Patents

Literature

1191 results about "Performance prediction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In computer science, performance prediction means to estimate the execution time or other performance factors (such as cache misses) of a program on a given computer. It is being widely used for computer architects to evaluate new computer designs, for compiler writers to explore new optimizations, and also for advanced developers to tune their programs.

Estimating expected performance of advertisements

InactiveUS20080249832A1Improving search engine providerImproving advertiser revenueMarketingSpecial data processing applicationsArtificial intelligenceSystems approaches

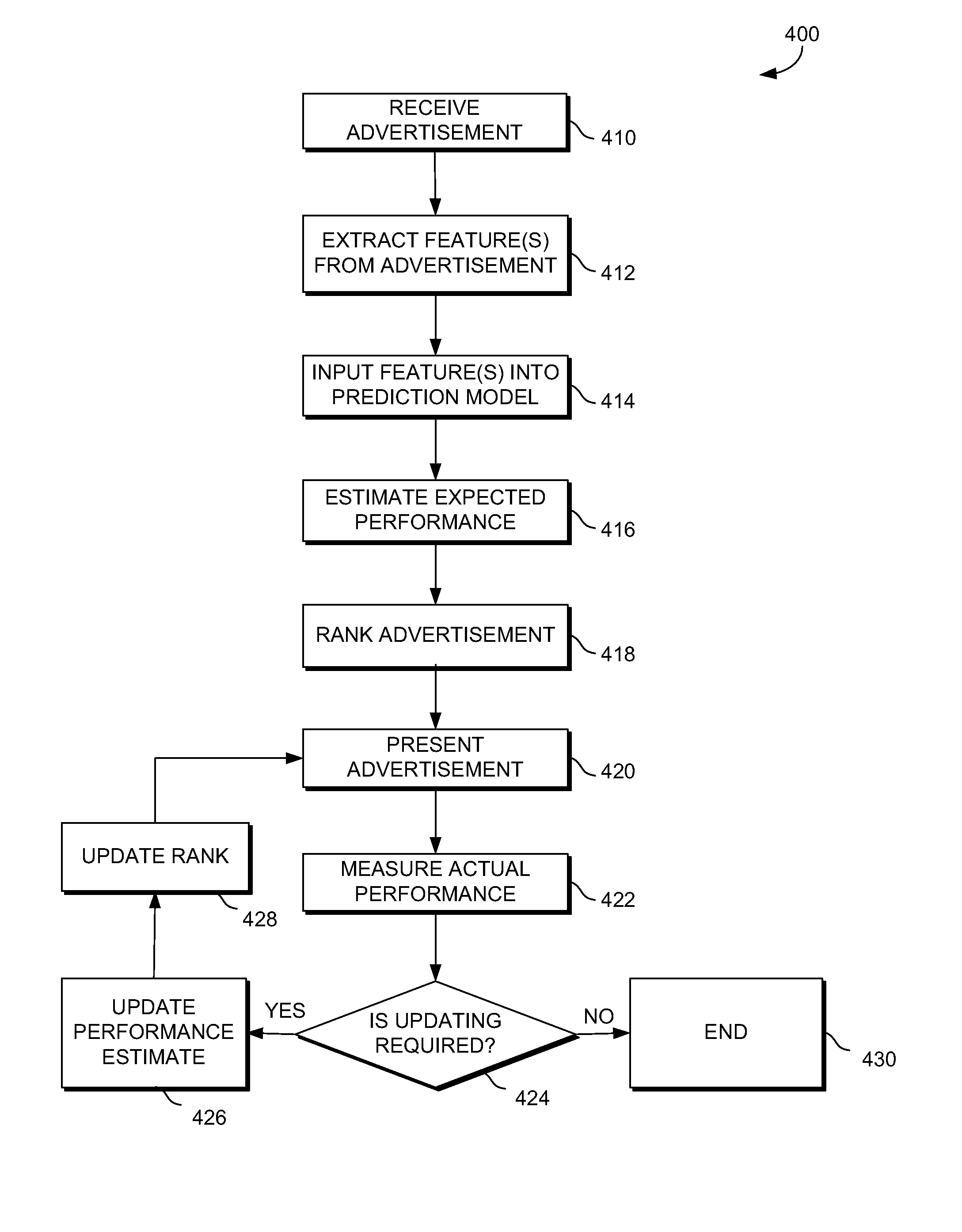

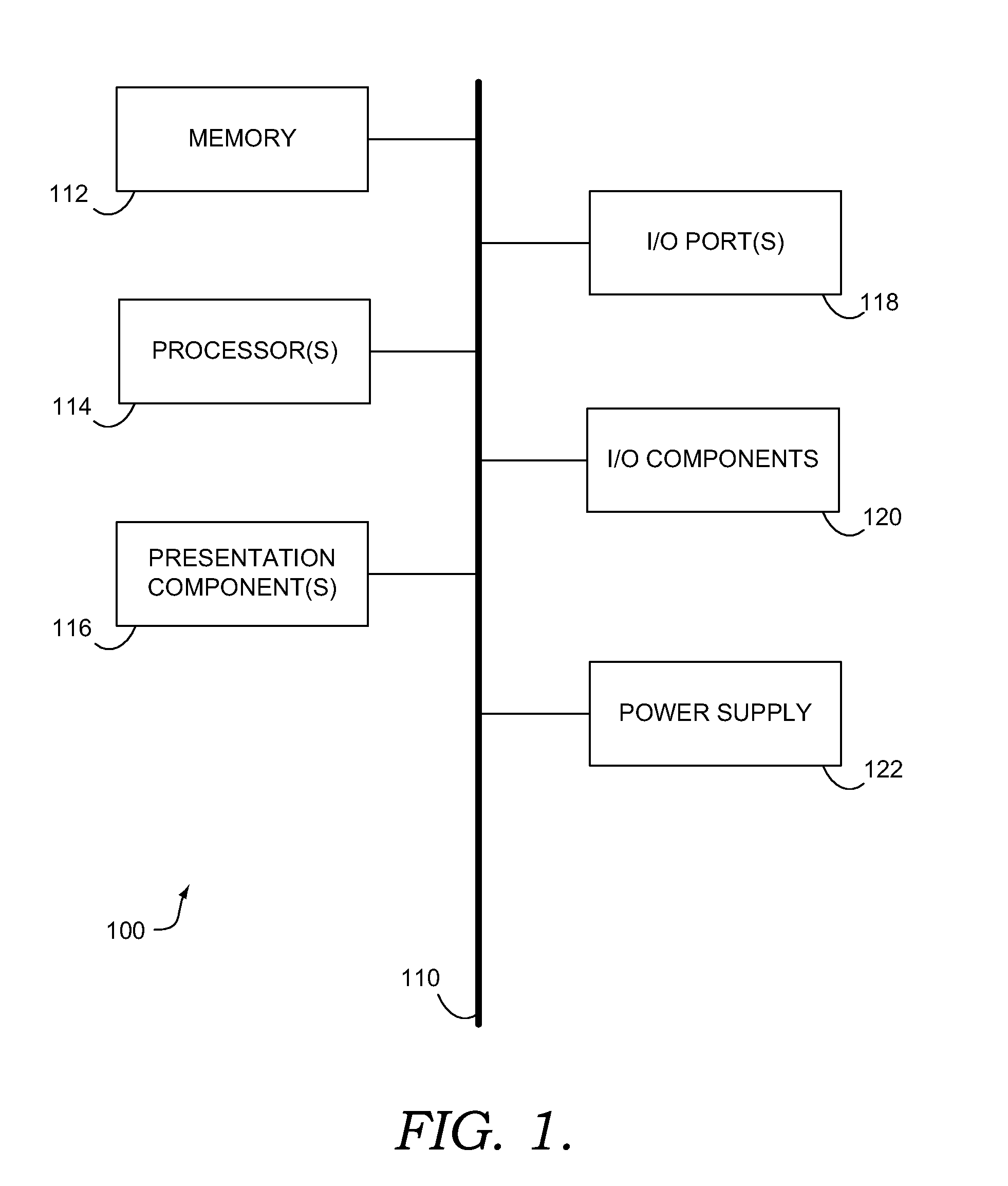

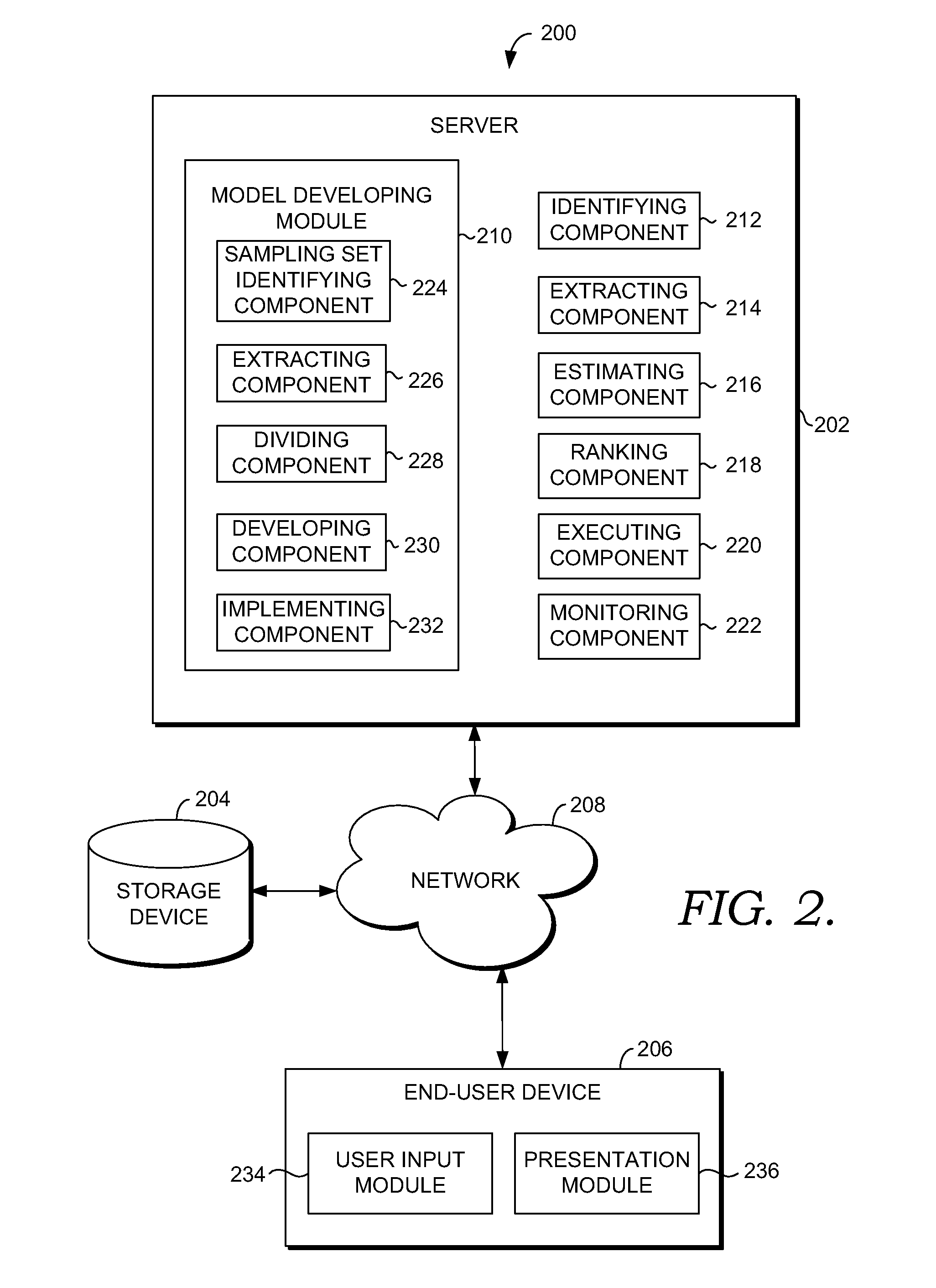

Systems, methods, and computer-readable media for estimating expected advertisement performance of advertisements are provided. An advertisement performance prediction model is developed using features extracted from a sample set. Once developed, advertisements that are not a part of the sample set are identified and features are extracted there from. The features are then input into the advertisement performance prediction model and expected performance of the corresponding advertisement is estimated. In embodiments, the estimated expected advertisement performance may be used to appropriately rank the advertisement relative to a plurality of other advertisements such that the advertisement will be displayed according to the advertisement ranking.

Owner:MICROSOFT TECH LICENSING LLC

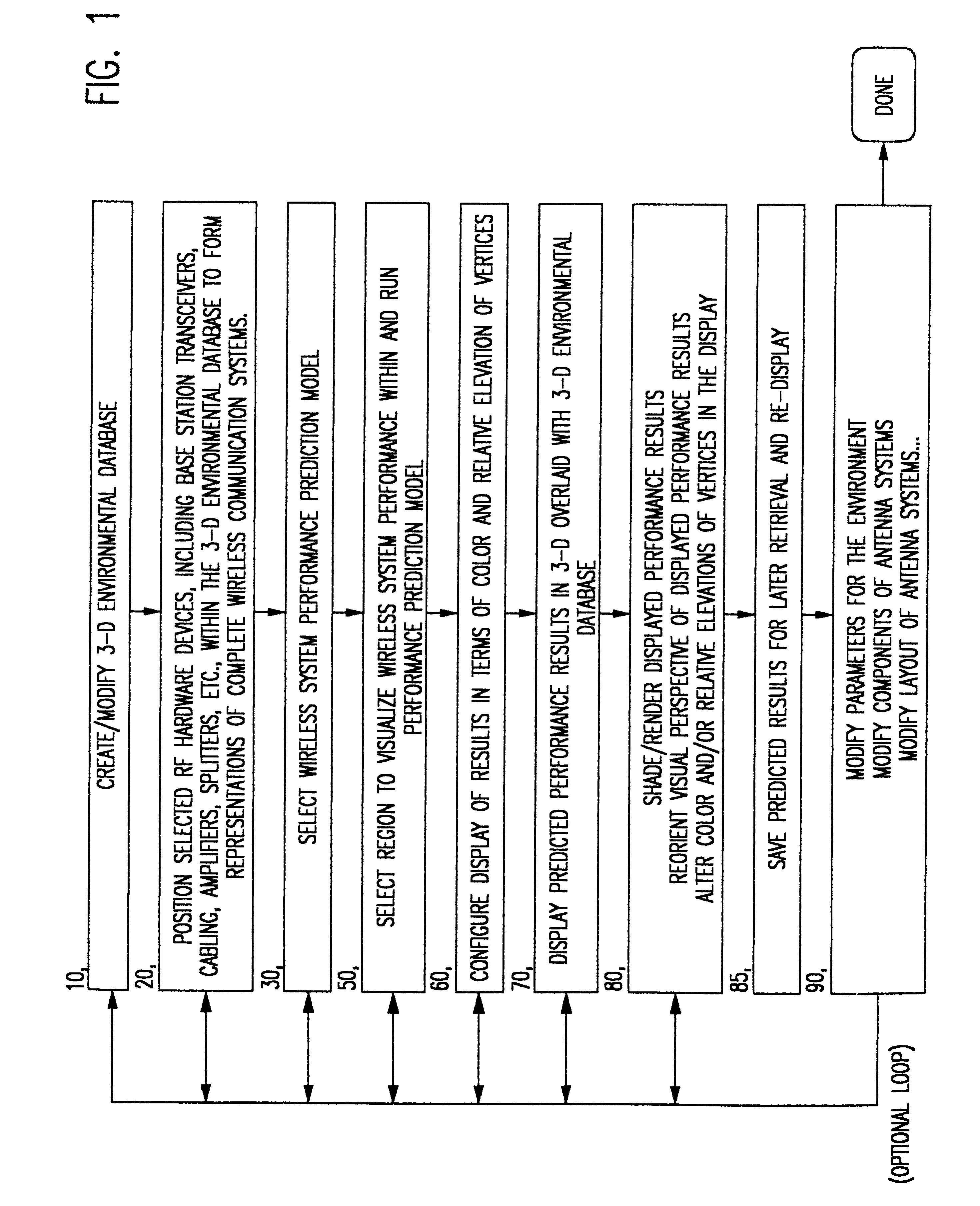

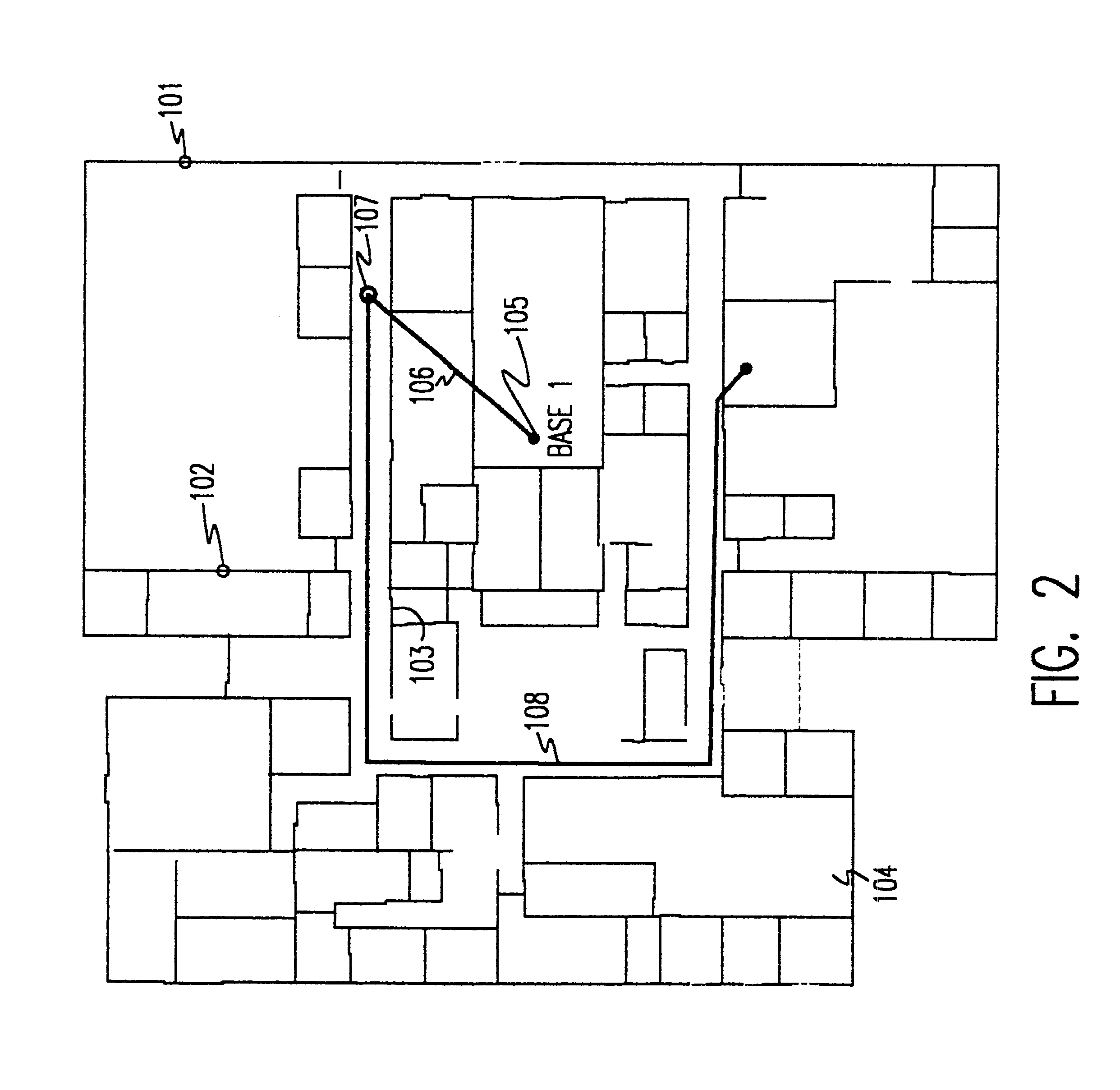

System for the three-dimensional display of wireless communication system performance

InactiveUS6499006B1Receivers monitoringRadio/inductive link selection arrangementsTerrainCommunications system

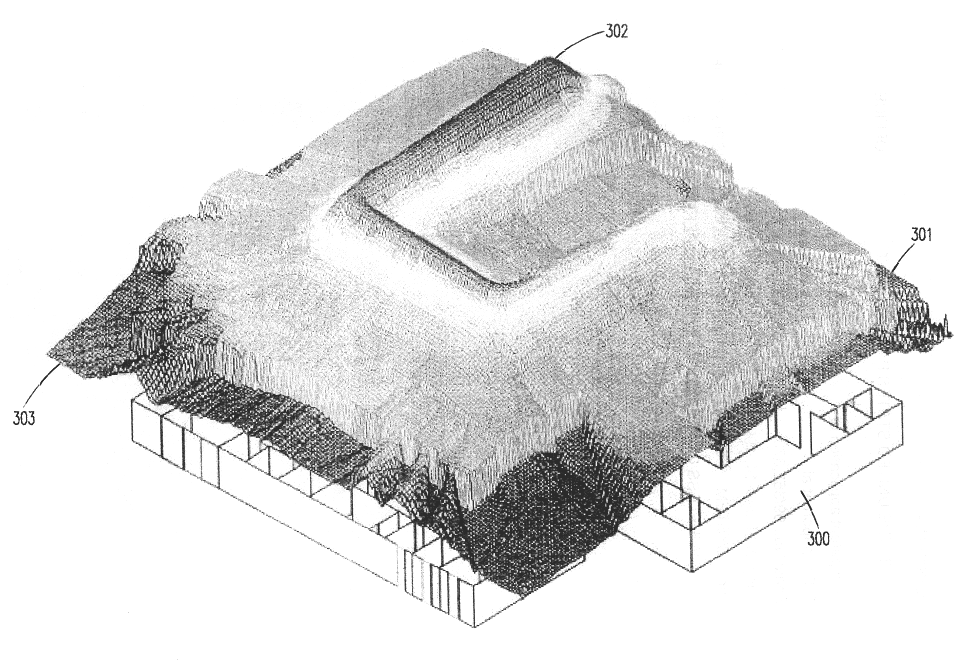

A method for displaying the results of predicted wireless communication system performance as a three-dimensional region of fluctuating elevation and / or color within a three-dimensional computer drawing database consisting of one or more multi-level buildings, terrain, flora, and additional static and dynamic obstacles (e.g., automobiles, people, filing cabinets, etc.). The method combines computerized organization, database fusion, and site-specific performance prediction models. The method enables a design engineer to visualize the performance of any wireless communication system as a three-dimensional region of fluctuating elevation, color, or other aesthetic characteristics with fully selectable display parameters, overlaid with the three-dimensional site-specific computer model for which the performance prediction was carried out.

Owner:EXTREME NETWORKS INC

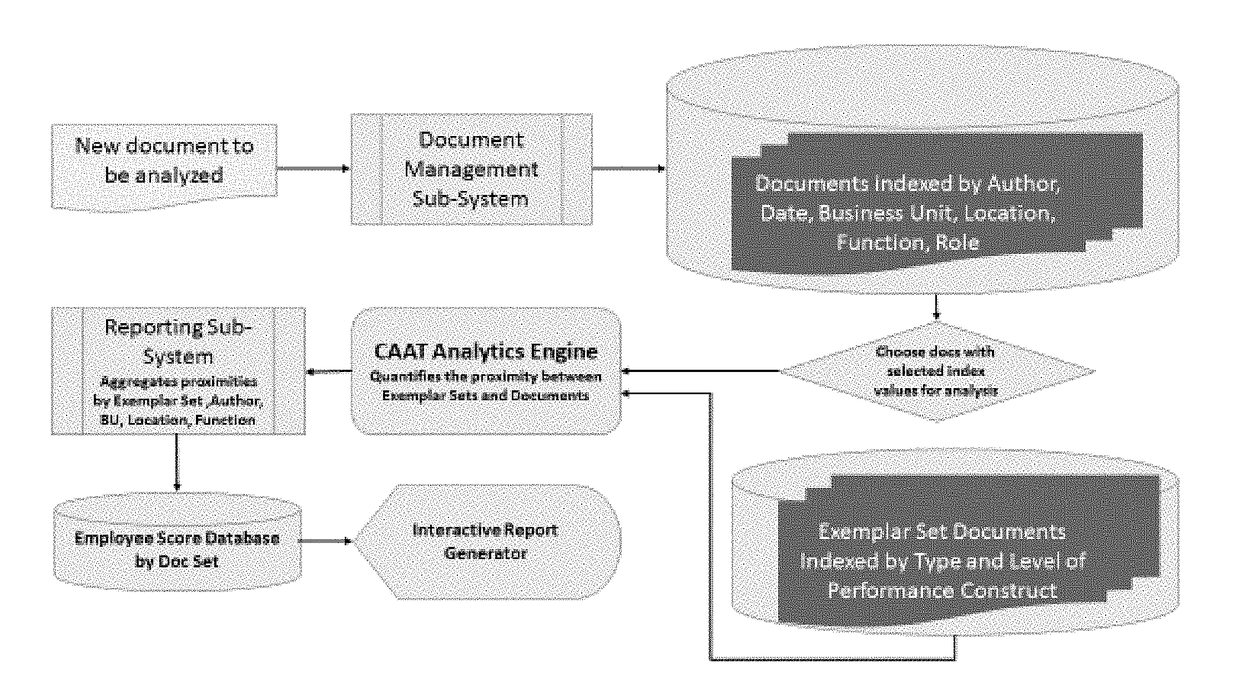

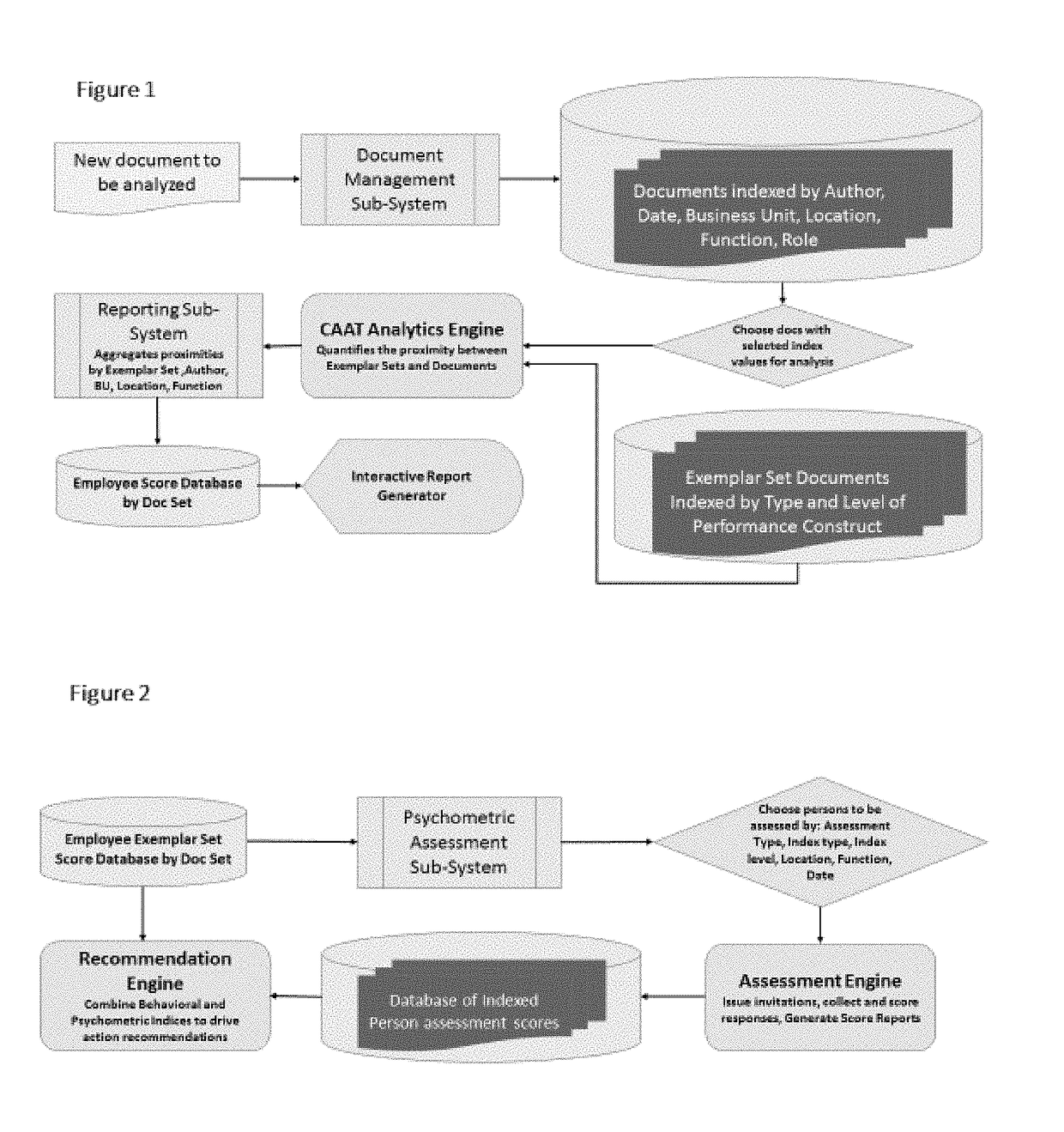

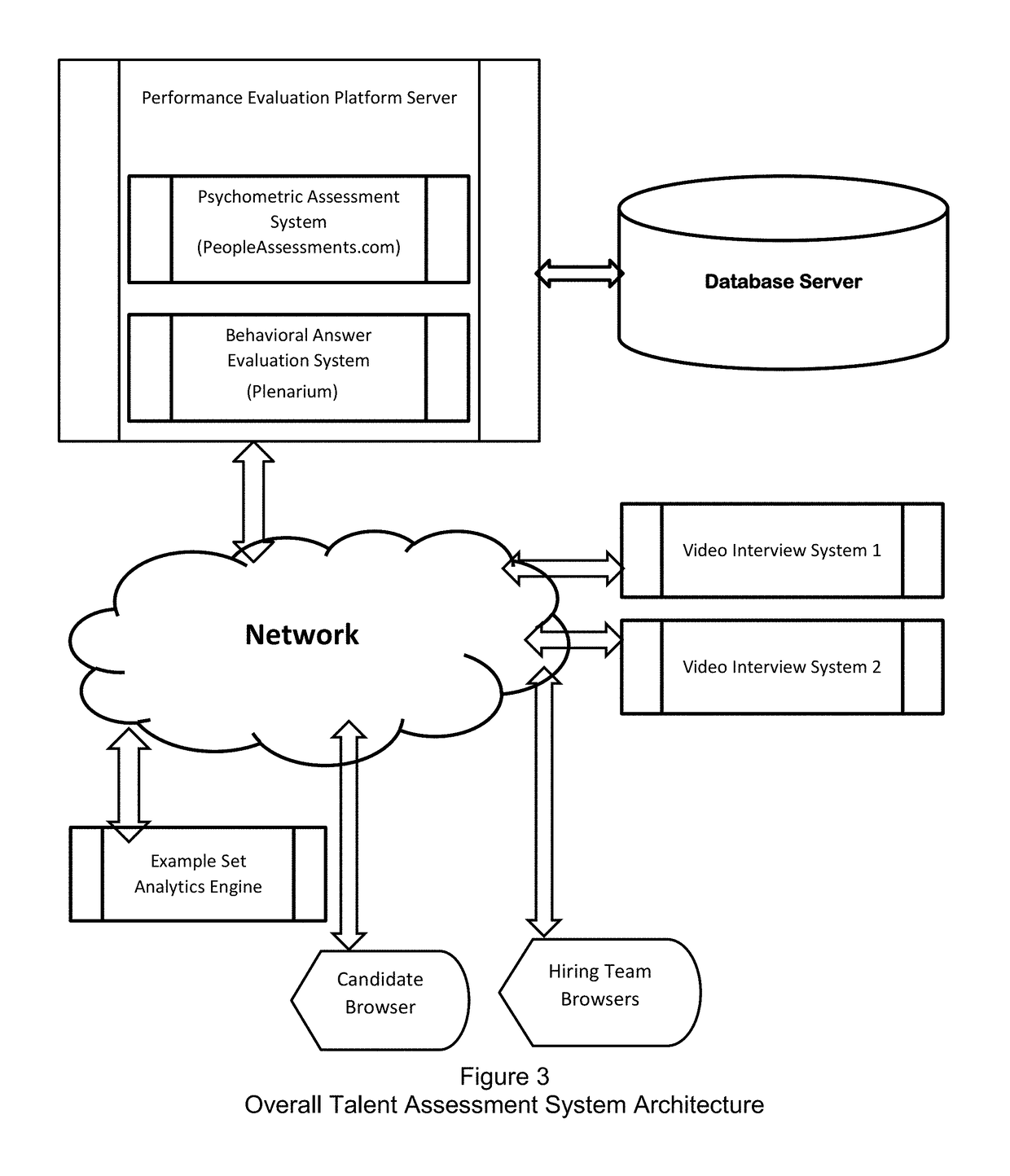

System and method for computerized predictive performance analysis of natural language

InactiveUS20180025303A1Improve impactExceptional valueMedical data miningMedical automated diagnosisComputer scienceHuman language

A method of behavior assessment or performance prediction, comprising: acquiring a video stream of an interviewee responding to a set of interview prompts or a corpus of documents of a subject; analyzing at least the semantic content of the video stream or corpus; statistically processing, with at least one automated processor, the semantic content according to a correspondence of the interviewee's response or subject's corpus to a set of classified exemplar responses, and a context, to classify the interviewee or subject with respect to the context; and generating at least one output selectively dependent on the classification of the interviewee or subject.

