Self-divergence type herringbone stake

A glyph and pile cap technology, applied in the field of self-tensioning herringbone piles, can solve problems such as inverted cone shear failure, mixed shear surface damage, and difficulty in controlling the construction of cast-in-situ piles, and achieve fast mechanical press-in construction and self-tensioning angle bearing Lego effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

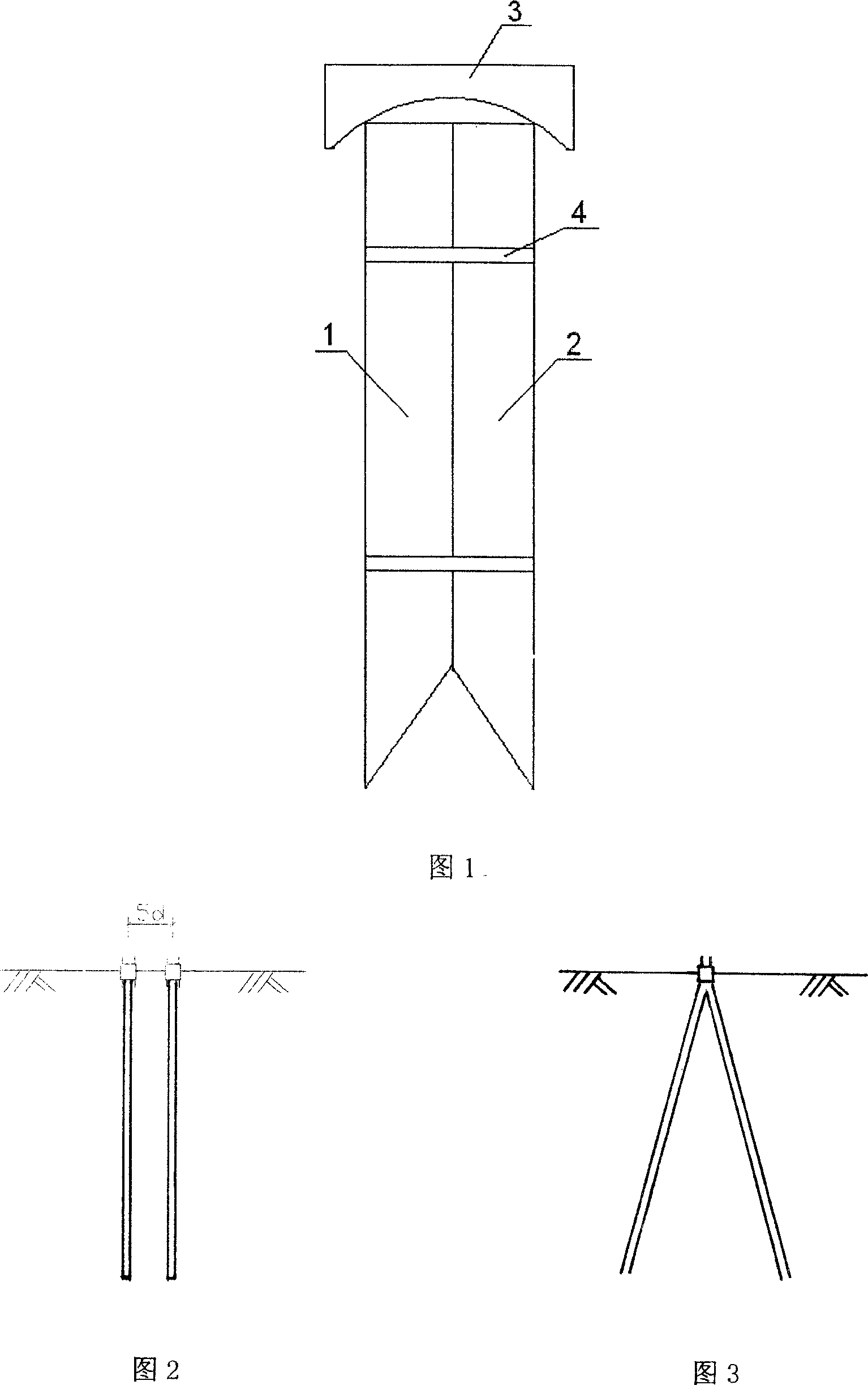

[0065] With reference to Fig. 1, a kind of self-tensioning type herringbone pile comprises 2 vertical piles 1,2 side by side, one end of these 2 vertical piles 1,2 is provided with pile cap 3 and pile cap 3 is vertical with these 2 vertical piles respectively. One end of the straight piles 1,2 is rotationally connected, and the other ends of the two vertical piles 1,2 are inclined surfaces and the end inclined surfaces of the two vertical piles 1,2 face each other. In this embodiment, a wire loop 4 for keeping the two vertical piles 1 and 2 close together is provided outside the two parallel vertical piles 1 and 2 .

