Patents

Literature

94results about How to "Improve the compressive capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-seismic prefabricated concrete solid square pile and production method thereof

ActiveCN102383418AImprove the forceReduce peak tensile stressMouldsMould auxillary partsPre stressPrecast concrete

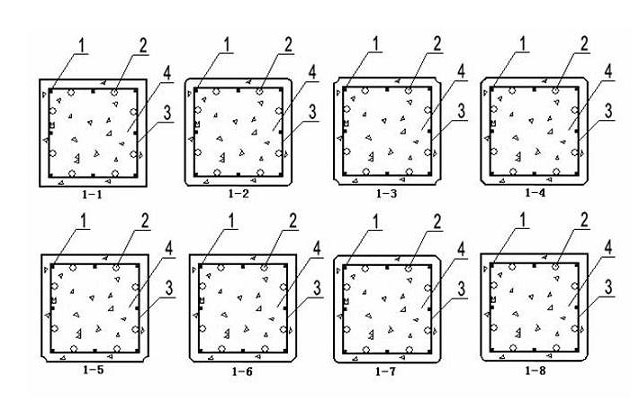

The invention discloses an anti-seismic prefabricated concrete solid square pile which comprises main reinforced bars, hoop reinforcements, anchoring bars, pile caps and concrete. A cross section main body of a pile body is square; the main reinforced bars are formed by sequentially permutating and combining prestress main reinforced bars and general main reinforced bars and penetrate through the pile body along the longitudinal direction of the pile body; the hoop reinforcements are arranged on the outer edges of the main reinforced bars and are spirally squared; the pile caps are respectively arranged at two ends of the pile body and consist of end plates and skirt edges; the main reinforced bars and the hoop reinforcements are connected by welding or binding to form a steel reinforcement cage; two ends of the prestress main reinforced bars are fixedly arranged on the end plate by riveting or using a bolt connecting mode; the general main reinforced bars are separated from the end plate and are shorter than the prestress main reinforced bars; and the anchoring bars are respectively arranged at two ends of the pile body. The anti-seismic prefabricated concrete solid square pile with the structure simultaneously has high press bearing capacity, tensile bearing capacity, shear bearing capacity and flexural bearing capacity and is a concrete solid square pile suitable for industrial mechanical production and is used for high seismic fortification intensity.

Owner:连云港固全新型建材有限公司

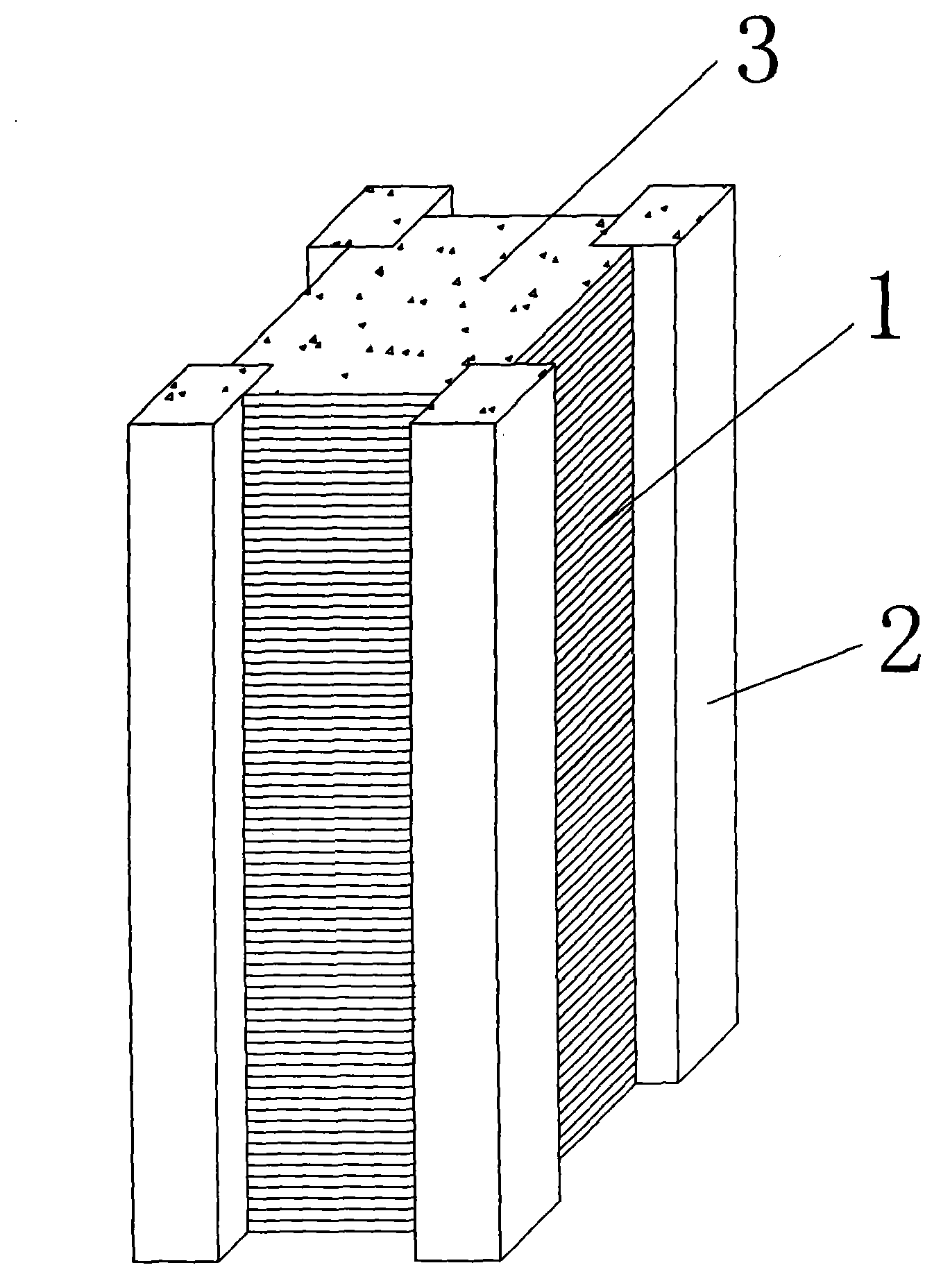

Double-steel-sheet and concrete combined core-tube structure with built-in corrugated steel sheets

InactiveCN103233509AImprove seismic performanceImprove structural rigidityShock proofingEngineeringSteel frame

The invention provides a double-steel-sheet and concrete combined core-tube structure with built-in corrugated steel sheets. The corrugated steel sheet and a plurality of steel cover plates are vertically welded and connected to form an elongated grille steel tube wall board by borrowing ideas from a steel tube and concrete combined structure, high-strength concrete is poured into grille steel tubes to form an elongated grille steel tube and concrete combined shear wall board, and the elongated grille steel tube wall board and in-tube concrete columns are used in a combined mode, complement each other's advantages and work cooperatively. The novel shear wall board is in welding connection with edge steel columns and edge steel beams, and an end portion steel tube concrete core column is arranged at the intersecting corner position of wall bodies of core-tube shear walls to form the novel double-steel-sheet and concrete combined core-tube structure with the built-in corrugated steel sheets. A steel frame-structural system of the novel combined structure core tubes has the advantages of being large in structural rigidity, high in compression bearing capacity, convenient to construct, strong in anti-bending capacity, high in yield load, good in anti-seismic ductility, good in energy dissipation capacity and the like, and the double-steel-sheet and concrete combined core-tube structure can be used for a 60-storey steel structure building and a super high-rise steel structure building with more than 60 storeys.

Owner:SOUTHEAST UNIV

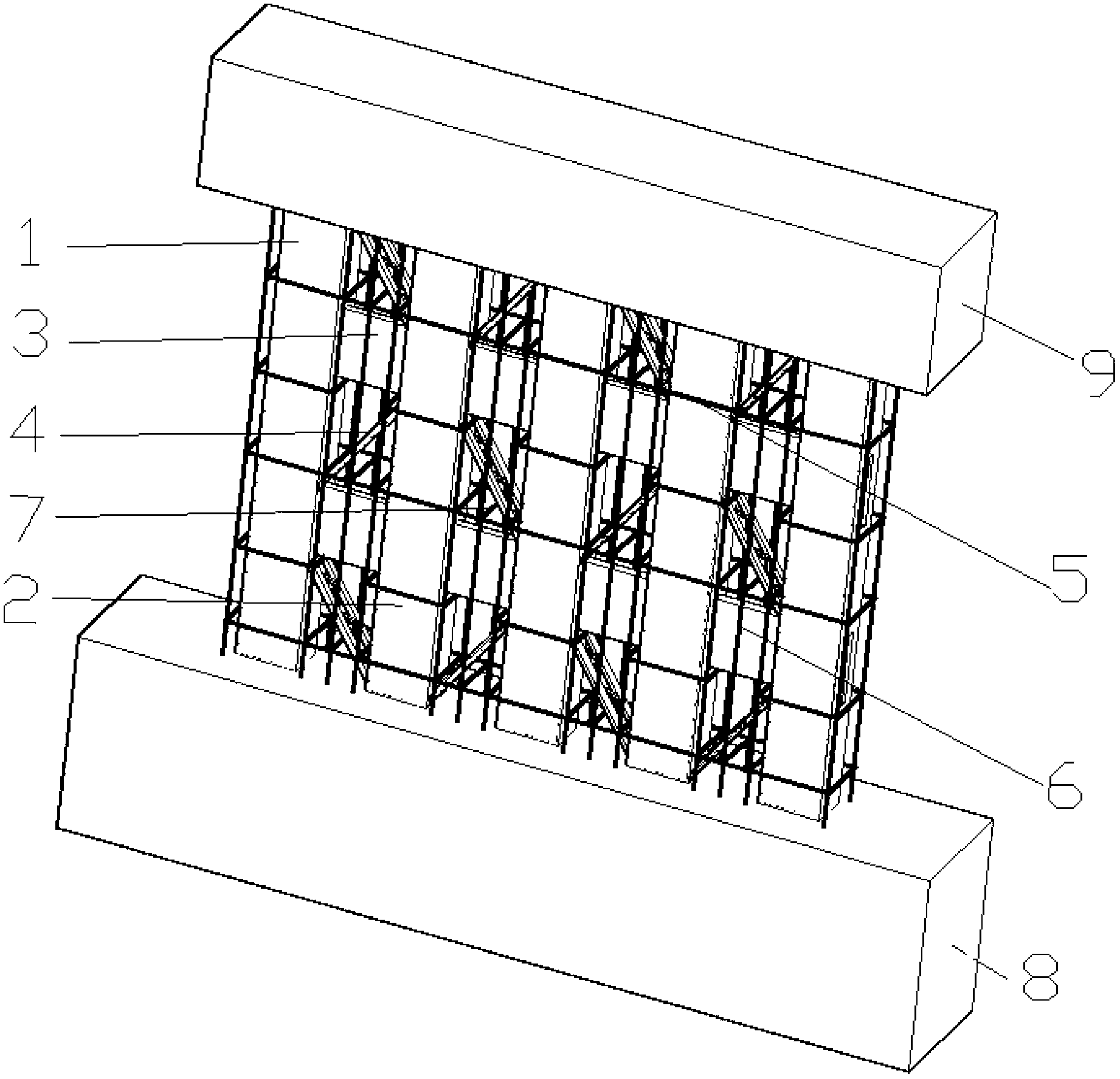

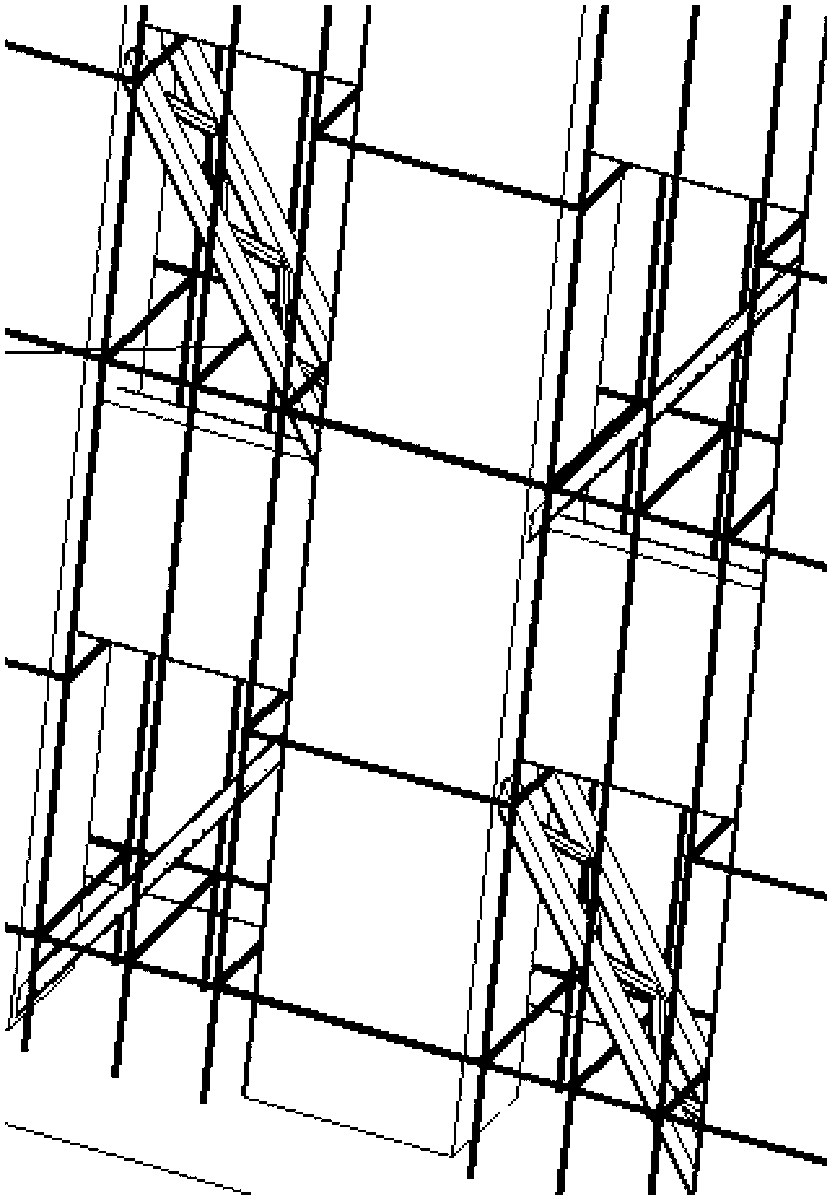

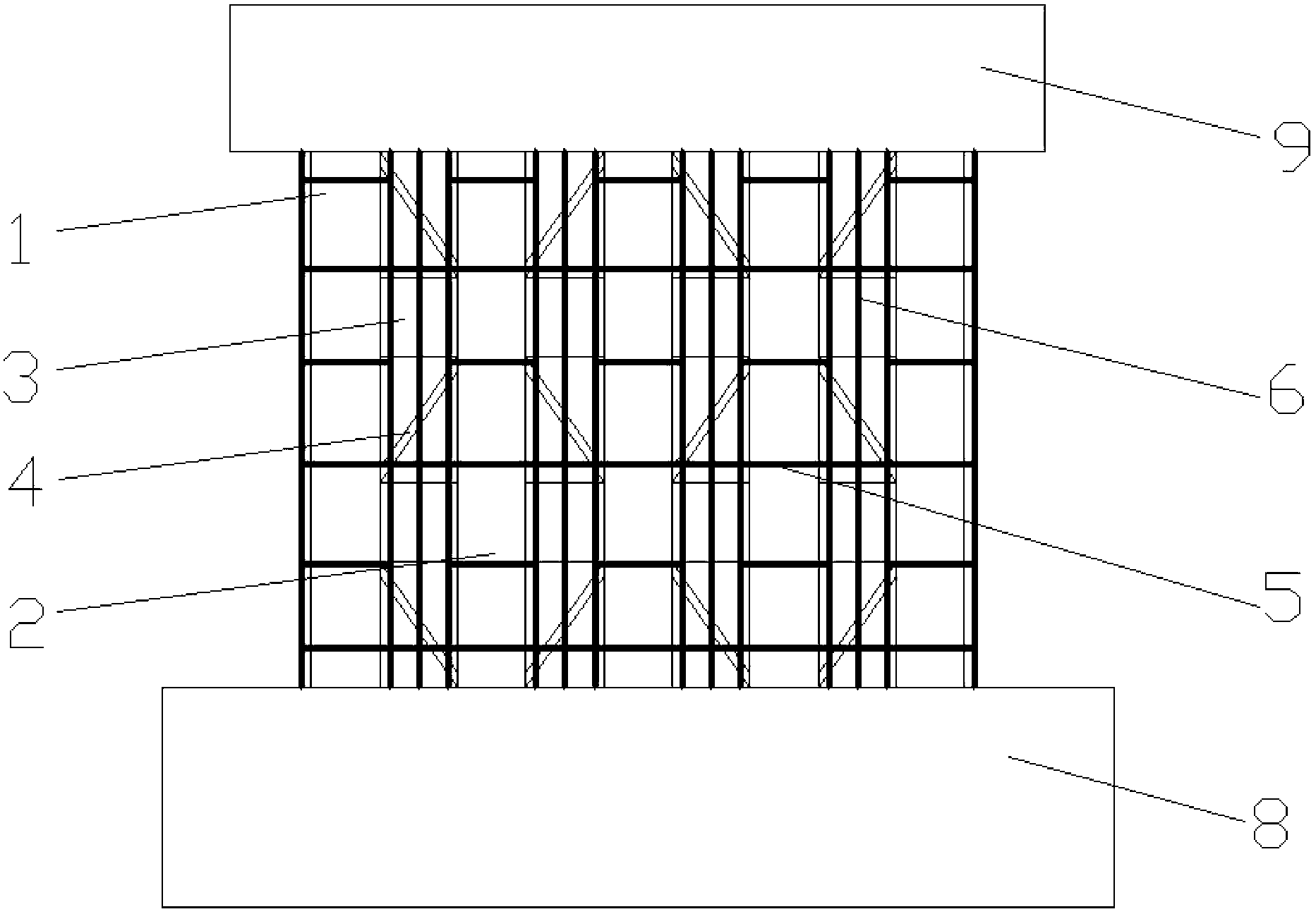

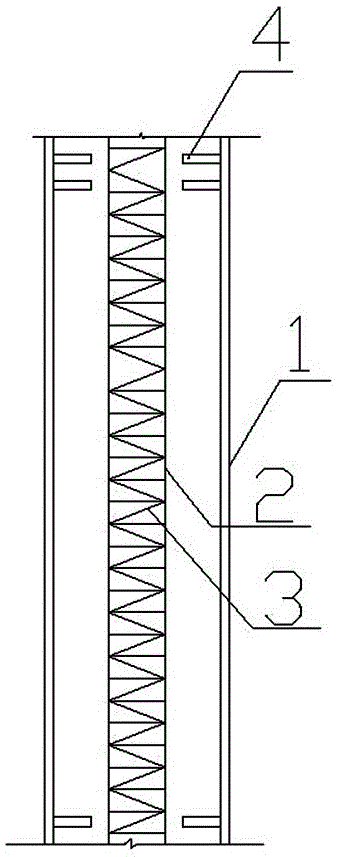

Steel tube reinforced concrete composite column-steel beam-lattice steel support shear wall and manufacturing method

ActiveCN102704593AGive full play to the anti-seismic abilityImprove the compressive capacityWallsBuilding material handlingReinforced concreteSteel bar

The invention discloses a steel tube reinforced concrete composite column-steel beam-lattice steel support shear wall and a manufacturing method, and belongs to the field of steel-concrete combined shear walls. The steel tube reinforced concrete composite column-steel beam-lattice steel support shear wall comprises steel tube reinforced concrete composite frame columns, steel tube reinforced concrete composite core columns, steel beams, lattice steel supports and a reinforced concrete shear wall body, wherein the two ends of the shear wall are provided with the steel tube reinforced concrete composite frame columns between which a plurality of parallel steel tube reinforced concrete composite core columns are arranged; the steel tube reinforced concrete composite frame columns are connected with the steel tube reinforced concrete composite core columns by the steel beams and the lattice steel supports and all the steel tube reinforced concrete composite core columns are connected by the steel beams and the lattice steel supports; the shear wall reinforcements are bound; and concrete is cast to construct the steel tube reinforced concrete composite column-steel beam-lattice steel support shear wall. The steel tube reinforced concrete composite column-steel beam-lattice steel support shear wall has the advantages of improved bearing capacity, slow attenuation in bearing capacity and rigidity, stable later anti-seismic performance, improved shear wall ductility and energy consumption performance due to existence of the combined steel structure framework, more superior anti-seismic performance, convenience in steel structure construction and capability of being used in high-rise or large-sized complex multi-storey buildings.

