Patents

Literature

217results about How to "Save building space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

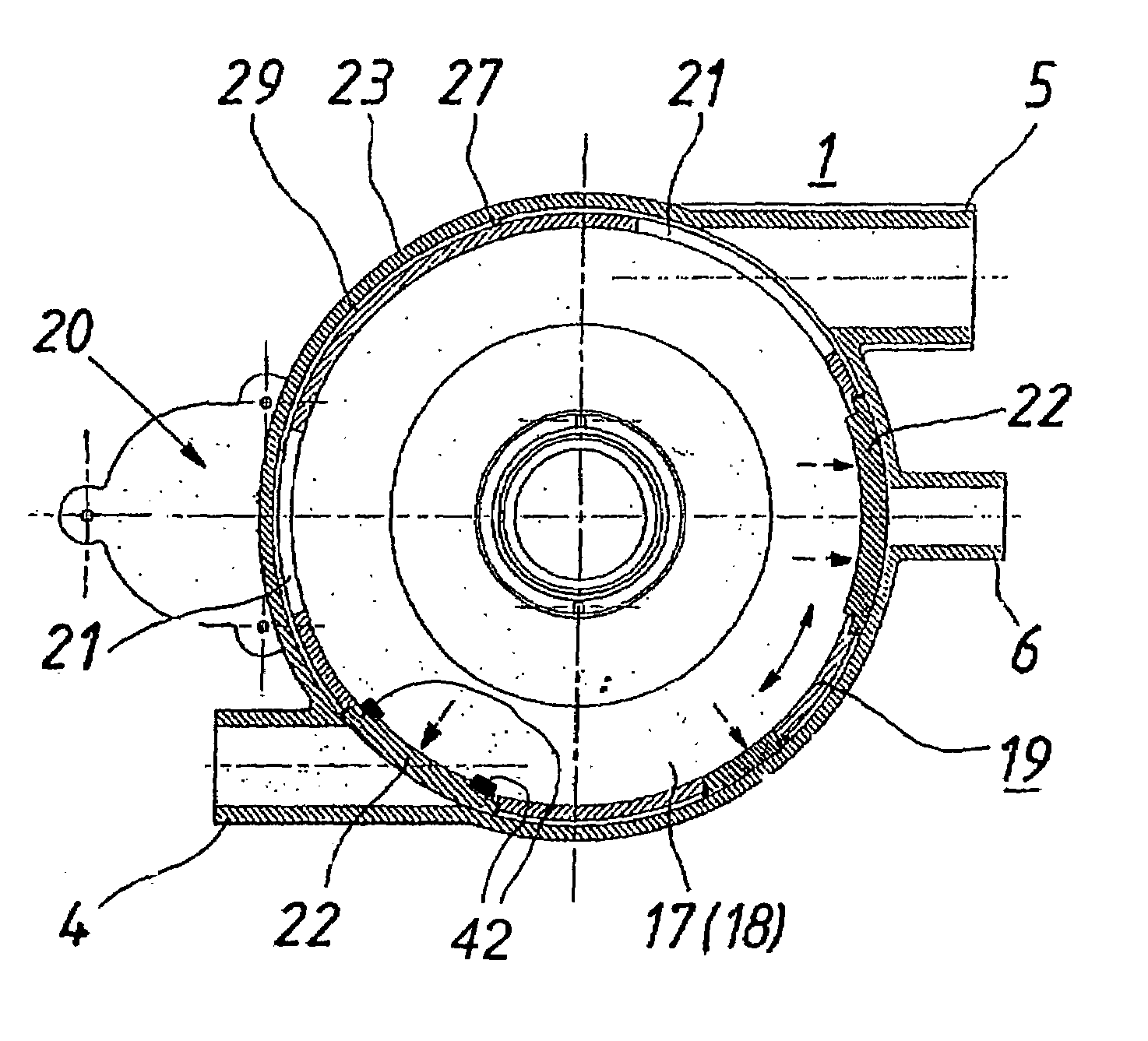

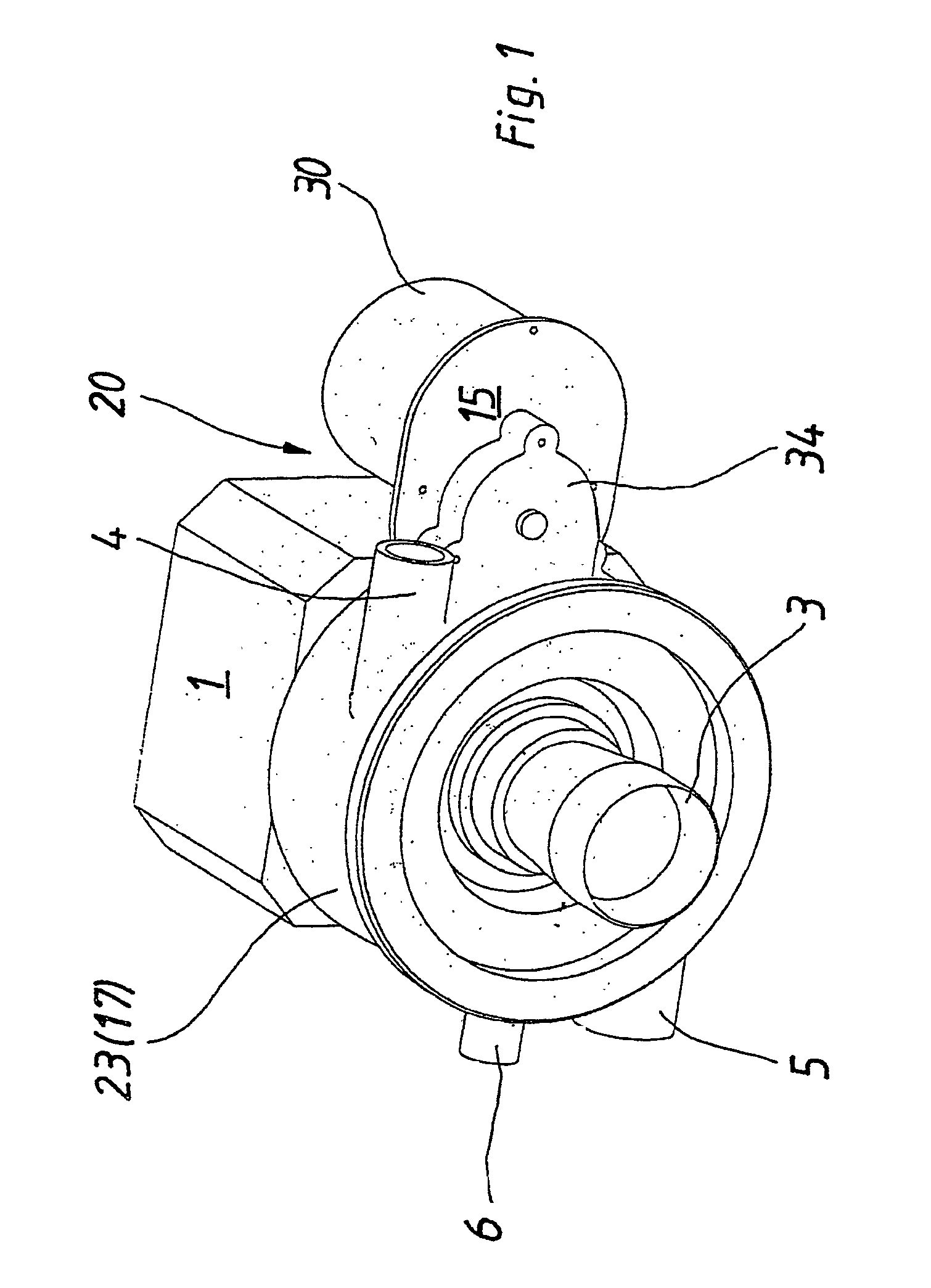

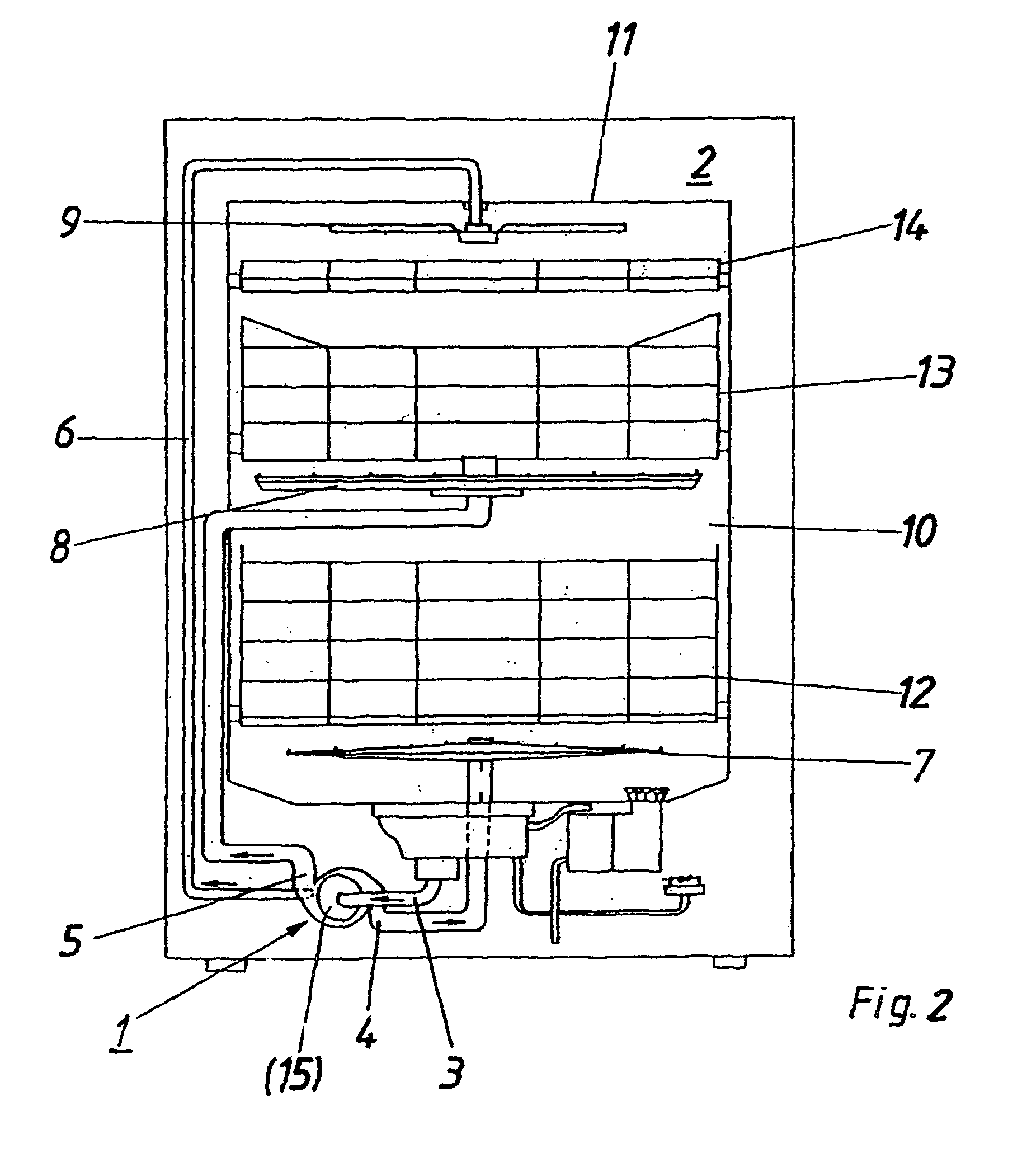

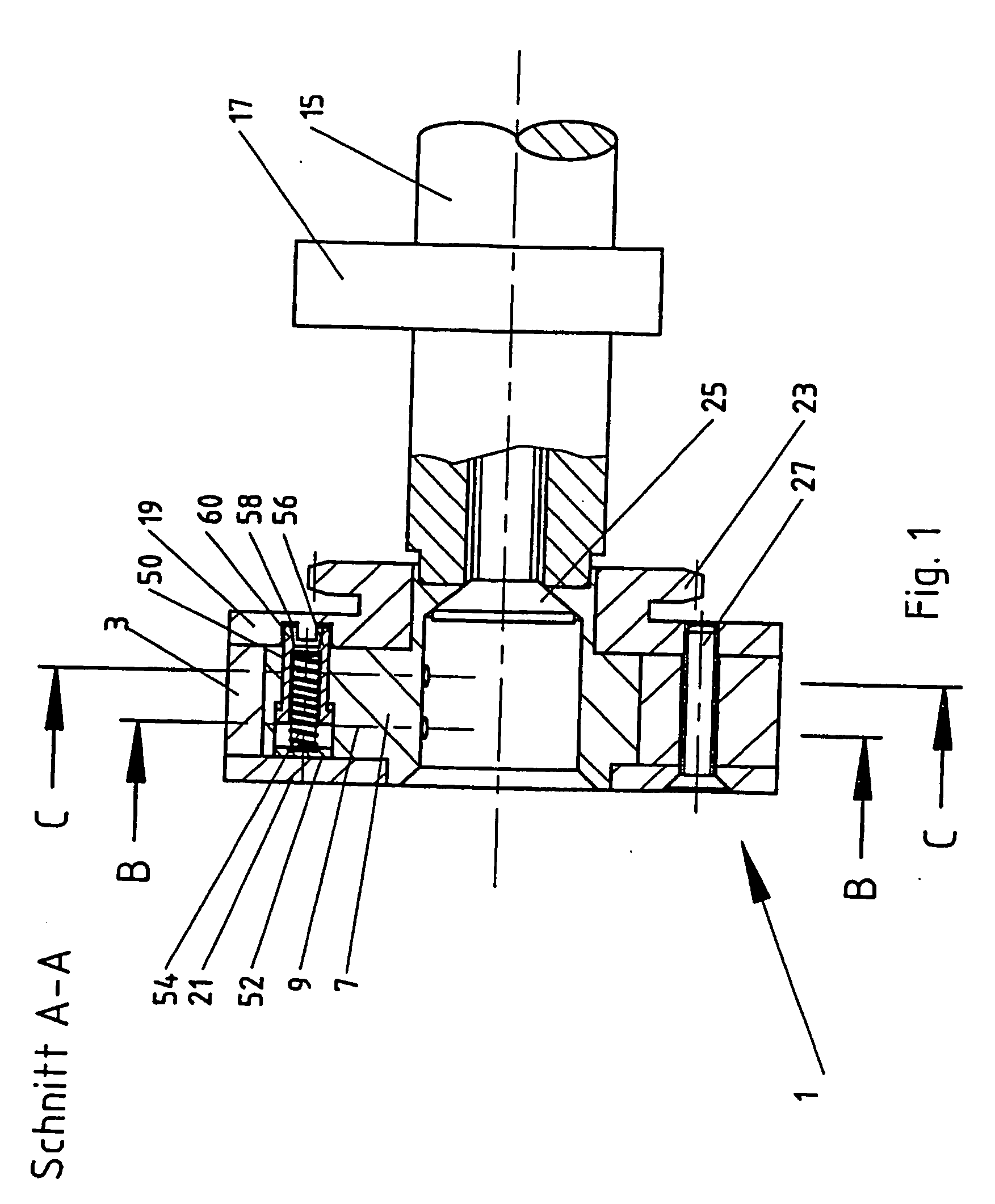

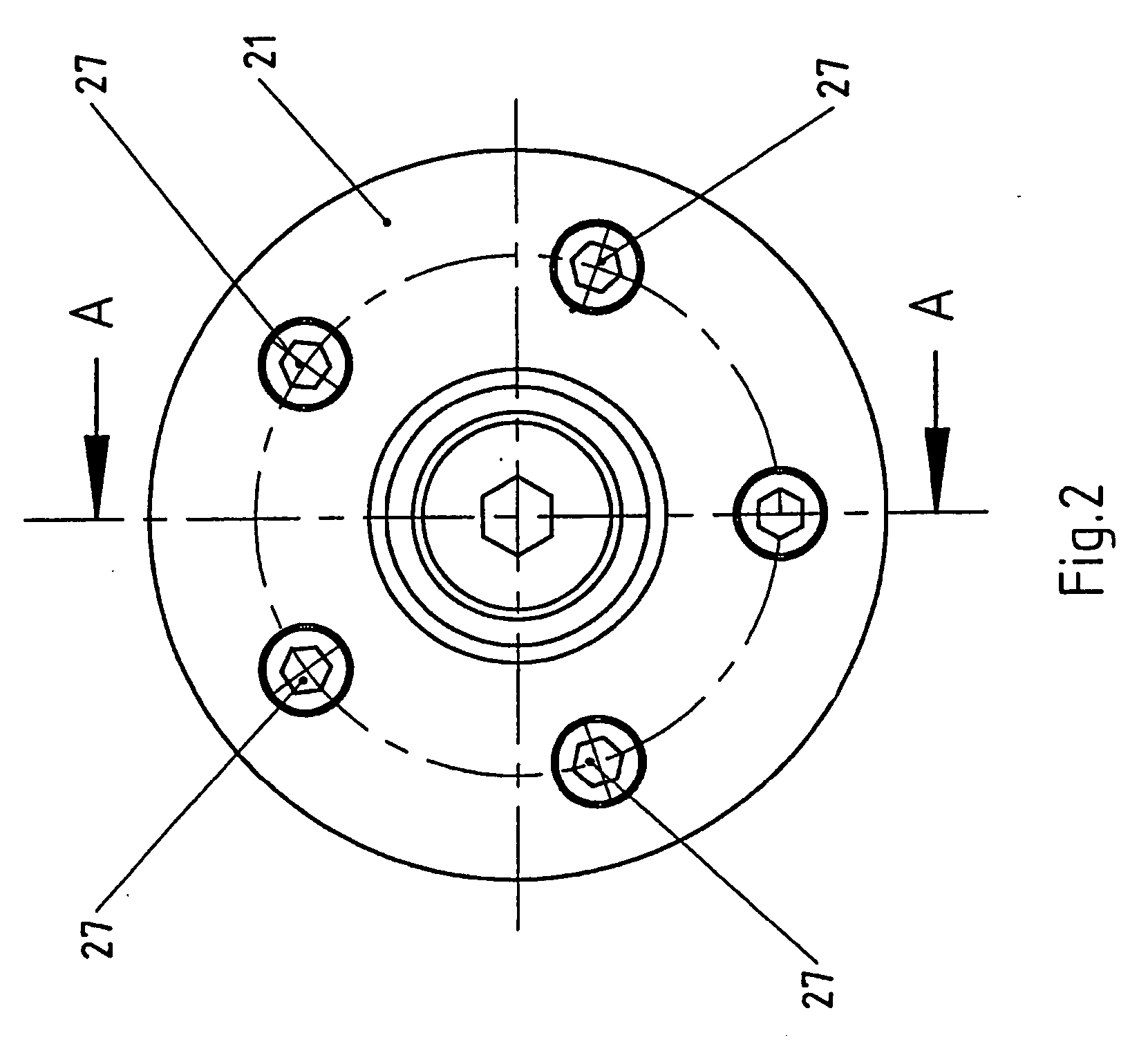

Dishwasher having spray arms and a circulation pump

InactiveUS7100623B2High degreeImprove hydraulic efficiencyTableware washing/rinsing machine detailsPump componentsImpellerCirculating pump

A dishwasher includes a number of spray arms, a circulation pump with a pump housing, an impeller, a suction port, and a number of discharge ports on the pump housing. The discharge ports are associated with the spray arms. A water diverter is located on a delivery side of the pump and generates a flow leading from the suction port selectably to one or more of the discharge ports. The water diverter includes a blocking element having a number of diaphragm openings positionable to one or more outlet positions by a drive via a rotation of the blocking element in a circumferential direction.

Owner:MIELE & CIE KG

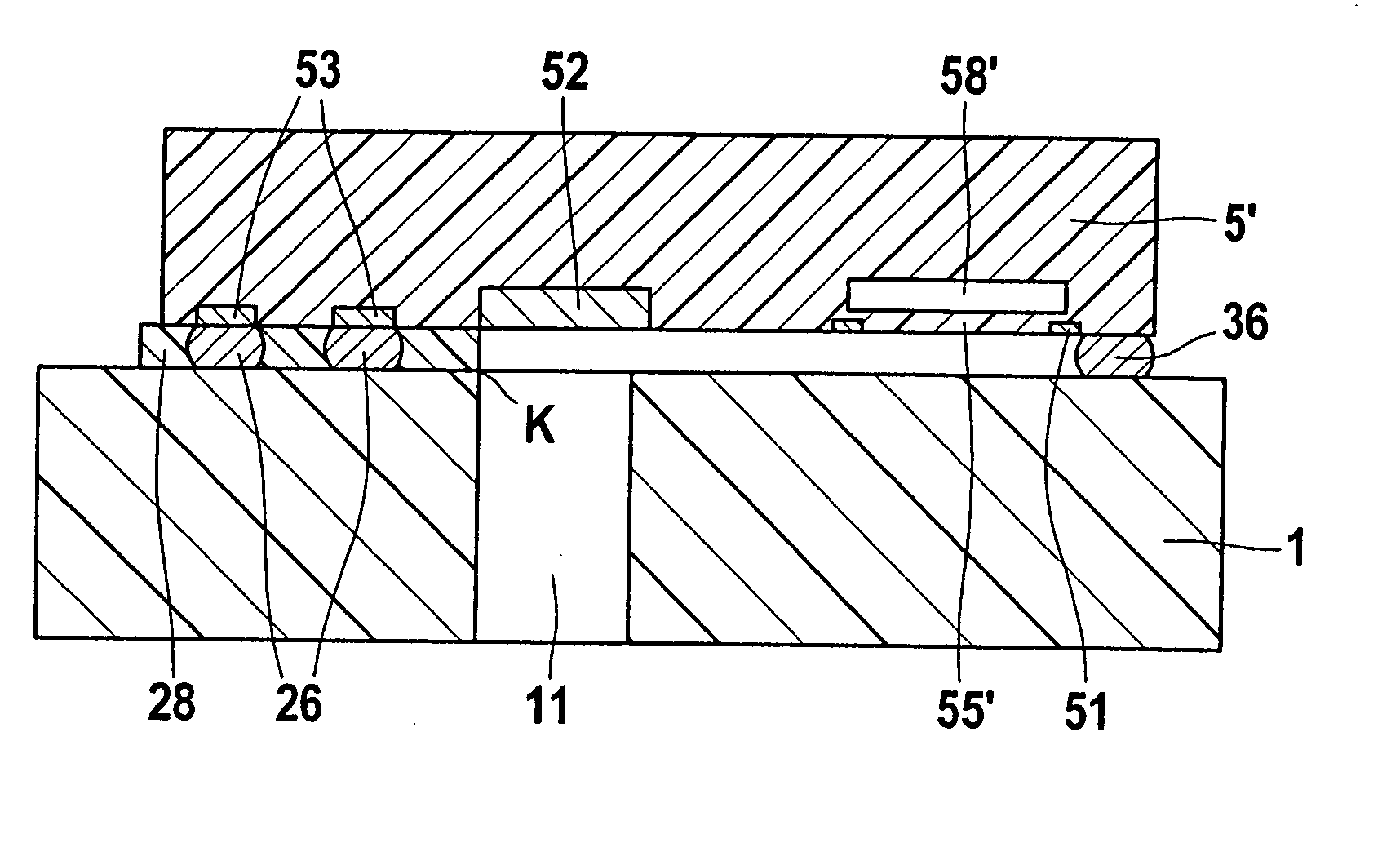

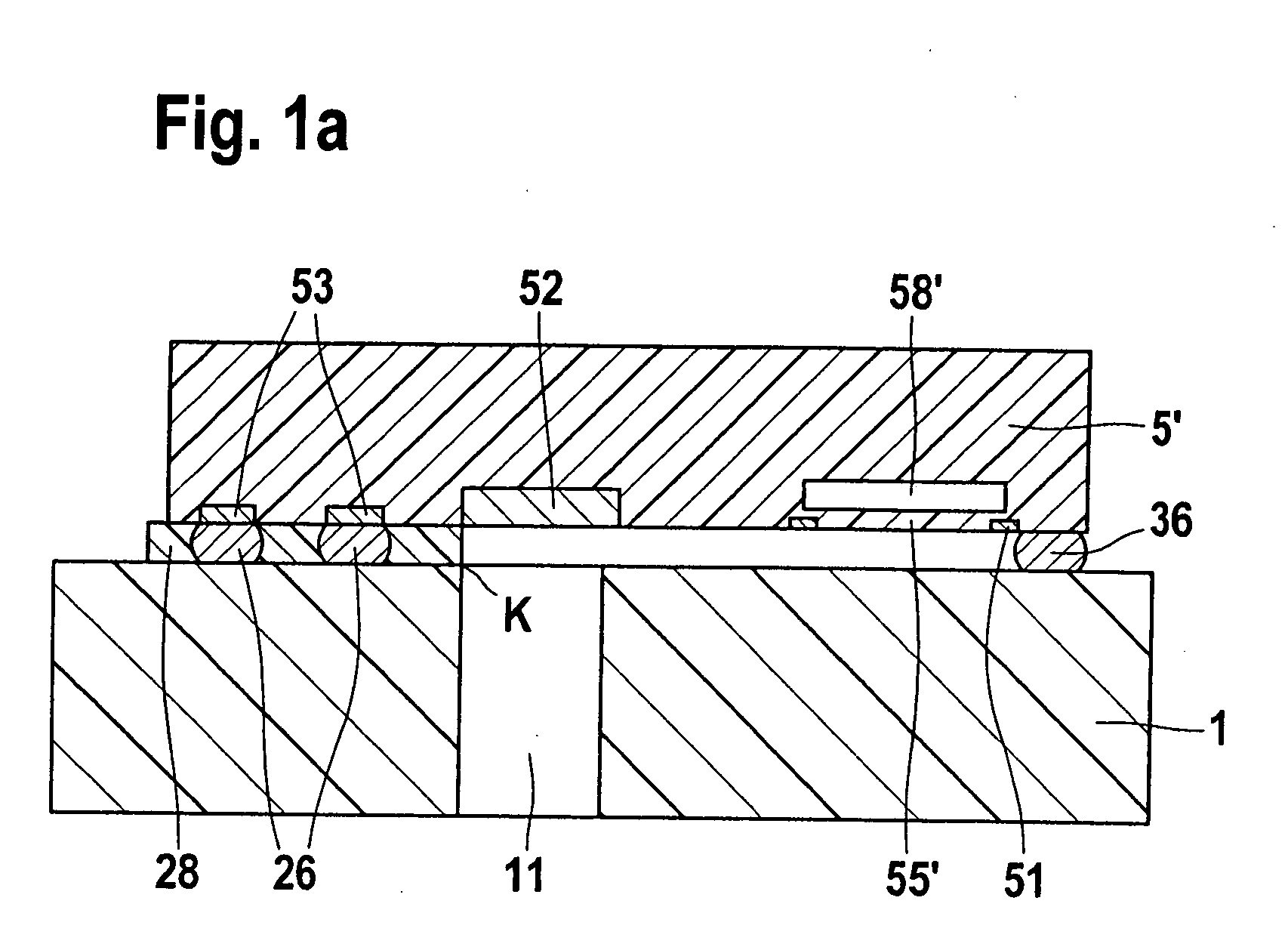

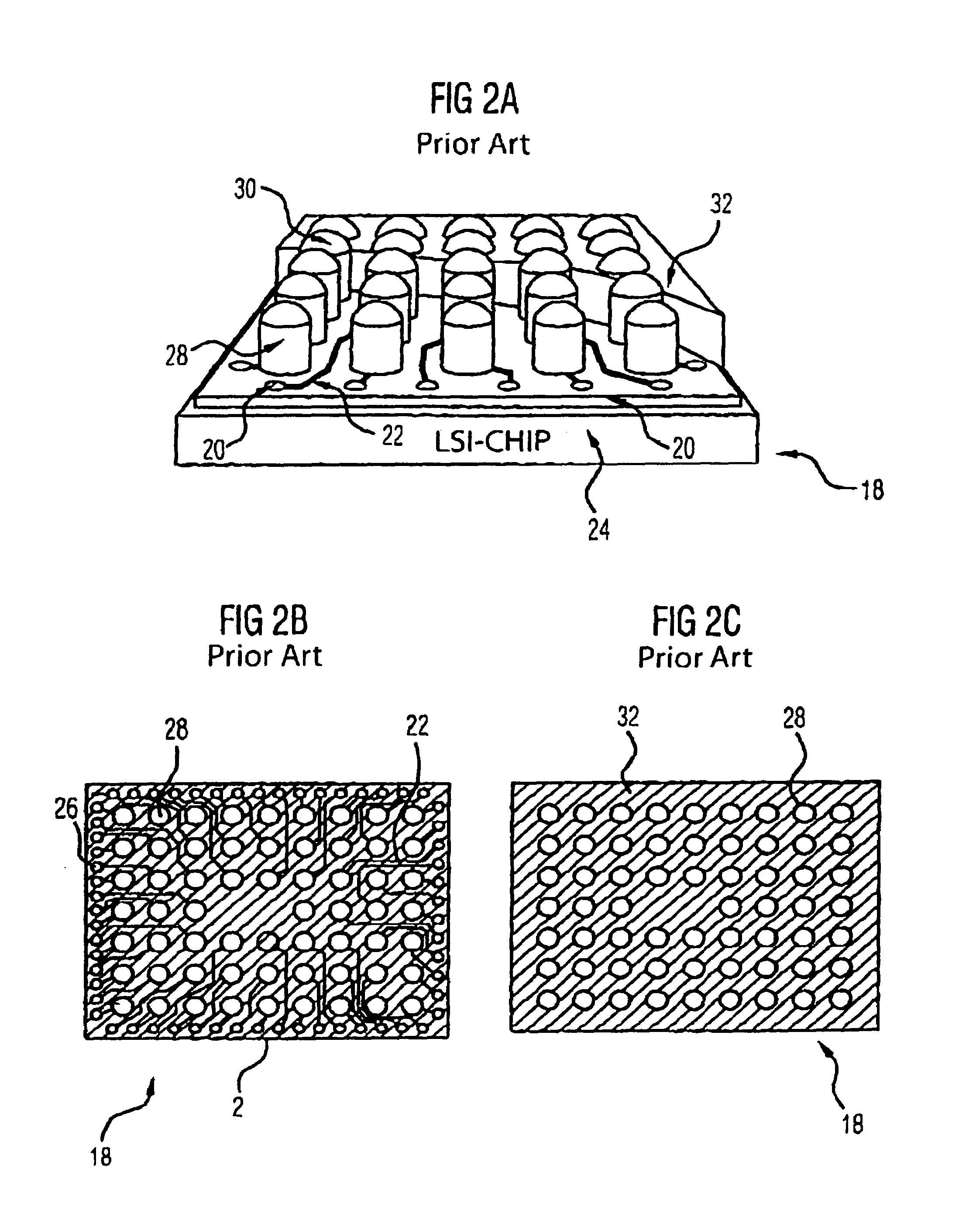

Method for mounting semiconductor chips and corresponding semiconductor chip system

InactiveUS20050194685A1Simple and cost-effectiveInsensitive to stressPrecision positioning equipmentSemiconductor/solid-state device detailsSemiconductor chipEngineering

A method for mounting semiconductor chips includes the steps of: a) providing a semiconductor chip having a surface that has a diaphragm region and a peripheral region, the peripheral region having a mounting region; b) providing a substrate which has a surface having a recess; c) mounting the mounting region of the semiconductor chip using a flip-chip technique onto the surface of the substrate in such a way that an edge of the recess lies between the mounting region and the diaphragm region; and d) underfilling the mounting region using an underfilling component, the edge of the recess being used a demarcation region for the underfilling component, so that no underfilling component is able to get into the diaphragm region. Also provided is a corresponding semiconductor chip system.

