Patents

Literature

31results about How to "Increase tightening force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

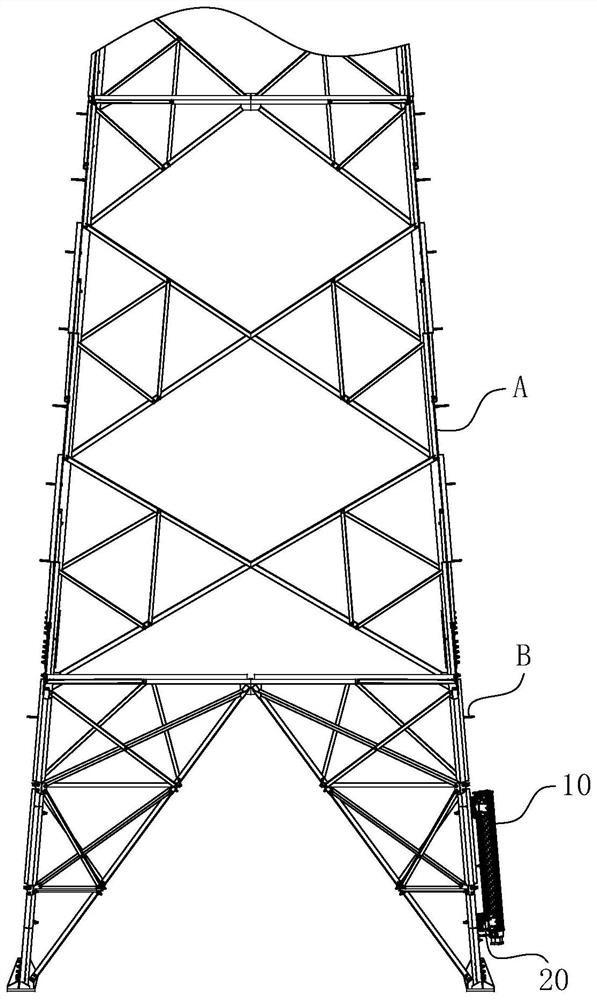

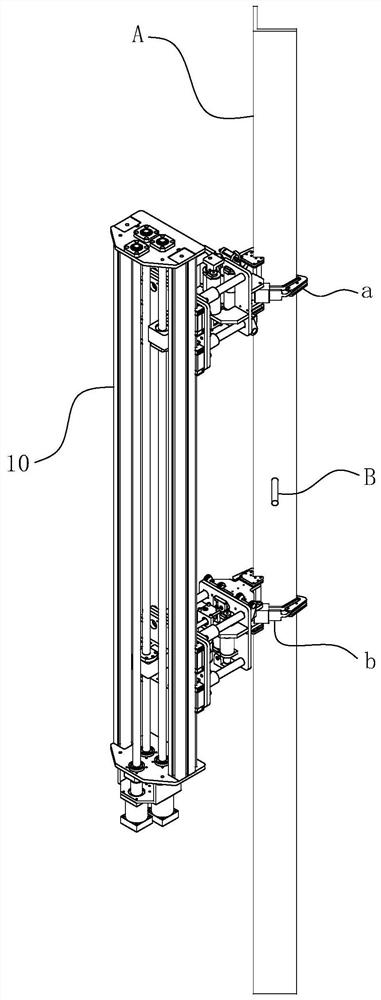

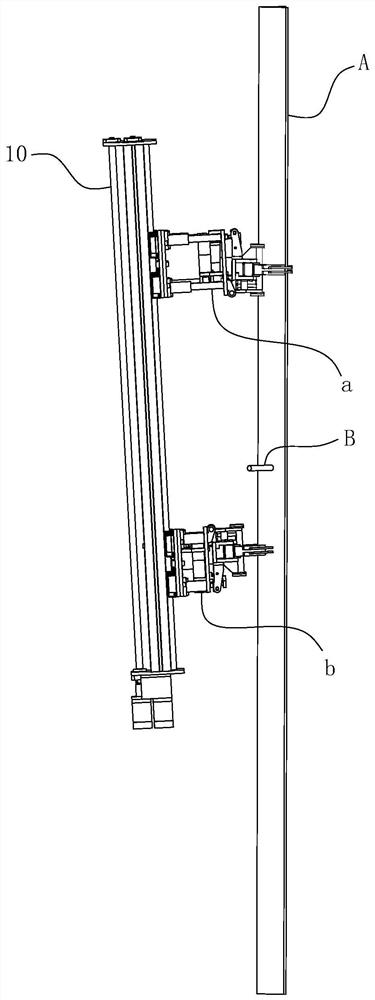

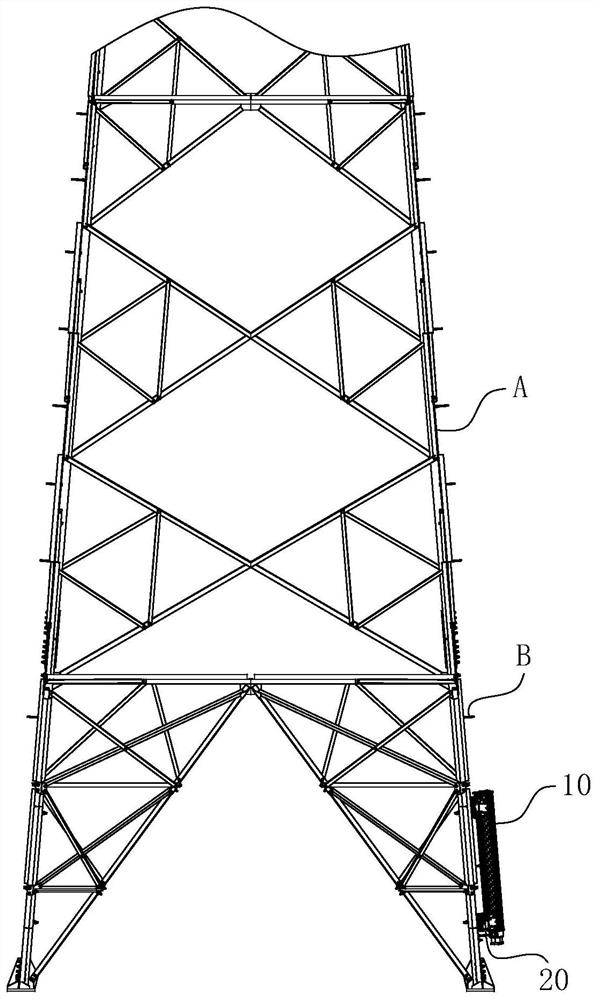

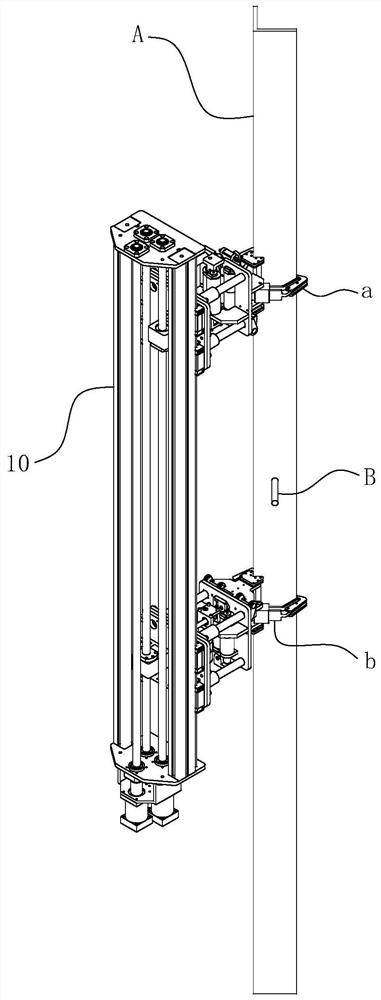

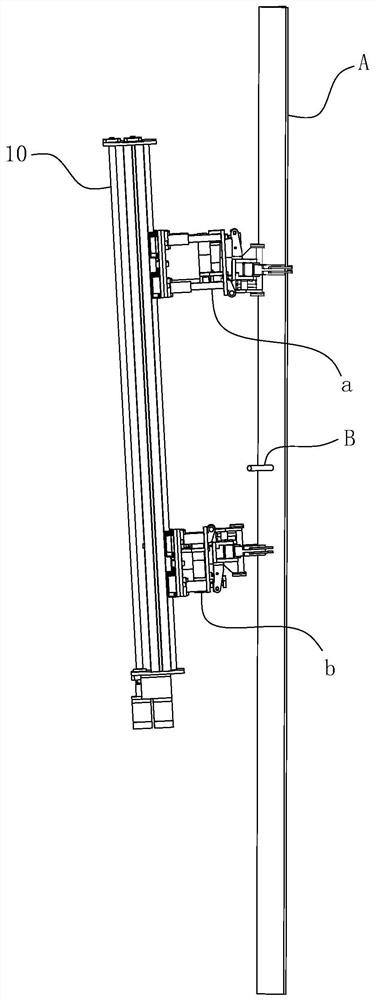

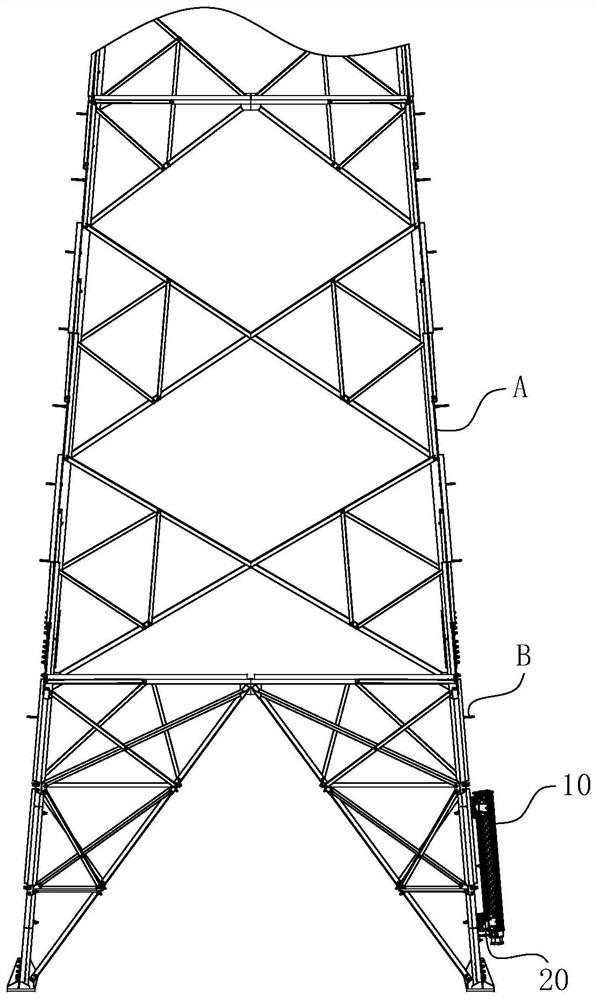

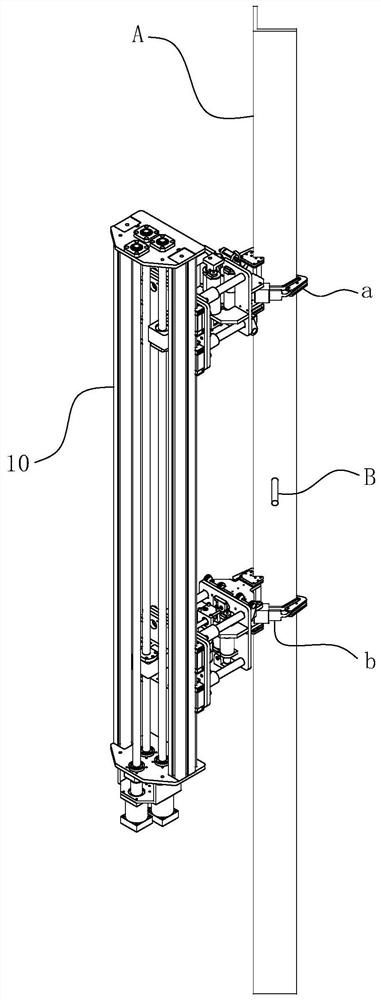

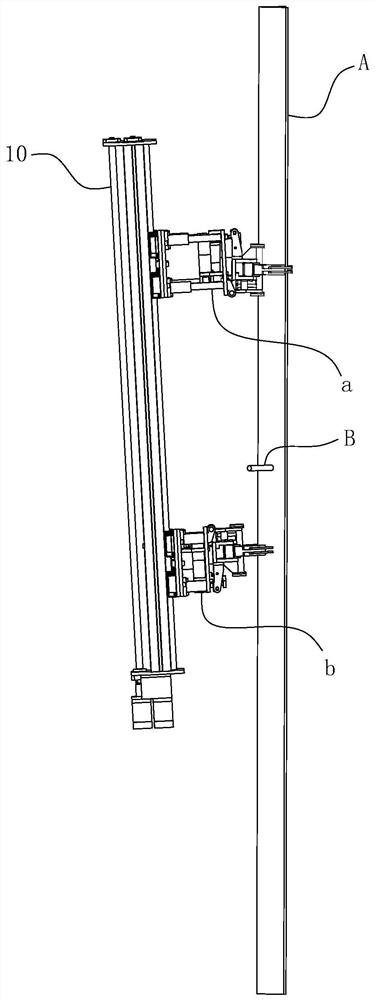

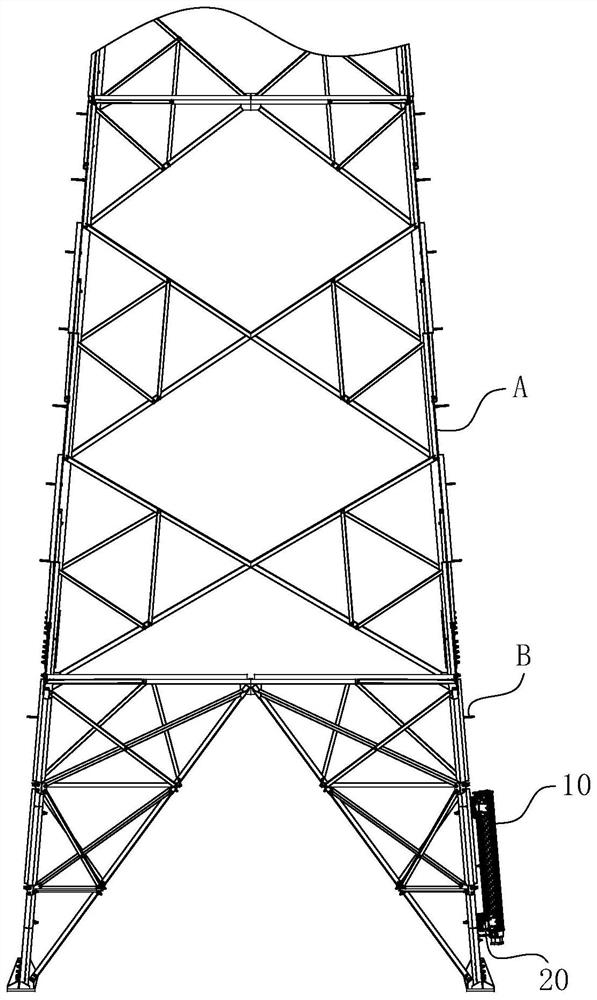

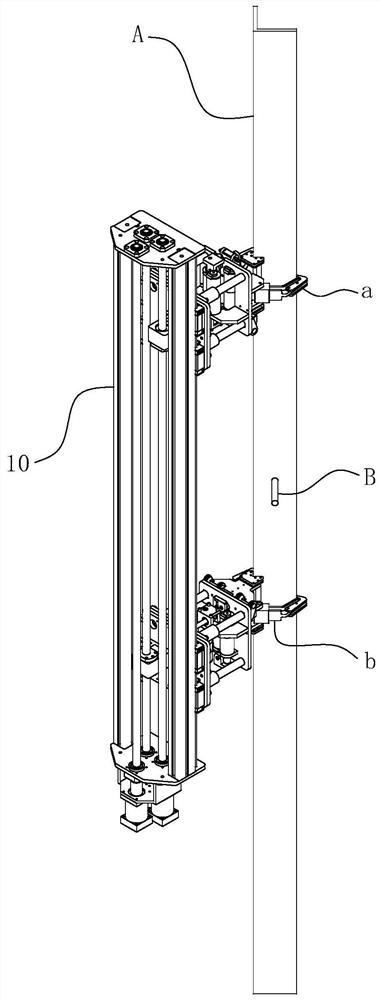

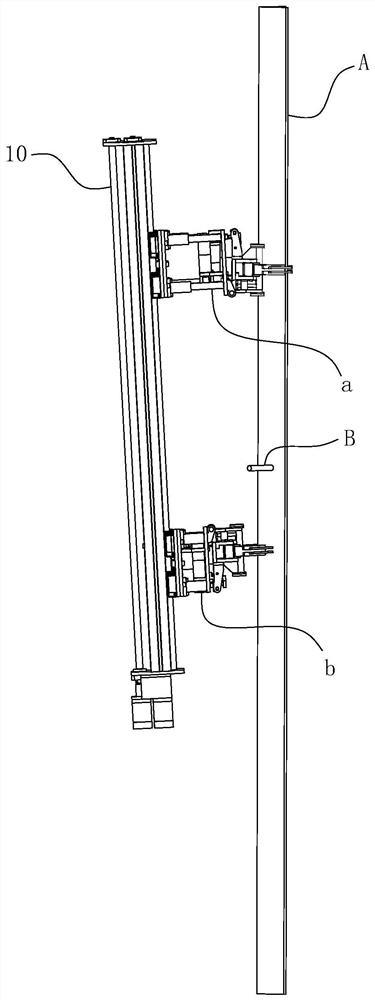

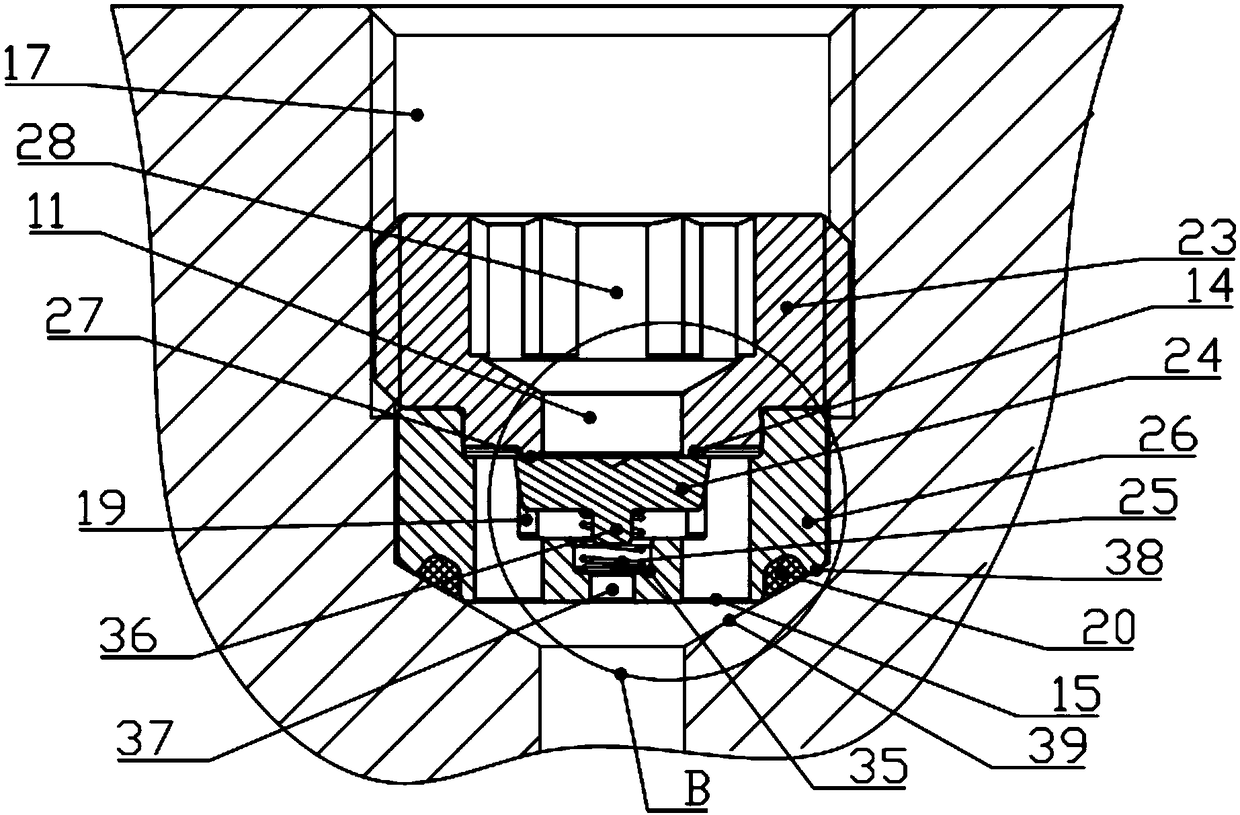

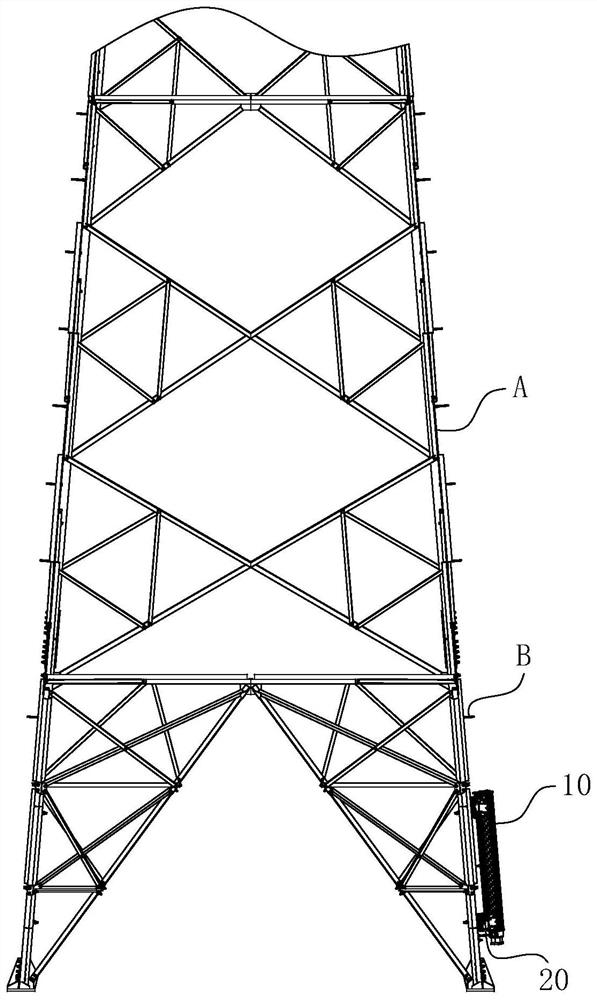

Climbing robot for angle steel tower

ActiveCN112356940AGuaranteed efficient obstacle clearanceGuaranteed clamping effectManipulatorVehiclesControl engineeringMachine

The invention belongs to the technical field of climbing robots for electric power operation, and particularly relates to a climbing robot for an angle steel tower. The robot comprises a main machineand clamping assemblies, the clamping assemblies comprise the upper clamping assembly and the lower clamping assembly, and at least one set of clamping assemblies can do reciprocating displacement motion parallel to the advancing path of the main machine relative to the main machine; each clamping assembly comprises a clamping jaw, an angle adjusting assembly and a lifting assembly, wherein the angle adjusting assembly is installed on the clamping jaw and can enable the main machine to generate pitching angle adjustment relative to the angle steel, and the lifting assembly can enable the clamping jaw to generate approaching and departing actions relative to the angle steel. The hinge axis of the angle adjusting assembly is horizontally arranged and is perpendicular to the length directionof the angle steel. The robot has high obstacle crossing capability and high climbing efficiency, and can synchronously guarantee the action stability and action reliability of climbing operation, sothat the manpower inspection cost can be greatly saved, the maintenance efficiency is improved, and the safe and reliable operation of a power transmission system is guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER +1

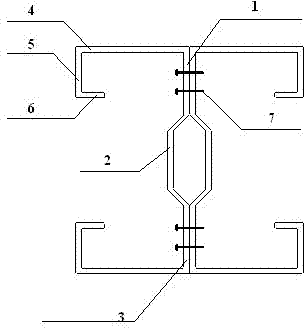

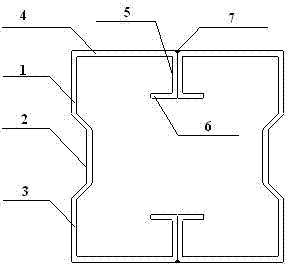

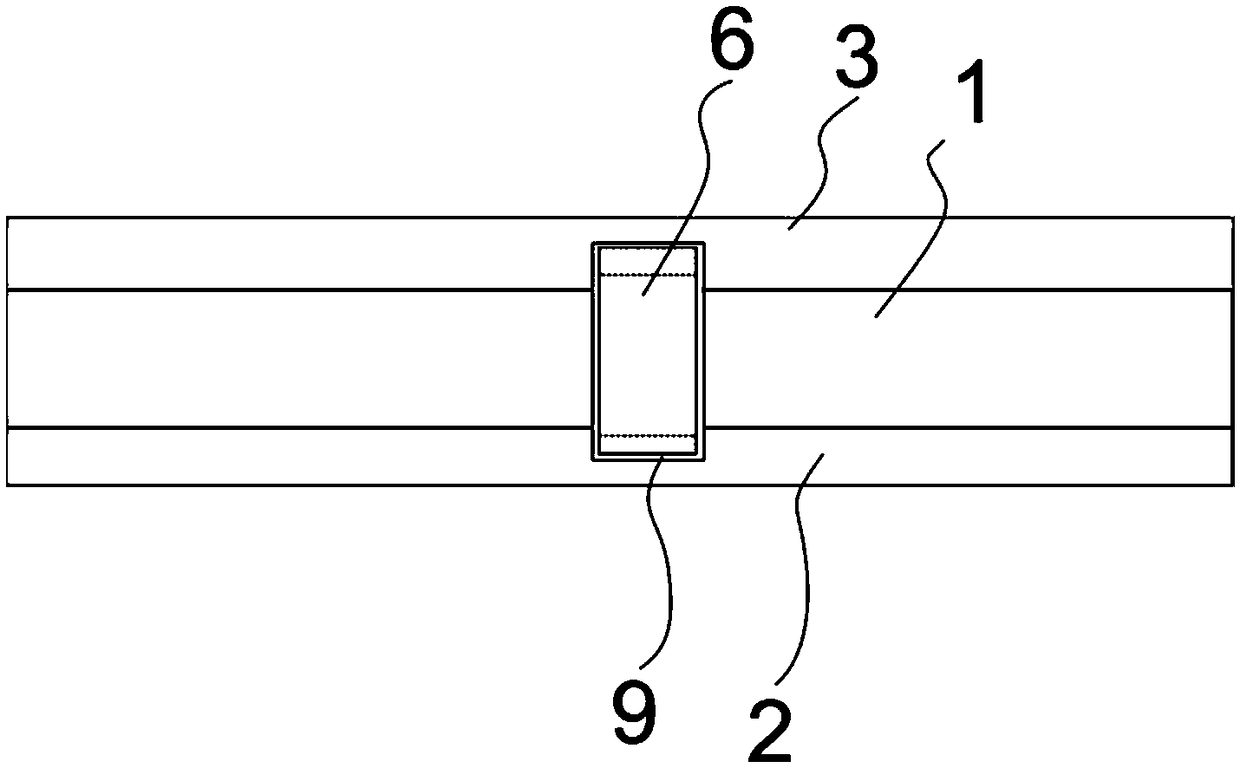

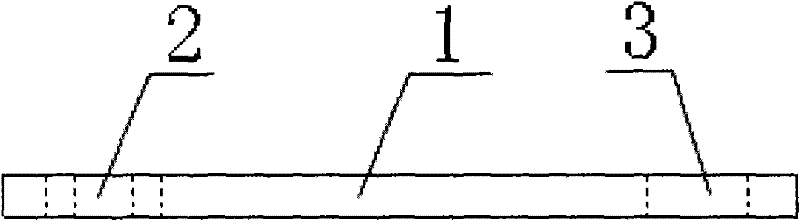

Double-limb splicing thin-walled cold-formed steel efficient component

InactiveCN103572892AImprove the compressive capacityReduce aspect ratioLoad-supporting elementsCompression memberFlange

The invention discloses a double-limb splicing thin-walled cold-formed steel efficient component. The double-limb splicing thin-walled cold-formed steel efficient component comprises two sigma-shaped web cold-formed thin-wall complex lipped steel channel opening components which is composed of upper webs, stiffening ribs, lower webs, flange edges, crimped edges and recrimped edges. The double-limb splicing thin-walled cold-formed steel efficient component is characterized in that the sigma-shaped web cold-formed thin-wall complex lipped steel channel opening components are spliced into in a back-to-back or face-to-face manner, and the connecting manner is that the upper webs and lower webs are connected through tapping screws, or the crimped edges are welded together in a welding manner. The double-limb splicing thin-walled cold-formed steel efficient component disclosed by the invention has the advantages that when the double-limb splicing thin-walled cold-formed steel efficient component is utilized as a compression member, the ratio of height to thickness of the webs is obviously reduced in a back-to-back double-limb splicing manner, the compressive capacity of the component is obviously strengthened, and the bearing capacity of the spliced components is obviously improved compared with the sum of bearing capacities of two single limb components; compared with the single limb component, the double-limb splicing thin-walled cold-formed steel efficient component has the advantages that the defects that the antitorque capacity of a single limb opening component is poor, the difference of the inertia moments of two main shafts is large and the like are overcome, the multi-time buckling of a steel plate also can provide the strong ring constraint on the interior concrete, the tightening ring force of the concrete is strengthened, and thus the bearing capacity of a compound section is improved.

