Patents

Literature

288results about How to "Non-magnetic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cu-Al2O3 nano strengthened dispersion alloy and preparation method thereof

The invention relates to a Cu-Al2O3 nanometer dispersion strengthening alloy and preparation thereof. The preparation includes the steps of Cu-Al alloy vacuum smelting, pulverizing, screening, internal oxidizing, hydrogen reducing, vacuum hot pressing, canned hot extruding, etc. Comparing with oxygen-free copper, sigma of the alloy of the invention is 2 to 6 times higher that of the oxygen-free copper, the anti-annealing softening temperature is up to over 900 DEG C, the conductivity is up to 96% IACA and more. The process of the invention is simple, the prepared Cu-Al2O3 nanometer dispersion strengthening alloy has high strength, high conductivity, electrical conductivity higher than 96% IACA, and is anti-annealing and antimagnetic. The alloy can not only used for large-scale integrated circuit lead frame, manufacturing of controlled thermonuclear reaction heat sink components, and is expecially suitable for manufacturing of microwave tube grid mesh, inertial instrument sensor, particle accelerator and other high-precise parts.

Owner:CENT SOUTH UNIV

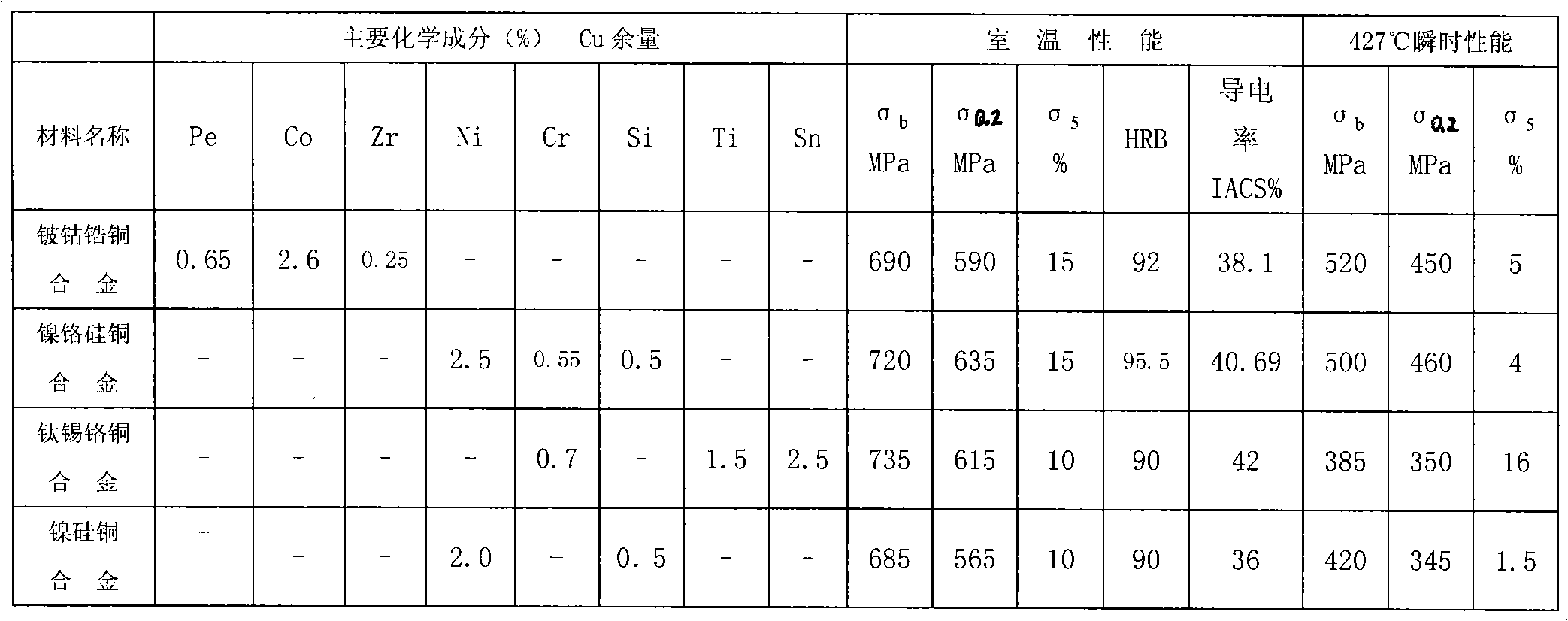

High-strength nickel-chromium-silicon-copper alloy material and processing technology thereof

The invention relates to a copper alloy material and a processing technology thereof, in particular to a high-strength nickel-chromium-silicon-copper alloy material and a processing technology thereof. The alloy material has low toxicity and low cost. The alloy material comprises the following components by mass: 2.1-2.9% of Ni, 0.4-0.7% of Cr, 0.3-0.7% of Si, not more than 0.3% of total impurities and the balance of Cu. The processing technology comprises the steps of casting, press processing, high-temperature solution hardening and heat treatment, cold press processing, aging heat treatment and mechanical processing.

Owner:SHENYANG XINGGONG COPPER IND

MIM manufacturing process for non-magnetic 17-4P stainless steel parts

The invention discloses an MIM manufacturing process for non-magnetic 17-4P stainless steel parts. The MIM manufacturing process comprises the following steps: putting a 17-4PH stainless steel powder and a binder into a kneading machine for mixing; cooling to a room temperature and then crushing by using a crusher, and then extruding a crushed material for pelletizing in an injection molding machine; processing a prepared feeding material in the injection molding machine into blanks; then catalyzing, debinding and removing polyformaldehyde from the injection blanks in a catalytic debinding furnace; putting well catalyzed and debound blanks into a vacuum furnace for debinding and sintering; and carrying out solution treatment on well sintered parts in a shielding gas protected continuous furnace or the vacuum furnace. The MIM manufacturing process provided by the invention adopts an MIM process and uses a 17-4PH powder sintered through nitrogen, and then the non-magnetic MIM metal parts with good compactness and corrosion resistance, and high tensile strength and yield can be obtained after solution treatment.

Owner:SHANGHAI FUTURE HIGH-TECH CO LTD

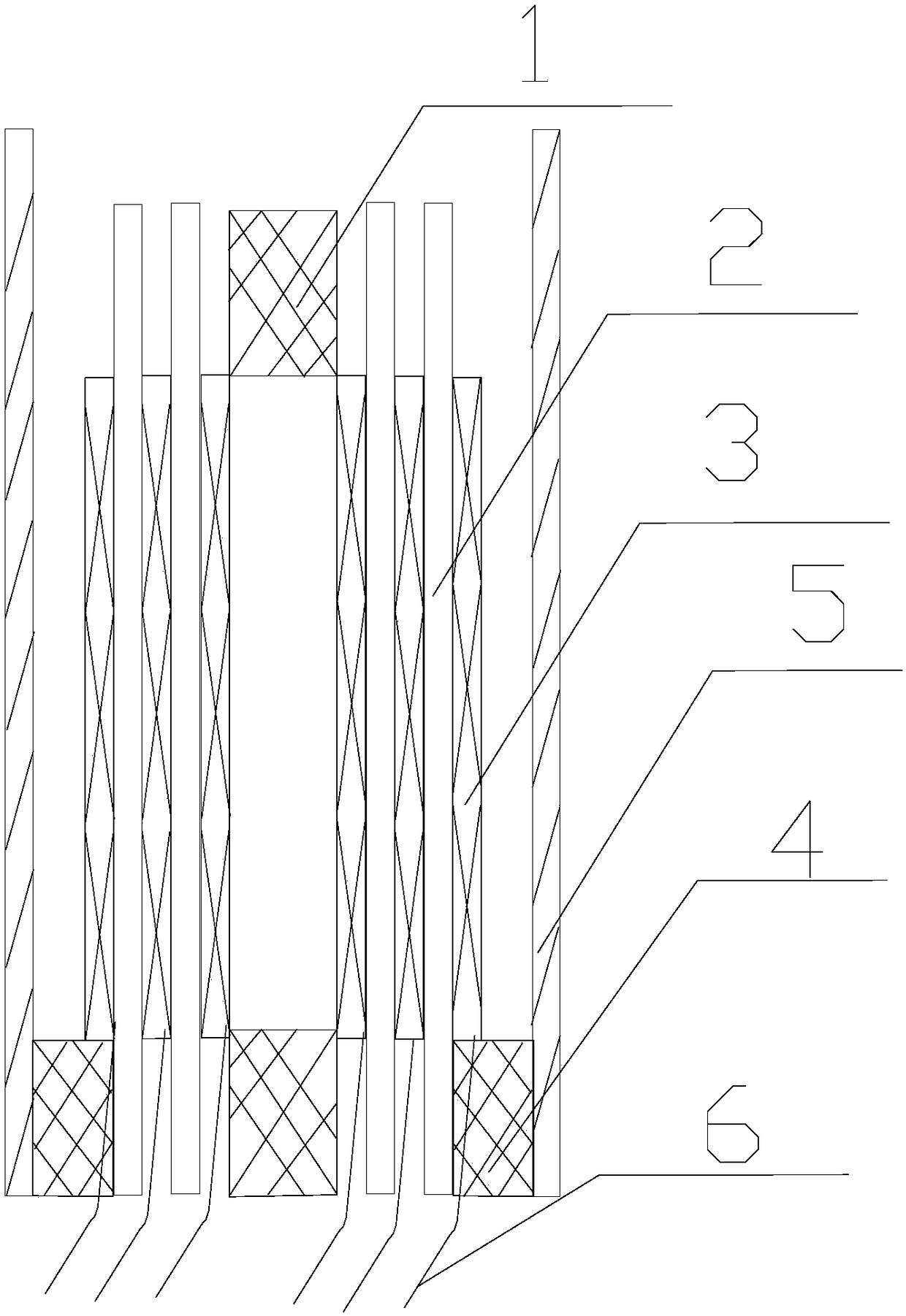

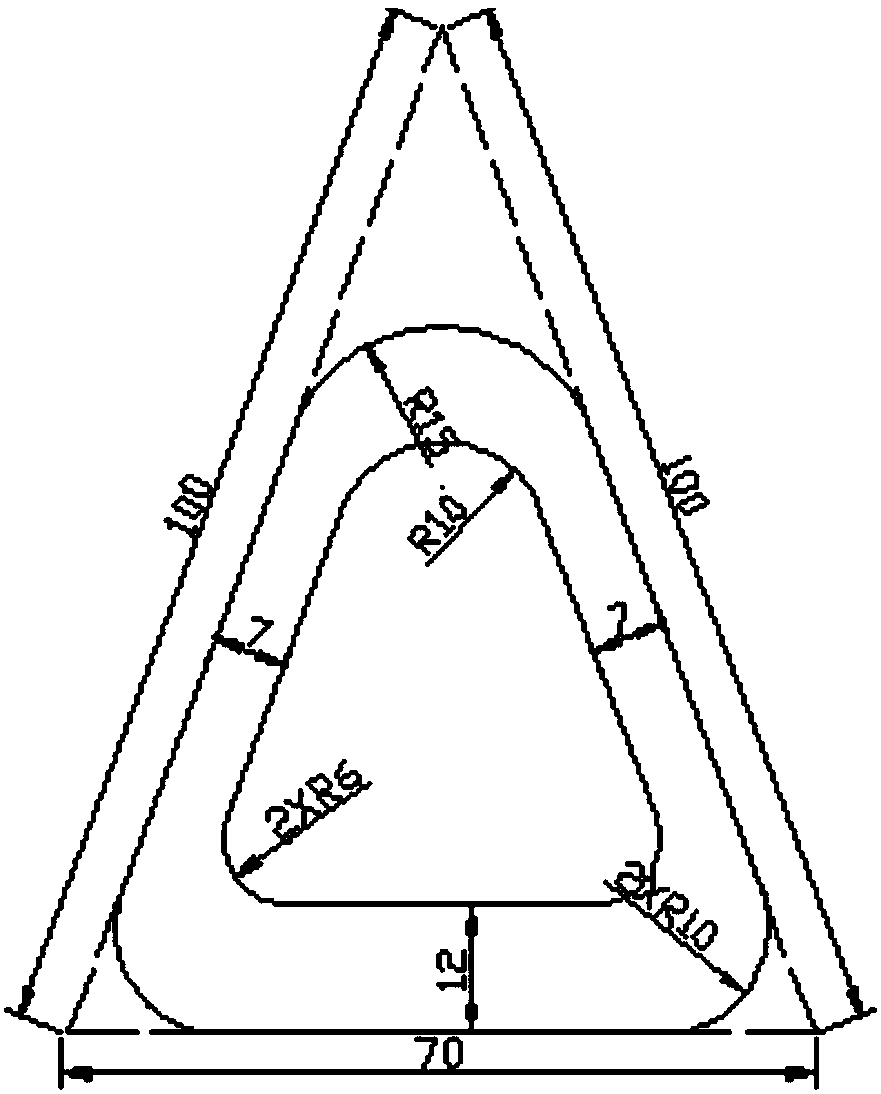

Method for processing composite fiber material spiral stirrup

The invention discloses a method for processing composite fiber material spiral stirrup. The method comprises the following steps of: gumming, premolding, semi-solidifying and drying, molding spiral stirrup, sizing and drying, and cutting and packaging. In the multiturn continuous closed-type composite material spiral stirrup of the invention, the continuous spiral composite material stirrup replaces the single-ring composite material stirrup, so that the spiral stirrup can save materials and man-hours in the same member, resists corrosion, and can also improve the bearing capacity of a girder or a column under the condition of constant section and equal spacing; the tensile strength of the composite material stirrup is three times that of steel bar; the weight is only one-fourth that of the steel bar; and the composite material stirrup has the advantages of no magnetism, water resistance, freeze resistance, strong chemical corrosive resistance and the like; and due to the adoption of a process for molding the composite fiber material spiral stirrup, the disadvantage that a conventional composite material is difficult to bend into the stirrups with different shapes after solidification and sizing is overcome, and the shape of the composite material steel bar can be changed so as to manufacture the spiral stirrup according to the requirements of people.

