Combined electrode of battery and preparation method thereof

A composite electrode and battery technology, applied in battery electrodes, electrode manufacturing, active material electrodes, etc., can solve problems affecting electron and ion transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment one composite electrode

[0032] The preparation method of composite electrode comprises the following steps:

[0033] a. Disperse carbon nanotubes and active materials evenly.

[0034] Use a digital balance to weigh a certain amount of active powder material, pour it into deionized water that has been added with surfactant, add carbon nanotubes at the same time, and place it on an ultrasonic cell pulverizer for 2-10 minutes of ultrasonication.

[0035] b. Prepare carbon nanotubes and active materials into a film with a three-dimensional porous network structure.

[0036] This step can use one of the vacuum filtration method or the natural deposition method.

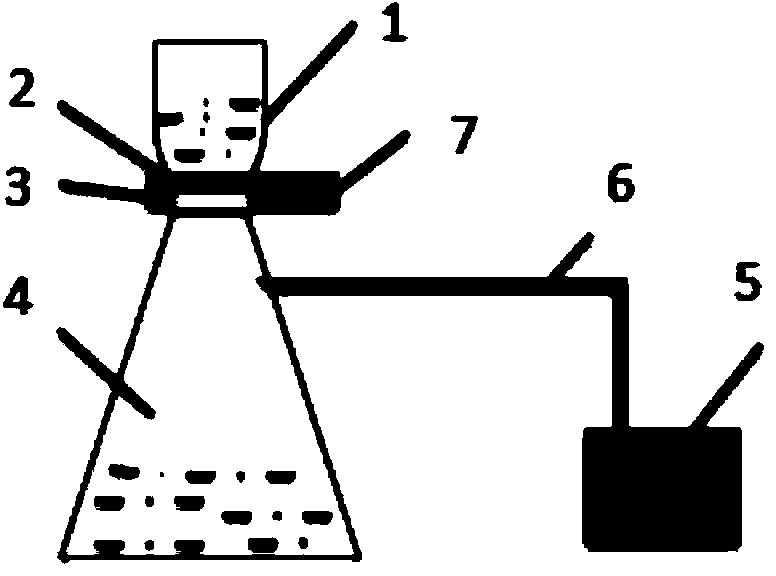

[0037] Vacuum filtration devices such as figure 1 As shown, it is composed of a buffer bottle 1, a suction filter bottle 4, a vacuum pump 5, an exhaust tube 6 and a clip 7, and an alumina template or a PVDF filter membrane 2 and a filter paper 3 are added between the buffer bottle ...

Embodiment 2

[0046] Embodiment two by Li(Ni 0.5 co 0.2 mn 0.3 )O 2 Shell-type Li-ion half-battery with composite electrodes composed of / CNT / SEI

[0047] The preparation of composite electrode: adopt the method in embodiment one, with Li(Ni 0.5 co 0.2 mn 0.3 )O 2 As the active material, single-walled carbon nanotubes are used as the conductive network, and the positive electrode of the three-dimensional conductive network is formed by vacuum filtration method, which is cut into a disc with a diameter of 3 / 8 inches, and a 2032 shell-type half-cell is composed of a separator and a lithium sheet. Through the first charge-discharge cycle, a SEI layer with high ion conductivity is coated in the three-dimensional network and on the surface of the active material to form the composite electrode described in this application.

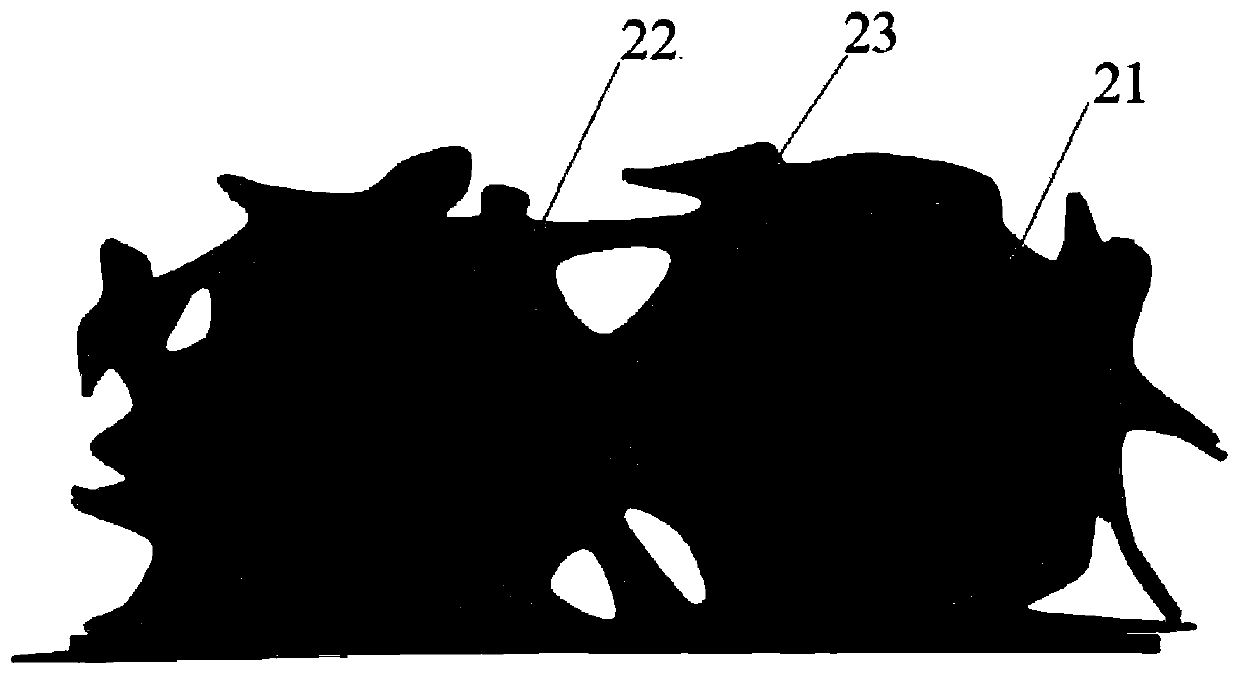

[0048] The schematic diagram of the composite electrode structure prepared in this example is shown in figure 2 As shown, the scanning electron micrograph before c...

Embodiment 3

[0049] Embodiment three by Li (Ni 0.5 co 0.2 mn 0.3 )O 2 Shell-type Li-ion half-battery with composite electrodes composed of / CNT / LiPON

[0050] The preparation of composite electrode: adopt the method in embodiment one to use Li(Ni 0.5 co 0.2 mn 0.3 )O 2 As the active material, single-wall carbon nanotubes are used as the conductive network, and the positive electrode of the three-dimensional conductive network is formed by vacuum filtration method. The coated LiPON solid electrolyte is prepared by radio frequency magnetron sputtering. The sputtering parameters are: radio frequency power 40-80W, working pressure 1-2Pa, working gas high-purity nitrogen, sputtering time 20-60min.

[0051] Battery preparation: Cut the prepared composite electrode into a disc with a diameter of 3 / 8 inches, and form a 2032 shell-type half-cell with a separator and a lithium sheet.

[0052] The structure of the composite electrode prepared in this example is the same as that of Embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com