Dust removing process of coal fine spraying system and apparatus thereof

A dust removal device and pulverized coal technology, which is applied in the direction of transportation and packaging, conveying bulk materials, blast furnace parts, etc., can solve the problems of increasing process equipment and investment costs, cumbersomeness, etc., to save building space, reduce investment costs, and simplify processes The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

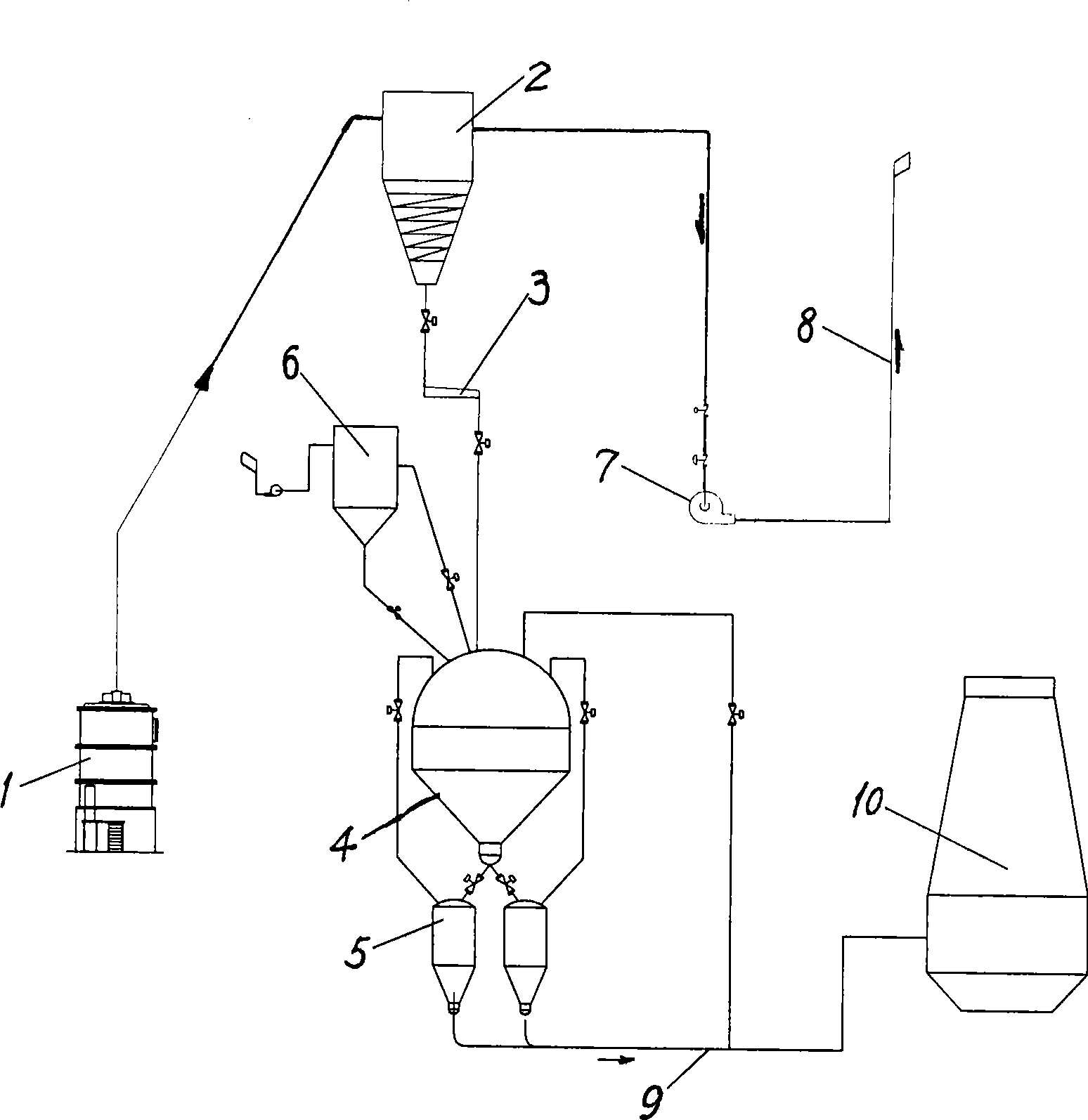

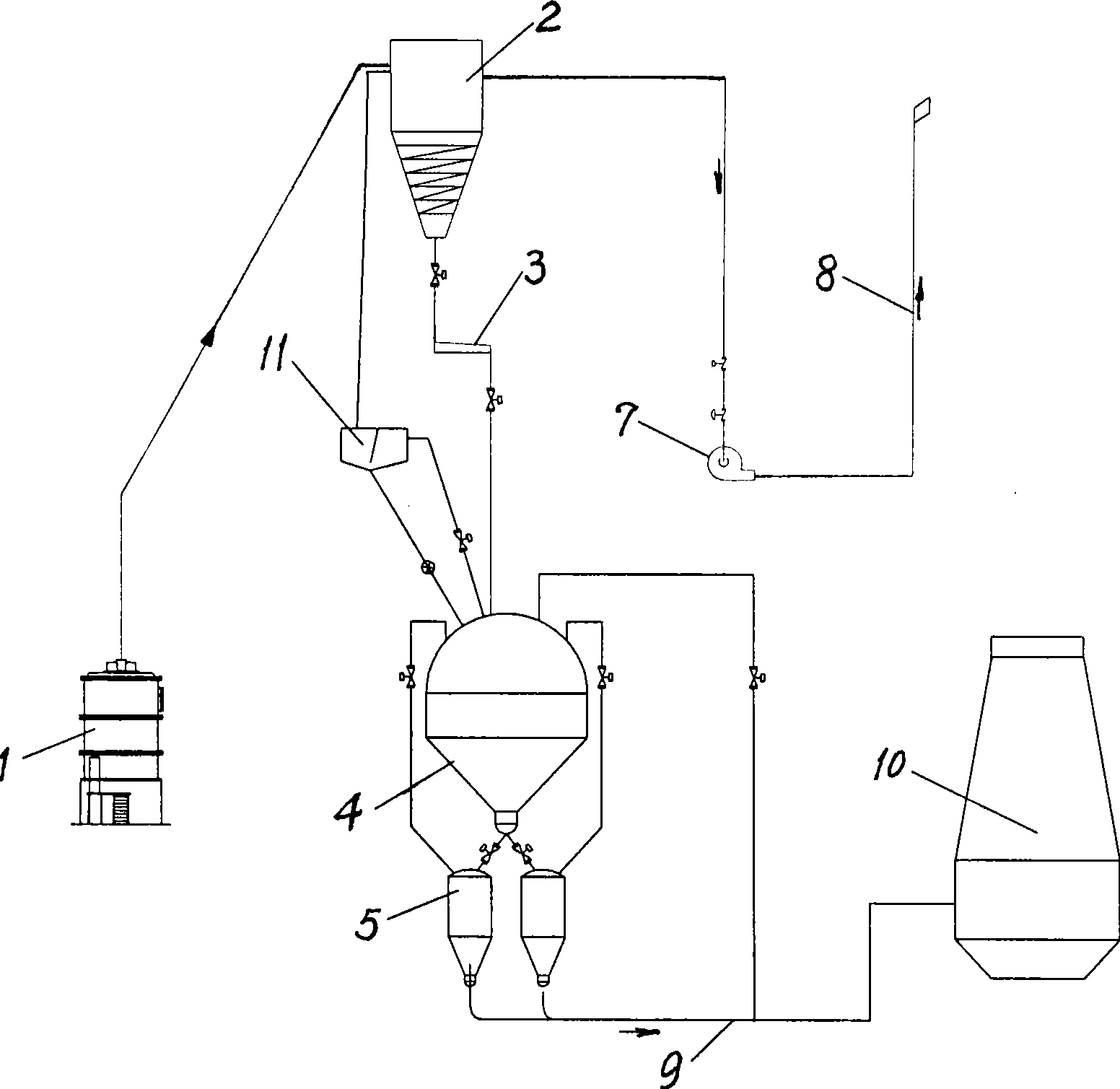

[0017] see figure 2 , according to the dedusting process of a kind of pulverized coal spraying system of the present invention, the coal that needs to be sprayed will be sent to the bag powder collector 2 by wind force after the coal powder that needs to be injected is made into coal powder through the coal mill 1, and the gas will be collected by the bag powder collector. , powder separation, after the pulverized coal is collected, it falls into the pulverized coal collection bin 4 through the feeder under the bag powder collector 2, that is, the powder feeder 3, and then unloads the pulverized coal from the pulverized coal collection bin 4 into the injection tank 5 , the injection tank 5 is injected into the blast furnace 10 through the injection main pipe 9 in a pneumatic manner.

[0018] Simultaneously, because this dedusting process has removed the cloth bag dust collector originally set on the top of the pulverized coal collection bin 4, the bag dust collector 2 above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com