Owner:SHENYANG JIANZHU UNIVERSITY

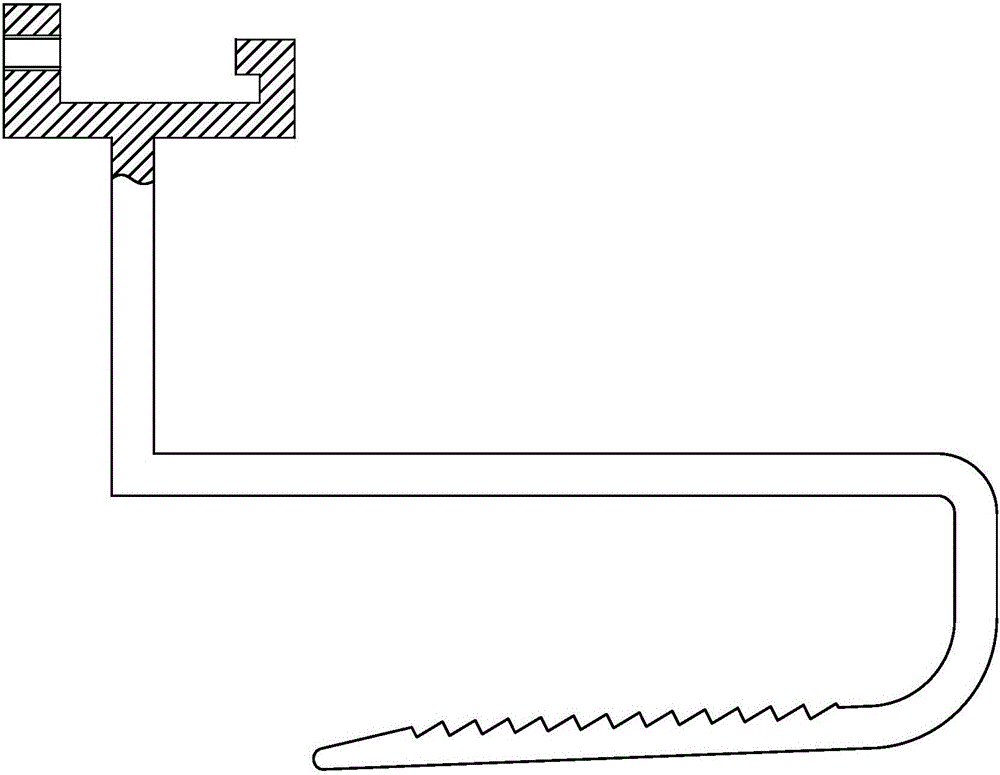

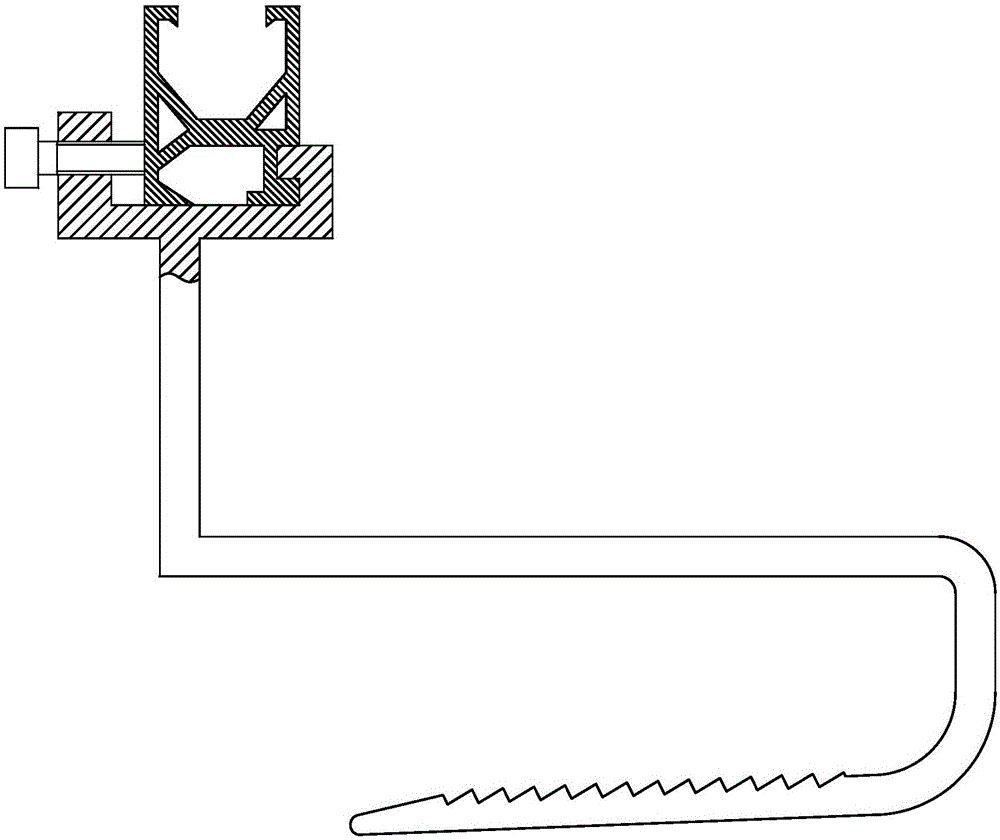

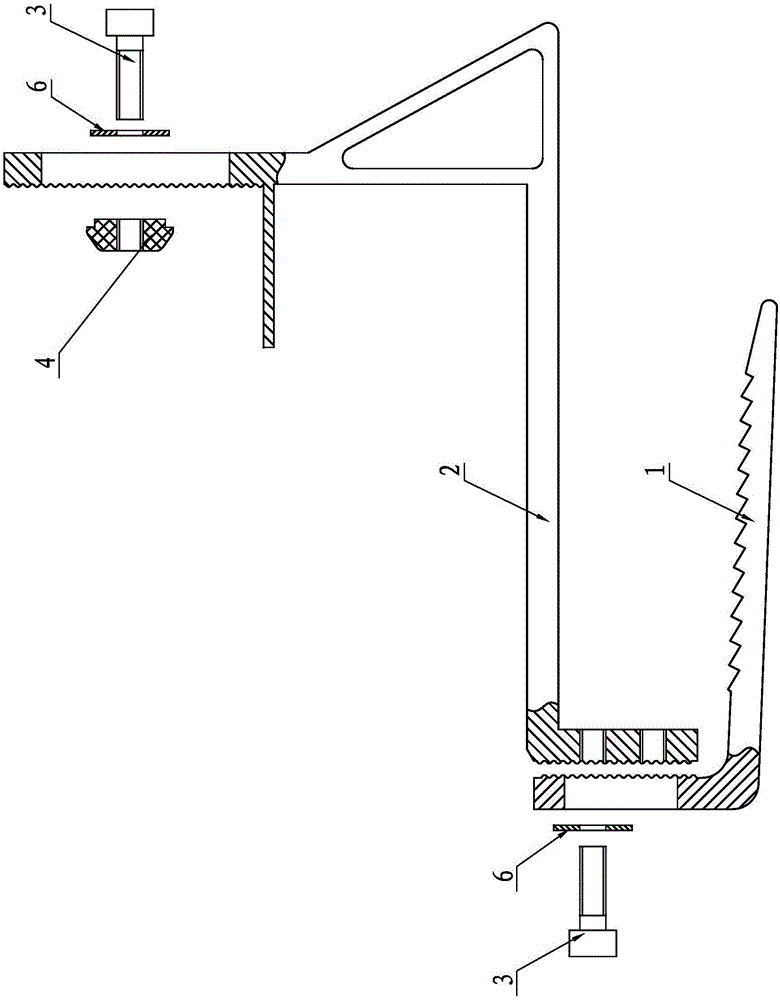

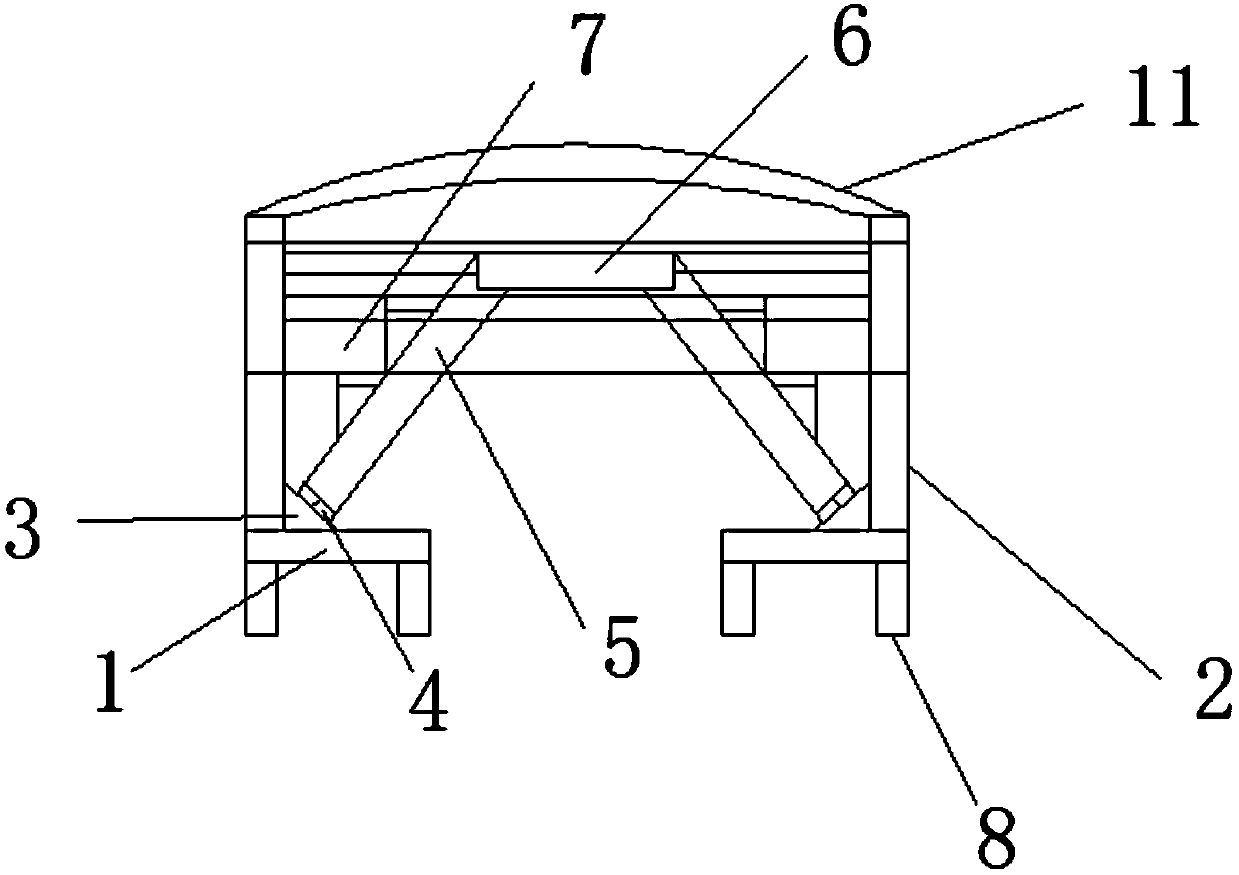

Fixed hook rack assembly for tile roof solar cell assembly

PendingCN106253808AReduced bearing forceImprove deformationPhotovoltaic supportsPhotovoltaic energy generationVertical edgeEngineering

The invention provides a fixed hook rack assembly for a tile roof solar cell assembly. The fixed hook rack assembly comprises a base, a guide rail installation rack, connecting screws and a guide rail connecting limit block, wherein the base comprises a fixed connecting edge and a clamping edge; a waist-shaped hole is formed in the fixed connecting edge; the guide rail installation rack comprises a connecting vertical edge, a horizontal edge and a guide rail installation edge; two ends of the horizontal edge are vertically and fixedly connected with the connecting vertical edge and the guide rail installation edge respectively; a connecting threaded hole is formed in the connecting vertical edge; one connecting screw passes through the waist-shaped hole and the connecting threaded hole to fix connect the fixed connecting edge and the connecting vertical edge; an anti-deformation support edge is arranged at the outer side edge of the connected part of the guide rail installation edge and the horizontal edge; a bearing edge is arranged on the guide rail installation edge; and a guide rail passes through a guide rail installation groove and the guide rail connecting limit block through the other connecting screw to be fixedly arranged on the guide rail installation edge. The fixed hook rack assembly is light in weight, good in bearing strength, not easy to deform, good in wind resistance and corrosion resistance and long in service life, and can meet the requirements of a solar bracket on a high-quality product, and a potential safety hazard is completely eradicated.

