Patents

Literature

217 results about "Detackifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A detackifier is a process chemical that is used for reducing tackiness of other substances. Spraying paint and paper making are processes where inputs may need to be detackified or "denatured".

Methods for improving proppant pack permeability and fracture conductivity in a subterranean well

ActiveUS20050059558A1Improve fluid flowIncrease productivityFluid removalFlushingParticulatesFracturing fluid

The present invention provides compositions and methods for enhancing subterranean well productivity by enhancing fracture conductivity. A method of increasing the conductivity of a fracture in a portion of a subterranean formation comprising providing a slurry comprising a fracturing fluid, a degradable material, and proppant particulates coated with a tackifying agent; allowing the degradable material to become at least temporarily attached to the tackifying agent coated onto the proppant particulates so as to avoid substantial segregation of the degradable material from the proppant particulates within the slurry; introducing the slurry to the fracture and allowing the proppant particulates and degradable material to form a substantially uniform particulate pack; and, allowing the degradable material to degrade and produce a particulate pack having voids therein.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods for improving proppant pack permeability and fracture conductivity in a subterranean well

ActiveUS7178596B2Improve fluid flowIncrease productivityFluid removalFlushingParticulatesFracturing fluid

The present invention provides compositions and methods for enhancing subterranean well productivity by enhancing fracture conductivity. A method of increasing the conductivity of a fracture in a portion of a subterranean formation comprising providing a slurry comprising a fracturing fluid, a degradable material, and proppant particulates coated with a tackifying agent; allowing the degradable material to become at least temporarily attached to the tackifying agent coated onto the proppant particulates so as to avoid substantial segregation of the degradable material from the proppant particulates within the slurry; introducing the slurry to the fracture and allowing the proppant particulates and degradable material to form a substantially uniform particulate pack; and, allowing the degradable material to degrade and produce a particulate pack having voids therein.

Owner:HALLIBURTON ENERGY SERVICES INC

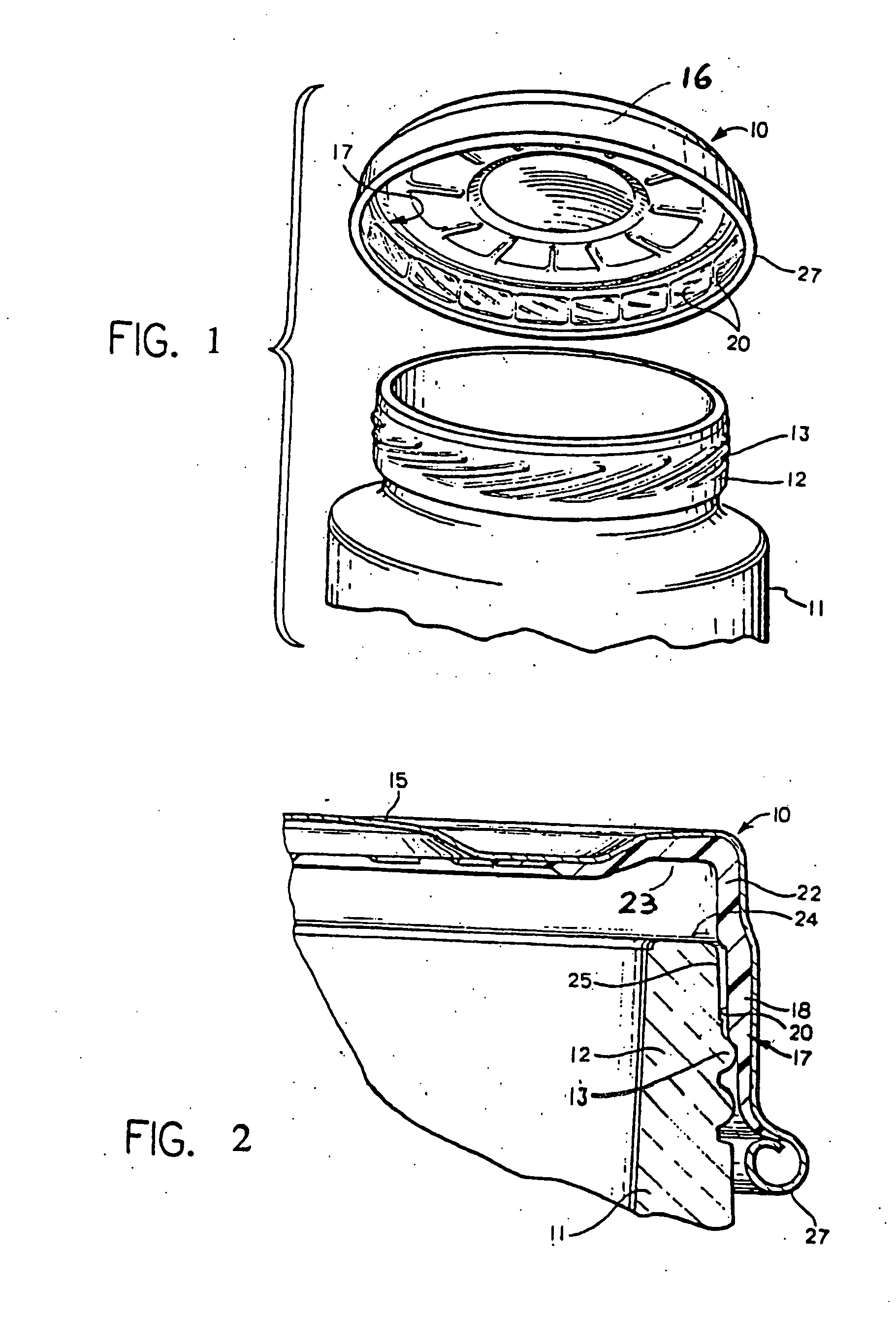

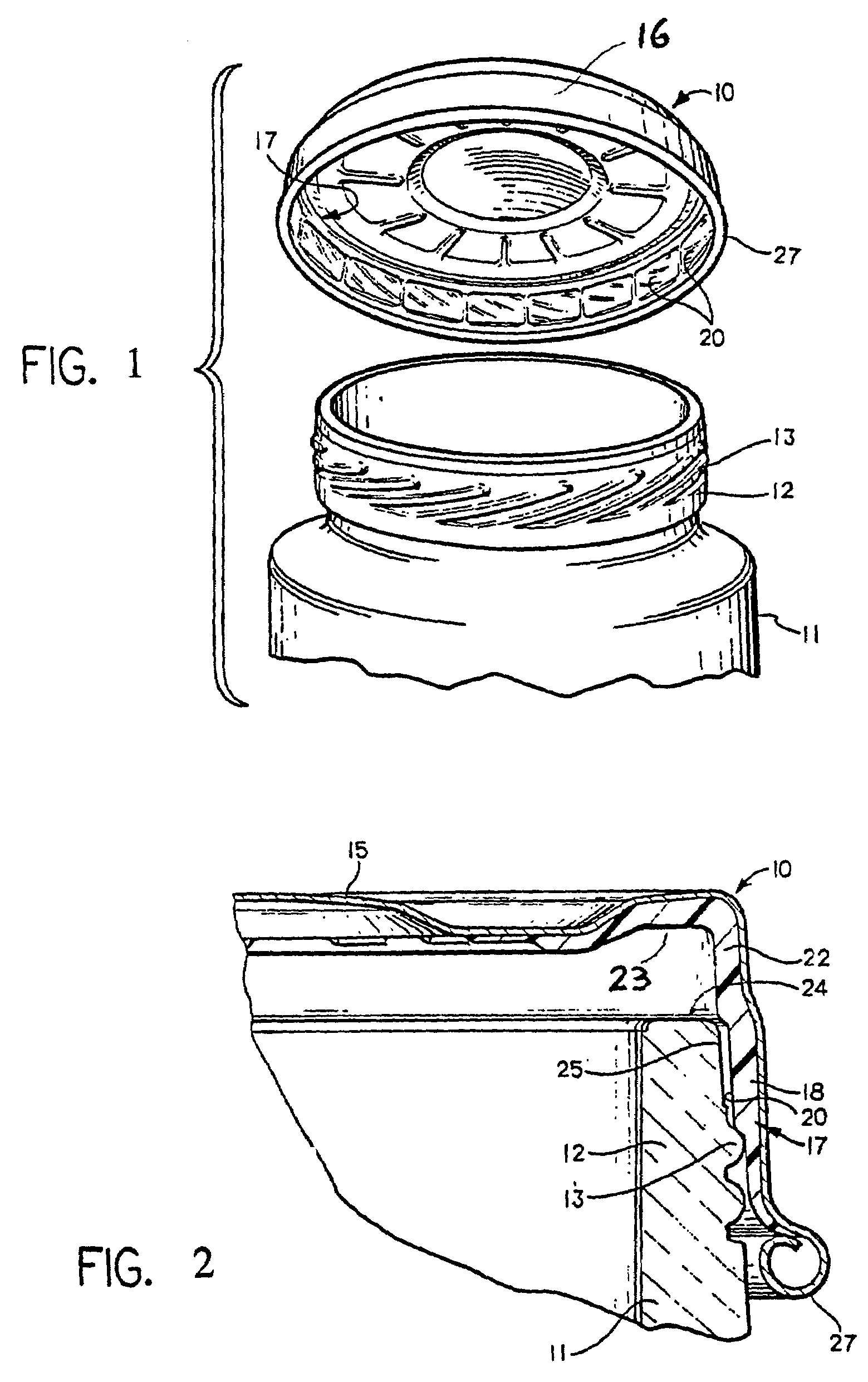

Elastomeric podalic pads

InactiveUS6187837B1Readily conformsSoft and deformableCosmetic preparationsImpression capsCushioningMicrosphere

Podalic foot pads of various shapes and configurations which utilize a padding material that is primarily an A-B-A triblock copolymer and a plasticizer. A-B diblock copolymers may be compounded into the padding material. An anti-bleed agent is preferably employed. The plasticizer may be a resin, mineral oil or otherwise. A detackifier may be employed such as grape seed oil or another slip agent. Antioxidants, pigments and micropsheres may be added to the material. The material has good cushioning properties.

