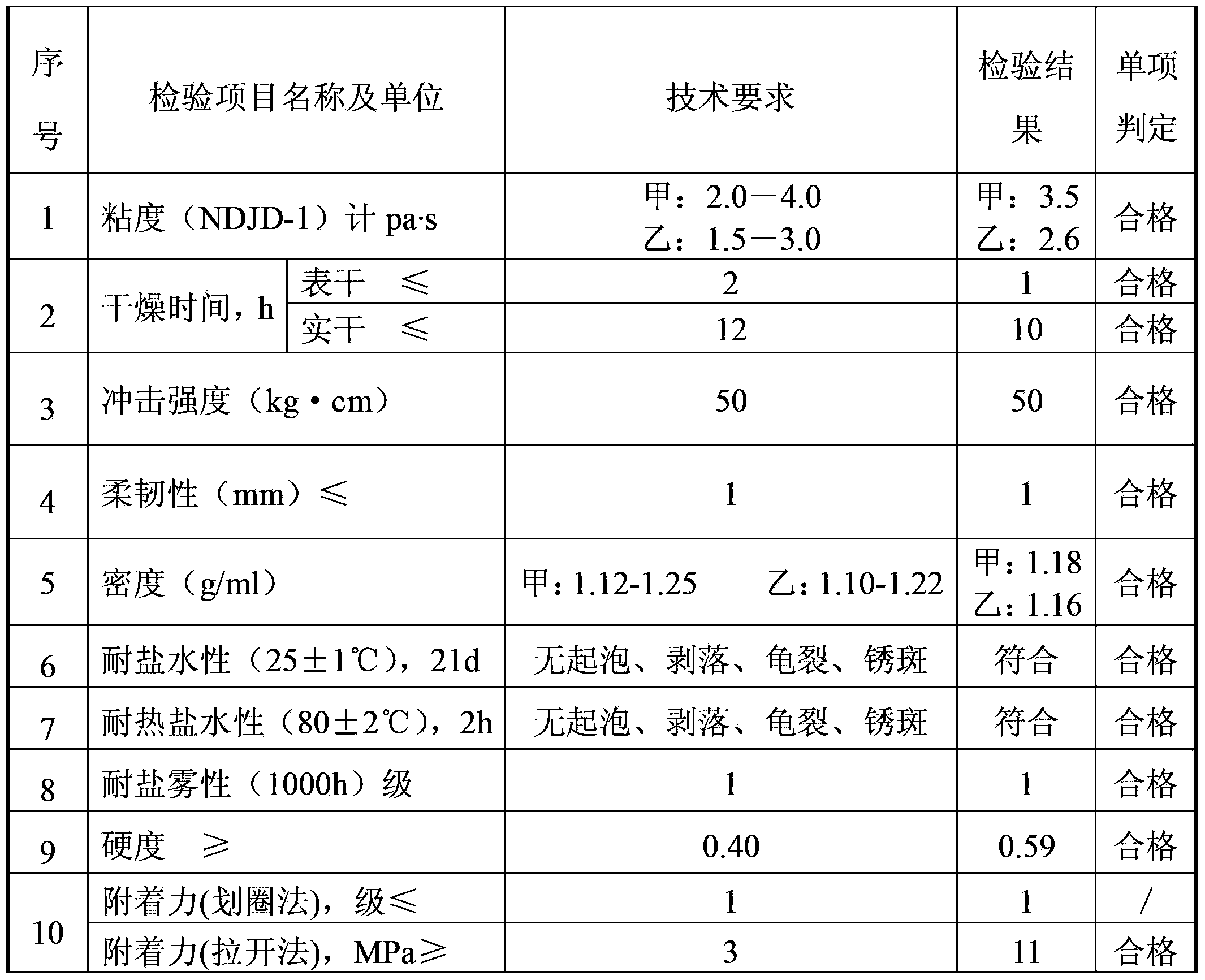

InactiveCN103360904AStrong adhesionHigh mechanical strengthAnti-corrosive paintsEpoxy resin coatingsEpoxyPetroleum resin

The invention relates to an epoxy coating and its preparation method. The coating provided by the invention comprises a component A and a component B, wherein the component A comprises 20-35 wt% of an epoxy resin liquid, 4-15 wt% of a phenolic resin liquid, 4-15 wt% of a petroleum resin liquid, 1-7 wt% of an anti-settling agent, 20-50 wt% of a filler, 4-15 wt% of a pigment, 5-20 wt% of a solvent and 0.3-5 wt% of a cosolvent; the component B comprises 30-80 wt% of a curing agent and 20-70 wt% of a solvent; and the mass ratio of the component A to the component B is 10-1:1. The coating provided by the invention has a light color, is suitable for a priming paint and a finishing coat, and has good waterproof and antirust properties.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Ink composition with high heat resistance and high light transmittance and purpose thereof

The invention provides an ink composition with high heat resistance and high light transmittance. The ink composition is an ultraviolet light curing material, which comprises a silicon-containing monomer having a mass percentage of 15 to 80%, a photocrosslinking initiator having the mass percentage of 1 to 10%, and a light curing monomer having the mass percentage of 15 to 75%. The ink compositionis used for film packaging of an OLED device, is capable of effectively blocking water and oxygen, and has high heat resistance and high transparency characteristics, and further prolongs the servicelife of the OLED device.

Owner:ZHEJIANG FORST NEW MATERIAL RES INST CO LTD

High-barrier composite film and production method thereof

InactiveCN101913282AImprove featuresPrevent moisture absorptionSynthetic resin layered productsFlat articlesLow-density polyethyleneBlow molding

The invention discloses a high-barrier composite film which comprises a film body, wherein the film body is formed by sequentially compounding an LDPE (Low-Density Polyethylene) outer layer, a PVDC (Polyvinyl Dichloride) middle layer and an LDPE inner layer. The high-barrier composite film is produced by the following steps of: respectively adding LDPE, PVDC and LDPE resin particles into three extruder hoppers of a composite film blow molding unit in the proportion of 36 percent:28 percent:36 percent; heating to a melting state by an extruder melting section; collecting into an upper die head, a middle die head and a lower die head of a composite die head for compounding; and blow-molding, cooling for moulding, drawing and carrying out corona treatment to obtain a finished film product with the thickness of 0.09-0.18mm. The invention has the advantages that three materials are compounded into a three-layer film by three extruders of the composite film blow molding unit, the materials with different performance are mutually compounded together in the extruding process and laminated on characteristics, and the finished film has needed favorable characteristics.

