Switchable lever for a valve drive of an internal combustion engine

a technology of internal combustion engine and switchable lever, which is applied in the direction of engine components, machines/engines, mechanical apparatus, etc., can solve the problems of complex operation of the axle, and achieve the effect of reducing component costs and minimizing the effort expended on displacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

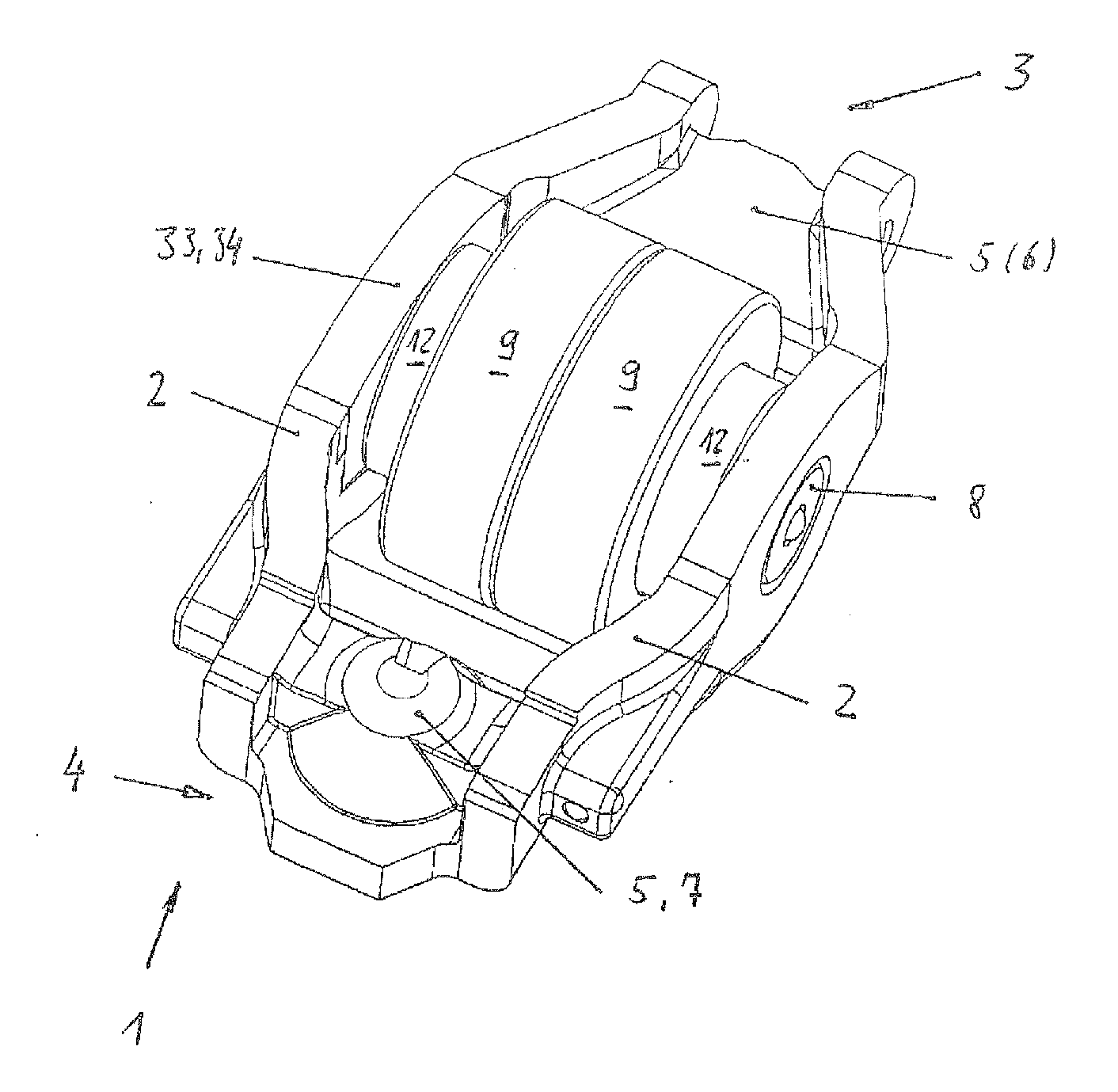