Owner:PURPLE INNOVATION LLC

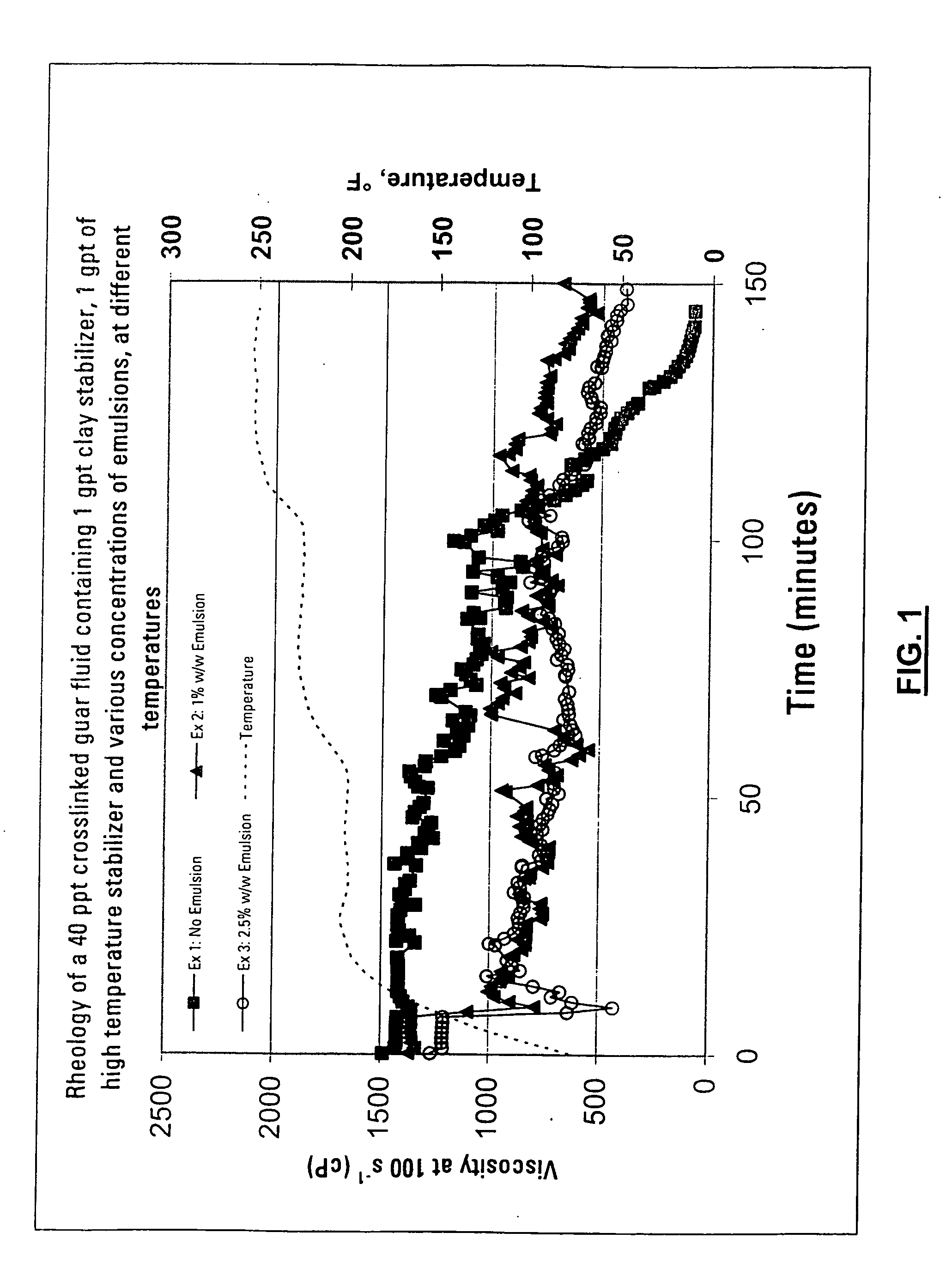

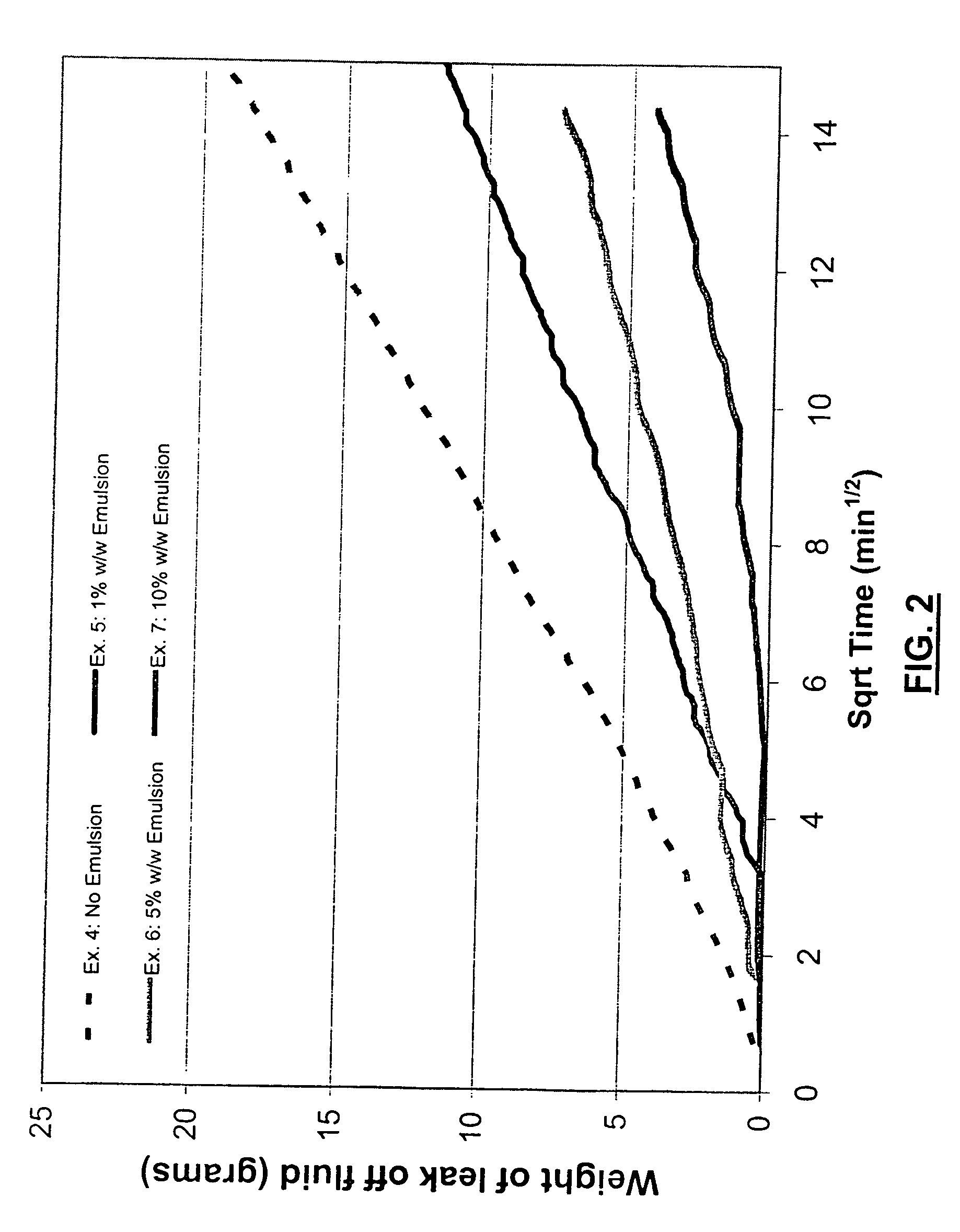

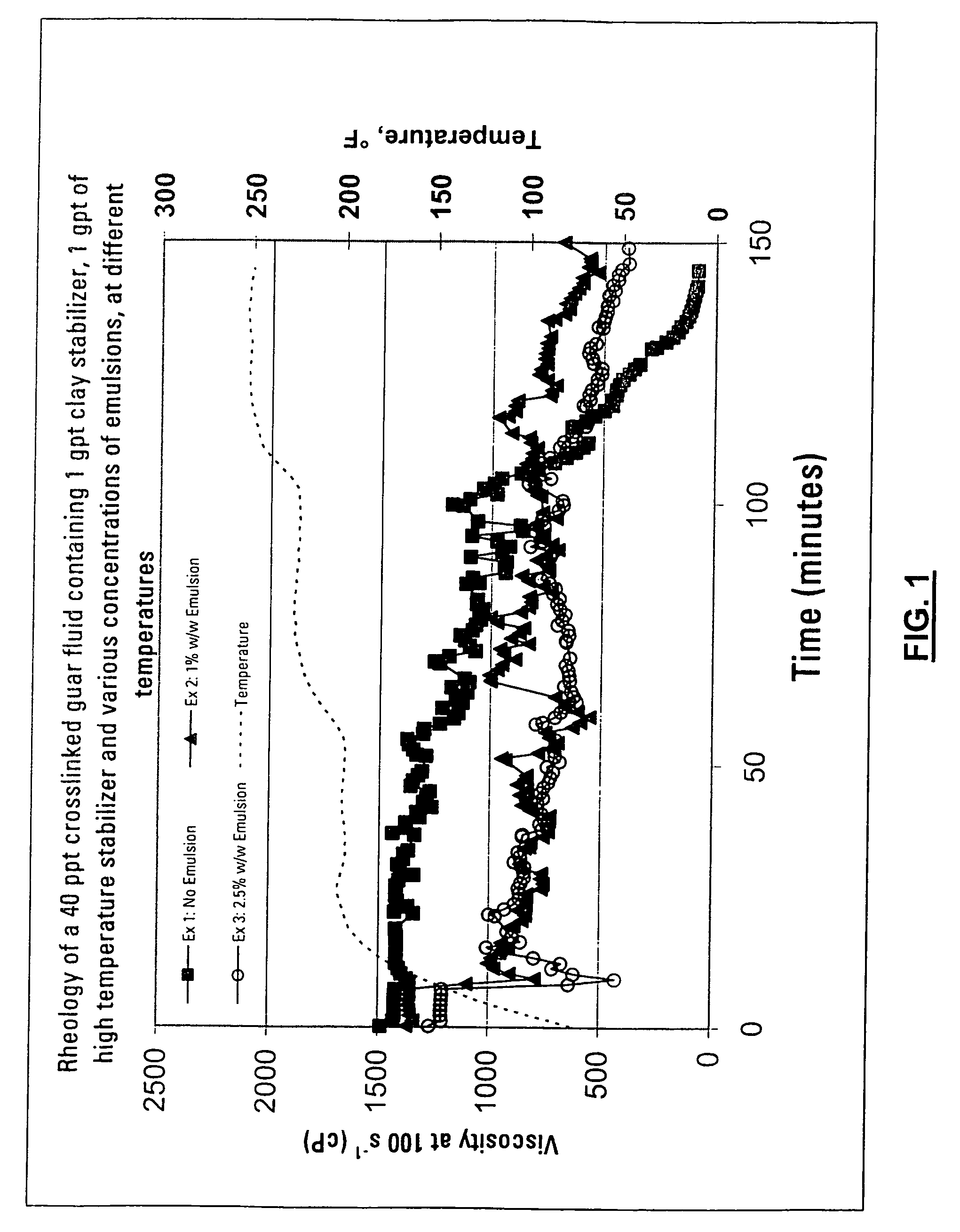

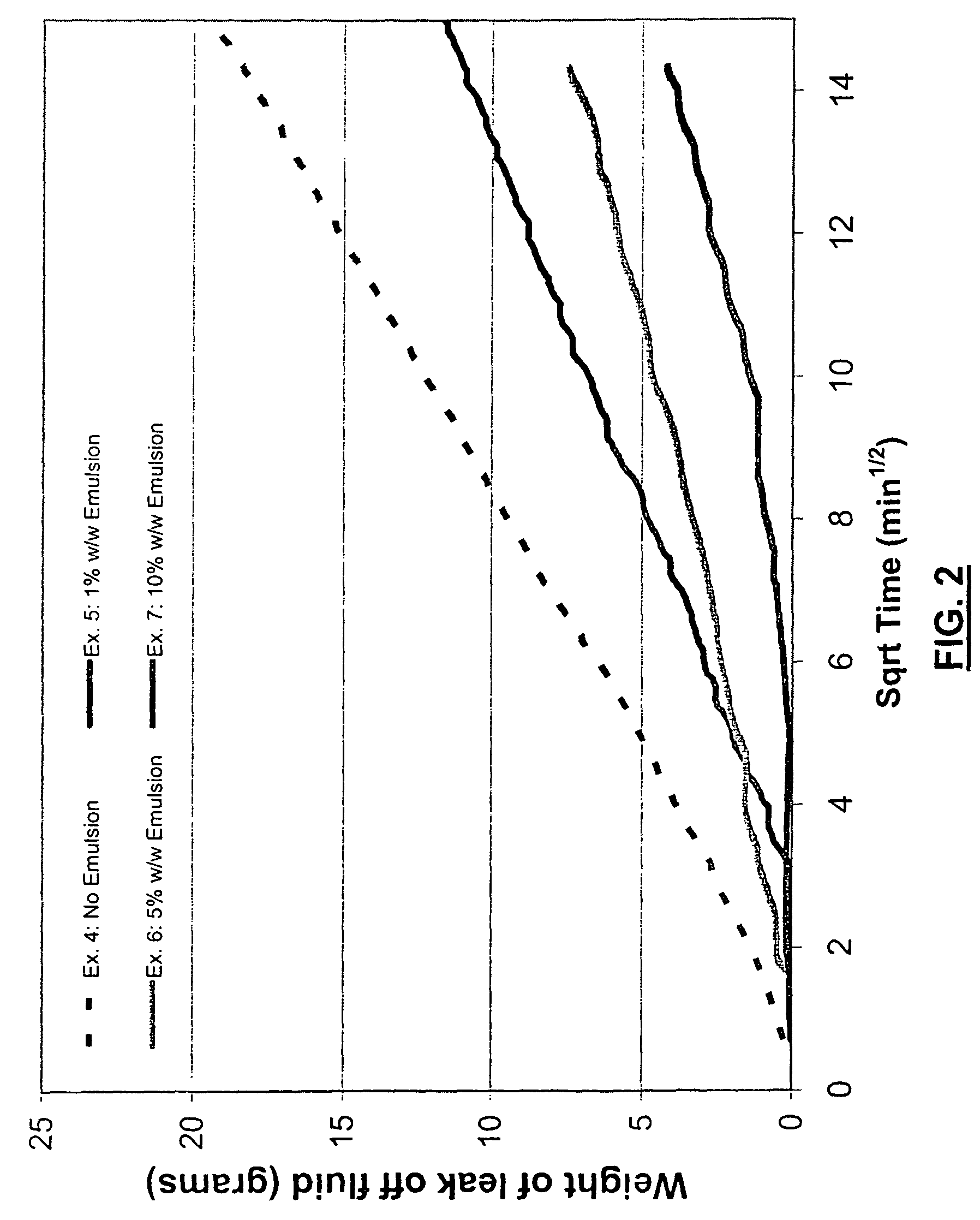

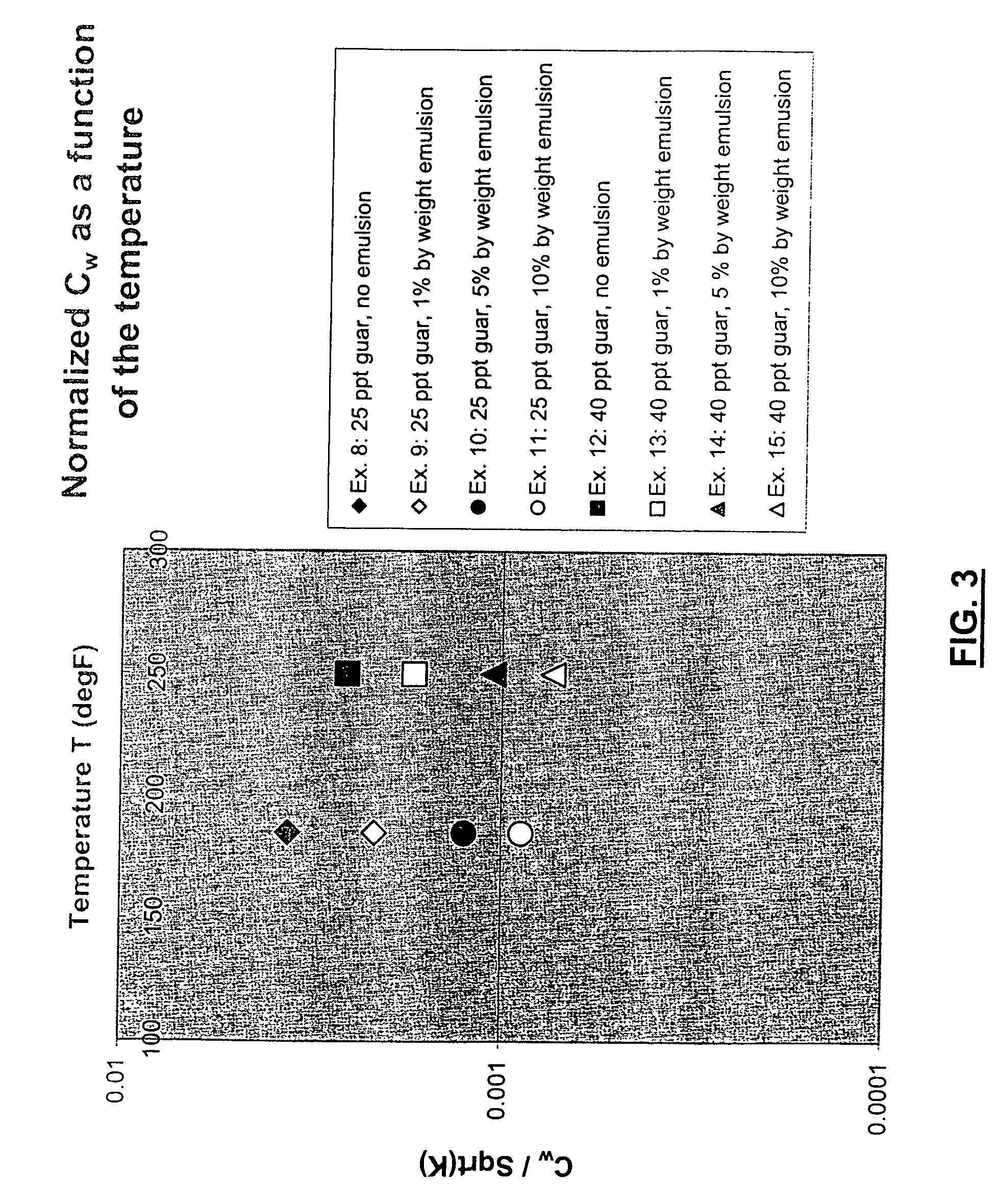

Methods of Limiting Leak Off and Damage In Hydraulic Fractures

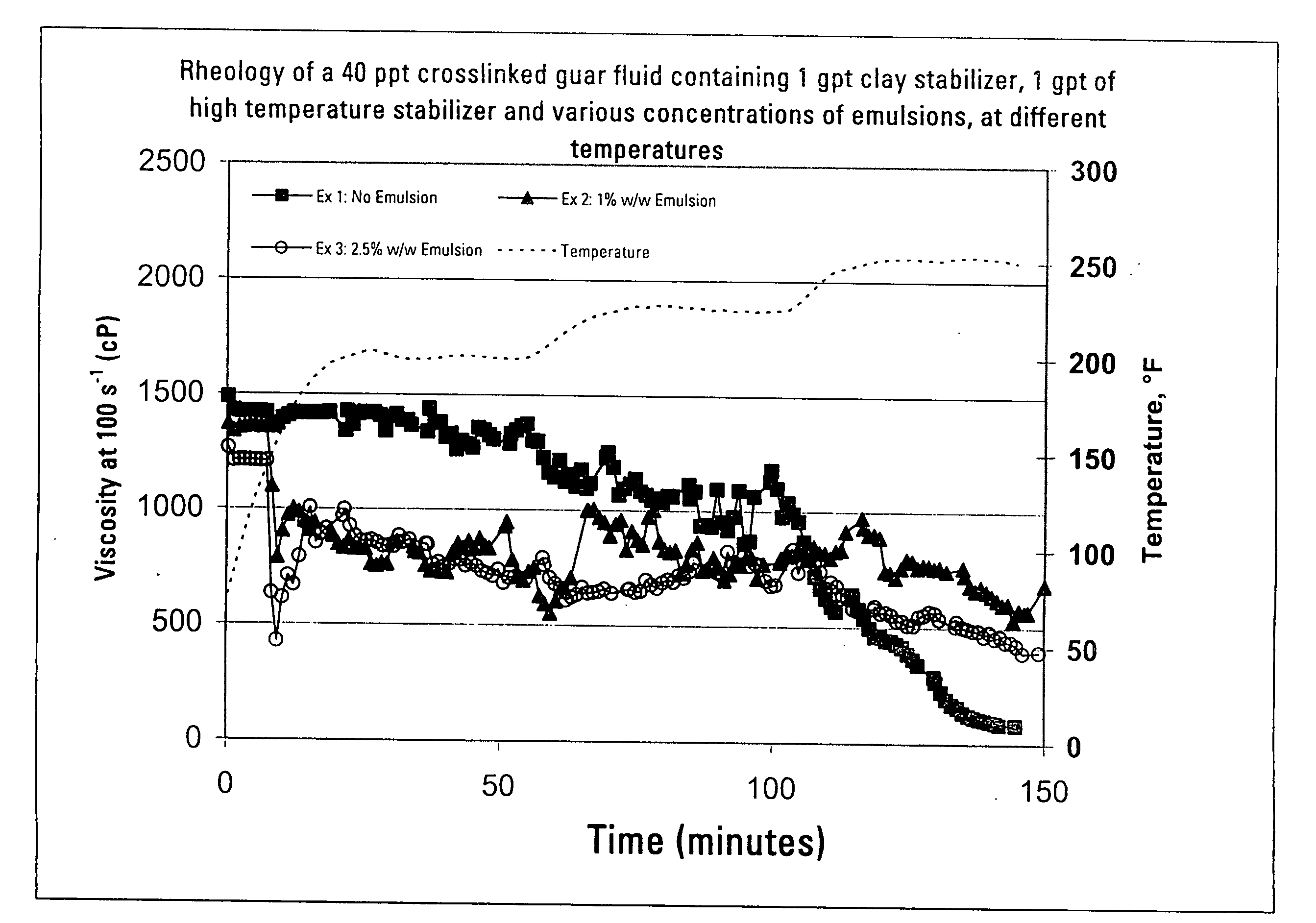

InactiveUS20080289828A1Improve cleanupEnhanced hydrocarbon productionFluid removalDrilling compositionMatrix damageEmulsion

Methods for treating a formation penetrated by a wellbore which improves fluid loss control during treatment. In some aspects, the treatments include preparing an aqueous fluid including one or more water inert degradable polymers and an optional viscosifier, injecting the aqueous fluid into the wellbore at a pressure equal to or greater than the formation's fracture initiation pressure, and thereafter injecting into the wellbore a proppant laden fluid at a pressure equal to or greater than the formation's fracture initiation pressure. The water inert degradable polymer may be a polymer such as an emulsion polymer or a latex polymer. Some methods of the invention use a fluid which may have a normalized leak off coefficient (Cw / sqrt(K)) equal to or less than about 0.0022, 0.0014, or 0.0010. A conventional fluid loss additive may or may not be used in conjunction with the treatment fluid and / or the proppant laden fluid. The water inert degradable polymer may or may not substantially enter formation pores. In another aspect, methods for reducing matrix damage to a formation during a treatment operation include preparing an aqueous treatment fluid formed of at least one water inert degradable polymer, and injecting the fluid at a pressure equal or greater than the formation's fracture initiation pressure.