Owner:BEIJING UNIV OF TECH

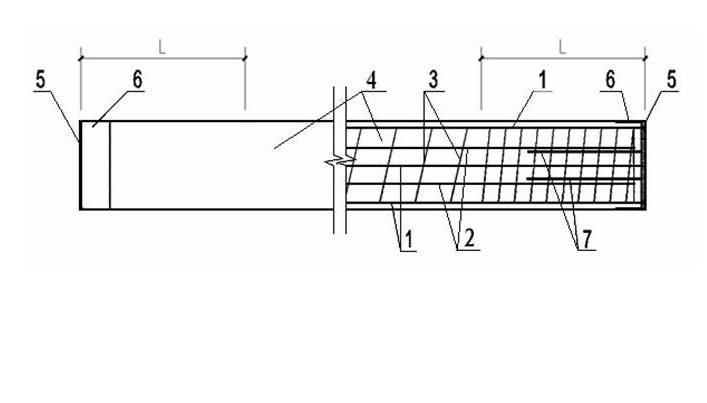

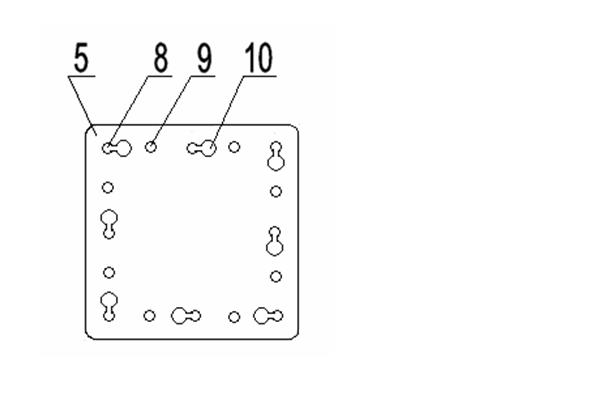

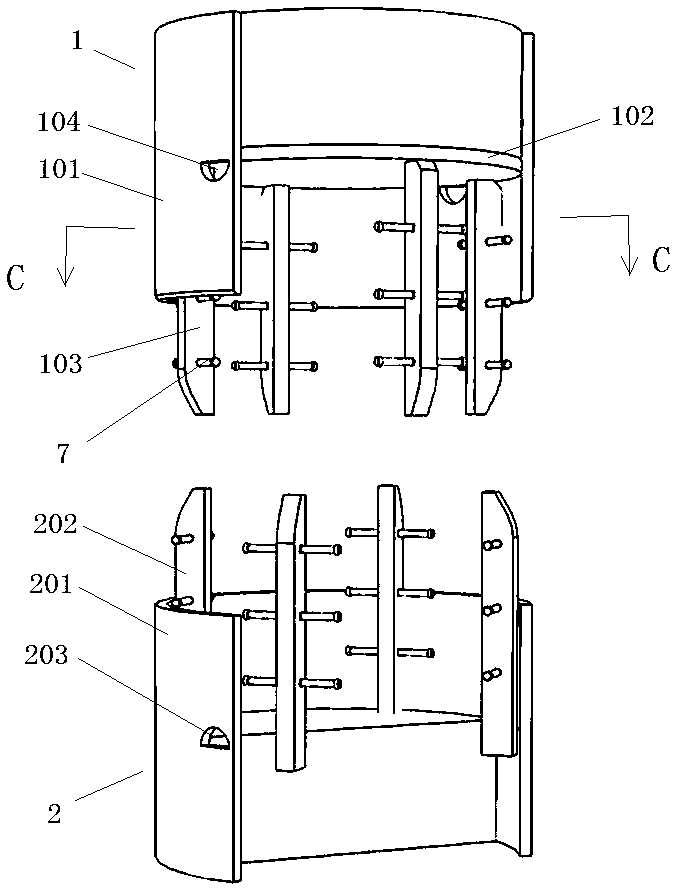

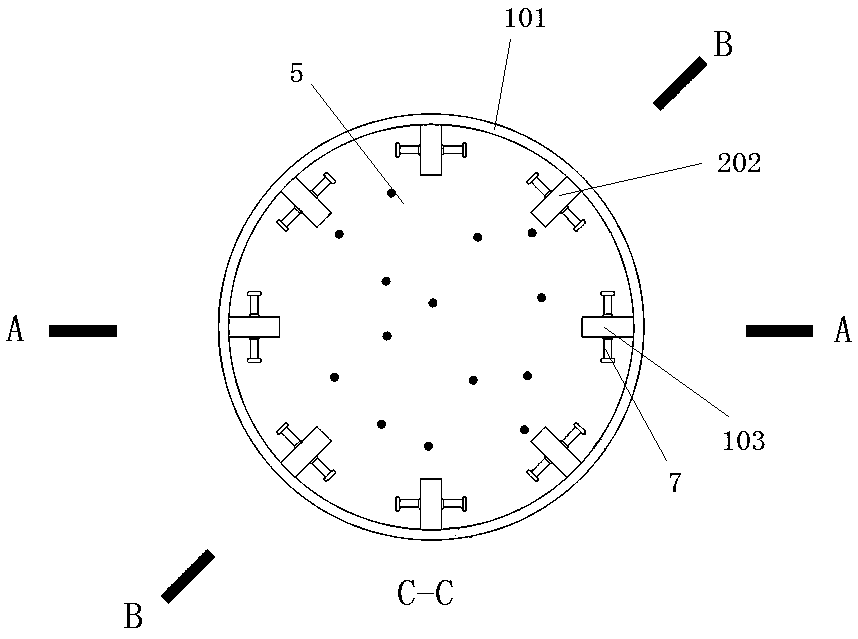

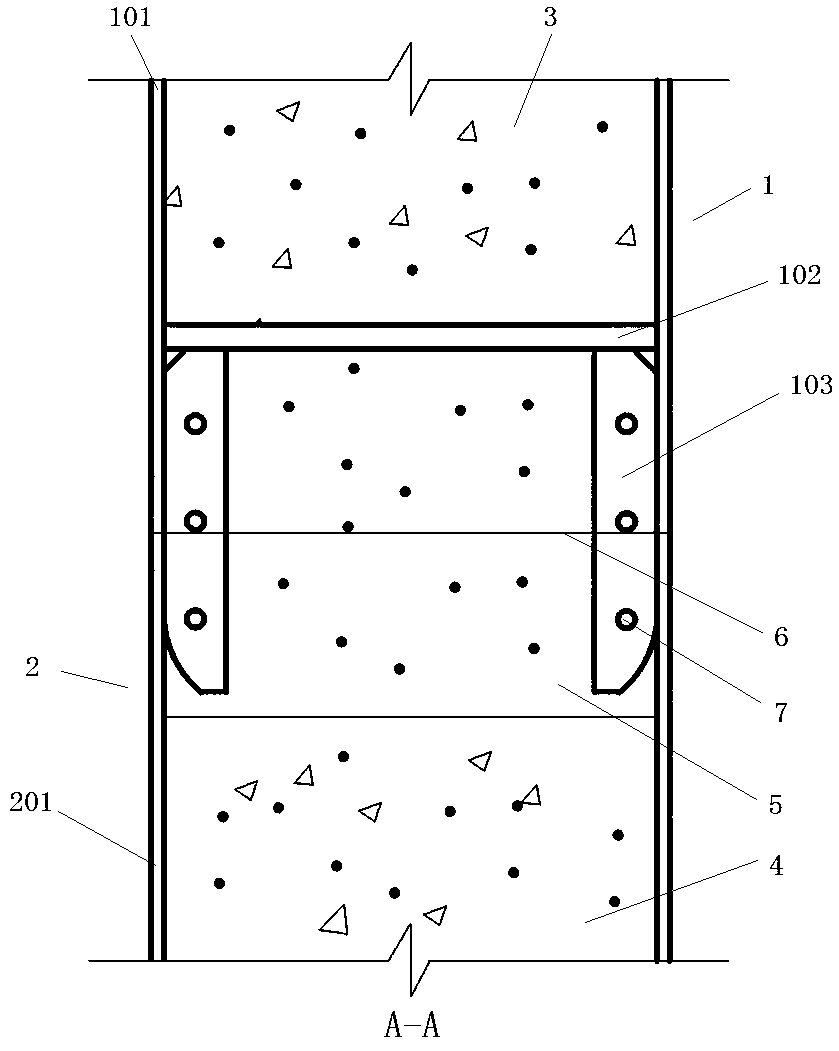

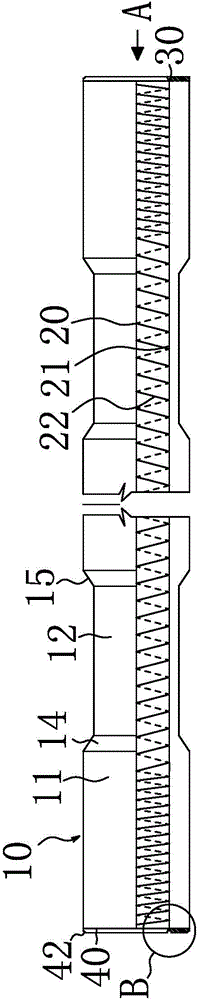

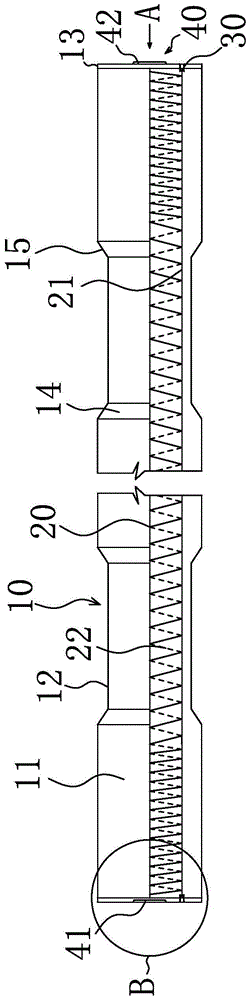

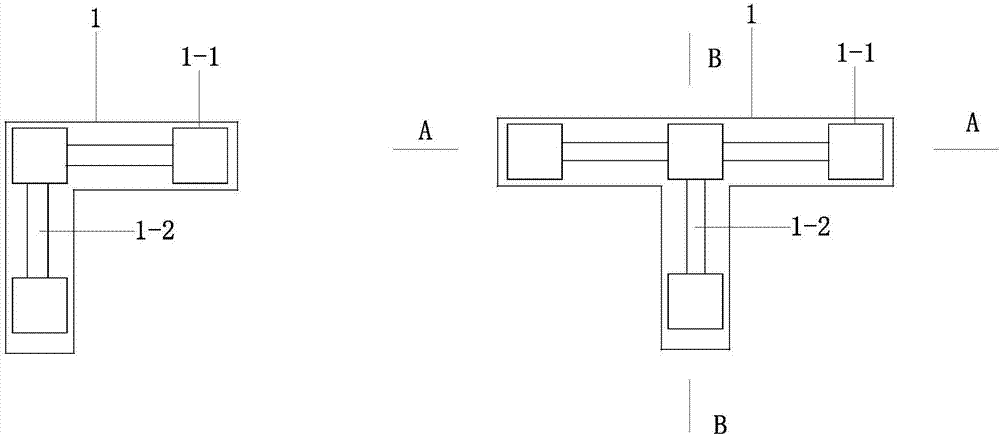

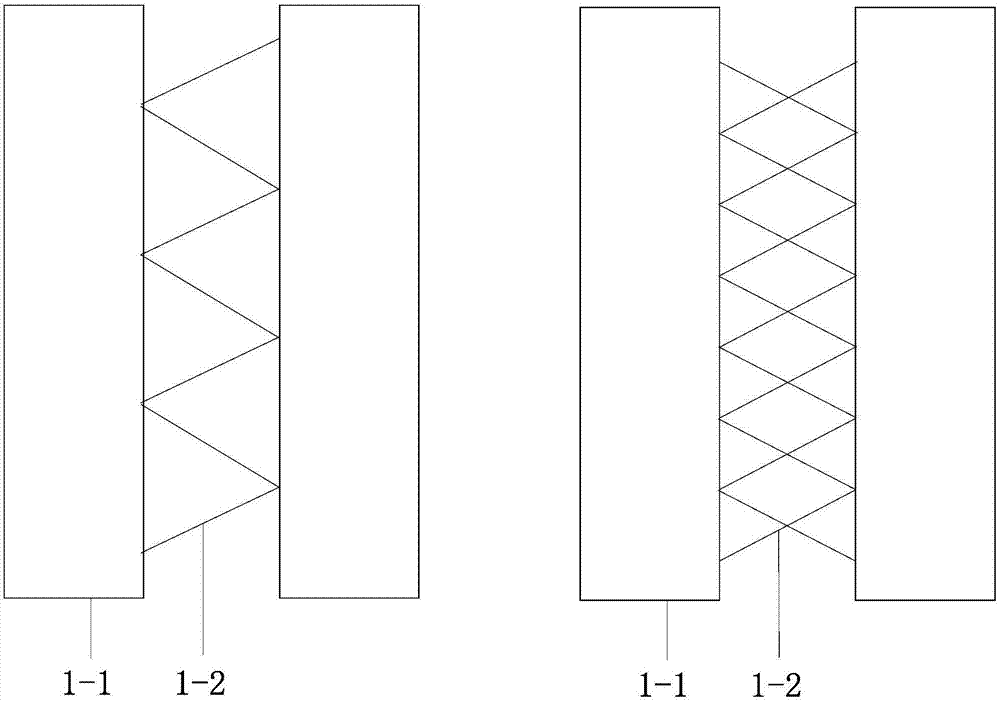

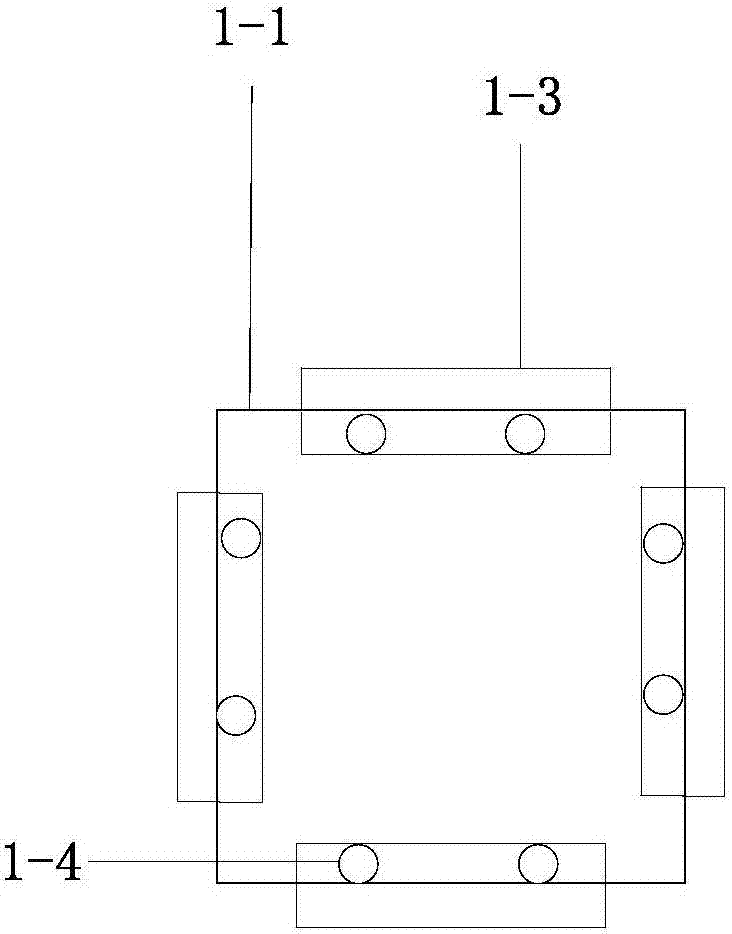

Self-positioning joint between fabricated concrete filled steel tubular columns and construction method thereof

ActiveCN108149844AImprove the compressive capacityImprove stabilityStrutsPillarsEngineeringStructural engineering

The invention relates to a self-positioning joint between fabricated concrete filled steel tubular columns and further relates to a construction method of the self-positioning joint between the concrete filled steel tubular columns. The self-positioning joint comprises the upper prefabricated column and the lower prefabricated column. The bottom of the upper prefabricated column and the top of thelower prefabricated column are welded together; upper column concrete is poured in the upper portion of the upper prefabricated column, and lower column concrete is poured in the lower portion of thelower prefabricated column; and cement-based grouting materials are poured in both of the lower portion of the upper prefabricated column and the upper portion of the lower prefabricated column. Theself-positioning joint is simple in structural design, safe, reliable, efficient, convenient, rapid and easy to mount, position and construct.

Owner:FUZHOU UNIV

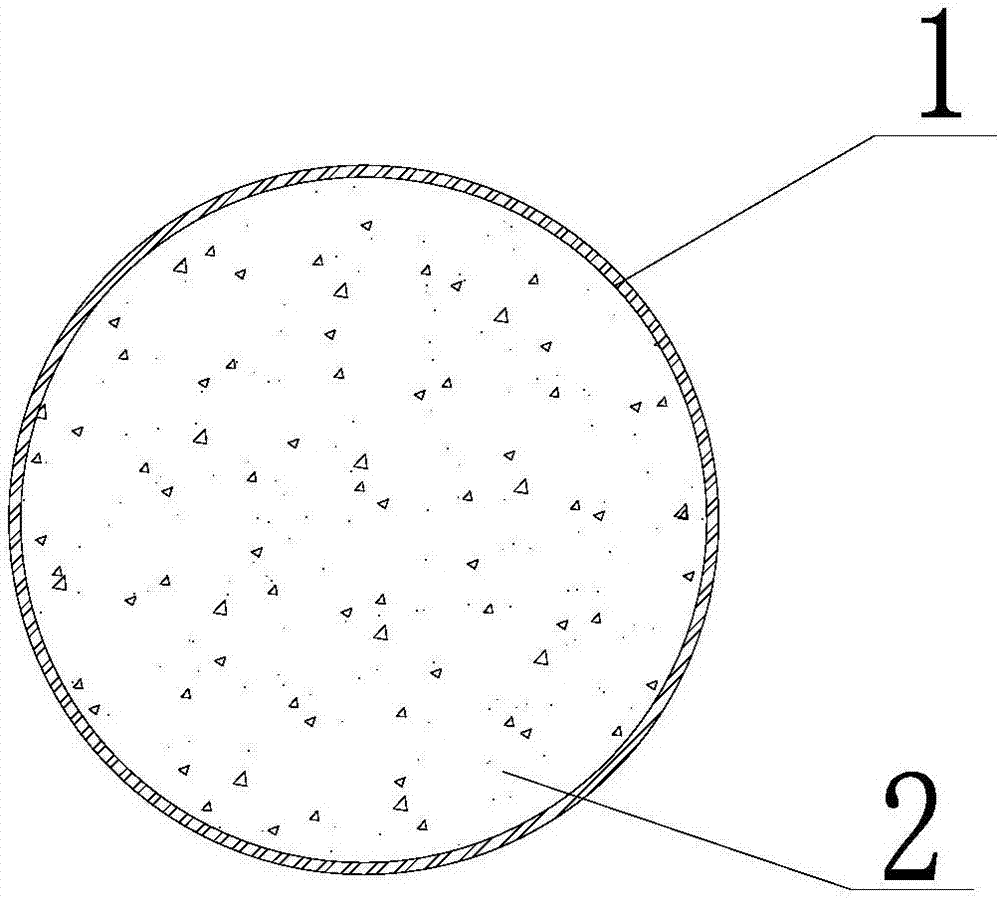

Space constraint multi-cavity pipe-in-pipe steel bar concrete huge column and construction method

ActiveCN105133793AImprove mechanical performanceWide range of sizesStrutsBuilding material handlingRebarMaterials science

The invention relates to a space constraint multi-cavity pipe-in-pipe steel bar concrete huge column and a construction method. A huge column comprises a core steel pipe concrete part and a steel-encased pipe concrete part. A core steel pipe forms an inner cavity. The inner cavity is filled with inner cavity concrete, and a steel bar frame is arranged through the middle part of the inner cavity. The core steel pipe and the steel-encased pipe form an outer cavity. The outer cavity is filled with outer cavity concrete, and at least a steel bar frame is arranged through the outer cavity. The core steel pipe and the steel-encased pipe are connected through a vertical connection plate and form a space steel pipe structure. The outer steel pipe of the huge column is connected with the inner steel pipe through the vertical connection plate, the space steel pipe structure is formed, and the force bearing performance of traditional steel pipe concrete can be raised effectively. The huge column has a strong anti-pressure capability, steel and concrete combined action performances are good under action of long-term load. The huge column has good earthquake resistant behavior, fireproof performance and construction convenience.

Owner:姚攀峰

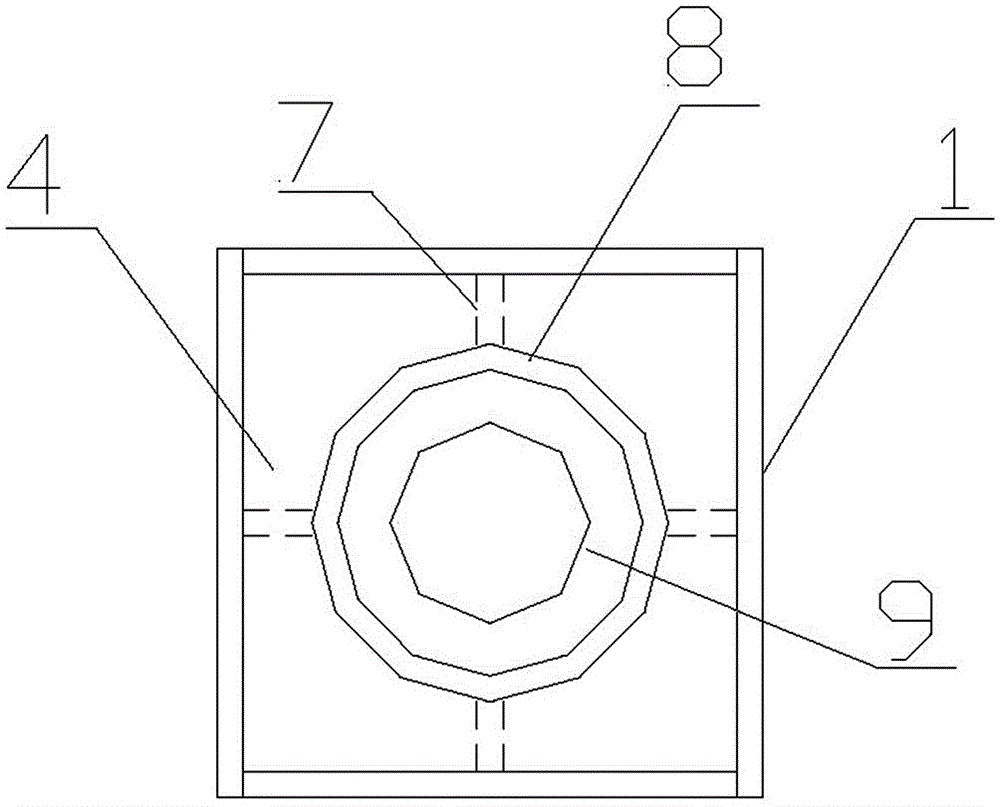

Corrugated steel plate confined concrete combination column and manufacturing method thereof

InactiveCN103015632AFatigue resistantImpact resistantStrutsPillarsSheet steelUltimate tensile strength

The invention discloses a corrugated steel plate confined concrete combination column which is a polygon tube formed by using a plurality of corrugated steel plates and a plurality of steel tubes as turning corners, wherein the corrugation directions of the corrugated steel plates are identical to the length direction of the polygon tube; and concrete is further filled into the polygon tube and the corners so as to manufacture the combination column. In addition to the excellent mechanical property of the conventional steel tube concrete, the combination column further has the following remarkable advantages that the load born by corrugated steel plate bears in the corrugation direction is small, so that the strength of the corrugated steel plate is mainly for providing annular restraint on the core concrete, then the compression bearing capacity of the core concrete is greatly improved, the compression bearing capacity of the combination column is improved to a large extent, the material is saved, and the engineering cost is reduced; the outer rigidity of the plane of the corrugated steel plate is large, and the corrugated steel plate is unlikely to bulge under the transverse expansion deformation action of the core concrete, so that the effective annual restraint of the corrugated steel plate to the core concrete is increased, and the compression bearing capacity of the combination column is further improved.

Owner:CHINA UNIV OF MINING & TECH

Construction method for non-prestressed centrifugal high-strength concrete pile planted pile

InactiveCN105421445AIncrease resistanceImprove pullout resistanceBulkheads/pilesHigh strength concreteSocial benefits

The invention provides a non-prestressed centrifugal high-strength concrete pile planted pile structure and a construction method thereof. The method comprises the construction steps that a pile planting machine is in place, the hole guiding operation is conducted, a bearing stratum is determined, base expansion is carried out, pile end cement paste is injected, pile periphery cement paste is injected and drill stems are pulled out, pile connection of pre-drilled holes is conducted, and non-prestressed centrifugal high-strength concrete piles are planted into pile holes. The pile planting construction method has the effects that damage to pile bodies is effectively reduced; the ductility of the pile bodies is improved more than 30%; the pile body cracking phenomenon is avoided; the whole performances of the pipe piles are improved more than 20%; the technique is simple, the cost is low and the cost performance is high; the centrifugal concrete piles which are high in vertical bearing capacity and horizontal pile foundation bearing capacity and capable of meeting the anti-seismic requirement can penetrate through a hard middle layer and a thick solidified layer and can be widely applied to foundation construction of various soil textures; it is ensured that the requirement of housing industrialization for quality is met; the pile planting construction method has good social benefits and popularization value.

