A method for preparing a high-strength and high-toughness layered structure barrier film

A film and composite film technology, applied in the field of organic-inorganic hybrid film materials, can solve the problems of thick film thickness and poor mechanical properties, achieve low cost, excellent toughness, improve oxygen and water vapor barrier and flame retardant. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

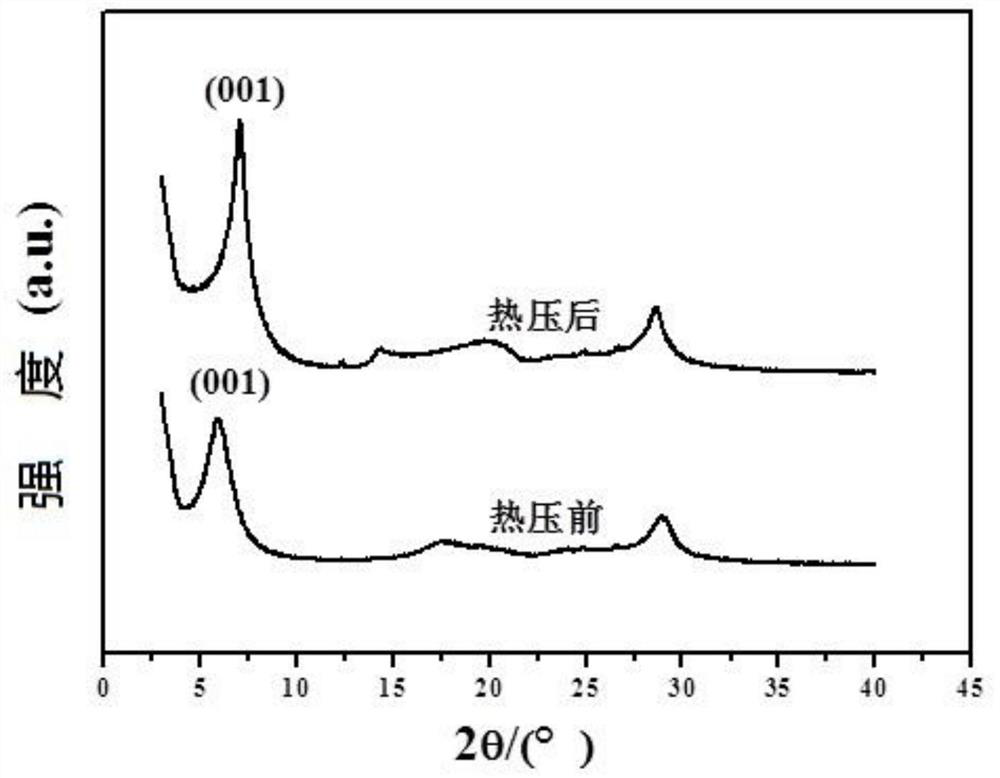

[0038]According to the preparation method of the present invention, the imitation shell film binary and ternary layered structure films are prepared by combining evaporation self-assembly and hot pressing technology, the preparation method is simple, the raw material price is cheap, the source is abundant, the cost is low, the environment is friendly, and it is beneficial to Mass production. Especially in the preparation method of the present invention can effectively reduce the consumption of graphene (GO), GO plays the reinforcing phase of the co-dispersant of montmorillonite suspension solution and montmorillonite-carboxymethyl cellulose mixed solution, obtains The GO / MMT-CMC ternary composite film has excellent strength, toughness and modulus.

[0039] The mass ratio of CMC and MMT in step (3) of the preparation method according to the present invention is 10:90 to 90:10; preferably 20:80 to 80:20. When the MMT exceeds 90%, the dispersion of MMT in the CMC is poor, result...

Embodiment 1

[0044] (1) 10 g of CMC was dissolved in 500 ml of distilled water and stirred at a constant speed for 4 hours at room temperature to obtain a CMC solution with a concentration of 2% by mass. Dissolve 3g of MMT powder in 100ml of deionized water and stir overnight at a speed of 500r / min to swell, then continue to emulsify the swollen MMT suspension overnight with an emulsifier at 8000r / min for 5 times to fully swell and peel off, and let it stand Over night, a suspension of MMT was obtained. Add 160g of 2wt% CMC solution dropwise into 27g of MMT suspension, stir at normal speed for 24h, then ultrasonically remove bubbles for 15min, and set aside.