Owner:河南大有塑业发展有限公司

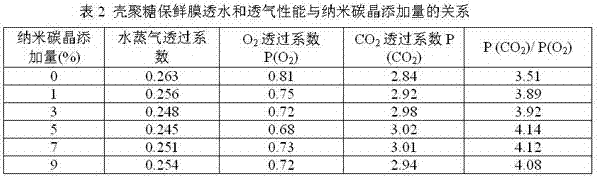

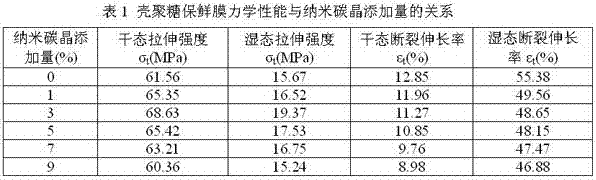

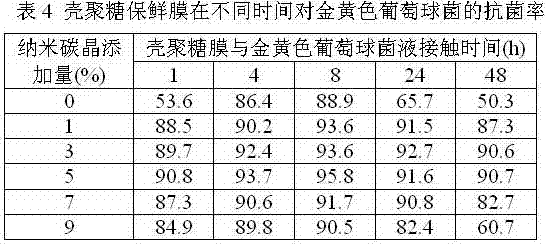

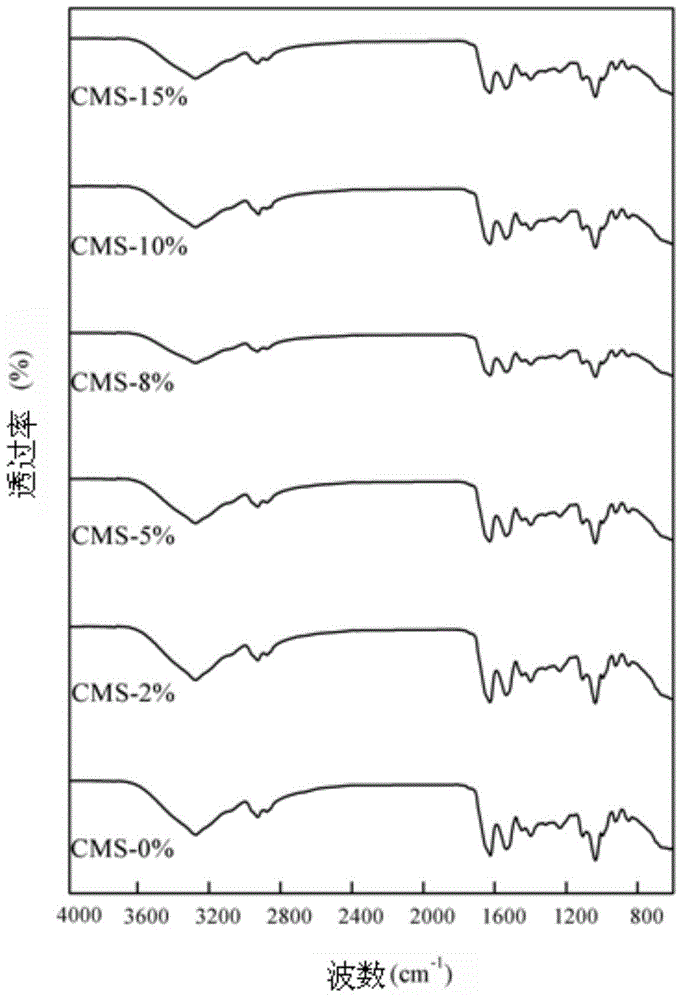

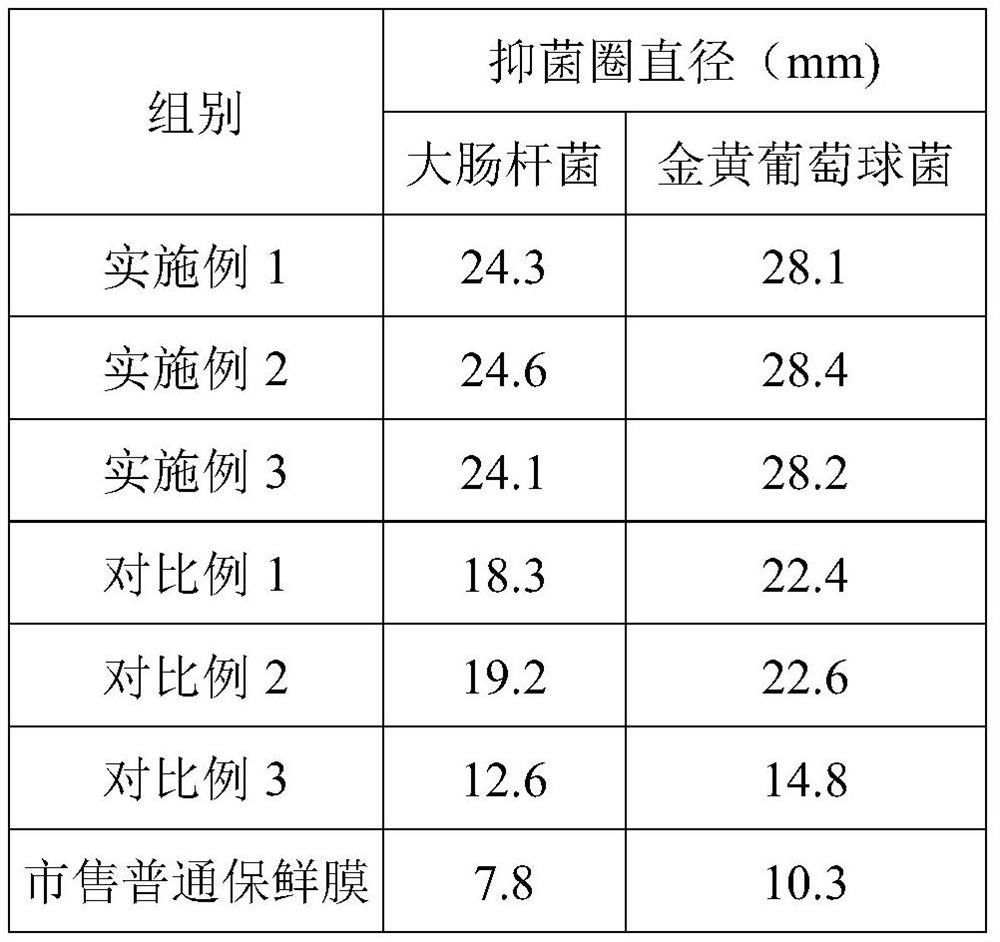

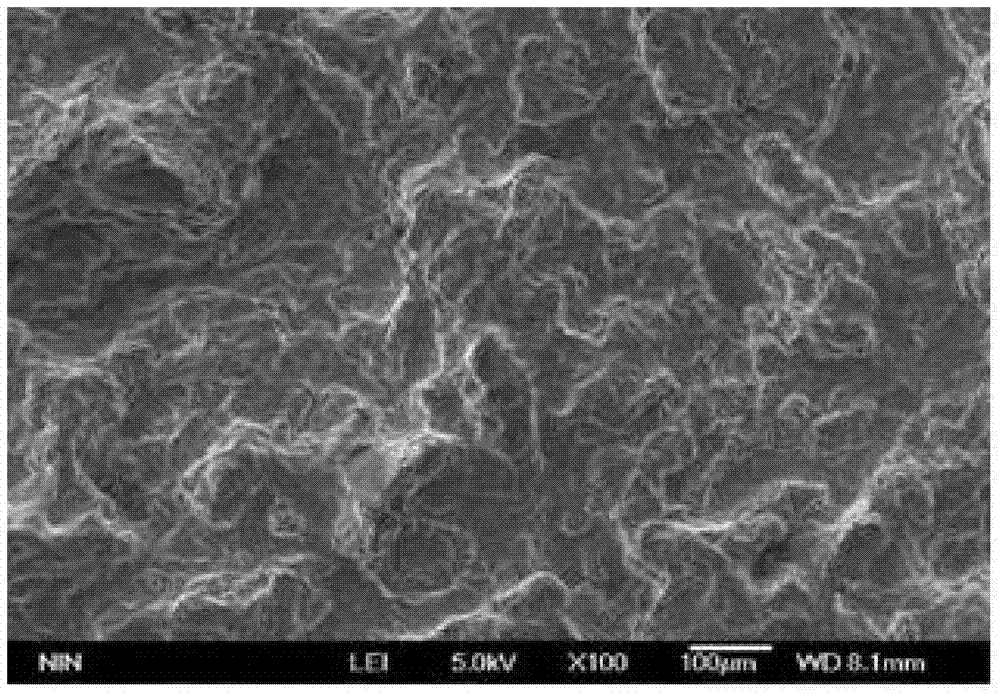

Preparation method of chitosan composite preservative film

The invention discloses a preparation method of a chitosan composite preservative film. The preparation method comprises the following steps: dissolving chitosan in an acetic acid solution, heating to 50 to 65DEG C, and stirring until the chitosan is completely dissolved, so as to obtain a solution A; dispersing modified nano carbon crystal in the solution A, wherein the adding amount of the modified nano carbon crystal is 1 to 9 percent; then adding a plasticizer which accounts for 0.2 to 1 percent of the volume of the solution A, and carrying out stirring, ultrasonic dispersion, standing and ultrasonic degassing for 10 to 15 minutes to obtain a solution B; casting the solution B to form a film, standing and drying at the drying temperature of 35 to 55DEG C; then putting into 0.01 to 0.02mol / L of NaOH solution, soaking for 0.5 to 1 hour, flushing with distilled water, uncovering the film and drying in the sun to obtain the composite preservative film. The chitosan composite preservative film disclosed by the invention has relatively low water vapor permeability, so that excessive loss of water in fruits and vegetables is avoided; the chitosan composite preservative film has relatively good sterilizing function and strong antibacterial durability, i.e., an obvious sterilizing effect can be realized within one hour, and the antibacterial rates for escherichia coli and staphylococcus aureus after 48 hours still can reach 90 percent or above, so the preservation time of the fruits and the vegetables is prolonged.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

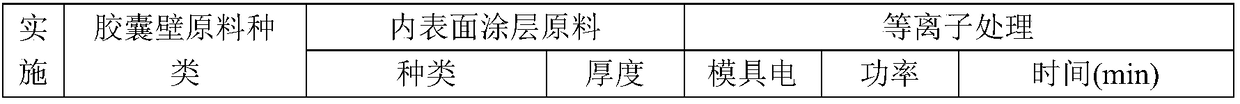

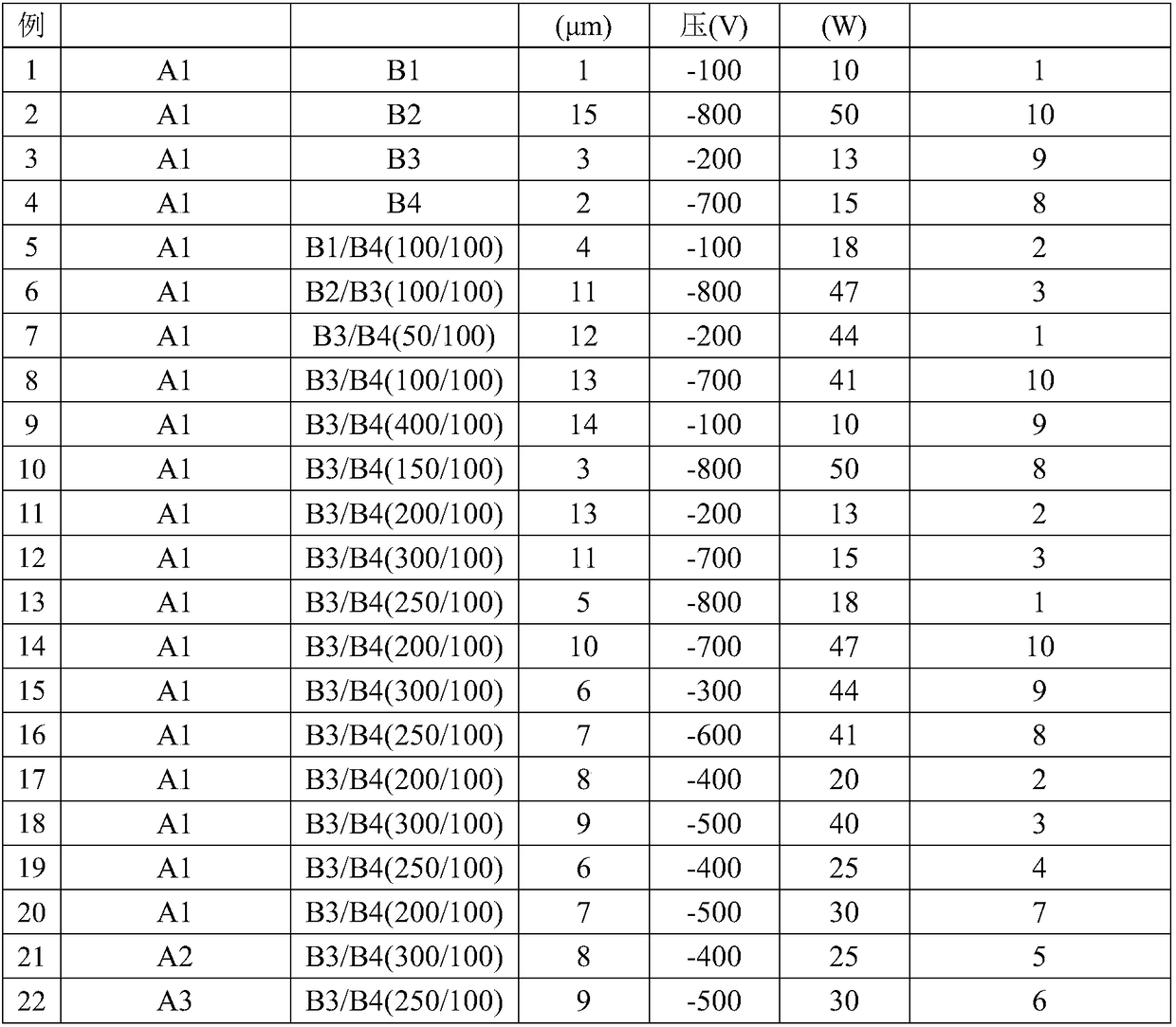

High-oxygen-isolation plant hollow capsule and preparation method thereof

InactiveCN108143724ALow oxygen transmission rateImprove oxygen barrier ratePowder deliveryCapsule deliveryHigh oxygenPlasma treatment

The invention discloses a plant hollow capsule. The inner surface of the capsule wall of the capsule contains one or more inner surface coatings, and the inner surface coatings contain one or more ofplant oil, animal oil, silicone oil or mineral oil. The plant hollow capsule has an extremely high oxygen isolation rate, the speed of oxygen entering the capsule is lowered, and the preservation timeof the capsule is prolonged. In addition, the roughness of the inner surface of the plant hollow capsule is extremely low, the adherence rate of the capsule content on the inner surface of the capsule is lowered, the toughness of the capsule is good, the piercing damage rate is low, and the capsule can be used for containing inhalable dry powder preparations and treating the diseases of the respiratory system. Meanwhile, the prepared plant hollow capsule is further subjected to plasma treatment, the performance above of the capsule is further improved, and the application range is wider.

Owner:上海祺宇生物科技有限公司

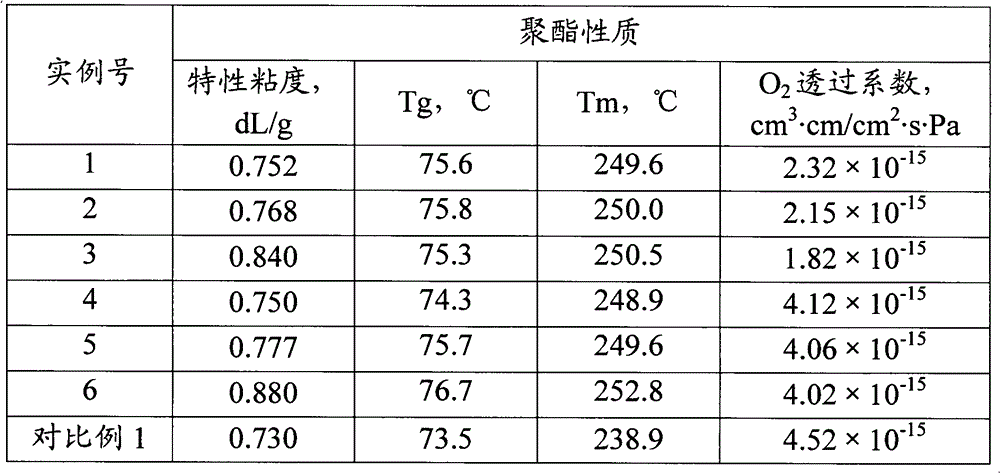

Barrier polyester and preparation method thereof

ActiveCN103059279AIncrease the degree of cross-linkingLow oxygen transmission rateBenzoic acidCarboxylic acid

The invention relates to a barrier polyester, which comprises terephthalic acid, ethylene glycol and a barrier comonomer. The barrier comonomer is a hydroxycarboxylic acid compound containing at least two substitutional groups or a benzoic acid derivative. The substitutional groups are selected from hydroxyl or carboxyl, but are not carboxyl at the same time. The barrier polyester is non-toxic, and has excellent mechanical properties, especially good barrier property for oxygen, as well as low oxygen penetration rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

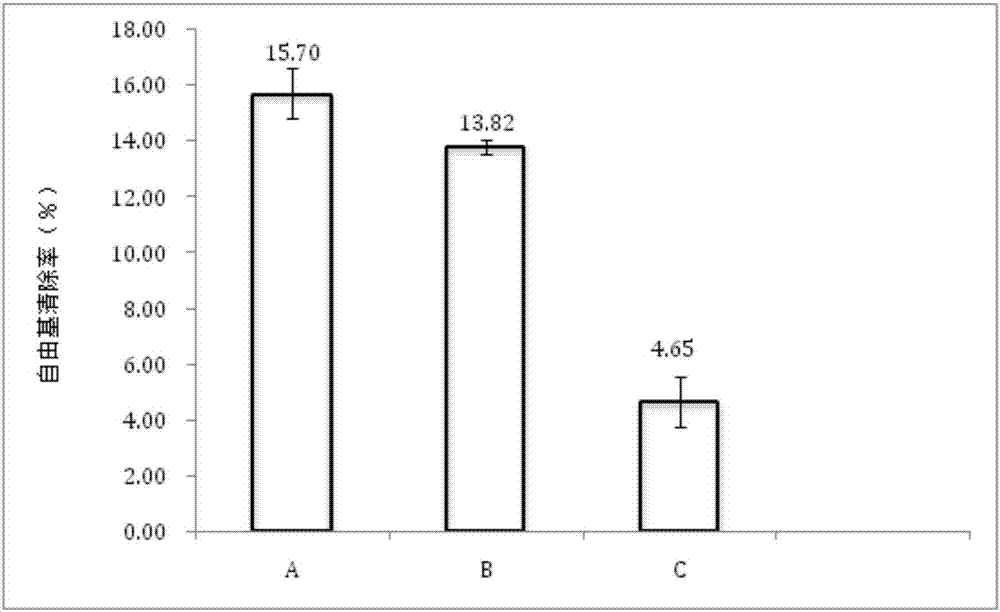

Degradable food preservative film and a preparing method thereof

ActiveCN107474501APossess active antibacterial effectAvoid pollutionMeat/fish preservationPolymer scienceGlycerol

The invention belongs to the field of food package materials, and provides degradable food preservative film. The preservative film includes degradable polymer resin and a plasticizer. The plasticizer at least includes one of glycerol monocaprylate and laurin. The degradable polymer resin base film at least includes one of polylactic acid and poly(3-hydroxybutyrate-4-hydroxybutyrate). The preservative film also includes an active bacteriostatic agent. Compared with degradable food preservative film in the prior art, the provided degradable food preservative film has lower oxygen permeability and oxidation resistance, can effectively retard chemical changes of foods, and can inhibit growth of aerobic bacteria on surfaces of foods.

