Structure for preventing concrete-filled steel tube arch bridge arch foot steel tube outer wrapped concrete from cracking

A technology of concrete filled steel tube and outsourcing concrete, which is applied in the direction of arch bridges, bridges, bridge forms, etc., can solve the problems of corrosion of steel bars and steel tubes, affecting structural safety, concrete falling off and damage, etc., and achieves the effect of improving the compressive bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, but are only examples, and will become clearer and easier to understand by illustrating the advantages of the present invention.

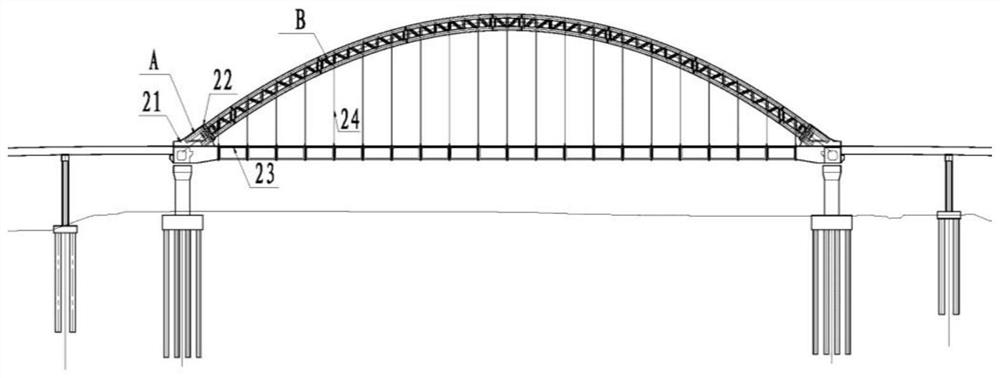

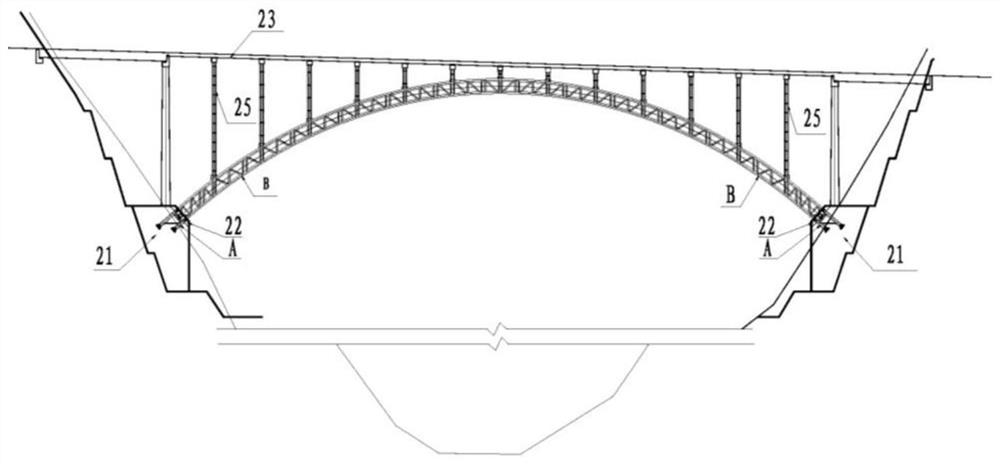

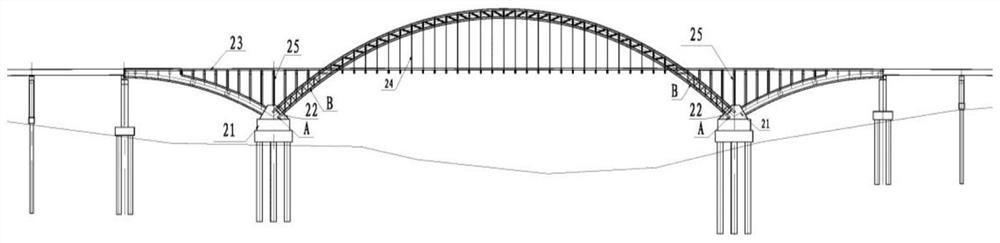

[0058] refer to Figure 1-20 Shown: the structure to avoid cracking of the steel pipe outsourcing concrete at the arch foot of the concrete-filled steel pipe arch bridge, which includes the conventional arch rib embedded section A, the conventional exposed arch rib section B, the chord joint steel pipe 14, the abutment pouring concrete section 21 and the abutment rear Pouring hinge section concrete 22;

[0059] The conventional arch rib embedded section A is connected with the conventional exposed arch rib section B through the chord joint steel pipe 14;

[0060]The conventional arch rib embedded section A is composed of arch rib embedded section upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com