Non-cured rubber asphalt waterproof paint and preparation method thereof

A technology of asphalt waterproof coating and non-curing rubber, which is applied in the direction of asphalt coatings and coatings, which can solve the problems of environmental protection, safety, poor water impermeability, low bonding strength, and long construction period, and achieve long-term stable performance and high heating temperature. Low, fast melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 3

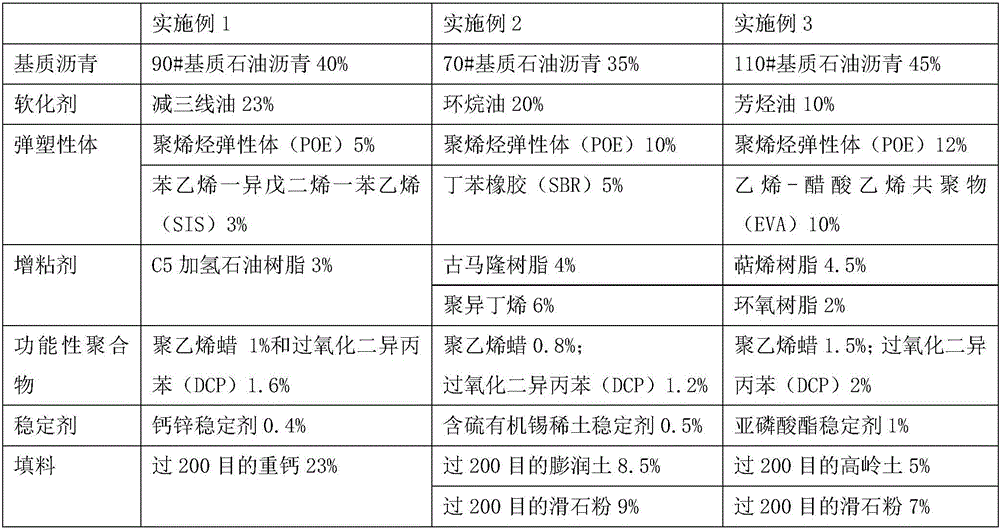

[0037] Embodiment 1-embodiment 3 see table 1

[0038] Table 1: (percentage is mass percent in Table 1)

[0039]

Embodiment 4

[0041] A preparation method of non-cured rubber asphalt waterproof coating, comprising the steps of:

[0042] (1) take by weighing (quality) according to embodiment 1 formula:

[0043] (2) Inject base asphalt into the reactor, heat up to 150°C, start stirring, add softener at 150rpm, stir at 150°C for 30 minutes, and stop stirring;

[0044] (3) Add the mixture and elastoplastic obtained in step (2) to the colloid mill, develop at 150°C for 9 minutes, heat up to 175°C, turn on the colloid mill, grind twice, and continue to develop at 150°C for 13 minutes;

[0045] (4) Stir for 60 minutes; add tackifier and functional polymer, and continue stirring for 30 minutes;

[0046] (5) Add filler, and continue to stir for 30 minutes after the filler is added;

[0047] (6) Add stabilizer and continue stirring for 30 minutes.

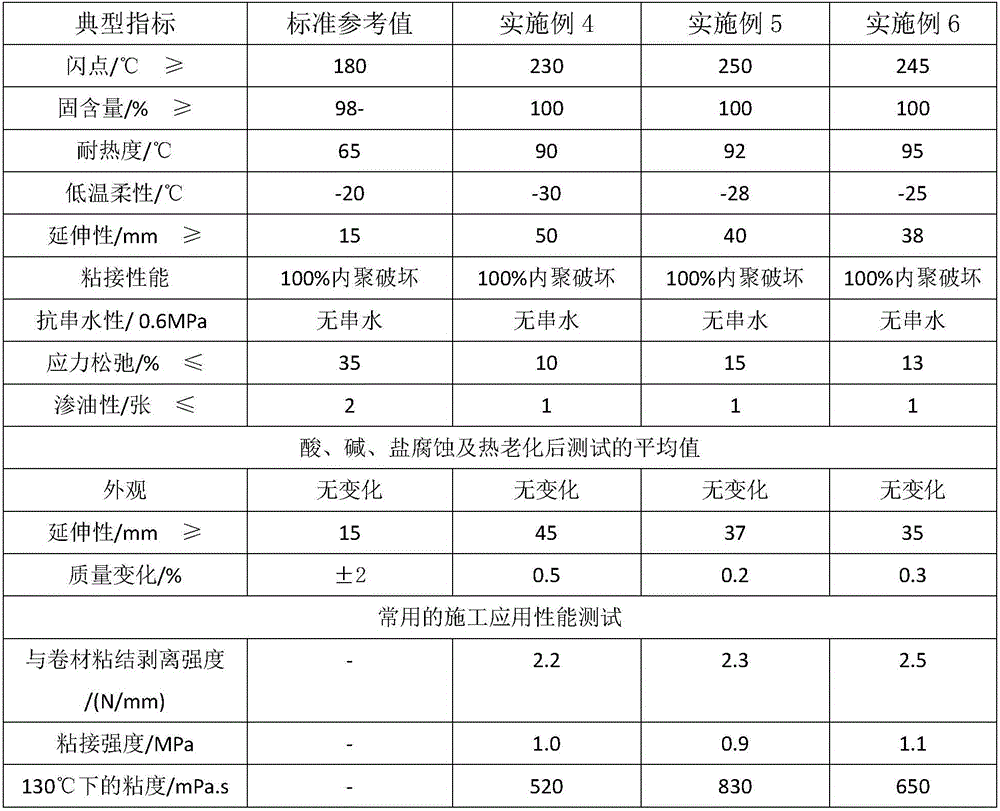

[0048] According to JC / T 2216-2014 non-curing rubber asphalt waterproof coating industry standard and common construction performance, the main performance indic...

Embodiment 5

[0050] A preparation method of non-cured rubber asphalt waterproof coating, comprising the steps of:

[0051] (1) take by weighing (quality) according to embodiment 2 formula:

[0052] (2) Inject base asphalt into the reactor, heat up to 140°C, start stirring, add softener at 200rpm, stir at 140°C for 35 minutes, and stop stirring;

[0053] (3) Add the mixture and elastoplastic obtained in step (2) to the colloid mill, develop at 140°C for 10 minutes, heat up to 170°C, turn on the colloid mill, grind 3 times, and continue to develop at 140°C for 20 minutes;

[0054] (4) Stir for 50 minutes; add tackifier and functional polymer, and continue stirring for 30 minutes;

[0055] (5) Add filler, and continue to stir for 30 minutes after the filler is added;

[0056] (6) Add stabilizer and continue stirring for 30 minutes.

[0057] According to JC / T 2216-2014 non-curing rubber asphalt waterproof coating industry standard and common construction performance, the main performance indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com