Owner:PLENARIUM INC

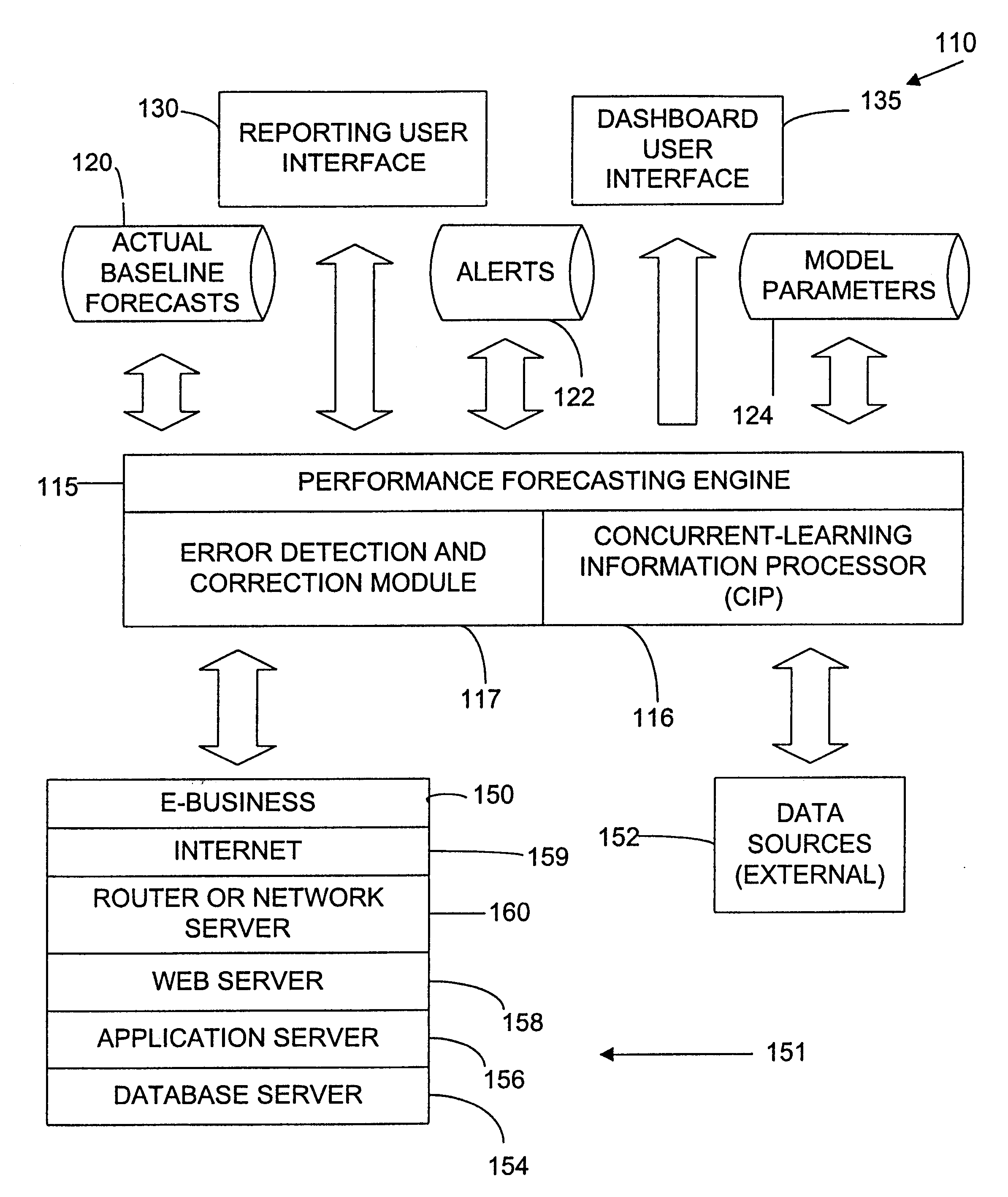

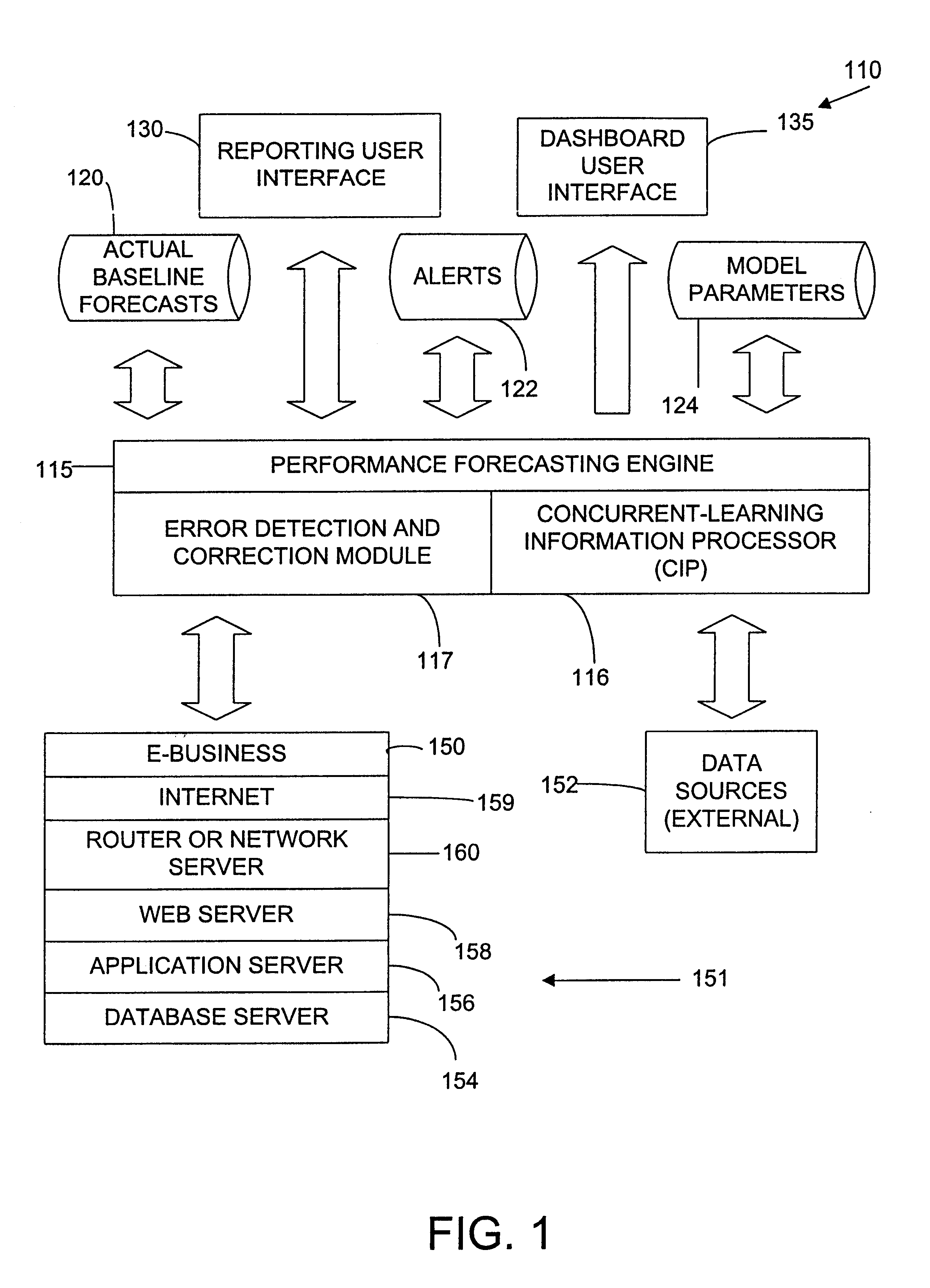

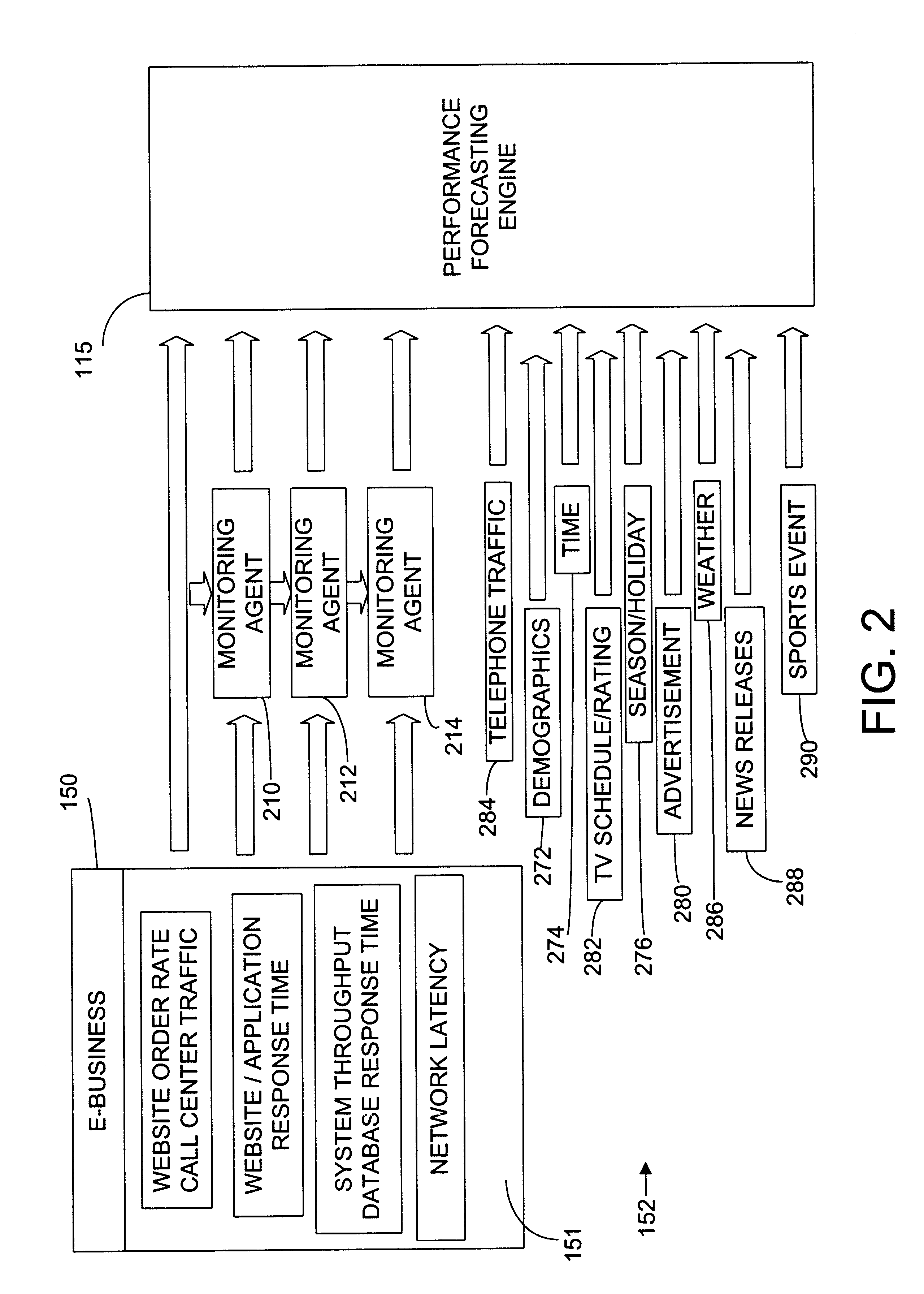

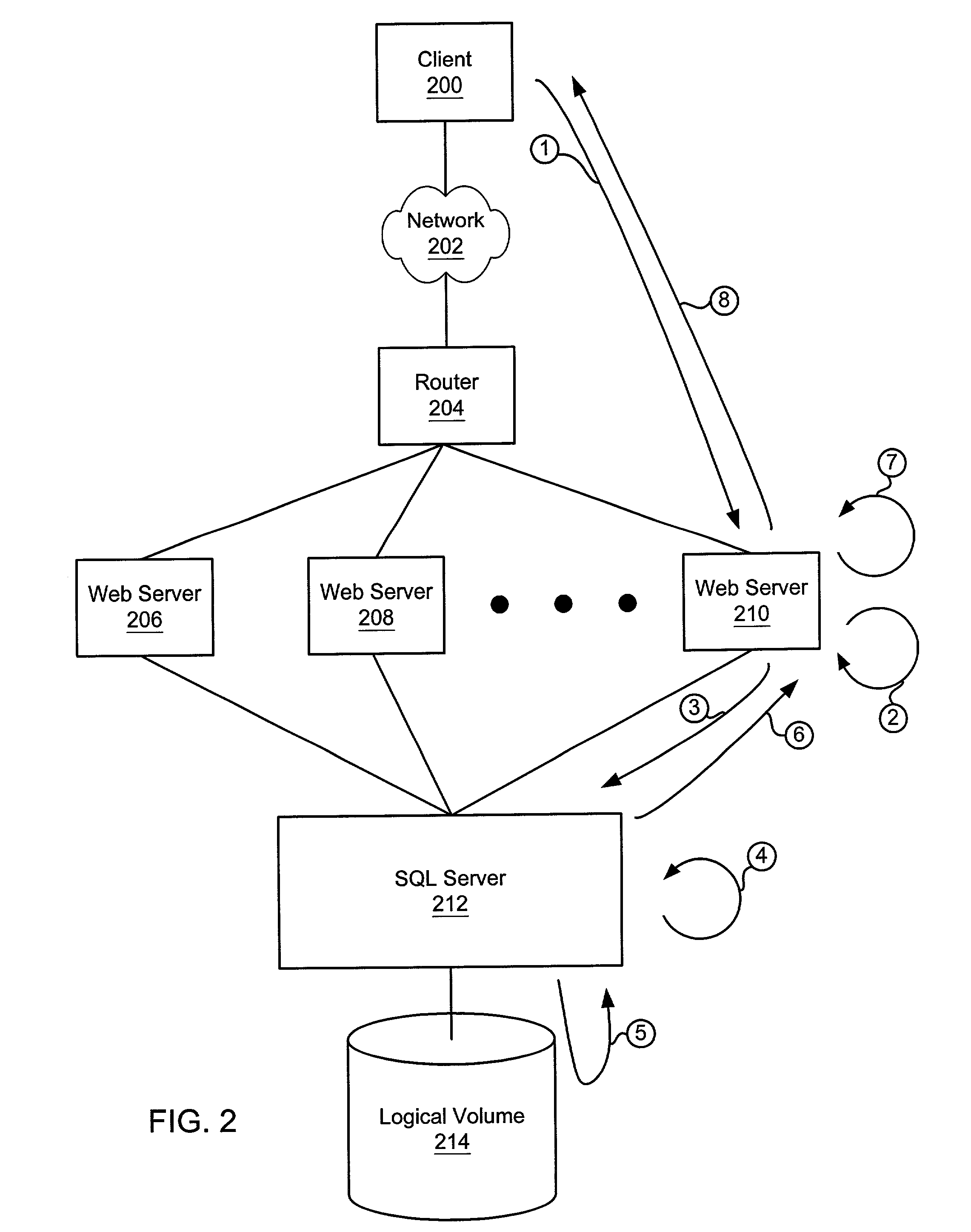

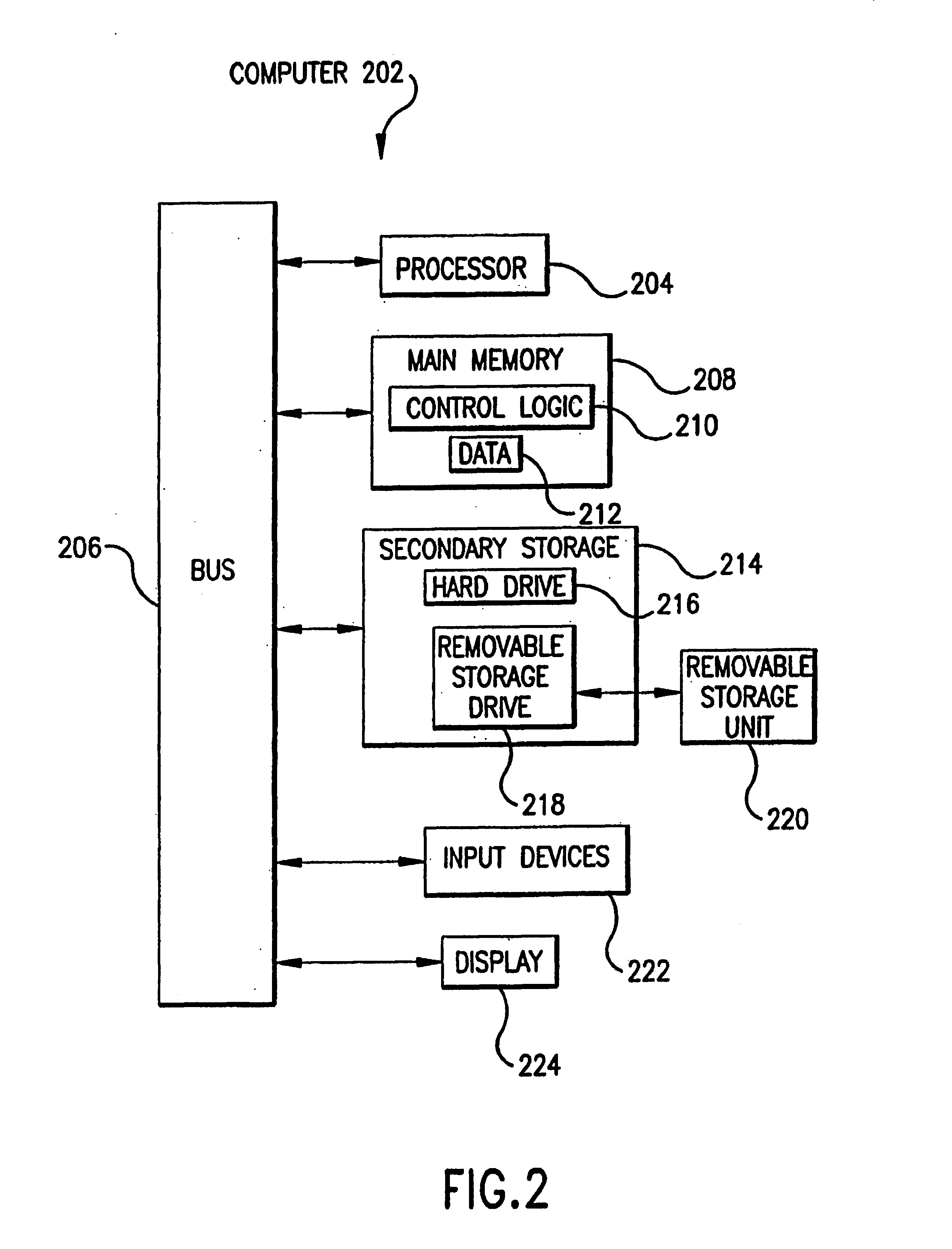

Enhanced computer performance forecasting system

ActiveUS6876988B2Accurate predictionEnsure correct executionDigital computer detailsHardware monitoringComputer performanceEngineering

A method and system for computing a performance forecast for an e-business system or other computer architecture to proactively manage the system to prevent system failure or slow response time. The system is adapted to obtain measured input values from a plurality of internal data sources and external data sources to predict a system's performance especially under unpredictable and dramatically changing traffic levels in an effort to proactively manage the system to avert system malfunction or slowdown. The performance forecasting system can include both intrinsic and extrinsic variables as predictive inputs. Intrinsic variables include measurements of the systems own performance, such as component activity levels and system response time. Extrinsic variables include other factors, such as the time and date, whether an advertising campaign is underway, and other demographic factors that may effect or coincide with increased network traffic.

Owner:NETUITIVE

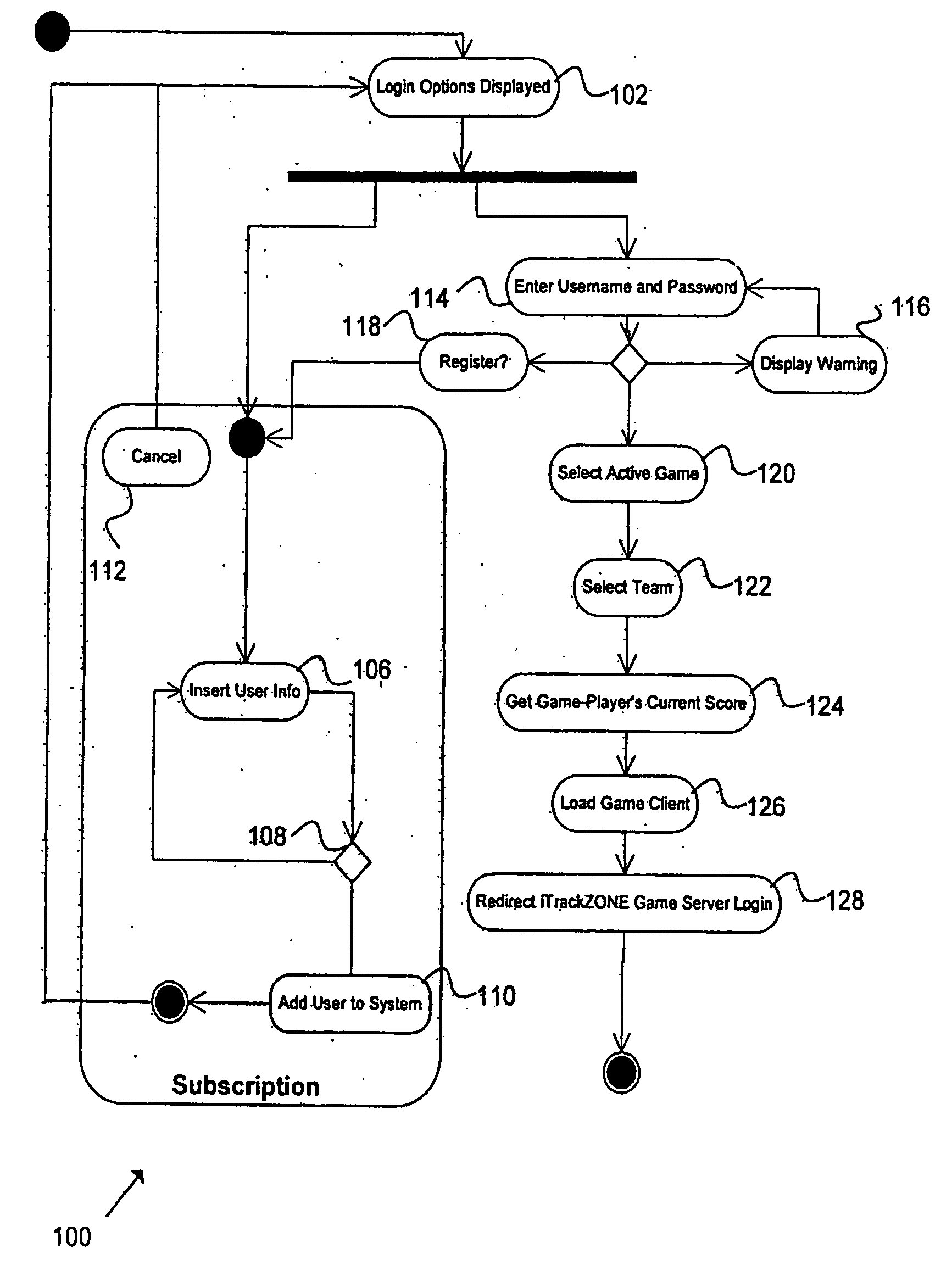

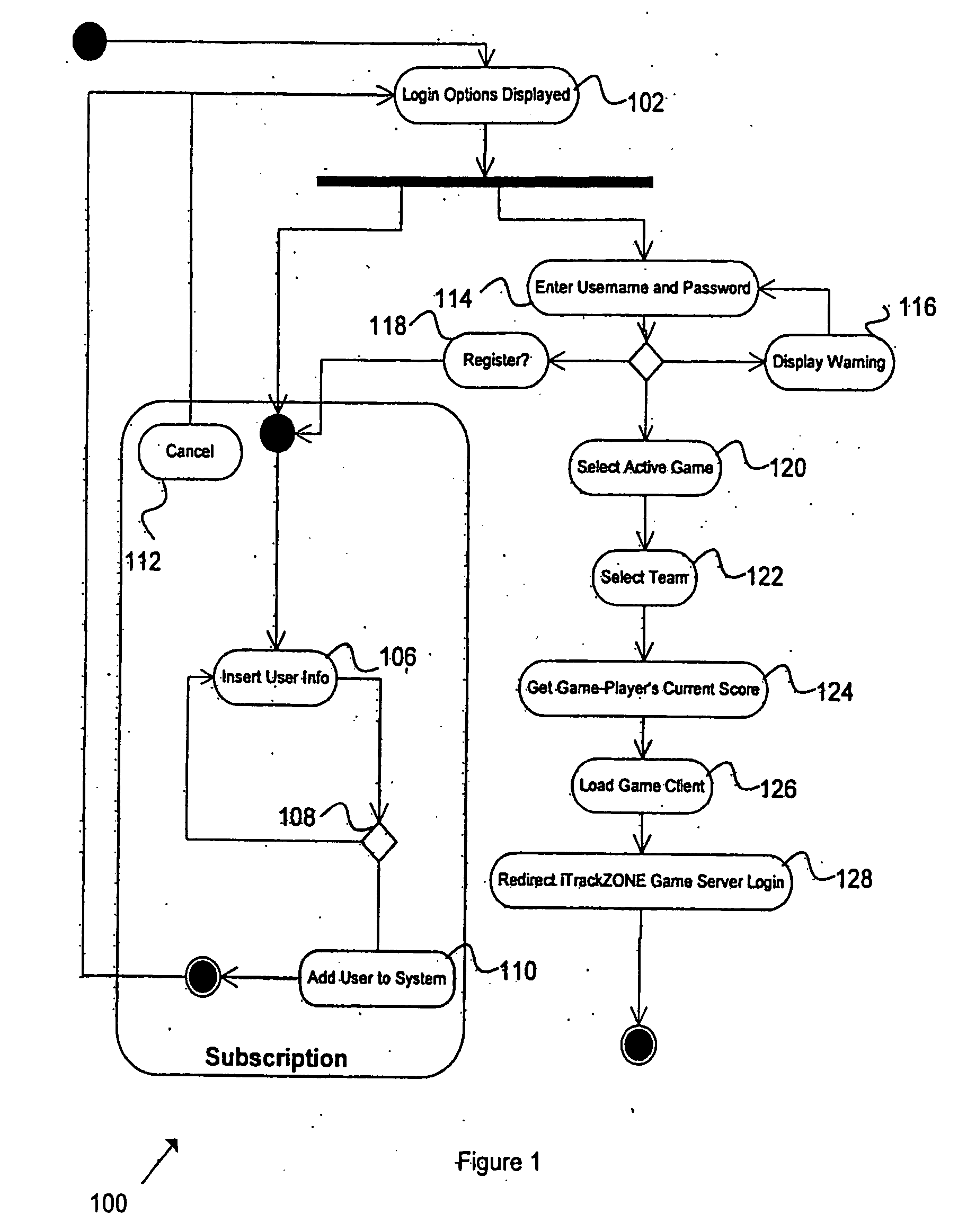

Method and apparatus for interactive real time distributed gaming

The present invention relates to an apparatus, system and method for playing interactive distributed gaming. One embodiment of the method comprises transmitting a performance prediction to a scoring database on a game server and determining an actual performance outcome. The actual performance outcome representation is transmitted to a remote terminal. The performance prediction is scored based on the actual performance outcome. In at least one embodiment, a predetermined ruleset is used to score the performance prediction based on the actual performance outcome.

Owner:JORDAN KENT WILCOXSON +1

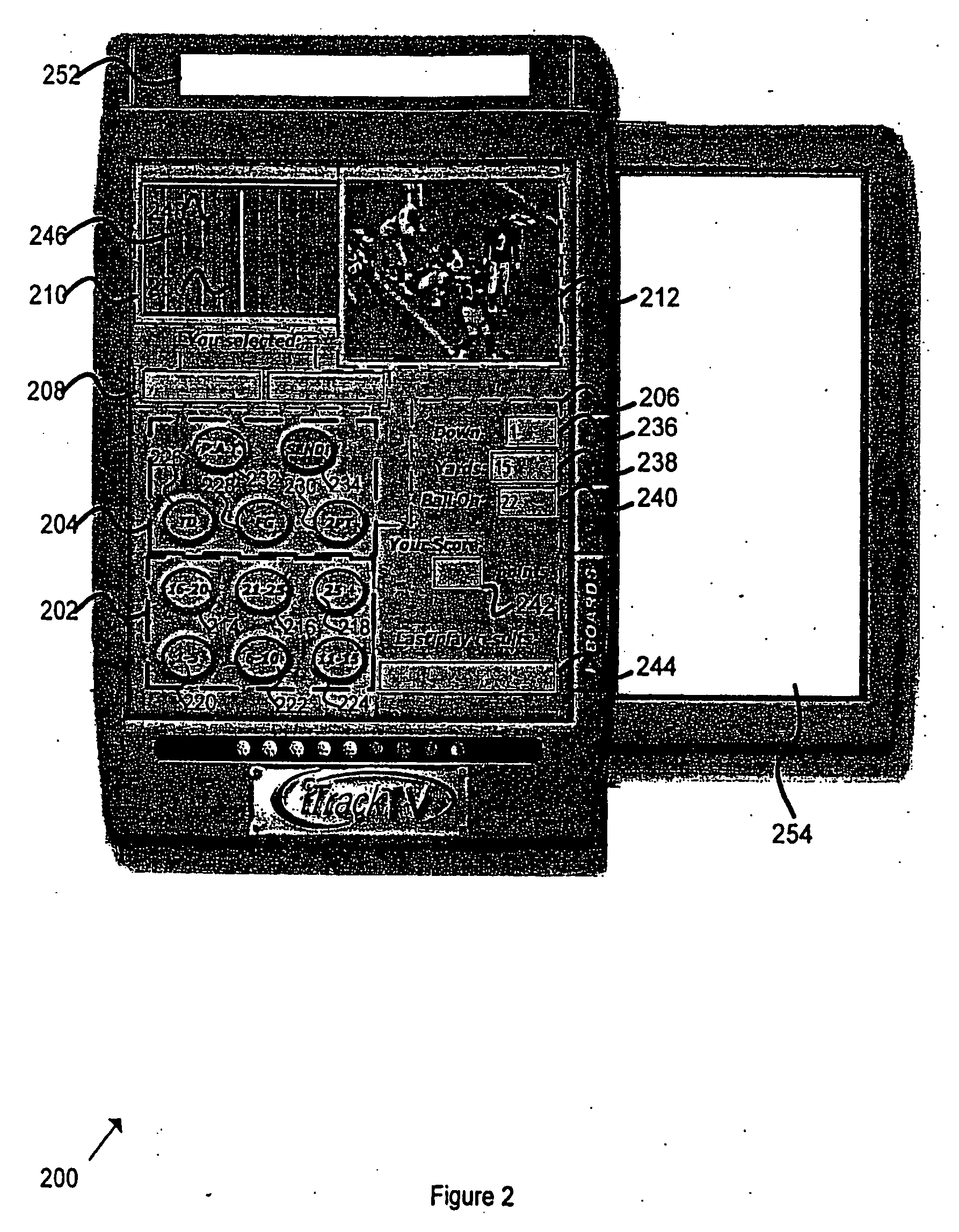

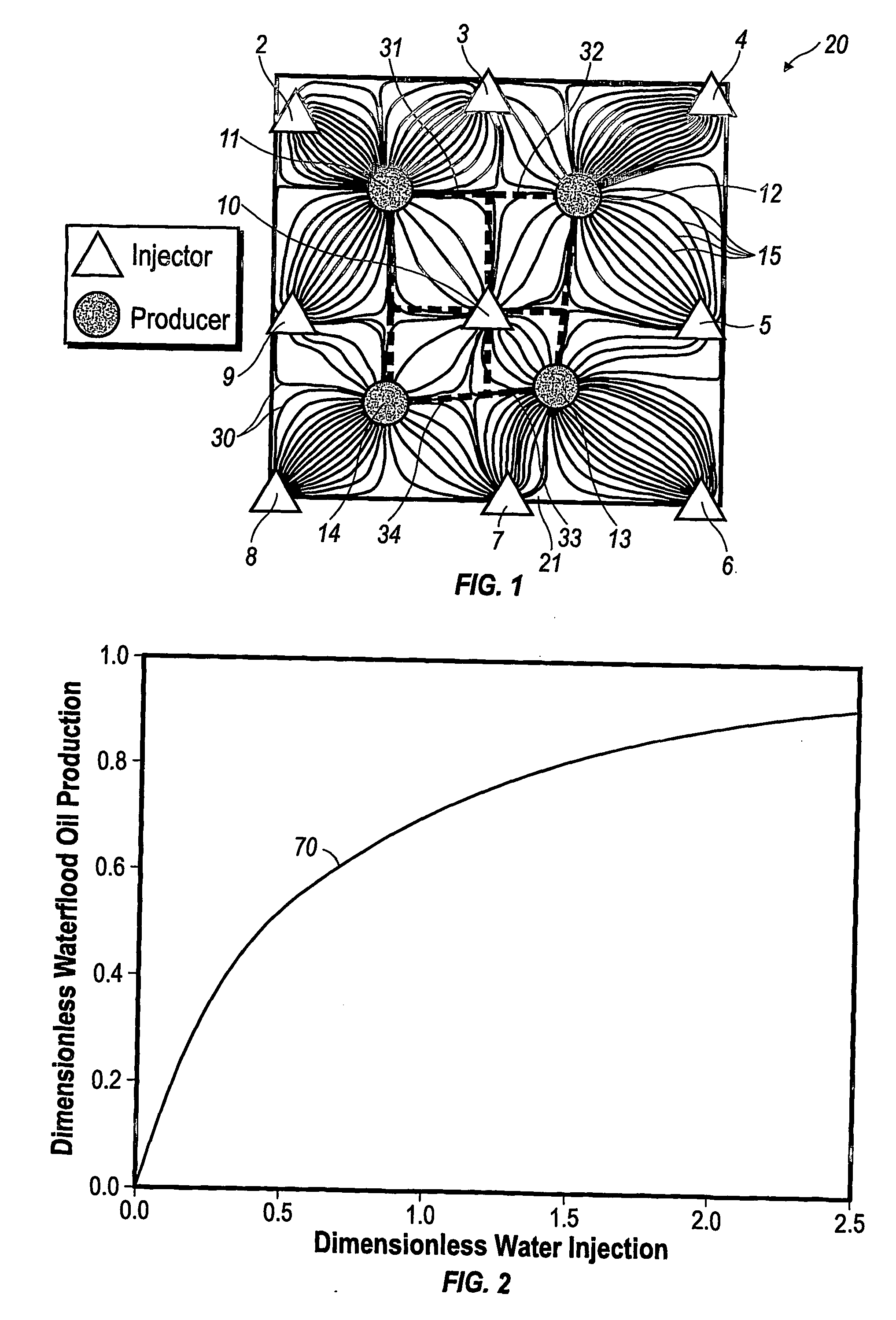

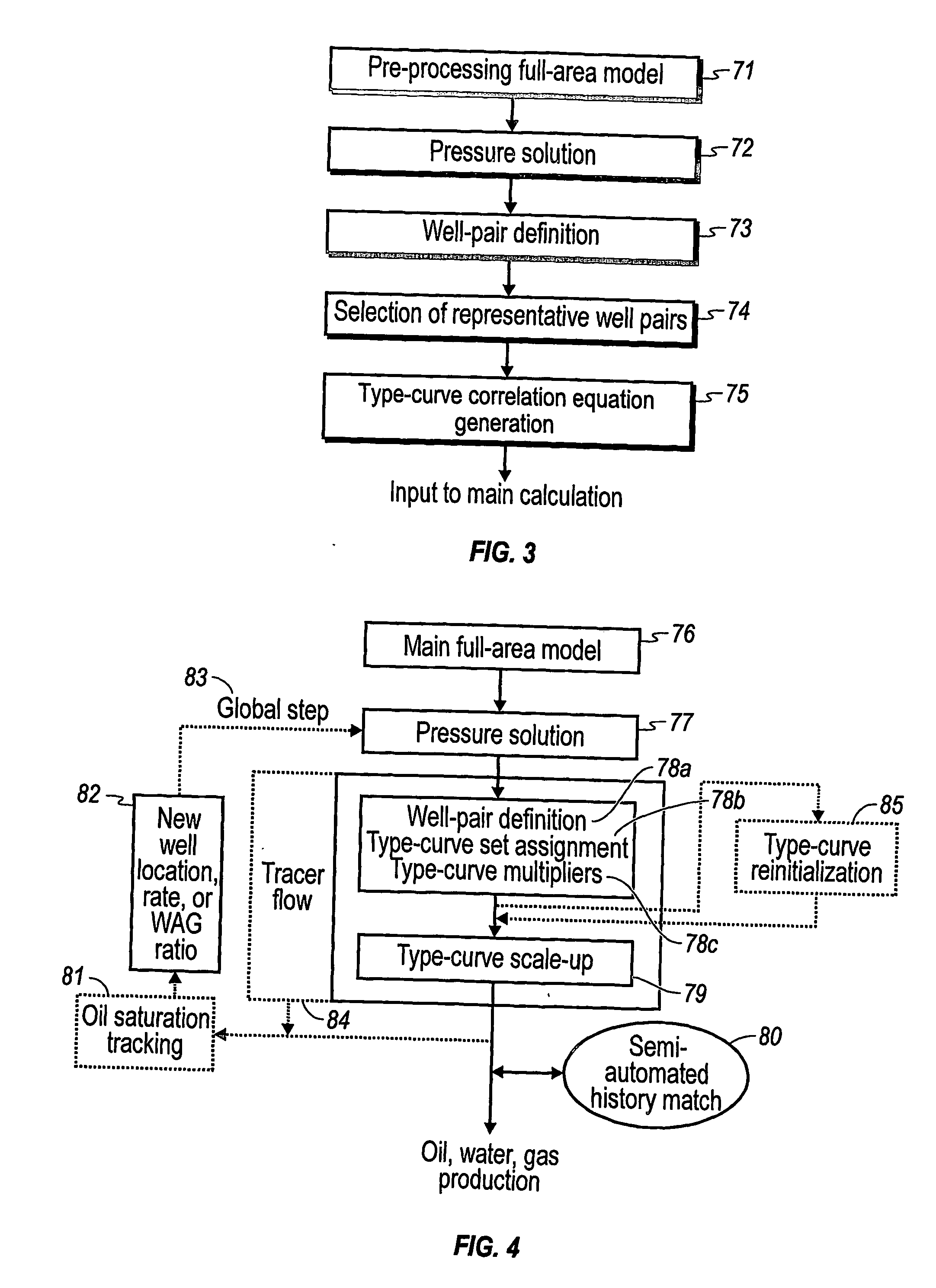

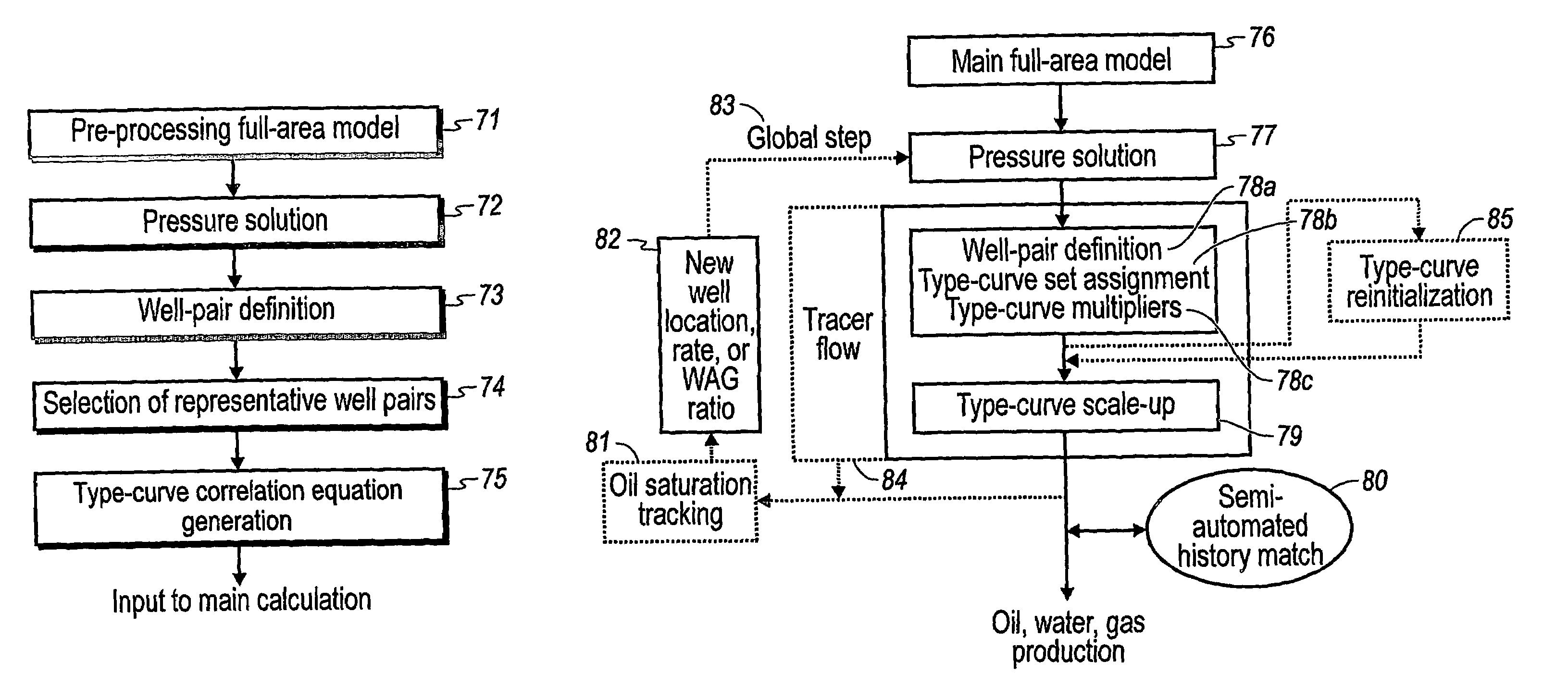

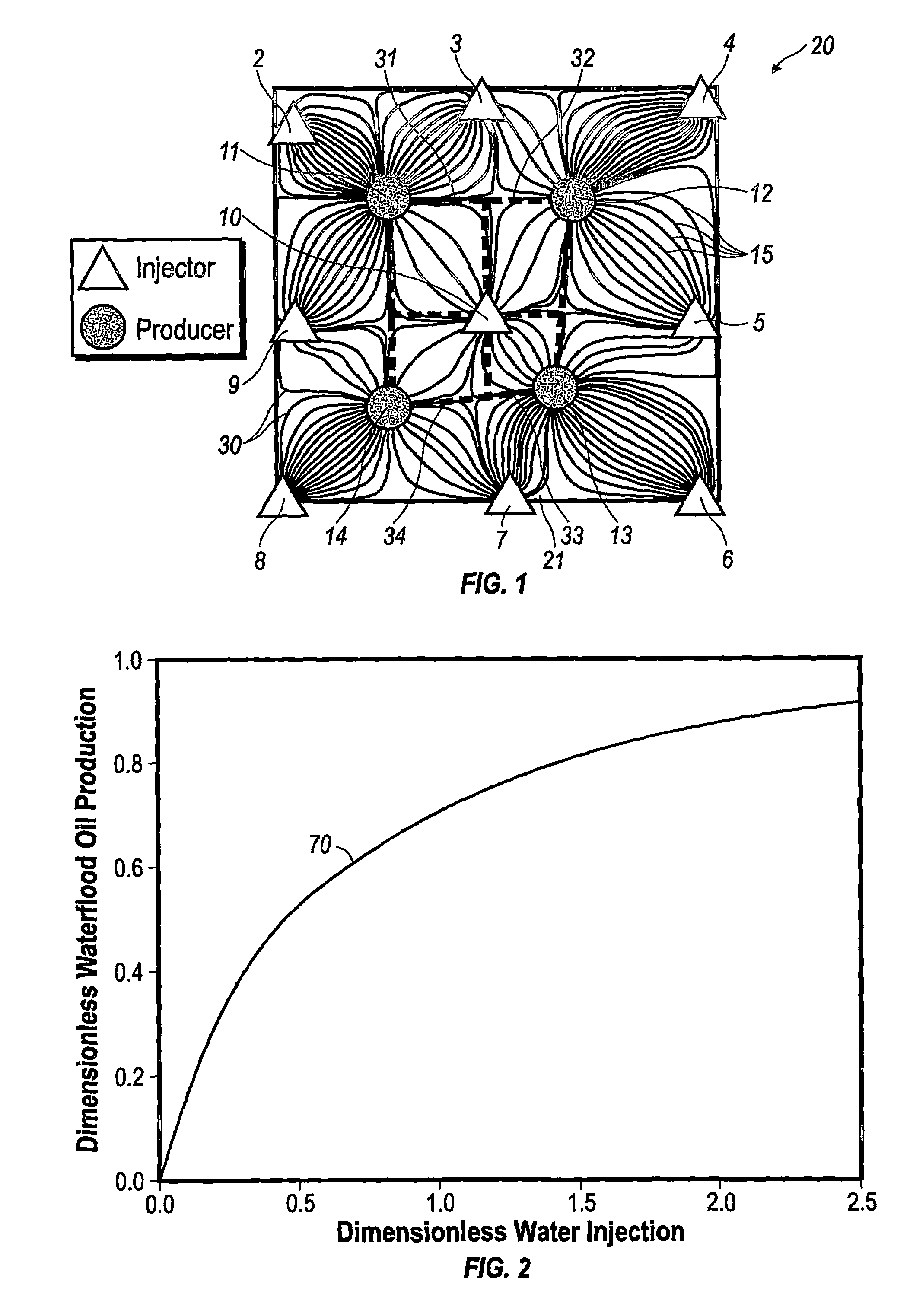

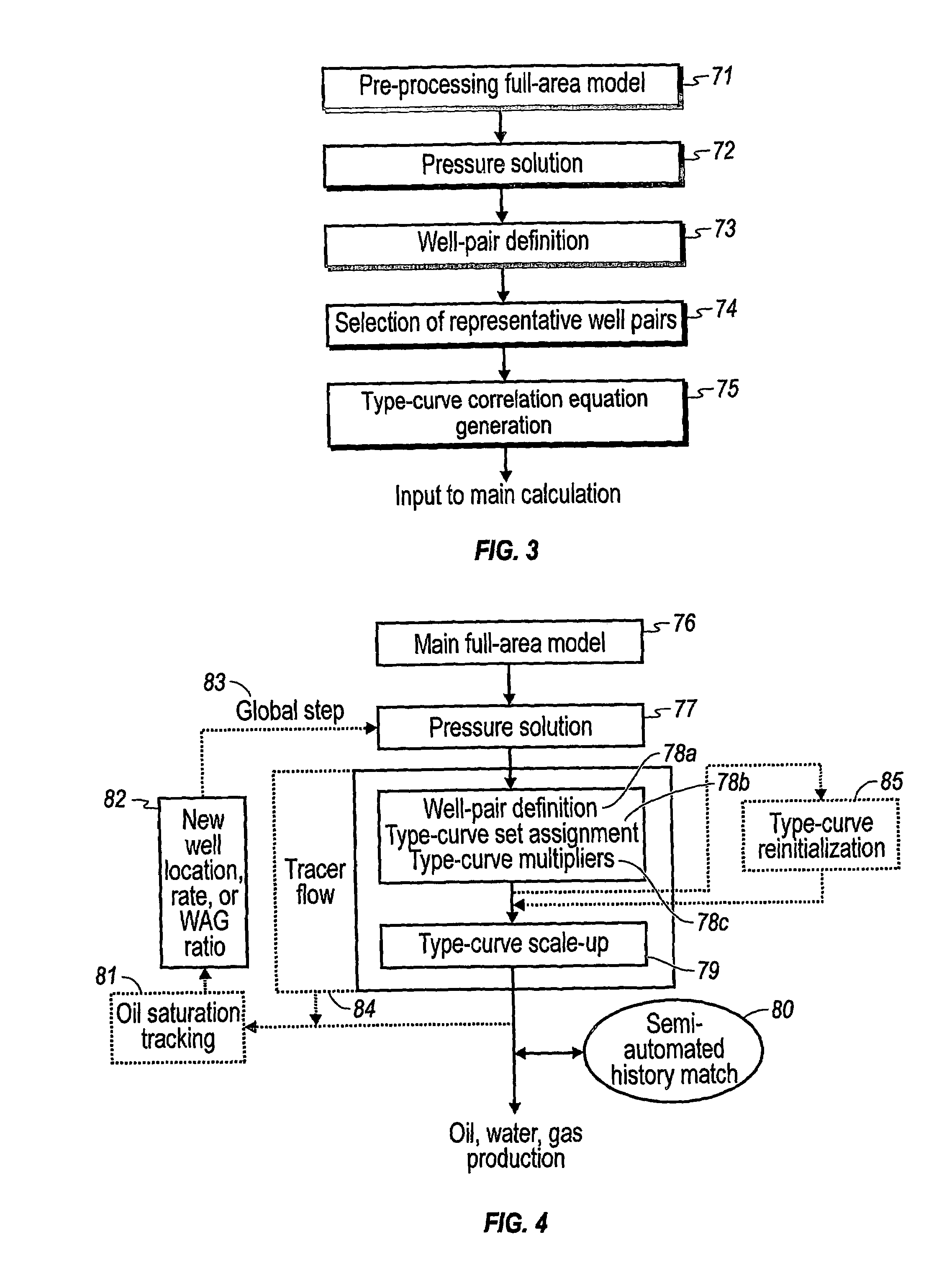

Performance prediction method for hydrocarbon recovery processes

The invention relates to a method for predicting the performance of large-scale hydrocarbon-bearing reservoir floods. One embodiment of the invention includes a method for predicting performance of a patterned flooding process in a subterranean hydrocarbon-bearing formation, said formation being penetrated by a plurality of injector wells and producer wells, comprising the steps of: determining flow-based pairs of injector to producer wells [FIG. 4, item 78a] (first well pairs) using a geological model [item 76]; developing a connective pore volume distribution curve for each first well pair item [78b]; selecting at least two first well pairs (selected well pairs) that reflect narrow and wide connective pore volume distributions that correspond to high and lower oil recovery levels; developing a 3-D simulation model for each selected well pair, performing a reservoir simulation for each selected well pair for the corresponding flooding process; and generating prototype performance curves for each selected well pair. An alternate embodiment of the invention includes a method for predicting the performance of large-scale hydrocarbon-bearing reservoir floods where injection well location, production well location, a process parameter, or a well processing rate is modified.