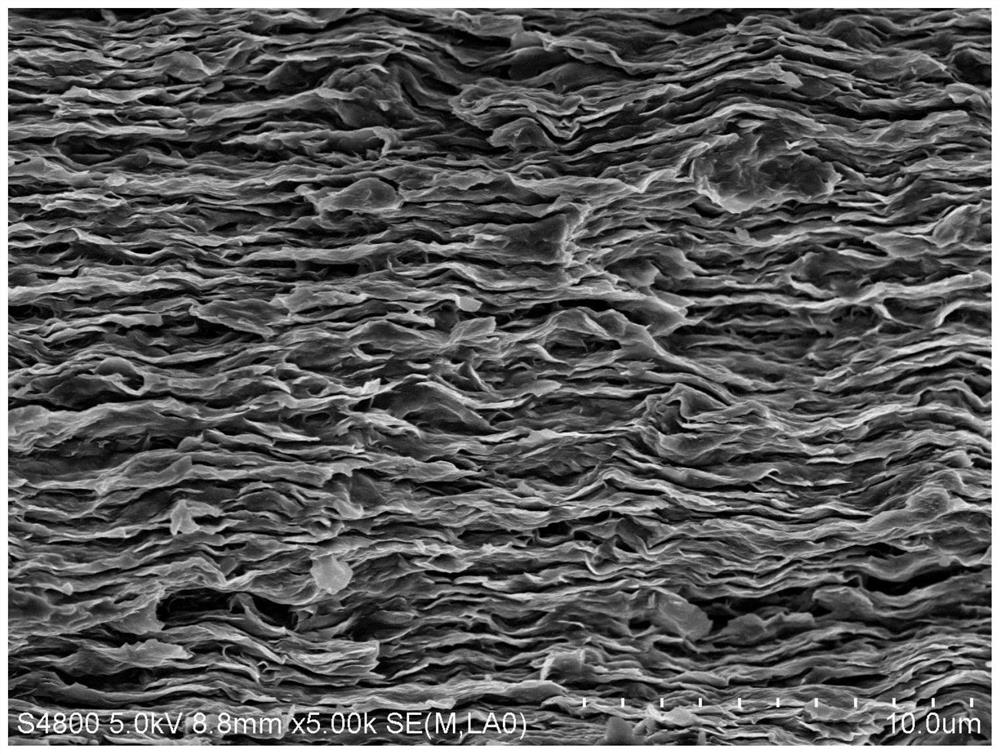

[0045] (2) Evaporative self-assembly: spread the mixed solution obtained in step (1) on a plastic surface dish by casting method, and dry overnight at 40° C. to obtain an MMT-CMC binary composite film.

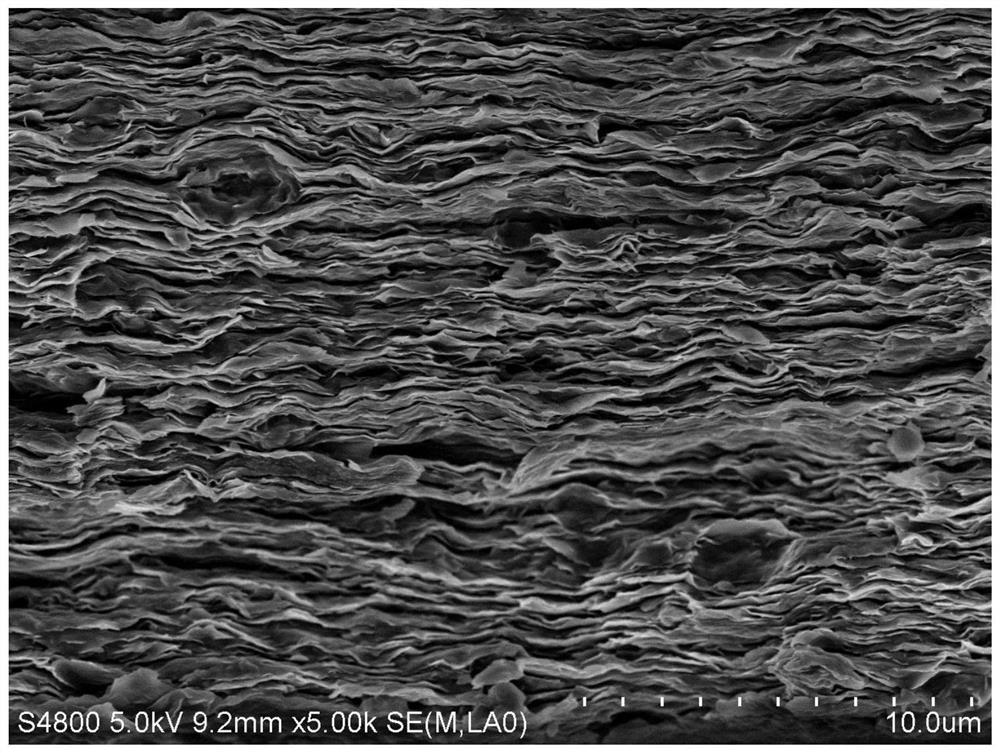

[0046] (3) Hot press film formation: on the basis of the composite film obtained by evaporating the self-assembled film in step (2...

Embodiment 2

[0048] (1) 10 g of CMC was dissolved in 500 ml of distilled water and stirred at a constant speed for 4 hours at room temperature to obtain a CMC solution with a concentration of 2% by mass. Dissolve 3g of MMT powder in 100ml of deionized water and stir overnight at a speed of 500r / min to swell, then continue to emulsify the swollen MMT suspension overnight with an emulsifier at 8000r / min for 5 times to fully swell and peel off, and let it stand Over night, a suspension of MMT was obtained. 100g of CMC with a concentration of 2wt% was added dropwise to 70g of MMT suspension, stirred at a constant speed for 24h, then ultrasonically removed for 15min, and set aside.

[0049] (2) Evaporative self-assembly: spread the mixed solution obtained in step (1) on a plastic surface dish by casting method, and dry overnight at 40° C. to obtain an MMT-CMC binary composite film.

[0050] (3) Hot press film formation: on the basis of the composite film obtained by evaporation in step (2), at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com