Patents

Literature

236results about How to "Excellent oxygen barrier properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymeric films

ActiveUS20090312462A1Excellent oxygen barrier propertiesSuitable for usePaper coatingDomestic articlesMolten statePolymer science

A polymer composition and its use for thin film packaging applications including on a dry basis: a) from 45 to 90% by weight of starch; b) from 0.1 to 15% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinyl alcohol which have a melting point compatible with the molten state of the starch component; and c) from 5 to 45% by weight of one or more plasticizers having a molecular weight in the range of 50-6000, more preferably 50-2500 and more preferably still 100-400 and desirably selected from the group consisting of sorbitol, glycerol, maltitol, xylitol, mannitol, erythritol, glycerol trioleate, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, polyethylene oxide, ethylene glycol, diethylene glycol or polyethylene glycol.

Owner:PLANTIC TECH

Pearlescent film coating systems and substrates coated therewith

ActiveUS6902609B2High degreeExcellent oxygen barrier propertiesConfectioneryPretreated surfacesPowder mixtureMedicine

The present invention is directed to film coating systems for use on oral dosage forms such as compressed tablets and orally-ingestible substrates which have improved pearlescent qualities. The film coating systems can be applied either directly to a substrate or after the substrate has been coated with a subcoat. In preferred aspects, the pearlescent film coating is prepared as a dry powder mixture containing a cellulosic polymer, a detackifier, a gloss enhancer, and a pearlescent pigment. Film coating compositions containing an aqueous suspension of the powder mixtures, methods of applying the coatings to substrates and the coated substrates are also disclosed.

Owner:BPSI HLDG LLC

Highly obstructed multilayer coextrusion thermal shrink film

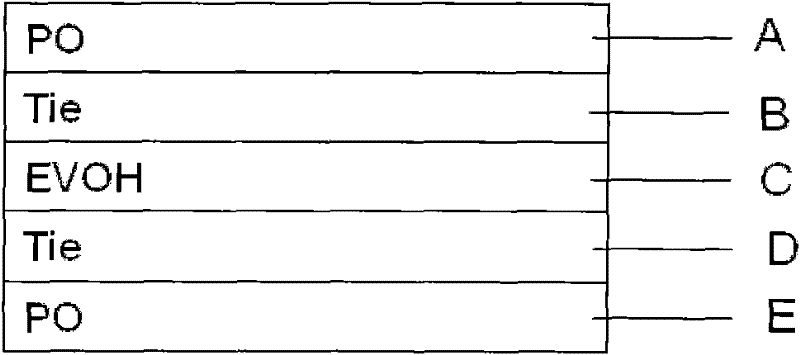

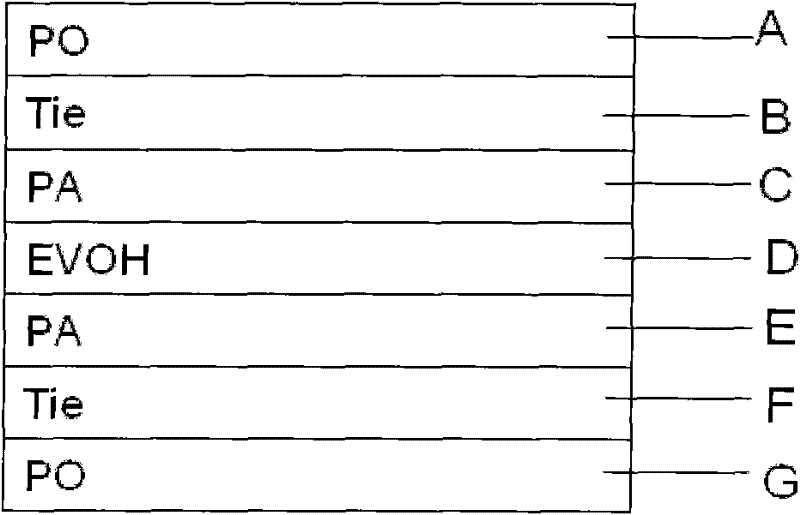

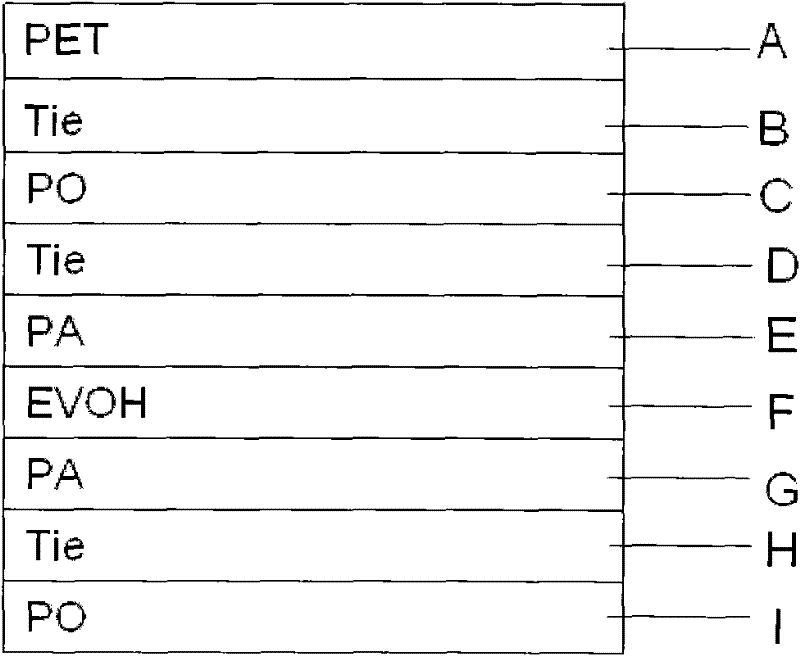

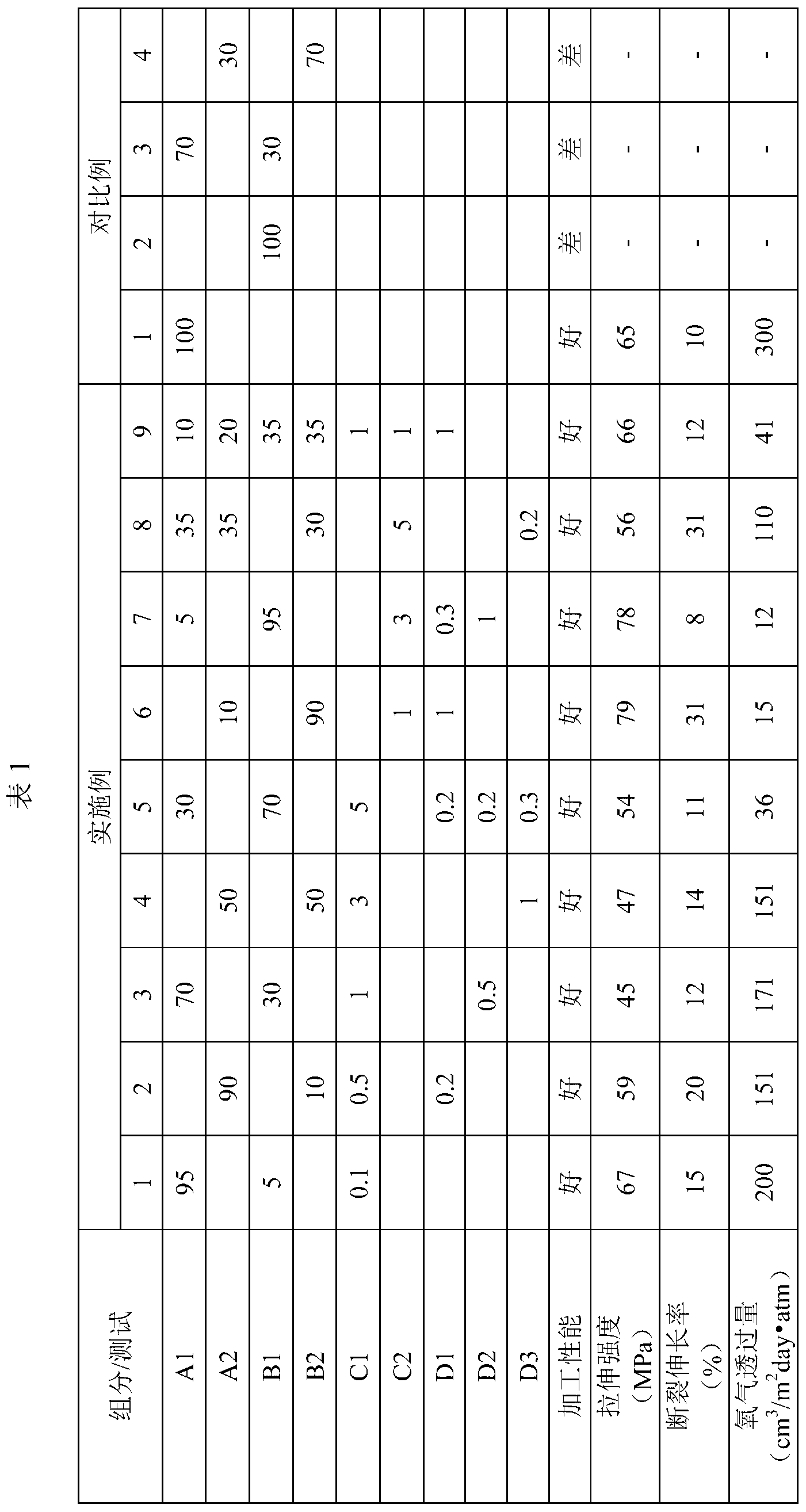

InactiveCN102555379AHigh tensile strengthExcellent oxygen barrier propertiesFlexible coversWrappersPolyolefinPolyamide

The invention discloses a highly obstructed multilayer coextrusion thermal shrink film which comprises a heat sealing layer, an outer surface layer, an obstruction layer and a bonding layer, wherein the heat sealing layer, the outer surface layer and the obstruction layer are contacted with a packaged object, and the bonding layer connects the outer surface layer, the heat sealing layer and the obstruction layer; the heat sealing layer comprises polyolefin resin; the outer surface layer comprises polyethylene with middle density and the like; the obstruction layer comprises at least one layer of one out of ethylene-vinyl alcohol copolymer or polyamide or the mixture of the two; and the structure of the multilayer coextrusion thermal shrink film has 5-9 layers. The highly obstructed multilayer coextrusion thermal shrink film has good oxygen obstruction performance and higher tensile strength, and even objects sensitive to air cannot suffer from the risk that the color is changed or even aged or the food flavor is changed due to entrance of oxygen after being stored for a longer time. Furthermore, the structure of the outer layer can improve the optical property, the mechanical property, the surface printing capability and the stretching capability, and resist high temperature sealing and burning.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

Polylactic acid alloy membrane and application thereof

ActiveCN103319865AImproved oxygen barrier propertiesThe process method is simpleCoatingsEnvironmentally friendlyPolylactic acid

The present invention discloses a polylactic acid alloy membrane, which comprises polylactic resin, polyvinyl alcohol resin and a bulking agent, wherein the three are in parts by weight of 1to 99 parts, 1 to 99 parts and 0.05to 5 parts respectively, with the total account of polylactic resin and polyvinyl alcohol resin in parts by weight of 100 parts. By the invention, the oxygen barrier property of the polylactic acid alloy membrane is effectively improved under the premise of keeping the membrane completely biodegradable and providing the membrane high mechanical strength. The technology method provided by the invention is easy with low cost, and is able to effectively promote widespread use of the environmentally friendly polylactic acid products.