Owner:EXXONMOBIL UPSTREAM RES CO

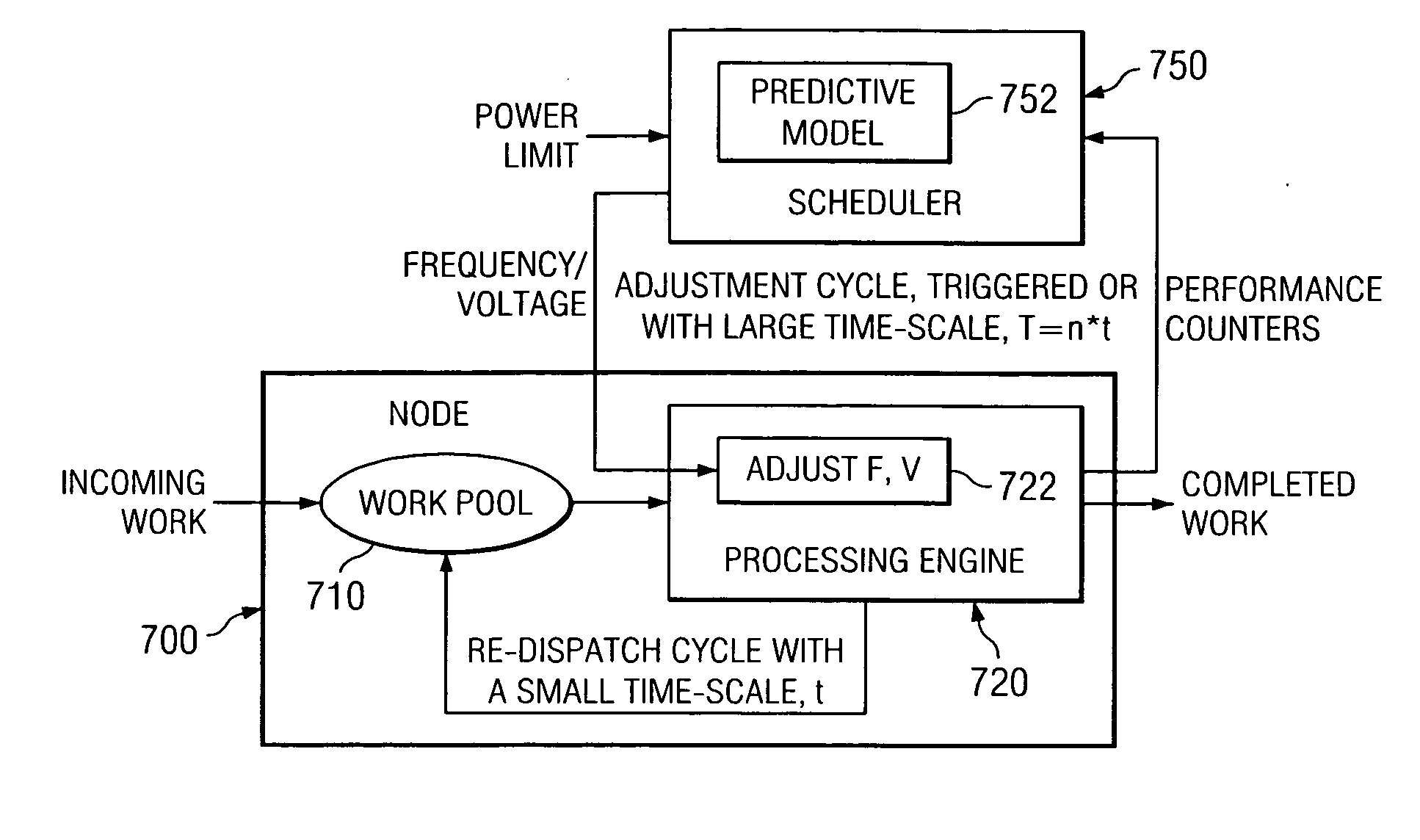

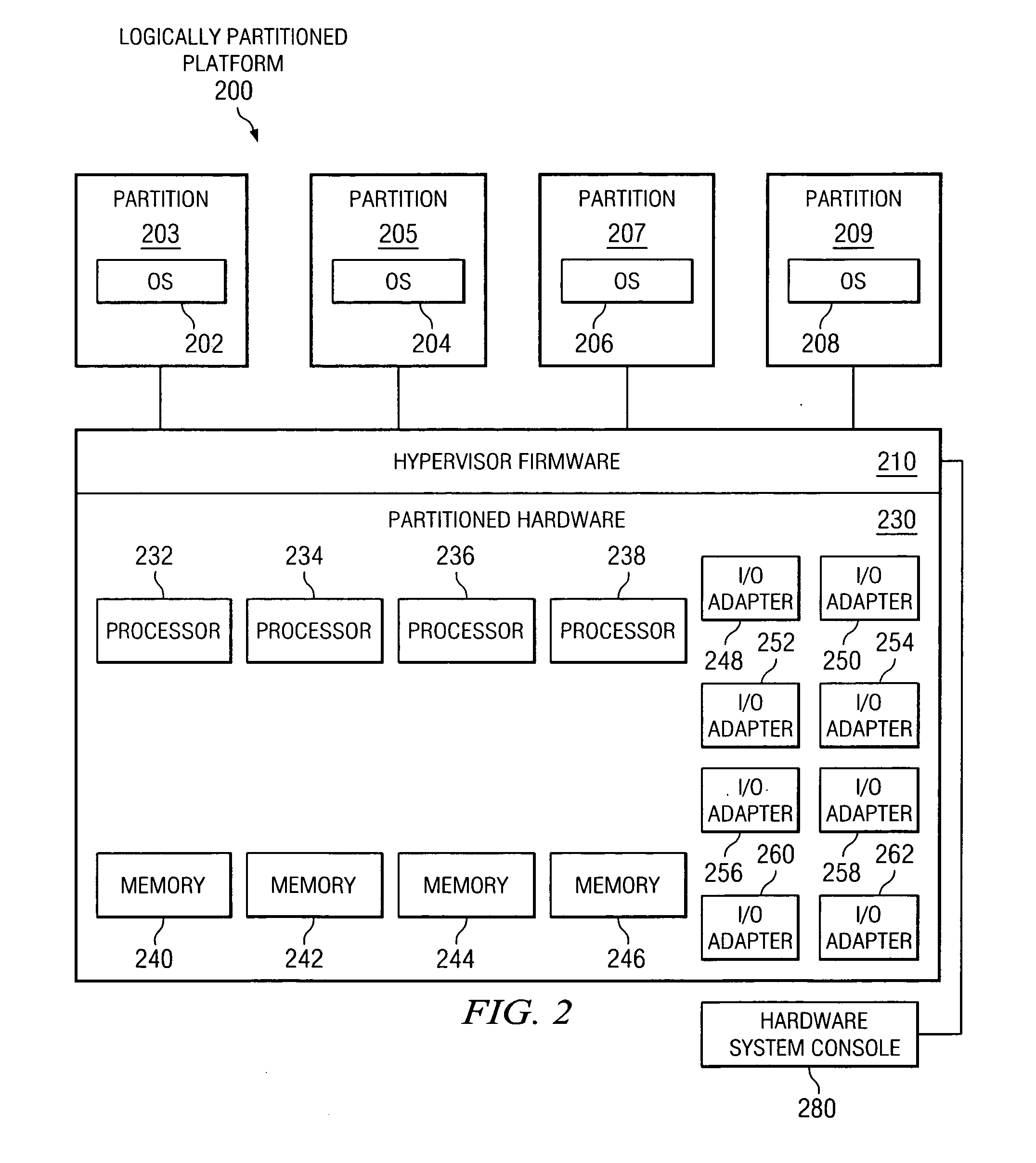

Scheduling processor voltages and frequencies based on performance prediction and power constraints

InactiveUS20060253715A1Energy efficient ICTError detection/correctionData processing systemOperational system

Owner:IBM CORP

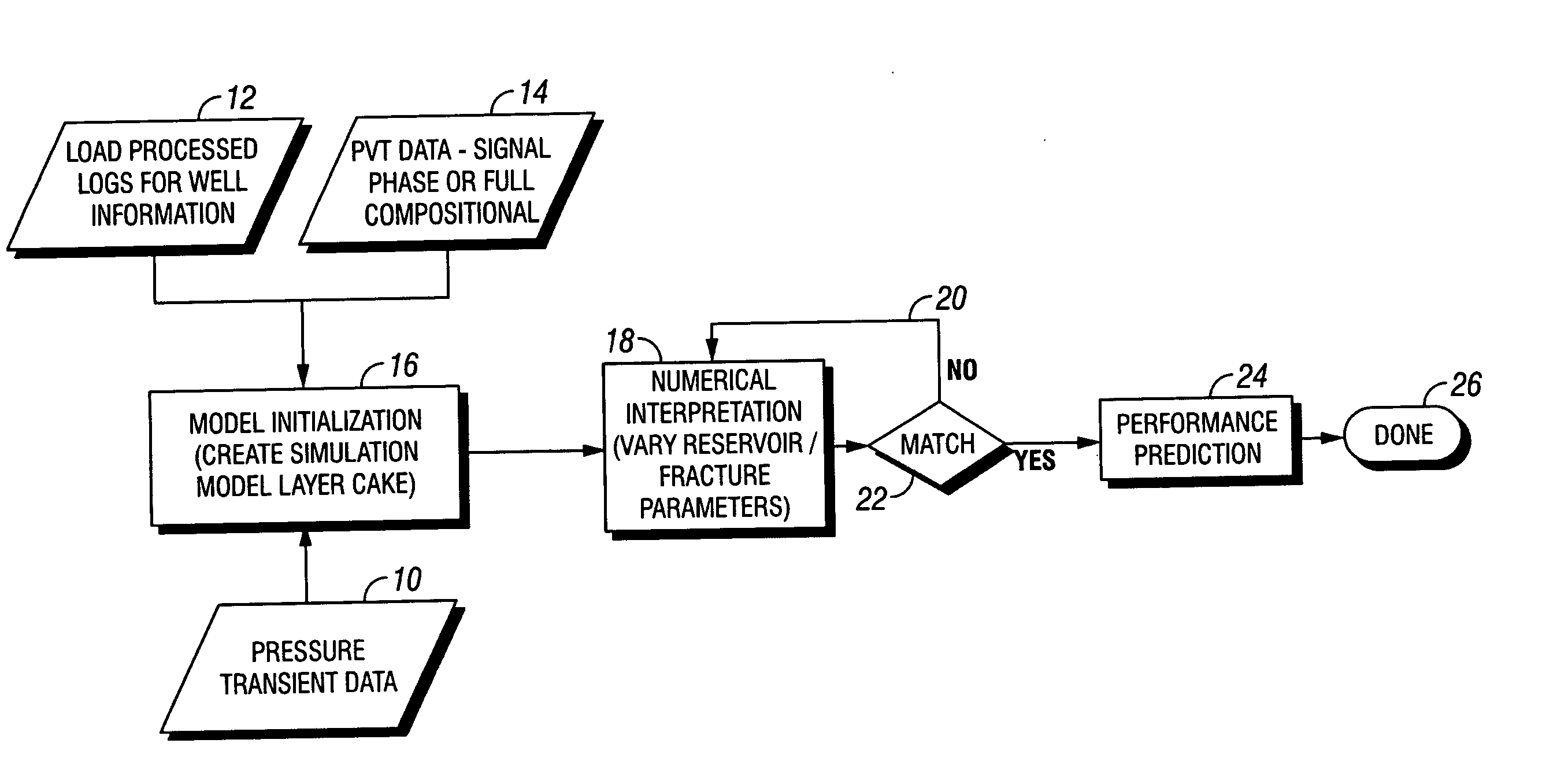

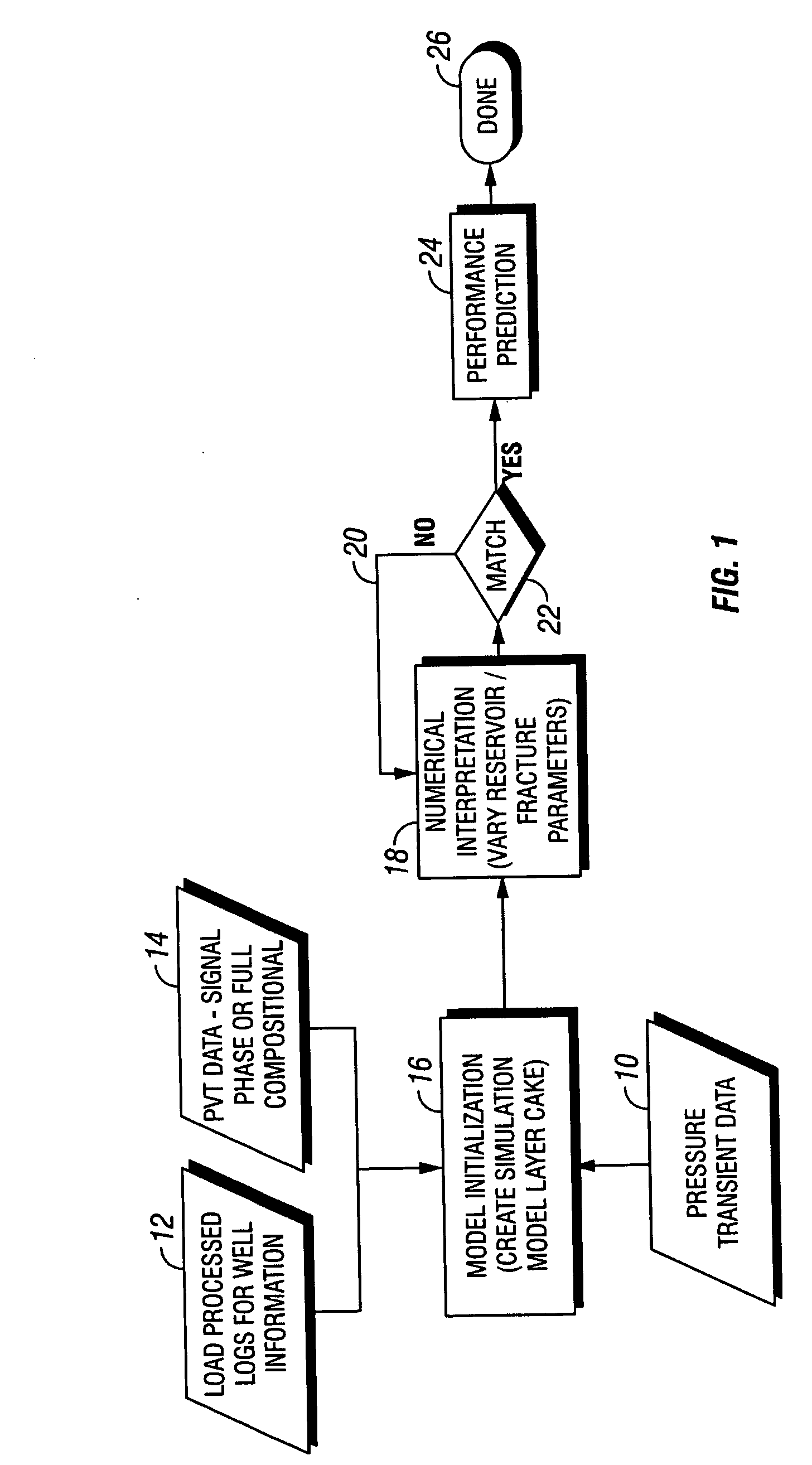

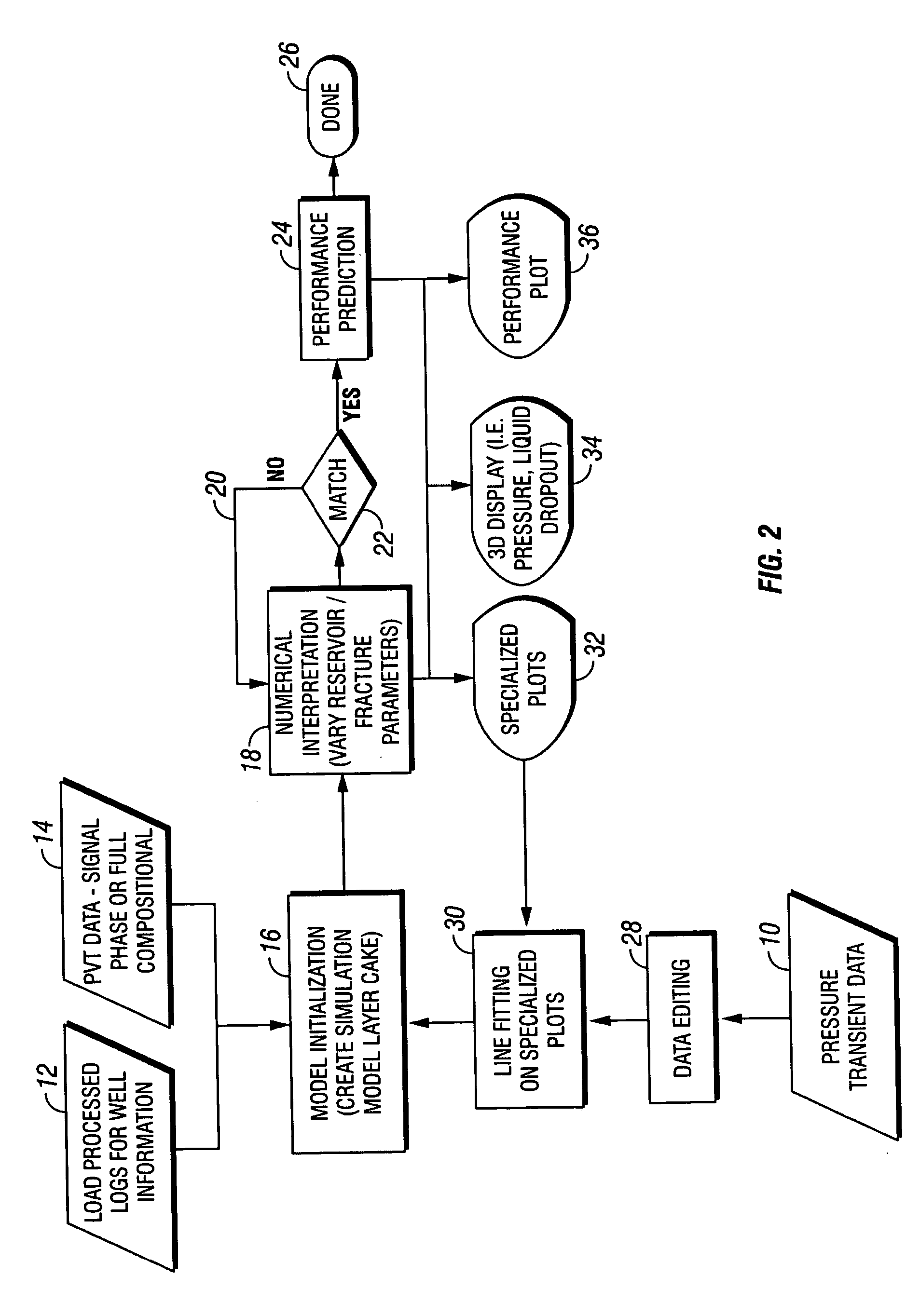

Method for simulation modeling of well fracturing

InactiveUS20060015310A1Reduce ambiguityRemove noiseGeometric CADFluid removalWell loggingModel system

A model system for simulating the performance of a subterranean well, starts with a base model wherein input logging data, pressure transient data and PVT data is introduced into the base model. A numerical interpreter then calculates the predicted performance of the well. A match system compares actual performance data with calculated performance data based on the base model through reiterative loop for modifying the base model to provide a match between the actual performance data and the predicted performance data to optimize the base model. The method for generating the optimized performance data in accordance with the subject invention incorporates the steps of introducing known pressure transient data, well logging data and PVT data for the well into a base model and producing a performance prediction from the base model. These results are compared with actual performance data and the model is modified to generate a performance prediction that matches the actual performance for producing an optimized model. The method is particularly useful because it accounts for and adjusts the performance prediction based on non-Darcy factors effecting the fluid parameters in the well.

Owner:SCHLUMBERGER TECH CORP

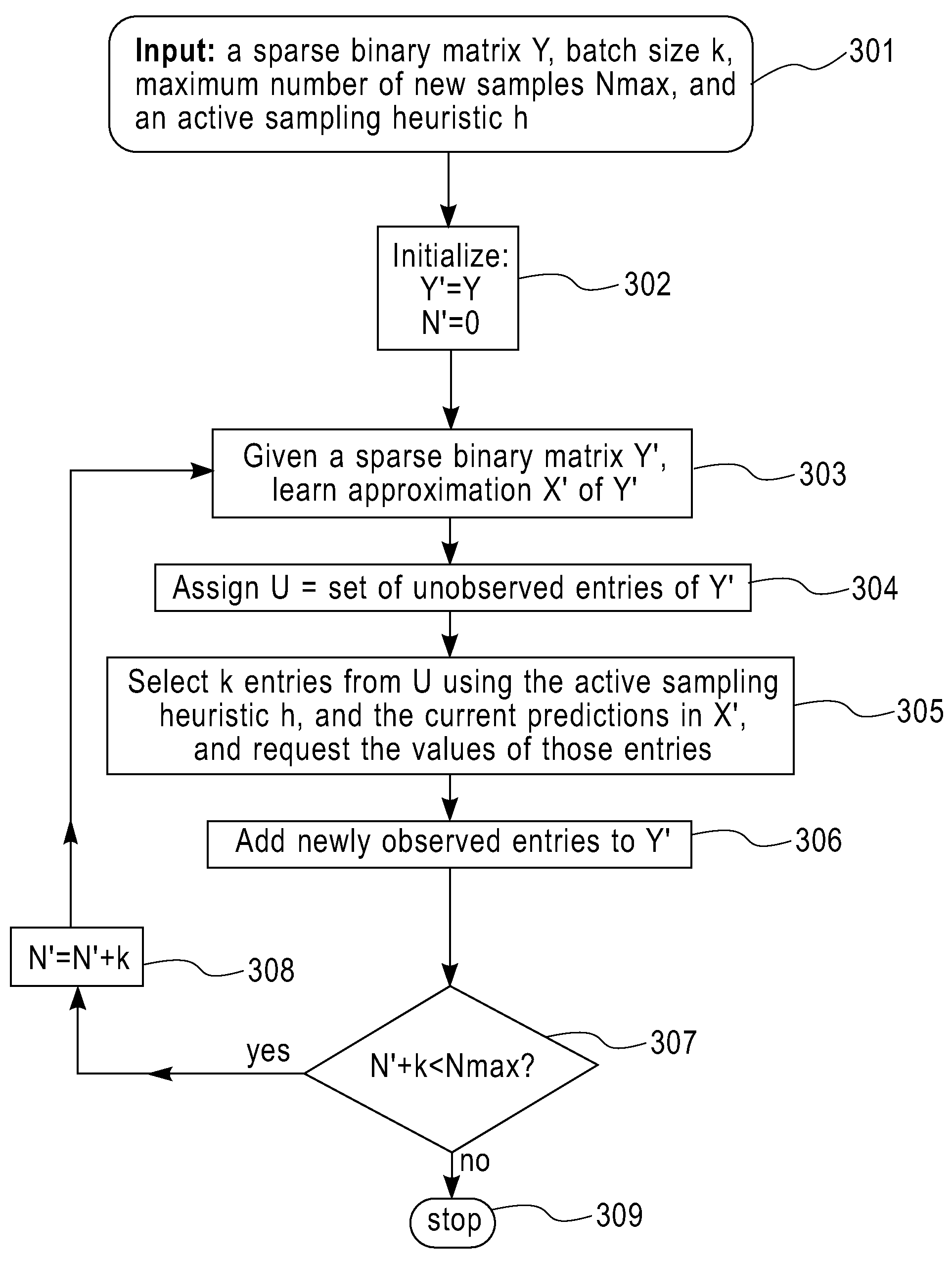

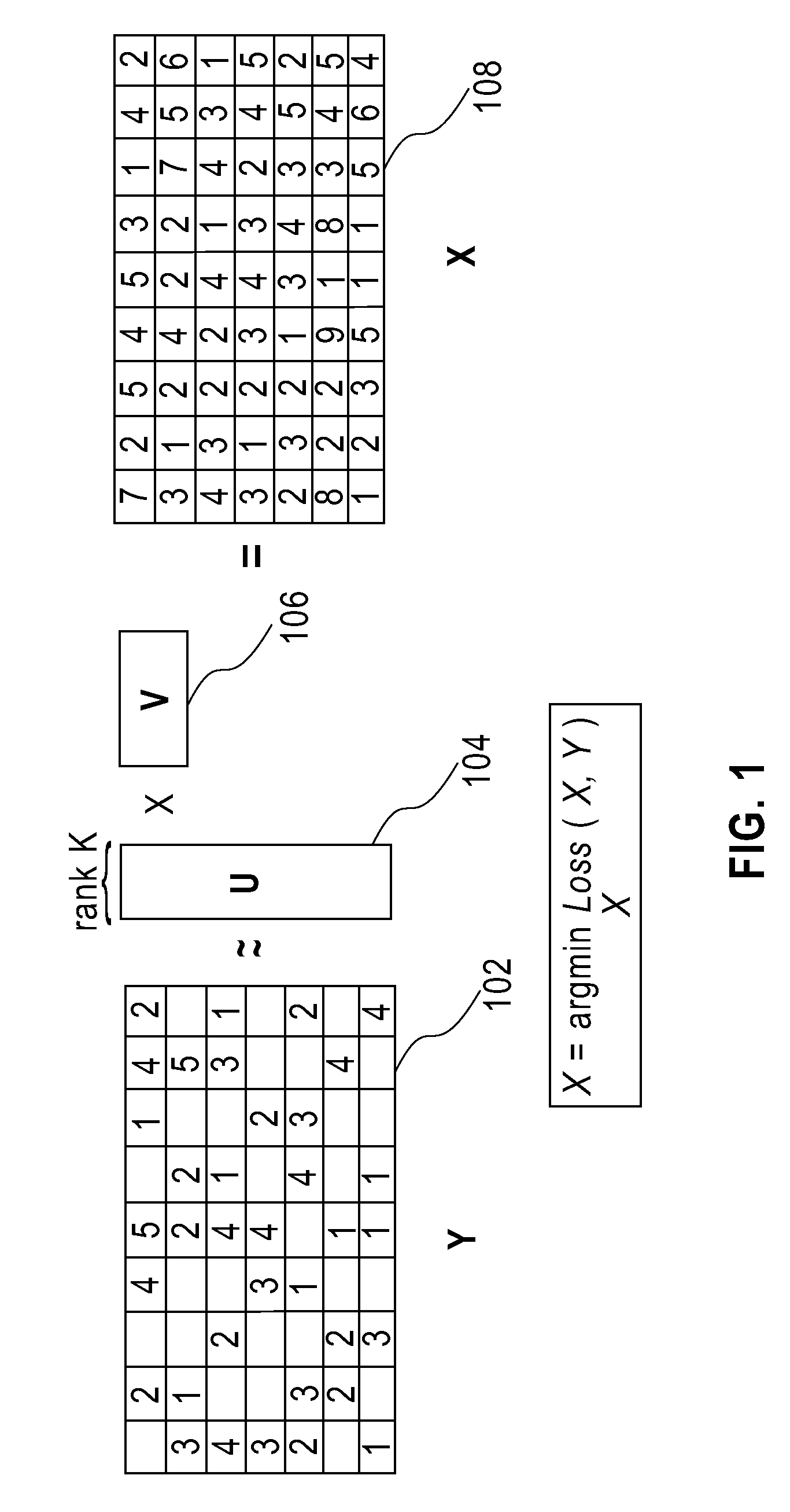

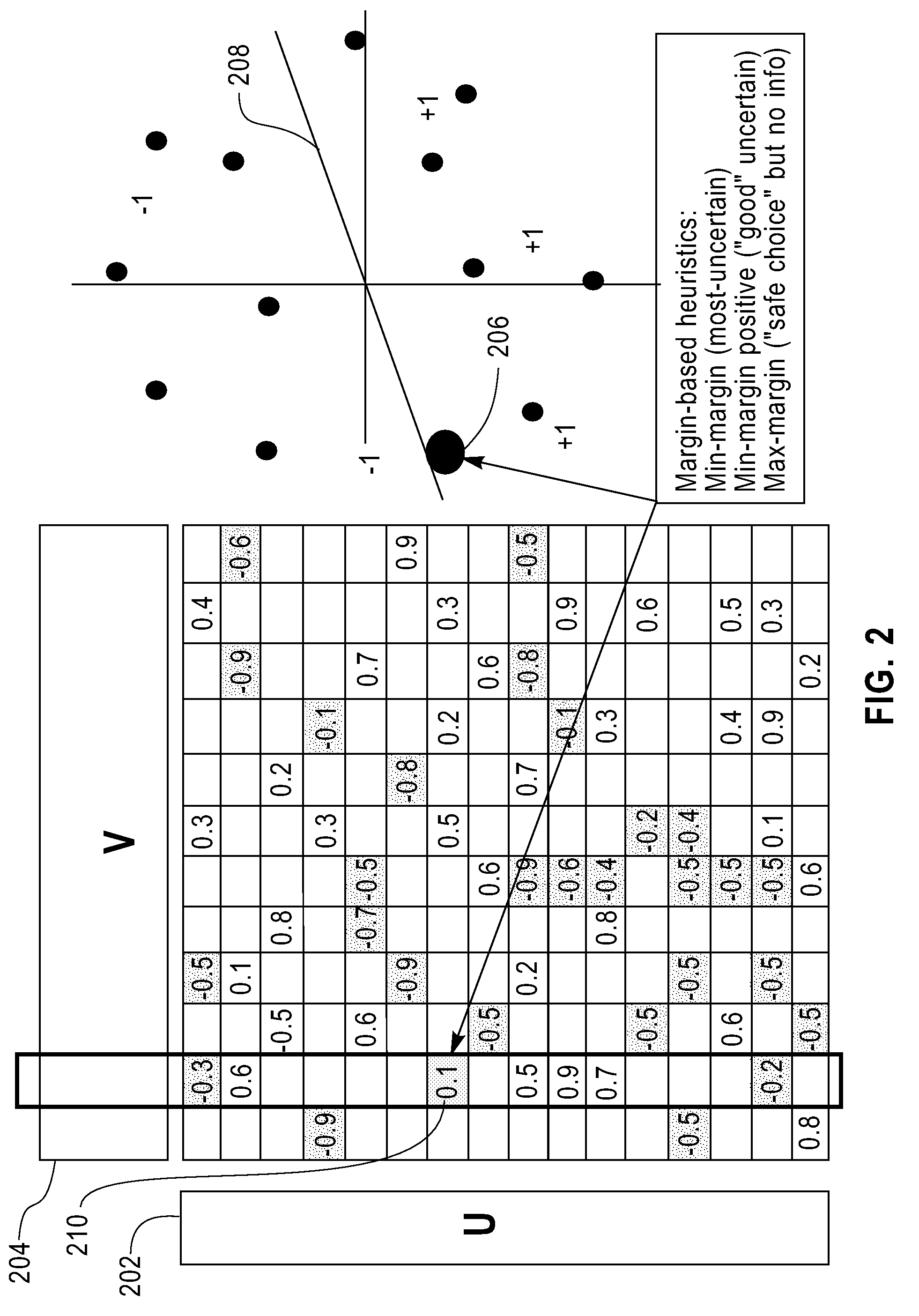

Active sampling collaborative prediction method for end-to-end performance prediction

Active sample collaborative prediction method, system and program storage device are provided. A method in one aspect may include determining approximation X for matrix Y using collaborative prediction, said matrix Y being sparse initially and representing pairwise measurement values; selecting one or more unobserved entries from said matrix Y representing active samples using said approximation X and an active sample heuristic; obtaining values associated with said unobserved entries; inserting said values to said matrix Y; and repeating the steps of determining, selecting, obtaining and inserting until a predetermined condition is satisfied.

Owner:IBM CORP +1

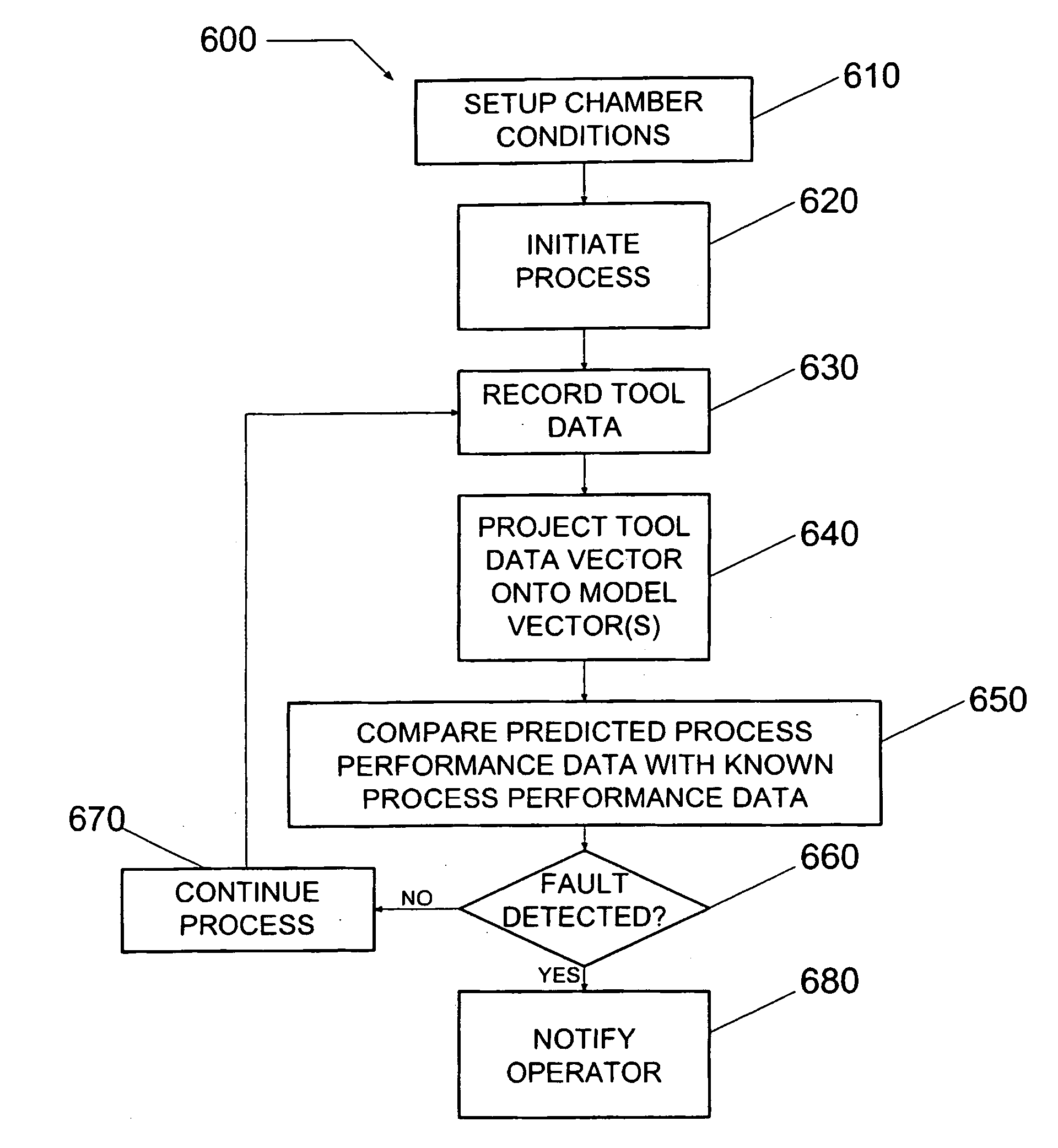

Method and system for predicting process performance using material processing tool and sensor data

InactiveUS20050252884A1Semiconductor/solid-state device testing/measurementElectric discharge tubesEngineeringMaterials processing

A material processing system including a process tool and a process performance prediction system. The performance prediction system includes sensors coupled to the tool to measure tool data and a controller coupled to the sensors to receive tool data, where the controller is configured to predict the process performance for the tool using the tool data. A method for detecting a fault in a material processing system using a process performance prediction model is also provided. The method includes preparing the tool, initiating a process in the tool, and recording tool data to form to a tool data matrix. The method also includes performing a matrix multiplication of the tool data matrix and a correlation matrix to form predicted process performance data, where the correlation matrix includes the performance prediction model, comparing the predicted data with target data, and determining a fault condition of the processing system from the comparing step.

