Nano-composite electric conduction anticorrosive paint and preparation method thereof

A conductive anti-corrosion and nano-composite technology, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve problems such as low solubility, and achieve the effects of simple process equipment, high corrosion resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

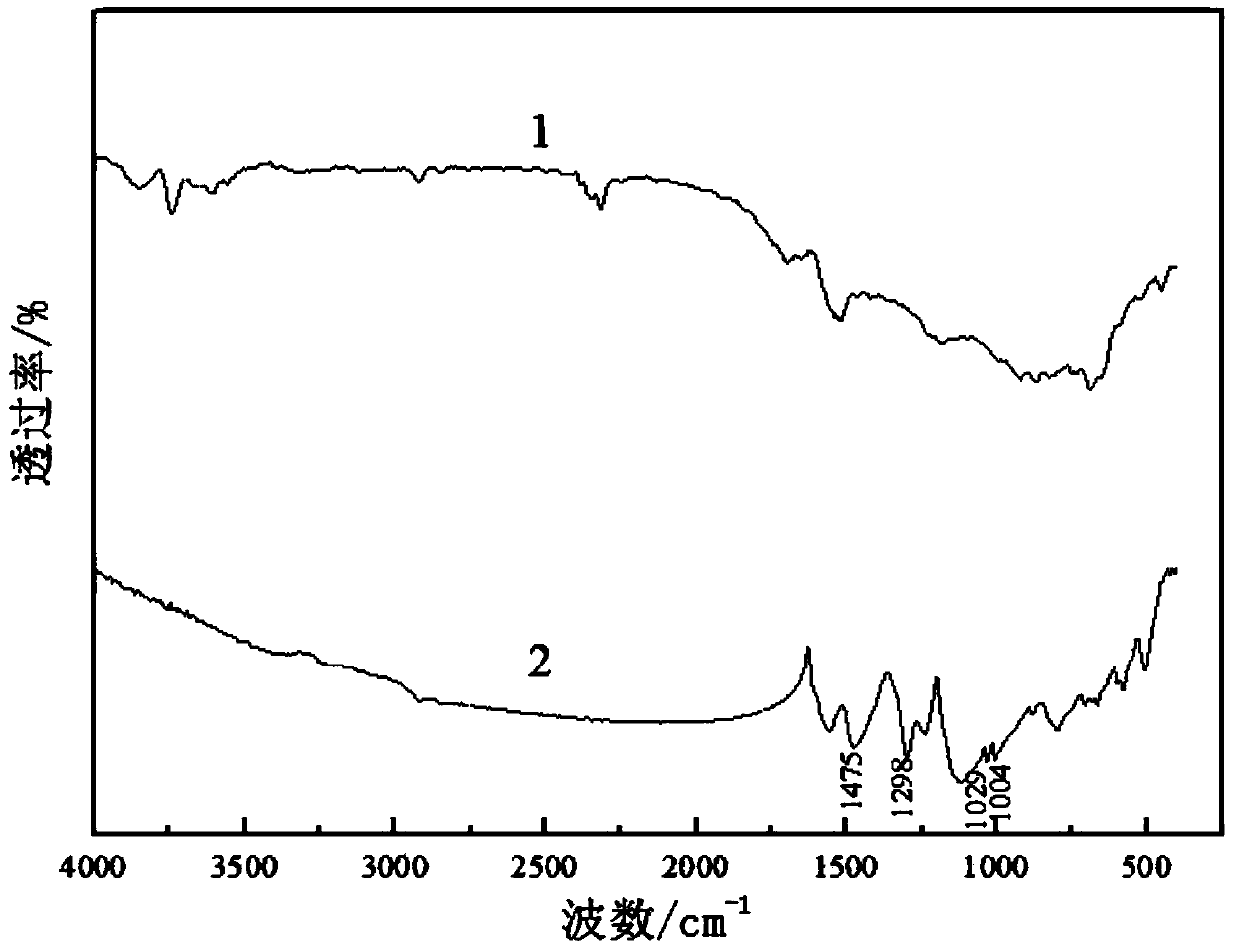

[0038] Step 1: Carbon nanotube (CNT) modification

[0039] Using 98% concentrated sulfuric acid and 65% concentrated nitric acid, press Prepare aqua regia in proportion to; then press m CNT : V Aqua regia Weigh (quantity) the ratio of =1mg:50mL to take multi-walled carbon nanotubes (CNT) and aqua regia. Disperse the weighed multi-walled carbon nanotubes in aqua regia, and ultrasonically treat them in a water bath for 2 hours, then wash the acidified multi-walled carbon nanotube mixed solution with distilled water to neutrality, and heat the resulting black solid at 50°C Vacuum drying for 24 hours to obtain surface-modified carbon nanotubes.

[0040] Step 2: Preparation of PANI-DBSA / CNT composite material

[0041] Press m CNT : M aniline : M Ammonium persulfate =1mg:28g:70g and weigh the surface-modified carbon nanotubes, aniline and ammonium persulfate. The weighed modified carbon nanotubes and aniline were dissolved in 100 ml of 1.0 mol / L phosphoric acid, and the weighed ammon...

Embodiment approach 2

[0047] Step 1: Carbon nanotube (CNT) modification

[0048] Using 98% concentrated sulfuric acid and 65% concentrated nitric acid, press Prepare aqua regia in proportion to; then press m CNT : V Aqua regia =10mg:55mL to weigh (quantify) multi-walled carbon nanotubes (CNT) and aqua regia. Disperse the weighed multi-walled carbon nanotubes in aqua regia, and ultrasonically treat them in a water bath for 2 hours, then wash the acidified multi-walled carbon nanotube mixed solution with distilled water to neutrality, and heat the resulting black solid at 50°C Vacuum drying for 24 hours to obtain surface-modified carbon nanotubes.

[0049] Step 2: Preparation of PANI-DBSA / CNT composite material

[0050] Press m CNT : M aniline : M Ammonium persulfate =10mg: 25g: 60g to weigh the surface modified carbon nanotubes, aniline and ammonium persulfate. The weighed modified carbon nanotubes and aniline were dissolved in 100 ml of 1.0 mol / L phosphoric acid, and the weighed ammonium persulfate ...

Embodiment approach 3

[0056] Step 1: Carbon nanotube (CNT) modification

[0057] Using 98% concentrated sulfuric acid and 65% concentrated nitric acid, press Prepare aqua regia in proportion to; then press m CNT : V Aqua regia =20mg:55mL Weigh (quantity) take multi-walled carbon nanotubes (CNT) and aqua regia. Disperse the weighed multi-walled carbon nanotubes in aqua regia, and ultrasonically treat them in a water bath for 2 hours, then wash the acidified multi-walled carbon nanotube mixed solution with distilled water to neutrality, and heat the resulting black solid at 50°C Vacuum drying for 24 hours to obtain surface-modified carbon nanotubes.

[0058] Step 2: Preparation of PANI-DBSA / CNT composite material

[0059] Press m CNT : M aniline : M Ammonium persulfate =30mg: 15g: 30g ratio to weigh the surface modified carbon nanotubes, aniline and ammonium persulfate. The weighed modified carbon nanotubes and aniline were dissolved in 100 ml of 1.0 mol / L phosphoric acid, and the weighed ammonium per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com