Hydraulic tool one-way valve and hydraulic tool

A hydraulic tool and one-way valve technology, applied in fluid pressure actuating devices, fluid pressure actuating system components, servo motors, etc., can solve problems such as insufficient sealing, reduced reliability, and low work efficiency, and achieve overcurrent The effect of high speed, improved reliability, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

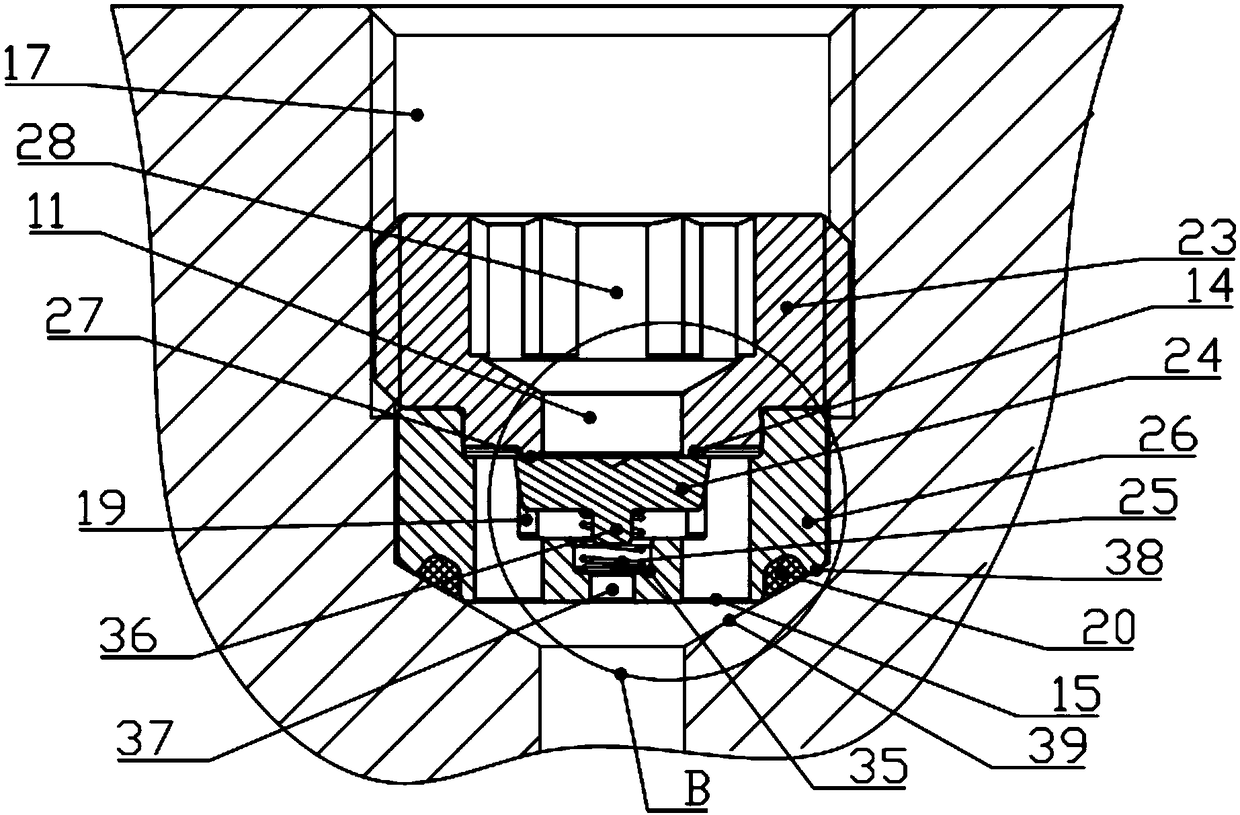

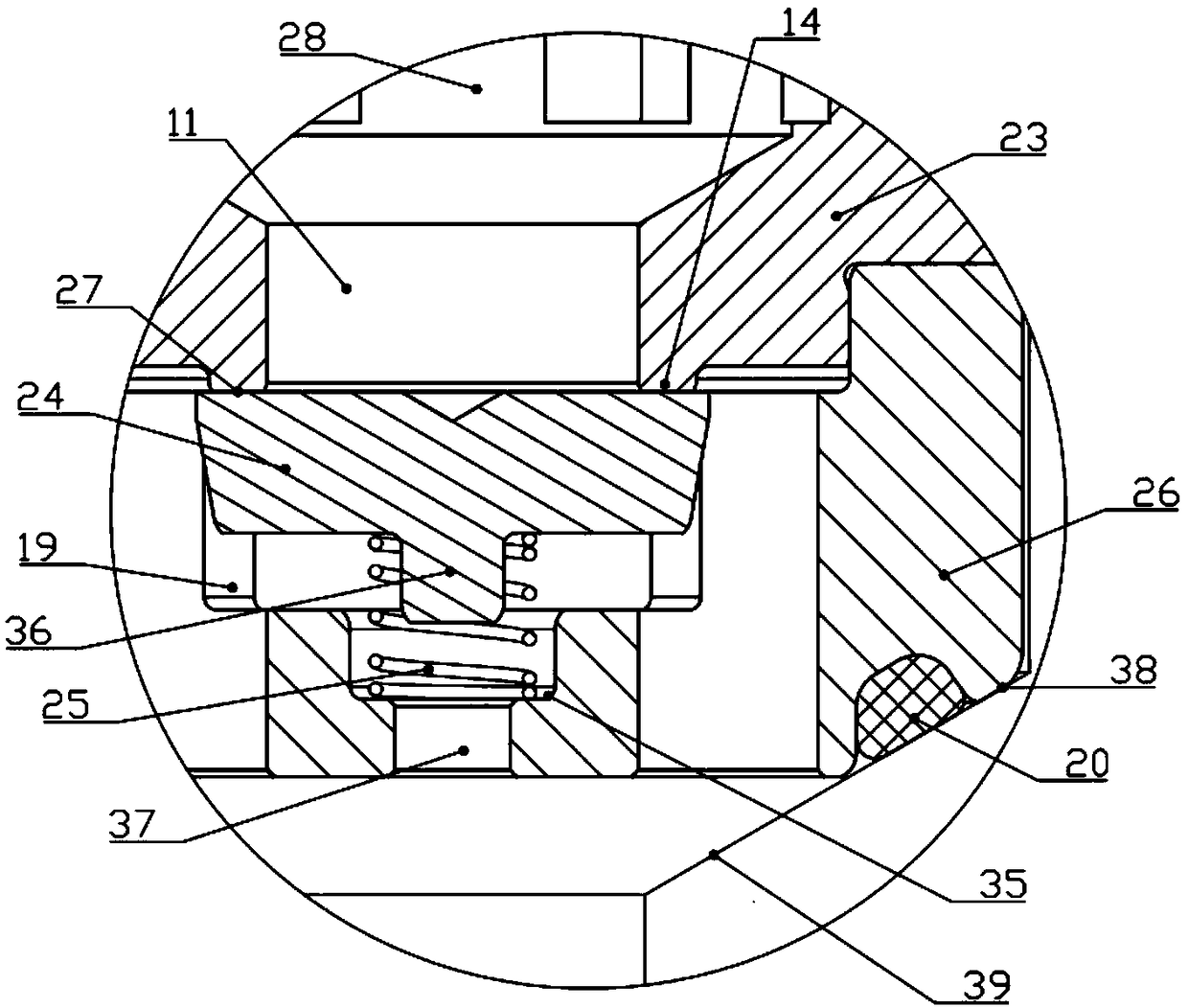

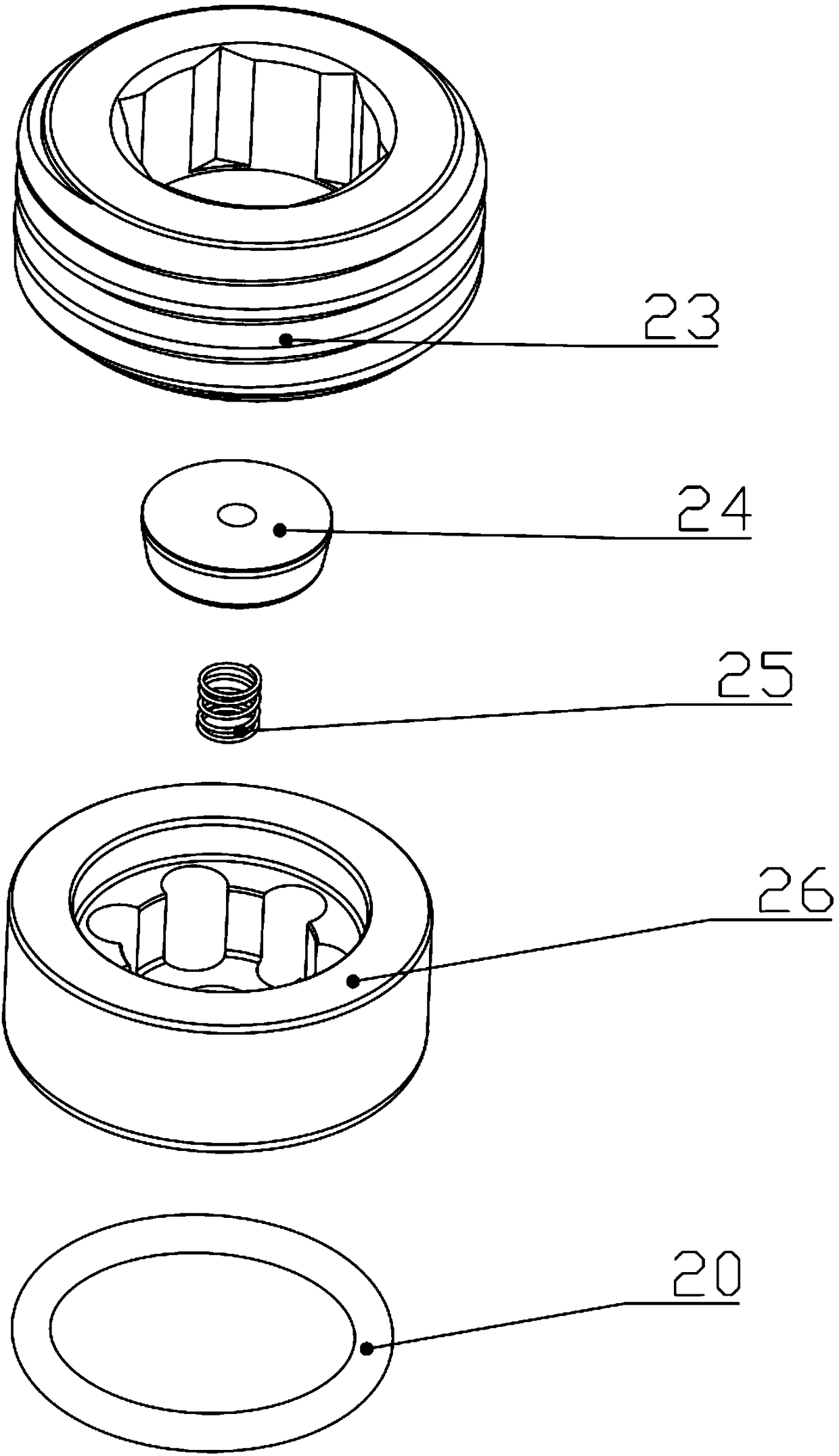

[0031] Embodiment one: if Figure 1-4 As shown, a check valve includes a valve seat 23 fixed in the valve hole 17, a valve body 26, and a valve core 24 and a spring 25 arranged between the valve seat 23 and the valve body 26. The valve seat 23 Open a through hole 11, the spring 25 abuts between the valve