Owner:蚌埠天成包装科技股份有限公司

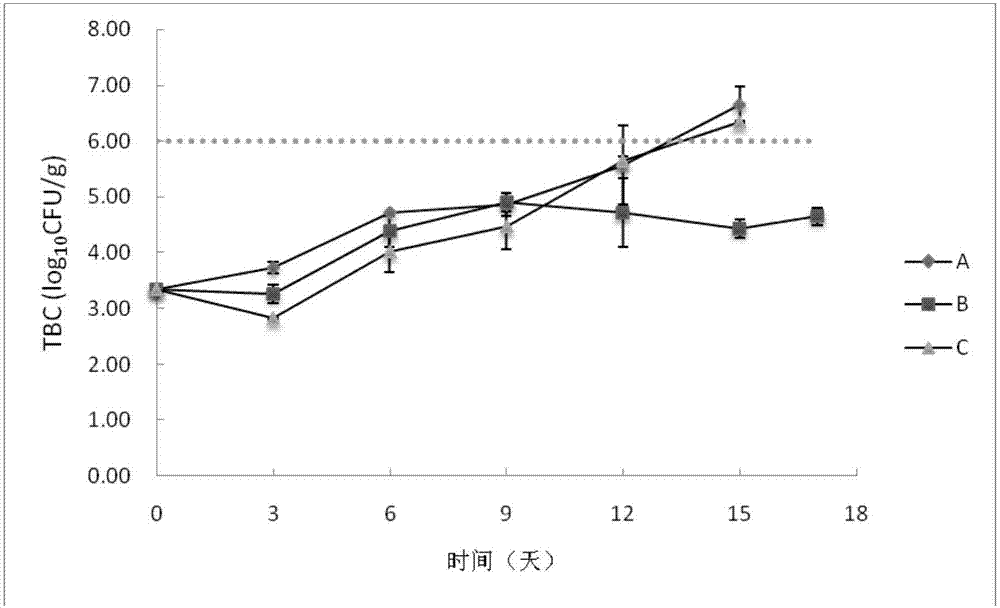

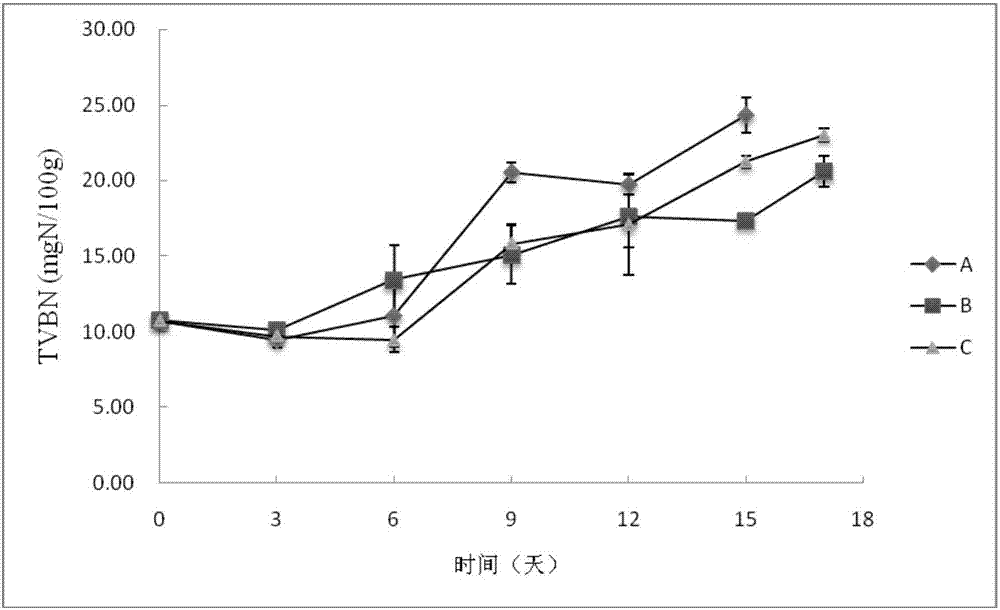

Cooled meat fresh-keeping storage method and electrostatic field fresh-keeping device used for keeping fresh

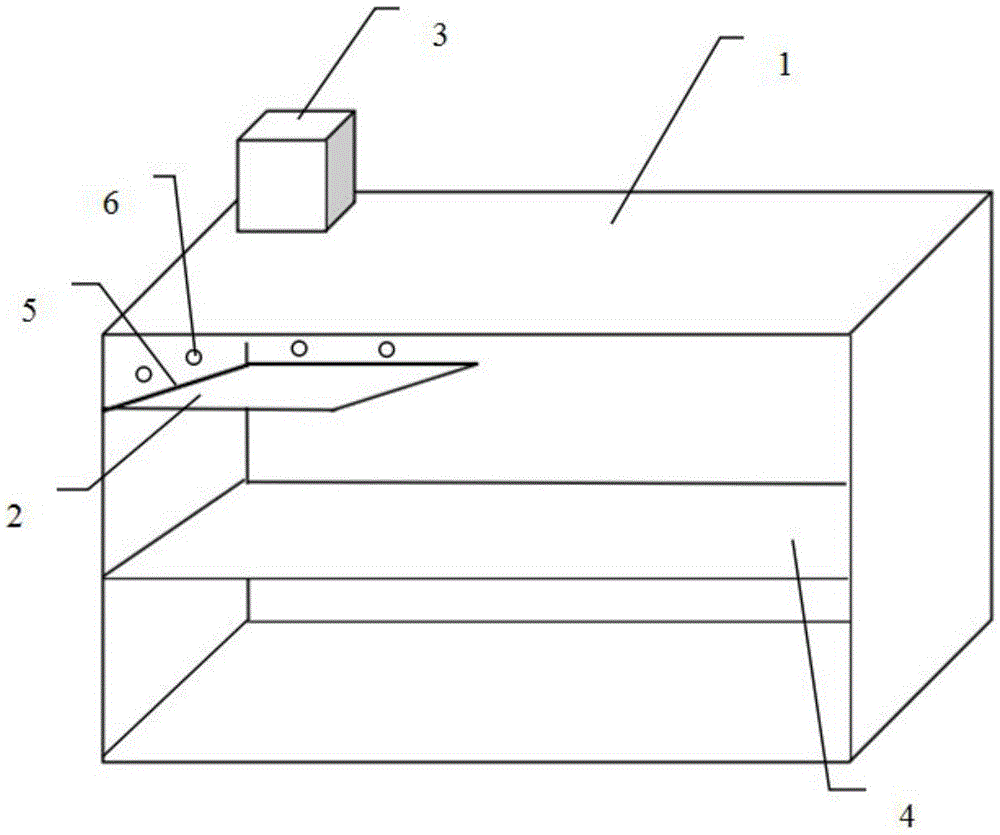

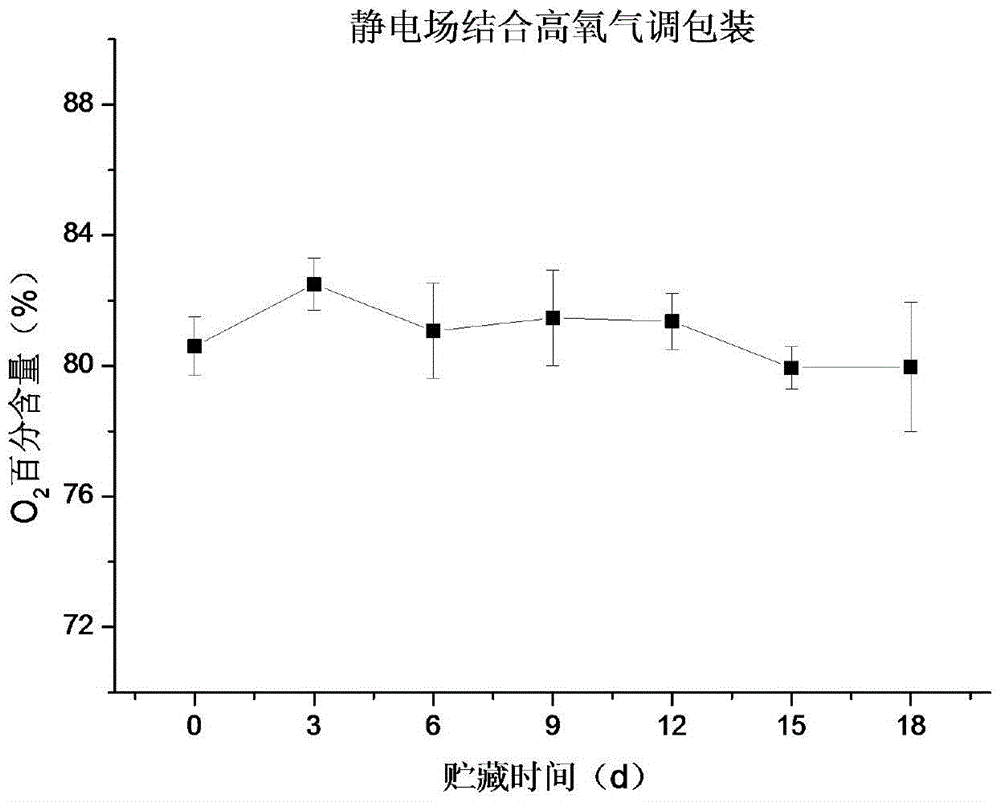

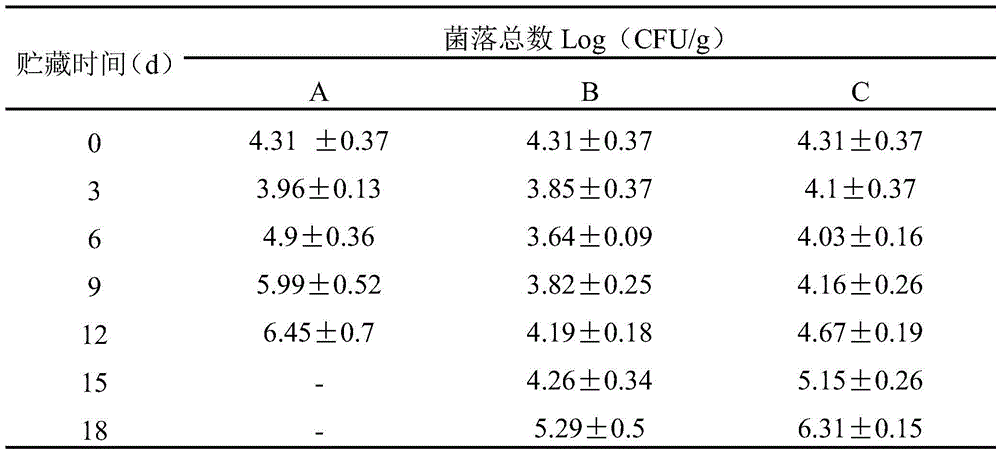

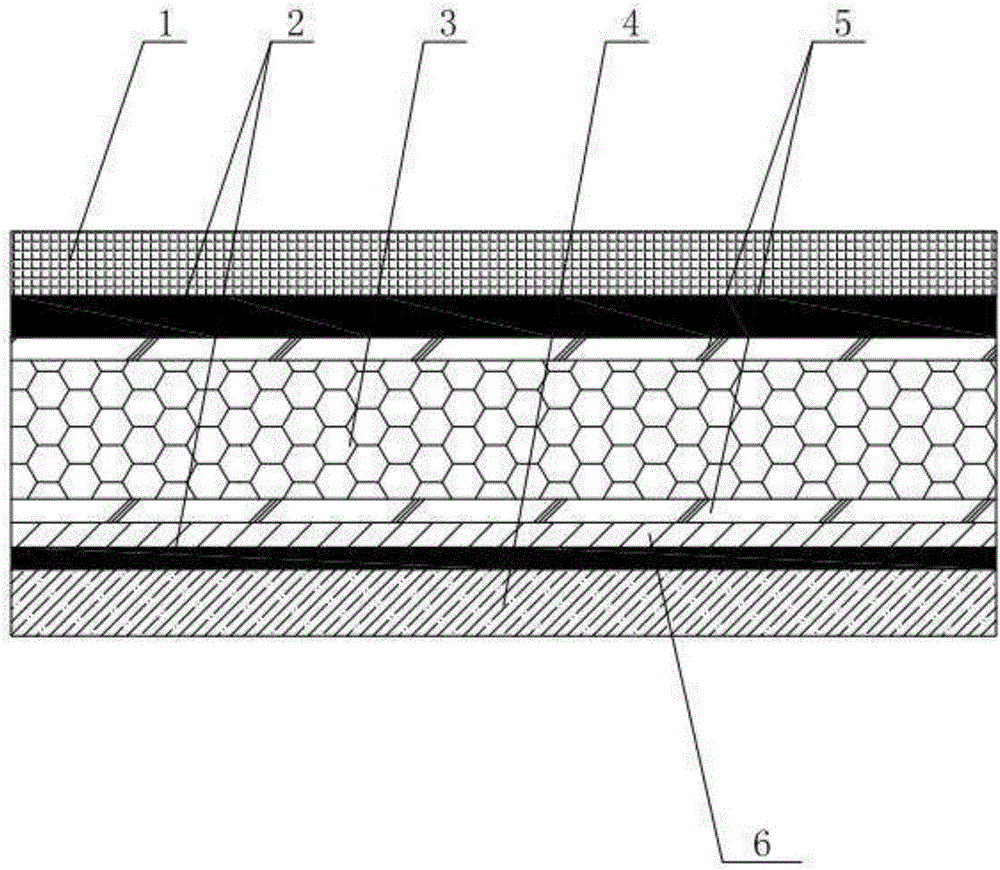

ActiveCN105638845AExtended storage timeImprove storage qualityFlexible coversWrappersElectricityModified atmosphere