Owner:TIANJIN JIANCHENGJIYE GRP

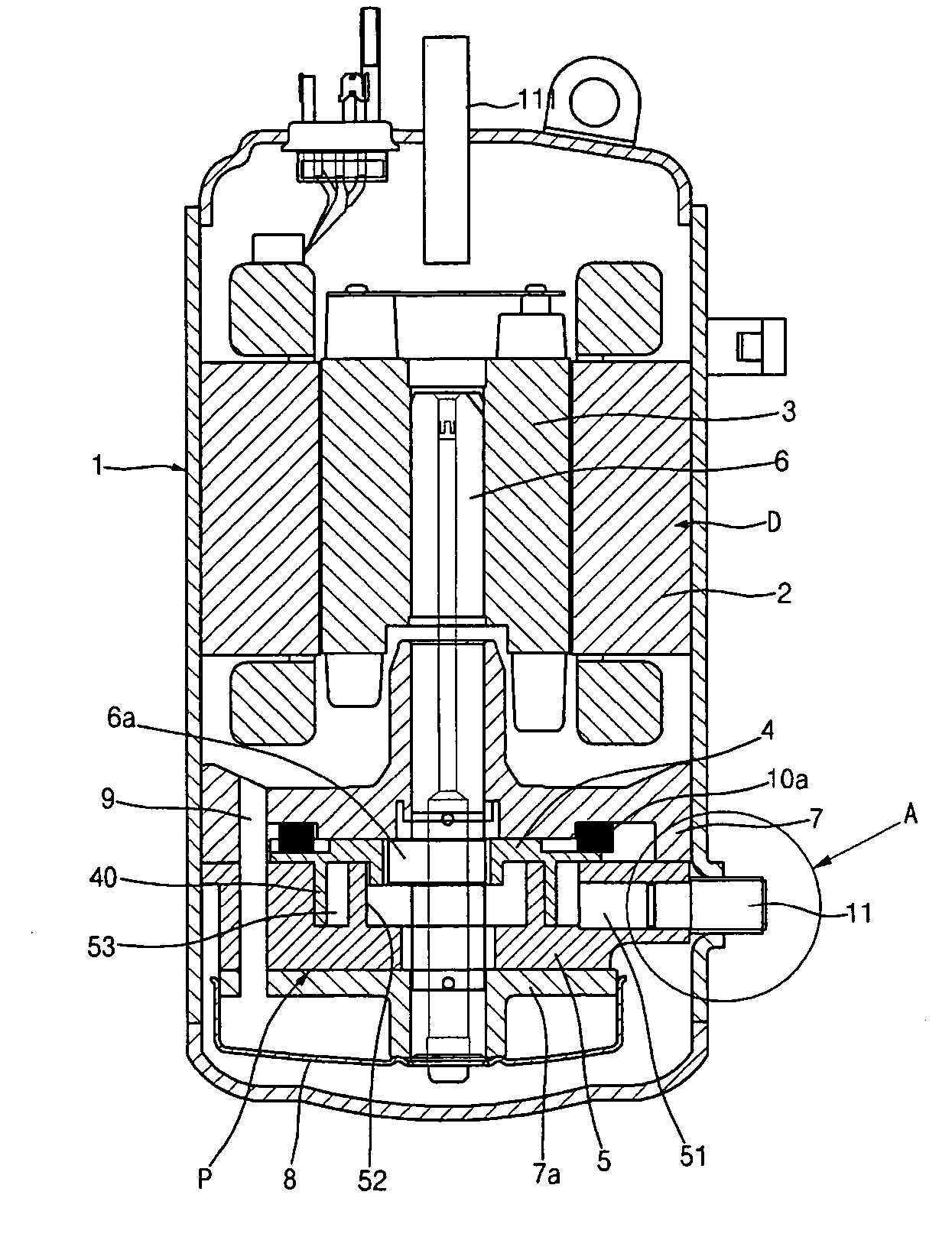

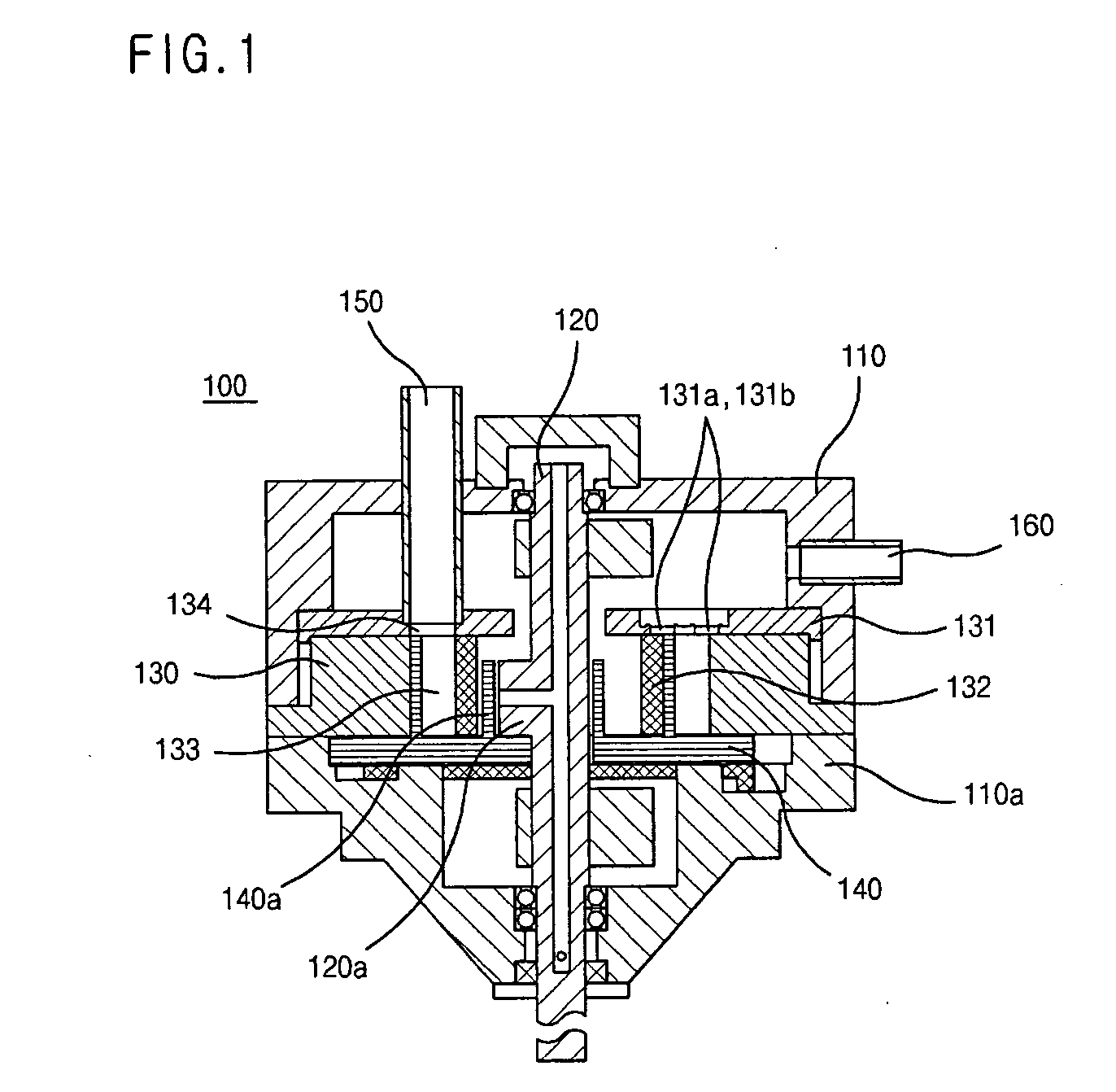

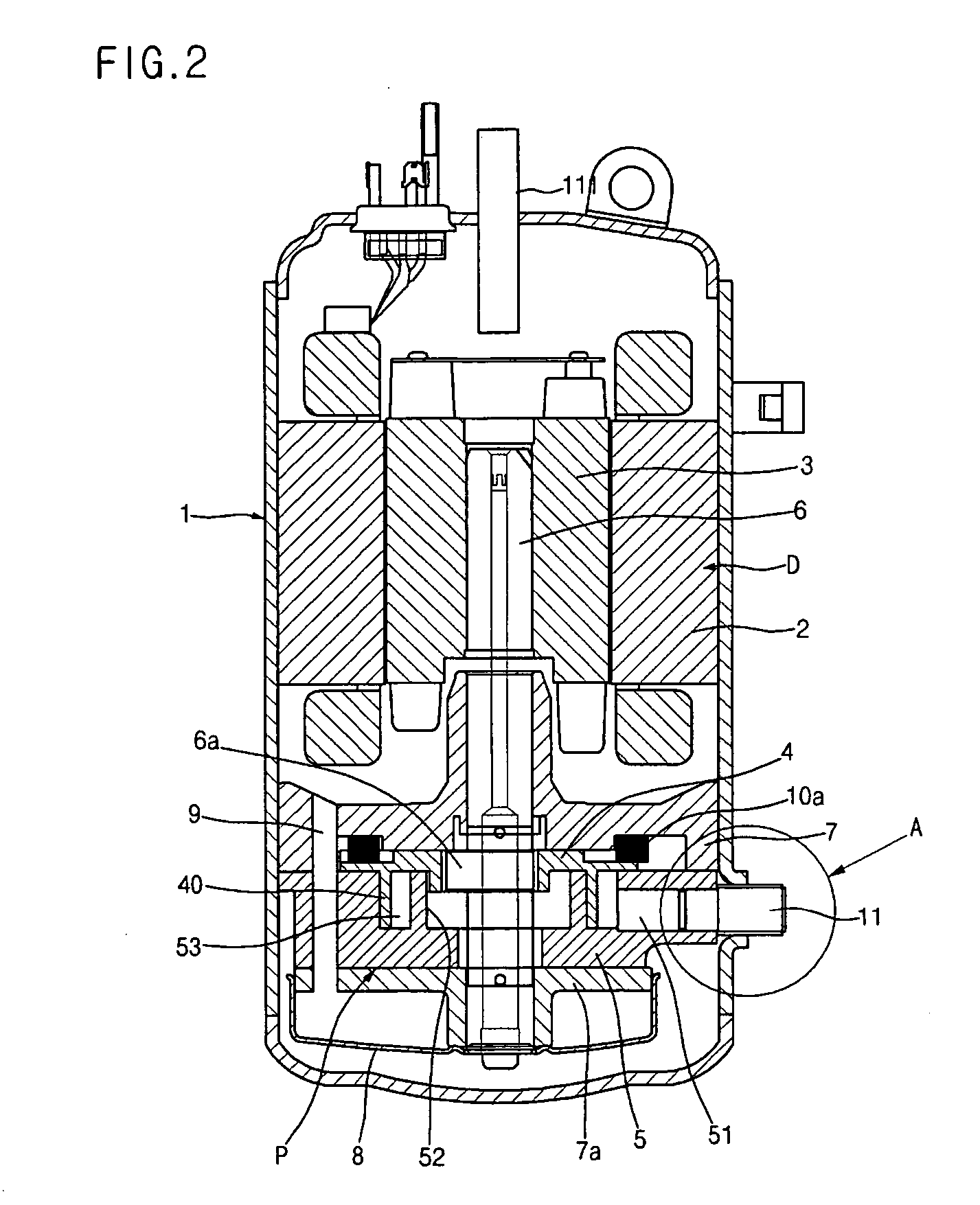

Orbiting vane compressor

InactiveUS20060073053A1Improve the compressive capacityImprove performanceRotary/oscillating piston combinations for elastic fluidsPump componentsRefrigerantFlange

Disclosed herein is an orbiting vane compressor having two compression chambers formed in a cylinder according to an orbiting movement of an orbiting vane. The orbiting vane compressor comprises a shell having an inlet tube and an outlet tube, the shell being hermetically sealed such that refrigerant gas is introduced through the inlet tube and is then discharged through the outlet tube, a rotary shaft disposed in the shell while being supported by upper and lower flanges, the rotary shaft being rotated by a drive unit, and a compression unit for compressing refrigerant gas introduced into a cylinder according to an orbiting movement of an orbiting vane, which is attached to the rotary shaft, and discharging the compressed refrigerant gas to the lower part of the cylinder.

Owner:LG ELECTRONICS INC

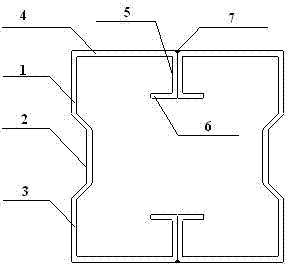

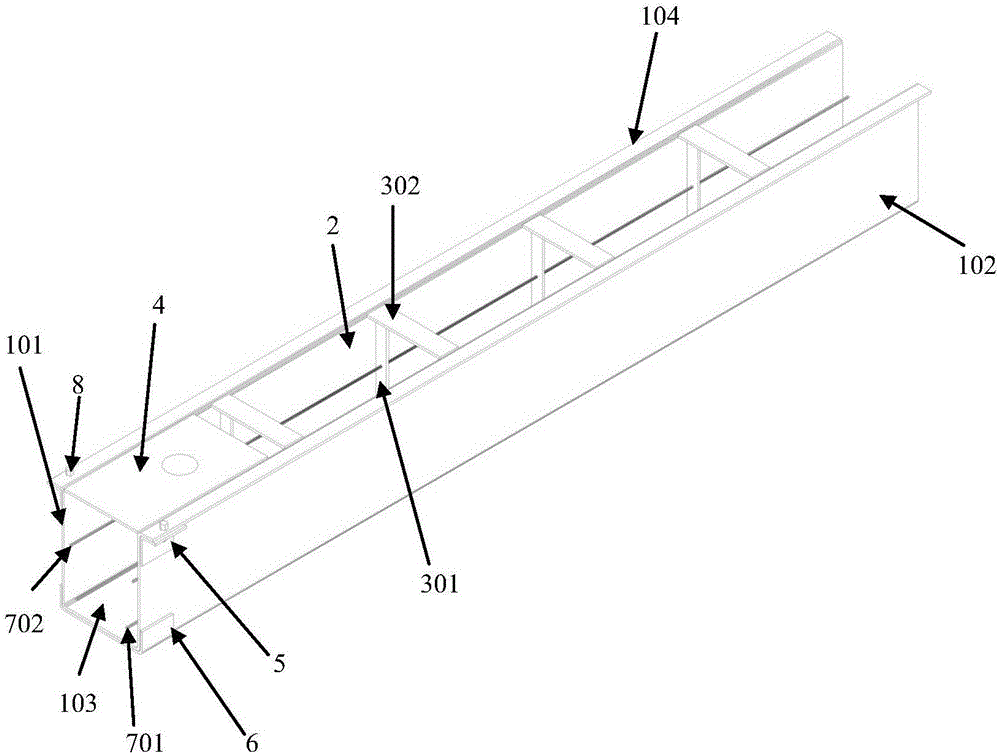

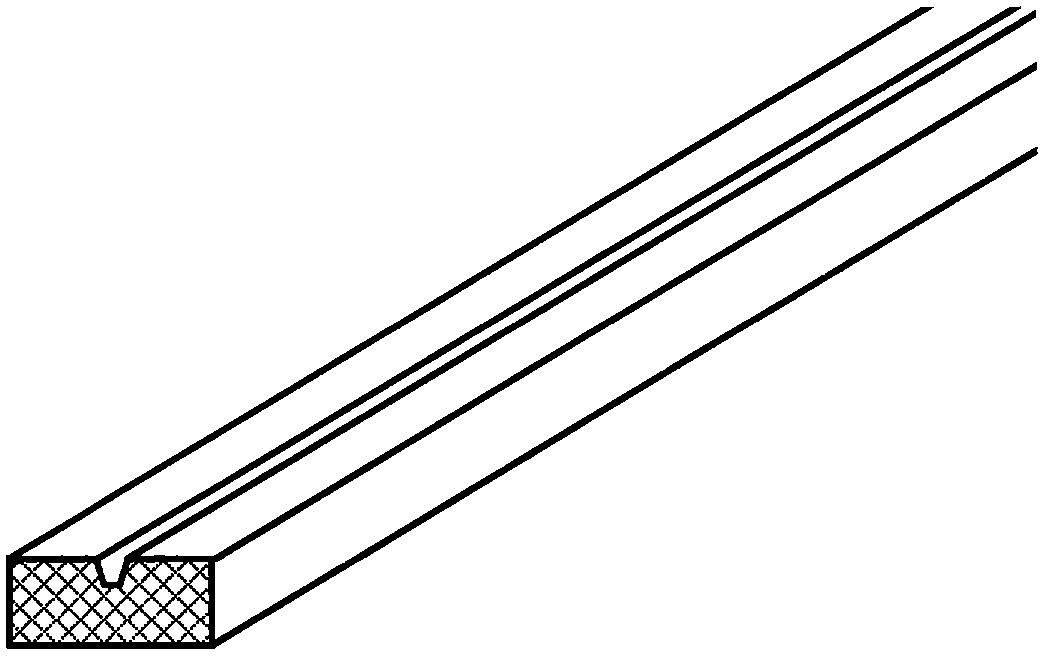

Double-limb splicing thin-walled cold-formed steel efficient component

InactiveCN103572892AImprove the compressive capacityReduce aspect ratioLoad-supporting elementsCompression memberFlange

The invention discloses a double-limb splicing thin-walled cold-formed steel efficient component. The double-limb splicing thin-walled cold-formed steel efficient component comprises two sigma-shaped web cold-formed thin-wall complex lipped steel channel opening components which is composed of upper webs, stiffening ribs, lower webs, flange edges, crimped edges and recrimped edges. The double-limb splicing thin-walled cold-formed steel efficient component is characterized in that the sigma-shaped web cold-formed thin-wall complex lipped steel channel opening components are spliced into in a back-to-back or face-to-face manner, and the connecting manner is that the upper webs and lower webs are connected through tapping screws, or the crimped edges are welded together in a welding manner. The double-limb splicing thin-walled cold-formed steel efficient component disclosed by the invention has the advantages that when the double-limb splicing thin-walled cold-formed steel efficient component is utilized as a compression member, the ratio of height to thickness of the webs is obviously reduced in a back-to-back double-limb splicing manner, the compressive capacity of the component is obviously strengthened, and the bearing capacity of the spliced components is obviously improved compared with the sum of bearing capacities of two single limb components; compared with the single limb component, the double-limb splicing thin-walled cold-formed steel efficient component has the advantages that the defects that the antitorque capacity of a single limb opening component is poor, the difference of the inertia moments of two main shafts is large and the like are overcome, the multi-time buckling of a steel plate also can provide the strong ring constraint on the interior concrete, the tightening ring force of the concrete is strengthened, and thus the bearing capacity of a compound section is improved.

Owner:SHENYANG JIANZHU UNIVERSITY

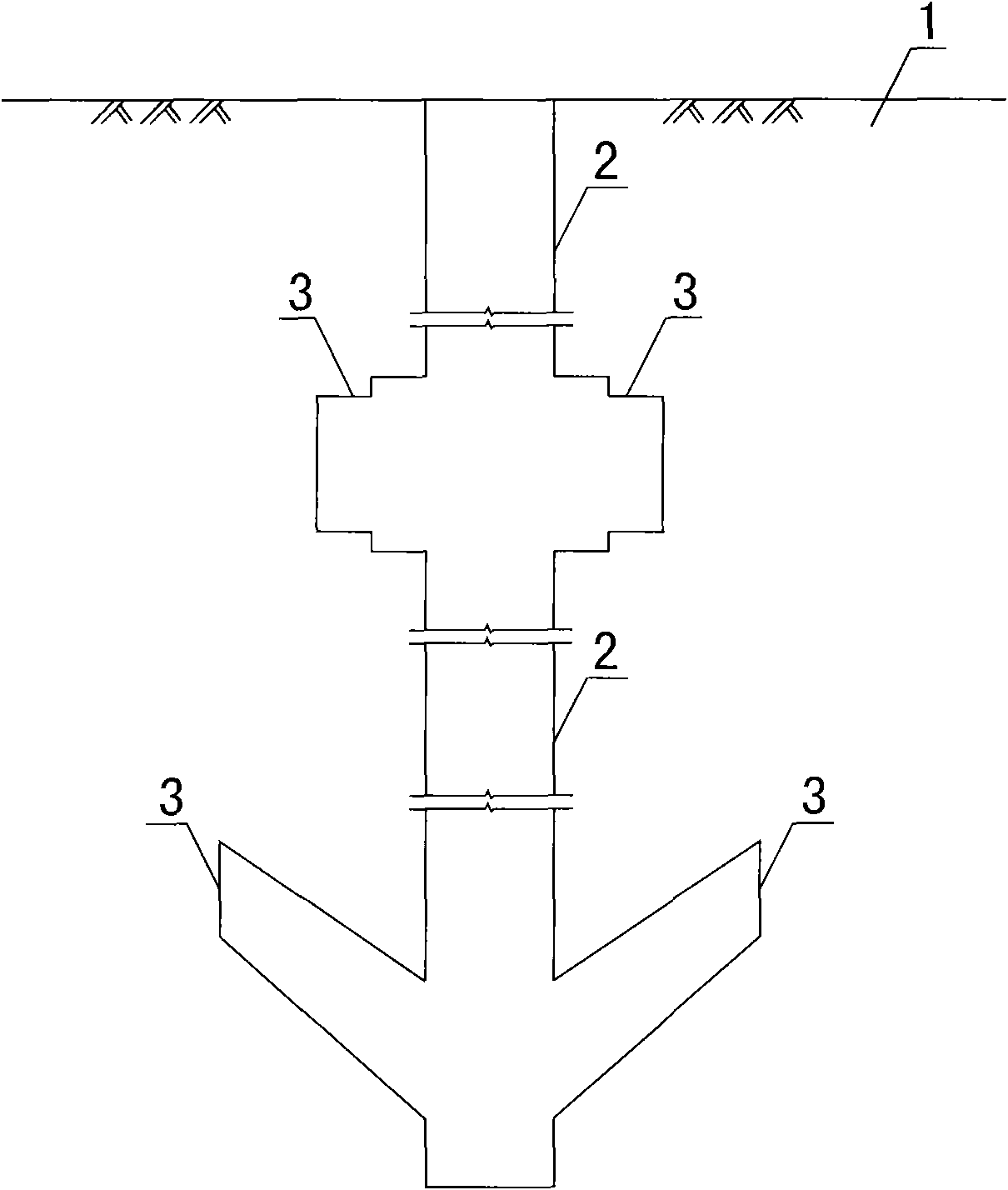

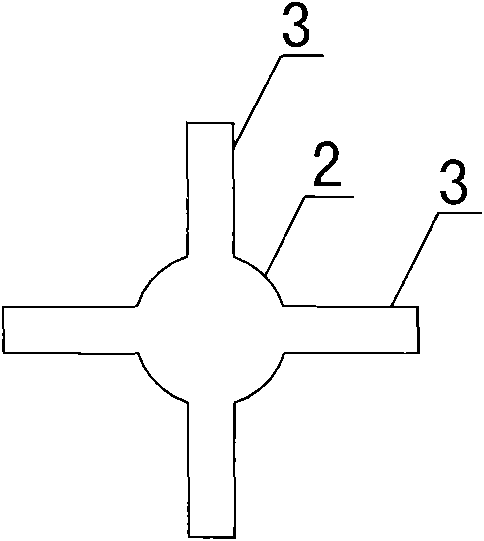

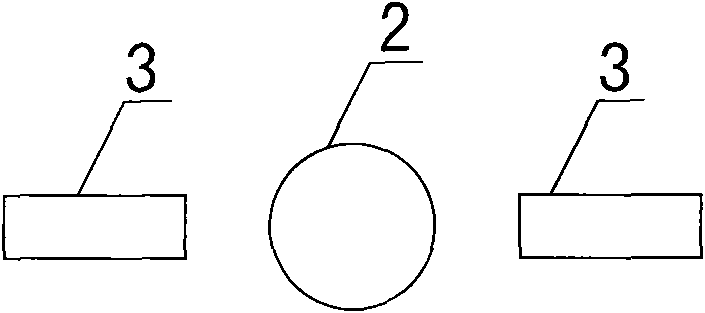

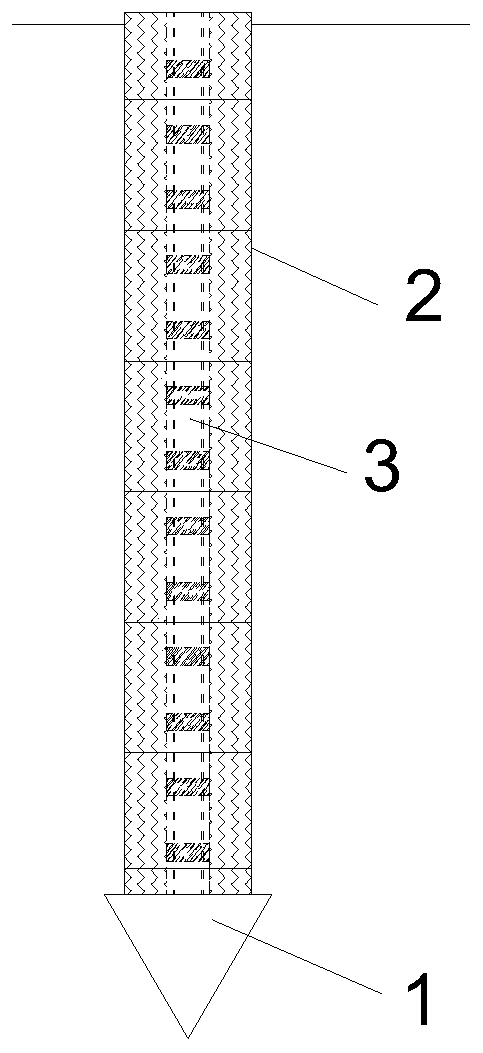

Wing-added hole-expanding pile and wing-added hole expander

InactiveCN101649611ANot easy to collapse holesImprove single pile pullout resistanceSoil-shifting machines/dredgersBulkheads/pilesCompression deviceContour line

The invention provides a wing-added hole-expanding pile and a wing-added hole expander. The wing-added hole-expanding pile can be added with stiffening wings (3) in a rock-soil mass (1) along a pile body (2). After hole-expanding construction is completed, the outer contour line of the section of the hole-expanding section pile is a concave curve or a combination of not less than two closed curves; large-scale hole-expanding construction around and on the bottom of the pile can be realized; holes are not easy to collapse after the hole-expanding construction; few pile-body materials are neededfor filling expanded holes; and a compact solid pile body can be formed after the hole-expanding construction is completed. Therefore, the anti-pulling / anti-compression bearing capacity of single pile can be greatly improved, and cost for pile foundation is saved. Compared with the prior hole-expanding equipment, the wing-added hole expander used in the construction of the wing-added hole-expanding pile has great improvement. The wing-added hole expander has the advantages of producing no slurry in a hole-expanding process and greatly reducing engineering cost for anti-pulling / anti-compression devices in geotechnical engineering, along with simple structure, high hole-expanding efficiency, good matching property with the prior piling machinery and capability of repeated use.

