Graphene lithium battery cathode slurry and preparation method thereof, and lithium battery positive plate

A technology of positive electrode slurry and positive electrode sheet, applied in the direction of graphene, electrode manufacturing, battery electrodes, etc., can solve the problems of battery rate performance decrease, lithium ion diffusion resistance increase, prolong lithium ion diffusion path, etc., and achieve good electrical conductivity and the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

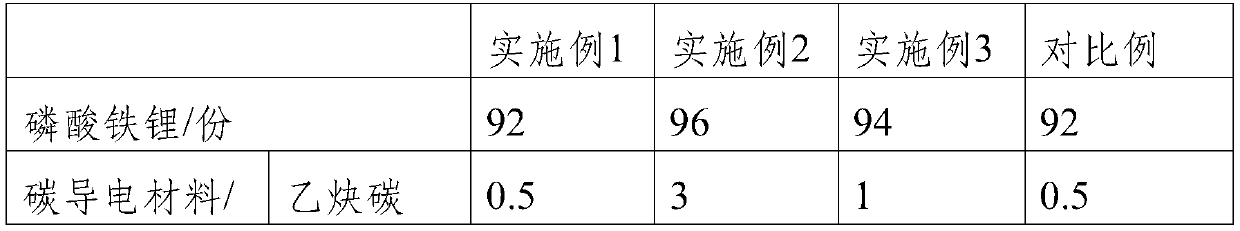

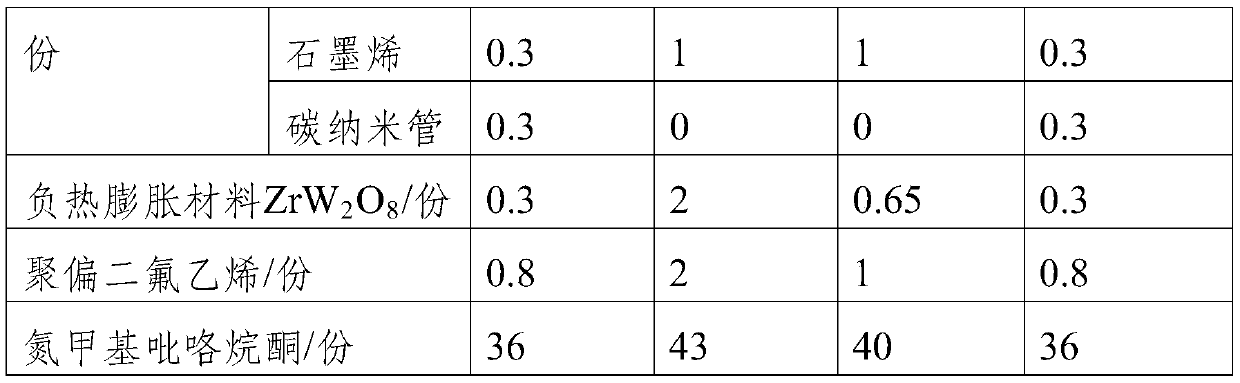

[0030] Embodiment (abbreviation S) 1-3 and comparative example

[0031] In parts by weight, the composition of the lithium battery cathode slurry of Examples 1-3 and comparative examples is shown in the table below:

[0032]

[0033]

Embodiment 4

[0035] Embodiment 4-5 is based on embodiment 3, the difference is that the negative thermal expansion material of embodiment 4 is ytterbium doped ZrW 2 o 8 , Zr 0.94 Yb 0.06 W 2 o 8-n (n is determined by the oxygen vacancies brought by unequal doping); Example 5 uses aluminum ion doping ZrW 2 o 8 , the aluminum doping amount is 3.2%.

[0036] The graphene used in Examples 1-5 and Comparative Examples is mechanically exfoliated graphene with few structural defects and an aspect ratio of not less than 500.

Embodiment 3

[0037] Example 3 sets up Example 3-A and Example 3-B side by side. Group A samples are physically blended, according to nitrogen methyl pyrrolidone, polyvinylidene fluoride, carbon conductive material, negative thermal expansion material, phosphoric acid Sequential feeding of iron lithium, high-speed stirring to disperse evenly. Embodiment and comparative example adopt following B group processing steps:

[0038] S1: Carbon conductive materials and negative thermal expansion materials are mixed with ethanol to make a dispersion, and then the dispersion is placed in a ball mill tank for ball milling to remove polar organic solvents, and the solid components in the dispersion are dried and sieved to obtain Conductive mixed powder, wherein the ball-to-material ratio of the ball to the powder in the dispersion is 1:1.2, the weight ratio of the powder to the polar organic solvent in the dispersion is 1:2.5, and the ball milling time is 24 hours;

[0039]S2: Put the conductive mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com