Owner:TOKYO ELECTRON LTD

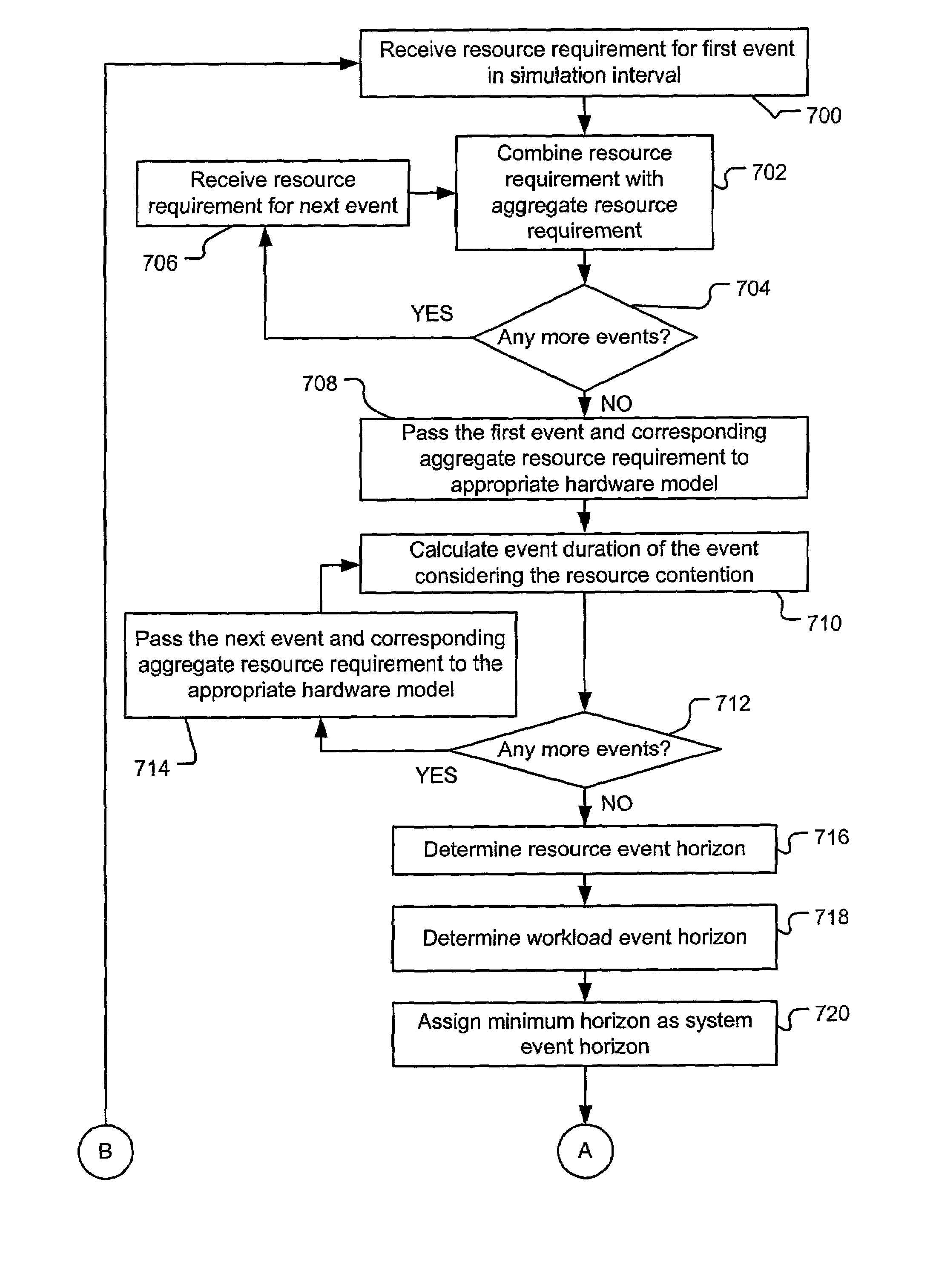

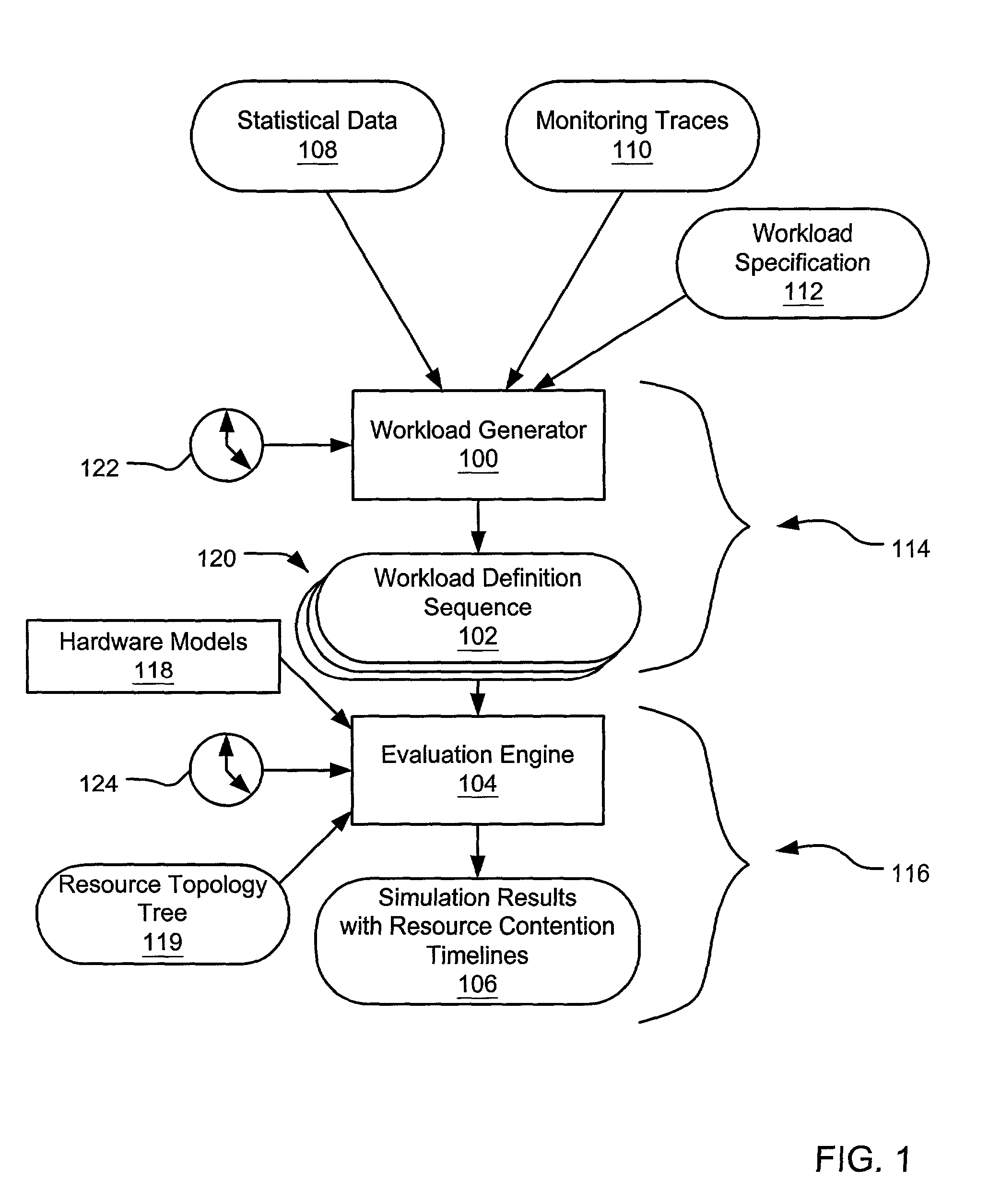

Evaluating hardware models having resource contention

InactiveUS7167821B2Analogue computers for electric apparatusDigital computer detailsParallel computingTime line

A performance prediction simulator gives effect to the resource contention among multiple resources in a simulated system by adjusting event durations appropriately. A resource topology tree defining the resource configuration of the system is input to the simulator. The simulator includes an evaluation engine that determines the amount of resource used during each simulation interval of the simulation and records the resource usage in a resource contention timeline, which can be displayed to a user. The amount of resource used during a simulation is also used to adjust the event duration calculations of the hardware models associated with each event.

Owner:MICROSOFT TECH LICENSING LLC

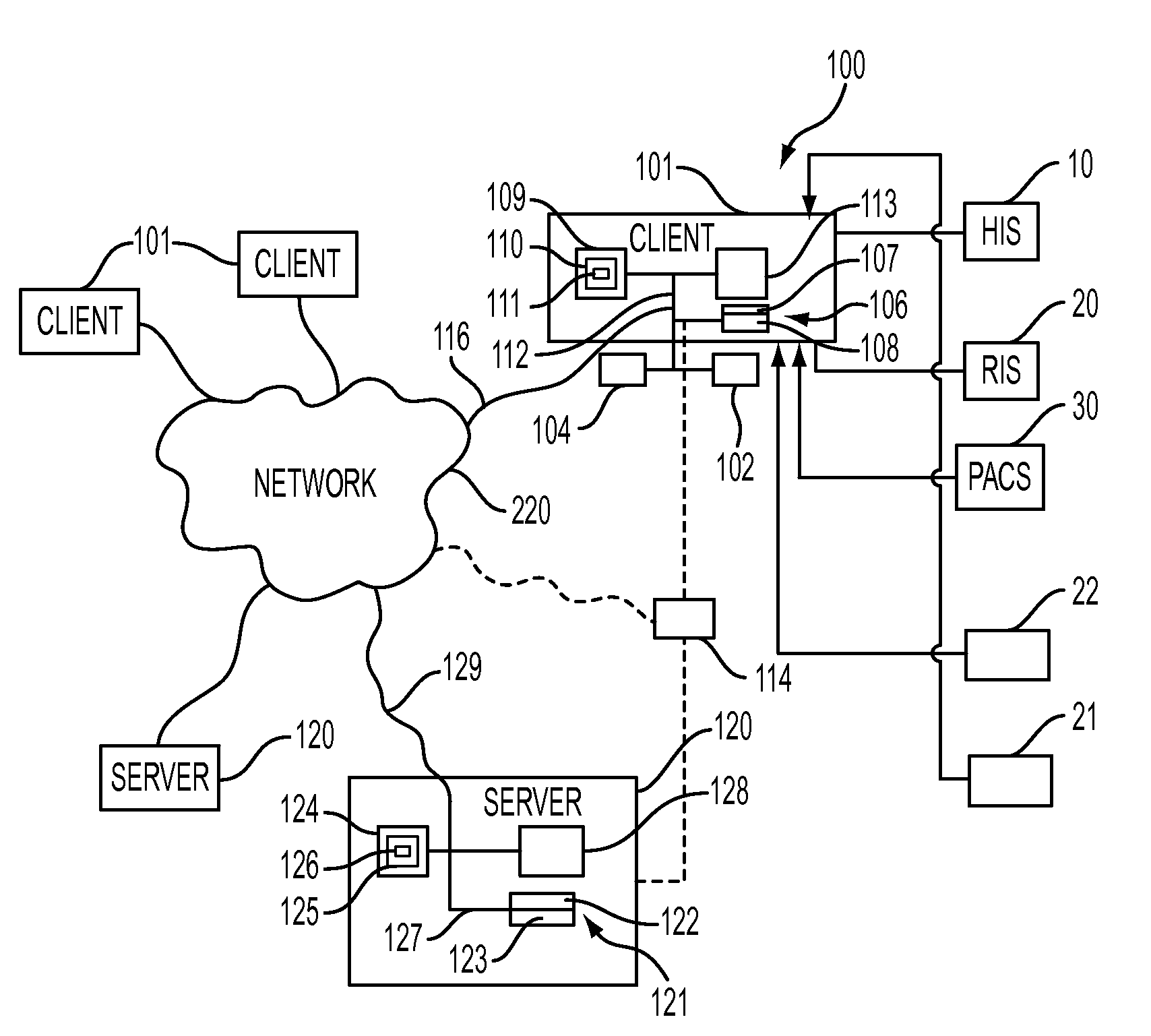

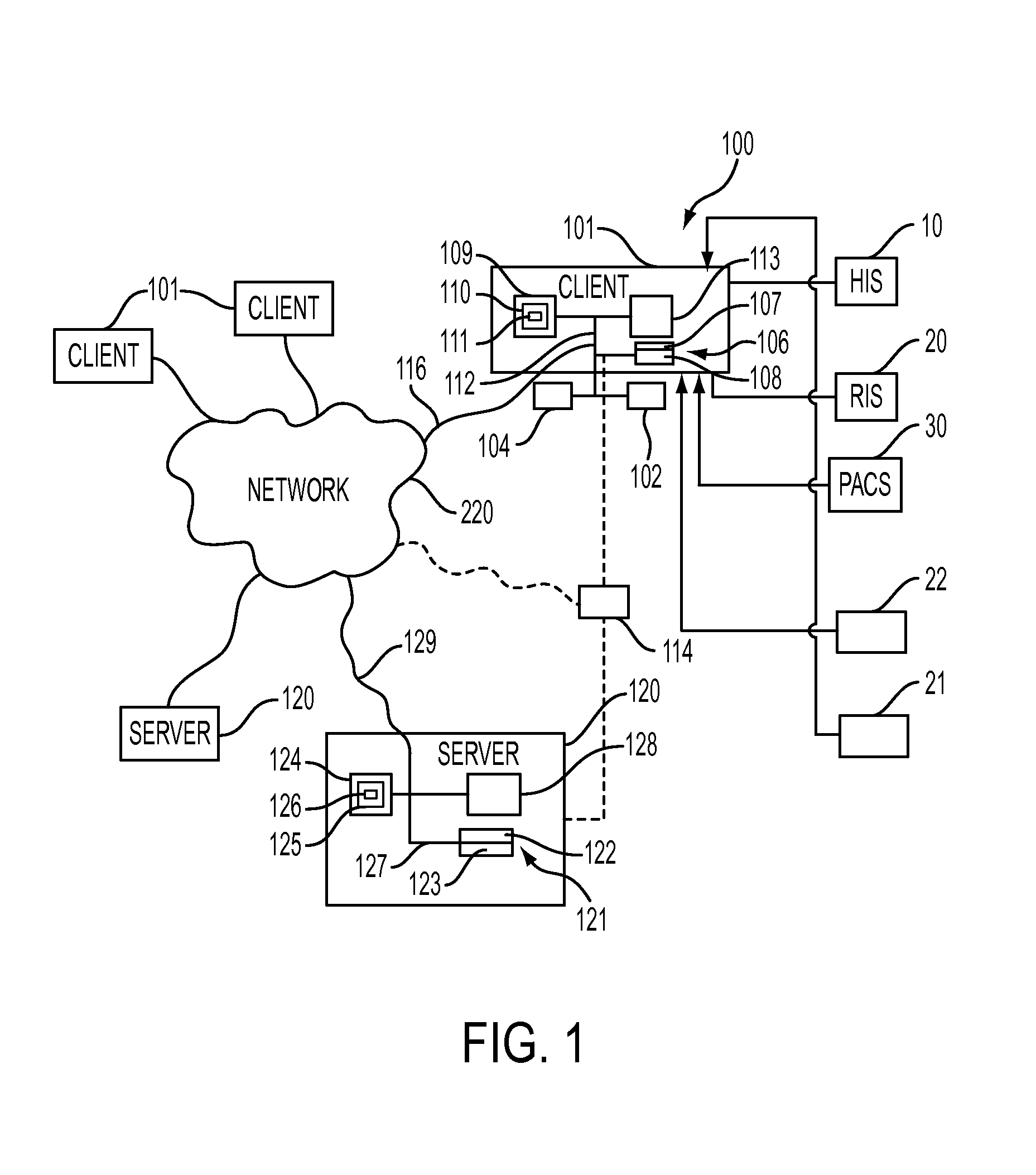

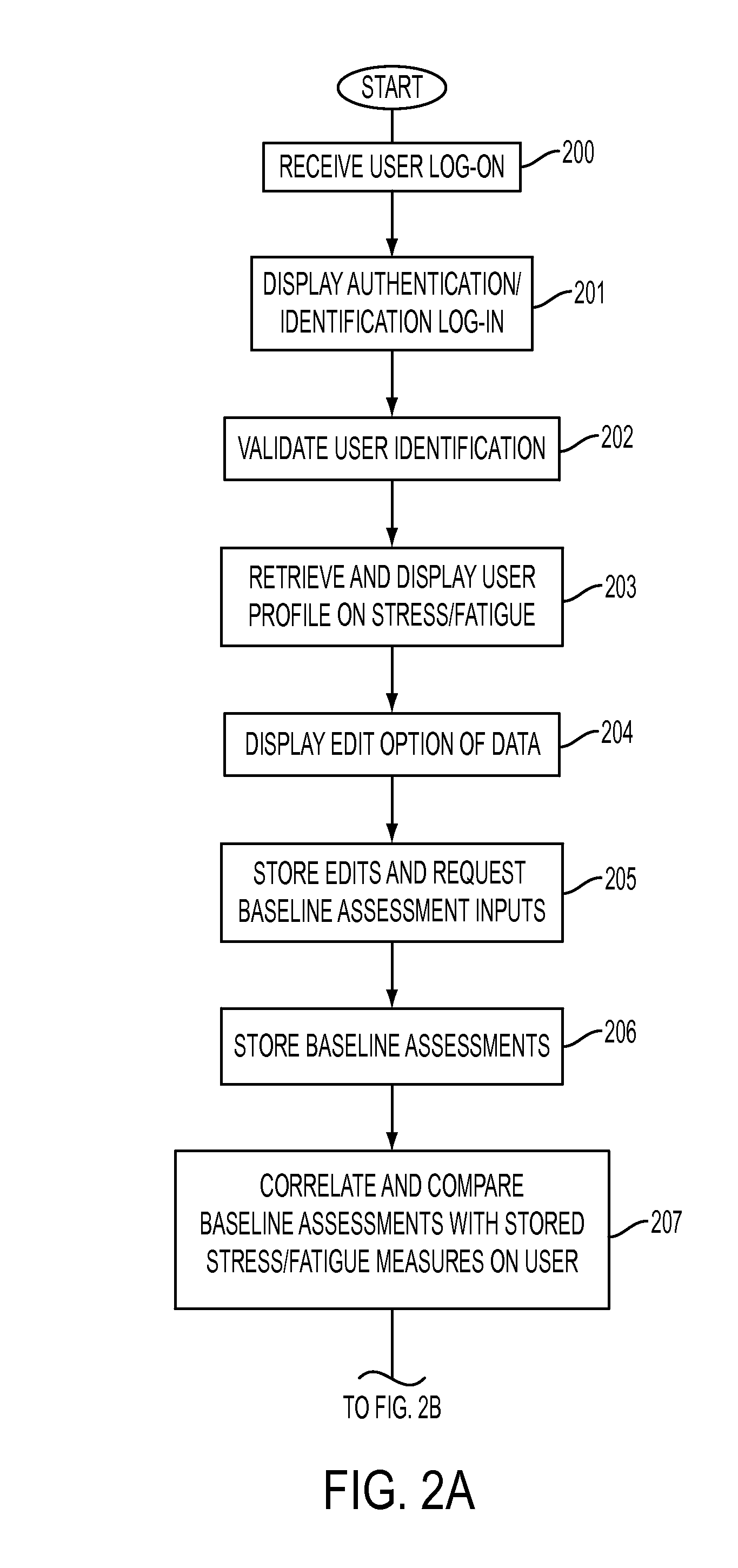

Method and apparatus for real-time measurement and analysis of occupational stress and fatigue and performance outcome predictions

ActiveUS20130006064A1Reducing occupational stress/fatigueImproving economicsEvaluation of blood vesselsSensorsIntervention measuresGuideline

The present invention relates to a method and apparatus to objectively measure stress and fatigue using measurement tools, record stress and fatigue related data in a standardized database, create automated prompts and alerts based upon pre-defined stress and fatigue thresholds (which are derived based upon individual end-user and task performance), provide a number of interventions (which can be preferentially selected by the individual end-user), create data-driven best practice guidelines though meta-analysis of the database, and provide an objective tool for comparative technology assessment.

Owner:REINER BRUCE

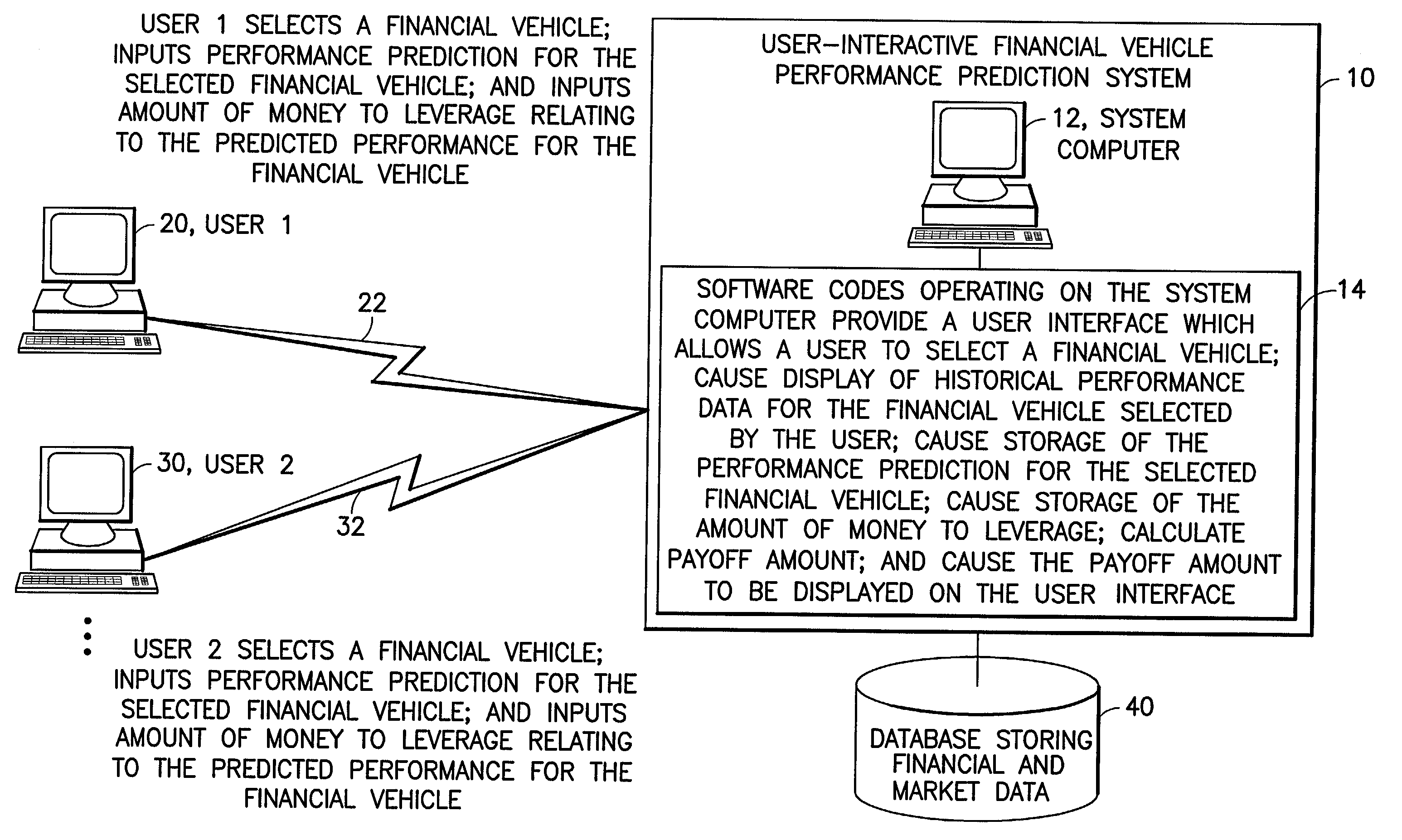

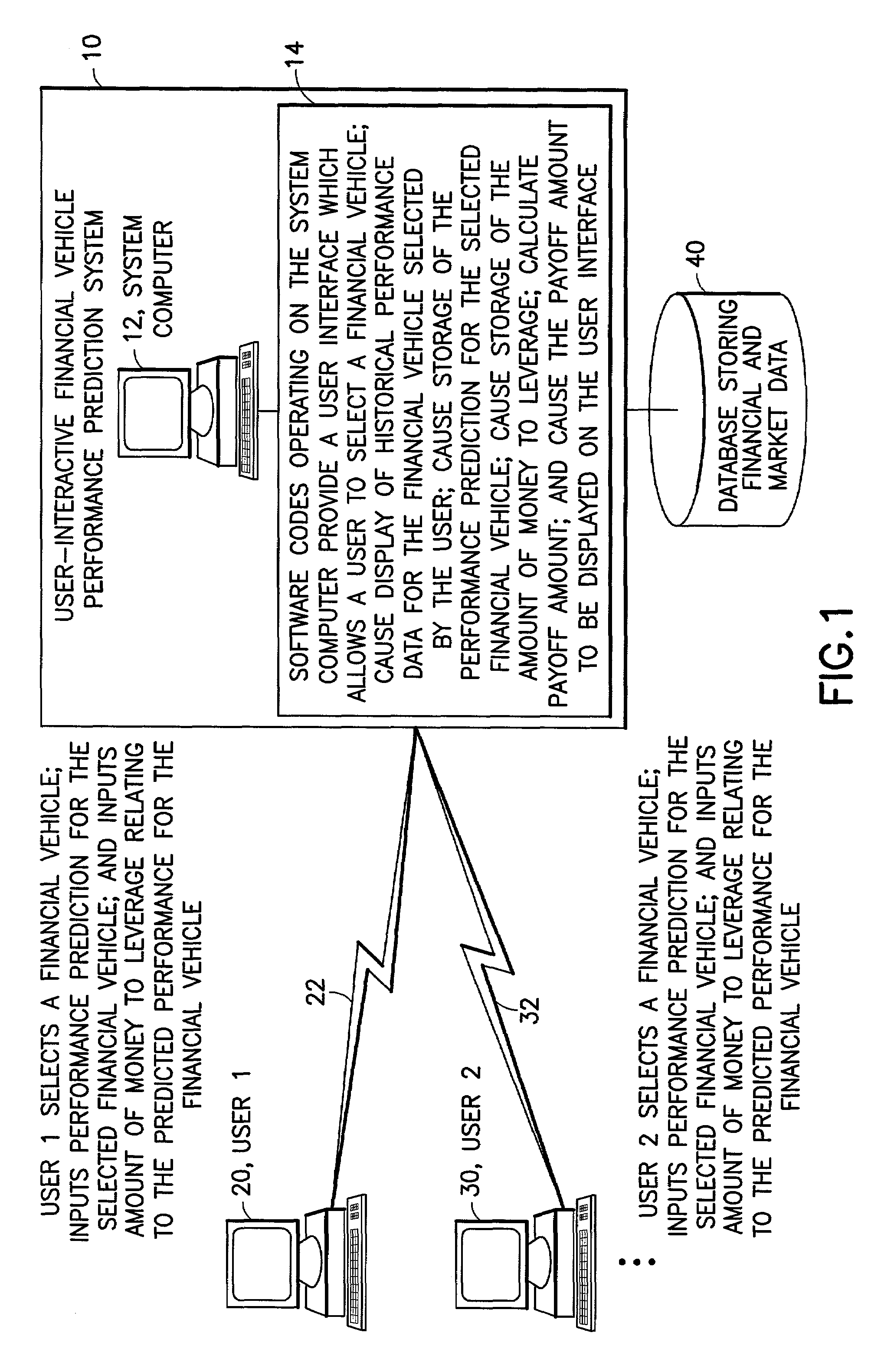

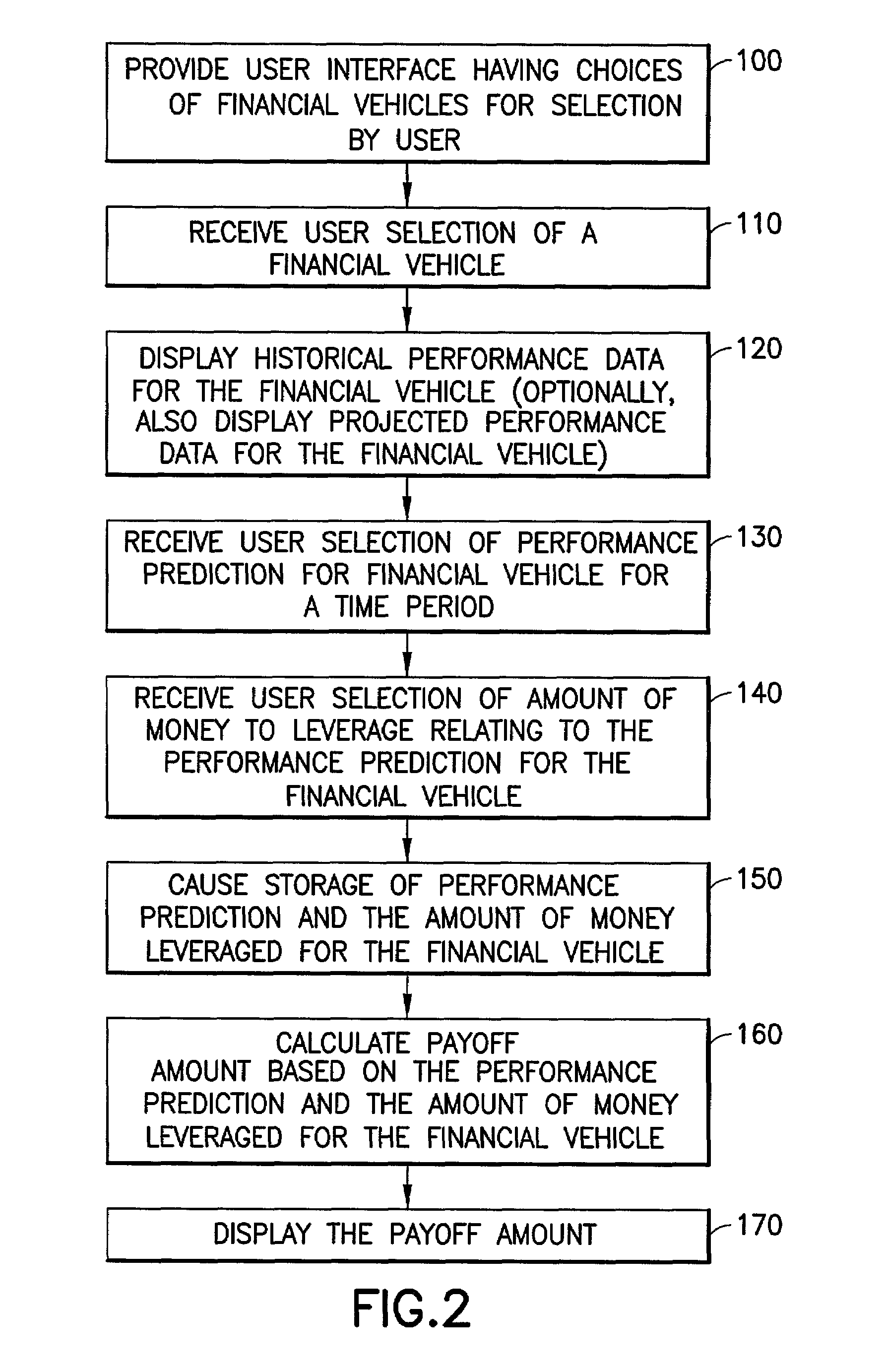

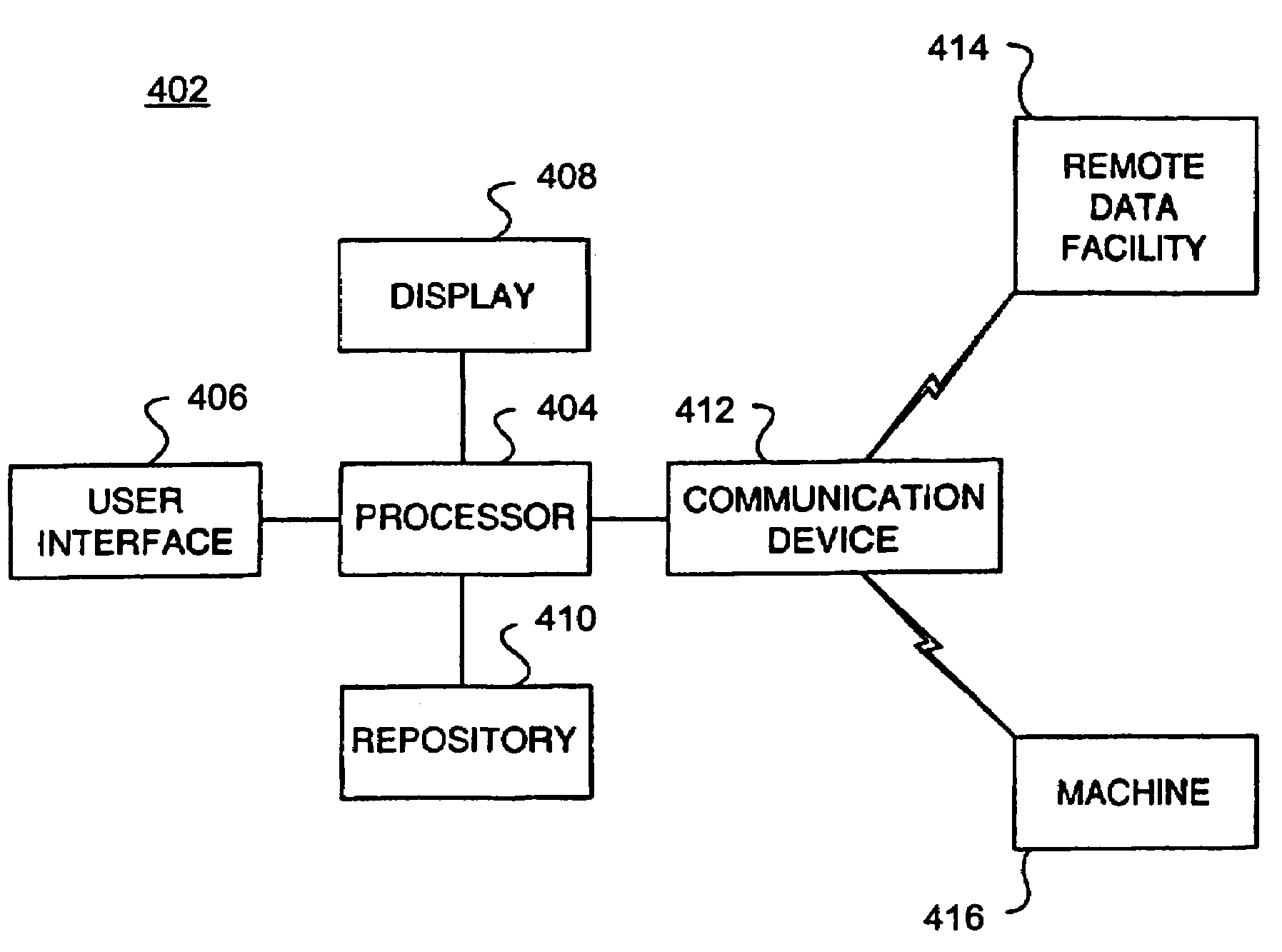

User-interactive financial vehicle performance prediction, trading and training system and methods

Methods and system for allowing a user, through a computer in telecommunication link with a system having access to financial and market data, to predict the performance of a financial vehicle and thereby provide training for trading options or evaluating predictions are provided. One method includes providing a user interface, via the computer, which allows the user to specify a financial vehicle; displaying, via the user interface, historical performance data for the financial vehicle specified by the user; displaying, via the user interface, projected performance data for the financial vehicle; receiving from the user, via the user interface, performance prediction for the financial vehicle for a time period; receiving from the user, via the user interface, amount of money to leverage relating to the performance prediction for the financial vehicle for the time period; storing the performance prediction for the financial vehicle and the amount of money leveraged; calculating payoff amount based on the performance prediction for the financial vehicle and the amount of money leveraged; and displaying, via the user interface, the calculated payoff amount.

Owner:JPMORGAN CHASE BANK NA

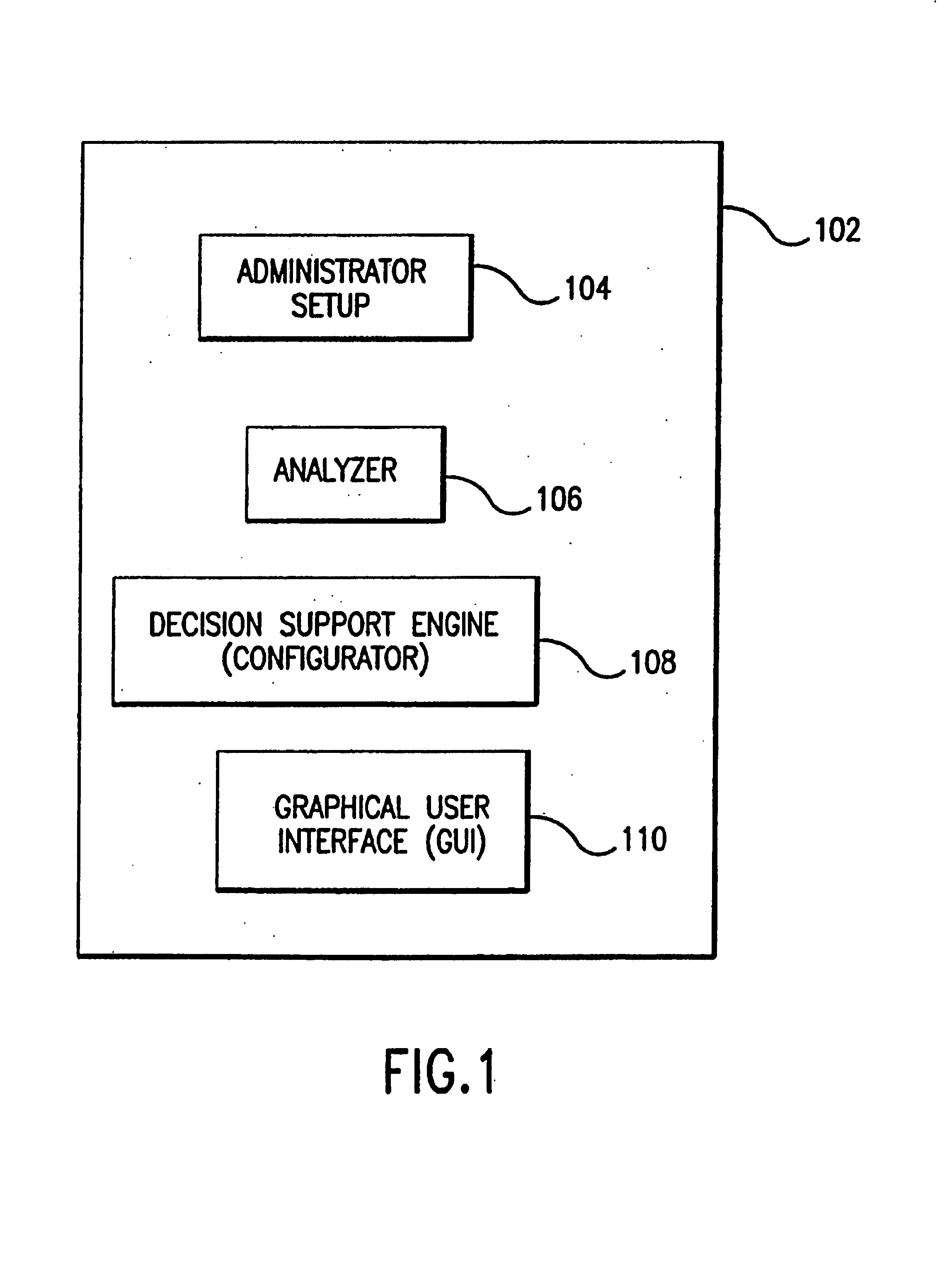

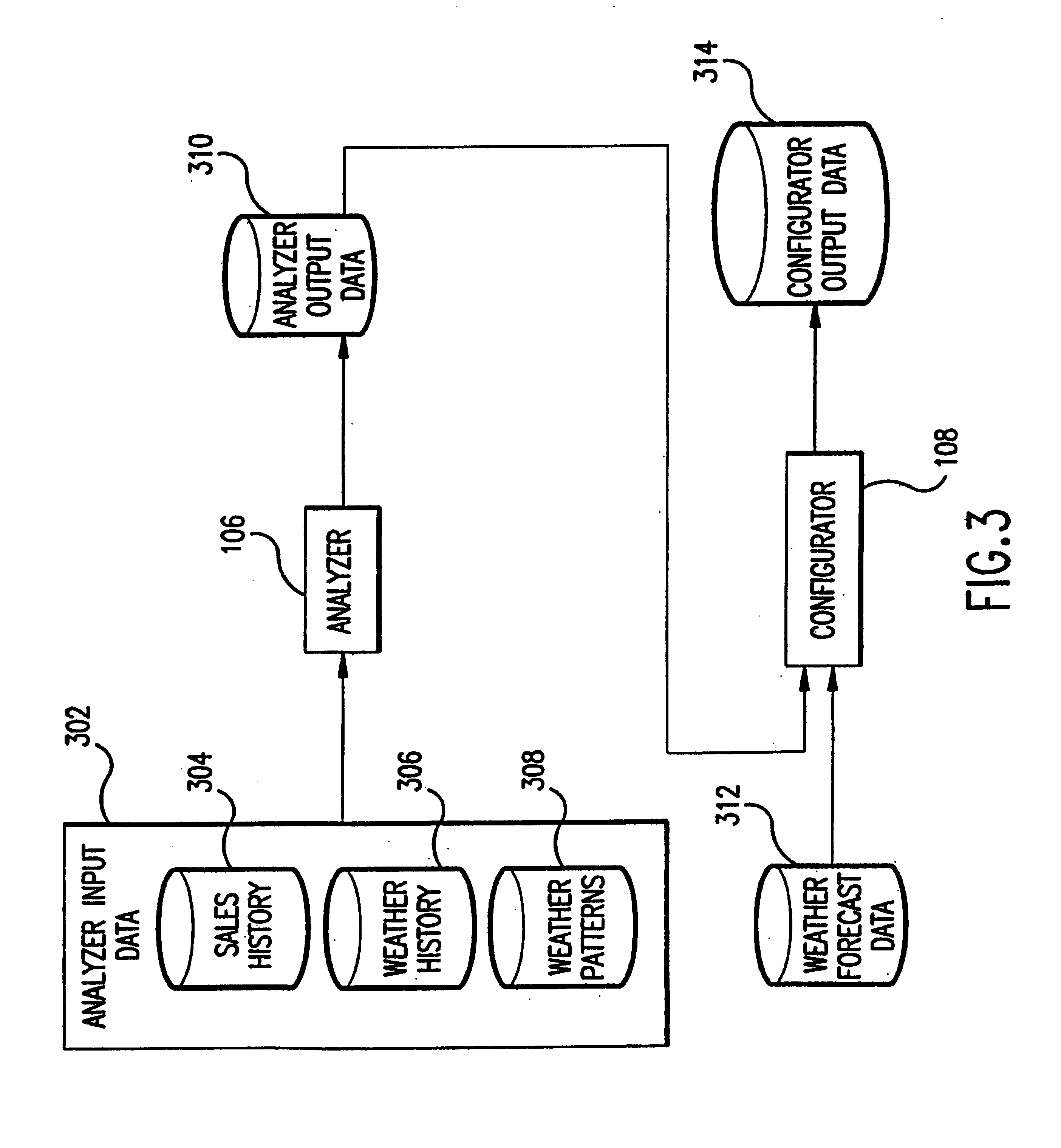

System and method for weather adapted, business performance forecasting

A system and method for forecasting future retail performance are described herein. The system includes a storage device that stores a sales history database, a weather history database, and a weather forecast database. An analyzer determines the extent to which past retail performance of a plurality of products at a plurality of locations was affected by weather using the sales history database and the weather history database. A configurator, coupled to the analyzer, estimates expected future retail performance of the products at the stores for a plurality of future time periods using the weather forecast database and results produced by the analyzer. A graphical user interface, coupled to the analyzer and the configurator, enables users to view and manipulate results produced by the analyzer and the configurator to thereby forecast future retail performance of the products at the locations.