Owner:张继红

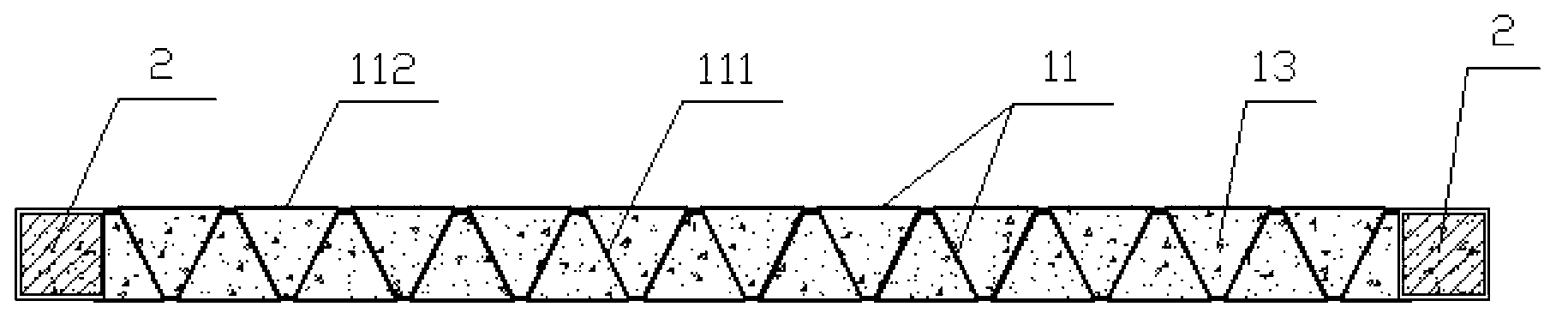

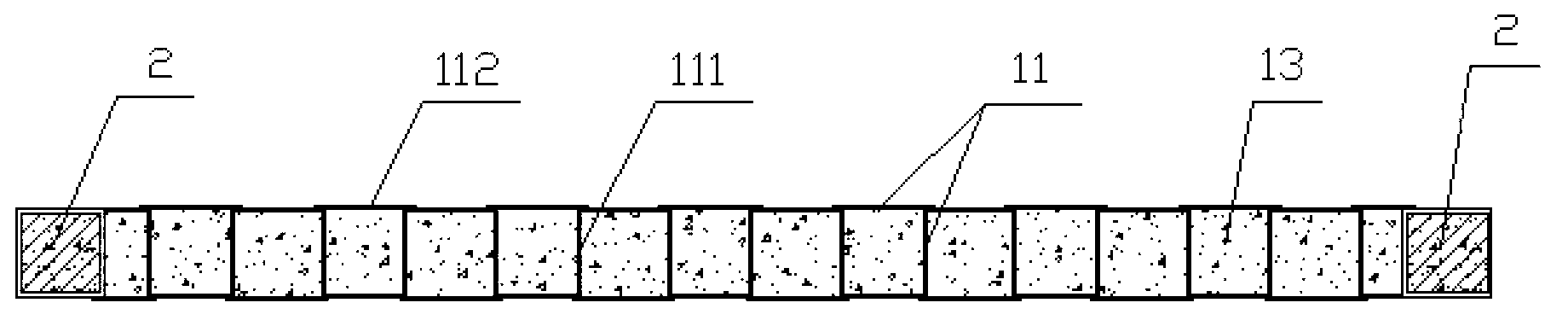

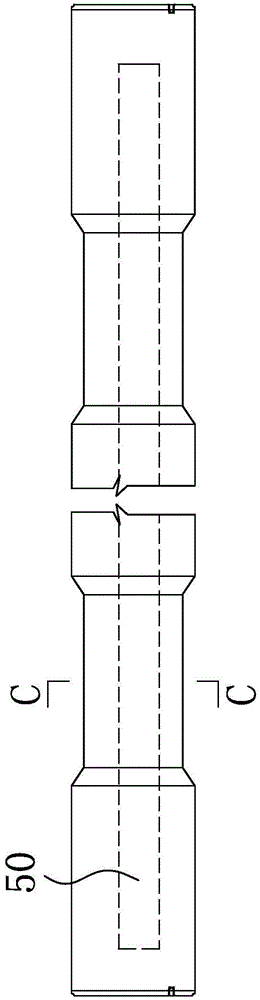

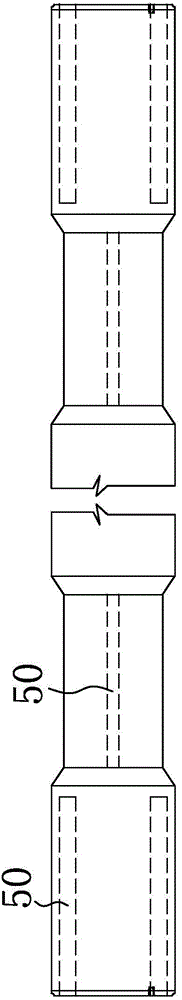

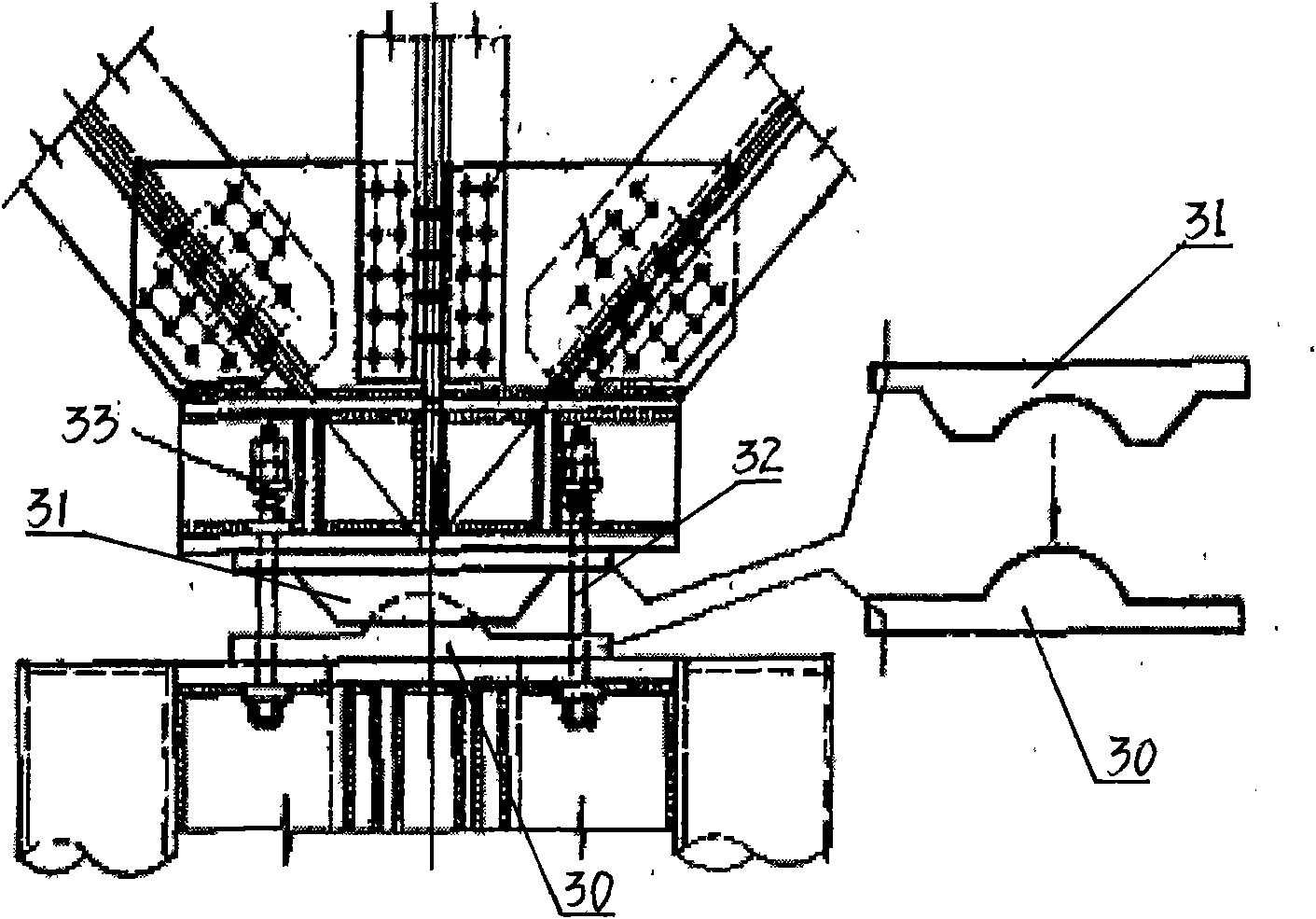

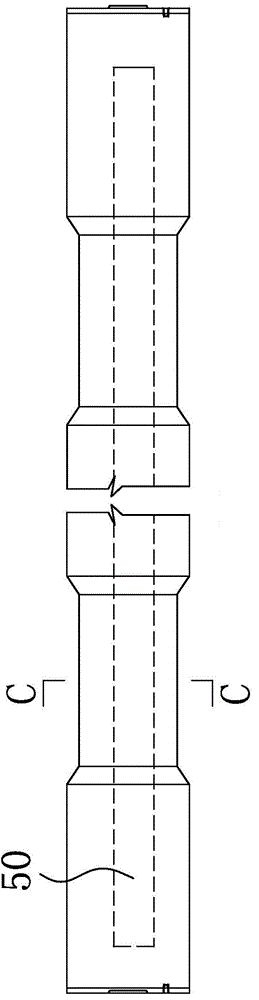

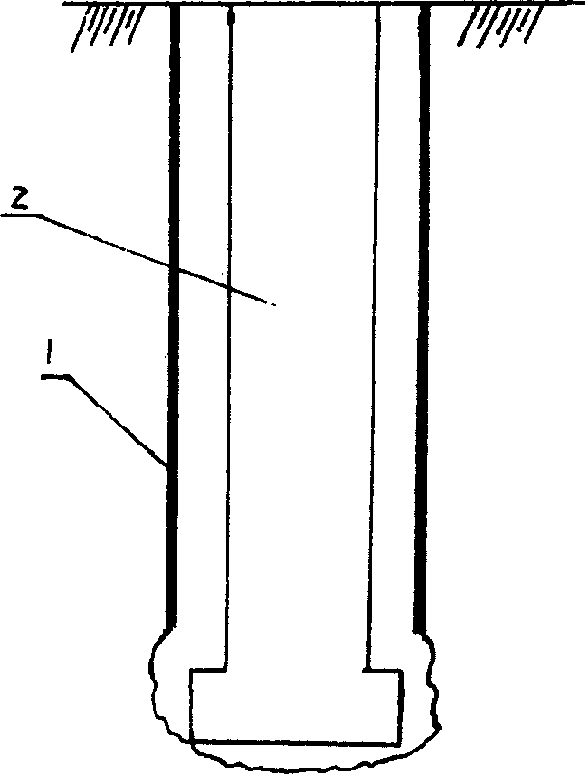

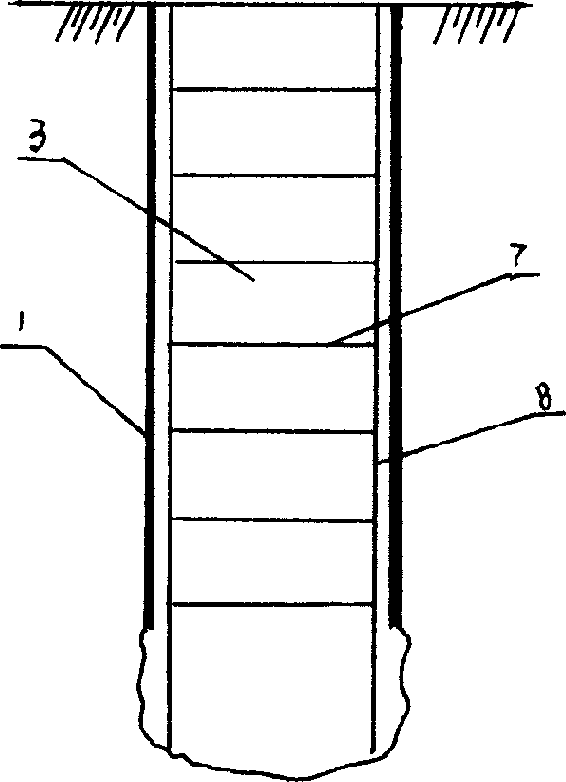

Variable-cross-section pile with end plates

The invention belongs to the technical field of prefabricated components in the building industry, and relates to a variable-cross-section pile with end plates. The variable-cross-section pile comprises a pile body, a steel reinforcement cage is arranged in the pile body, the steel reinforcement cage comprises a plurality of vertical steel bars and a spiral-shaped spiral steel bar fixedly connected with the vertical steel bars, the pile body comprises a plurality of large-cross-section piles and small-cross-section piles mutually connected, two ends of the pile are respectively provided with an end plate, a plurality of tension nuts are fixedly in the end plates, two ends of the vertical steel bars are provided with pier heads whose external diameter is greater than the external diameter of the vertical steel bars, the pier heads are positioned in the tension nuts and can be clamped by the tension nuts, sidewalls of the tension nuts are also communicated with clamping holes, and the clamping holes are positioned on the end plates. According to the variable-cross-section pile, the connection of the pile body is firm, and the installation is convenient.

Owner:周兆弟

Self-positioning internally-installed steel bar U-shaped composite beam

InactiveCN106284841AReduce steel consumptionEasy constructionFloorsLoad-supporting elementsEconomic benefitsSteel bar

The invention relates to a self-positioning internally-installed steel bar U-shaped composite beam. The self-positioning internally-installed steel bar U-shaped composite beam comprises a U-shaped steel beam housing and concrete components; the middle part of the self-positioning internally-installed steel bar U-shaped composite beam is provided with a U-shaped steel-clad concrete component provided with an opening; each end part of the self-positioning internally-installed steel bar U-shaped composite beam is provided with a rectangular steel-clad concrete component; each beam top flange of a corresponding end part of the self-positioning internally-installed steel bar U-shaped composite beam is provided with a steel angle, a linear upper cover plate is arranged on the beam top flanges, and a groove steel component is arranged on the bottom flanges. The beam end bearing capacity is improved by arrangement of the steel angles, the linear upper cover plate, and the groove steel component, beam torsional stiffness is increased, beam local and entire stability are ensured, installation and construction are convenient, and construction speed is increased greatly. According to the self-positioning internally-installed steel bar U-shaped composite beam, full utilization of the high strength of steel and the high compression bearing capacity of concrete is achieved, steel amount is reduced, cost is reduced, hot rolling or cold rolling is adopted, the self-positioning internally-installed steel bar U-shaped composite beam can be produced via one time moulding, structure deformation caused by welding is reduced, structure reliability is improved, the self-positioning internally-installed steel bar U-shaped composite beam is beneficial for industrial production of steel structures, and excellent social and economic benefit is achieved.

Owner:SHANGHAI RUIYI REAL ESTATE DEV CO LTD

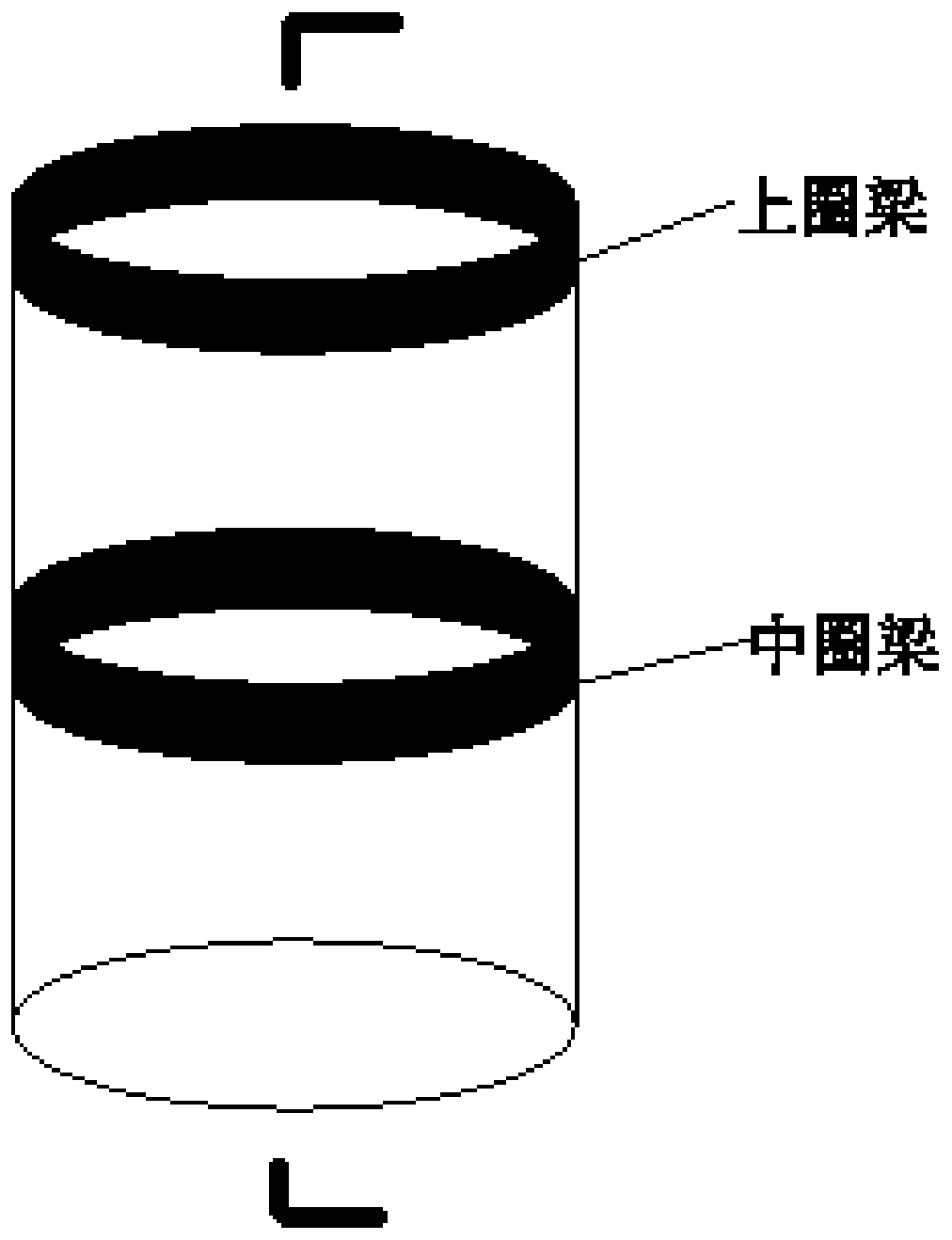

Method for reinforcing electric power tunnel by means of fiber grid enhanced polymer mortar and material

ActiveCN110952996AImprove crack resistanceIncrease ultimate bearing capacityUnderground chambersTunnel liningCelluloseGlass fiber

The invention discloses a method for reinforcing an electric power tunnel by means of fiber grid enhanced polymer mortar and a material, and belongs to the technical field of fiber grid enhanced cement-based composite material reinforcing. Raw material components comprise cement, polymers, polyvinyl alcohol fibers, alkali-resistant glass fibers, sand, water, a water reducer, starch ether, cellulose ether and the like. The method comprises the steps that pre-repairing such as filling and blocking is conducted on masonry or concrete tunnel wall cracks with the polymer mortar, and the mortar is embedded into the cracks; the surfaces of rusted steel bars are painted with a steel bar corrosion remover, and the tunnel wall is painted with one or two layers of an interface agent; and structural reinforcing is conducted on the tunnel and the well wall through multiple layers of the fiber grid enhanced polymer mortar. In order to improve the anti-seismic overall property, 1-3 fiber rib enhancedconcrete ring beams are arranged; and pretreatment is conducted firstly, and then reinforcing is conducted.

Owner:BEIJING UNIV OF TECH

Universal spherical joint supporter with anti-loosening position-limiting structure

ActiveCN101560793AGood architectural effectSmall building effectBuilding constructionsPull forceVertical edge

A universal spherical joint supporter with an anti-loosening position-limiting structure comprises a main spherical joint structural part consisting of a main top base with a concave spherical surface and a main bottom base with a convex spherical surface; the main bottom base consists of a base body, at least three reinforced plates and a steel ball; the steel ball is a convex ball component arranged in the bottom base; the reinforced plates are distributed in the bottom base radially and vertically by taking the vertical middle axis line of the steel ball as a central line; each reinforced plate is provided with a vertical edge closely to the middle axial line of the steel ball; a spherical concave position used for bearing the steel ball is arranged on an upper plate of the reinforced plate closely to the middle axis line by taking the spherical center of the steel ball as a center, and a convex claw is arranged in a space between every two adjacent reinforced plates on the main bottom base correspondingly to the lower circumference of the main top base, thus forming the position-limiting structure of the spherical joint. The position-limiting structure can play roles of preventing loosening, restricting the rotation of the top base around the axis line and bearing the pulling force and has excellent bearing performance; and when the position-limiting structure bears the pulling force, the spherical joint part can rotate slightly and simultaneously.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