Owner:常州博疆新材料科技有限公司

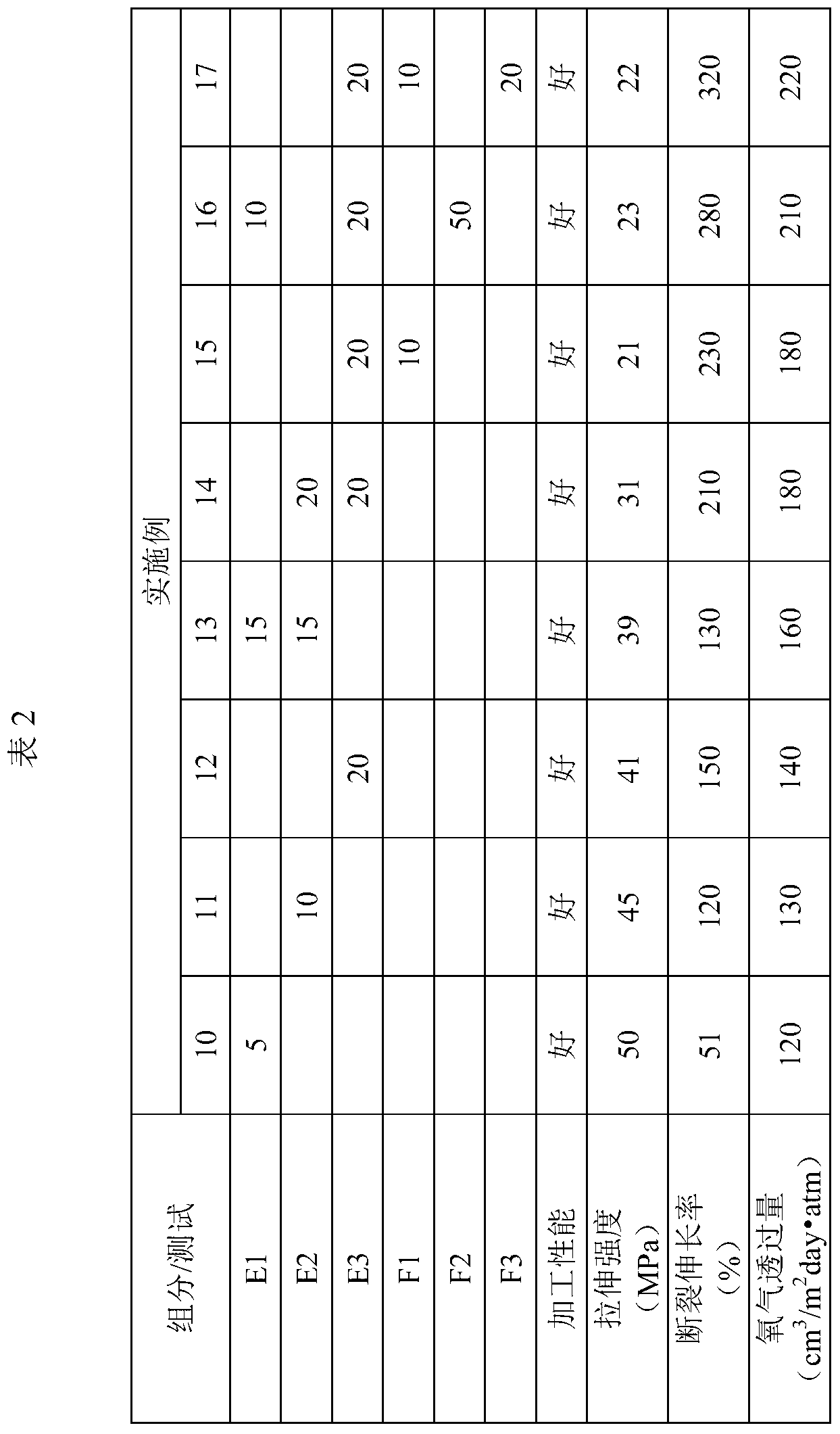

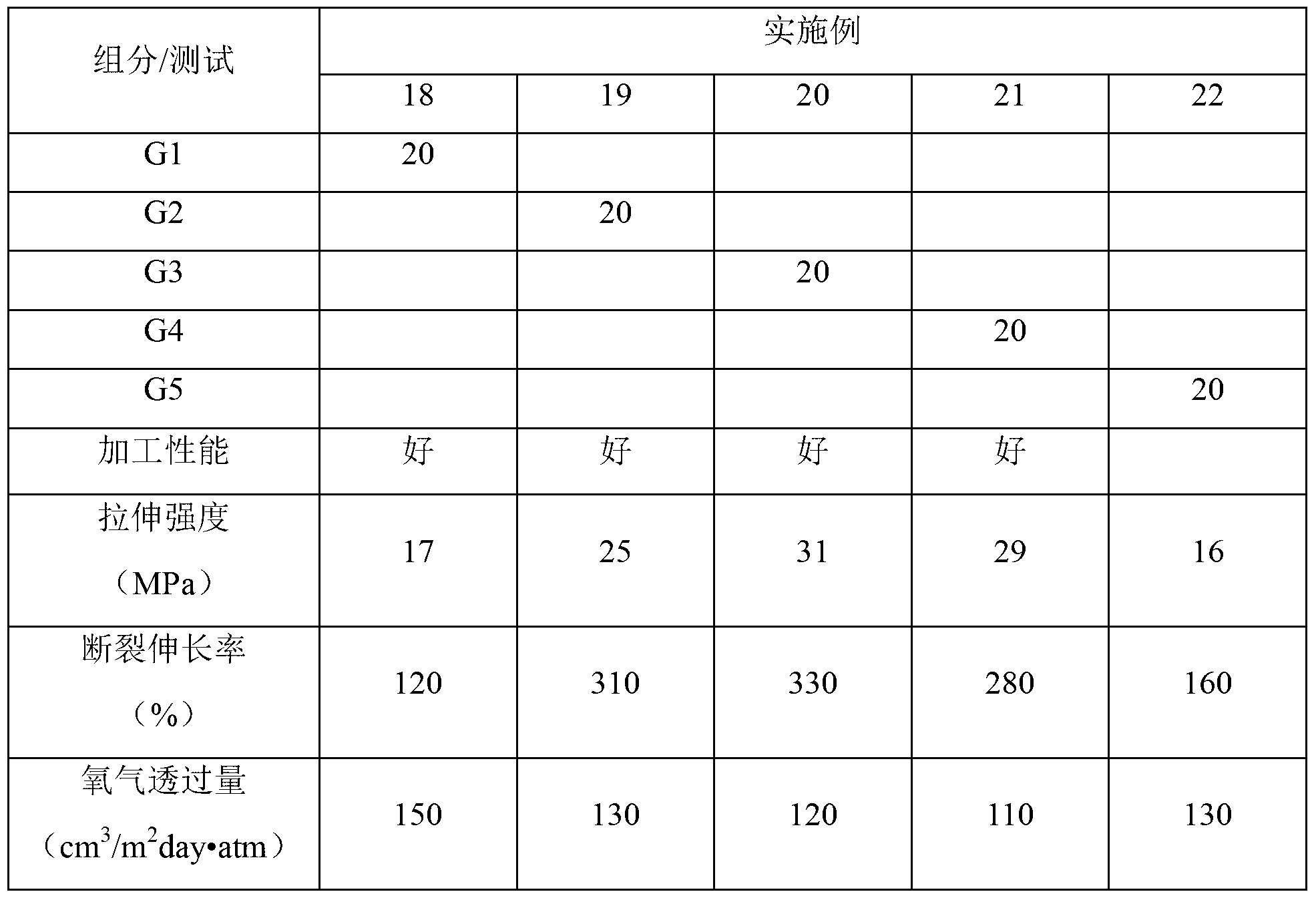

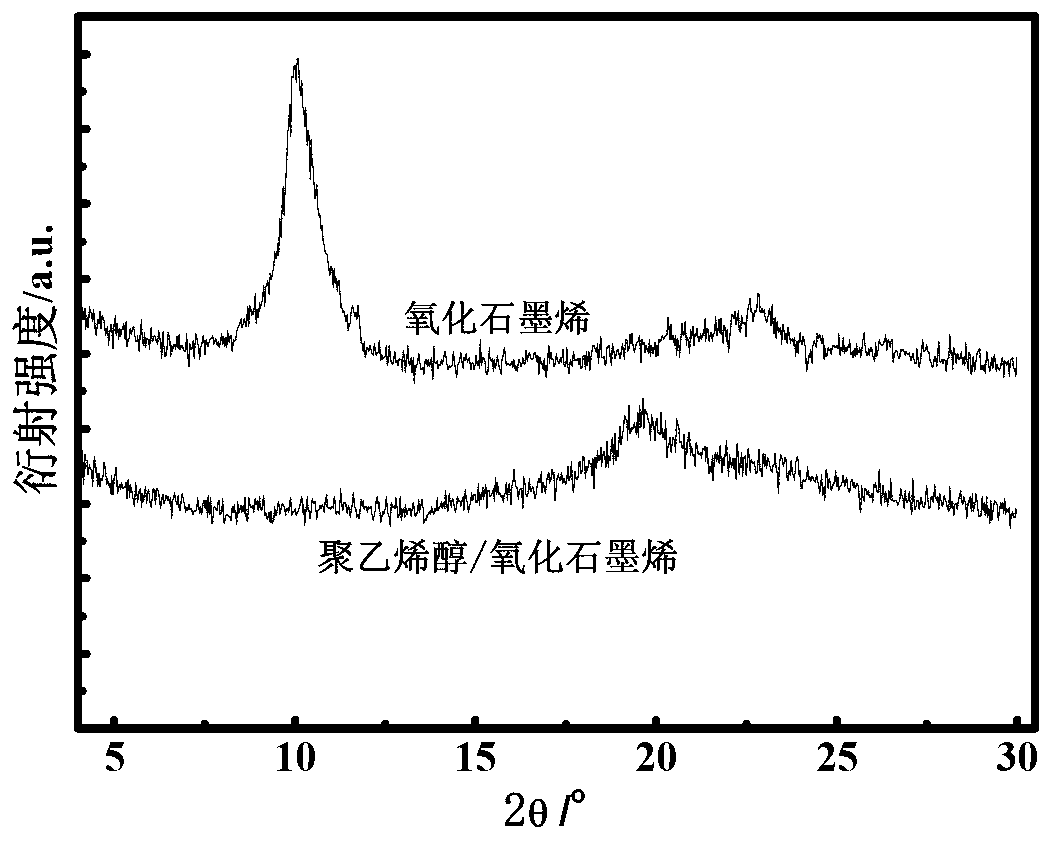

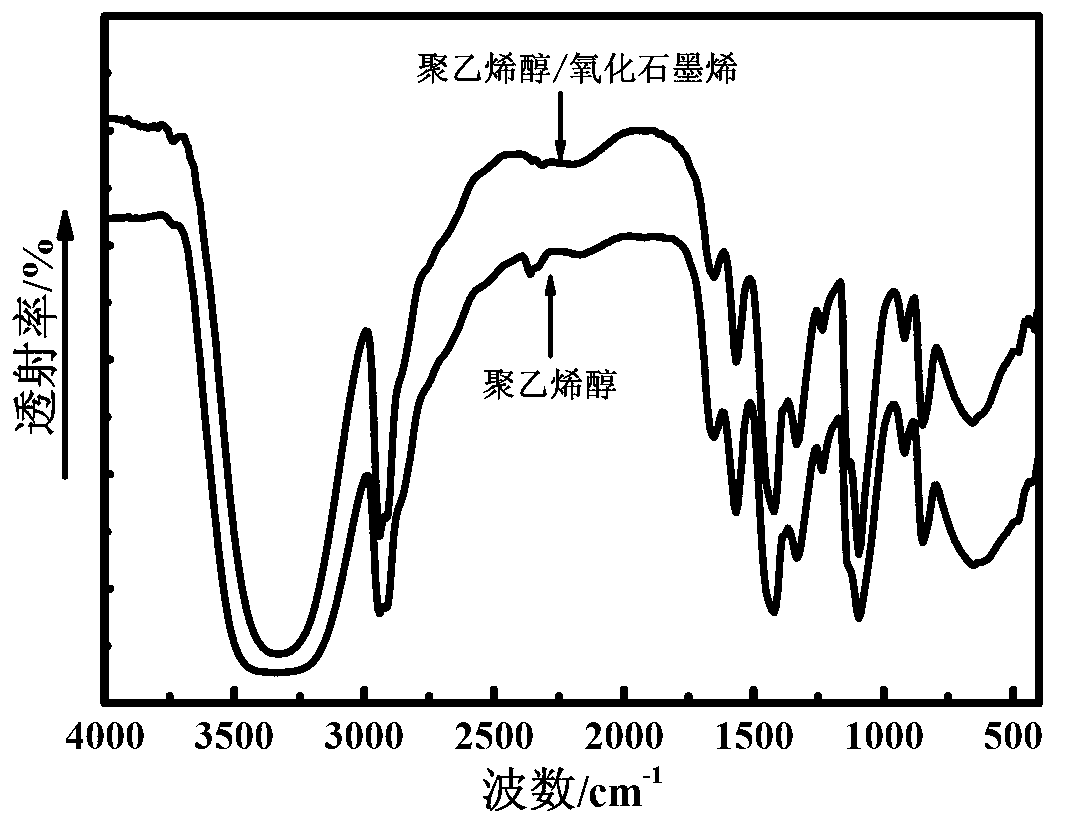

Polyvinyl alcohol/graphene oxide composite film preparation method

The invention discloses a polyvinyl alcohol / graphene oxide composite film preparation method. The method is carried out in the following steps: preparing a graphene oxide colloidal suspension liquid; preparing a polyvinyl alcohol and graphene oxide dispersion solution; coating a mould and non-isothermally drying; and demoulding so as to obtain a polyvinyl alcohol / graphene oxide composite film. A coating technology and a non-isothermally drying method are utilized to prepare the polyvinyl alcohol / graphene oxide composite film, the method has not only high safety but also good environment friendliness; moreover, the oxygen permeation coefficient of the composite film is reduced by 95.8 to the maximum extant, so that the composite film has ultrahigh oxygen barrier property and can satisfy the packaging requirements of various foods, pharmaceuticals and other products, and a problem that the polyvinyl alcohol / graphene oxide composite film prepared by the prior art has poor oxygen barrier property is solved; and the method is simple in technology and low in cost and has great application and popularization values.

Owner:唐炜程

Tube container having barrier property

InactiveUS20060121228A1Improve barrier propertiesSimply and conveniently manufacturedSynthetic resin layered productsBagsPolyolefinDecomposition

A tube container having a barrier property is provided. A single-layer or 3-layer tube container is manufactured by molding a dry-blended composition including a polyolefin resin and a nanocomposite of a resin having a barrier property and an intercalated clay, and a compatibilizer. The single-layer or 3-layer tube container can be simply manufactured and has a superior barrier property, thereby preventing the decomposition of contents, compared to a conventional 5-layer tube container.

Owner:LG CHEM LTD

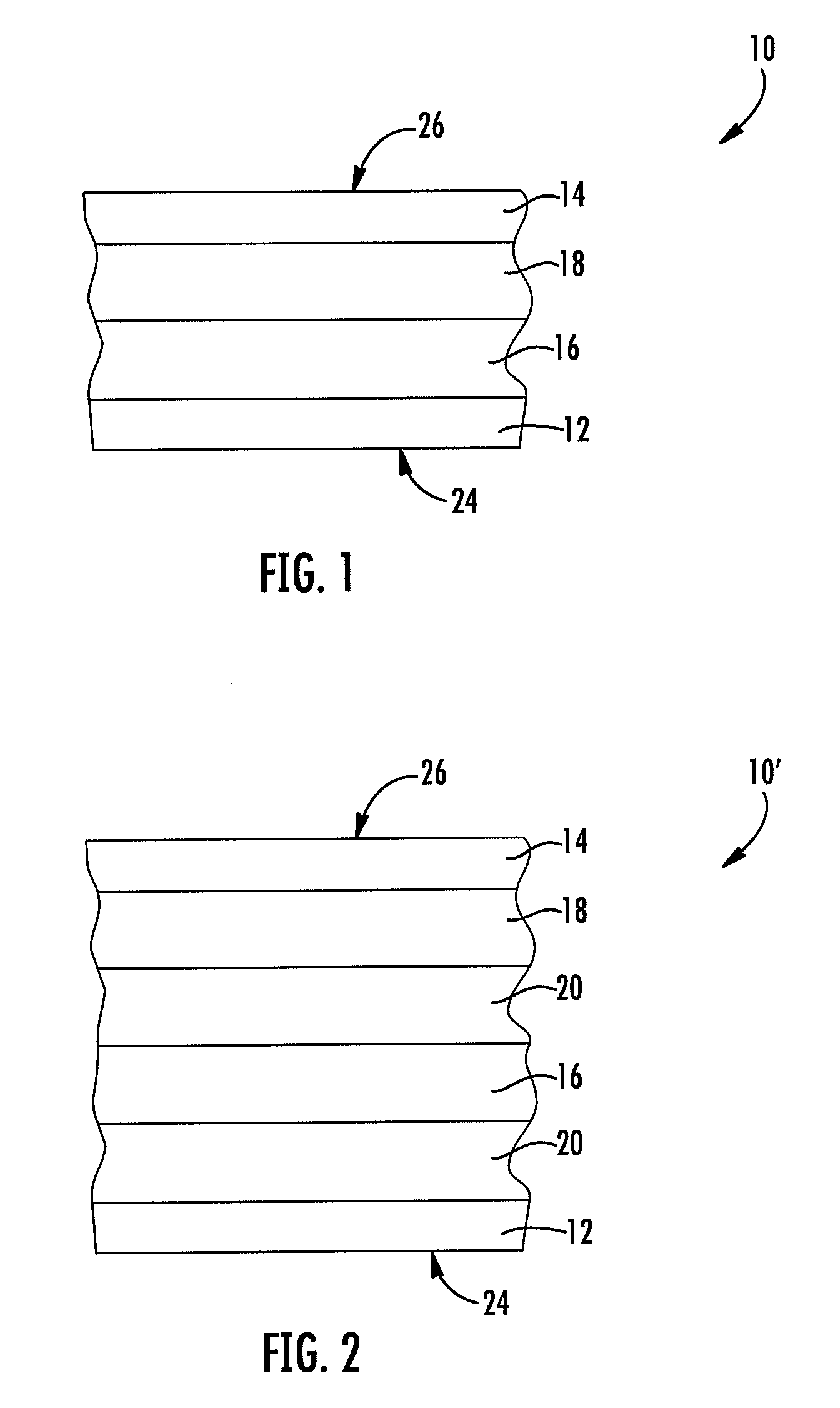

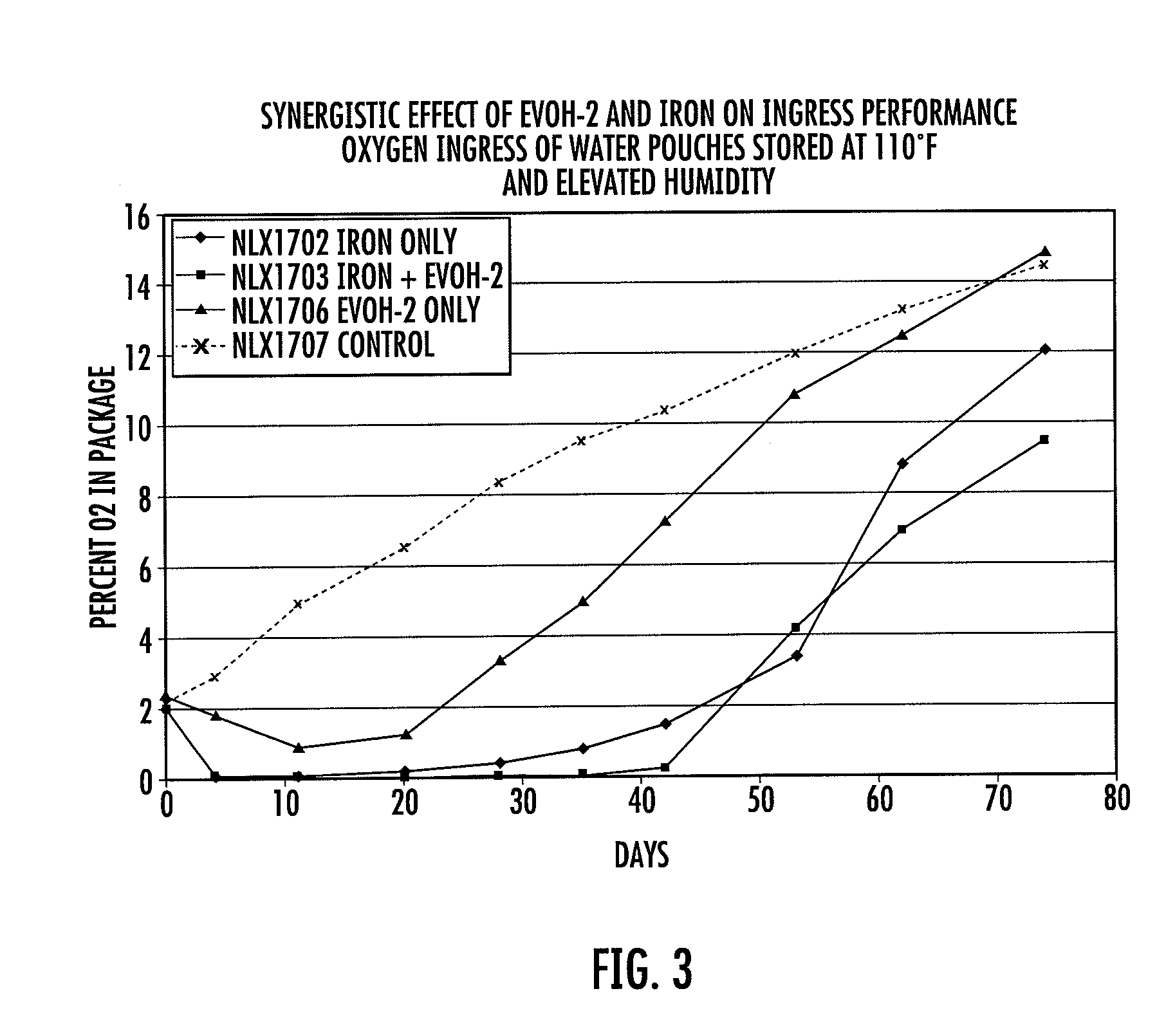

Multilayer Film Having Active Oxygen Barrier Layer and Iron-Based Oxygen Scavenging Layer

InactiveUS20090061062A1Excellent oxygen barrier propertiesImprove oxygen absorption effectFatty substance preservation using additivesSynthetic resin layered productsPolymer scienceBackbone chain

The present invention provides a multilayer film having an active oxygen barrier and at least one layer containing an iron-based oxygen scavenging composition. In one embodiment, the active barrier layer comprises a composition that is a blend of a thermoplastic resin (A) having carbon-carbon double bonds substantially in its main chain, a transition metal salt (B), and an oxygen barrier polymer (C). In some embodiments the active barrier layer may also include a compatibilizer (D). The layer containing the iron-based oxygen scavenging composition helps to maintain the oxygen barrier properties of the active barrier layer, and under both retort and non-retort conditions. As a result, the useful shelf life of the multilayer film can be extended.