Owner:ROBERT BOSCH GMBH

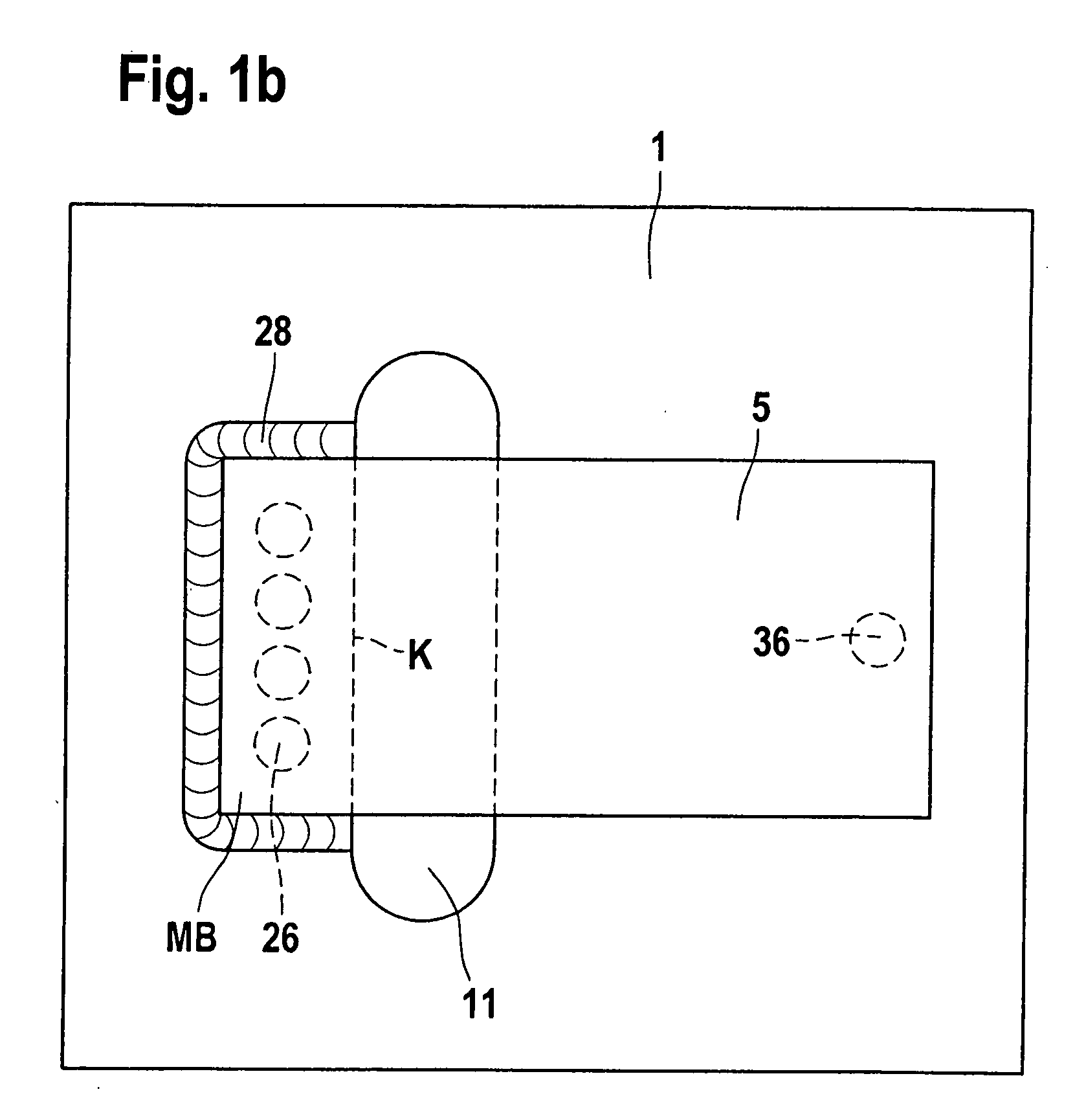

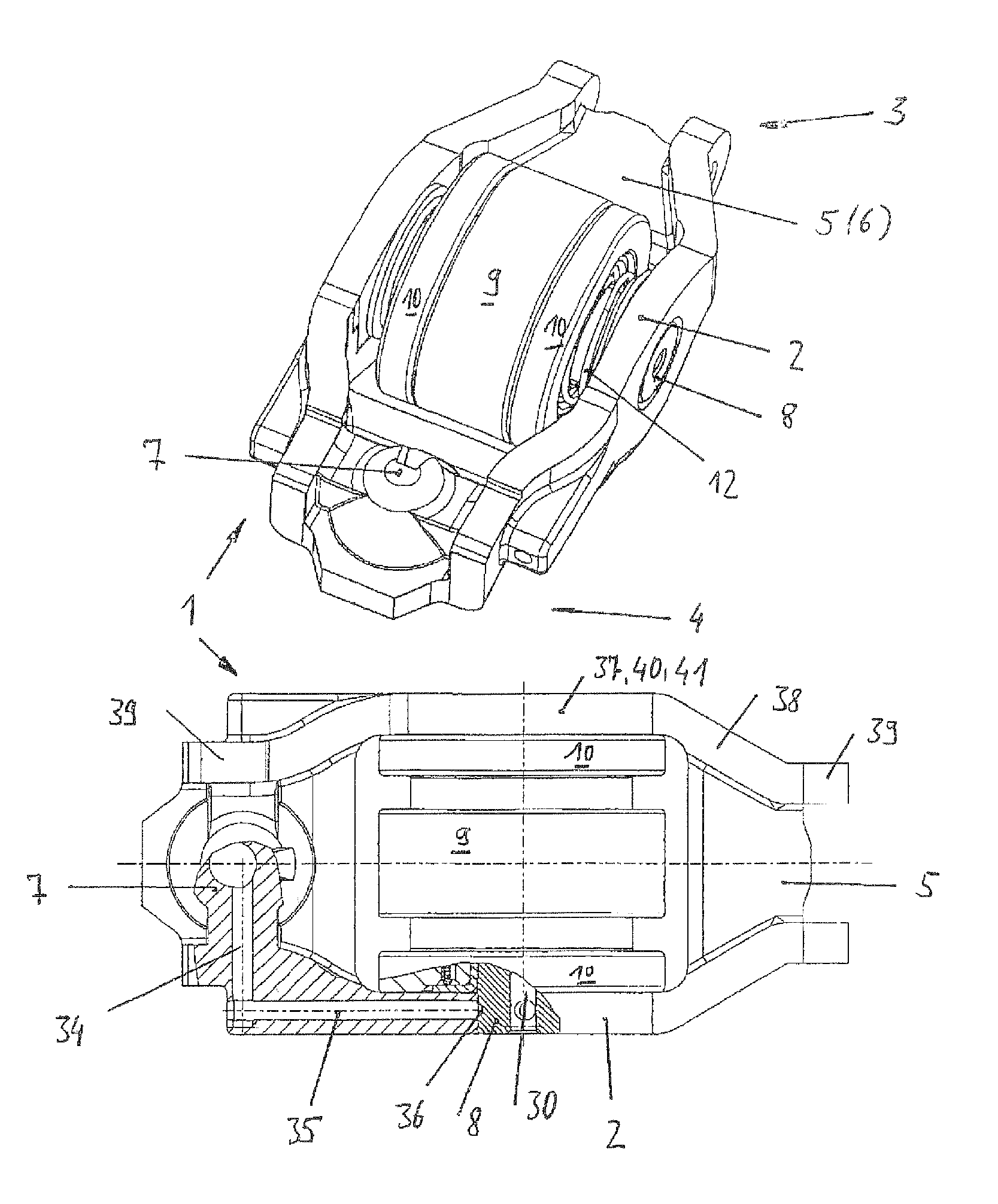

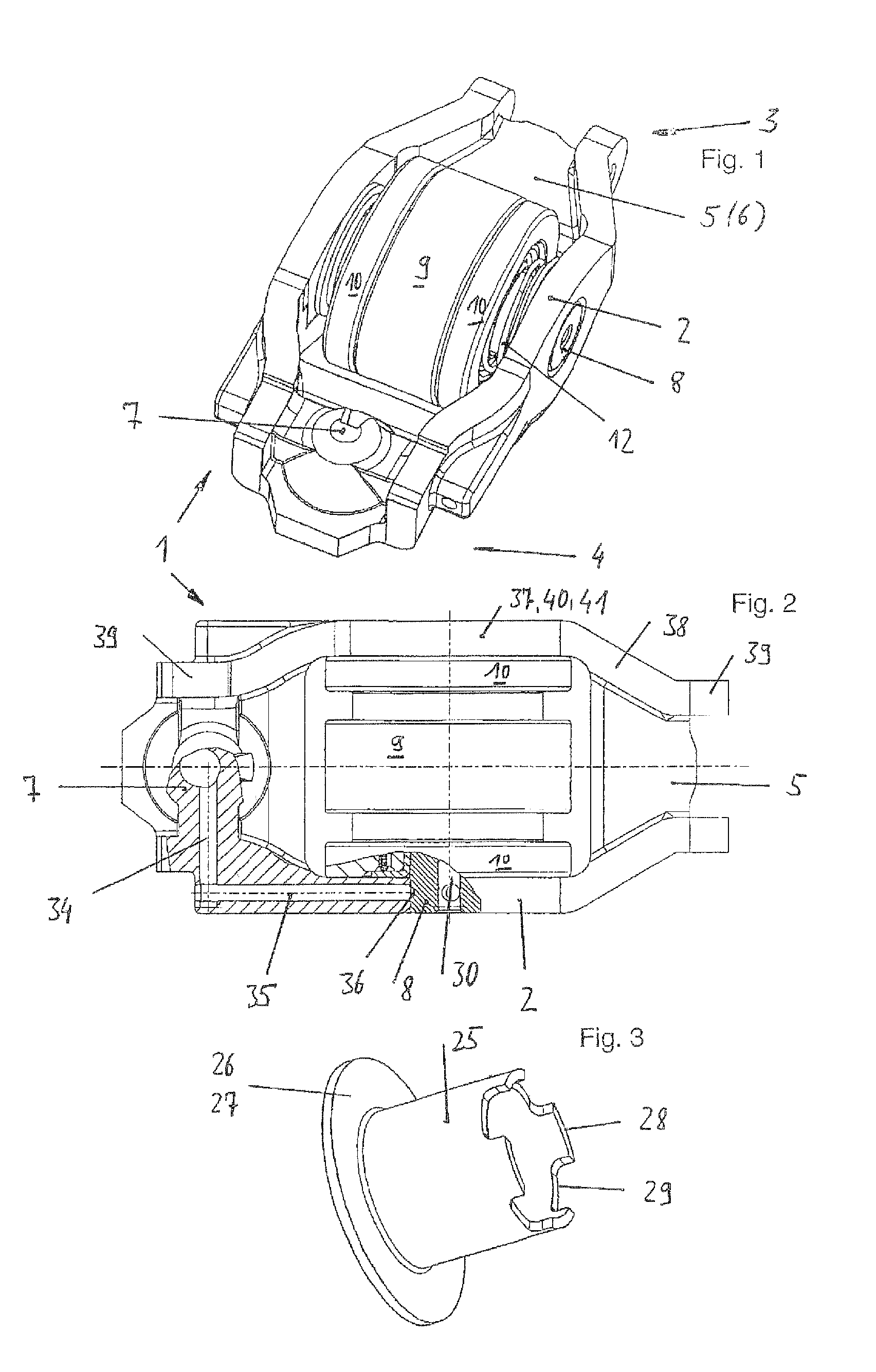

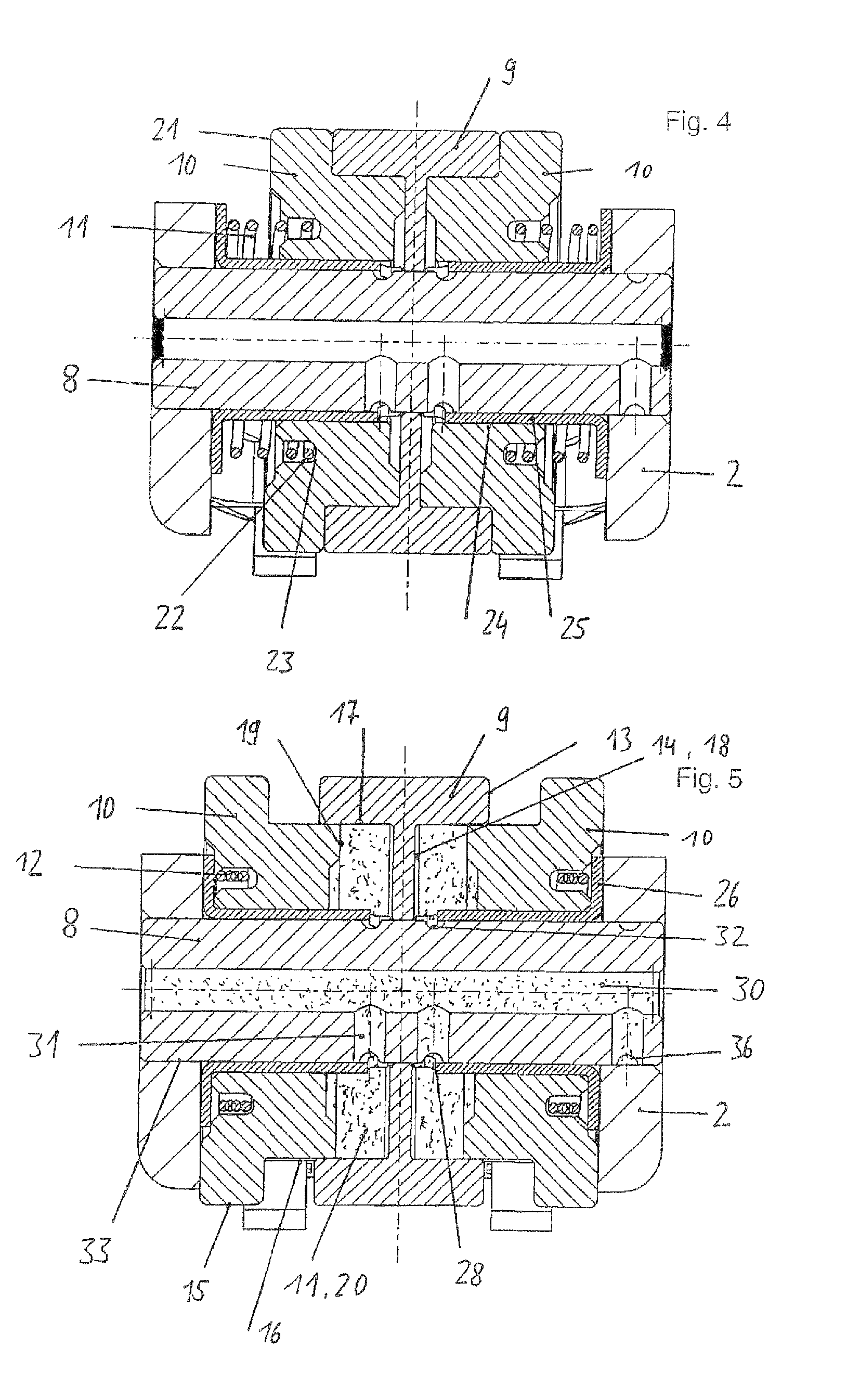

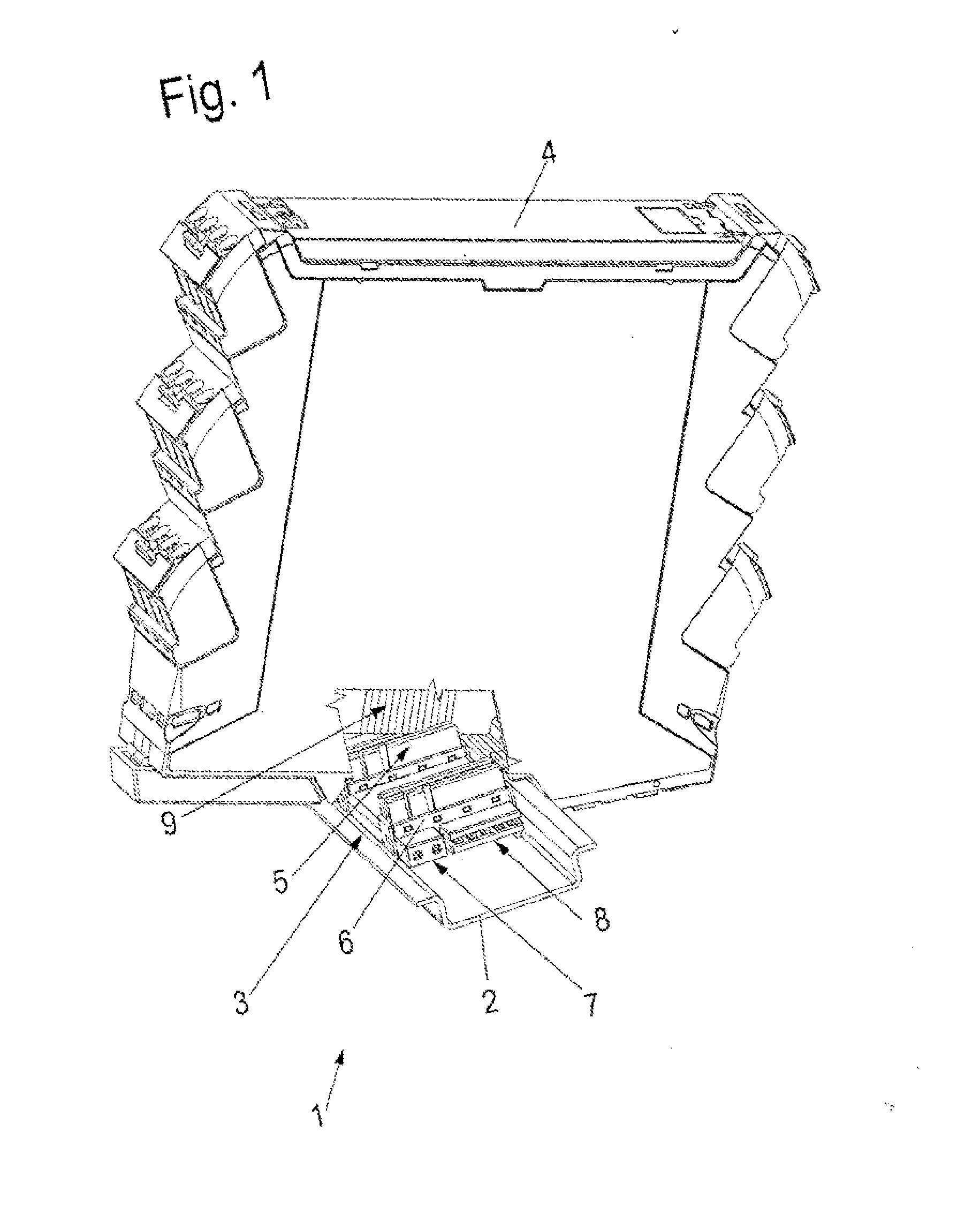

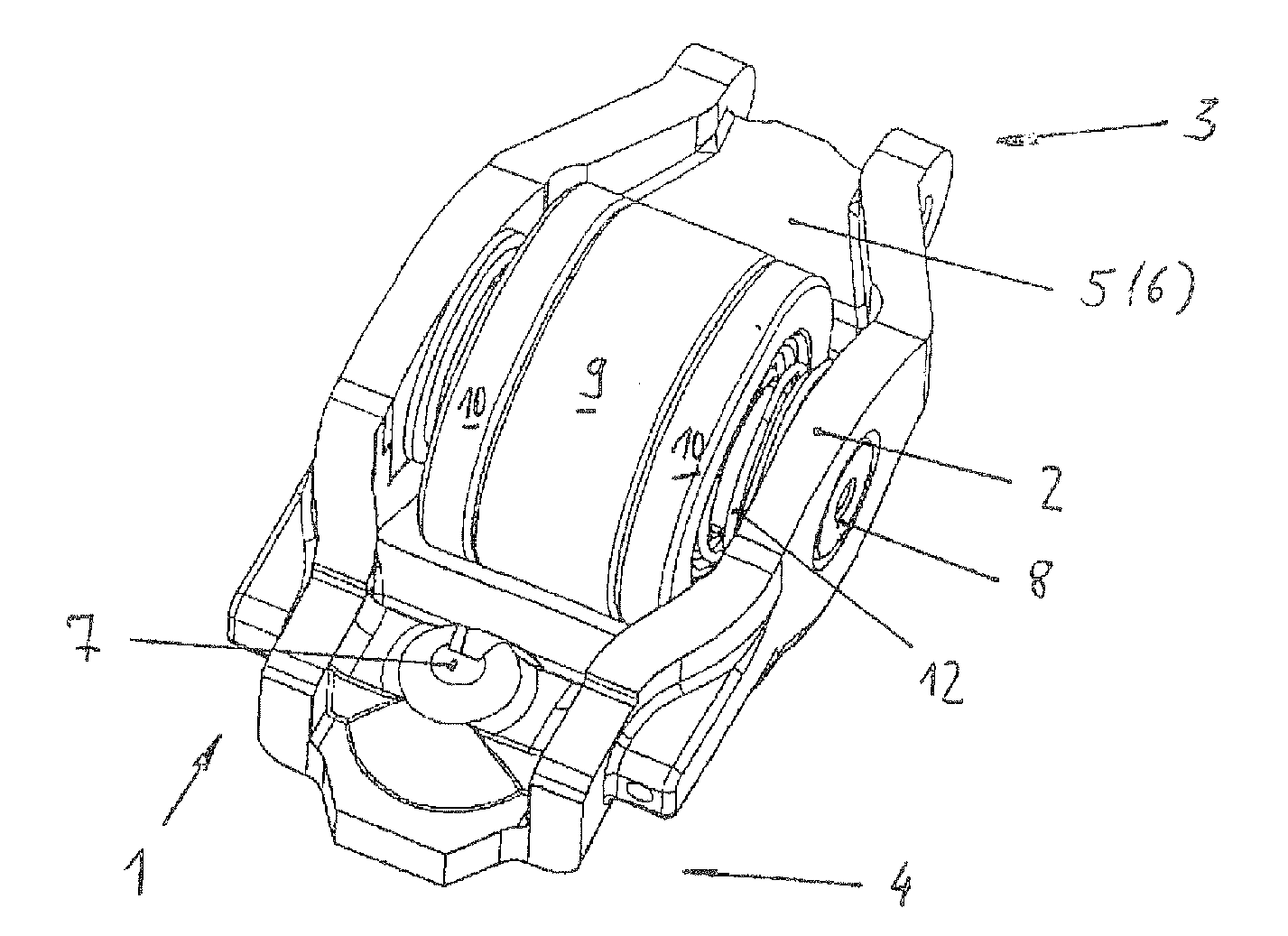

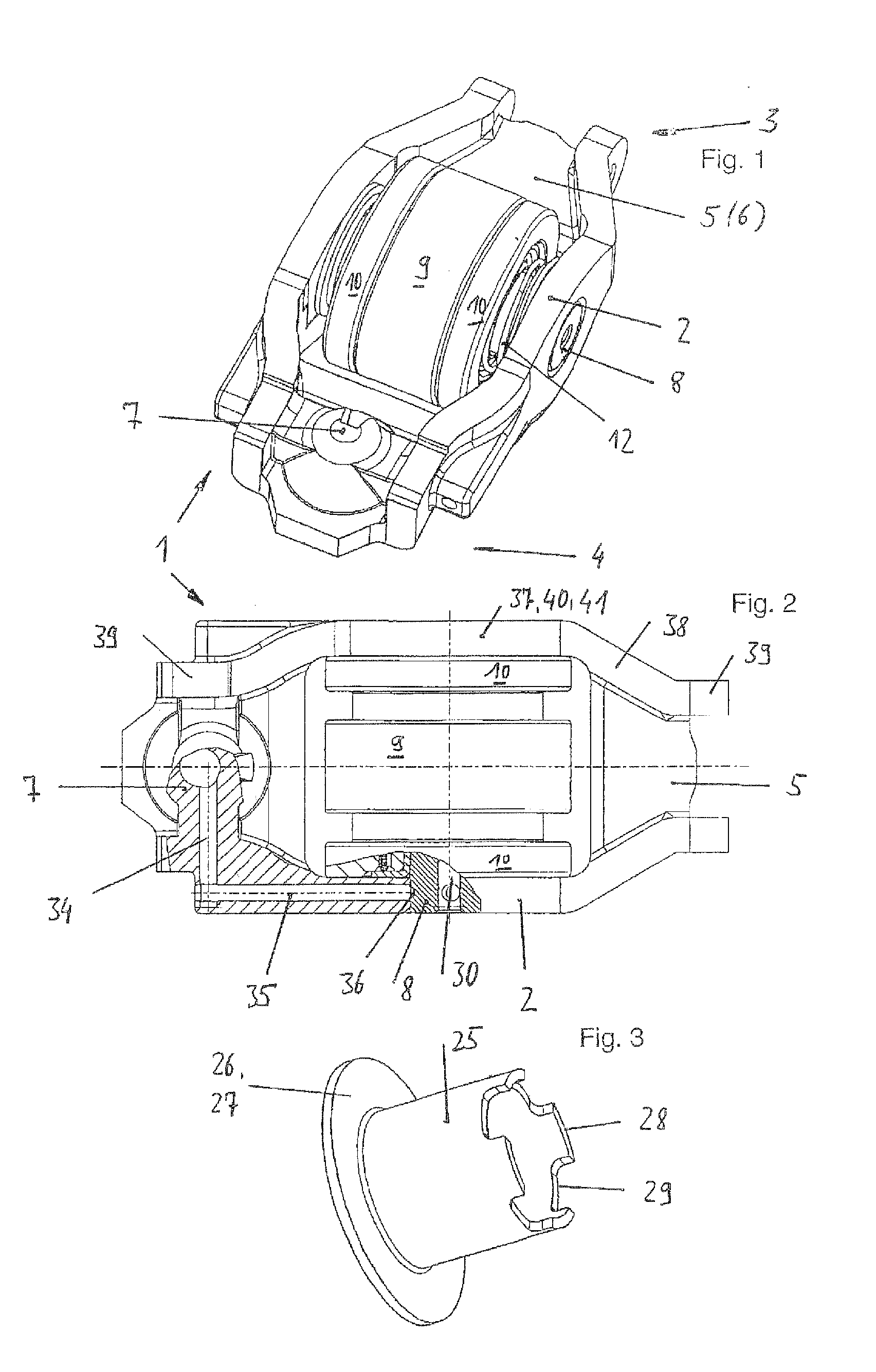

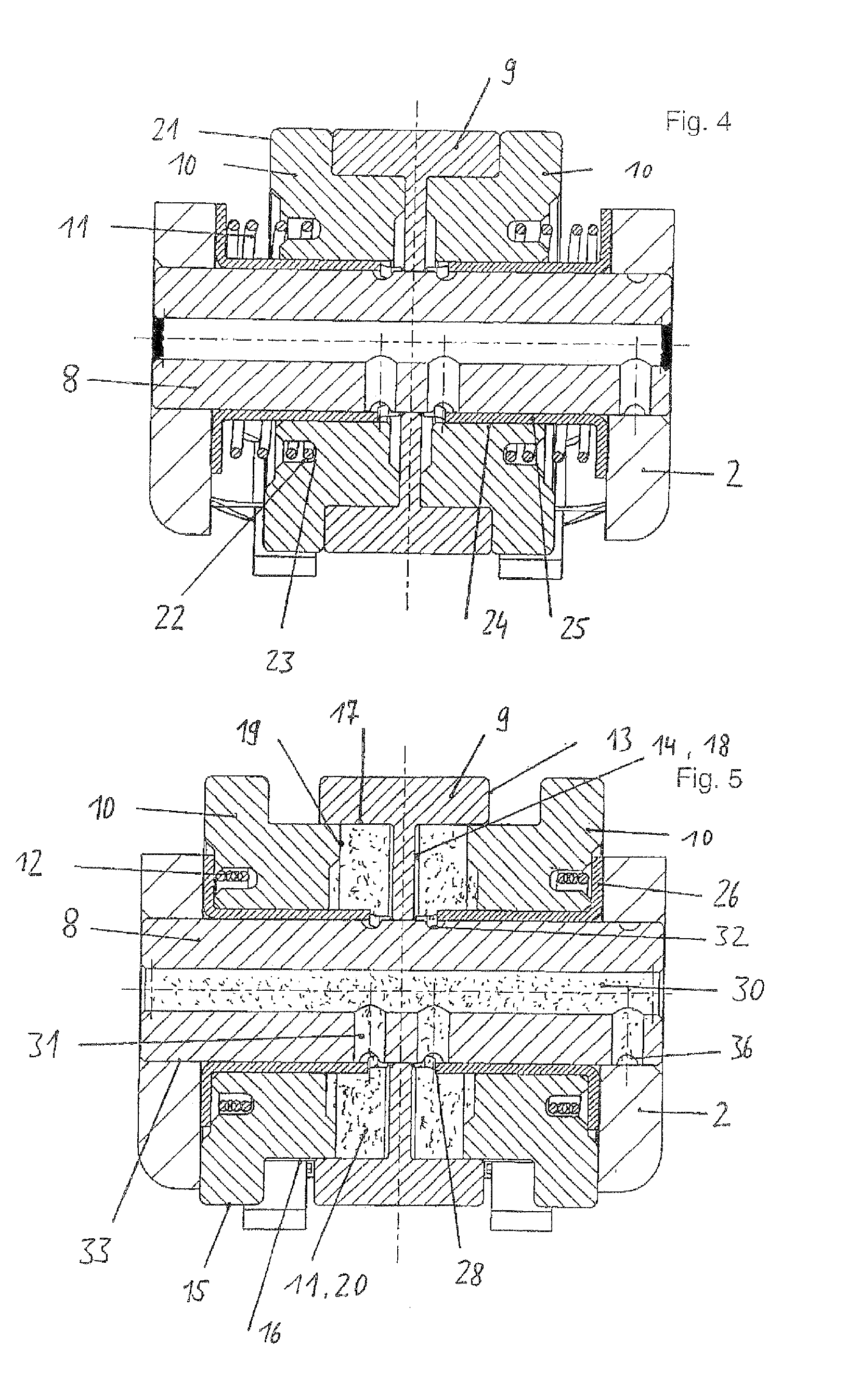

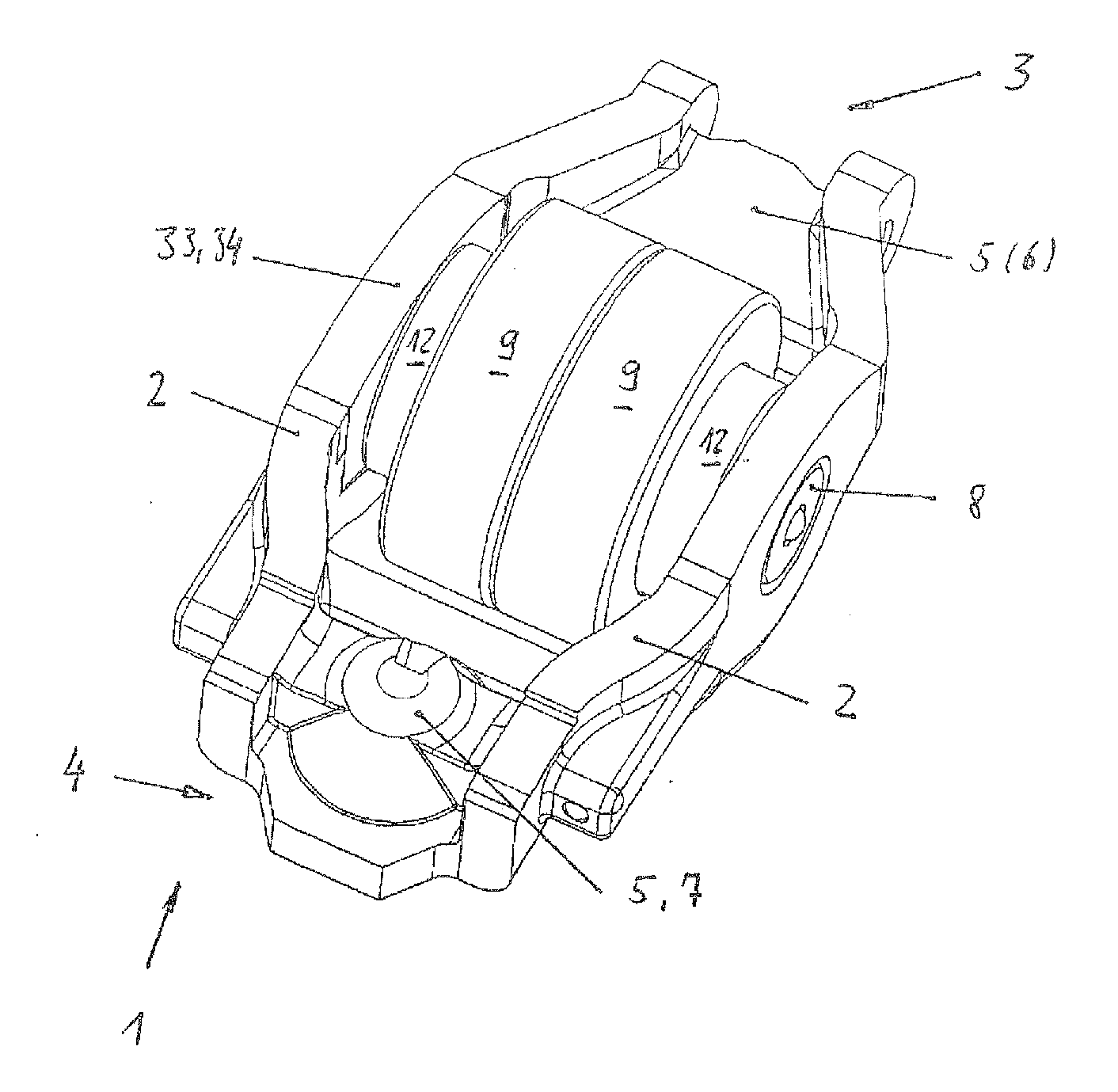

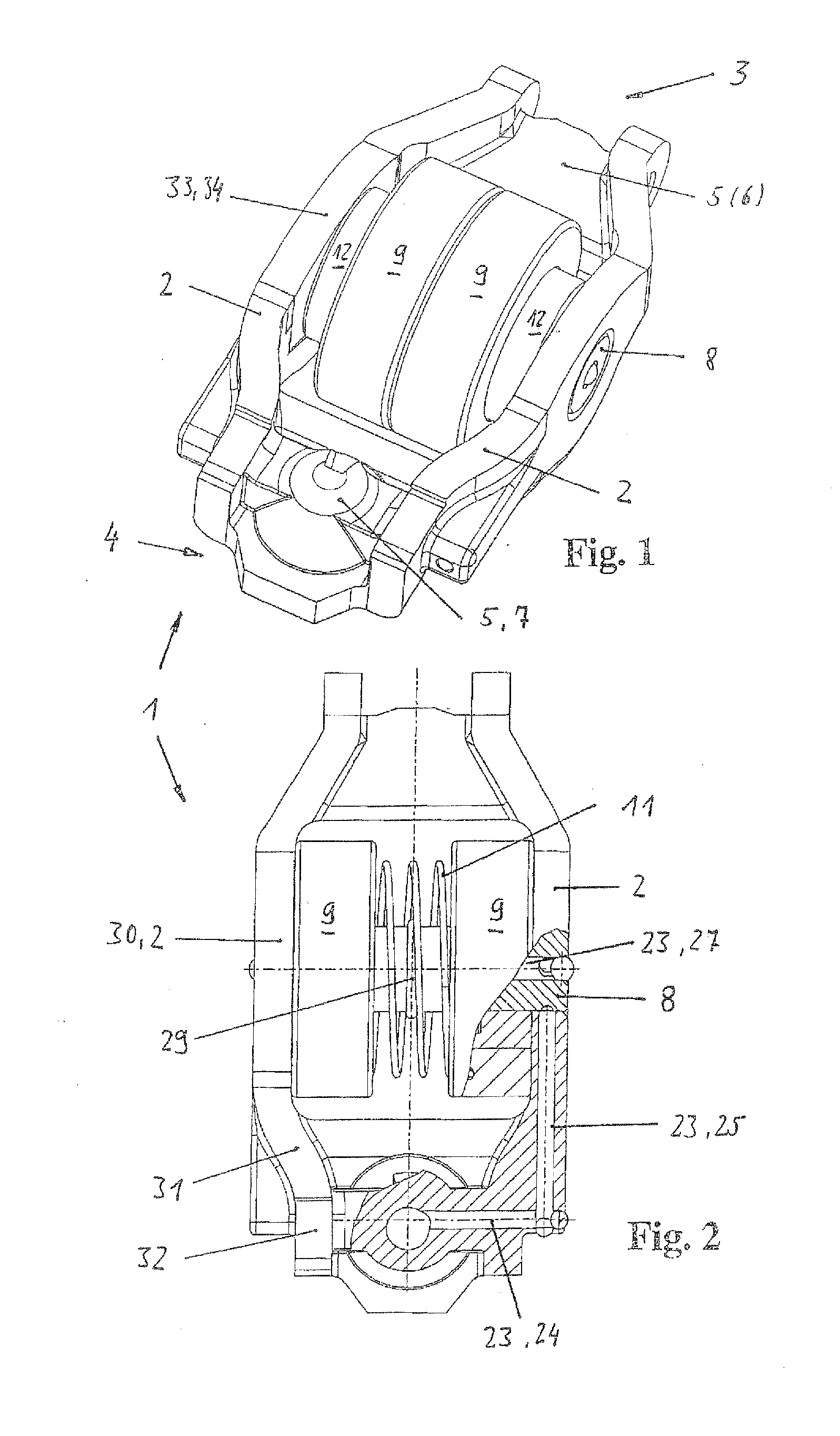

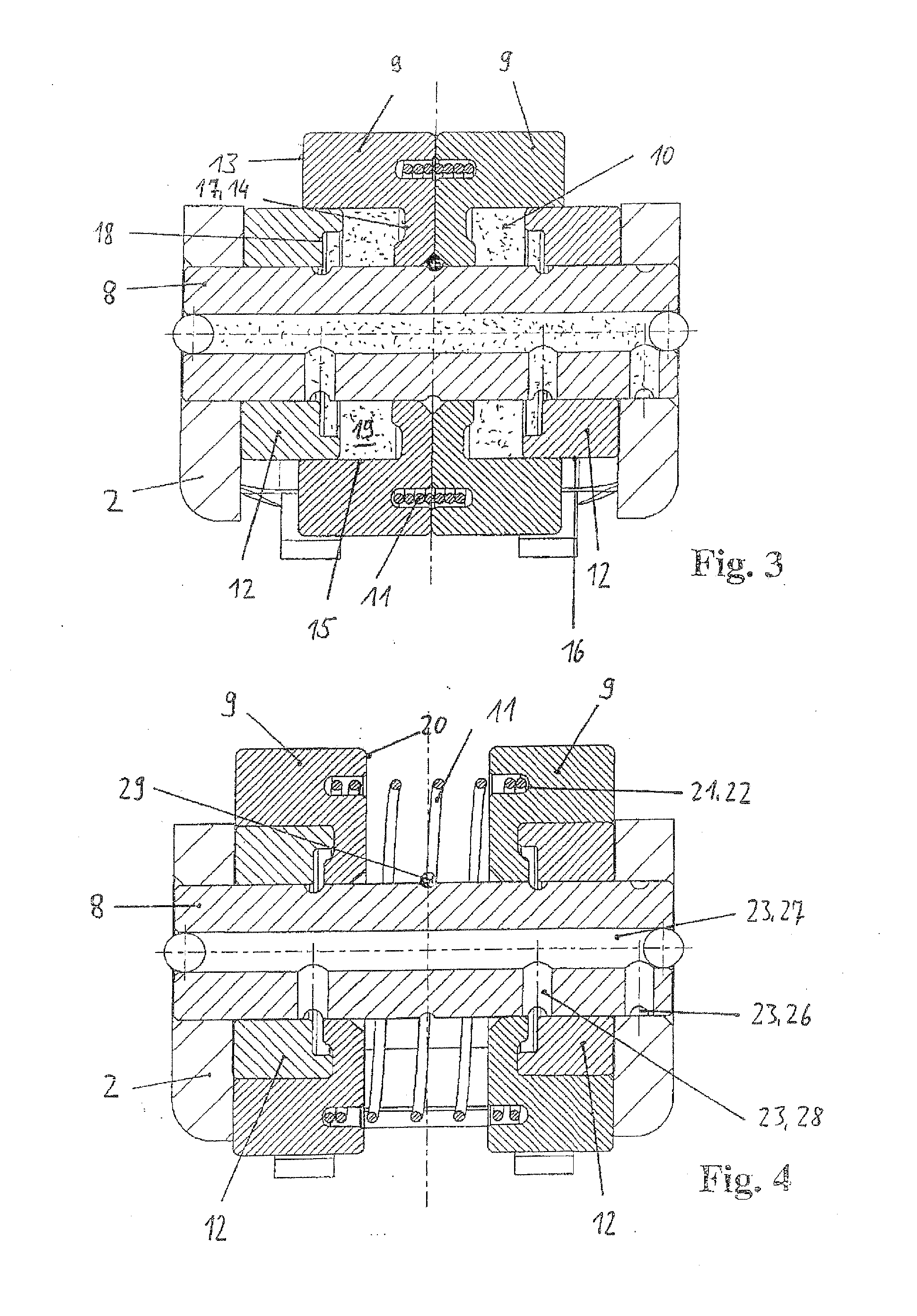

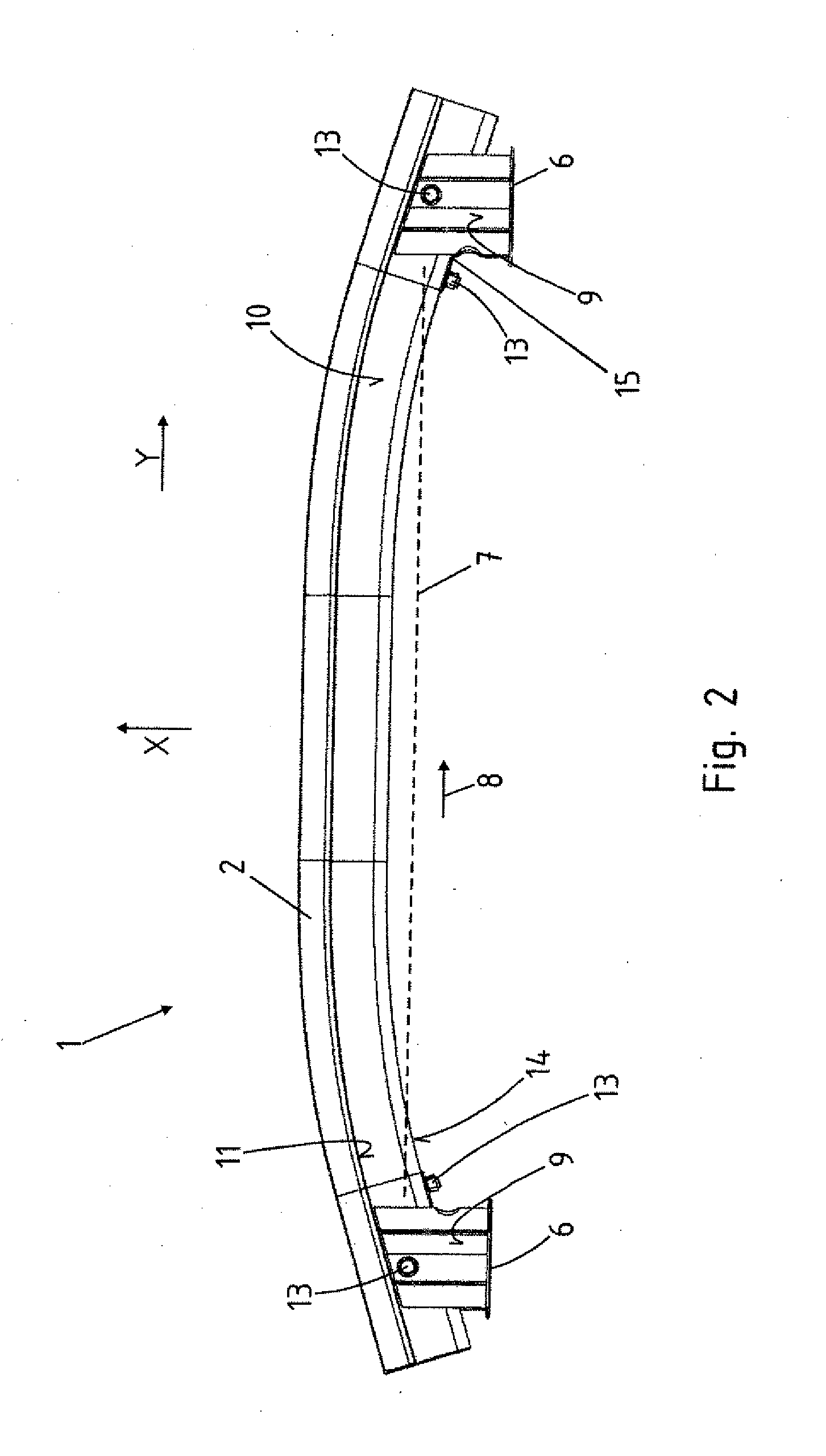

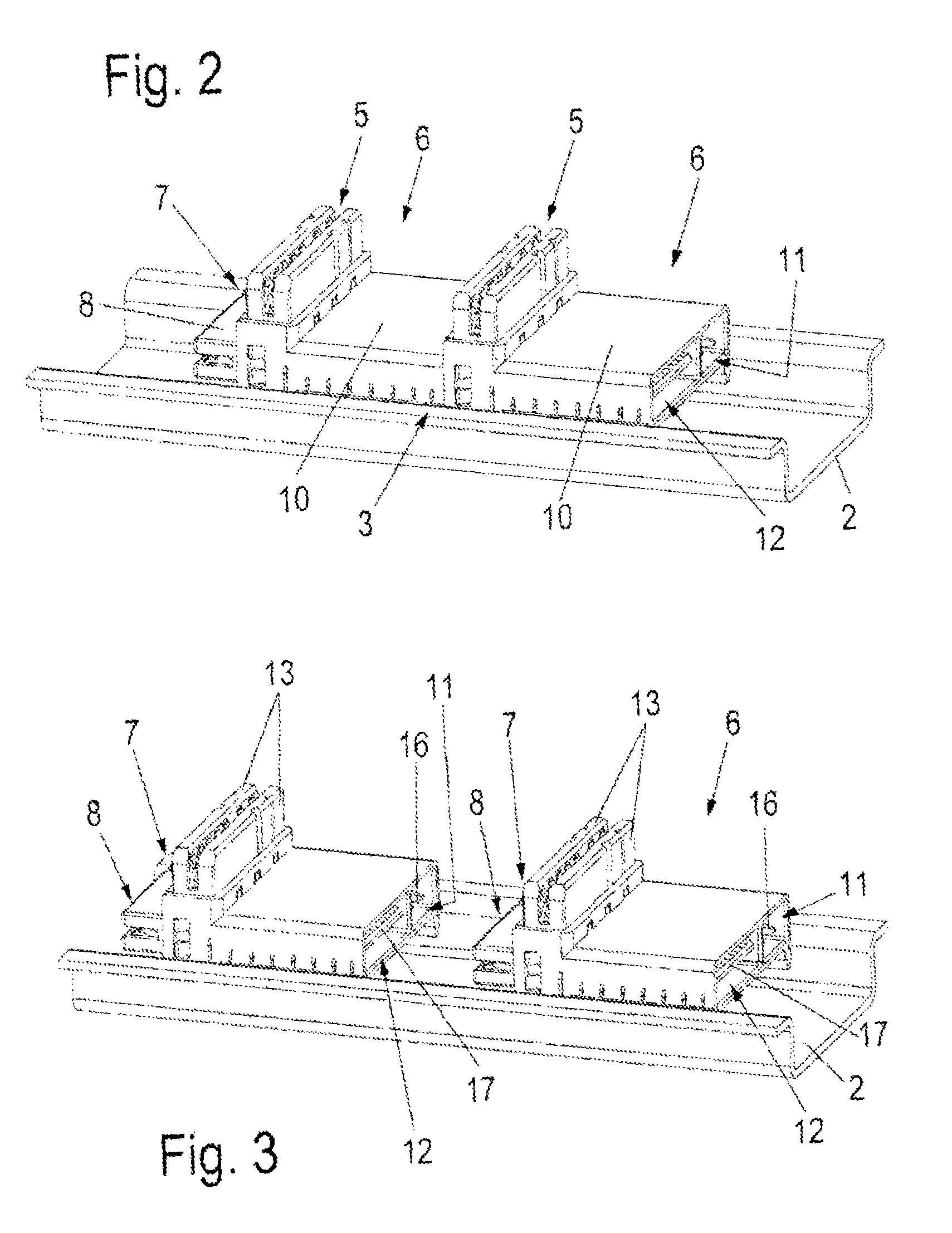

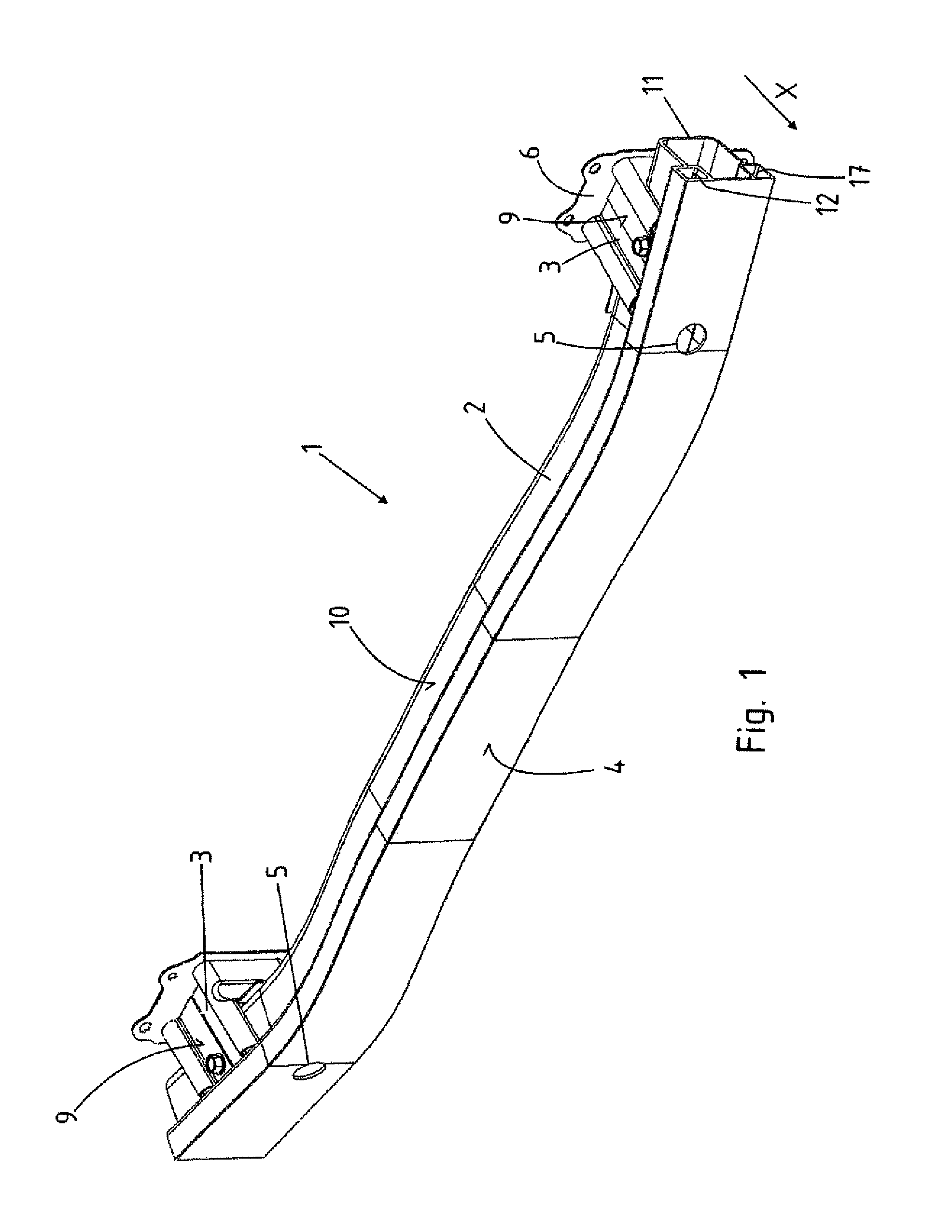

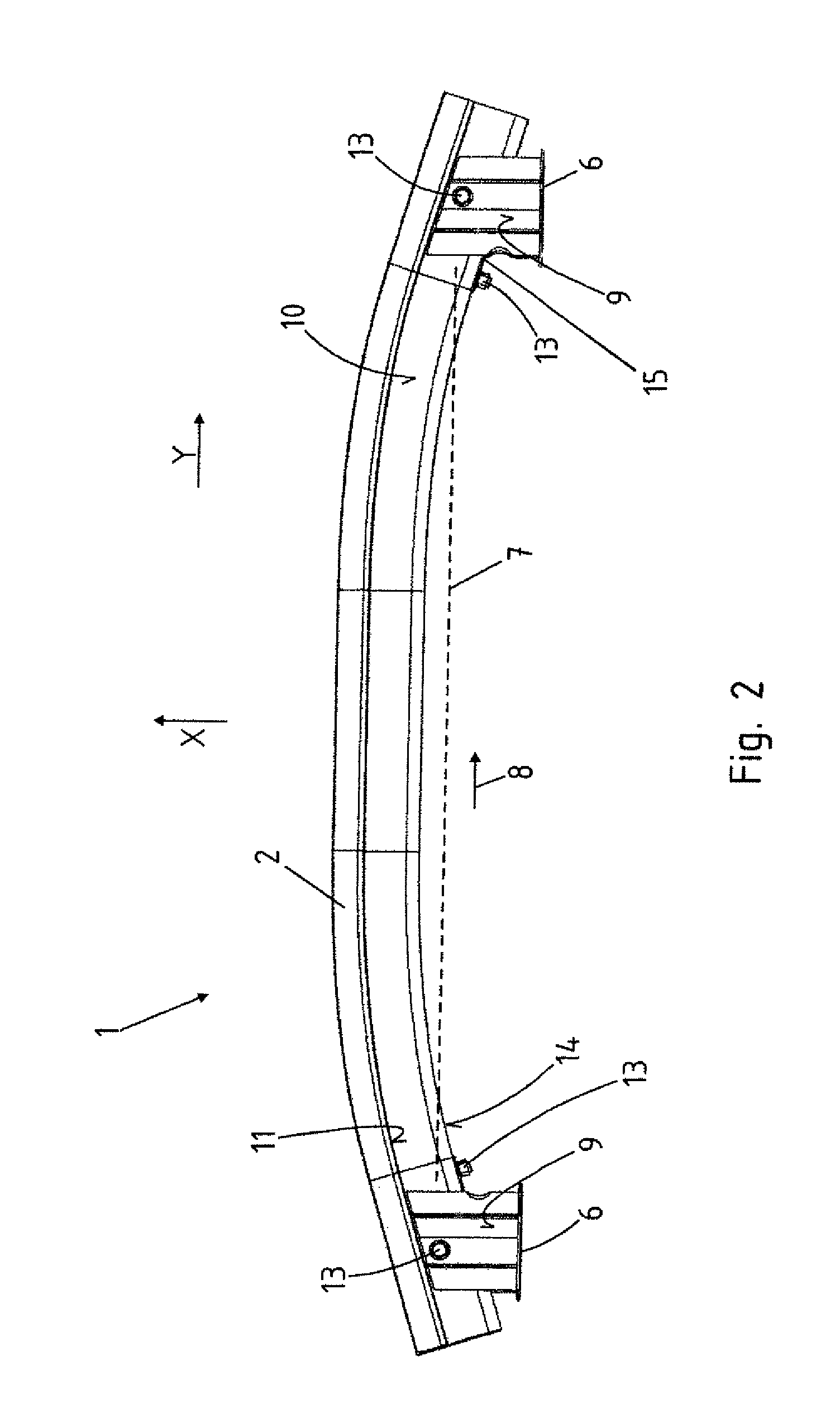

Switchable lever for a valve drive of an internal combustion engine

InactiveUS8677958B2Save building spaceMinimized surface pressureValve arrangementsMachines/enginesExternal combustion engineGas exchange

A switchable lever for a valve drive of an internal combustion engine, which has an elongated housing with two side walls. A crossbar for a gas-exchange valve system and another end of the housing has a hearing for pivotable support of the crossbar. An axle is held nondisplaceably in the side walls. An axially fixed low-lift cam roller is seated centrally on the axle and is flanked on both sides by a high-lift cam roller. The high-lift cam rollers are displaceable: (a) into a first position, away from each other, to toward the side walls such that contact of