Patents

Literature

134 results about "Degradation test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alternatively, there are step-stress tests in which the degradation or performance data that can be directly related to the presumed failure of the product in question are monitored over the duration of the test. This test is essentially a degradation test in time-varying conditions.

Degradation modeling and lifetime prediction method considering effective shocks

InactiveUS20190138926A1Improve forecast accuracyMethod is numerousDesign optimisation/simulationProbabilistic networksPredictive methodsSimulation

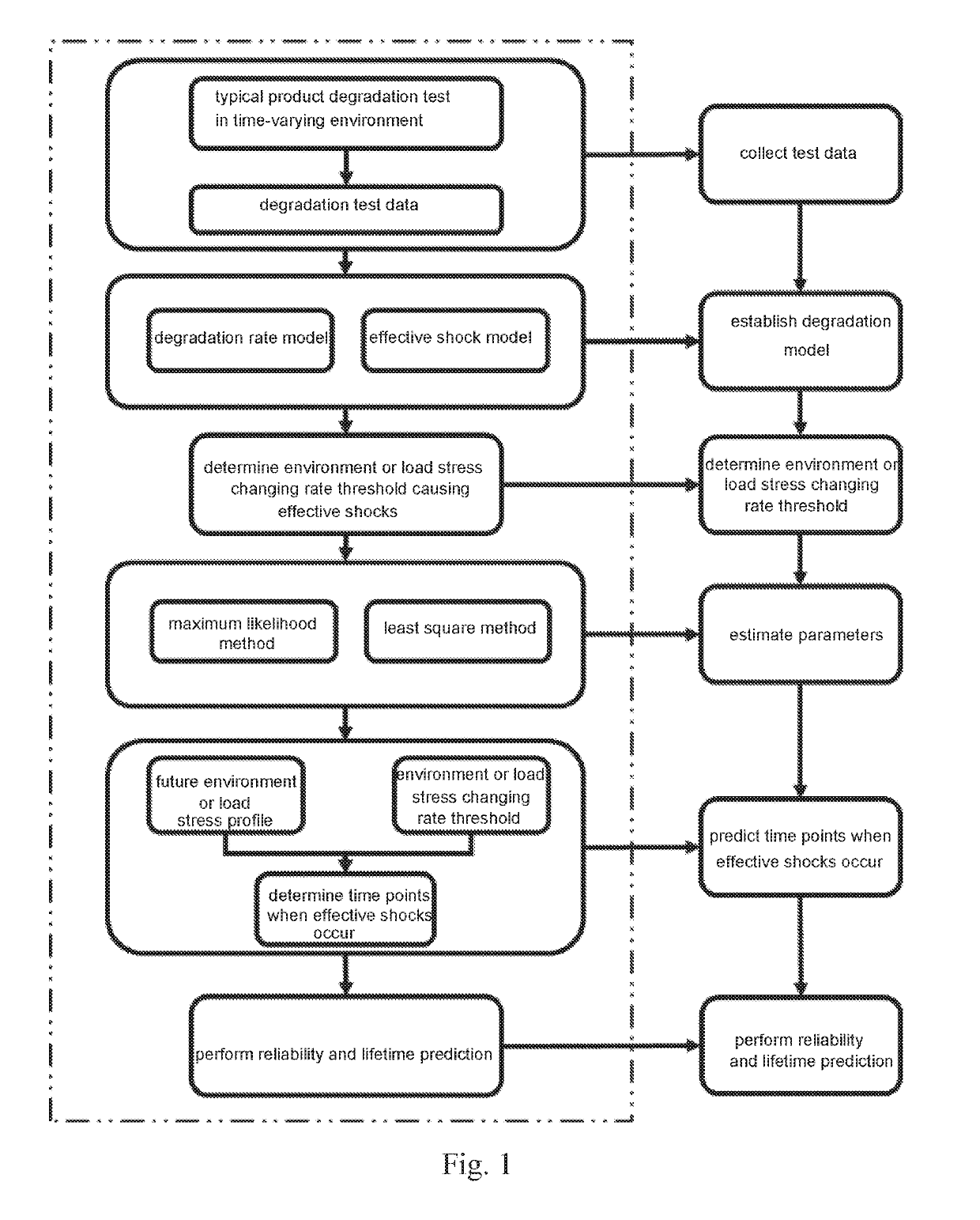

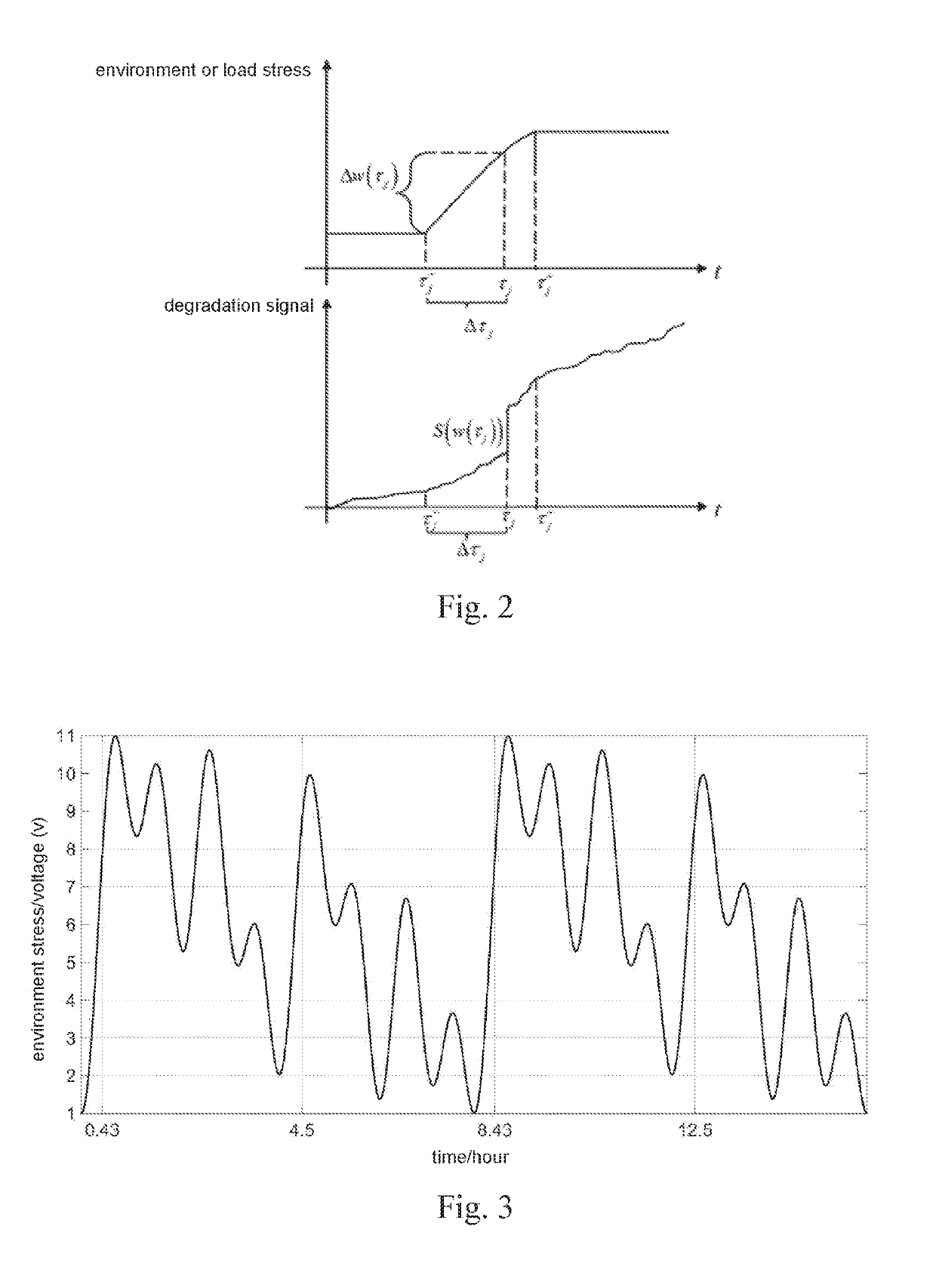

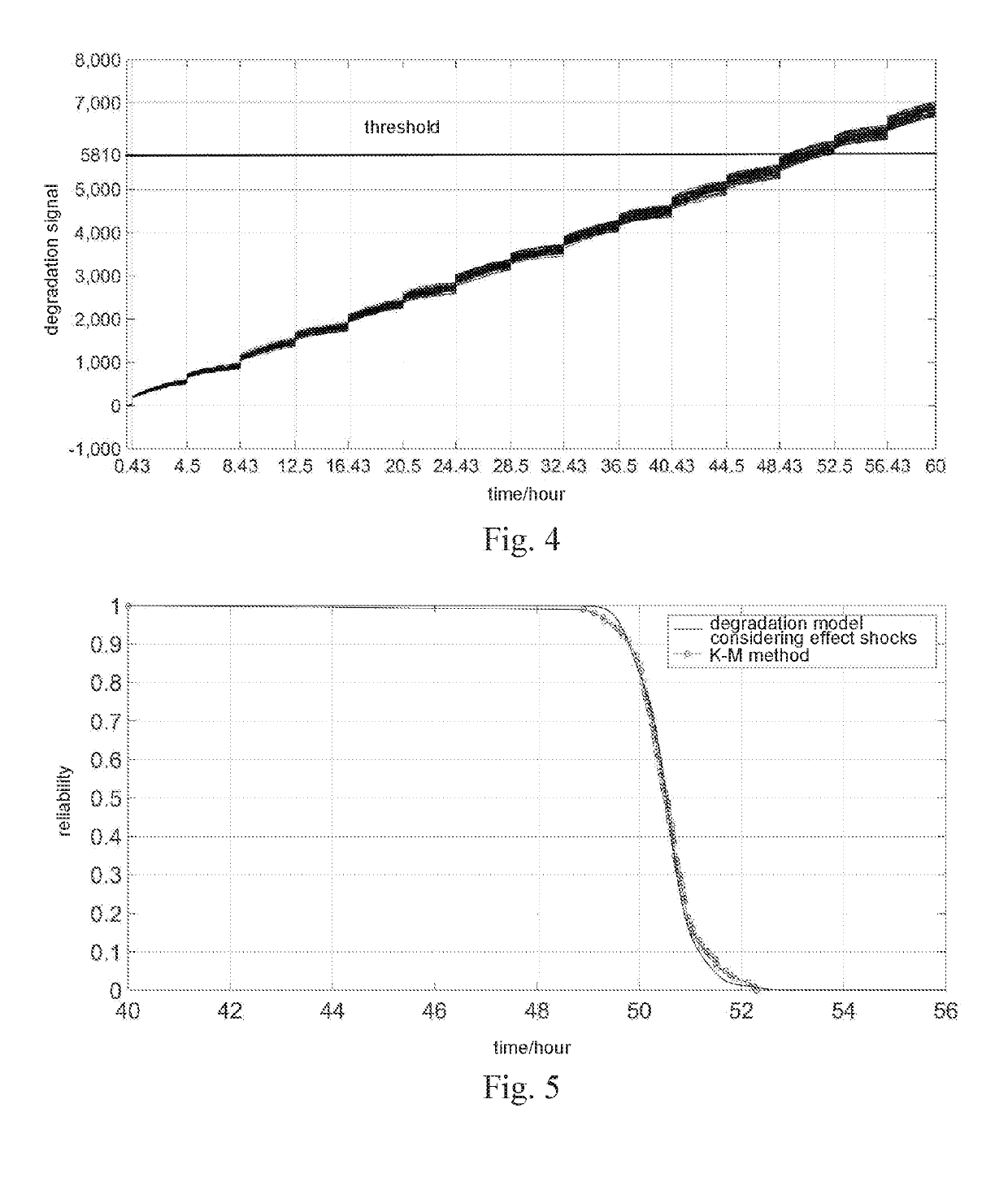

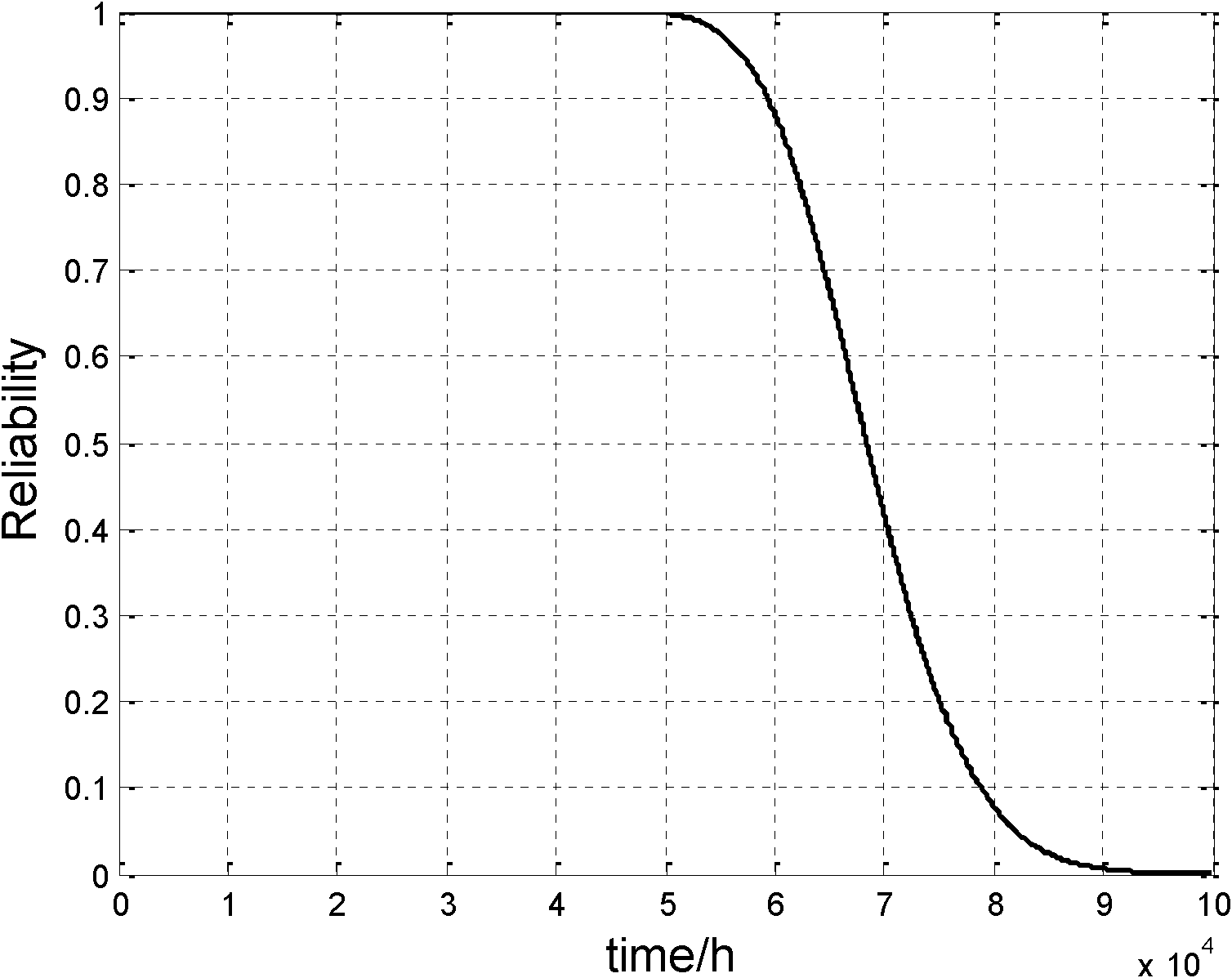

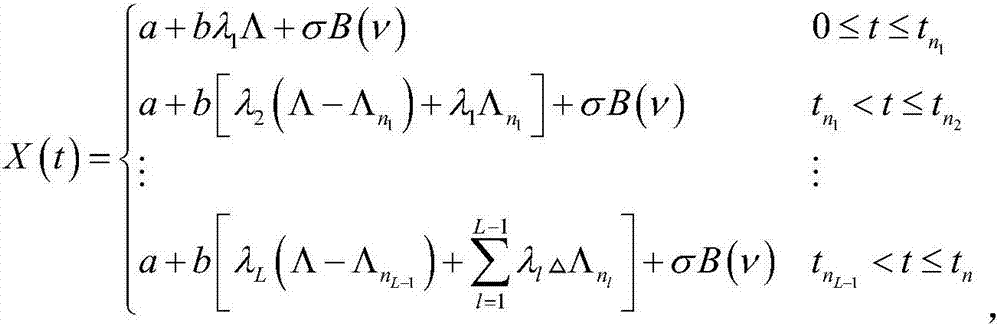

A degradation modeling and lifetime prediction method considering effective shocks includes steps of: first collecting degradation test data, then establishing a performance degradation model, and determining an environment or load changing rate threshold of a product subjected to effective shock based on the test data; estimating parameters in the model, and determining effective shock occurrence times based on the future environmental or load profile, and finally preforming lifetime and reliability prediction. Specific steps are as follows: step 1: collecting degradation test data; step 2: establishing a degradation model; step 3: determining an environment or load changing rate threshold; step 4: estimating the parameters; step 5: predicting the times that effective shocks occur; and step 6: performing reliability prediction. The present invention considers effects of effective shocks caused by sharp environment or load changes on product performance degradation, which makes the prediction method more realistic and improves the prediction accuracy.