Owner:CRYOVAC ILLC

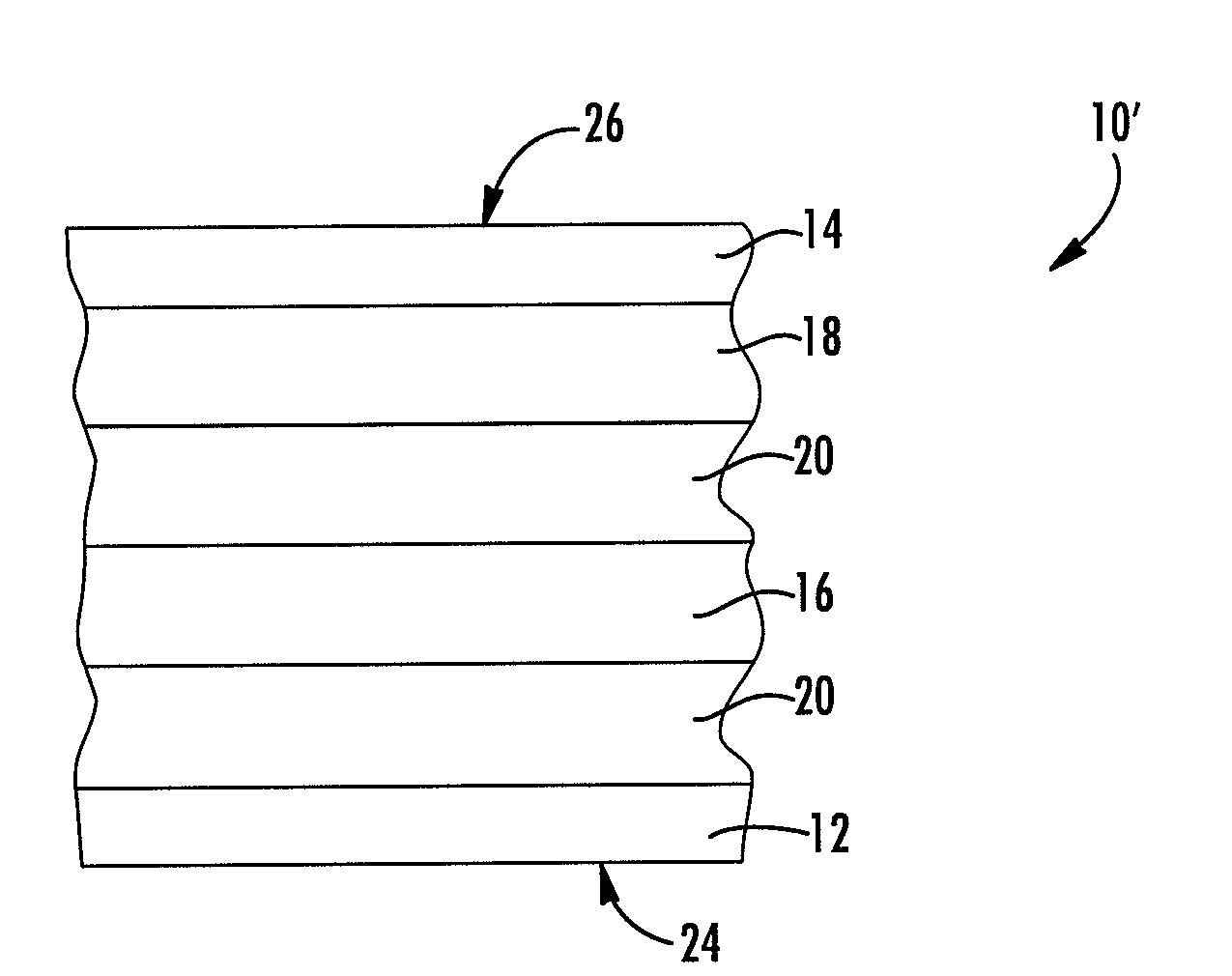

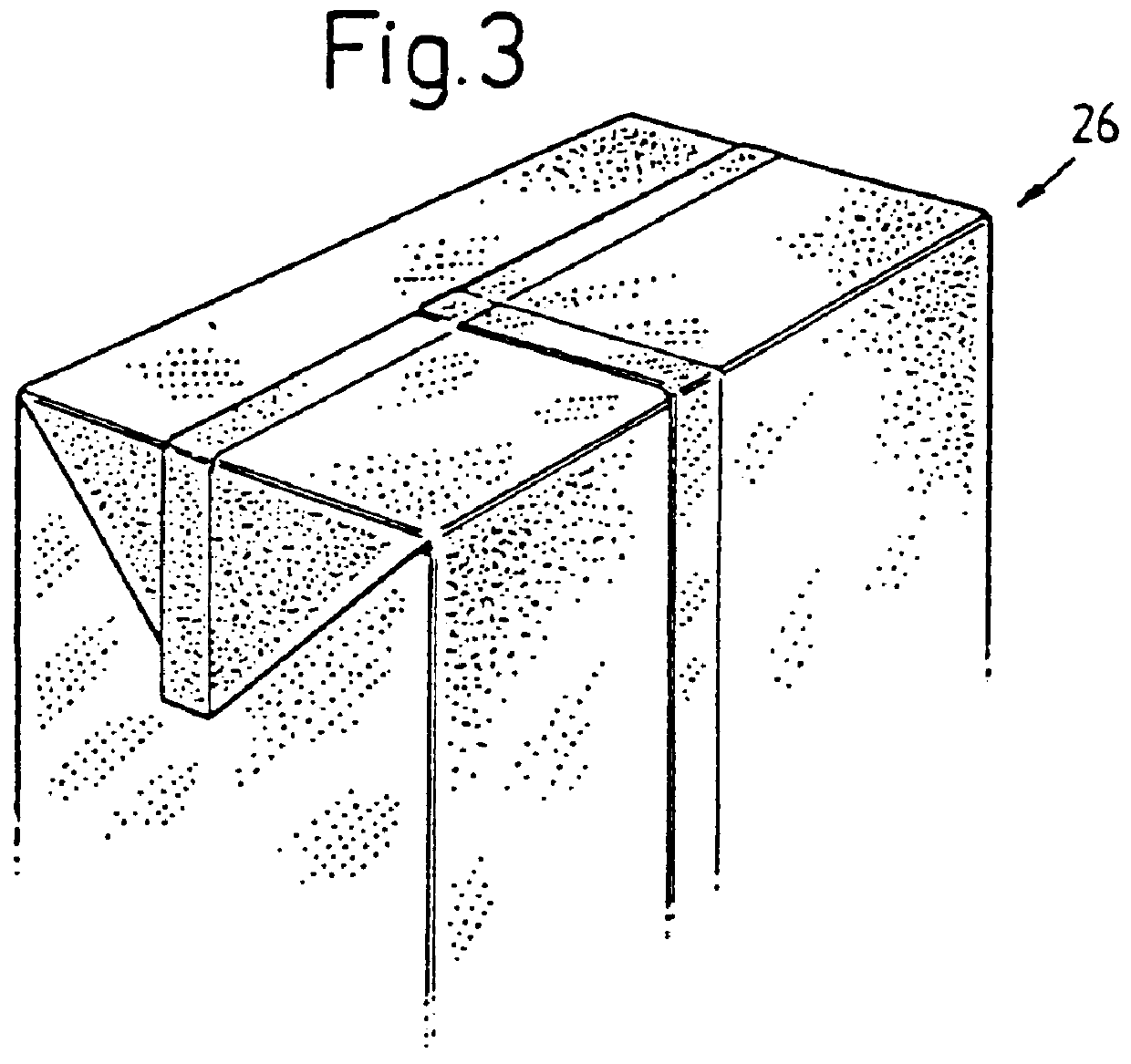

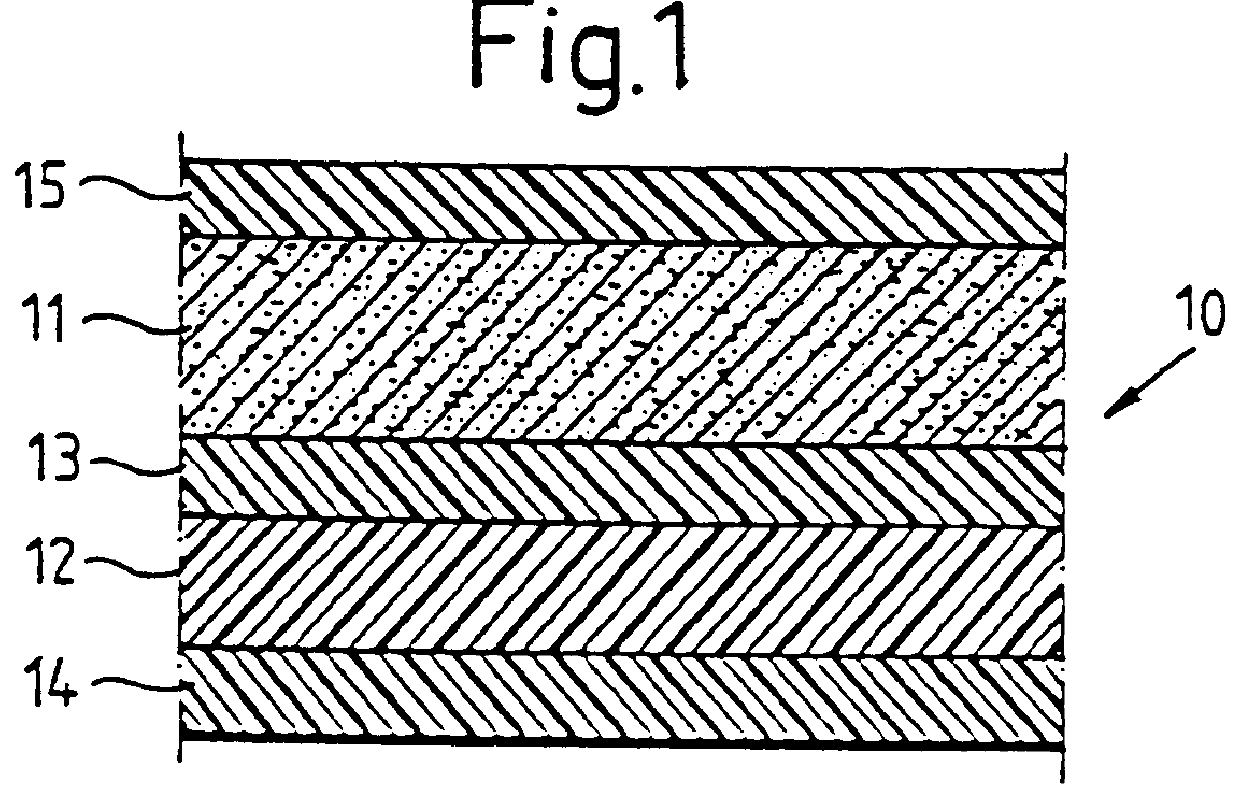

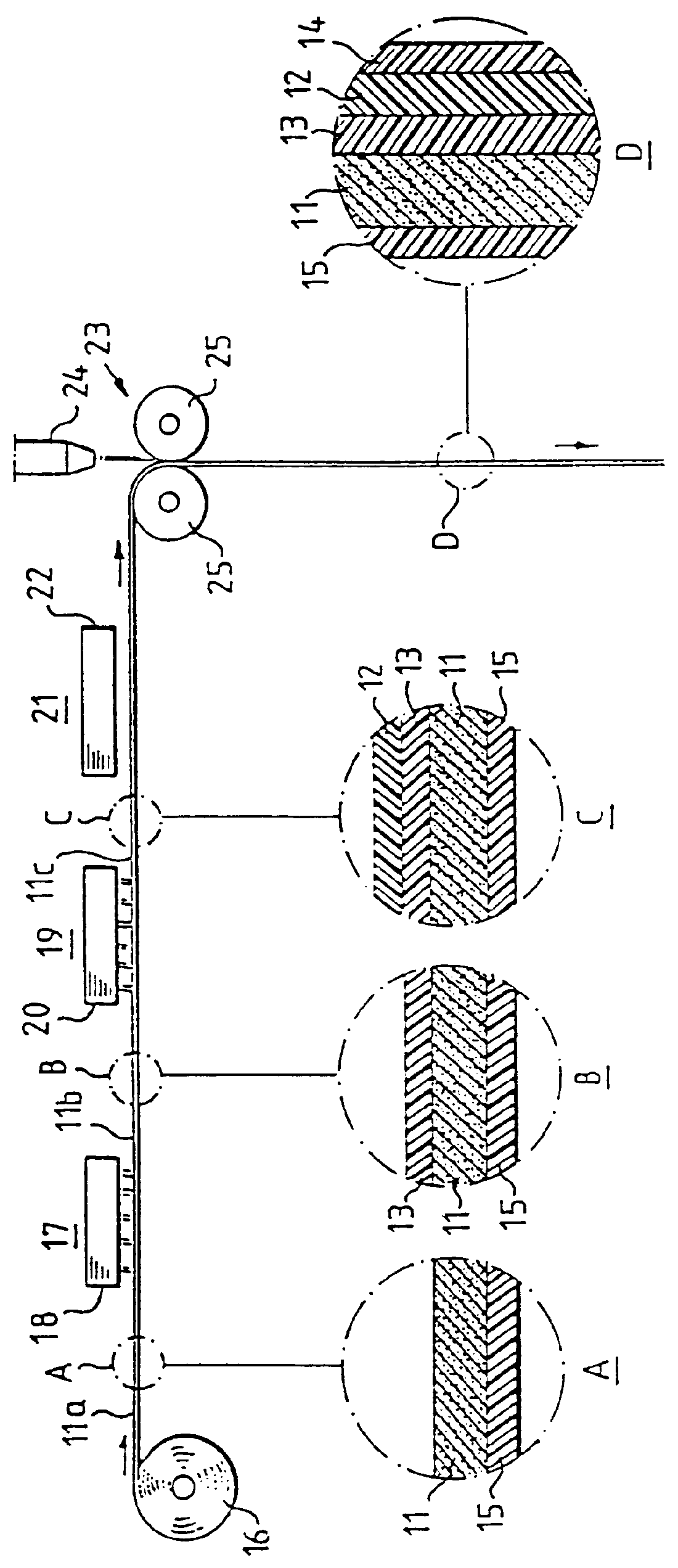

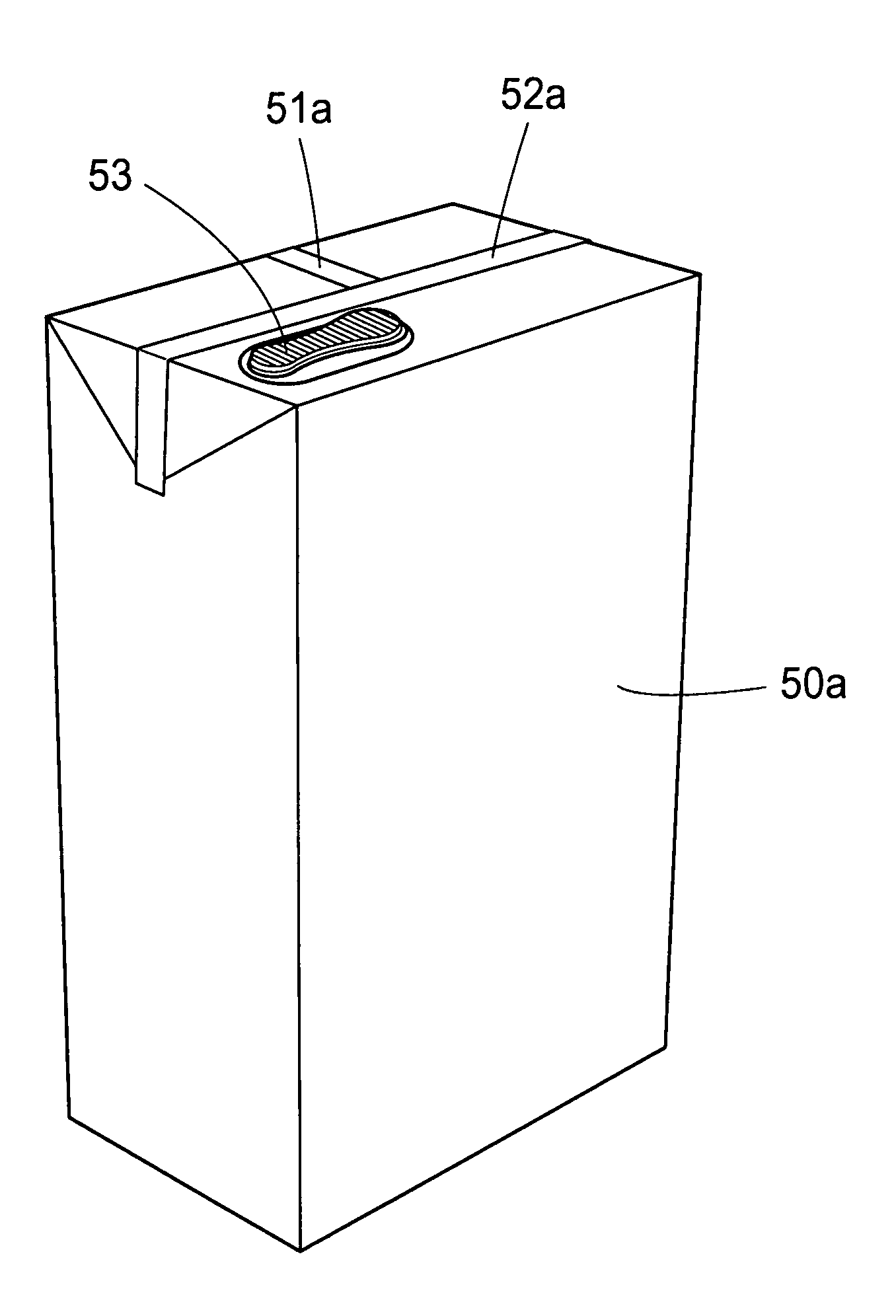

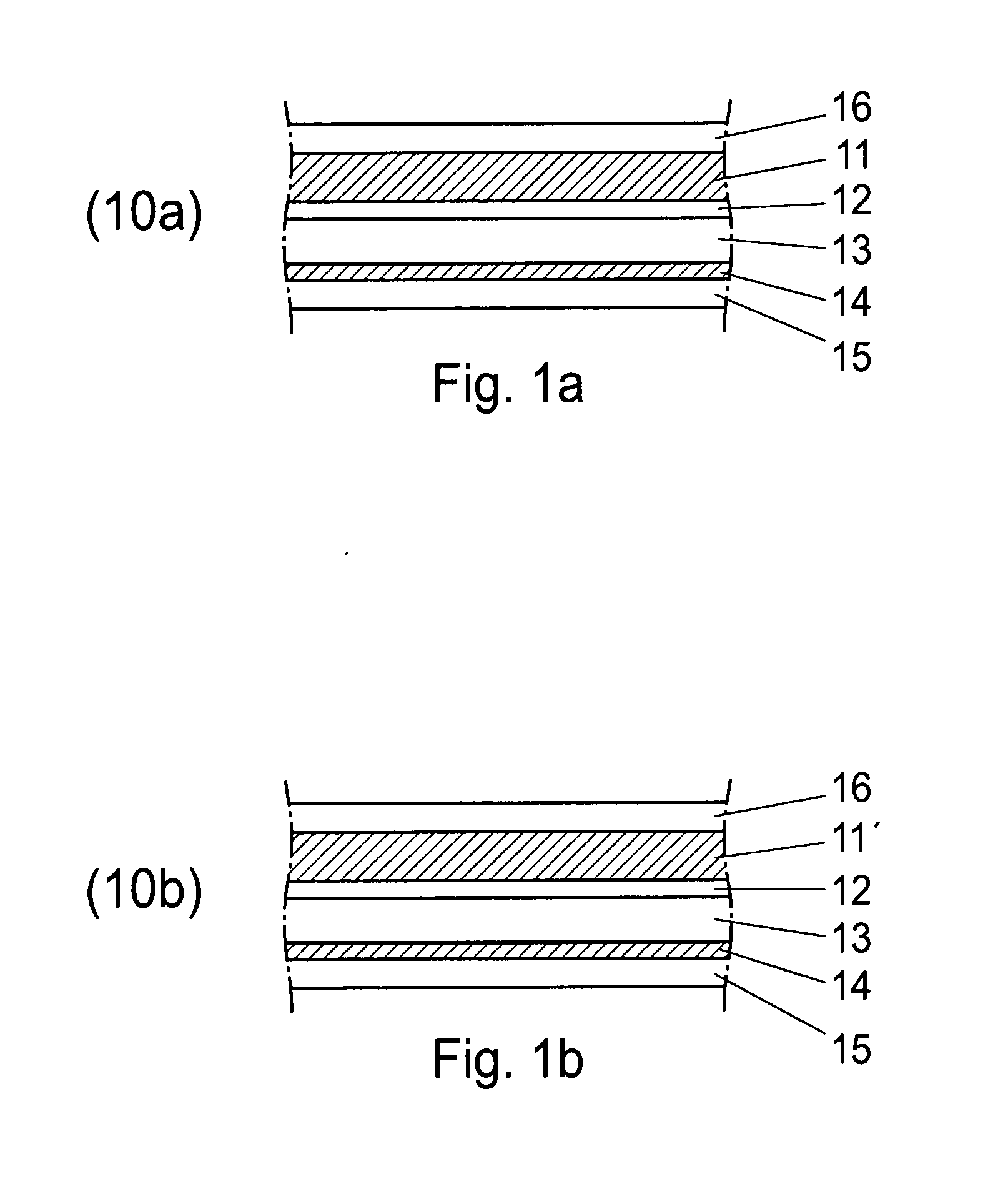

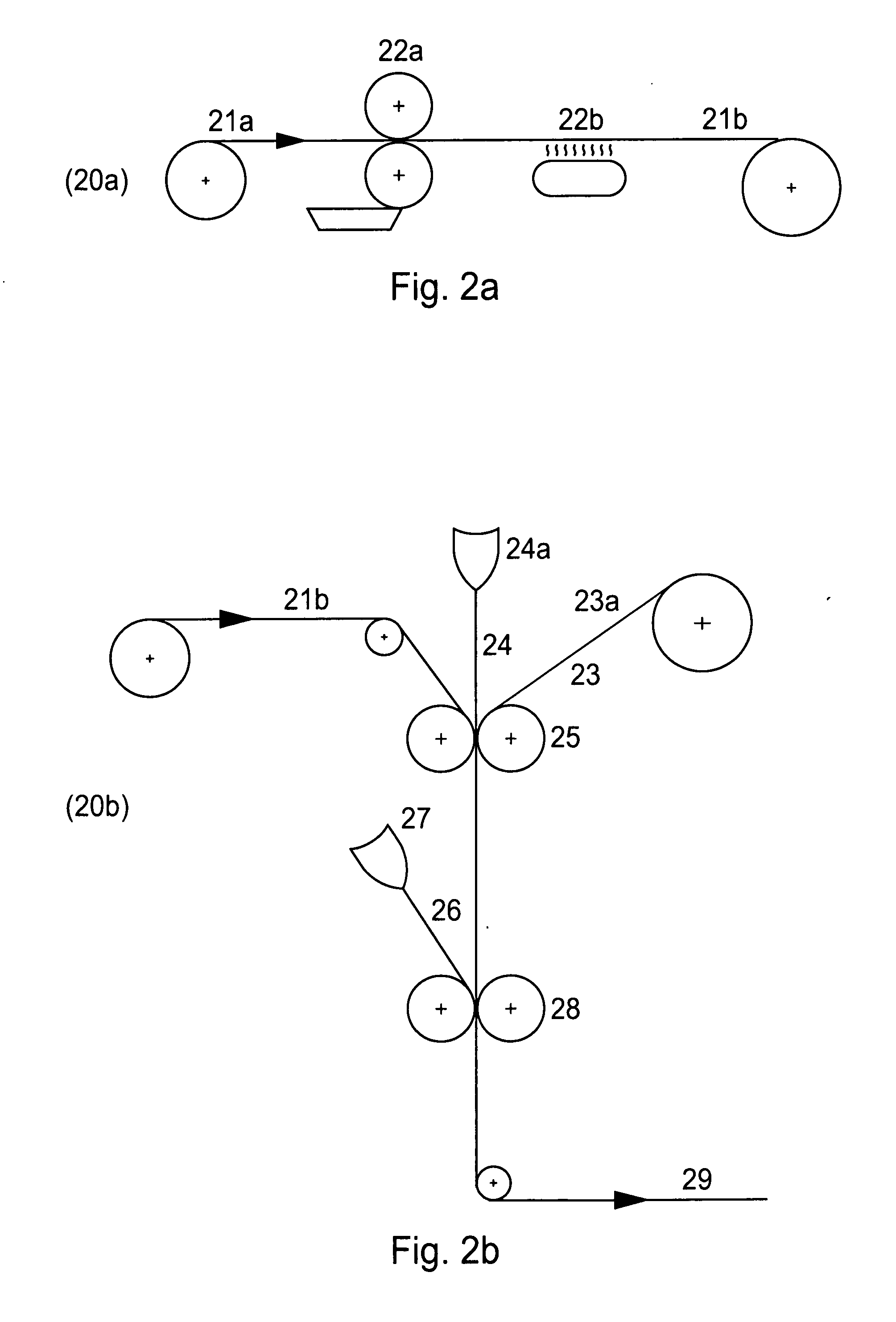

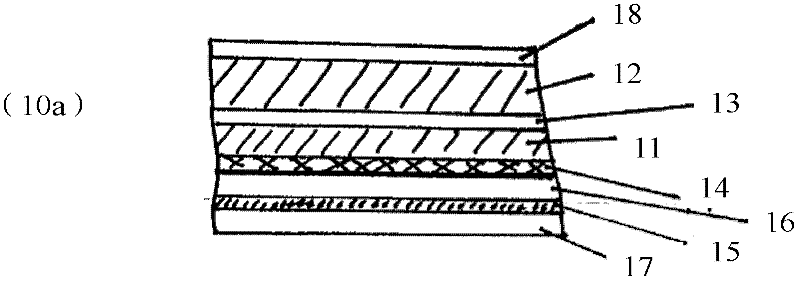

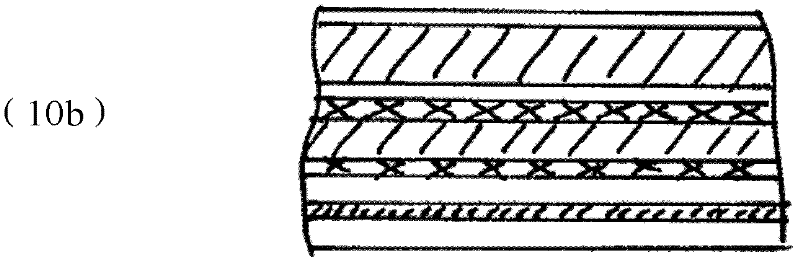

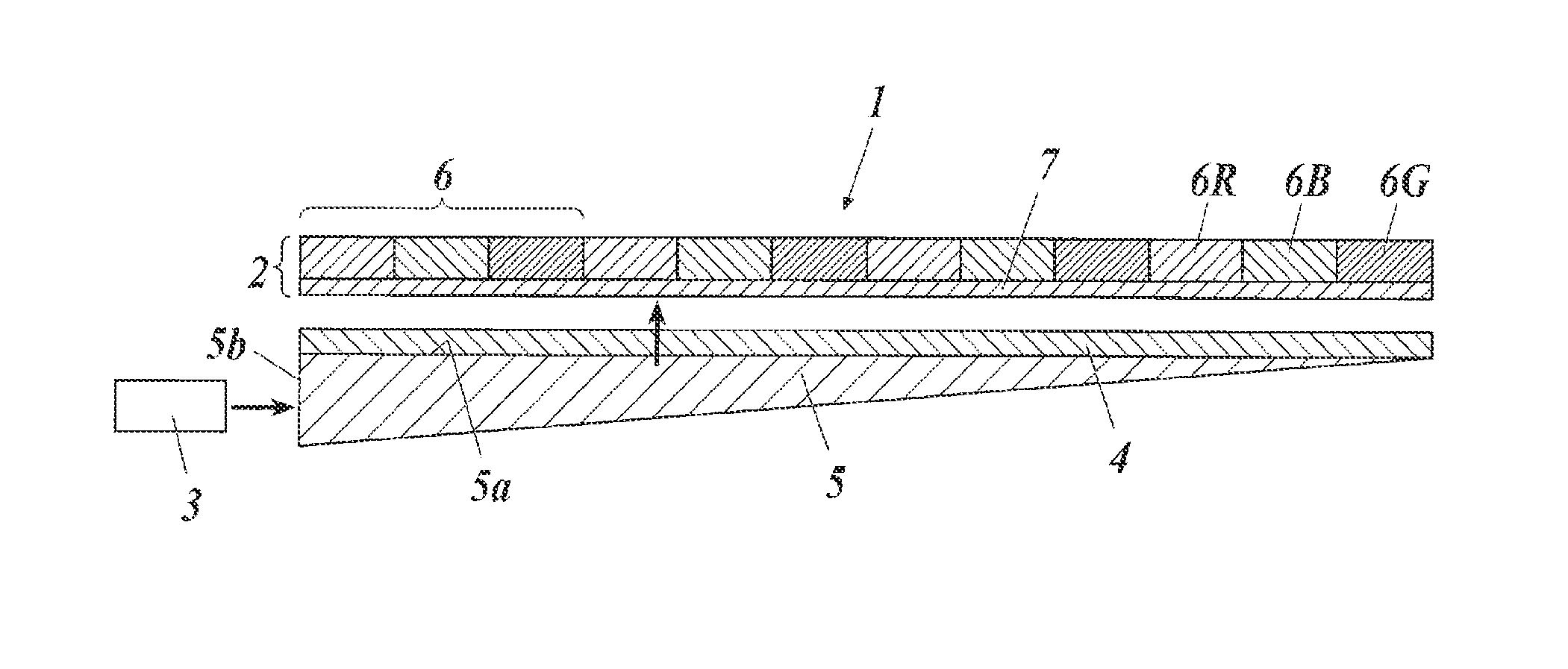

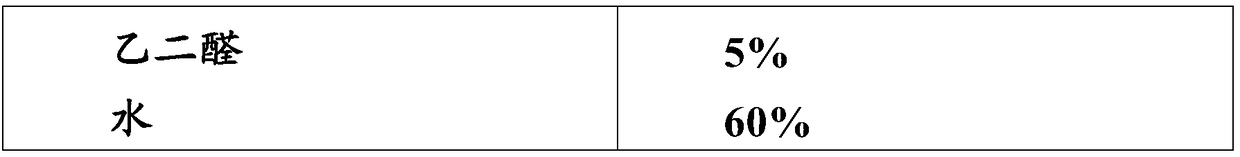

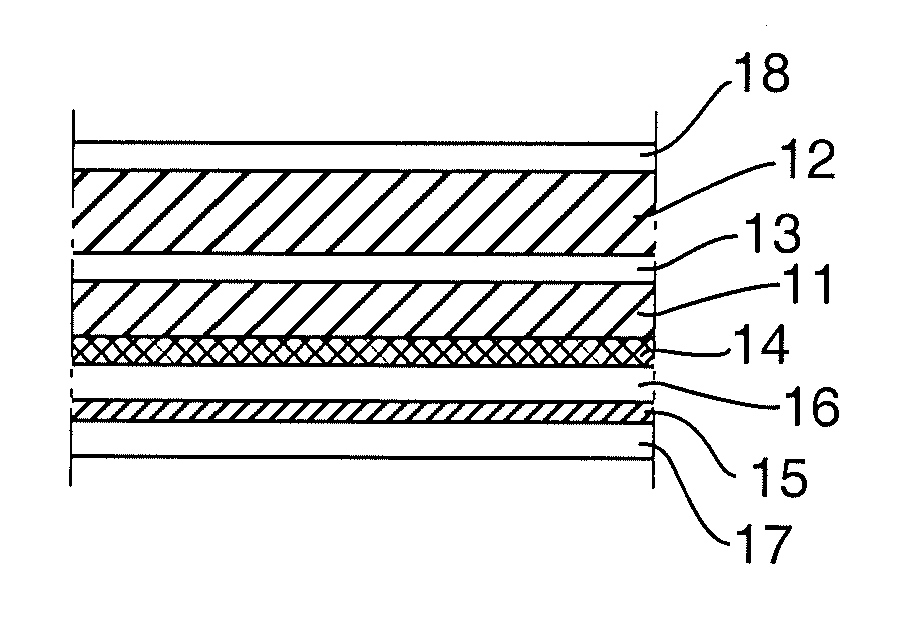

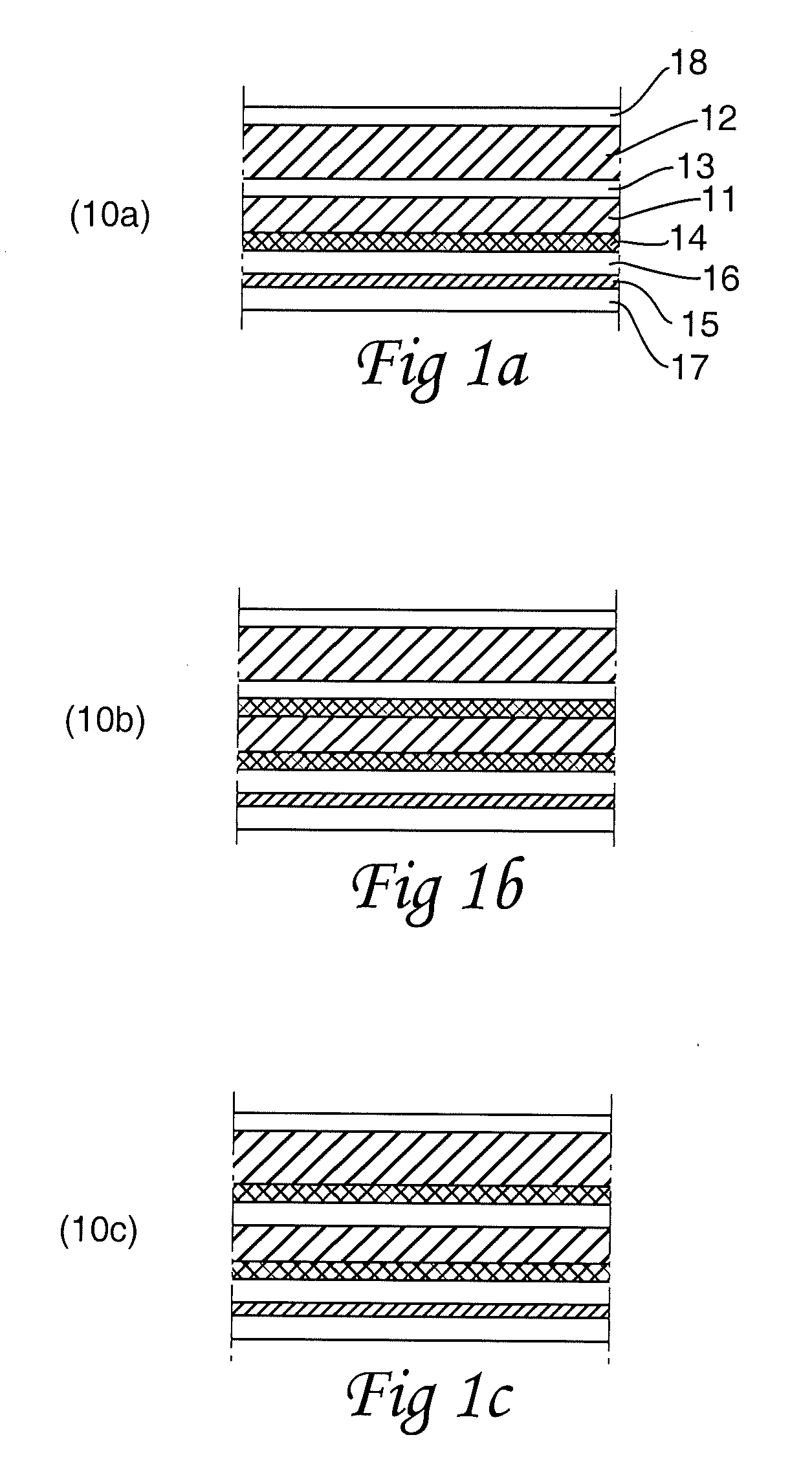

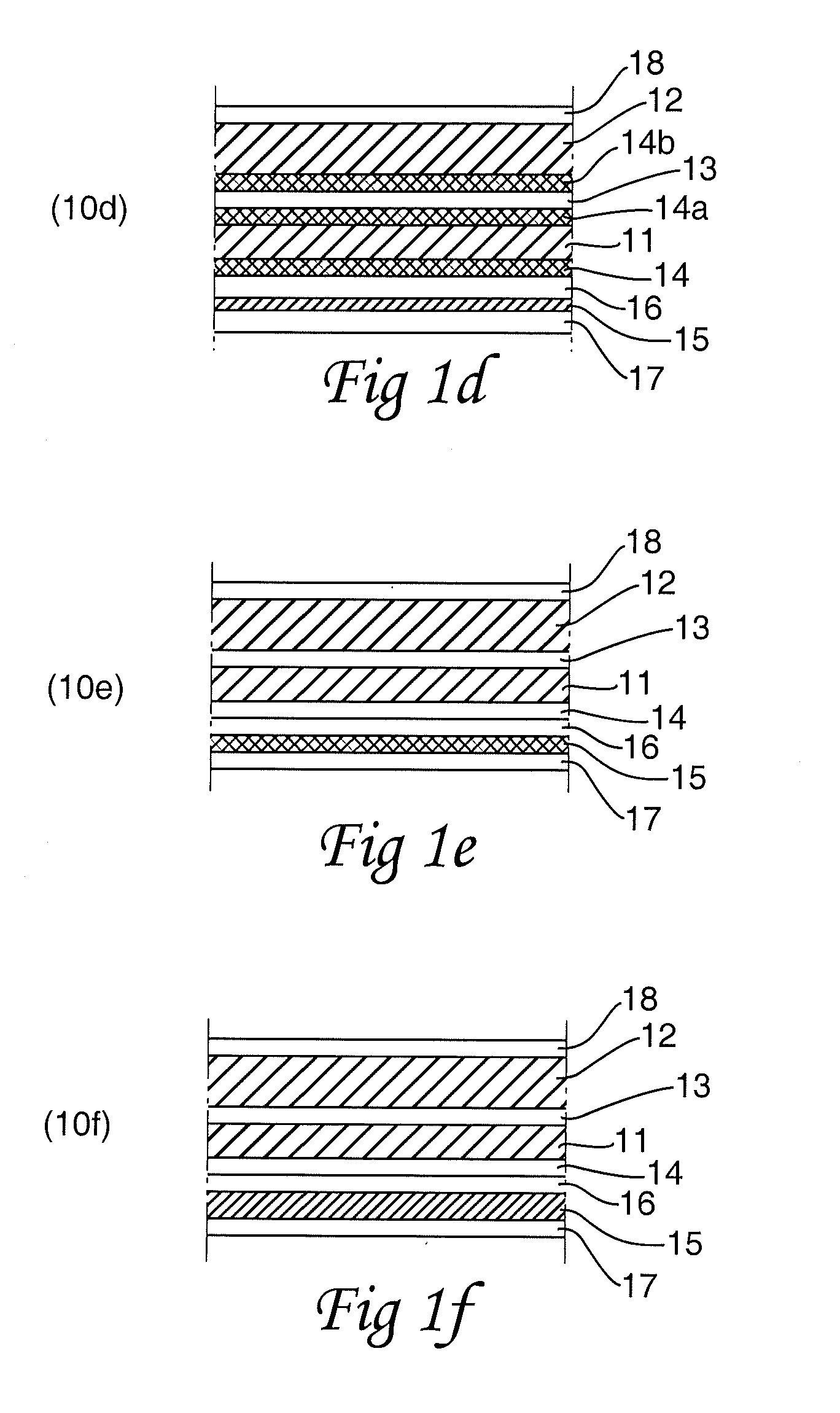

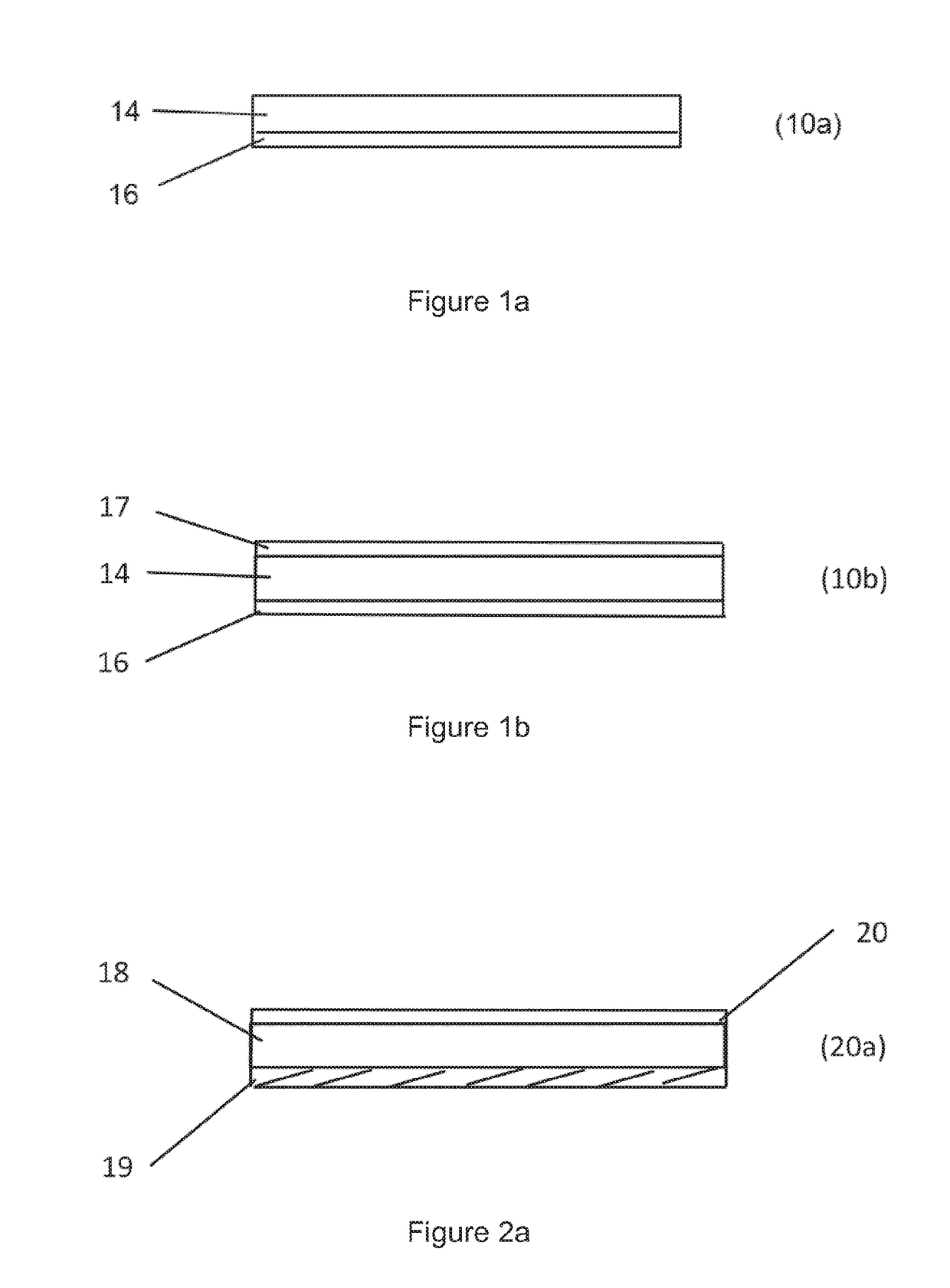

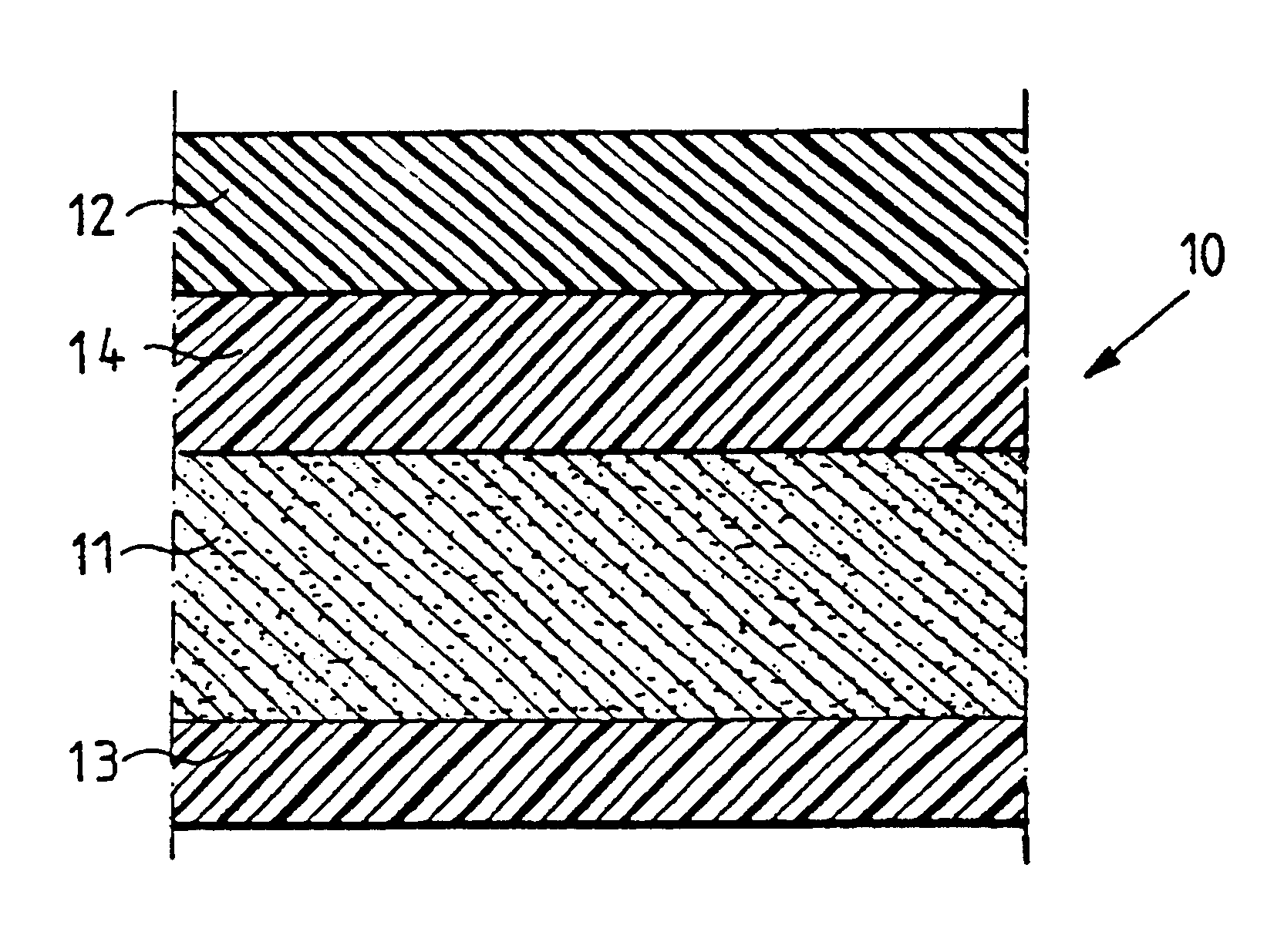

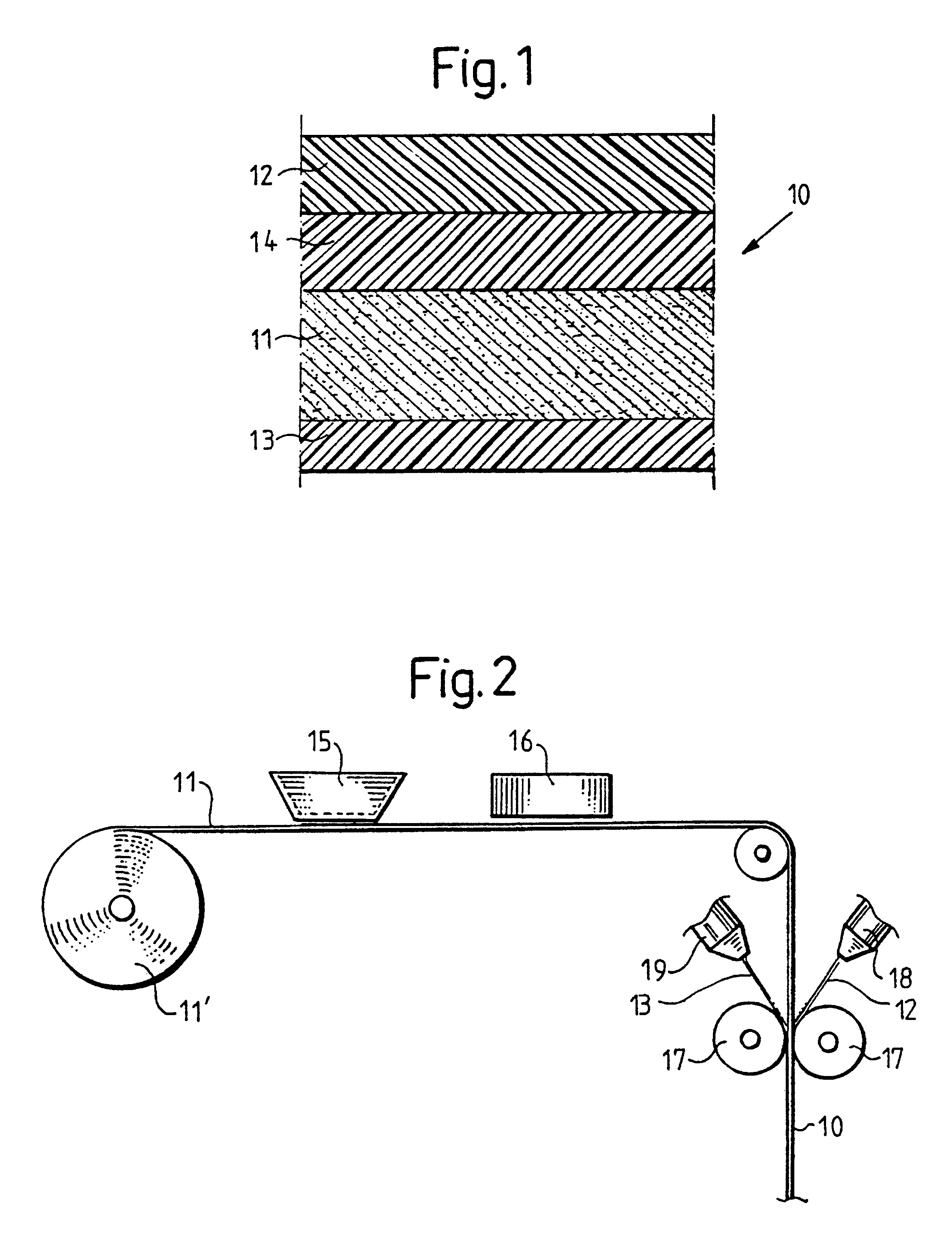

Laminated packaging material, a method of producing the material, and a packaging container produced from the material

InactiveUS6071576AExcellent oxygen barrier propertiesReduce lossesWrappersPretreated surfacesAlcoholPolyvinyl alcohol

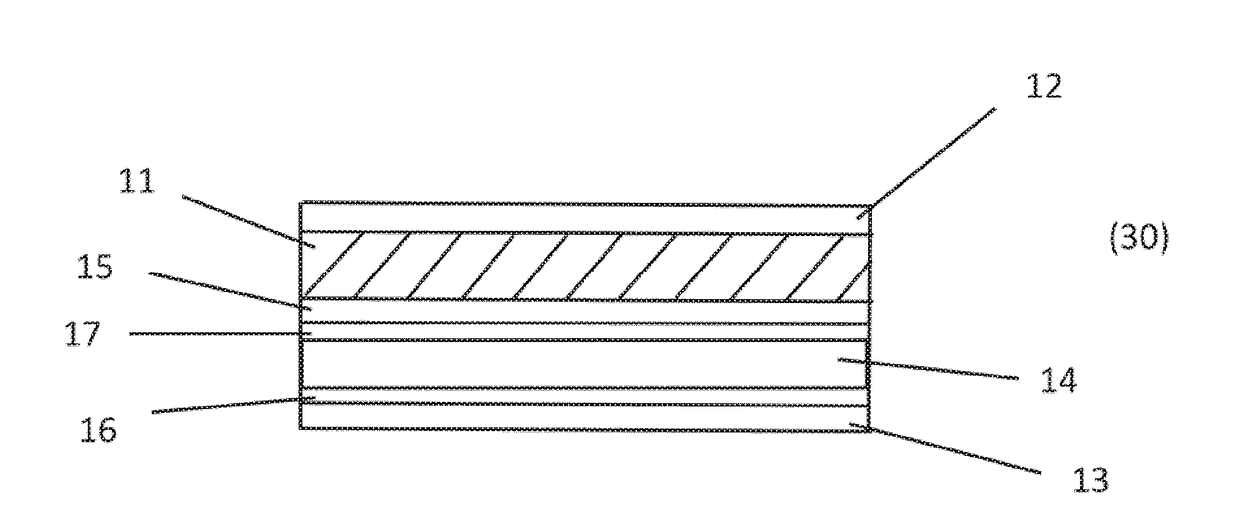

PCT No. PCT / SE96 / 01320 Sec. 371 Date Apr. 14, 1998 Sec. 102(e) Date Apr. 14, 1998 PCT Filed Oct. 17, 1996 PCT Pub. No. WO97 / 14629 PCT Pub. Date Apr. 24, 1997The disclosure relates to a laminated packaging material (10) comprising a core layer (11) of paper