Highly obstructed multilayer coextrusion thermal shrink film

A heat-shrinkable film, multi-layer co-extrusion technology, applied in the direction of layered products, synthetic resin layered products, flexible coverings, etc. Good oxygen barrier properties, high tensile strength, improved optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

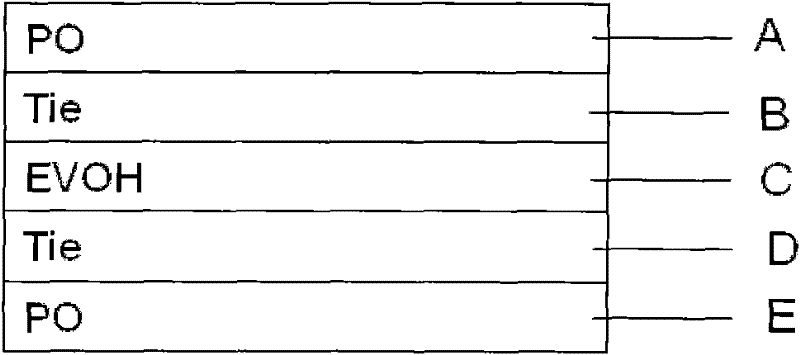

[0031] as attached figure 1 The structure shown is a five-layer co-extruded heat-shrinkable film consisting of two layers of polyolefin resin (A and E), one layer of ethylene-vinyl alcohol copolymer barrier layer (C) and two layers of bonding material (B and D) form. The thickness ratio of each layer is A: B: C: D: E = 30%: 15%: 10%: 15%: 30%. The film with this structure has good heat sealing performance, and has better oxygen barrier and moisture barrier capabilities. .

[0032] The first layer A uses an extruder to make the main raw material resin ethylene-α-olefin copolymer or a mixture of multiple ethylene-α-olefin copolymers (the weight content ranges from 0% to 60%), wherein the weight content of α-olefin is 1 %~20%; Ethylene and EMAA [is an ionomer of ethylene-(meth)acrylic acid zinc salt, sodium salt, lithium salt, etc.], EVA (ethylene and acetic acid copolymer), EBA (butyl acrylate and ethylene copolymer) The copolymer, in which the weight content of the carboxyli...

Embodiment 2

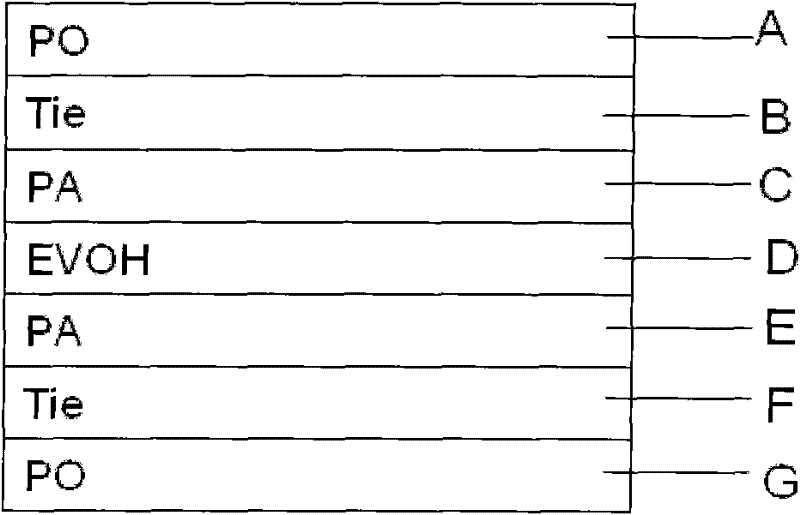

[0038] as attached figure 2 The structure shown is a five-layer co-extruded heat-shrinkable film consisting of two layers of polyolefin resin (A and G), two layers of PA barrier layers (C and E), one layer of ethylene-vinyl alcohol copolymer The barrier layer (D) is formed with two layers of bonding material (B and F). The thickness ratio of each layer is A:B:C:D:E:F:G=27%:15%:8%:8%:8%:15%:17%. It has good oxygen and water vapor barrier properties, high shrinkage rate, and can be used for fresh-keeping shrink packaging of chilled meat and cheese.

[0039] The uppermost layer A uses an extruder to make the main raw material resin ethylene-α-olefin copolymer or a mixture of multiple ethylene-α-olefin copolymers (the weight content ranges from 0% to 60%), wherein the weight content of α-olefin is 1%. ~20%; the copolymer of ethylene and EMAA, EVA, EBA, wherein the weight content of the carboxylic acid monomer is 5% ~ 25%, after uniform stirring in the mixing hopper at the front...

Embodiment 3

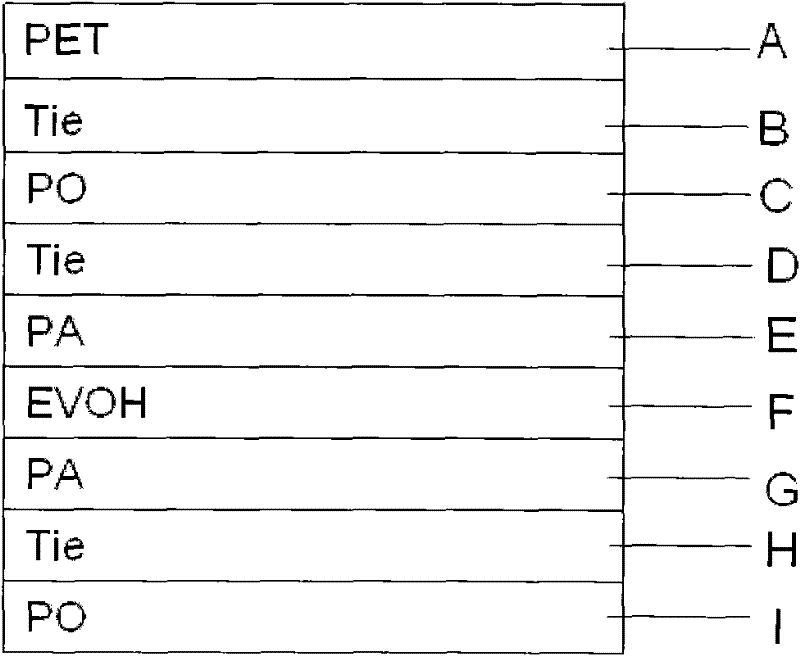

[0046] as attached image 3 The structure shown is a five-layer co-extruded heat-shrinkable film. The multi-layer co-extruded shrinkable film consists of two layers of polyolefin resin (C and I) in the outer layer of polyethylene phthalate (PET (A)), two layers of PA barrier layer (E and G), a barrier layer of ethylene-vinyl alcohol copolymer (F) and three layers of bonding material (B, D and H). It has good oxygen and water vapor barrier properties, high shrinkage rate, and good surface printing effect. It can be used for fresh-keeping shrink packaging of chilled meat and cheese.

[0047] The uppermost layer A, the main raw material resin PET and additives are uniformly stirred in the mixing hopper at the front end of the extruder by an extruder, and the resin is plasticized at 160-280°C, and extruded into the uppermost layer A of the mold in the runner;

[0048] For the second layer B, use an extruder to plasticize the adhesive material resin at 160-280°C, and extrude it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com