Fixed hook rack assembly for tile roof solar cell assembly

A solar cell and assembly technology, applied in the field of solar photovoltaic power stations, can solve the problems of poor bearing strength of the vertical rod at the top of the hook, inability to adapt to different angles of light, and low connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

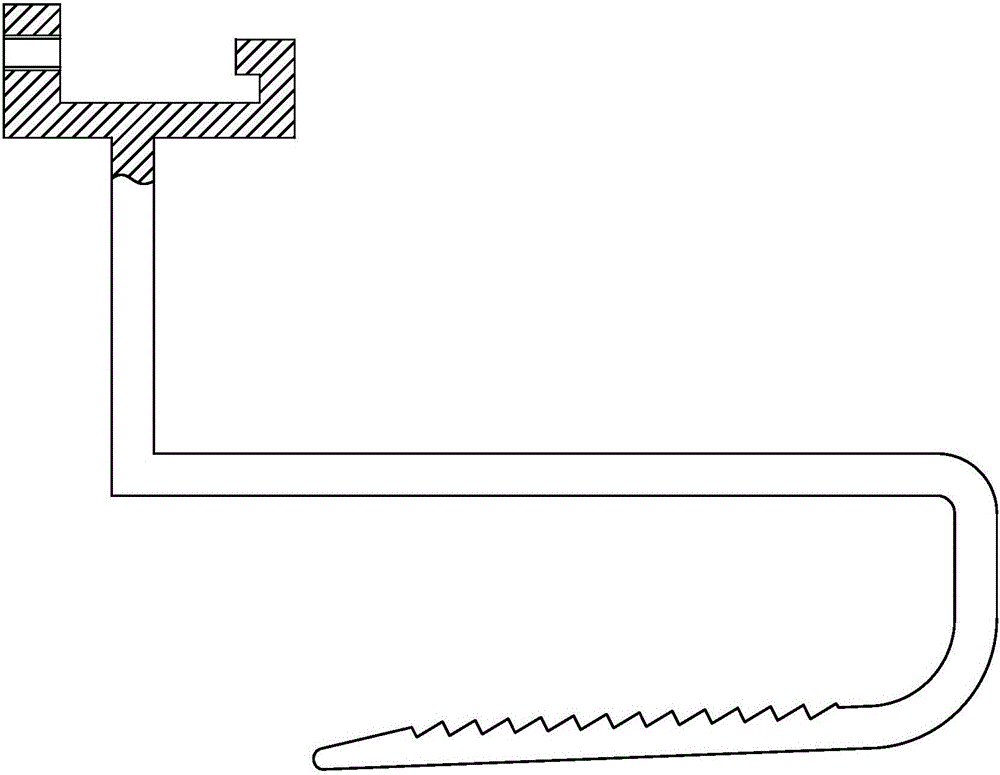

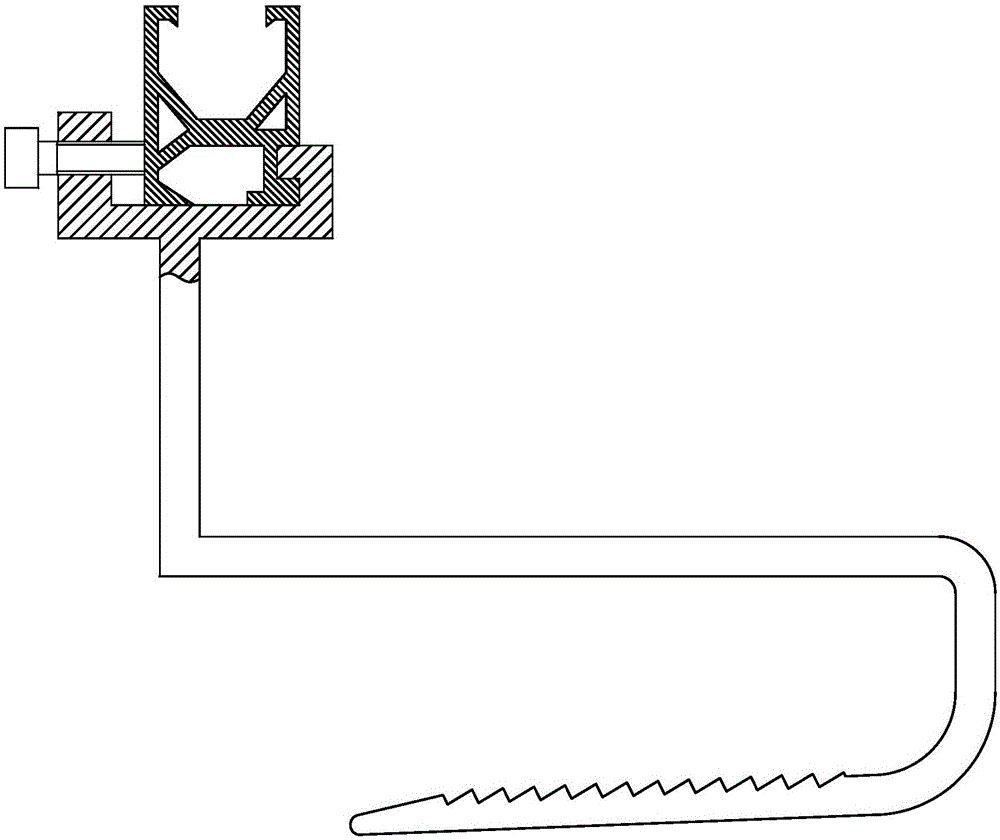

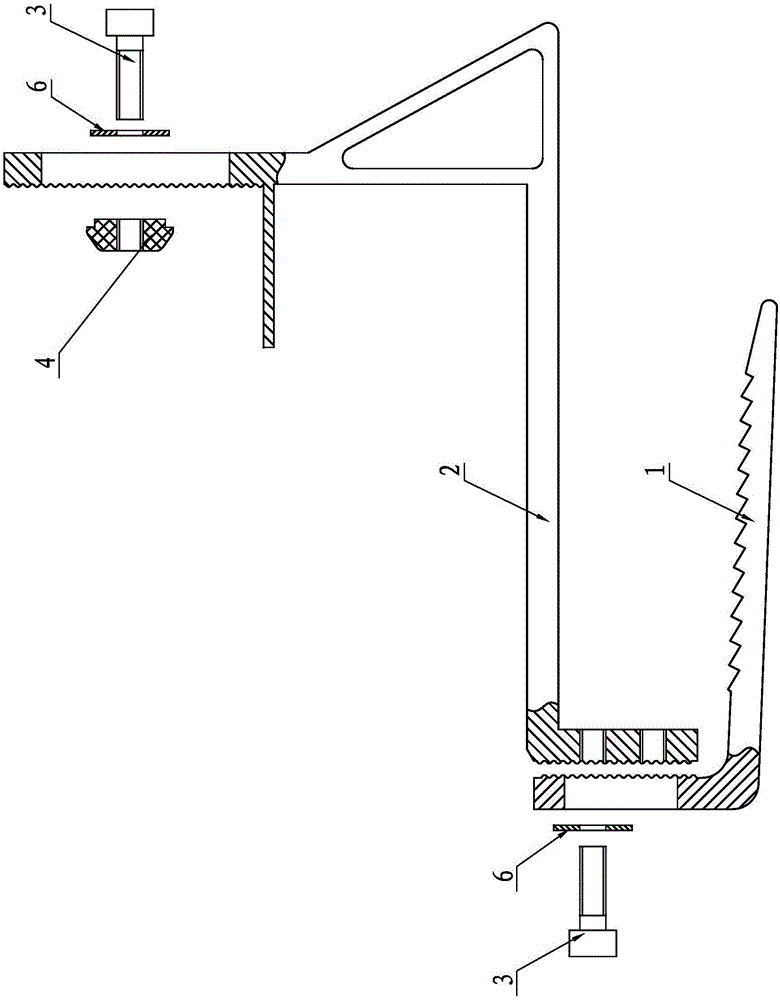

[0025] Embodiment 1: A tile roof solar battery module fixing hook frame assembly, such as Figure 3 ~ Figure 7 As shown, it includes a base 1, a guide rail mounting frame 2, a connecting screw 3 and a guide rail connection limit block 4. The base 1 includes a fixed connection side 11 and a clamping side 12, and the fixed connection side 11 and the clamping side 12 are fixedly connected in an L shape. , a waist-shaped hole 13 is provided on the fixed connecting edge 11, and an engaging structure is provided on the inner connecting surface of the fixed connecting edge 11 and the inner engaging surface of the clamping edge 12, and the guide rail mounting frame 2 includes connecting vertical edges 21, The horizontal side 22 and the guide rail installation side 23 are vertically fixedly connected to one end of the vertical side 21 and the horizontal side 22, and the other end of the horizontal side 22 is vertically fixedly connected to the guide rail installation side 23, and a conn...

Embodiment 2

[0026] Embodiment 2: The difference with Embodiment 1 is that, as Figure 8 As shown, an engaging structure is provided on the outer connecting surface of the fixed connection side 11, and an installation hole is provided on the clamping side 12, and the clamping side 12 and the transverse side 22 are installed oppositely.

Embodiment 3

[0027] Embodiment 3: The difference from Embodiment 1 is that the deformation-preventing support edge 25 is arc-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com