Preparation method of chitosan composite preservative film

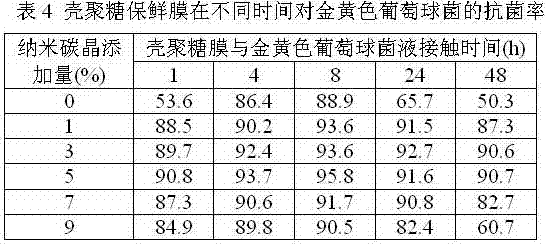

A composite preservation and chitosan technology, applied in the field of degradable materials, can solve the problems of chitosan performance changes, limited use conditions, limited antibacterial ability, etc., and achieve strong antibacterial persistence, inhibition of aerobic respiration, and good sterilization functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of chitosan composite plastic wrap, comprising the following steps:

[0020] 1) Dissolve 0.5 g of chitosan in 100 ml of acetic acid solution with a volume fraction of 1%, heat to 50°C, and stir until the chitosan is completely dissolved to obtain solution A;

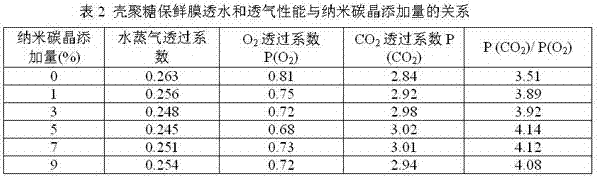

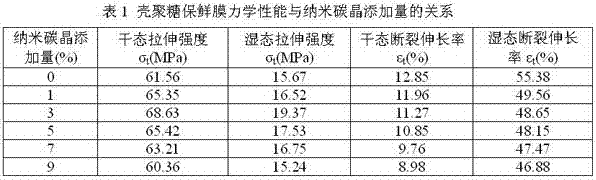

[0021] 2) Disperse the modified nano-carbon crystals in solution A, the amount of modified nano-carbon crystals added is 1%, and then add 0.2% of the volume of solution A plasticizer (glycerol), stirring, ultrasonic dispersion, static Placed, ultrasonic degassed for 10min, to obtain solution B; the stirring speed was 500r / min, the stirring time was 1.5h, the ultrasonic frequency was 35KHz, and the ultrasonic time was 15min; The mass sum ratio of polysaccharides and modified nano-carbon crystals;

[0022] 3) Inject the solution B in step 2) into a horizontally placed clean glass tank to form a film, let it stand for 1h, and dry it under an infrared lamp for 10min at a drying temperature of 35°...

Embodiment 2

[0025] A preparation method of chitosan composite plastic wrap, comprising the following steps:

[0026] 1) Dissolve 5.5 g of chitosan in 100 ml of acetic acid solution with a volume fraction of 1%, heat to 65°C, and stir until the chitosan is completely dissolved to obtain solution A;

[0027] 2) Disperse the modified nano-carbon crystals in solution A, the amount of modified nano-carbon crystals is 9%, and then add 1% of the volume of solution A plasticizer (glycerol), stirring, ultrasonic dispersion, static Placed, ultrasonic degassed for 15min to obtain solution B; the stirring speed was 600r / min, the stirring time was 1h, the ultrasonic frequency was 45KHz, and the ultrasonic time was 10min; The ratio of the mass sum of the sugar and the modified nano-carbon crystal;

[0028] 3) Inject the solution B in step 2) into a horizontally placed clean glass tank to form a film, let it stand for 1.5 hours, and dry it under an infrared lamp for 5 minutes at a drying temperature of...

Embodiment 3

[0031] The addition amount of the modified nano-nano-carbon crystal in step 2) is 5%, and the others are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com