Owner:SCHLUMBERGER TECH CORP

Essentially gas-impermeable thermoplastic sealant

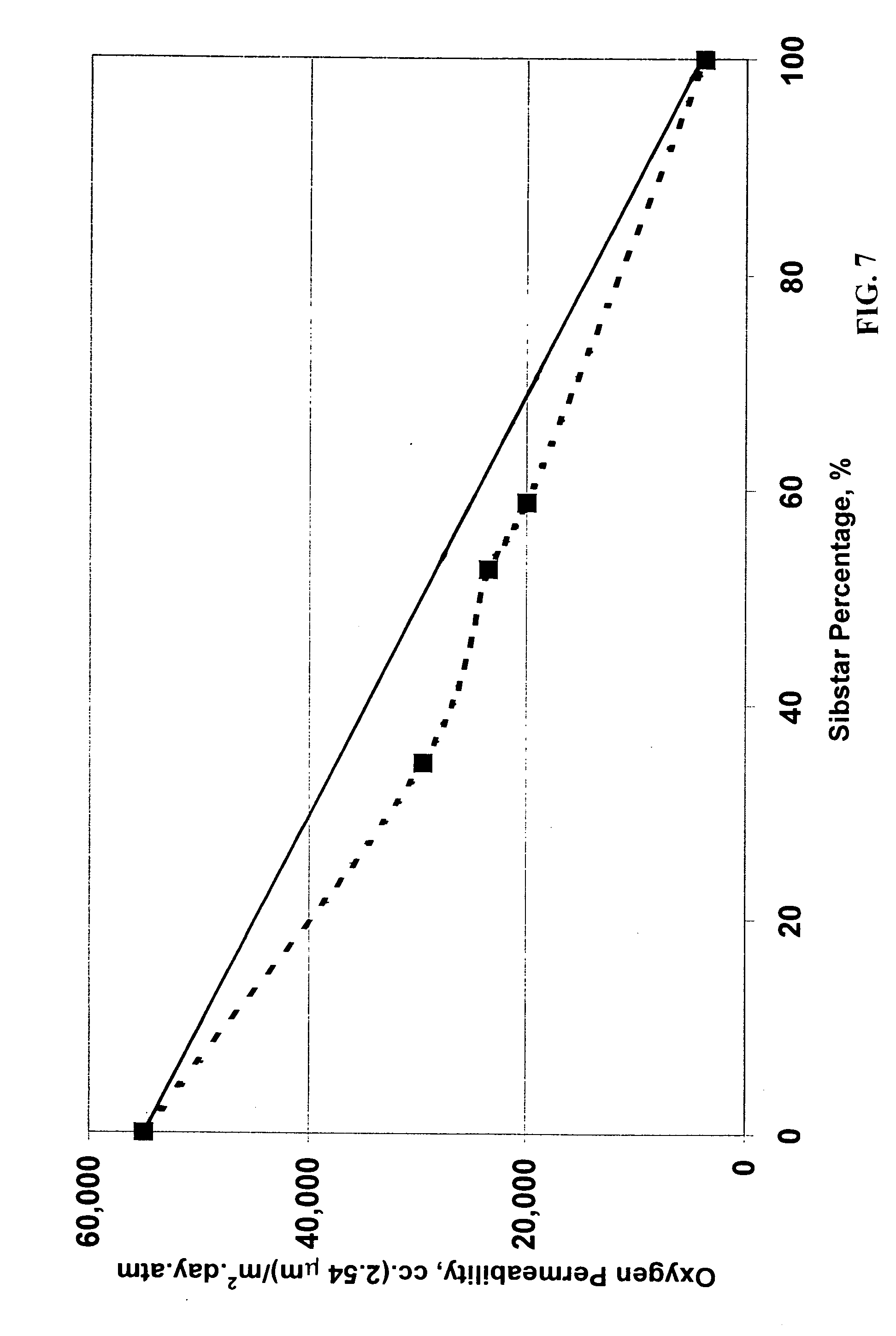

InactiveUS20060229402A1Improve barrier propertiesExtended shelf lifeCapsClosure using stoppersThermoplasticPolymer science

A thermoplastic essentially oxygen-impermeable plasticized sealant is formed by melt-blending a hydrogenated styrene-conjugated diene-styrene (SMS) block copolymer rubber with a polystyrene-polyisobutylene-polystyrene (SIBS) block copolymer rubber and a polyolefin plastic with a liquid polyisobutylene (PIB) oil plasticizer provided the PIB oil is present (i) in the range from 5% to less than 50% by weight of the sealant and (ii) in relation to total rubber, in the range from 0.3 to 0.8. The required minor amount of PIB oil, relative to total rubber, in combination with SIBS present in a minor amount relative to the amount of plasticized sealant, provides the sealant with unexpectedly better oxygen barrier properties and load bearing at 82° C. (180 ° F.) than a comparable blend of SIBS with mineral oil; the sealant is also essentially free of tack, adhesive properties and oil-bleed, with essentially no detackifier present. The PIB-oil plasticized SIBS sealant has a haze of less than 15%; a composite made by melt-bonding a core layer between polyC2-C3olefin sheets, maintains a haze less than 14%. The plasticised sealant is particularly useful for sealing elements for containers in which foods, beverages and medical products must be preserved for a long period.

Owner:GLS

Methods for preparing slurries of coated particulates

Methods of creating a stable slurry of coated particulates wherein the slurry is capable of being stored for at least 2 hours before use comprising the steps of: providing resin coated particulates wherein the resin comprises a resin that does not completely cure unless it is at least one of exposed to a temperature above about 175° F. or exposed to an external catalyst; and, substantially suspending the resin coated particulates in a servicing fluid to create a stable resin coated particulate slurry. Methods of creating a stable slurry of coated particulates wherein the slurry is capable of being stored for at least 2 hours before use comprising the steps of: providing tackifier coated particulates; and, substantially suspending the tackifier coated particulates in a servicing fluid to create a tackifier coated particulate slurry.