one high-lift cam per high-lift cam roller is possible, and (b) into a second position, toward each other, such that they are located outside an engagement region of the high-lift cams, and as a result of which contact of a low-lift or zero-lift cam with the low-lift cam roller is possible.

Owner:SCHAEFFLER TECH AG & CO KG

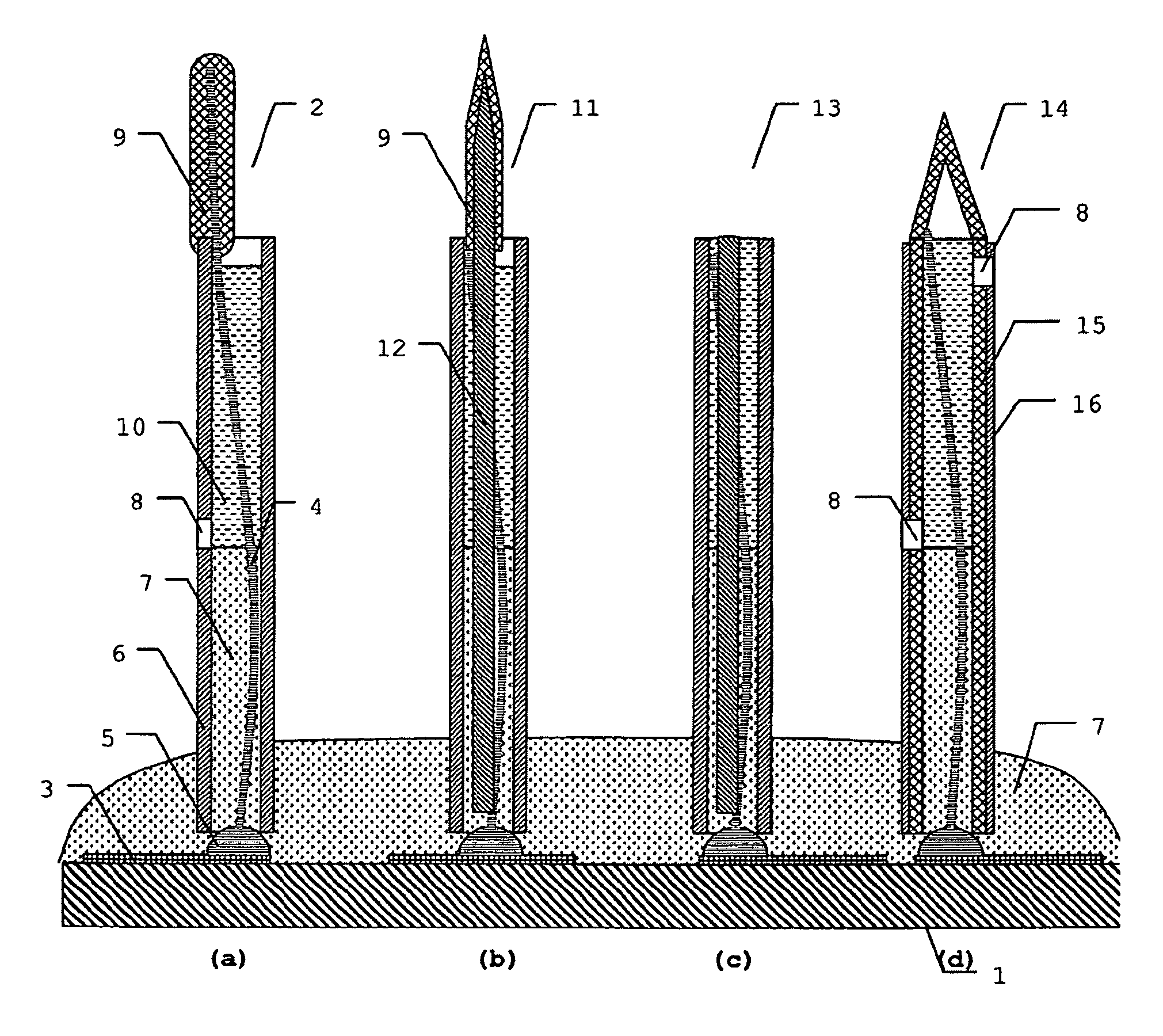

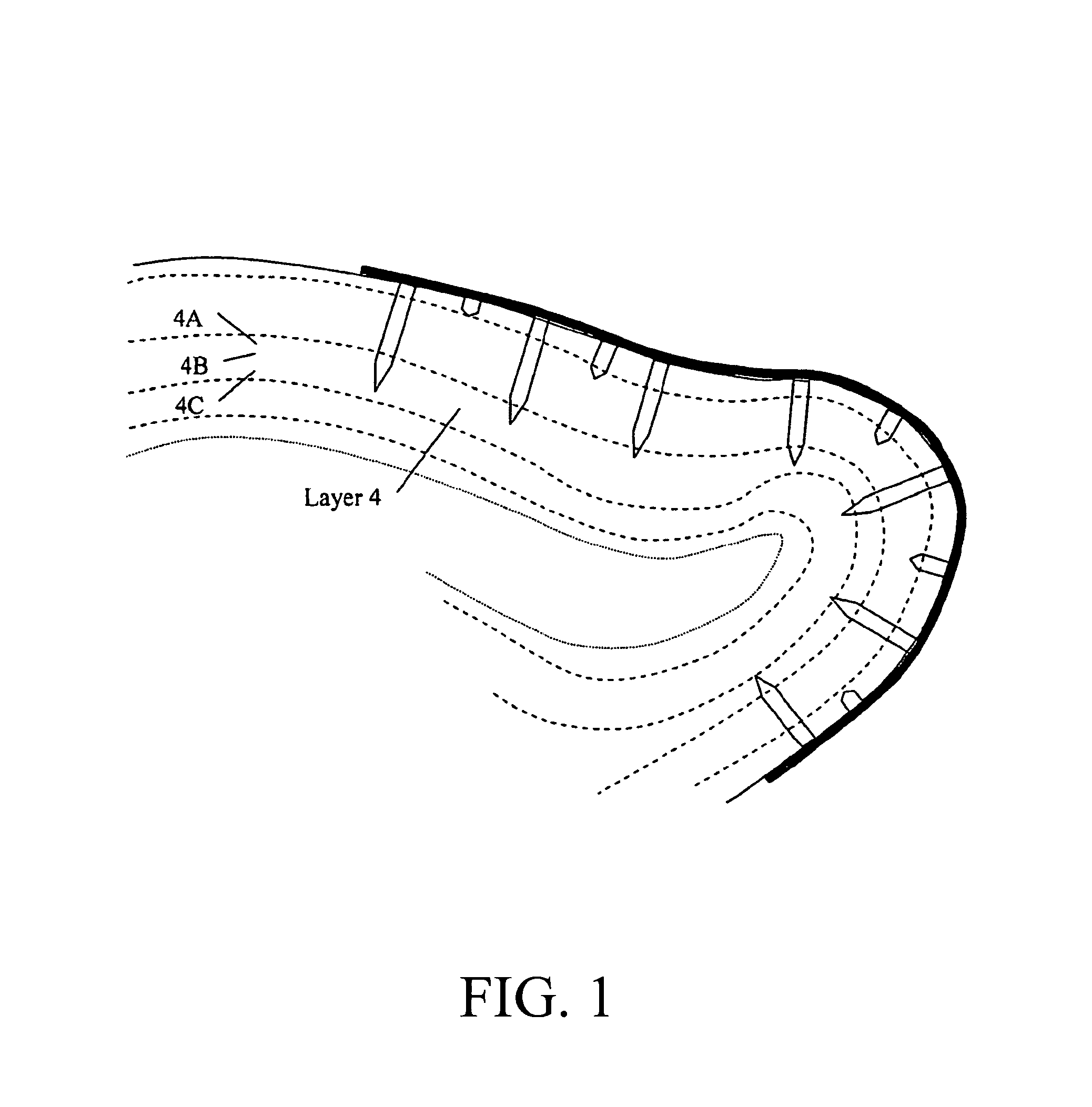

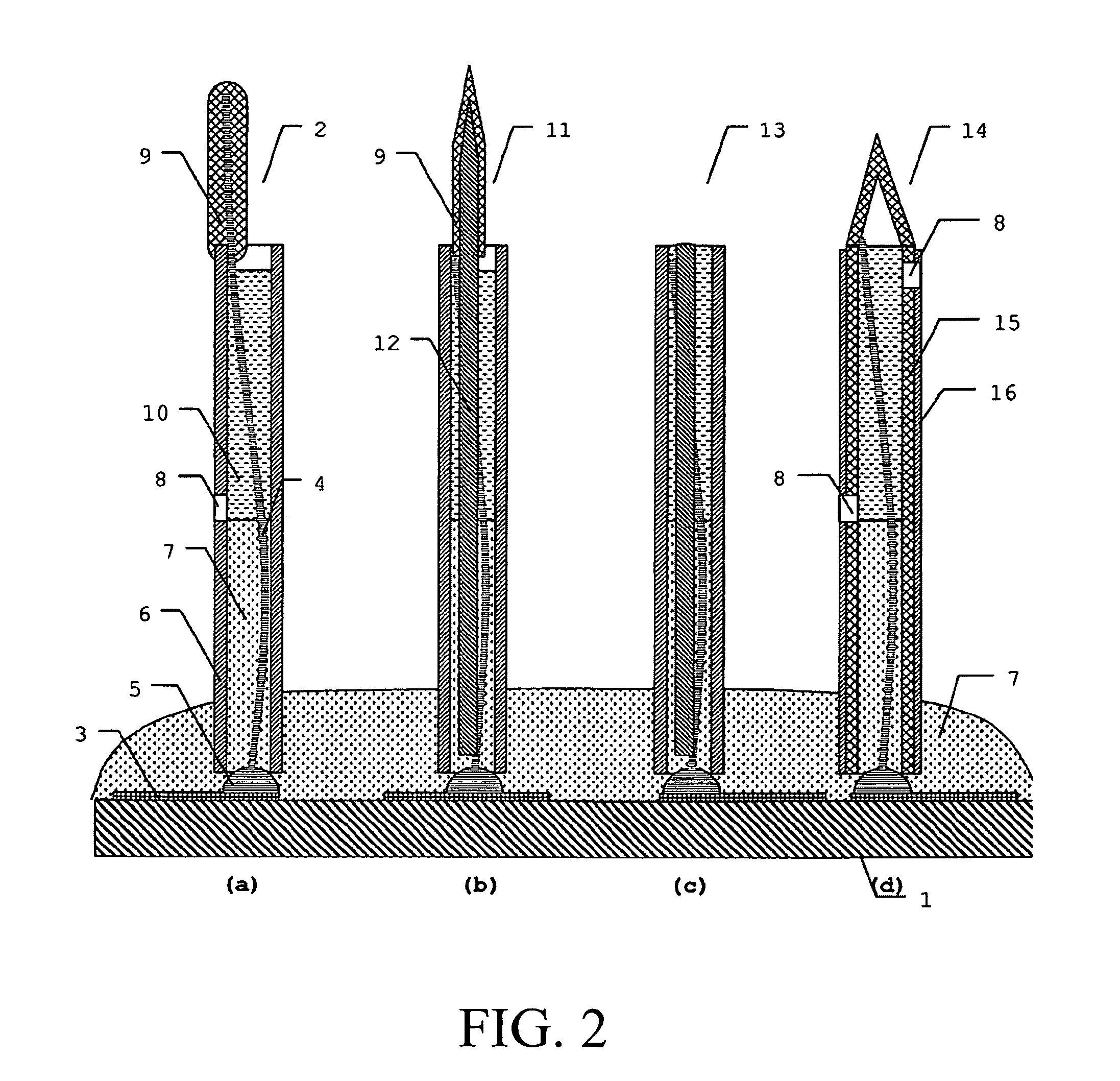

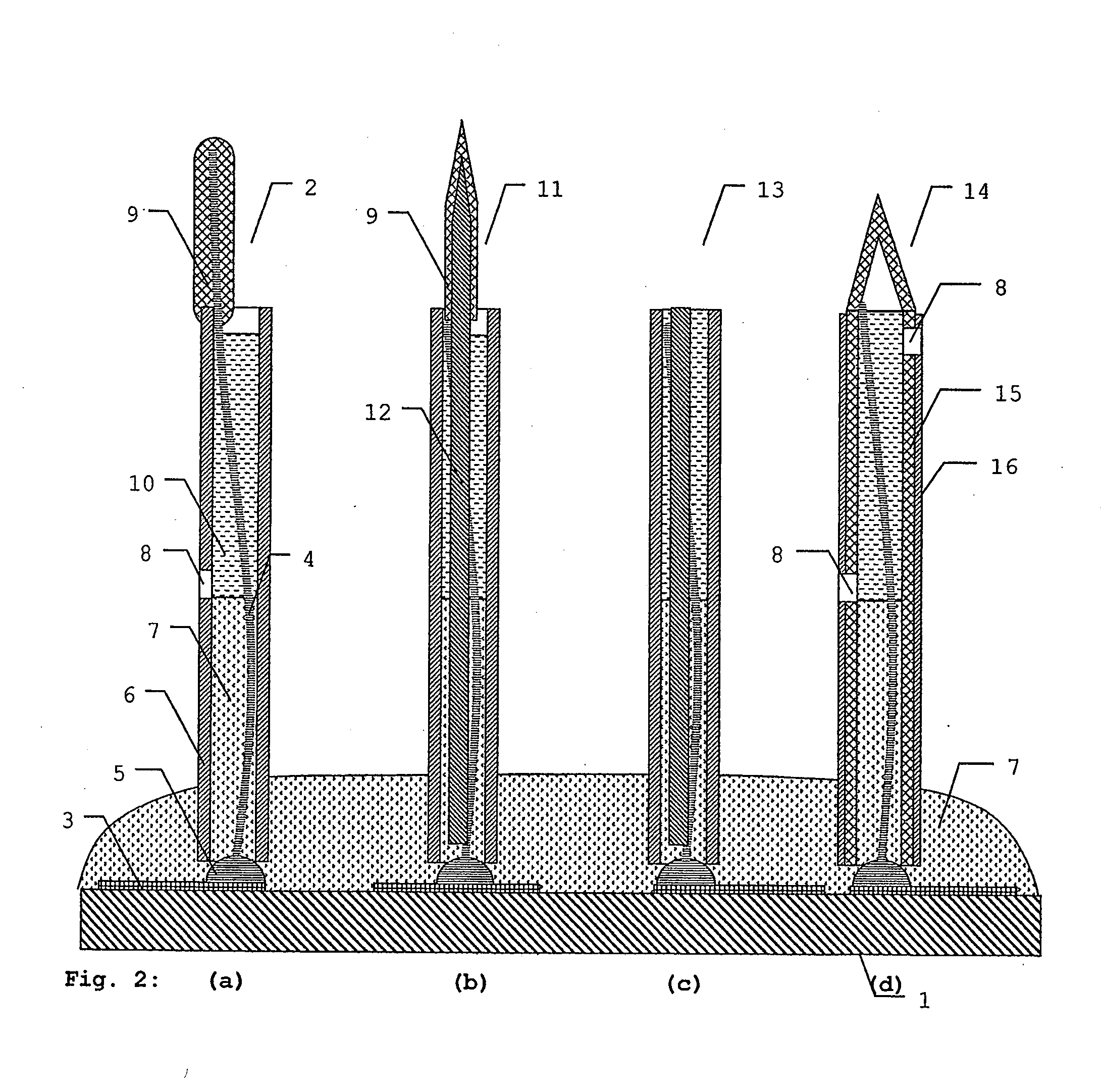

Biostable neuroelectrode

ActiveUS8489203B2Conducive to stable operationReduce power consumptionHead electrodesSensorsNeurophysiologyNeuronal organization

A device for deriving electrical signals or for electrically simulating neuronal tissue. Neuroelectrodes form an interface between the biological tissue and technical systems. Existing neuroelectrodes for contacting low-lying neuronal layers diminish their properties by the interaction with biological tissue. In order to improve the long-time behavior, neuroelectrodes filled with bioactive substances are used. The neuroelectrode is formed on a flexible or rigid substrate with the aid of a line and of a microcapillary. The inside of the microcapillary serves as a container for the bioactive substance. The biostable neuroelectrode is used for deriving electrical signals or for electrically stimulating neuronal tissue in the fields of neurology and neurophysiology.