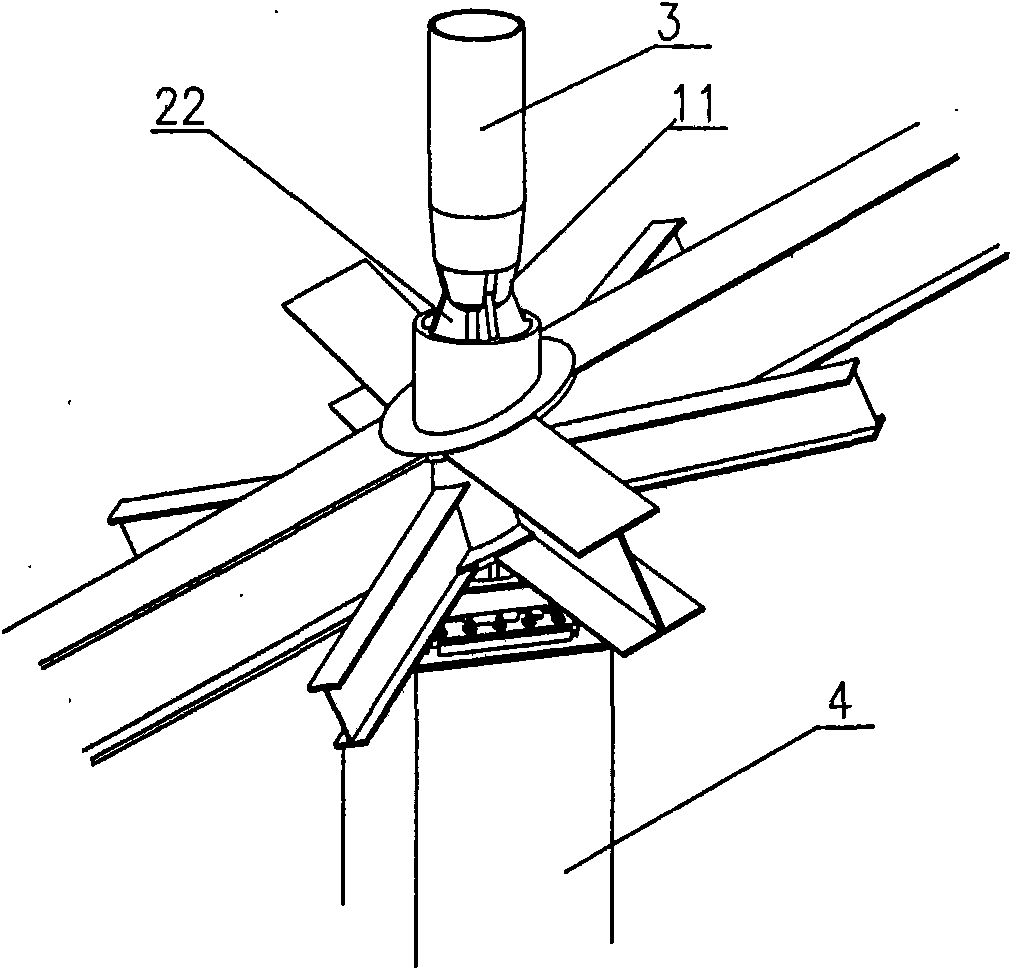

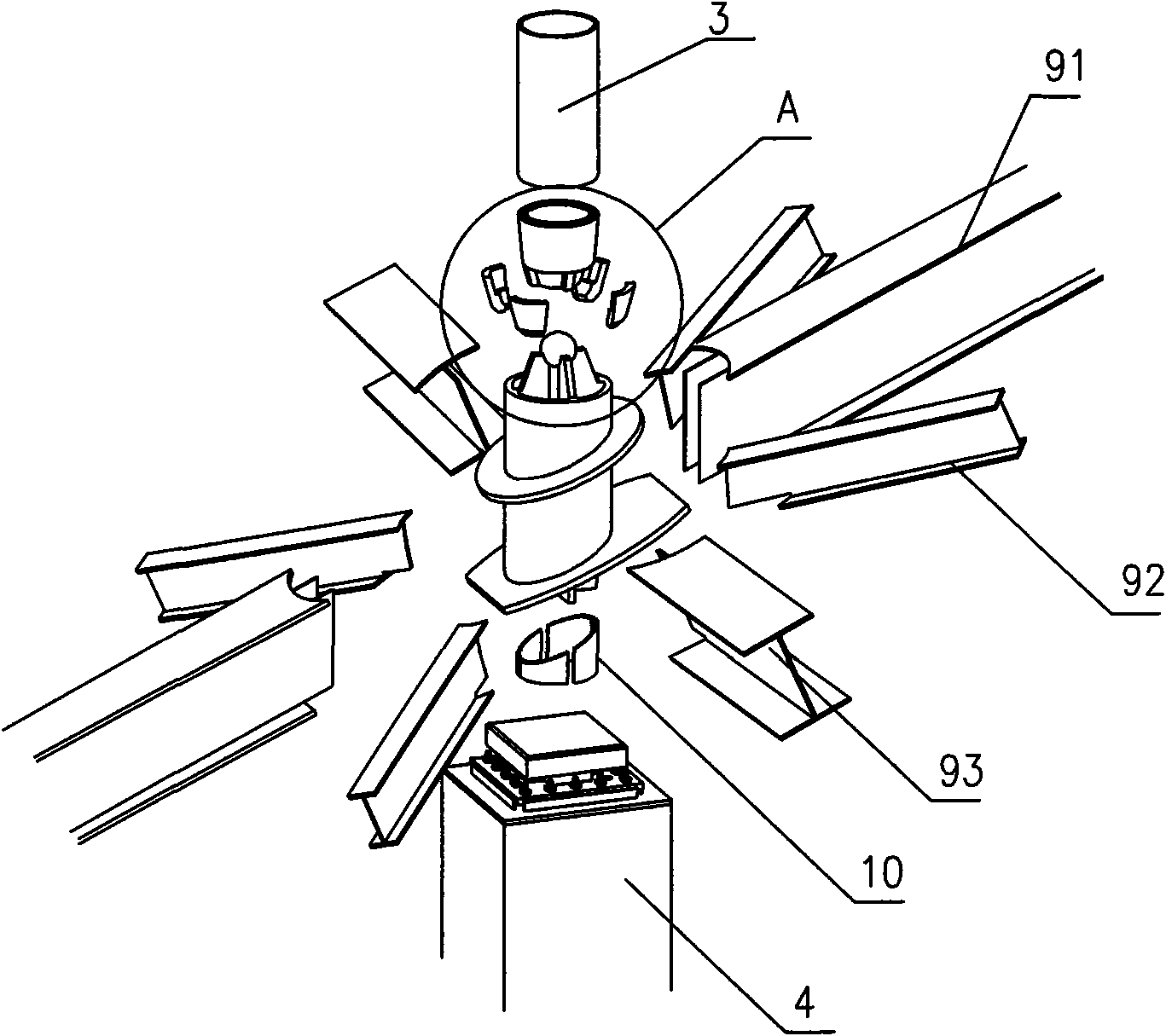

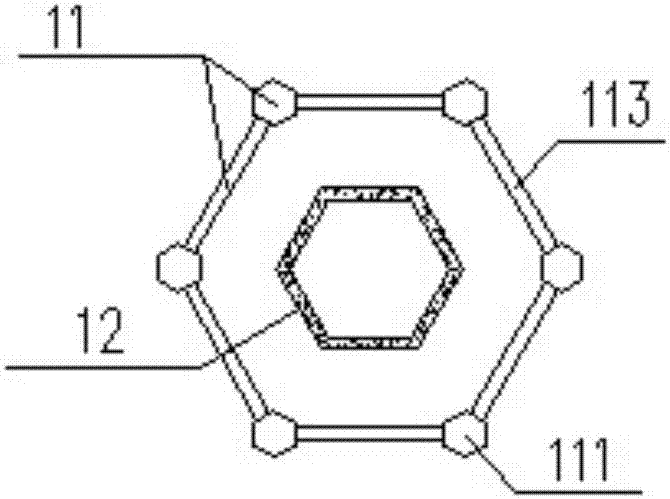

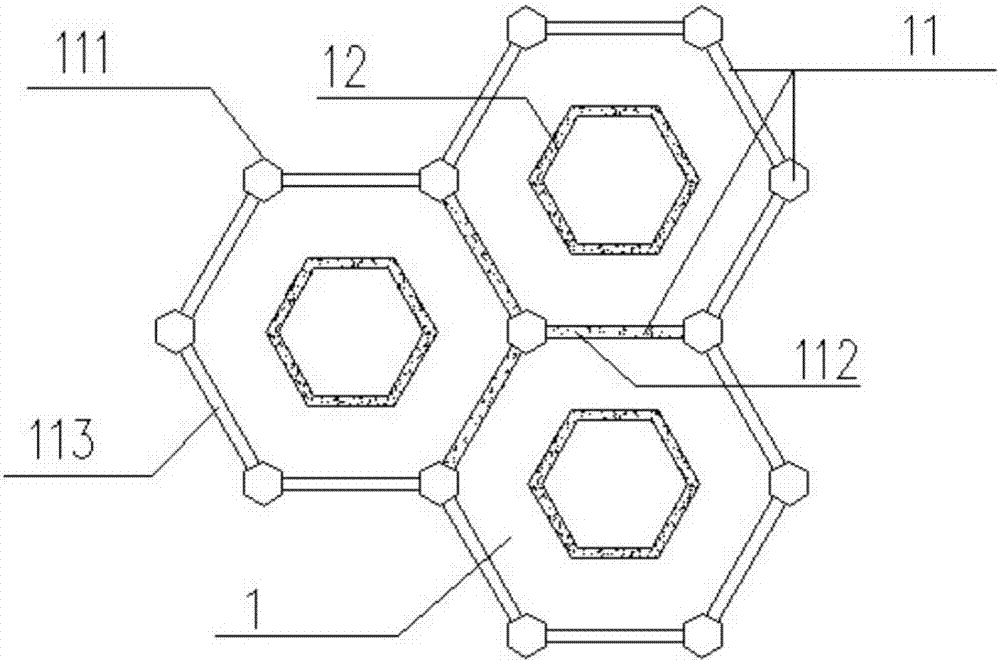

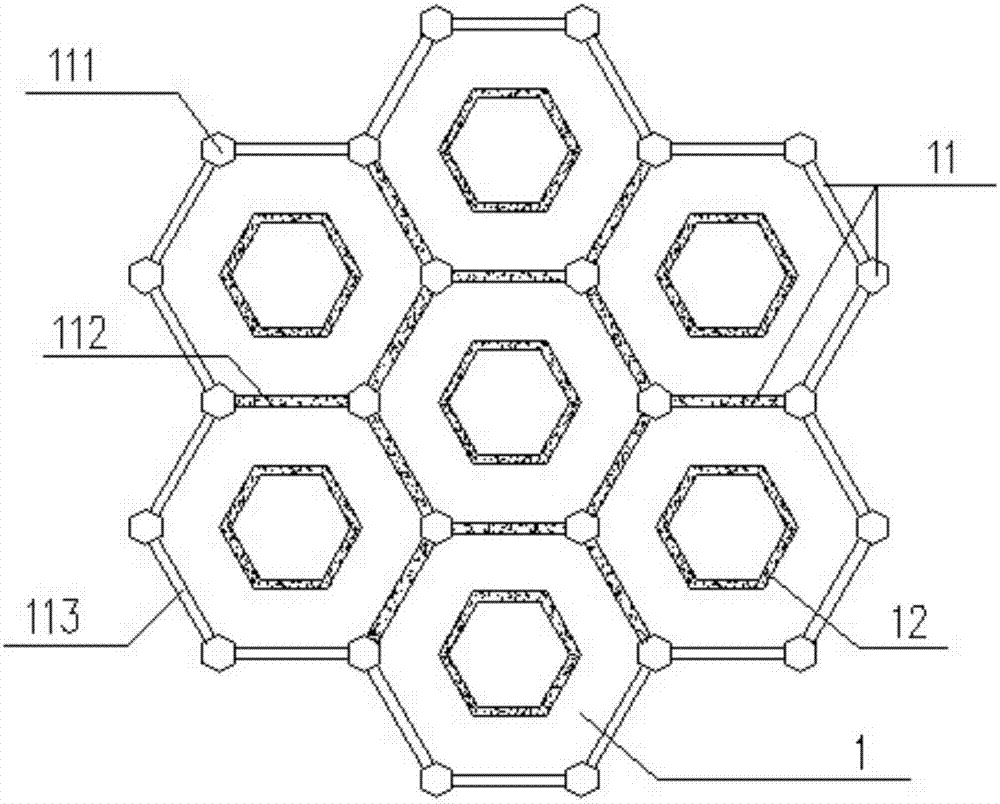

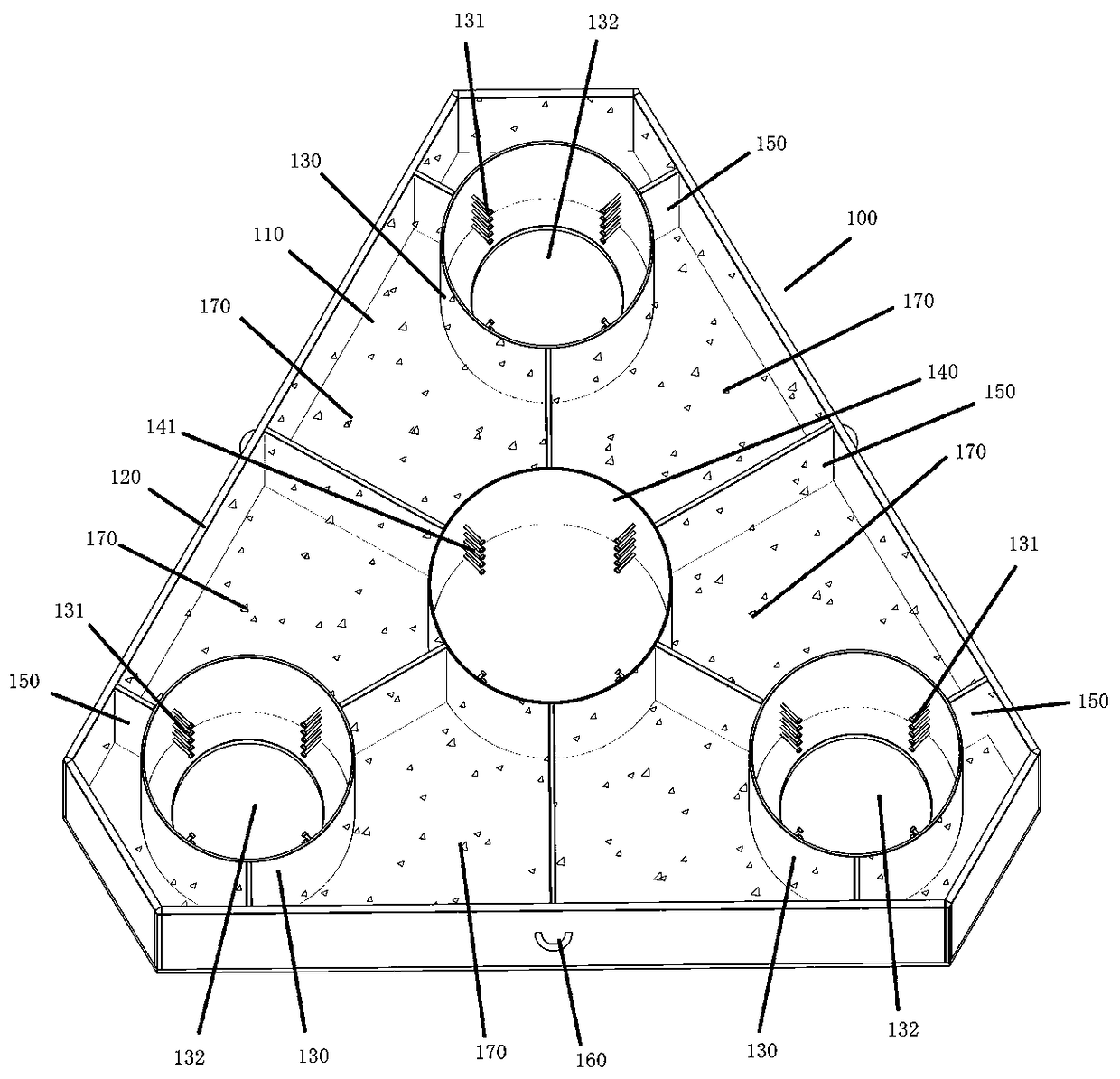

Super high-rise tower structure system of hexagonal barrels arranged in honeycomb-shaped cluster

ActiveCN107060096AReduce in quantityImprove carrying capacityWallsExtraordinary structuresHoneycomb PatternVertical load

The invention provides a super high-rise tower structural system of hexagonal barrels arranged in a honeycomb-shaped cluster. According to a honeycomb structure, a plurality of structural units of giant hexagonal barrels are combined in a cluster mode; and along with the increase of the height of a building, the number of the structural units of the giant hexagonal barrels is gradually reduced, and a novel pagoda-shaped super high-rise structural system is formed. A hexagonal barrel structure composed of giant hexagonal concrete filled steel tubular columns and grilling tubular type double steel plate concrete shear walls is adopted inside the super high-rise tower structural system, and the giant vertical load and the giant horizontal load of the super high-rise building are borne; and a frame tube structure composed of giant hexagonal concrete filled steel tubular columns and giant oblique supporting frames is adopted outside the super high-rise tower structural system, and the requirement for natural lighting of the super high-rise building can be met. The super high-rise tower structural system of the hexagonal barrels arranged in the honeycomb-shaped cluster has the advantages of large structural rigidity, rich facade shape, simplicity, stability, good wind stability performance, good anti-seismic capability, convenient construction and the like, and a super high-rise building structure over one thousand meters can be built.

Owner:SOUTHEAST UNIV

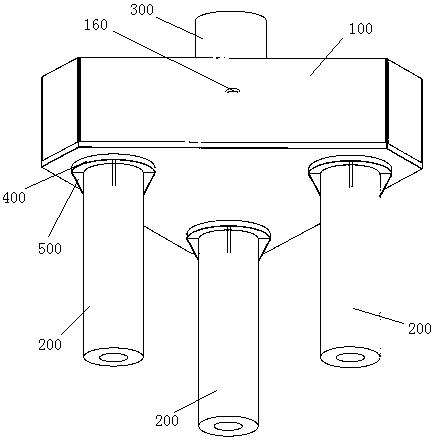

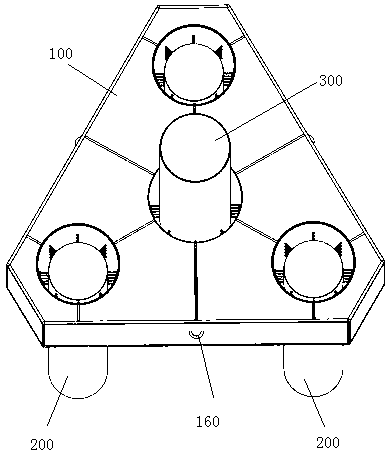

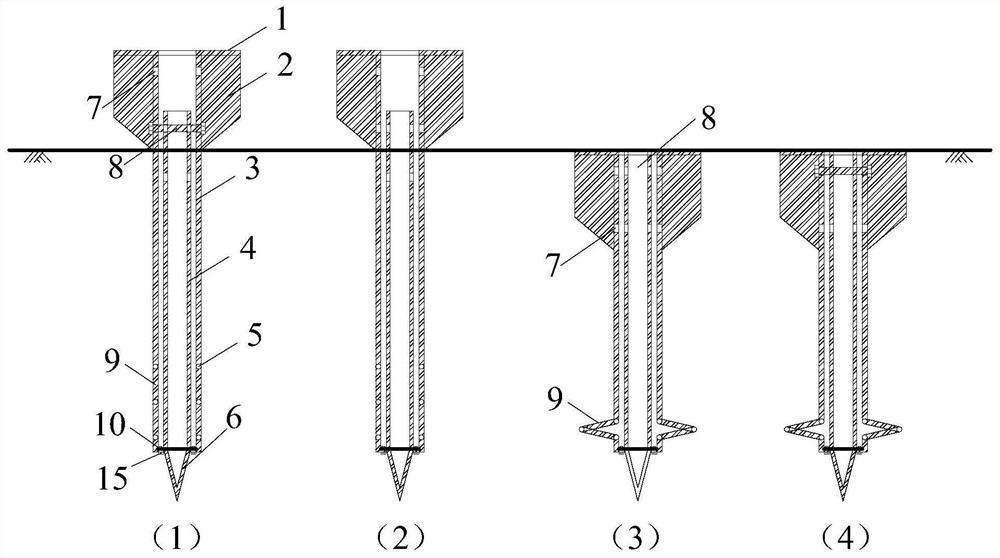

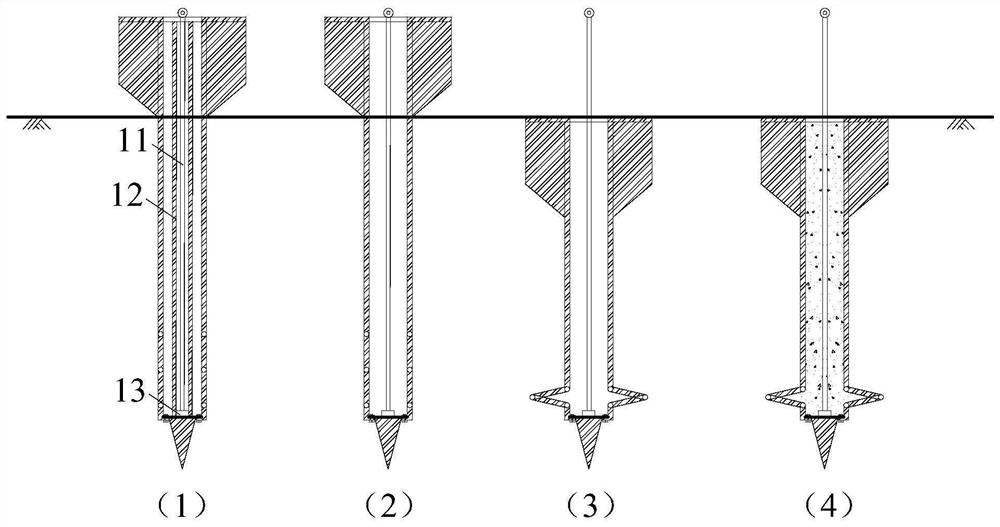

Fabricated concrete-filled steel tube pile foundation and construction method thereof

PendingCN109403366AImprove the compressive capacityImprove overall bearing capacityBulkheads/pilesSteel tubeModularity

The invention relates to a fabricated concrete-filled steel tube pile foundation and a construction method thereof. The fabricated concrete-filled steel tube pile foundation includes a bearing platform, wherein a support pile for supporting the bearing platform is arranged under the bearing platform; and a support column extending upwards is arranged at the upper end of the bearing platform. The support pile has high bearing capacity and is not prone to cracking and breaking; the adverse effect of large-capacity concrete of a traditional bearing platform is effectively reduced; the modular production is adopted, so that the installation is convenient; the processing quality is good; and the construction period is short.

Owner:FUZHOU UNIVERSITY

Steel-wood combined column and combination method

PendingCN109750794AIncrease the differenceImprove the forceStrutsPillarsMechanical propertyCombination method

The invention relates to a steel-wood combination column and a combination method. The steel-wood combined column comprises profile steel and glued wood. The profile steel comprises cross-shaped steeland short straight-line-shaped steel; the cross-shaped steel is provided with four end parts; short straight-line-shaped steel is welded on two sides of each end part; short straight-line-shaped steel is welded to two sides of each end part of the cross-shaped steel and then the welded cross-shaped steel is in a T shape. The glued wood is clamped in the space between the cross-shaped steel and the short straight-line-shaped steel, the glued wood, the cross-shaped steel and the short straight-line-shaped steel are provided with preset holes corresponding to one another in position, and a plurality of sets of bolts penetrate through the short straight-line-shaped steel on opposite sides of the periphery, the glued wood and the cross-shaped steel between the straight-line-shaped steel to integrally lock and connect the whole. A rubber pad is clamped between the profile steel and the glued wood. The steel-wood combined column combines two materials of steel and wood, improves the mechanical property of steel-wood combined columns, prolongs the service life of connection, and gives play to the combination advantages.