Owner:HALLIBURTON ENERGY SERVICES INC

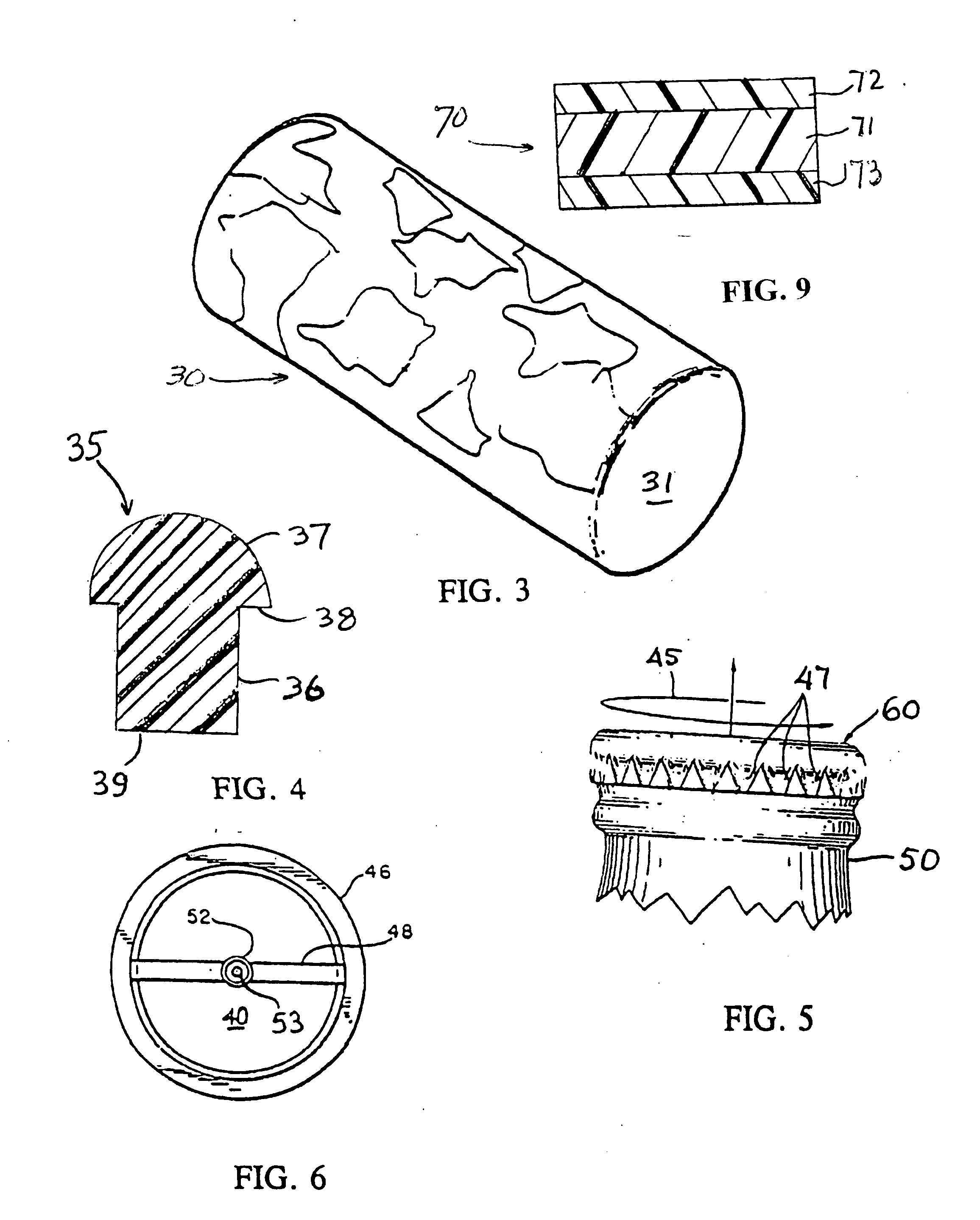

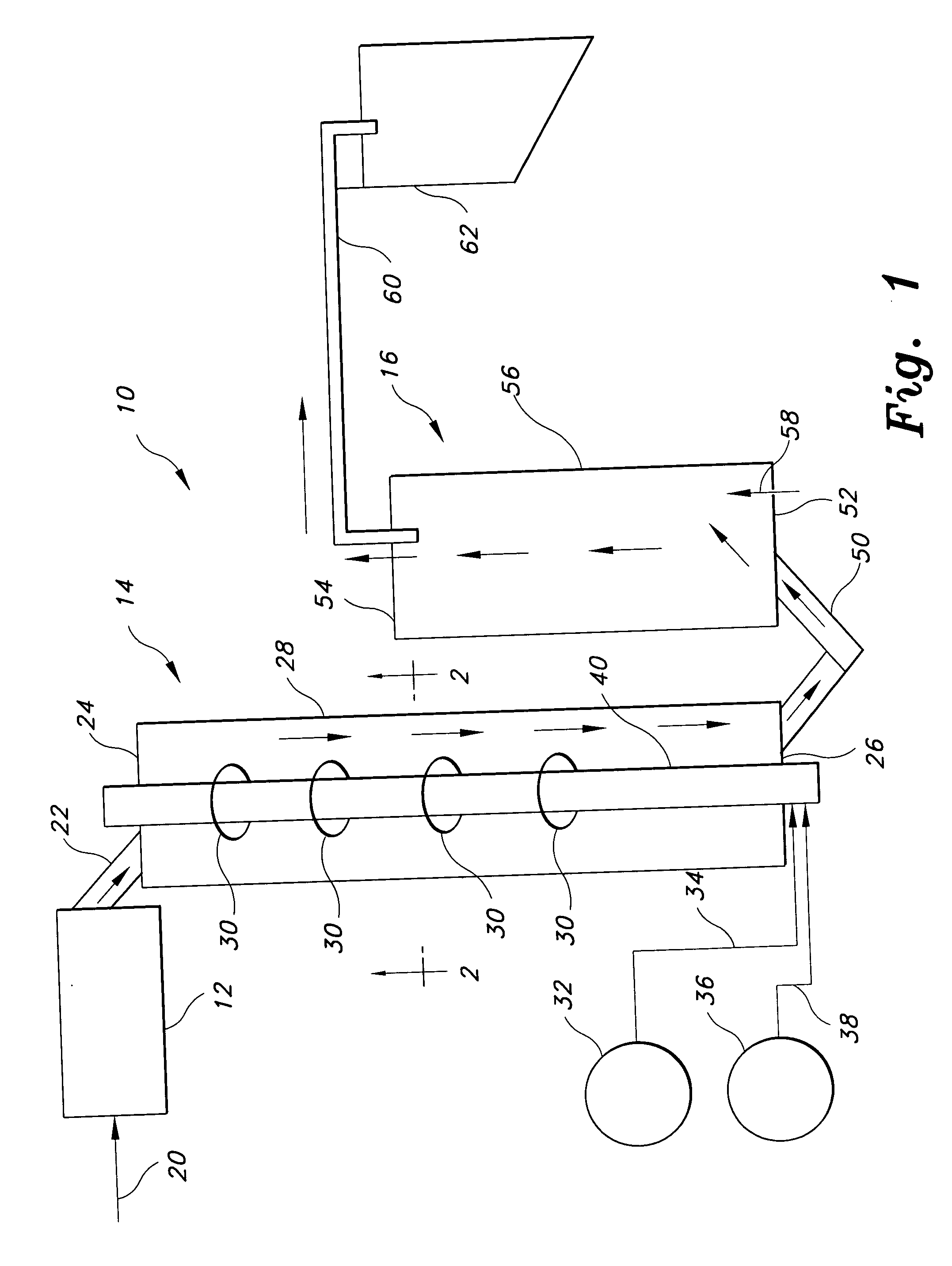

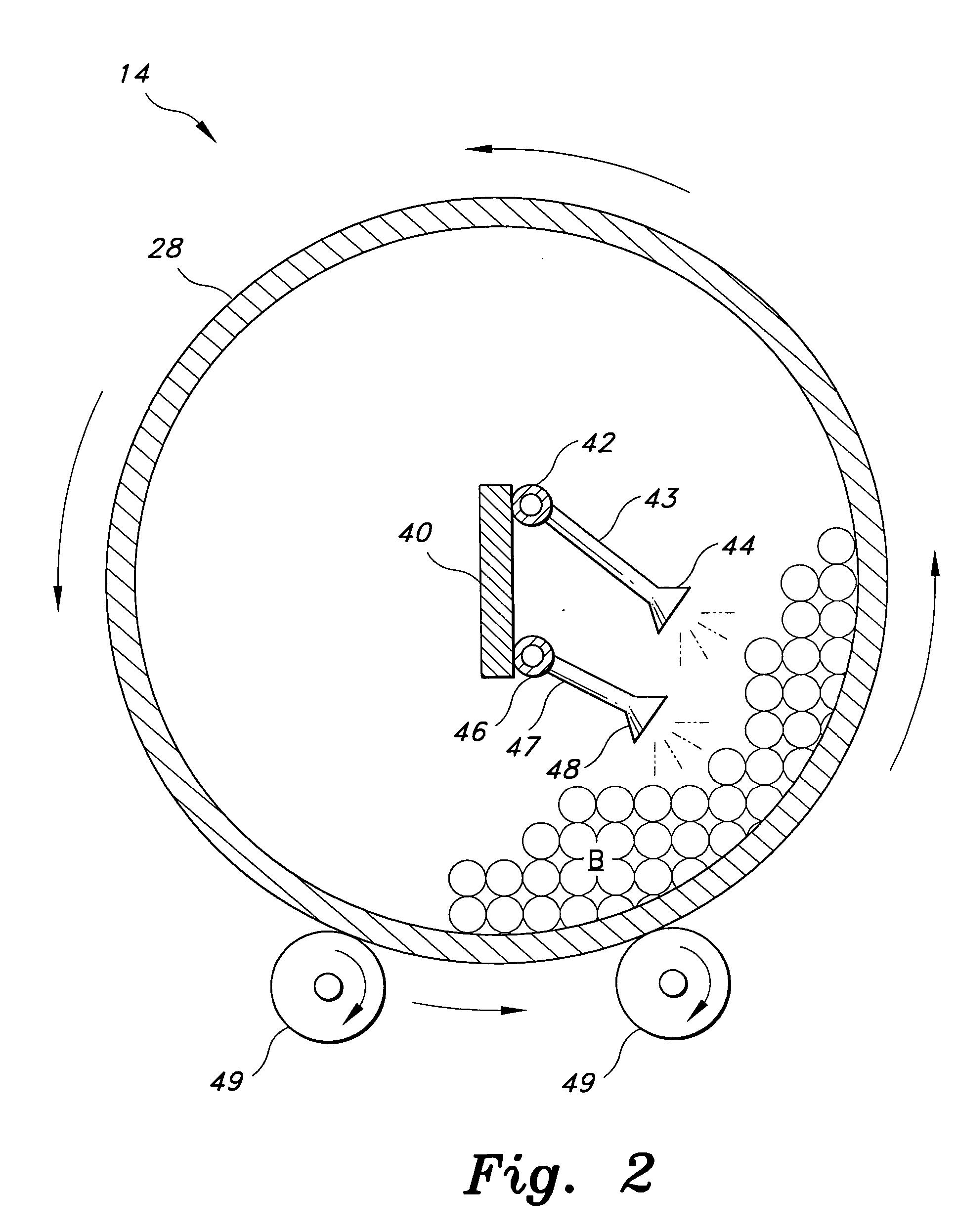

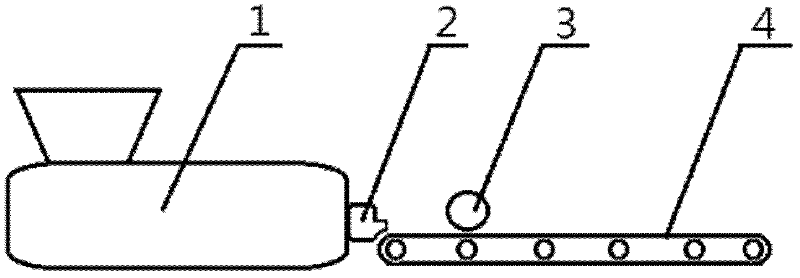

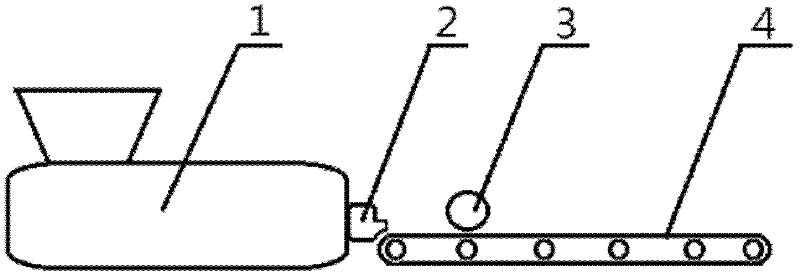

Coating for fertilizer

InactiveUS20050076687A1Maintain reaction temperatureImparts physical strengthBiocideGas treatmentVegetable oilPolymer chemistry