Owner:BEIHANG UNIV

Accelerated degradation test prediction method based on fuzzy theory

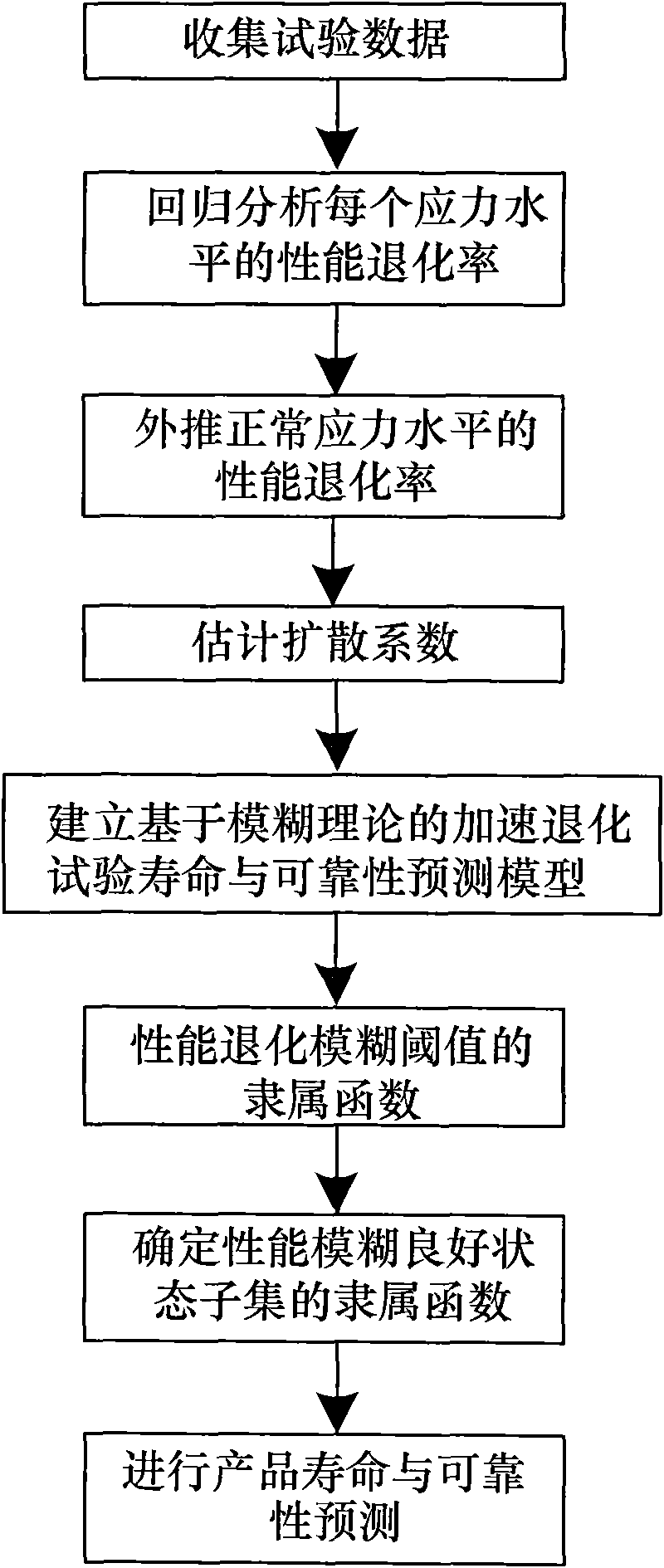

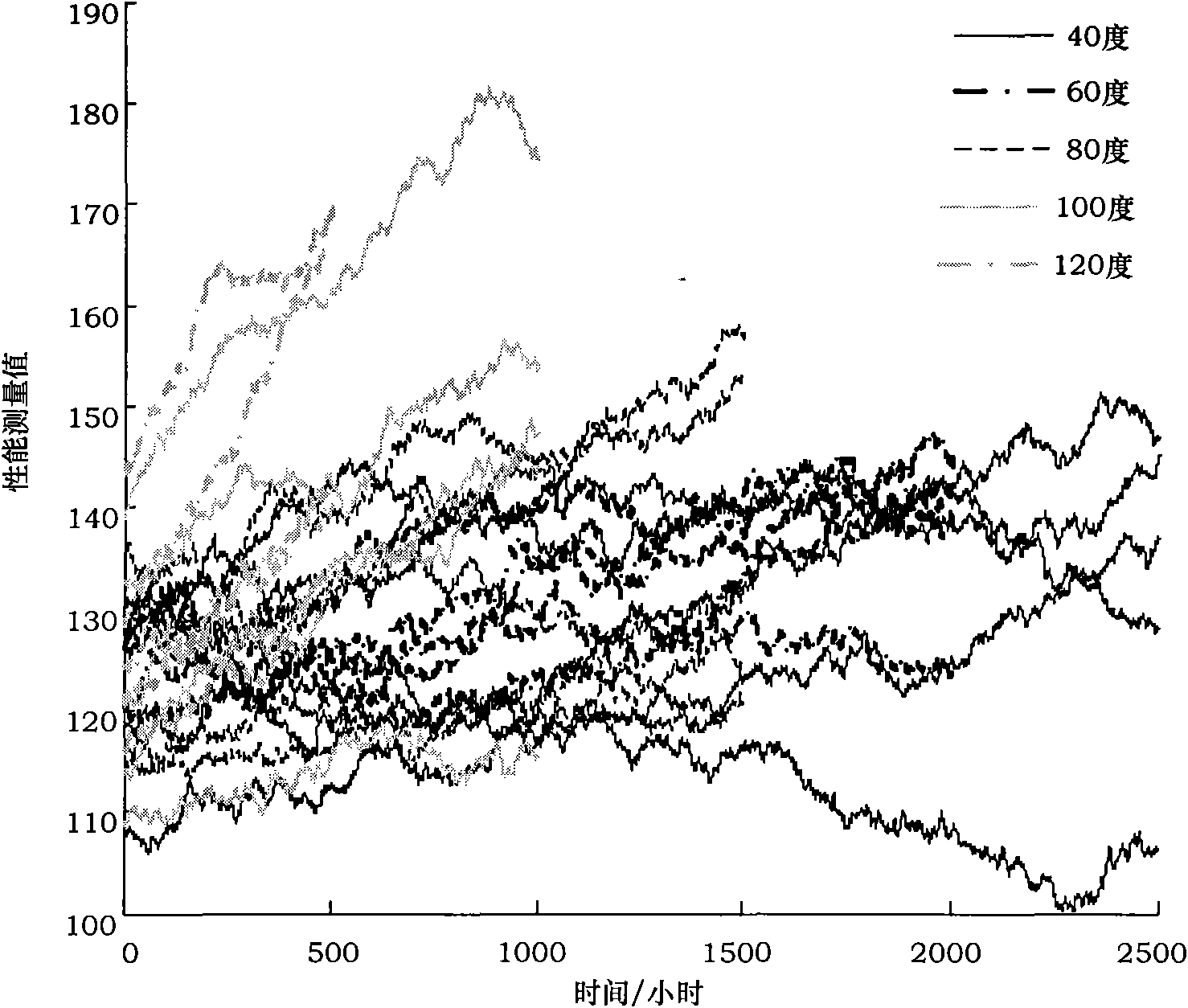

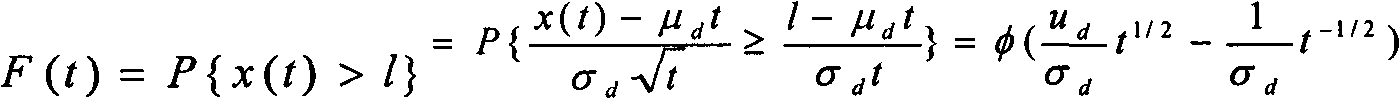

InactiveCN101666662AReasonable forecastAvoid aggressive situationsMeasurement devicesComplex mathematical operationsRegression analysisBrownian excursion