core 24 and the valve body 26, the lower end surface of the valve seat 23 is protruded with a boss 14, under the elastic force of the spring 25, the upper end of the valve core 24 The plane of the boss 14 can abut against the plane of the boss 14 and form a first sealing surface 27. The valve body 26 is provided with an inner side wall 19 that is suitable for the shape and size of the valve core 24, and the inner side wall 19 can be opposite to the The spool 24 is radially limited so that the spool 24 can always move along its axial direction, the bottom end of the valve seat 23 is provided with a through hole 11, and the bottom end of the valve body 26 is evenly distributed w...

Embodiment 2

[0047] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that, as Figure 5-7 As shown, the hydraulic check valve in this embodiment is used at the oil outlet of the pump core assembly 31, and the oil outlet check valve arranged in the oil outlet passage 3 includes an oil outlet valve body 7 and an oil outlet valve seat 8 , the oil outlet valve seat 8 is provided with an oil outlet 9, such as Figure 7 As shown, the upper end surface of the oil outlet valve seat 8 is an inclined surface, and an O-shaped sealing ring 20 is installed on the inclined surface, and the oil outlet valve seat 8 is squeezed on the tapered surface of the inner wall of the oil outlet valve hole by the O-shaped sealing ring 20 Form a seal, and the seal here is to prevent oil from rushing in from the oil outlet 9 to cause leakage. The oil enters the oil outlet valve seat 8 through the oil outlet 9 , pushes the spool 24 away, and the oil enters the flow channel 18 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com