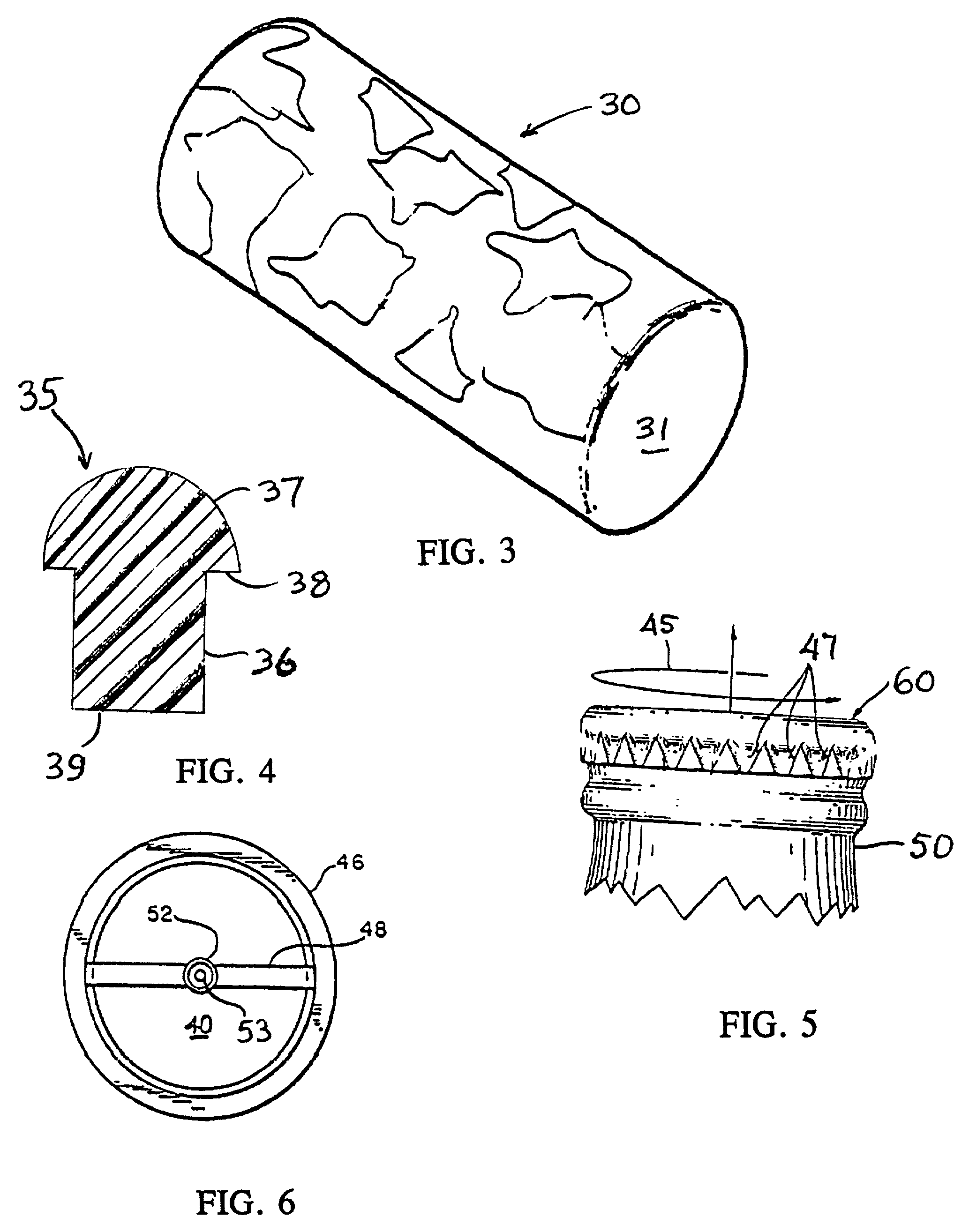

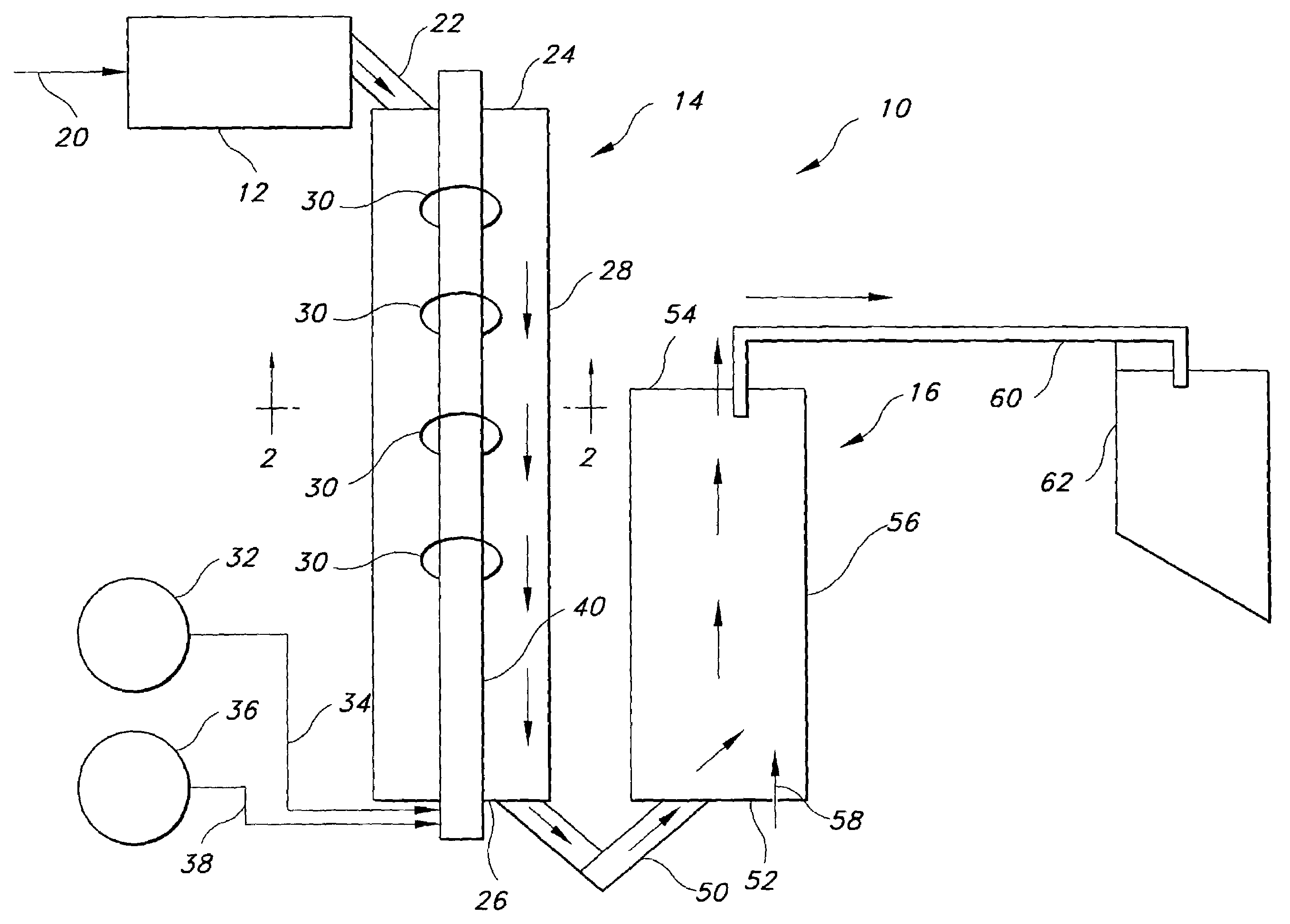

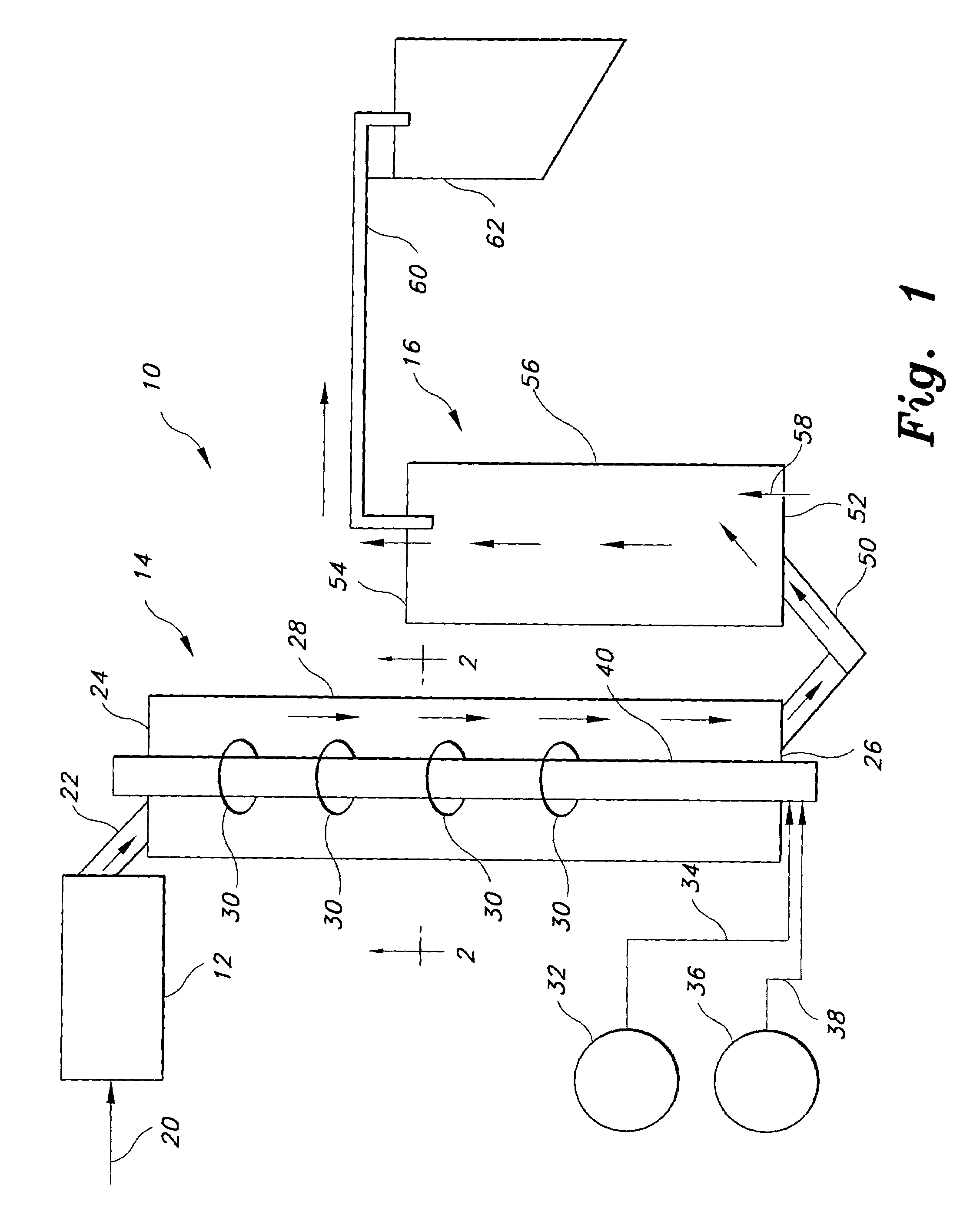

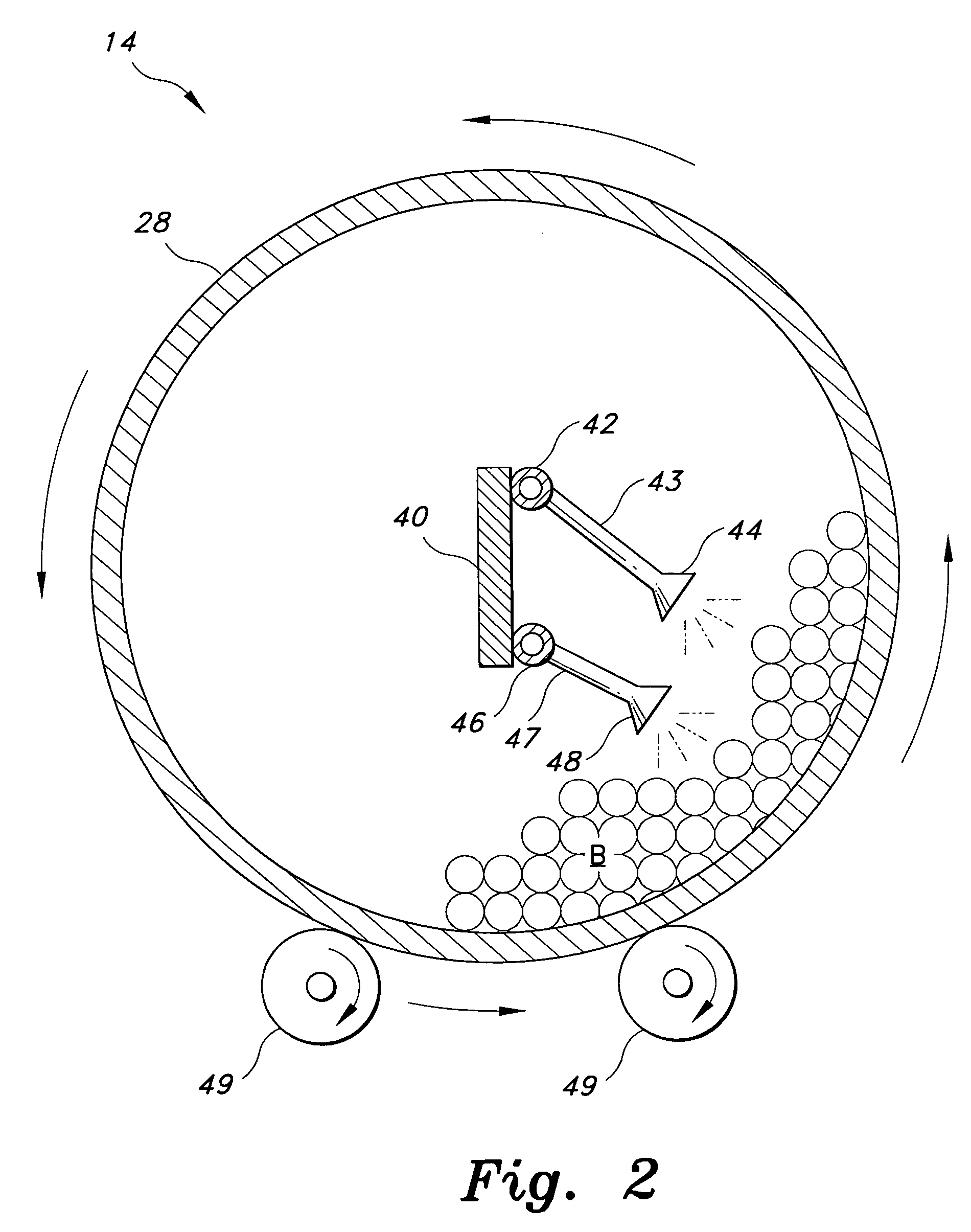

Method and apparatus for coating fertilizer in pellet or other form to impart time-release characteristics and the resulting coated pellet product. The polyurethane coating encapsulates fertilizer particles, forming a hydrophobic coating for slow-release qualities. The urethane polymer coating is formulated with an isocyanate and a combined fluid of a polyether polyol, a methyl ester derivative of plant or vegetable oil, a T-12 curing catalyst, barium sulfate, and an oil-based dye. The barium sulfate imparts physical strength to and enhances color quality of the polyurethane coating, and acts as a detackifier and maintains temperature in the coating reactor. The inventive formulation is effective in the practical polymer coating of sulfate-based or other fertilizer pellets in an inventive time-release fertilizer product. An apparatus is provided for carrying out the coating process.

Owner:WHITTINGTON PATSIE A

Essentially gas-impermeable thermoplastic elastomer

A thermoplastic elastomer (“TPE”) which is oxygen-permeable is provided with excellent barrier properties against oxygen by melt-blending with a liquid polyisobutene oil plasticizer in an amount insufficient to render the plasticized elastomer tacky. If made tacky, enough detackifier is used to allow the product to be formed into a removable seal. The TPE may be a conventional thermoplastic vulcanizate or a block copolymer of a vinylaromatic compound, typically styrene, and a conjugated diene, typically butadiene or isoprene, or mixtures thereof; the block may be a diblock, triblock or higher block, but the preferred polyblock copolymer is a triblock with styrene end-blocks and a butadiene / isoprene mid-block. Preferably the diene mid-block is hydrogenated to provide a poly(lower)monoolefin mid-block. When the TPE is a TPV, some or all of the mineral oil used to make the TPV processable may also be substituted with the polyisobutene plasticizer. The elastomeric product is particularly useful for sealing elements for containers in which foods, beverages and medical products must be preserved for a long period.

Owner:AVIENT CORP

Aging-resistant EVA film adhesive for solar cell package and method for preparing same

InactiveCN1699458AImprove performanceImprove heat resistanceElectrical equipmentGlass/slag layered productsCross-linkAdhesive

The invention relates to an aging-resistant EVA film adhesive for solar cell package and method for preparation, wherein the preparation constituents include ethane-vinyl acetate copolymer (EVA), cross-linking and curing agent, ultraviolet light absorbent, anti-oxidant, and hindered amine light-stability agent. The preparation comprises the steps of mixing homogeneously, blending extrusion, flow casting the extrudate, cooling down, drawing, and winding.

Owner:SOUTH CHINA UNIV OF TECH

Pearlescent film coating systems and substrates coated therewith

ActiveUS6902609B2High degreeExcellent oxygen barrier propertiesConfectioneryPretreated surfacesPowder mixtureMedicine

The present invention is directed to film coating systems for use on oral dosage forms such as compressed tablets and orally-ingestible substrates which have improved pearlescent qualities. The film coating systems can be applied either directly to a substrate or after the substrate has been coated with a subcoat. In preferred aspects, the pearlescent film coating is prepared as a dry powder mixture containing a cellulosic polymer, a detackifier, a gloss enhancer, and a pearlescent pigment. Film coating compositions containing an aqueous suspension of the powder mixtures, methods of applying the coatings to substrates and the coated substrates are also disclosed.

Owner:BPSI HLDG LLC

Fog-resistant packaging film

InactiveUS6706389B1Alter property of filmFilm/foil adhesivesSynthetic resin layered productsAcetic acidPolymer science

A packaging film includes a heat sealable layer coated with one or more antifogging agents disposed in a binder, an antiblocking agent, and no more than about 800 ppm slip agent. The heat sealable layer includes a polymer that includes mer units derived from ethylene while the binder includes a polymer that includes mer units derived from an ester of (meth)acrylic acid and / or vinyl acetate monomers. The antiblocking agent can be in any layer of the film where it provides the desired effect. Such a film, as well as packages made therefrom, can be used to package a variety of products, having particular utility with respect to moist products.

Owner:CRYOVAC ILLC

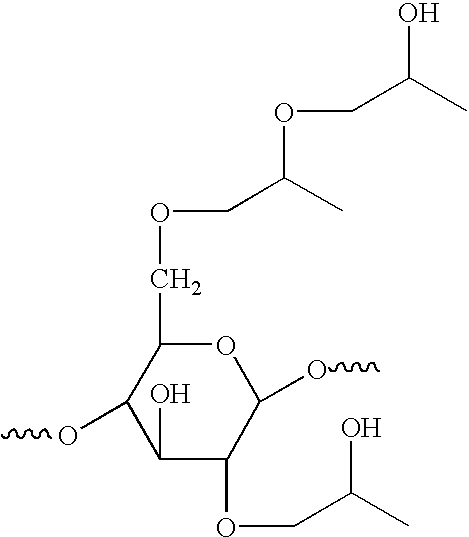

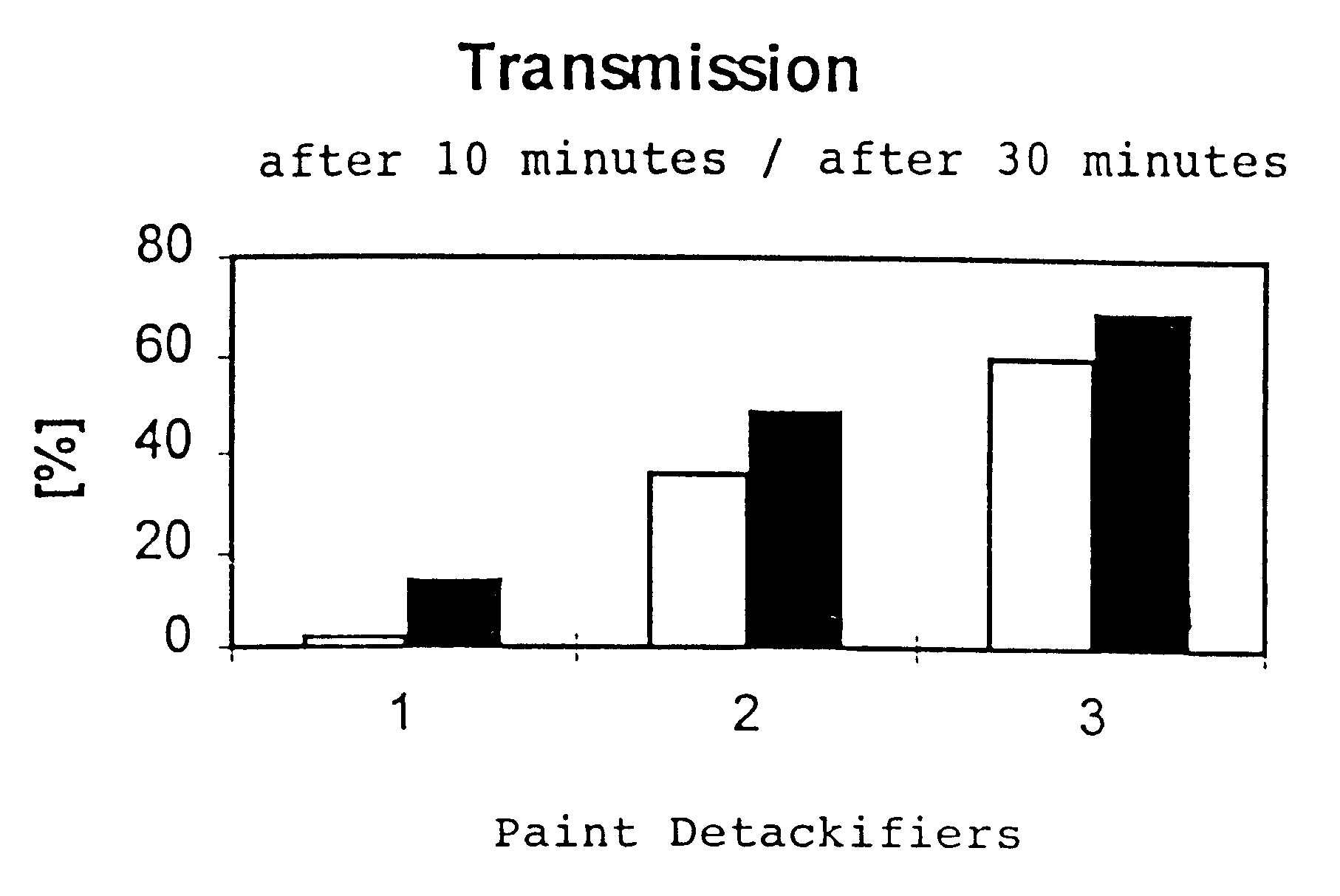

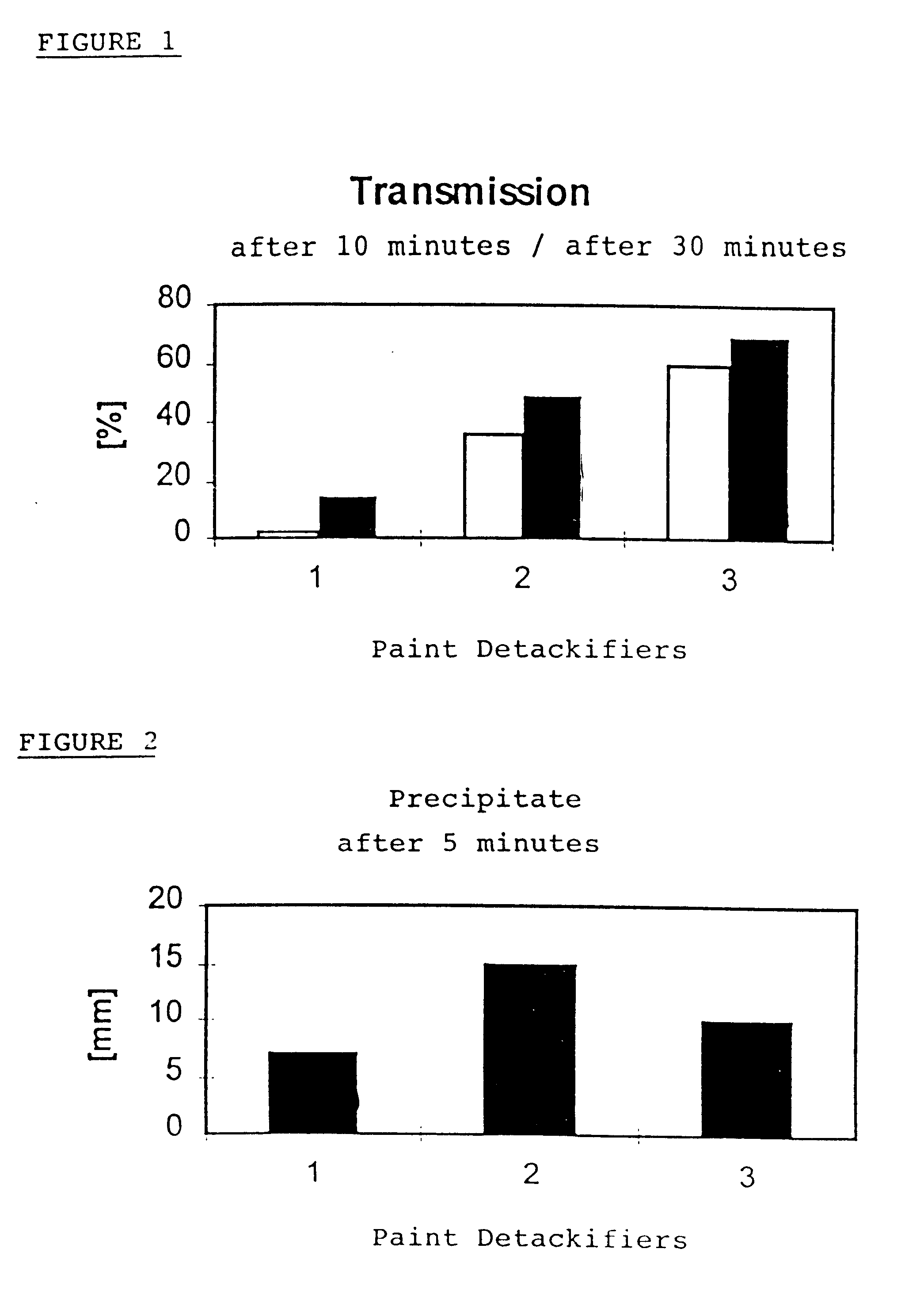

Agents for unsticking paint, and sedimentation agents

Paint detackifiers and / or sedimentation agents are provided which contain amorphous alumina and / or alumina in pseudoboehmite or boehmite form having an average crystallite size of from 0.1 to 15 nm and / or the hydrates and hydroxyalkylpolysaccharides thereof.