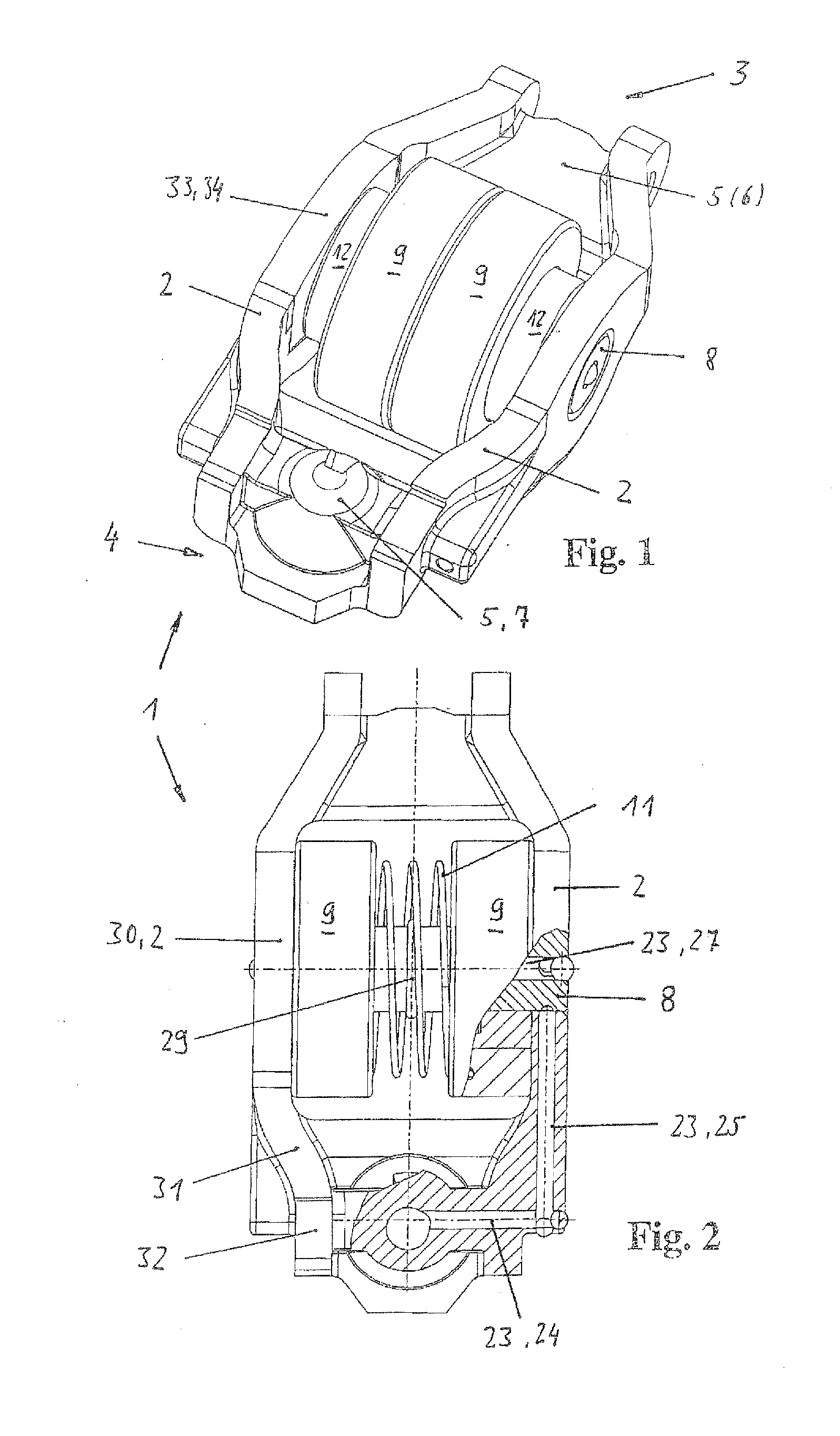

[0022]A switchable lever 1 in the form of a rocker arm lever for a valve drive of an internal combustion engine is illustrated. Said lever has a box-shaped geometry in top view and consists of two upright side walls 2, the ends 3, 4 of which are connected on their lower side by a cross bar 5. The side walls 2 have an expanded center section 30 which is adjoined by intermediate sections 31 which face each other and peter out in rectilinear end sections 32.

