Building finish material, composite raw material and dosage proportion

A facing material and construction technology, applied in the field of architectural facing materials, can solve the problem that the service life of soft porcelain is not as good as that of the ceramic surface, and achieve the effect of flexible adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

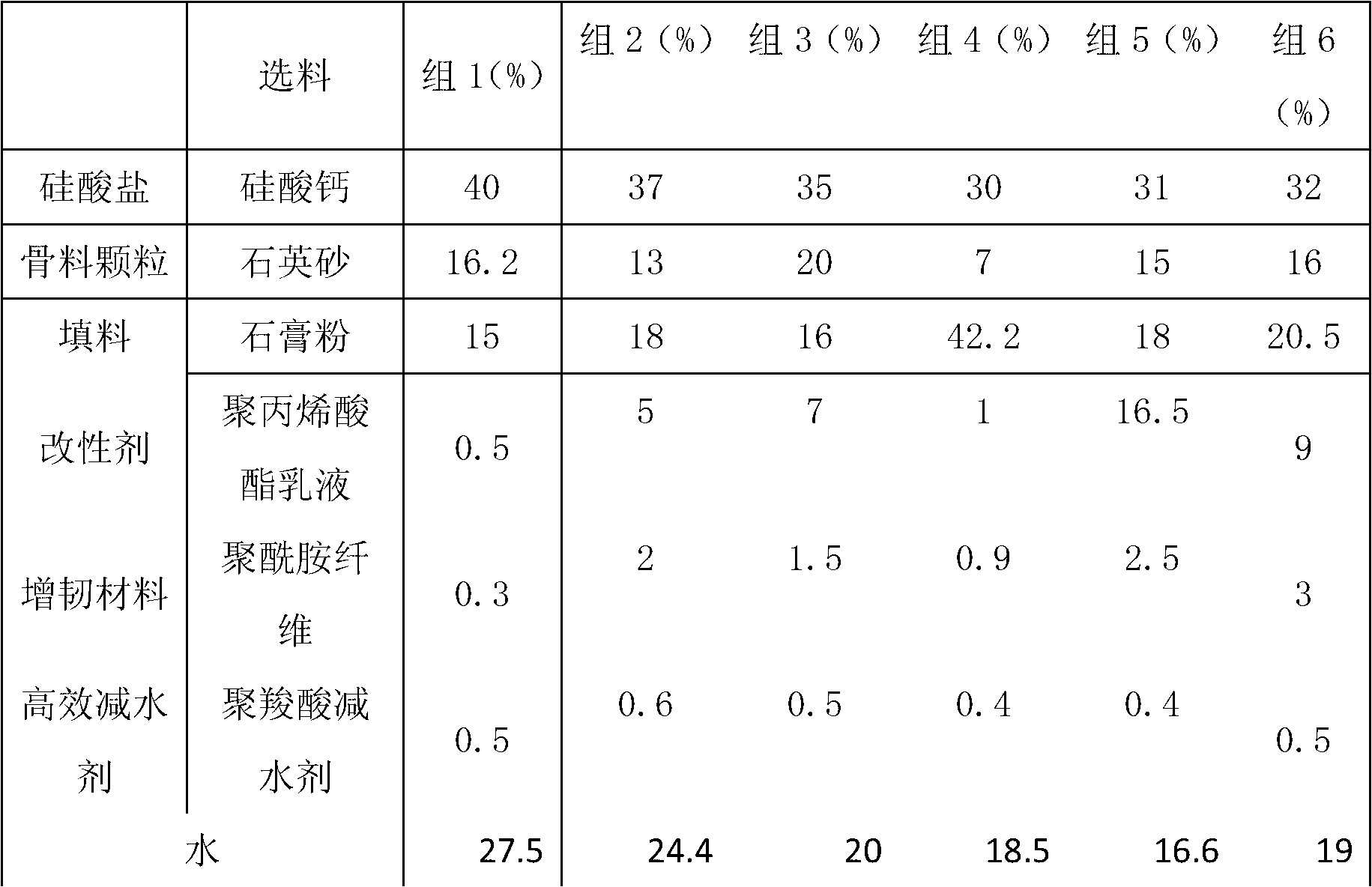

[0038]Embodiment 1 prepares composition, parameter of building facing material

[0039]

[0040] flexibility test

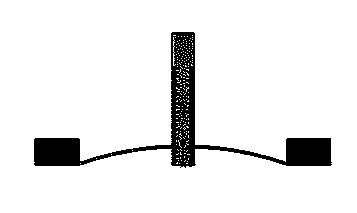

[0041] Get the obtained extra-thin flexible sheet, cut into 60mm wide × 240mm long, about 3mm thick, bend along the 240mm length of the sheet until an arch about 15mm high is formed, and the sheet does not produce cracks or breaks. Such as figure 2 . Changes occurring within 10 mm of the edge of the sheet are not considered. It can be used for non-planar protection and decoration such as cylinders and cylinders. The sheet is slowly bent against the surface of a cylinder with a diameter of 200mm, and the sheet will crack or break.

Embodiment 2

[0042] Embodiment 2 prepares composition, parameter of building facing material

[0043]

[0044]

[0045] flexibility test

[0046] Get the obtained extra-thin flexible sheet, cut into 60mm wide × 240mm long, about 3mm thick, bend along the 240mm length of the sheet until an arch about 15mm high is formed, and the sheet does not produce cracks or breaks. Changes occurring within 10 mm of the edge of the sheet are not considered. It can be used for non-planar protection and decoration such as cylinders and cylinders. The sheet is slowly bent against the surface of a cylinder with a diameter of 200mm, and the sheet does not produce cracks or breaks.

Embodiment 3

[0047] Embodiment 3 prepares composition, parameter of building facing material

[0048]

[0049] flexibility test

[0050] Get the obtained extra-thin flexible sheet, cut into 60mm wide × 240mm long, about 3mm thick, bend along the 240mm length of the sheet until an arch about 15mm high is formed, and the sheet does not produce cracks or breaks. Such as figure 2 . Changes occurring within 10 mm of the edge of the sheet are not considered. It can be used for non-planar protection and decoration such as cylinders and cylinders. The sheet is slowly bent against the surface of a cylinder with a diameter of 200mm, and the sheet does not produce cracks or breaks.

[0051] The amount of water used varies with the season, eg more in summer and less in winter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com