Owner:SASOL GERMANY GMBH

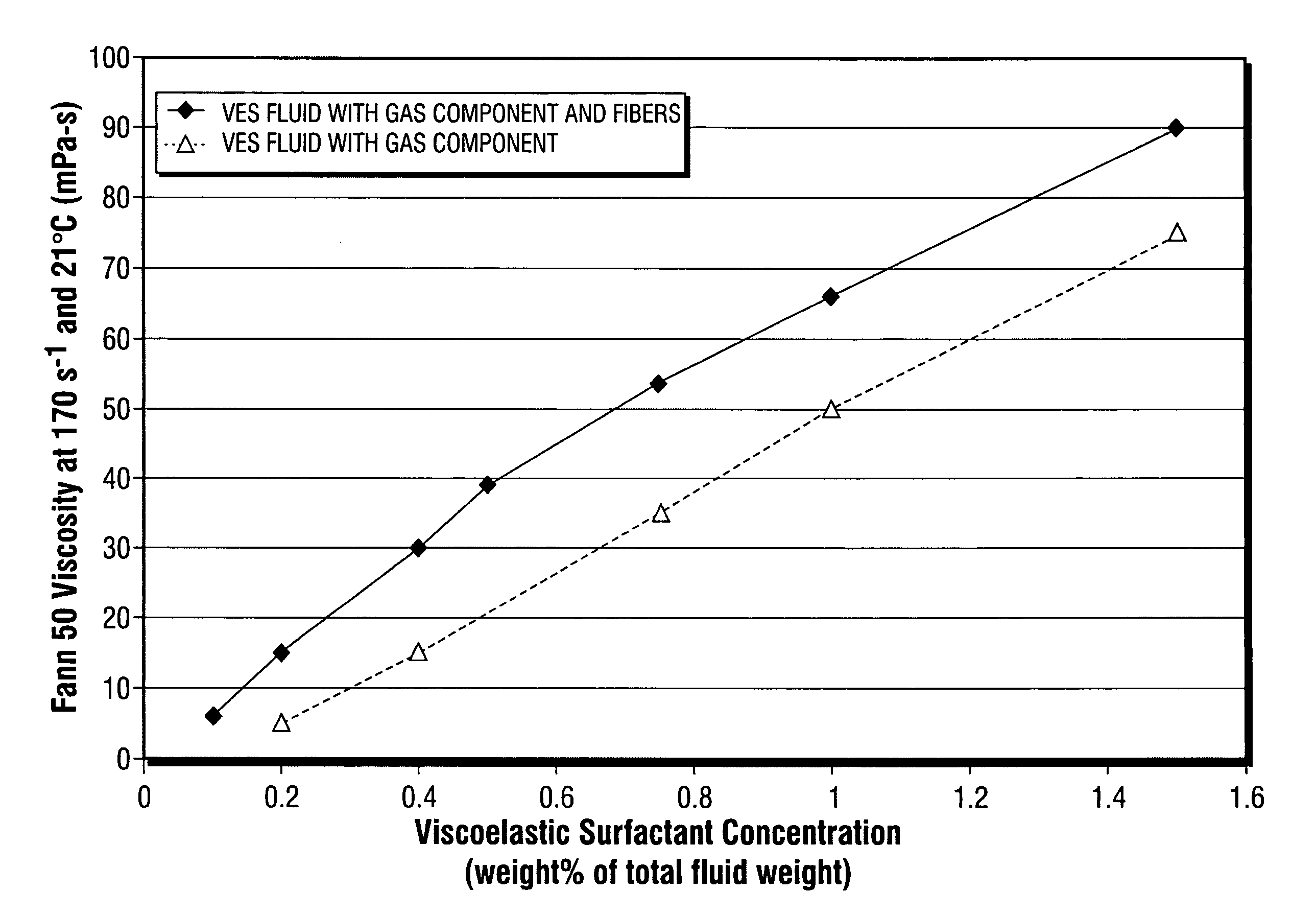

Fiber laden energized fluids and methods of use

ActiveUS7665522B2Good proppant suspension and transport propertyExcellent gas phase stabilityFluid removalFlushingFiberGas phase

The present invention relates to aqueous oilfield treatment fluids containing a gas component and fibers, wherein the fluids may further include a viscosifying agent and / or proppant. The fluids have good proppant suspension and transport properties as well as excellent gas phase stability. Use of fluids comprising an aqueous medium, a gas component, viscosifying agent, and fibers for hydraulically fracturing a subterranean formation, cleanup operations, and gravel packing a wellbore, are also disclosed.

Owner:SCHLUMBERGER TECH CORP

Method for decreasing lost circulation during well operations using water absorbent polymers

InactiveUS20030141062A1Reduce circulation lossIncrease in sizeLiquid/gas jet drillingFluid removalSuperabsorbent polymerDetackifier

Disclosed is a method and gellable composition for decreasing the loss of fluid during well drilling or servicing operations. The gellable composition comprises a superabsorbent polymer in an acidic aqueous liquid in which the superabsorbent is not swellable. Preferably the gellable composition also contains a viscosifier, preferably chitosan. The method is practiced by forming the gellable composition, placing it at the location of fluid loss in a well, and mixing it with a basic aqueous liquid to raise the pH and thus allow the superabsorbent to expand in volume. Advantageously, the superabsorbent, chitosan, and an acid, preferably a solid acid, preferably sulfamic acid, are admixed to form an additive for preparing the gellable composition.

Owner:COWAN JACK C +2

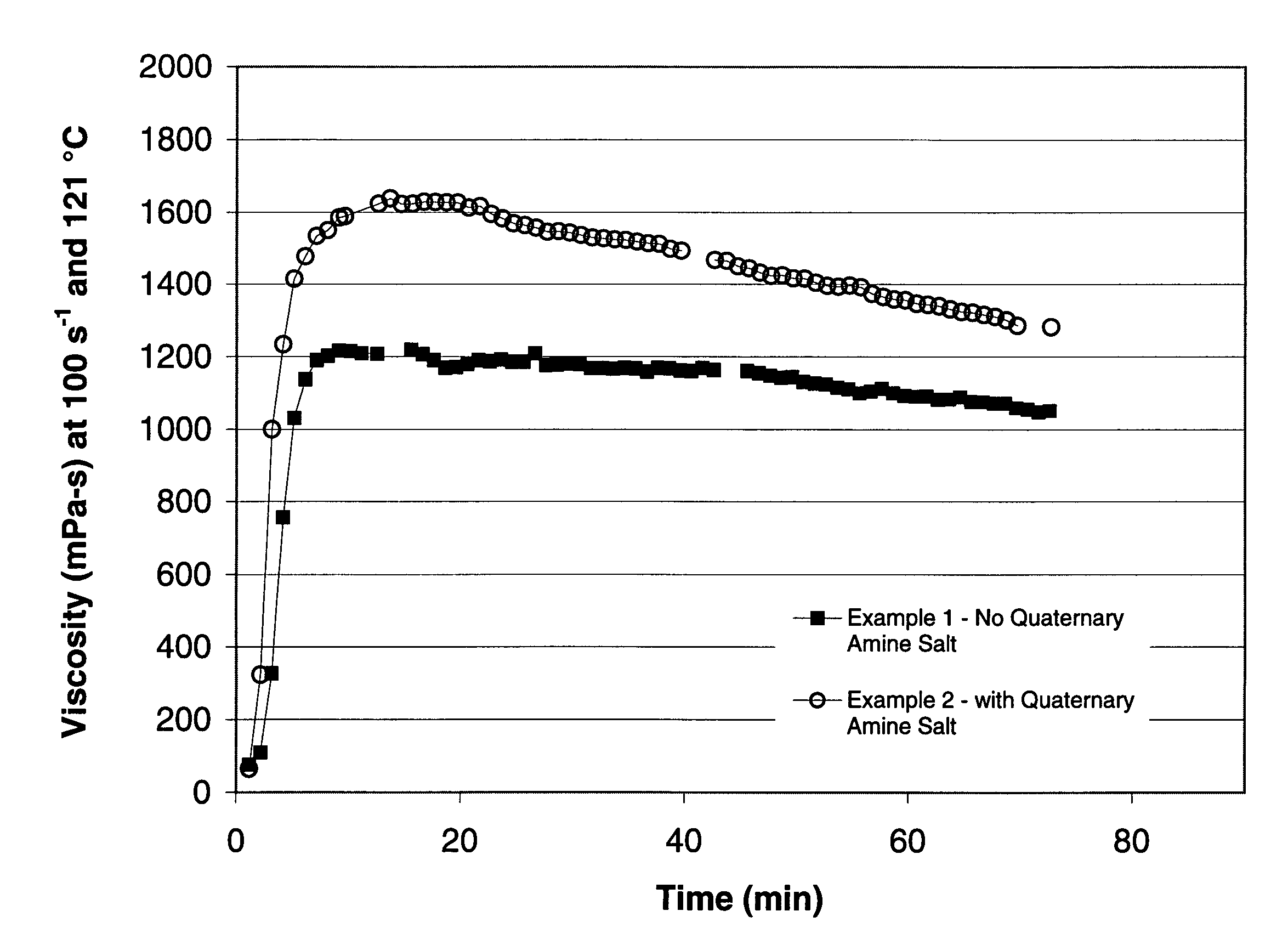

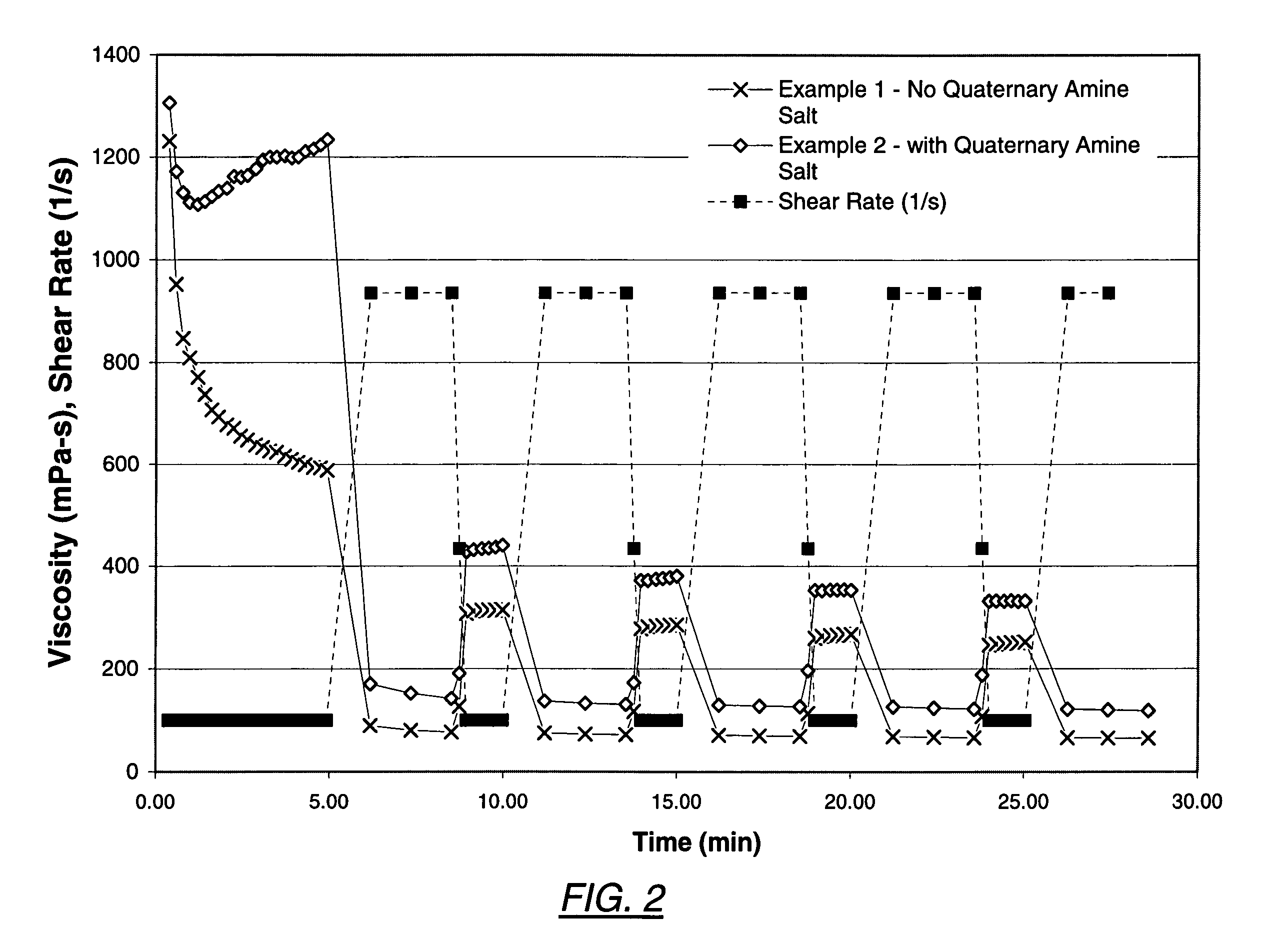

Methods of fracturing formations using quaternary amine salts as viscosifiers

ActiveUS7287593B2Improved viscosity propertiesFluid removalDrilling compositionFluid compositionDetackifier

Treatment methods including preparation of an aqueous treatment fluid composition composed of a carboxy modified polymer, a crosslinking agent, and a viscosifying quaternary amine salt, and subsequently introducing the composition into a the formation to treat. The treatment method is particularly useful for fracturing a subterranean formation. The polymer and crosslinker may be premixed and injected into a wellbore, then mixed therein with the quaternary amine salt to treat the formation. In another aspect, the polymer, crosslinker, and quaternary amine salt are mixed, injected into a wellbore, and introduced in the formation for treatment.

Owner:SCHLUMBERGER TECH CORP

Methods of limiting leak off and damage in hydraulic fractures

Methods for treating a formation penetrated by a wellbore which improves fluid loss control during treatment. In some aspects, the treatments include preparing an aqueous fluid including one or more water inert degradable polymers and an optional viscosifier, injecting the aqueous fluid into the wellbore at a pressure equal to or greater than the formation's fracture initiation pressure, and thereafter injecting into the wellbore a proppant laden fluid at a pressure equal to or greater than the formation's fracture initiation pressure. The water inert degradable polymer may be a polymer such as an emulsion polymer or a latex polymer. Some methods of the invention use a fluid which may have a normalized leak off coefficient (Cw / sqrt(K)) equal to or less than about 0.0022, 0.0014, or 0.0010. A conventional fluid loss additive may or may not be used in conjunction with the treatment fluid and / or the proppant laden fluid. The water inert degradable polymer may or may not substantially enter formation pores. In another aspect, methods for reducing matrix damage to a formation during a treatment operation include preparing an aqueous treatment fluid formed of at least one water inert degradable polymer, and injecting the fluid at a pressure equal or greater than the formation's fracture initiation pressure.

Owner:SCHLUMBERGER TECH CORP

Coating for fertilizer

InactiveUS7452399B2Imparts physical strengthAbrasion resistance is very highBiocideGas treatmentVegetable oilPolymer chemistry

Method and apparatus for coating fertilizer in pellet or other form to impart time-release characteristics and the resulting coated pellet product. The polyurethane coating encapsulates fertilizer particles, forming a hydrophobic coating for slow-release qualities. The urethane polymer coating is formulated with an isocyanate and a combined fluid of a polyether polyol, a methyl ester derivative of plant or vegetable oil, a T-12 curing catalyst, barium sulfate, and an oil-based dye. The barium sulfate imparts physical strength to and enhances color quality of the polyurethane coating, and acts as a detackifier and maintains temperature in the coating reactor. The inventive formulation is effective in the practical polymer coating of sulfate-based or other fertilizer pellets in an inventive time-release fertilizer product. An apparatus is provided for carrying out the coating process.