Owner:ORTMANN VALERIJ

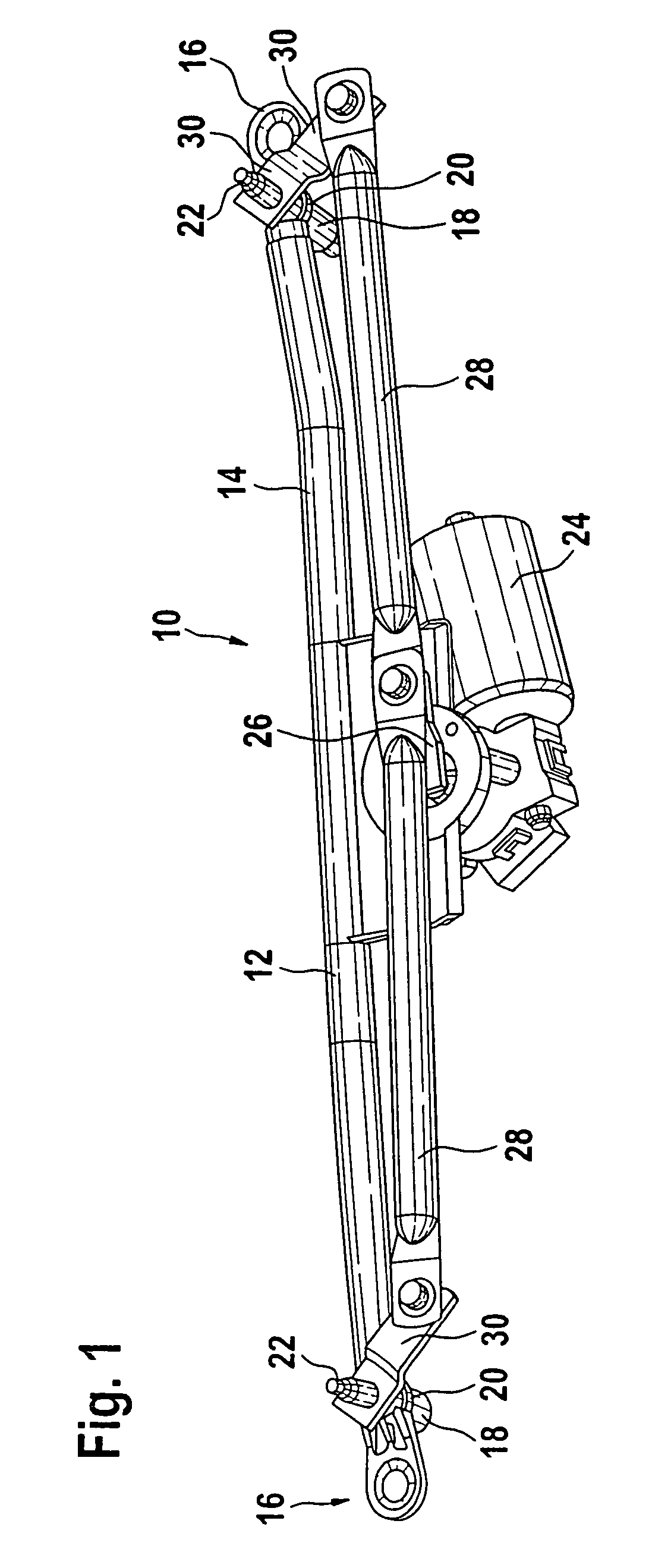

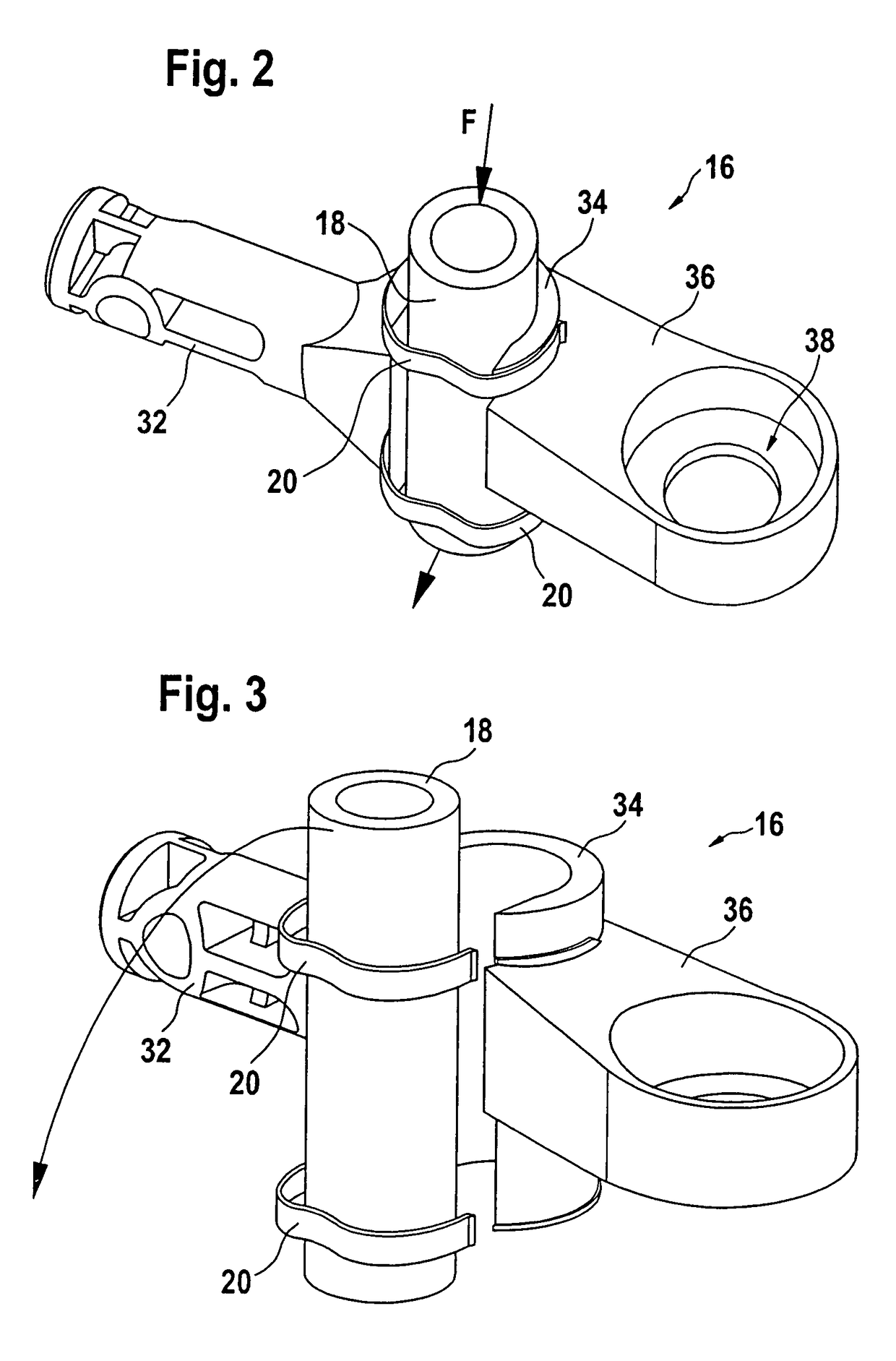

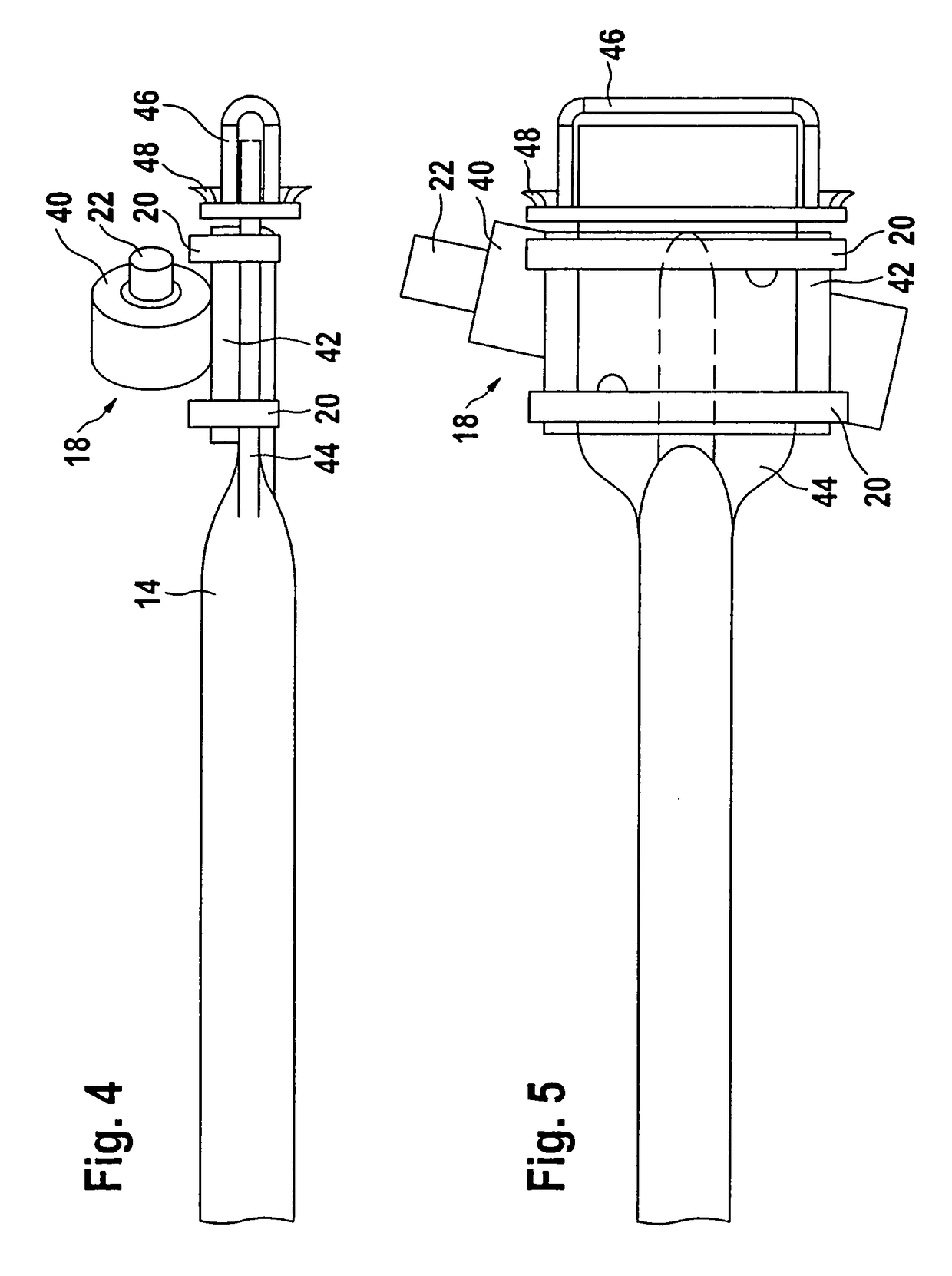

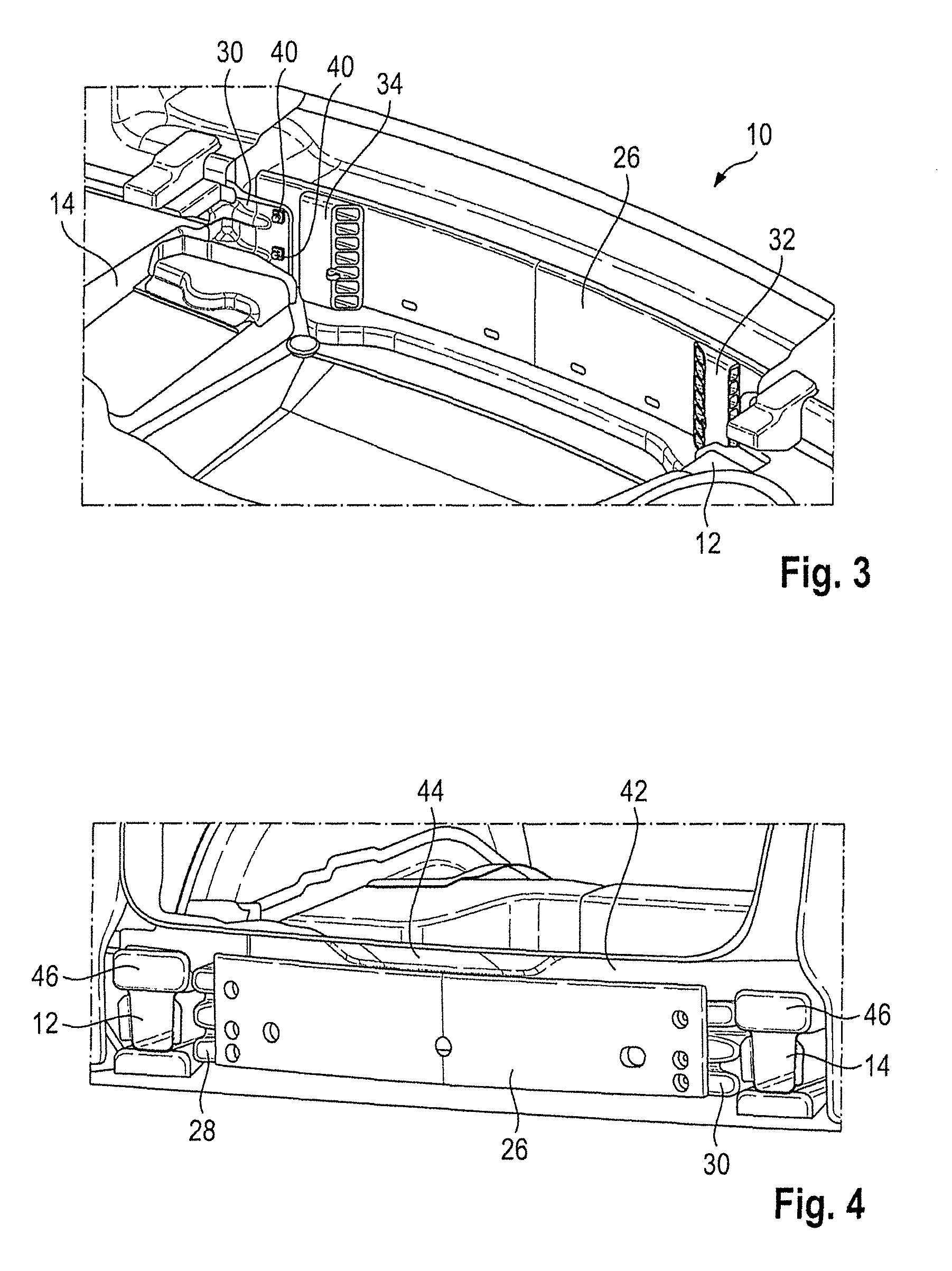

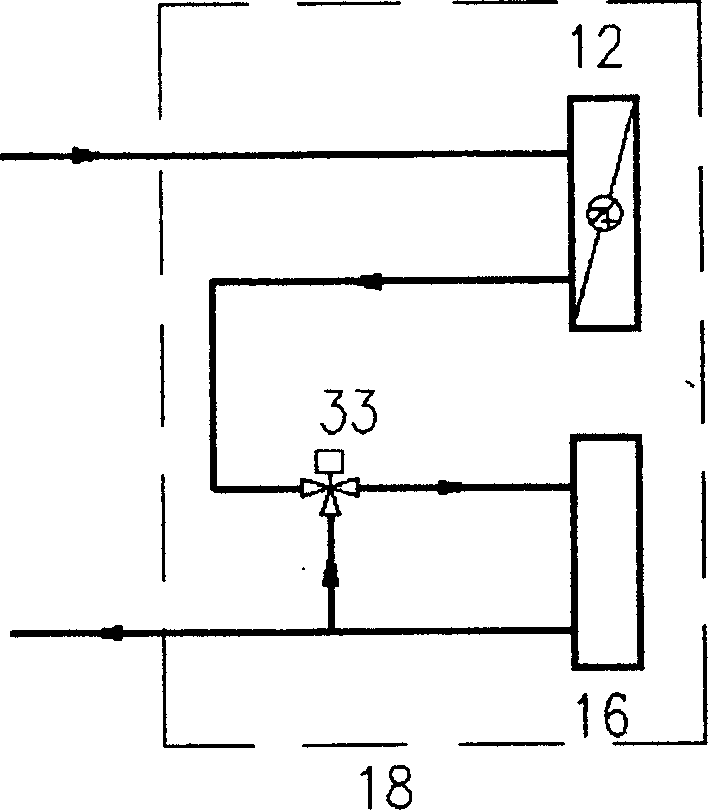

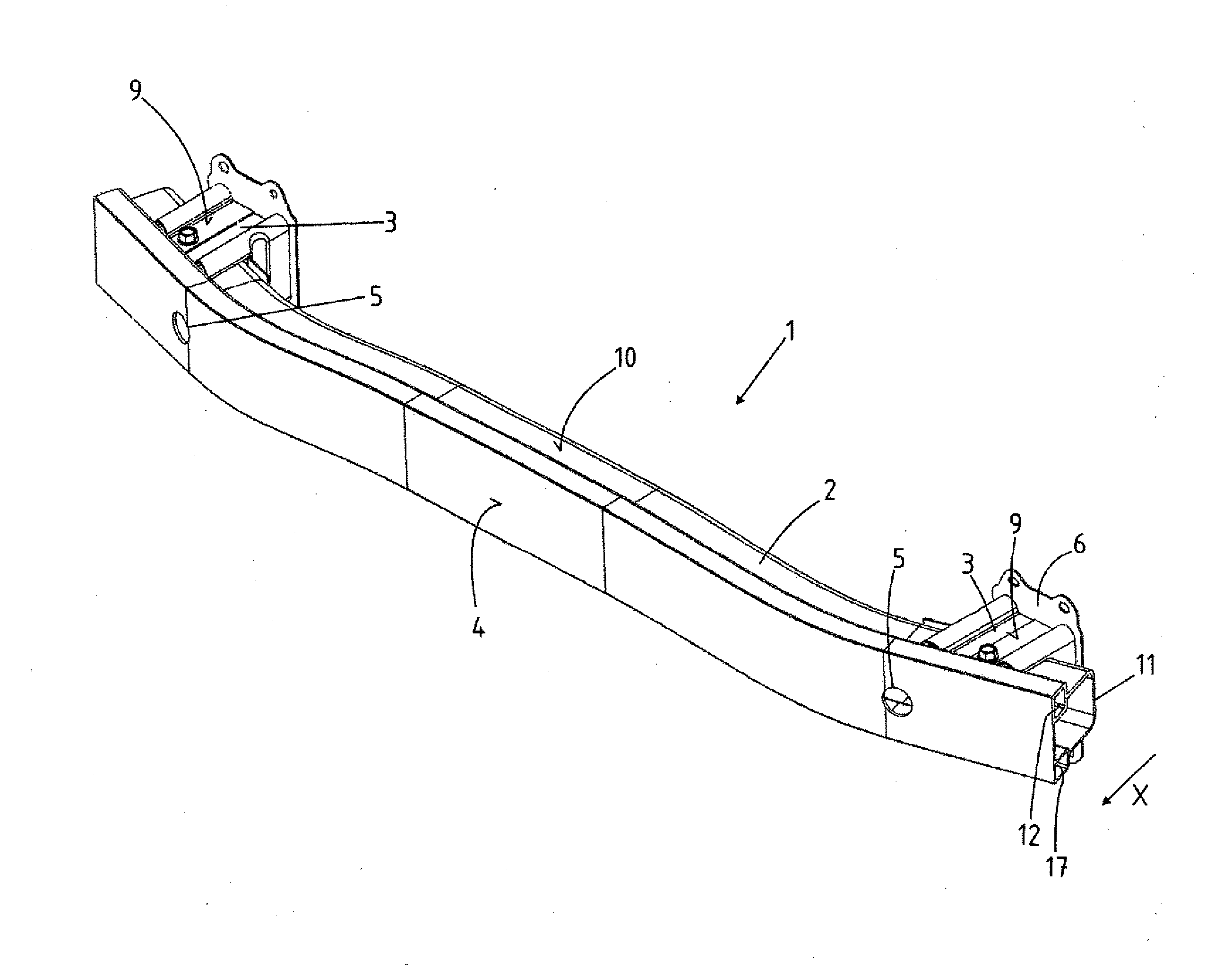

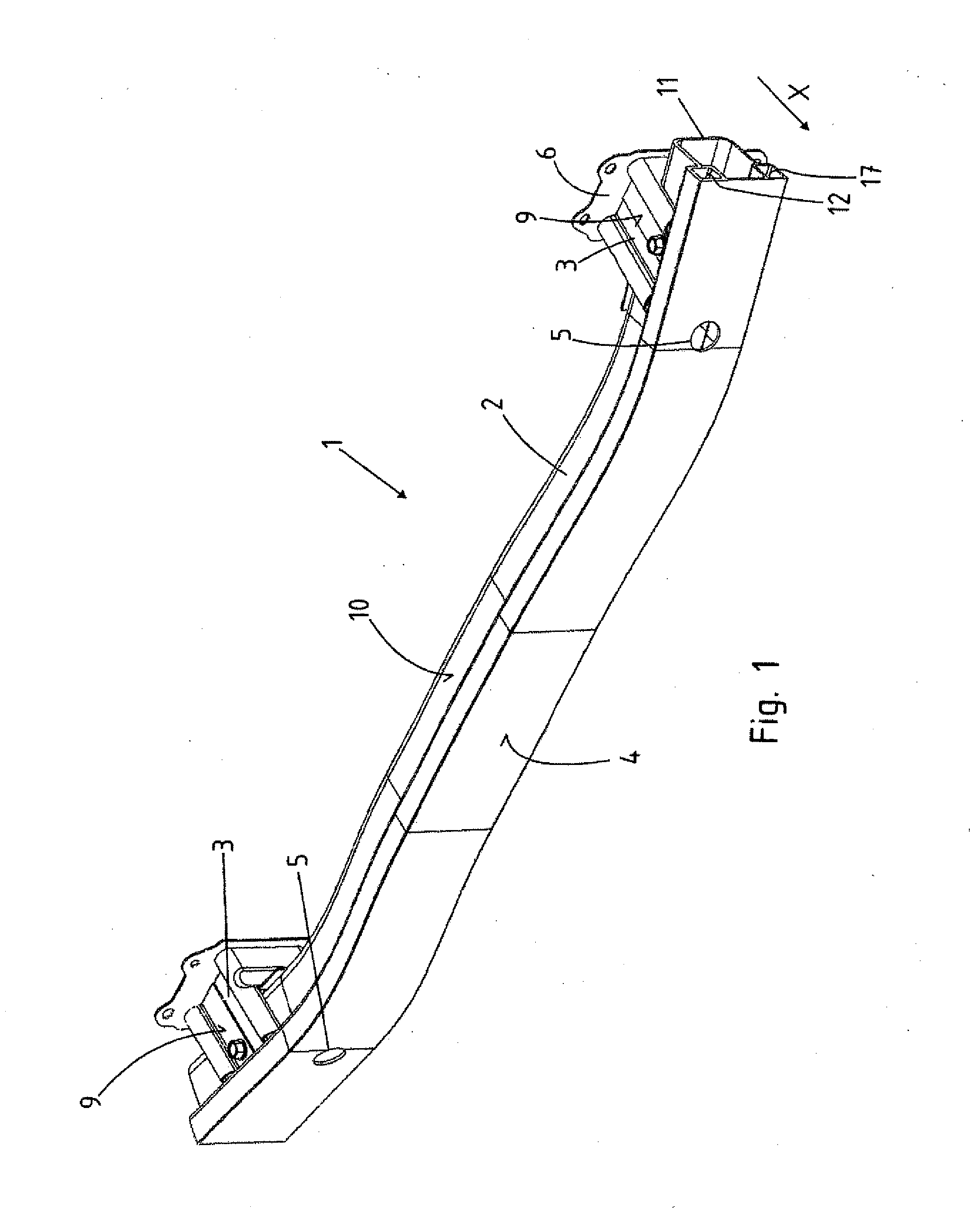

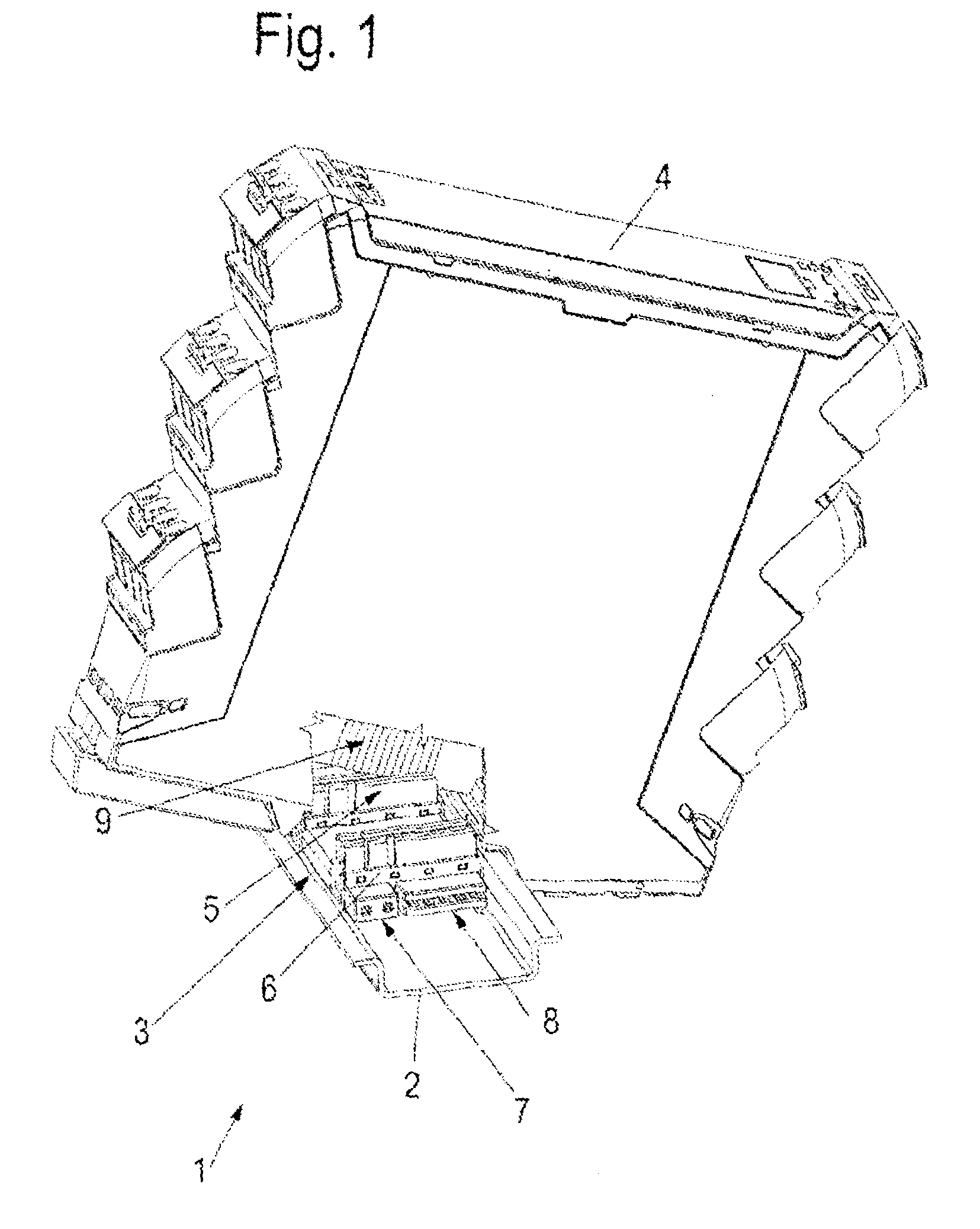

Windscreen wiper device, in particular for a motor vehicle

InactiveUS8117710B2Save building spaceSecurely holdFurniture joining partsWindowsMobile vehicleMotor vehicle part

The invention relates to a windshield wiper device (10), in particular for a motor vehicle, comprising a support (12), on which a bearing (18) is arranged, which supports a wiper shaft (22). In this case, a retaining element (20) is provided, which detachably connects the bearing (18) to the support.

Owner:ROBERT BOSCH GMBH

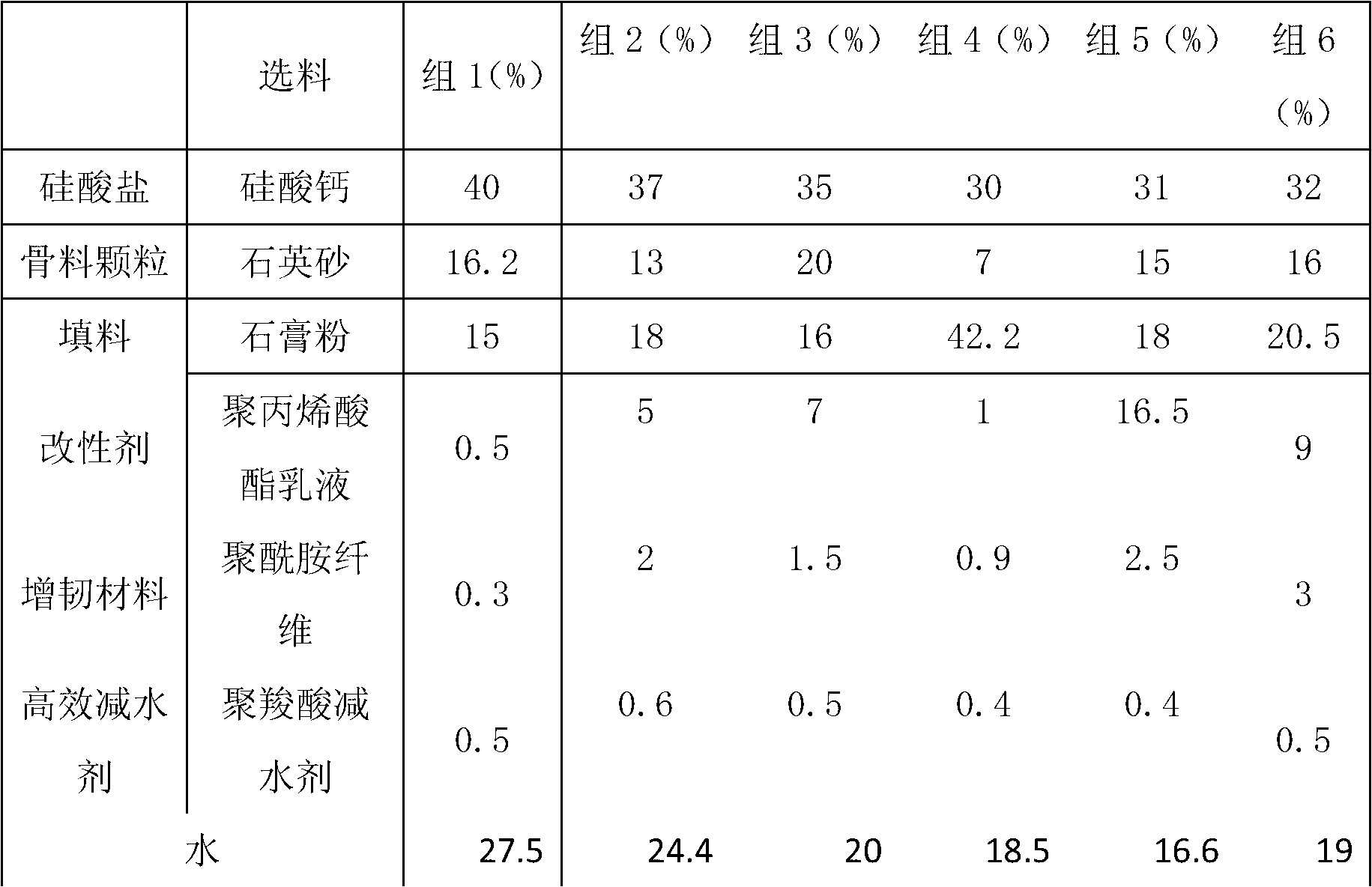

Building finish material, composite raw material and dosage proportion

InactiveCN102701641ALighten the loadFlexible and lightConstruction engineeringStructural engineering

The invention relates to a building finish material, in particular to composite a raw material and the dosage proportion of the building finish material as well as flexible plates and building decorative plates made of the building finish material. The building plates made of the building finish material has the characteristics of light weight, thinness, flexibility, and good adhesion to a wall body.

Owner:CHONGQING LONGZHE HIGH TECH MATERIAL

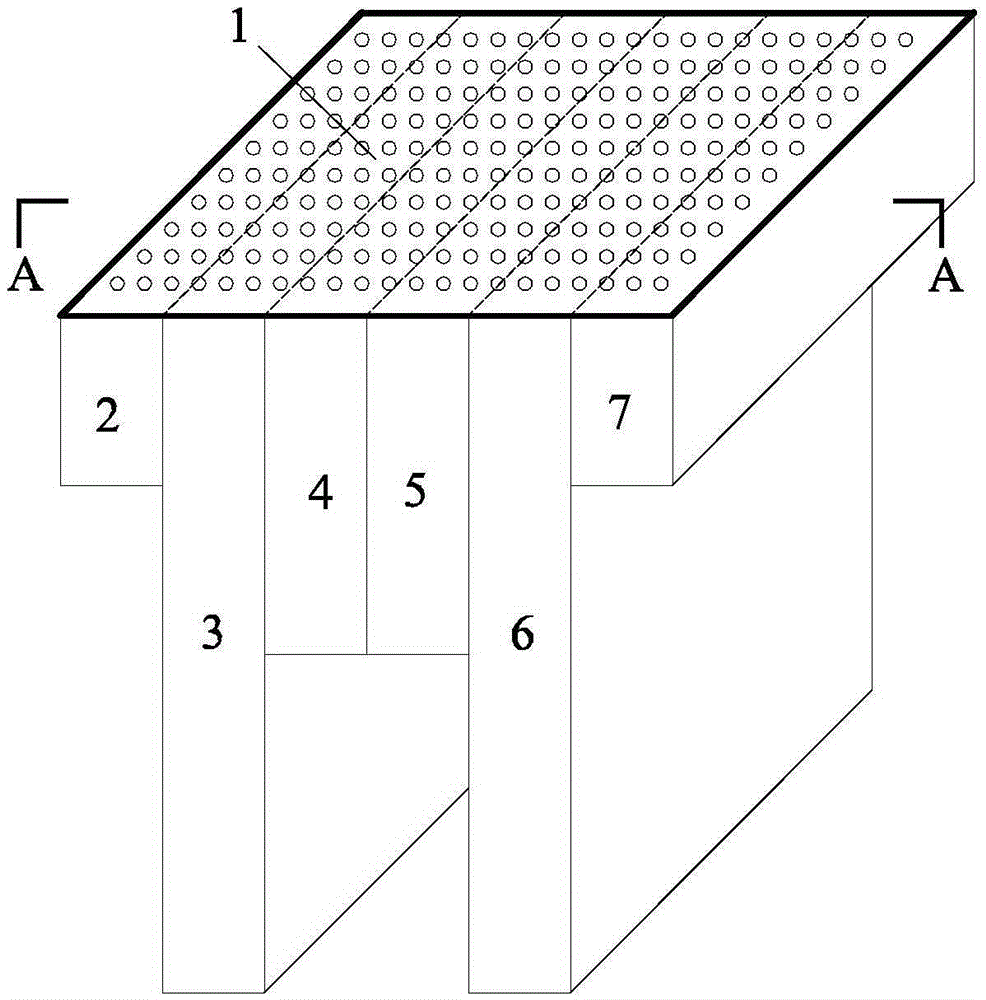

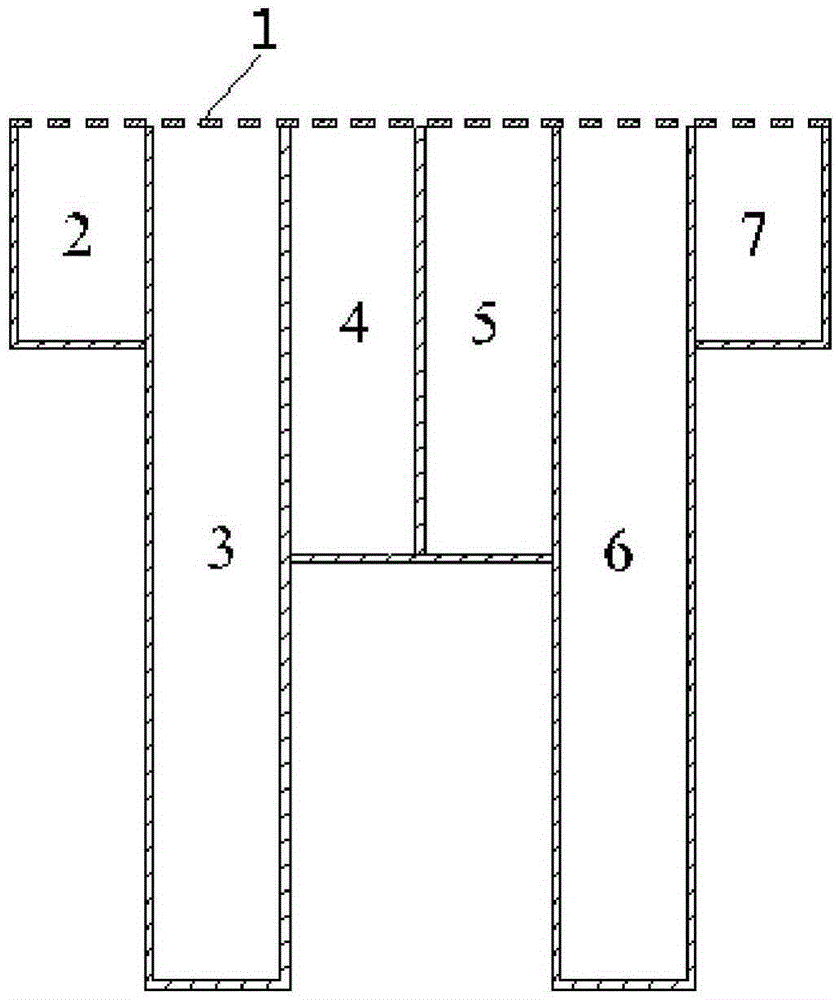

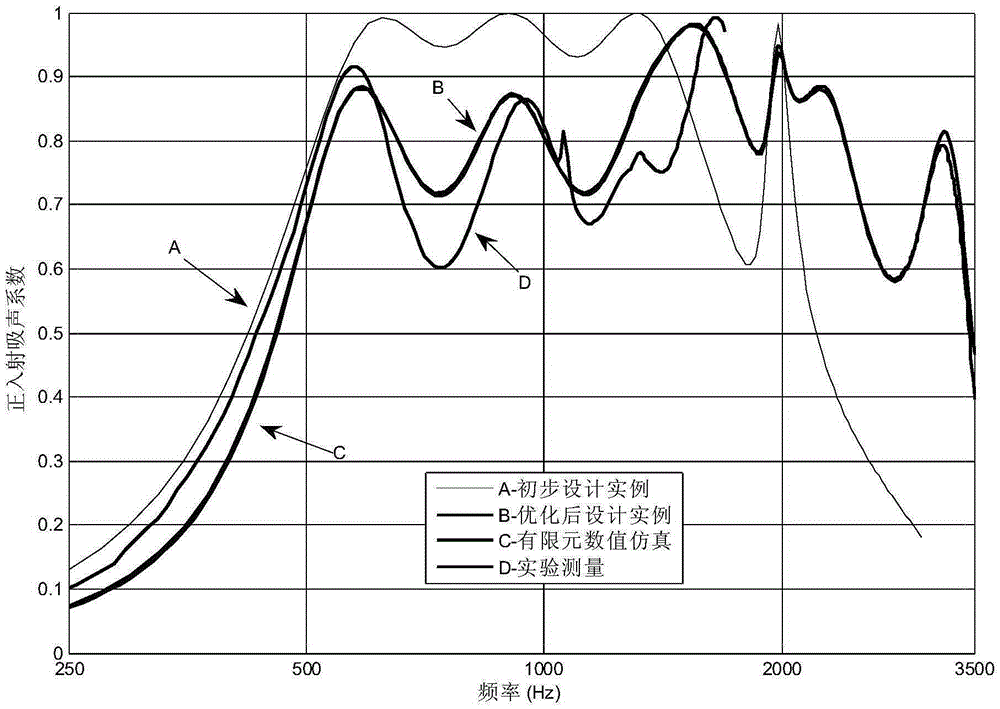

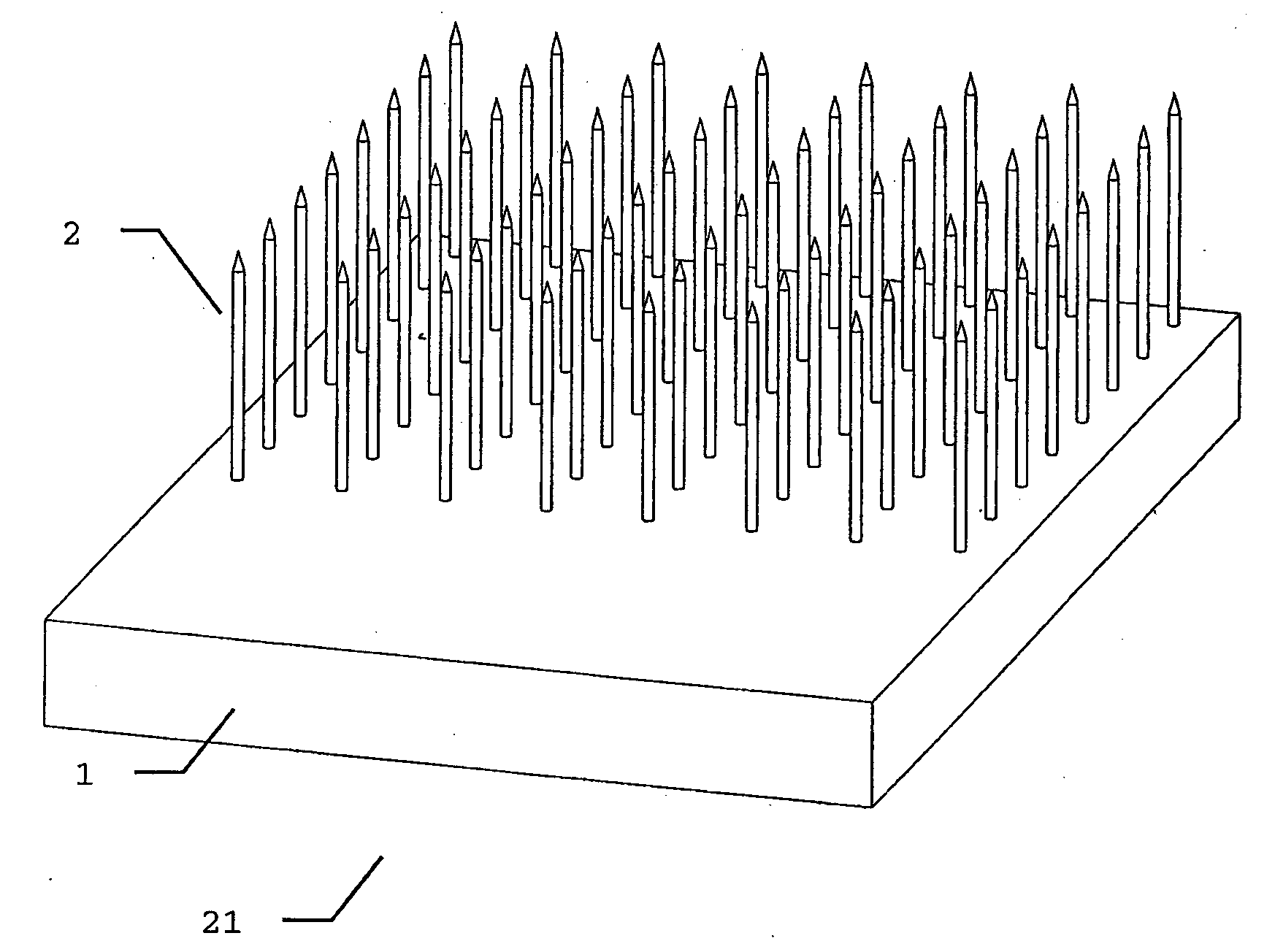

Broadband micro-perforated board sound absorber, absorber performance prediction method and absorber structure design method

ActiveCN105427853AHigh performance sound absorptionSave installation spaceGeometric CADSound producing devicesFrequency spectrumEngineering

The invention discloses a broadband micro-perforated board sound absorber, a sound absorber performance prediction method and a sound absorber structure design method. The sound absorber comprises a surface micro-perforated board and a back chamber with unequal periodicity depth, and the back chamber is used for expanding sound absorption bandwidth of the sound absorber. The performance prediction method is used for predicting a sound absorption coefficient frequency spectrum of the sound absorber, through finite element simulation and experiment measurement verification, the performance prediction method is accurate and reliable; the structure design method used for effectively realizing the broadband micro-perforated board sound absorber comprises steps that (1), a depth matrix of the periodic back chamber is designed on the basis of the secondary residual sequence combination arrangement theory; and (2), evaluation is realized on the basis of the performance prediction method, combination of parameters of the sound absorber are sequentially determined, including total sound absorber width of the periodic back chamber, depth of each sub back chamber, board thickness of the micro-perforated board, aperture and perforated percentage. Through the sound absorber performance prediction method and the sound absorber structure design method, the micro-perforated board sound absorber having the broadband sound absorption performance can be accurately, reliably and simply designed.

Owner:SOUTHEAST UNIV

Biostable Neuroelectrode

ActiveUS20110106229A1Conducive to stable operationReduce power consumptionHead electrodesSensorsNeurophysiologyElectric signal

The invention relates to a device for deriving electrical signals or for electrically stimulating neuronal tissue. Neuroelectrodes form an interface between the biological tissue and technical systems. Existing neuroelectrodes for contacting low-lying neuronal layers diminish their properties by the interaction with biological tissue. In order to improve the long-time behavior, neuroelectrodes filled with bioactive substances are used. The neuroelectrode is formed on a flexible or rigid substrate with the aid of a line and of a microcapillary. The inside of the microcapillary serves as a container for the bioactive substance. The biostable neuroelectrode is used for deriving electrical signals or for electrically stimulating neuronal tissue in the fields of neurology and neurophysiology.

