Transparent gas barrier film materials and production method thereof

A technology of gas barrier and film materials, which is applied in the field of transparent gas barrier film materials and its preparation, can solve the problems of limited room for improvement in the oxygen barrier performance of composite oxygen barrier packaging films, restrictions on the application expansion of packaging materials, and irregular properties, etc., to achieve Meet the effect of environmental protection and sustainable development, simple environmental protection and sustainable development, excellent air tightness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

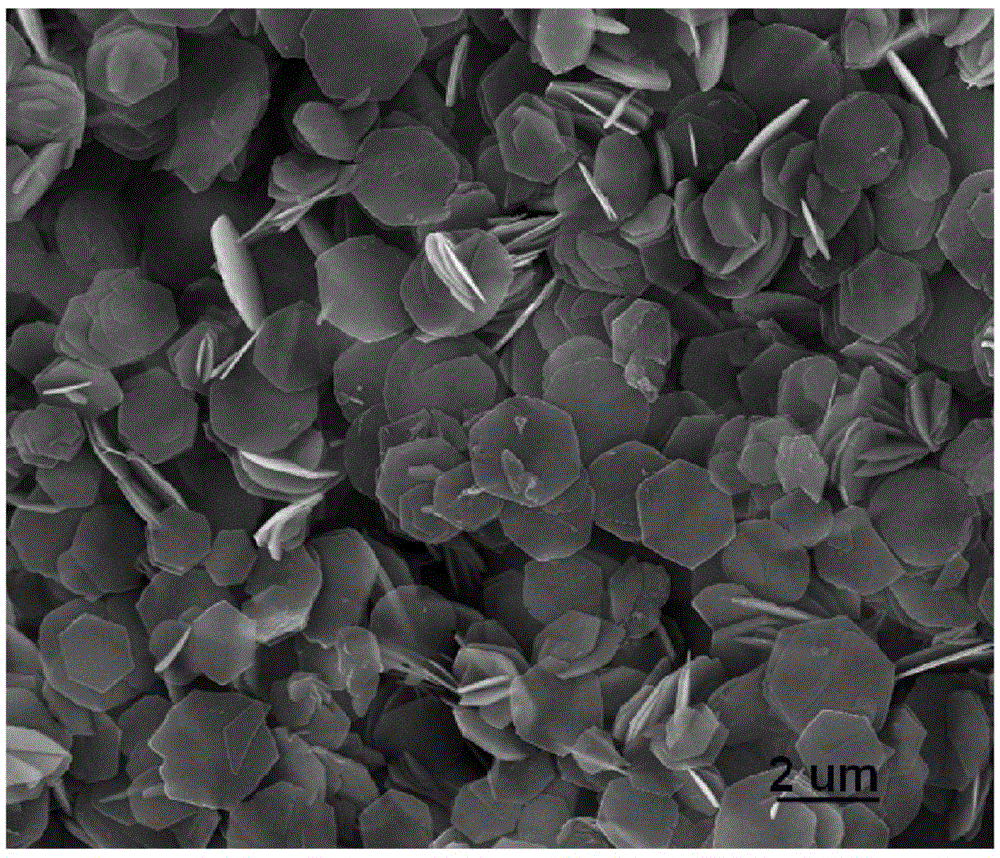

[0028] A. Weigh 5.1282g Mg(NO 3 ) 2 ·6H 2 O, 3.7513g Al(NO 3 ) 3 9H 2 Dissolve O in 50ml of deionized water, weigh 4.0000g of urea and dissolve in 50ml of deionized water, mix the prepared nitrate mixed solution with the prepared urea solution, stir, and crystallize at 110°C for 24 hours. 2 The deionized hot water is centrifugally washed to neutrality to obtain the precursor of hydrotalcite nanosheets;

[0029] B. configuration mass concentration is the chitosan solution of 4%, fully dispersed in the 50mL chitosan solution by obtaining 1g hydrotalcite nanosheet in A step;

[0030] C. Clean the polytetrafluoroethylene filter membrane with a thickness of 0.1 mm and a pore size of 50 mesh with ethanol for 30 minutes, and finally clean it with deionized water to obtain a hydrophilic filter membrane for use;