The invention discloses a cooled meat fresh-keeping storage method and an electrostatic field fresh-keeping device for keeping fresh. The method comprises the following step of combining an electrostatic field fresh-keeping method and high-oxygen modified atmosphere packaging to carry out fresh-keeping storage on cooled meat, and further comprises the following steps: carrying out the high-oxygen modified atmosphere packaging on the cooled meat by adopting a high-barrier-property packaging material; and carrying out the fresh-keeping storage on the cooled meat subjected to the high-oxygen modified atmosphere packaging in a sealed low-temperature environment provided with the electrostatic field fresh-keeping device. The electrostatic field fresh-keeping device comprises a sealed box body or wall body and an electrostatic field generation device, wherein the electrostatic field generation device comprises an electrostatic field generation device body and electrodes; the electrodes are arranged in the sealed shell and are fixed on an inner wall of the sealed box body or wall body through an insulating material; the electrostatic field generation device body is arranged at the outer part of the sealed box body or wall body; the electrodes are electrically connected with the electrostatic field generation device body so that a space electrostatic field is formed in the sealed box body or wall body; and more than one electrode is arranged and the electrodes are distributed at different positions of the space in the sealed box body or wall body.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI +1

Solar back plate with high barrier property

InactiveCN106218155ALow costGood environmental performanceSynthetic resin layered productsPhotovoltaic energy generationPhysicsReflectivity

The invention relates to a solar back plate with the high barrier property. The solar back plate comprises a polyester film, a high reflection layer and a bonding layer-bonded weather resistance layer are sequentially arranged on one side of the polyester film, and a high reflection layer, barrier layers and a bonding layer-bonded weather resistance bonding layer are sequentially arranged on the other side of the polyester film; the barrier layers comprise the oxygen barrier layer and the vapor barrier layer. The solar cell back plate is obviously superior to an existing back plate, the electrical insulation property and the vapor barrier property are improved by arranging the polyester film, and the solar back plate is high in damp-heat resistance and aging resistance, long in life, high in weather resistance and reflection rate and excellent in aging resistance. By adopting a gelatin material as the oxygen barrier layer and adopting an inorganic material as the vapor barrier layer, the solar back plate is low in cost, the vapor barrier layer and the oxygen barrier layer can barrier vapor and oxygen respectively, the barrier property of the back plate is promoted, and the vapor and oxygen transmission rate of the solar back plate is obviously decreased.