or paperboard and a layer (12) of polyvinyl alcohol serving as oxygen gas barrier on one side of the core layer. In order to avoid excessively large quantities of polyvinyl alcohol on application of the oxygen gas barrier layer (12), a layer (13) is applied which serves as a binder and consists of a mixture of polyvinyl alcohol and a gel-forming substance, for example agar, between the polyvinyl alcohol layer (12) and the core layer (11), with the aid of which excessive penetration of polyvinyl A alcohol into the core layer (11) is effectively counteracted, at the same time as the applied binder layer (13) smoothes and evens out the coarse surface structure of the core layer (11) and forms a smooth substrate for the polyvinyl alcohol layer (12). The quantity of gel-forming substance in the binder layer (13) may amount to between 1 and 20 per cent of the total weight of the mixture.

Owner:TETRA LAVAL HLDG & FINANCE SA

Method for the preparation of NFC films on supports

InactiveUS20140255688A1Excellent oxygen barrier propertiesReduce porosityCellulose coatingsCellulosic plastic layered productsCellulosePolymer science

The present invention concerns a method of preparing a film of nanofibrillated cellulose (NFC) on at least one surface of a support material, wherein the film is applied and spread directly onto a surface of the plastic support material in the form of a suspension of nanofibrillated cellulose, whereby the nanofibrillated cellulose forms a film. Further, the invention concerns a structure containing or consisting of a film of nanofibrillated cellulose prepared using said method.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

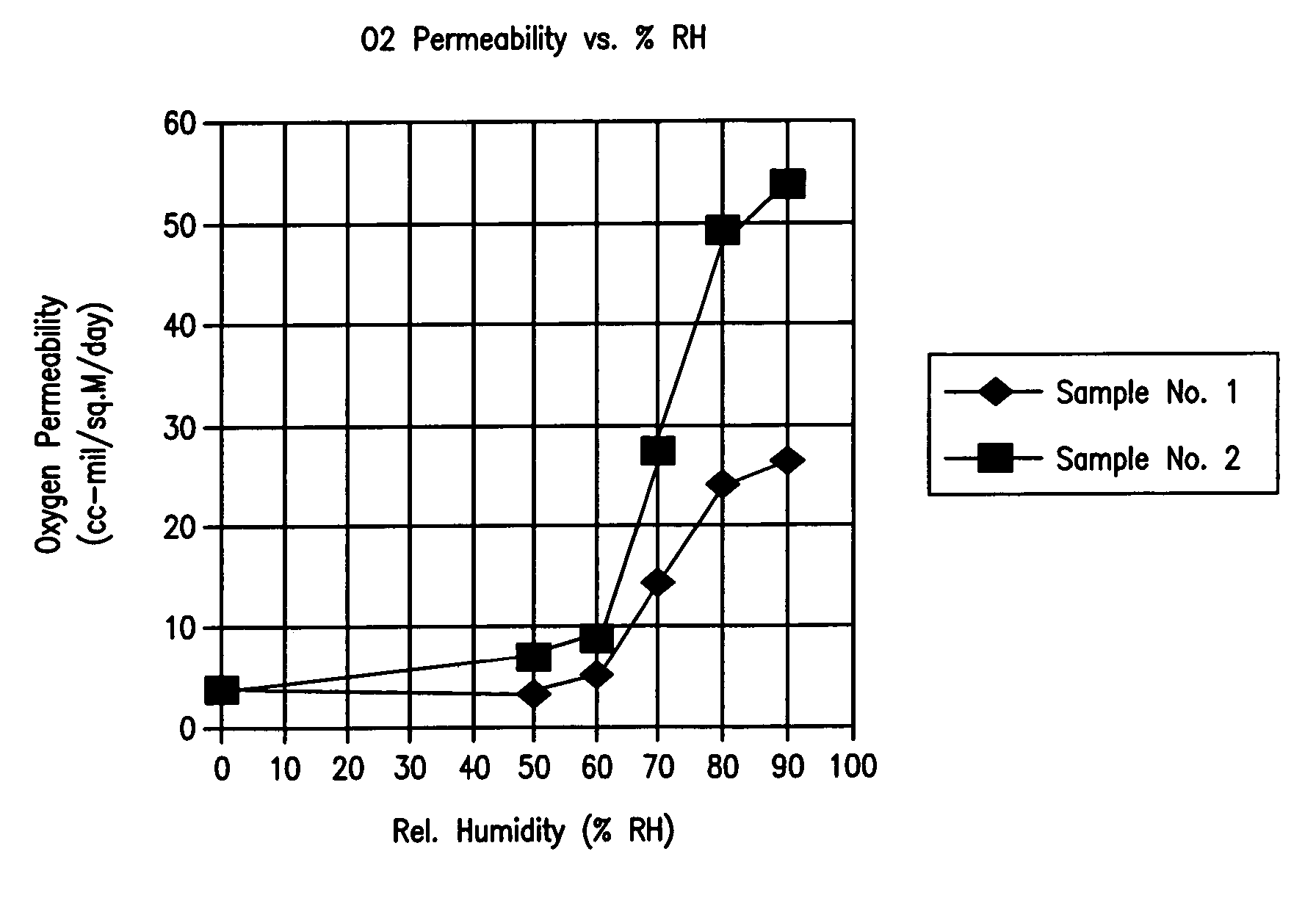

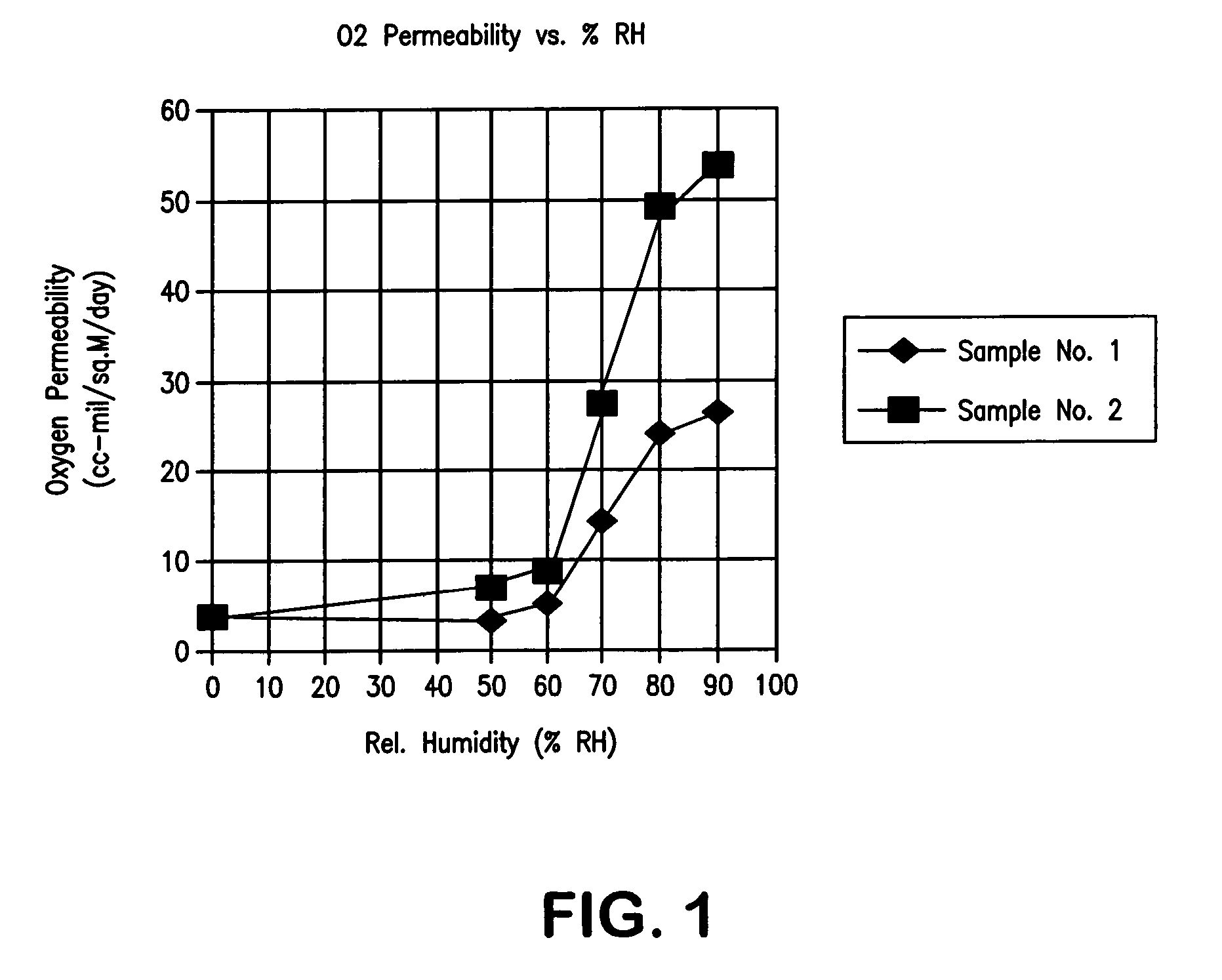

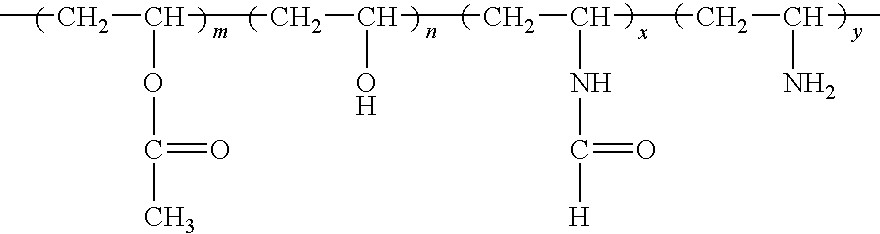

Coated polymeric film with oxygen barrier properties

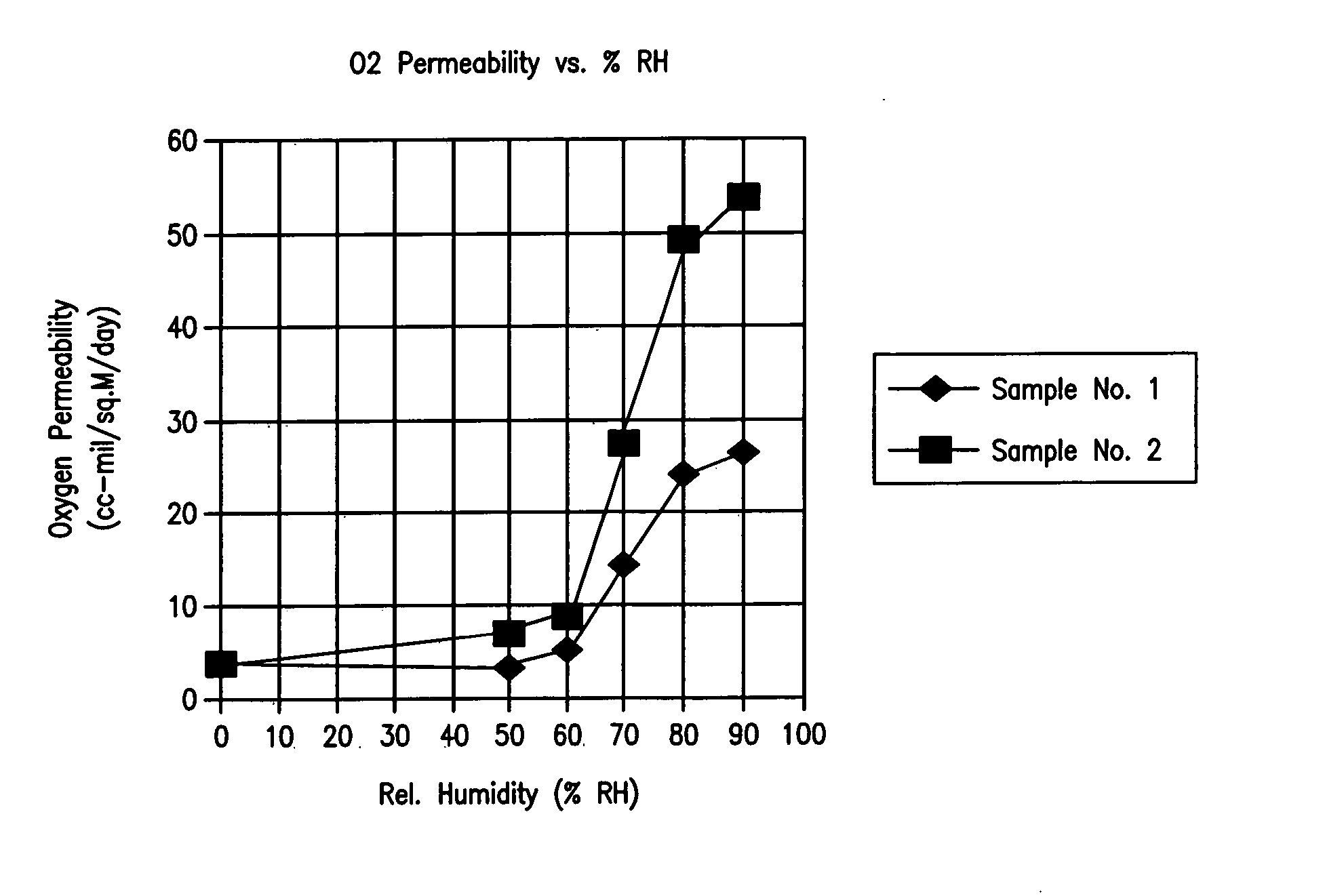

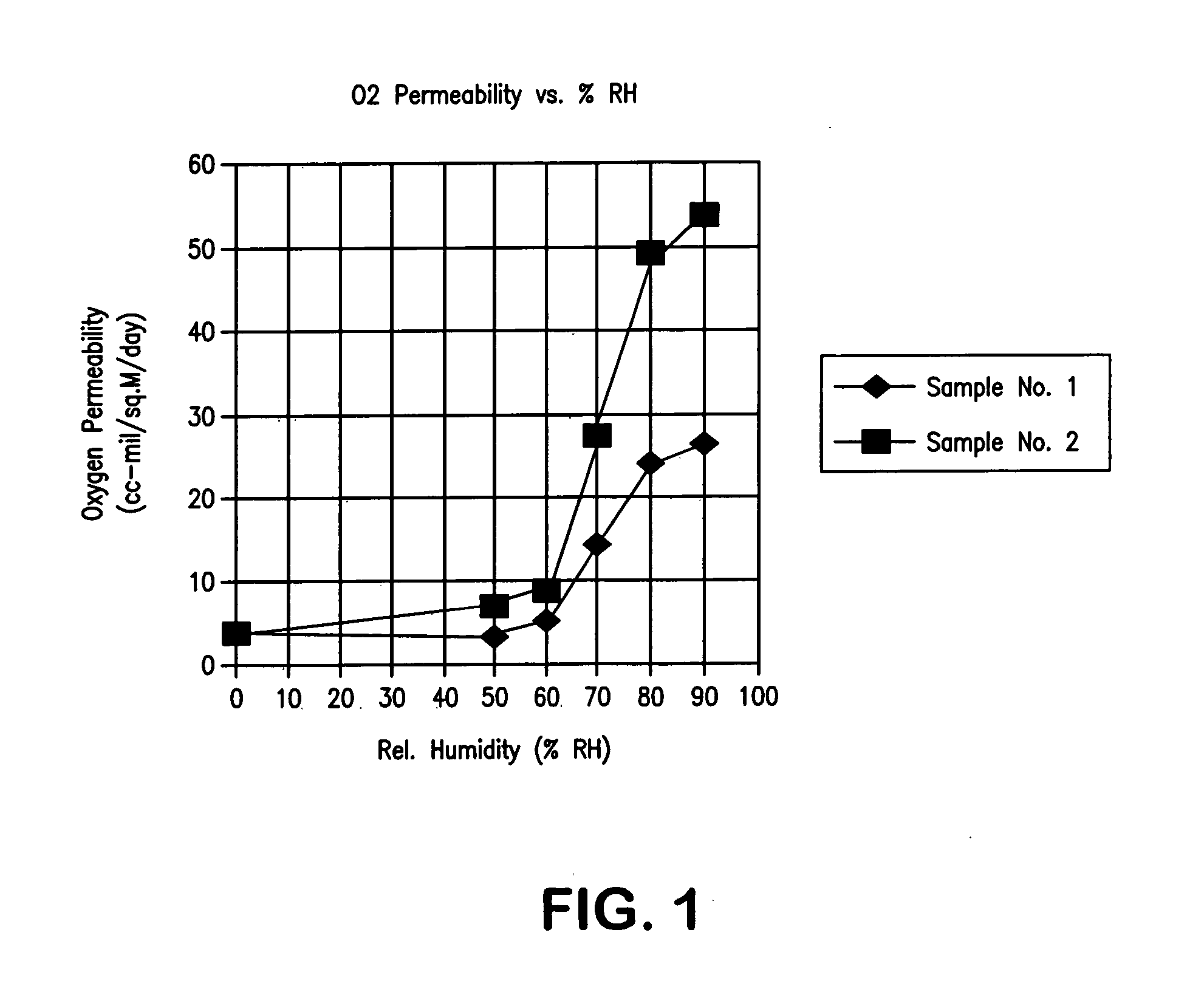

ActiveUS7521103B2Excellent oxygen barrier propertiesSynthetic resin layered productsPretreated surfacesPolyesterPolymer thin films

A coating compositions for providing substrates with oxygen barrier properties is disclosed. The substrate may be, for instance, a film, such as a polyester film. The coating composition includes a copolymer of maleic acid and acrylic acid and a copolymer of vinyl alcohol and a vinylamine. The barrier coating formed from the coating composition is typically less than about 1 micron in thickness and provides reduced oxygen transmission even at relatively high relative humidities.