Owner:CHANGZHOU ALLSTAR ENERGY TECH CO LTD

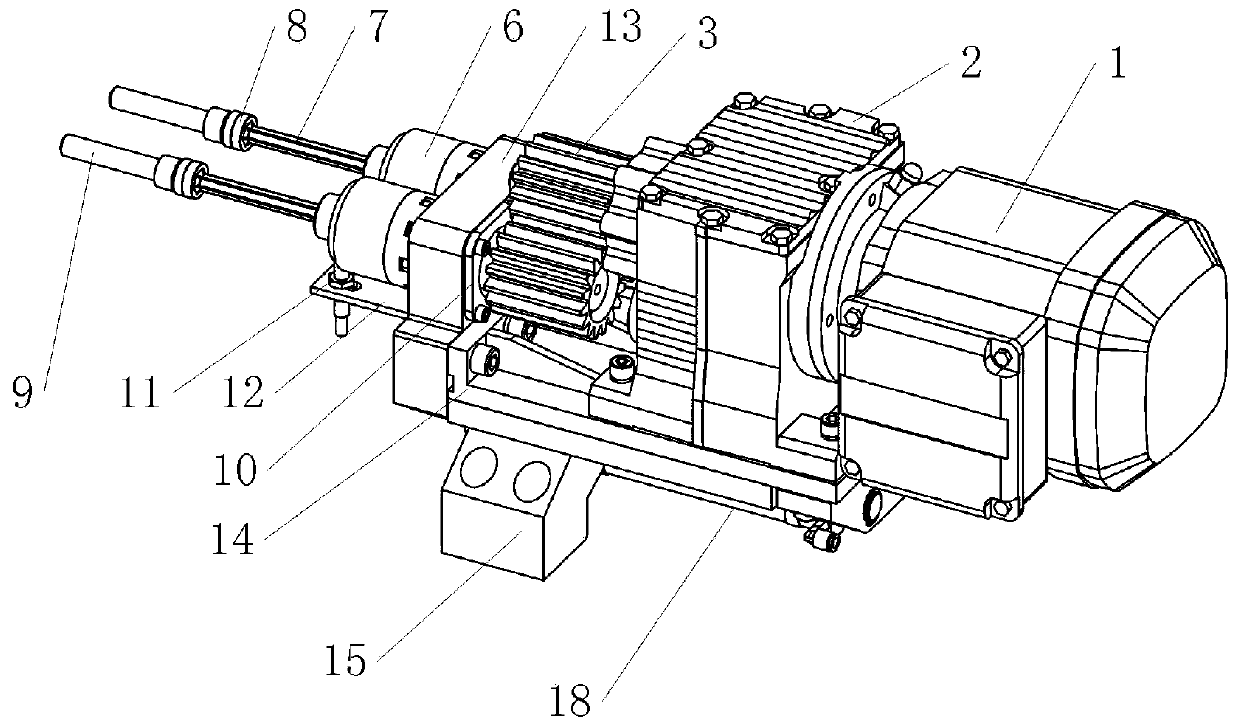

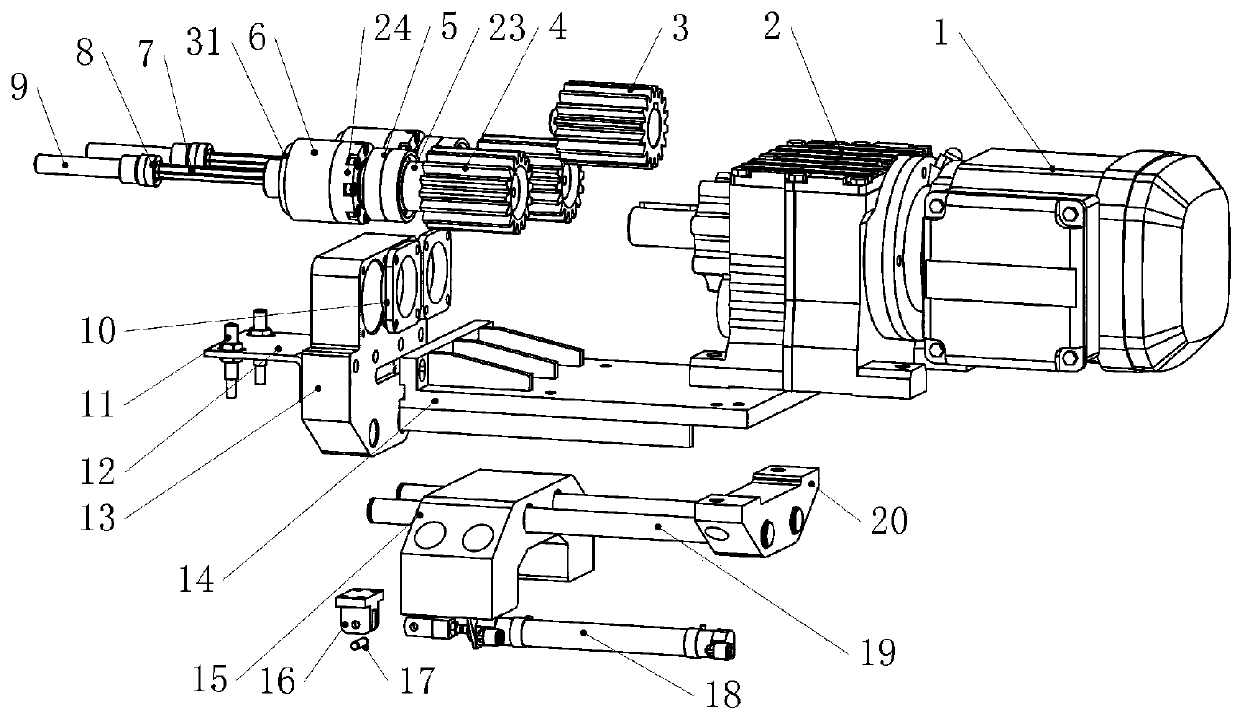

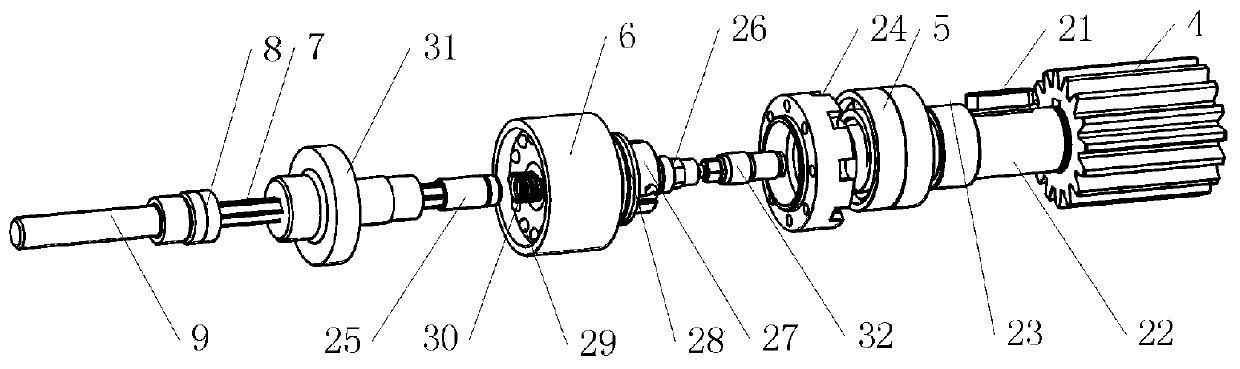

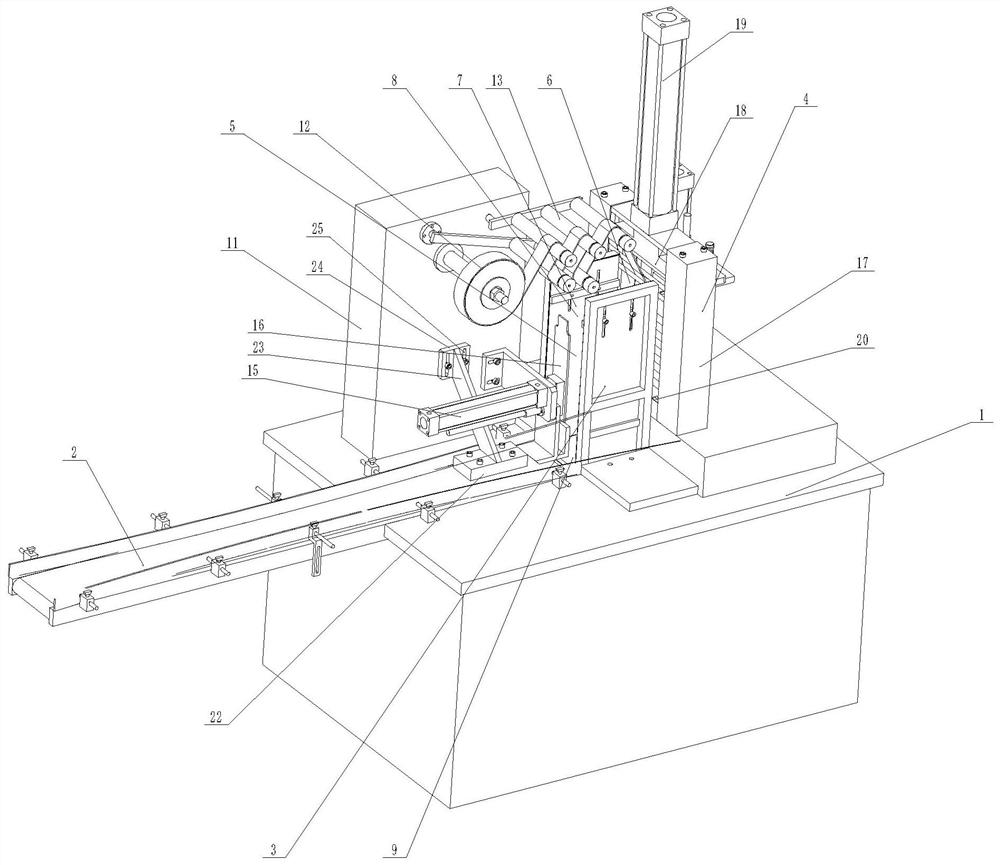

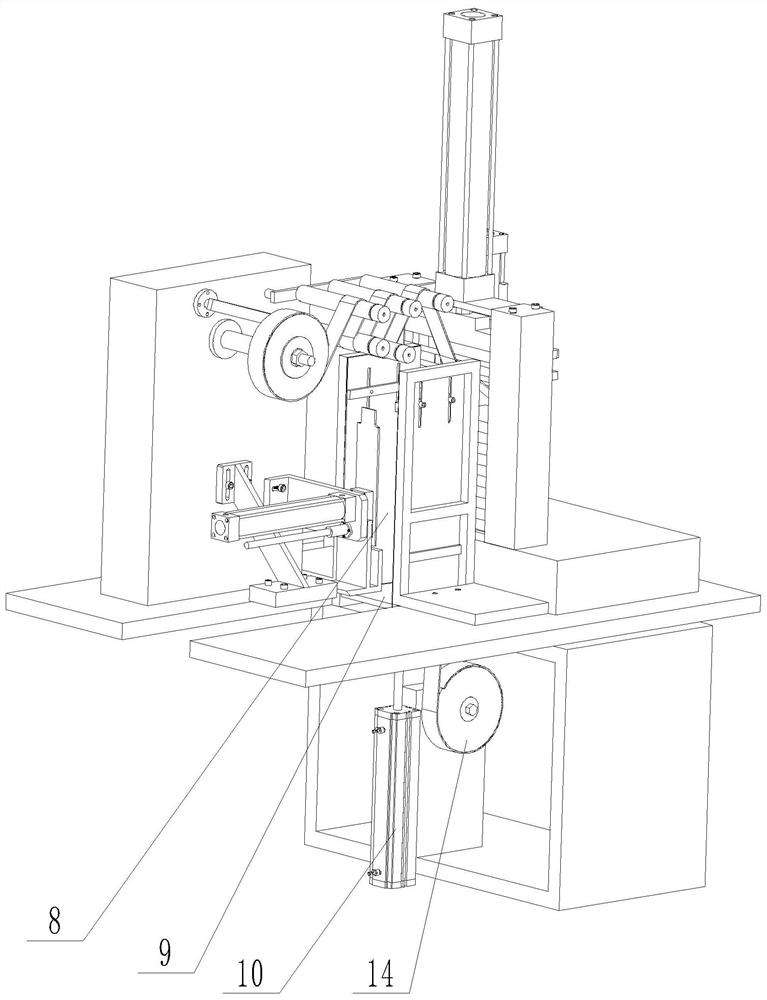

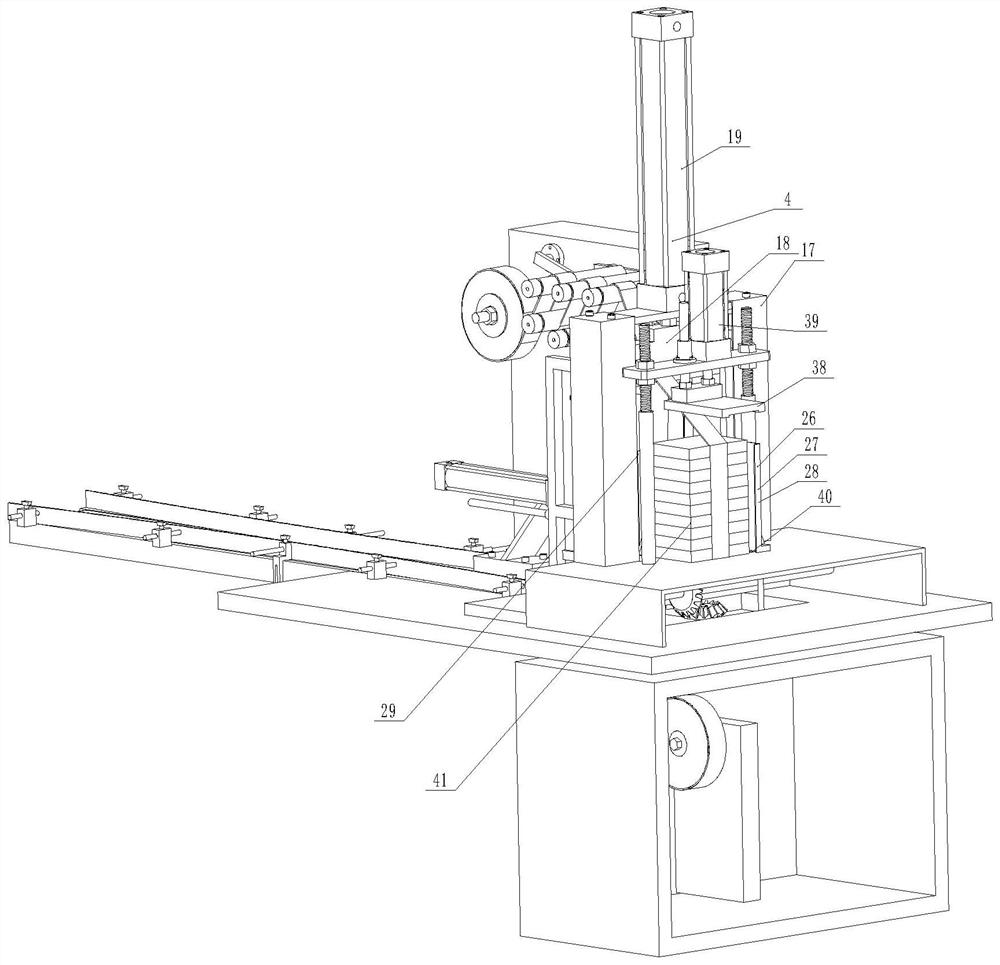

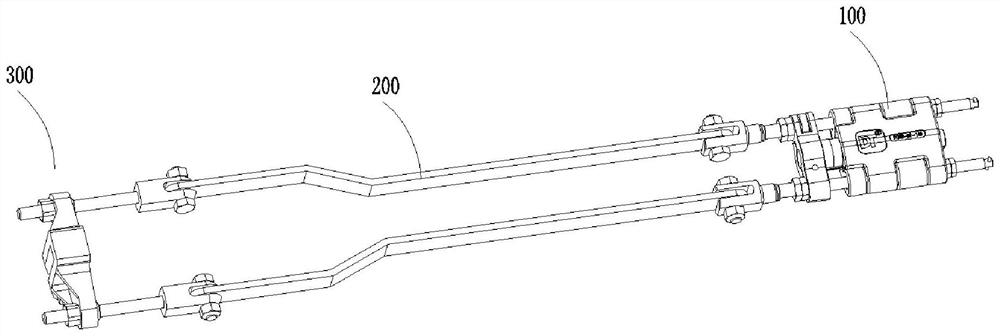

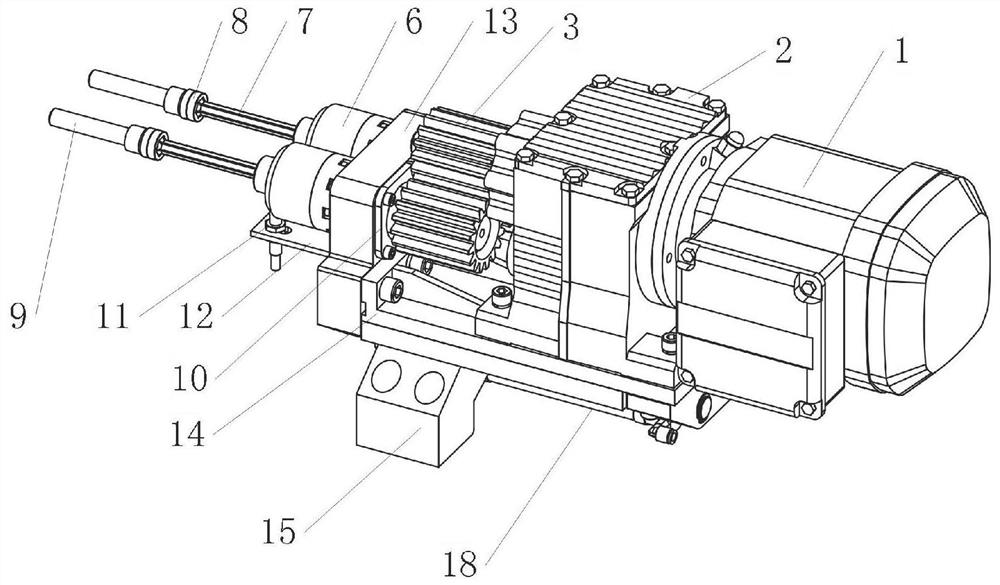

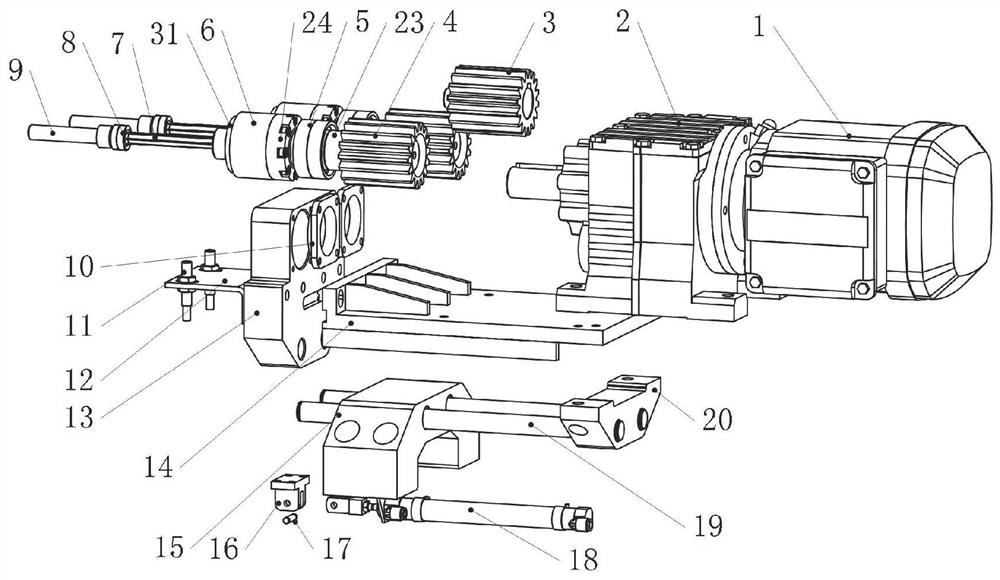

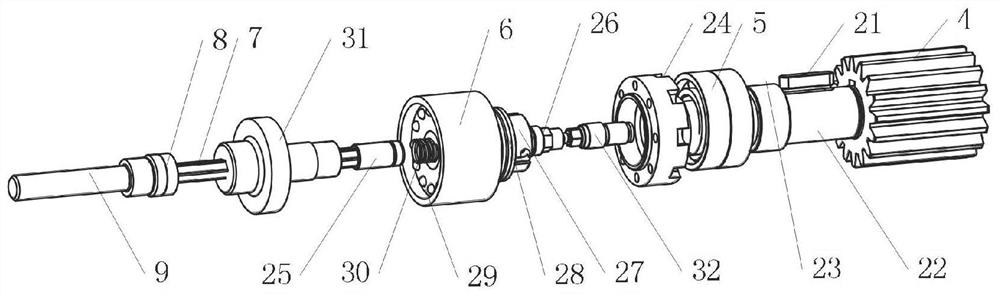

Installation type double-shaft automatic tightening device and operation method thereof

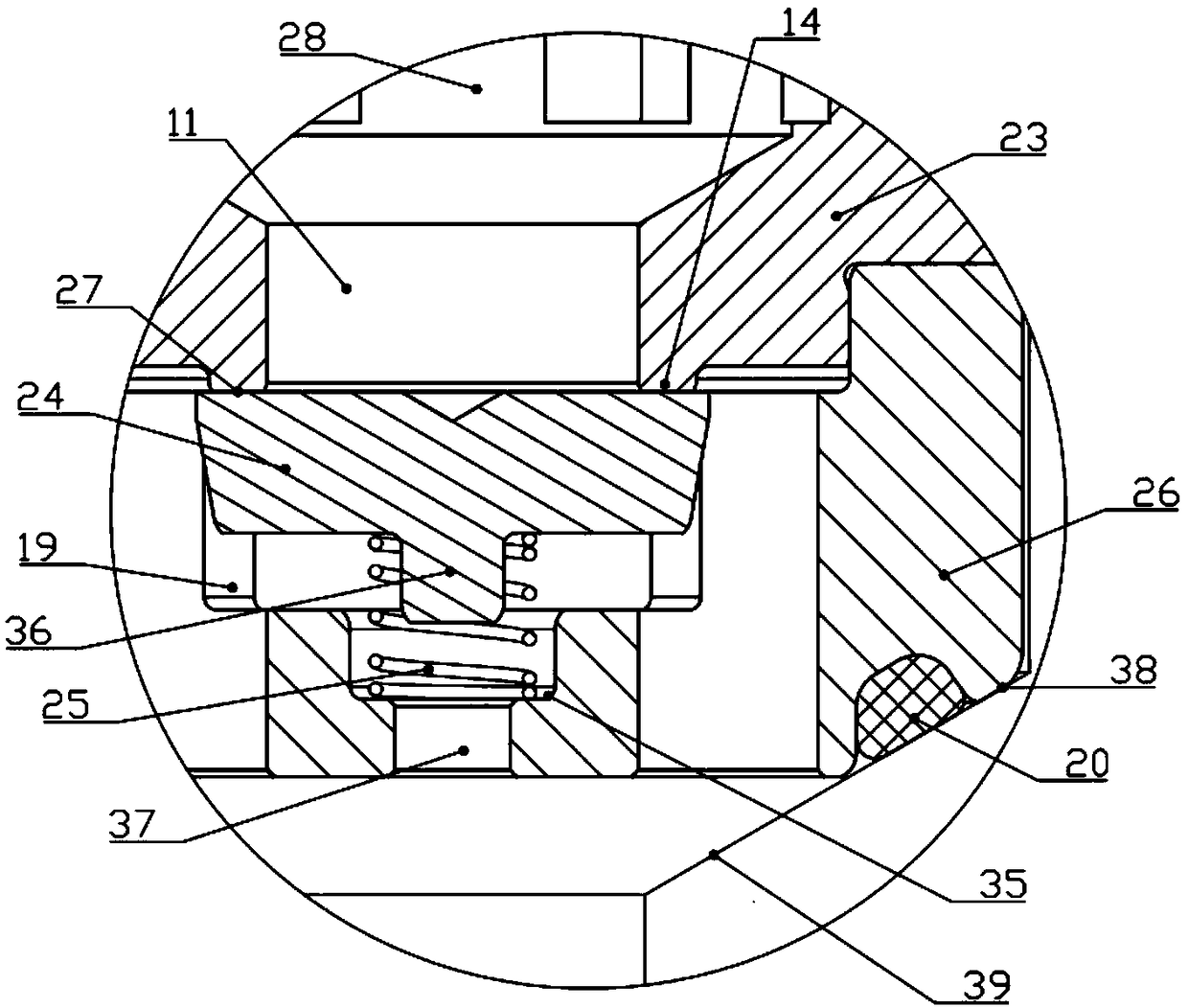

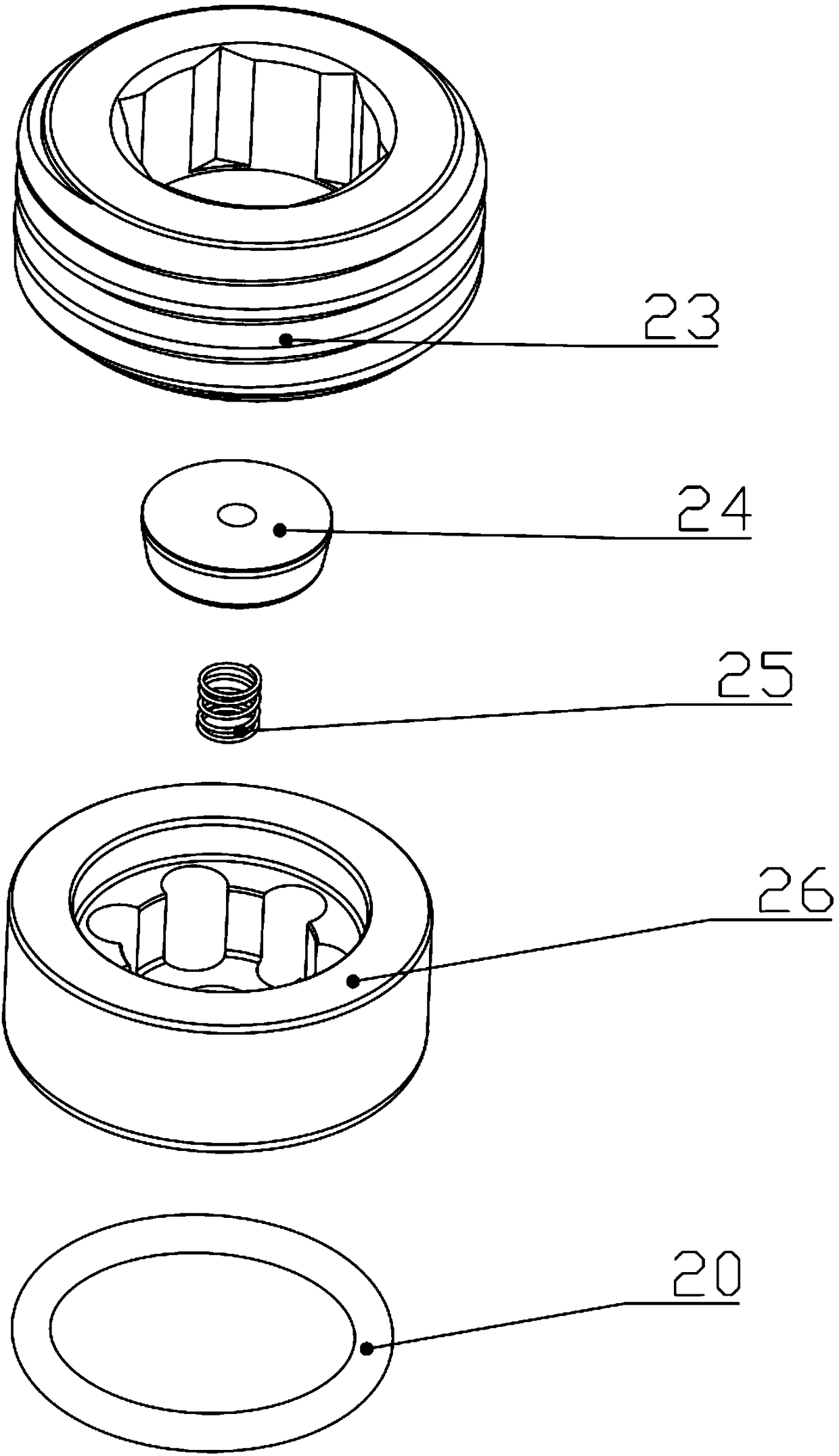

The invention discloses an installation type double-shaft automatic tightening device. The installation type double-shaft automatic tightening device comprises a drive support, a front supporting base, a rear supporting base, a switch support, a servo motor, a speed reducer, a gear unit, tightening shafts, a cylinder and a fixed base. The front end of the drive support and the front supporting base are connected through bolts. The tail end of the drive support and the rear supporting base are connected through bolts. The switch support is located on the front portion of the front supporting base, and the whole is located below the two tightening shafts. Each tightening shaft comprises a supporting shaft, a shaft end flange, a sleeve, a rectangular key, a bearing, a fastening nut, a straight through connector, a switching connector, a piston, a disc spring, a spring, a pressing sleeve, a tightening sleeve and a transmission shaft. The supporting shafts are connected with driven gears through keys. The servo motor drives a driving gear to rotate through the speed reducer. The installation type double-shaft automatic tightening device is suitable for being applied to places where spaces are small and the interval between two shafts is small.