Owner:ORTMANN VALERIJ

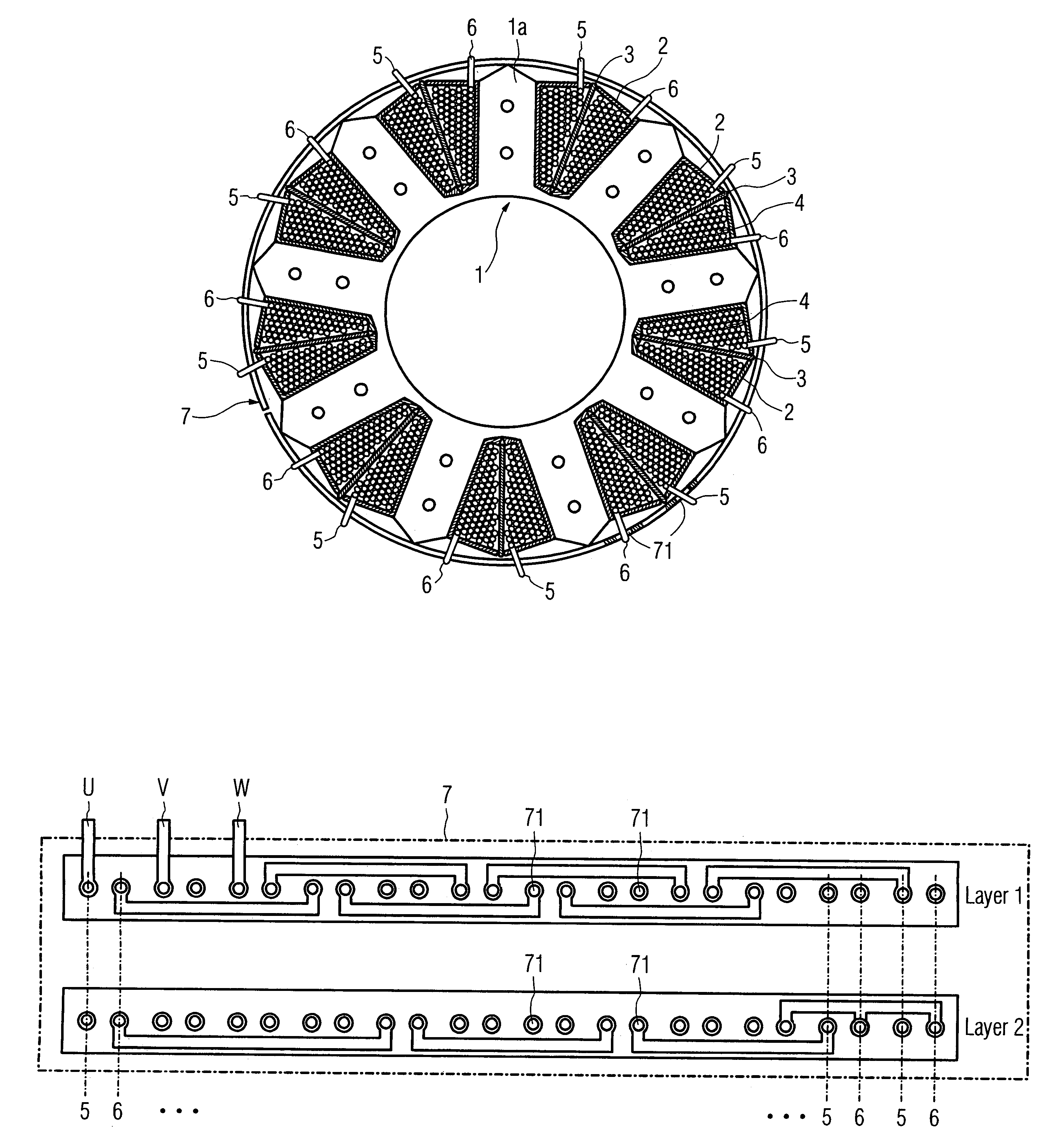

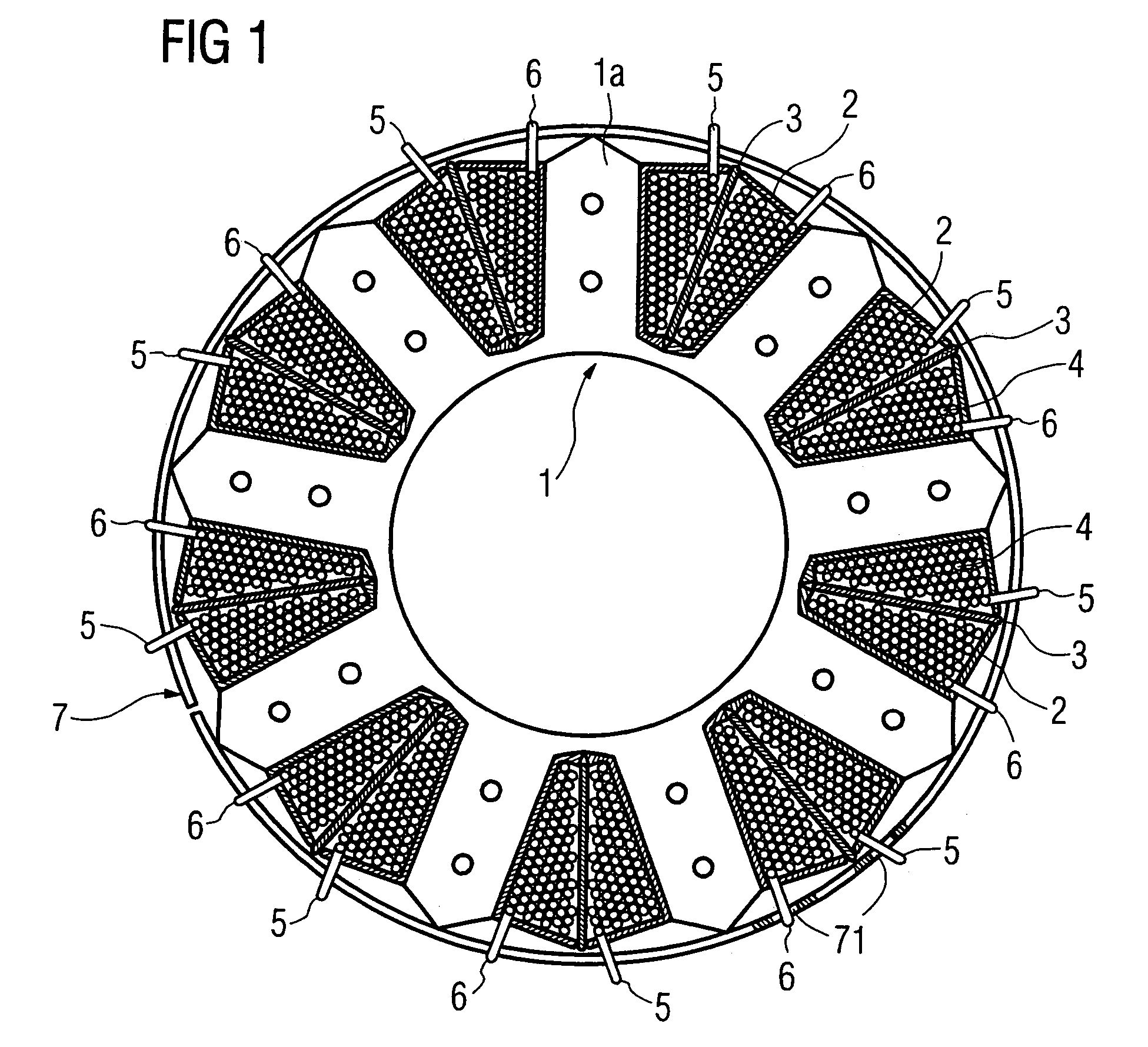

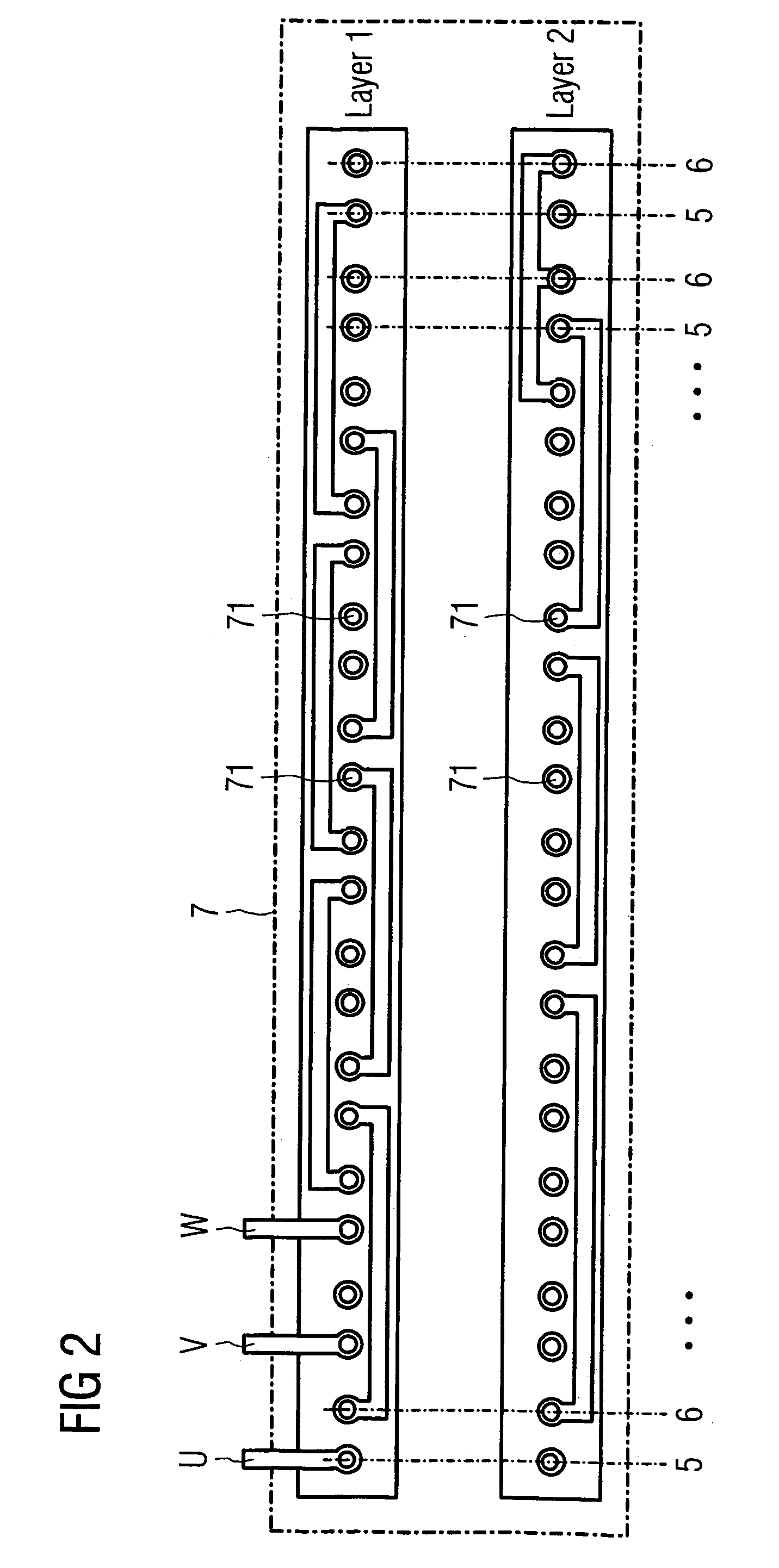

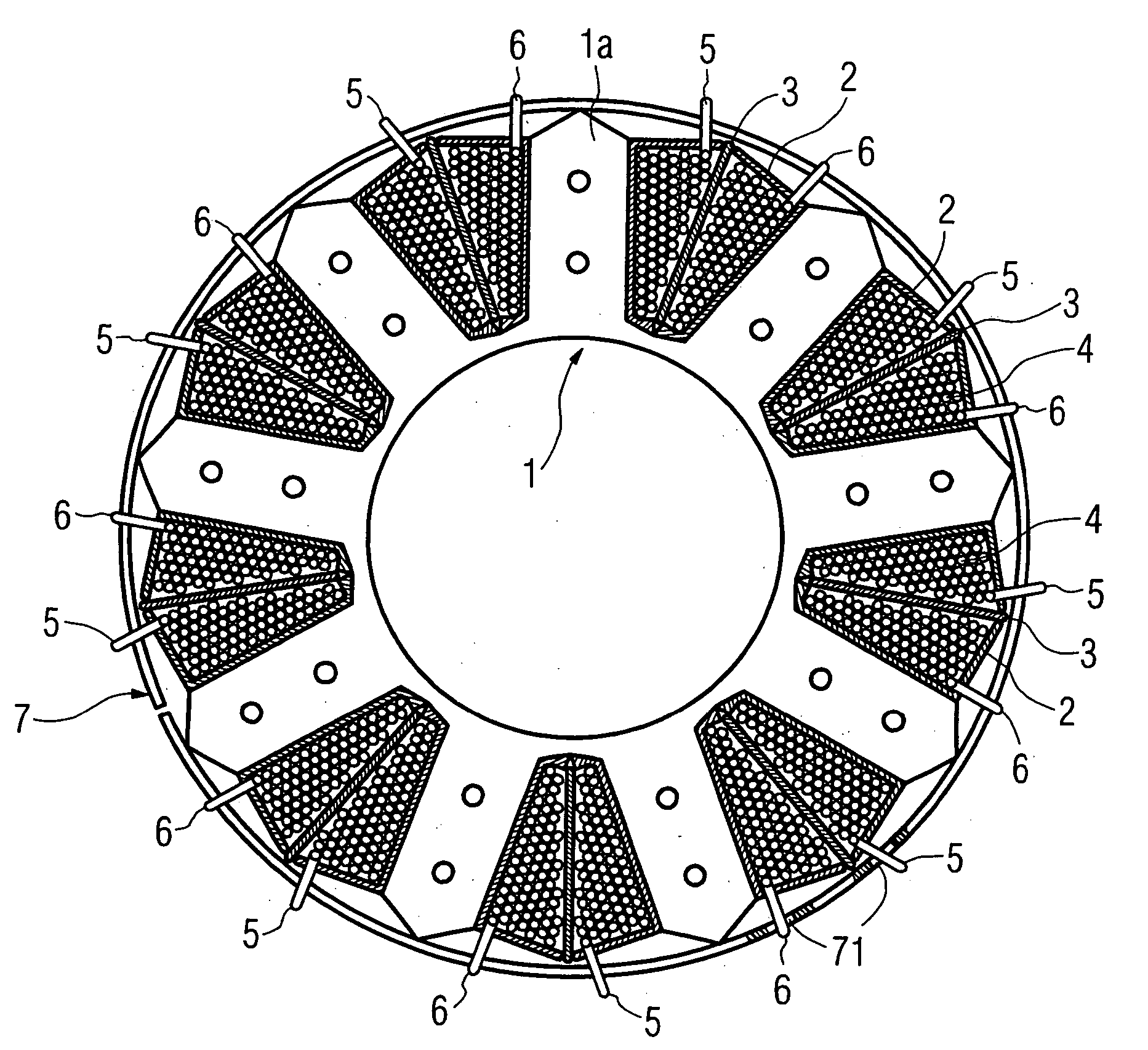

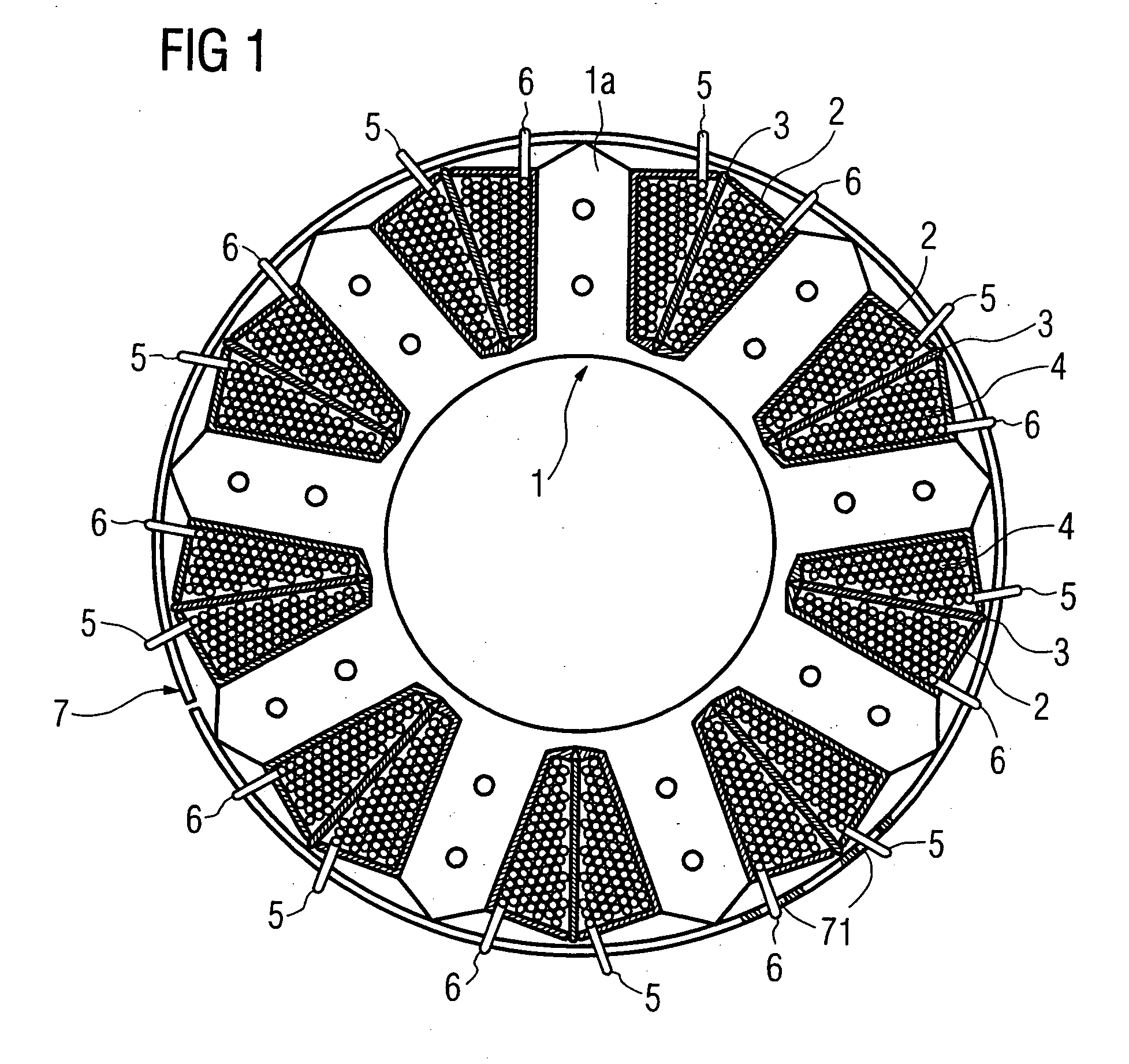

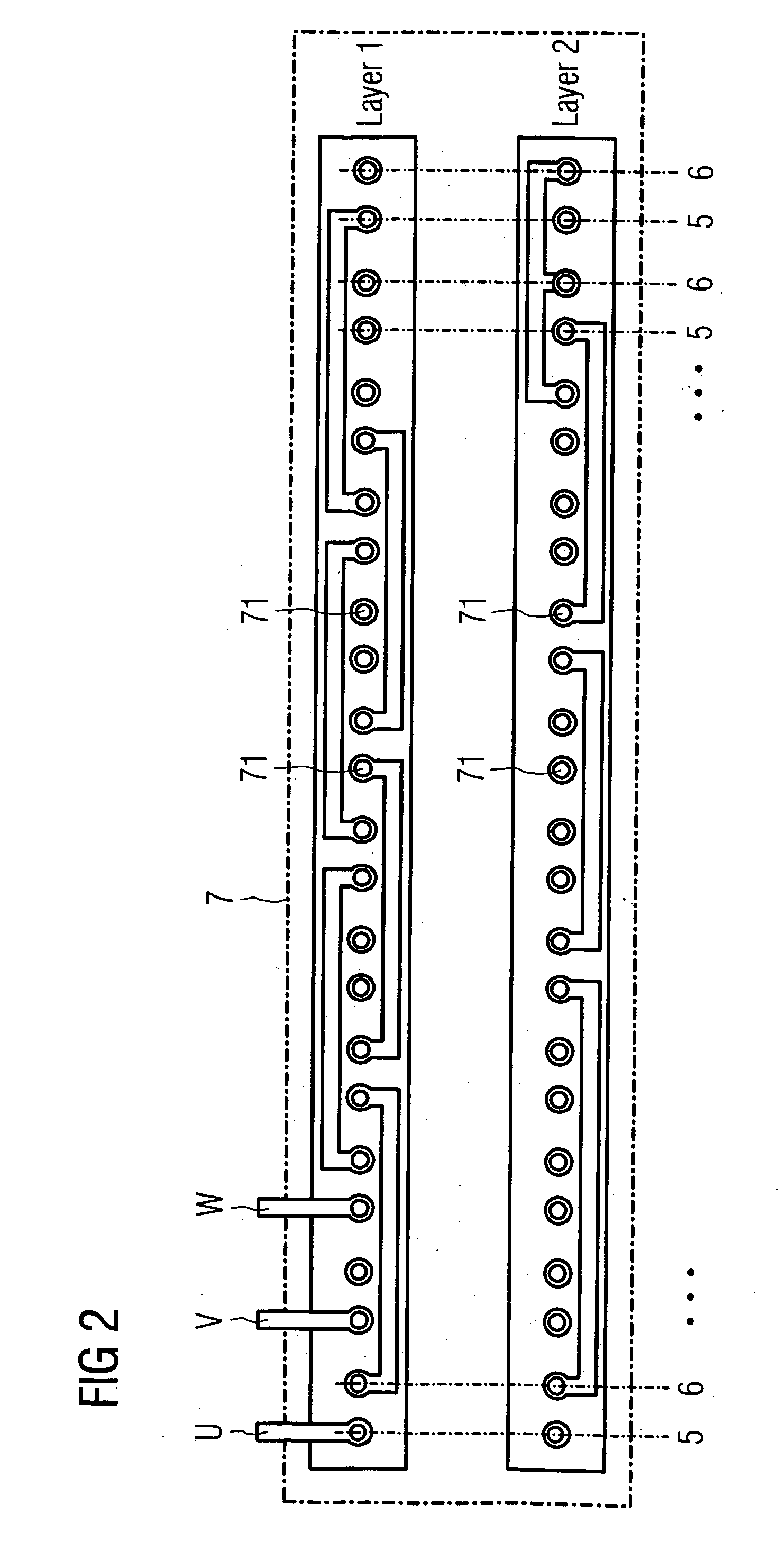

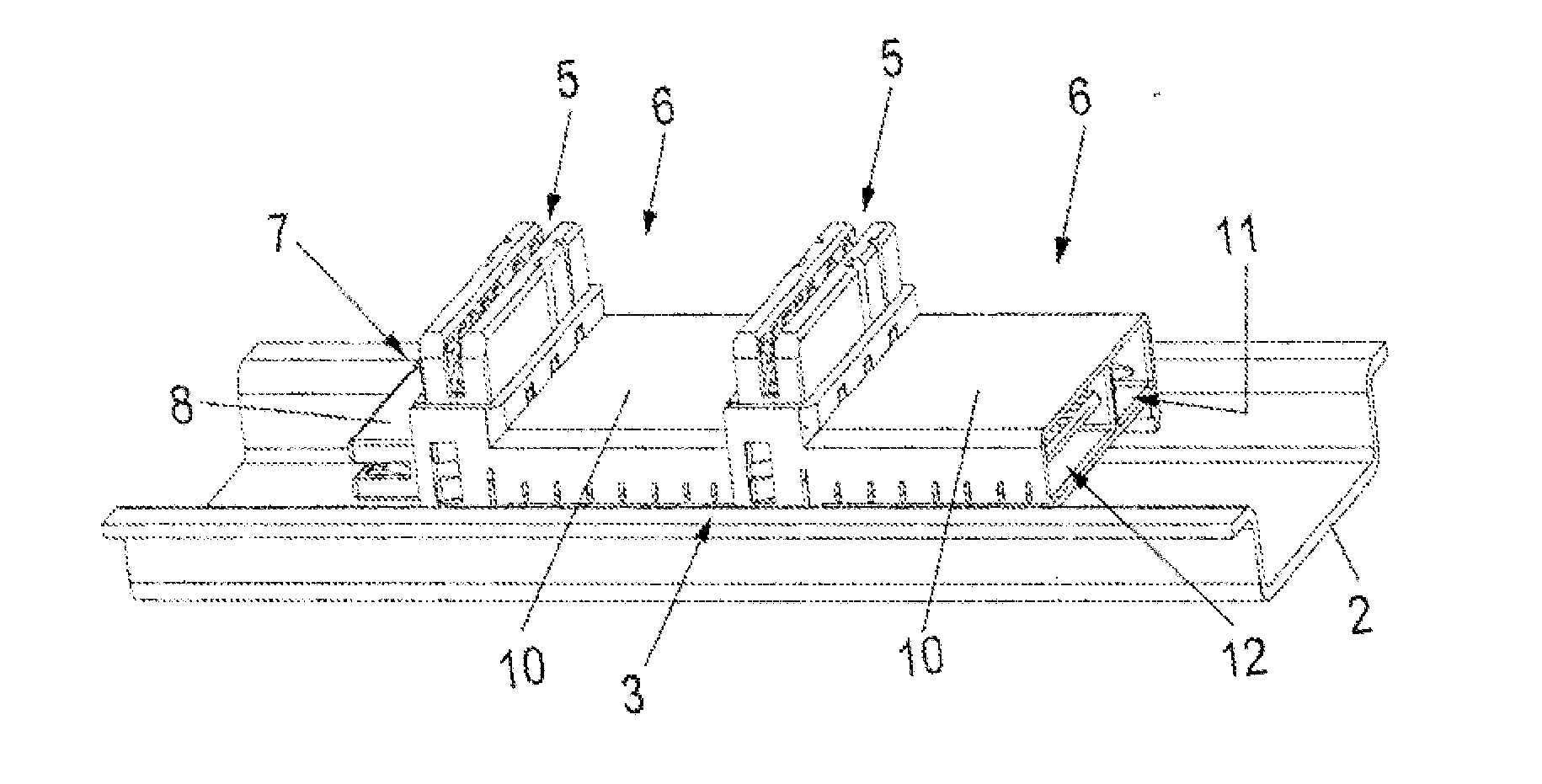

Electric machine with a circuit board for wiring lines of a winding system

InactiveUS7202582B2Easy to assembleSave building spacePrinted circuit assemblingWindingsWind systemElectric machine

An electric machine includes a stator having a plurality of slots and a winding system having windings placed in the slots. The windings of the winding system are interconnected by at least one flexible circuit board which is constructed for attachment to a radial surface area of the stator and for connection to the windings.

Owner:SIEMENS AG

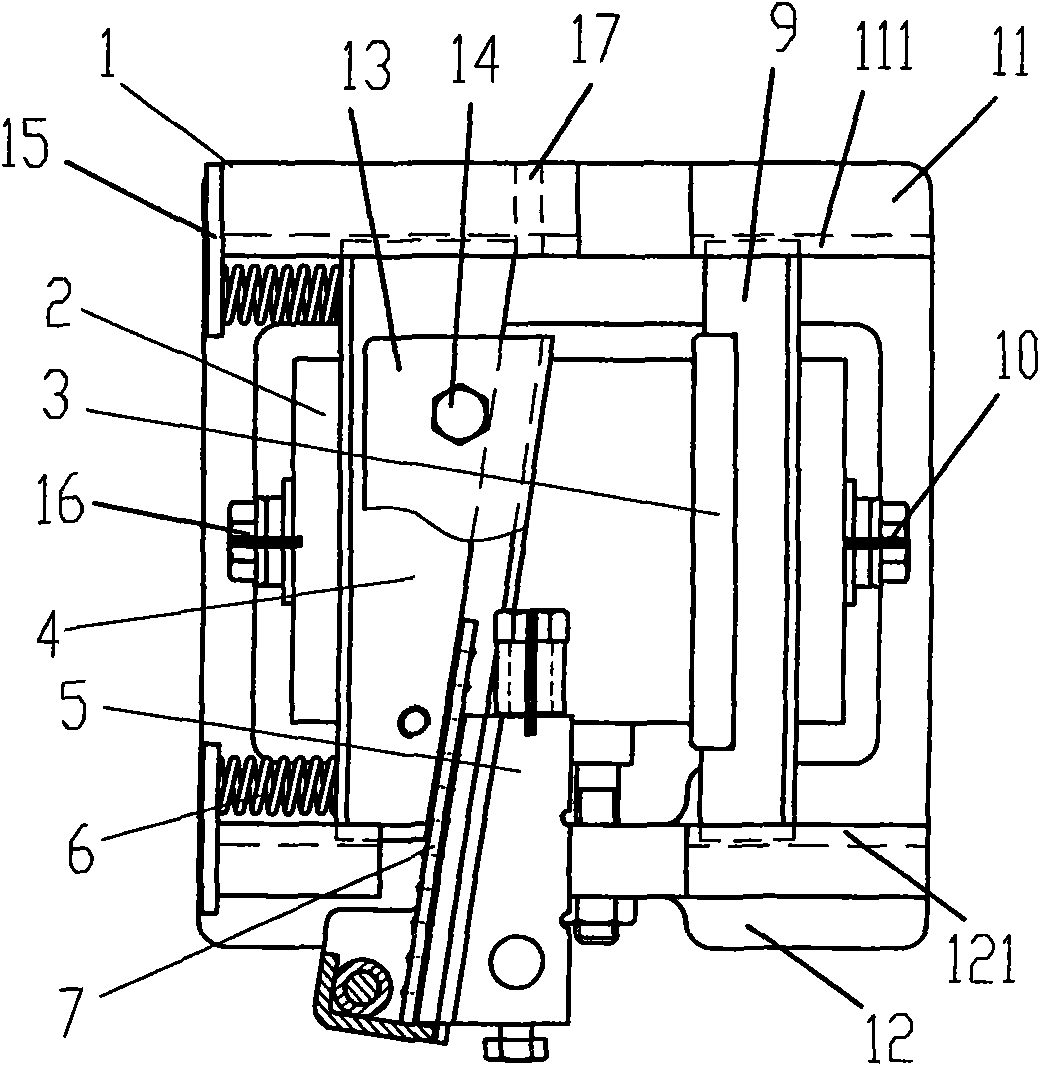

Asymmetric progressive safety gear

The invention relates to an asymmetric progressive safety gear, a gear body thereof is arranged at a car or a counterweight of an elevator, a guide track passes through the gear body, the guide track is taken as the boundary, a sliding block is inserted between the upper side and the lower side of the gear body on one side in a sliding manner, a friction plate is arranged on the inner side surface of the sliding block, the inner side surface of the friction plate is parallel to the guide track, and a spacing is kept; the sliding block is fixedly connected with one end of a U-shaped leaf spring; a moving wedge block is inserted between the upper side and the lower side at the other side of the gear body in a sliding manner, a pressing plate with a tilted inner side surface is respectively fixedly connected on the inside and the outside of the moving wedge block, and the moving wedge block is fixedly connected with the other end of the U-shaped leaf spring; a roller row is arranged between the moving wedge block and a sliding wedge block, the inner side surface is parallel to the guide track of the elevator, and a spacing is kept; the sliding wedge block is fixedly connected with a transmission mechanism, the transmission mechanism is controlled by a speed limiter to act; and a reset part is arranged between the moving wedge block and / or the sliding block and the gear body. The asymmetric progressive safety gear can prevent the transverse movement of the elevator car when the car or the counterweight of the elevator stops working, the size is small and the weight is light.

Owner:HANGZHOU HUNING ELEVATOR PARTS CO LTD

Electric machine with a circuit board for wiring lines of a winding system

InactiveUS20050194851A1Easy to assembleSave building spacePrinted circuit assemblingWindingsFlexible circuitsWind system

An electric machine includes a stator having a plurality of slots and a winding system having windings placed in the slots. The windings of the winding system are interconnected by at least one flexible circuit board which is constructed for attachment to a radial surface area of the stator and for connection to the windings.