Owner:SHENYANG POLYTECHNIC UNIV

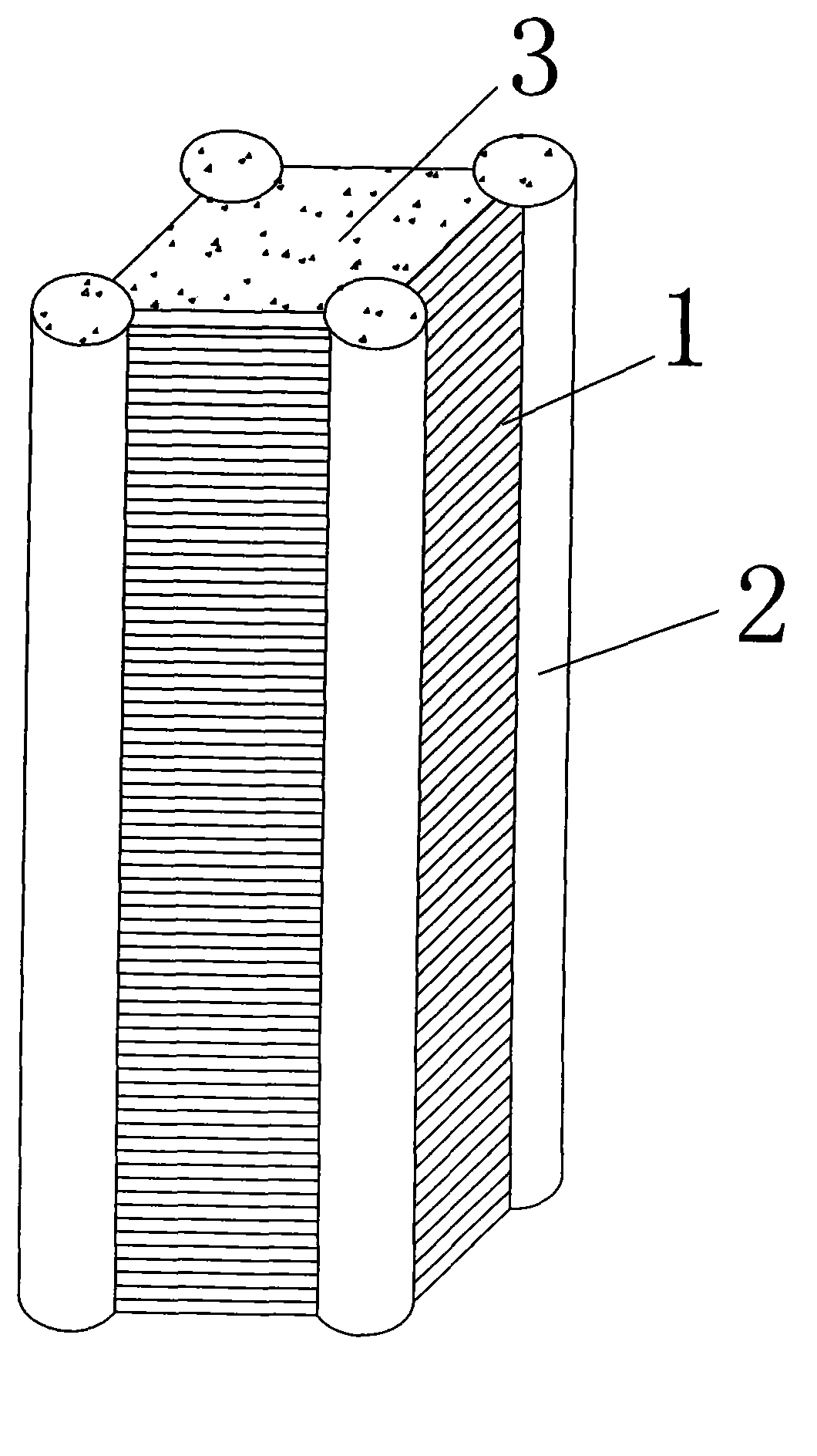

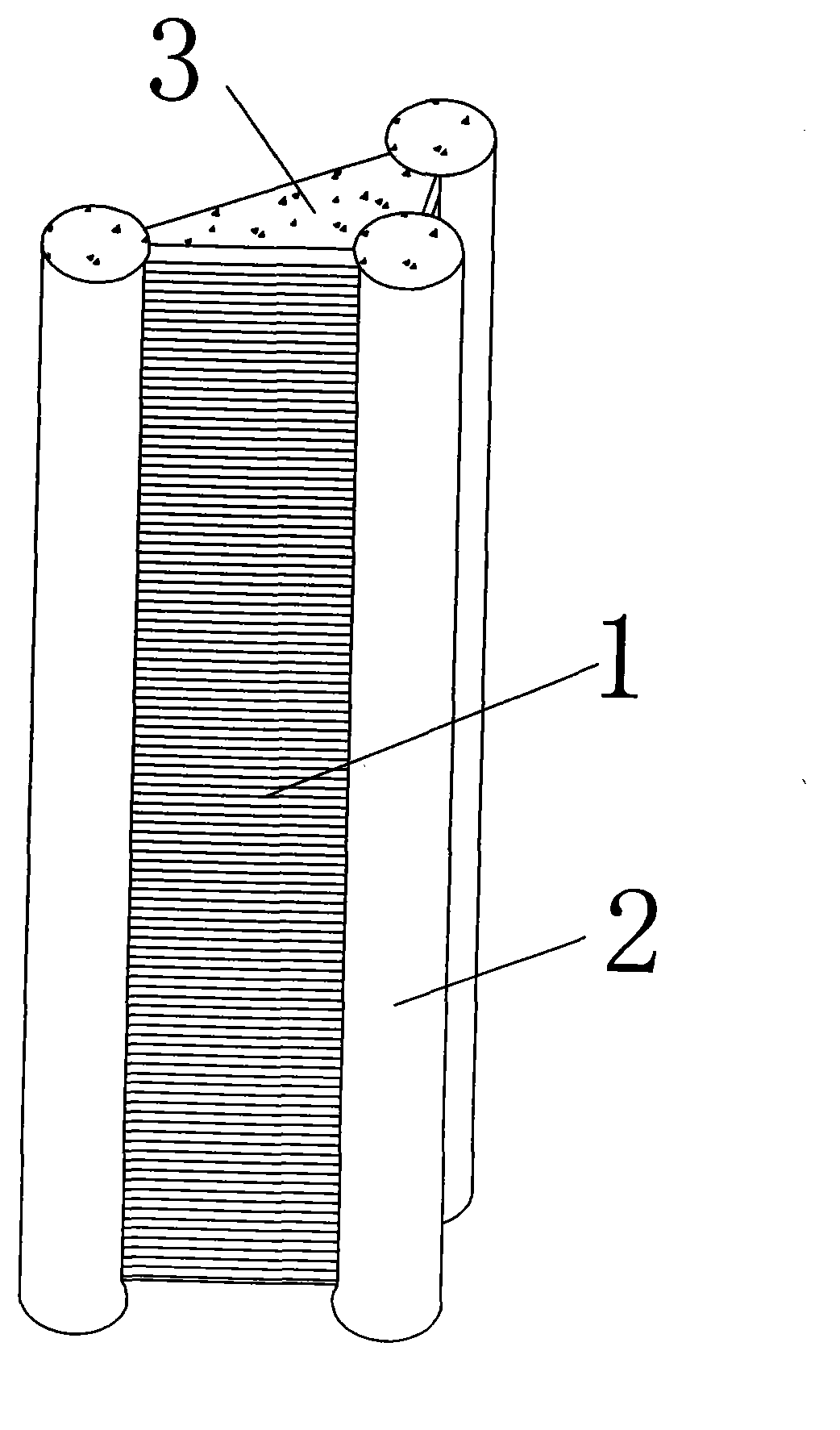

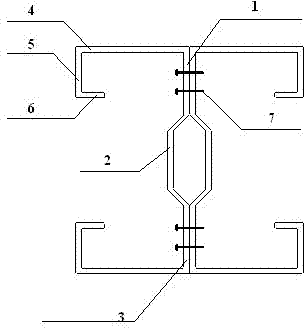

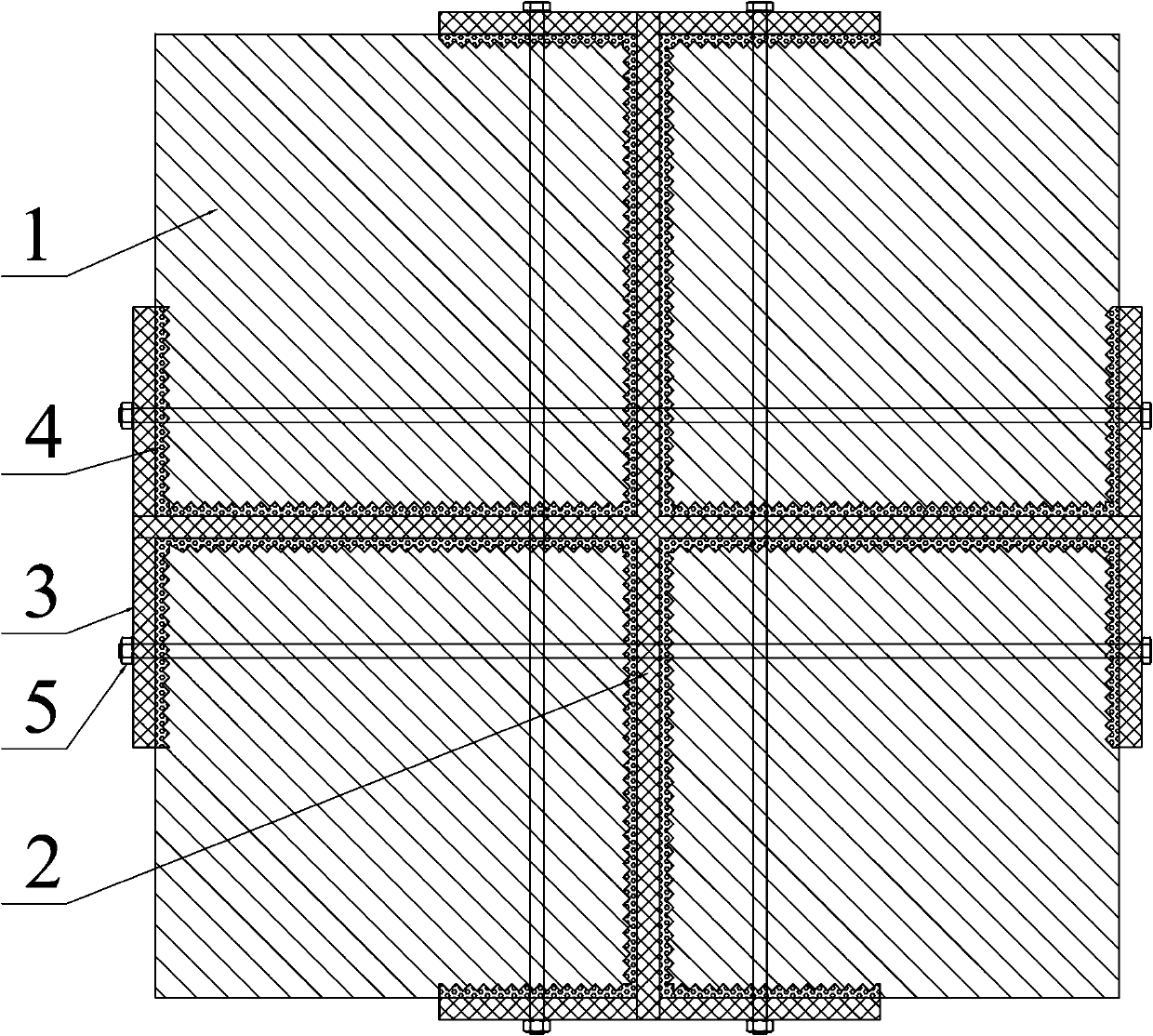

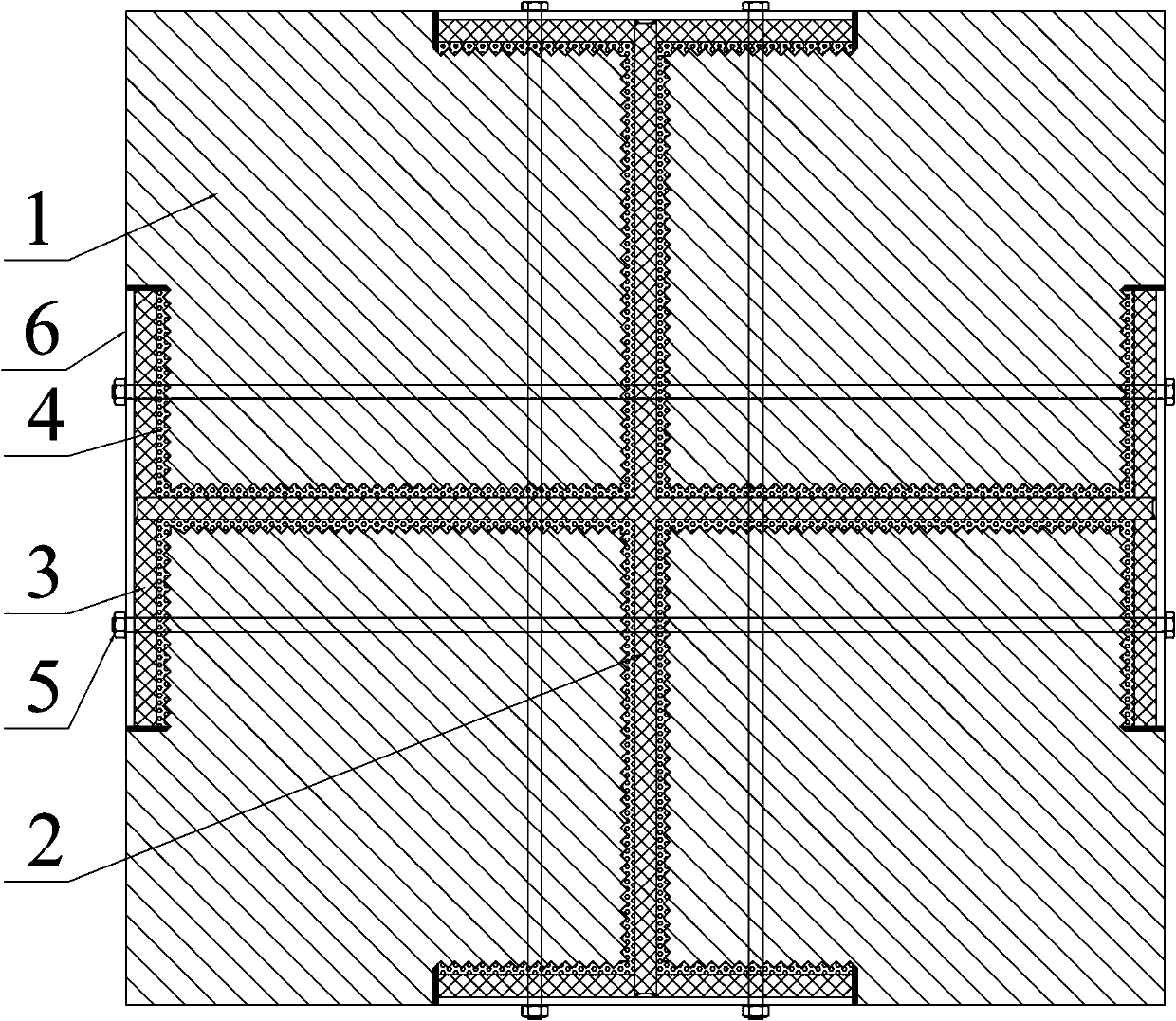

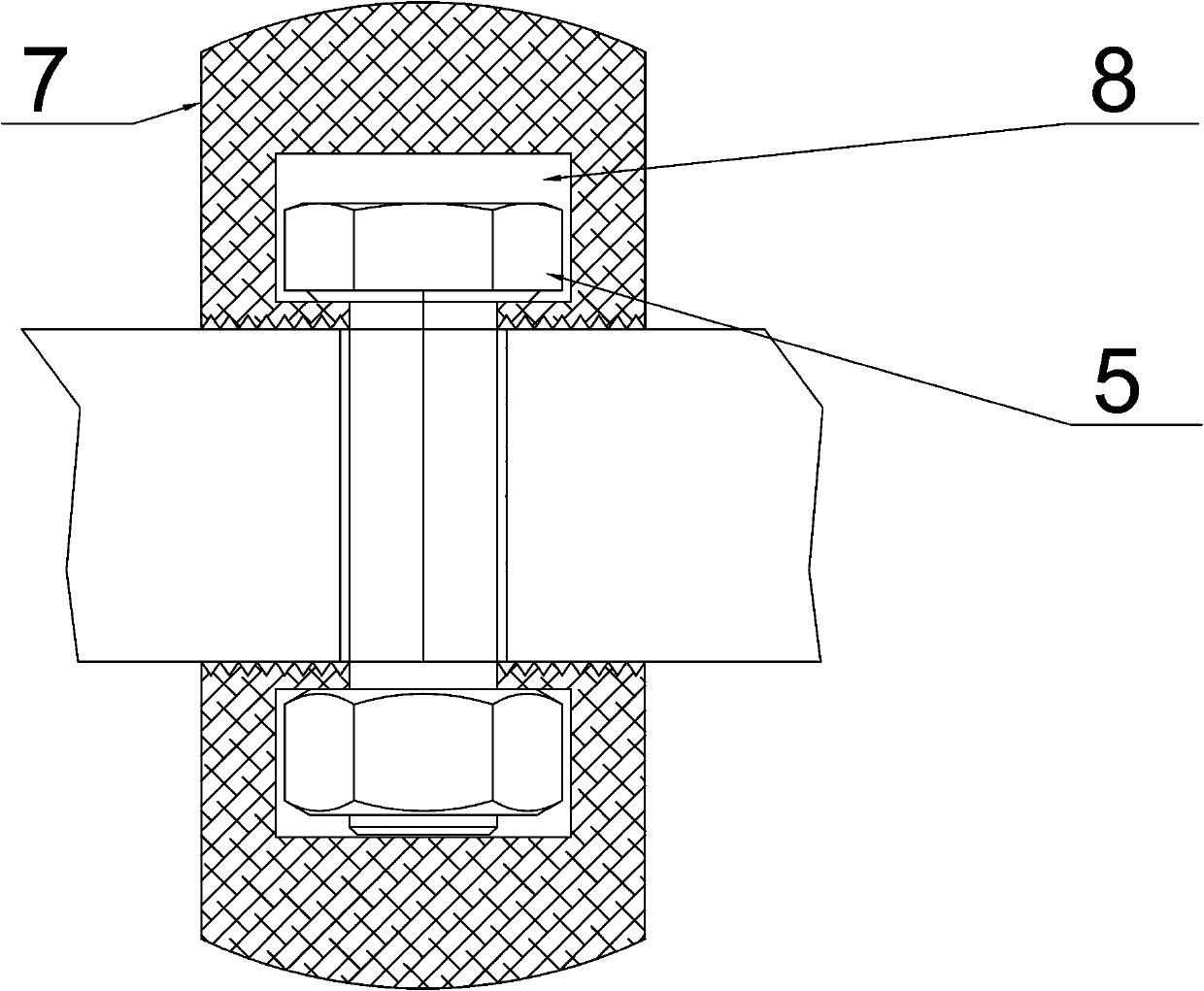

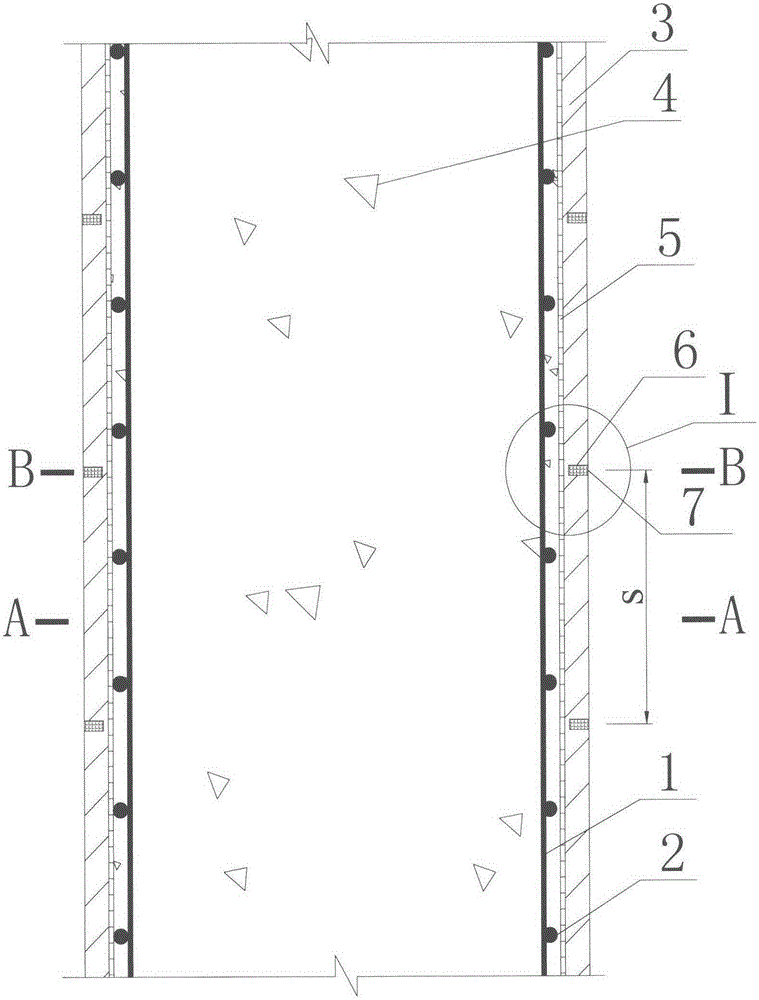

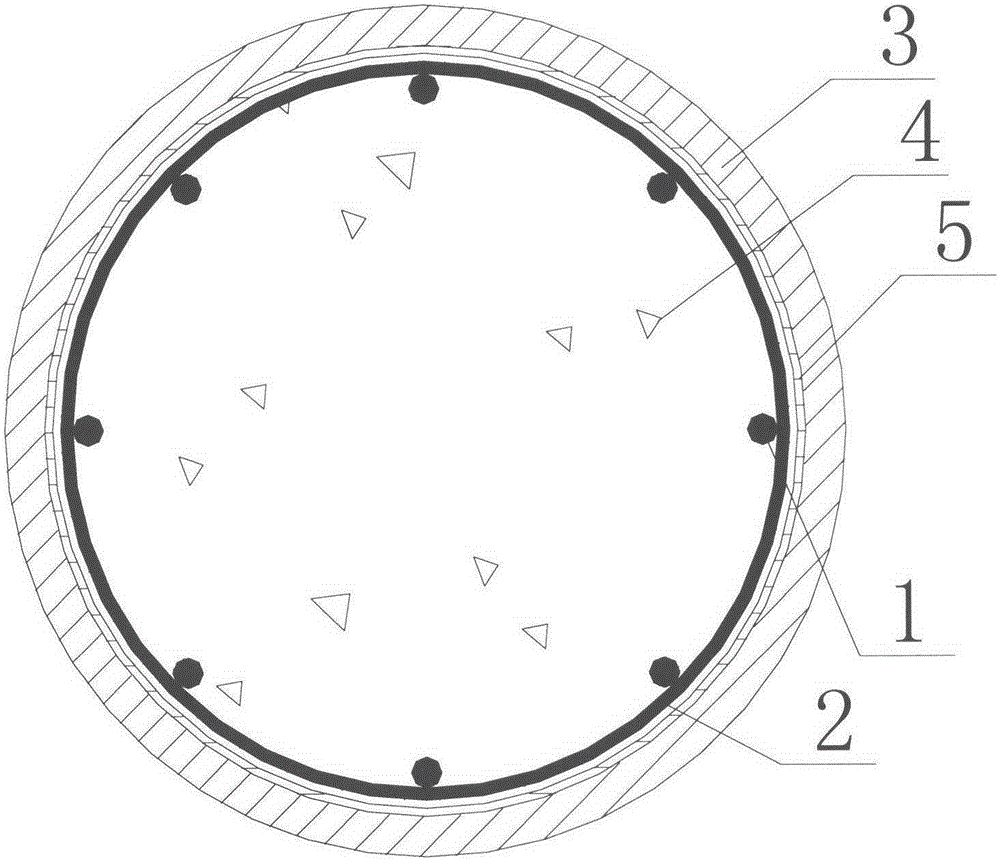

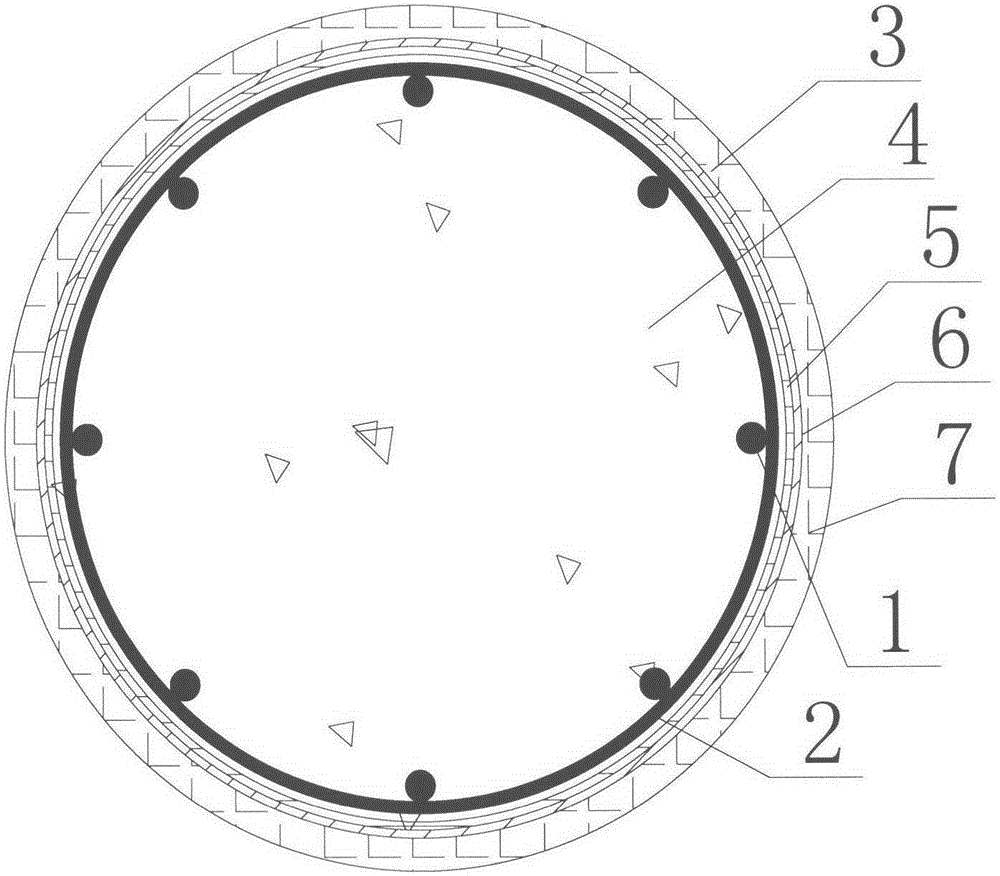

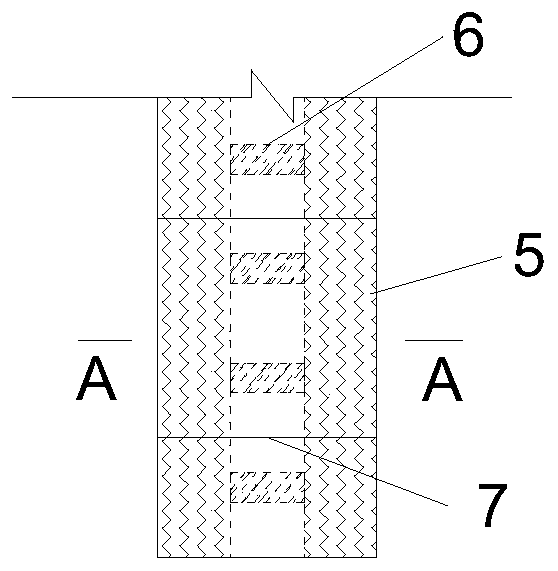

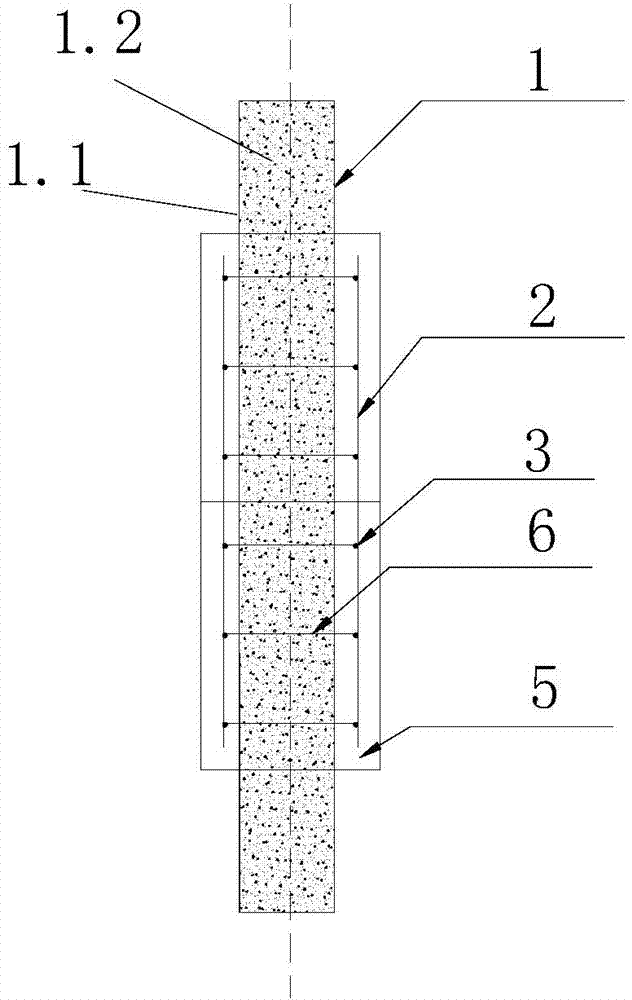

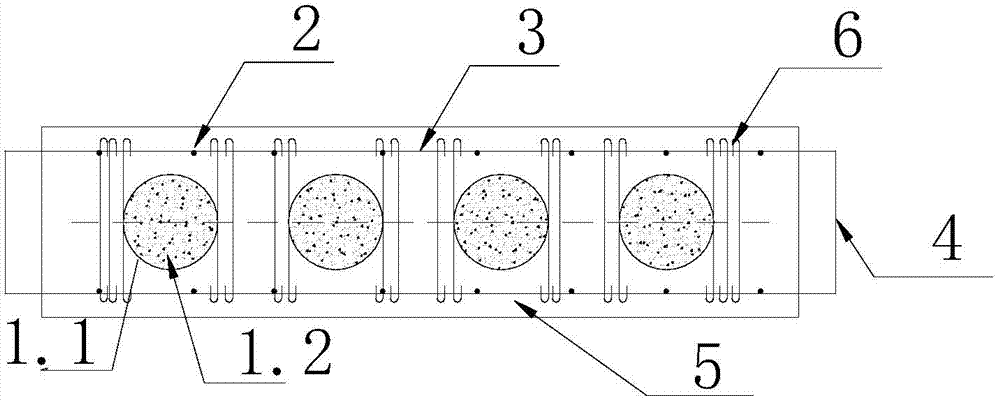

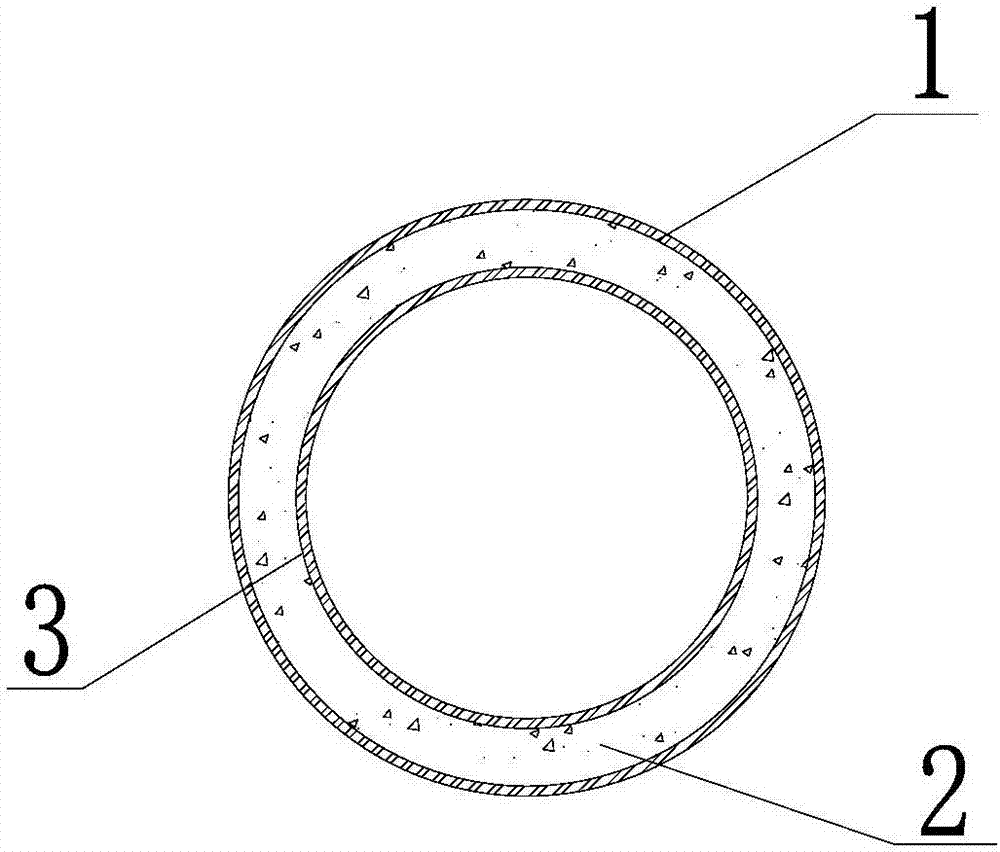

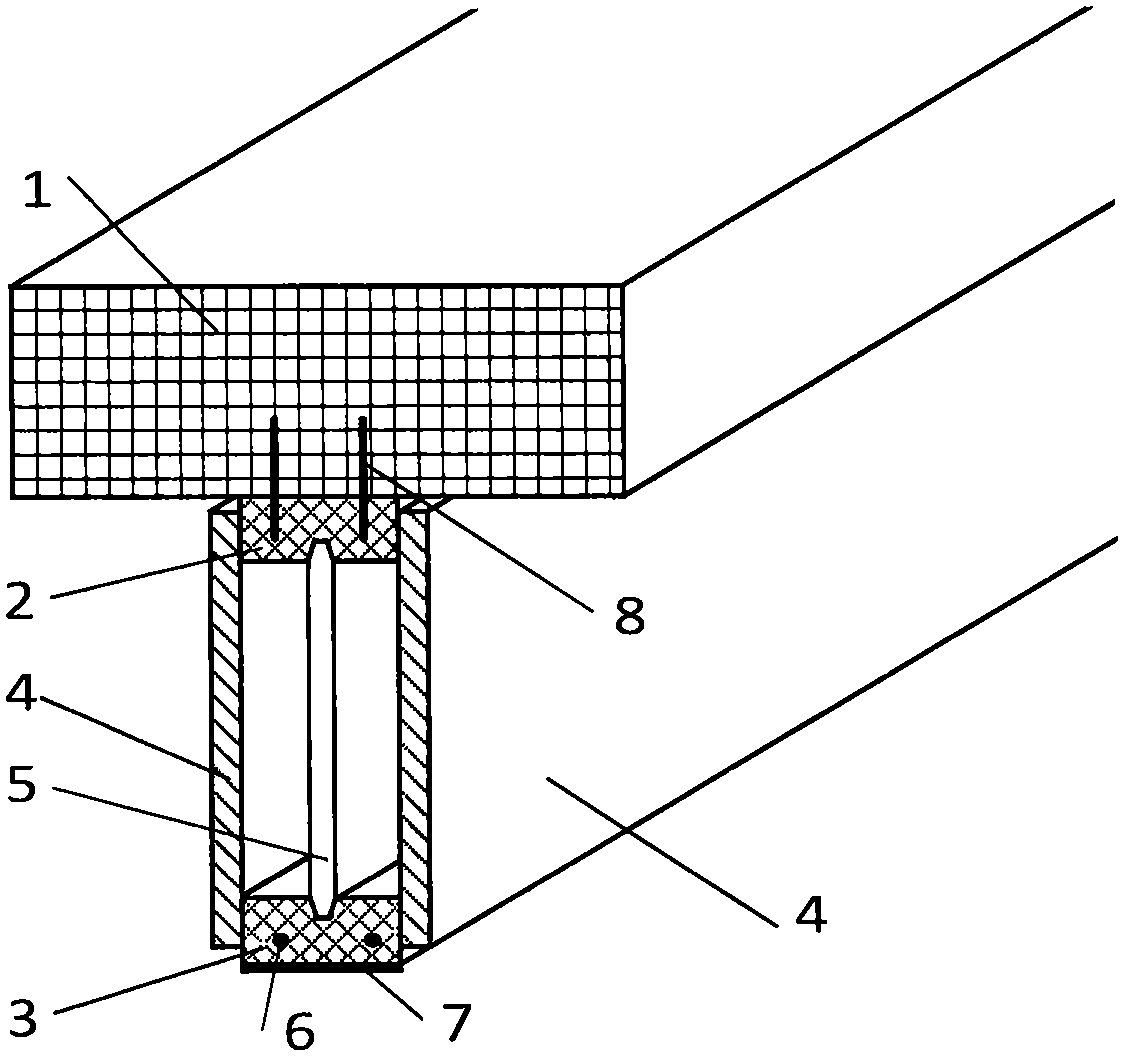

Restricted type steel tube concrete member

ActiveCN105178512AEliminate the effect of bearing vertical stressThe effect of eliminating vertical stressStrutsBridge structural detailsFiber-reinforced compositeVertical load

A restricted type steel tube concrete member jointly consists of a longitudinal bar (1), a stirrup (2), a steel tube (3), core concrete (4) and a boundary layer (5), and is characterized in that the steel tube (3) is filled with the core concrete (4); the boundary layer (5) is arranged between the steel tube (3) and the core concrete (4); one or more than one pressure reducing notch (6) is formed in the surface of the steel tube (3); the length of each pressure reducing notch (6) equals the annular periphery of the member in the perimeter direction; the depth of each pressure reducing notch (6) is greater than or equals 80% of the thickness of the steel tube (3) and smaller than the thickness of the steel tube (3); the sum of widths of the pressure reducing notches (6) is not smaller than 2% of the length of the member; a fiber reinforced composite material (7) is arranged in each pressure reducing notch (6); and a fiber direction of the fiber reinforced composite material (7) is along the ring direction of the member. The technical shortcoming that the steel tube in a common steel tube concrete structure mainly bears vertical stress and is easy to bend is overcome. The restricted type steel tube concrete member is suitable to be a vertical load-bearing member of various bridges and buildings.