Owner:YANSHAN UNIV

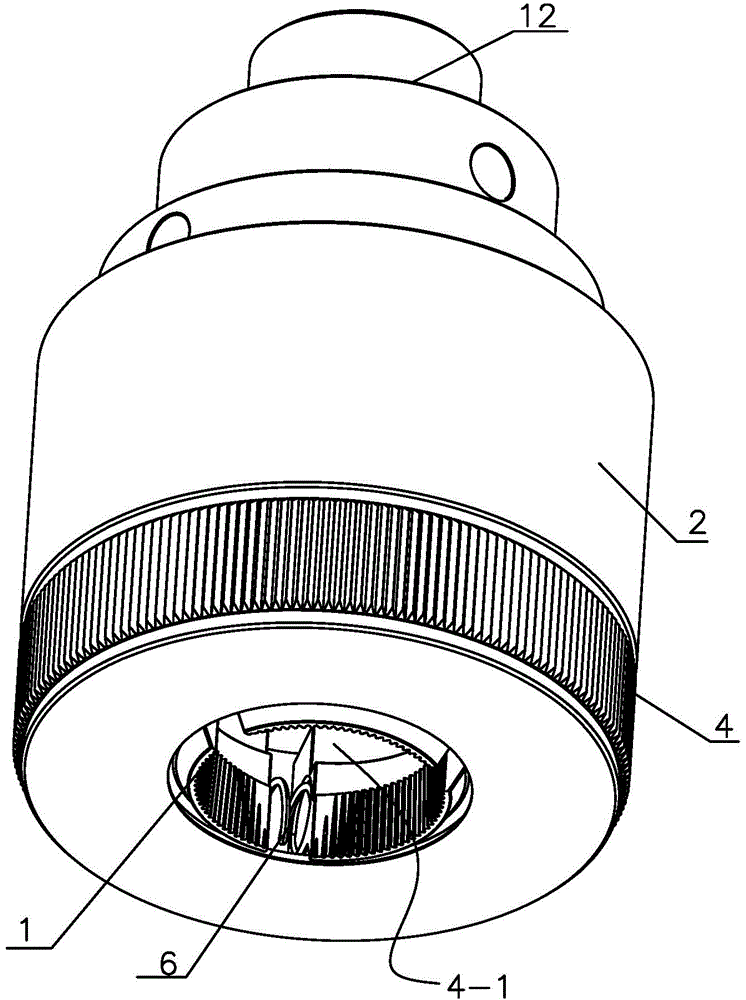

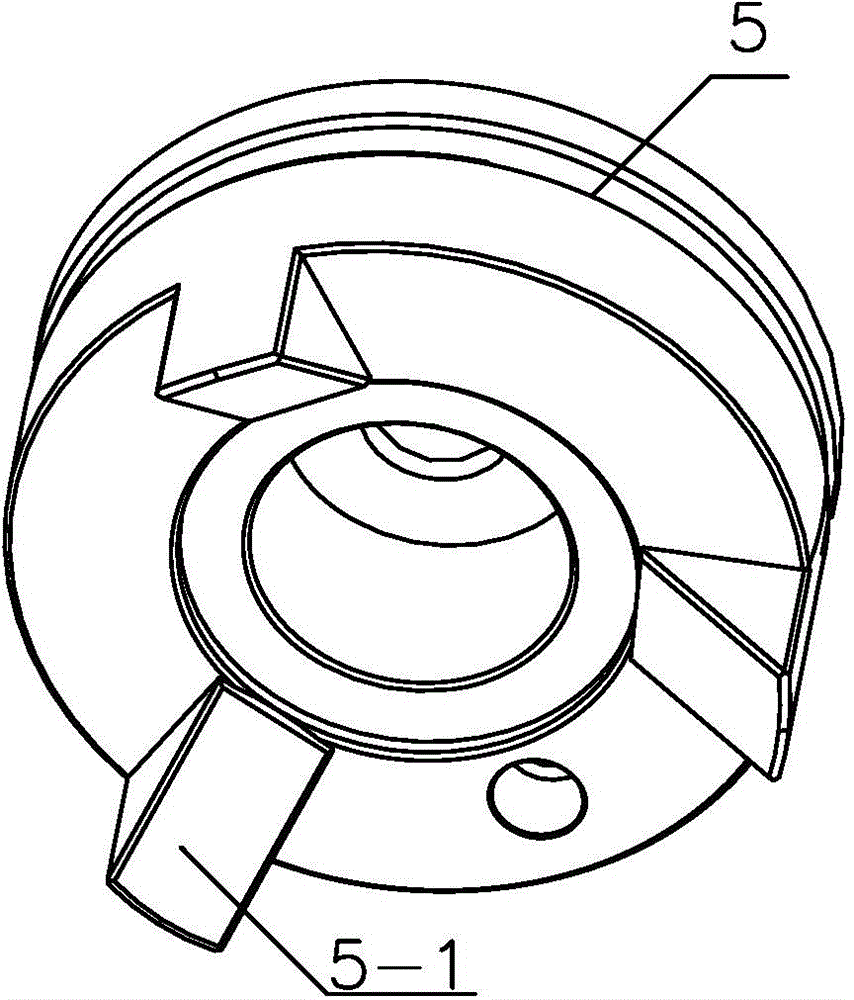

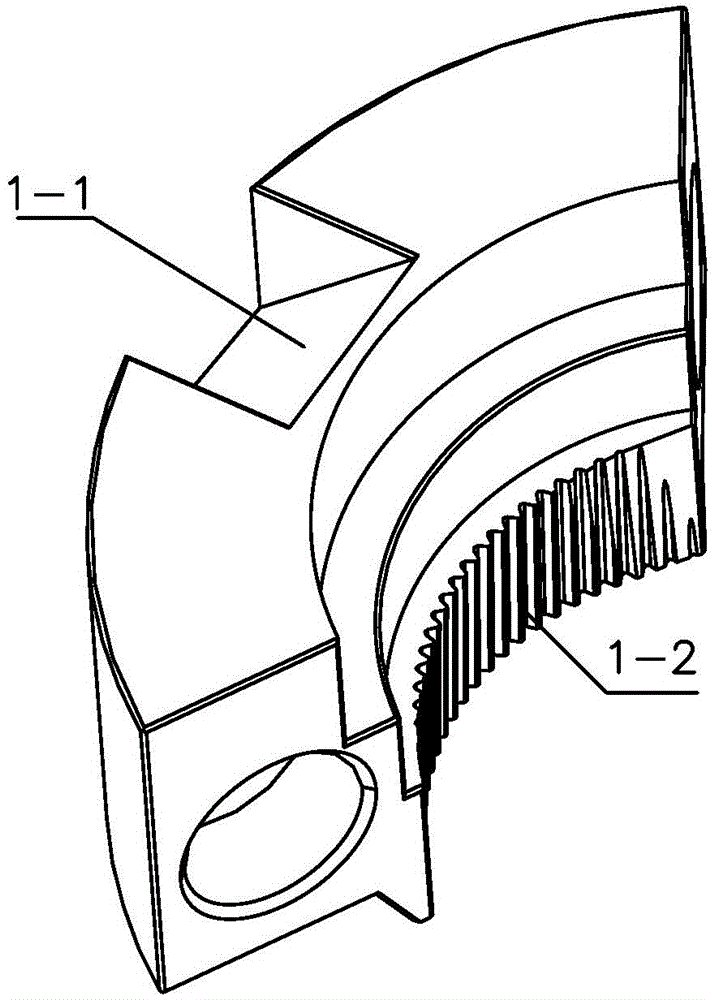

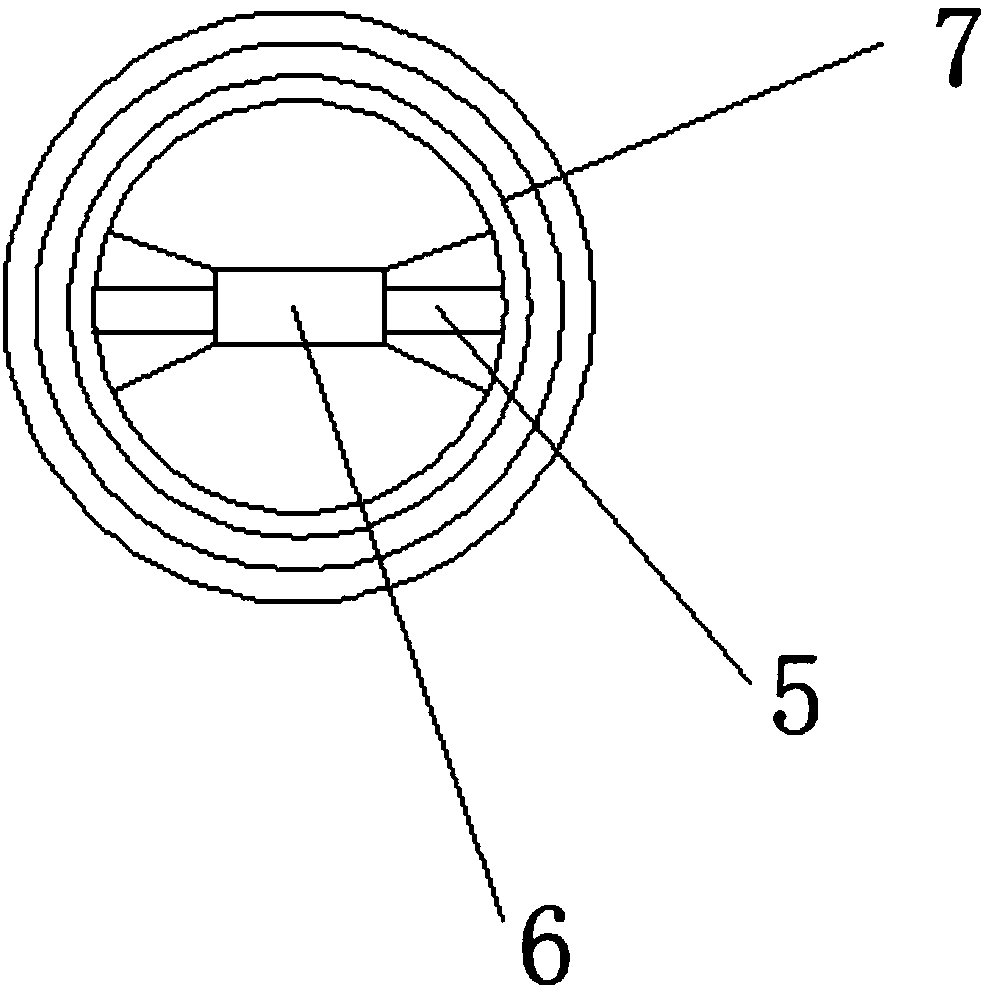

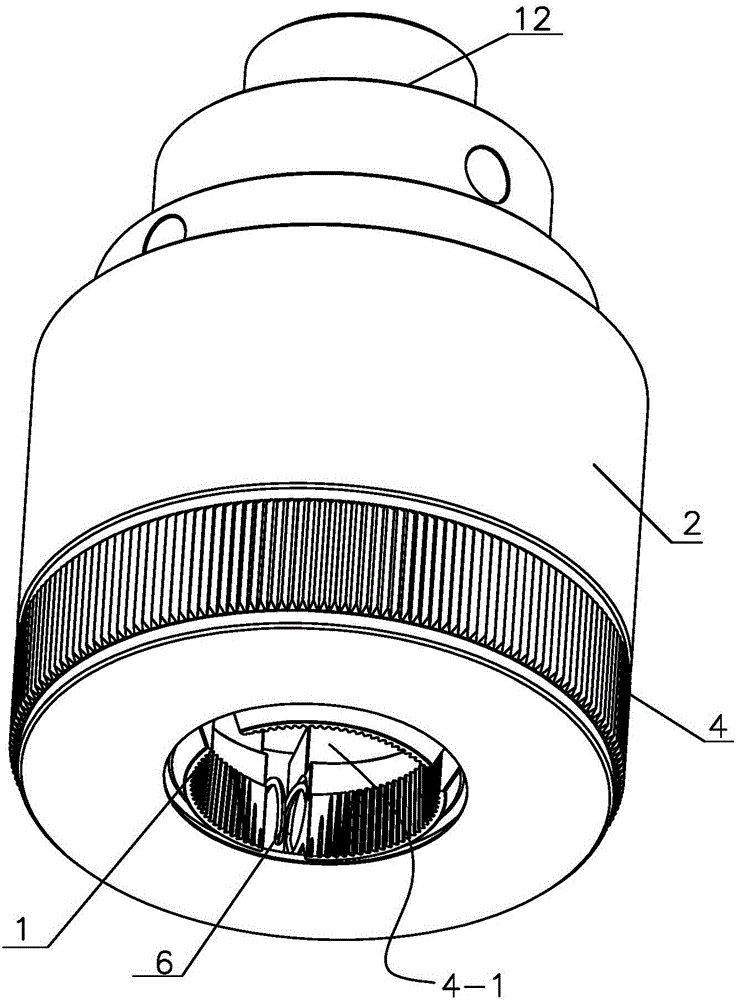

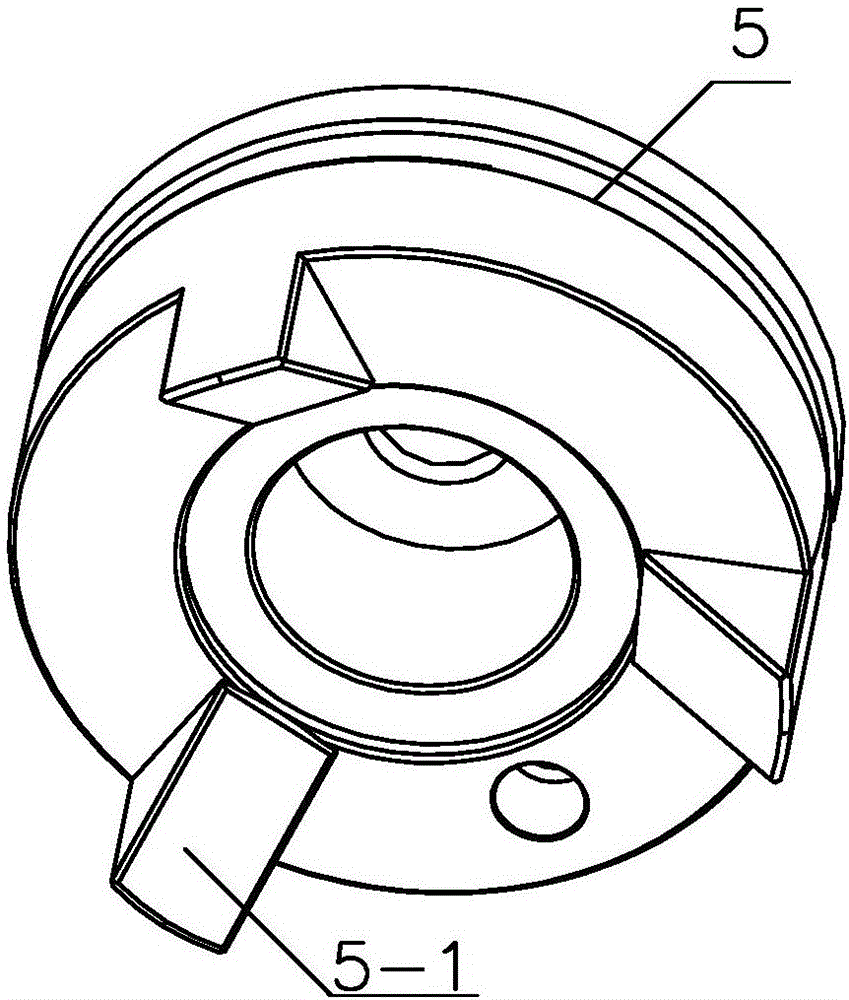

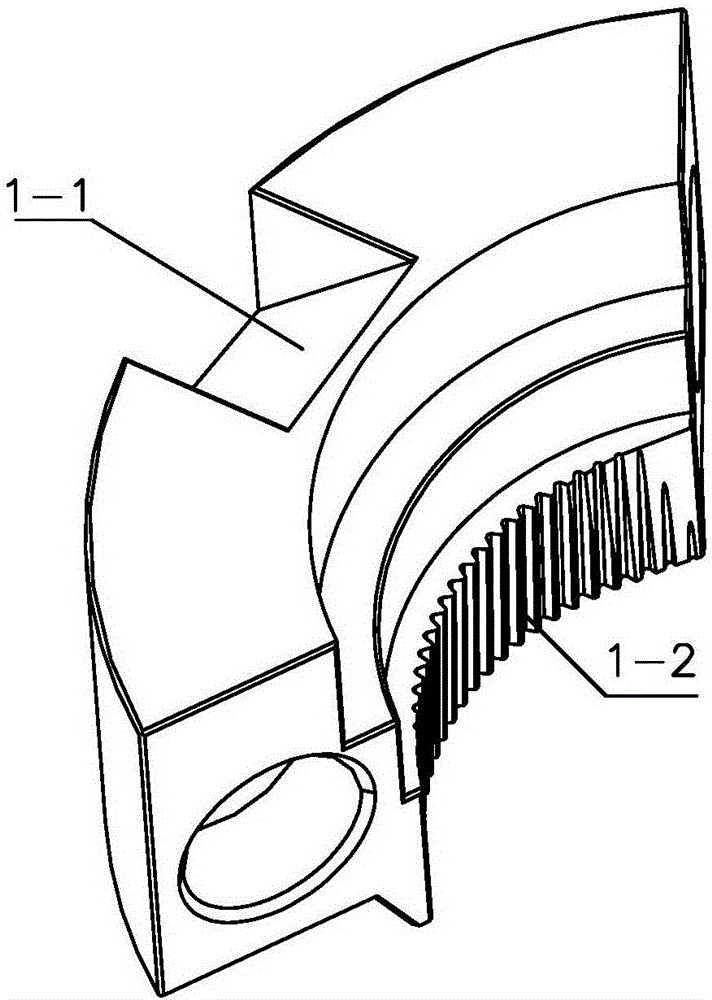

Cap-screwing machine chuck

ActiveCN104058355ASimple designThe whole machine is excellentThreaded caps applicationMechanical engineeringBottle cap

The invention relates to a cap-screwing machine chuck, which is used for clamping a bottle cap. The cap-screwing machine chuck comprises a plurality of jaws, a jaw base and a pusher; the jaws are used for clamping the bottle cap; the jaws are evenly mounted around the jaw base; the pusher is used for pushing the jaws to move, and can push the jaws to shift oppositely or relatively under the action of power. The cap-screwing machine chuck adopts wedge structures to drive the jaws to shift for grabbing and releasing, changing the conventional way of action which drives the jaws to swing for grabbing and releasing; the jaws of the cap-screwing machine chuck are always stressed for clamping in the horizontal direction, while the conventional jaw has an articulating point and the characteristic of articulation is utilized to swing the jaw, which is equivalent to lever motion, so the grabbing force and stability of the conventional jaws are not as good as the grabbing force and stability of the cap-screwing machine chuck; moreover, the design of the mechanism for driving the jaws to move is simplified, so the entire machine becomes more excellent and the cost is reduced.

Owner:CHANGZHOU HUITUO TECH

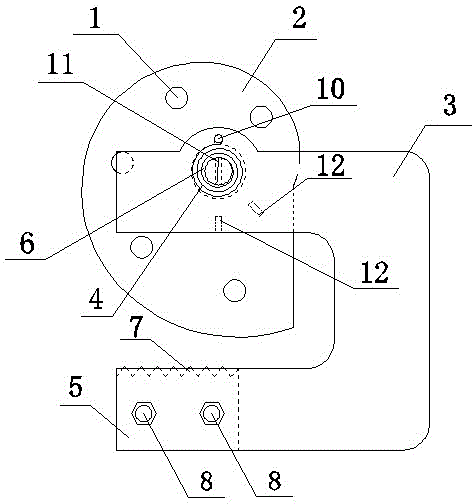

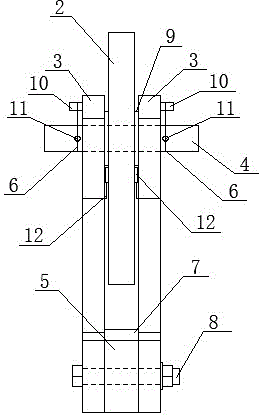

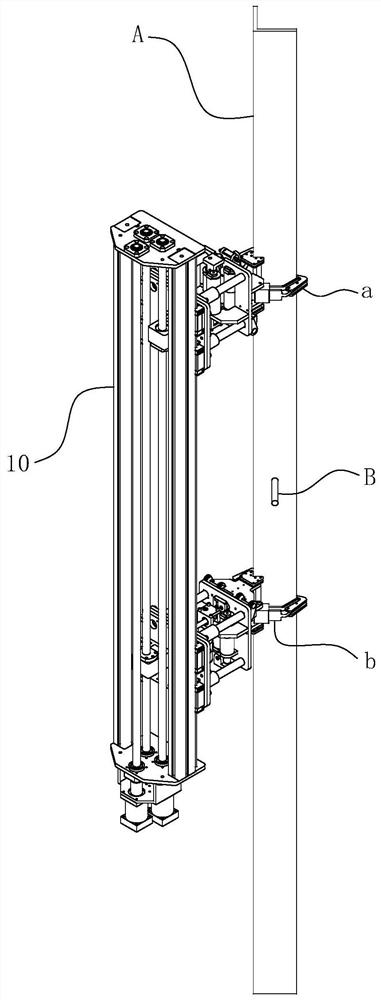

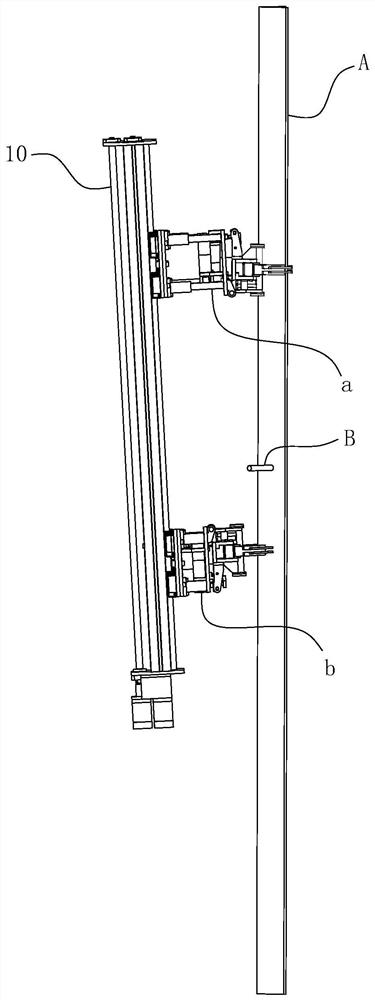

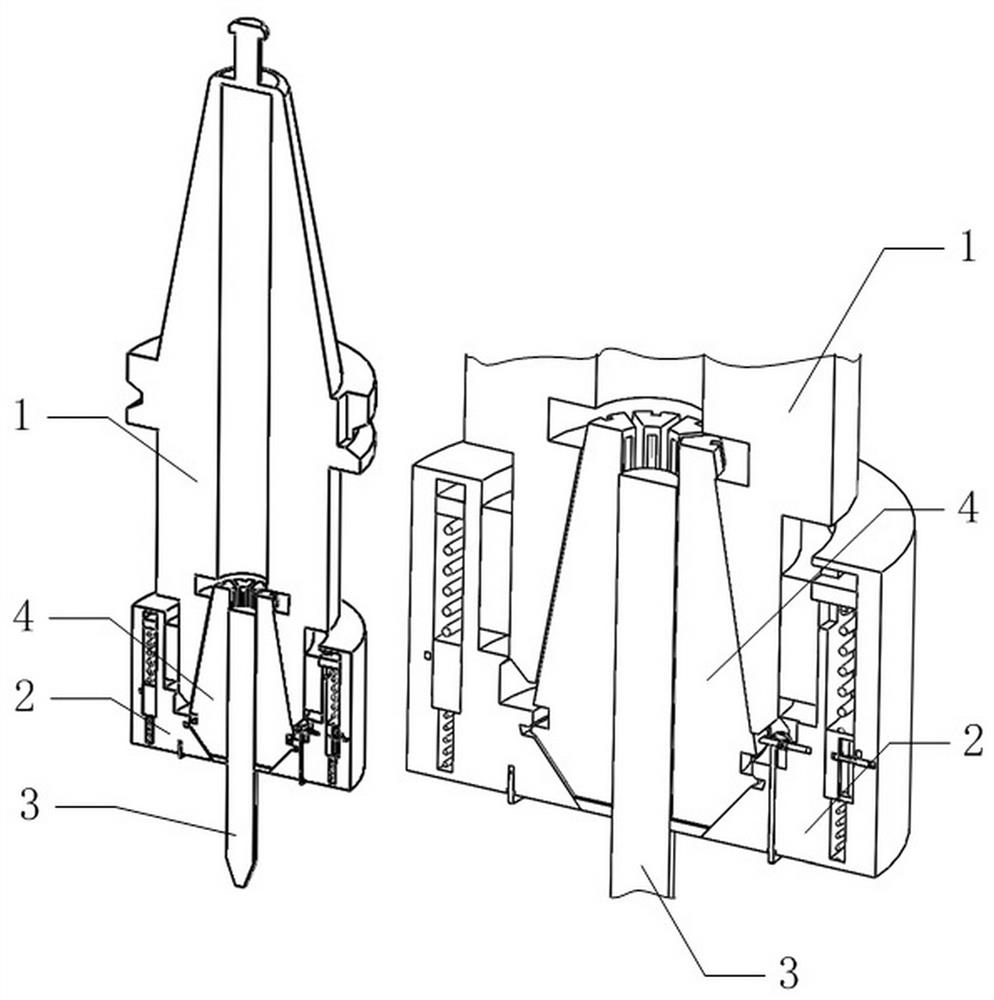

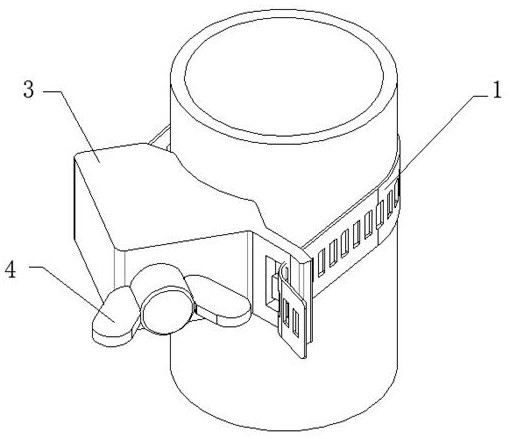

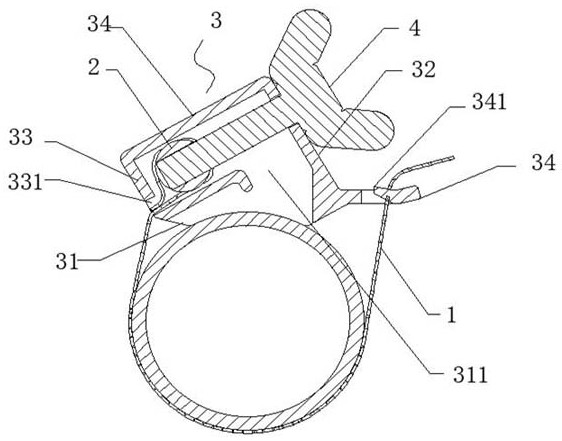

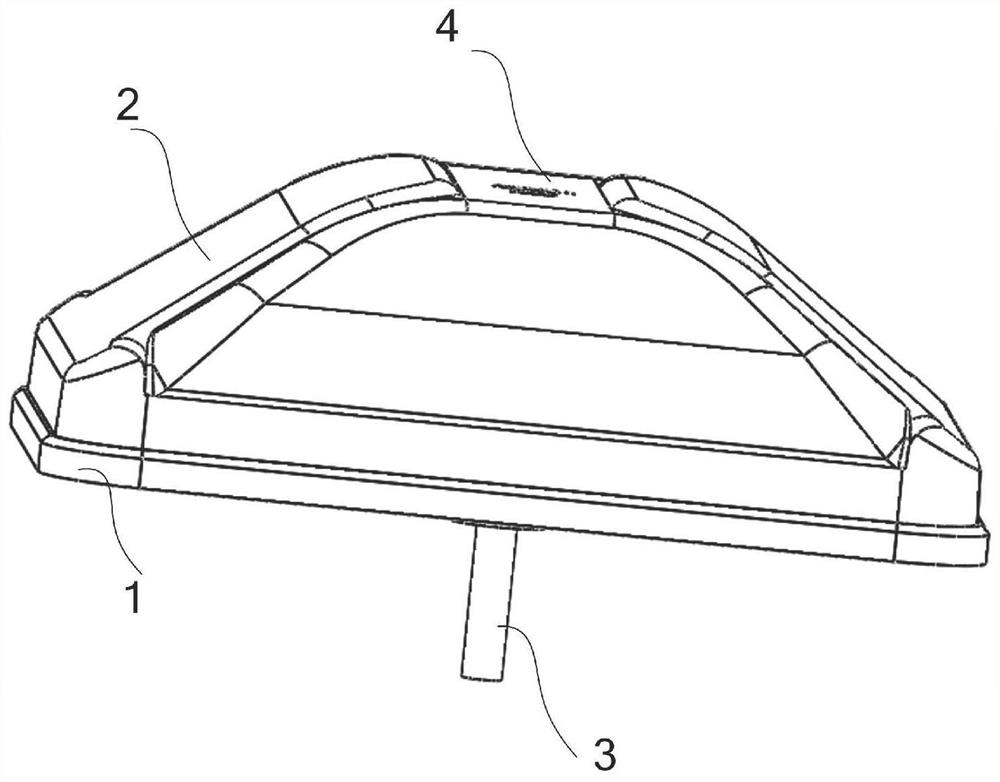

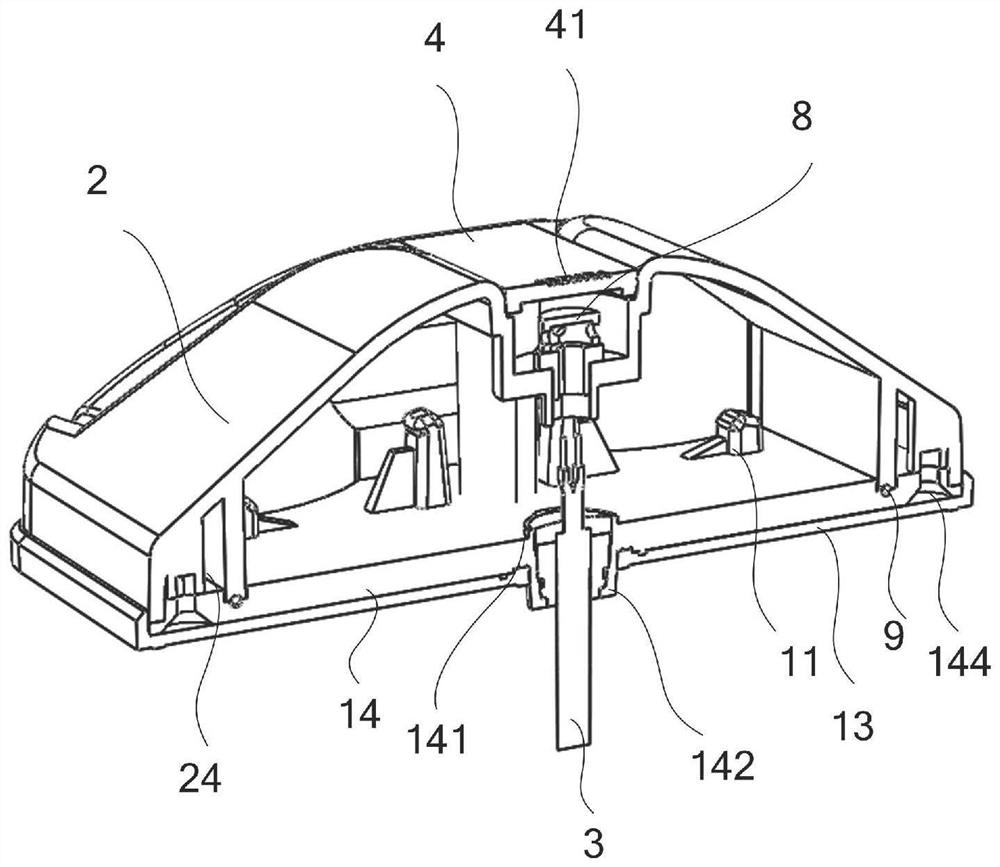

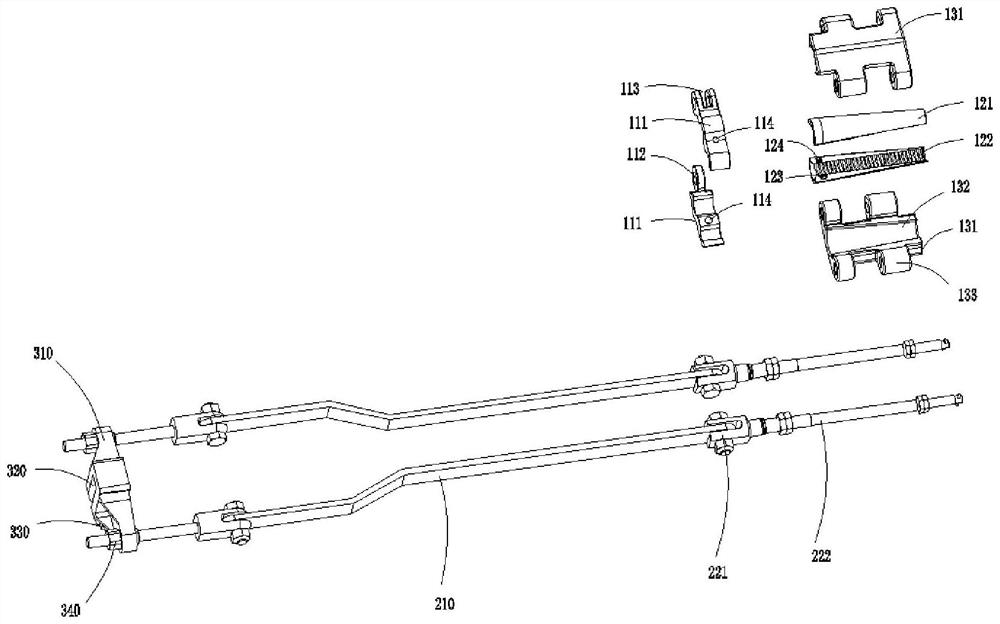

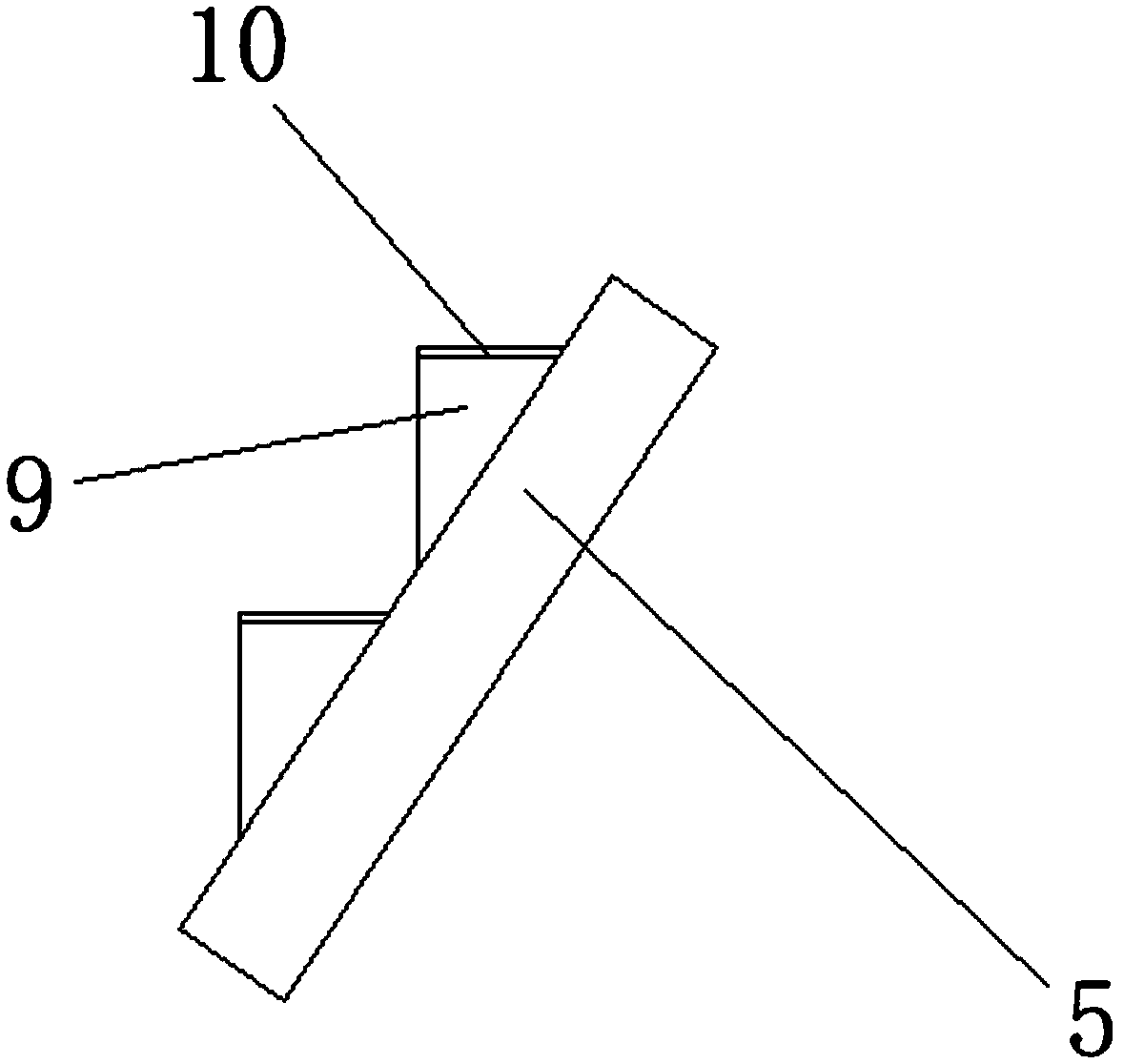

Clamping jaw for climbing robot

PendingCN112278107AEnsure movement stabilityEnsure operation reliabilityVehiclesReciprocating motionControl engineering

The invention belongs to the technical field of electric power operation climbing robots, and particularly relates to a clamping jaw for a climbing robot. The clamping jaw comprises a fixing base anda clamping end, the clamping end is formed by matching two symmetrical claw rods, the claw rods can do linear reciprocating motion in the axial direction of a matched rotary sliding sleeve, and the rotary sliding sleeve is hinged to a fixed seat through a vertical hinge base; the fixed seat comprises a lower mounting plate, a push-pull plate is arranged right above the lower mounting plate, and two shaft ends of a vertical push-pull shaft at the tail end of each claw rod are respectively matched with an orientation groove at the lower mounting plate and a guide groove at the push-pull plate; the push-pull plate can generate a horizontal reciprocating action vertical to the direction of the vertical push-pull shaft; the fixing seat further comprises a V-shaped block. Force closure and shapeclosure in the climbing process along the angle steel tower can be achieved, so that the action stability and the action reliability of climbing operation of the climbing robot are effectively guaranteed, the manpower inspection cost can be greatly saved, the maintenance efficiency is improved, and safe and reliable operation of a power transmission system is guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER +1