Owner:PANALEC

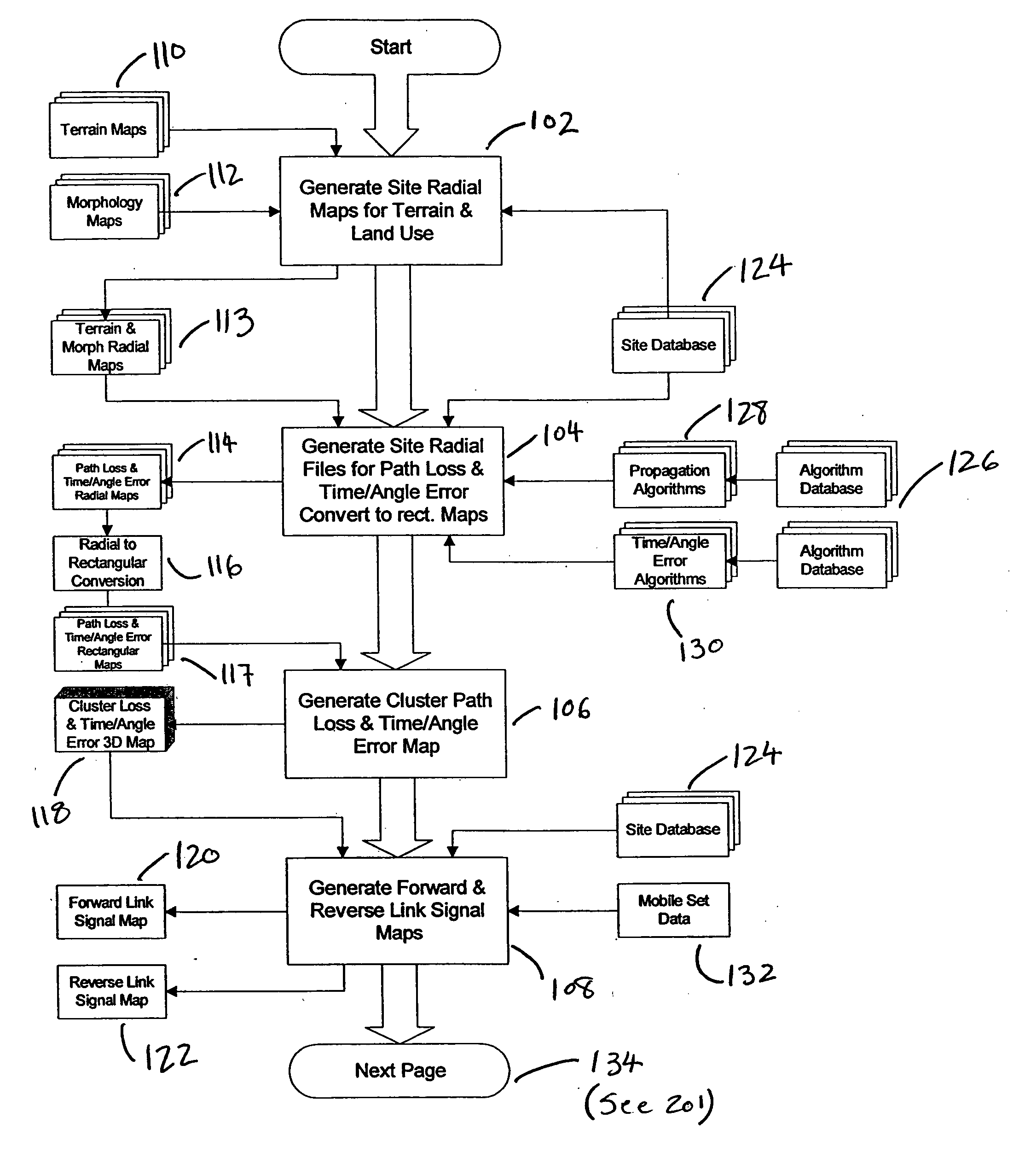

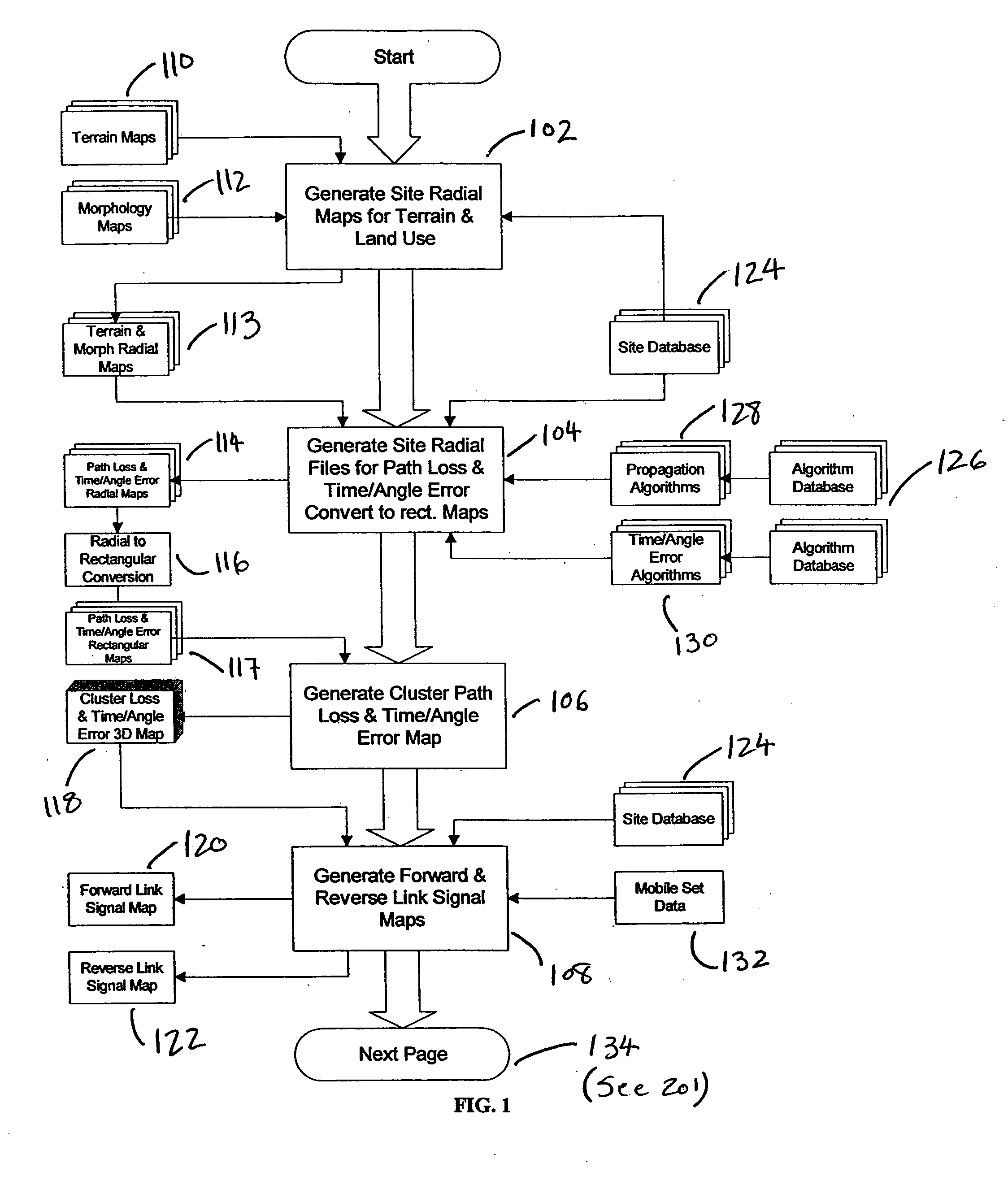

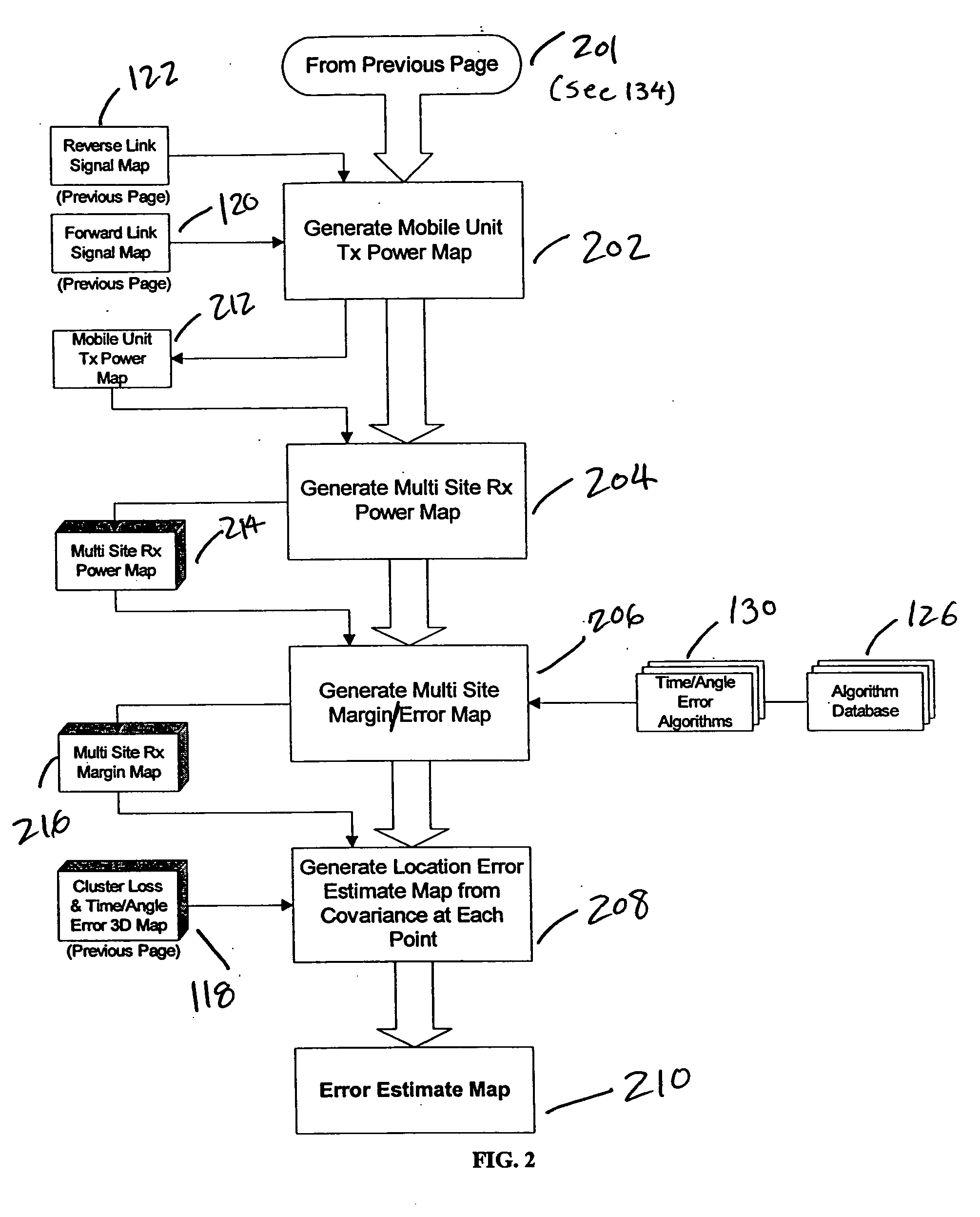

System and method for wireless location performance prediction

InactiveUS20050282540A1Eliminate redundancySite increaseNetwork traffic/resource managementRadio/inductive link selection arrangementsGraphicsGraphical user interface

The software of the present invention predicts the performance of a wireless location system, including its accuracy, availability, and coverage. The tool can determine if the deployed location sensors meet, exceed, or fall short of providing the expected coverage and performance. The tool allows the location system designer to eliminate redundancies if not all sensors are needed and propose additional sites where coverage holes are present. The software tool includes a graphical user interface for ease of use.

Owner:WORKDAY INC

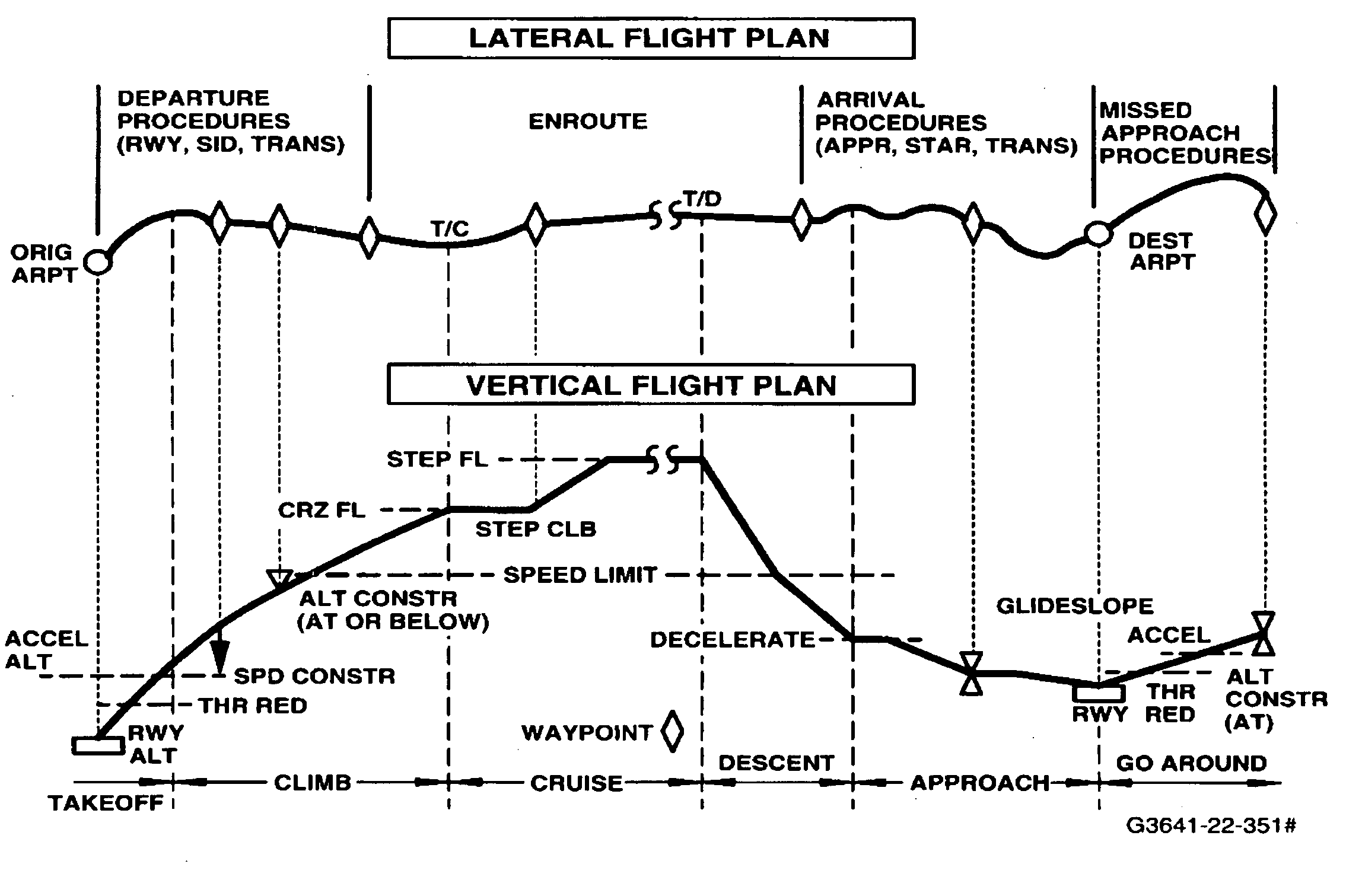

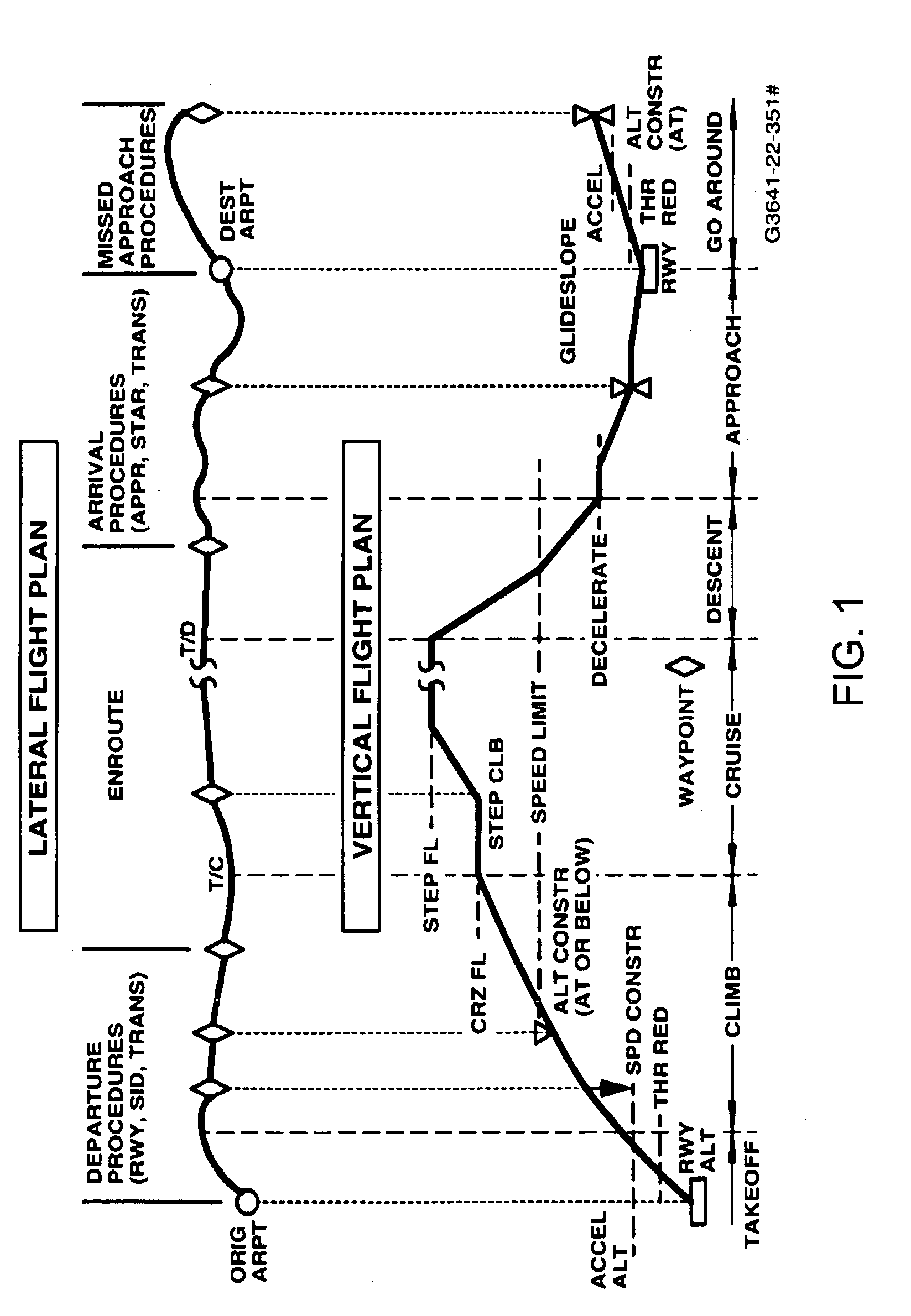

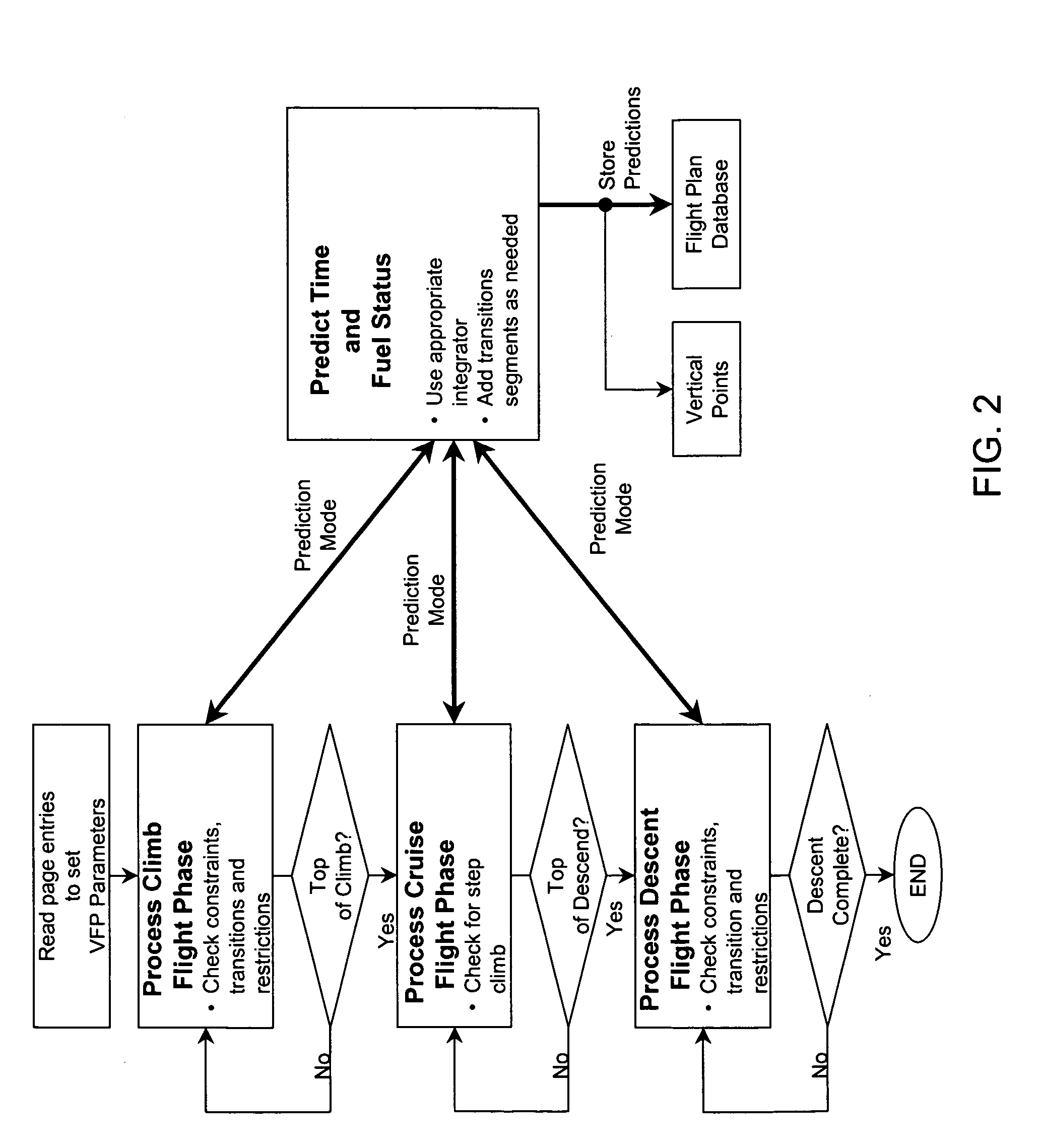

System and method for vertical flight planning

ActiveUS20050283281A1Easy to modifyEasily and quickly realizedAnalogue computers for vehiclesAnalogue computers for trafficFlight vehicleAirplane

A method for performing performance prediction with respect to a vertical flight plan. A system performs performance prediction with respect to a vertical flight plan of an aircraft that includes determining which vertical flight plan rules of a plurality of vertical flight rules that have been loaded in a predictions processor are active by monitoring for criteria that are used to initiate or terminate one or more of the vertical flight plan rules. Aircraft state is predicted at waypoints along a lateral flight path in view of active vertical flight plan rules, and the predicted aircraft state is updated within an integrated flight plan database that stores prediction performance data associated with the aircraft's flight.

Owner:HONEYWELL INT INC

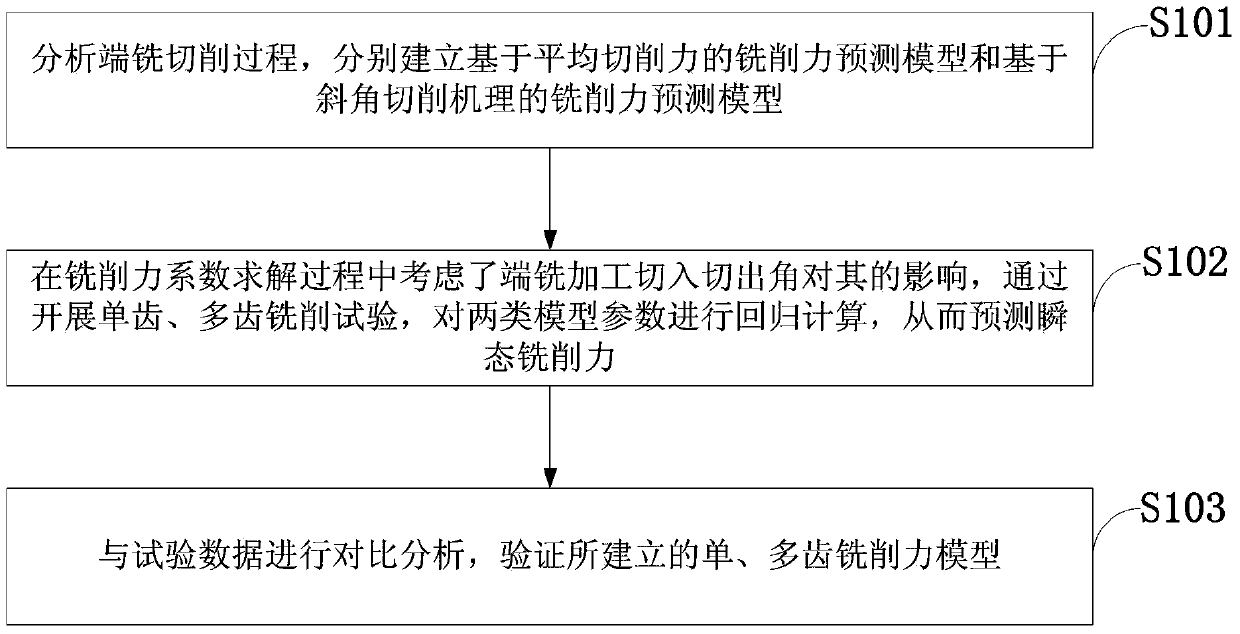

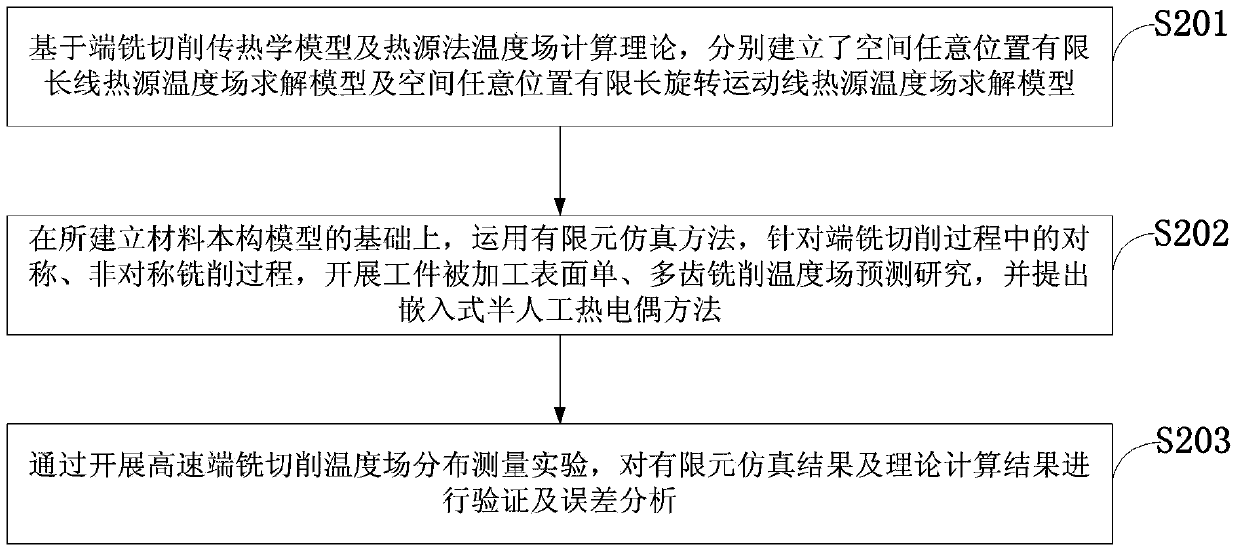

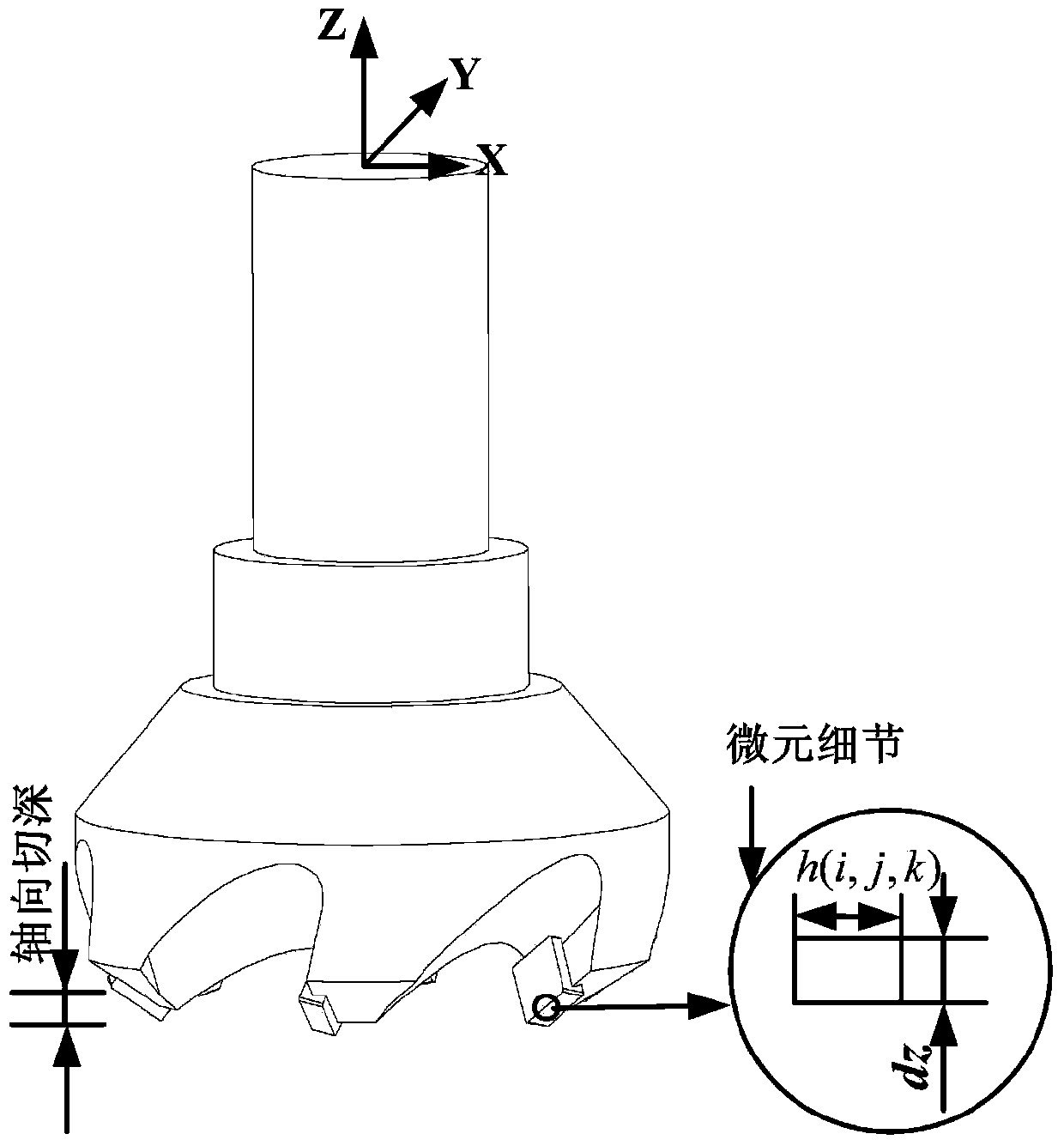

Method of cutting force prediction and temperature prediction for end-milling cutting

ActiveCN104268343ASimple methodEasy to operateSpecial data processing applicationsMethod developmentCutting force model

The invention discloses a method of cutting force prediction and temperature prediction for end-milling cutting, the method development of the cutting force prediction is based on a milling forces prediction model of average cutting forces and a milling forces prediction model of bevel angle cutting mechanism and is characterized by performing regression calculating on the two model parameters, predicting transient cutting force, performing comparative analysis with test data, and verifying established single-tooth and multi-teeth cutting force models; the method of cutting force temperature prediction establishes a temperature field solution model of a limited long-line heat source of space optional positions and a temperature field solution model of a limited long-rotation movement line heat source of space optional positions; by means of a limited element simulation method, an embedding semi-artificial thermocouple method is put forward, and by carrying out high speed end-milling cutting temperature field distribution measurement, verification and error analysis are performed on a limited element simulation result and a theoretical calculation result. The method of the cutting force prediction and the temperature prediction of the end-milling cutting has the advantages that the method is simple, operation is easy, reference foundation is provided for end-milling cutting technology, and the method is more beneficial to production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