Owner:NANJING FORESTRY UNIV

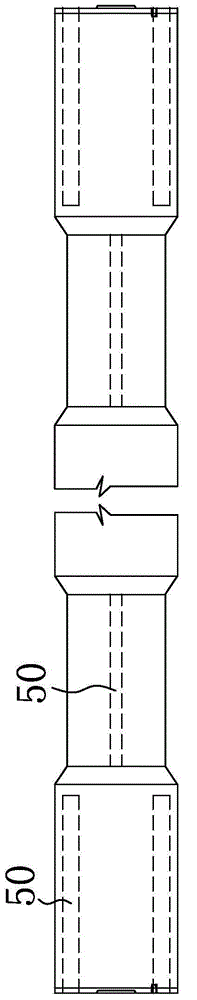

Precast pile with concave clamping platform and convex clamping platform

The invention belongs to the technical field of preformed units in the building industry and relates to a precast pile with a concave clamping platform and a convex clamping platform. The precast pile solves the technical problems that in the prior art, connection is not convenient and not firm. The precast pile comprises a pile body. The pile body is internally provided with a reinforcement cage. The reinforcement cage comprises a plurality of longitudinal reinforcement bars and spiral reinforcement bars fixedly connected with the longitudinal reinforcement bars. The two ends of the pile body are provided with a concave-convex clamping platform mechanism. When two adjacent pile bodies get close to each other, the concave-convex clamping platform mechanism can enable the two pile bodies to be matched in a clamped and connected manner so that the two pile bodies can be connected. According to the precast pile, the pile bodies can be quickly and firmly connected.

Owner:周兆弟

Method realizing drainage and consolidation of hydraulic fill soil as well as soil mass improvement through utilizing straw pile

The invention relates to the technical field of hydraulic fill soil improvement through using a straw pile, in particular to a method realizing drainage and consolidation of hydraulic fill soil as well as soil mass improvement through utilizing the straw pile. The method comprises the following steps that the straw pile is pressed into the hydraulic fill soil, wherein the diameter of a straw piletop is larger than that of a straw pile body, the contact between the hydraulic fill soil and the straw pile body can be delayed when the straw pile is pressed, and the resistance is reduced; an anti-pressure pile core is drawn out, wherein the anti-pressure pile core is made of a steel pipe, and the anti-pressure pile core can be drawn out and recycled from the straw pile body after pile pressingis finished; the straw pile can form a hollow straw drainage cavity by utilizing good permeability, abilities to degrade fiber cloth, water permeability and slurry-blocking property of straw, whereinan inner lining ring is arranged in the straw pile body, so that the straw pile body after being subjected to pressing of the hydraulic fill soil is prevented from collapsing towards the hollow cavity, the blockage is avoided, and water is conveniently discharged from the hollow cavity; and a drainage pipe is inserted into the straw pile body at regular intervals for drainage so that the hydraulic fill soil can be consolidated. According to the method, the pile top can be slowly decomposed and the straw pile body can be decayed and degraded, organic matter of the hydraulic fill soil can be increased, and the looseness, water permeability and air permeability of the local hydraulic fill soil can be improved. s

Owner:JIANGSU OCEAN UNIV

Prefabricated irregular side column, prefabricated assembly type beam-column joint and construction method thereof

ActiveCN106948549AImprove the compressive capacityIncrease the bearing areaStrutsBuilding material handlingSheet steelAbnormal shaped

Owner:北京宝贵石艺科技有限公司

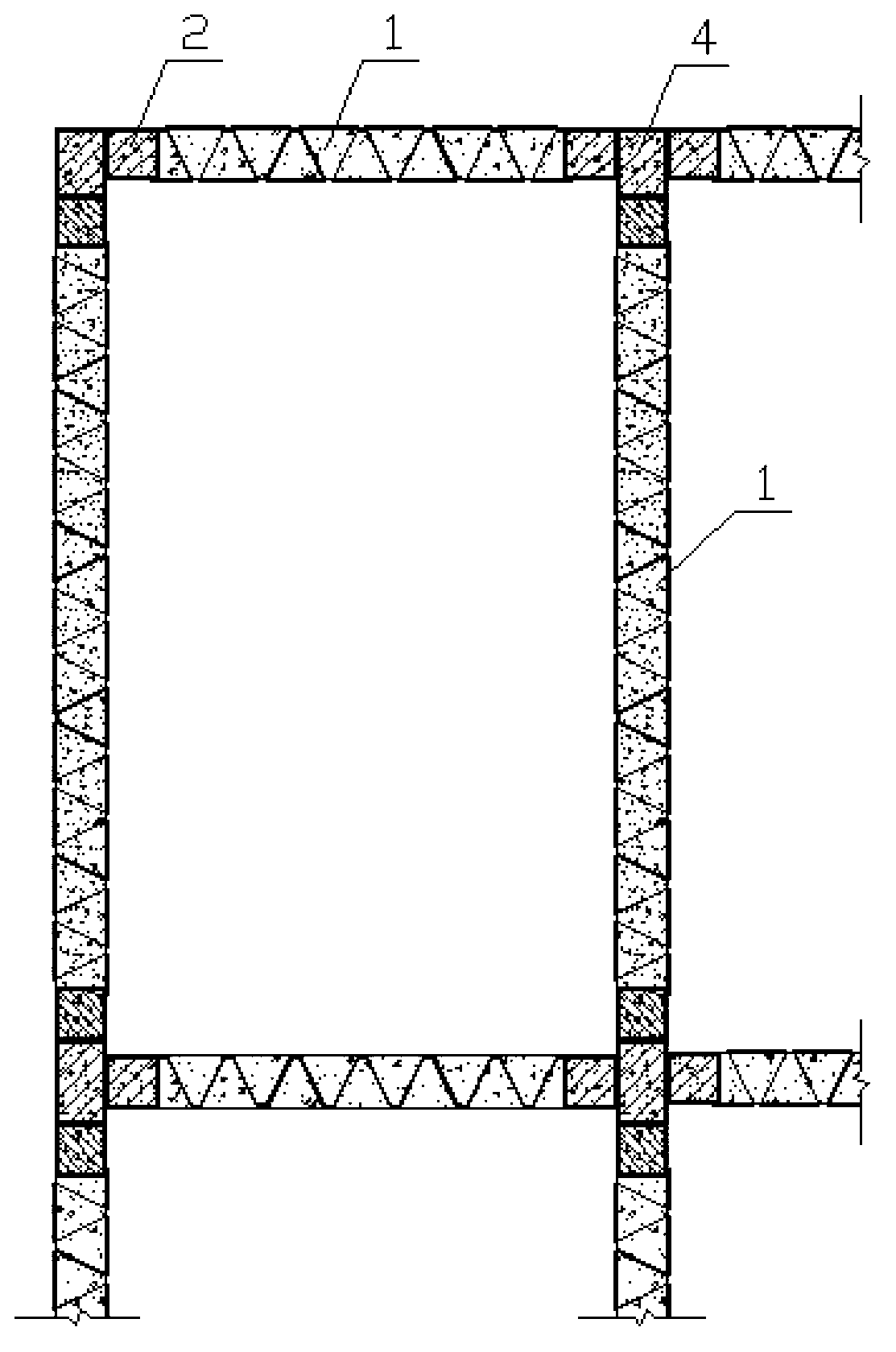

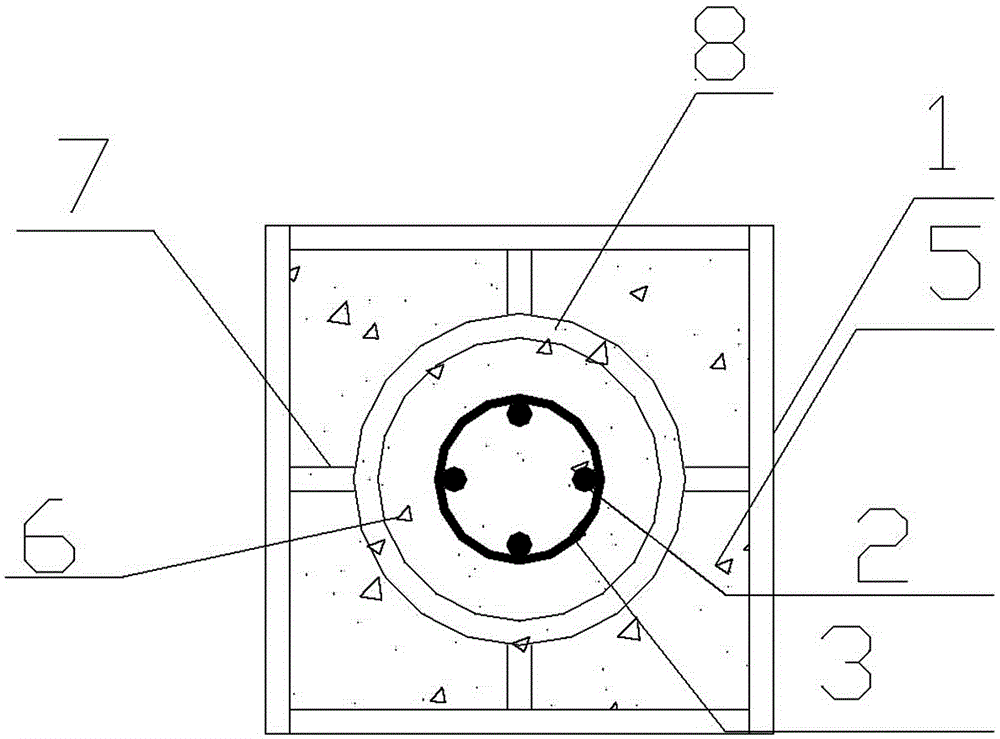

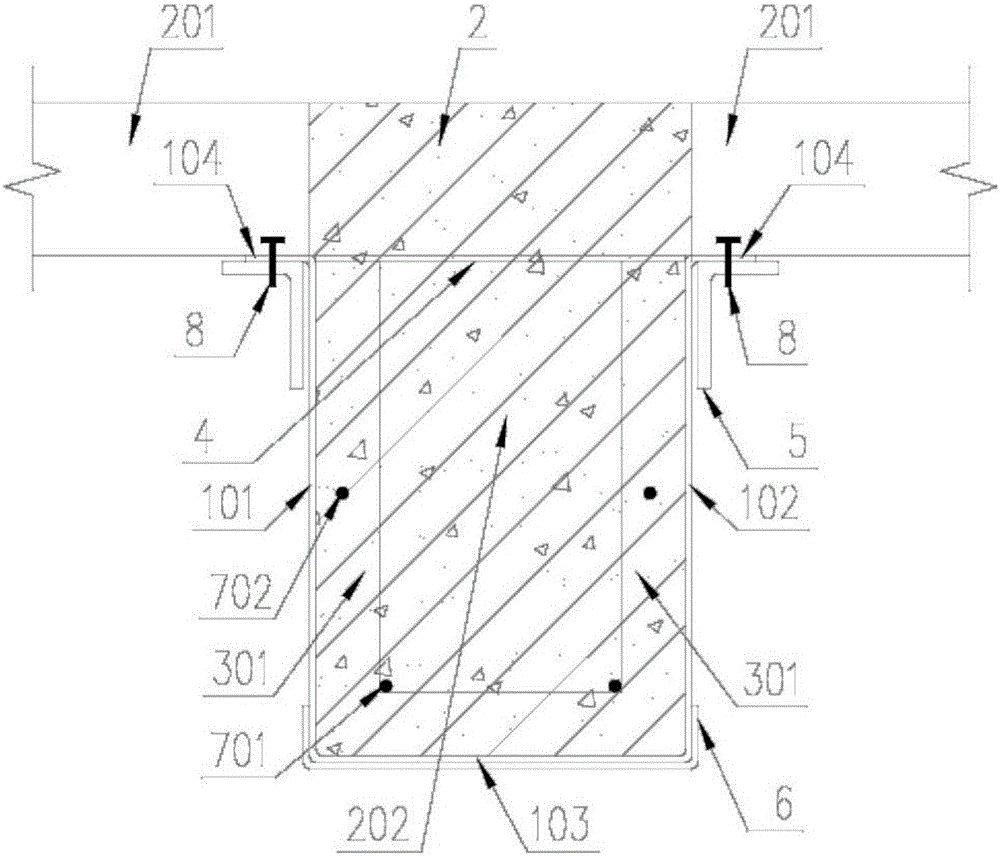

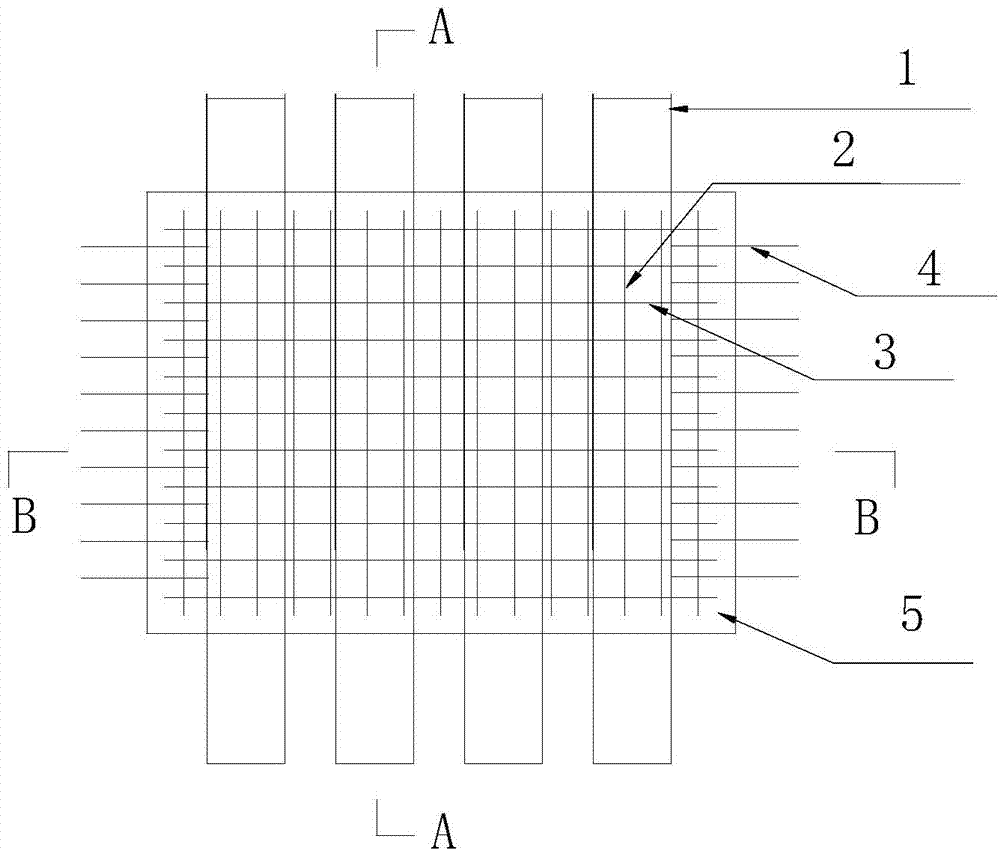

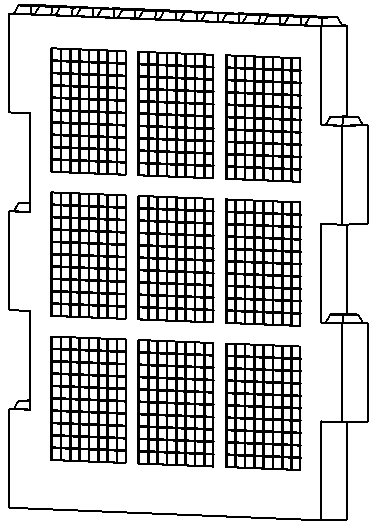

Concrete filled steel tube core column reinforced prefabricated assembly type shear wall unit

ActiveCN103790266AImprove the compressive capacityIncreased shear capacityWallsRebarUltimate tensile strength

The invention discloses a prefabricated assembly type concrete filled steel tube core column reinforced shear wall unit, and belongs to the field of constructional engineering. The shear wall unit comprises a double-layer reinforcing mesh, outer wrapped concrete and lacing wires and further comprises a plurality of round concrete filled steel tube core columns, and the round concrete filled steel tube core columns are vertically fixed into a cavity of the double-layer reinforcing mesh at an equal interval; after the reinforcing mesh and steel tubes are fixedly bound, the outer wrapped concrete is poured to form a shear wall; the upper ends of the round concrete filled steel tube core columns and the lower ends of the round concrete filled steel tube core columns stretch out of the outer wrapped concrete, and the round concrete filled steel tube core columns are composed of round steel tubes and concrete poured in cavities of the round steel tubes in a filled mode. According to the prefabricated assembly type concrete filled steel tube core column reinforced shear wall unit, by the utilization of the high bearing capacity and the high ductility of the concrete filled steel tube core columns, the anti-bending capacity, the shearing resistance and the hysteretic energy dissipation capacity of the shear wall are effectively improved, and good anti-seismic property is achieved. The prefabricated assembly type concrete filled steel tube core column reinforced shear wall unit is simple in construction technology, the overall quality of a building can be guaranteed through prefabrication and site assembly, the construction operation speed is improved, and the labor intensity is lowered.

Owner:江苏莱士敦建筑科技有限公司

Method for construction of cast-in-place concrete anchor pile

InactiveCN1214158CImprove the compressive capacityImprove pullout resistanceBulkheads/pilesRebarBuilding construction

A construction method for in-situ pouring concrete anchor pile includes tamping external sleeve pipe into foundation, tamping the fundation by weight hammer reciprocating along the sleeve pipe to form a hole under pipe bottom, taking the weight hammer out, inserting the reinforcing bar cage with an expandable part into sleeve pipe, inserting internal sleeve pipe into the reinforcing bar cage, repeatedly filling and tamping in internal sleeve pipe until the expandable part is expanded to form a horn shape,and lifting up the internal and external sleeve pipes while filling concrete in it to form a rigid concrete pile.

Owner:王继忠

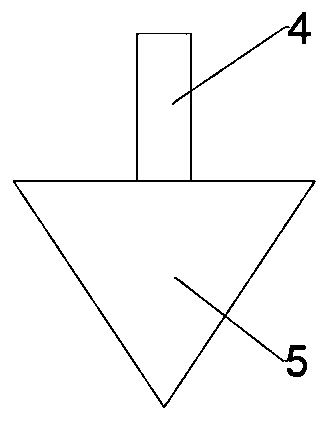

Static pressure type rear support spiral pile based on bionics and construction method thereof

The invention discloses a static pressure type rear support screw pile based on bionics, which comprises a pile tip, an outer sleeve, a flange and an empennage, the empennage is arranged at the upperend of the outer sleeve, the flange is arranged at the top ends of the empennage and the outer sleeve, an outer support blade is arranged at the lower part of the outer sleeve, and when the outer support blade is pressed at the top of the outer sleeve, the outer supporting blades are unfolded outwards. A built-in steel pipe or a flexible anchor rod is arranged in the outer sleeve, and the pile tipis fixedly connected with the built-in steel pipe or the flexible anchor rod. By optimally designing the pile body, the side resistance is small during static pressure pile sinking penetration, the outer supporting blades are unfolded through secondary sinking of the outer sleeve, the vertical uplift and compression resistance bearing capacity of the outer supporting blades is improved, the horizontal bearing capacity of the outer supporting blades is improved through the arrangement of the empennage, and the uplift bearing capacity of the pile side and the blades is improved by utilizing thecharacteristics of compression shrinkage and tension expansion of negative poisson ratio materials. The method has the advantages of small soil disturbance, low construction noise and environmental friendliness.