Owner:WUXI SUNOCEAN

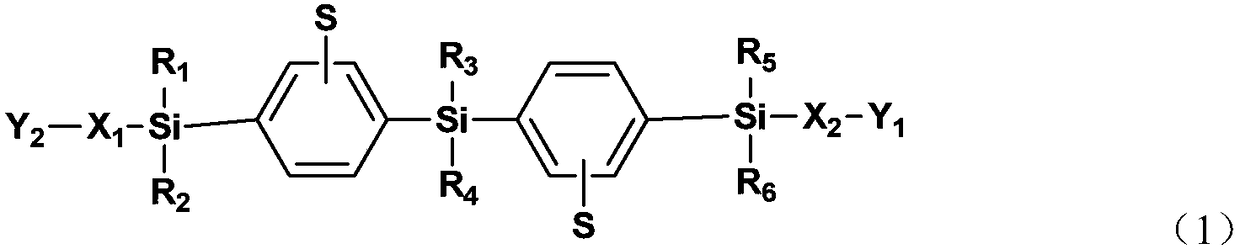

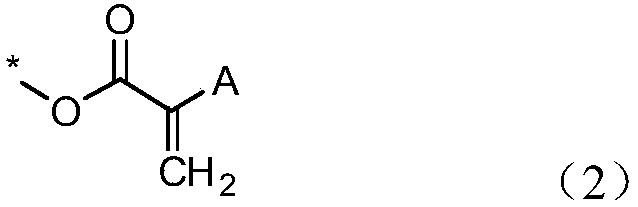

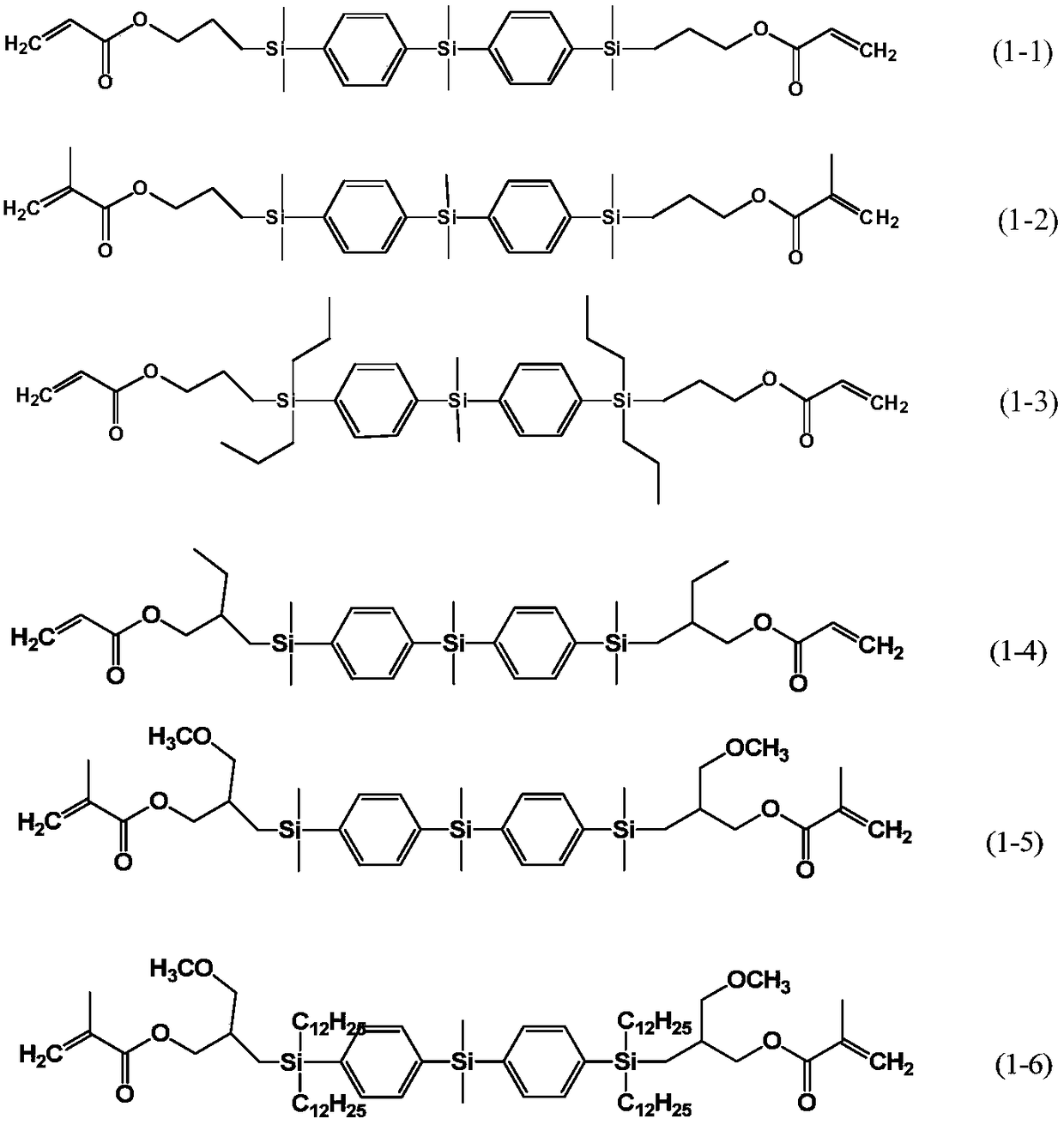

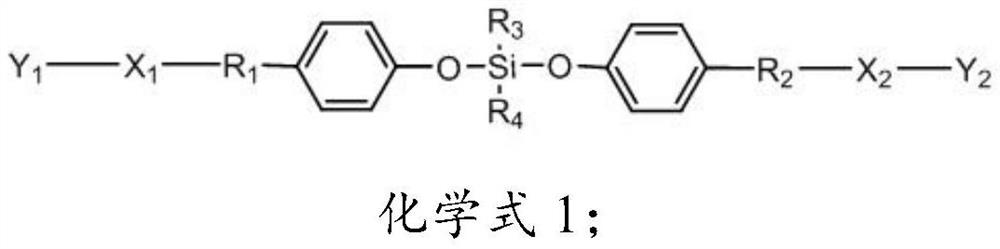

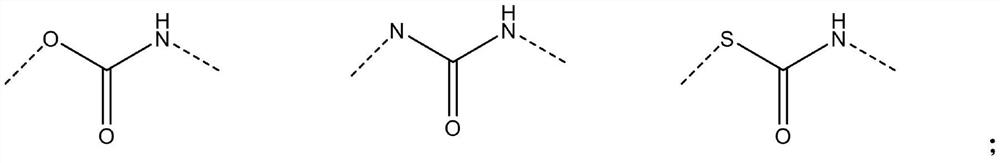

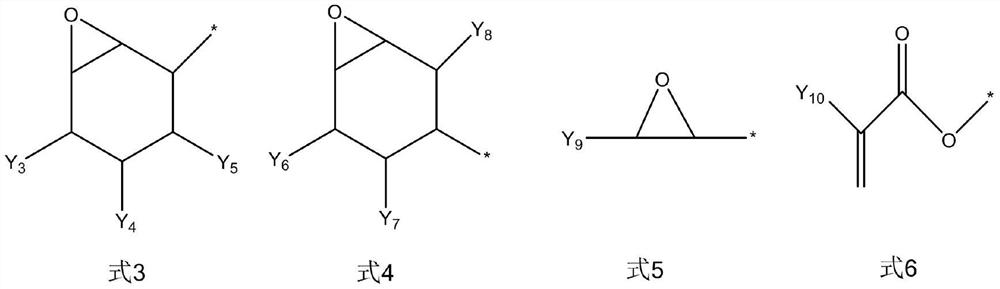

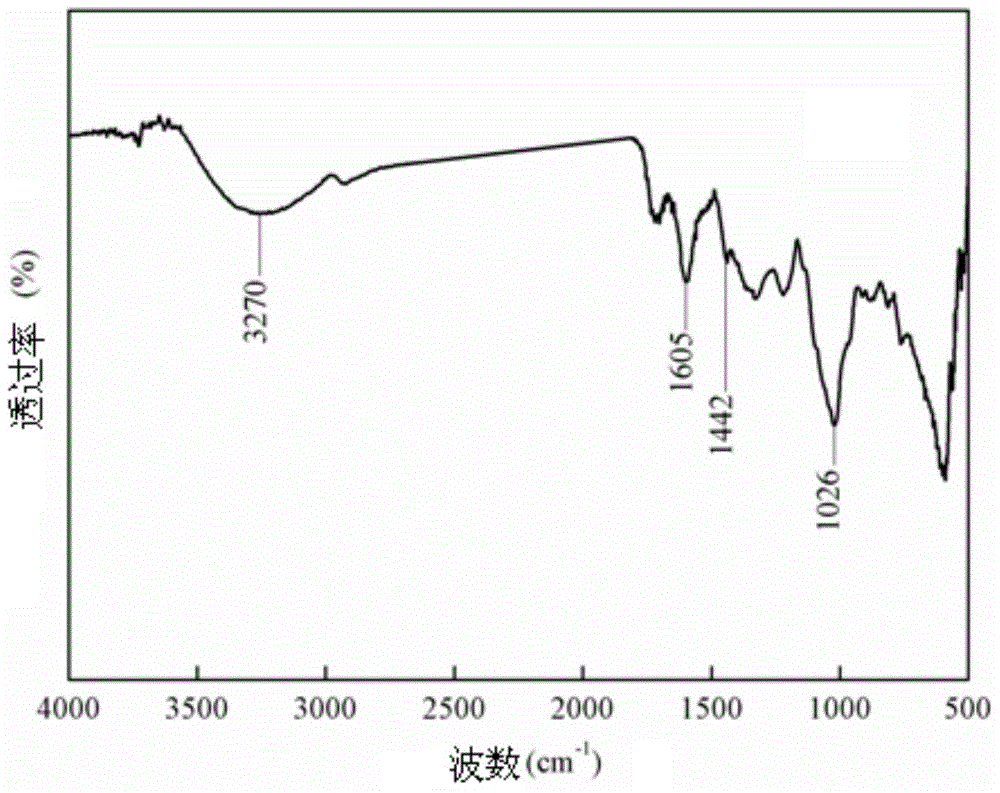

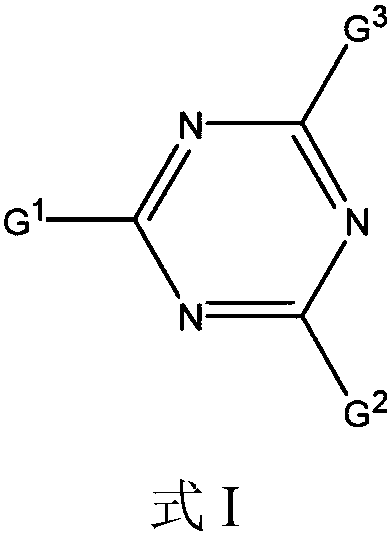

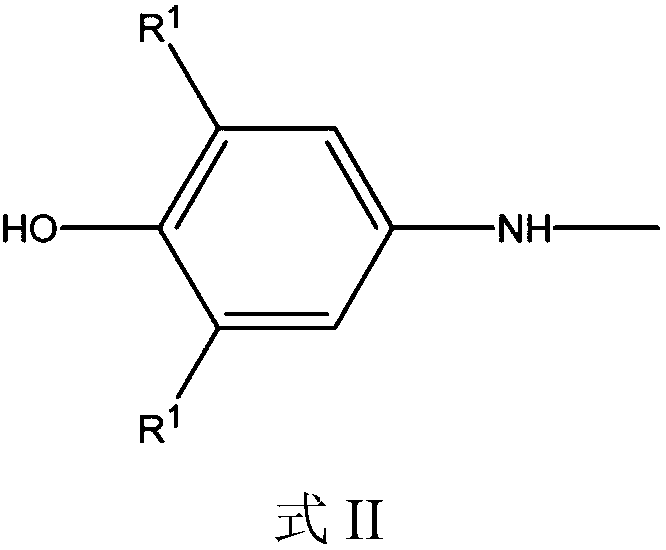

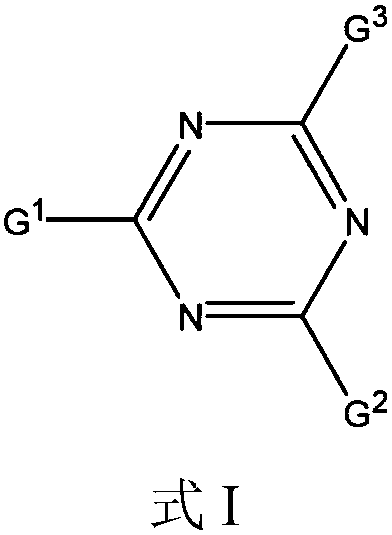

Compound for packaging film, ink composition containing compound and packaging structure

InactiveCN113185544AHigh light transmittanceFast curingGroup 4/14 element organic compoundsSolid-state devicesEpoxyPolymer science

The invention discloses a compound for packaging a film. The structural general formula of the compound for packaging the film is as follows: chemical formula 1. A curable silicon-containing monomer in the chemical formula 1 is used as a polymerization monomer. Due to a benzene ring and an epoxy group contained in the monomer, when the curable silicon-containing monomer is matched with a photocuring epoxy alkyl group-containing diluent monomer, a formed polymer film has higher light transmittance, higher curing speed and lower plasma etching rate, thereby better meeting the requirements of packaging films in the prior art.

Owner:JILIN OPTICAL & ELECTRONICS MATERIALS

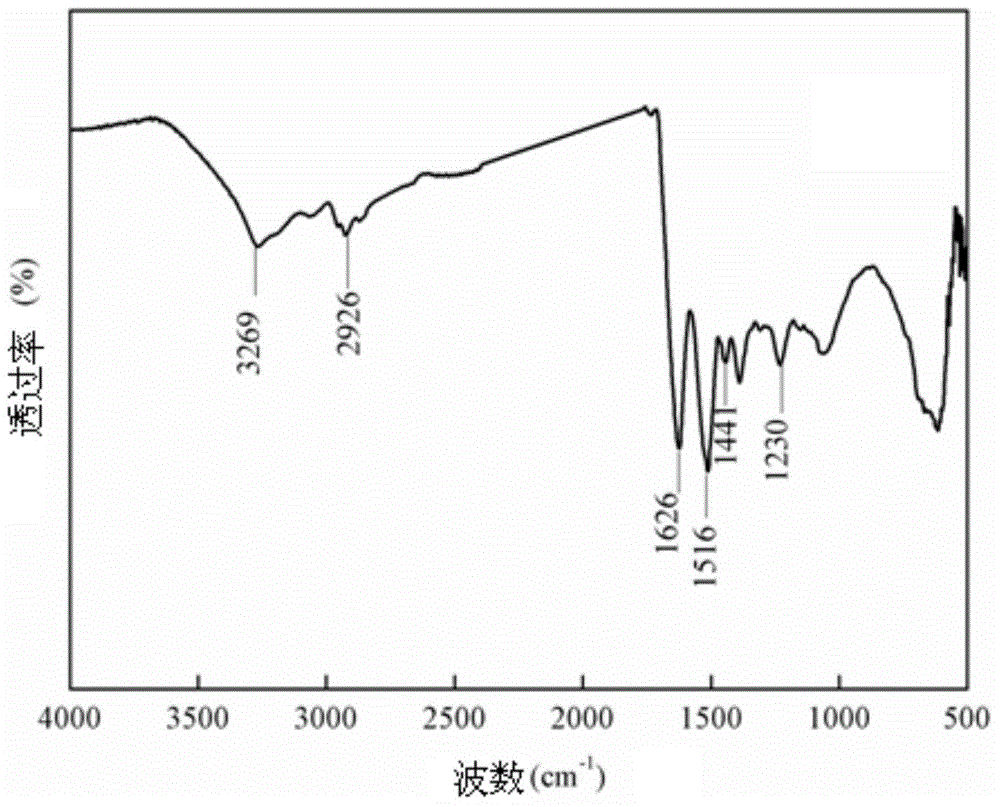

Chestnut shell extract-containing soy protein isolate-based film and preparation method thereof

The invention relates to a chestnut shell extract-containing soy protein isolate-based film and a preparation method thereof. The chestnut shell extract-containing soy protein isolate-based film solves the technical problem that the existing soy protein isolate-based film has low strength. The chestnut shell extract-containing soy protein isolate-based film is prepared from soy protein isolate powder, chestnut shell extract and glycerin. The preparation method comprises the following steps of dissolving the soy protein isolate powder in water to obtain a protein solution, dissolving the chestnut shell extract in water to obtain an extract solution, adding the extract solution and glycerin into the protein solution, carrying out homogenization emulsification to obtain a homogenate, adjusting a pH value of the homogenate, carrying out heating, carrying out cooling to obtain a film-forming solution, carrying out curtain coating on a substrate by the film-forming solution, and carrying out curing drying to obtain the chestnut shell extract-containing soy protein isolate-based film. The chestnut shell extract-containing soy protein isolate-based film has film tensile strength of 1.34-2.17MPa, breaking elongation of 185-217% and an oxygen permeation rate of 0.43-2.4cc / (m<2>. day) and can be used as a food package material.