Owner:沈锋

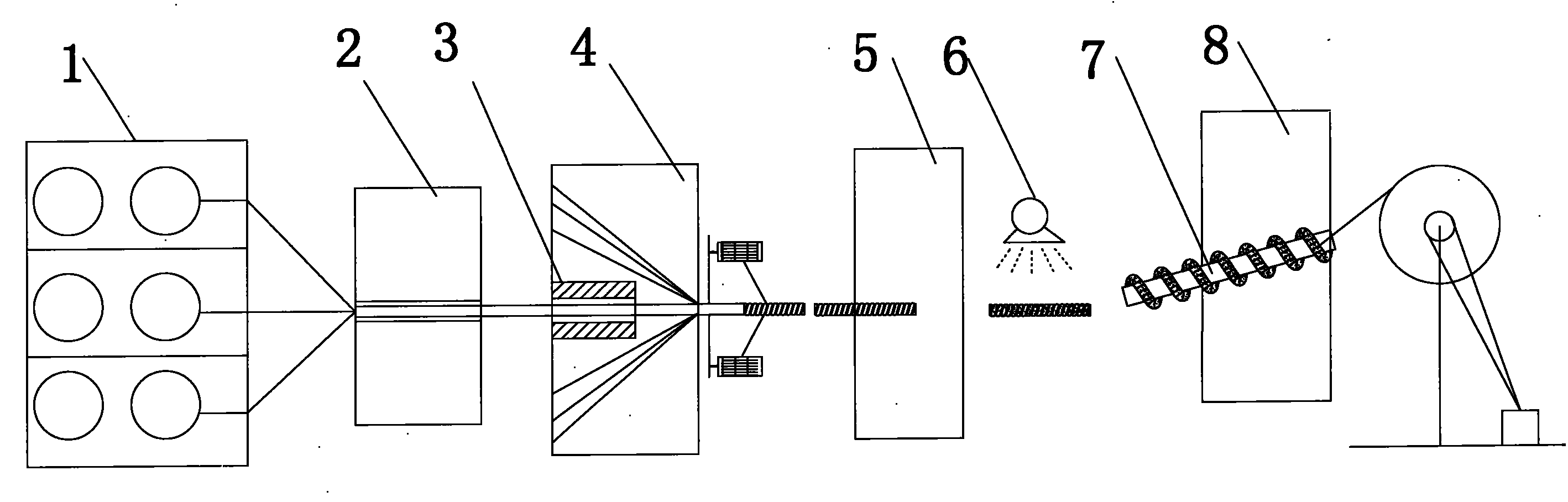

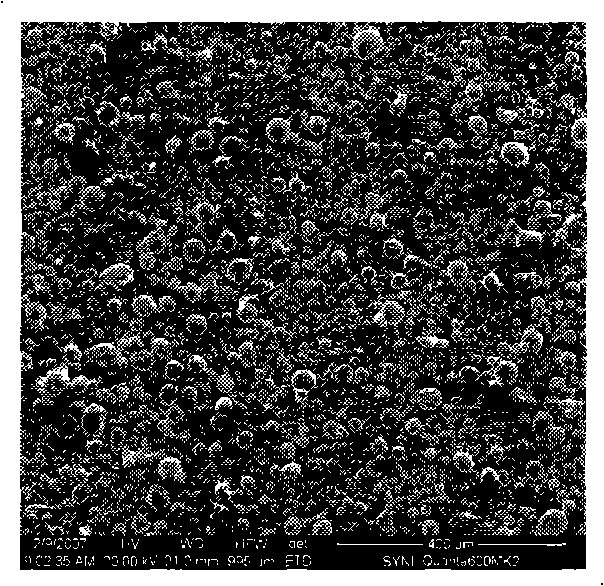

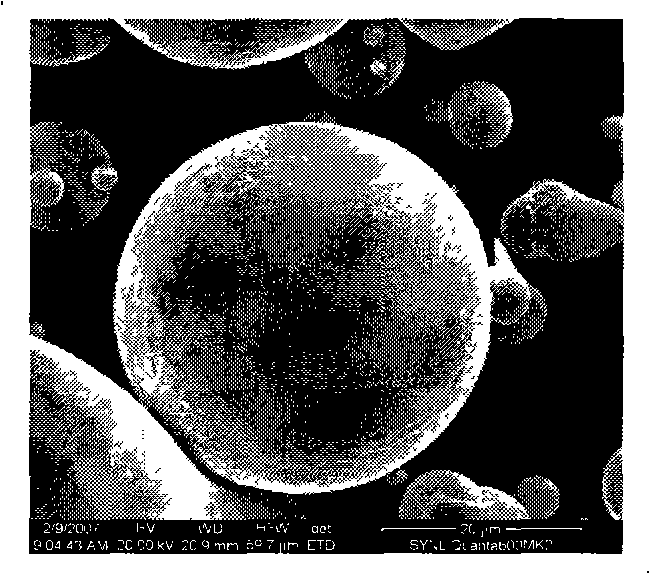

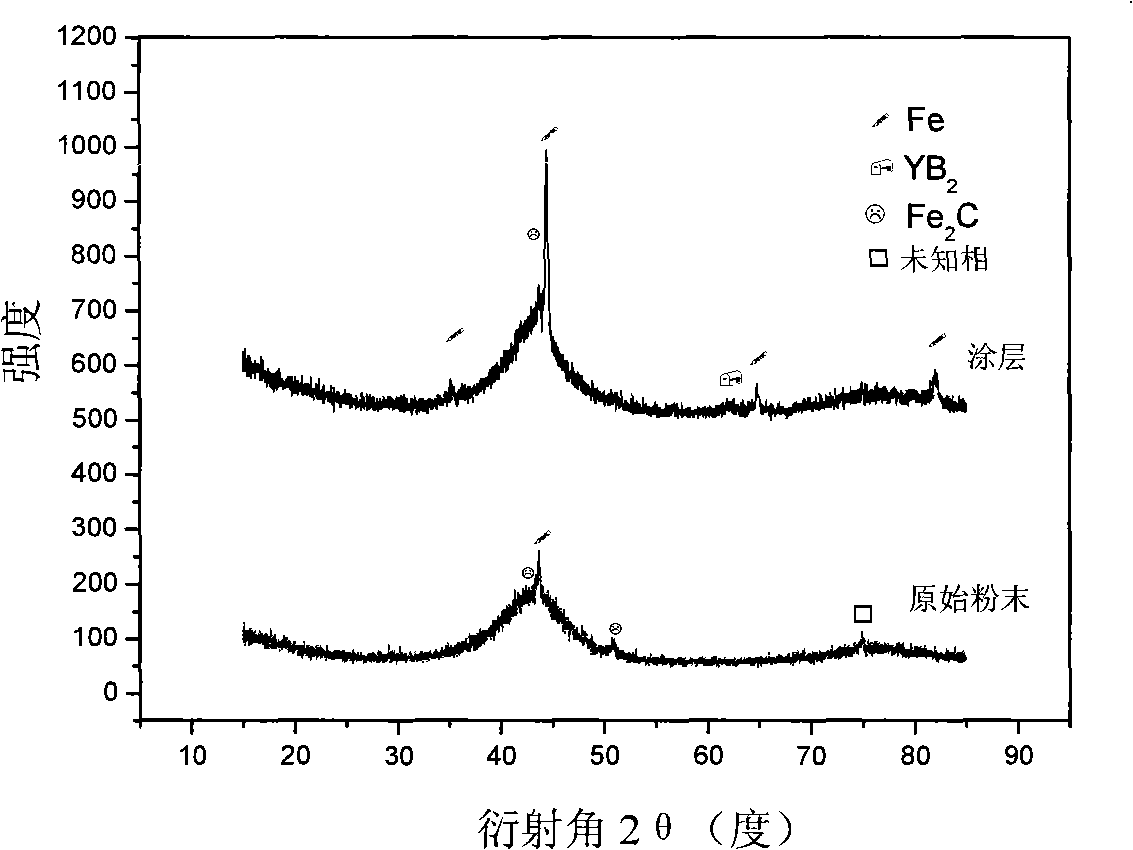

Preparation of non-magnetic high corrosion resistant amorphous steel coating

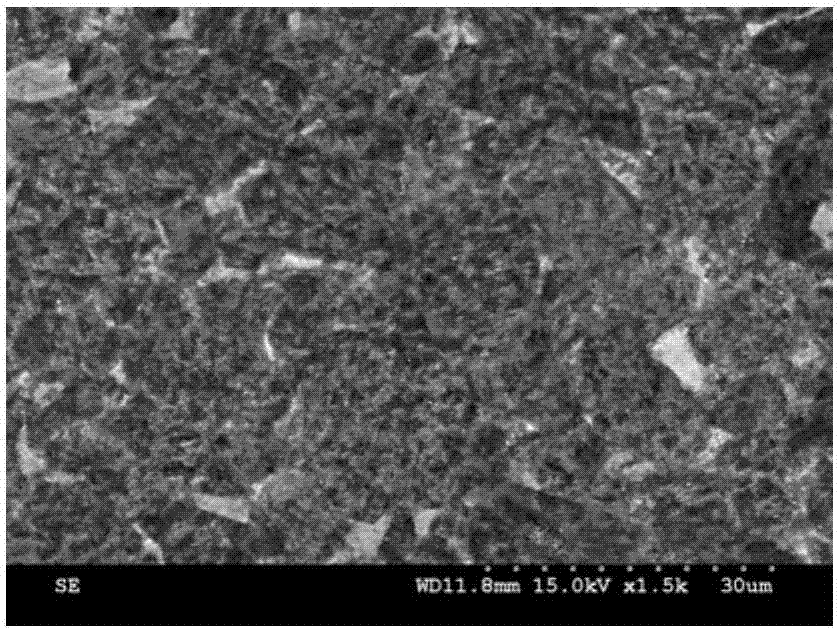

InactiveCN101323951AImprove mechanical propertiesGood physical propertiesMolten spray coatingHeat inorganic powder coatingSurface engineeringVoid ratio

The invention relates to a ferrous alloy with strong performance of glass formation and a technique method for preparing the coating of the amorphous alloy, in particular to a preparation method of non-magnetic amorphous steel coating with the performance of high anticorrosion and wearing resistance. The method of the invention solves the problem that large brittleness is existed in Fe-based large bulk of amorphous alloy and is a restriction as the structural material to go to engineering application, while the invention causes the application of bulk amorphous alloy to surface engineering field (especially amorphous alloy coating) to be possible. By adopting the Fe-based bulk amorphous alloy to prepare Fe-based amorphous alloy coating, firstly, mater alloy is produced by a method of vacuum induction melting according to needed components; then gas atomization technology is adopted to prepare amorphous alloy powder; supersonic thermal spray technology is adopted to prepare Fe-based amorphous alloy coating. The non-magnetic amorphous steel coating with high anticorrosion performance and wearing resistance produced by the invention is uniform, has low void ratio (less than 0.1 percent), is non-magnetic and has the performance of high anticorrosion and wearing resistance as well as vast application prospect to shell material of ships.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

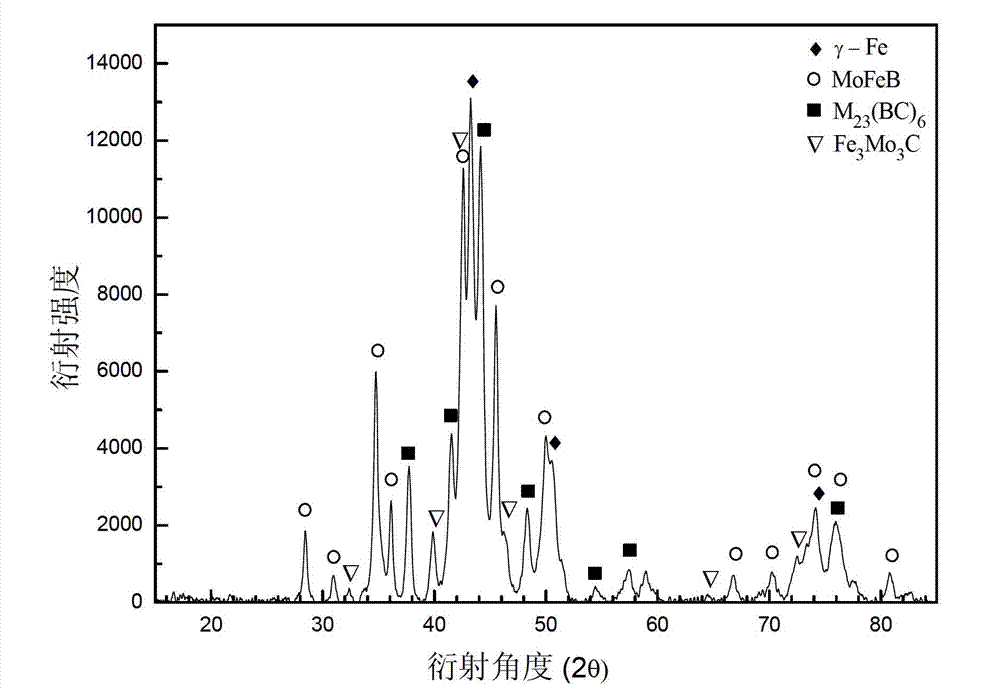

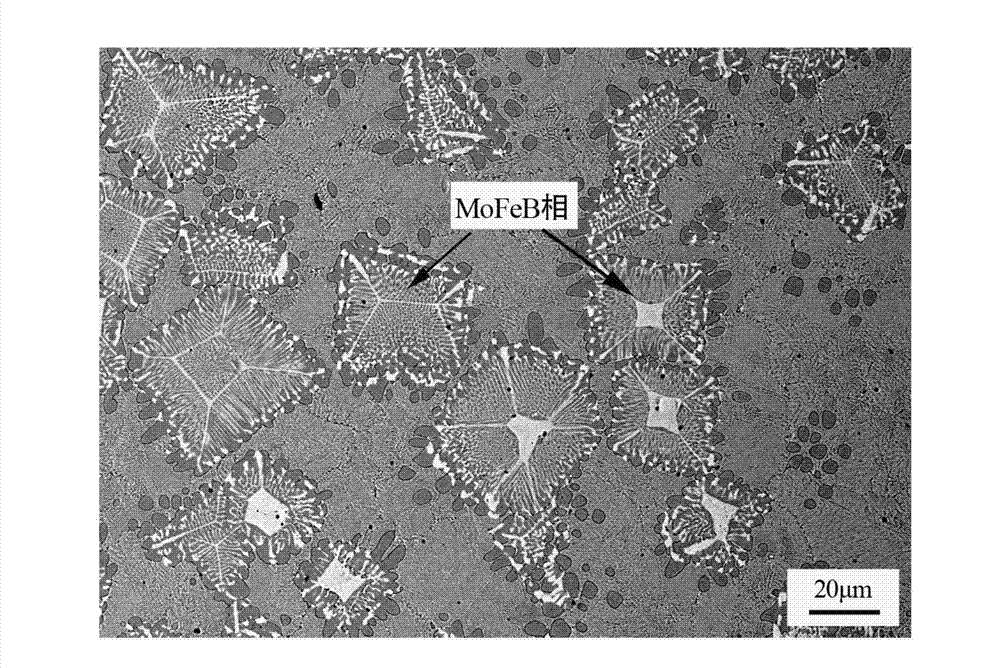

Alloy powder material for Fe-based nonmagnetic cladding layer and cladding layer preparing method

InactiveCN103042317AHigh hardnessImprove wear resistanceMolten spray coatingPlasma welding apparatusChromium carbideFerrosilicon

The invention discloses an alloy powder material for a Fe-based nonmagnetic cladding layer and a cladding layer preparing method, and belongs to the field of surface coating. The alloy powder comprises reduction ferrous powder, electrolytic manganese powder, high carbon ferro-chrome, ferro-molybdenum, ferrosilicon, ferro-boron, chromium carbide and boron carbide, and comprises following elementary compositions: 5-20wt% of Cr, 15-30wt% of Mo, 1-4wt% of C, 0.5-3wt% of B, 0.1-1.5wt% of Si, 0-15wt% of Mn, and the balance Fe. The Fe-based multi-element alloy cladding layer is prepared by plasma arc overlaying technology. The prepared cladding layer is nonmagnetic, high in hardness, and less prone to cracking and generating other cladding defects.