Owner:MITSUBISHI POLYESTER FILM

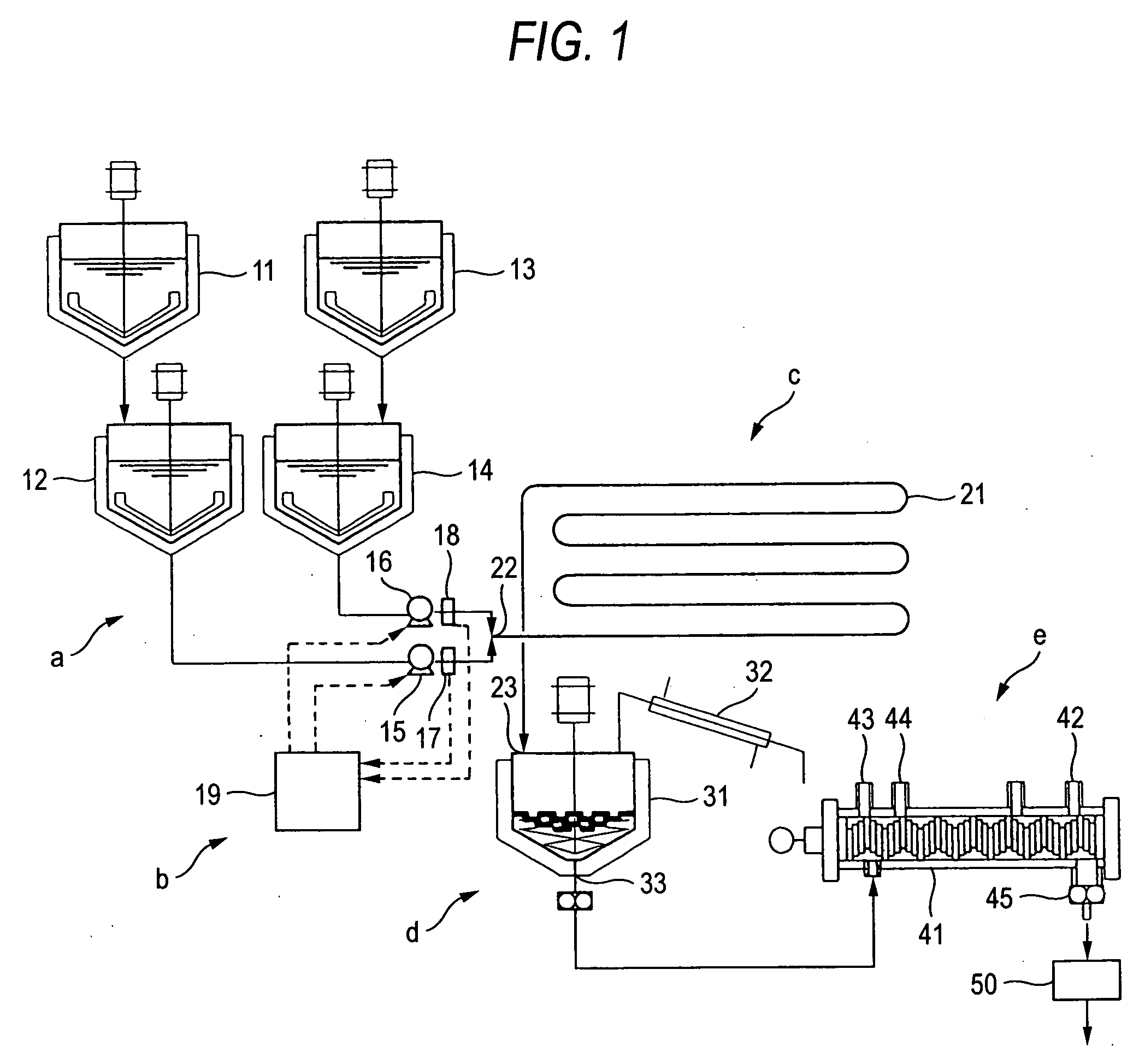

Packaging laminate, method for manufacturing of the packaging laminate and packaging container produced therefrom

InactiveUS20110132975A1Excellent gas barrier performanceImprove adhesionWrappersVacuum evaporation coatingPaper sheetPolyolefin

A non-foil packaging laminate for liquid food packaging comprises a core layer of paper or paperboard, outermost liquid tight, heat sealable layers of polyolefin and, applied onto the inner side of the layer of paper or paperboard, and an oxygen gas barrier layer formed by liquid film coating of a liquid gas barrier composition and subsequent drying. The liquid composition contains a polymer binder dispersed or dissolved in a liquid medium. The disclosure also involves a method for manufacturing of the packaging laminate and a packaging container made from the packaging laminate.

Owner:TETRA LAVAL HLDG & FINANCE SA

Multi-layered biaxial stretch blow molded bottle and method for production thereof

InactiveUS7666486B2Improve propertiesExcellent oxygen barrier propertiesEnvelopes/bags making machinerySynthetic resin layered productsBlow moldingEngineering

A multi-layer biaxially stretched blow bottle having a 3-layer structure of PET / nylon MXD6 / PET or a 5-layer structure of PET / nylon MXD6 / PET / nylon MXD6 / PET, wherein the oxygen gas transmission coefficient of the nylon MXD6 layer is at most 6.0×10−14 cm3·cm / cm2·sec·cmHg as measured under conditions of a temperature of 23° C. and a relative humidity of 80%, and a production process of the bottle by biaxial stretch blow molding at a low stretching temperature and high draw ratios.

Owner:KUREHA KAGAKU KOGYO KK

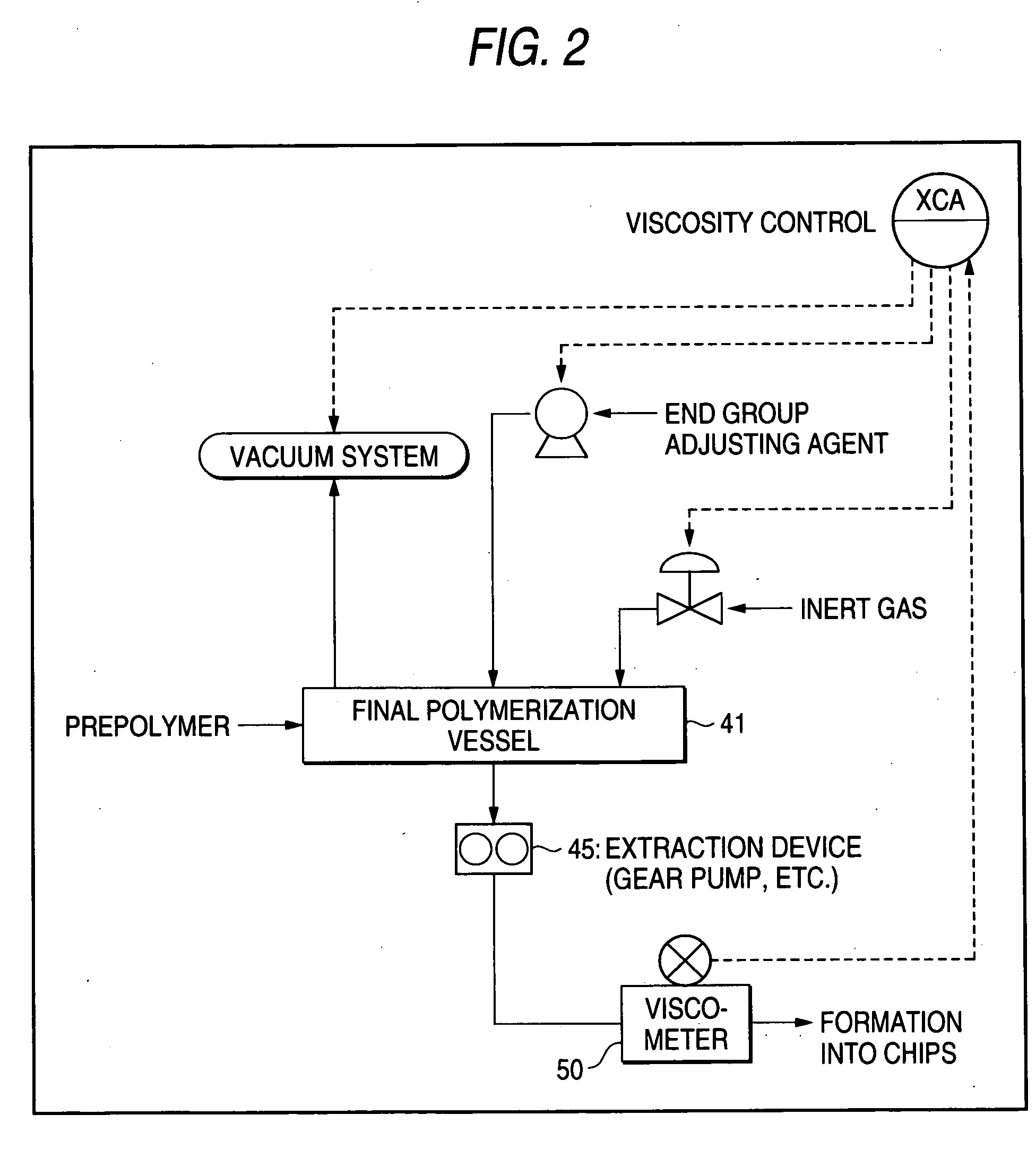

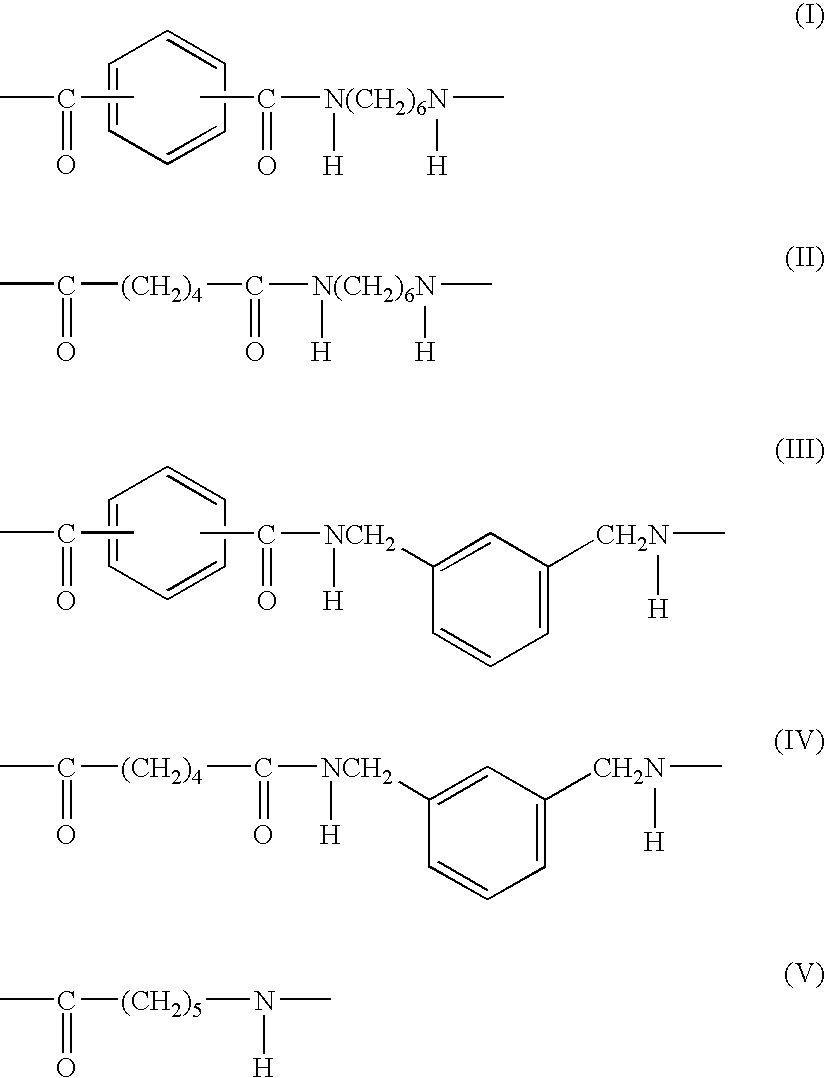

Method for continuous production of polyamide

InactiveUS20060122360A1Quality improvementExcellent oxygen barrier propertiesCeramic shaping apparatusChemical/physical/physico-chemical stationary reactorsPolyamideCarboxylic acid

Provided is a continuous production method of a polyamide with stabilized polymerization degree and good quality, particularly an aromatic-containing polyamide. A continuous production method of a polyamide, comprising (a) a raw material preparation step of individually melting a diamine and a dicarboxylic acid, or producing a salt of amine and carboxylic acid in water, (b) a raw material introduction step of continuously introducing the prepared raw materials into a tubular reaction apparatus, (c) an amidation step of passing the introduced raw materials through the tubular reaction apparatus, thereby effecting amidation to obtain a reaction mixture containing an amidated product and a condensed water, (d) an initial polymerization step of introducing the reaction mixture into a continuous reaction apparatus capable of separation and removal of water, and elevating the polymerization degree while separating and removing water at a temperature higher than the melting point of the finally obtained polyamide to obtain a polyamide prepolymer, and (e) a final polymerization step of introducing the polyamide prepolymer into a continuous reaction apparatus capable of separation and removal of water, and further elevating the polymerization degree at a temperature higher than the melting point of the finally obtained polyamide to obtain a polyamide adjusted to a desired relative viscosity [RV].

Owner:TOYO TOYOBO CO LTD

Container for retort packaging, resin composition, and gas-barrier film prepared therefrom

InactiveUS6143384AExcellent oxygen barrier propertiesExcellent not in resistanceCosmetic preparationsOrganic detergent compounding agentsCross-linkChemical structure

Owner:TOPPAN PRINTING CO LTD

High barrier packaging laminate, method for manufacturing of the packaging laminate and packaging container

ActiveCN102470642AImprove resistance to damageFull strengthSynthetic resin layered productsPaper/cardboard layered productsPolymer scienceFood packaging

Owner:TETRA LAVAL HLDG & FINANCE SA

Barrier film with reduced dynamic coefficient of friction

InactiveUS6893730B2Reduce coefficient of frictionReduce dynamic coefficient of frictionWrappers shrinkageFilament/thread formingDynamical frictionPolyamide

Oxygen barrier films having a greatly improved dynamic coefficient of friction, and specifically, oxygen barrier films having an exceptionally low dynamic coefficient of friction, reduced moisture sensitivity and good oxygen barrier properties over a wide range of relative humidities. The low coefficient of friction is obtained by using film layers which are blends of a polyamide component and a high density polyethylene which surround an oxygen barrier layer, such as an ethylene vinyl alcohol layer.

Owner:HONEYWELL INT INC

Light-emitting material, method for producing same, optical film, and light-emitting device

InactiveUS20160149091A1High transparencyIncreased durabilityMaterial nanotechnologyNanoopticsLong term degradationSemiconductor Nanoparticles

The purpose of the invention is to provide a high-transparency light-emitting material of sufficient durability to minimize long-term degradation of semiconductor nanoparticles due to oxygen, etc.; and a method for producing said material. This light-emitting material is characterized in containing semiconductor nanoparticles, a metal alkoxide, and a silicon compound.

Owner:KONICA MINOLTA INC

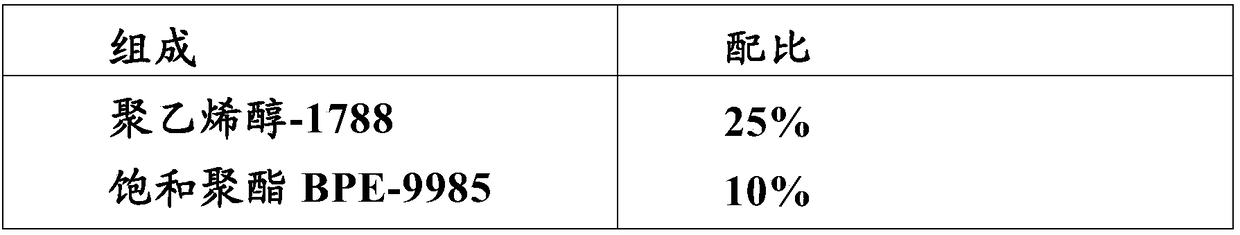

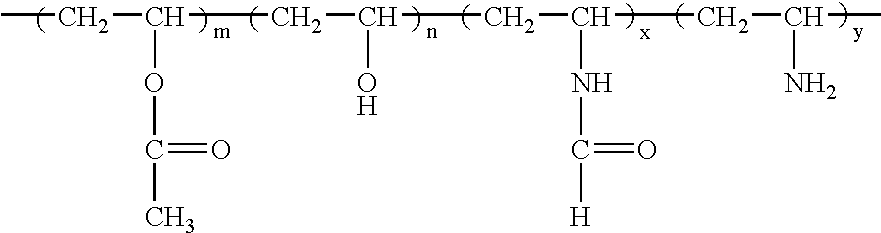

Method for fabricating obstruction coating film of modified polyvinyl alcohol and coating film produced thereby

InactiveCN1687264AReduce hydrogen bondingImprove water resistanceCoatingsPVA - Polyvinyl alcoholPolymer chemistry

The present invention provides a modified polyvinyl alcohol high-barrier coating film and its preparation method. Said method uses PVOH as raw material, and adopts the following steps: after the raw material is catalyzed, making modification, then adding adjuvant to make them into coating material, applying said coating material on the base film so as to form high-barrier coating film. After the PVOH molecular chain is partially catalyzed and condensed, the hydrogen bond action force in the molecular can be reduced, so that its water-proof property can be greatly raised.