Owner:SIEMENS AG

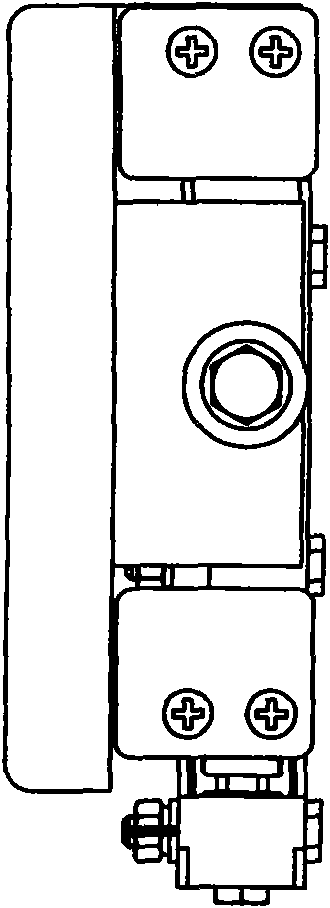

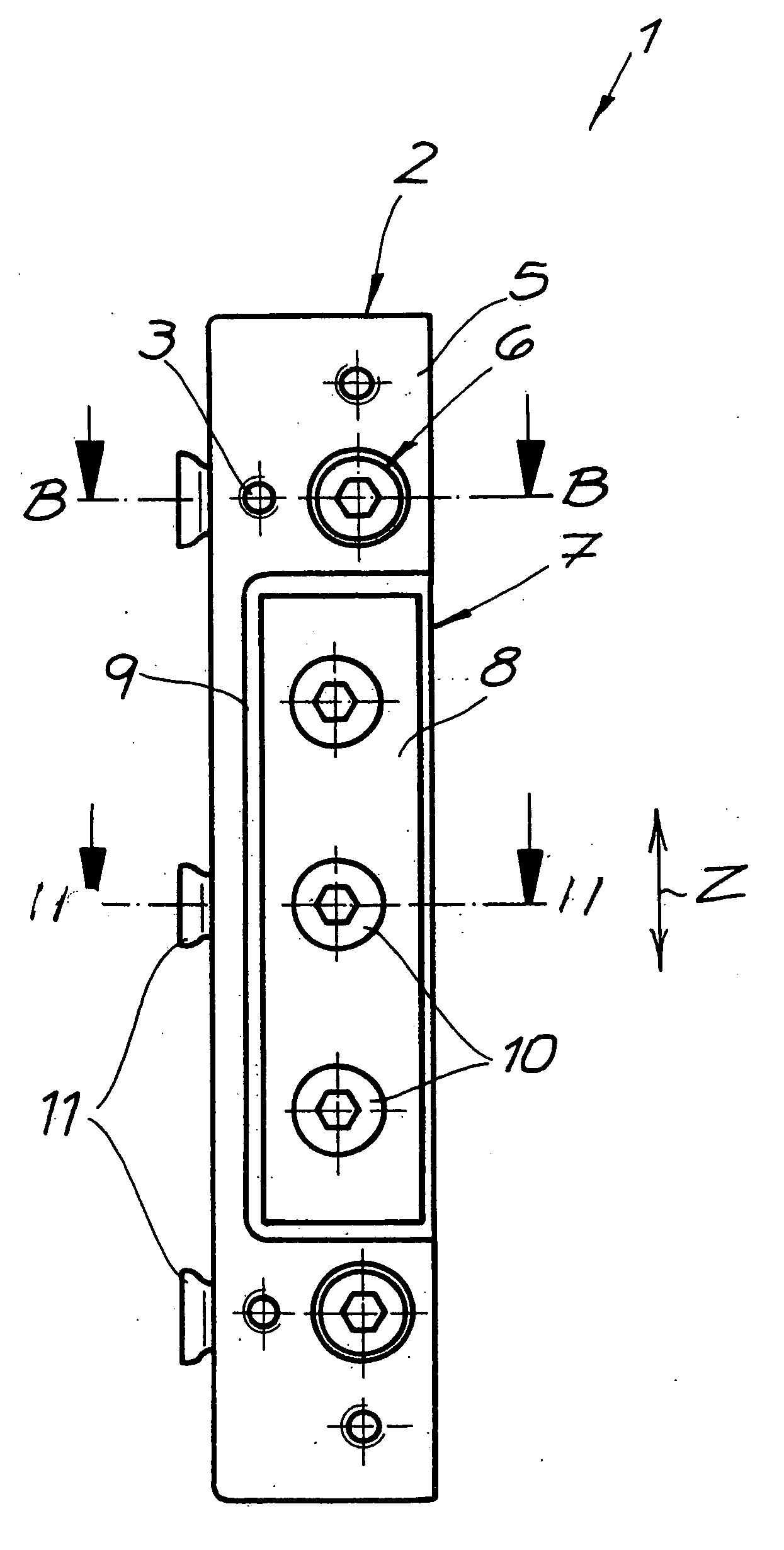

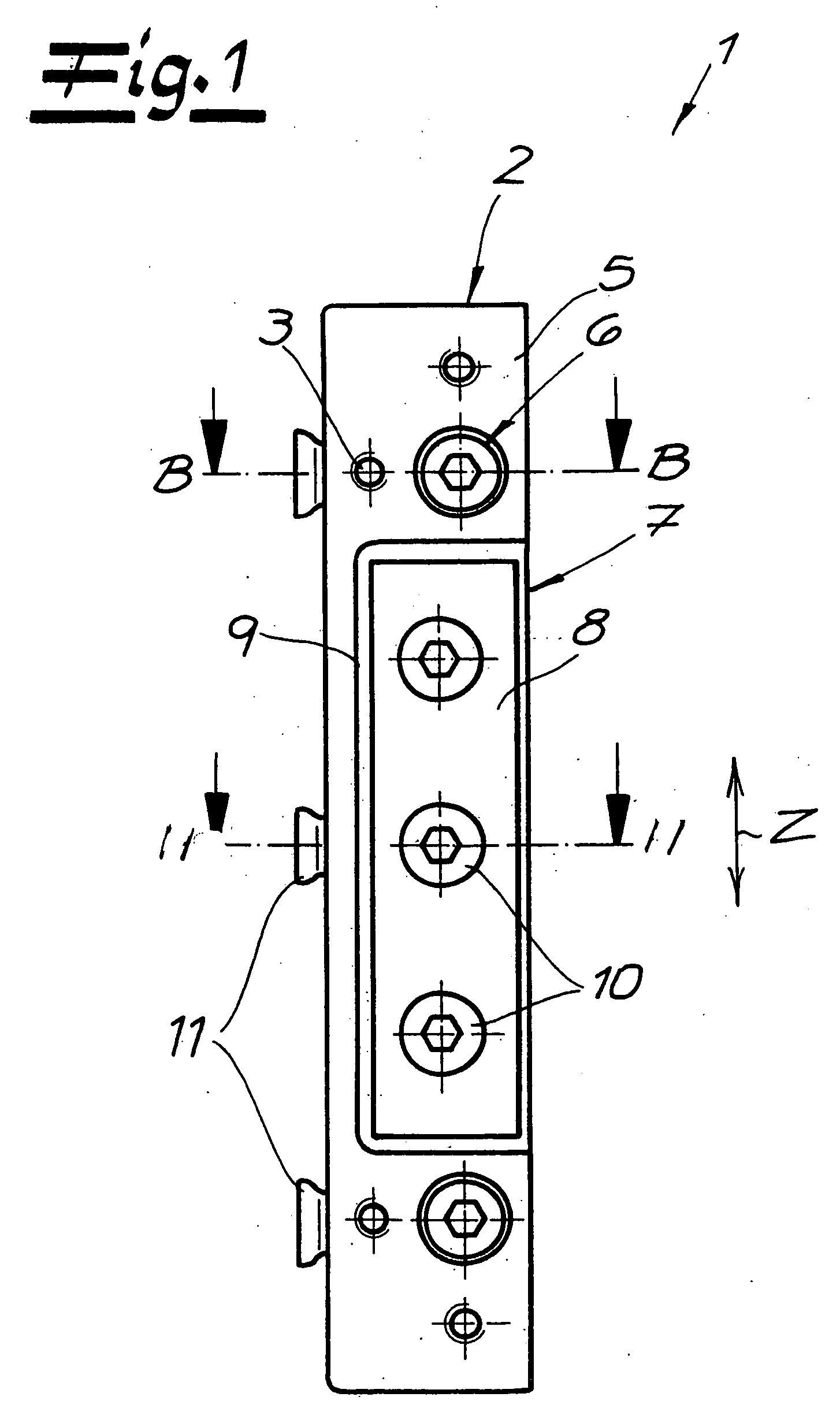

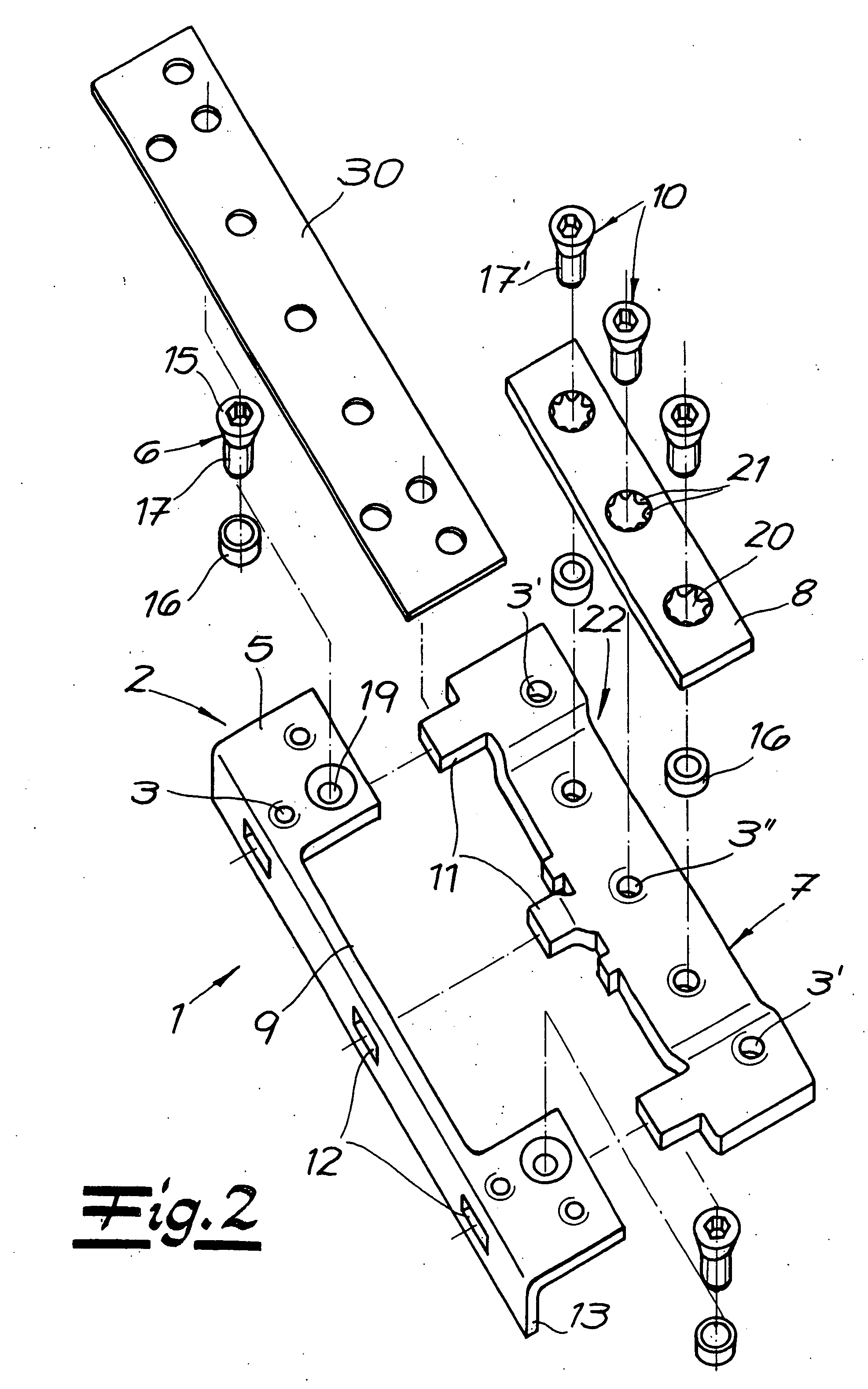

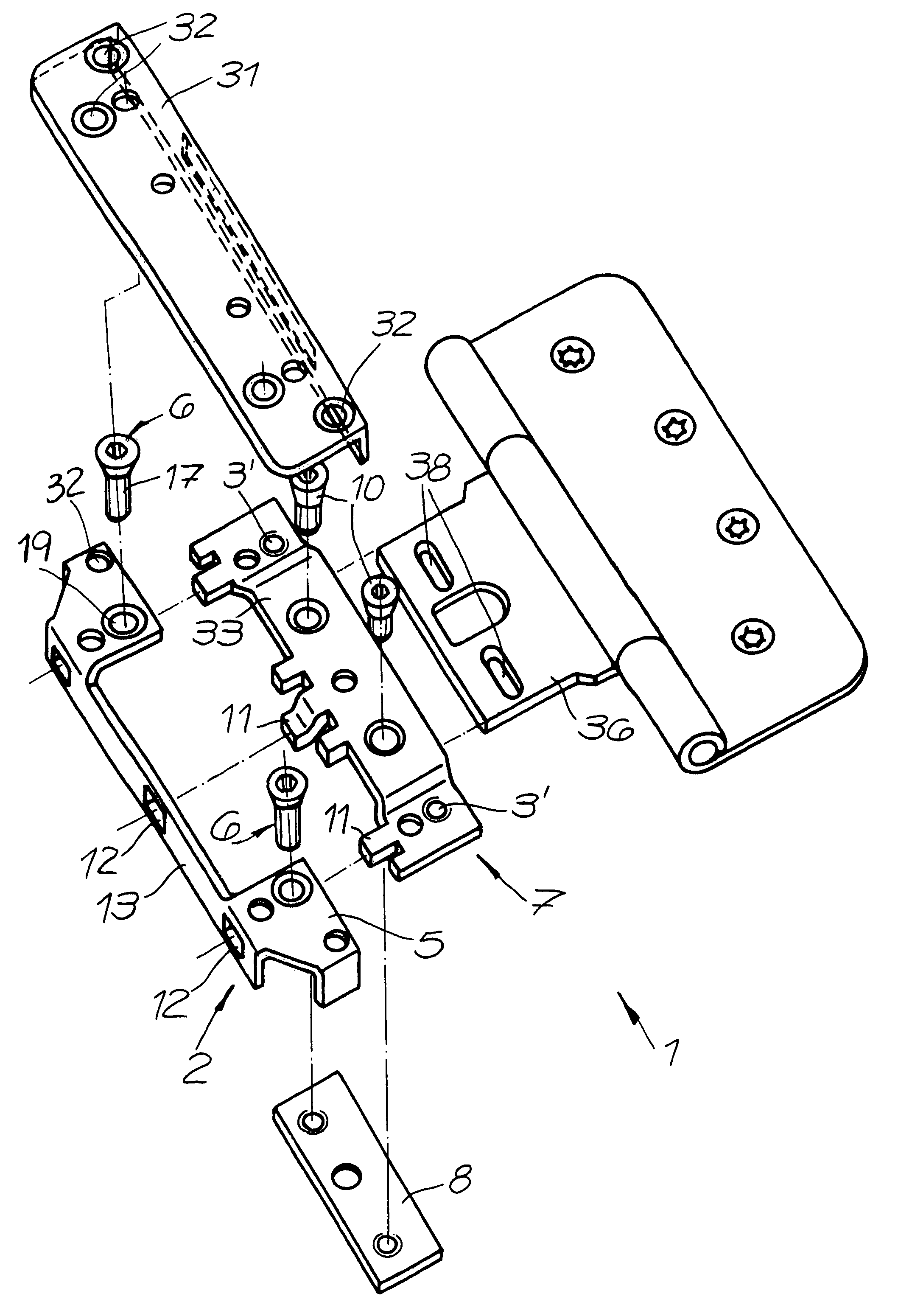

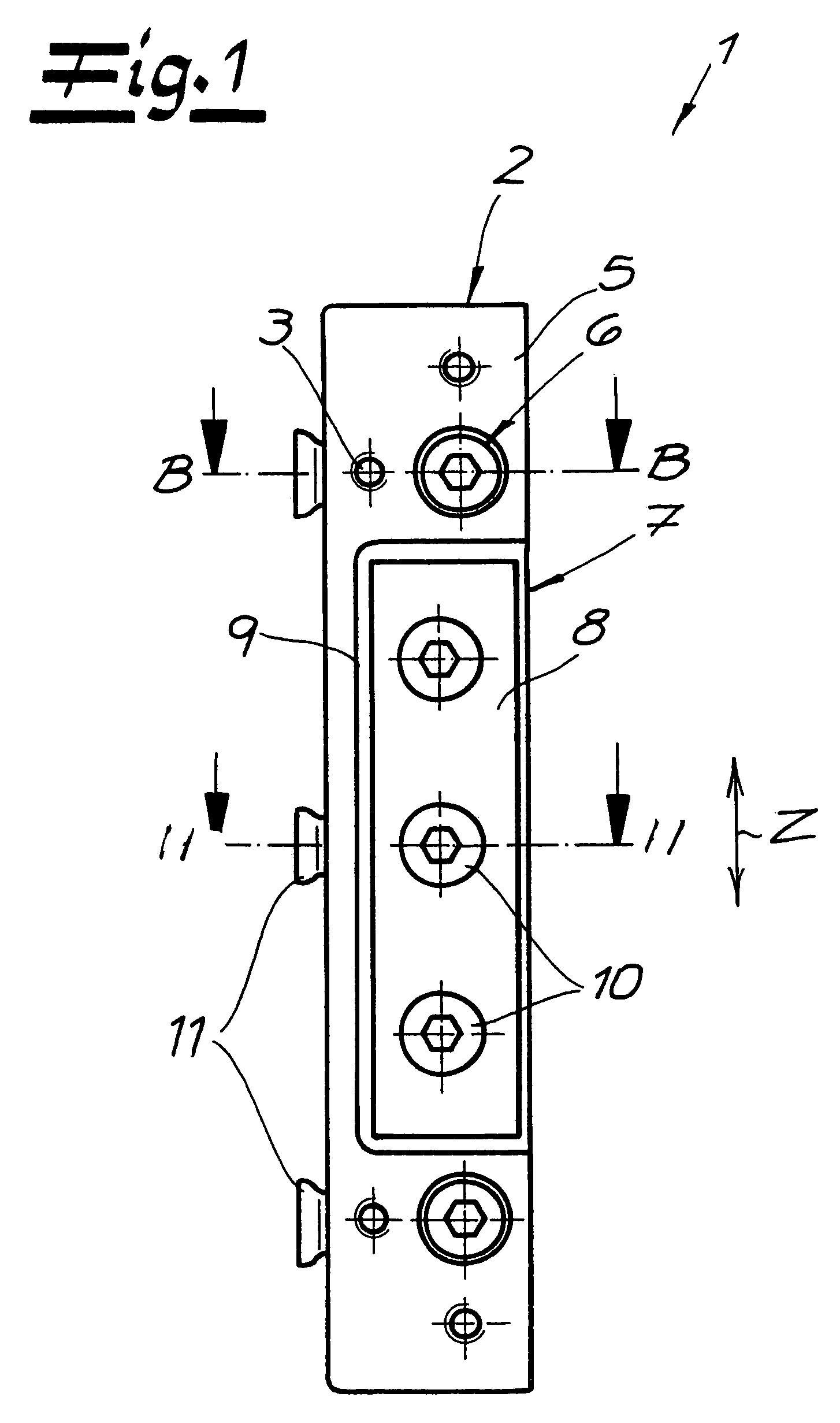

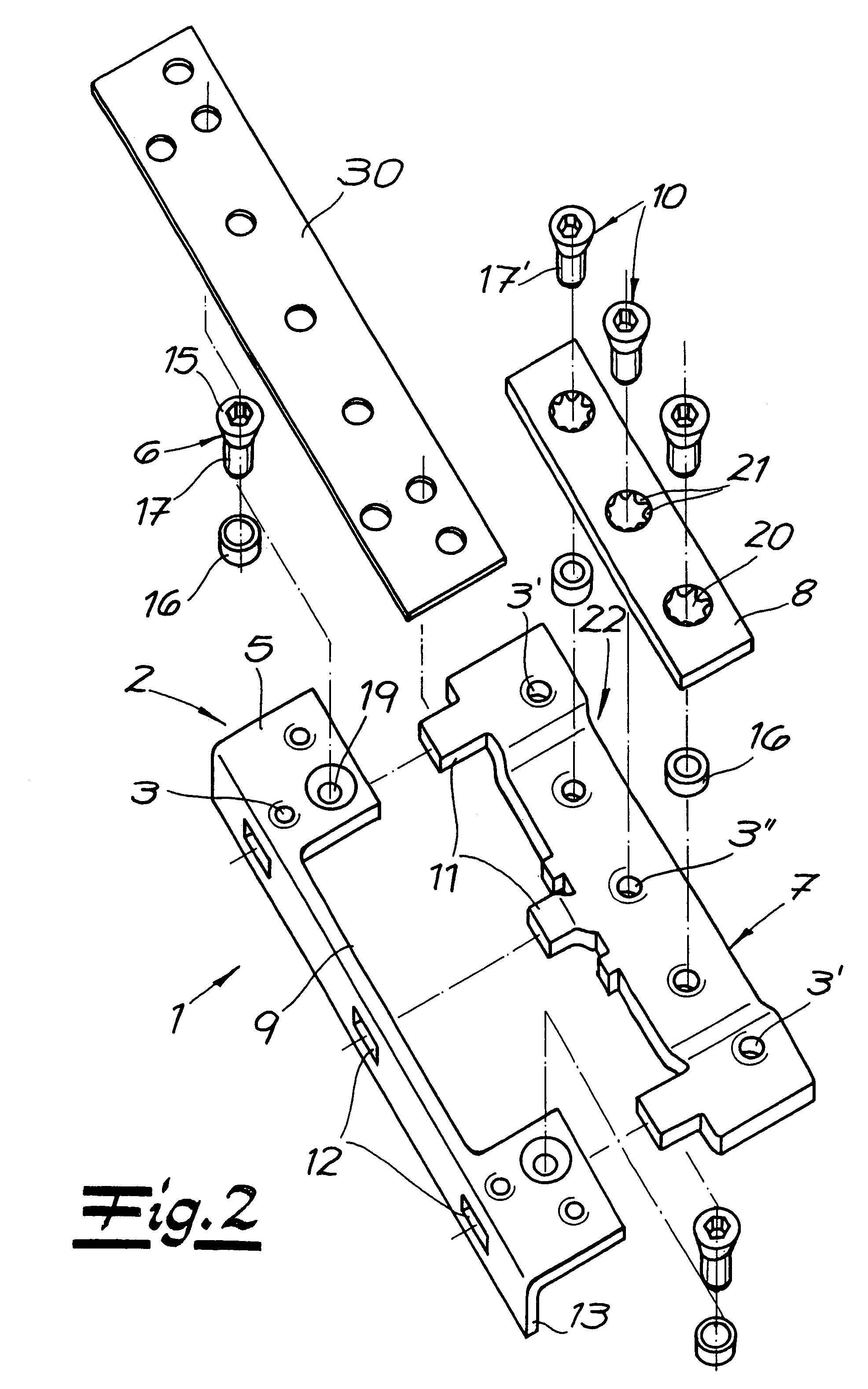

Hinge-plate accommodation element for attaching a hinge plate

InactiveUS20070028420A1Simple designNarrow profilePin hingesMulti-purpose toolsEngineeringBiological activation

A hinge plate accommodation element for attaching a hinge plate has a holder bracket that has a first shank for attachment on the frame side and an angled short shank, a bracing plate that is connected with the short shank of the holder bracket, so as to pivot, a pressure plate that is disposed on the bracing plate with binding screws, and can be adjusted relative to the bracing plate by means of activation of the binding screws, and adjusting screws that are inserted into bores of the holder bracket, so as to rotate, and engage into threaded bores of the bracing plate.

Owner:SIMONSWERK

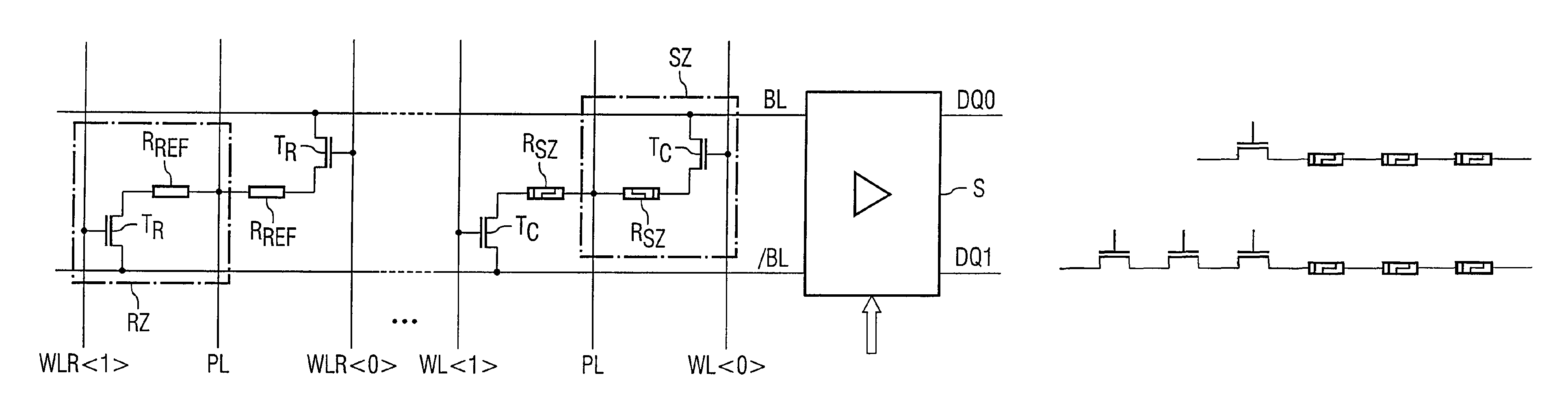

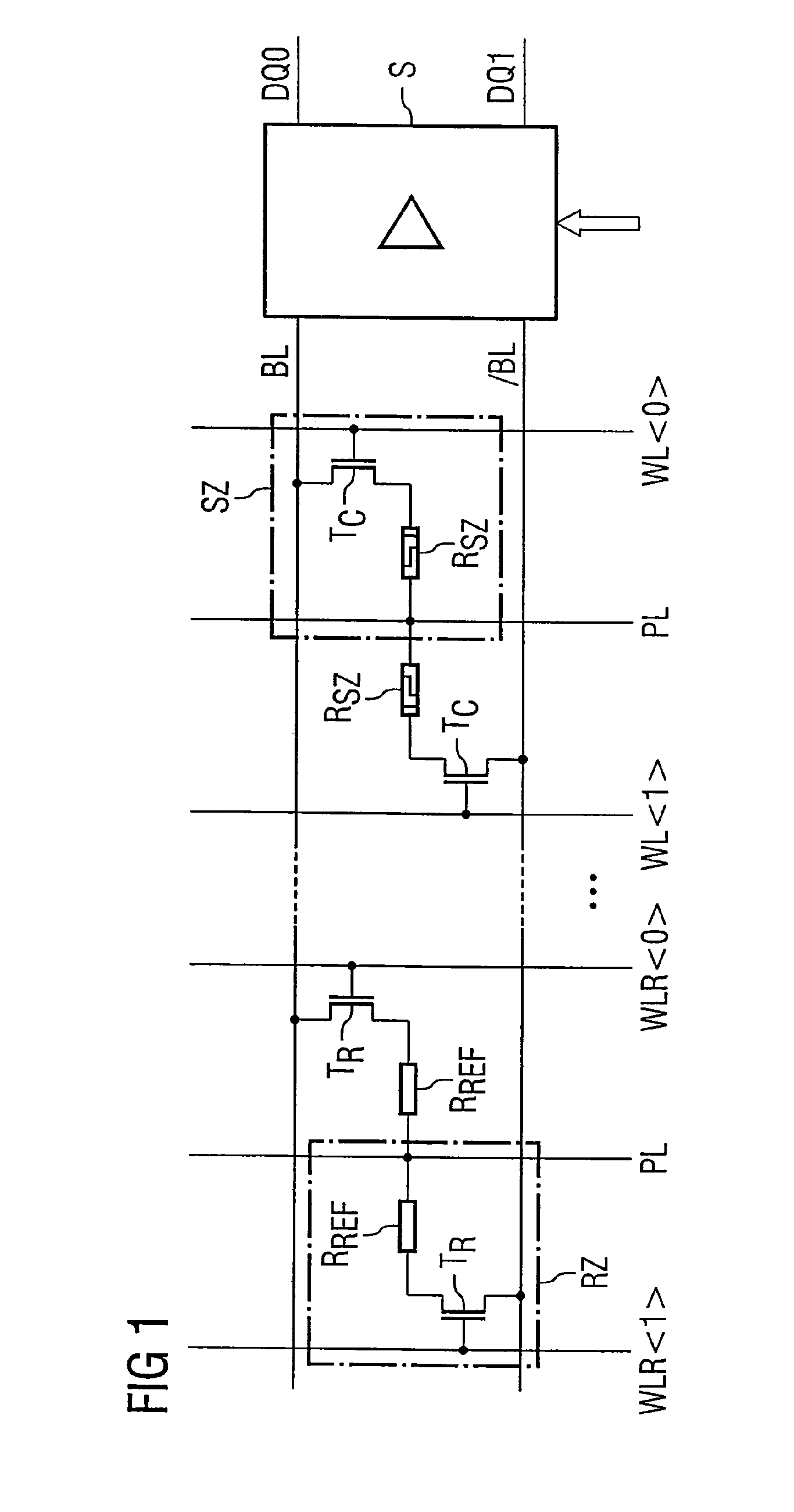

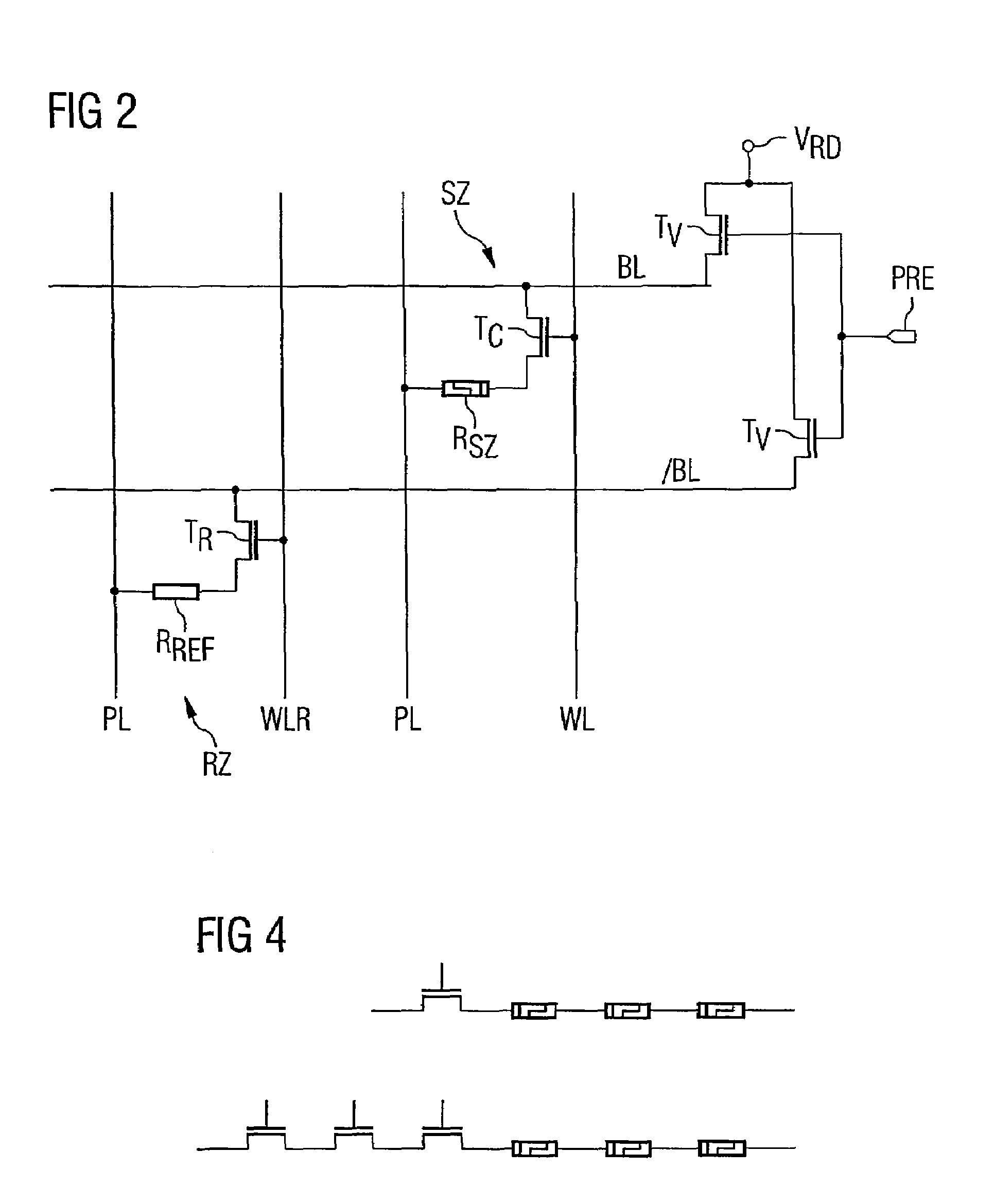

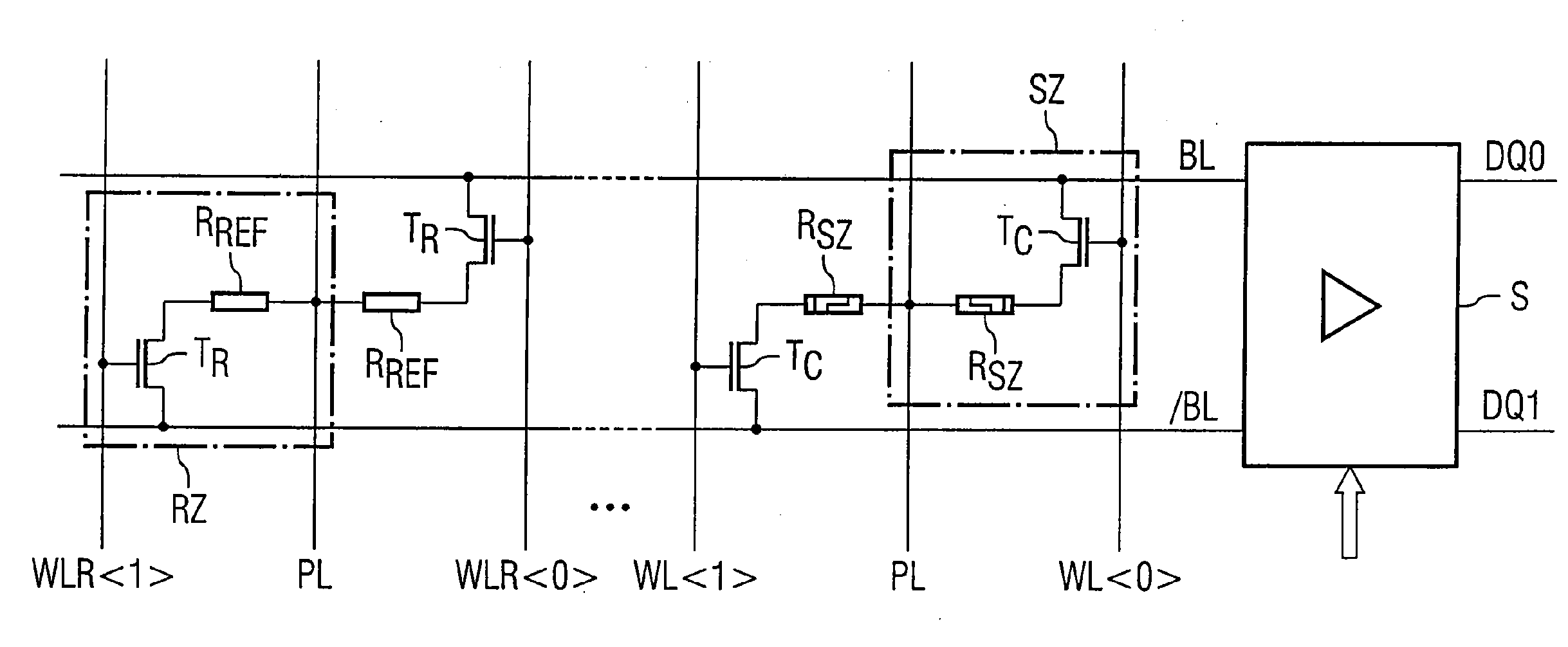

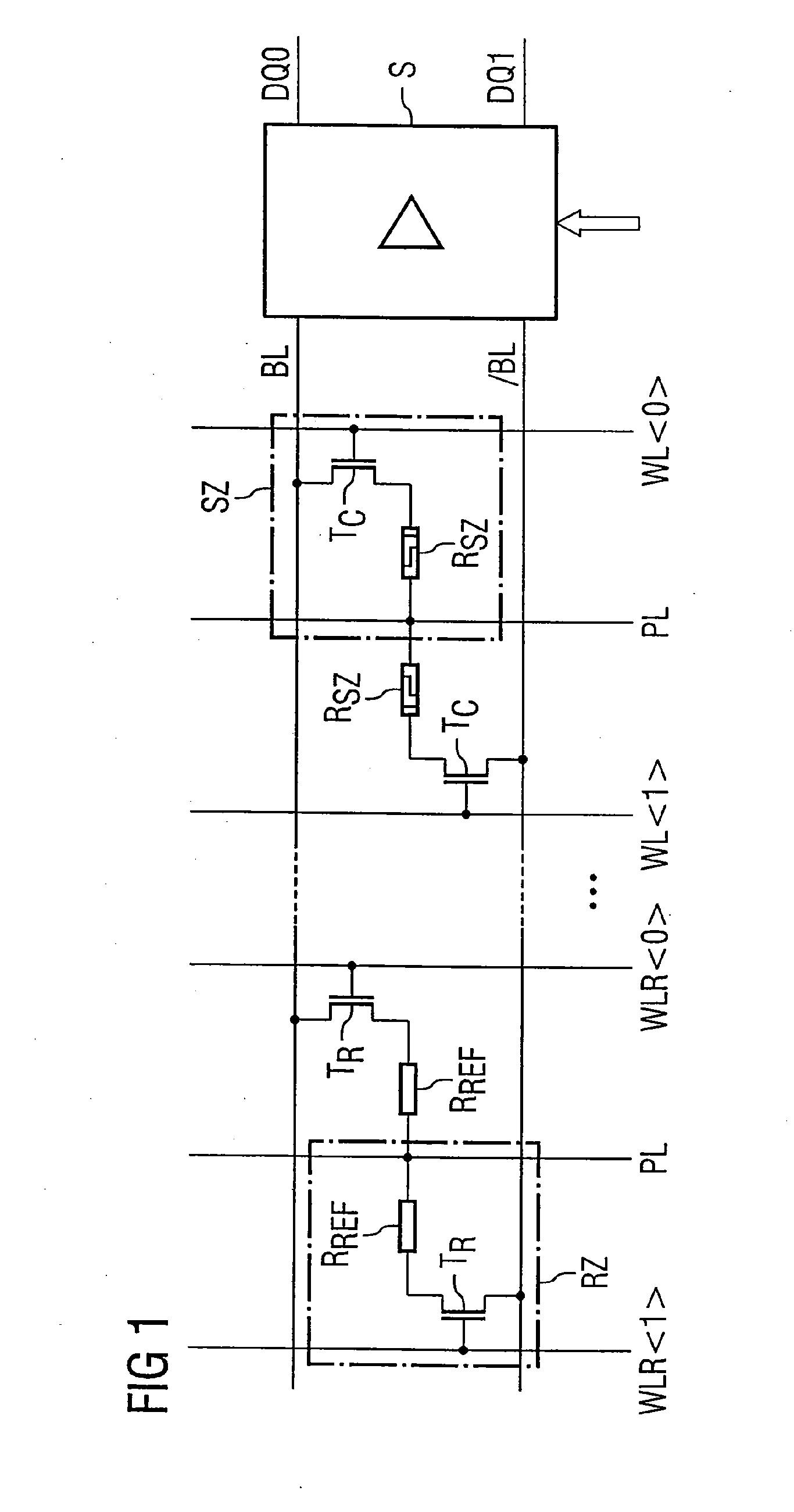

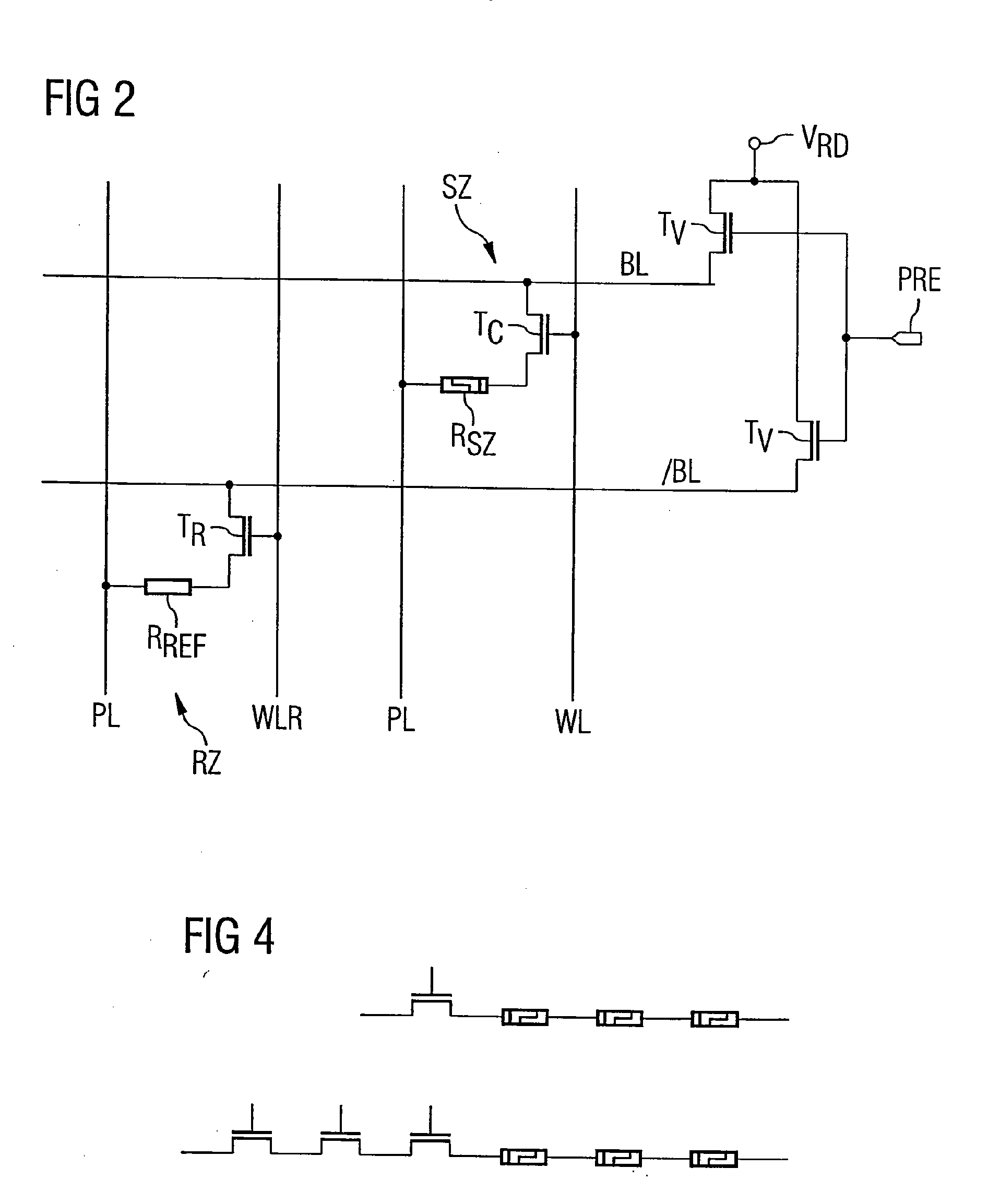

Memory with resistance memory cell and evaluation circuit

InactiveUS7499349B2Reliable compensationIncrease signal strengthRead-only memoriesDigital storageMemory circuitsReference memory

A memory circuit comprising a memory cell which has a resistance memory element and is connected between a ground terminal and a capacitor has a reference memory cell with a reference resistor which is connected between the ground terminal and a reference capacitor, in which case, during the reading operation of the memory cell, the memory cell and the reference memory cell are switched on in order to charge or discharge the capacitor and the reference capacitor, and an evaluation device evaluates the difference between the electrical potentials of the capacitor and the reference capacitor at a predetermined instant after the switching-on of the memory cell and the reference memory cell.

Owner:POLARIS INNOVATIONS LTD

Memory with resistance memory cell and evaluation circuit

InactiveUS20070147102A1Reliable compensationIncrease signal strengthRead-only memoriesDigital storageCapacitanceHemt circuits

A memory circuit comprising a memory cell which has a resistance memory element and is connected between a ground terminal and a capacitance has a reference memory cell with a reference resistance which is connected between the ground terminal and a reference capacitance, in which case, during the reading operation of the memory cell, the memory cell and the reference memory cell are switched on in order to charge or discharge the capacitance and the reference capacitance, and an evaluation device evaluates the difference between the electrical potentials of the capacitance and the reference capacitance at a predetermined instant after the switching-on of the memory cell and the reference memory cell.

Owner:POLARIS INNOVATIONS LTD

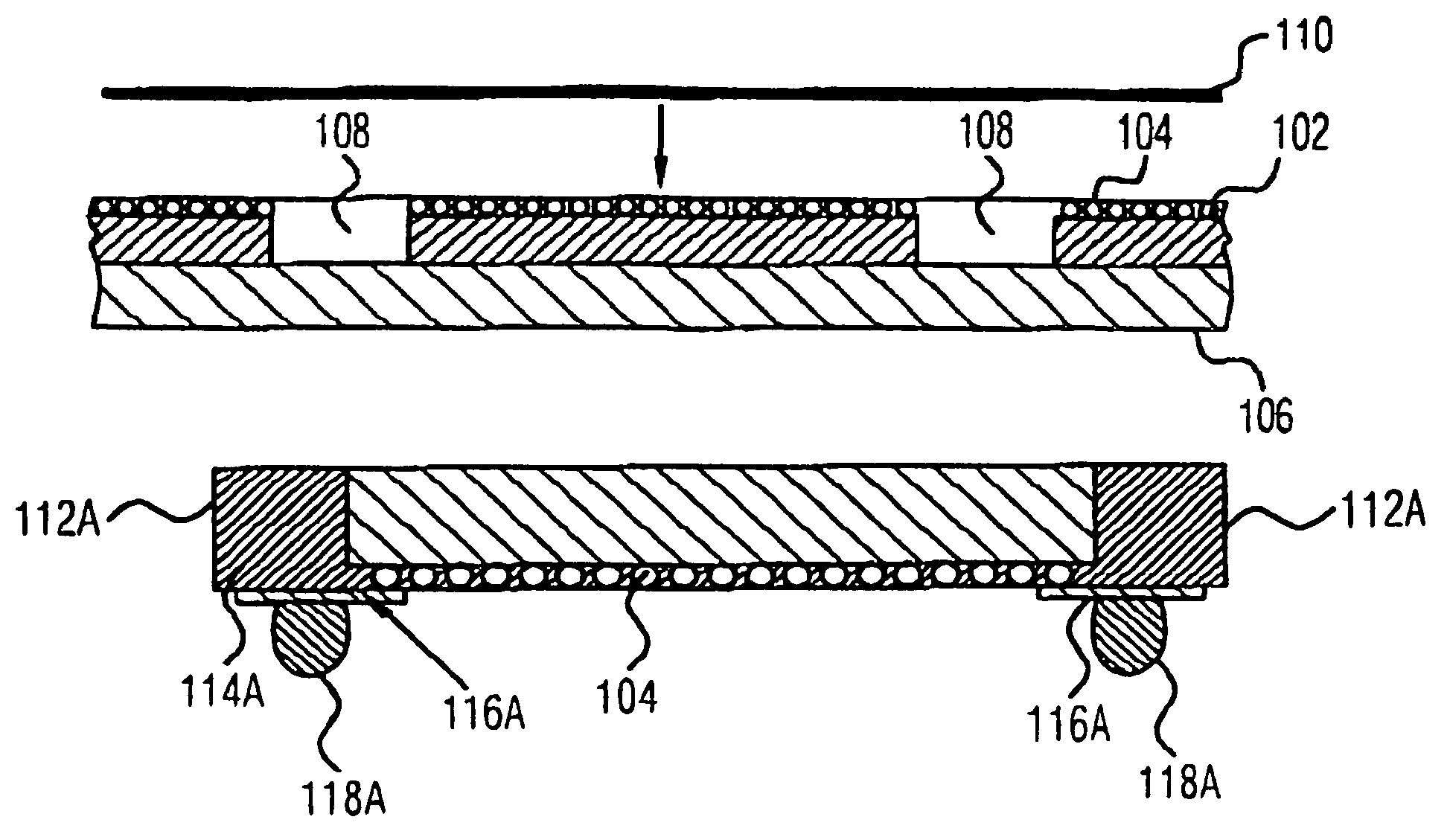

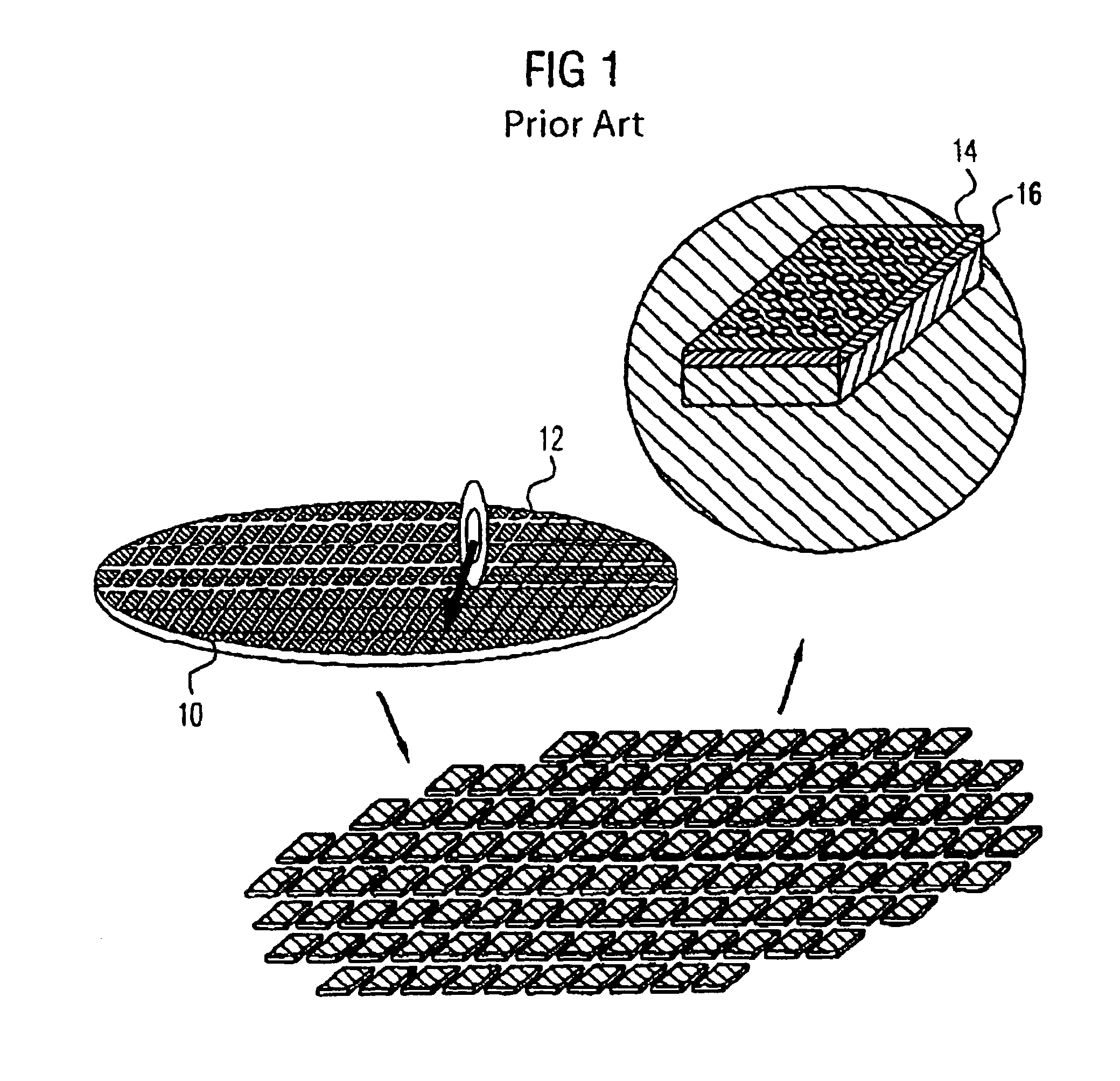

Method for producing encapsulated chips

ActiveUS7011989B2Increase the areaPromote redistributionSemiconductor/solid-state device detailsSolid-state devicesWaferingEngineering

A method for producing encapsulated chips includes preparing a wafer with contacts projecting from a surface of the wafer. The wafer is disposed on a dicing substrate and diced into a plurality of spaced chips on the dicing substrate. The contacts are covered with a protection arrangement, then injection molding being conducted to introduce encapsulation material into the contacts and the trenches. Then the protection arrangement is removed so that the contacts are exposed.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