Owner:WHITTINGTON PATSIE A

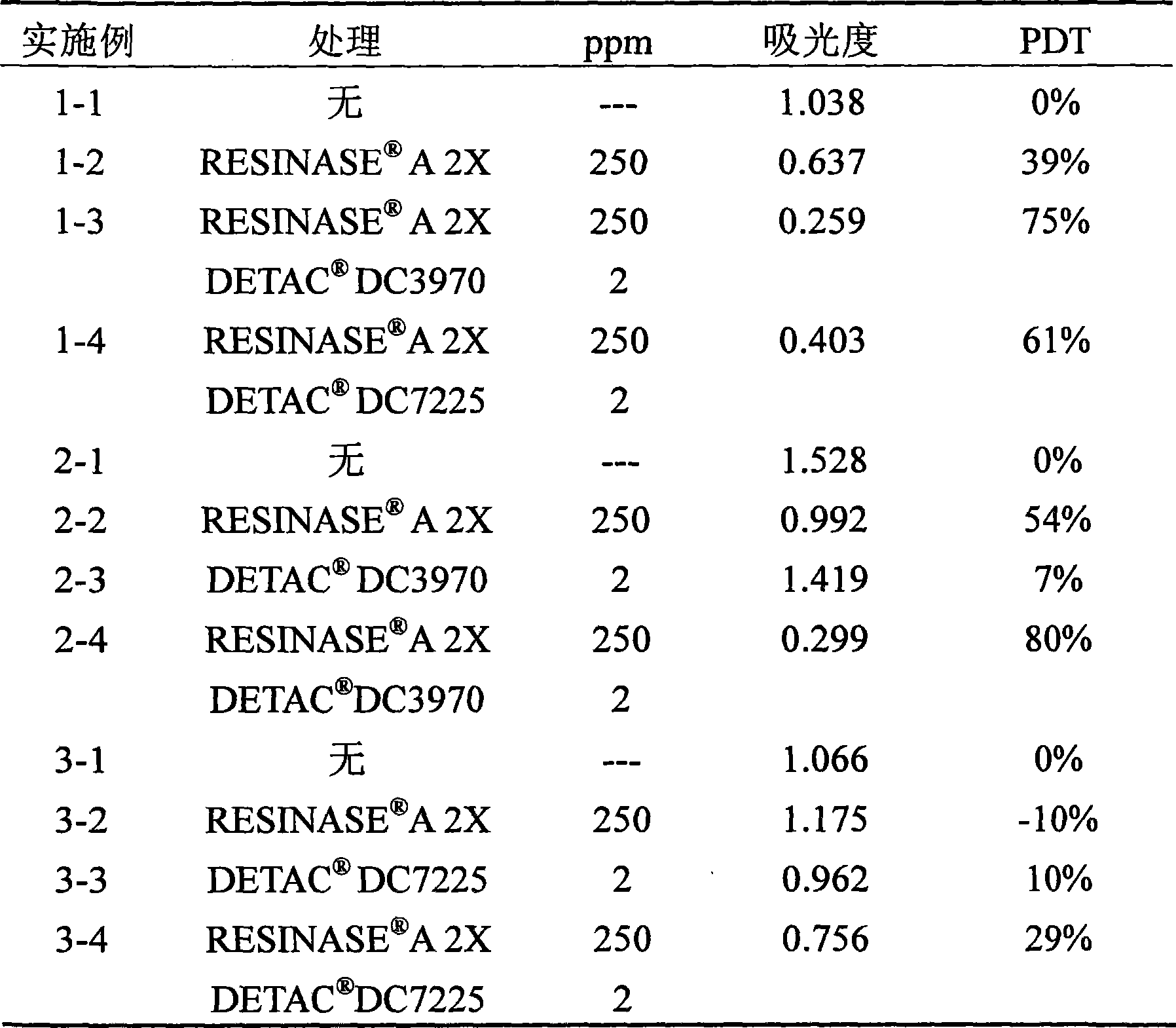

Pitch and stickies control in pulp and papermaking processes

ActiveCN101548045AFats/resins/pitch/waxes removal in pulpMicroorganism/enzyme additionProcess equipmentPapermaking

Owner:SOLENIS TECH CAYMAN

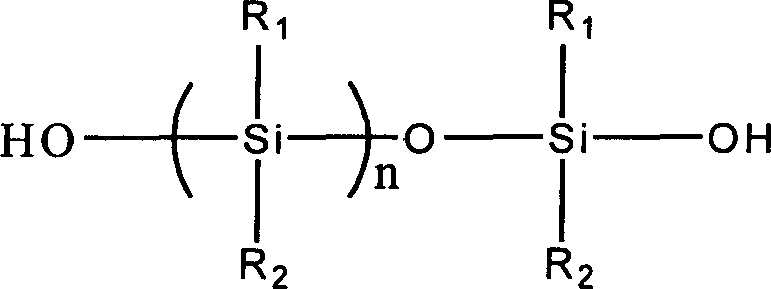

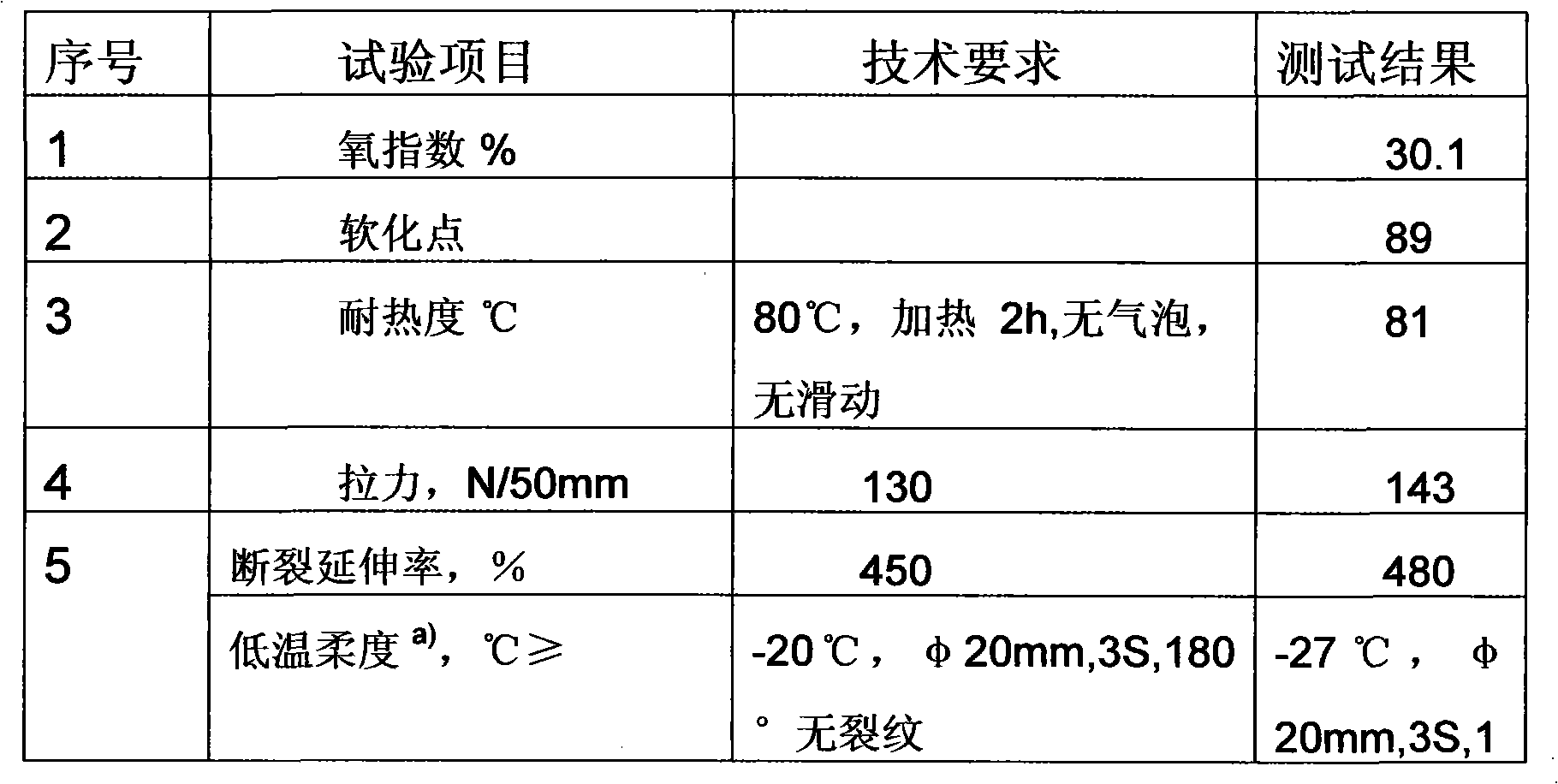

Bicomponent normal temperature crosslinked aqueous organosilicon rubber waterproof paint and method for preparing same

InactiveCN1670098AStrong adhesionAchieve coatingAntifouling/underwater paintsPaints with biocidesPolymer scienceEmulsion

The invention relates to a dual-component environment-friendly type organic silicon rubber waterproofing paint and its preparation process. The paint contains component A which is made of organosilicon emulsion, strengthening agents, fillers and catalyst, and component B which is made of polyfunctional group organosilicon cross linking agents and tackiness agent. The dual-component environment-friendly type organic silicon rubber waterproofing paint is preparing by compounding of the said components A and B in definite proportions. The tensile strength of the said organic silicon rubber waterproofing paint solidified film is more than 2.0 MPa and the elongation percentage is more than 500%. It also has strong adhesive force for the surface of many base materials such as metal, treatment or untreatment wood, tar mats, ceramic tiles, roofing and asphalt felts.

Owner:SOUTH CHINA UNIV OF TECH

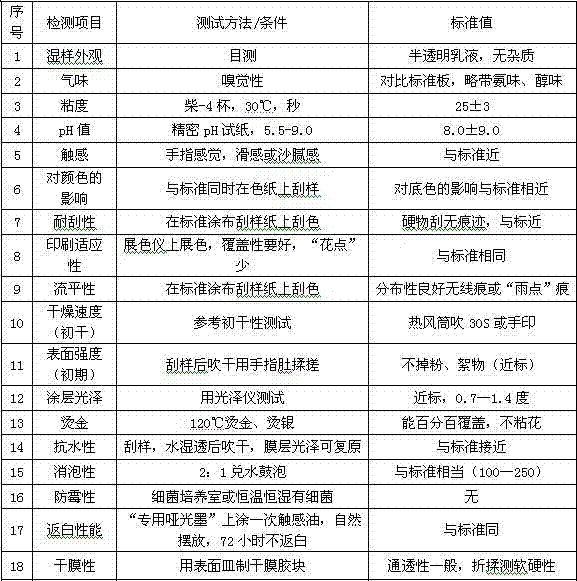

Water-based matt handfeel oil and preparation method thereof

ActiveCN103031050AImprove performanceStrong adhesionAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

The invention relates to the technical field of preparation of handfeel oil, in particular to water-based matte handfeel oil and a preparation method thereof. The water-based matt handfeel oil consists of the following raw materials in part by weight: 72 to 87 parts of matt resin, 7 to 14 parts of bright resin, 2 to 5 parts of alcohol, 1 to 4 parts of water, 1 to 4 parts of handfeel agent, 0.5 to 1.5 parts of anti-sticking agent, 2 to 4 parts of flatting agent, 2 to 8 parts of wear-resistant agent, 0.1 to 1.5 parts of mildew preventive, 0.2 to 0.6 part of defoaming agent, 0.2 to 0.8 part of thickening agent and 0.5 to 1.4 parts of handfeel crosslinking agent. By adoption of polyester polyol and aziridine crosslinking agent, the wear resistance, the attachment fastness and the chemical resistance of the handfeel oil are greatly improved and high practicability is achieved. The preparation method is simple in process, low in production cost and favorable for popularization and application.

Owner:广东佳景科技股份有限公司

Polyurethane binder

Polyurethane adhesive consists of polyurethane performed polymer 70-90wt% and anchoring agent 10-30wt% which contains hydroxyl group or epoxy group and is prepared by polymerizing at least two unsaturated monomers from free radical. At lest one monomer is polymerized unsaturated monomer containing hydroxyl group or epoxy group with hydroxyl group value:15.5-55, functionality:2-6; epoxy equivalent:1420-7000 and functionality:2-6. It achieves good viscidity and thermal stability, and better heat resistance. It can be used for composite plate, foam polypropylene and polyester plastic.

Owner:DINGSHENG SPECIAL CHEM

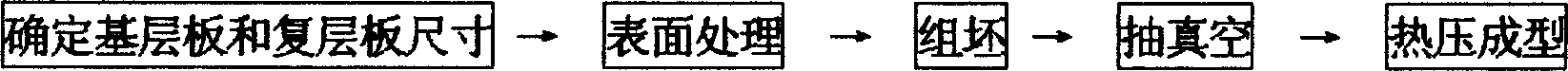

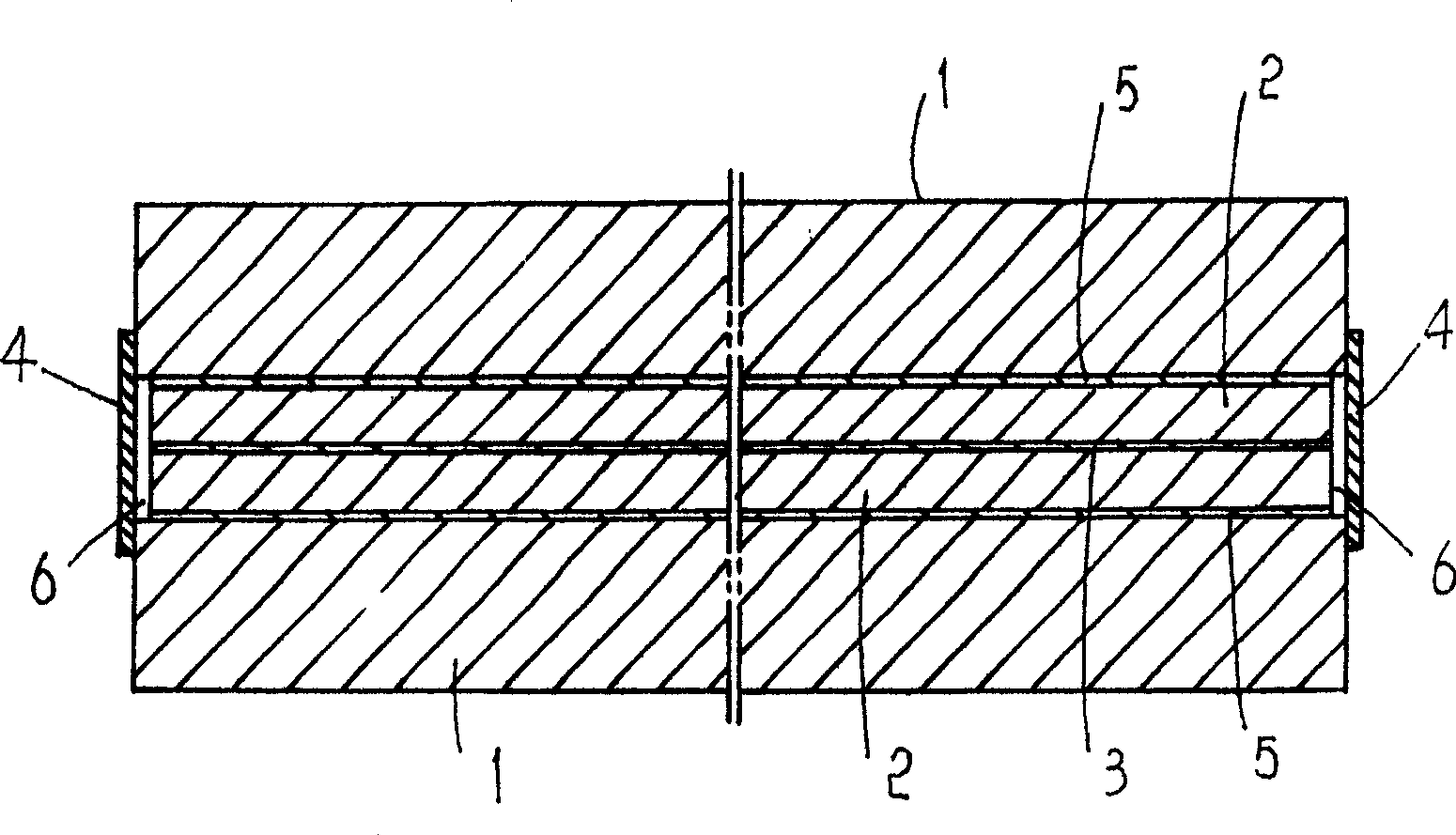

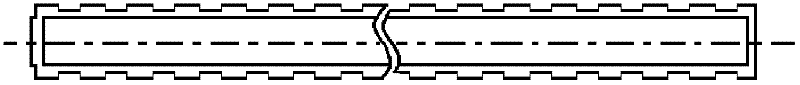

Processing method of press forming soldering high rolling composite blank

InactiveCN1686653AReduce welding workloadReduce edge lossWelding/cutting media/materialsAuxillary arrangementsManufacturing technologyDetackifier

A technology for making the combined blank includes providing the basic metal plate and additional metal plate, cleaning their surfaces, putting two additional metal plates between two basic ones, putting solder between the basic and additional metal plates, putting the high-temp detackifier between two additional metal plates, welding sealing plates on their periphery while pressing, drilling holes, vacuumizing, heating, hot pressing and cooling.