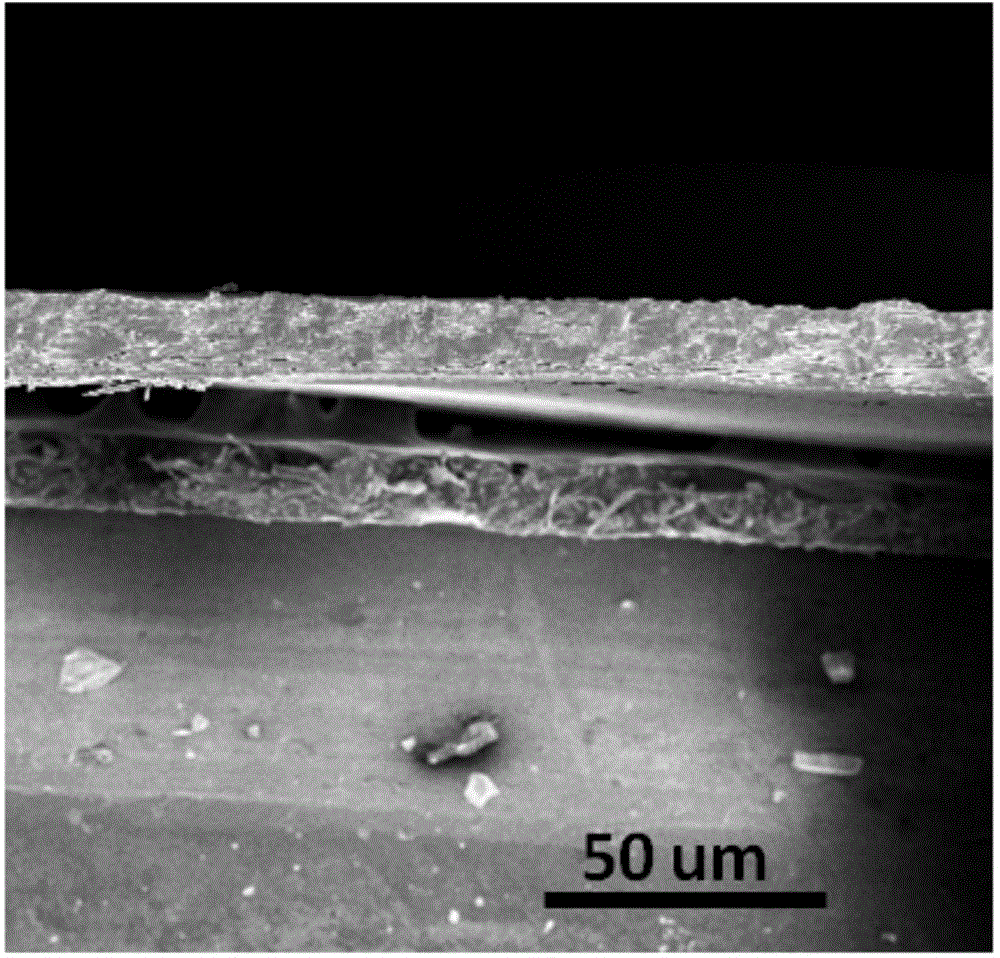

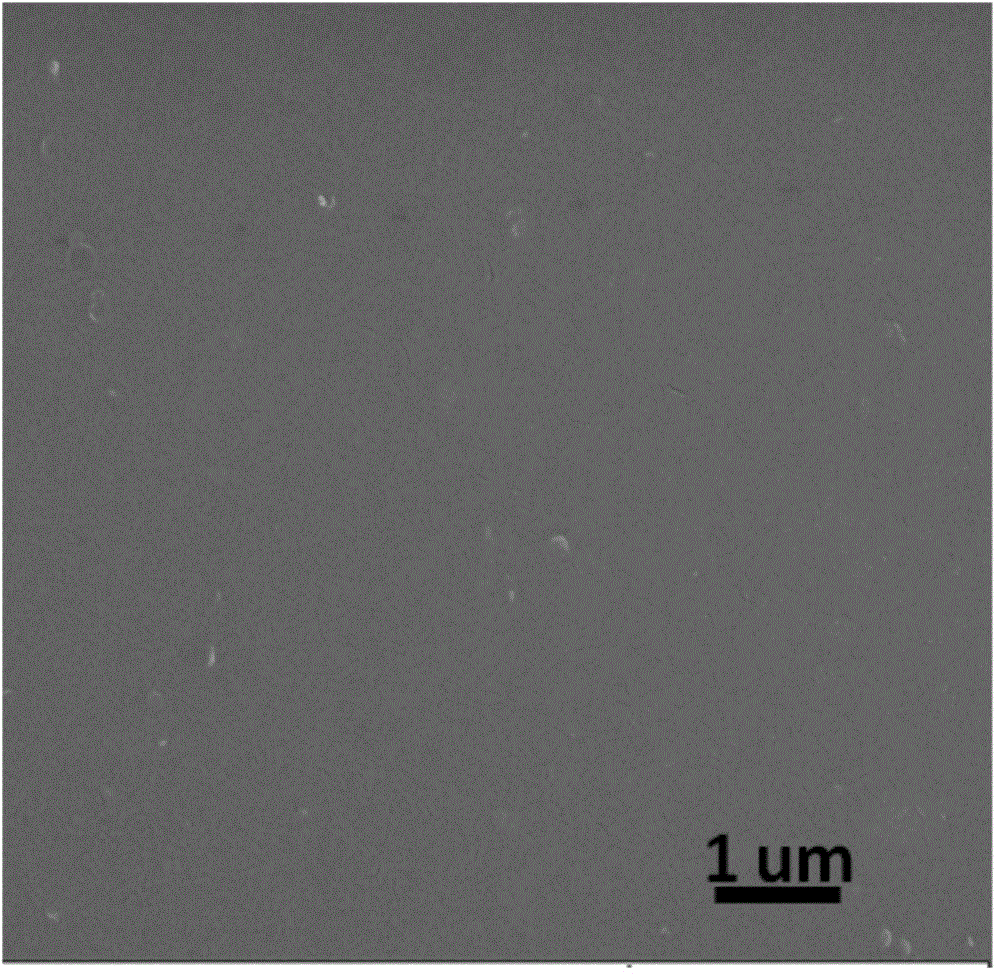

[0031] D. Put 5cm 2 The hydrophilic filter membrane treated in the C step is placed at the bottom of the funnel, then the 35ml hydrotalcite and chitosan mixed solution...

Embodiment 2

[0034] A. Weigh 5.1282g Mg(NO 3 ) 2 ·6H 2 O, 3.7513g Al(NO 3 ) 3 9H 2 Dissolve O in 50ml of deionized water, weigh 4.0000g of urea and dissolve it in 50ml of deionized water, mix the prepared nitrate mixed solution with the prepared urea, stir, and crystallize at 110°C for 24 hours. 2 deionized hot water centrifugal washing to neutral to obtain hydrotalcite nanosheet precursor;

[0035] B. configuration concentration is the polyvinyl alcohol solution of 3.5% concentration fraction, fully disperses in 80mL polyvinyl alcohol solution in the 2g hydrotalcite nanoplate that obtains in A step;

[0036] C. Clean the base polytetrafluoroethylene filter membrane with a thickness of 0.1 mm and a pore size of 100 mesh with ethanol for 30 minutes, and finally clean it with deionized water to obtain a hydrophilic filter membrane for use;

[0037] D. Put 5cm 2 The hydrophilic filter membrane treated in step C is placed at the bottom of the funnel, and then 50ml of the mixed solution ...

Embodiment 3

[0040] A. Weigh 5.1242g Mg(NO 3 ) 2 ·6H 2 O, 3.5413g Al(NO 3 ) 3 9H 2 Dissolve O in 50ml of deionized water, weigh 3.900g of urea and dissolve in 50ml of deionized water, mix the prepared nitrate mixed solution with the prepared urea solution, stir, crystallize at 110°C for 24 hours, and remove CO 2 deionized hot water centrifugal washing to neutral to obtain hydrotalcite nanosheet precursor;

[0041] B. configuration concentration is the carboxymethyl cellulose solution of 3.5% concentration fraction, fully disperse in 80mL carboxymethyl cellulose solution in the 0.8g hydrotalcite nanosheet obtained in A step;

[0042] C. Clean the base polytetrafluoroethylene filter membrane with a thickness of 0.1 mm and a pore size of 120 mesh with ethanol for 30 minutes, and finally clean it with deionized water to obtain a hydrophilic filter membrane for use;

[0043] D. Put 5cm 2 The hydrophilic filter membrane treated in the C step is placed at the bottom of the funnel, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Oxygen transmission rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com