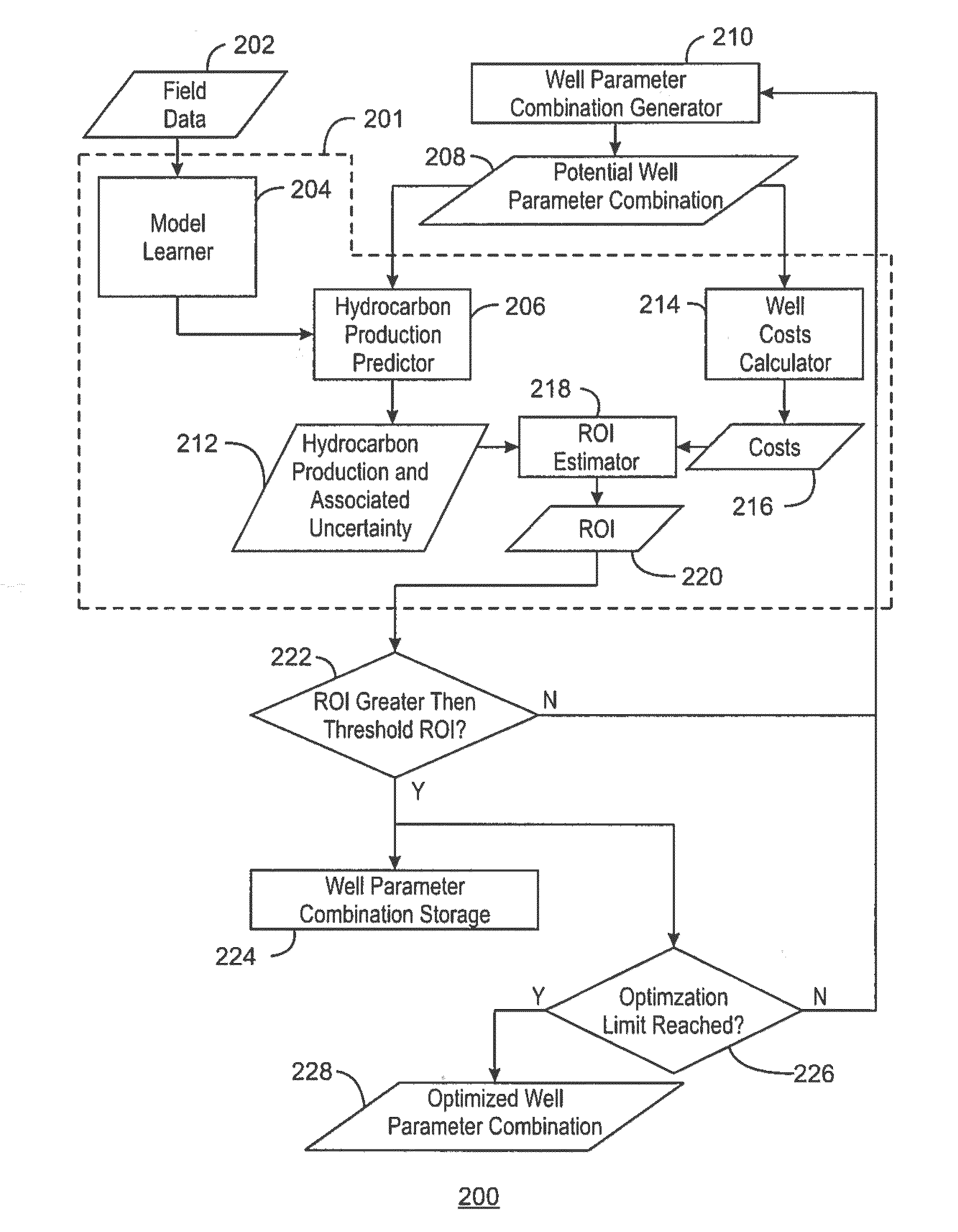

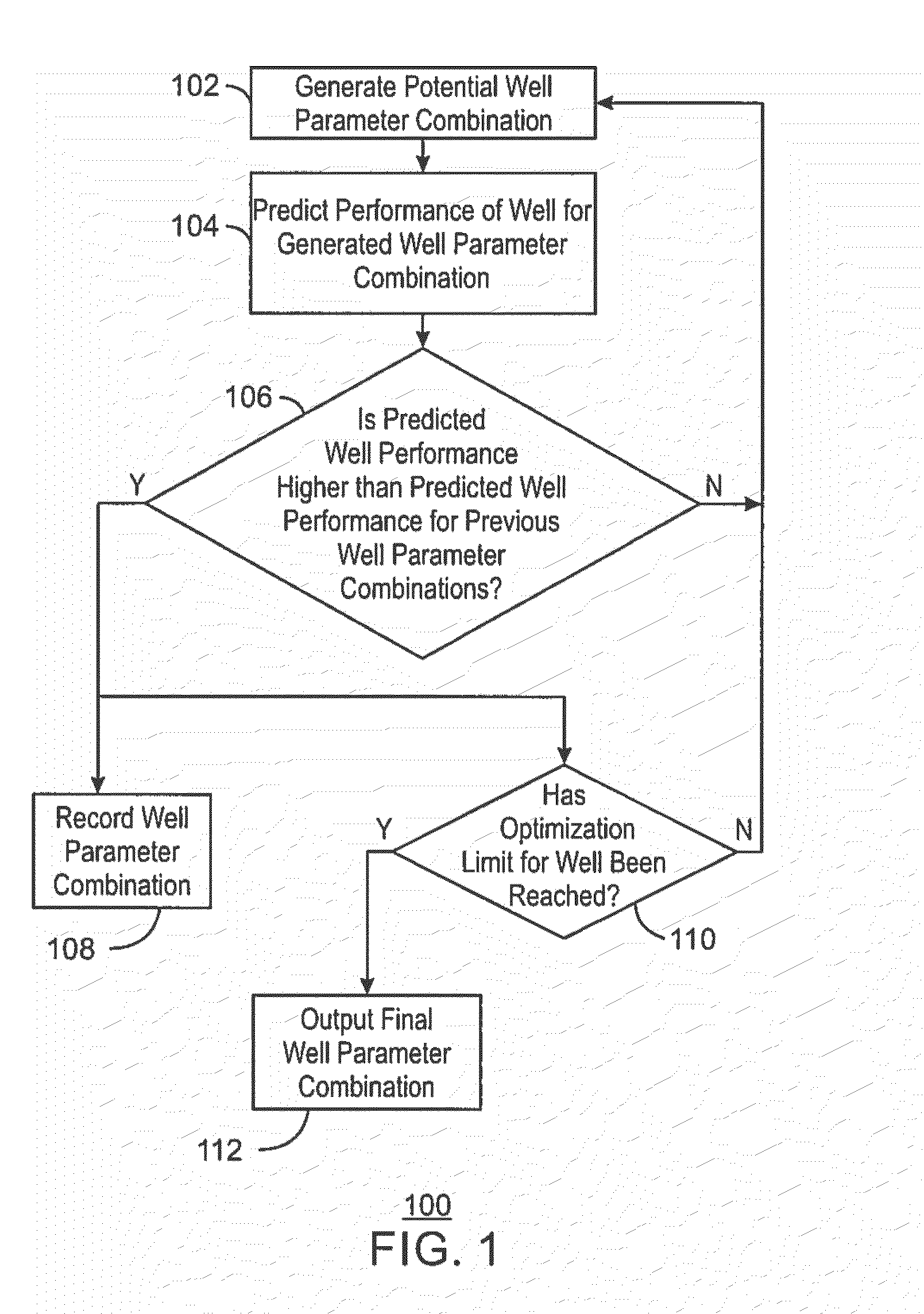

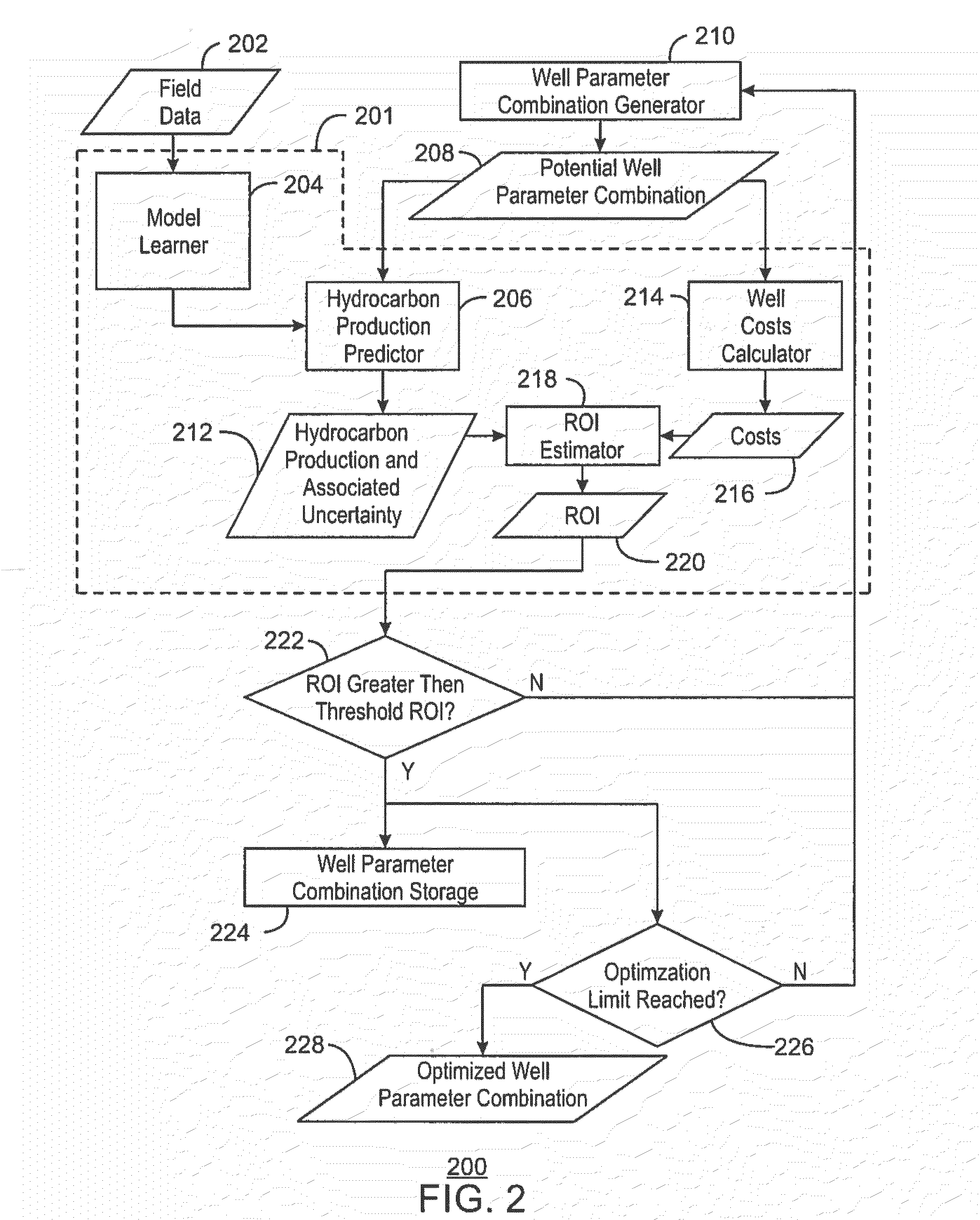

Determining Well Parameters For Optimization of Well Performance

ActiveUS20140365409A1Predictive performanceDigital computer detailsFluid removalPredicting performanceField data

Systems and methods for determining well parameters for optimization of well performance. The method includes training, via a computing system, a well performance predictor based on field data corresponding to a hydrocarbon field in which a well is to be drilled. The method also includes generating, via the computing system, a number of candidate well parameter combinations for the well and predicting, via the computing system, a performance of the well for each candidate well parameter combination using the trained well performance predictor. The method further includes determining, via the computing system, an optimized well parameter combination for the well such that the predicted performance of the well is maximized.

Owner:EXXONMOBIL UPSTREAM RES CO

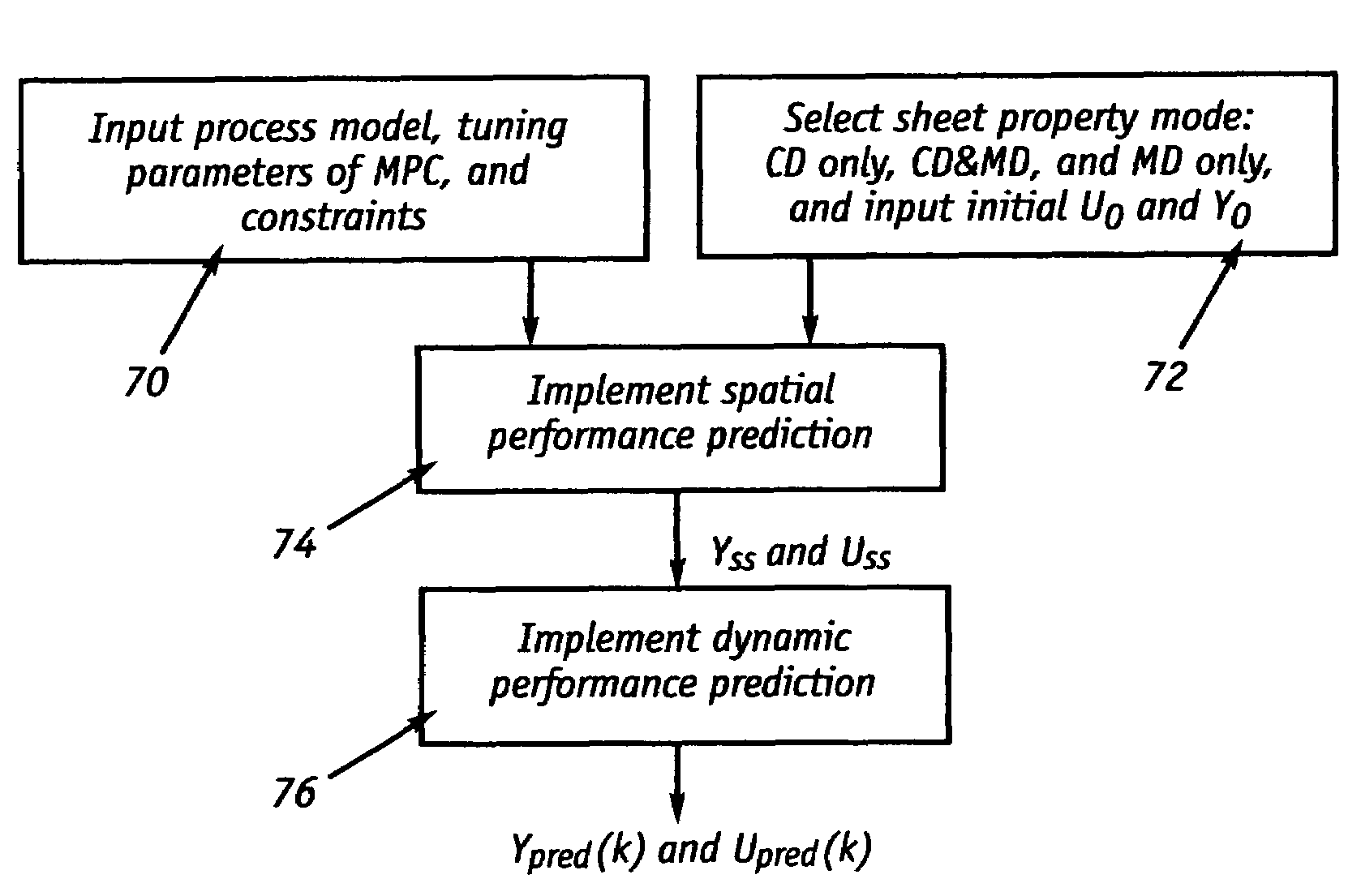

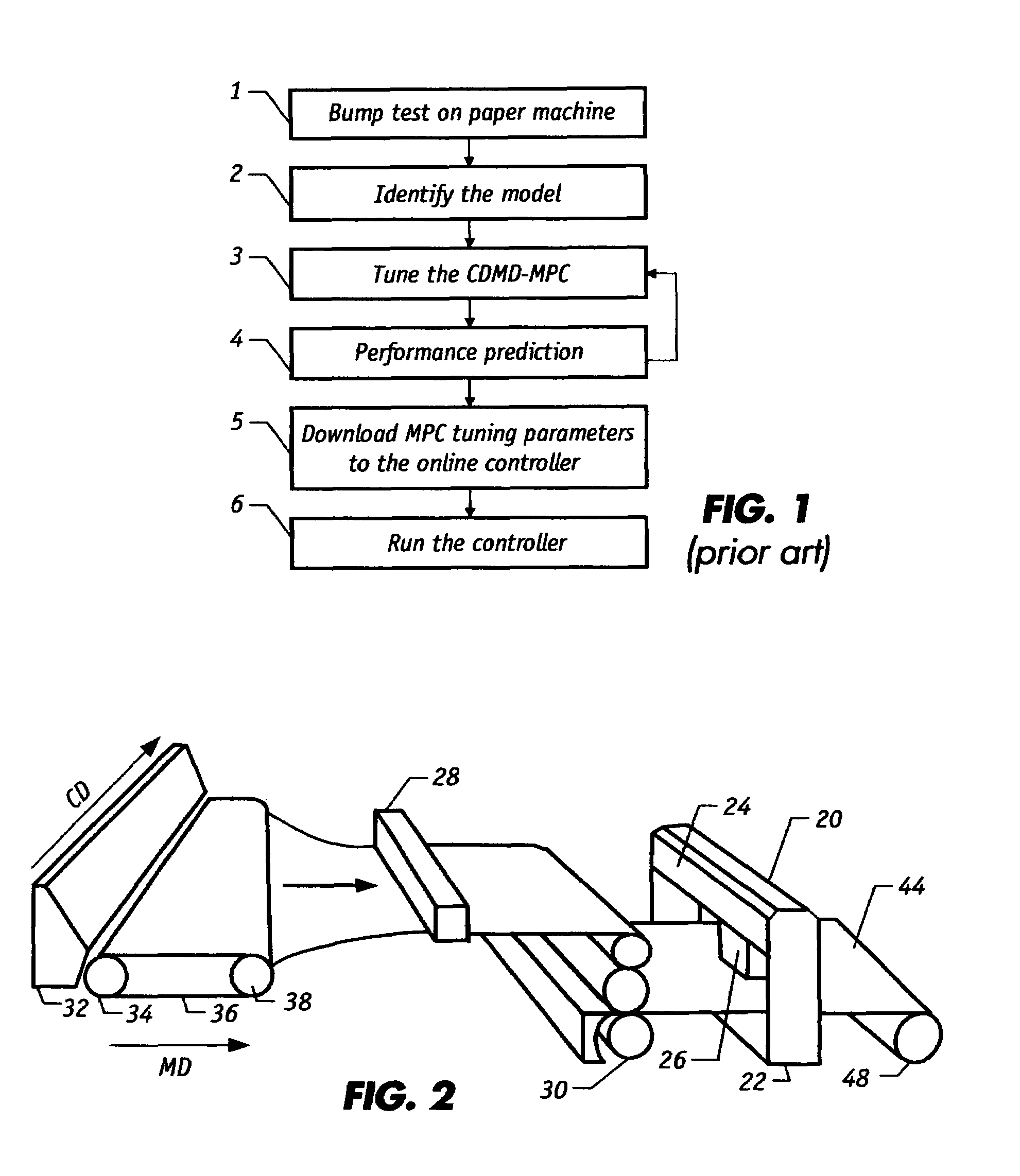

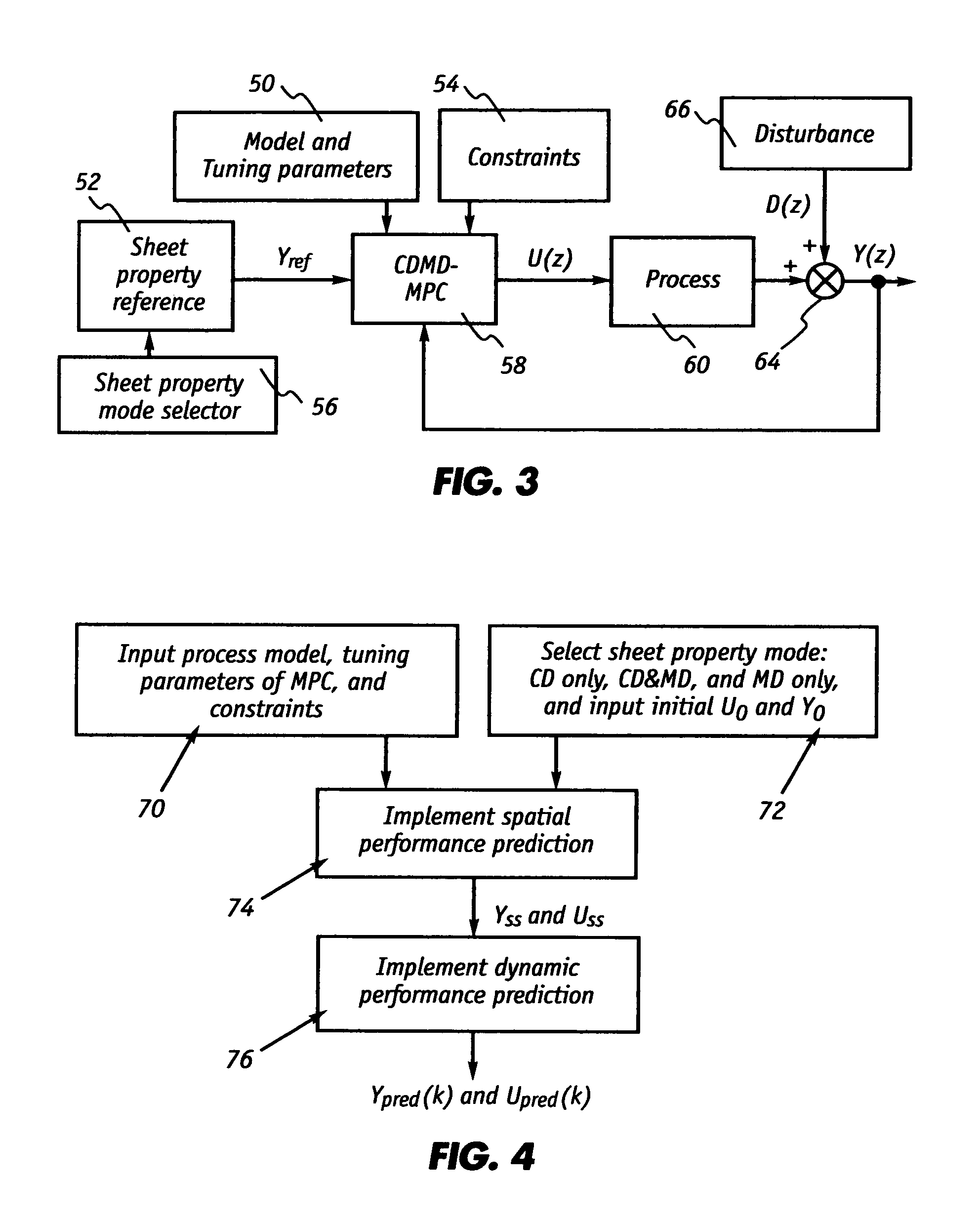

Fast performance prediction of multivariable model predictive controller for paper machine cross-directional processes

ActiveUS7454253B2Efficient solutionMinimize the differenceElectric/magnetic detection for well-loggingDigital differential analysersPredictive controllerActuator

A technique for fast performance prediction of multivariable model predictive controllers (MPC) for large-scale spatially-distributed dynamic systems is provided. When operating an MPC for a two-dimensional sheetmaking process, the controller's performance can be separated into spatial performance and dynamic performance. The steady-state spatial performance for different sheet property modes is first predicted, thereafter, the dynamic performance is predicted on the basis of the steady-state actuator profiles. During the steady-state spatial performance prediction, the original MPC's cost function is approximated to be a steady-state cost function. Then the steady-state measurement profiles and the actuator profiles are calculated through the steady-state cost function. The actuator profiles in time series can be efficiently solved by minimizing the difference between the actuator profiles and the steady-state actuator profiles in the face of constraints. Finally, the model can be employed to expeditiously compute the measurement profiles in times series.

Owner:HONEYWELL ASCA INC

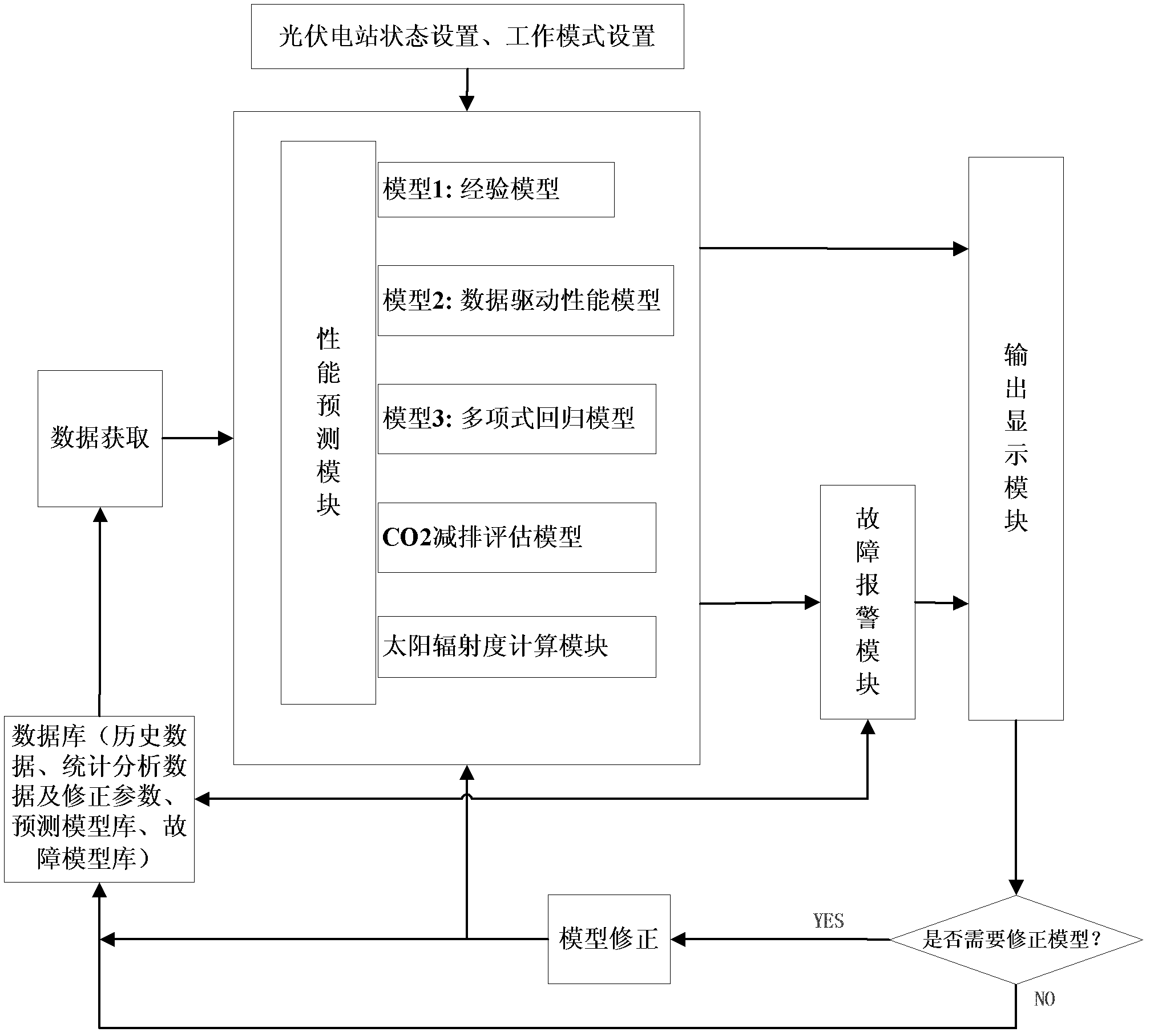

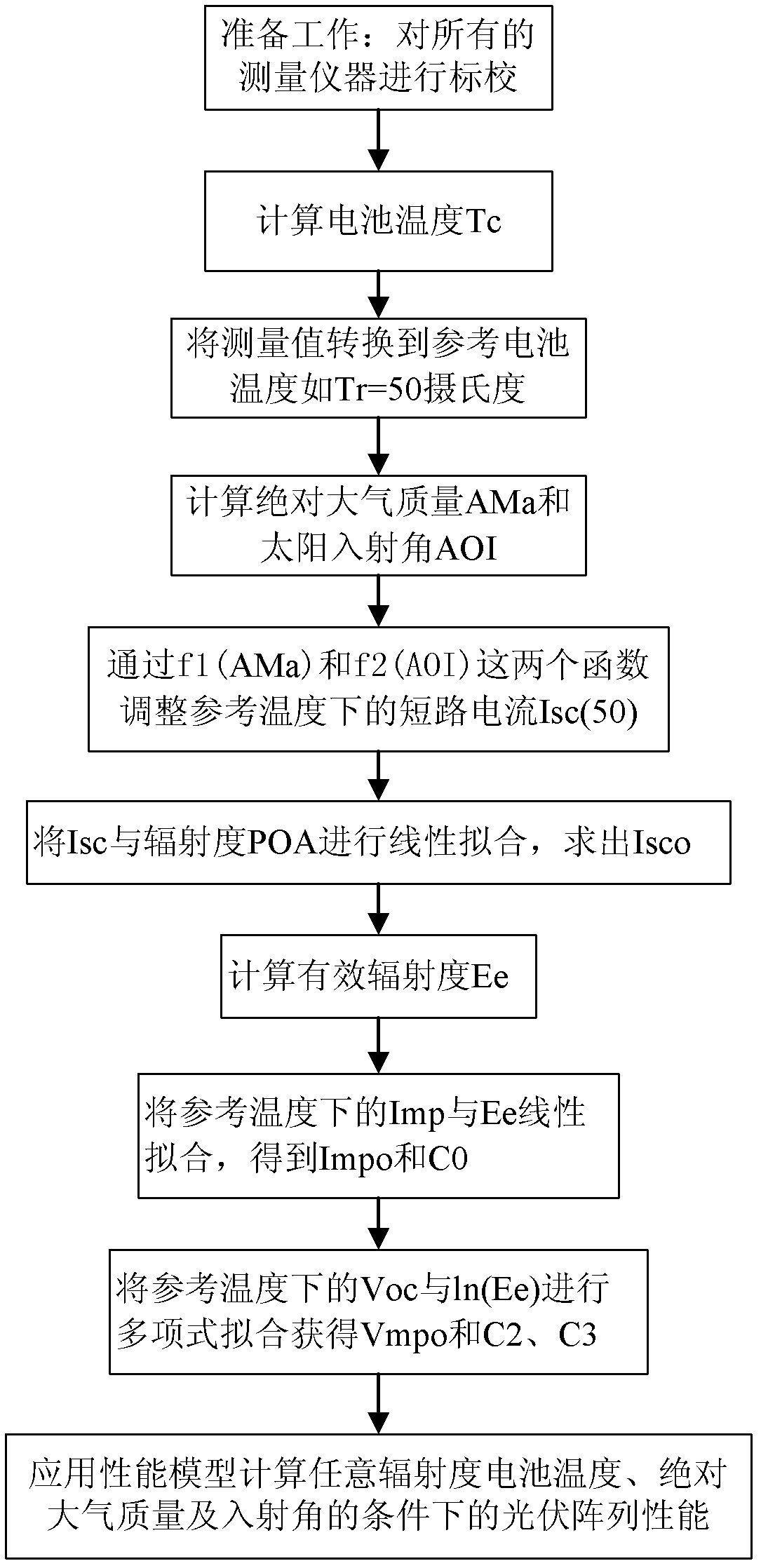

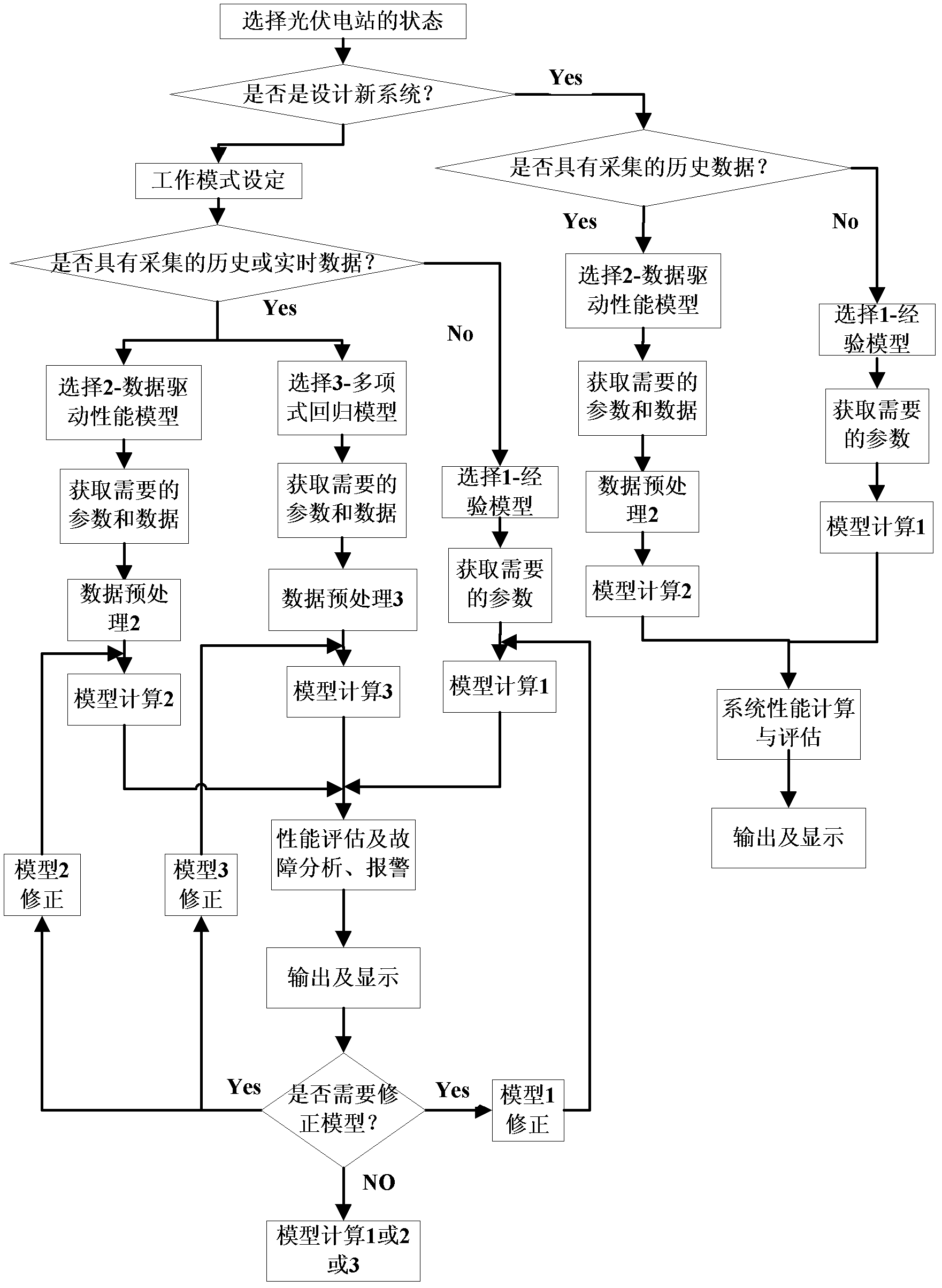

Performance prediction and fault alarm method for photovoltaic power station

InactiveCN102566435AImprove accuracyEasy to troubleshootAdaptive controlReal-time dataPolynomial regression model

The invention discloses a performance prediction and fault alarm method for a photovoltaic power station. The method comprises the following steps of: a, setting the station of the power station; b, setting the operation mode of the power station; c, judging whether required real-time data or historical data exists or not; d, predicting the performance of the power station through an experience model if the state in the step a is that a new photovoltaic power station is required to be designed and the required real-time data or historical data in the step c does not exist, and predicting the performance of the power station through a data drive performance model if the required real-time data or historical data in the step c exists; e, predicting the performance of the power station through the data drive performance model or a polynomial regression model if the photovoltaic power station in the step a is operated and the required real-time data or historical data in the step c exists, and predicting the performance of the power station through the experience model if the required real-time data or historical data in the step c does not exist; f, comparing actual performance with the predicted performance, and performing fault alarm; and g, correcting the models on line by a Kalman filtering method and returning to the step c, and otherwise, directly returning to the step e. By the method, solar energy resources can be utilized to the maximum extent, and power utilization cost can be reduced; and the accuracy of performance prediction and fault diagnosis is improved.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

Performance prediction method for hydrocarbon recovery processes

The invention relates to a method for predicting the performance of large-scale hydrocarbon-bearing reservoir floods. One embodiment of the invention includes a method for predicting performance of a patterned flooding process in a subterranean hydrocarbon-bearing formation, said formation being penetrated by a plurality of injector wells and producer wells, comprising the steps of: determining flow-based pairs of injector to producer wells [FIG. 4, item 78a] (first well pairs) using a geological model [item 76]; developing a connective pore volume distribution curve for each first well pair item [78b]; selecting at least two first well pairs (selected well pairs) that reflect narrow and wide connective pore volume distributions that correspond to high and lower oil recovery levels; developing a 3-D simulation model for each selected well pair, performing a reservoir simulation for each selected well pair for the corresponding flooding process; and generating prototype performance curves for each selected well pair. An alternate embodiment of the invention includes a method for predicting the performance of large-scale hydrocarbon-bearing reservoir floods where injection well location, production well location, a process parameter, or a well processing rate is modified.