Owner:NORTHEAST FORESTRY UNIVERSITY

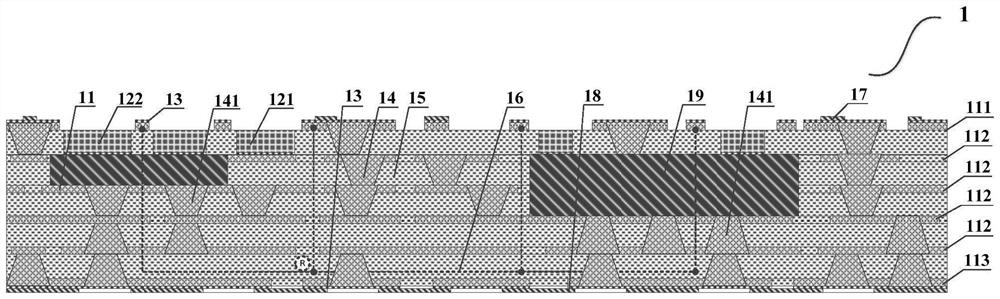

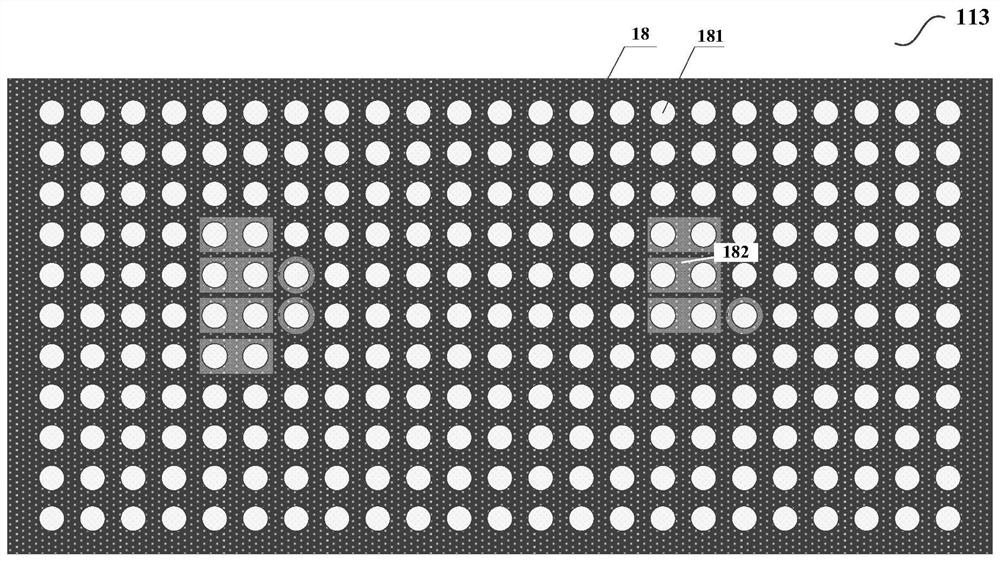

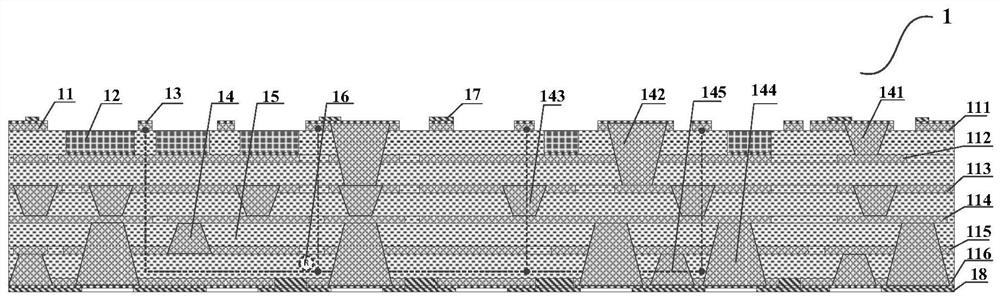

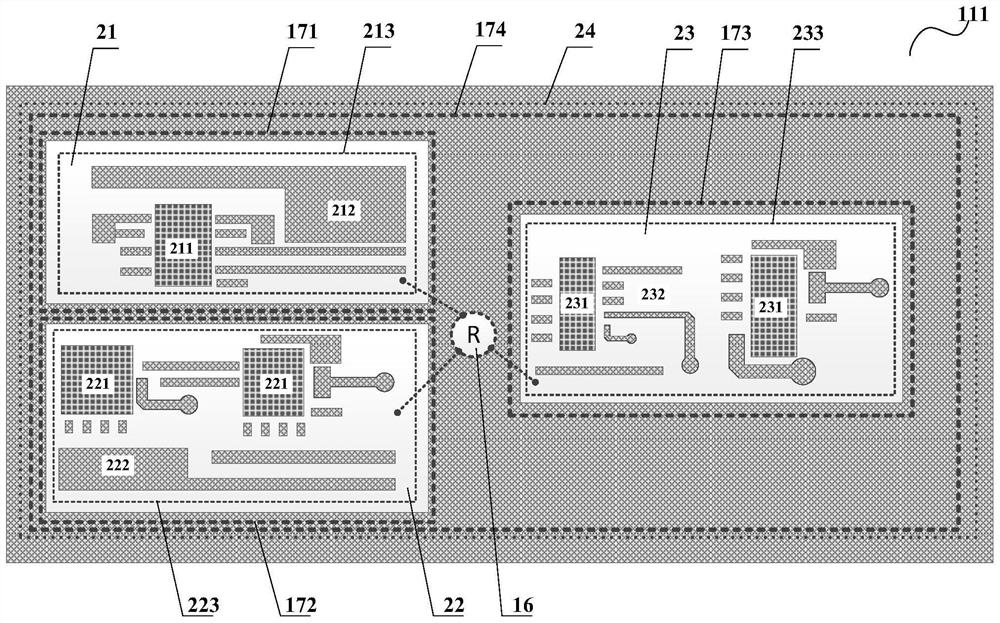

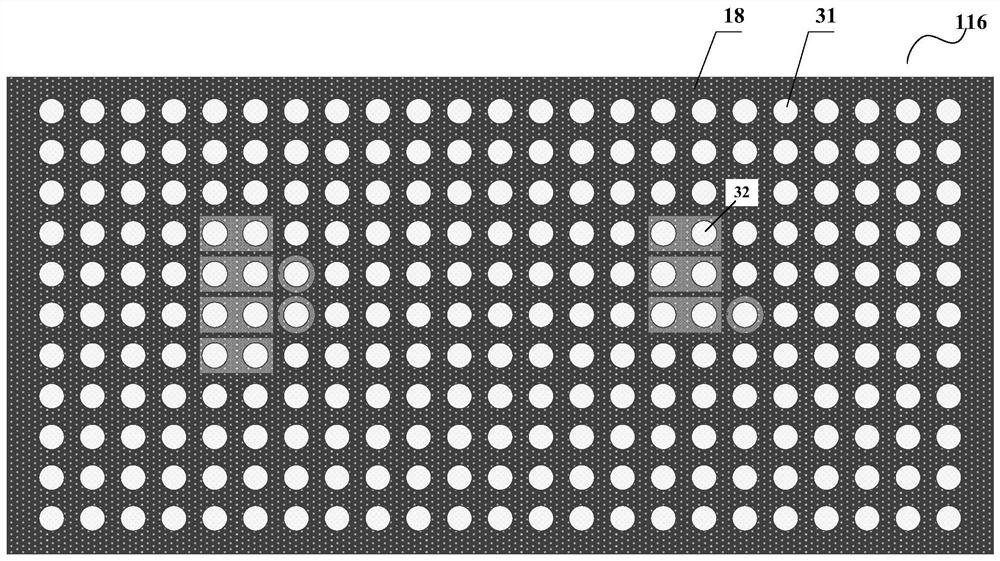

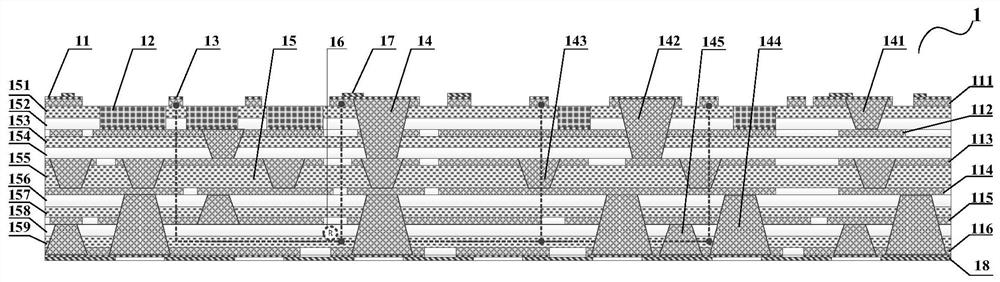

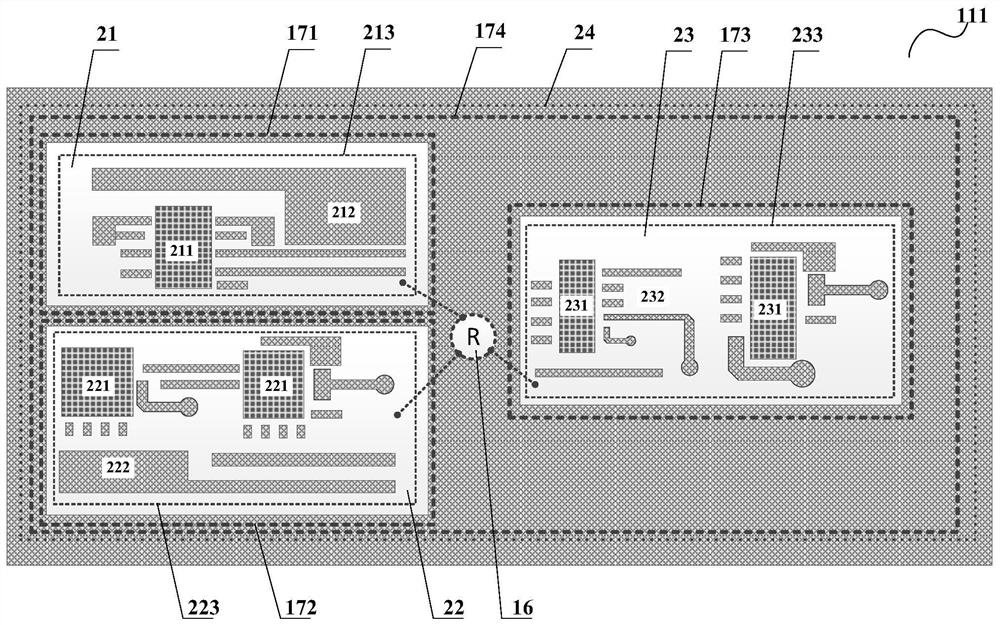

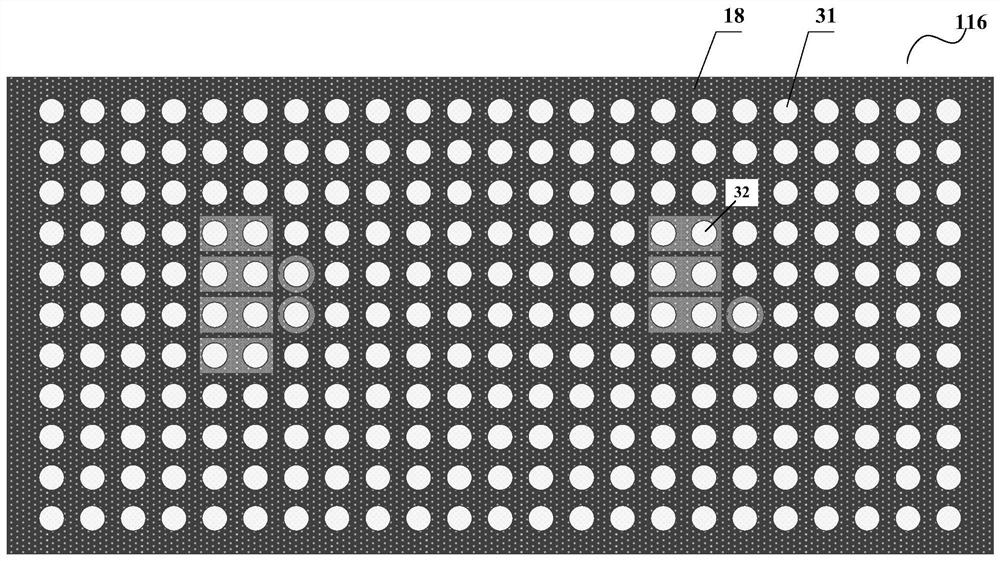

Airtight high-thermal-conductivity LCP packaging substrate and multi-chip system-in-package structure

ActiveCN112349700AGood thermal conductivityLow moisture absorptionSemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

The invention discloses an airtight high-thermal-conductivity LCP packaging substrate and a multi-chip system-in-package structure. The LCP packaging substrate comprises n graphical metal circuit layers distributed from the surface to the bottom surface, wherein the n graphical metal circuit layer on the bottom surface is provided with a structure used for welding BGA solder balls; n-1 insulating dielectric layers which are positioned between the adjacent graphical metal circuit layers; a plurality of blind grooves which are positioned in the insulating medium layer between the first graphical metal circuit layer and the second graphical metal circuit layer, wherein openings of the blind grooves face the first graphical metal circuit layer on the surface, each blind grooves comprises acommon chip mounting blind groove and a high-power chip mounting blind groove; a metal block which is positioned in the insulating dielectric layer and is connected with the bottom of the high-powerchip mounting blind groove; and a plurality of blind holes which penetrate through and are connected with the adjacent graphical metal circuit layers. The LCP package substrate can meet the system-in-package requirements of multiple chips, high airtightness requirements, high electromagnetic shielding, high thermal conductivity requirements and high reliability interconnection.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

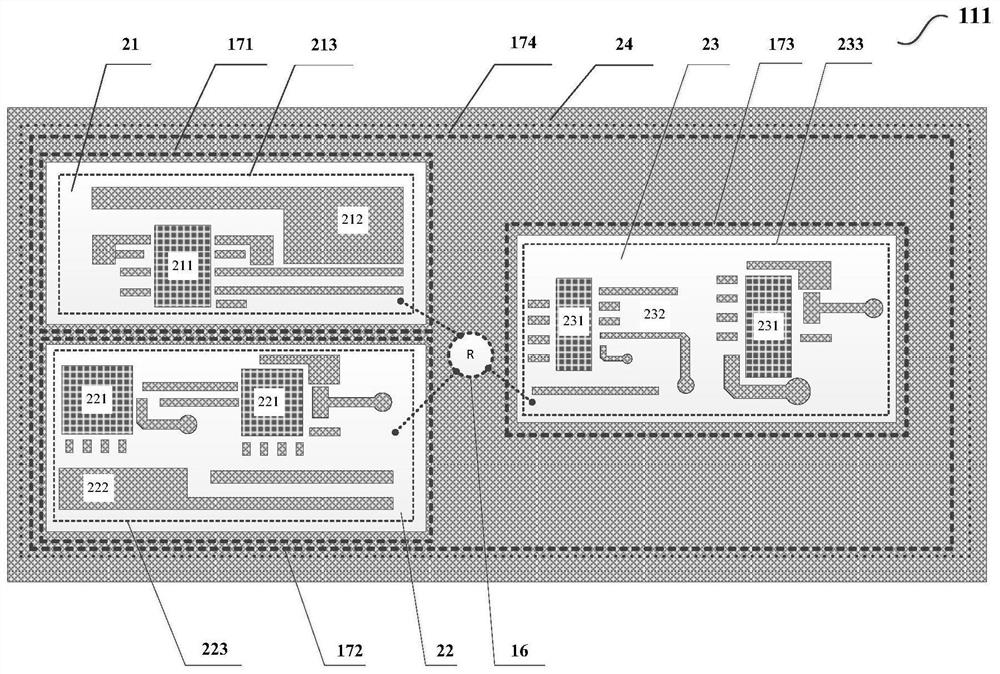

Six-layer wiring LCP packaging substrate, manufacturing method and multi-chip system-in-package structure

ActiveCN112349689AExcellent high-frequency transmission characteristicsLow moisture absorptionSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectromagnetic shielding

The invention discloses a six-layer wiring LCP packaging substrate, a manufacturing method and a multi-chip system-in-package structure, and the LCP packaging substrate comprises six graphical metal circuit layers which are distributed from the surface to the bottom surface, wherein the graphical metal circuit layers sequentially comprises a first graphical metal circuit layer, a second graphicalmetal circuit layer, a third graphical metal circuit layer, a fourth graphical metal circuit layer, a fifth graphical metal circuit layer and a sixth graphical metal circuit layer; five insulating dielectric layers which are positioned between the adjacent graphical metal circuit layers; a plurality of blind grooves which are positioned in the insulating medium layer between the first graphical metal circuit layer and the second graphical metal circuit layer, wherein openings of the blind grooves face the first graphical metal circuit layer; and a plurality of blind holes which are positionedbetween the graphical metal circuit layer and the insulating dielectric layer. According to the LCP packaging substrate, the system-level packaging requirements of multiple chips, high airtightness requirements, high electromagnetic shielding and high reliability interconnection are met.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

A kind of flexible colorless and transparent polyimide film and preparation method thereof

ActiveCN107936275BLow oxygen transmission rateLow water vapor transmission rateCoatingsPhotovoltaic energy generationPolymer sciencePtru catalyst

A flexible colorless and transparent polyimide film and a preparation method thereof belong to the field of polyimide films, and solve the problems of low oxygen and water vapor permeability and high thermal expansion coefficient of the existing polyimide film. The invention includes: dissolving diamine and dianhydride in an organic solvent to generate polyamic acid glue, adding dehydrating agent and catalyst to complete chemical imidization reaction to generate polyimide glue, and precipitating and drying it in a solvent to obtain Polyimide resin, dissolve it in an organic solvent to obtain a polyimide resin glue, vacuum degassing it, coat it on a glass plate, heat it up and then cool it down to obtain a flexible, colorless and transparent polyimide The surface of the buffer layer is treated to form a layer of buffer layer; a layer of polyimide resin glue is coated on the surface of the buffer layer, and the temperature is increased after heating to obtain a flexible colorless transparent polyimide film with a composite structure. The present invention has low oxygen transmission rate, low water vapor transmission rate, low thermal expansion coefficient and high visible light transmission rate.