Owner:BEIJING UNIV OF TECH

Age hardening austenitic stainless steel and preparation method thereof

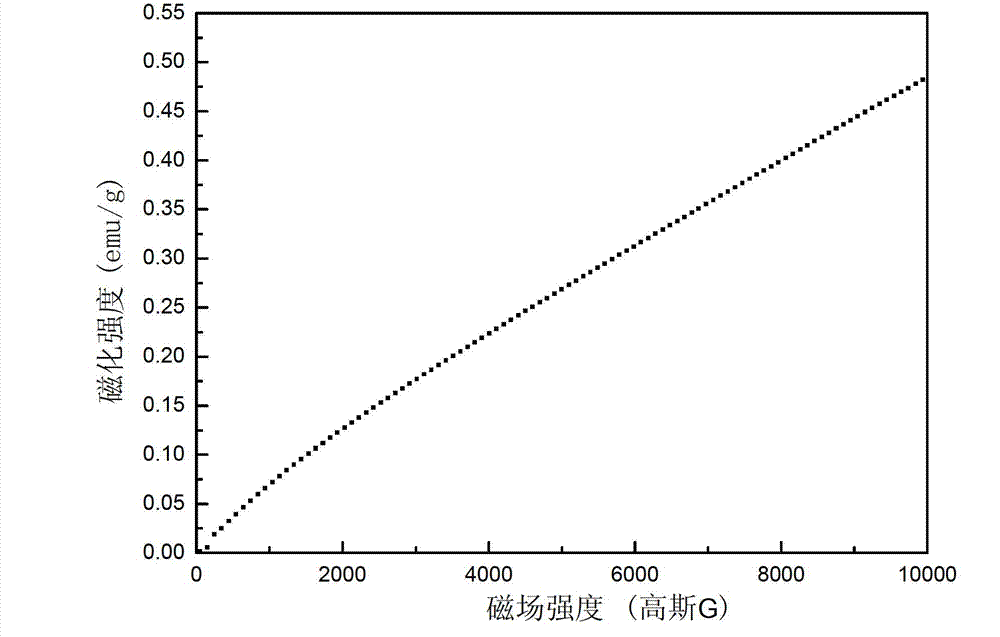

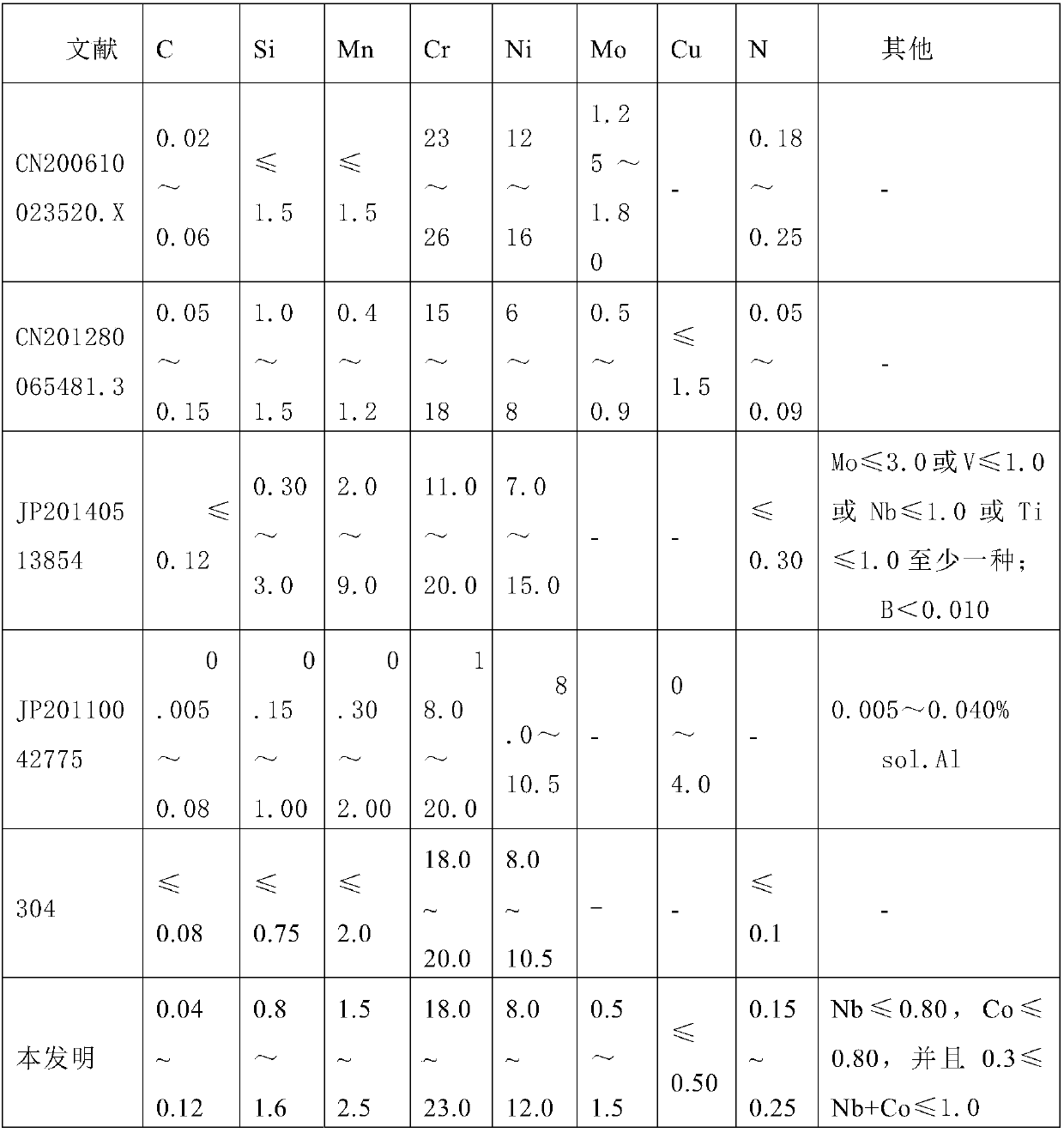

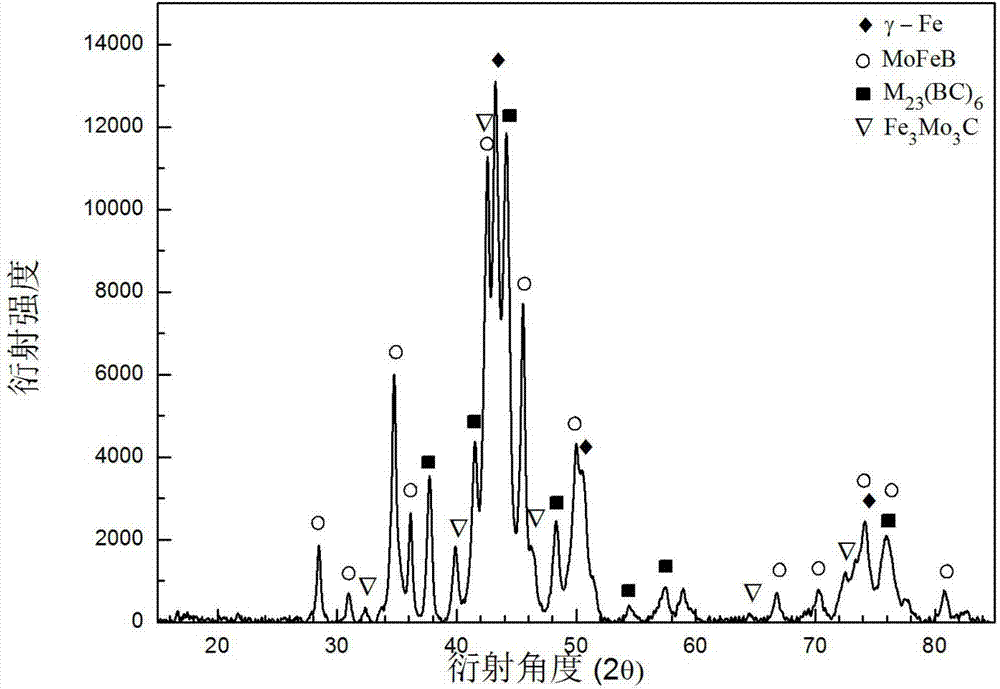

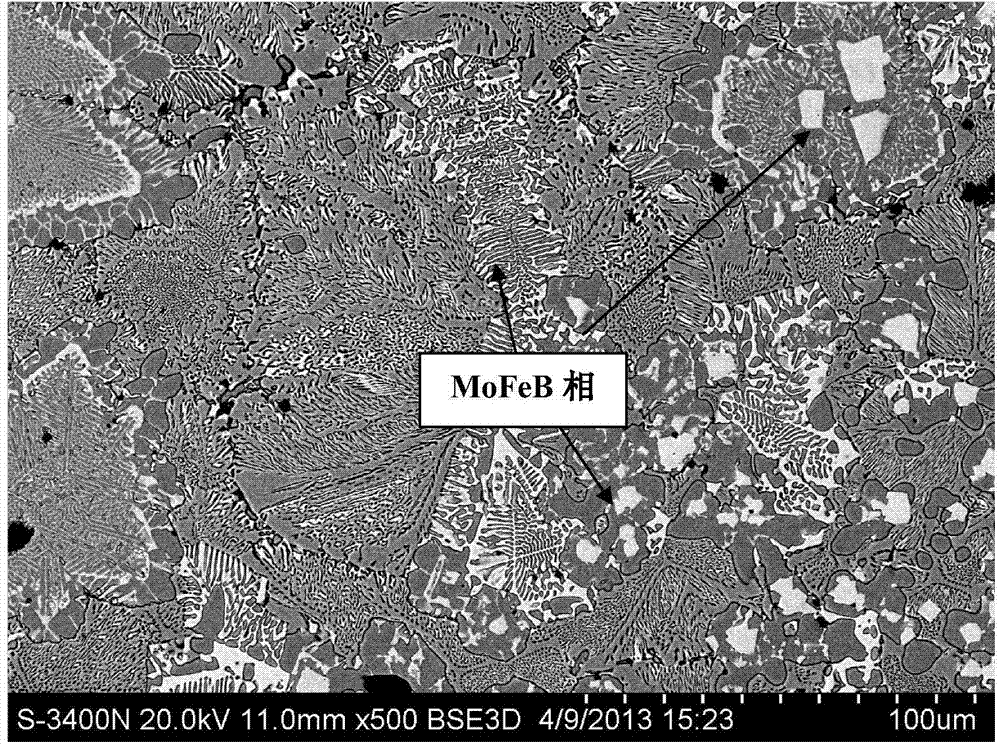

The invention discloses age hardening austenitic stainless steel. The stainless steel comprises the following components of, in percentage by weight, 0.04%-0.12% of carbon, 0.8%-1.6% of silicon, 1.5%-2.5% of manganese, 18.0%-23.0% of chrome, 8.0%-12.0% of nickel, 0.5%-1.5% of molybdenum, less than or equal to 0.50% of copper, 0.15%-0.25% of nitrogen, less than or equal to 0.80% of niobium, less than or equal to 0.80% of cobalt, larger than or equal to 0.3% and less than or equal to 1.0% of niobium and cobalt, and the balance iron and inevitable impurities. The invention further discloses a preparation method of the stainless steel. An austenitic stainless steel hard-state wire rod with high strength, no magnetism and good corrosion resistance is obtained through chemical component design and manufacturing process control, the method can be used for processing and manufacturing of wire rods such as high-performance stainless steel springs, the tensile strength of the wire rods reaches more than 1600 MPa, and the PREN value is larger than or equal to 23 or more.

Owner:宝武特种冶金有限公司

Glass fiber reinforced plastic lighting fixture shell and processing technology thereof

ActiveCN102675846ALong-lasting anti-aging propertiesHigh glossProtective devices for lightingCorrosionAluminium alloy

The invention relates to a glass fiber reinforced plastic lighting fixture shell, belonging to the technical field of outdoor lighting fixture processing. According to the processing technology disclosed by the invention, organic glass fiber reinforced plastic substitutes for aluminium, aluminium alloy or magnesium alloy material, wherein the organic glass fiber reinforced plastic comprises the following raw material components: unsaturated polyester resin, polyester gel coat resin, roving checked cloth, a chopped fiber felt, a surface mat, a curing agent, an accelerating agent, a demoulding agent and a thin film. The processing technology of the glass fiber reinforced plastic lighting fixture shell comprises the following steps of: automatically inspecting a construction site, carrying out pre-treatment on a mould, selecting a reinforcing material, cutting the reinforcing material, selecting a polyester resin glue solution, preparing the polyester resin glue solution, carrying out gel coat construction, pasting, solidifying, and carrying out product inspection, thus the glass fiber reinforced plastic lighting fixture shell is obtained. The glass fiber reinforced plastic lighting fixture shell product disclosed by the invention has the advantages of corrosion resistance, flame retardance, light weight, high strength, ageing resistance, strong designability, safety, skid resistance, excellent electrical property, no magnetic property and safety in use in anti-electromagnetic anti-knock environment.

Owner:SHANDONG YICHANG LIGHTING TECH

Powdered alloy material for Fe-based non-magnetic clad layer

The invention discloses a powdered alloy material for a Fe-based non-magnetic clad layer, and is applied to the surface coating field. The powder comprises reduced iron powder, electrolytic manganese powder, high-carbon ferro-chrome, ferromolybdenum, ferroboron, ferrotungsten, chromium carbide and boron carbide. The powdered alloy material comprises the following element contents: 6-18wt% of Cr, 5-10wt% of Mo, 2-5wt% of W, 0.5-2wt% of C, 0.5-3wt% of B, 0-15wt% of Mn and the balance of Fe. The powdered alloy material is subjected to a plasma arc surfacing process to prepare the Fe-based multi-element clad layer. The prepared clad layer is non-magnetic, has relatively high hardness, and is not likely to generate cracks or other cladding defects.

Owner:BEIJING UNIV OF TECH

Nickel-free black tin cobalt alloy plating solution and electroplating technology by using same

The invention relates to a nickel-free black tin cobalt alloy plating solution and an electroplating technology by using same. The parameters and contents of all components of the plating solution are as follows: the content of tin ions in a tin salt is 0.05-6g / L; the content of cobalt ions in a cobalt salt is 0.05-0.8g / L; the content of third metallic ions is 0.02-50g / L; the content of a complexing agent is 0.1-180g / L; the content of a blacking agent is 0.1-50g / L; the content of a PH buffer is 5-300g / L; the baume degree of the plating solution is 6-250; the temperature is 20-55 DEG C; and PH is 9-13. According to the technology provided by the invention, tin is taken as a main alloy layer and few cobalt and third and fourth metal ions are added in tin to form a ternary or quaternary alloy system; the cobalt content in the common black tin cobalt alloy plating solution excesses 8g / L, but the cobalt content is reduced to 0.05g / L according to the new electroplating technology provided by the invention; the special biodegradable or non-biodegradable stabilizing complexing agent and PH buffer are used, so that the production cost is lowered; and the nickel-free black tin cobalt alloy plating solution meets the limitation requirement on CO in the European Union Rosh standard, Germany LMBG standard, Mattel children toy standard, European Oeko-Tex Standard 100 standard and the like.

