Flame-retardant self-adhesive coiled material

A flame-retardant, self-adhesive technology, applied to building insulation materials, roofs using flexible materials, building components, etc., can solve the problem of non-flame-retardant waterproof membranes, achieve excellent adhesion performance, good flame-retardant effect, The effect of excellent environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

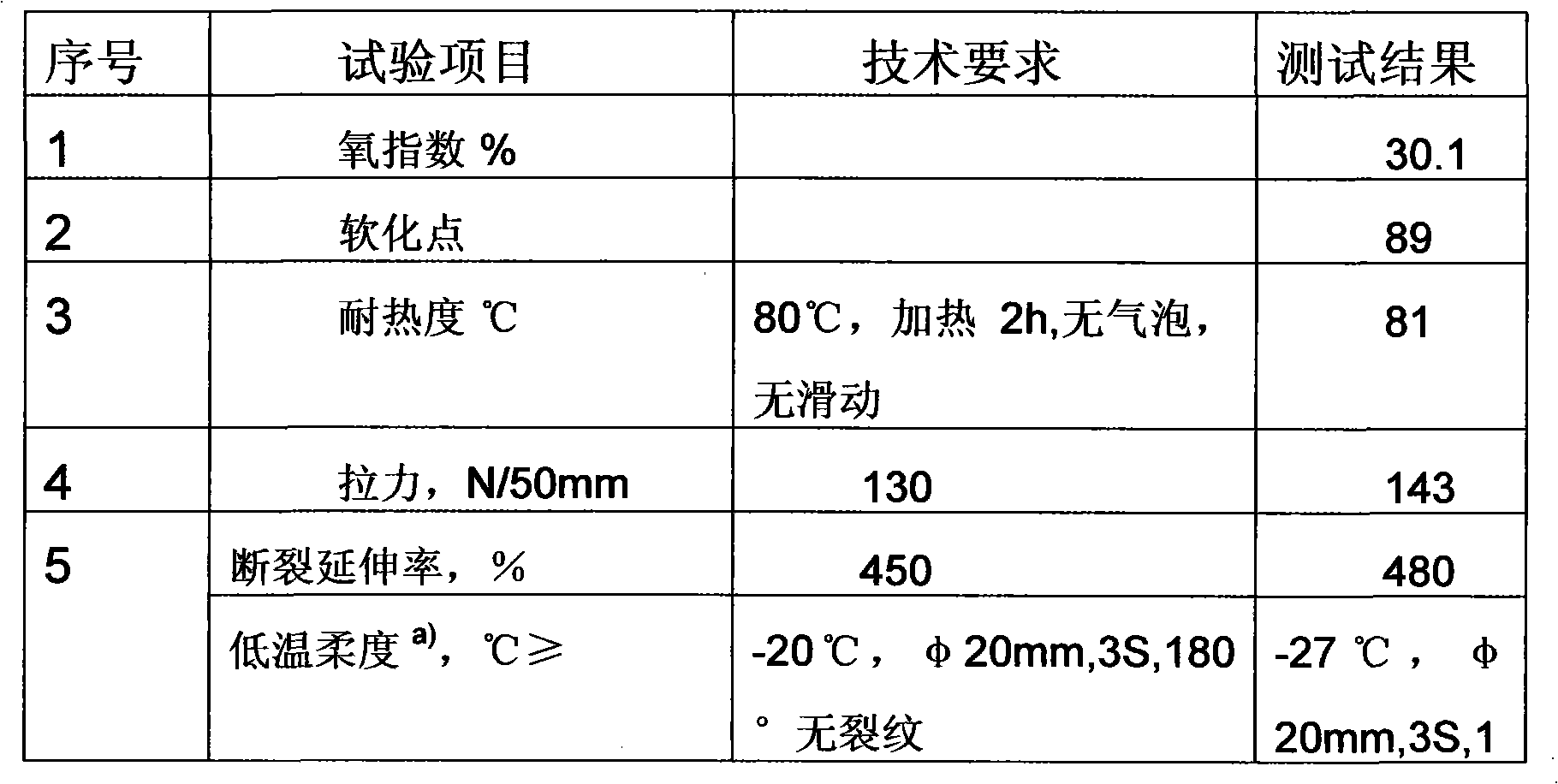

[0024] The distribution ratio according to mass components is as follows: 100 parts of asphalt, 12 parts of polymer modifier, 14 parts of tackifier, and 90 parts of flame retardant. Add the accurately weighed asphalt and polymer modifier in sequence to the mixing equipment , tackifier, and flame retardant are stirred to achieve macroscopic uniformity, and the flame-retardant self-adhesive polymer modified bitumen waterproof membrane is obtained through the coil forming process. According to the building materials industry standard JC / T840-1999 "Self-adhesive polymer modified bitumen waterproof membrane", the performance test is carried out, and the test results are shown in Table 1.