Owner:长春聚明光电材料有限公司 +1

Antibacterial fresh-keeping material containing nano-silver and preparation method of antibacterial fresh-keeping material

ActiveCN111763365AHas broad-spectrum antibacterial effectLow oxygen transmission rateBio-packagingHollow articlesFresh foodMaterials science

The invention belongs to the technical field of preparation of fresh-keeping materials, and particularly relates to an antibacterial fresh-keeping material containing nano-silver and a preparation method of the antibacterial fresh-keeping material. The nano-silver-containing fresh-keeping material provided by the invention comprises the following components in parts by weight: 80-100 parts of polyethylene, 20-30 parts of a dispersing agent, 5-12 parts of an adhesive and 3-10 parts of composite nano-silver powder. The antibacterial fresh-keeping film or fresh-keeping bag containing nano-silver,provided by the invention, can efficiently inhibit the growth of various pathogenic microorganisms in a broad-spectrum manner, is excellent in sterilization and mildew resistance, effectively prevents the loss, oxidation, decay or degradation of moisture or oil of fresh foods, prolongs the shelf life, and improves the quality guarantee effect.

Owner:ANSON NANO BIOTECH ZHUHAI

Tantalum alloy surface modified composite Hf-Ta coating layer and preparation method thereof

ActiveCN105506427AImprove antioxidant capacityImprove high temperature oxidation resistanceMetallic material coating processesSand blastingSlurry

The invention discloses a tantalum alloy surface modified composite Hf-Ta coating layer. The tantalum alloy surface modified composite Hf-Ta coating layer consists of the following components in percentage by mass: 19.5-24.5% of Ta, 0.5-2.5% of Si, 0.5-1.2% of B, 0.5-2.5% of Al, 0.5-2.0% of Cr, and the balance being Hf. In addition, the invention further discloses a method for preparing the modified composite Hf-Ta coating layer; and the method comprises the following steps: (1) a tantalum alloy is washed by acid after being polished, and then is subjected to the sand blasting treatment and the degreasing treatment; (2) modified composite Hf-Ta slurry is prepared; and (3) the slurry is pre-positioned on the surface of the tantalum alloy to obtain a pre-positioned layer; and then, the high-temperature fusion sinteringis performed to prepare the modified composite Hf-Ta coating layer. The modified composite Hf-Ta coating layer can prominently improve the oxidation resistance of the tantalum alloy in environments of ultrahigh temperature and low oxygen pressure, and can provide short-time protection for the tantalum alloy in an ultrahigh-temperature oxidation environment and an ablation environment.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A kind of tantalum alloy surface modified composite HF-TA coating and preparation method thereof

ActiveCN105506427BImprove antioxidant capacityImprove high temperature oxidation resistanceMetallic material coating processesSand blastingCerium

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A kind of flexible oled and preparation method thereof

ActiveCN102760846BHigh light transmittanceGood flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodePolyethylene terephthalate glycol

The invention discloses a preparation method for a flexible organic light emitting diode (OLED), comprising the following steps: (1) a polyethylene terephthalate (PET) sheet is fixed at a support plate by binder as a base plate; the surface of the base plate is cleaned and dried; a barrier layer which is formed by successive alternating deposit of thin polymer films and thin inorganic material films with high transmittance is prepared on the base plate; the refractive index of the thin polymer films and the thin inorganic material films matches with the refractive index of the base plate; (2) an indium tin oxide (ITO) film and a metal layer are prepared at the base plate equipped with the barrier layer and etching of a metal line and an ITO line and making of polyimide (PI) patterns and RIB patterns are completed; during etching of the metal line and the ITO line, mechanical stirring or ultrasonic stirring are performed on the etching liquid; (3) then the base plate is put in an evaporation chamber for evaporation of an organic function layer and a negative electrode; (4) a thin film packaging layer is prepared on the surface of the negative electrode by vacuum evaporation and the packaging layer is formed by alternating deposit of at least one layer of organic material and at least one layer of inorganic material; and (5) the base plate is stripped off the support plate.

Owner:TRULY SEMICON

Six-layer wiring LCP packaging substrate, manufacturing method and multi-chip system-in-package structure

ActiveCN112349686ALow moisture absorption and water permeability and oxygen transmission rateHigh electromagnetic shieldingSemiconductor/solid-state device detailsSolid-state devicesEngineeringSystem in package

The invention discloses a six-layer wiring LCP packaging substrate, a manufacturing method and a multi-chip system-in-package structure, and the LCP packaging substrate comprises six graphical metal circuit layers which are distributed from the surface to the bottom surface, wherein the six graphical metal circuit layers sequentially comprises a first graphical metal circuit layer, a second graphical metal circuit layer, a third graphical metal circuit layer, a fourth graphical metal circuit layer, a fifth graphical metal circuit layer and a sixth graphical metal circuit layer; five insulatingdielectric layers which are positioned between the adjacent graphical metal circuit layers; a plurality of blind grooves which are positioned in the insulating medium layer between the first graphical metal circuit layer and the second graphical metal circuit layer, wherein openings of the blind grooves face the first graphical metal circuit layer; and a plurality of blind holes which are positioned between the graphical metal circuit layer and the insulating dielectric layer. The LCP packaging substrate of the airtight packaging structure can meet the system-level packaging requirements of multiple chips, high airtight requirements, high electromagnetic shielding and high reliable interconnection.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

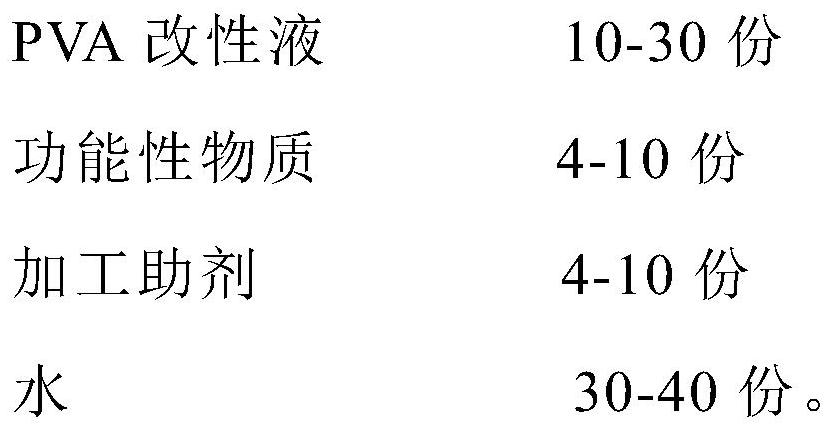

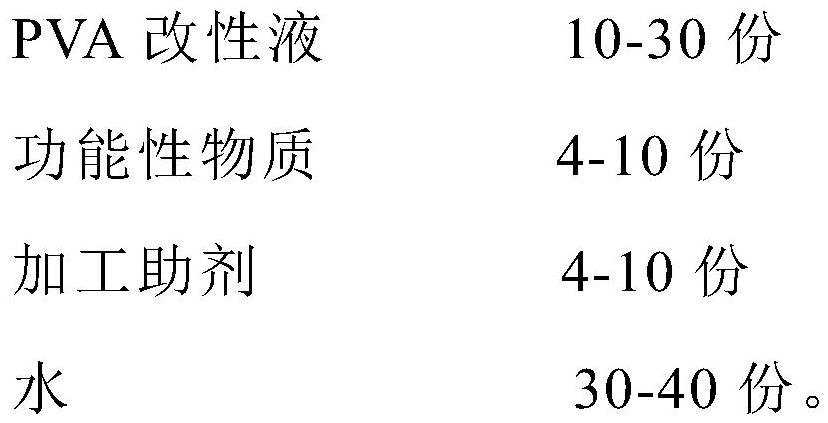

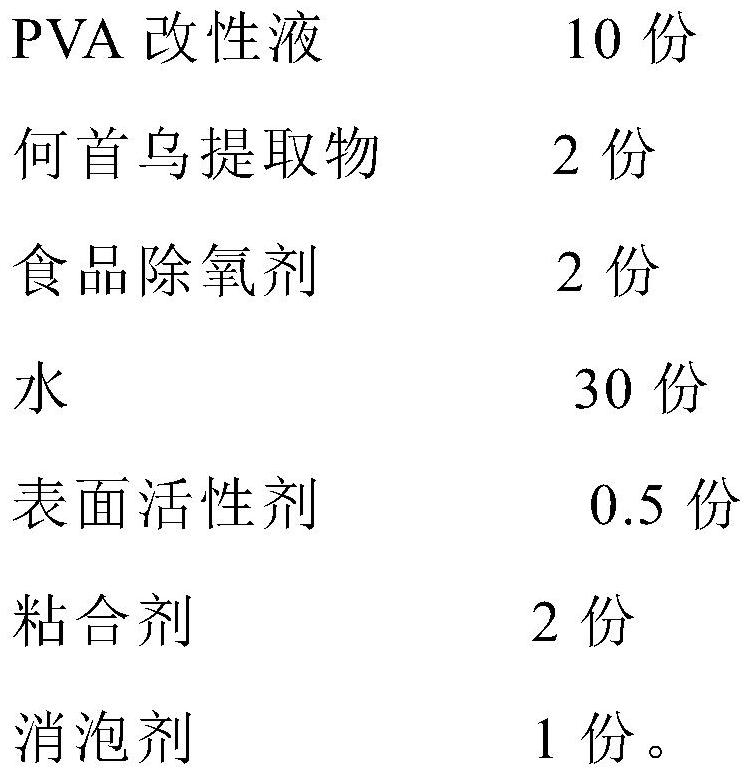

High-barrier PVA coating liquid and application thereof

ActiveCN112795248AImprove hydrophobicityReduce transmittanceCoatingsAntioxidant capacityPhysical chemistry

The invention relates to the technical field of packaging materials, and in particular, relates to high-barrier PVA coating liquid and application thereof. Dried products of edible mushrooms are easy to absorb moisture and damp when stored in a humid environment, and decay and deteriorate under the action of oxygen, so that the edible value is lost, and a pure PE packaging bag is relatively good in moisture resistance, but relatively poor in oxygen barrier performance. Aiming at the technical problems, the invention provides the high-barrier PVA coating liquid, modified graphene is added into the components of the high-barrier PVA coating liquid, the modified graphene has high hydrophobicity, the high-barrier PVA coating liquid is coated on the surface of a PE packaging film, so that the water vapor transmission rate of a packaging bag can be effectively reduced, copper atoms are further loaded on the surface of a molecular structure of the modified graphene, the high reducibility is achieved, and oxygen in the external environment can be effectively prevented from entering the PE packaging bag; the high-barrier PVA coating liquid is also added with a plant extract with relatively strong oxidation resistance and a food deoxidant, so that the oxygen barrier performance of the packaging bag is effectively improved.

Owner:南通英韦尔新材料科技有限公司

Packing container for plant fruit or fruit stone and packing method therefor

This invention provides one package container and the container package method to prevent plant fruit or fruit core microbe generation, wherein the container comprises food package bag with moisture degree below 10g / m<2> and oxidation degree as 10cc / m<2>.24hrs.atm. The invention comprises inner package and one shell in shape of plant core or fruit and the package drier and deoxidant between the food package and inner package.