Owner:杜强

Inexpensive non-magnetic stainless steel and manufacturing method thereof

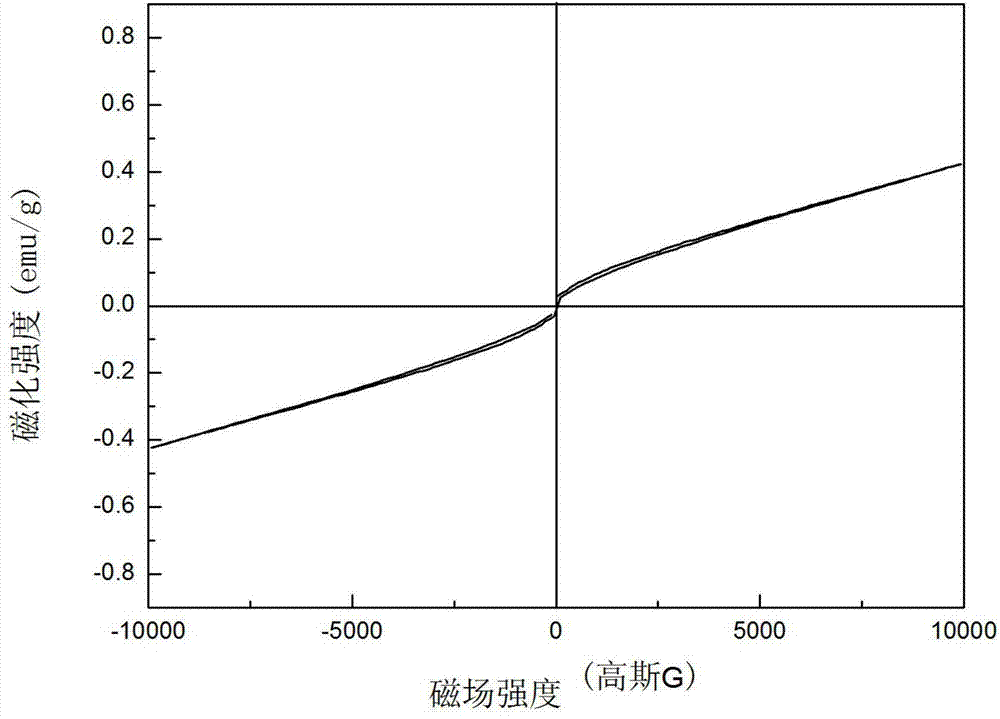

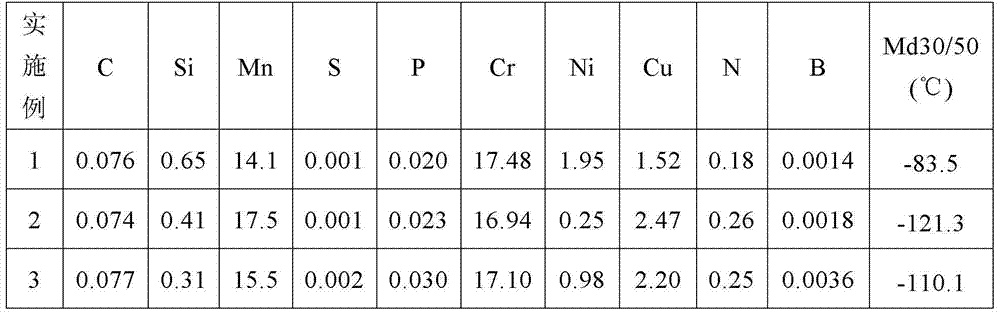

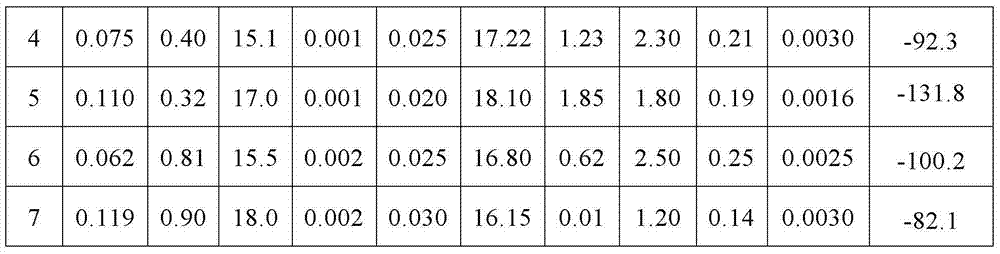

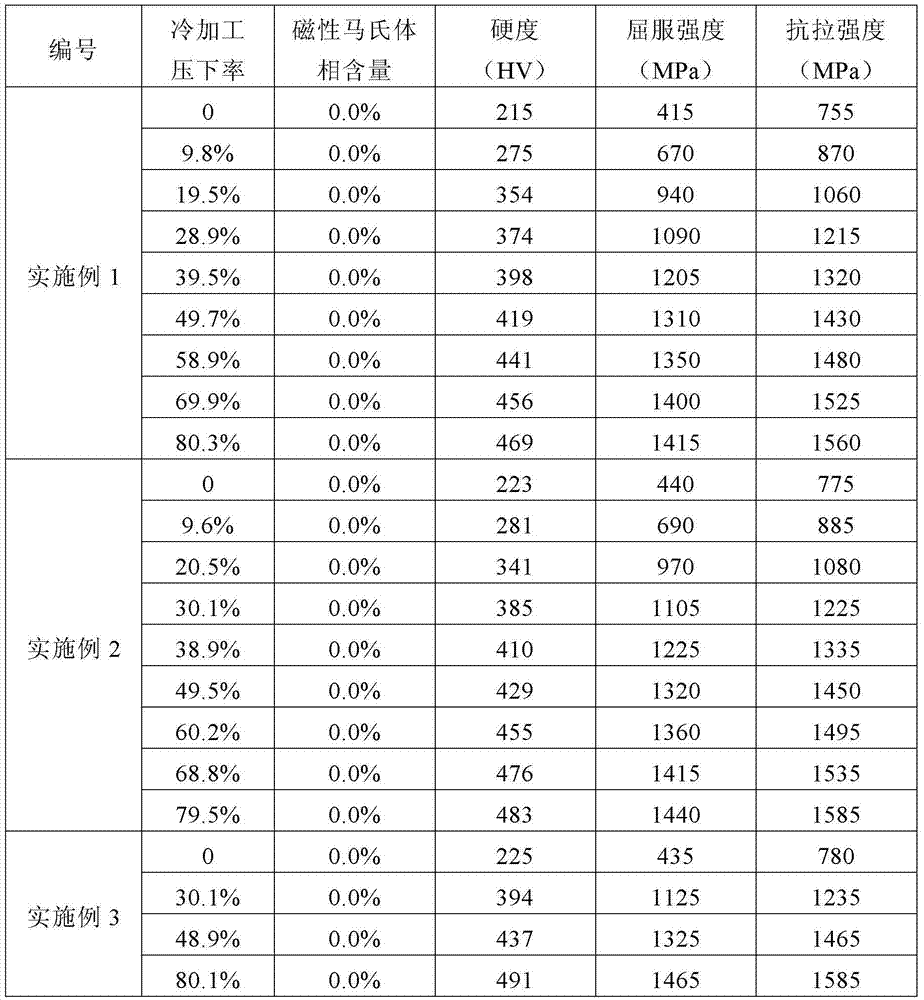

InactiveCN104513933AReasonable ingredient controlEase of mass productionElectrical devicesNon magnetic

The invention relates to an inexpensive non-magnetic austenite stainless steel and a manufacturing method thereof. The components comprise, by weight, 0.05-0.12% of C, 0.2-1.0% of Si, 14.0-18.0% of Mn, 16.0-19.0% of Cr, 0-2.0% of Ni, 1.0-3.0% of Cu, 0.1-0.3% of N, 0.001-0.004% of B, and the balance of Fe and unavoidable impurities. According to the present invention, the finished product can maintain the non-magnetic state after 80% of the finished product is subjected to cold rolling reduction; low nickel pig iron with a nickel content of 1-2 wt% and produced by using inexpensive laterite-nickel ore can be adopted as the nickel resource raw material without application of other nickel-containing resources, such that the consumption of the high nickel iron or pure nickel can be substantially saved, and the low cost characteristic is provided; and the inexpensive non-magnetic austenite stainless steel of the present invention has characteristics of no magnetism, high strength, and excellent cold processing performance, and can be widely used in the industries of electrical devices, electronics, instrumentations, springs, zippers and the like.

Owner:BAOSTEEL STAINLESS STEEL

Method for preparing tungsten-nickel hard alloy

InactiveCN101857926AImprove acid and alkali resistanceGood acid and alkali resistanceCemented carbideVacuum furnace

The invention discloses a method for preparing a tungsten-nickel hard alloy. The method comprises the following steps of: preparing the following raw materials in percentage by weight: 90 percent of WC powder, 9.6 percent of Ni powder and 0.4 percent of Cr3C2 powder; after performing ball-milling on the raw materials for 36 hours, cutting and precipitating for 24 hours; drying for 100 + / -5 minutes; controlling the temperature to be 85+ / -5 DEG C; blending glue by adding 10ml of the glue into per kilogram of mixed raw materials; doping a forming agent SBS by adding 0.1Kg of the forming agent SBS into per kilogram of the mixed raw materials; pressing and forming; sintering the mixed materials by using a vacuum furnace; controlling the temperature to be raised to 1,450 DEG C from 300 DEG C; cooling to normal temperature; and discharging a product out of the furnace. Due to the adoption of the method, a material has improved acid and alkali resistance but no magnetism and is suitable to be used for producing a movement axis of an acid-alkali flow instrument and the movement axis of an instrument and a meter needing avoiding magnetic interference.

Owner:厦门百克精密钨钢刀模有限公司

Titanium alloy for manufacturing tool and preparation method thereof

The invention discloses a titanium alloy for manufacturing a tool and a preparation method thereof. The titanium alloy for manufacturing a tool consists of the following components in percentage by weight: 76.6 percent of Ti, 3 percent of Al, 4 percent of V, 5 percent of Cr, 2 percent of Fe, 7 percent of Mo, 1 percent of W, 1 percent of Zr, 0.2 percent of O and 0.2 percent of Si. The preparation method of the titanium alloy comprises the following steps of: I, mixing; II, manufacturing an electrode; III, smelting in a vacuum furnace for three times; IV, cogging; and V, rolling. The titanium alloy has the beneficial effects that the HRC (Rockwell Hardness) value of the tool produced by using the titanium alloy disclosed by the invention is over 55, and the titanium alloy is light and non-magnetic, is low in production cost, and has a wide market prospect; and the production benefit of an enterprise can be increased greatly.

Owner:陈国财

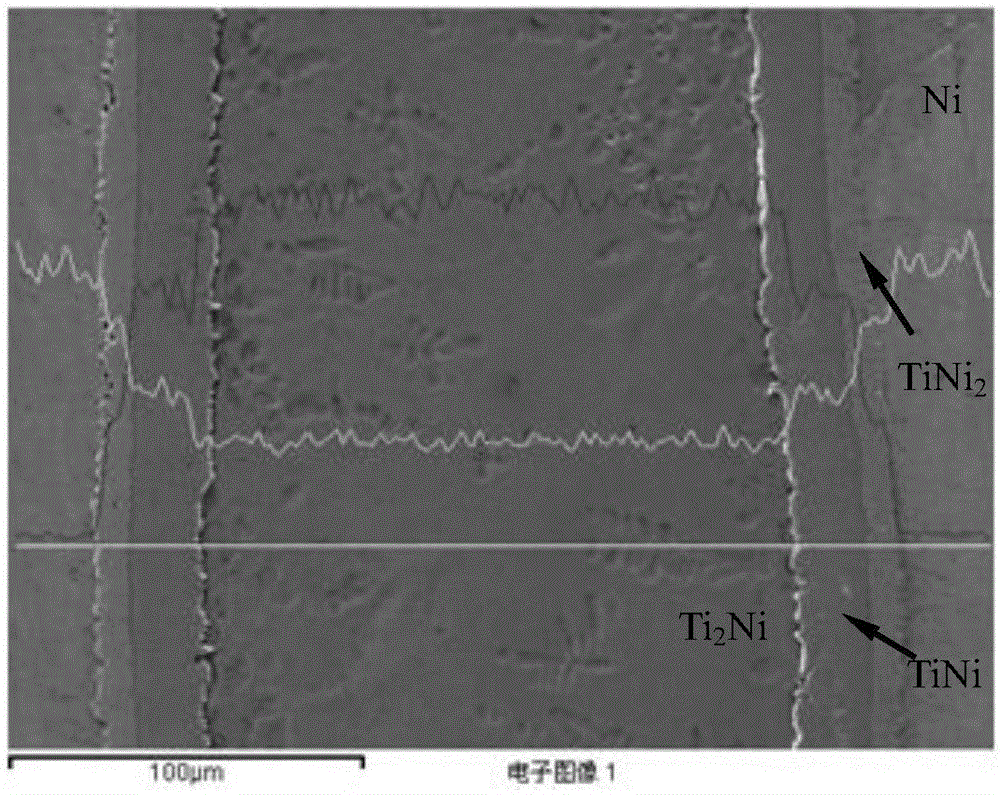

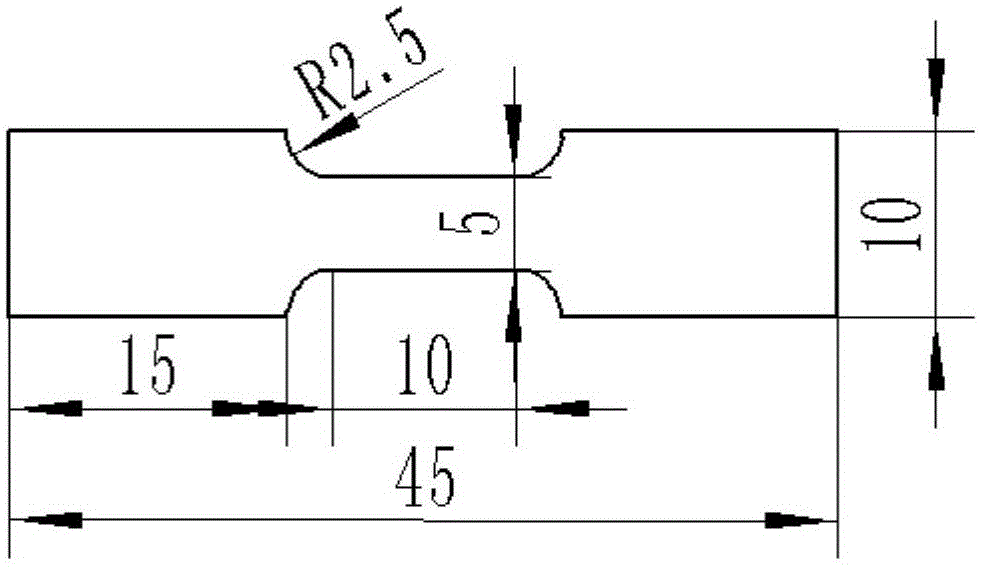

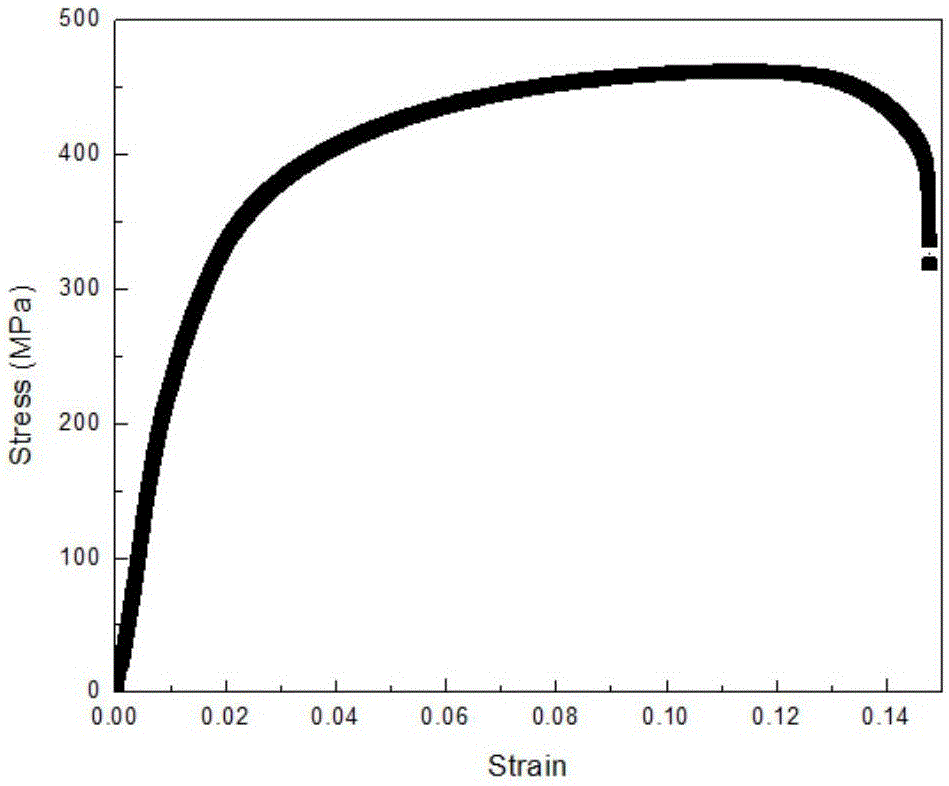

Layered Ti-Ni shape memory composite material and preparation method thereof

ActiveCN105058914AHigh specific strengthImprove toughness and plasticityMetal rolling arrangementsMetal layered productsBiocompatibility TestingTitanium