Owner:EXXONMOBIL UPSTREAM RES CO

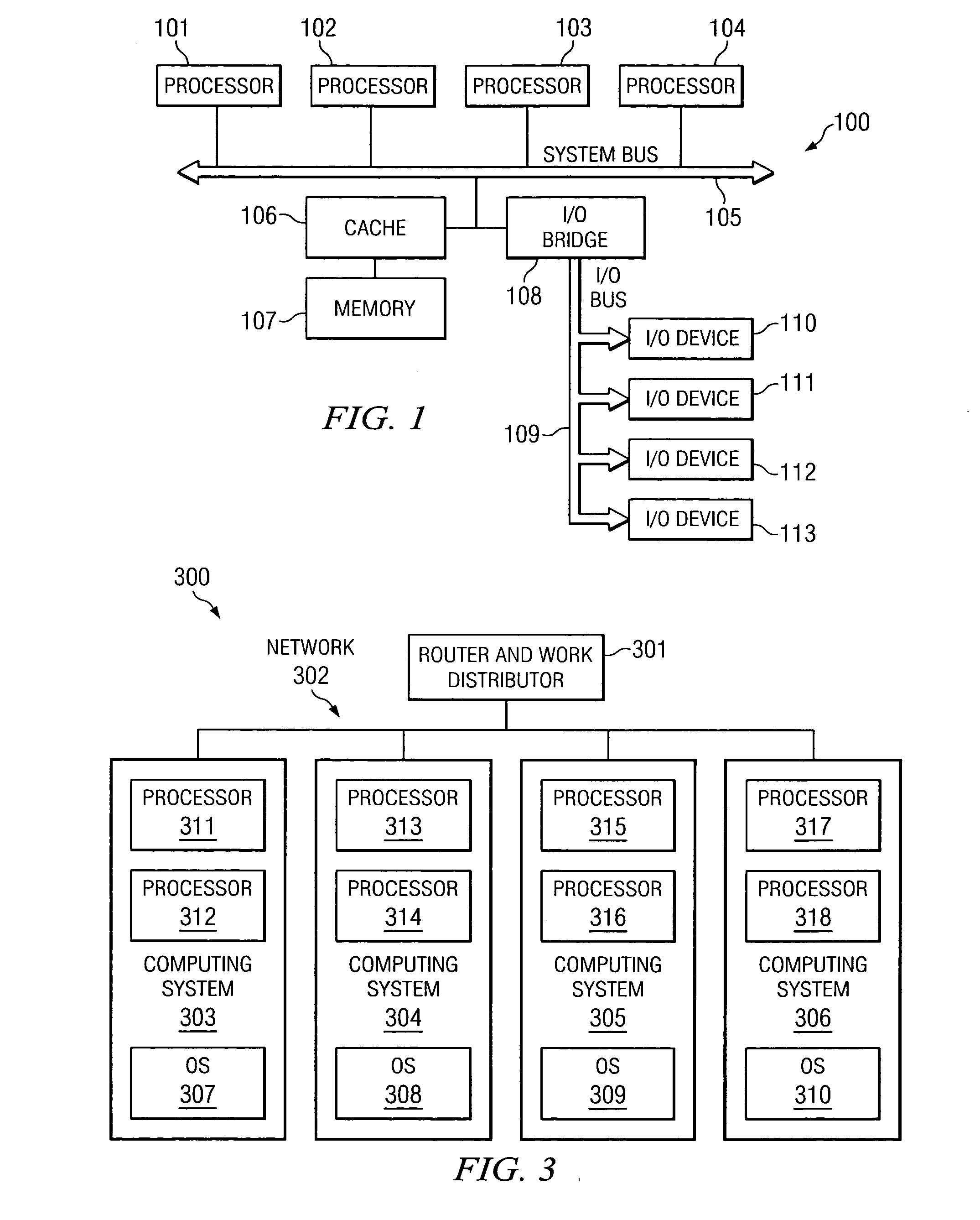

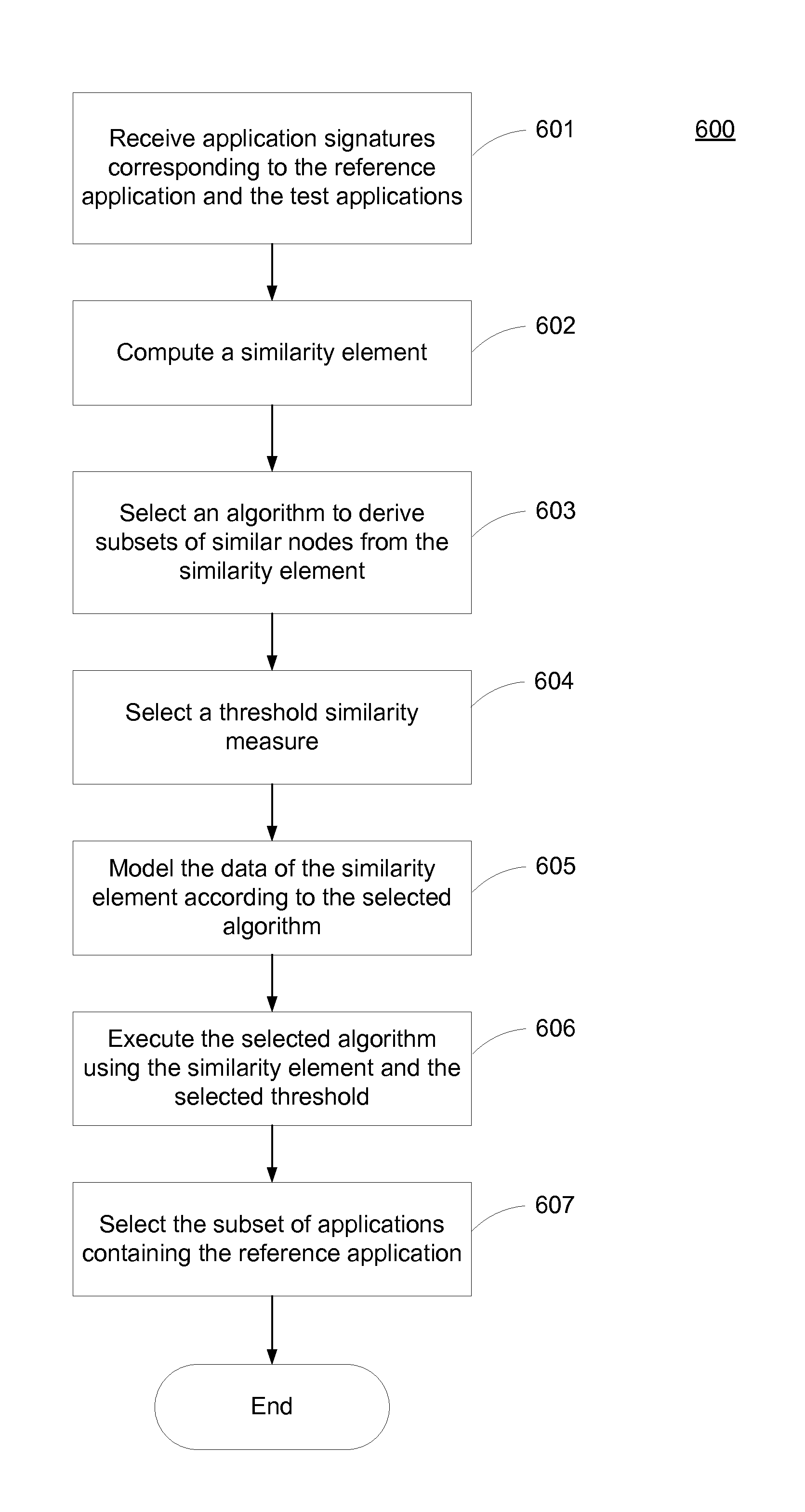

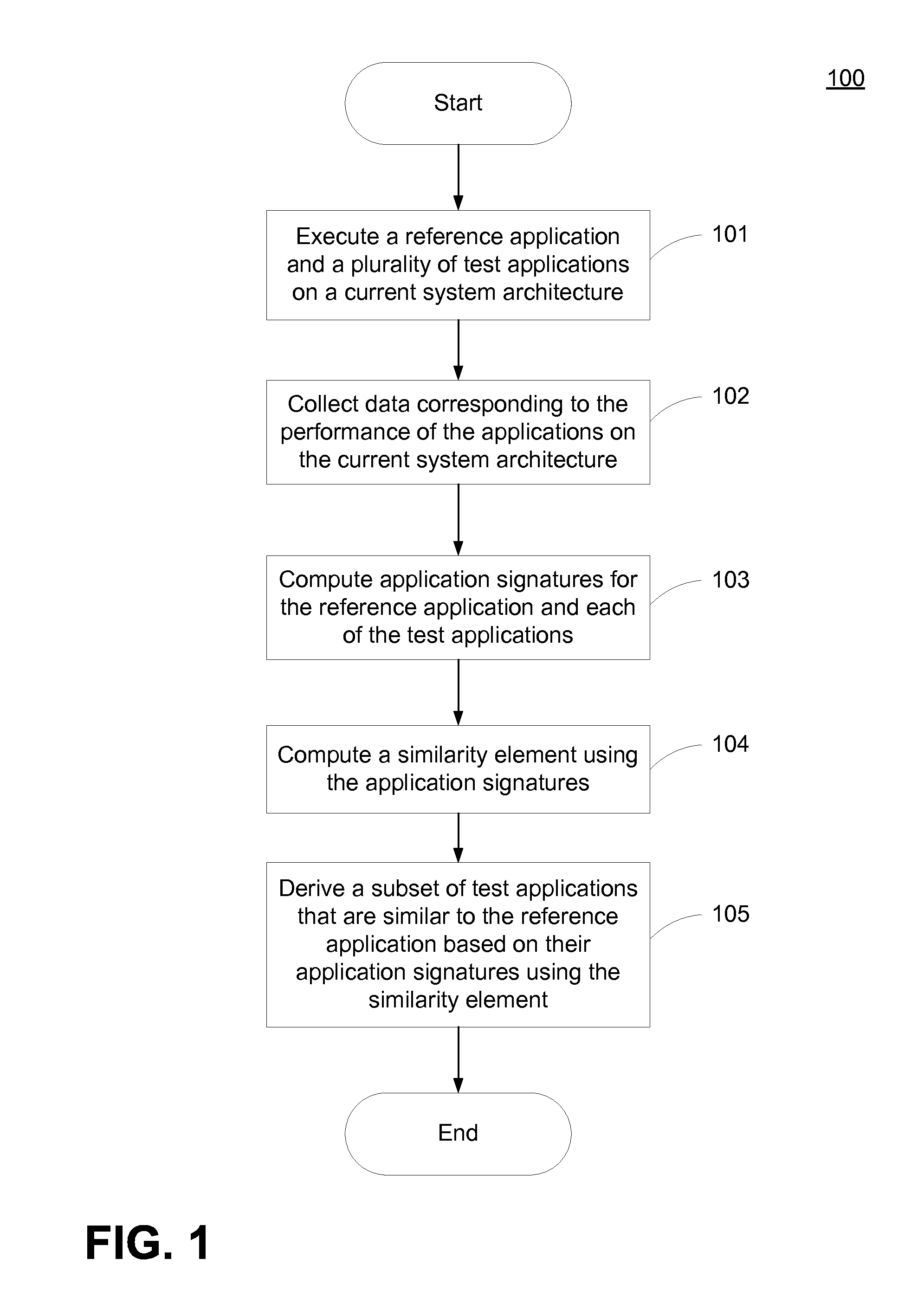

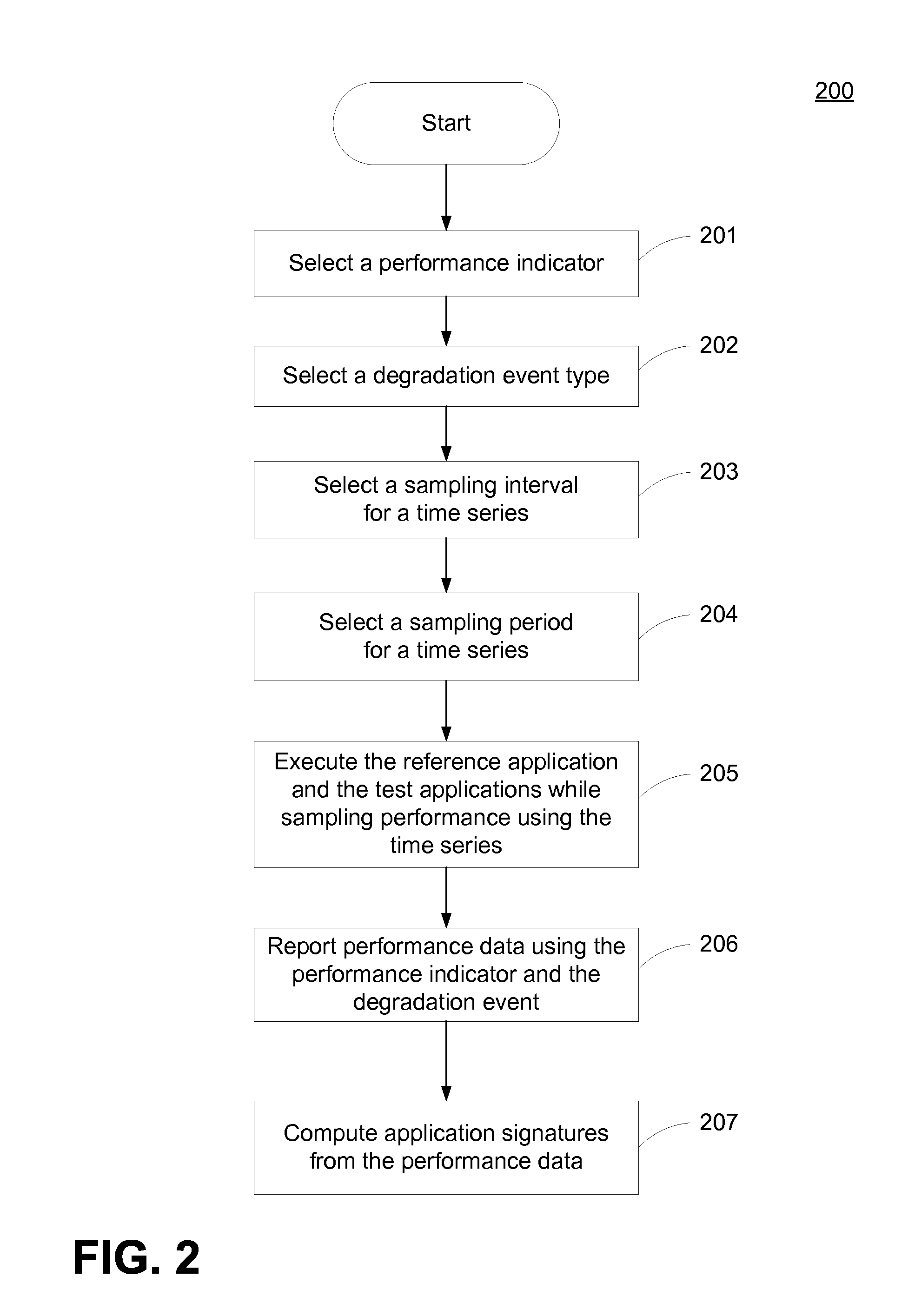

Method and System for Predicting Performance of Software Applications on Prospective Hardware Architecture

InactiveUS20120197626A1Error detection/correctionSpecific program execution arrangementsHardware architectureParallel computing

A system and method for identifying optimal system architectures for a reference application are provided. The system and method comprise executing a reference application and a plurality of test applications on a current system architecture and sampling performance data for each of the applications. The performance data is used to compute an application signature for each application. A similarity element is derived from the application signatures that illustrates the similarity between each application and every other application. Using a similarity threshold and an algorithm, a subset of test applications that are similar to the reference application are derived.

Owner:R2 SOLUTIONS

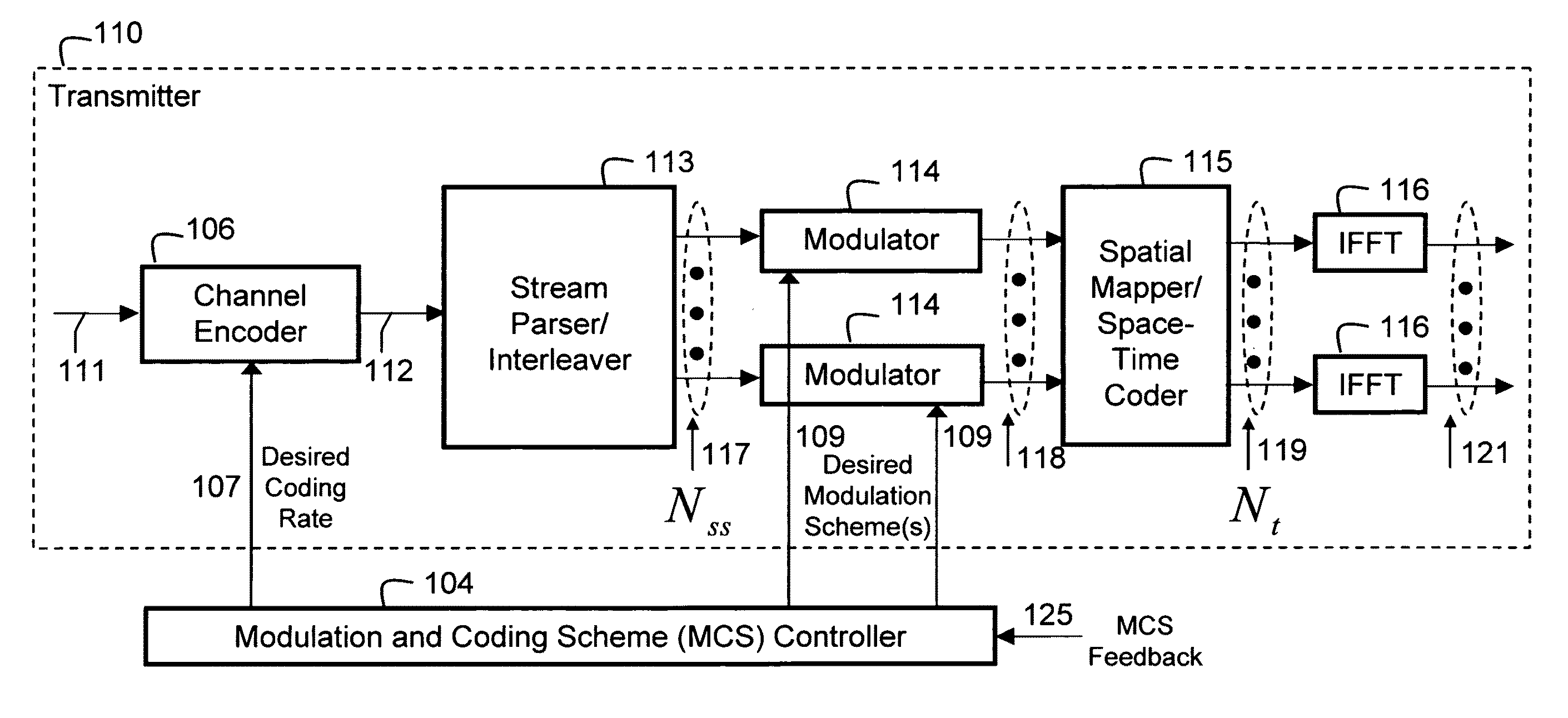

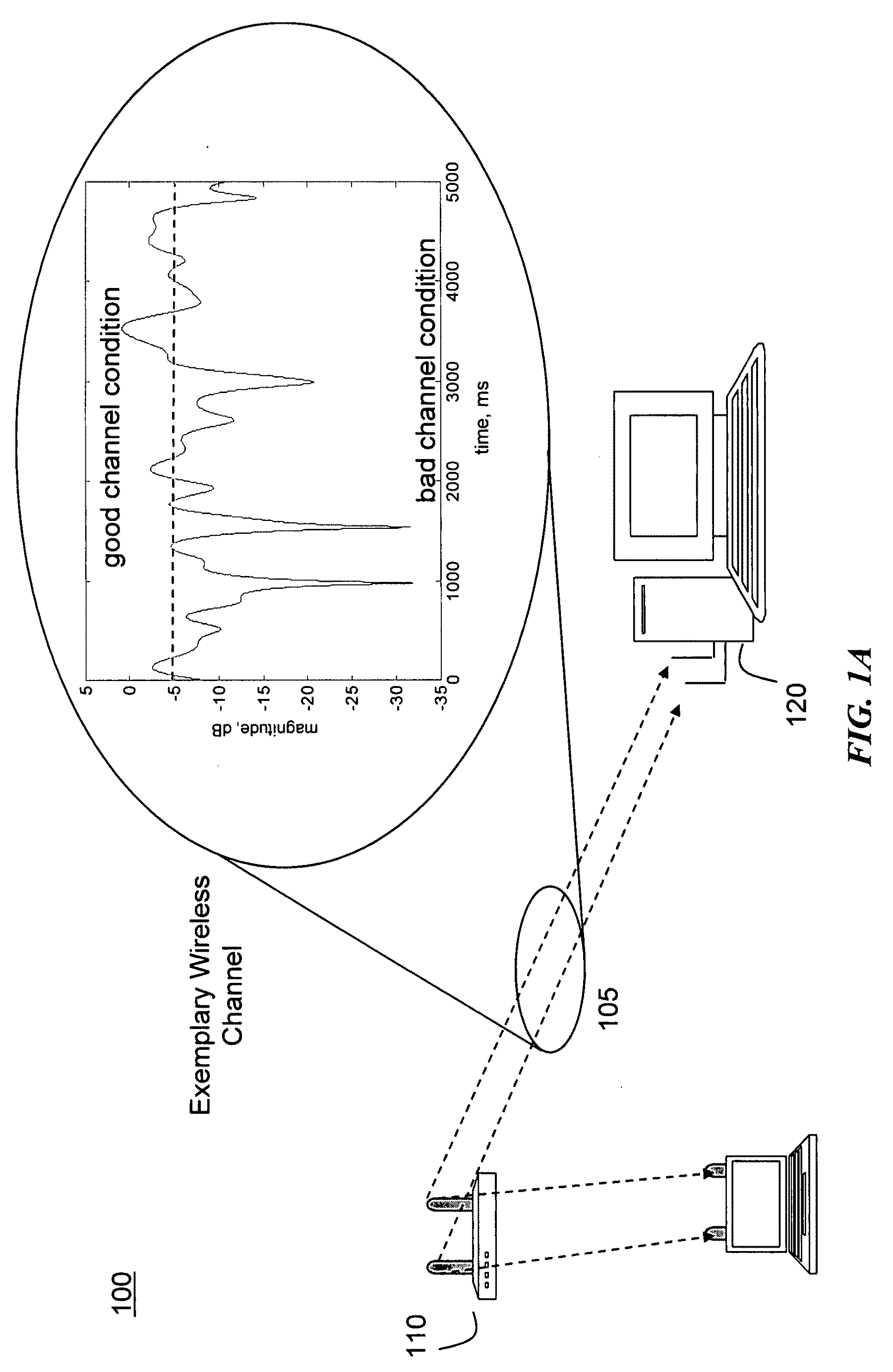

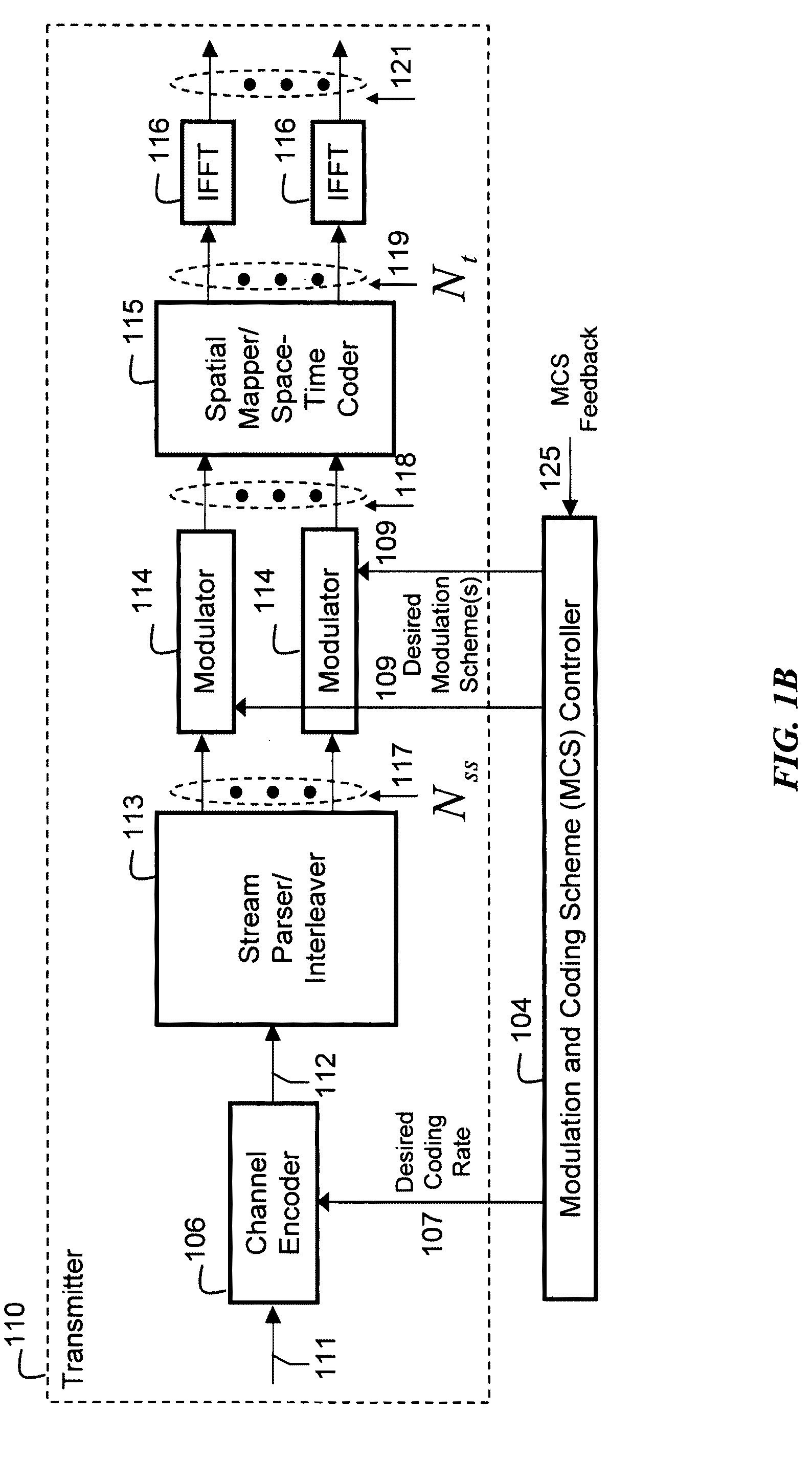

Performance-based link adaptation techniques

InactiveUS20090116589A1Amplitude-modulated carrier systemsTransmission monitoringChannel state informationCommunications system

A multiple carrier wireless communications system includes a channel predictor, a performance predictor, and a link adapter. The channel predictor is configured to predict channel state information for a next packet based on channel state information for the current packet. The performance predictor includes an uncoded performance predictor configured to predict system performance at an input of a decoder based on a modulation type and the predicted channel state information for the next packet, and a decoder input-output performance mapper configured to determine a required coding rate based on a requested system performance and the predicted system performance at the input of the decoder. The link adapter includes a modulation and coding scheme (MCS) updater configured to identify a MCS based on the required coding rate.

Owner:RENESAS ELECTRONICS CORP

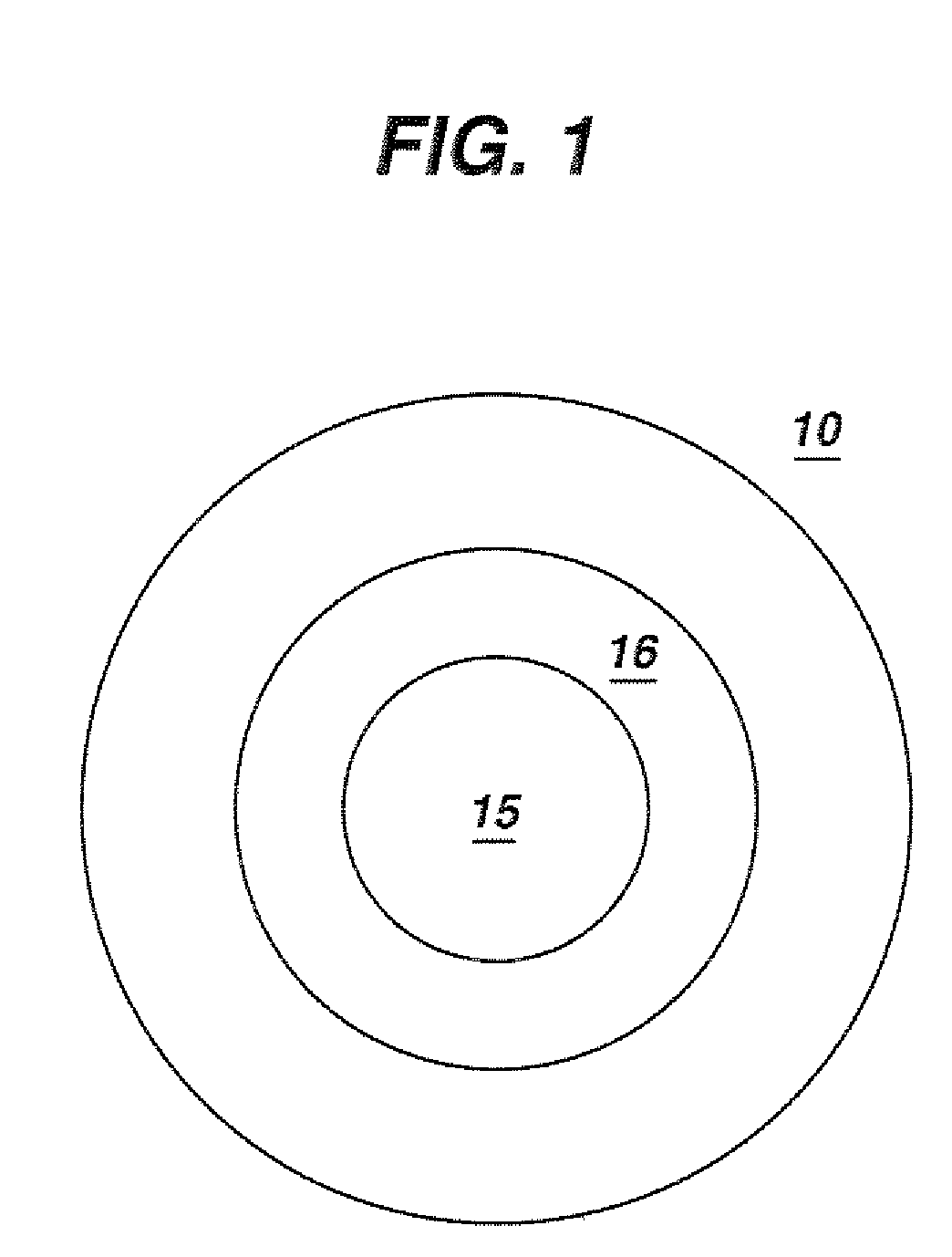

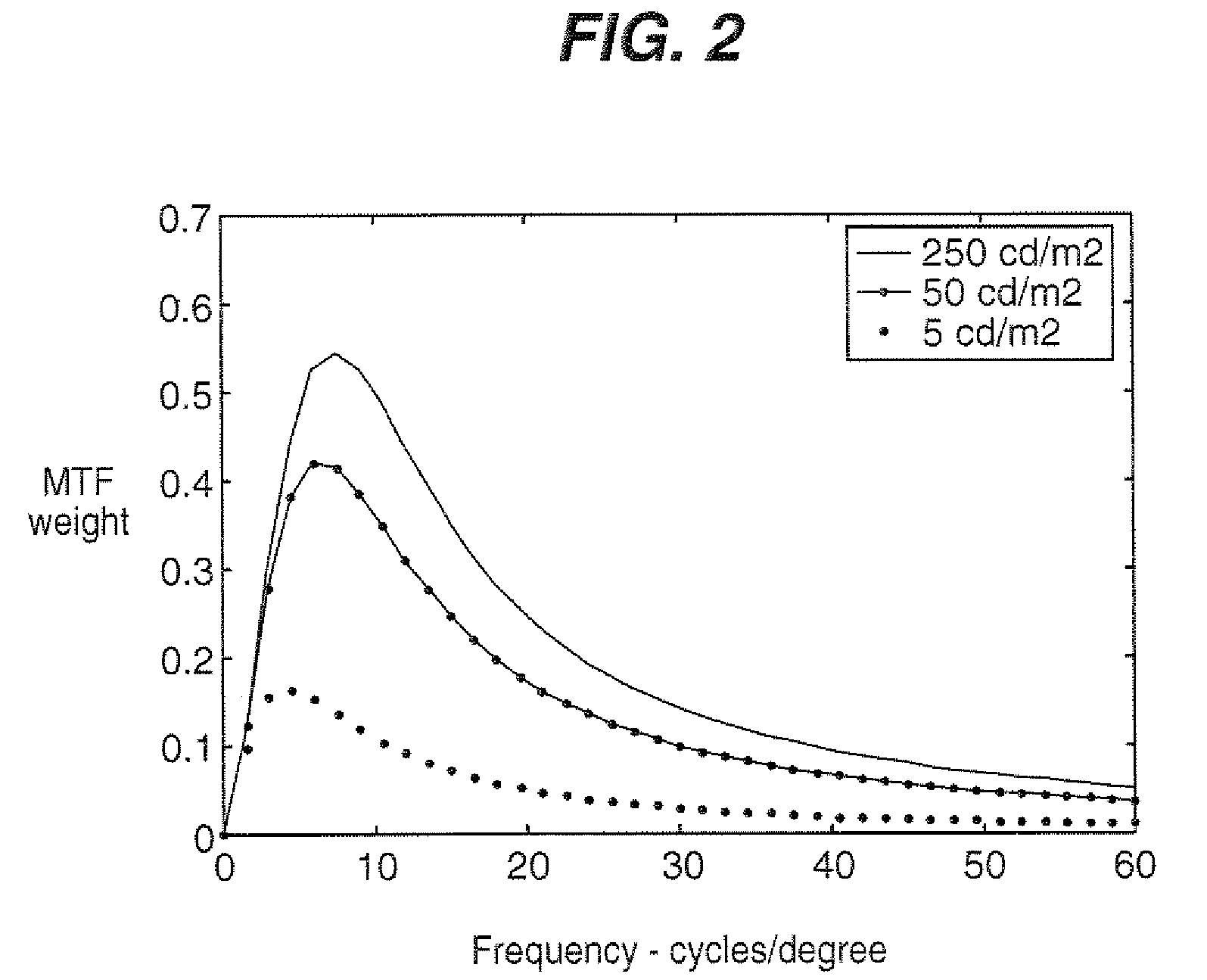

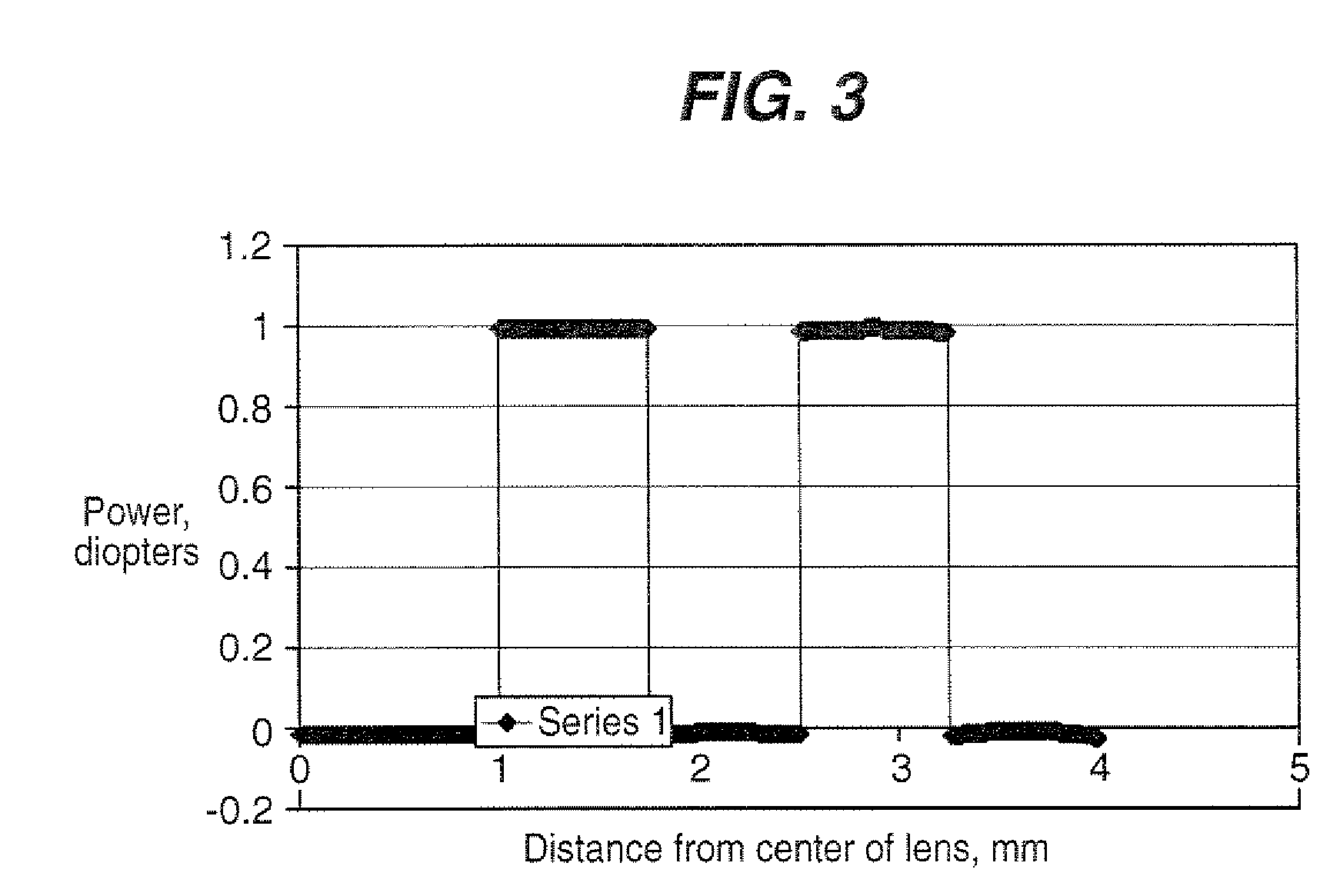

Method of designing multifocal contact lenses

ActiveUS7625086B2Computation using non-denominational number representationEye diagnosticsEngineeringContact lens

The invention provides methods for designing contact lenses that provides improved efficiency in lens design compared to conventional methods. It is a discovery of the invention that improved performance and reduced design time can be obtained by utilizing a visual performance prediction model as a part of the design process.

Owner:JOHNSON & JOHNSON VISION CARE INC

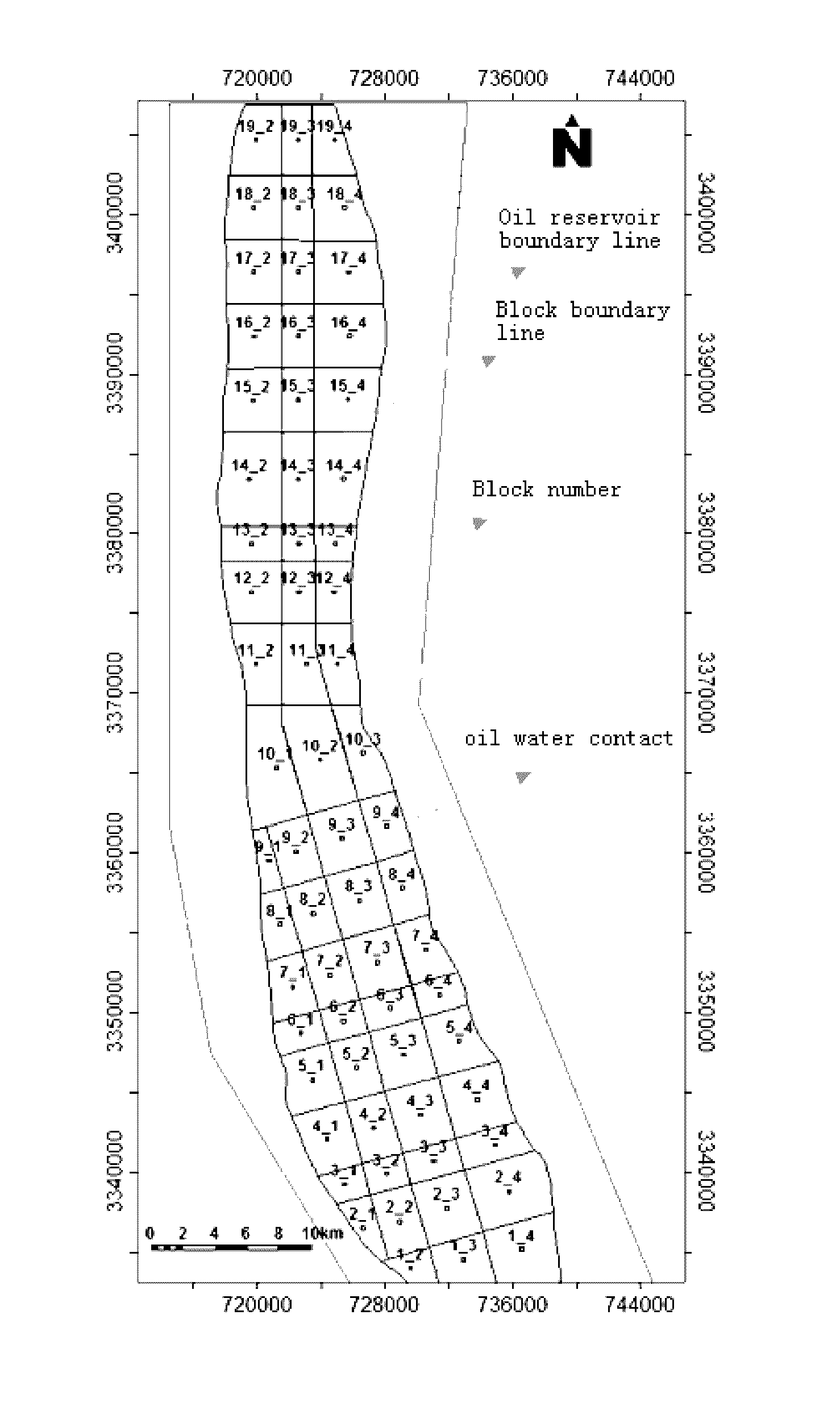

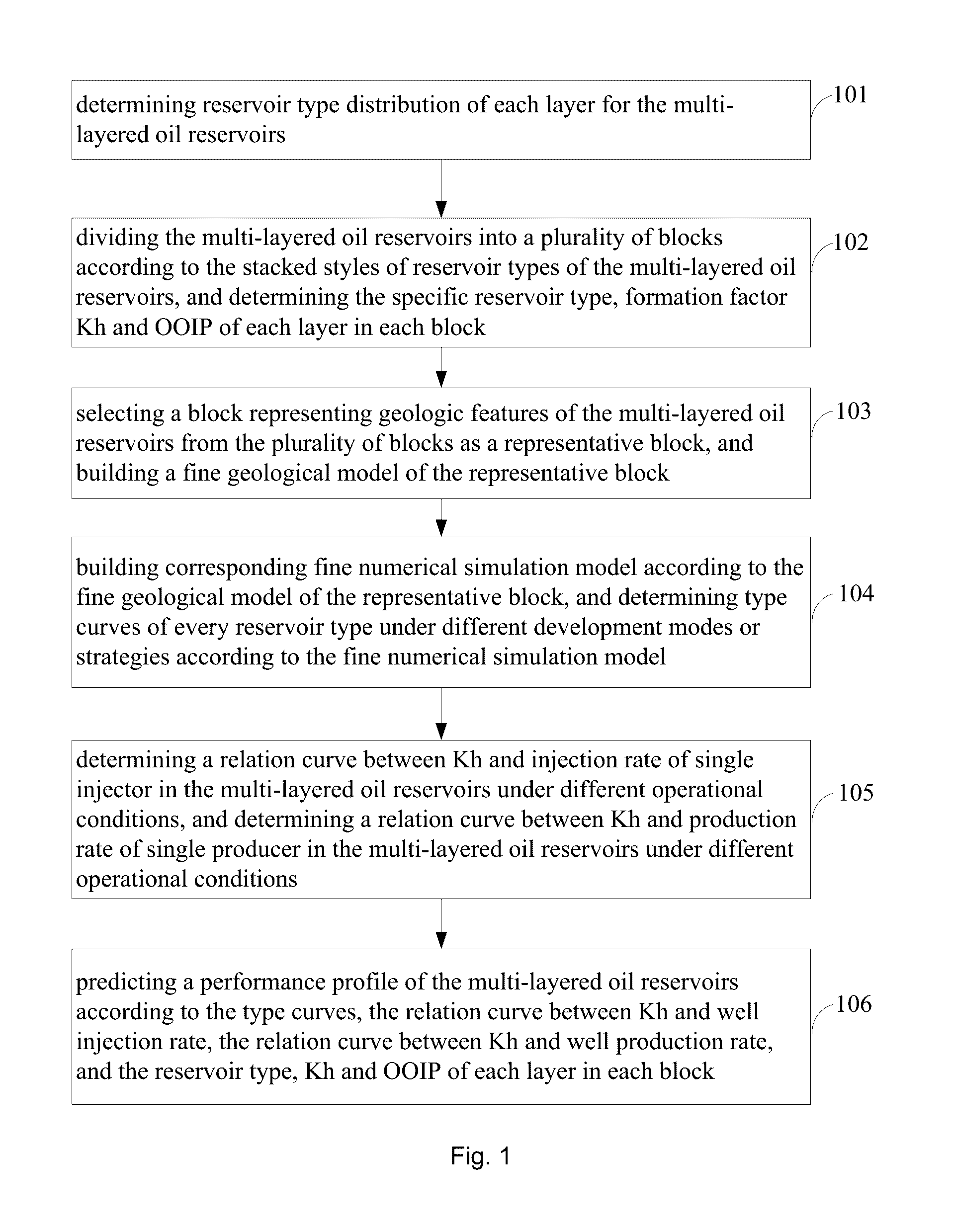

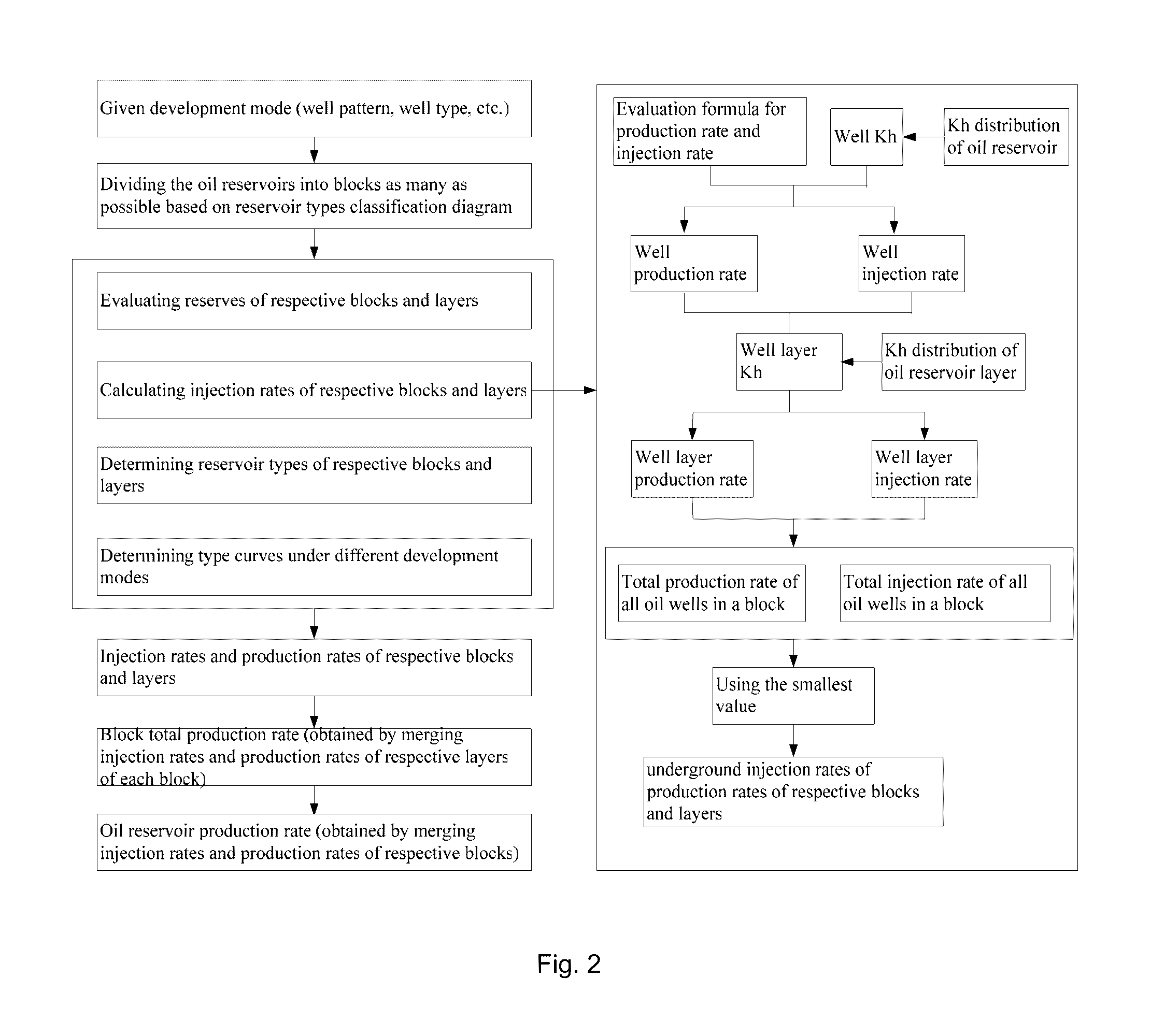

Method and Apparatus for Performance Prediction of Multi-Layered Oil Reservoirs

InactiveUS20160376885A1Decreasing man-powerConvenience to workElectric/magnetic detection for well-loggingConstructionsReservoir typeProduction rate

The present invention discloses a method and an apparatus for predicting performance profiles of multi-layered oil reservoirs, wherein the method comprises: dividing the multi-layered oil reservoirs into a plurality of blocks, and determining a reservoir type, formation factor Kh and an evaluated reserves of each layer in each block; selecting a block representing geologic features of the multi-layered oil reservoirs from the plurality of blocks as a representative block, to build a fine geological model of the representative block; building corresponding fine numerical simulation model according to the fine geological model of the representative block, and determining type curves of different reservoir types under different development strategies; determining a relation curve between Kh and well injection rate for injectors and a relation curve between Kh and well production rate for producers in the multi-layered oil reservoirs under different restrictive conditions; predicting performance of the multi-layered oil reservoirs according to the type curve, the relation curve between Kh and well injection rate, the relation curve between Kh and well production rate, and the reservoir type, formation factor Kh and evaluated reserves of each layer in each block.