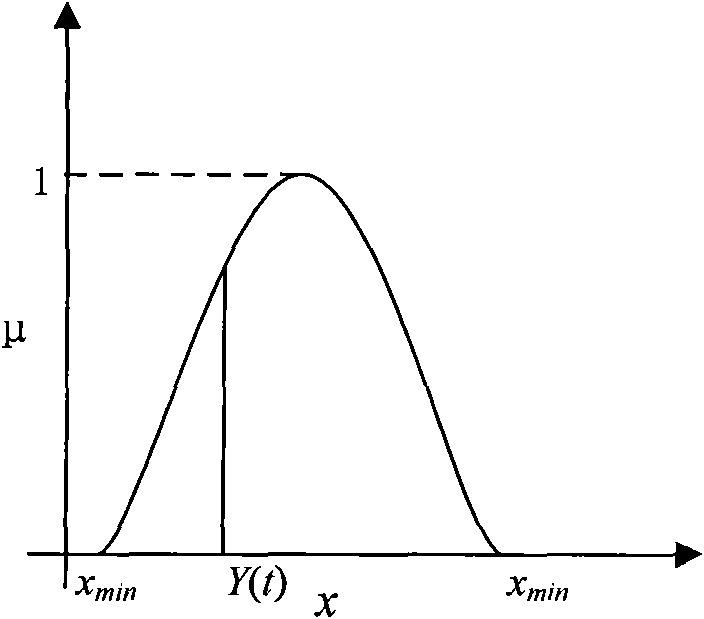

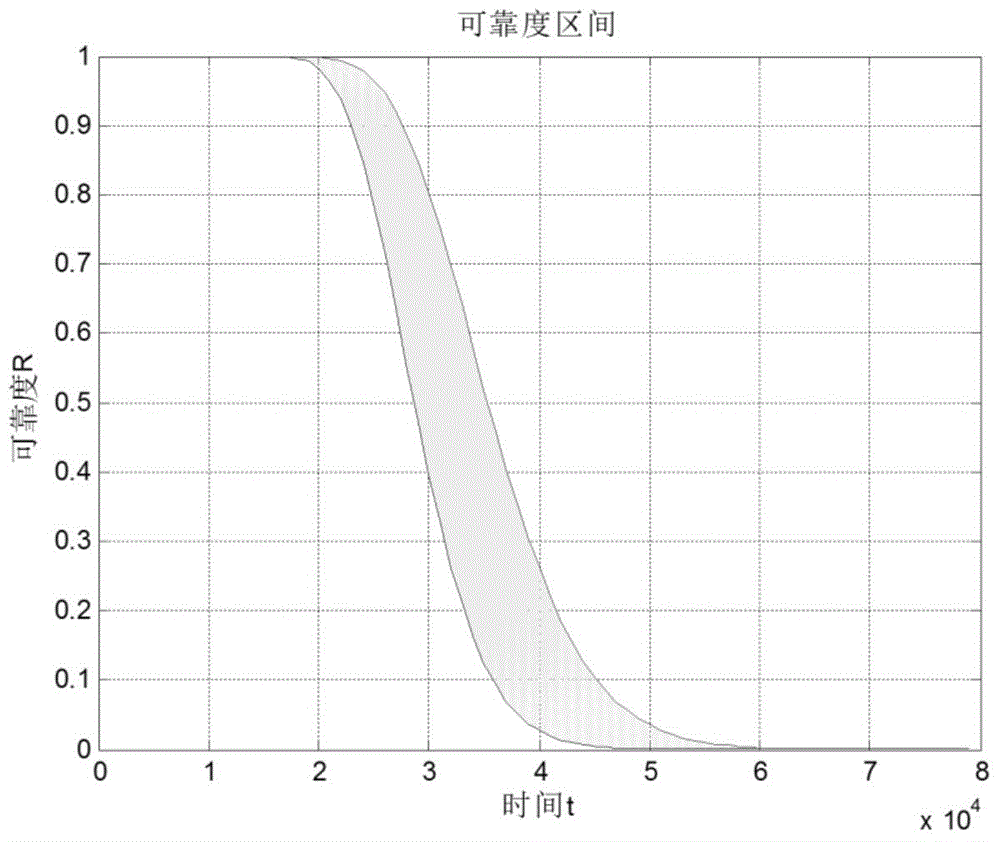