Embodiment 2

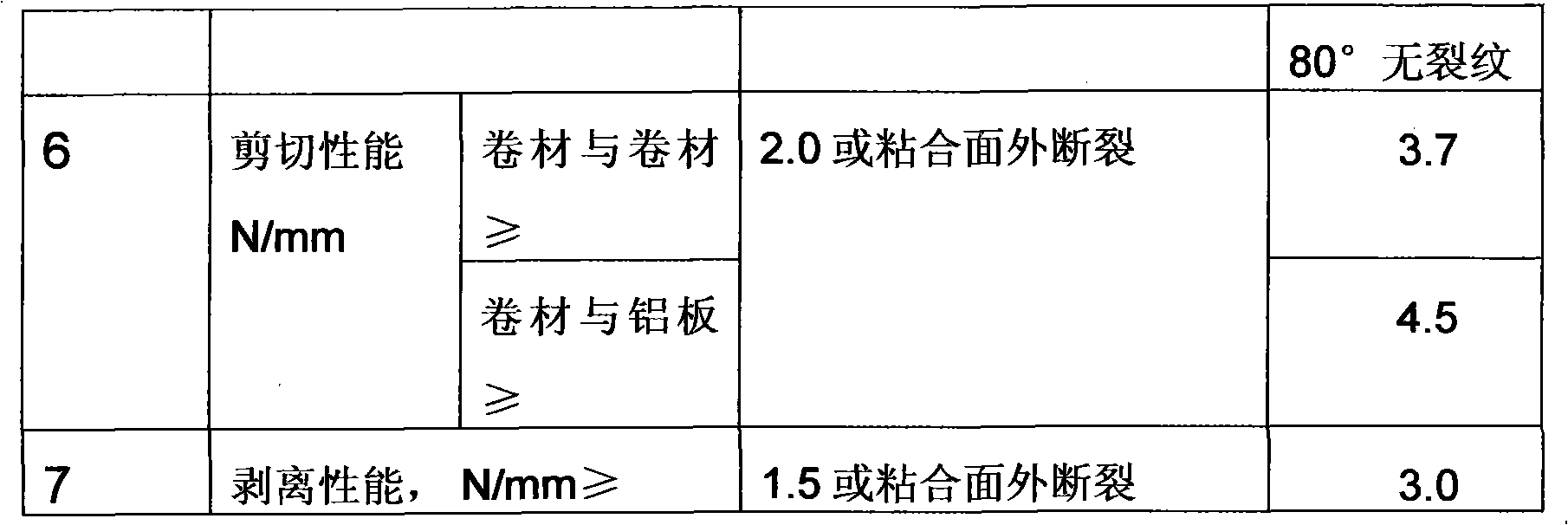

[0026] The distribution ratio according to mass components is as follows: 100 parts of asphalt, 18 parts of polymer modifier, 11 parts of tackifier, and 100 parts of flame retardant. Add the accurately weighed asphalt and polymer modifier in sequence to the mixing equipment , tackifier, and flame retardant are stirred to achieve macroscopic uniformity, and the flame-retardant self-adhesive polymer modified bitumen waterproof membrane is obtained through the coil forming process. According to the building materials industry standard JC / T840-1999 "Self-adhesive polymer modified bitumen waterproof membrane", the performance test is carried out, and the test results are shown in Table 2