The invention discloses a layered Ti-Ni shape memory composite material and a preparation method thereof and belongs to the technical field of preparation of functional composite materials. Pure titanium and pure nickel are used as initial raw materials, a titanium plate and a nickel plate are subjected to surface pretreatment, accumulative composite rolling and diffusion annealing, controlled cooling is adopted, and the multi-phase and multi-layer structure shape memory composite material with a Ti layer serving as the outmost layer and a Ti-Ni layer and an Ni layer coated with the Ti layer is prepared. The shape memory composite material prepared with the method has the characteristics that the material is high in specific strength, good in plasticity and toughness, high in fatigue strength, high in interface bonding, excellent in conductivity, free of magnesium and toxicity, high in corrosion resistance, good in biocompatibility and the like. The preparation method has the advantages of simple process and convenience in operation.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

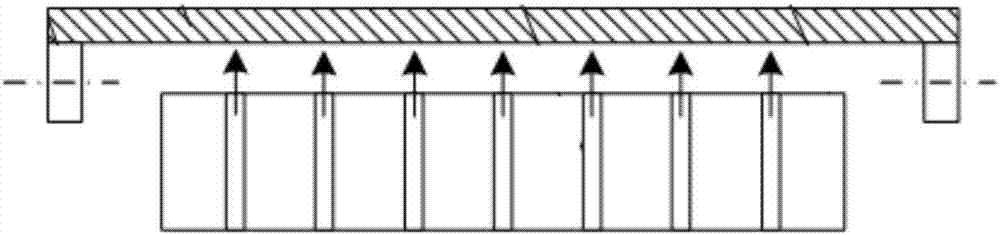

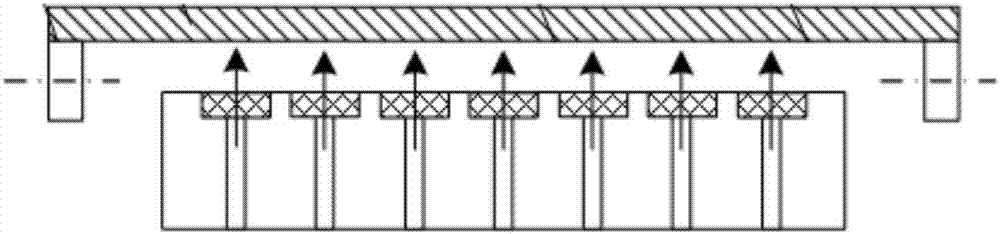

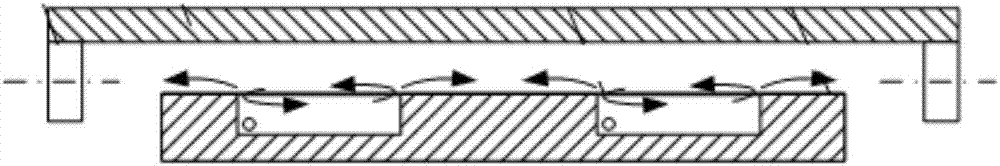

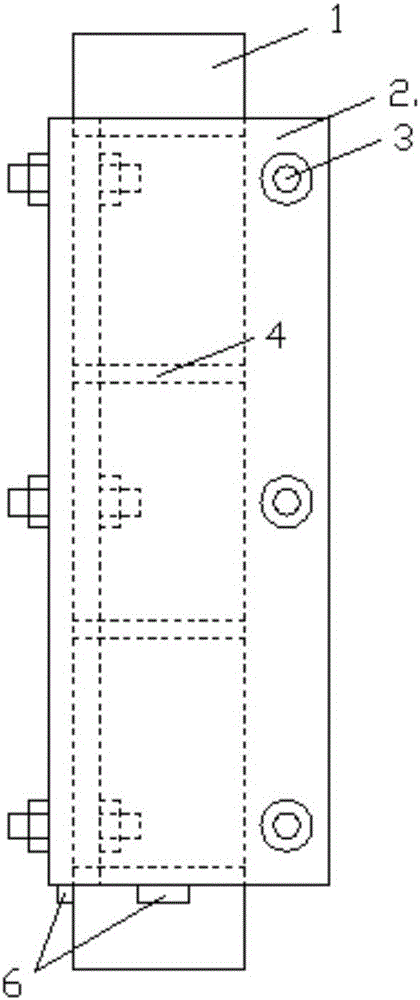

Glass substrate air flotation device with deformation detection function and detection method

ActiveCN106938785ANo pollution in the processNo feverConveyorsFluid pressure measurementEngineeringPressure reduction

The invention discloses a glass substrate air flotation device with a deformation detection function. The glass substrate air flotation device comprises a transporting platform, a fixed platform and a base. The fixed platform is connected with the base through supporting columns. Driving devices used for driving a glass substrate to move are arranged on the two sides of the transporting platform. The transporting platform is provided with a plurality of conveying air holes arranged evenly. A sintered metal porous material is embedded in the top end of each conveying air hole. The bottom of each conveying air hole is connected with an air conveying pipe. The air conveying pipes are connected with a pressure reduction valve through a flowmeter. The pressure reduction valve is connected with an air source through a hose. At least two small holes are formed in the periphery of each conveying air hole of the transporting platform, the bottom of each small hole is connected with a pressure sensor through an air pipe, and the pressure sensors and the signal output end of the flowmeter are connected with an input conversion module. The glass substrate air flotation device with the deformation detection function has the advantages of being clean, free of pollution, heating and magnetism generation and the like, and a pneumatic system is easy to maintain and simple in structure.

Owner:JIANGSU UNIV OF SCI & TECH

Economical austenitic stainless steel and technique for producing the same

The invention relates to an economic austenite stainless steel and a production technique thereof. The economic austenite stainless steel comprises the following compositions by weight percent: equal to or less than 0.10 of C, 12.50 to 15.0 of Cr, 12.00 to 15.00 of Mn, 0.50 to 1.50 of Ni, 0.40 to 0.80 of Cu, 0.08 to 0.16 of N, 0.40 to 0.80 of Si, less than or equal to 0.035 of P, less than or equal to 0.020 of S, 0.08 to 0.18 of Re, and the balance of Fe and unavoidable impurities. The invention takes the condition of general atmosphere corrosion resistance into consideration in the composition design, also considers lowest cost principle and further considers that the invention is beneficial to improving forging, rolling and heat processing performances and cold processing performance, is economical and practical and has no magnetic property.

Owner:NANJING IRON & STEEL CO LTD

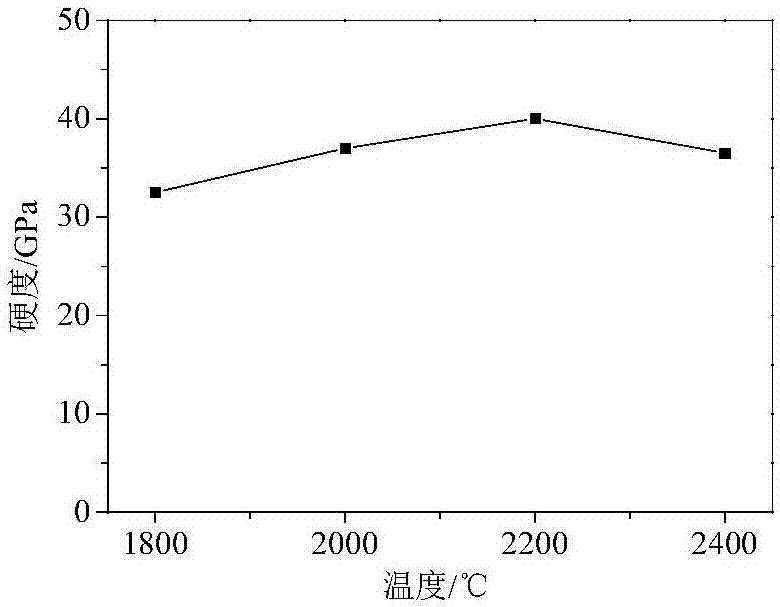

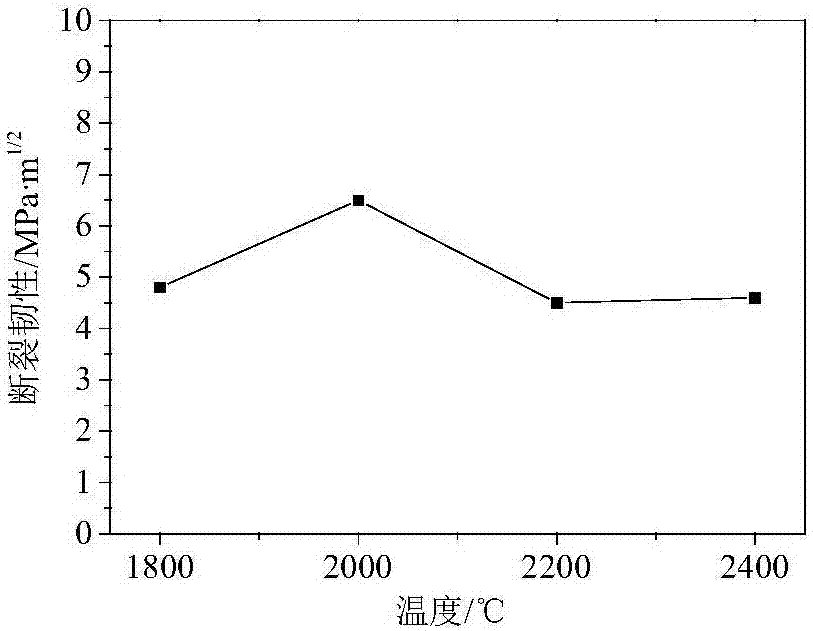

Polycrystalline cubic boron nitride, preparation method and application of polycrystalline cubic boron nitride and cutter which comprises polycrystalline cubic boron nitride

The invention relates to the field of superhard materials, and specifically provides a polycrystalline cubic boron nitride, a preparation method and application of the polycrystalline cubic boron nitride and a cutter which comprises the polycrystalline cubic boron nitride. The polycrystalline cubic boron nitride is mainly prepared from, in parts by volume, 55-65 parts of cubic boron nitride, 30-38parts of carbide of transition metal and 5-7 parts of metal powder, wherein the transition metal is at least one element of the subgroups of 4 or 5 or 6 in the periodic table, and the metal powder includes at least one of Al or Si or Ti. The polycrystalline cubic boron nitride is mainly prepared from the cubic boron nitride, carbide of the transition metal and metal powder according to specific volume fractions, and through scientific cooperation of the raw materials, the polycrystalline cubic boron nitride has the advantages of high hardness and good wear resistance.

Owner:FUNIK ULTRAHARD MATERIAL

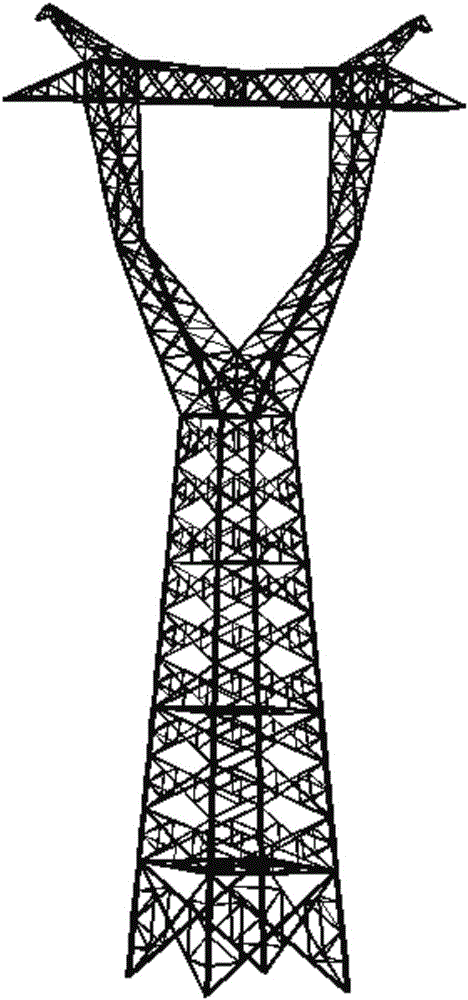

Reinforcement device for preventing flexural-torsional buckling of angle steel for iron towers

Owner:SHANDONG UNIV

Preparation method of sintered NdFeB magnet with high coercivity

InactiveCN108389711ALow melting pointReduce magnetismInductances/transformers/magnets manufactureMagnetic materialsRare earthPermeation

The invention discloses a preparation method of a sintered NdFeB magnet with high coercivity. The sintered NdFeB magnet is prepared by taking NdFeB alloy with a positive ratio being 2:14:1 as main alloy and taking rare-earth dysprosium / terbium-copper / aluminum / nickel alloy as auxiliary alloy and by a dual-alloy method, wherein the rare-earth dysprosium / terbium-copper / aluminum / nickel alloy is a liquid-phase sintering additive, is also a grain boundary phase and has favorable wettability with the main phase having the positive ratio being 2:14:1, the rare-earth dysprosium / terbium-copper / aluminum / nickel alloy used as the grain boundary phase is uniformly distributed at a grain boundary of the main phase having the positive ratio being 2:14:1, on one hand, an exchange coupling effect among crystal grains of the main phase is effectively prevented; and on the other hand, Dy / Tb permeations occurs around the crystal grains, the coercivity can be improved, and meanwhile, the residual magnetismand the magnetic energy product are not remarkably reduced.

Owner:NINGBO ZHAOBAO MAGNET

Nickel-titanium system shape memory alloy

The invention discloses nickel-titanium system shape memory alloy. The nickel-titanium system shape memory alloy is formed by compounding six metal elements of nickel, titanium, copper, chromium, manganese and cadmium. The nickel-titanium system shape memory alloy comprises, by weight, 60.3%-64.9% of nickel, 21.4%-22.5% of titanium, 7.4%-8.3% of copper, 2.8%-3.7% of chromium, 1.9%-2.7% of manganese and 1.6%-2.5% of cadmium. The nickel-titanium system shape memory alloy is composed of the six metal elements of nickel, titanium, copper, chromium, manganese and cadmium and has the advantages that the memory resilence function is achieved, magnetism does not exist, abrasion, corrosion and high temperature are resisted, and toxicity does not exist.