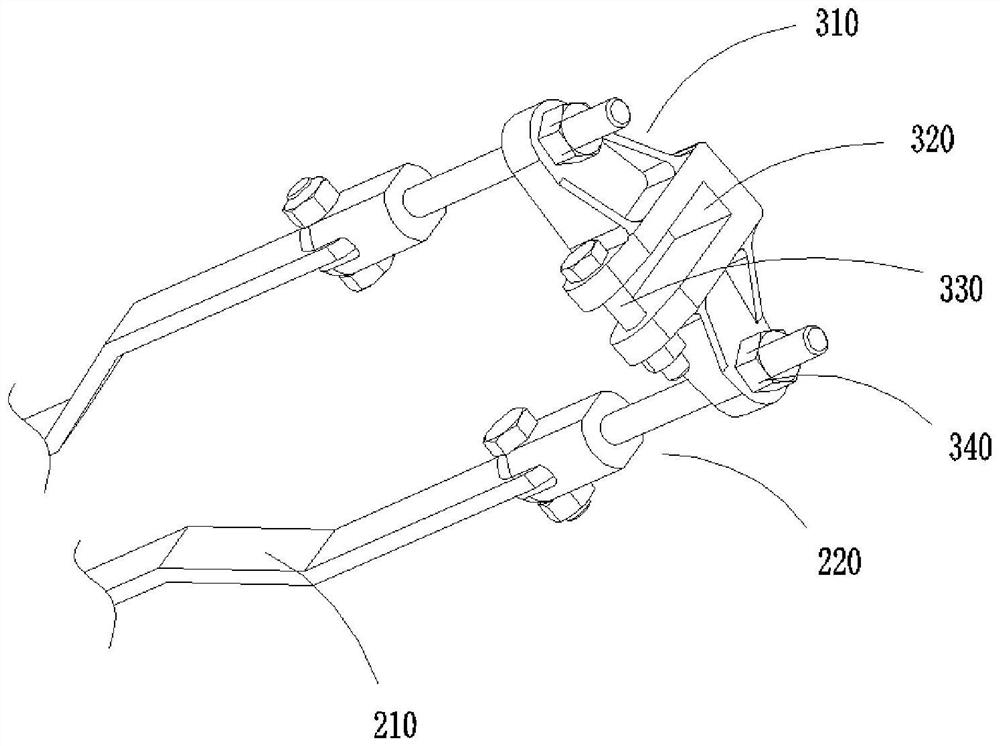

Climbing robot

PendingCN112278108AEnsure movement stabilityEnsure operation reliabilityVehiclesReciprocating motionEngineering

The invention belongs to the technical field of electric power operation climbing robots, and particularly relates to a climbing robot. The climbing robot comprises a main machine and a clamping jaw;the clamping jaw comprises a fixed seat and a clamping end, the clamping end is formed by two symmetrical jaw rods in a matched mode, the jaw rods can do linear reciprocating motion in the axial direction of a matched rotary sliding sleeve, and the rotary sliding sleeve is hinged to a fixed seat through a vertical hinge seat; the fixed seat comprises a horizontally-arranged lower mounting plate, apush-pull plate is arranged over the lower mounting plate, and the two shaft ends of a vertical push-pull shaft at the tail end of each claw rod are matched with a directional groove in the lower mounting plate and a guide groove in the push-pull plate respectively. The push-pull plate is driven by a horizontal driving assembly to generate a horizontal reciprocating action vertical to the direction of the vertical push-pull shaft; the fixed seat further comprises a V-shaped block. Force closure and shape closure in the climbing process along the angle steel tower can be achieved, so that theaction stability and the action reliability of climbing operation are effectively guaranteed, and safe and reliable operation of a power transmission system is guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER +1

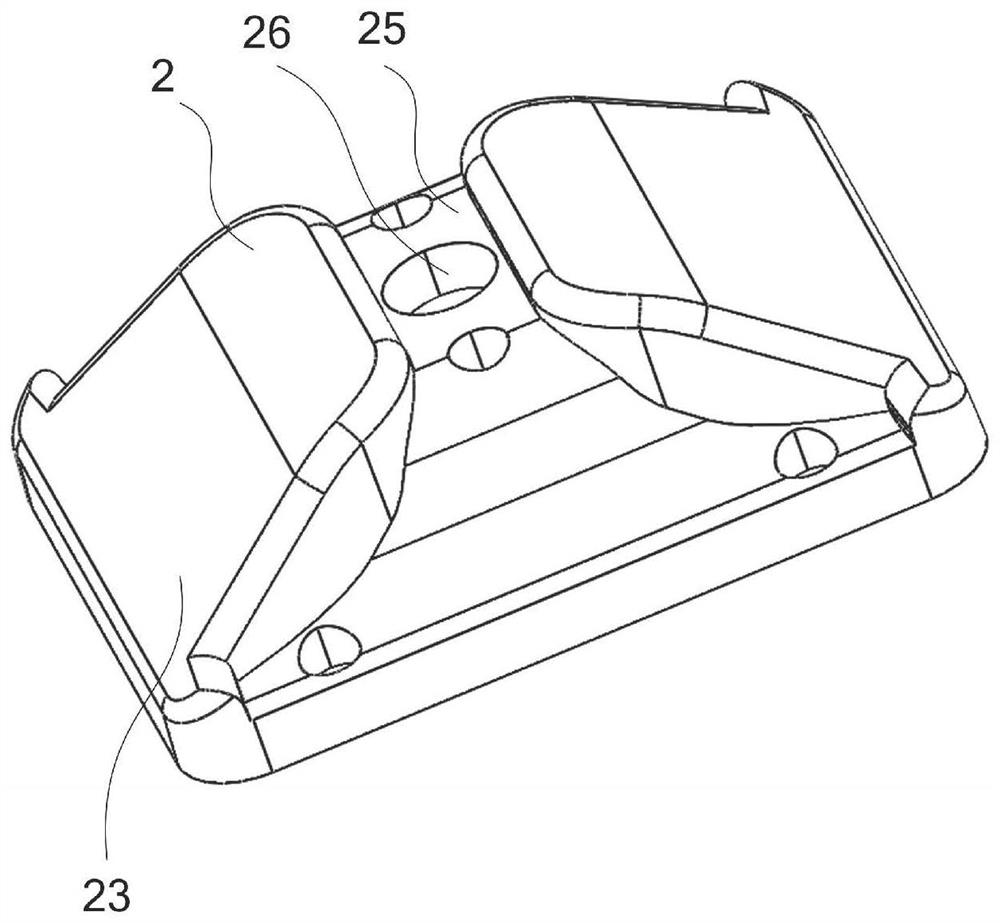

Resin molded body and method of molding the same

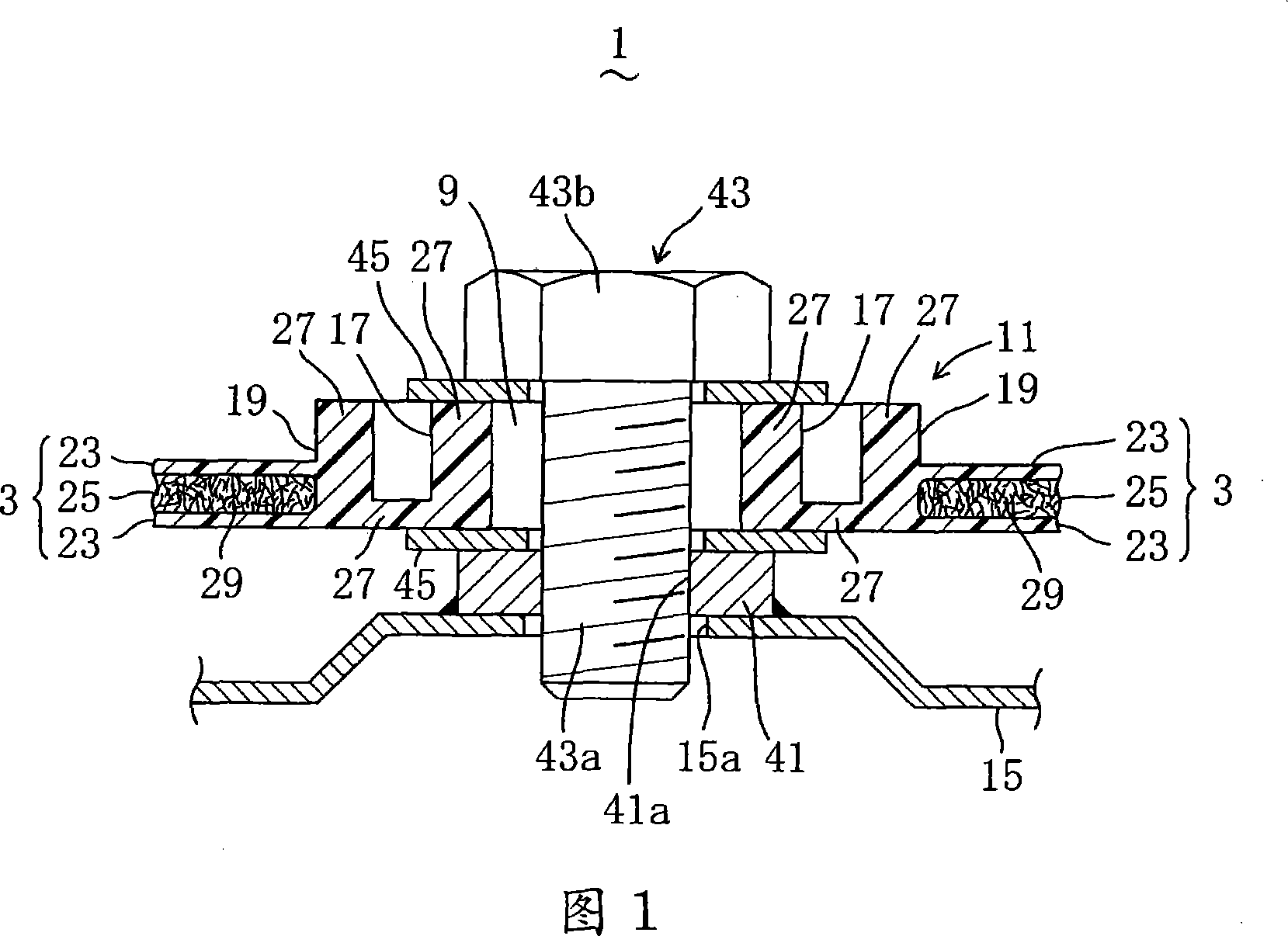

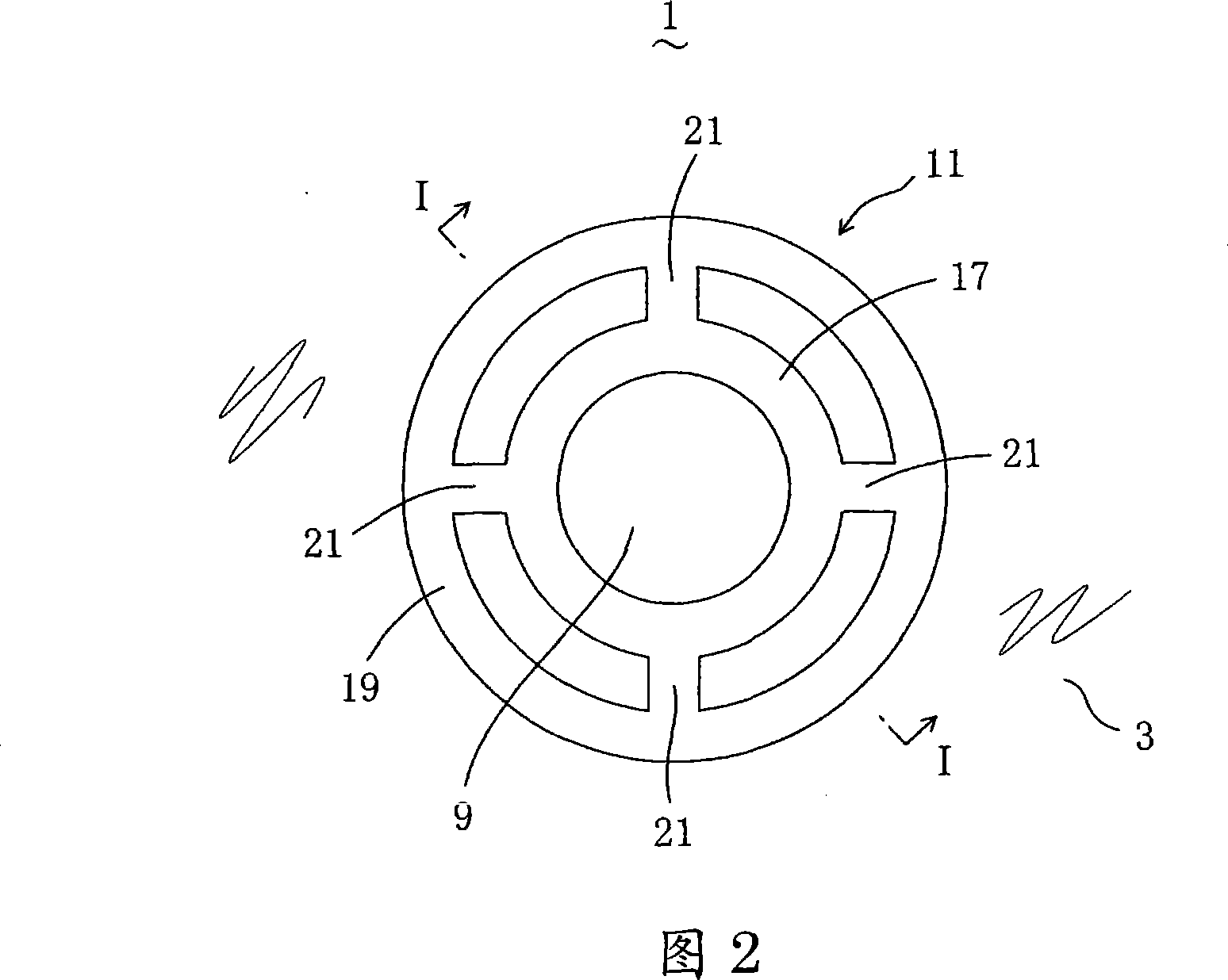

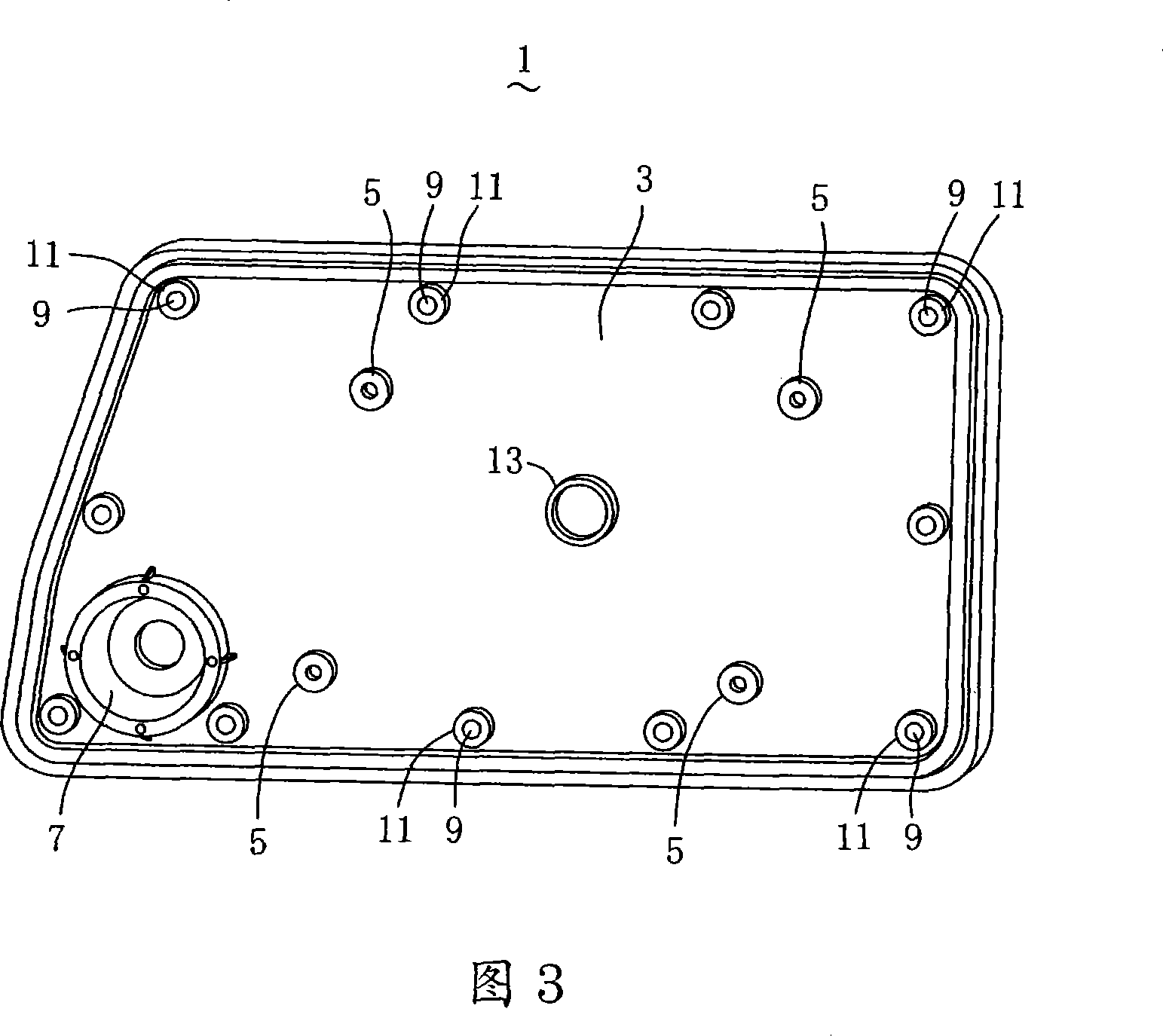

ActiveCN1993214AImprove rigidityAvoid deformationThin material handlingEngineeringMechanical engineering

A method of molding a resin molded body, wherein an annular mounting seat (11) integrally formed projectedly from one surface of a panel body (3) so as to surround a through hole (9) is formed of an inner mounting seat part (17) and an outer mounting seat part (19) formed double on the inner and outer sides and connecting mounting seat parts (21) connecting the inner mounting seat part (17) to the outer mounting seat part (19) at four positions. Skin layers (23) are formed on the surfaces of a door inner panel (1). An expansion layer (25) having a large number of voids is formed in the panel body (3). The mounting seat (11) and the panel body (3) between the inner mounting seat part (17) and the outer mounting seat part (19) are formed of a solid layer (27) without the expansion layer (25). Thus, the resin molded body having a lightweight but highly rigid mounting seat can be provided.

Owner:DAIKYONISHIKAWA CORP

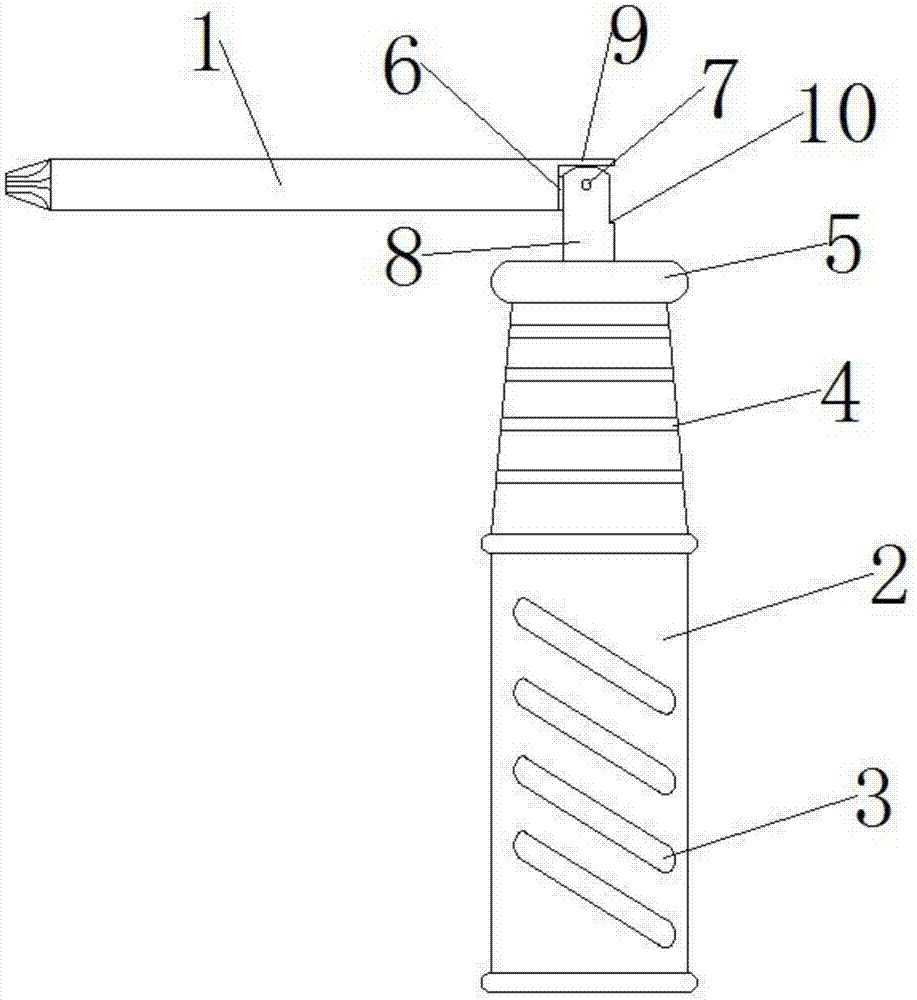

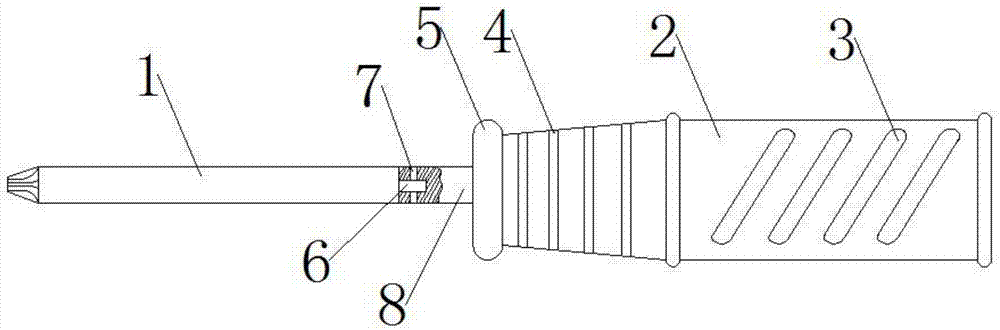

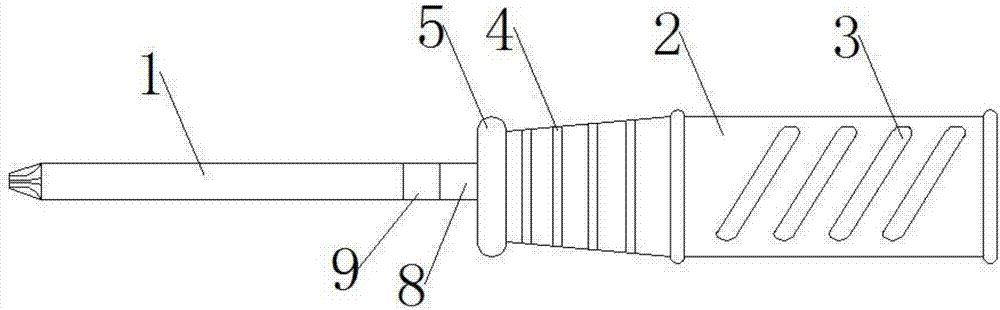

Bendable screwdriver

The invention discloses a bendable screwdriver. The bendable screwdriver comprises a screwdriver rod I and a rotating pin; one end of the screwdriver rod I is provided with a cross quincuncial screwdriver blade; the other end of the screwdriver rod I is provided with a supporting rod; a screwdriver rod II is into the supporting rod; the rotating pin is inserted into a connecting hole of the screwdriver rod II and the supporting rod; a check block is arranged by the side of the supporting rod; the sidewall of the screwdriver rod II is provided with a check block groove; the other end of the screwdriver rod II is provided with a knife handle; the outer wall of the knife handle is provided with a skid-proof lug boss; the taper part of the knife handle is provided with a four circles of skid-proof grooves; and the outer wall of the knife handle is provided with a protruding ring body. According to the bendable screwdriver disclosed by the invention, the screwdriver rod I and the screwdriver rod II are configured as a separable structure, are easy to maintain and are convenient to replace, so the practicability of the screwdriver rod is improved, and the service life of the screwdriverrod is prolonged.