Owner:吉欣(英德)热轧不锈复合钢有限公司 +2

Water soluble rubber separant

Owner:东莞市福斯特橡塑科技有限公司

Bicomponent addition type room curing silicon rubber and preparation method thereof

The invention discloses a bicomponent addition type room curing silicon rubber and a preparation method thereof. A component A of the room curing silicon rubber comprises the following components in part by weight: 30 to 60 parts of allyl-terminated organic polysiloxane of which the viscosity is 450 to 1,000 mPa.s, 15 to 30 parts of 400-1,000-mesh quartz powder, 23 to 35 parts of 600-1,200-mesh aluminum oxide, 0.1 to 5 parts of coloring agent, and 0.5 to 3 parts of platinum catalyst; a component B comprises the following components in part by weight: 30 to 55 parts of the allyl-terminated organic polysiloxane of which the viscosity is 450 to 1,000 mPa.s, 20 to 30 parts of the 400-1,000-mesh quartz powder, 18 to 30 parts of the 600-1,200-mesh aluminum oxide, 0.1 to 5 parts of inhibiting agent, 0.5 to 3 parts of hydrogen-containing silicone oil containing 0.17 to 1.2 parts of hydrogen, 0.5 to 6 parts of viscosity increaser, 0.3 to 1 part of anti-settling agent and the like. The prepared bicomponent addition type room curing silicon rubber has high heat conductivity and fluidity and can achieve cohesive failure by being bonded with metals such as aluminum, copper, stainless steel and the like and plastics such as PBT, ABS, PC, epoxy resin and the like, the bonding strength can be over 0.5 MPa, and the properties such as viscosity, hardness, density, strength, linear shrinkage and the like of a liquid silicon rubber are basically not influenced.

Owner:TONGJI UNIV

Method for preparing release paper with concave-convex grooved texture

The invention belongs to a method for preparing release paper with concave-convex grooved texture. The formula of the release paper comprises 60 t0 85 weight parts of inorganic powder material, 10 to 40 weight parts of high polymer, 0.5 to 5 weight parts of antisticking agent, 0.3 to 3 weight parts of lubricating agent, 0.1 to 2 weight parts of foaming agent and 0.1 to 3 weight parts of activator. The preparation method comprises: stirring the inorganic powder material and the activator; adding the high polymer, the lubricating agent and the foaming agent and stirring; uniformly mixing, adding the antisticking agent, continuously stirring till the mixture is uniform, and obtaining a mixed material; and feeding the mixed material into paper film forming equipment to form paper films, and rolling the paper films with a circular shaft to obtain the release paper. When the method disclosed by the invention is adopted, the need of cutting trees is obviated; the cost is low; the need of film spraying and silicon applying is obviated in a production process; organic solvent is not used; the manufacturing process is simplified; and the energy consumption is low. The method has the characteristics of water resistance, dampness resistance and high strength, contributes to relief of environmental problems and is in accordance to environment-protection and energy-conservation requirements.

Owner:HUNAN FUTAI DIGITAL MATERIAL TECH

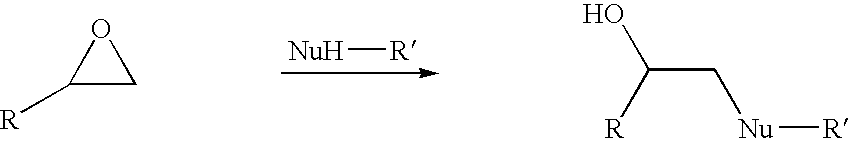

Hydrophobically modified fluid loss additives and viscosifier products

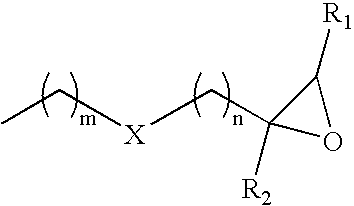

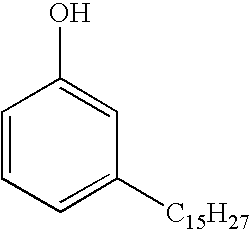

A wellbore fluid that includes an oleagninous continuous phase; a non-oleaginous phase; and a polymeric additive formed by reaction of at least one lipophilic epoxy modifier and at least one epoxide-reactive agent, wherein the at least one epoxide-reactive agent comprises at least one selected from lignins, tannins, biopolymers, starches, carboxy methyl cellulose, polyacrylates, polyacrylamides, and synthetic polymers is disclosed.

Owner:MI

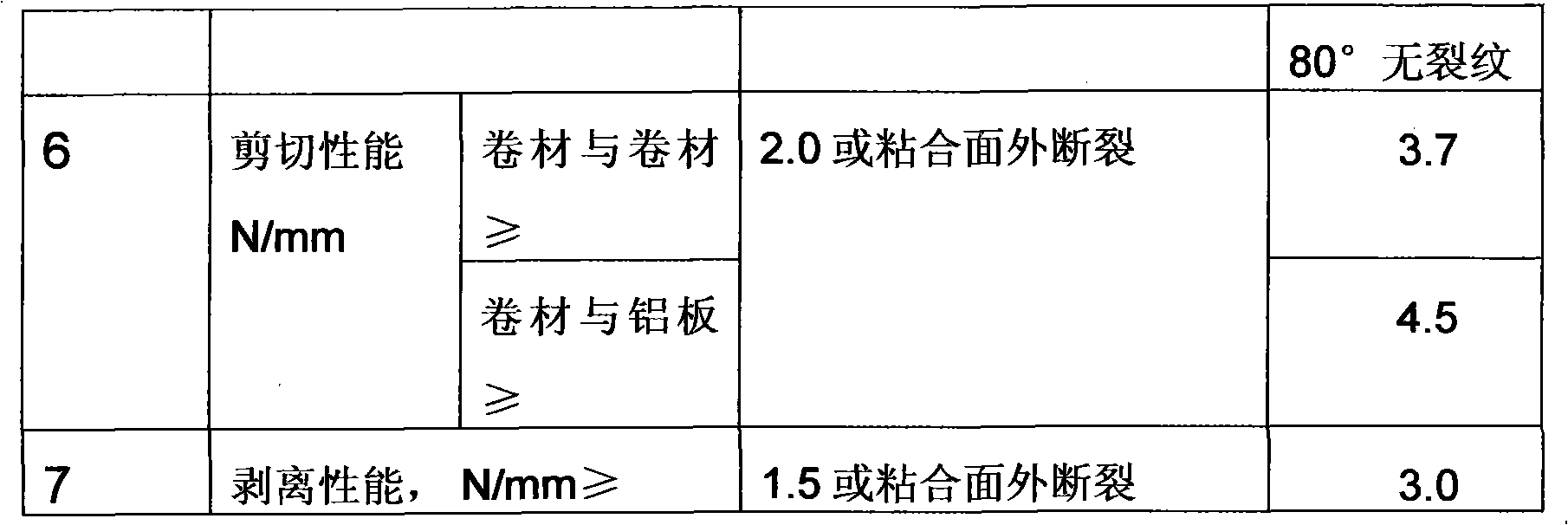

Flame-retardant self-adhesive coiled material

InactiveCN101818549AImprove flame retardant performanceEnvironmental protection is goodRoof covering using flexible materialsGlass/slag layered productsGlass fiberPolymer modified

The invention discloses a flame-retardant self-adhesive coiled material, which has a three-layer composite structure and is characterized in that the middle layer is a glass fiber felt and both the upper and lower surfaces of the glass fiber felt are polymer modified asphalt layers into which a flame retardant and an adhesion promoter are added. The invention provides a formula and a process for preparing the flame-retardant self-adhesive polymer modified asphalt water-proof coiled material. The flame-retardant self-adhesive polymer modified asphalt is prepared by mixing the flame retardant, the adhesion promoter, polymer, asphalt and the like. The invention further provides a method for preparing the coiled material.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

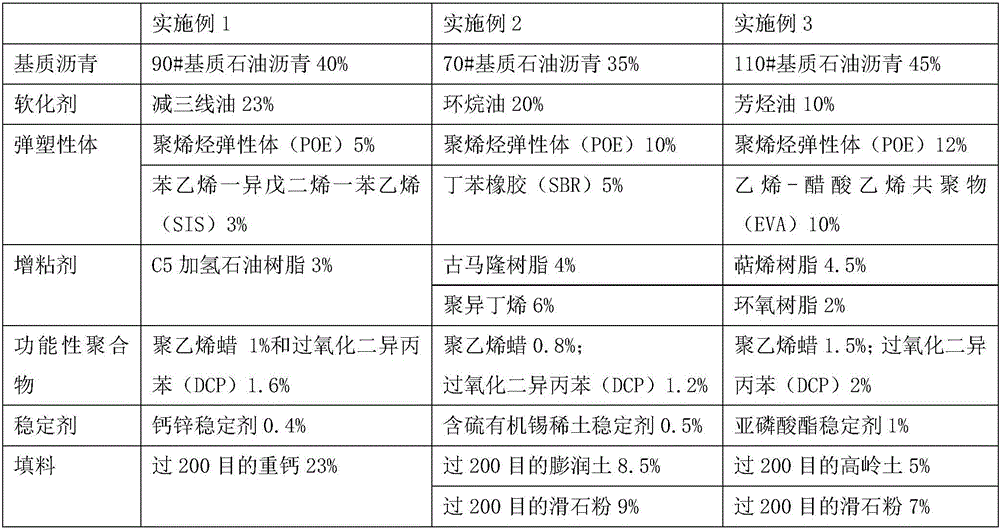

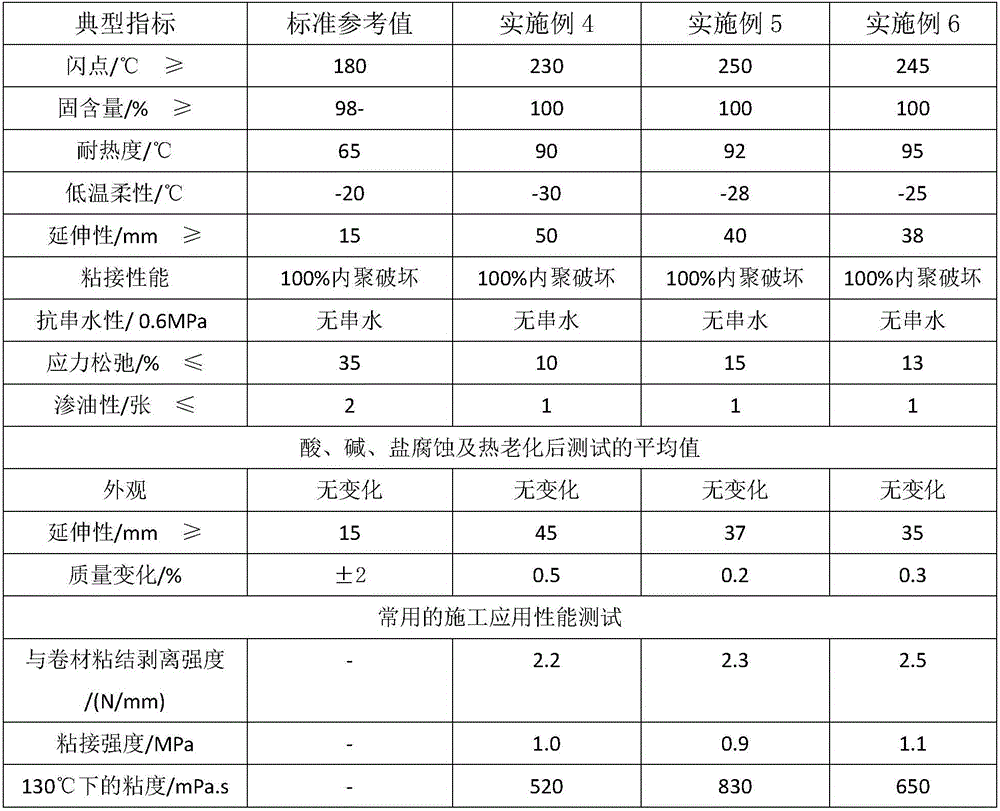

Non-cured rubber asphalt waterproof paint and preparation method thereof

InactiveCN106634602ANot affected by adhesive propertiesImprove thermal stabilityBituminous coatingsBituminous waterproofingPolymer science

The invention discloses a non-cured rubber asphalt waterproof paint and a preparation method thereof. The preparation method comprises the following steps: 1) weighing a matrix asphalt, a softener, an elastic plastic body, an adhesion agent, a functional polymer, a stabilizing agent and a filling material; 2)injecting the matrix asphalt to a reaction vessel, heating the materials, stirring the materials, adding the softener, and stirring the materials; 3) adding the obtained mixture and the elastic plastic body in a colloid grinder, growing the materials, opening the colloid grinder, grinding the materials, and continuously growing the materials; 4) adding an adhesion agent and a functional polymer, continuously stirring the materials; 5) adding a filling material and stirring the materials; and 6) adding a stabilizing agent, and stirring the material. The paint has high heat resistance, good construction property, good thermostability, chemical stability and anti-ultraviolet aging capability, bond property is not influenced due to extraneous environment, the paint has construction property for a wet basic layer, can increase the interfacial affinity interaction with the wet basic layer, and construction quality and progress can be effectively guaranteed, and the paint is environmentally friendly.

Owner:LOGISTICS UNIV OF CAPF

Pitch and stickies control in pulp and papermaking processes

InactiveUS20080169073A1Avoid depositionCellulosic pulp after-treatmentMicroorganism/enzyme additionProcess equipmentPapermaking

Methods for inhibiting the depositions of organic contaminants from pulp in pulp and papermaking systems are disclosed. A combination of an enzyme and a nonionic polymeric detackifier are added to the pulp or applied to deposition-prone process equipment surfaces of a pulp and papermaking system.

Owner:HERCULES INC

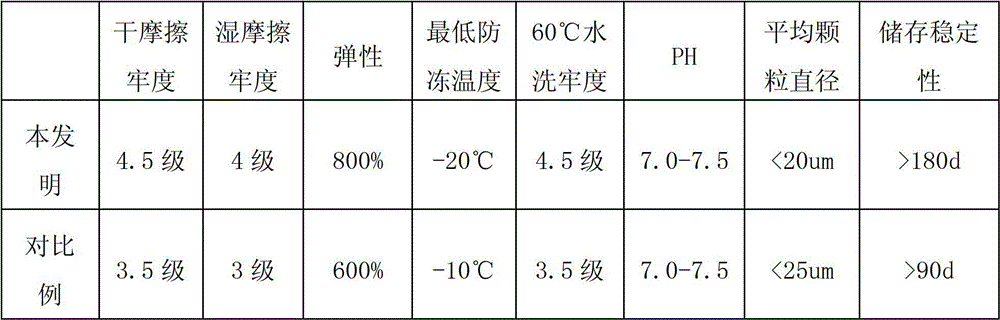

Machine printing binder for printing textiles and preparation method thereof

ActiveCN102720075ASolve the problem of antifreezeMeet the performance requirements of dry and non-sticky handsDyeing processWaxScreen printing

The invention relates to a machine printing binder for printing textiles. The machine printing binder for printing textiles is characterized by comprising the following constituents according to part by weight: 70-100 parts of waterborne acrylic emulsion, 20-40 parts of waterborne polyurethane resin, 20 parts of glycerol, 10-20 parts of deionized water, 1 part of defoamer, 2-4 parts of abherent, 2 parts of antiblocking feel auxiliary, 6 parts of waterborne emulsion wax, 0.6 parts of multifunctional regulator, 1.6 parts of emulsifying thickener, 1.4-3.5 parts of waterborne thickener and 10 parts of ultrafine silicon dioxide. Sizes of the machine printing binder for printing textiles are printed on a screen printing machine continuously for 4-8 hours without blocking meshes; and printing products are placed for 24 hours at minus 20 DEG C, are good in feel and elasticity, and do not crack in stretching or fall off.

Owner:中山市中益油墨涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com