Embodiment 3

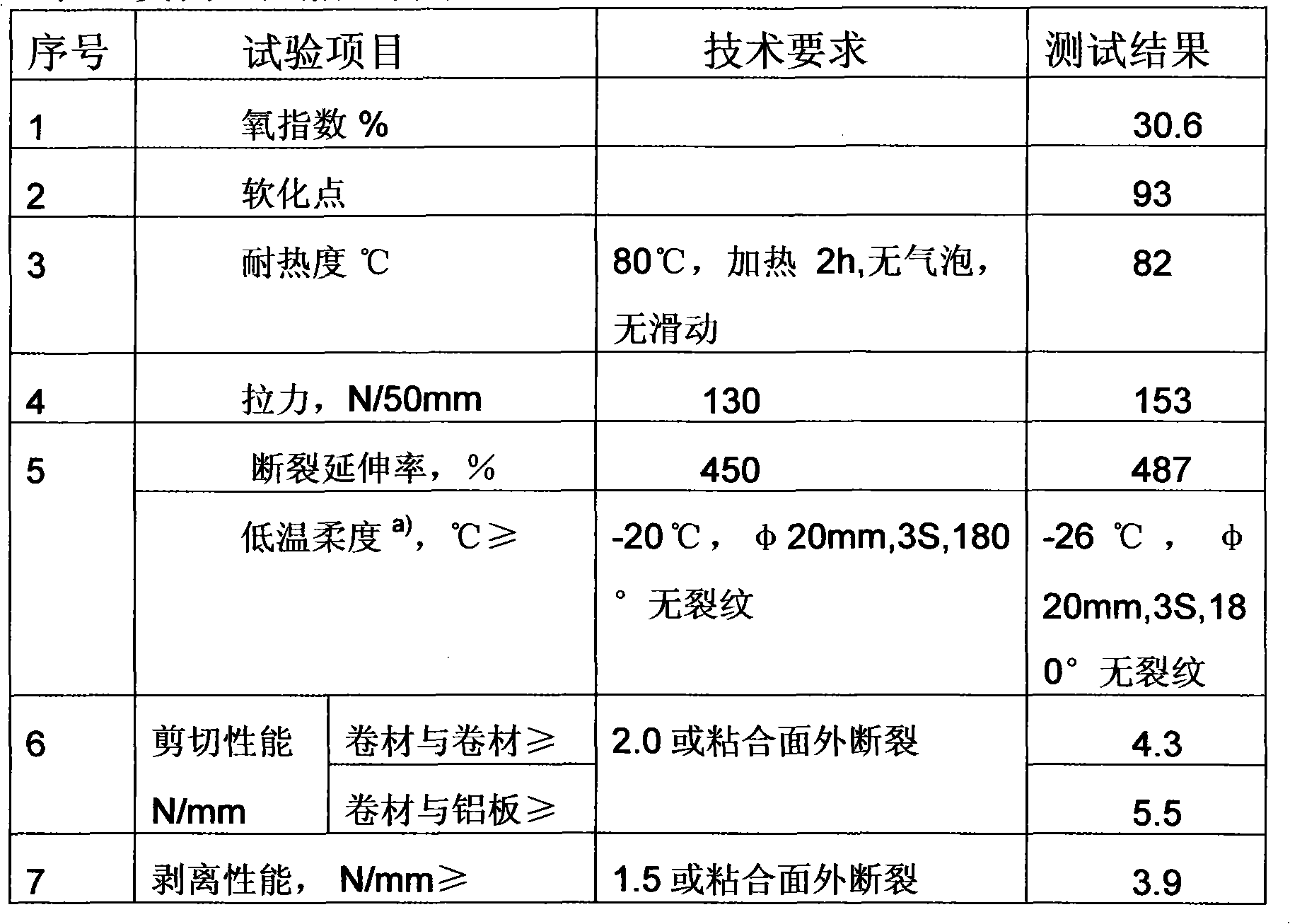

[0028] The distribution ratio according to mass components is as follows: 100 parts of asphalt, 15 parts of polymer modifier, 17 parts of tackifier, and 120 parts of flame retardant. Add the accurately weighed asphalt and polymer modifier in sequence to the mixing equipment , tackifier, and flame retardant are stirred to achieve macroscopic uniformity, and the flame-retardant self-adhesive polymer modified bitumen waterproof membrane is obtained through the coil forming process. According to the building materials industry standard JC / T840-1999 "Self-adhesive polymer modified bitumen waterproof membrane", the performance test is carried out, and the test results are shown in Table 3.

[0029] The waterproof performance test of the product is carried out according to the building materials industry standard JC / T840-1999 "self-adhesive polymer modified asphalt waterproof membrane", and the product performance can meet the requirements.

[0030] Product flame retardant performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com