Owner:HOHAI UNIV +3

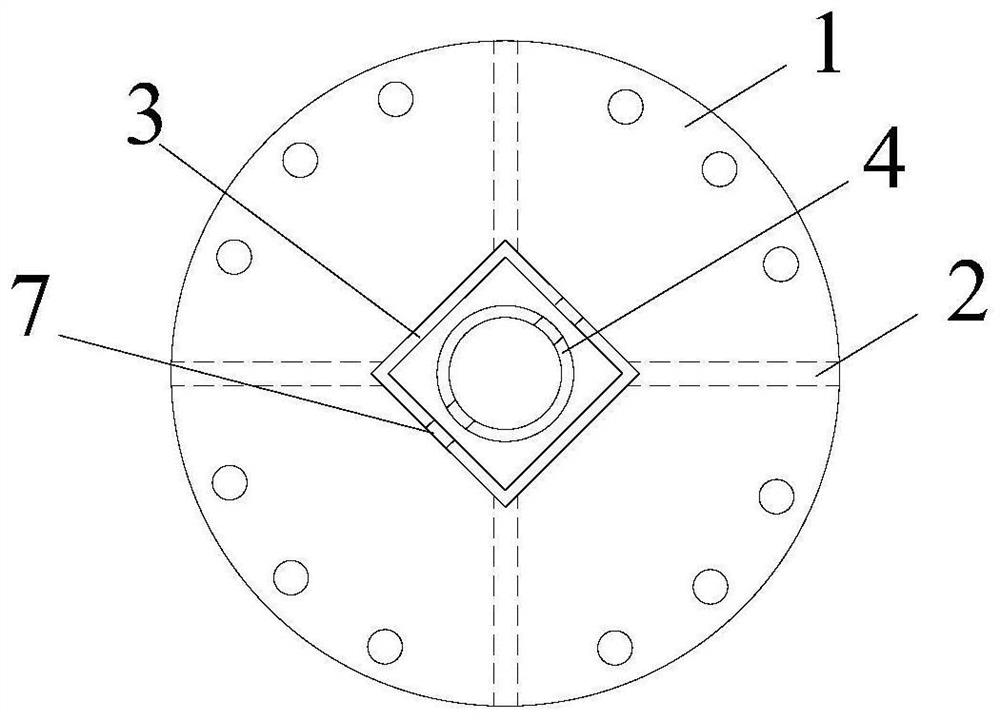

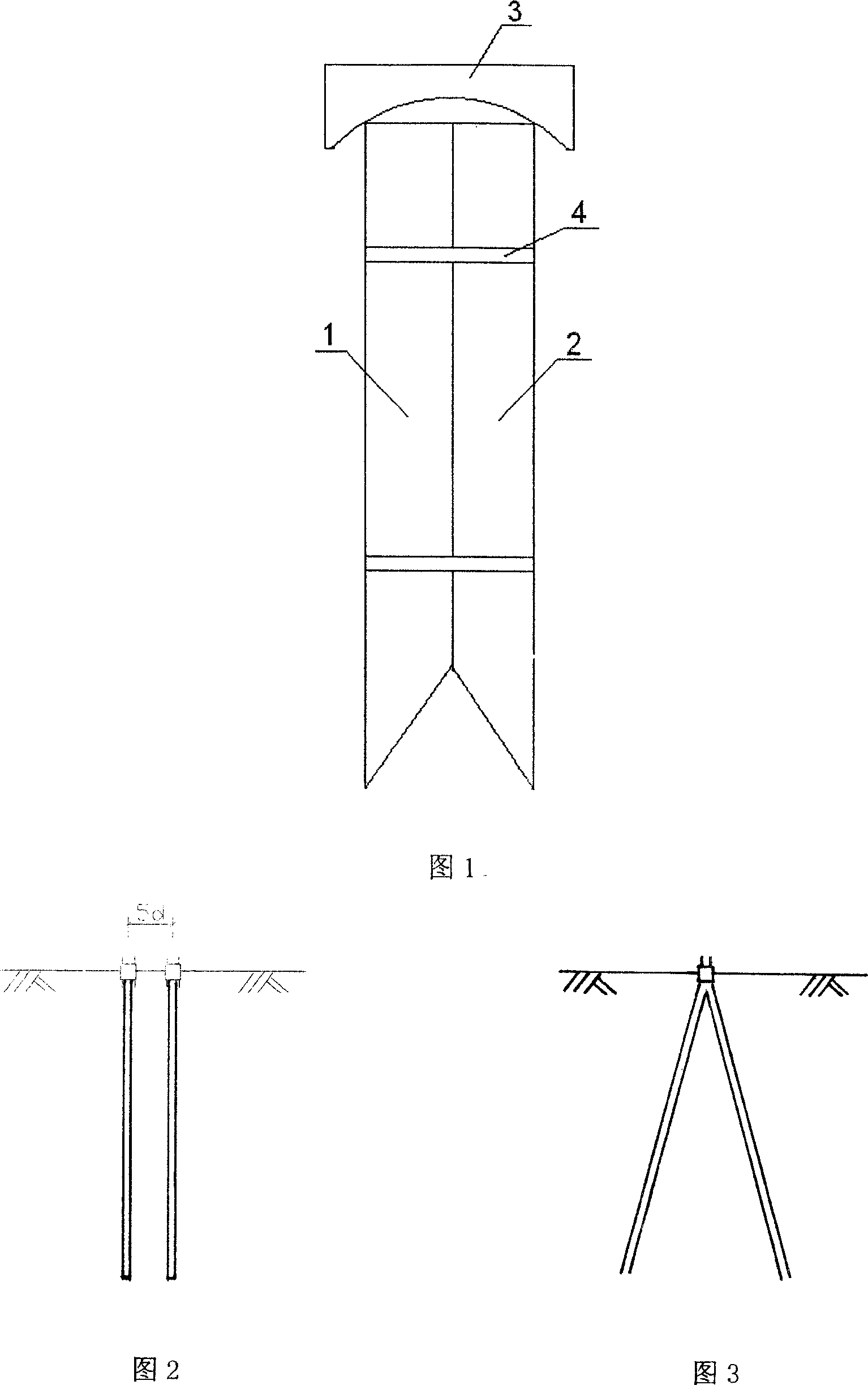

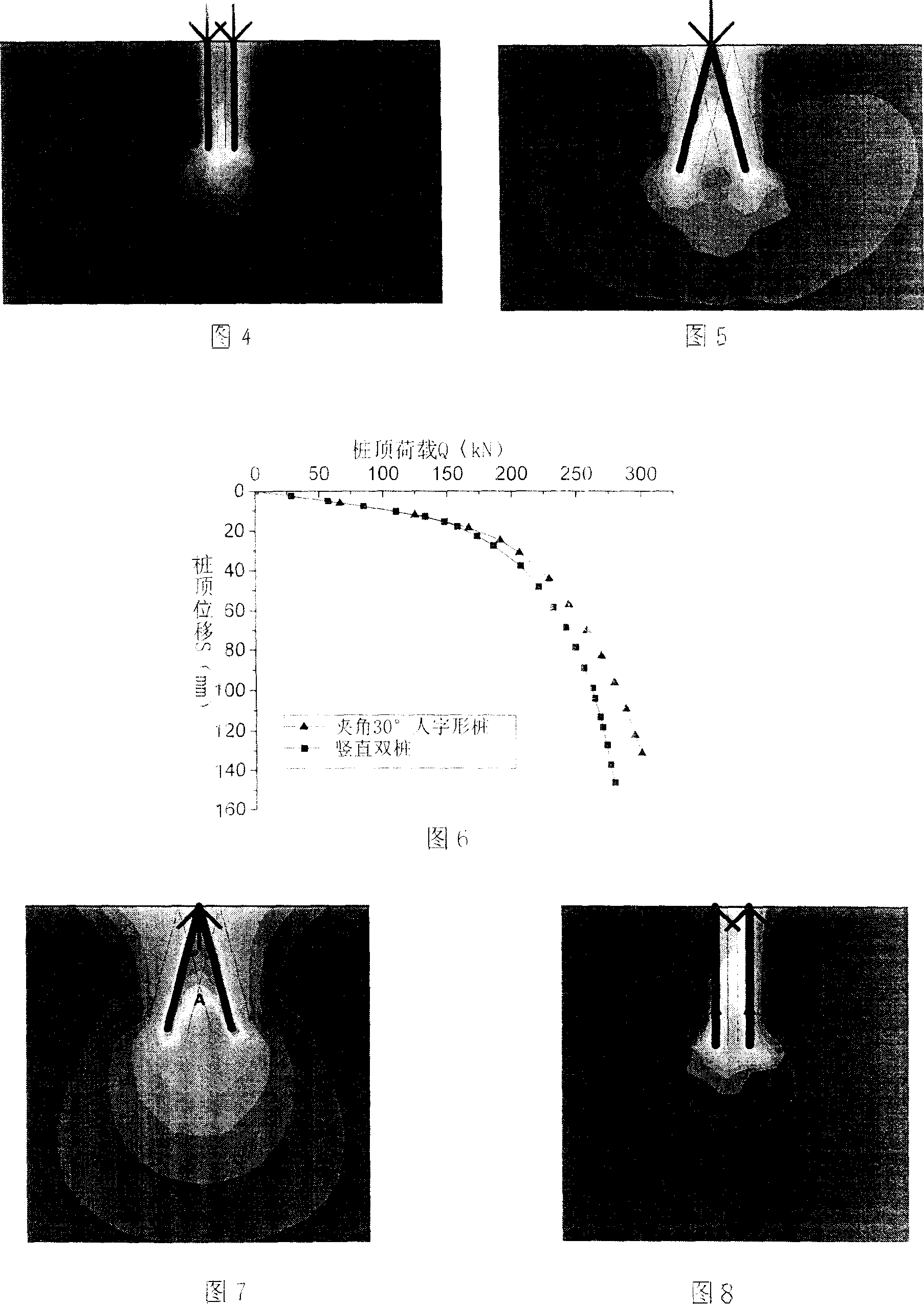

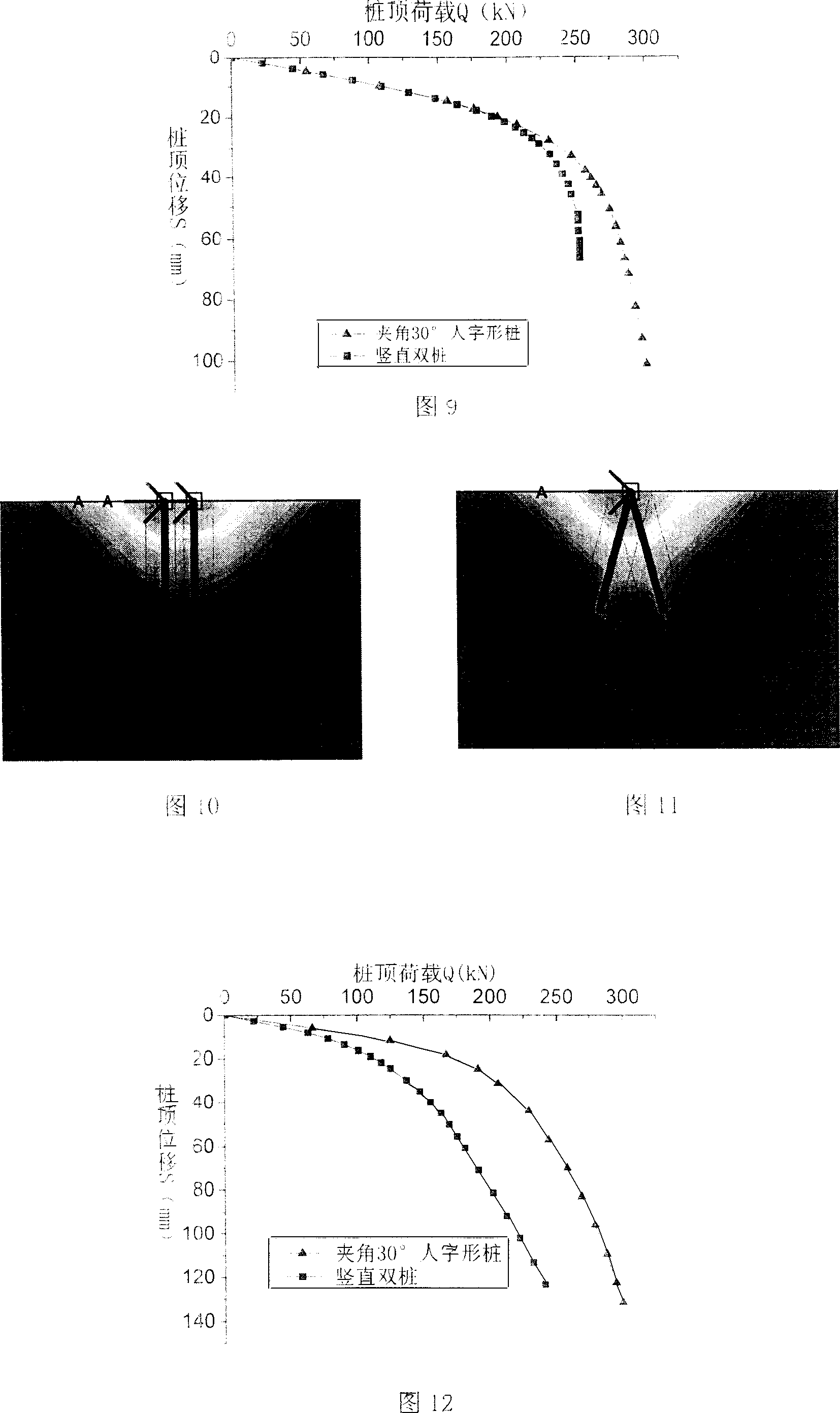

Self-divergence type herringbone stake

InactiveCN1995552AGuaranteed StrengthSelf-tensioning angle high bearing capacityBulkheads/pilesPile capEngineering

The invention discloses a self-opening herringbone pile, comprising two parallel upright piles (1, 2). Pile caps (3) are set on ends of two upright piles (1, 2) and pile caps (3) are connected with ends of two upright piles (1, 2) reelingly. Another ends of two upright piles (1, 2) are slopes and slopes of ends are face-to-face. In the invention pile prefabrication ensures strength. The construction speed of mechanical indentation is rapid and the self-opening angle bears high loads. The end of pile is prefabricated into slope so that the pile opens angle automatically to form herringbone pile in mechanical indentation process. When pile driver presses one time two upright piles are formed. Compared with forming upright pile the speed is two times.

Owner:NANJING UNIV OF TECH

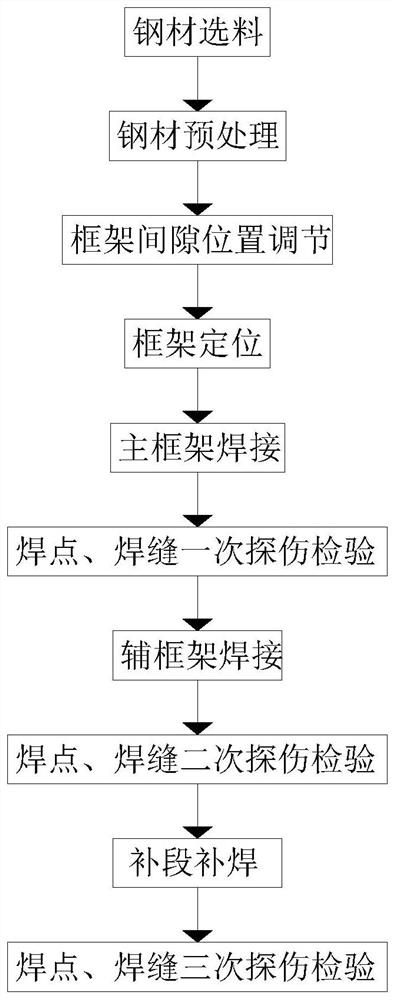

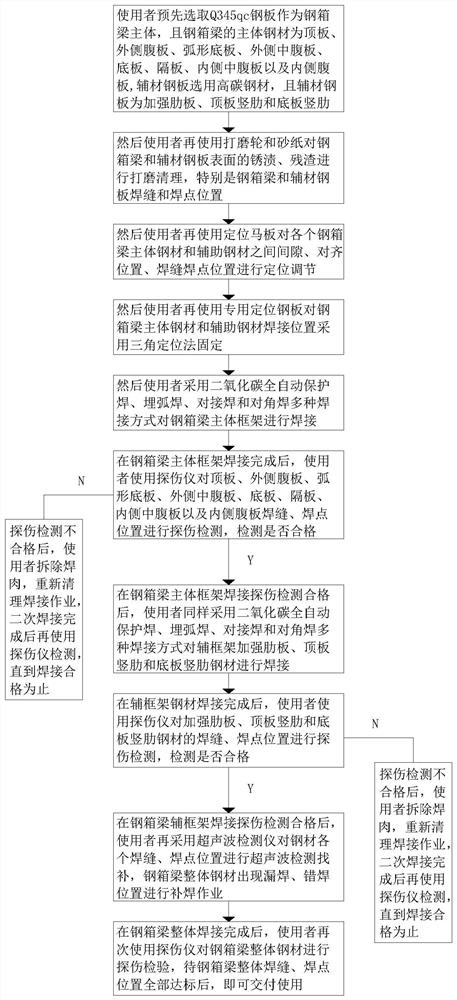

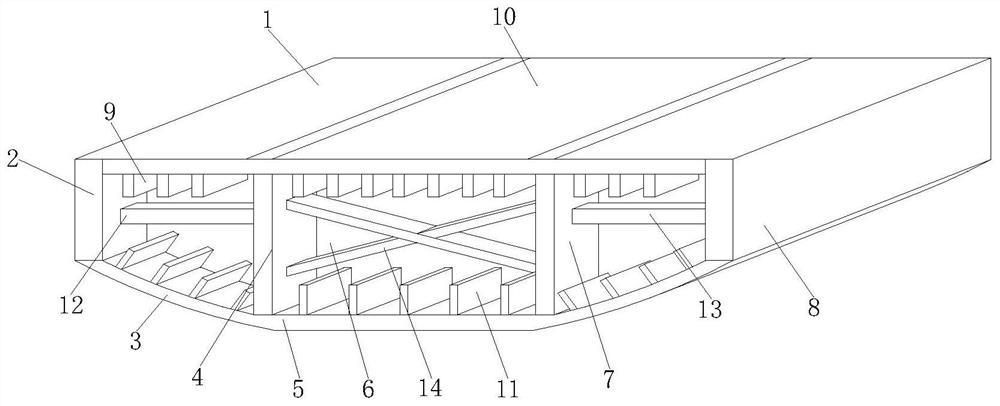

Steel box girder construction welding process

InactiveCN113500273AImprove welding stabilityStress reliefWelding accessoriesStructural engineeringWeld seam

The invention discloses a steel box girder construction welding process. The steel box girder construction welding process comprises the following steps that 1, steel material selection is achieved: a Q345qc steel plate is selected by a user as a steel box girder main body in advance, the main body steel of the steel box girder comprises a top plate, an outer side web plate, an arc-shaped bottom plate, an outer side middle web plate, a bottom plate, a partition plate, an inner side middle web plate and an inner side web plate, and an auxiliary material steel plate selects a high-carbon steel material; auxiliary material steel plates are reinforcing rib plates, top plate vertical ribs and bottom plate vertical ribs. According to the steel box girder construction welding process, precise selection is carried out from material selection through flow matching of steel material selection, steel material pretreatment, frame gap position adjustment, frame positioning, main frame welding, welding spot and welding seam primary flaw detection, auxiliary frame welding, welding spot and welding seam secondary flaw detection, section repair welding and welding spot and welding seam three-time flaw detection; and meanwhile, the overall quality of the foundation steel material is improved, a main frame and an auxiliary frame are welded in a sectional type welding mode, flaw detection is conducted in time after each stage is completed, and the welding quality of all the stages is improved.

Owner:TUNNEL ENG CO LTD OF CHINA RAILWAY 18TH BUREAU GRP

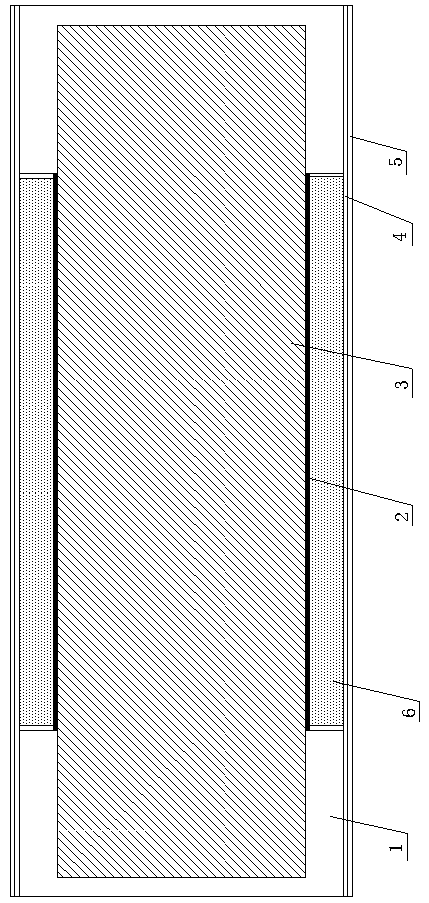

Concrete-filled hollow steel tube supporting structure suitable for subway deep foundation pit

The invention discloses a concrete-filled hollow steel tube supporting structure suitable for a subway deep foundation pit. The supporting structure comprises a first steel tube (1), a second steel tube (3) and a concrete layer (2), wherein the first steel tube (1) with the diameter being 600-1200 mm is arranged on the outermost layer and used for directly bearing an external load; the second steel tube (3) with the diameter being determined according to the thicknesses of the first steel tube (1) and the concrete layer (2) is arranged inside the first steel tube (1) and used for tightly pressing the concrete layer (2); and the concrete layer (2) with the thickness being 50-200 mm is arranged between the first steel tube (1) and the second steel tube (3) and used for enabling the first steel tube (1) and the second steel tube (3) to be connected, so that the integral concrete-filled steel tube supporting structure is formed. The concrete-filled steel tube supporting structure has the bearing capacity which is equal to or higher than that of a steel tube support under the condition that the size is reduced, and meanwhile, the self weight of the structure can also be lowered, and transportation and mounting of the supporting structure are facilitated.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Straw-steel composite fabricated load-bearing wall and manufacturing method thereof

ActiveCN107740532AImprove insulation effectLight in massBuilding componentsThermal insulationSteel frame

Disclosed are a straw-steel composite fabricated load-bearing wall and a manufacturing method thereof. At present, most of adopted fabricated composite wall bodies use ordinary concrete as a structural layer, and the thermal insulation performance of the ordinary concrete needs to be improved; a current solution is that fine stone concrete is adopted, while the method takes strength sacrifice as prerequisite, and the most of current concrete composite wall bodies are non-load-bearing wall bodies; and it is the research direction at the present stage to develop a composite wall body which can bear and is good in heat insulation performance. The straw-steel composite fabricated load-bearing wall comprises a steel frame used for assembling, and the two inner wall side surfaces of the steel frame are provided with steel wire nets; a defined space in the steel frame is filled with straw plates, and wall body vertical connecting openings used for direct abutting joint are formed in the upperend and the lower end of the steel frame; and wall body connecting openings used for staggered abutting joint are formed in the left end and the right end of the steel frame.

Owner:HARBIN UNIV OF SCI & TECH

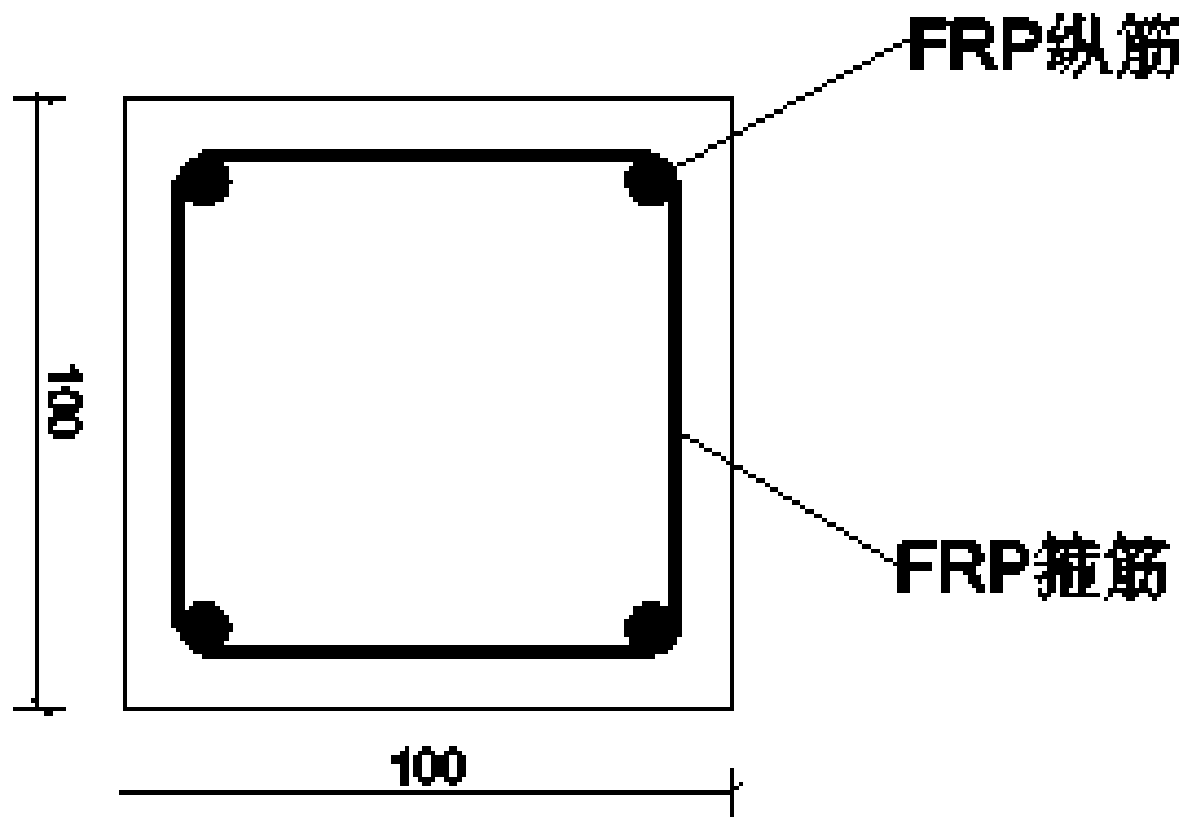

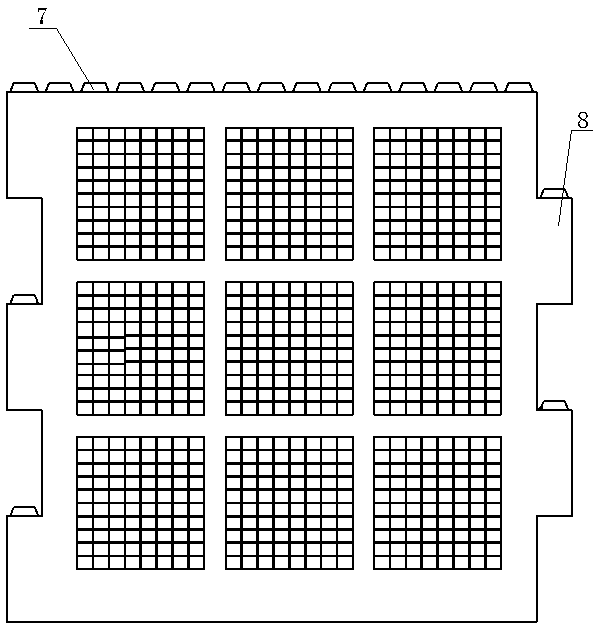

Lightweight concrete-bamboo glue-laminated panel T-shaped beam

PendingCN108316556AIncrease stiffnessChange the unfavorable situation of poor rigidityGirdersJoistsFiberShear stress

The invention provides a lightweight concrete-bamboo glue-laminated panel T-shaped beam which comprises a concrete (1), an upper flange (2), a lower flange (3), a side web (4), a middle web (5), a reinforcing steel bar (6), FRP (Fiber Reinforced Plastic) (7) and a shear key (8). The lightweight concrete-bamboo glue-laminated panel T-shaped beam is characterized in that the concrete (1) is locatedon the top part of the T-shaped beam and is used for bearing the pressure; the side web (4) and the middle web (5) are located on the middle parts of the upper flange (2) and the lower flange (3) andare used for bearing the shear stress; the upper flange (2) is located on the upper part of a box beam; the lower flange (3) is located on the lower part of the box beam; the upper flange and the lower flange are used for bearing the pulling stress; the reinforcing steel bar (6) is located in the lower flange (3); the FRP (7) is adhered to the bottom part of the lower flange (3); the reinforcing steel bar (6) and the FRP (7) are used for bearing the pulling stress; the concrete (1) and the upper flange (2) are connected through the shear key (8). By fully utilizing the characteristics of the eight materials, the lightweight concrete-bamboo glue-laminated panel T-shaped beam provided by the invention has the characteristics of light weight, high strength and great rigidity, and can be applied to bending members in the field of civil construction.

Owner:NANJING FORESTRY UNIV

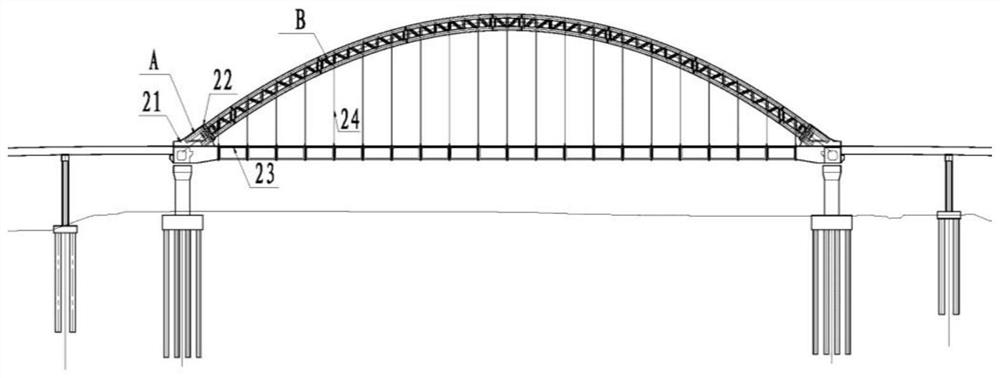

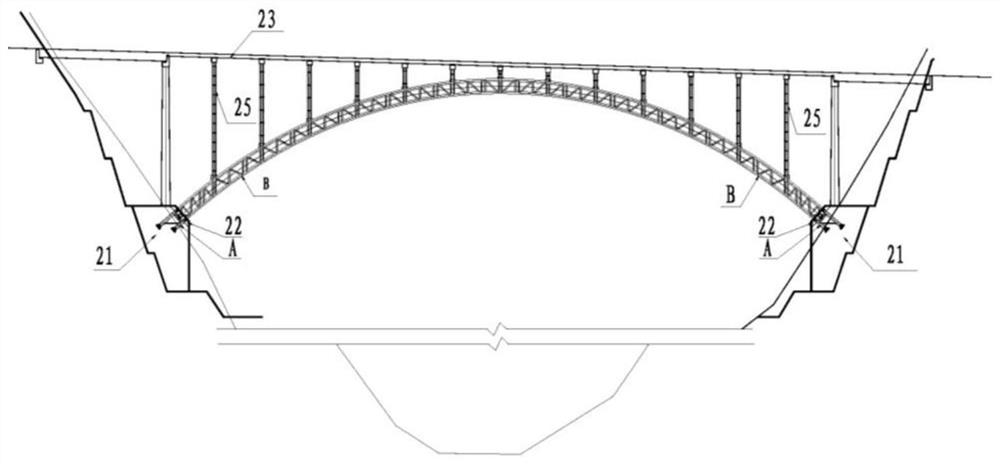

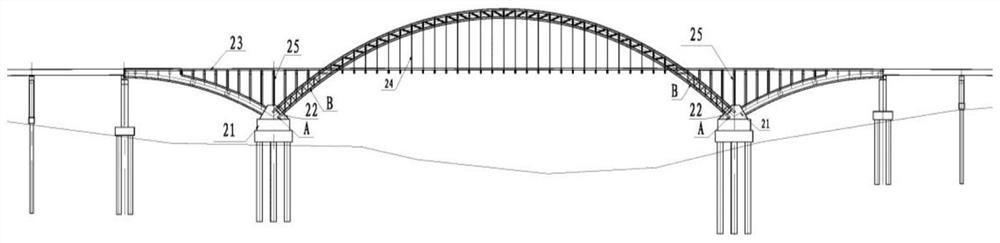

Structure for preventing concrete-filled steel tube arch bridge arch foot steel tube outer wrapped concrete from cracking

The invention discloses a structure for preventing concrete-filled steel tube arch bridge arch foot steel tube outer wrapped concrete from cracking. An exposed arch rib section (D) is composed of a conventional exposed arch rib section (B), chord member shear nails (15), a bearing plate (16), chord member inner side stiffening rings (17), bearing plate stiffening rib plates (18), an annular sealing steel belt (19) and a rubber water stop strip (20). Shear nails (15) are welded to the lowermost ends of arch rib upper chords (1) and arch rib lower chords (2) in the exposed arch rib sections (D)and the outer surfaces of the bearing plate (16), embedded section upper chords (3) and embedded section lower chords (4). The defect that in the prior art, due to the fact that the side resistance between the outer pipe wall of an arch rib steel tube and concrete is too large, arch foot steel outer wrapped concrete cracks is overcome, and the advantages that it can be guaranteed that an arch footof an arch bridge made of concrete-filled steel tubes has enough durability and safety and the service life are achieved.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com