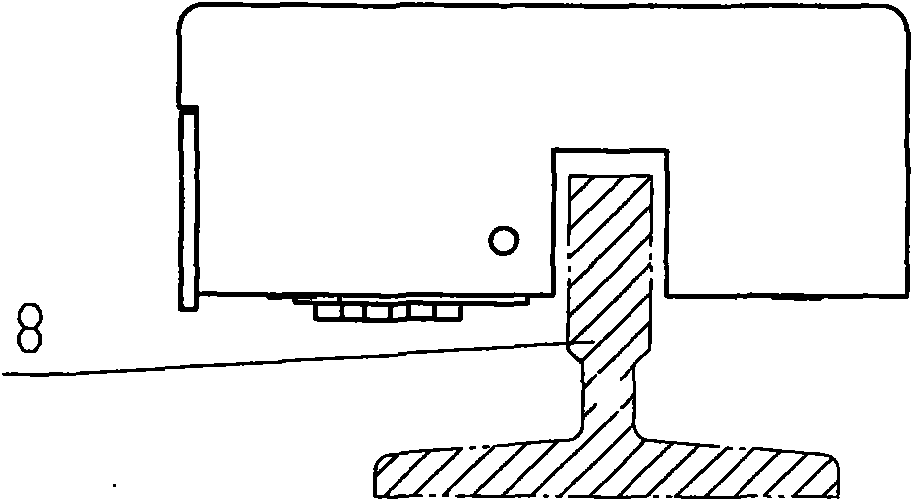

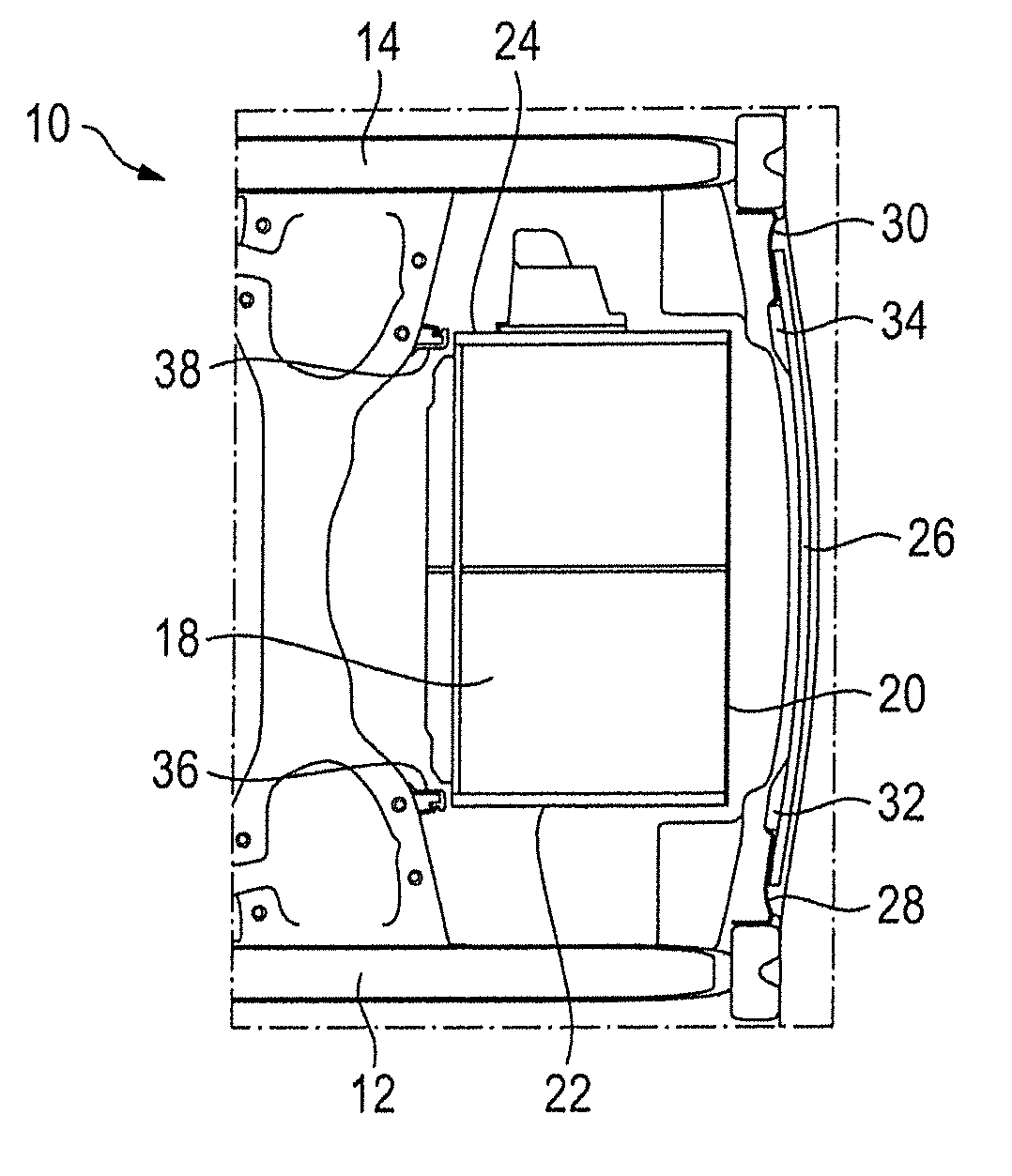

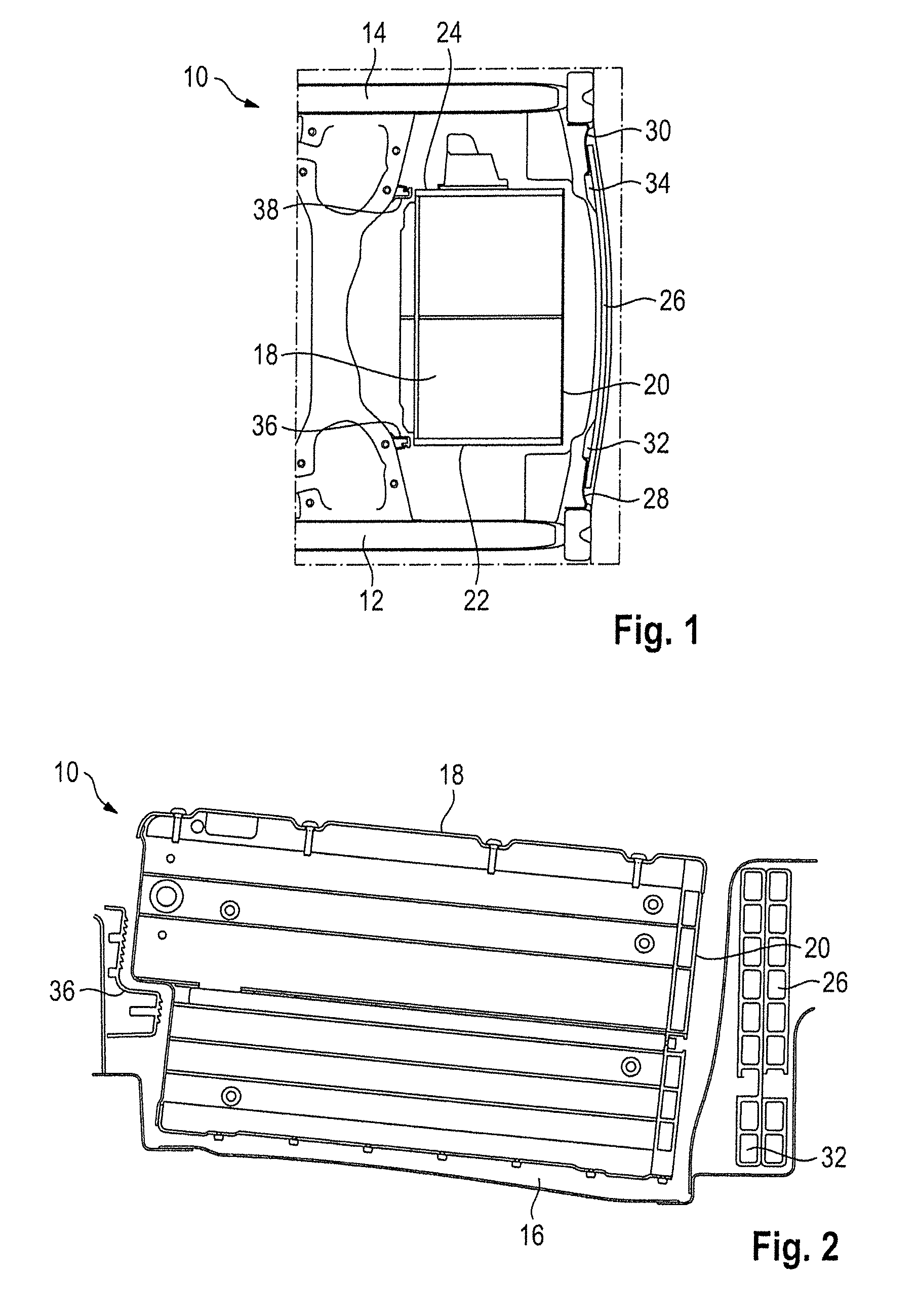

Motor vehicle rear

ActiveUS9126637B2Reduce riskSmall structureElectric propulsion mountingUnderstructuresEngineeringMotorized vehicle

A motor vehicle rear (10) has left and right longitudinal members (12) forming a supporting structure of the motor vehicle. A receiving housing (18) is arranged between the longitudinal members (12) for receiving a traction battery. The receiving housing (18) has a left and right side walls (22, 24) running in the forward direction of travel. A back wall (20) is connected to the left and right side walls (22) and running transverse to the forward direction of travel. An impact profile (26) is connected to the left and right longitudinal members (12, 14) and absorbs impact energy in the event of a rear crash. Left and right reinforcing elements (32 34) connect the impact profile (26) to the respective left and right side walls (22, 24) for reinforcing the impact profile (26) and conducting away some of the impact energy into the left and right side walls (22, 24).

Owner:DR ING H C F PORSCHE AG

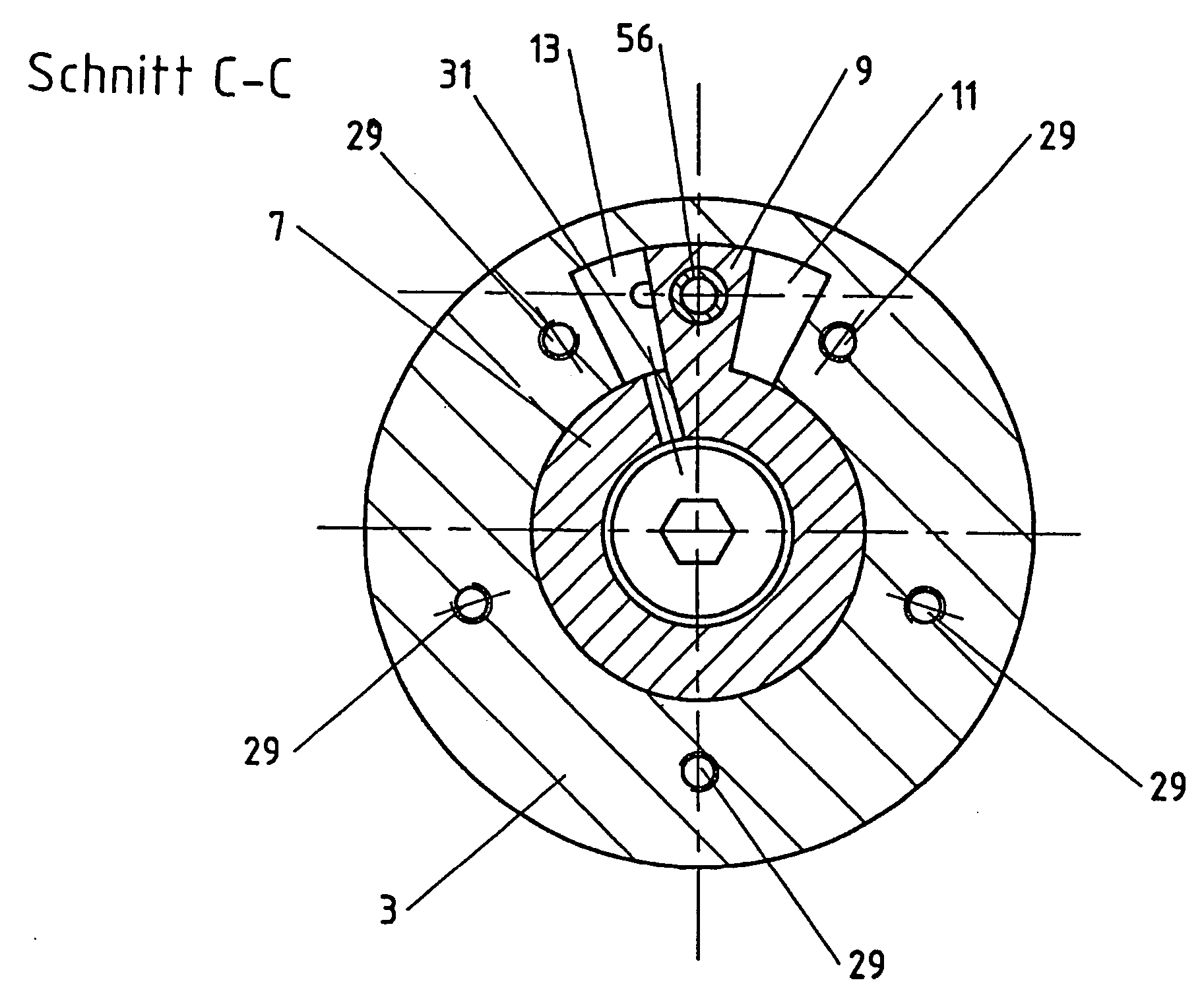

Camshaft adjuster with play-free locking

InactiveUS20060201463A1Easy to produceLittle rattling noiseValve arrangementsYielding couplingEngineeringCamshaft

Camshaft adjusters according to the swivel motor principle may be provided with a bar which arrests the rotor in a position relative to the stator. A bar according to the invention is provided with two portions, between which a change of power transmission takes place during the arresting process.

Owner:HYDRAULIK RING

Hinge-plate accommodation element for attaching a hinge plate

InactiveUS7571516B2Simple designNarrow profilePin hingesMulti-purpose toolsEngineeringBiological activation

A hinge plate accommodation element for attaching a hinge plate has a holder bracket that has a first shank for attachment on the frame side and an angled short shank, a bracing plate that is connected with the short shank of the holder bracket, so as to pivot, a pressure plate that is disposed on the bracing plate with binding screws, and can be adjusted relative to the bracing plate by means of activation of the binding screws, and adjusting screws that are inserted into bores of the holder bracket, so as to rotate, and engage into threaded bores of the bracing plate.

Owner:SIMONSWERK

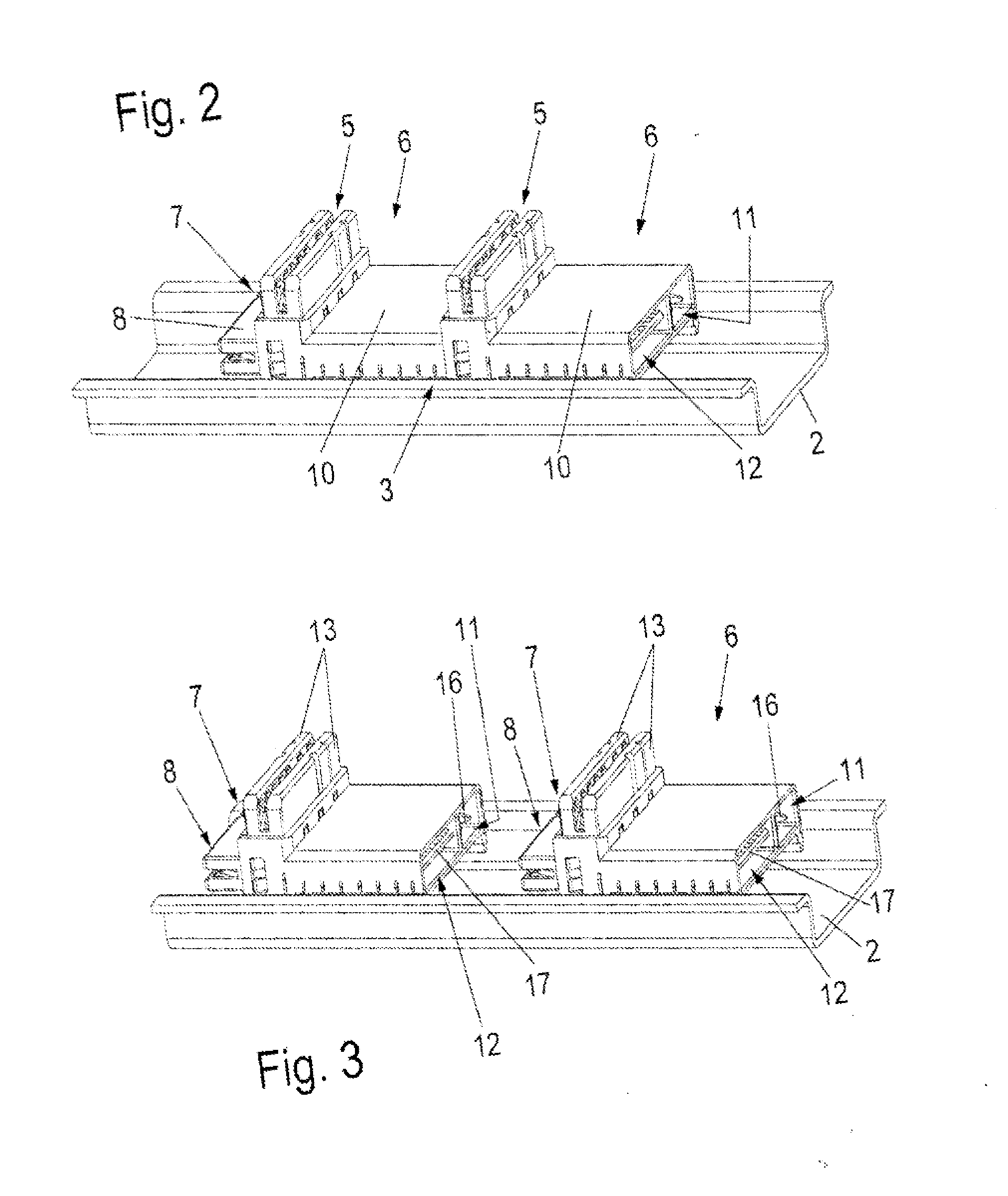

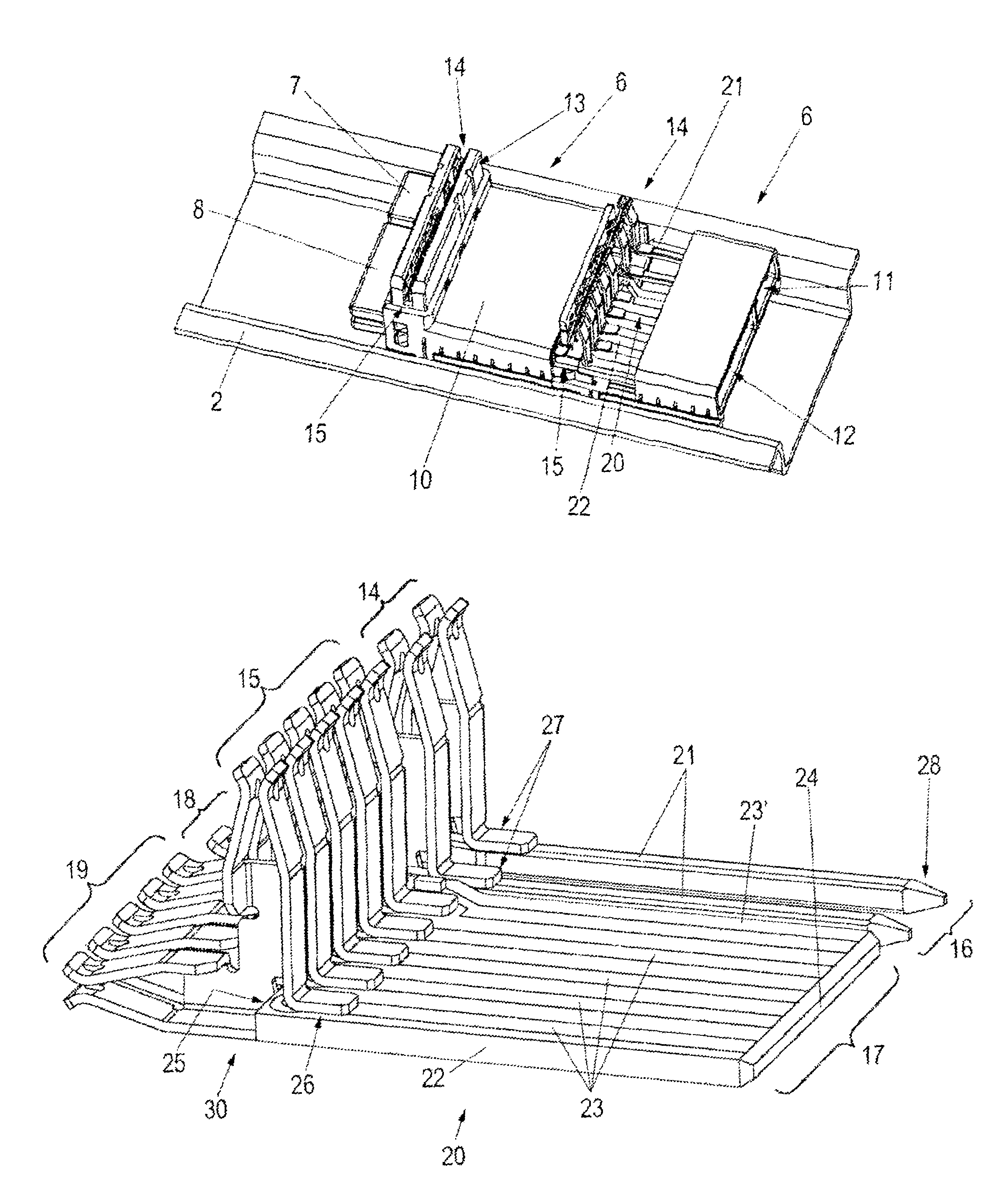

Mounting rail bus system

ActiveUS20130045613A1Reduce the required powerSmall multiplicityCoupling device connectionsElectrically conductive connectionsElectrical conductorComputer module

A mounting rail bus system for supplying power voltage and data signals to a plurality of modules, including a plurality of longitudinally-arranged bus devices mounting the modules in parallel spaced transverse relation on a mounting rail, each of the bus devices including a printed circuit board having parallel strip conductors for transmitting data signals, and a pair of power contact pins for transmitting a power voltage, characterized by the provision of a plurality of generally L-shaped double bushing contact elements have module bush segments for respectively connecting the strip conductors and the contact pins of the bus device with the associated module, and orthogonally arranged partner bush segments for connecting together the strip conductors and pin contacts of adjacent bus devices, respectively, whereby power voltage and data signals are transmitted from the bus device both to the associated module and to the adjacent partner bus device.

Owner:WEIDMULLER INTERFACE GMBH & CO KG

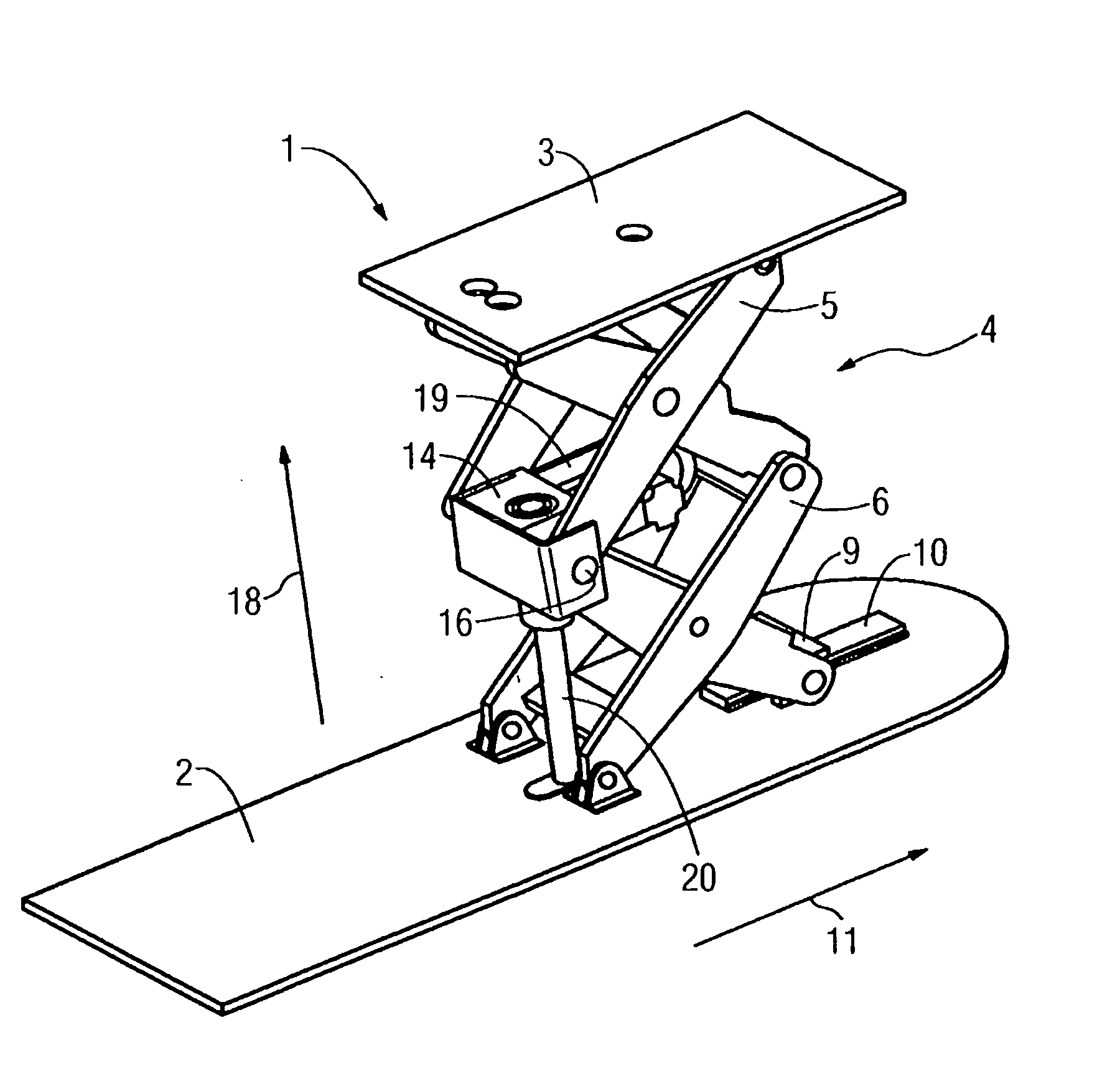

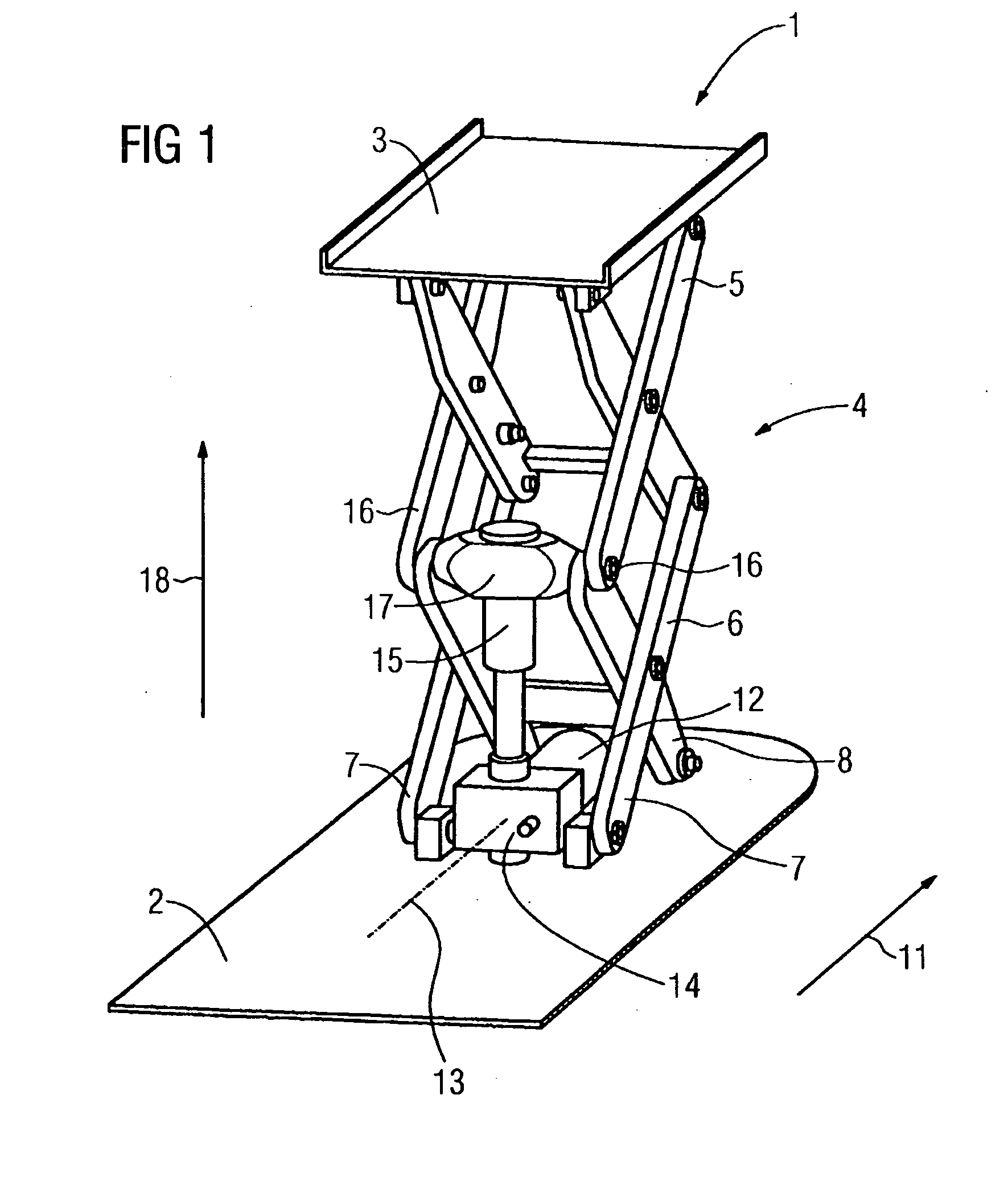

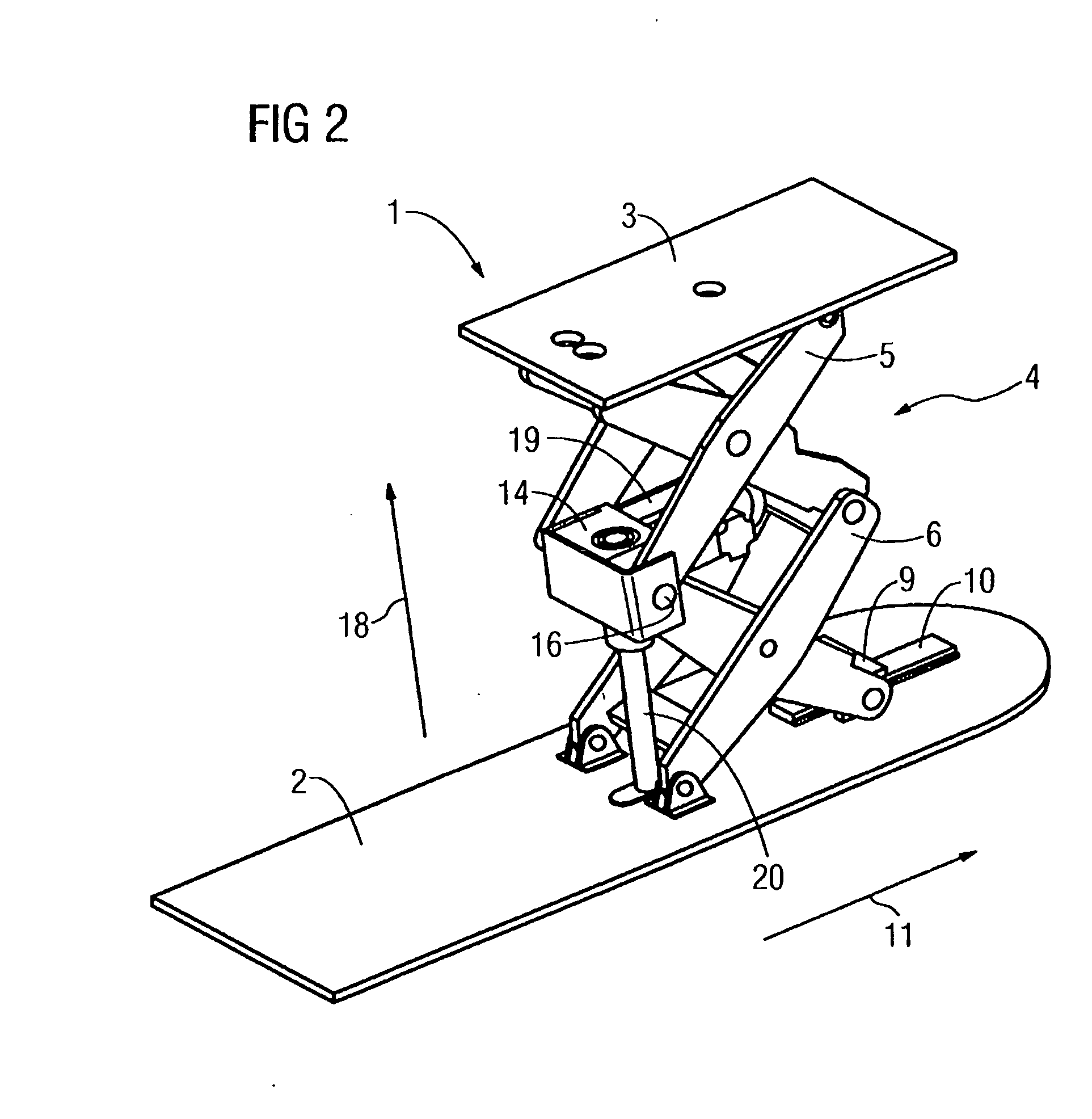

Lifting Device

InactiveUS20070221895A1Reduce maintenanceSave building spaceLifting framesIndustrial engineeringLinkage concept

Owner:SIEMENS AG

Switchable lever for a valve drive of an internal combustion engine

InactiveUS20110265751A1Minimize effortSave building spaceValve arrangementsMachines/enginesExternal combustion engineEngineering

A switchable lever for a valve drive of an internal combustion engine, which has an elongated housing with two side walls. A crossbar for a gas-exchange valve system and another end of the housing has a hearing for pivotable support of the crossbar. An axle is held nondisplaceably in the side walls. An axially fixed low-lift cam roller is seated centrally on the axle and is flanked on both sides by a high-lift cam roller. The high-lift cam rollers are displaceable: (a) into a first position, away from each other, to toward the side walls such that contact of one high-lift cam per high-lift cam roller is possible, and (b) into a second position, toward each other, such that they are located outside an engagement region of the high-lift cams, and as a result of which contact of a low-lift or zero-lift cam with the low-lift cam roller is possible.

Owner:SCHAEFFLER TECH AG & CO KG

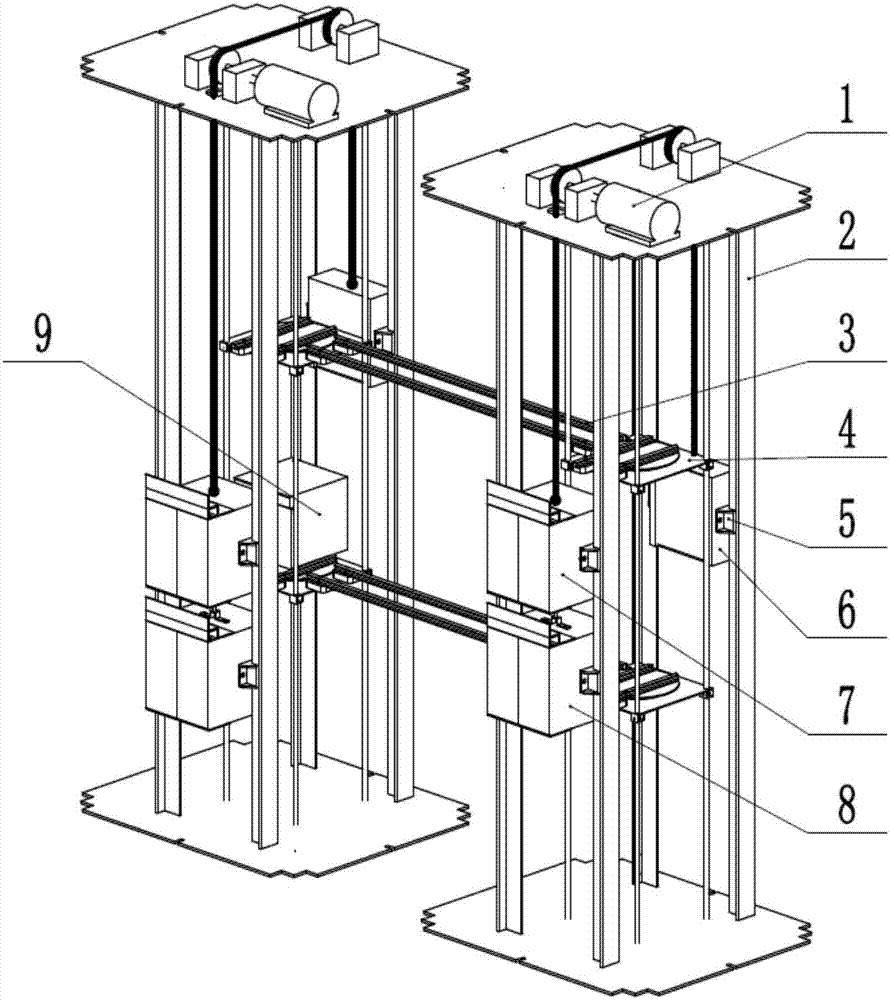

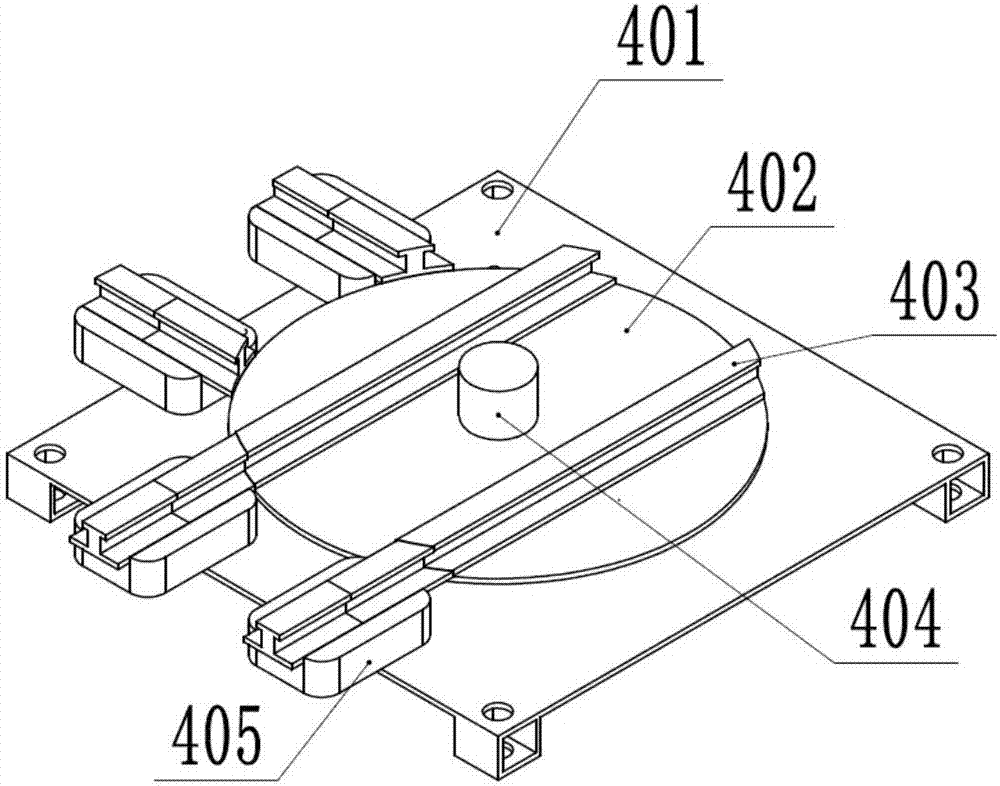

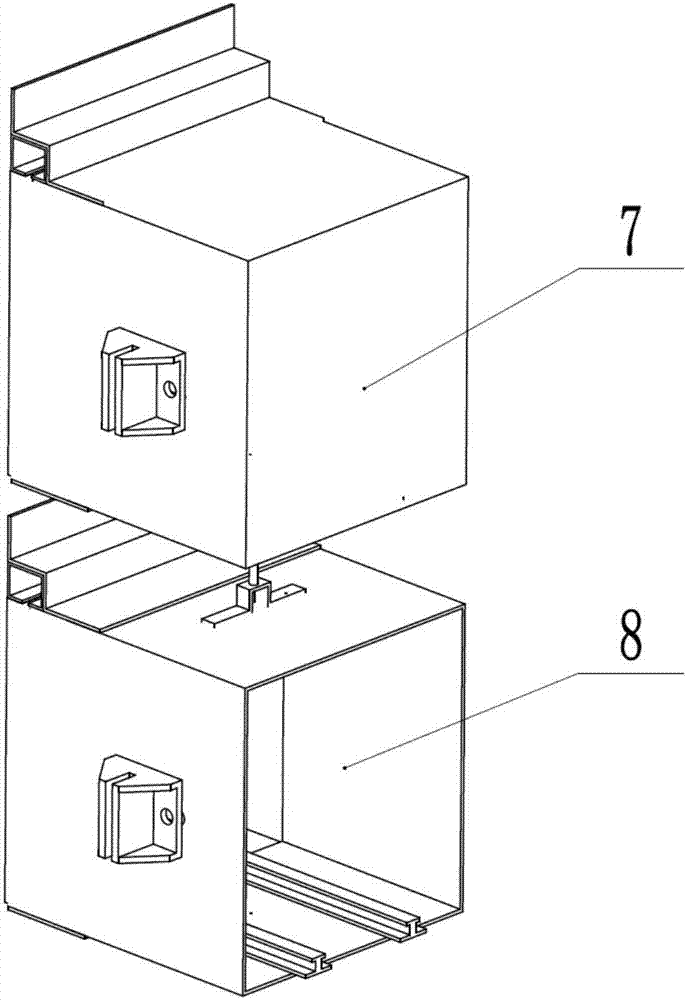

Double-shaft elevator capable of horizontally and vertically operating

InactiveCN106927336AImprove transportation efficiencySave building spaceElevatorsBuilding liftsTraction systemEngineering

An elevator that can run horizontally and vertically facing double shafts belongs to the technical field of elevators and includes a traction system, a T-shaped guide rail, a horizontal guide rail, a rotating chassis, guide shoes, a counterweight, an active car, a follower car and a moving car The car is characterized in that: the traction system is located on the top of the elevator, the T-shaped guide rail is installed in the shaft, the rotating chassis is located in the lower middle and upper middle of the elevator shaft, and the active car pulls the follower car , the active car, follow-up car, mobile car and counterweight are restricted on the T-shaped guide rail through guide shoes. The invention has the advantages of high transportation efficiency, saving building space, and realizing multi-faceted transportation of people flow.