Owner:ZHANGJIAGANG JIASHENG MACHINERY

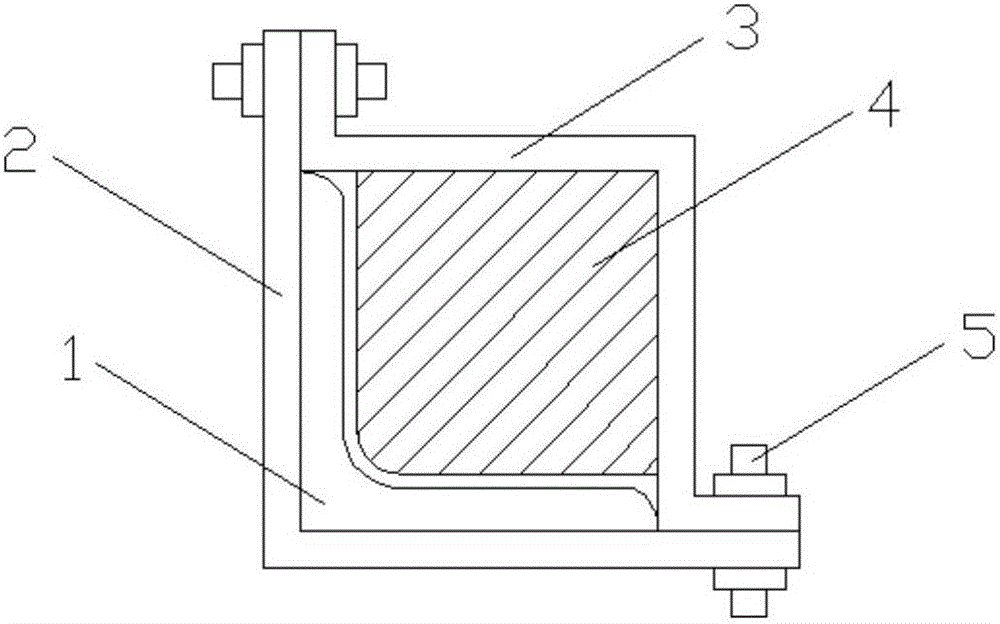

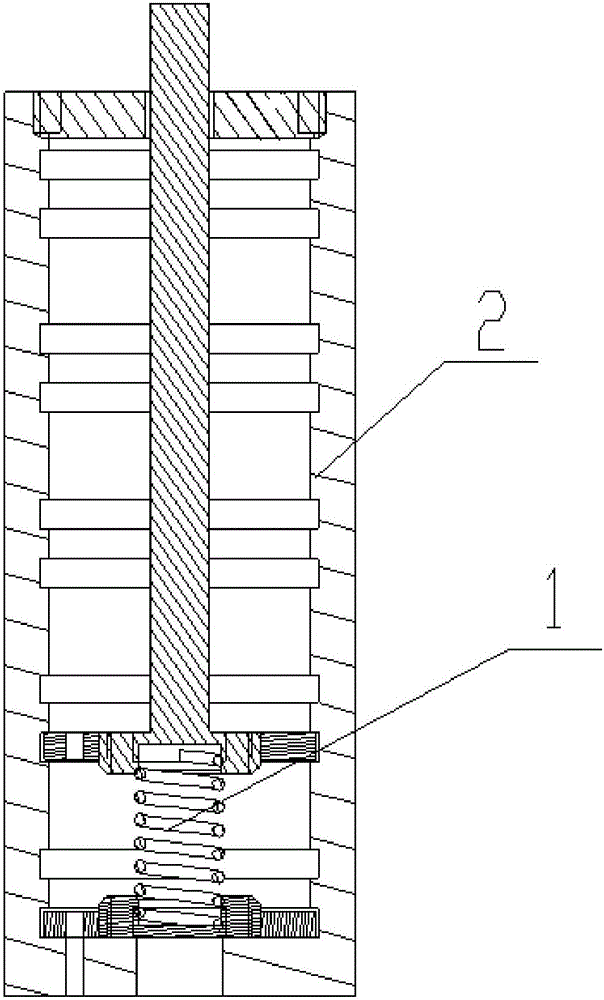

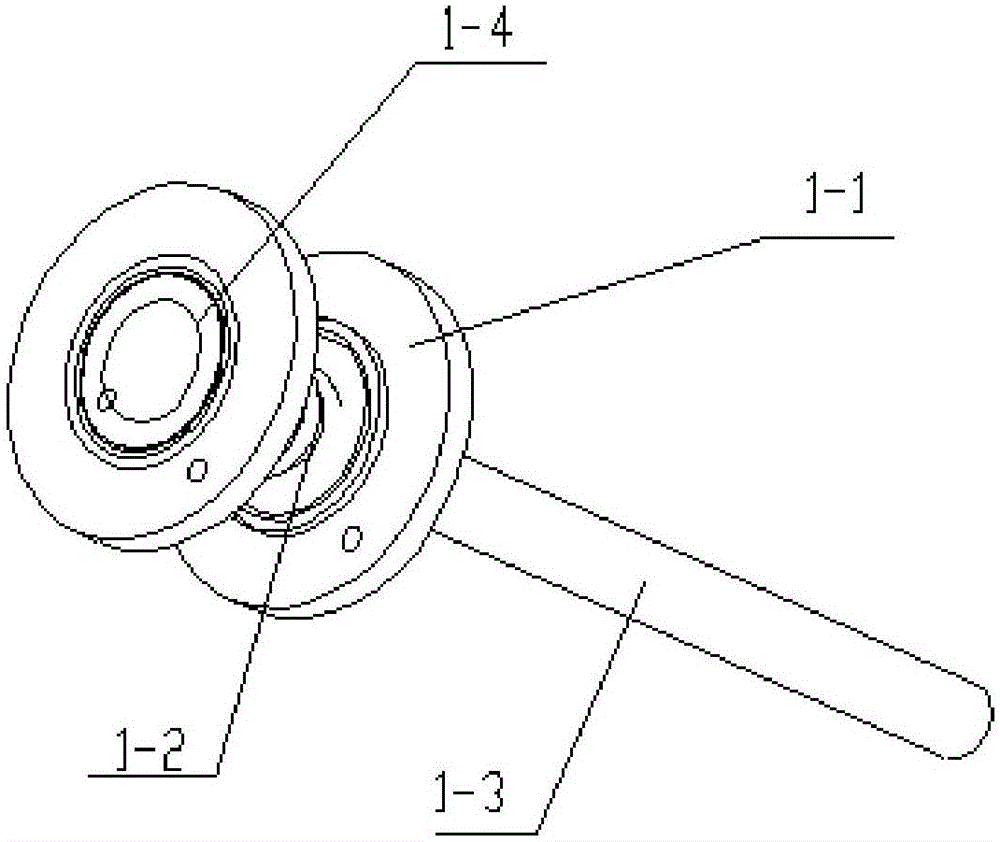

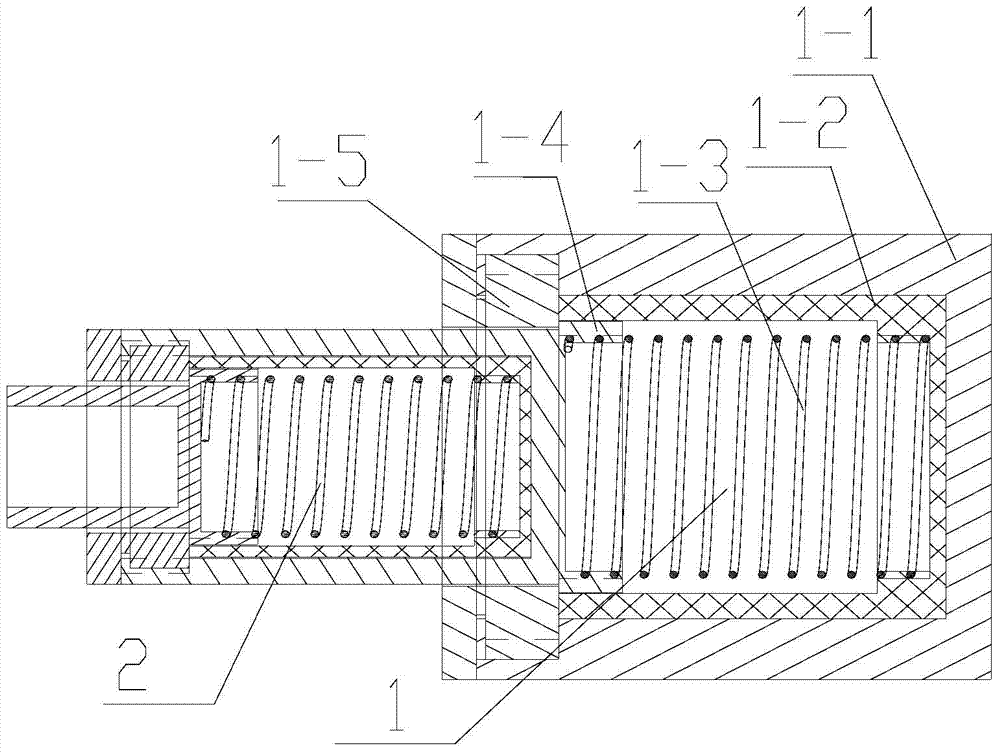

Shape memory alloy driving actuator and driving method thereof

ActiveCN106438244AGreat driving forceLarge displacementMachines/enginesMechanical power devicesTime sequenceReciprocating motion

The invention discloses a shape memory alloy driving actuator and a driving method thereof, and belongs to the technical field of actuators. The shape memory alloy driving actuator comprises a driving unit and a shell. The driving unit comprises two shape memory alloy rings, a shape memory alloy spring and a pin shaft. The two ends of the shape memory alloy spring are connected with the first shape memory alloy ring and the second shape memory alloy ring correspondingly, and the first shape memory alloy ring is connected with the pin shaft. The shape memory alloy rings and the shape memory alloy spring are each made of a dual-stroke shape memory alloy material. A plurality of grooves are evenly formed in the side wall of an inner cavity of the shell in the axial direction. According to the shape memory alloy driving actuator, timing sequence motion of the driving unit cooperates with locating of the grooves in the shell to drive the pin shaft to achieve telescopic motion. The shape memory alloy driving actuator has the beneficial effects of being large in driving force, large and controllable in displacement, simple in structure, capable of achieving reciprocating motion, low in cost, free of noise and magnetism, convenient to mount and the like and can be widely applied to electromechanical systems.

Owner:湖北三江航天红林探控有限公司

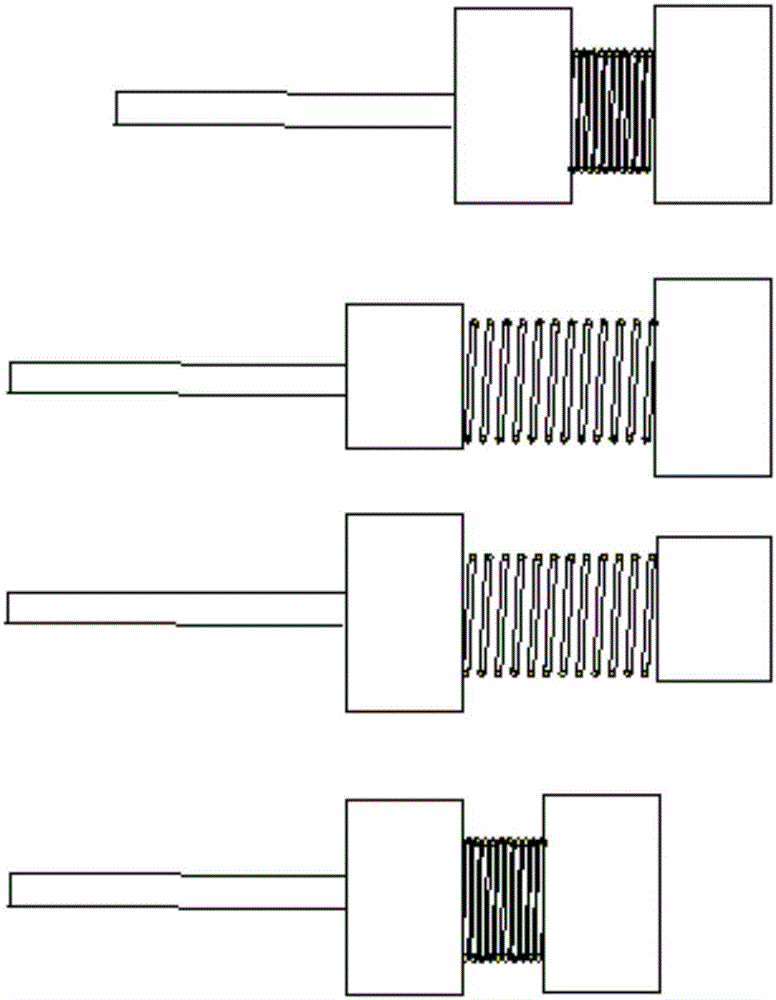

Telescoping actuator

The invention discloses a telescoping actuator which is formed by orderly connecting multiple actuating units in series. Each actuating unit contains a housing, a heat-insulated sleeve, a spring, a push rod and a cover, wherein the housing is a cylinder with one end having an inner bore; the heat-insulated sleeve is arranged in the inner bore of the housing; the spring is a shape memory alloy spring and is arranged in the heat-insulated sleeve; the push rod is a ladder-like cylinder formed by a large cylinder and a small cylinder; the large cylinder extends into the sleeve to connect the spring; the small cylinder has an inner bore used as a housing of the next actuating unit; and the cover is used for sealing the end of the housing. Actuating displacement of the actuator is the sum of each actuating unit's actuating displacement, and response time of the actuator is the slowest response time among the actuating units. The actuator provided by the invention has advantages of large actuating displacement, fast response time, large driving force, simple structure, repeated use and high reliability.