[0066] Referring to Fig. 14, when using the present invention for construction, 1) the two piles are hoisted in place with iron wires together; 2) the pile driver presses in and cuts the iron wires; ; 4) Press into place to expose the top of the pile.

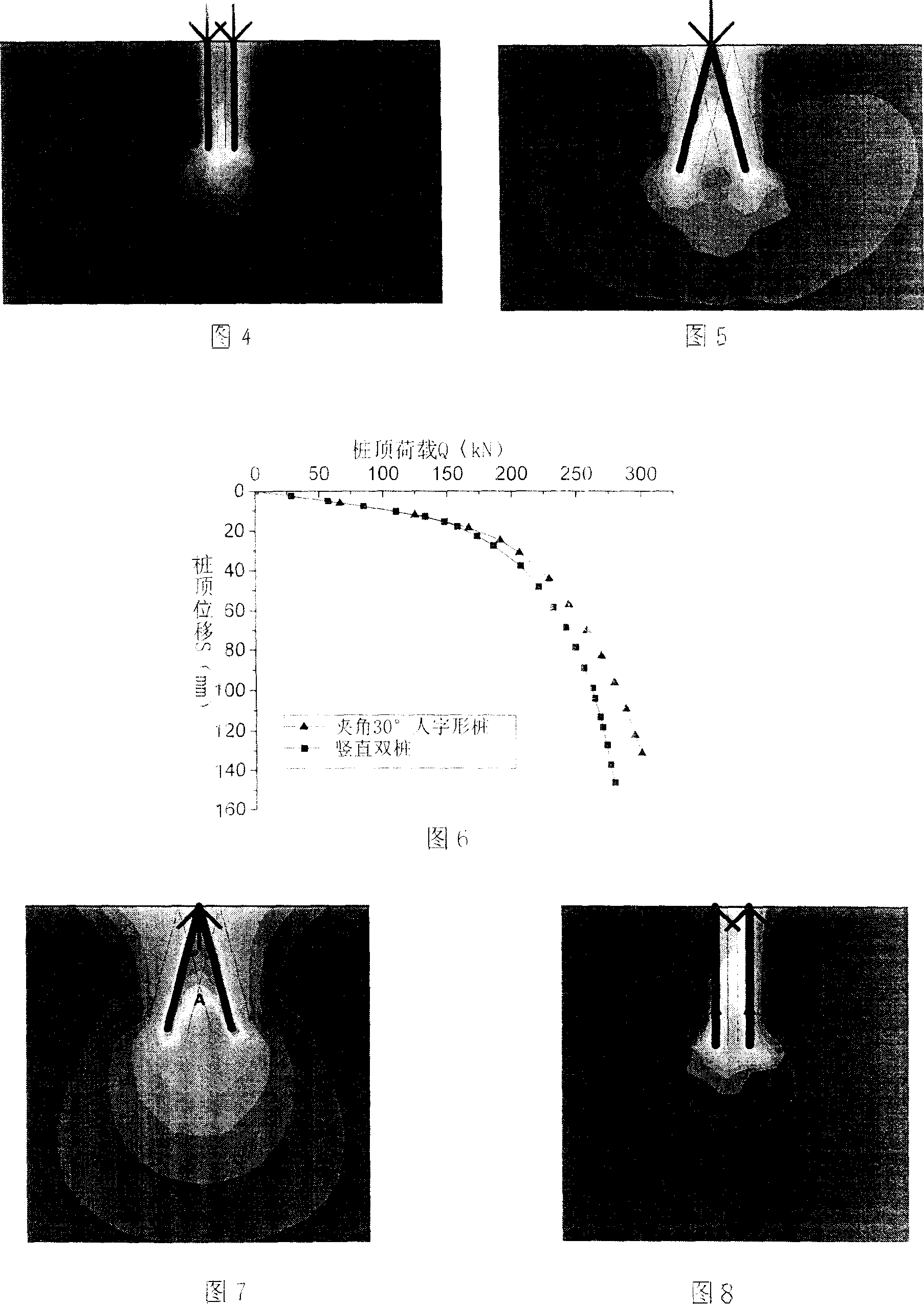

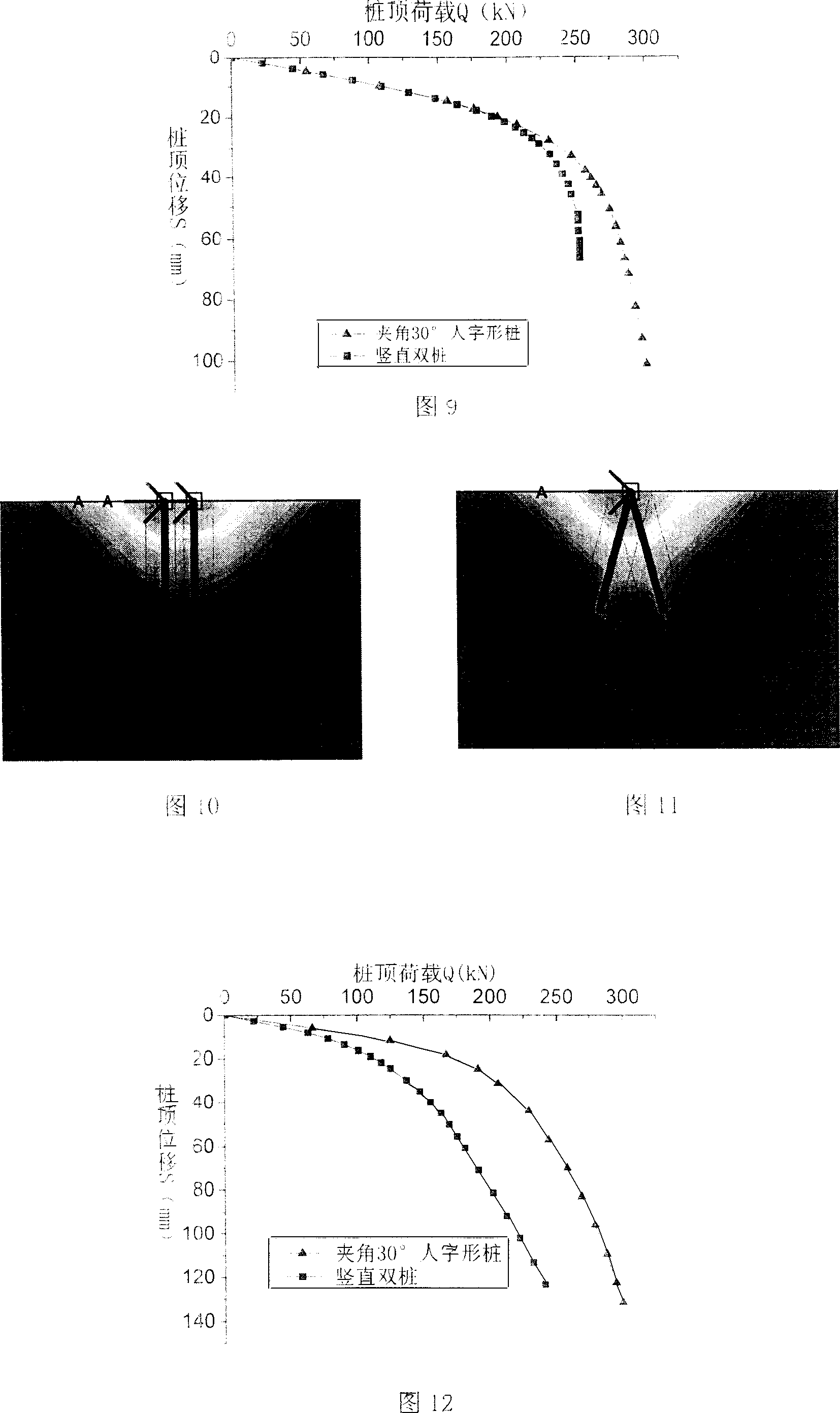

[0067] With reference to Fig. 2~12, utilize the professional finite element software Plaxis of geotechnical en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com