Owner:HAINAN SHINER IND

Transparent biaxially oriented polypropylene film with low moisture vapor and oxygen transmission rate

InactiveUS20080205800A1High transparencyExcellent oxygen barrier propertiesSynthetic resin layered productsBagsPolyolefinPolymer science

A laminate film comprising a polyetheramine resin-containing layer, an adhesion-promoting tie-layer, and a core layer comprising of high crystalline propylene homopolymer and crystalline Fischer-Tropsch wax with an optional amount of hydrocarbon resin which exhibits excellent transparency and oxygen and moisture barrier properties. The laminate film could further have additional layers such as a second polyolefin resin-containing layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

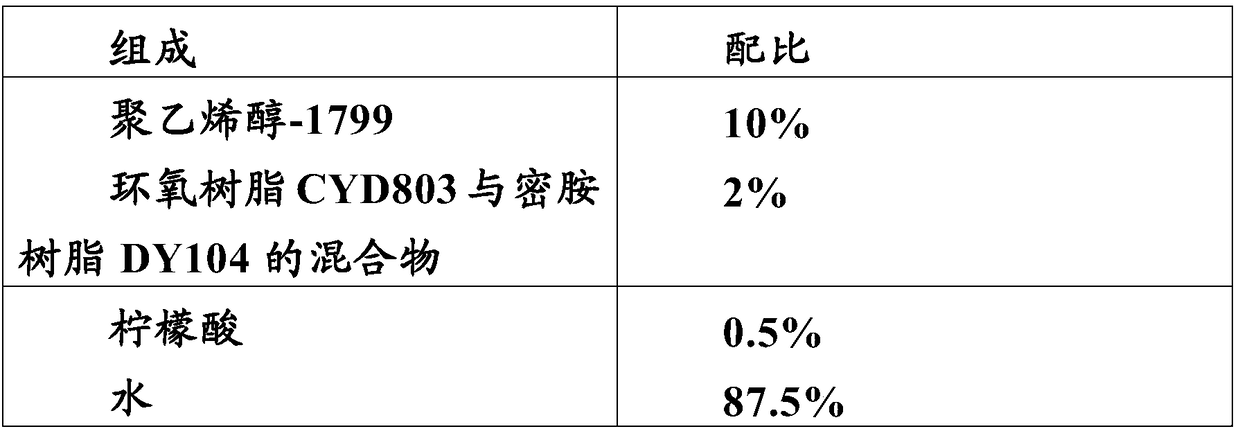

High-barrier water-based adhesive

ActiveCN109161363ALow costNo emissionsNon-macromolecular adhesive additivesLamination ancillary operationsAdhesive cementPolymer science

The invention relates to the field of packaging materials, in particular to a high-barrier water-based adhesive as well as a preparation method and an application of the water-based adhesive. The invention further relates to a composite film, a preparation method and an application of the composite film and a package comprising the composite film. The composite film comprises an adhesion barrier layer formed by the water-based adhesive.

Owner:刘建林

Highly moisture proof film and method of manufacturing the same

ActiveUS7501176B2Increased compact structureExcellent oxygen barrier propertiesSynthetic resin layered productsPretreated surfacesVolumetric Mass DensityMoisture

The present invention makes it possible to provide a film exhibiting an excellent oxygen-gas barrier properties and an excellent moisture proofness, the film containing at least a multivalent metal salt of a polycarboxylate-based polymer (A), the film having the density which is not lower than 1.80 g / cm3; the surface ratio α [the peak surface S1 (3700 to 2500 cm−1) / the peak surface S2 (1800 to 1500 cm−1)] of an infrared absorption spectrum which is not larger than 2.5; and the peak ratio β [the peak A1 (1560 cm−1) / the peak A2 (1700 cm−1)] of the infrared absorption spectrum which is not smaller than 1.2, by means of applying a solution containing the polycarboxylate-based polymer (A) and the multivalent metal compound (B) to a substrate, thus obtaining a dried film, and thereafter treating the dried film with heat under predetermined conditions. Accordingly, the present invention makes it possible to provide packaging materials and packaging containers for not only foods which are required not to contact an oxygen gas, but also foods, beverages, chemicals, pharmaceuticals, and precision metal parts such as electronic parts, as well as members of electronic equipment, all of which are required to be protected from moisture.

Owner:TOPPAN PRINTING CO LTD

High barrier packaging laminate, method for manufacturing of the packaging laminate and packaging container

InactiveUS20120100320A1Excellent gas barrier performanceImprove adhesionSynthetic resin layered productsWood working apparatusSolventLiquid composition

A non-foil packaging laminate for liquid food packaging comprises a first layer of paper situated towards the inner side of the packaging laminate and a second layer of paper situated towards the outer side of the packaging laminate, with the first and second paper layers laminated to each other by a first intermediate bonding layer in a sandwich structure. The packaging laminate further comprises a gas barrier coating layer, coated onto the inner side of the first paper layer by liquid film coating of a liquid gas barrier composition onto the first paper layer and subsequent drying, the liquid composition containing a polymer binder dispersed or dissolved in an aqueous or solvent medium, and a further barrier layer towards water vapour laminated and bonded to the barrier-coated inside of the first paper layer. Also disclosed is a method for manufacturing the laminate, and a packaging container made from the laminate.

Owner:TETRA LAVAL HLDG & FINANCE SA

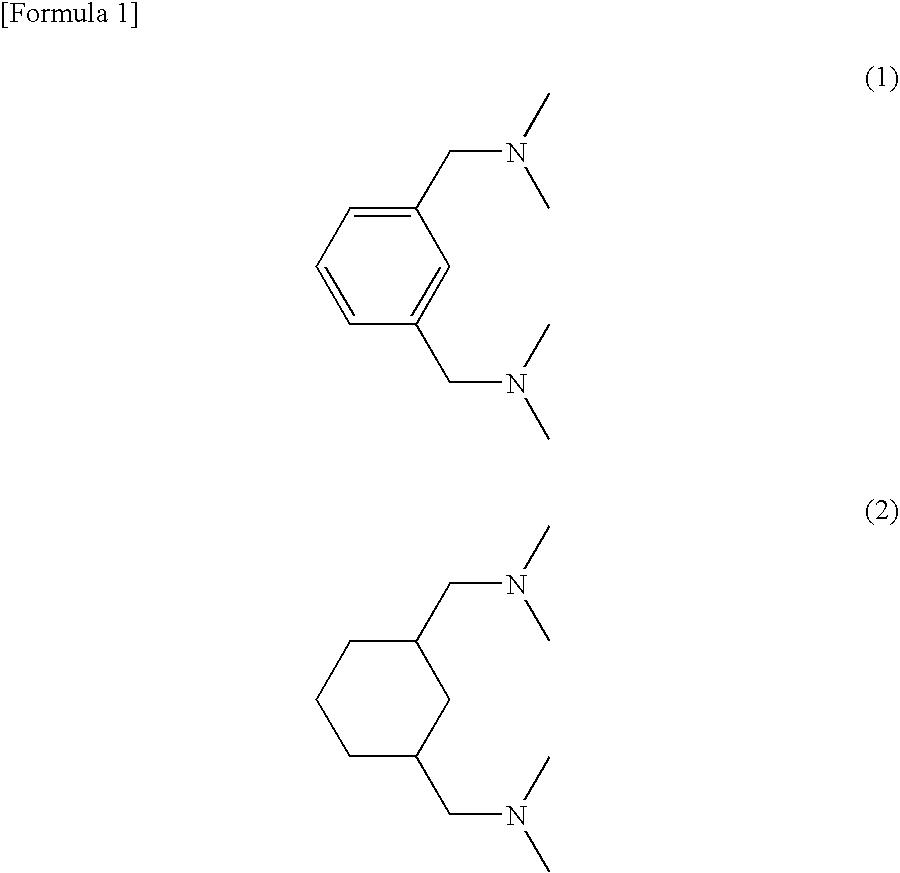

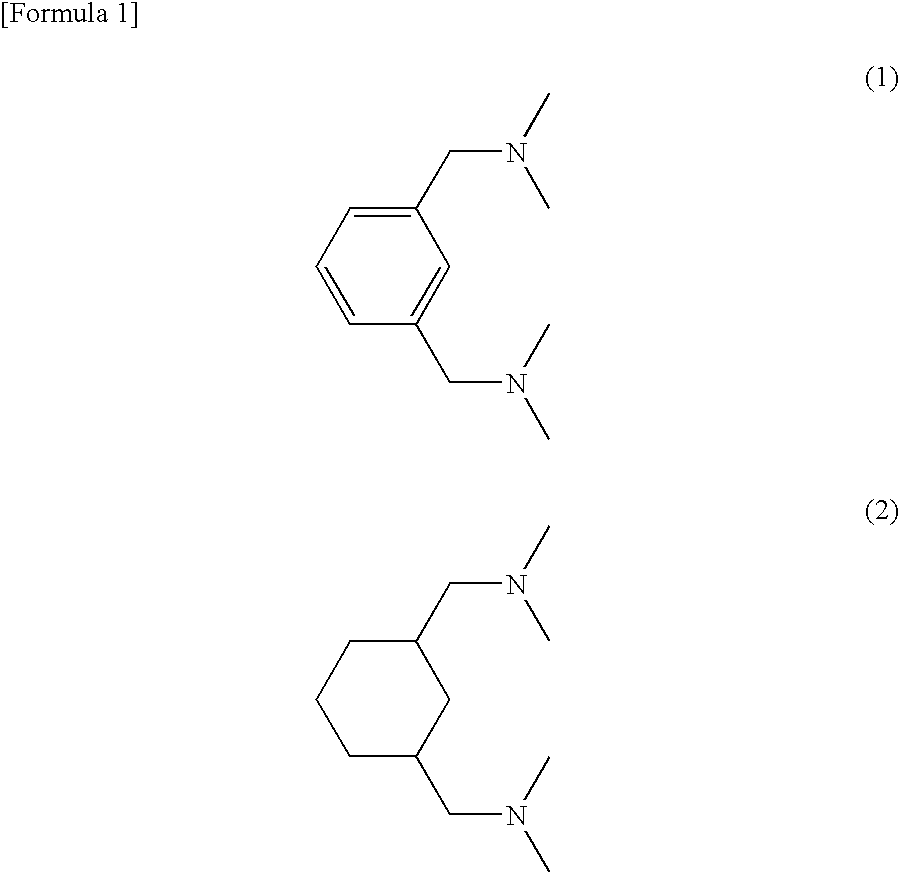

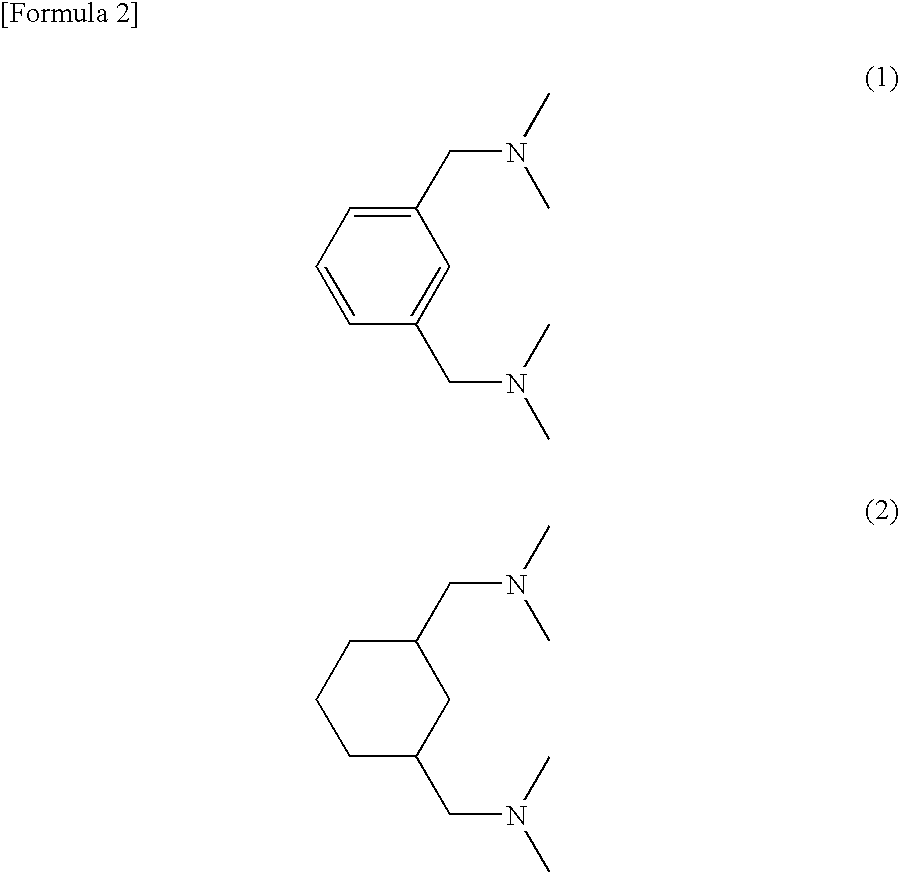

Gas barrier film

InactiveUS20090263654A1Excellent oxygen barrier propertiesExcellent in barrier property water vapor barrier propertyFilm/foil adhesivesSynthetic resin layered productsPolyesterWater vapor

The present invention relates to a gas barrier film where a polyurethane type resin layer and an inorganic layer are disposed in this order from a polyester type resin film side on at least one surface of a polyester type resin film, wherein the polyurethane type resin constituting said polyurethane type resin layer is a resin containing a skeleton represented by the following formula (1) and / or the following formula (2).The present invention provides a gas barrier film having excellent oxygen insulation and water vapor insulation.

Owner:TORAY IND INC

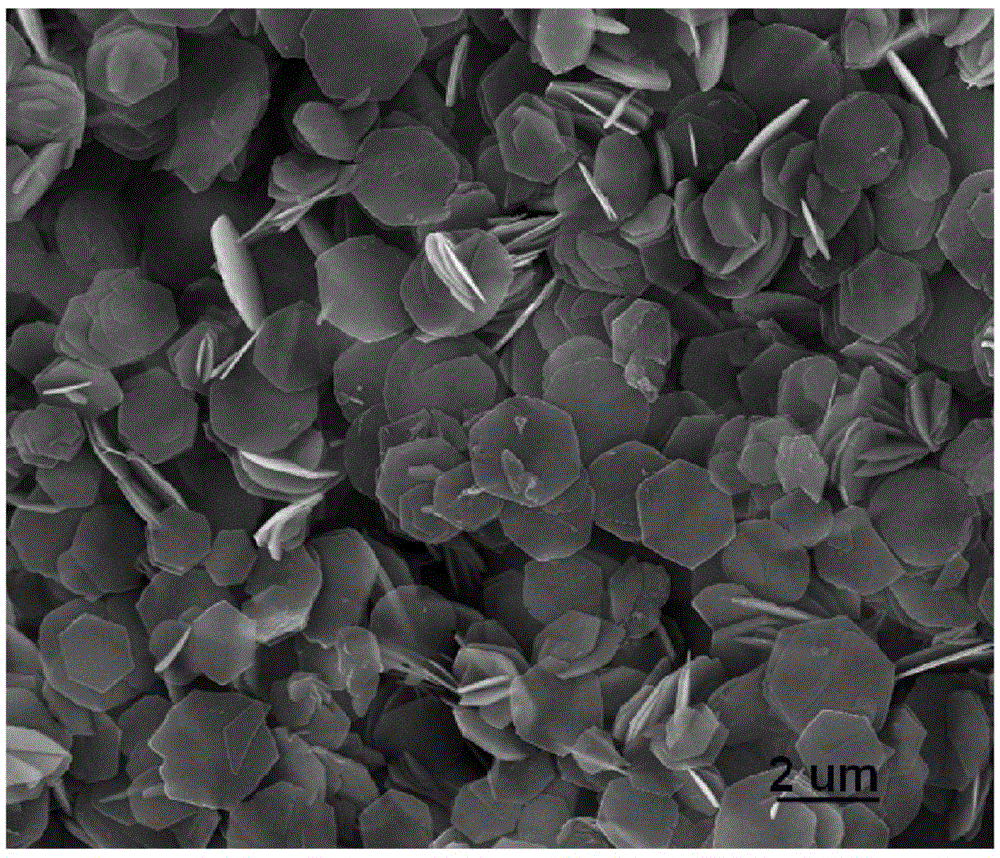

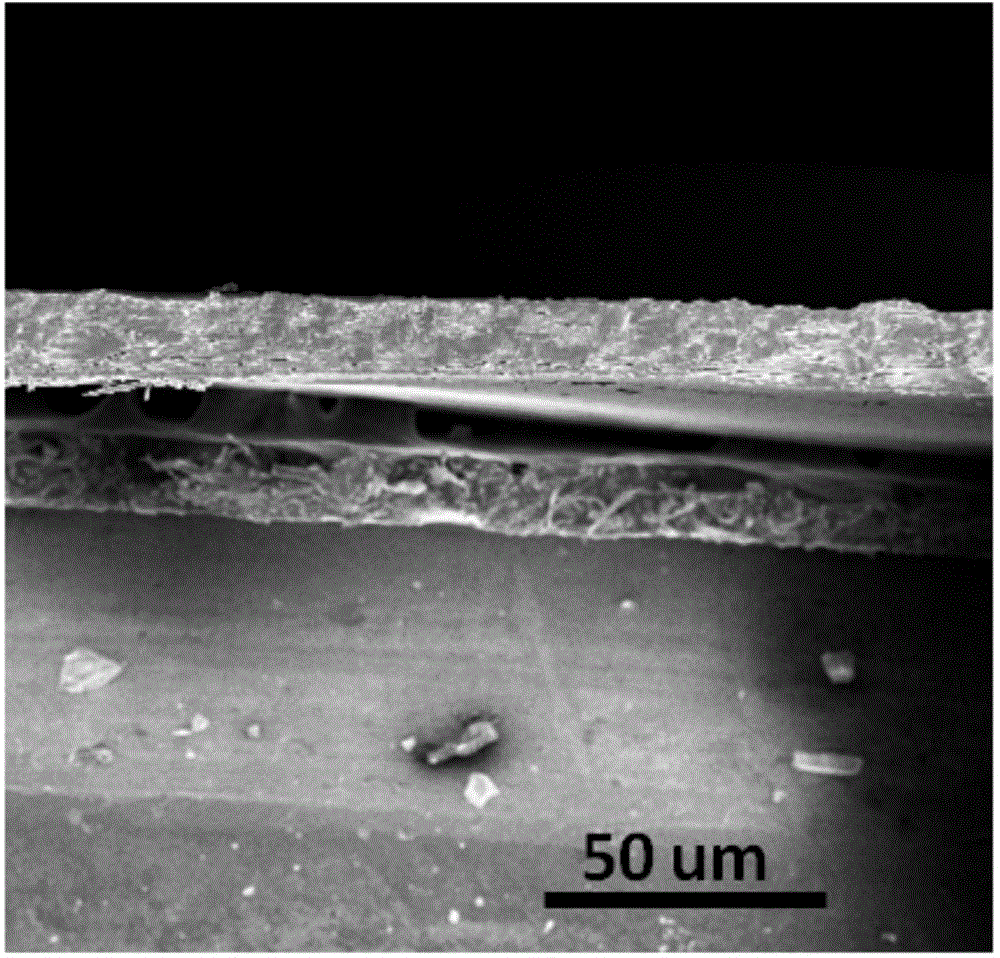

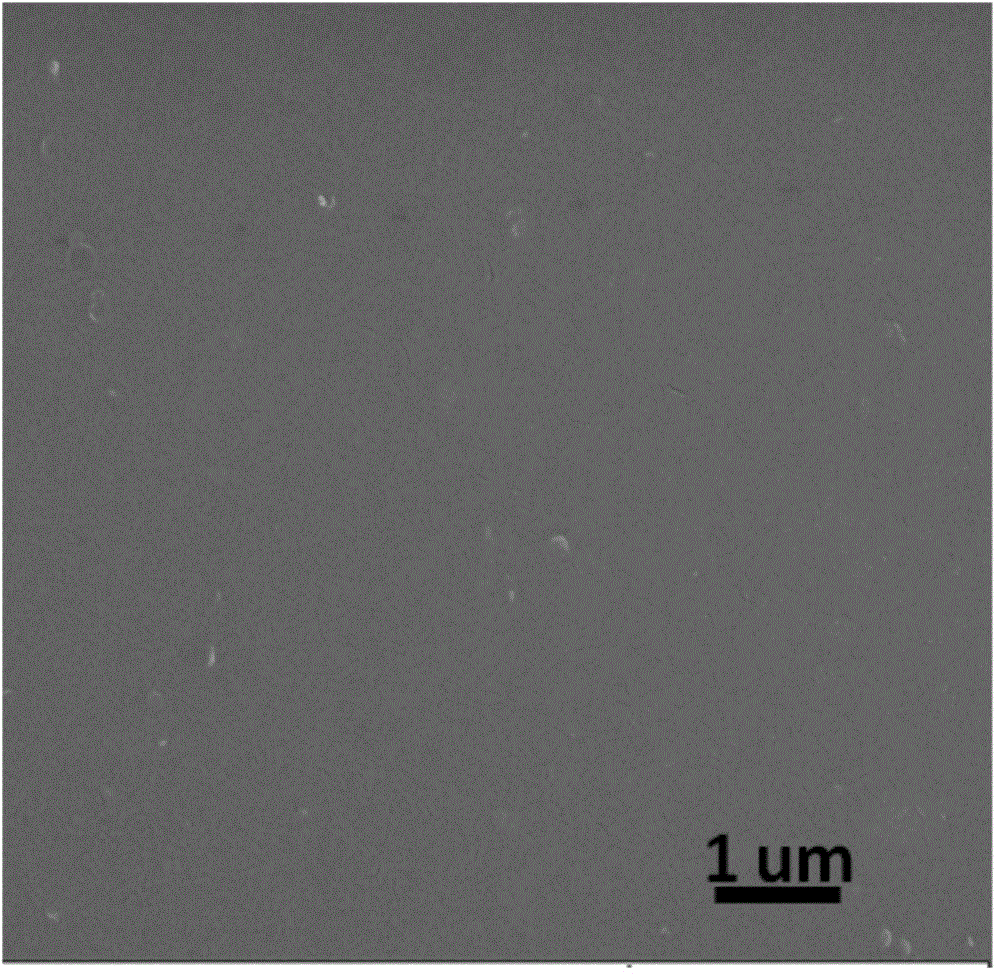

Transparent gas barrier film materials and production method thereof

The invention discloses transparent gas barrier film materials and a production method thereof. A large length-diameter ratio of hydrotalcite nano-sheet serves as a precursor, the hydrotalcite whish is of a two-dimensional layered structure and various commercial packaging polymer raw materials are composited into a film by a simple suction filter deposition film forming technology, a diffusion path of gas molecules in the composite film can be significantly extended due to the large length-diameter ratio and the two-dimensional ordered structure of the hydrotalcite, and accordingly the barrier performance of the film materials is further improved. The finally produced transparent gas barrier film is ultra-low in oxygen transmissibility in comparison with a detection limit of an instrument and accordingly the problem that the requirement of the current barrier packaging field for the oxygen resistance performance of materials is high can be solved. According to the suction filter deposition film forming method, the production is simple, the raw material sources are wide, the material selection is convenient, the cost is low, and the environment-friendly and sustainable development requirements are met in comparison with the traditional method and accordingly the transparent gas barrier film materials comprise the potential application value in the fields of food, medicine packaging, electronic device packaging and the like.