Owner:英立(江苏)机电有限公司

Clamping assembly with angle and height adjusting function

PendingCN112339878AGuaranteed efficient obstacle clearanceGuaranteed clamping effectVehiclesClassical mechanicsControl theory

The invention belongs to the technical field of electric power operation climbing robots, and particularly relates to a clamping assembly with an angle and height adjusting function. The clamping assembly comprises a clamping jaw, an angle adjusting assembly and a lifting assembly, wherein the angle adjusting assembly is mounted on the clamping jaw and can adjust the pitch angle of relative anglesteel, and the lifting assembly can enable the clamping jaw to move close to or away from the angle steel. The hinge axis of the angle adjusting assembly is horizontally arranged and is perpendicularto the length direction of angle steel. The clamping assembly enables a climbing robot to have extremely high obstacle crossing capacity and climbing efficiency, the action stability and the action reliability of climbing operation of the climbing robot can be synchronously guaranteed, and therefore the manpower inspection cost can be greatly reduced, the maintenance efficiency can be improved, and safe and reliable operation of a power transmission system can be guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER CO LTD +1

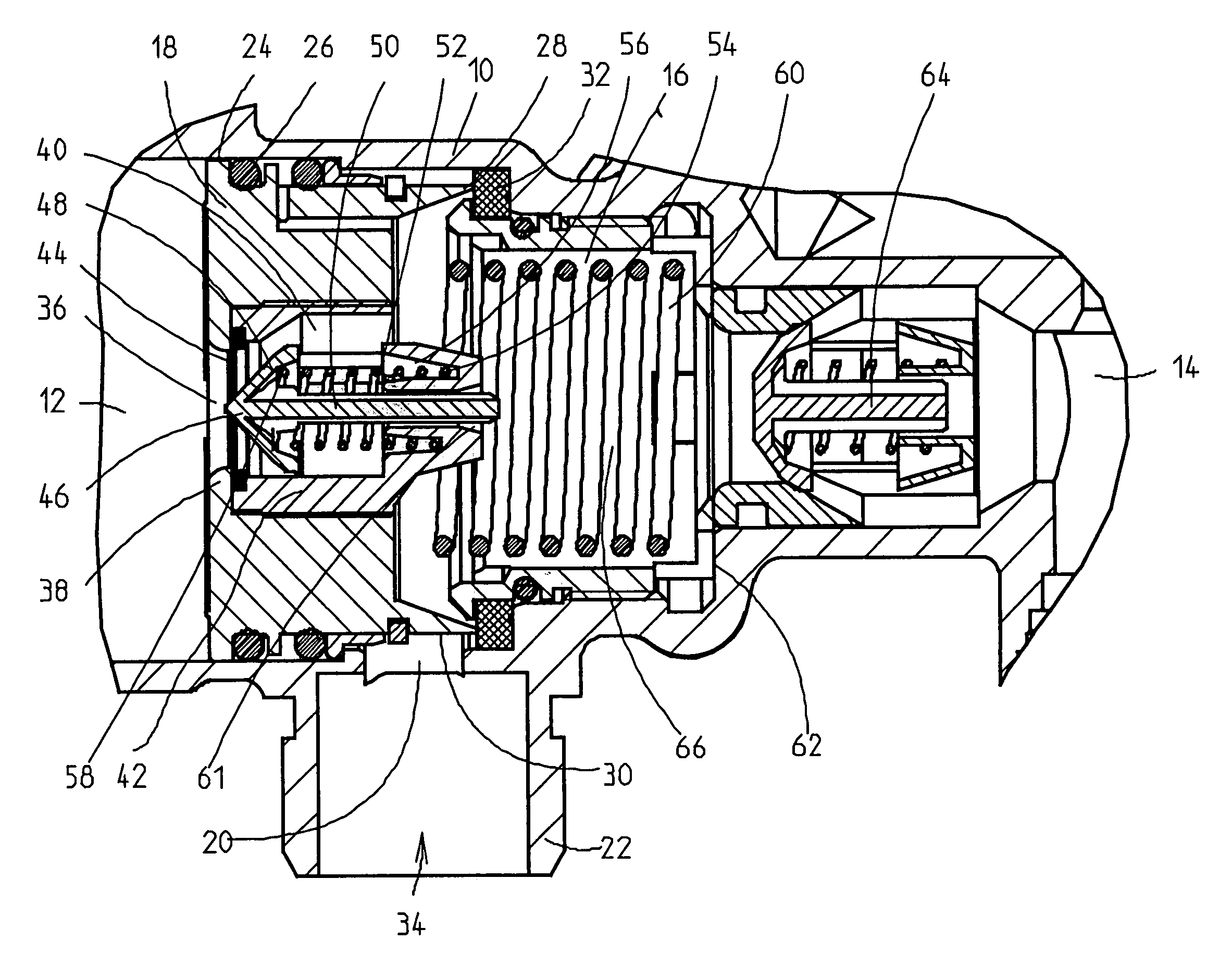

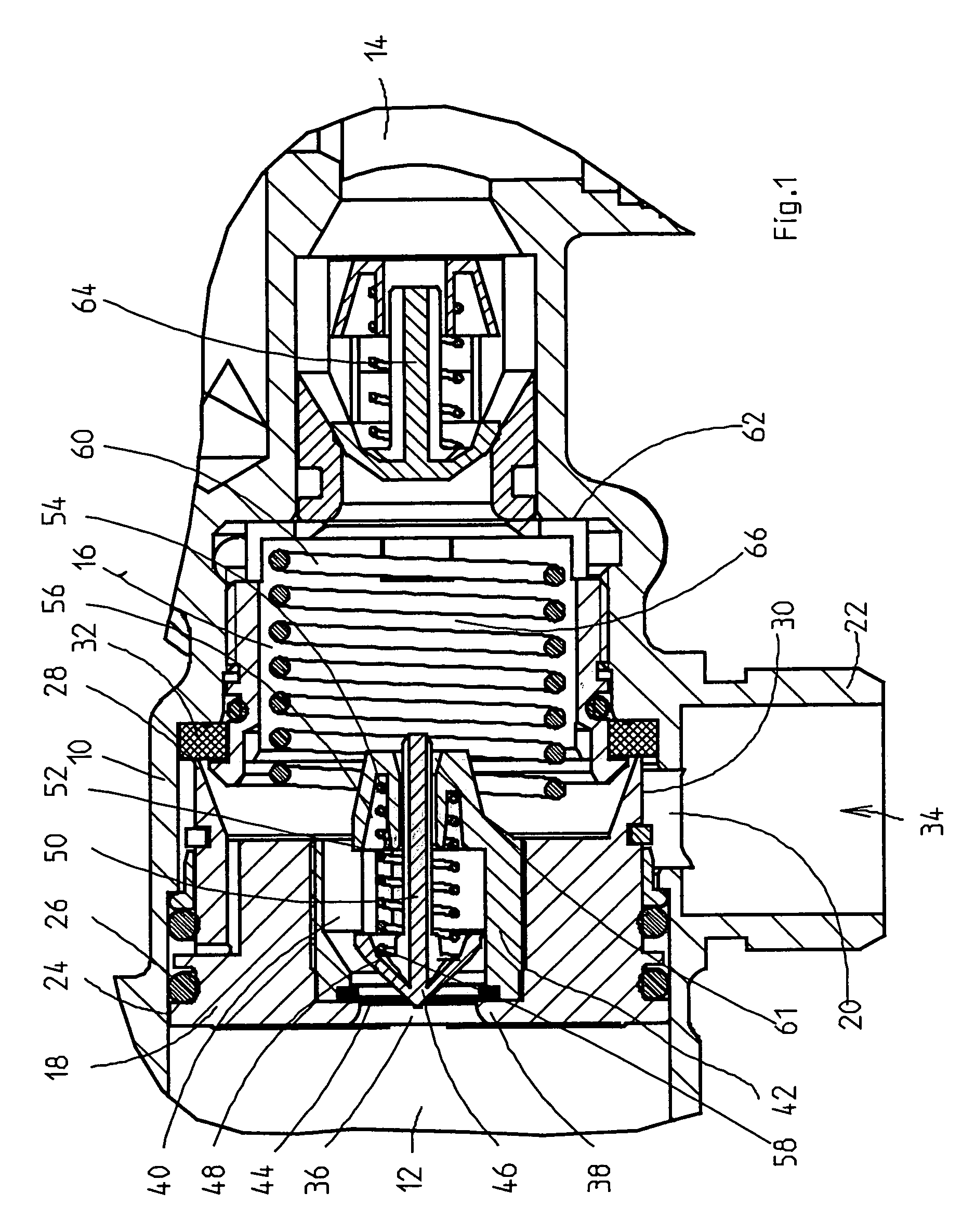

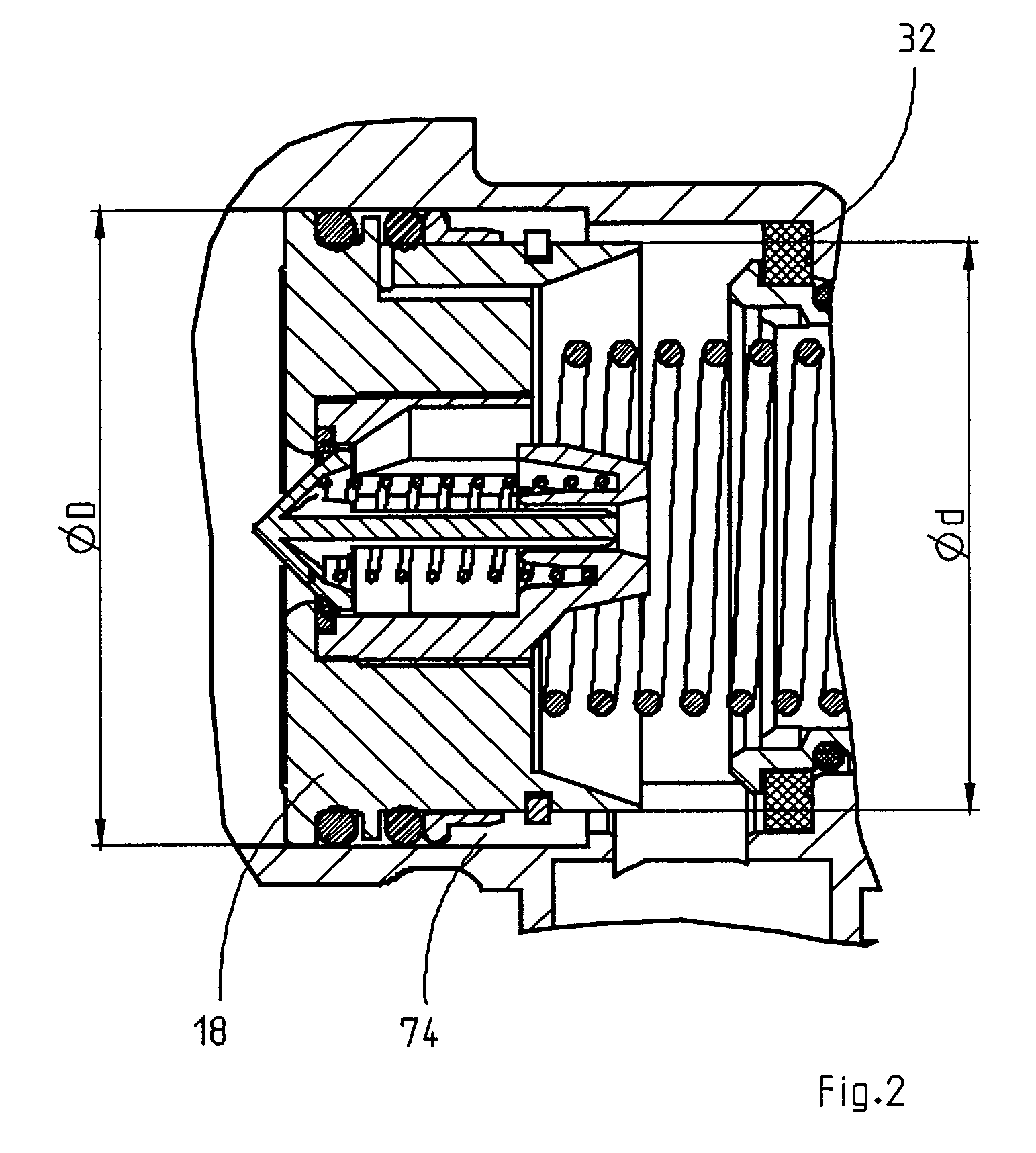

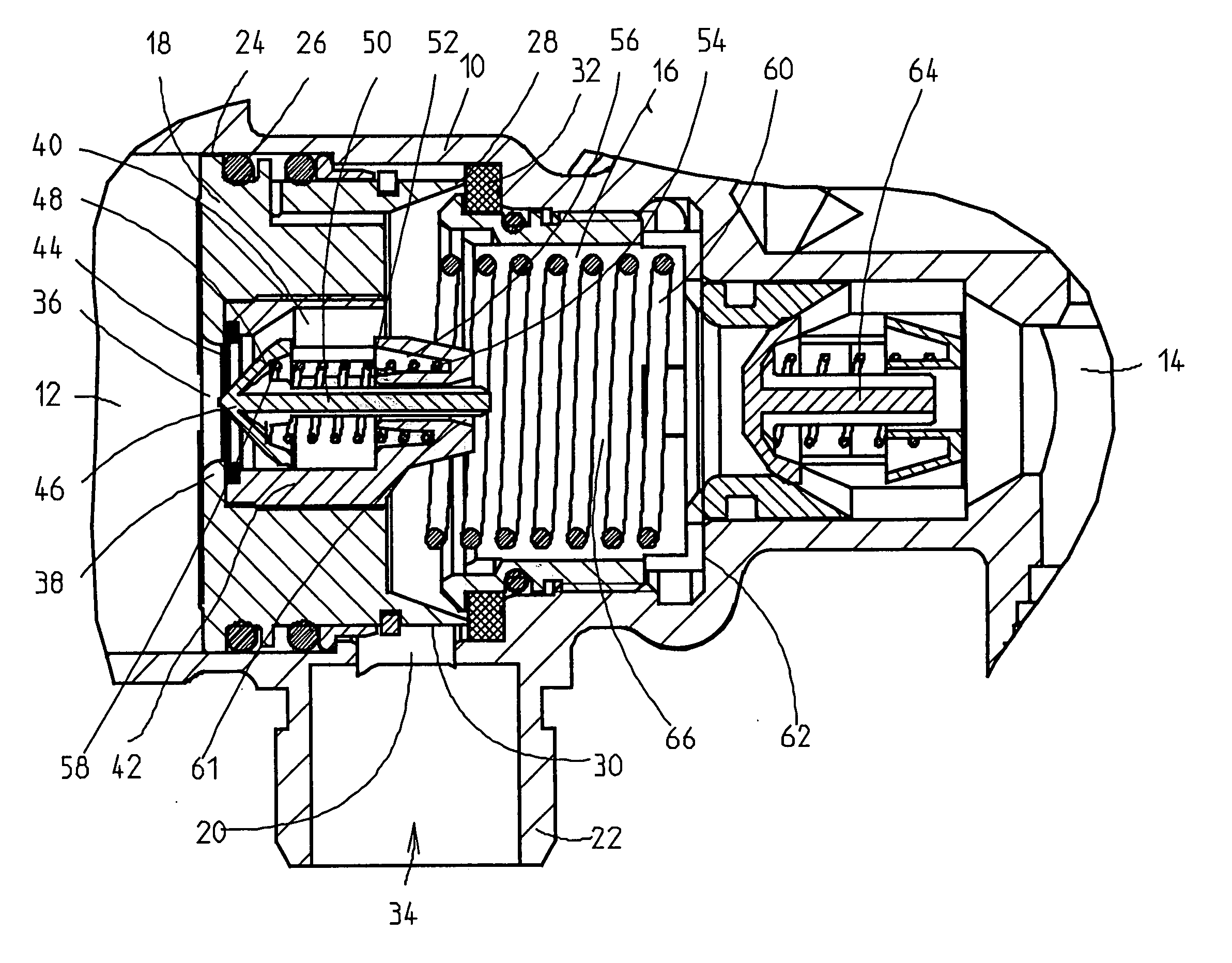

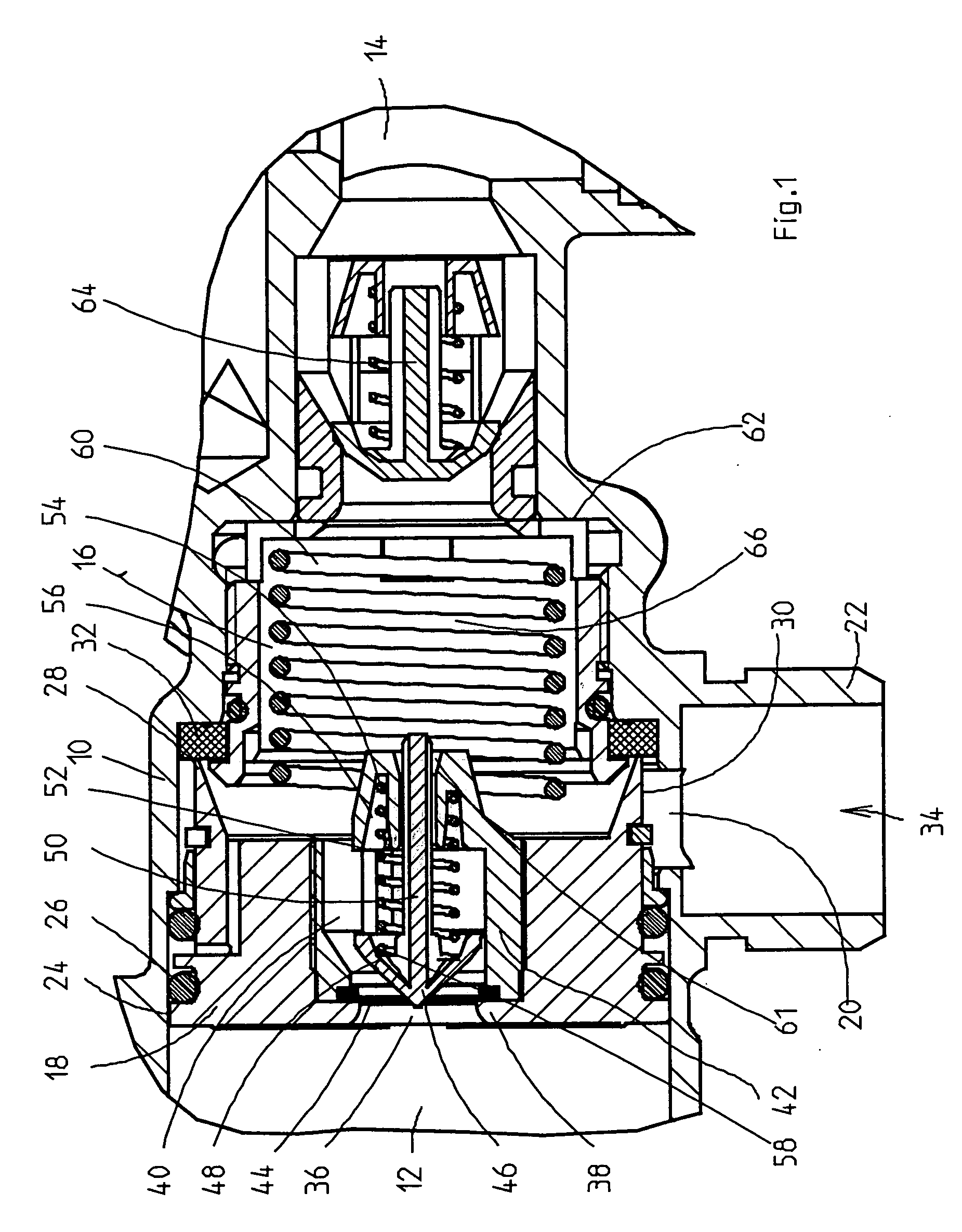

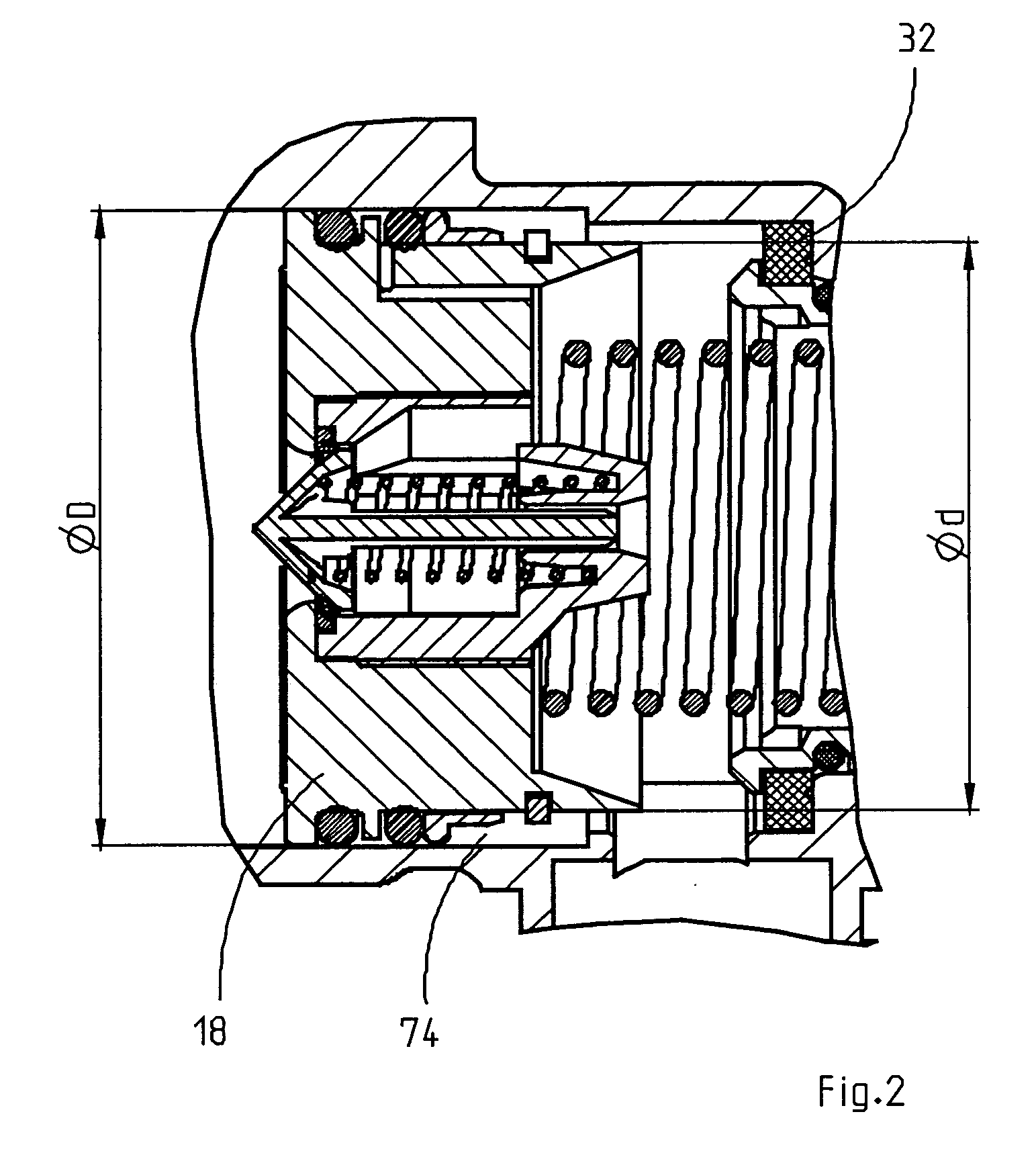

Pipe disconnector with increased sealing power

ActiveUS7575016B2Increase tightening forceIncrease powerLighting and heating apparatusCheck valvesEngineeringInlet pressure

A system disconnector for disconnecting an upstream liquid system providing an inlet pressure from a downstream liquid system by a release valve (34) in response to a pressure drop between the systems, includes an upstream backflow preventer (40), a downstream backflow preventer (64) and a release valve body piston (18) arranged between the backflow preventers (40, 64). A pressure difference between the inlet pressure and a middle pressure between the backflow preventers (40,64) counteracts a spring (60) biasing the release valve body in the opening direction, the release valve body (18) having an effective pressurized surface (d) smaller than the surface effective for the inlet pressure. A hollow space (74) defined by the release valve body is connected to the middle pressure (66). A shiftable seat (76) provided in hollow space (74), is movable with respect to the release valve body to a fixed stop (84) upstream of the valve seat (32).

Owner:HANS SASSERATH GMBH & CO KG

Pipe disconnector with increased sealing power

ActiveUS20070079873A1Increase tightening forceIncrease powerLighting and heating apparatusCheck valvesBackflow prevention deviceEngineering

A system disconnector for physically disconnecting an upstream liquid system from a downstream liquid system by means of a release valve (34) in response to a pressure drop between the upstream and downstream liquid system, with an upstream backflow preventer (40), a downstream backflow preventer (64) and a release valve body (18) in the form of a piston which is, regarding the flow, arranged between the backflow preventers (40, 64), an inlet pressure of the upstream liquid system upstream from the upstream backflow preventer (40), a middle pressure in a middle pressure space (66) between the release valve body (18) and the downstream backflow preventer (64) and an outlet pressure of the downstream liquid system downstream of the downstream backflow preventer (64), wherein a pressure difference between the inlet pressure and the middle pressure counteracts a spring (60) biasing the release valve body in the opening direction and wherein the release valve body (18) has an effective pressurized surface (d) which is smaller than the surface effective for the inlet pressure whereby a hollow space (74) is defined by the release valve body and the hollow space is connected to the middle pressure space (66) wherein a shiftable seat (76) adapted to be moved in the moving direction of the release valve body is provided in the hollow space (74), movable with respect to the release valve body up to a casing fixed stop (84) which is arranged in the flow direction upstream of the valve seat (32) of the release valve (34).

Owner:HANS SASSERATH GMBH & CO KG

Hydraulic tool one-way valve and hydraulic tool

PendingCN109268334AReduce weightPrevent reverse oil returnServomotor componentsServomotorsEngineeringValve seat

The invention belongs to the technical field of hydraulic tools, and particularly relates to a hydraulic tool one-way valve and a hydraulic tool. The one-way valve comprises a valve seat and a valve body which are fixed in a valve hole and a valve core and a spring which are arranged between the valve seat and the valve body, the spring abuts against the valve core and the valve body, and the plane of the upper end of the valve core and the lower end face of the valve seat abut and form a first sealing face under the elasticity of the spring; a plurality of overflowing holes are uniformly distributed in the bottom of the valve body, when the upper end face of the valve core is separated from the lower end face of the valve seat, the overflowing holes are communicated with the through hole,and mediums in the through hole flows out from the overflowing holes. According to the one-way valve, the shape of the valve core is changed, plane sealing is adopted by the part between the valve core and the valve body, the sealing performance of the one-way valve is greatly improved by matching with the reduced sealing contacting face between the valve core and the valve body, and the oppositeposition oil returning of the one-way valve in the working process is prevented.

Owner:TAIZHOU JULI TOOLS

Self-locking type safety clamp capable of being rapidly mounted and detached

InactiveCN104595298AEasy to assemble and disassembleImprove efficiencyFriction grip releasable fasteningsEngineeringTorsion spring

The invention relates to a self-locking type safety clamp capable of being rapidly mounted and detached. The self-locking type safety clamp is characterized by mainly comprises a locking piece (2) and two U-shaped clamping plates (3), wherein the locking piece (2) is mounted between the upper ends of the two U-shaped clamping plates (3) by a pin shaft (4) and is fixedly connected with the pin shaft (4); a torsion spring (6) for controlling a rotary angle of the locking piece (2) is arranged between the two ends of the pin shaft (4) and the two U-shaped clamping plates (3); the locking piece (2) is made of abnormal circular arc steel with a certain outer edge spiral curvature; a plurality of rope hanging holes (1) for hanging a rope end of a safety rope are formed in the surface of the locking piece (2). According to the self-locking type safety clamp capable of being rapidly mounted and detached, the difficulties that a clamp mounting and detaching procedure is complicated and potential safety hazards exist in a clamp mounting process are overcome; the problem that a bolt is not fastened in place in a manual mounting process is avoided and the whole efficiency of safe work is improved.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

Walking control method based on climbing robot for angle steel tower

ActiveCN112441157AStrong ability to overcome obstaclesImprove climbing efficiencyVehiclesClimbing robotsHuman power

The invention belongs to the technical field of climbing robots for electric power operation, and particularly relates to a walking control method based on a climbing robot for an angle steel tower. The walking control method comprises two sets of clamping assemblies for clamping the angle steel at the same time; the lower clamping assembly is loosened; a control host is parallel to the currentlyclamped angle steel; the lower clamping assembly moves upwards along the host. The upper clamping assembly is loosened, and the control host is parallel to the currently clamped angle steel; the hostmoves upwards relative to the lower clamping assembly. The upper clamping assembly clamps the angle steel; therefore, a round of walking control action is completed. By means of the walking control method, the climbing robot can have high obstacle crossing capacity and high climbing efficiency; meanwhile, the action stability and the action reliability of climbing operation can be synchronously guaranteed, so that the manpower inspection cost can be greatly saved, the maintenance efficiency can be improved, and safe and reliable operation of a power transmission system can be guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER +1

