Double-limb splicing thin-walled cold-formed steel efficient component

A technology of cold-formed thin-walled steel and cold-formed thin-walled steel, applied to building components, elongated structural components for load-bearing, structural elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

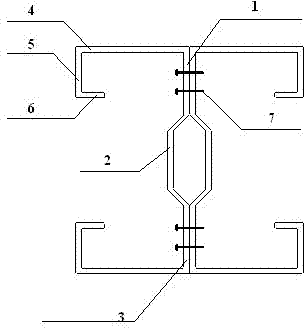

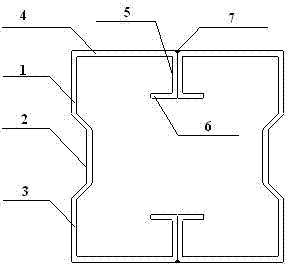

[0011] Such as figure 1 As shown in -2, the cold-formed cold-formed thin-walled steel high-efficiency member is composed of upper web 1, stiffener 2, lower web 3, flange 4, curling 5, and re-curling 6. Thin-wall complex beaded channel steel opening member, Σ-type web stiffened cold-formed thin-walled complex beaded channel steel open member in the form of "back-to-back" or "face-to-face" The two limbs are assembled into one body, and the connection method is through self-tapping screws 7. Connect the upper web 1 and the lower web 3, or weld the curling 5 together by welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com