Superconducting eddy current brake for high-speed train

A technology for eddy current brakes and high-speed trains, applied in asynchronous inductive clutches/brakes, electric braking systems, motor vehicles, etc., can solve the problems of large electric power consumption, decreased braking force, and non-adjustable braking force, and achieve energy reduction Consumption, increase the effect of braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

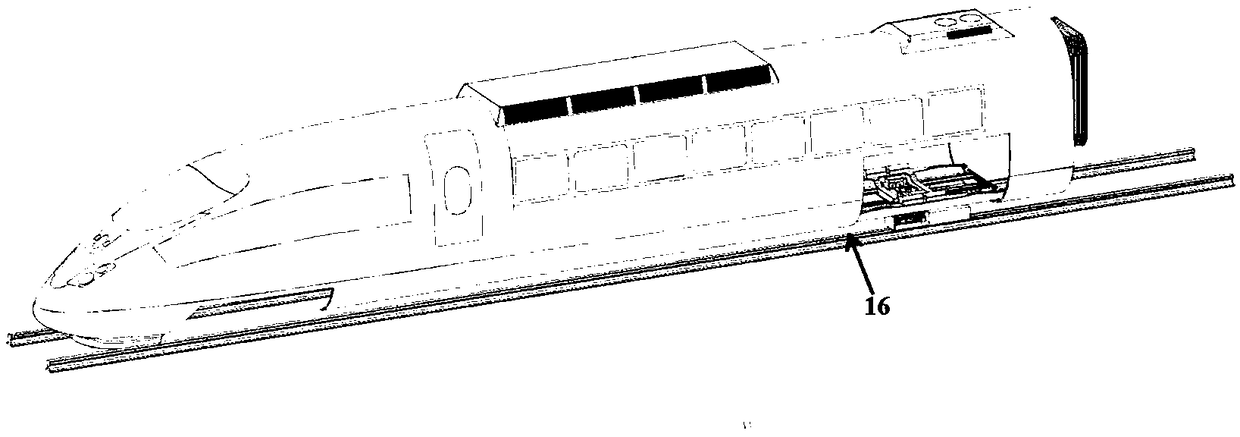

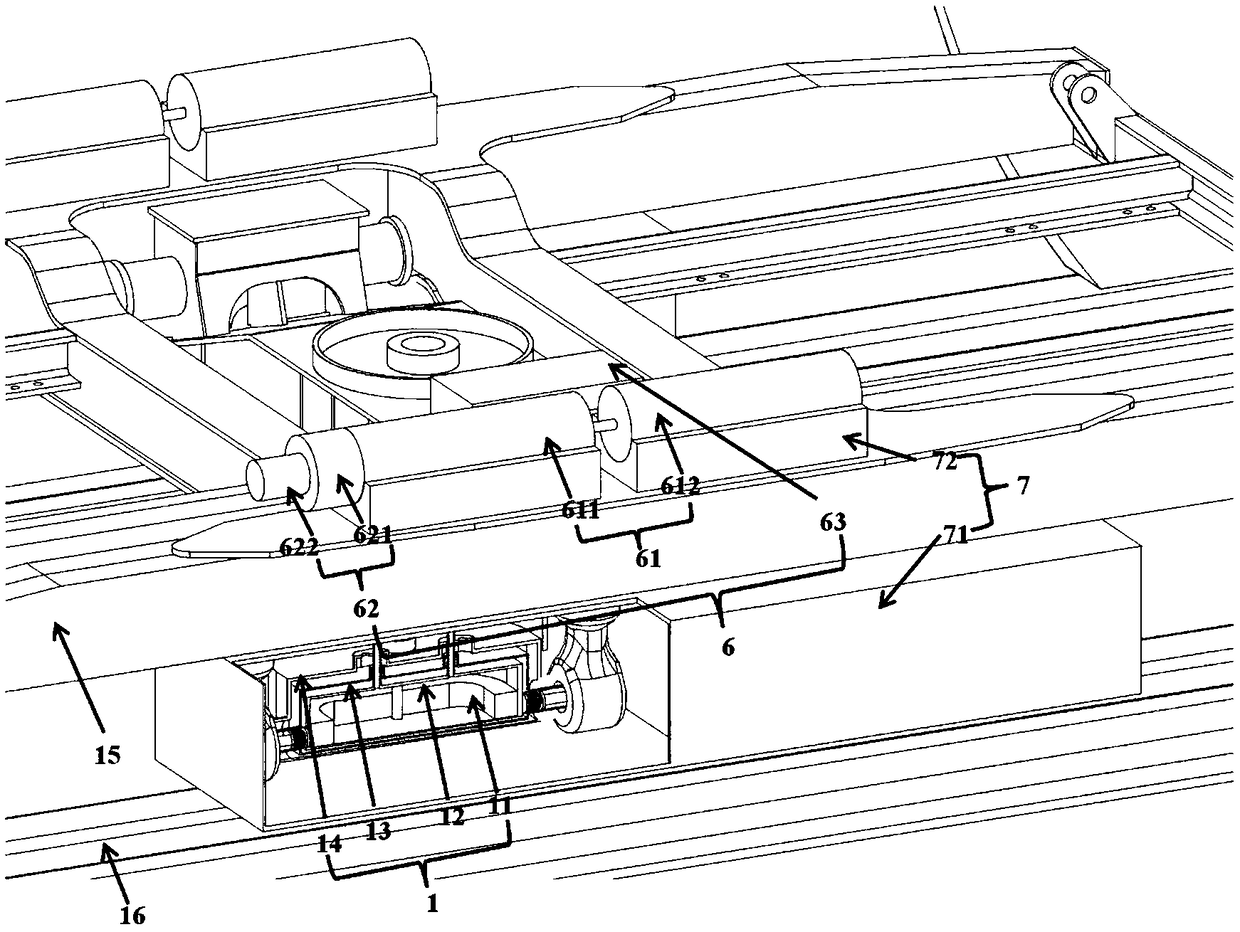

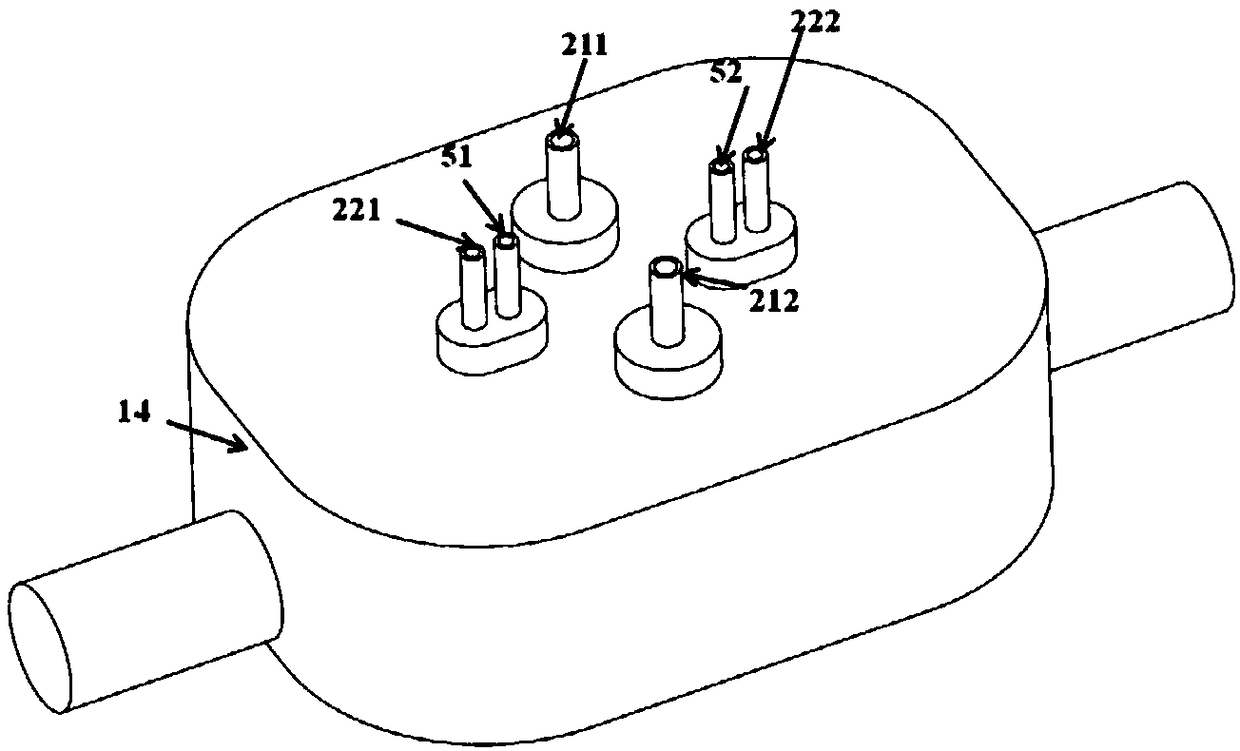

[0029] Embodiment 1: As shown in the figure, the superconducting eddy current brake for high-speed trains proposed by the present invention mainly includes a superconducting magnet unit 1, a low-temperature refrigeration unit 6 and a connection unit 7, and the superconducting eddy current brake for high-speed trains includes two The superconducting magnet unit 1 is bound on the bogie 15 through the connection unit 71 . The superconducting magnet unit 1 is located directly above the guide rail 16 of the high-speed train, and retains a certain air gap, and the superconducting magnet unit 1 and the two guide rails 16 below generate an eddy current effect to produce an eddy current effect that is consistent with the direction of travel of the high-speed train. opposite braking force.

[0030] Specifically, each of the two superconducting magnet units 1 includes a pair of superconducting coils 11 to form alternating N and S poles.

[0031] Specifically, the superconducting magnet ...

specific Embodiment approach 2

[0048] Embodiment 2: This embodiment differs from Embodiment 1 in that: the material of the superconducting coil is a high-temperature superconducting wire, block or strip, and other parameters are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com