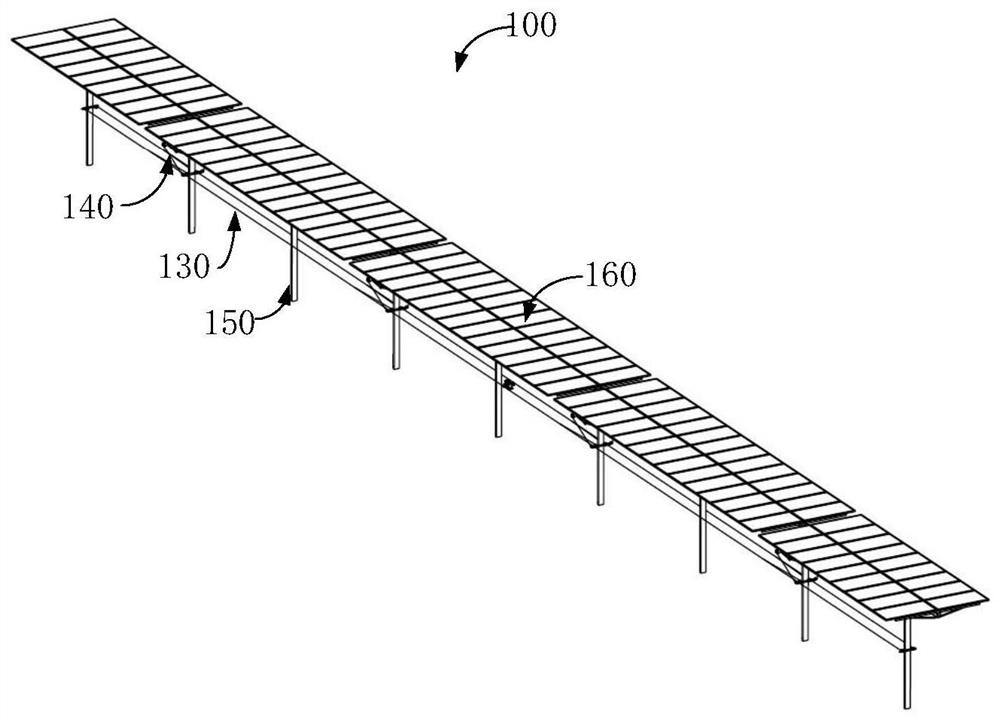

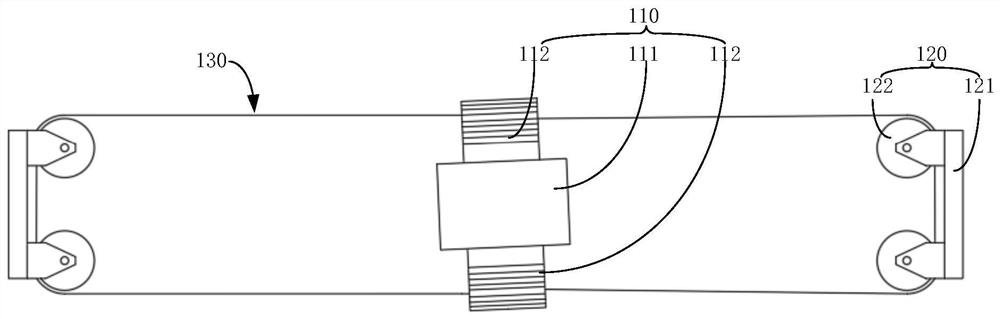

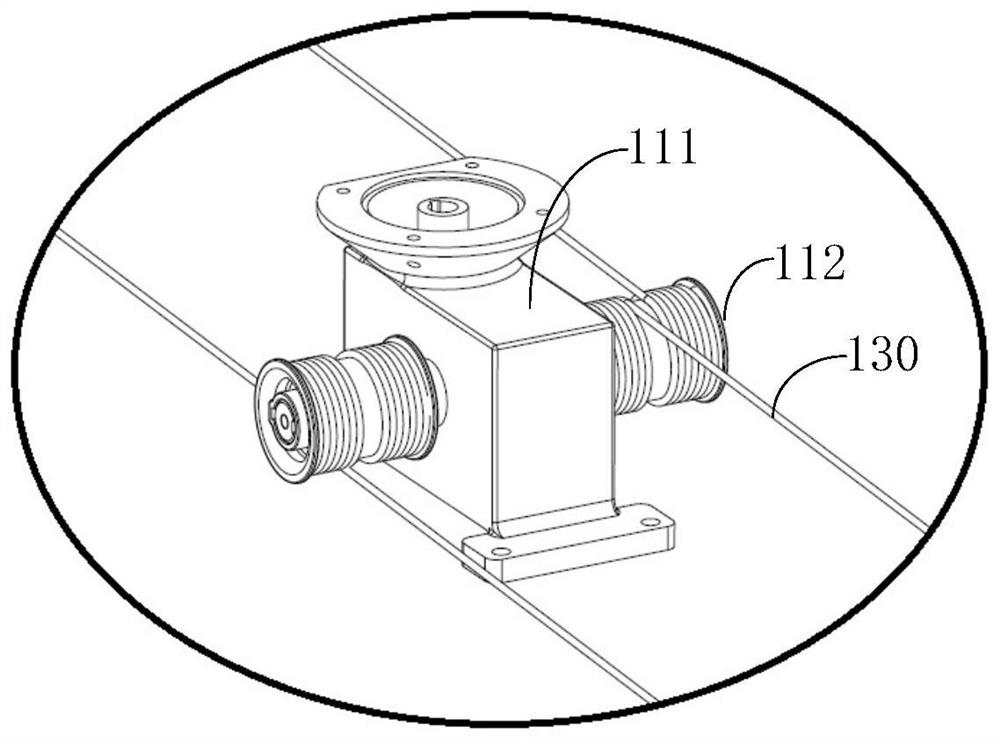

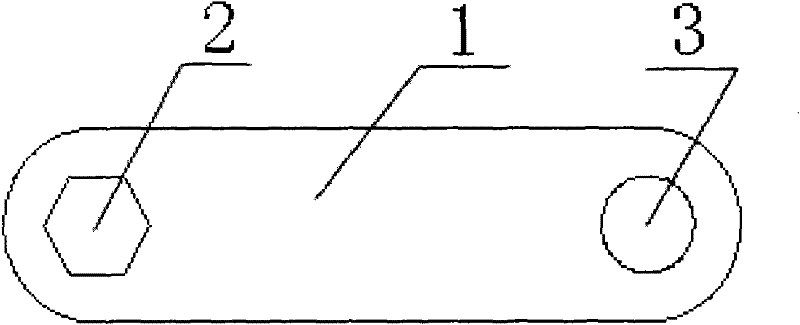

Solar tracking system

PendingCN113110610AStrong stabilityImprove conversion efficiencyControl using feedbackPhysicsSolar tracking system

The invention discloses a solar tracking system, which comprises a speed reducing mechanism, two steering mechanisms, an annular cable, a plurality of rotating mechanisms, at least one bracket and a plurality of solar panels, wherein the two steering mechanisms are located on the two sides of the speed reducing mechanism, and are sleeved with the annular cable, the multiple rotating mechanisms are in transmission connection with the annular cable, the two sides of the speed reducing mechanism are each provided with at least two rotating mechanisms, the rotating mechanisms are assembled on the brackets, each bracket is provided with the solar panel, the two sides of the annular cable are wound around the speed reducing mechanism, and the speed reducing mechanism drives the annular cable to move so as to drive the multiple rotating mechanisms to rotate synchronously and further drive the brackets and the solar panels to rotate. According to the invention, in the rotating process of a plurality of rotating mechanisms, the stability is higher, and the conditions of asynchronous rotation and unstable rotation are not easily caused.

Owner:SHANGHAI SIPOOO NEW TECH CO LTD

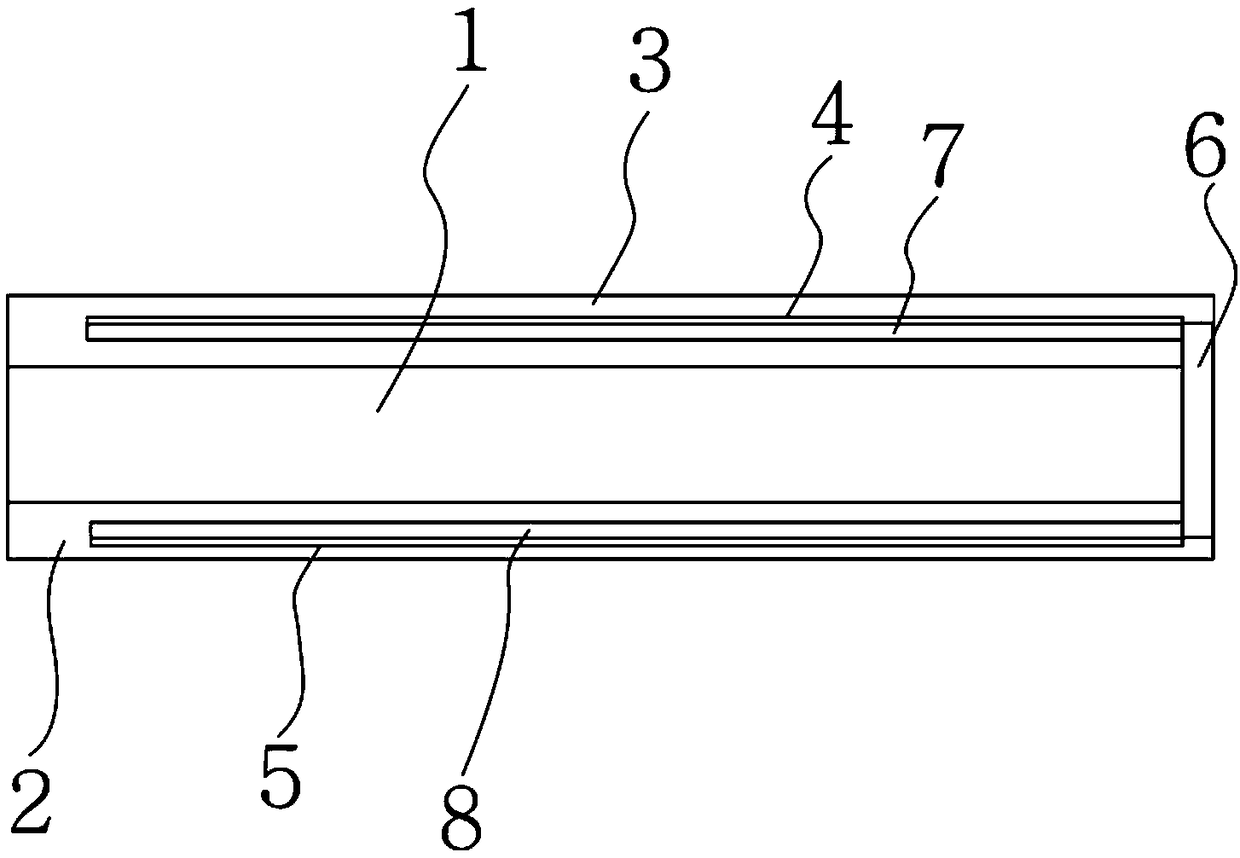

Thermal insulation board with prevention of falling of thermal insulation layer

The invention provides a thermal insulation board with the prevention of the falling of a thermal insulation layer. The thermal insulation board comprises a thermal insulation layer, an adhesive layeradhered to the thermal insulation layer and a protective layer. A horizontal first clamping slot is arranged in the protective layer, a horizontal second clamping slot is arranged in the adhesive layer, and the first clamping slot and the second clamping slot are symmetric with each other. The first clamping slot and the second clamping slot extend to the same side of the protective layer and theadhesive layer, and clamping devices are inserted into the first clamping slot and the second clamping slot. The thermal insulation board has the advantages that the warping and falling of the thermal insulation layer can be prevented.

Owner:TIANJIN YUSHEN ENERGY SAVING THERMAL INSULATION MATERIAL

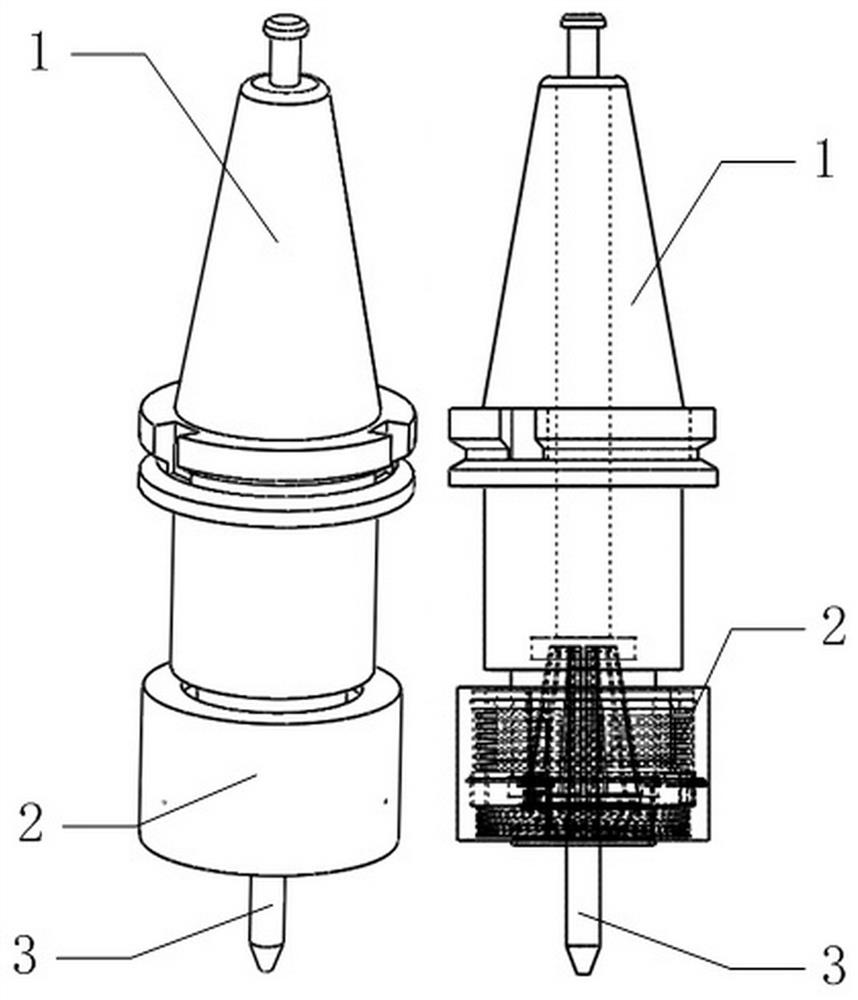

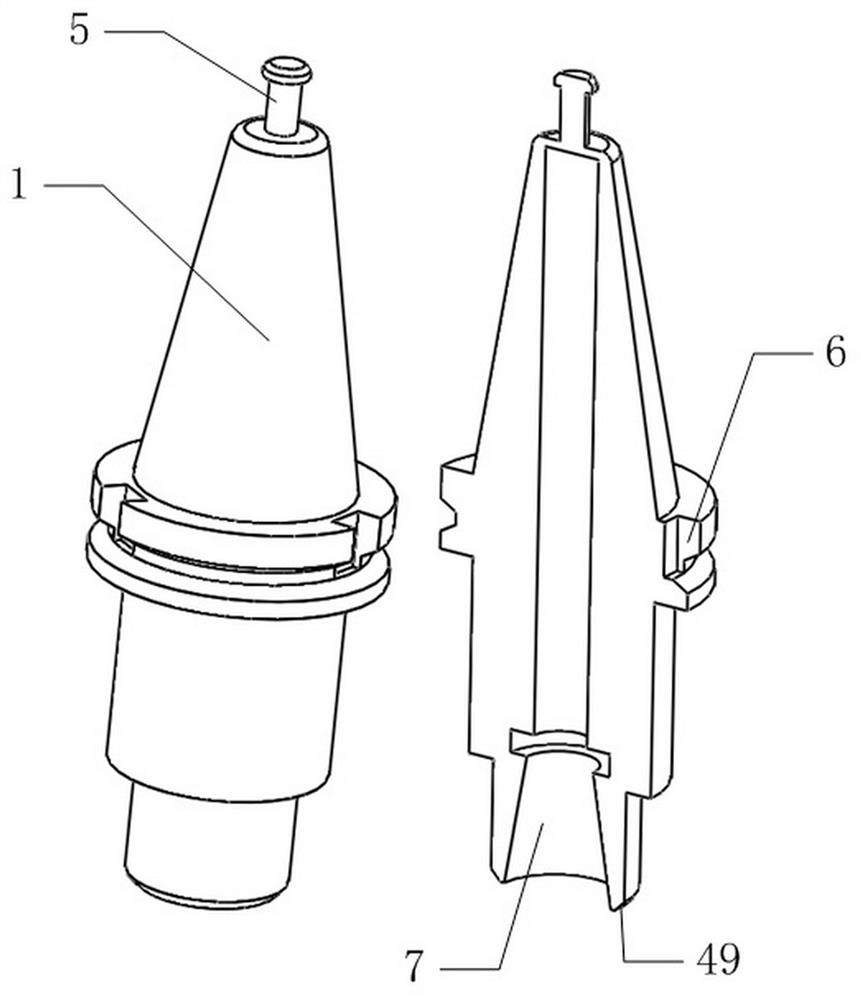

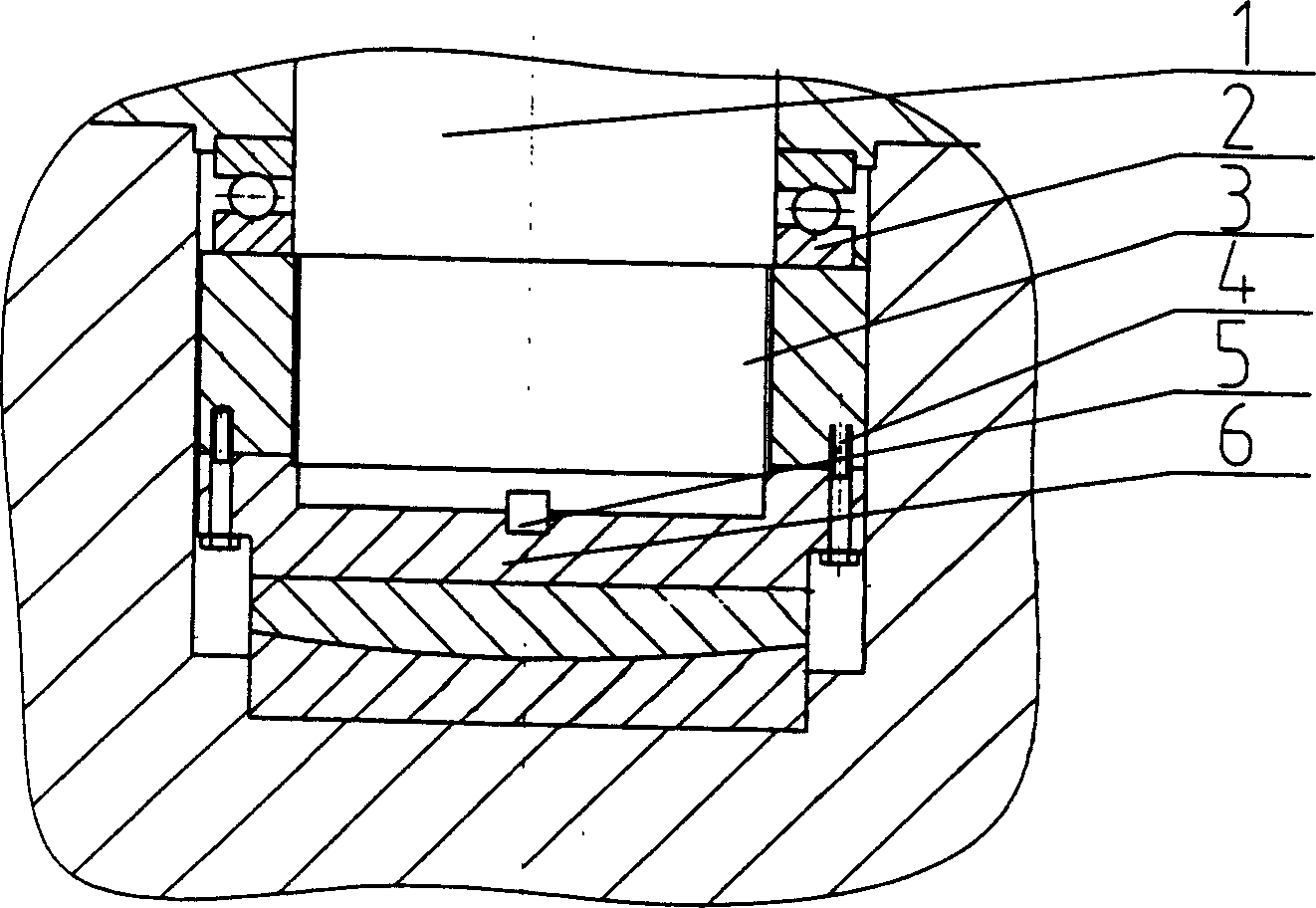

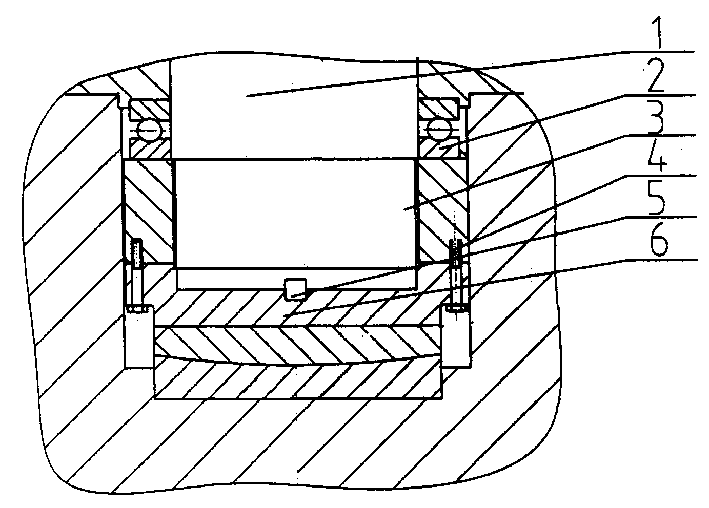

A sandwich device for a machining center

ActiveCN112207308BIncrease tightening forceImprove stabilityChucksPositioning apparatusPull forceEngineering

The invention belongs to the technical field of sandwich devices, and in particular relates to a sandwich device of a machining center, which includes a tool handle, a collet, and a collet. , after the threaded sleeve drives the collet to move up so that the upper tapered surface on the collet contacts the inverted tapered groove tapered surface on the tool holder, and then continues to rotate the collet, the collet can be compressed to a greater degree, so During this process, the jacket moves up to a greater extent, and the jacket will cause the connecting rod to have a relationship with the second slope, and release the limit to the limit ring, so that the limit ring will move upward; the tension of the first spring is released, and this When the user rotates the collet, the rotational force will suddenly decrease. After sensing the force reduction, people will realize that the tool may be worn or the tool is not installed, and then the rotating collet will stop; to a certain extent It can prevent the damage to the collet caused by the continuous rotation of the collet.

Owner:DONGGUAN JIR FINE MACHINERY

Dish-shaped quick hose clamp

InactiveCN112253581AImprove tightening forceEasy to loosen and tighten adjustmentsFriction grip releasable fasteningsSteel platesSteel belt

The invention relates to a dish-shaped quick hose clamp. The dish-shaped quick hose clamp is characterized by comprising a steel belt, a steel belt lock head, a clamp body and a butterfly bolt; and multiple positioning holes are formed in the steel belt in the extending direction at equal intervals. In the dish-shaped quick hose clamp, a cavity for containing the steel belt lock head is formed inthe clamp body, one end of the steel belt is wound and fixed to the steel belt lock head, the steel belt is wound on a fixed object, and after the steel plate penetrates through a stopping plate on the clamp body to be tensioned, pre-locking is achieved; then the butterfly bolt penetrates through a butterfly bolt embedding hole in the clamp body to cooperate with a threaded hole in the steel beltlock head, one end of the steel belt is fixed through the stopping plate, and then the butterfly bolt is rotated to enable the steel belt lock head to move along the extending line of the cavity of the clamp body so as to lock the steel belt; and the tightening force of the hose clamp is improved, and meanwhile subsequent loosening and tightening adjustment is facilitated.

Owner:RUGAO KK TELECOM MATERIALS

Packing box strapping machine

ActiveCN113386994AIncrease tightening forceStrong tightening forceBinding material applicationBundling machine detailsStrappingPalletizer

The invention provides a packing box strapping machine. The packing box strapping machine is characterized in that a conveyor belt, a stacking mechanism and a lower disconnecting link are arranged on a workbench in the material feeding and discharging direction; the stacking mechanism comprises a packing box arrangement box; the feeding side and the discharging side of the packing box arrangement box are communicated in a penetrating mode; an arrangement cavity is formed in the packing box arrangement box; a lifting table is arranged at the bottom of the arrangement cavity; a first air cylinder is connected to the lower portion of the lifting table; a bearing frame is located at one side of the conveyor belt; a strap of a strap supply roller is vertically arranged at the discharging side of the packing box arrangement box from top to bottom after passing through multiple stages of supporting rollers and is wound by a glue collecting roller at the bottom of the workbench; a pusher plate of a second air cylinder is parallel to the arrangement direction of the packaging boxes; a cutter is arranged at the top of a cutter carrier; a cutter is driven by a third air cylinder to move up and down along the cutter carrier; and a fusing table matched with a cutting edge of the cutter is arranged in a cutter containing groove. The packing box strapping machine is provided with a stabilizing device when medical packing boxes are vertically stacked and strapped, the strapping stability of the straps is high, and the strapping effect is good.