Owner:安剑涛

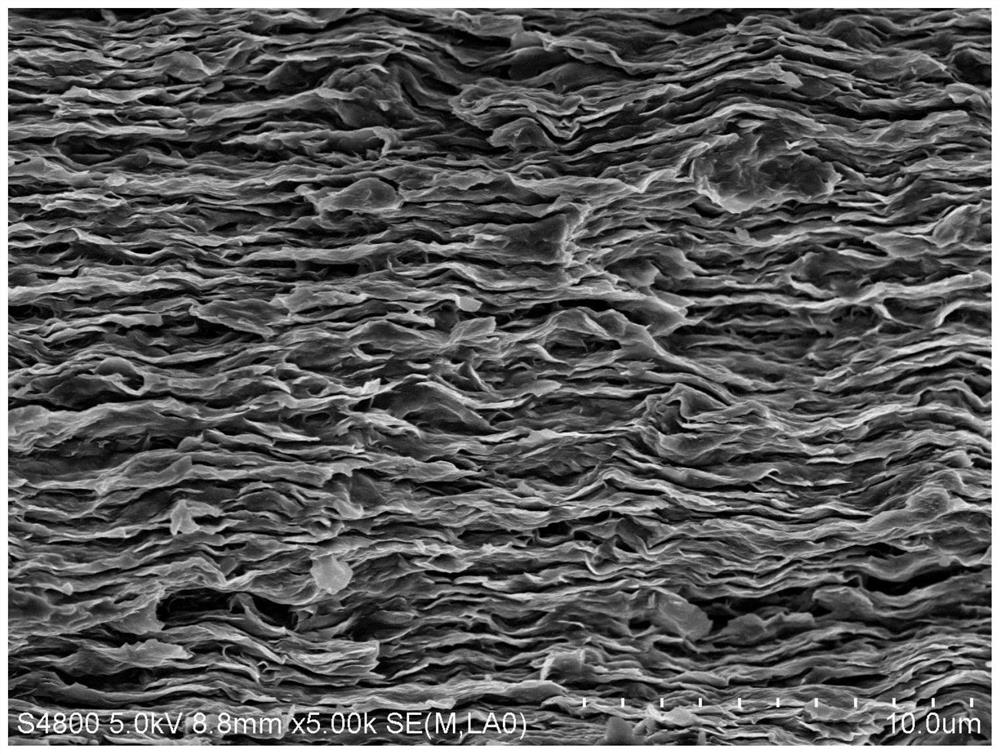

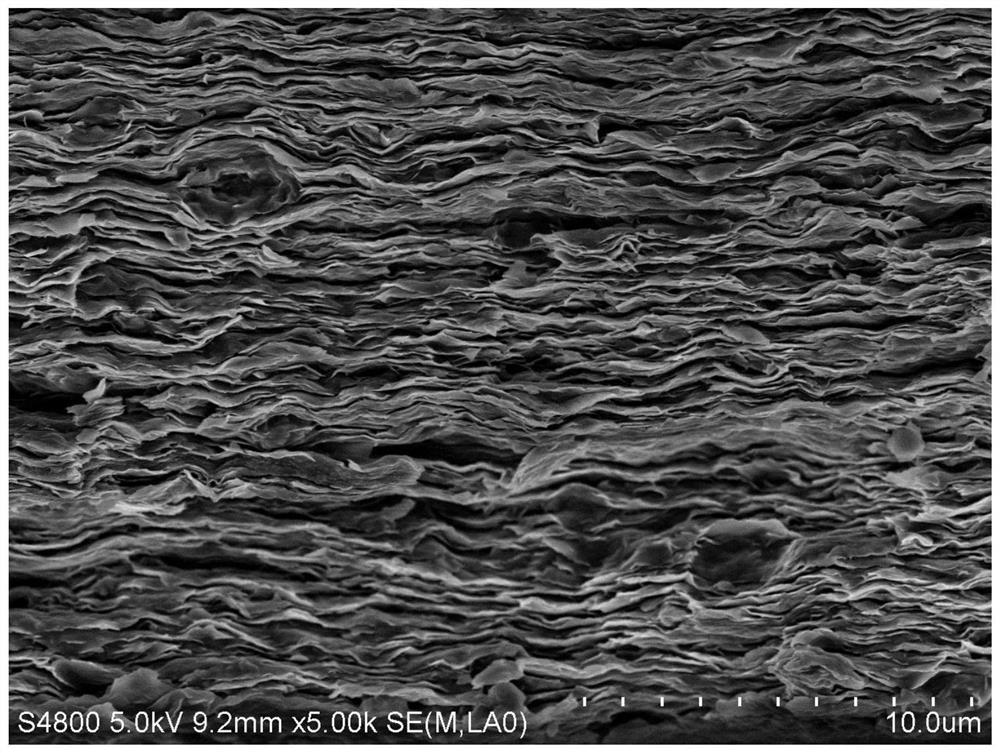

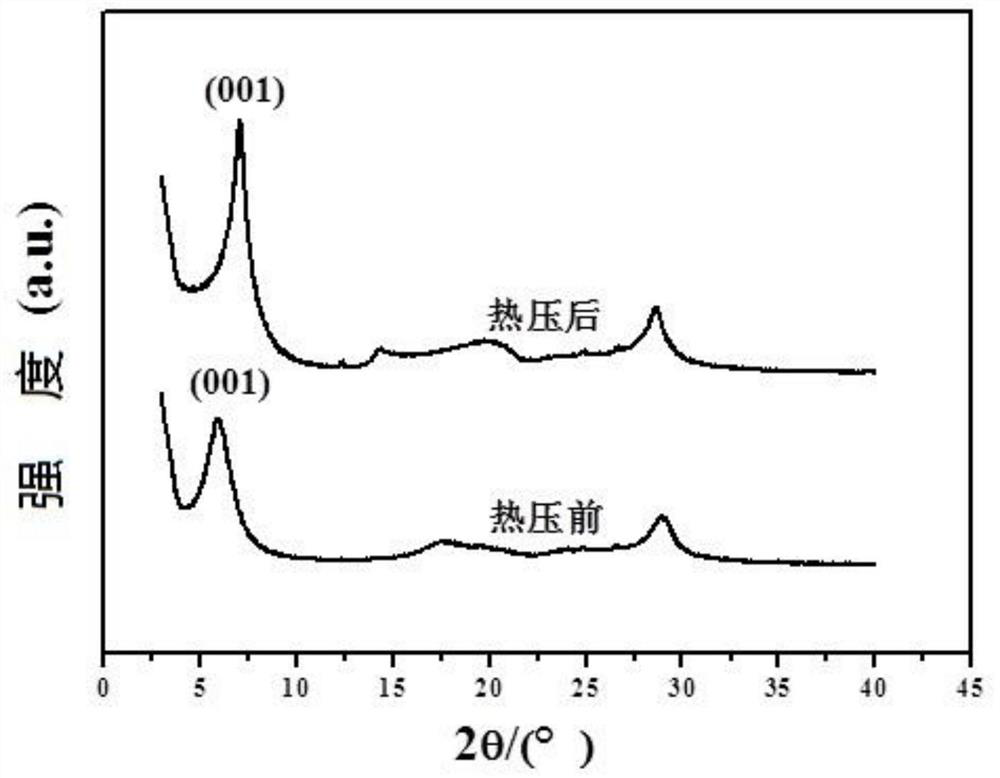

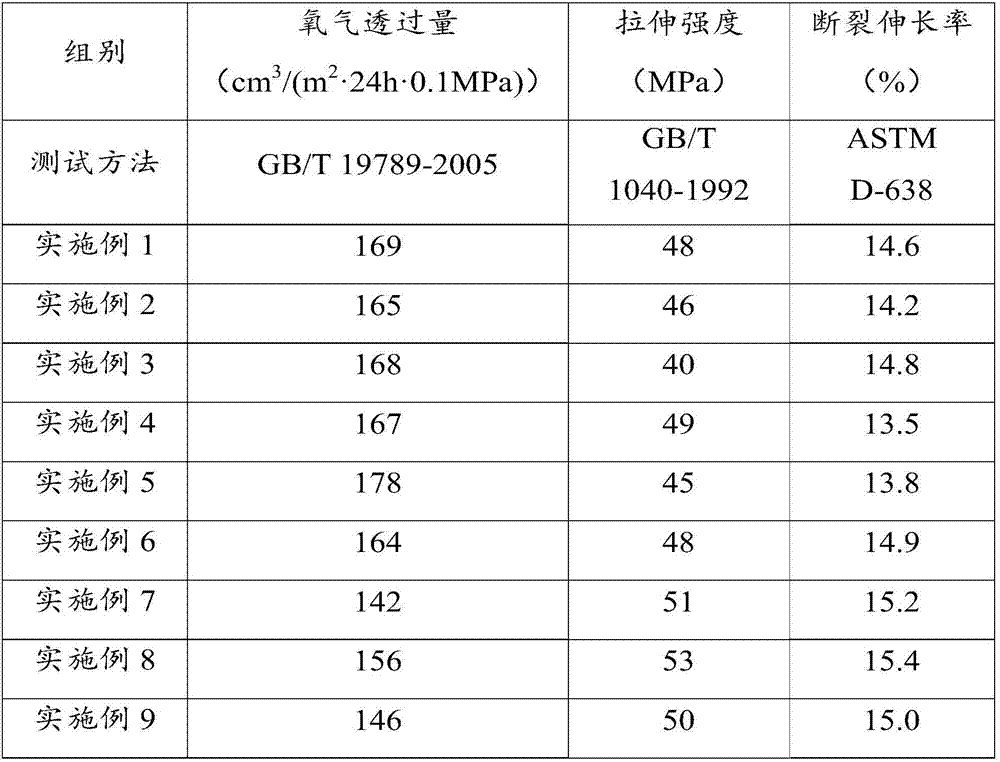

A method for preparing a high-strength and high-toughness layered structure barrier film

The invention combines evaporation self-assembly and hot pressing technology to prepare shell imitation binary and ternary layered structure films, the preparation method is simple, the raw material price is cheap, the source is abundant, the cost is low, the environment is friendly, and it is beneficial to large-scale production. The tensile strength of the film prepared by the present invention is as high as 320 MPa or more, the modulus has also been greatly improved, and the toughness is excellent; the excellent flame retardancy and gas barrier properties of the GO sheet and the MMT sheet are used to improve the barrier properties of the hybrid film. Oxygen and water vapor barrier and flame retardancy, such as the oxygen transmission rate of the organic-inorganic hybrid film is reduced by more than 50%; by adjusting the ratio between montmorillonite, graphene oxide and carboxymethyl cellulose, the Regulation of organic-inorganic hybrid membranes.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Air-isolating type environment-friendly composite material as well as preparation method and application thereof

InactiveCN107501881AEnvironmental protection is goodGood processing performancePolylactic acidPropylene carbonate

The invention relates to the field of degradable plastics, and in particular provides an air-isolating type environment-friendly composite material as well as a preparation method and application thereof. The air-isolating type environment-friendly composite material is mainly prepared from the following raw materials in parts by weight: 20-60 parts of polylactic acid (PLA), 20-40 parts of poly(butyleneadipate-co-terephthalate) (PBAT), 5-20 parts of poly(propylene carbonate) (PPC), 1-10 parts of PLA / nano-titanium nitride masterbatch, 3-15 parts of filler, 1-5 parts of thermoplastic elastomer, 0.5-1 part of a lubricating agent and 1-3 parts of a chain extender, wherein the PLA / nano-titanium nitride masterbatch is mainly prepared from the following raw materials in parts by weight: 80-120 parts of PLA, 0.3-1.2 parts of nano-titanium nitride, 0.3-1.2 parts of a hydrolysis-resistant stabilizer and 0.5-1.5 parts of a chain extender. The composite material has the advantages of being good in environmental protection property, high in gas barrier property, good in thermal stability and good in mechanical performance.

Owner:青岛百佳创想新材料有限公司

A kind of degradable food preservation film and preparation method thereof

The invention belongs to the field of food package materials, and provides degradable food preservative film. The preservative film includes degradable polymer resin and a plasticizer. The plasticizer at least includes one of glycerol monocaprylate and laurin. The degradable polymer resin base film at least includes one of polylactic acid and poly(3-hydroxybutyrate-4-hydroxybutyrate). The preservative film also includes an active bacteriostatic agent. Compared with degradable food preservative film in the prior art, the provided degradable food preservative film has lower oxygen permeability and oxidation resistance, can effectively retard chemical changes of foods, and can inhibit growth of aerobic bacteria on surfaces of foods.

Owner:蚌埠天成包装科技股份有限公司

Vinyl polymer nano composite material containing polar side group and preparation method thereof

The invention provides a vinyl polymer nano composite material containing a polar side group and a preparation method thereof. The nano polymer composite material comprises: a component A which is a vinyl polymer containing the polar side group; a component B which is a layered silicate, modified layered silicate and / or graphene substance; a component C which is an organophenol and / or organic amine compound; wherein the component A is 100% by mass, the component B is 0.1% to 20.0% by mass; and the component C is 0.01% to 1.8% by mass. The component A in a bulk form is melt-blended with the component B and the component C at 170-240DEG C for extruding and granulating, or the component A is mixed with the component B and the component C in a solution form to prepare a suspension. After a solvent is removed, the obtained solid is washed, filtered, and dried to obtain the nano polymer composite material. The thermal stability of the obtained nano-composite material is obviously improved, the problem of high-temperature discoloration of the polymer is effectively solved, and the barrier property of the nano-composite material is also improved.

Owner:北京引发科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com