Owner:SHANDONG JIANZHU UNIV

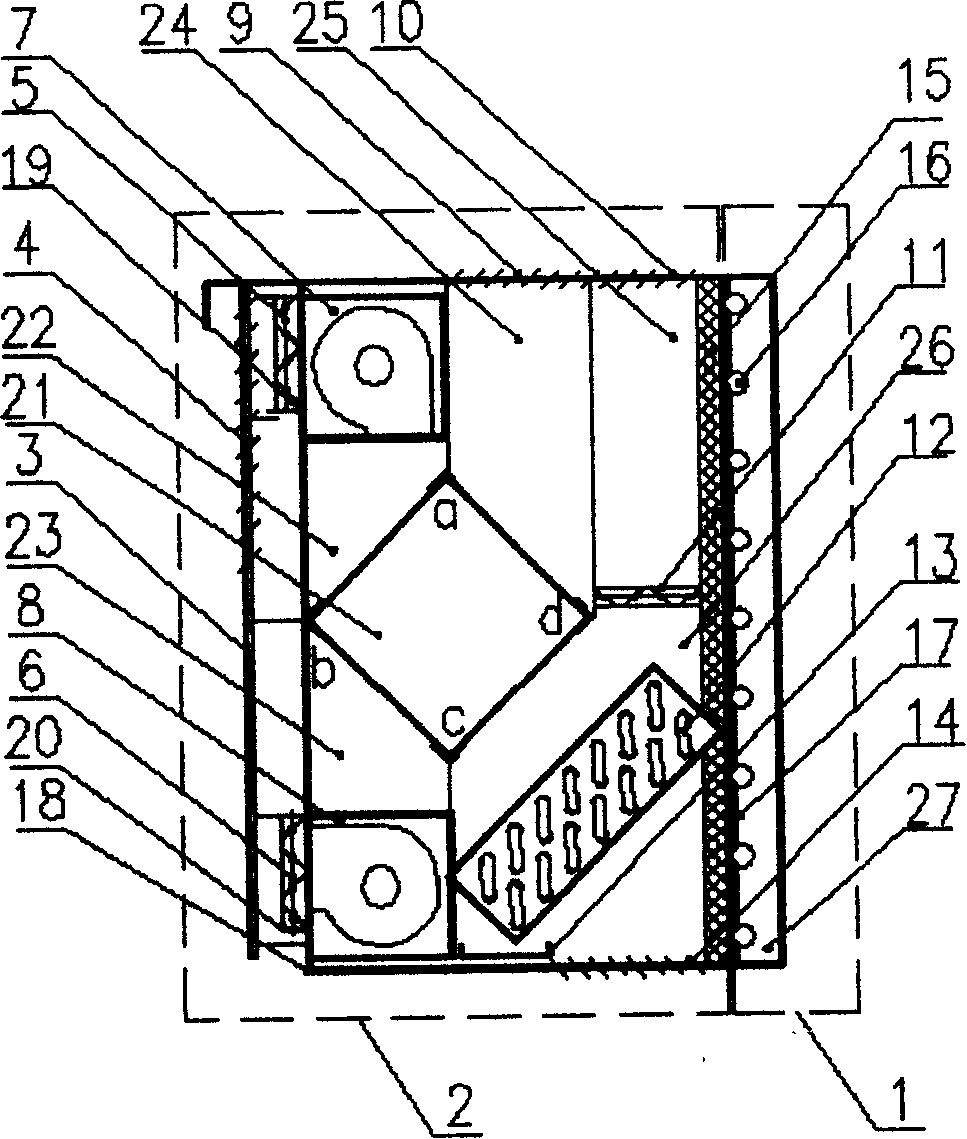

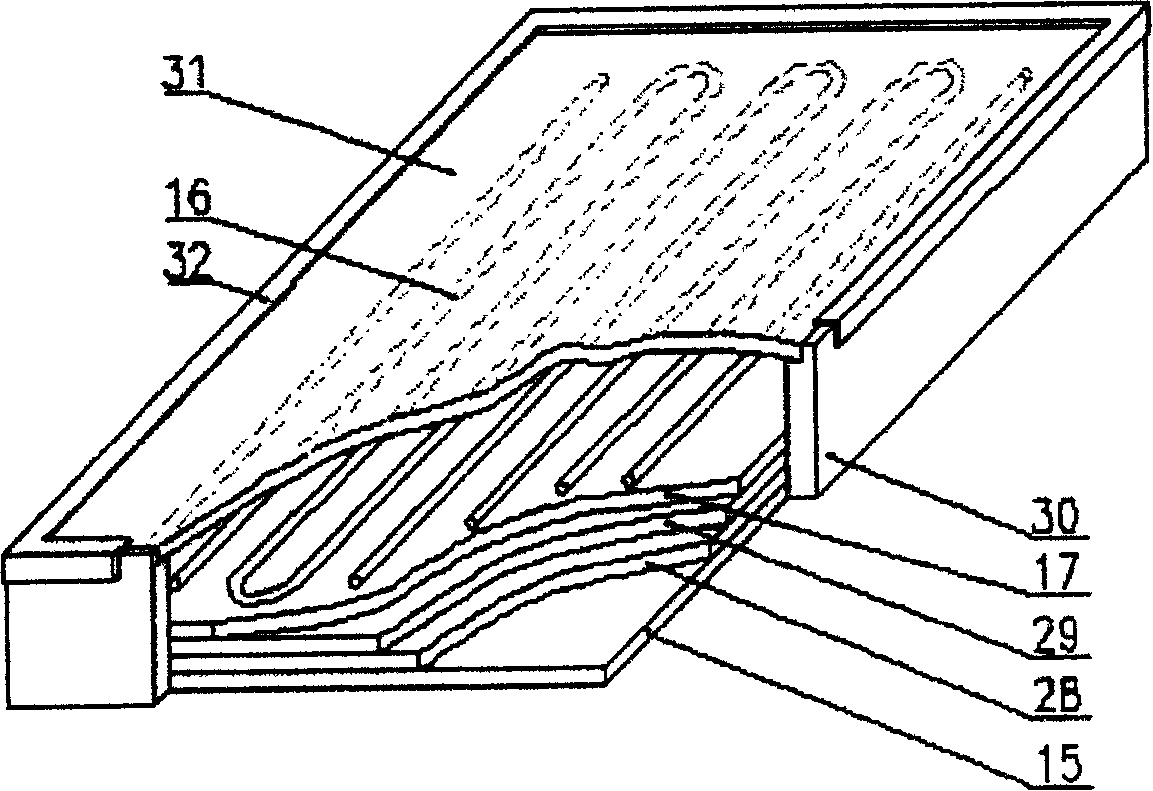

Displacement ventilation radiator

InactiveCN1560522AImprove comfortImprove air qualityLighting and heating apparatusAir conditioning systemsFresh airEngineering

The invention is a substitute ventilation radiator belonging to heating and ventilating air condition refrigerating field. The invention includes a radiator, substitute ventilator. The radiator is arranged on the board at one side of the substitute ventilator, the board of the substitute ventilator is used as the bottom board, and the radiator and the substitute ventilator are arranged together back to back. It has characters of substitute ventilation and radiation cooling and heating technology, it can supply fresh wind to room with substitute method, eliminates the humid charge in the room, satisfies the demands of people for fresh air; it can cool or heat the room with radiator, bears the sensible cool or heat charge in the room, upgrades the comfort level and the air quality in room, saves the air condition consumption and the construction space.

Owner:SHANGHAI JIAO TONG UNIV

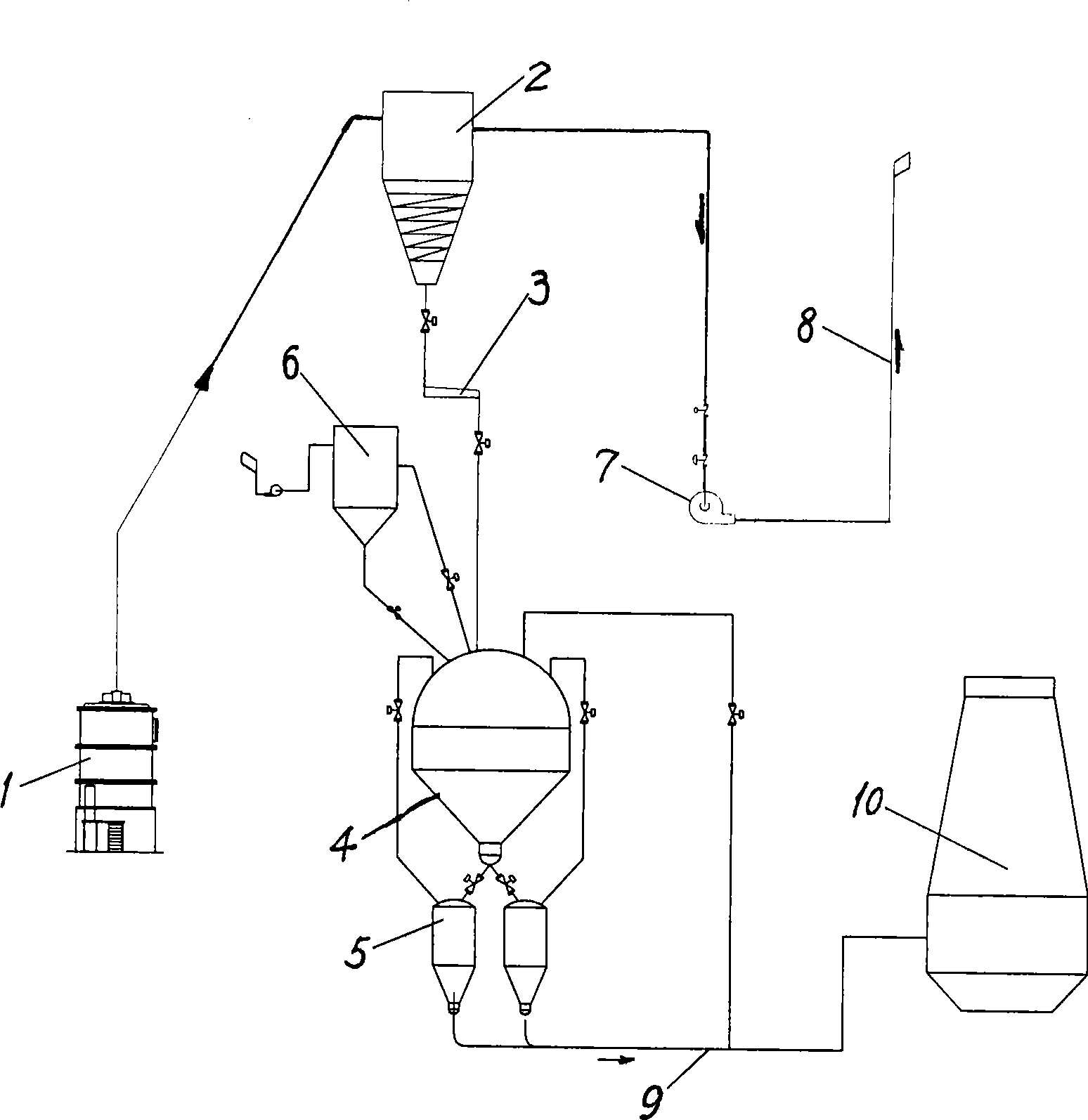

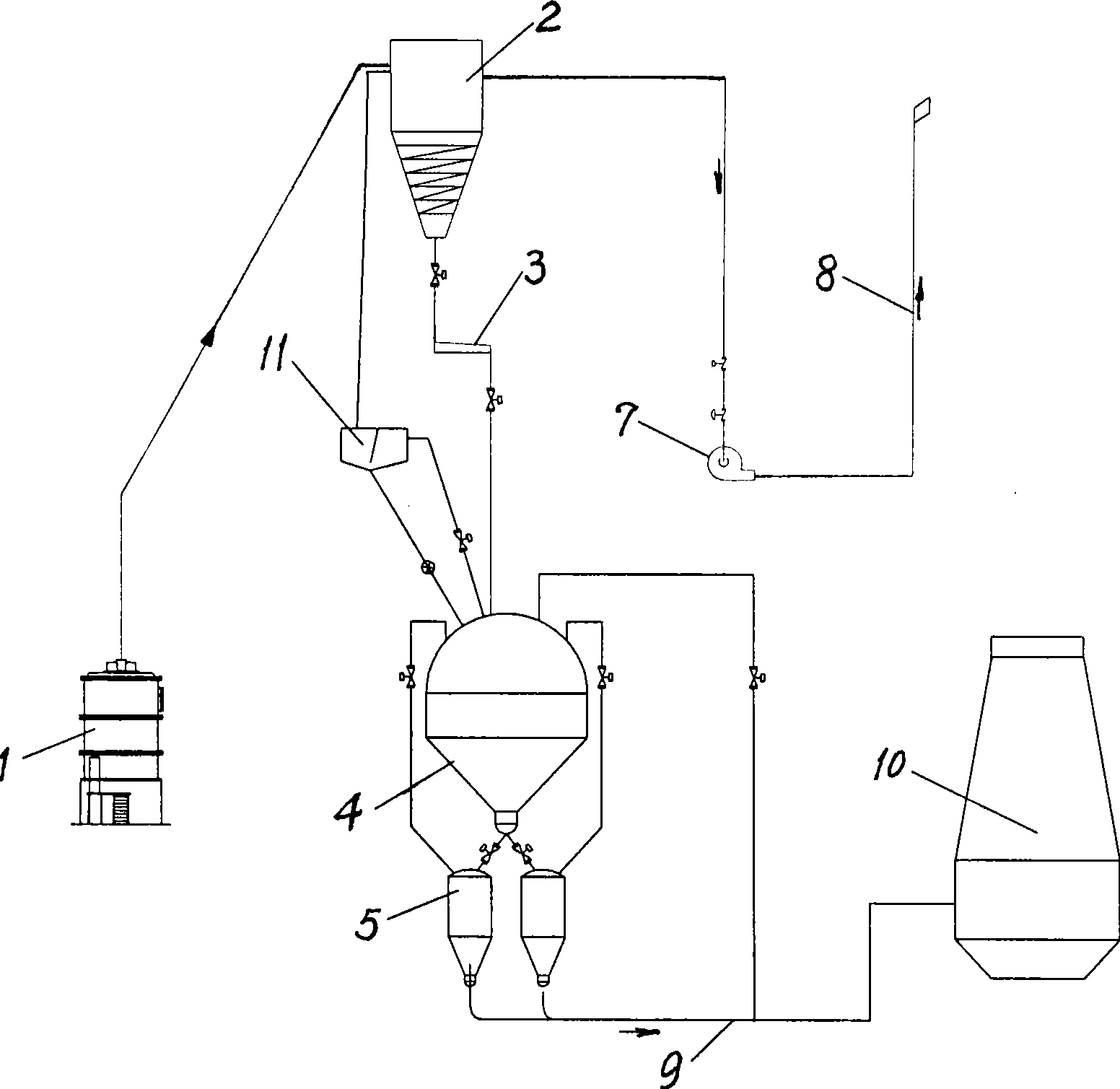

Dust removing process of coal fine spraying system and apparatus thereof

InactiveCN101417752ASimple process equipmentSave building spaceBlast furnace componentsBlast furnace detailsProcess equipmentAtmospheric air

The invention relates to a dust removal process of a pulverized coal making and spraying system, and after coals to be sprayed are ground to powder by a coal mill, and the gas and powder are separated by a bag powder collecting device, and the pulverized coal is gathered into a pulverized coal collecting bin, and then unloaded to a spraying pot, and the spraying pot uses a pneumatic method to transport the pulverized coal into metallurgy furnaces. The dust removal process removes a bag dust remover originally arranged at the top of the pulverized coal collecting bin, and uses the bag powder collecting device on the pulverized coal collecting bin to replace functions of the bag dust remover, and the bag powder collecting device can be directly used for carrying out the gas-powder separation of mixtures in the pulverized coal collecting bin to discharge the purified waste gas into air through a pipe on the pulverized coal collecting bin and connected with an inlet of the bag powder collecting device. The dust removal device arranges a discharging pipe on the pulverized coal collecting bin, and connects the discharging pipe to the inlet of the bag powder collecting device and removes the bag dust remover arranged at the original pulverized coal collecting bin, thus simplifying the process equipment, saving the construction space and reducing the investment cost.

Owner:BAOSTEEL ENG & TECH GRP

Switchable lever for a valve drive of an internal combustion engine

InactiveUS20110265750A1Minimize effortLower component costsValve arrangementsMachines/enginesExternal combustion engineEngineering

A switchable lever for a valve drive of an internal combustion engine which has two side walls with ends connected by a crossbar. There is a gas-exchange valve system in the crossbar at one end and a bearing for the pivotable support of the crossbar at the other end. An axle is held nondisplaceably in the side walls, between the ends, with two cam rollers running on the axle. The cam rollers are displaceable axially on the axle toward each other into a first position such that the cam rollers run up to each other on a longitudinal center plane of the lever and away from each other into a second position. One of the positions serves for a high-lift cam contact and the other position serves for a low-lift or zero-lift cam contact.

Owner:SCHAEFFLER TECH AG & CO KG

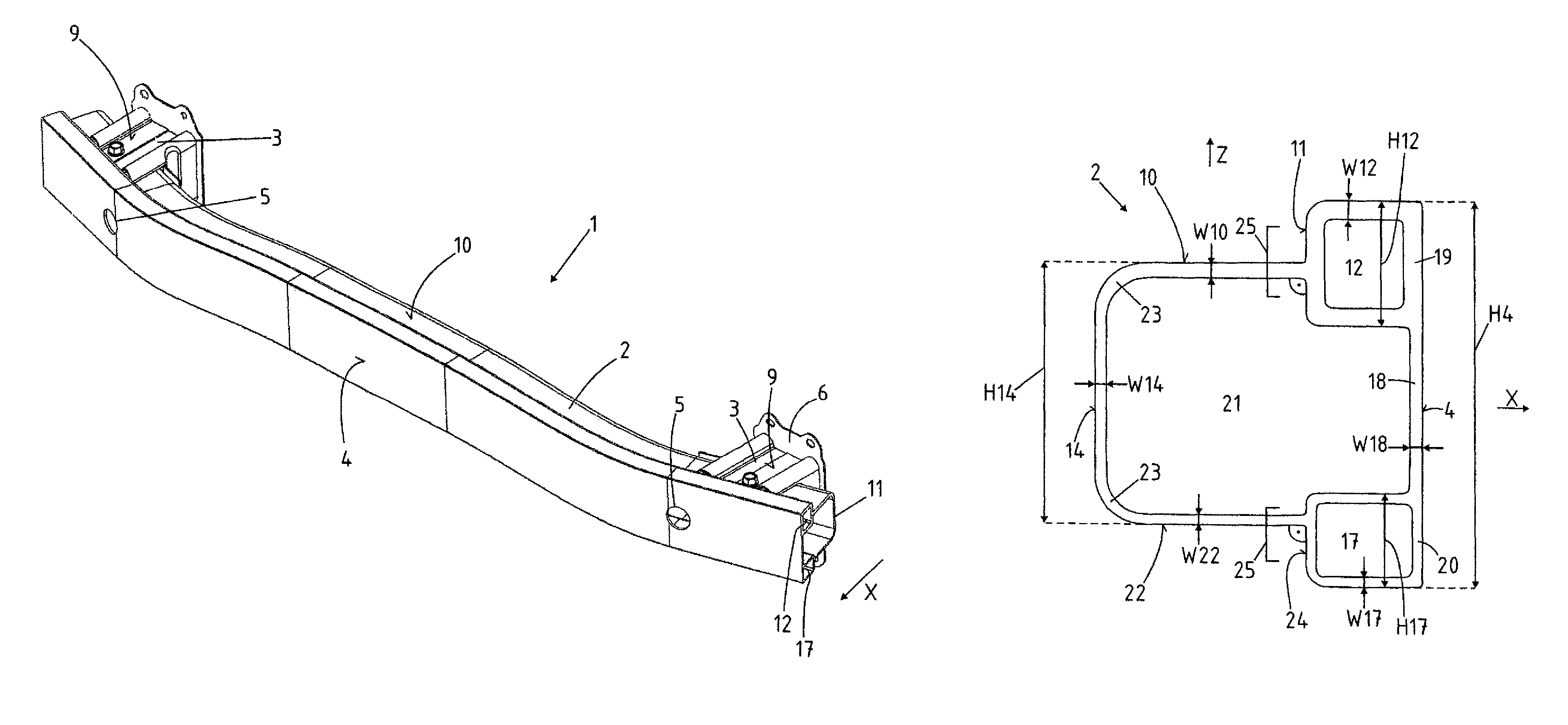

Bumper arrangement for a motor vehicle

A bumper arrangement for a motor vehicle includes a bumper arrangement for a motor vehicle, including a cross member made of a lightweight metal and constructed as multi-chamber section which has at least one front chamber and at least one main chamber, wherein the front chamber is arranged in front of the main chamber in longitudinal direction of the motor vehicle, wherein the main chamber has a greater cross sectional surface than the at least one front chamber, wherein the cross member has a front side facing in a driving direction of the motor vehicle and a rear side facing away from the driving direction, wherein the front side has a height in vertical direction of the motor vehicle, which is greater than a height of the rear side, wherein at least one wall of the at least one front chamber forms a portion of the front side; and crash boxes arranged in respective end regions of the cross member for coupling the bumper arrangement with the motor vehicle. The cross member can be formed as extruded part.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

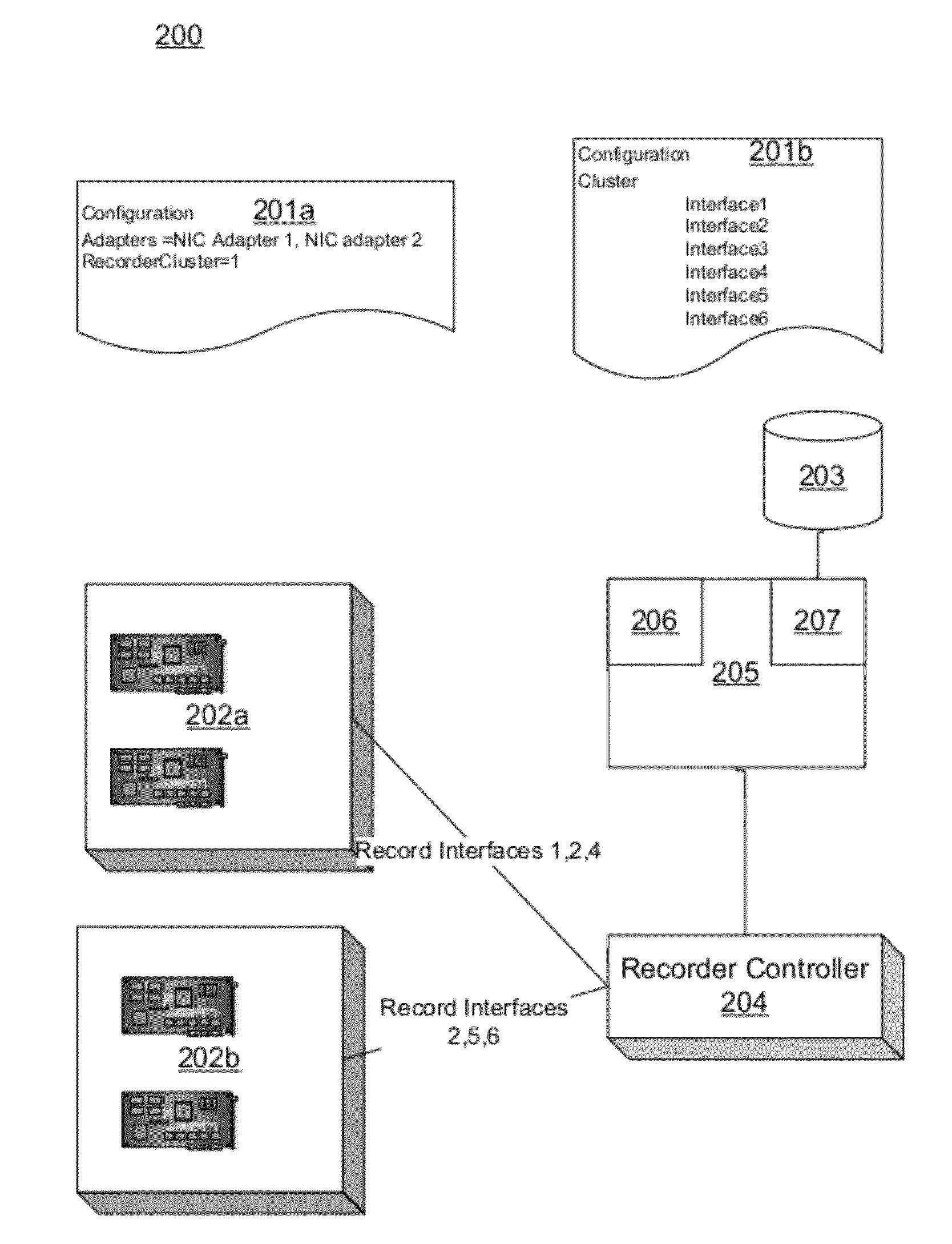

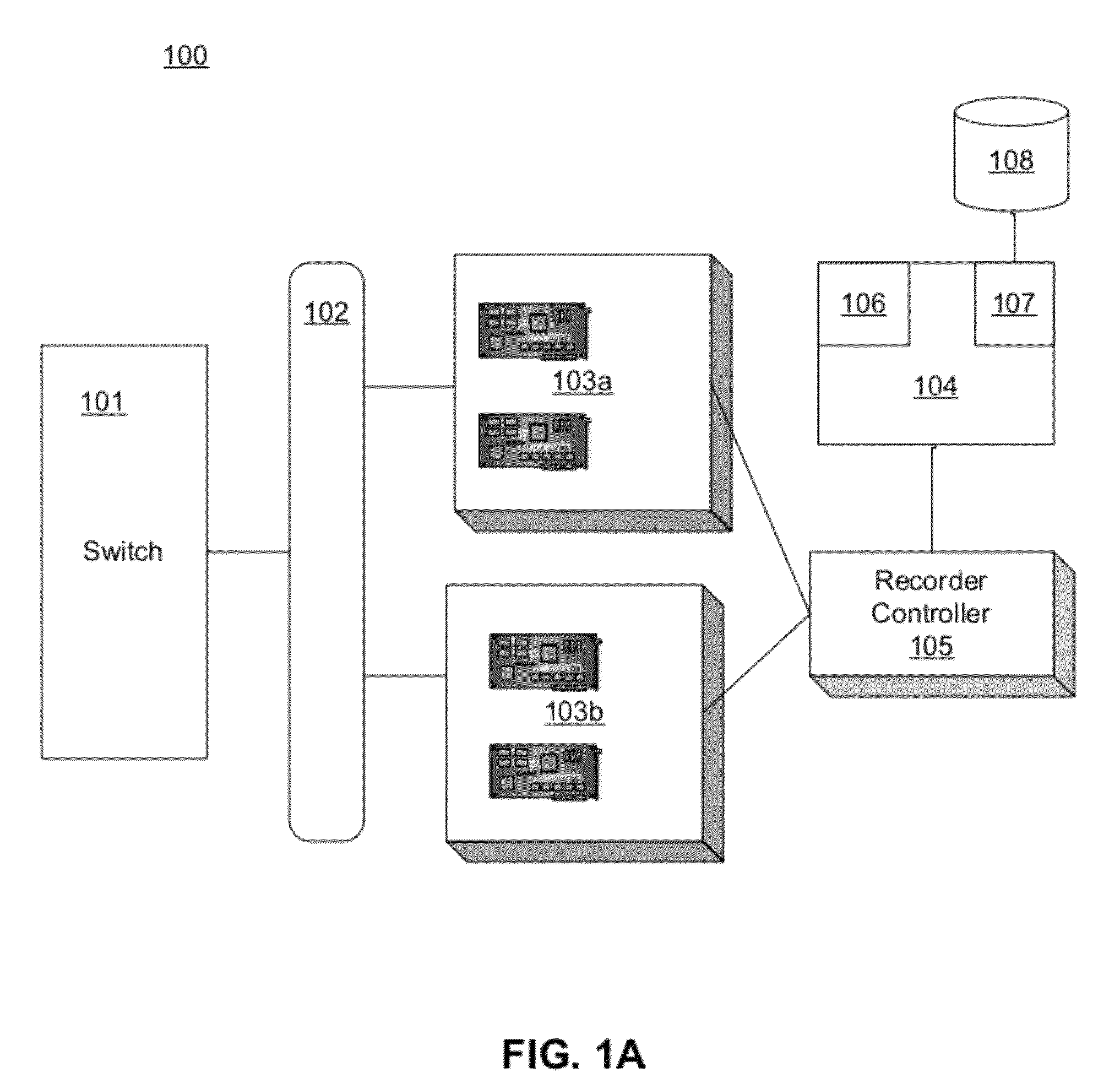

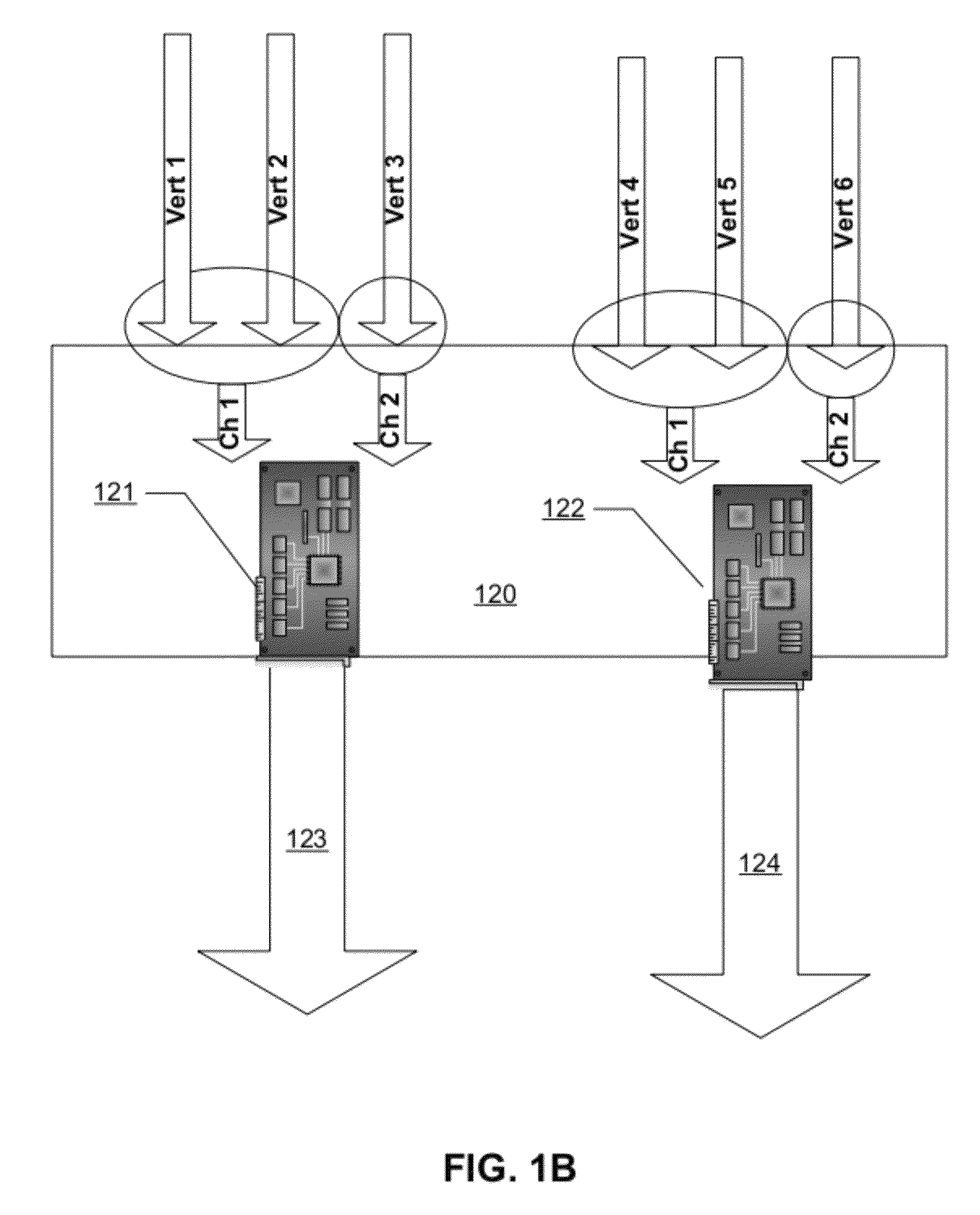

System and method for pooled IP recording

ActiveUS8345828B2Reduction of the hardware necessarySave building spaceAutomatic call-answering/message-recording/conversation-recordingAutomatic exchangesAdaptive routingComputer science

Embodiments of the present invention provides systems and methods for pooled IP recording. An exemplary method of the present invention comprises monitoring a user's logon, associating a communication device to the user, assigning an interface to a recorder associated with the communication device, and recording data from the communication device sent over the interface. Another exemplary method of the present invention comprises detecting a recorder failure and dynamically routing an interface associated with the failed recorder to at least one other recorder.

Owner:VERINT AMERICAS

Mounting rail bus system

ActiveUS8961201B2Small multiplicityReduce the required powerCoupling device connectionsElectrically conductive connectionsElectrical conductorContact element

A mounting rail bus system for supplying power voltage and data signals to a plurality of modules, including a plurality of longitudinally-arranged bus devices mounting the modules in parallel spaced transverse relation on a mounting rail, each of the bus devices including a printed circuit board having parallel strip conductors for transmitting data signals, and a pair of power contact pins for transmitting a power voltage, characterized by the provision of a plurality of generally L-shaped double bushing contact elements have module bush segments for respectively connecting the strip conductors and the contact pins of the bus device with the associated module, and orthogonally arranged partner bush segments for connecting together the strip conductors and pin contacts of adjacent bus devices, respectively, whereby power voltage and data signals are transmitted from the bus device both to the associated module and to the adjacent partner bus device.

Owner:WEIDMULLER INTERFACE GMBH & CO KG

Bumper arrangement for a motor vehicle

A bumper arrangement for a motor vehicle includes a bumper arrangement for a motor vehicle, including a cross member made of a lightweight metal and constructed as multi-chamber section which has at least one front chamber and at least one main chamber, wherein the front chamber is arranged in front of the main chamber in longitudinal direction of the motor vehicle, wherein the main chamber has a greater cross sectional surface than the at least one front chamber, wherein the cross member has a front side facing in a driving direction of the motor vehicle and a rear side facing away from the driving direction, wherein the front side has a height in vertical direction of the motor vehicle, which is greater than a height of the rear side, wherein at least one wall of the at least one front chamber forms a portion of the front side; and crash boxes arranged in respective end regions of the cross member for coupling the bumper arrangement with the motor vehicle. The cross member can be formed as extruded part.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

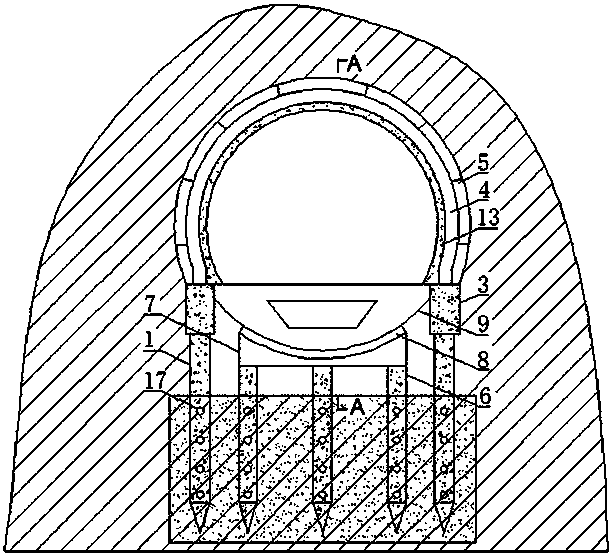

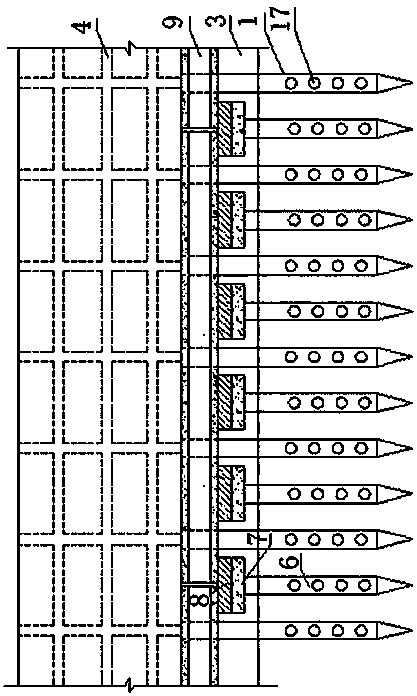

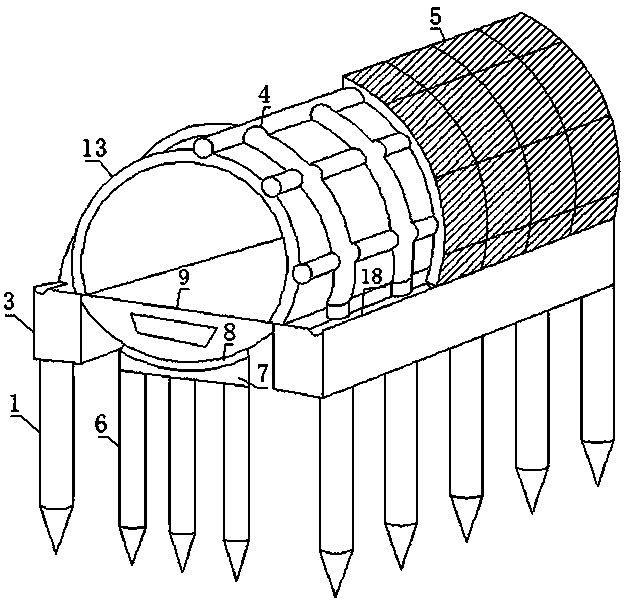

Unfavorable geological body crossing tunnel casing bridge underground structure and construction method thereof

ActiveCN108086994AWith vibration isolation functionResistance to deformationUnderground chambersTunnel liningStructure of the EarthKarst

An unfavorable geological body crossing tunnel casing bridge underground structure and a construction method thereof belong to the field of tunnel engineering. The unfavorable geological body crossingtunnel casing bridge underground structure comprises a primary lining system, a casing bridge structure and a second lining. The construction method comprises that pipe pieces are embedded onto steeltube arches through grooves, the steel tube arches are connected with first-type support piles through diameter-variable connectors, grade beams are poured on the connecting parts of the first-type support piles, the diameter-variable connectors and the steel tube arch to form the primary lining system; second-type support piles are between the grade beams on both sides of an excavated section, capping beams are poured at the tops of the second-type support piles, a layer of rubber cushion is laid on the capping piles, box girder inverted arches are hoisted onto the rubber cushion to form a casing bridge structure; the primary lining system and the casing bridge structure are connected in a poured mode through the box girder inverted arches and prefabricated reinforcing bars of the gradebeams on both sides; the second lining is poured to form the unfavorable geological body crossing tunnel bridge casing underground structure. The unfavorable geological body crossing tunnel bridge casing underground structure and construction method thereof can cross unfavorable geological bodies such as karst caves, underground rivers and soft ground, and meanwhile, can effectively transfer surrounding rock pressure, reduce deformation of tunnels and ensure construction safety.

Owner:甘肃智广地质工程勘察设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com