[0023]There is a gas-exchange valve system 6 in the crossbar 5 at the one end 3 and a bearing 7, which is designed as a dome-shaped formation and is intended for the pivotable supporting of the lever 1, at the other end 4. An axle 8 is held nondisplaceably in the side walls 2 between the ends 3, 4. Two axially displaceable cam rollers 9 run slideably on said axle.

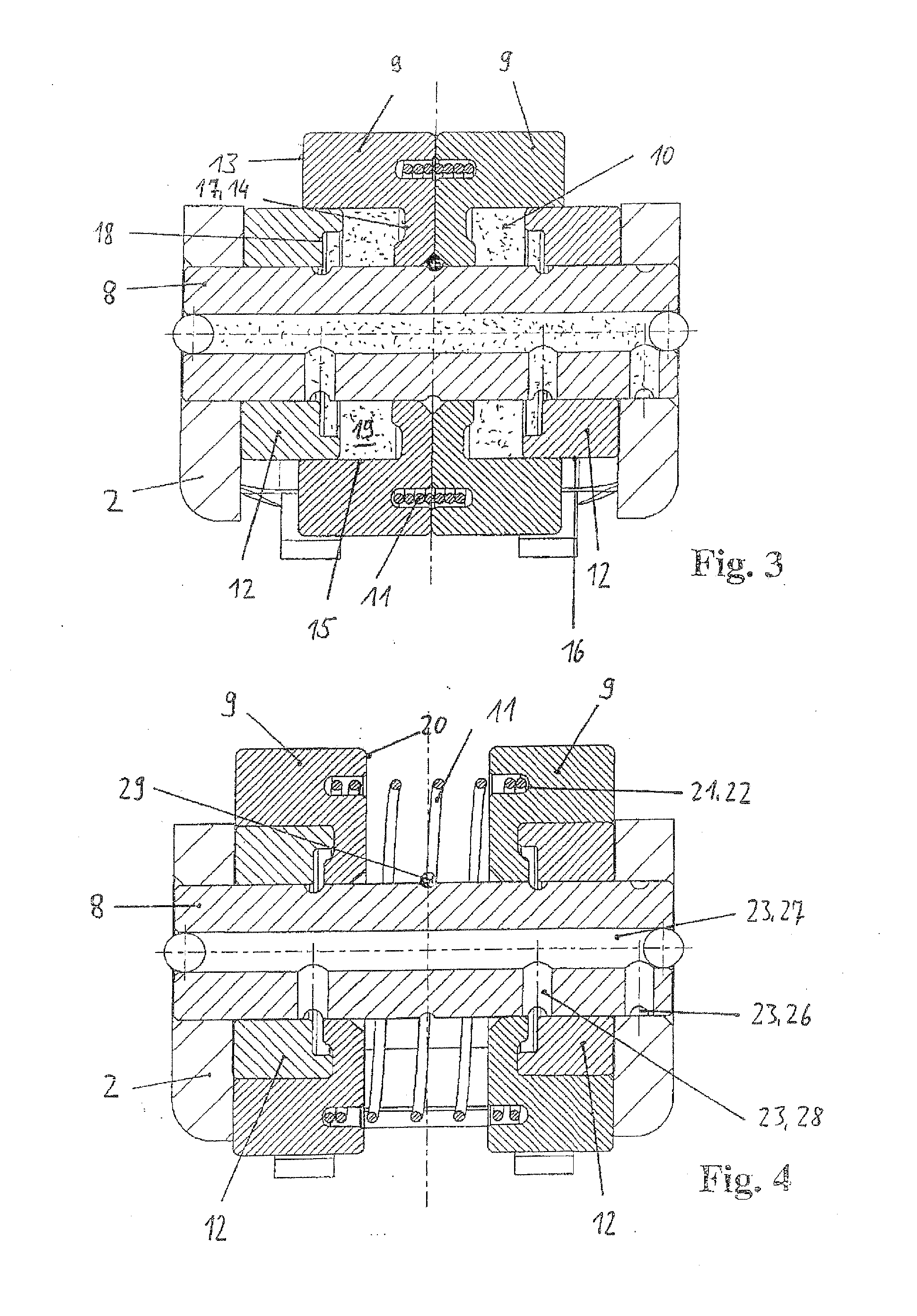

[0024]FIG. 3 shows a first position of the cam rollers 9, in which said cam rollers run up to each other on a longitudinal center plane of the lever 1. For the correct cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com