Owner:湖北三江航天红林探控有限公司

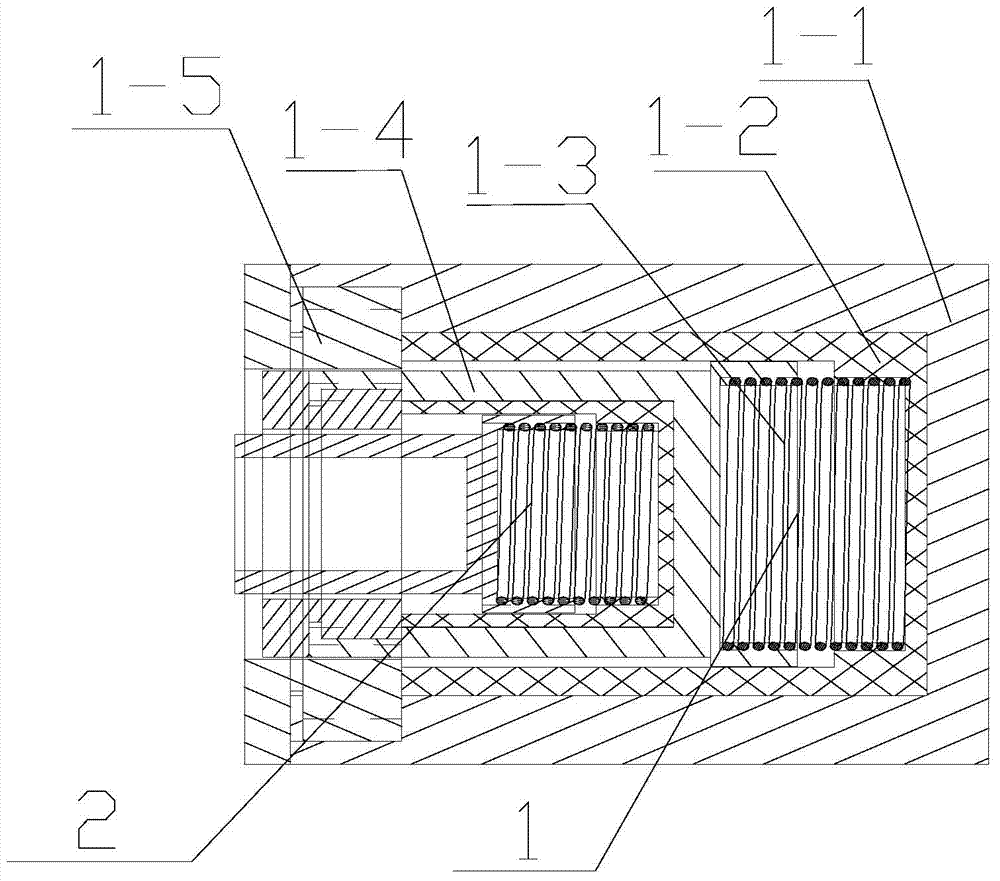

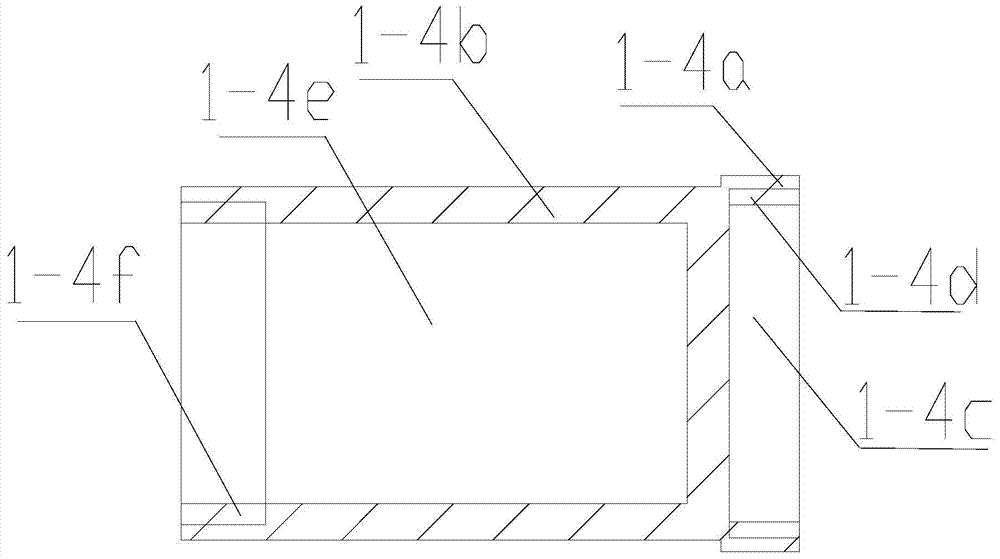

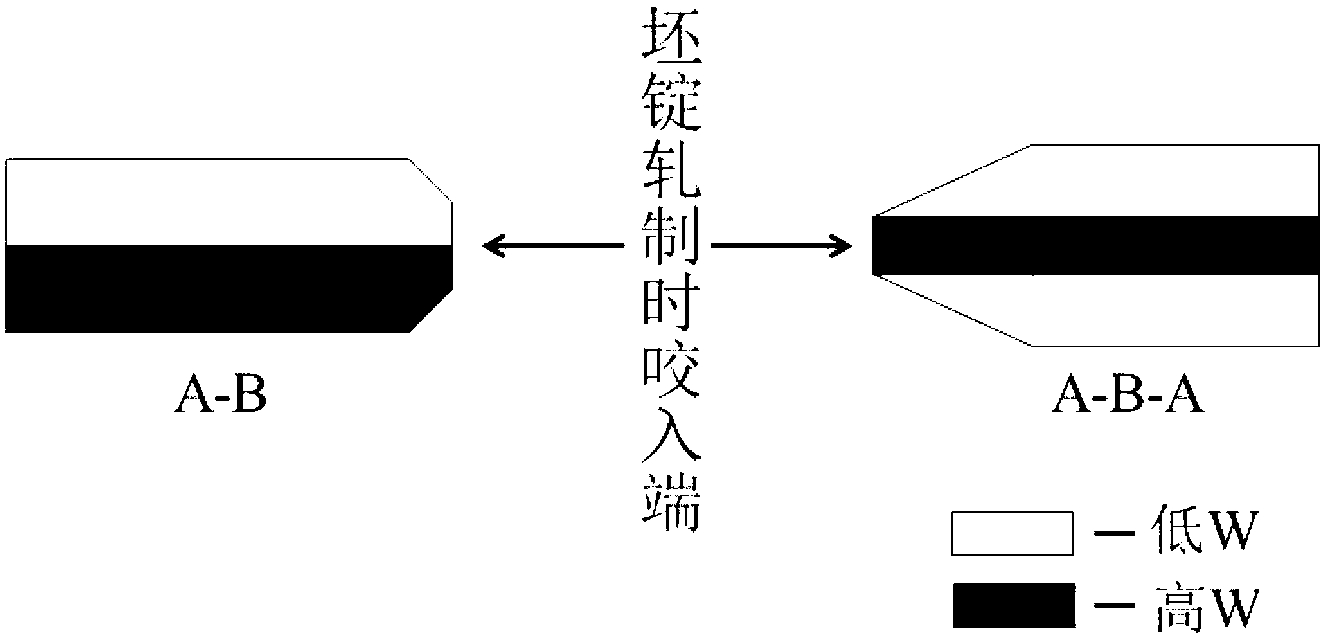

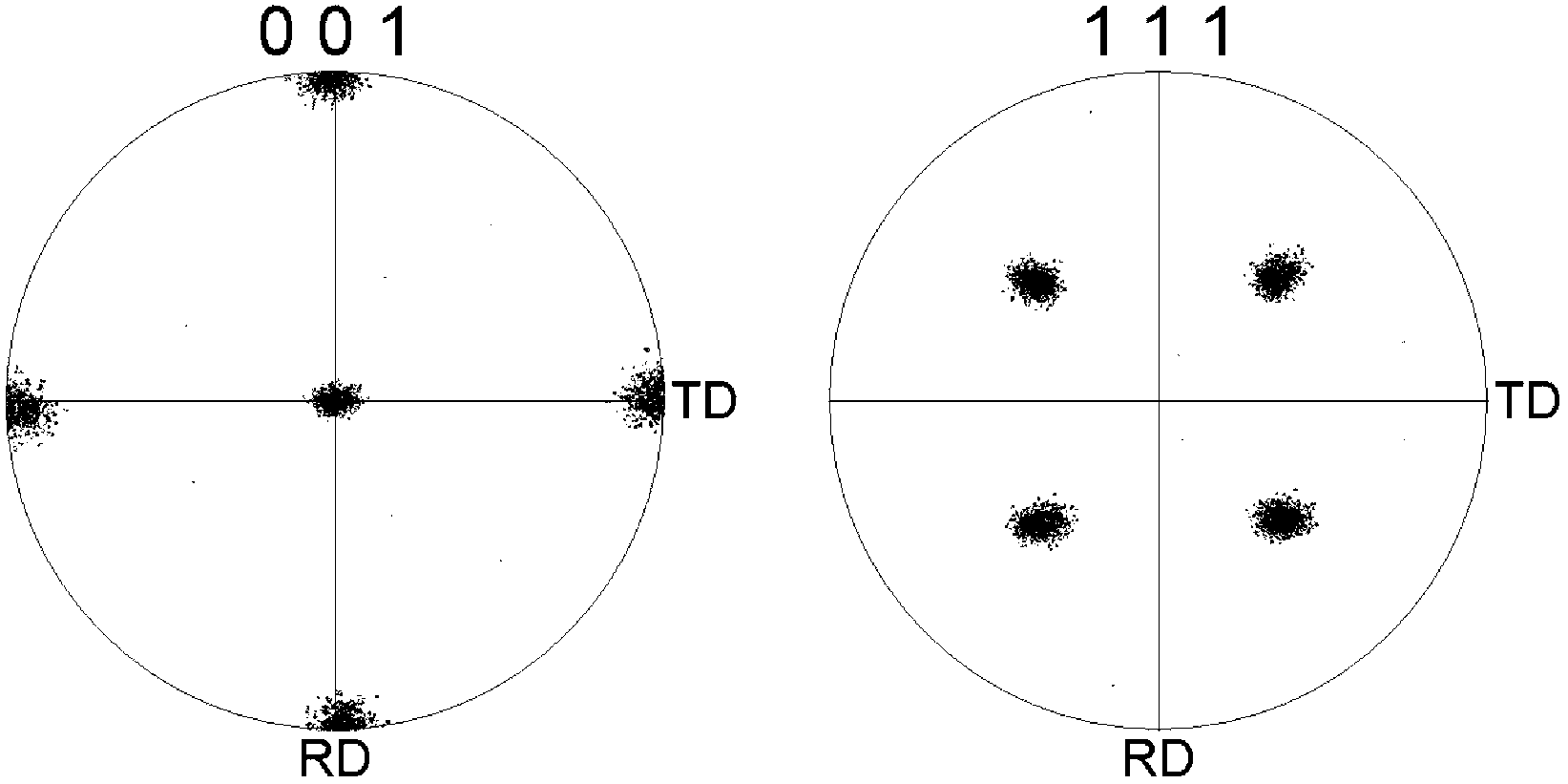

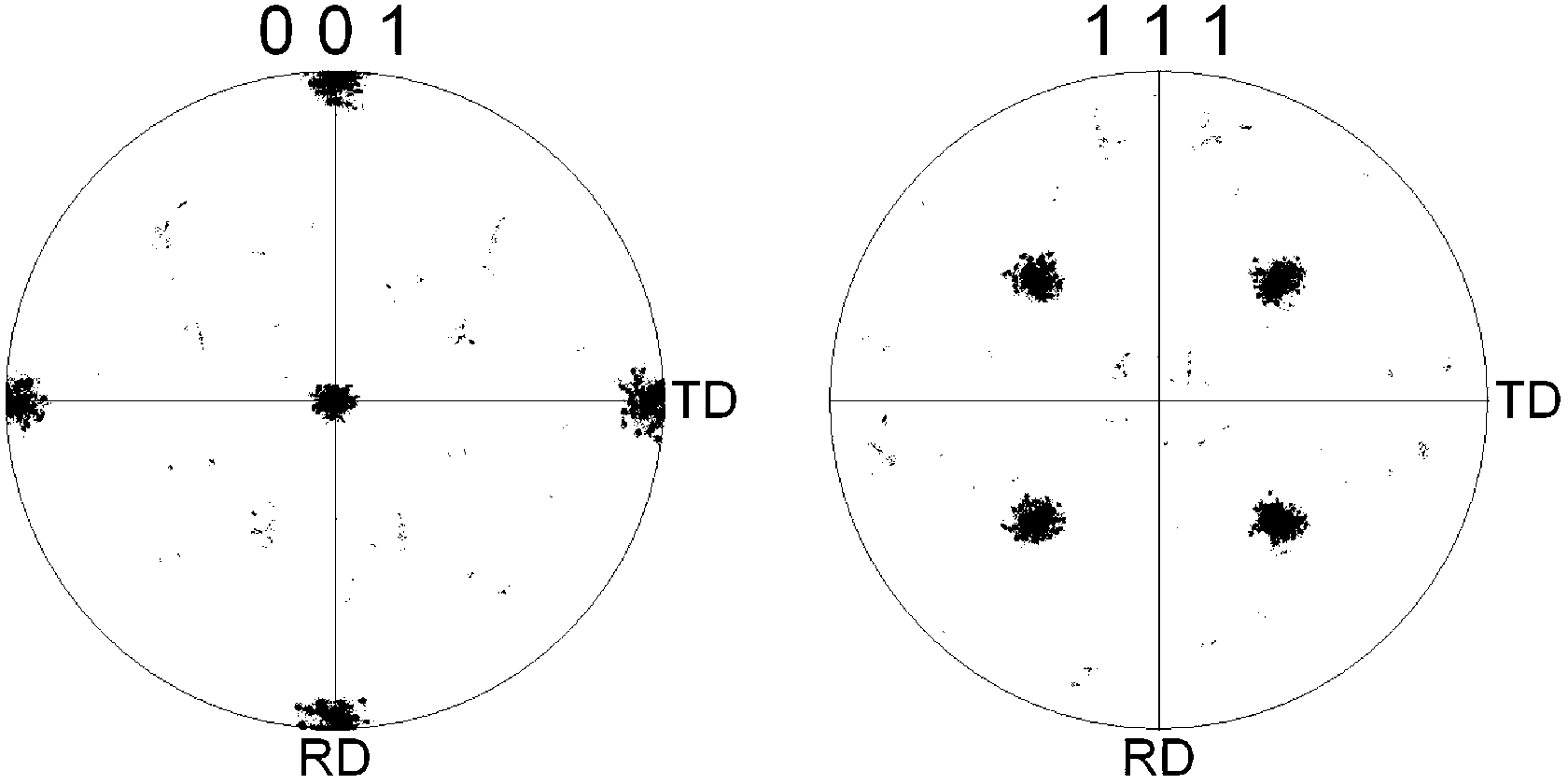

Method for preparing strong-cube-texture low-magnetism compound Ni-W alloy base bands

ActiveCN103236321AHigh strengthImproved cubic texture contentSuperconductors/hyperconductorsSuperconductor devicesUltimate tensile strengthHot Temperature

The invention discloses a method for preparing strong-cube-texture low-magnetism compound Ni-W alloy base bands and belongs to the technical field of high-temperature coated superconductive base bands. Raw materials including nickel blocks and tungsten blocks with purity larger than 99.9% are utilized, billets of Ni-W alloy are prepared by vacuum induction melting, initial compound billets are obtained via hot forging and hot pack rolling, and compound tungsten alloy base bands with strong cube textures on surfaces, no magnetism in core layer and high strength are obtained finally after recrystallization annealing. Via a special method for preparing the compound billets, the compound tungsten alloy base bands with high performance are obtained, and the prepared compound tungsten alloy base bands have the advantages of high cube texture content, low magnetism, high strength and the like, and the method is easy for large-scale industrial production.