Owner:PETROCHINA CO LTD

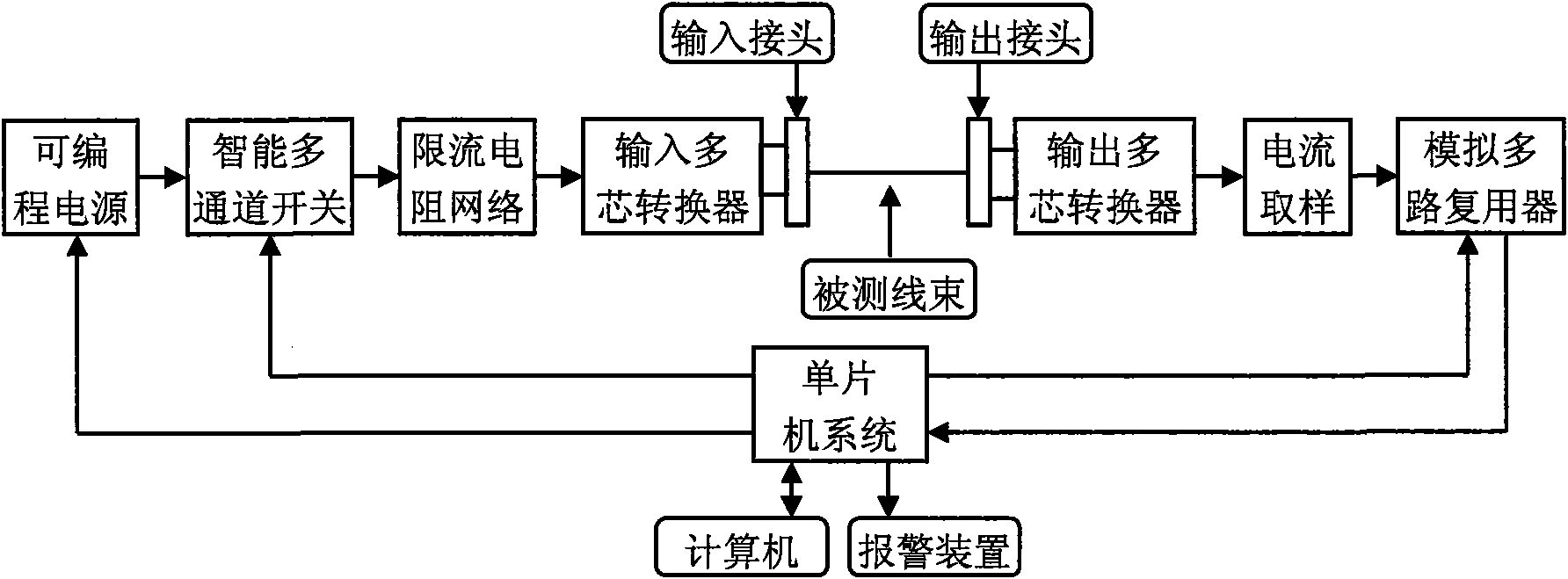

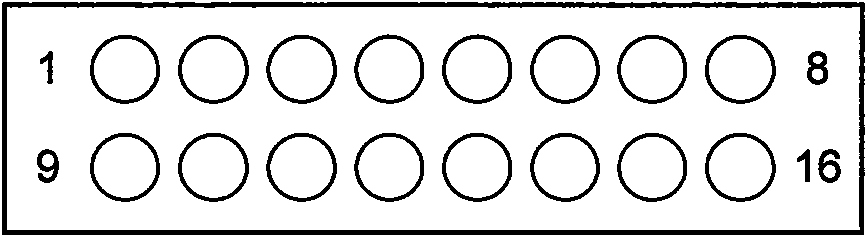

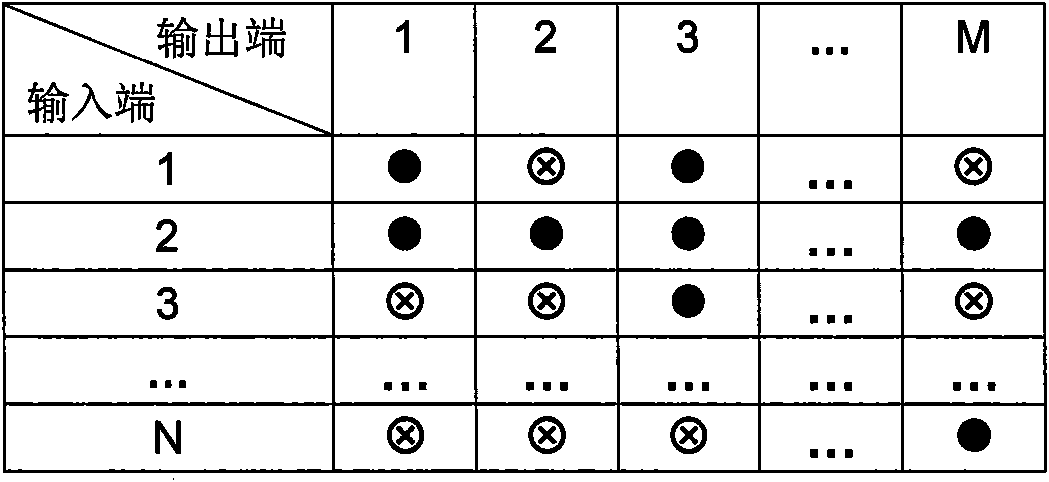

Intelligent multi-core cable harness detection device

InactiveCN101937038AEliminate disturbing effectsHigh measurement accuracyCurrent/voltage measurementElectrical testingExtensibilityEngineering

The invention relates to an intelligent multi-core cable harness detection device. The device consists of a programmable power supply, an intelligent multi-channel switch, a current-limiting resistor network, a multi-core converter, a current sampling module, an analog multiplexer, a single-chip, a computer and detection software. The device can automatically analyze short-circuit performance, open-circuit performance and conduction performance of a multi-core cable harness. A harness system state is determined through a harness performance testing matrix graphical detection result and by comparing the result with a pre-stored standard, and different fault types are indicated by colors; and meanwhile, a fault alarm can be sent by an alarm device with sound and changing light. The device has the characteristics of simple and convenient operation, high testing efficiency, high system extensibility and the like, and can be directly used for development of harness-related products, quality control and performance detection.

Owner:CHINA FIRST AUTOMOBILE

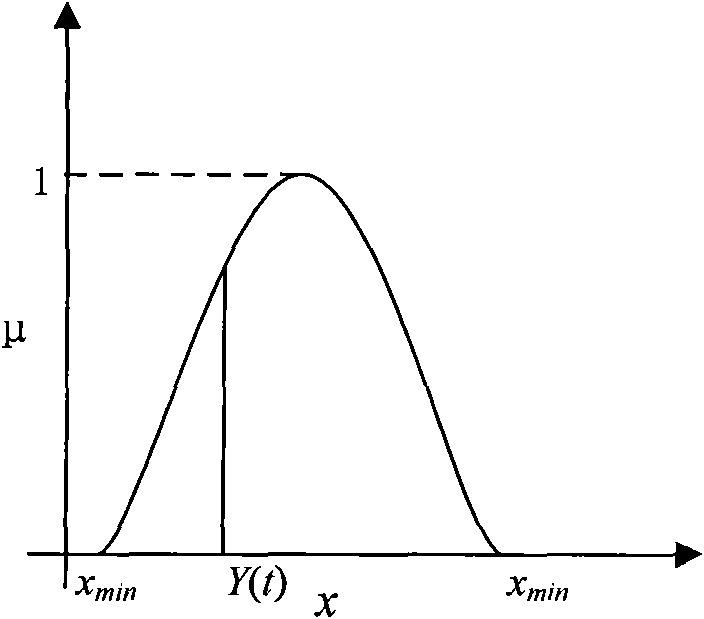

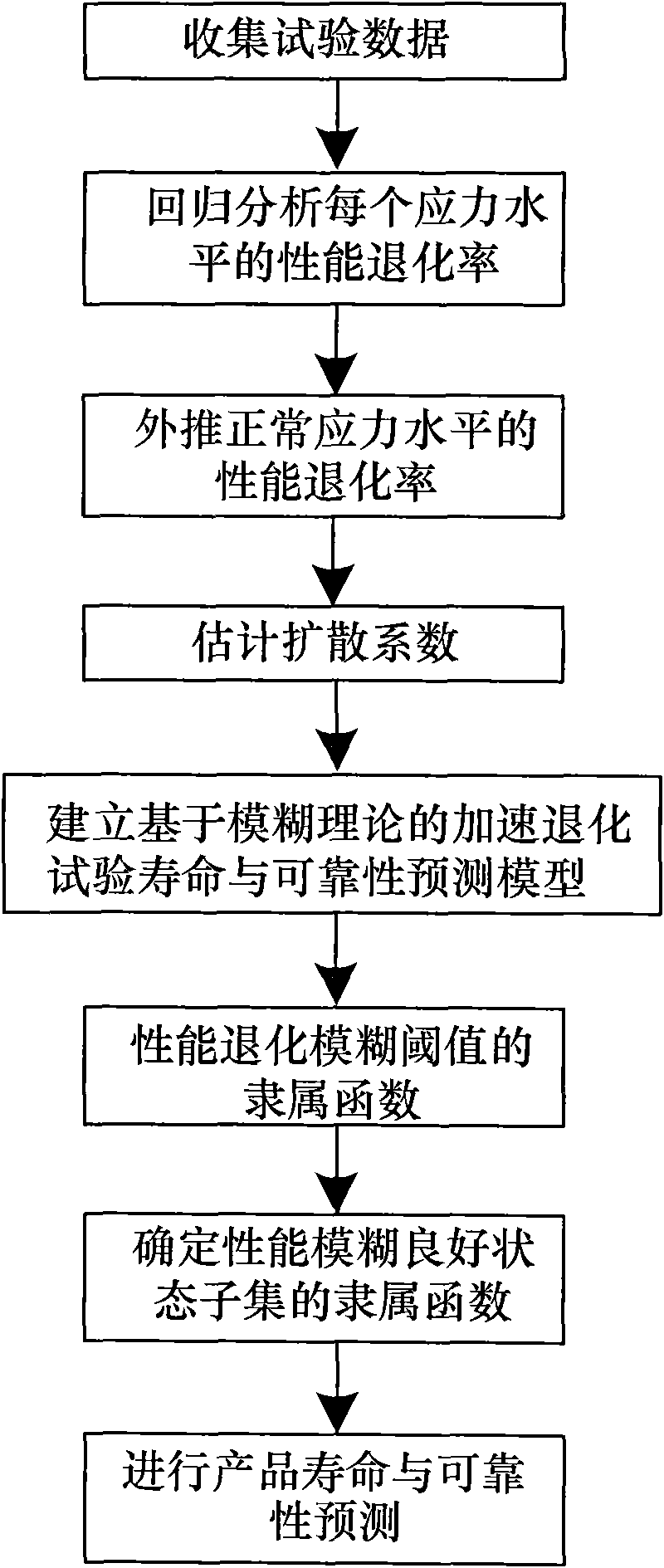

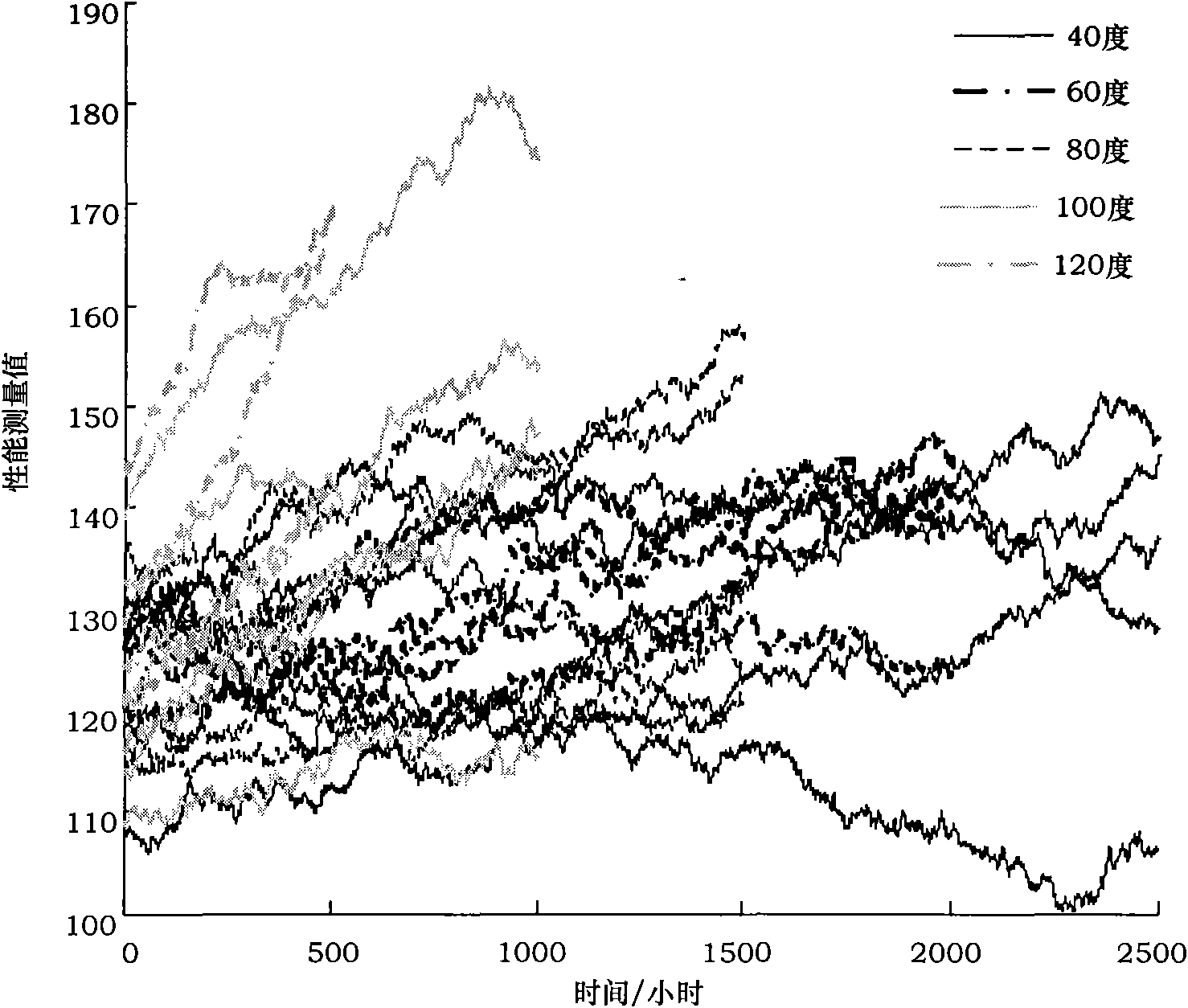

Accelerated degradation test prediction method based on fuzzy theory

InactiveCN101666662AReasonable forecastAvoid aggressive situationsMeasurement devicesComplex mathematical operationsRegression analysisBrownian excursion

The invention discloses an accelerated degradation test prediction method based on fuzzy theory, which comprises the following steps: collecting test data; performing the analysis of regression aimingat performance degradation data under each stress level; extrapolating the performance degradation rate of the product under a normal stress level; estimating a diffusion coefficient sigma in an excursion Brownian motion with drift by adopting a maximum likelihood estimation method; establishing an accelerated degradation test life and reliability predication model based on the fussy theory; andpredicting the life and the reliability of the product by adopting the fussy life and reliability prediction model. The method firstly introduces the fussy concept into an accelerated degradation testto enable the prediction result of the accelerated degradation test to be more reasonable, avoids the condition of rash routine reliability estimation result through considering the fussiness fuzziness of the performance degradation threshold, solves the problem of failed performance degradation in the engineering reality, and is suitable for the accelerated degradation tests of step stress and progressive stress and unaccelerated performance degradation prediction for the problem of the performance degradation failure.

Owner:BEIHANG UNIV

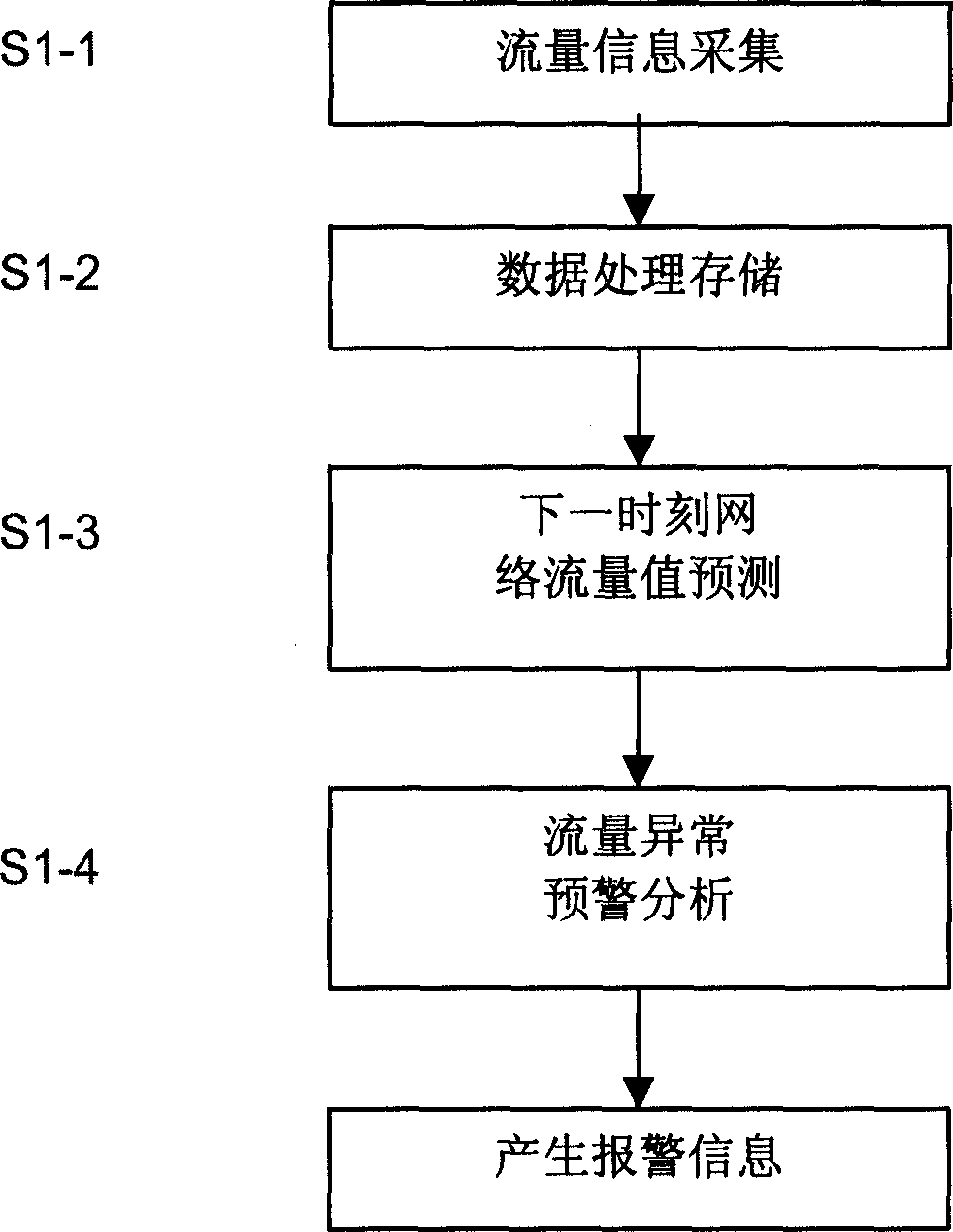

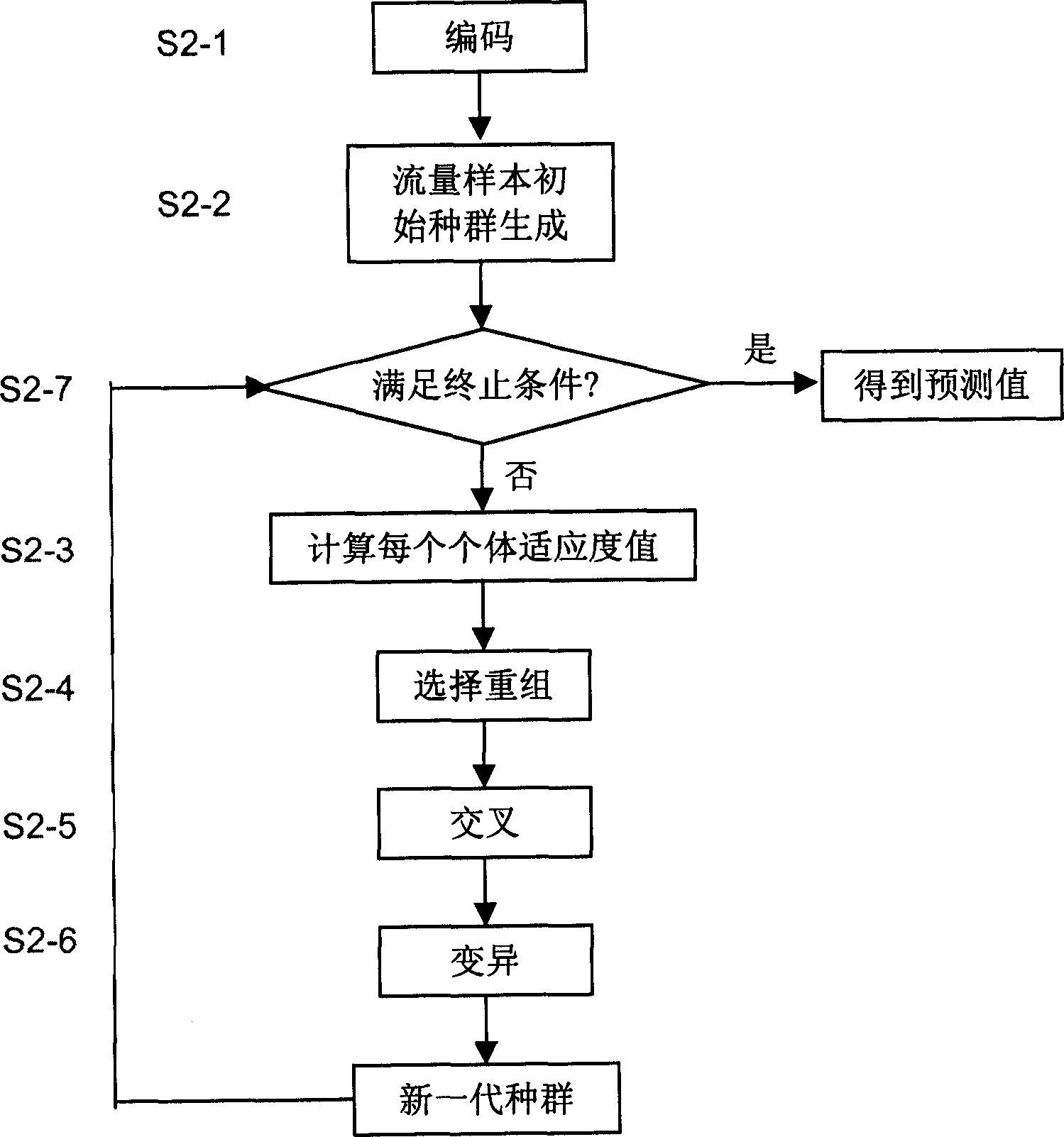

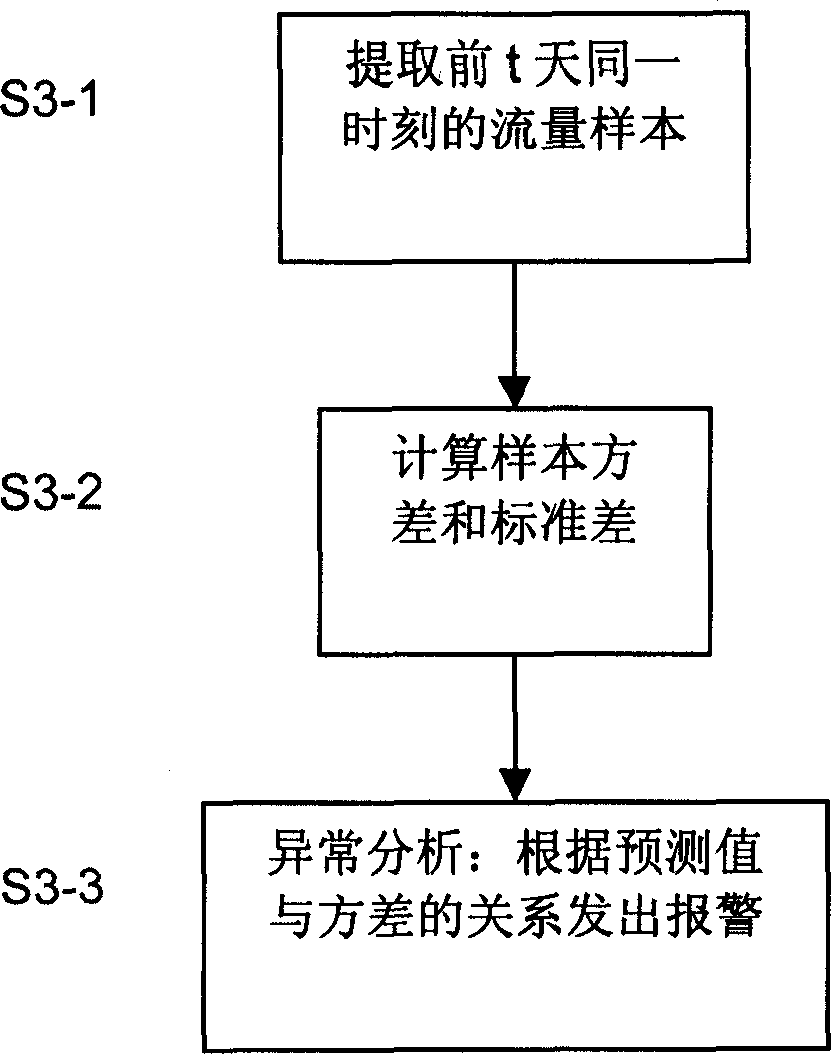

Adaptive network flow forecasting and abnormal alarming method

InactiveCN1617512AExact expected valueAdaptableData switching networksTraffic predictionGenetic algorithm

This invention provide a network flow performance prediction and abnormal alarming technology and a method based on the genetic algorithms, which utilizes genetic algorithms to predict the flow state of the next time from the horizontal time degree then to utilize the statistics method to judge the abnormal situation of said flow based on the flow sample in a related time period of each day in the historical flow information from the longitudinal time degree. The method is realized by four steps of network flow data collection, process and storage, prediction and abnormal alarming.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

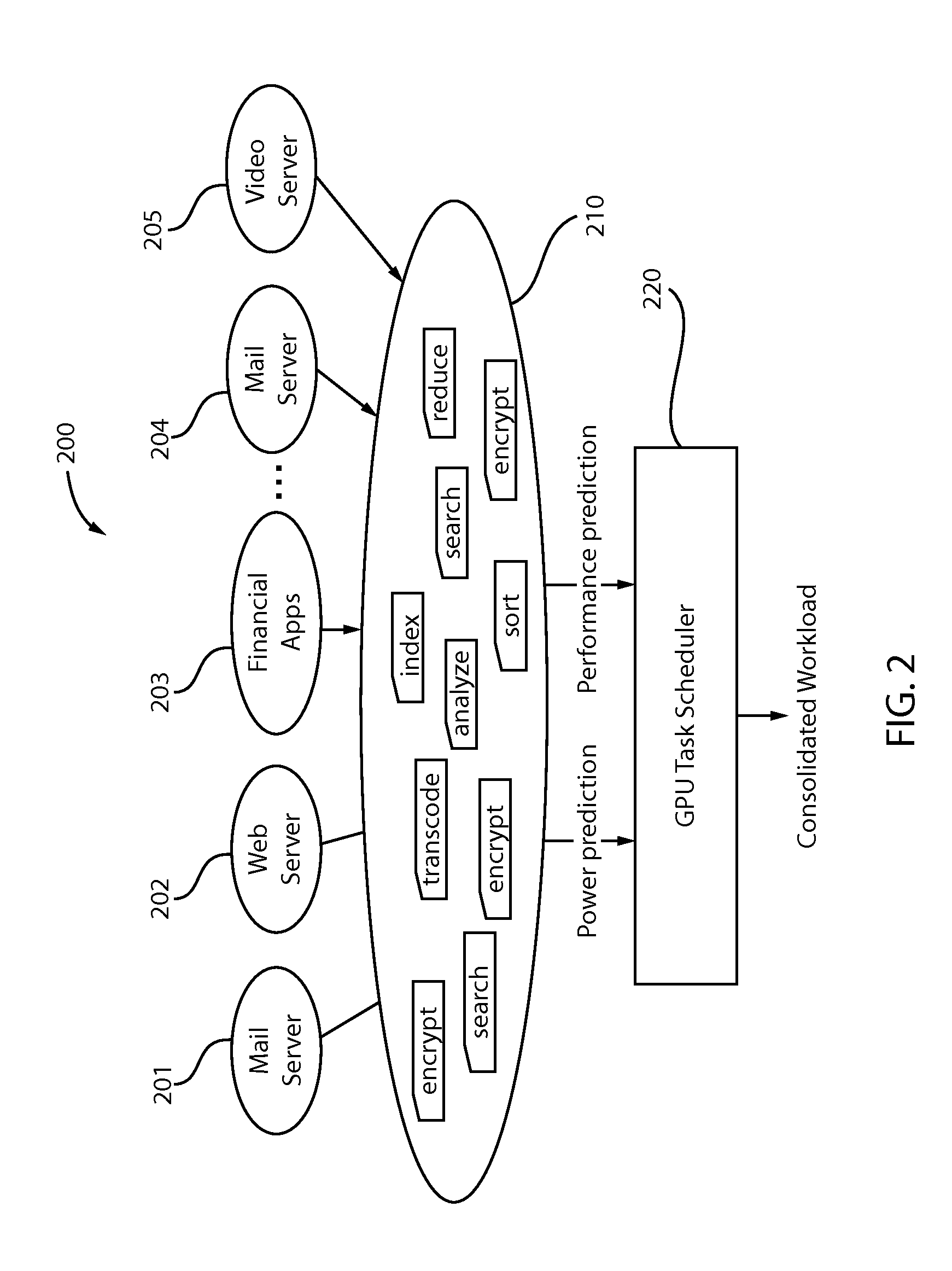

Energy-aware task consolidation on graphics processing unit (GPU)

A method includes configuring a shared library, stored in a memory, to be loaded into applications to intercept graphics processing unit (GPU) computation requests for different types of workload kernals corresponding to the applications. The method further includes generating a power prediction and a performance prediction for at least one candidate kernel combination for execution on a GPU responsive to the GPU computations requests. The at least one candidate kernel combination pertains to at least two of the workload kernals. The method also includes rendering a decision of whether to execute the at least one candidate kernel combination or to execute the at least two of the workload kernals pertaining thereto separately, based on the power prediction and the performance prediction.

Owner:NEC CORP

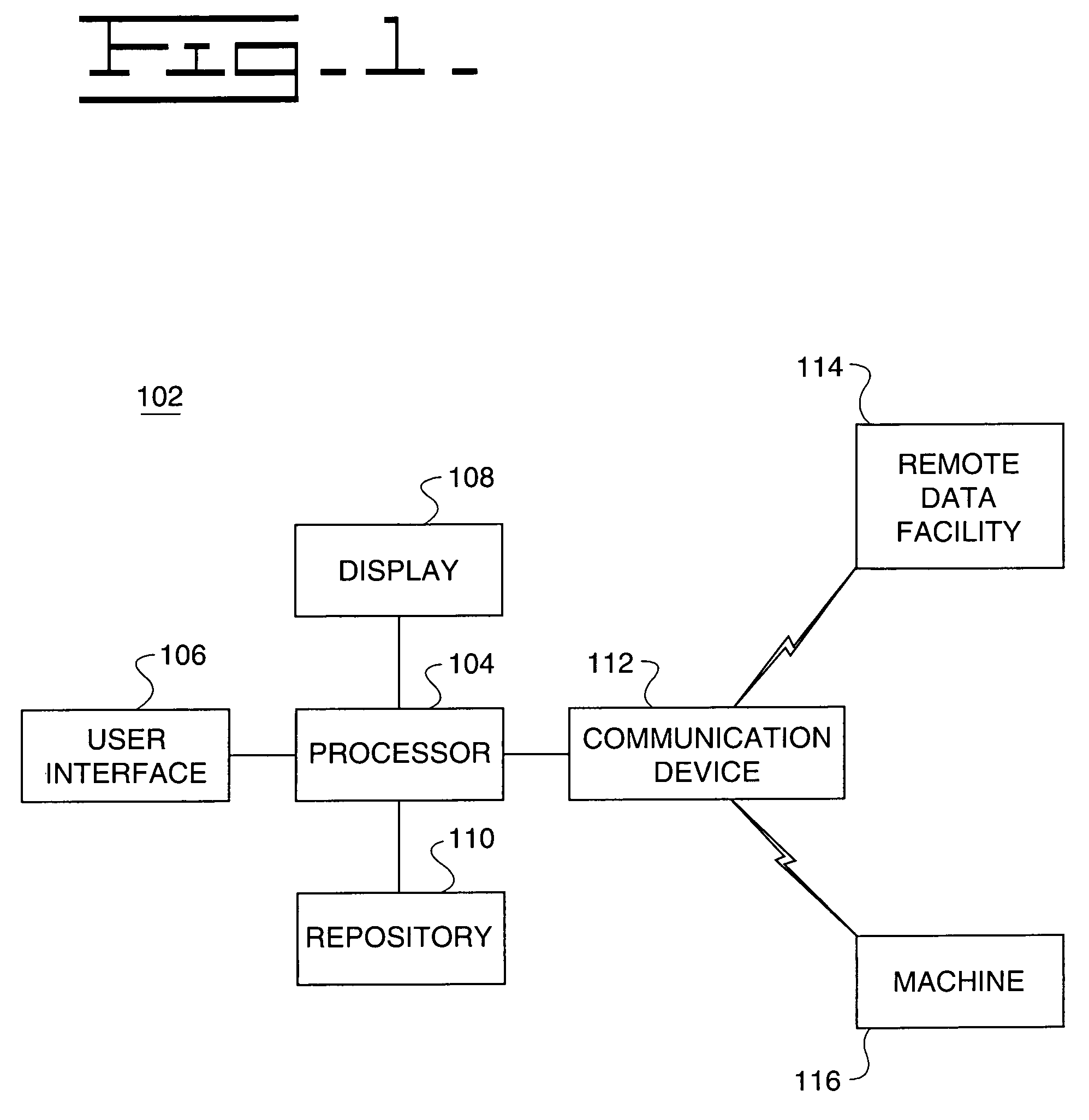

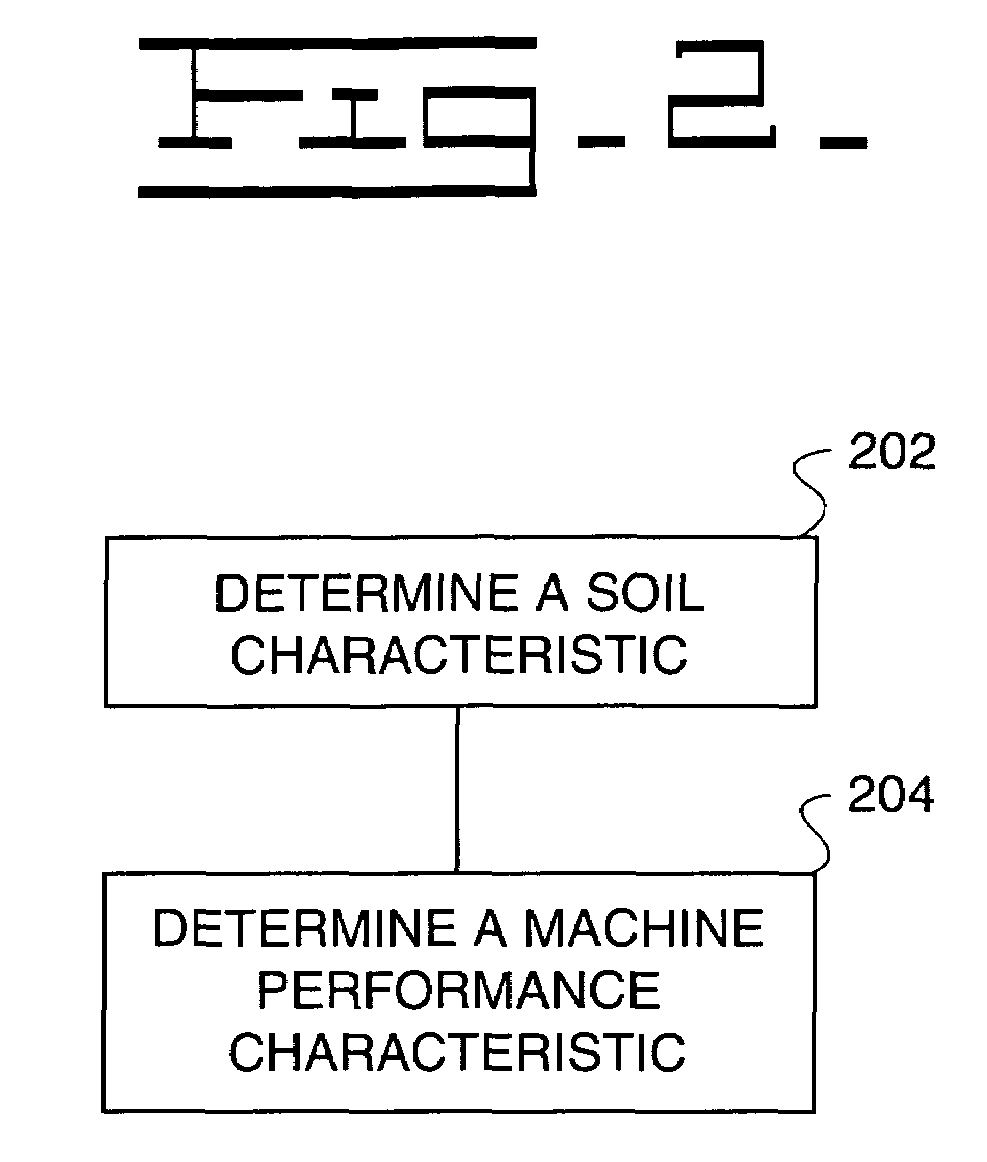

Method and system of forecasting compaction performance

ActiveUS7191062B2Digital computer detailsSpecial data processing applicationsSoil characteristicsEngineering

The present invention is associated with a system and method of managing a compaction process. The method may include establishing a soil characteristic and establishing a machine performance characteristic in response to the soil characteristic. The machine performance characteristic may include a predictive compaction characteristic associated with a particular machine.

Owner:CATERPILLAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com