Owner:HUBEI QIANJIANG PHARMA

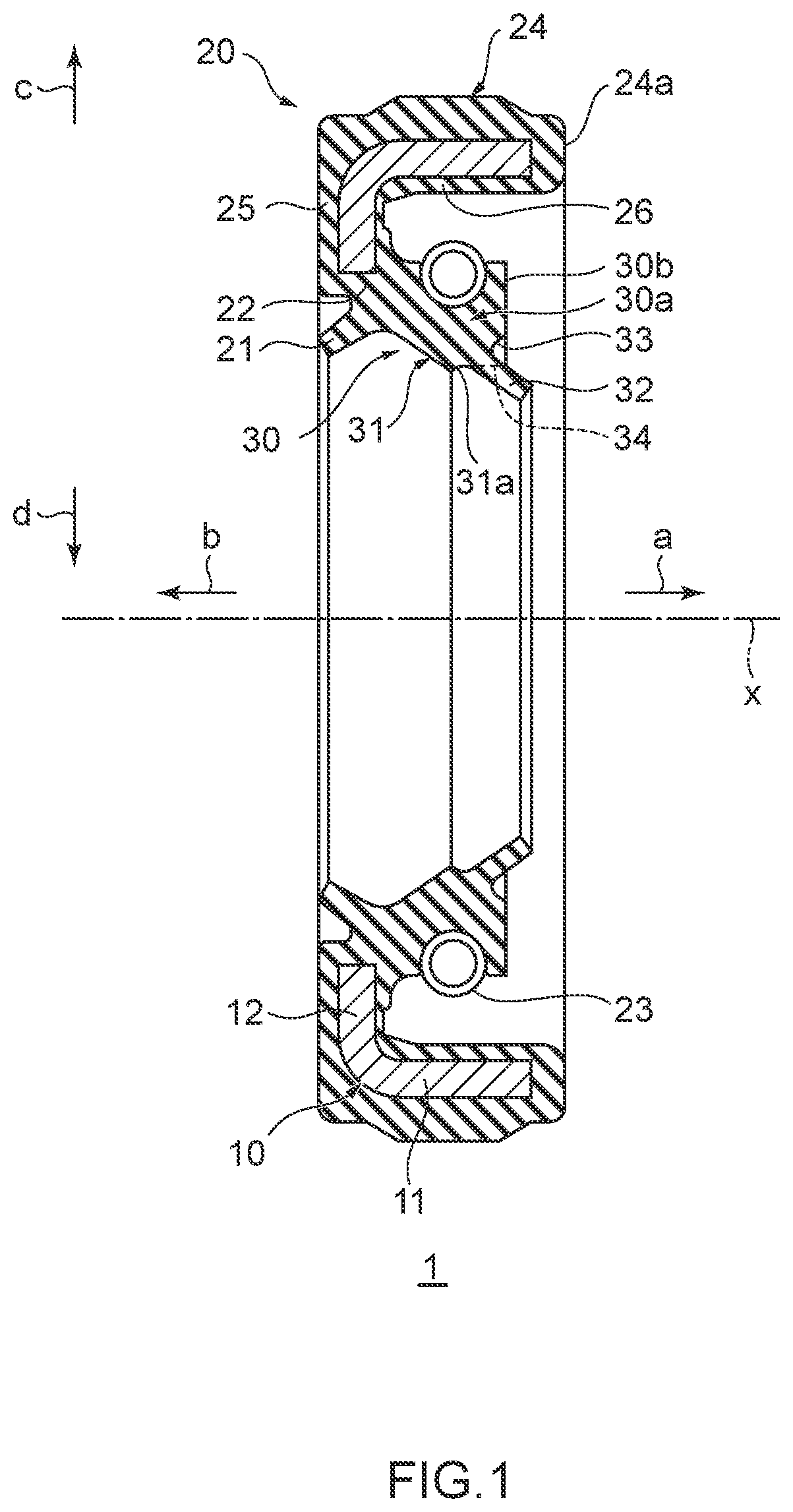

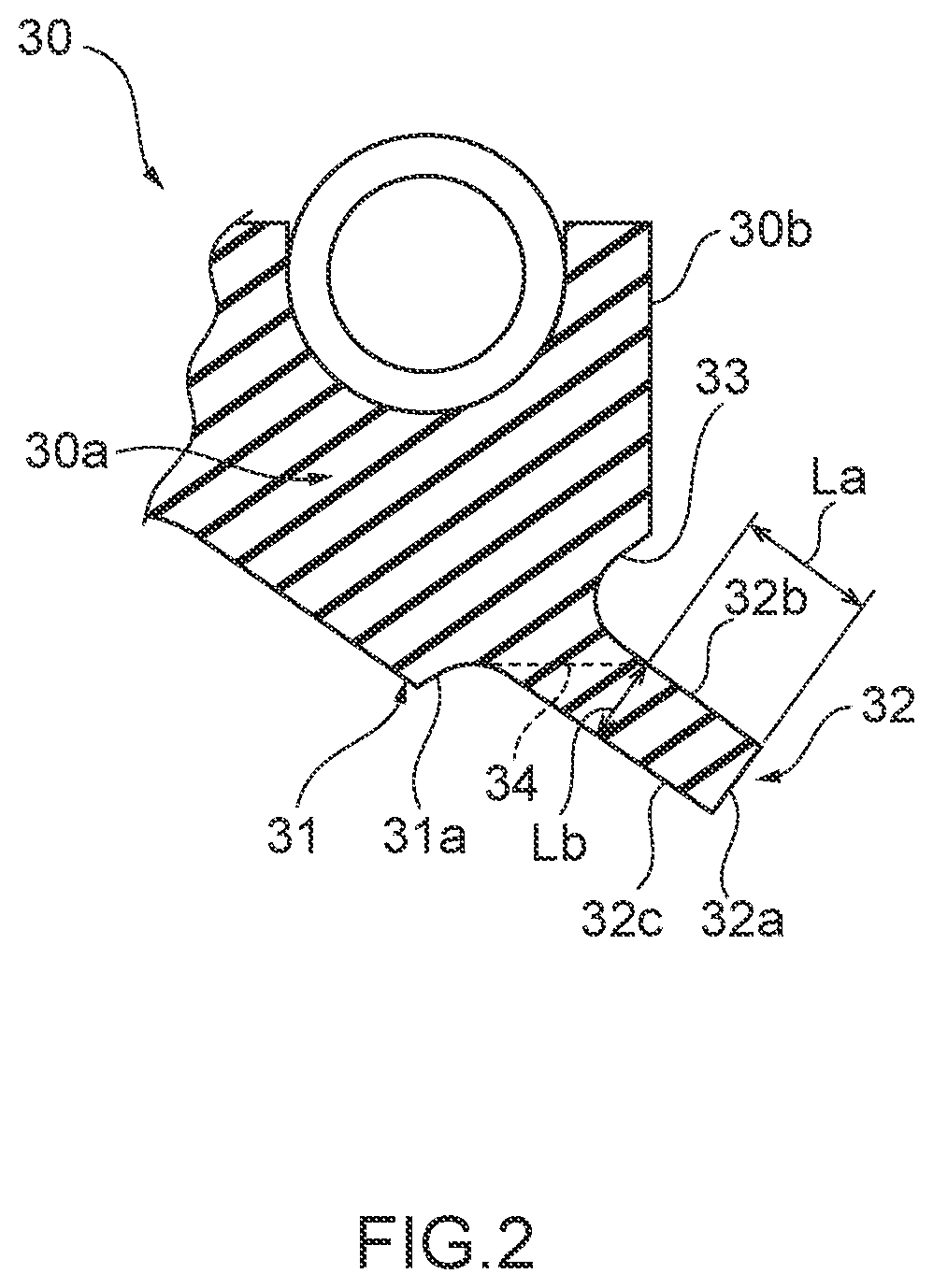

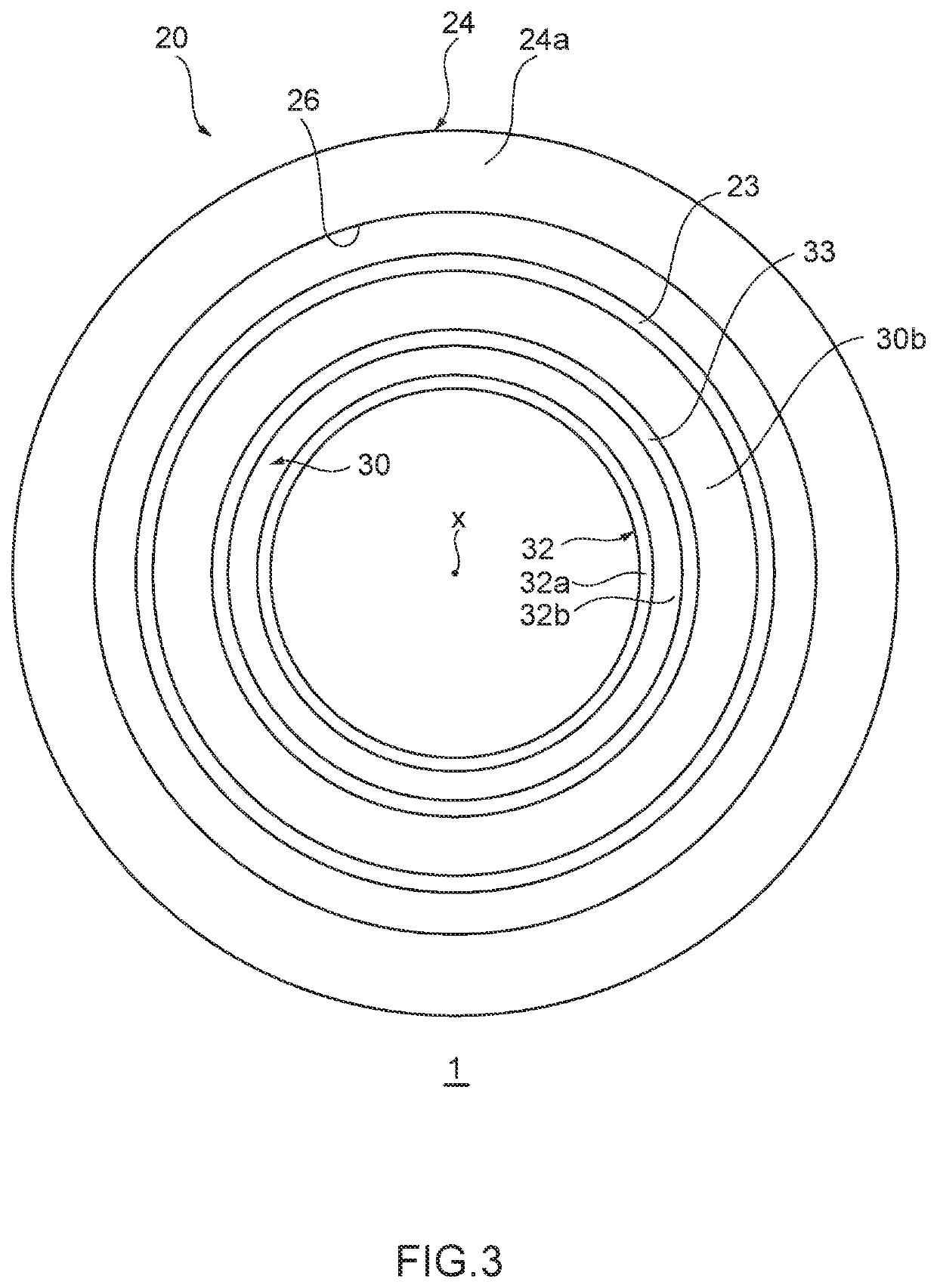

Sealing device

PendingUS20220243822A1Increase tightening forceReduce forceEngine sealsEngineeringMechanical engineering

Owner:NOK CORP

Vehicle-mounted radar mounting assembly, vehicle-mounted radar and vehicle

ActiveCN111610493ASimple structureOverall small sizeWave based measurement systemsVehicle componentsIn vehicleAutomotive engineering

The invention relates to the technical field of signal detection, in particular to a vehicle-mounted radar mounting assembly, a vehicle-mounted radar and a vehicle, which are simple in structure, small in overall size, good in sealing effect and convenient to mount. The vehicle-mounted radar installation assembly comprises a bottom plat; two installation supports are oppositely arranged on the bottom plate, and each installation support is used for installing a radar circuit board at a set angle; a wiring harness installation hole is further formed in the bottom plate, the wiring harness installation hole is located between the two installation supports, and the wiring harness installation hole is connected with a wiring harness arranged in the wiring harness installation hole in a sealedmode; the first cover body and the bottom plate are connected in a sealed mode to form a sealed area, and the installation support is located in the sealed area.

Owner:SHANGHAI YUXING ELECTRONICS TECH CO LTD

Universal strain clamp anti-falling external member and installation method

PendingCN114188912AIncrease tightening forceMaintain moderate tensionAdjusting/maintaining mechanical tensionApparatus for overhead lines/cablesWire tensionEngineering

The invention discloses a universal strain clamp anti-falling external member and an installation method, and belongs to the technical field of electric power protection fitting structures. The universal strain clamp anti-falling external member comprises a front-end self-locking clamp, a pull rod piece and a rear-end buckling clamp, the front-end self-locking clamp is fixed on a front-end strain wire, and the pull rod piece is fixed on the rear-end buckling clamp; the front-end self-locking clamp is fixed at the end part of the front-end self-locking clamp, the rear-end buckling clamp is fixed at the end part of the rear-end U-shaped ring, the PT adjusting plate or the PD extension plate, the two groups of pull rod pieces are arranged in bilateral symmetry and are respectively connected with the left and right ends of the front-end self-locking clamp and the rear-end buckling clamp, and the protective hardware fitting for bearing the mechanical tension of the wire is only composed of three parts. The tightening clamp adopts an inner taper sleeve and an outer taper sleeve, is light and simple, is convenient to install, and is installed without depending on a steel anchor ring of a wire tension crimping pipe, so that the anti-falling external member for the strain clamp has better universality.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

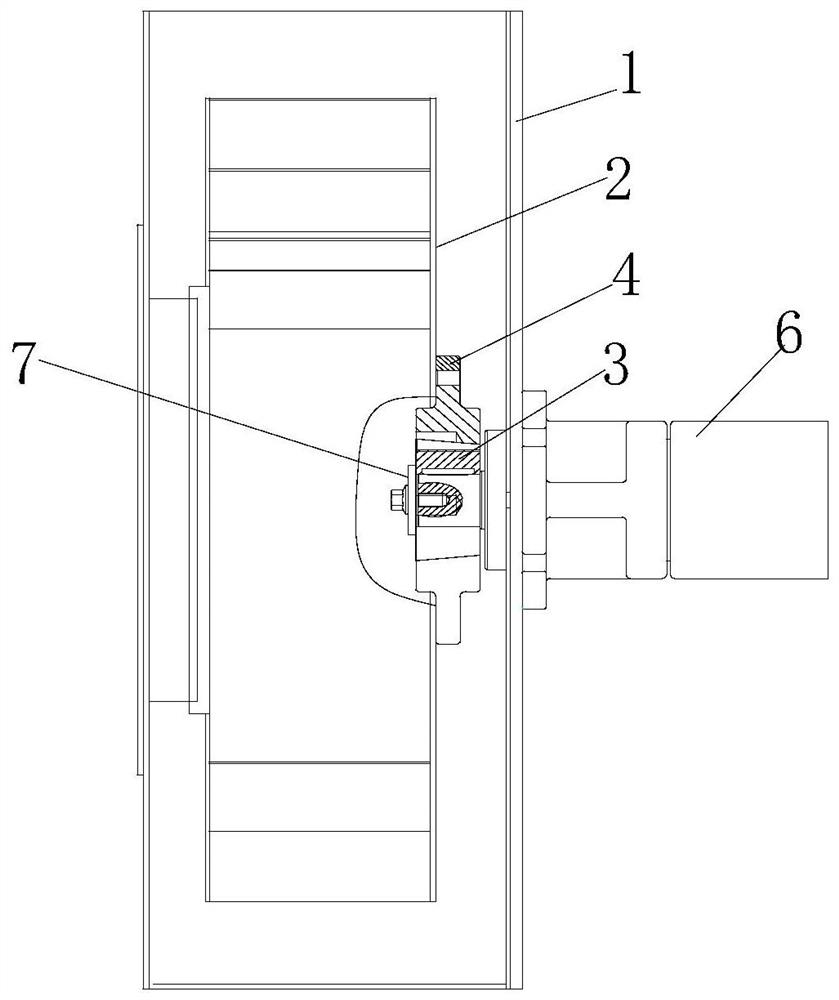

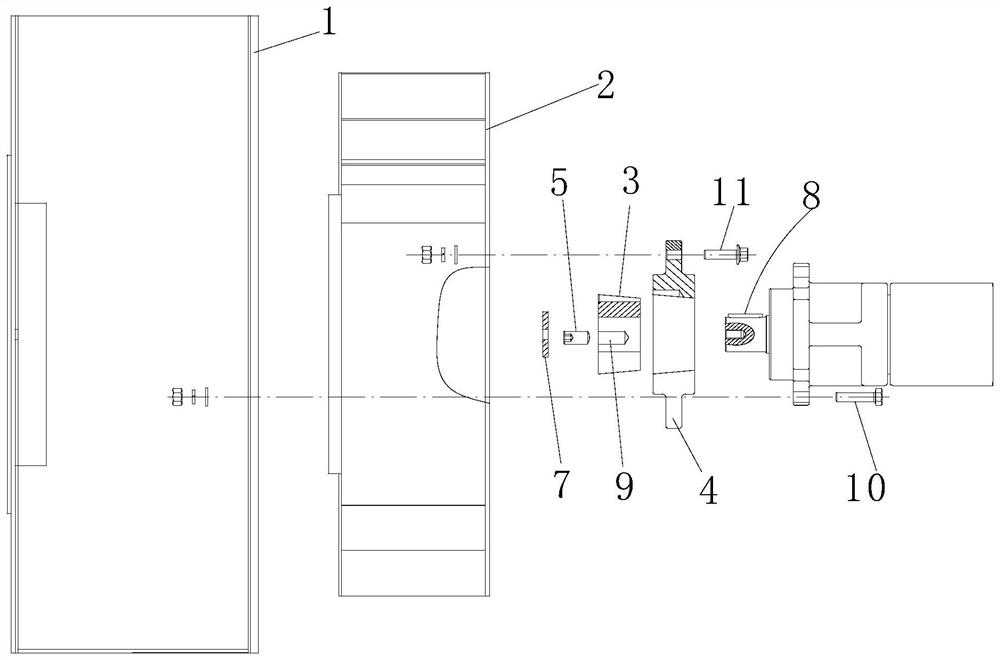

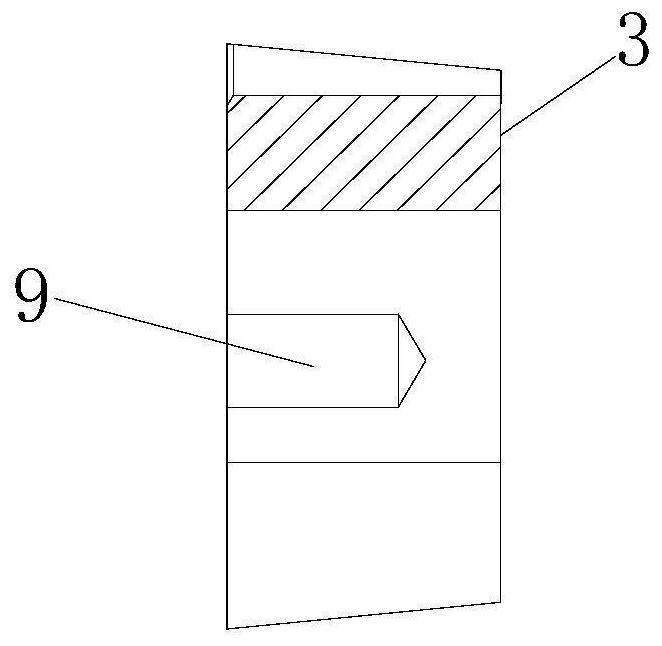

A mounted double-axis automatic tightening device and its operating method

ActiveCN110640448BImprove work efficiencyIncrease tightening forceMetal working apparatusReduction driveDrive shaft

The invention discloses an installation type double-axis automatic tightening device, which comprises a drive bracket, a front support base, a rear support base, a switch bracket, a servo motor, a reducer, a gear unit, a tightening shaft, a cylinder and a fixing base, and the front end of the drive bracket It is connected with the front support base by bolts, and the end of the drive bracket is connected with the rear support base by bolts. The switch bracket is located in front of the front support base, and is located under the two tightening shafts as a whole. The tightening shaft includes support shafts, shaft end flanges, sleeves, rectangular Keys, bearings, fastening nuts, straight joints, adapters, pistons, disc springs, springs, compression sleeves, tightening sleeves and drive shafts, the support shaft is connected to the driven gear through the key, and the servo motor drives the drive gear to rotate through the reducer . The invention provides an installed double-shaft automatic tightening device suitable for small space and small distance between two shafts.

Owner:YANSHAN UNIV

Double-spiral space structure of inclined steel column

InactiveCN110273464ARelieve pressureReduce impact forceShock proofingStructural engineeringSteel columns

The invention discloses a double-spiral space structure of an inclined steel column. The double-spiral space structure of the inclined steel column comprises a base, fixing columns, the inclined steel column and a spiral supporting plate, wherein the base is positioned at the bottom end of the fixing column; the inclined steel column is positioned at one side of each fixing column, and the bottom ends of the fixing columns are connected to the base; the spiral supporting plate is positioned right above the inclined steel column; a reinforcing supporting cushion is welded on the surface of the top end of the base; one side of the reinforcing supporting cushion is welded to the surface of one side of the fixing column; a joining plate is welded to the top end of the inclined steel column; and a fixing buckling plate is welded on the surface of the inclined steel column. According to the double-spiral space structure of the inclined steel column, the fixing buckling plate welded on the surface of the inclined steel column is capable of fixing the spiral supporting plate, thus the holding floating force of the spiral supporting plate is improved, and the spiral supporting plate is prevented from displacing; a reinforcing hood which is connected to the top ends of the fixing columns through a clamping buckle is capable of improving compressive force between the fixing columns, and thus the fixing columns are prevented from displacing; and the jointing plate welded on the top end of the inclined steel column is capable of preventing the inclined steel column from non-uniform stressing.

Owner:江苏广新重工有限公司

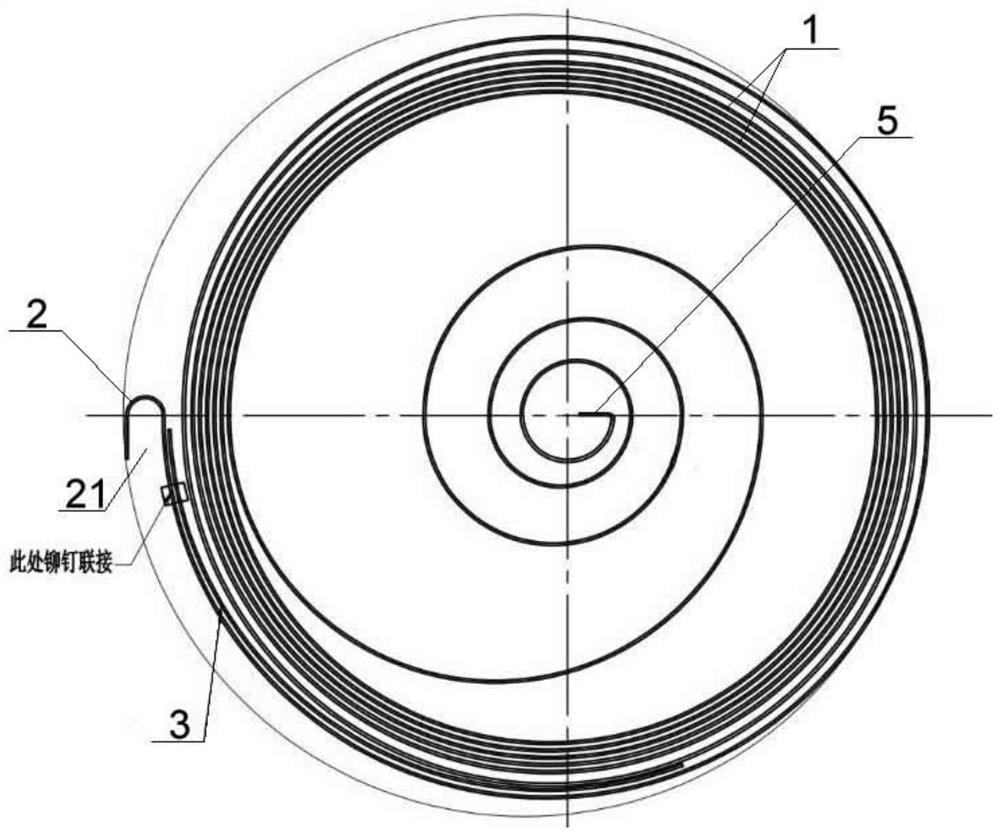

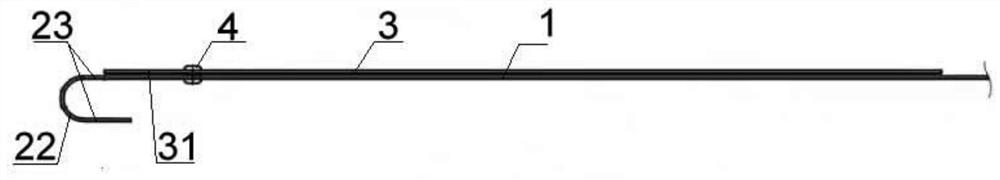

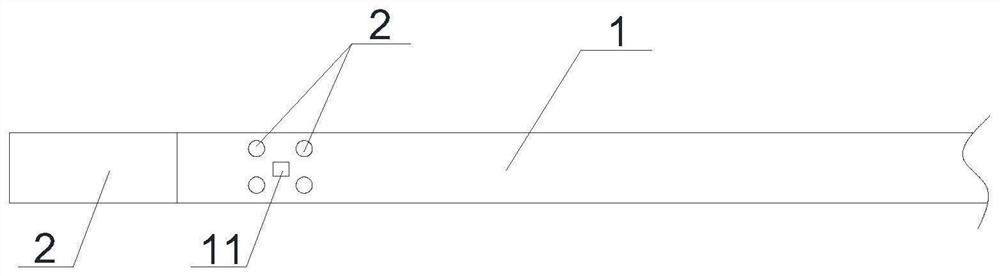

A reinforced coil spring

ActiveCN113446340BDoes not increase maximum pull-out forceIncrease tightening forceWound springsCoil springEngineering

The invention relates to a kind of reinforcement which can not only enhance the tightening force of the outermost coil spring sheet of the coil spring, but also does not increase the maximum pull-out force of the coil spring, and at the same time can improve the use effect of the ear hook, and at the same time, the production cost is low and the production is convenient. A type reel coil spring, the inner side of the outermost coil spring is provided with a piece of spring steel, and the outer end of the spring steel is fixedly connected with the outermost coil spring, and the inner end of the spring steel is The head is located between the outermost coil spring and the second outer coil spring. Advantages: First, a spring steel sheet added to the reinforced coil spring can not only enhance the tightening force of the outermost coil spring of the coil spring, but also will not increase the maximum pull-out force of the coil spring, and the production cost is low. 2. The ear hook in the coil spring of a reinforced hose reel has better overall strength, and the opening of the ear hook is not easy to expand during use.

Owner:YONGKANG HAILI IND

Transmission connection structure of fan impeller of sweeper truck

PendingCN113513494AReduce stressReduce breakagePump componentsRoad cleaningSet screwElectric machinery

The invention relates to a transmission connection structure of a fan impeller of a sweeper truck, and belongs to the technical field of environmental sanitation machinery. The transmission connection structure comprises a volute, the impeller, a conical shaft sleeve, an impeller flange, set screws, a motor output shaft and a pressing plate. The volute and a motor and the impeller flange and the impeller are fixed by fasteners, and the motor output shaft is connected with the conical shaft sleeve through a flat key; the outer circumference of the conical shaft sleeve is in conical surface fit with the hollow circumference of the impeller flange, the conical shaft sleeve extends into a middle hole of the impeller flange from one side of the conical shaft sleeve, and the pressing plate is attached to the other side of the conical shaft sleeve; the conical shaft sleeve is symmetrically provided with two first semicircular blind holes, a first half-thread through hole and a through slot; the impeller flange is symmetrically provided with two second half-thread through holes and a second semicircular blind hole; and the two first semicircular blind holes and the two second half-thread through holes are oppositely combined to form two first circular holes respectively, the first half-thread through hole and the second semicircular blind hole are oppositely combined to form a second circular hole, and the screws can be screwed into the first circular holes or the second circular hole. According to the transmission connection structure, besides the flat key transmission force, the screwing force, the elastic force and the friction force are increased, so that the connection between the fan impeller and the motor is tighter.

Owner:NANJING AEROSUN MORITA ENVIRONMENTAL PROTECTION S&T

Nut locking structure for screw press

InactiveCN1565838AImprove radial bearing capacityIncrease tightening forcePressesEngineeringScrew press

The invention relates to a nut looseness preventing structure applicable for screw press especially improvement of nut looseness preventing structure in bolt and slide block device of screw press. The nut has a slot on bottom, a slot on upper part of nut seat, and the two slots are connected and fixed by a flat key. The nut and nut seat outer rim are connected and fixed by a bolt. By dividing the nut into two parts of nut and nut seat and replacing the original straight pin by a flat key, the nut radial bearability can be improved greatly.

Owner:SHANGHAI YUNLIANG FORGING PRESS

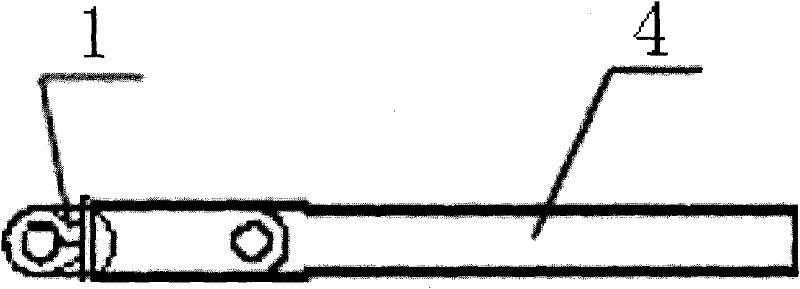

Fastening spanner for large-diameter and high-strength bolt and use method thereof

InactiveCN102343567AMeet the design requirementsImprove construction efficiencySpannersWrenchesEngineeringHigh intensity

The invention relates to the field of fastening members with heads or rods having special shapes when the connection of an object adopts a bolt connection mode, in particular to a fastening spanner for a large-diameter and high-strength bolt and a use method thereof. The fastening spanner for the large-diameter and high-strength bolt comprises a base plate (1) and is characterized in that a screw cap hole (2) is arranged at one end of the base plate (1) and is a regularly-hexagonal hole; and a connecting hole (3) is arranged at the other end of the base plate (1) and is a round hole. The use method of the fastening spanner for the large-diameter and high-strength bolt is characterized in that the screw cap hole (2) on the base plate (1) is sleeved outside the screw cap of the bolt and is screwed; a sleeve (4) is sleeved outside one end of the connecting hole (3) of the base plate (1) and is screwed; and the sleeve is taken down and a chain block (5) is started for continuously screwing the bolt. The invention has the advantages of wide application range, high construction quality, simpleness in operation, safety and reliability.

Owner:SHANGHAI BAOYE GRP CORP

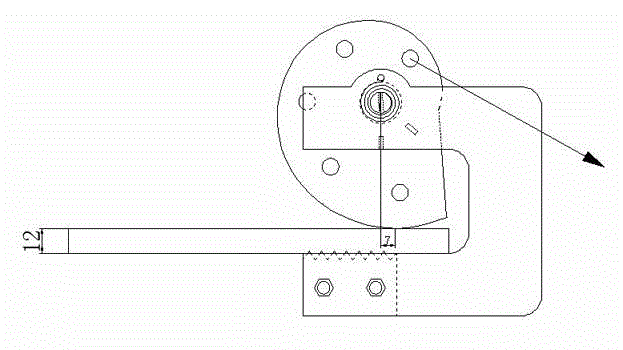

Capping machine claw head

ActiveCN104058355BImprove gripIncrease tightening forceThreaded caps applicationMechanical engineeringEngineering

The invention relates to a cap-screwing machine chuck, which is used for clamping a bottle cap. The cap-screwing machine chuck comprises a plurality of jaws, a jaw base and a pusher; the jaws are used for clamping the bottle cap; the jaws are evenly mounted around the jaw base; the pusher is used for pushing the jaws to move, and can push the jaws to shift oppositely or relatively under the action of power. The cap-screwing machine chuck adopts wedge structures to drive the jaws to shift for grabbing and releasing, changing the conventional way of action which drives the jaws to swing for grabbing and releasing; the jaws of the cap-screwing machine chuck are always stressed for clamping in the horizontal direction, while the conventional jaw has an articulating point and the characteristic of articulation is utilized to swing the jaw, which is equivalent to lever motion, so the grabbing force and stability of the conventional jaws are not as good as the grabbing force and stability of the cap-screwing machine chuck; moreover, the design of the mechanism for driving the jaws to move is simplified, so the entire machine becomes more excellent and the cost is reduced.

Owner:CHANGZHOU HUITUO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com