Owner:BEIJING UNIV OF CHEM TECH

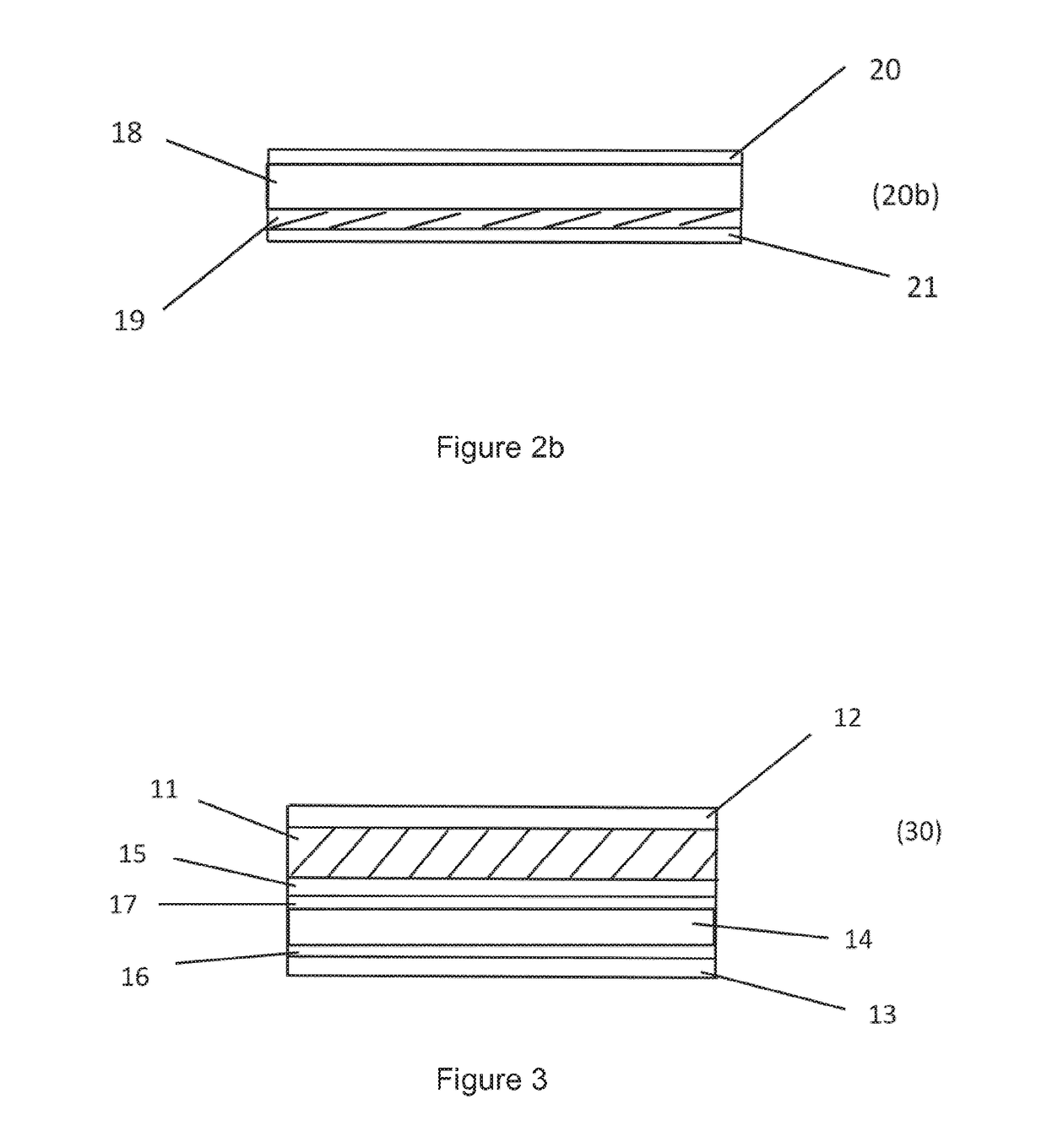

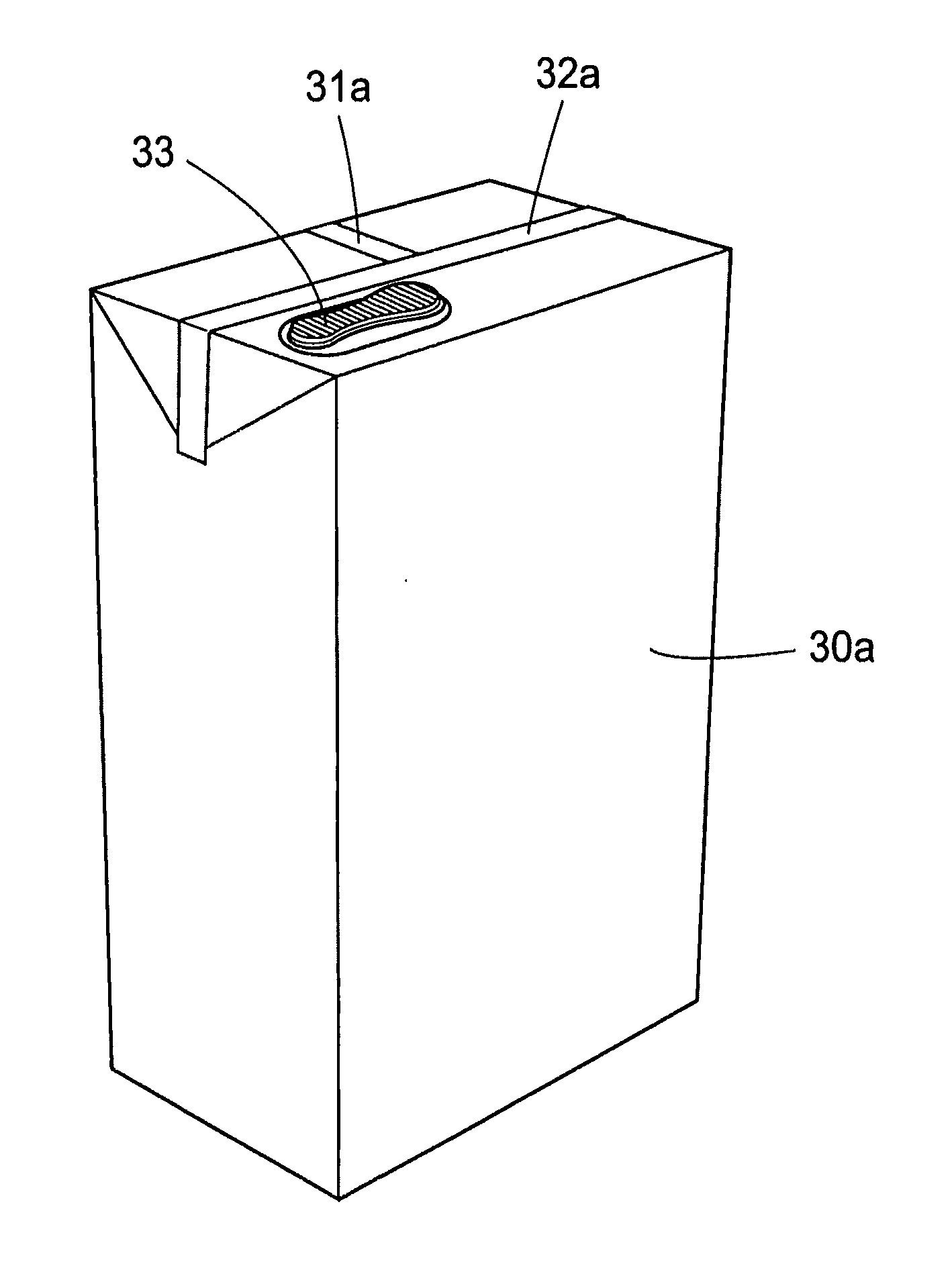

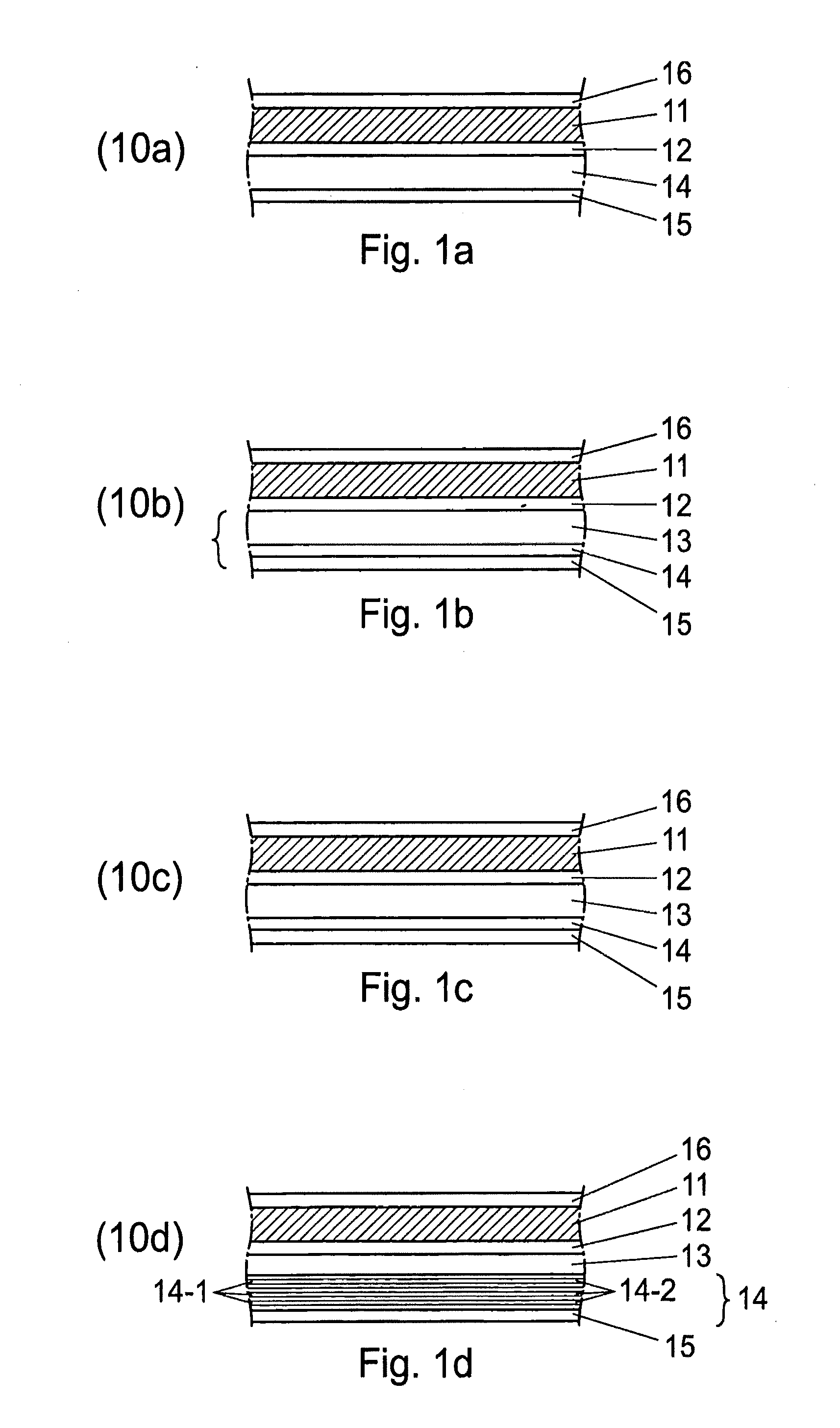

Barrier film or sheet and laminated packaging material comprising the film or sheet and packaging container made therefrom

ActiveUS20180319143A1Improve moisture resistanceImprove availabilitySynthetic resin layered productsPaper/cardboard layered productsCelluloseEngineering

The present invention relates to barrier films or sheets comprising cellulose nanofibrils and to laminated packaging materials comprising such films, in particular intended for liquid food packaging.The invention also relates to a packaging container comprising the laminated packaging material or being made from the laminated packaging material, in particular to a packaging container intended for liquid food packaging.

Owner:TETRA LAVAL HLDG & FINANCE SA

Packaging laminate, method for manufacturing of the packaging laminate and packaging container produced therefrom

InactiveUS20110248076A1Improve adhesionImprove barrier propertiesDomestic containersCoatingsCardboardLiquid medium

A non-foil packaging laminate for liquid food packaging comprises a core layer of paper or paperboard, outermost liquid tight, heat sealable layers of polyolefin and, applied onto the inner side of the layer of paper or paperboard, an oxygen gas barrier layer formed by liquid film coating of a liquid gas barrier composition and subsequent drying, the liquid composition containing a polymer binder dispersed or dissolved in a liquid medium. The laminate further comprises a layer of a polyolefin-based matrix polymer with inorganic filler particles distributed therein and inorganic particles dispersed also in the gas barrier layer from the liquid gas barrier composition. Also disclosed is a method for manufacturing the packaging laminate and a packaging container made from the packaging laminate.

Owner:TETRA LAVAL HLDG & FINANCE SA

Polymeric film or coating comprising hemicellulose

ActiveUS20100129642A1Improve resistance performanceImprove the immunityPigmenting treatmentWater-repelling agents additionCross-linkOligomer

A film forming composition and a polymeric film or coating comprising hemicellulose and at least one component selected from the group consisting of plasticizers, cellulose, and an oligomer or polymer, is disclosed, said polymeric film or coating further comprising at least one additive / reactant increasing the liquid / moisture resistance and mixed with and / or reacting with the hemicellulose and said at least one component before or in conjunction with the forming of the film or coating. The use of said film or coating is also disclosed. Further, a method for the manufacture of said polymeric film or coating is disclosed, as well as a method for improving the liquid / moisture resistance of hemicellulose. Said at least one additive / reactant increasing the liquid / moisture resistance is either a cross-linking agent or a hydrophobizing agent. In another preferred embodiment the additive is a 2:1 layered phyllosilicate. The additive forms a nanocomposite with the hemicellulose as a matrix. The hemicellulose / phyllosilicate nanocomposite reinforced material provides excellent liquid / moisture resistance. Heat treatment of all of the films increases their liquid / moisture resistance and reduces their oxygen permeability.

Owner:SEELUTION AB

Coated polymeric film with oxygen barrier properties

ActiveUS20070031654A1Excellent oxygen barrier propertiesFilm/foil adhesivesSynthetic resin layered productsPolyesterPolymer thin films

A coating compositions for providing substrates with oxygen barrier properties is disclosed. The substrate may be, for instance, a film, such as a polyester film. The coating composition includes a copolymer of maleic acid and acrylic acid and a copolymer of vinyl alcohol and a vinylamine. The barrier coating formed from the coating composition is typically less than about 1 micron in thickness and provides reduced oxygen transmission even at relatively high relative humidities.

Owner:MITSUBISHI POLYESTER FILM

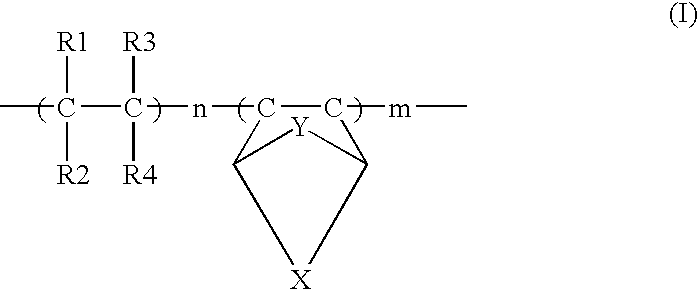

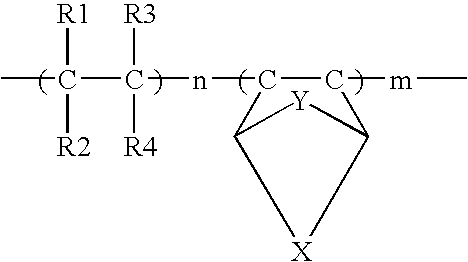

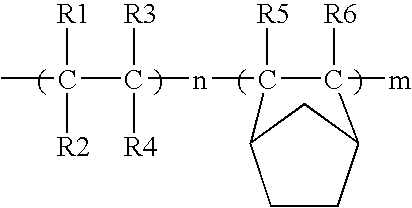

Electrophoretic support

InactiveUS20070051630A1Improve rigidityExcellent oxygen barrier propertiesCellsSludge treatmentFluorescenceElectrophoresis

The present invention relates to electrophoresis and in particular low fluorescent electrophoretic supports for hydrogels used for separation of fluorescence labelled biomolecules. More particularly, the invention relates to use of a polymer having the following formula: wherein n=0-100 000 R1, R2, R3 and R4=H, F, Cl, Br, I, methyl groups or non-aromatic hydrocarbon chains (optionally containing branches or cyclic structures) such as ethyl, ethenyl, propyl, isopropyl, propenyl, butyl, branched butyl, butenyl, cyclobutyl, pentyl, branched pentyl, pentenyl, cyclopentyl, hexyl, branched hexyl, cyclohexyl; X, Y=methylene groups or non-aromatic hydrocarbon chains (optionally containing branches or cyclic structures) such as ethylene, ethenylene, propylene, isopropylene, propenylene, butylene, branched butylene, butenylene; Y can optionally be absent as a low fluorescent support film of an electrophoretic hydrogel for slab gel electrophoresis. The invention also relates to composites of such films and hydrogels as well as kits for 2D electrophoresis.

Owner:GE HEALTHCARE BIO SCI CORP

Laminated packaging material, a method of producing the same, as well as packaging containers

InactiveUS6495223B1Excellent gas barrier performanceExcellent oxygen barrier propertiesFlexible coversWrappersCross-linkPolyvinyl alcohol

A laminated packaging material for liquid-tight, dimensionally stable packages has superior gas-barrier properties, particularly oxygen barrier properties. The laminated packaging material includes a core layer and a barrier layer juxtaposed to the core layer. The barrier layer is formed from a polyvinyl alcohol, a polysaccharide and a cross-linking agent, the polysaccharide being chitosan and the cross-linking agent being a dialdehyde compound. A method for making the laminated packaging material is also disclosed.

Owner:TETRA LAVAL HLDG & FINANCE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com