Method for numerously preparing asphalt-based graphene material with low cost

A graphene and pitch-based technology, applied in the field of carbon materials, can solve problems that hinder the promotion and application of graphene materials, environmental pollution, and complex processes, and achieve the effects of easy large-scale production, wide application, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

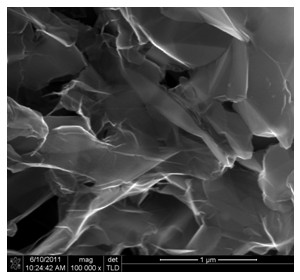

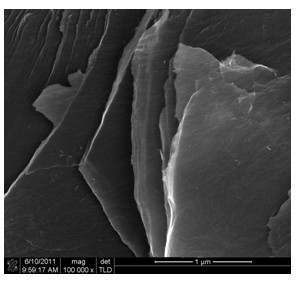

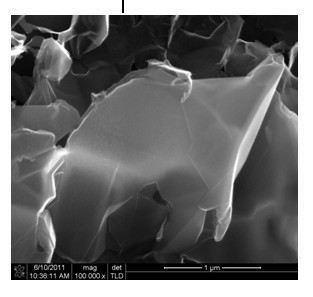

Image

Examples

Embodiment 1

[0042] Grind the coal tar pitch to 200 mesh and put it into the polymerization kettle. Before 100°C, the temperature is raised freely, and after 100°C, the temperature is raised at a speed of 20°C / min, and nitrogen is introduced from the beginning of the temperature rise. 2 , N 2 The flow rate is 50mL / min. When the temperature rises to 300°C, adjust the rotational speed to 1000rpm and stir for 5 hours to obtain prepared asphalt. Put the prepared asphalt into the atmosphere furnace (N 2 The flow rate is 50 mL / min), and then the temperature is raised to 500 °C at 2 °C / min and then kept for 10 h, and the pyrolysis product is taken out after cooling to room temperature with the furnace. Put the pyrolysis product into a vacuum furnace (vacuum degree 100 Pa), then raise the temperature to 2200 °C at 2 °C / min, keep it for 5 h, and take it out with the furnace cooling to room temperature to obtain the graphene material. The prepared graphene material has the following properties: t...

Embodiment 2

[0044] Grind the mesophase pitch to 200 mesh and put it into the polymerization tank. Before 200°C, the temperature is raised freely, and after 200°C, the temperature is raised at a speed of 10°C / min, and Ar is introduced from the beginning of the temperature rise. 2 , Ar 2 The flow rate is 100mL / min. When the temperature rises to 400°C, adjust the rotational speed to 50rpm and stir for 1 hour to obtain prepared asphalt. Put the prepared asphalt into the atmosphere furnace (N 2 The flow rate is 50mL / min), and then the temperature is raised to 1000°C at 100°C / min and then kept for 5 hours, and the pyrolysis product is taken out after cooling to room temperature with the furnace. Put the pyrolysis product into a vacuum furnace (vacuum degree 1.0×10 3 Pa), then heated up to 1900°C at 20°C / min and kept for 0.1 h, then cooled to room temperature with the furnace and taken out to obtain graphene materials. The prepared graphene material has the following properties: the yield i...

Embodiment 3

[0046] Weigh coal tar pitch and petroleum pitch at a ratio of 50:50 (weight ratio), grind them to 200 mesh and put them into a polymerization kettle. Before 100°C, the temperature is raised freely, and after 100°C, the temperature is raised at a speed of 5°C / min. Into N 2 , N 2 The flow rate is 200mL / min. When the temperature rises to 200°C, adjust the rotational speed to 500rpm and stir for 4 hours to obtain prepared asphalt. Put the prepared pitch into the atmosphere furnace (Ar 2 The flow rate is 200mL / min), and then the temperature is raised to 500°C at 2°C / min, and then kept for 10h, and the pyrolysis product is taken out after cooling to room temperature with the furnace. Put the pyrolysis product into a vacuum furnace (vacuum degree 10 Pa), then raise the temperature to 2000 °C at 50 °C / min, keep it for 10 h, and take it out as the furnace cools to room temperature to obtain the graphene material. The prepared graphene material has the following properties: the yiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com