Owner:深创超导(深圳)科技有限公司

High-strength and high-conductivity copper alloy for power switch spring contact and preparation method of high-strength and high-conductivity copper alloy

ActiveCN103352137AGood mechanical and electrical propertiesImprove electrical performanceElectric fieldHigh conductivity

The invention relates to a CuCrZrTi alloy and a preparation method thereof, and aims at providing a novel high-strength and high-conductivity copper alloy material capable of replacing CuCo2Be and a preparation method of the novel copper alloy material. The alloy comprises the following metals by weight percentage: 0.5-1.2% of Cr, 0.03-0.3% of Zr, 0-0.1% of Ti and the balance of Cu and unavoidable impurities. The raw materials are subjected to vacuum melting, alloying, cast ingot casting, hot extrusion, cold processing, intermediate annealing, vacuum aging heat treatment and machining to form the alloy. The prepared copper alloy has good electrical and mechanical properties, is non-magnetic, resists low temperature, is free from sparks during impact, can replace the CuCo2Be material, and avoids environmental pollution during manufacturing of a toxic element Be and operation of an electric field, and since the prepared copper alloy has the better electrical properties, the commercial application and popularization of the spring contact are more competitive.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

High-wear-resisting high-chromium alloy material

The invention discloses a high-wear-resisting high-chromium alloy material. The high-wear-resisting high-chromium alloy material comprises the following main components in percentage by mass: 3.0%-3.3% of C, 31.0%-33.0% of Cr, 0.8%-1.0% of Mo, 0.6%-0.7% of B, 0.8%-1.0% of Cu, 0.6%-0.7% of Ni, 0.3%-0.5% of Al, 0.3%-0.4% of Ti and 0.6%-0.8% of Nb as well as the following secondary components in percentage by mass: 0.005%-0.008% of Mg, 0.01%-0.03% of Zn, less than or equal to 0.025% of S, less than or equal to 0.03% of P and the balance of Fe. According to the manner, the high-temperature resistance, corrosion resistance, wearing resistance and the like of the high-chromium alloy can be improved.

Owner:KUSN QIAORUI METAL PRODS

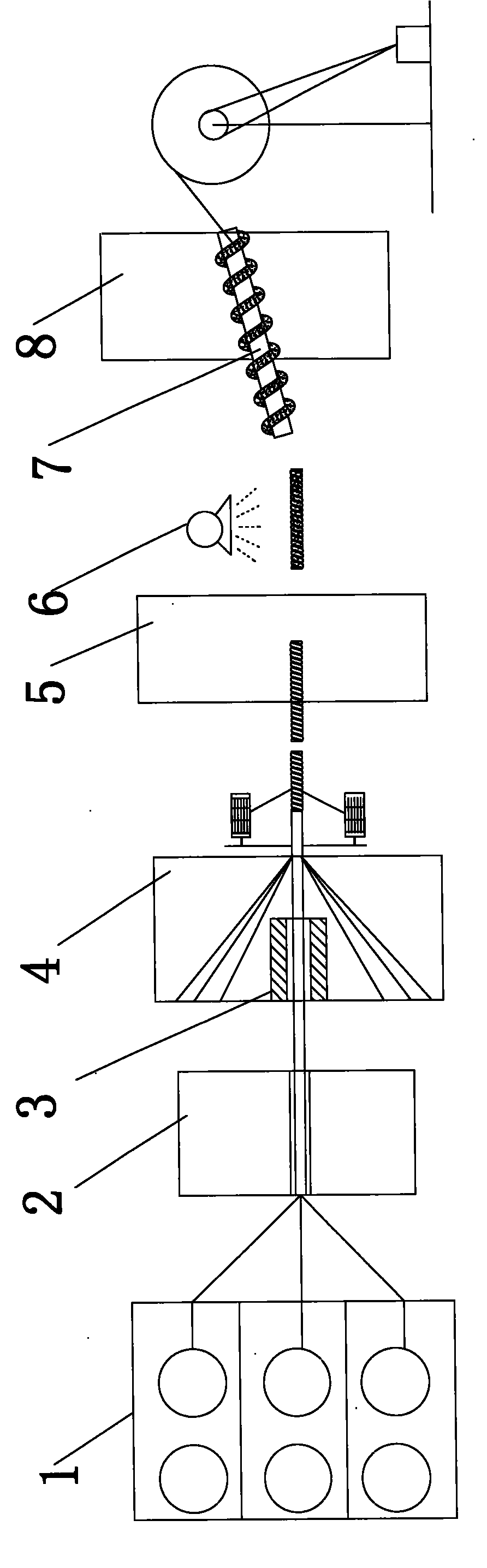

Method for manufacturing fiber reinforced resin based composite reinforcements

ActiveCN102935722AWith electrical insulationNon-magneticResin-Based CompositeUltimate tensile strength

The invention discloses a method for manufacturing fiber reinforced resin based composite reinforcements, which comprises the following steps of: putting fibers in an impregnation device to carry out impregnation treatment; winding the fibers treated by the impregnation device by using a spiral winding device; putting the fibers subjected to winding by the spiral winding device into a sand adding device so as to add sand on the fibers; putting the fibers treated by the sand adding device into a gelling device for gelling; putting the fibers subjected to gelling into a curing device for curing; and putting the fibers subjected to curing into a post-curing device for post-curing, thereby obtaining a fiber reinforced resin based composite reinforcement. The fiber reinforced resin based composite reinforcement manufactured by using the method disclosed by the invention has the characteristics of electrical insulation, non-magnetism, good bonding property with cement concrete, acid resistance, alkali resistance, corrosion resistance, light specific gravity, high strength, weld-free continuous reinforcement, and the like.

Owner:SICHUAN AEROSPACE WU YUAN COMPOSITE

Austenitic stainless steel

The invention relates to an austenite stainless steel comprising by weight Cr12%-14%, Mn 16%-18%, C 0.03%-0.15%, and N 0.15%-0.35%, the remainder are Fe and unavoidable foreign matters, which are Si, P, S and Ni, the allowable percentages by weight of which are Si<=1.0%, P<=0.035%, S<=0.03%, and Ni<=0.35%. The austenite stainless steel is of excellent cold and hot machining plasticity, good tensile property, is free from any magnetism after tensioning, and is of good resistance to corrosion and relatively cheap price.

Owner:宁波耀义新材料有限公司

Bionic flexible swing actuator

InactiveCN108288922AImprove flexibilityLarge swingPiezoelectric/electrostriction/magnetostriction machinesElectricityEngineering

The invention discloses a bionic flexible swing actuator and belongs to the technical field of bionic robots. The bionic flexible swing actuator comprises: a frame which is internally hollow; a dielectric elastomer which is pressed against both sides of the frame after being pre-stretched, wherein the portion of the dielectric elastomer in the hollow part of the frame is an active area, and the dielectric elastomer is formed by superposing multiple layers of single-layer dielectric elastic bodies; a flexible electrode which is coated on the left and right surfaces of each layer of dielectric elastic bodies in the active area; ribs located at the bottom ends of the frame to match the shape of the frame; a protective layer which is a flexible insulating waterproof film and used for wrappingthe entire mechanism; wires which are connected to the active area of each layer of dielectric elastic bodies. The bionic flexible swing actuator has the advantages of good flexibility, large swing amplitude, fast response time, simple structure, reusable use, low cost, no noise, no magnetism and convenient installation.

Owner:XIAOGAN RUICHUANG MACHINERY TECH CO LTD

Nickel-free ferrous tin-cobalt alloy plating solution and process for utilizing plating solution for electroplating

The invention relates to a nickel-free ferrous tin-cobalt alloy plating solution and a process for utilizing the plating solution for electroplating. The plating solution comprises the following compositions: 0.2 to 6 g / L of tin, 0.6 to 4 g / L of cobalt, 8 to 180 g / L of complexant, 2 to 20 g / L of melanizing agent and 50 to 320 g / L of pH buffer. The parameters of the plating solution are as follows: the Baume of the plating solution is between 10 and 25 baume degrees; the temperature is between 28 and 48 DEG C; and the pH is between 10 and 13. The coating of the nickel-free ferrous tin-cobalt alloy plating solution is an alloy layer taking the tin as a main material, and a small amount of cobalt is added into the coating to form a binary alloy system; the cobalt content in a general ferrous tin-cobalt alloy plating solution exceeds 8 g / L, but the novel electroplating process can reduce the cobalt content to 0.8 g / L; and due to adoption of the special biodegradable stable complexant and the special biodegradable pH buffer, the production cost can be reduced, novel EU standards can be reached simultaneously, and various problems of the prior ferrous tin-cobalt alloy plating solution and the prior process can be solved.

Owner:佛山市兴中达化工实业有限公司

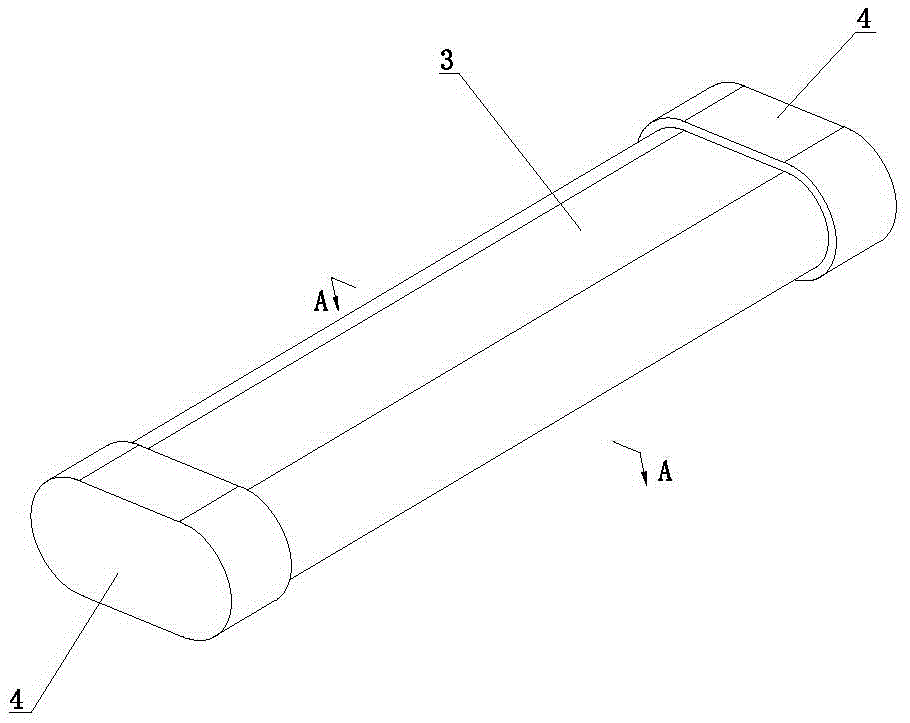

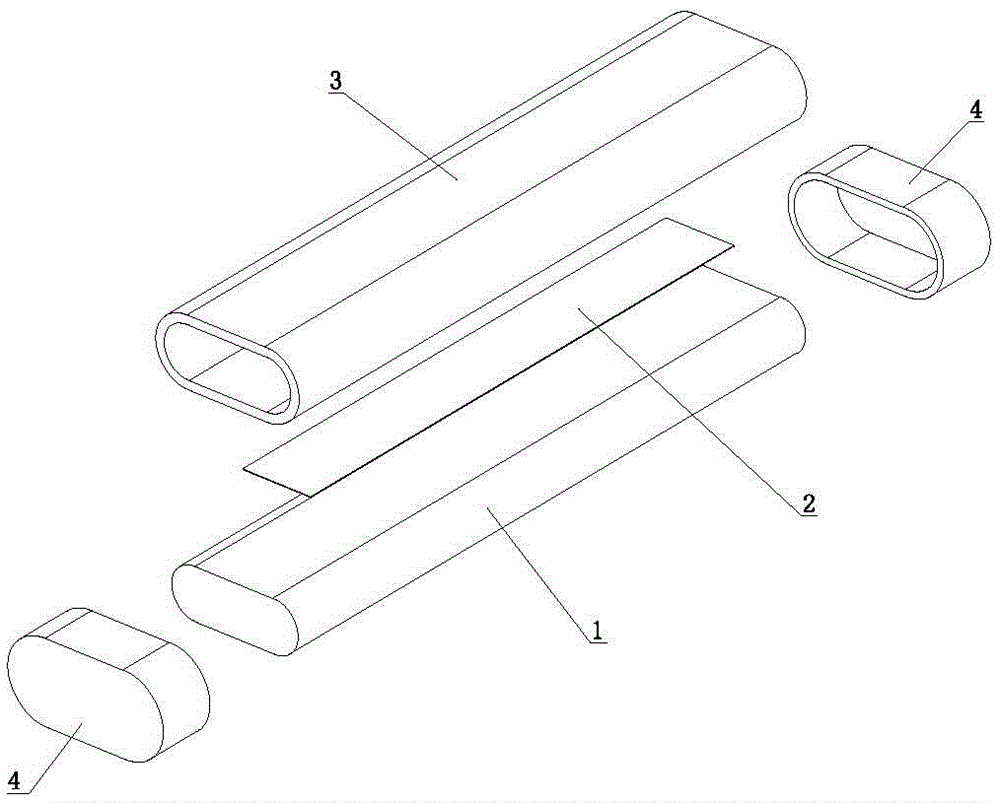

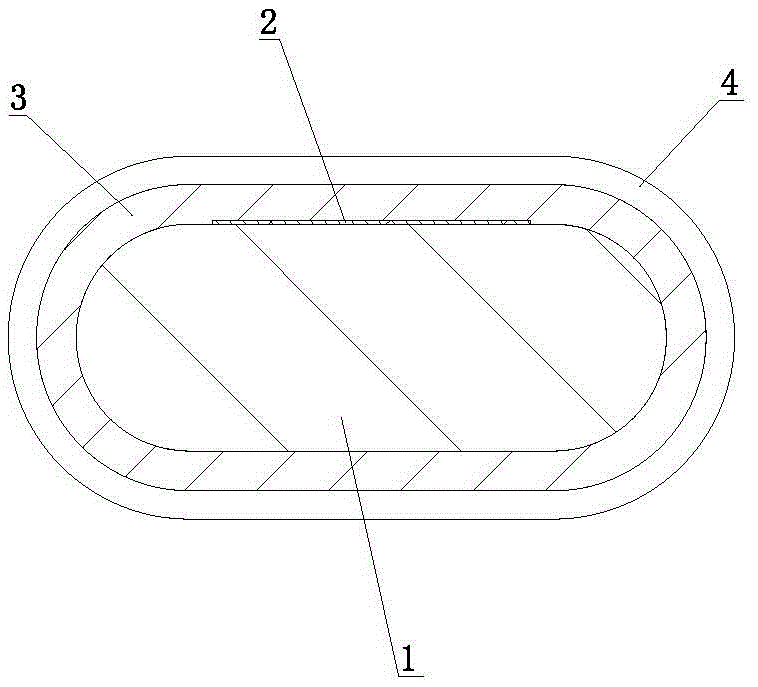

Composite flexible magnetic strip and preparation method thereof

InactiveCN105845309AImprove magnetismImprove corrosion resistancePermanent magnetsInductances/transformers/magnets manufactureEngineeringCorrosion

A composite flexible magnetic strip and a preparation method thereof, comprising a rubber magnetic body, a flexible elastic layer, and a soft head; the rubber magnetic body is used as a skeleton, and the periphery of the skeleton length direction is covered with a flexible elastic layer, and the flexible elastic layer and the rubber magnetic body They are tightly combined; at both ends of the rubber magnetic body, a head is provided, and the head is tightly combined with the flexible elastic layer to form a closed state; the thickness of the flexible elastic layer is between 0.03mm and 1mm. Due to the way of composite extrusion, the flexible elastic layer and the rubber magnetic body are closely combined in structure, there is no gap between them, and air will not enter to cause rust, and the two are difficult to peel off and delaminate. Both the flexible elastic layer and the flexible elastic layer have good flexibility, and will not be deformed or creasing. The two ends of the rubber magnetic body are provided with sealing heads that are tightly combined with the flexible elastic layer to completely cover the cross section, so that the rubber magnetic body is completely isolated from the external environment, and the rubber magnetic body is better protected.

Owner:安吉司润磁性材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com