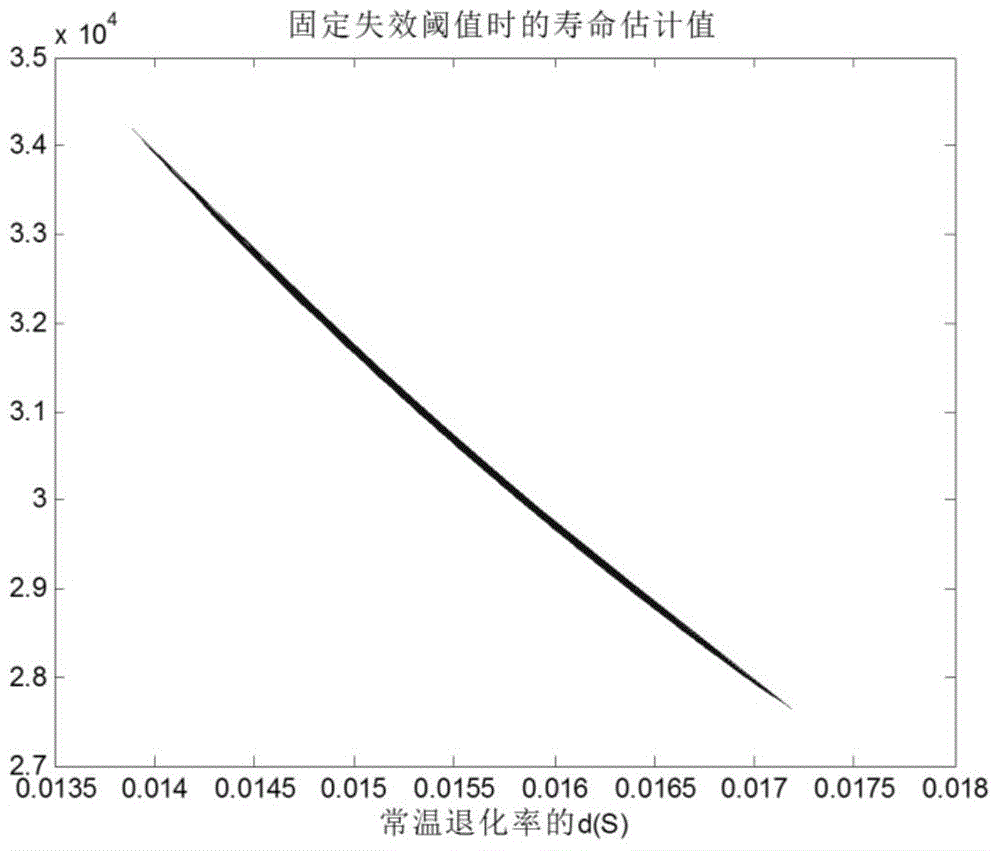

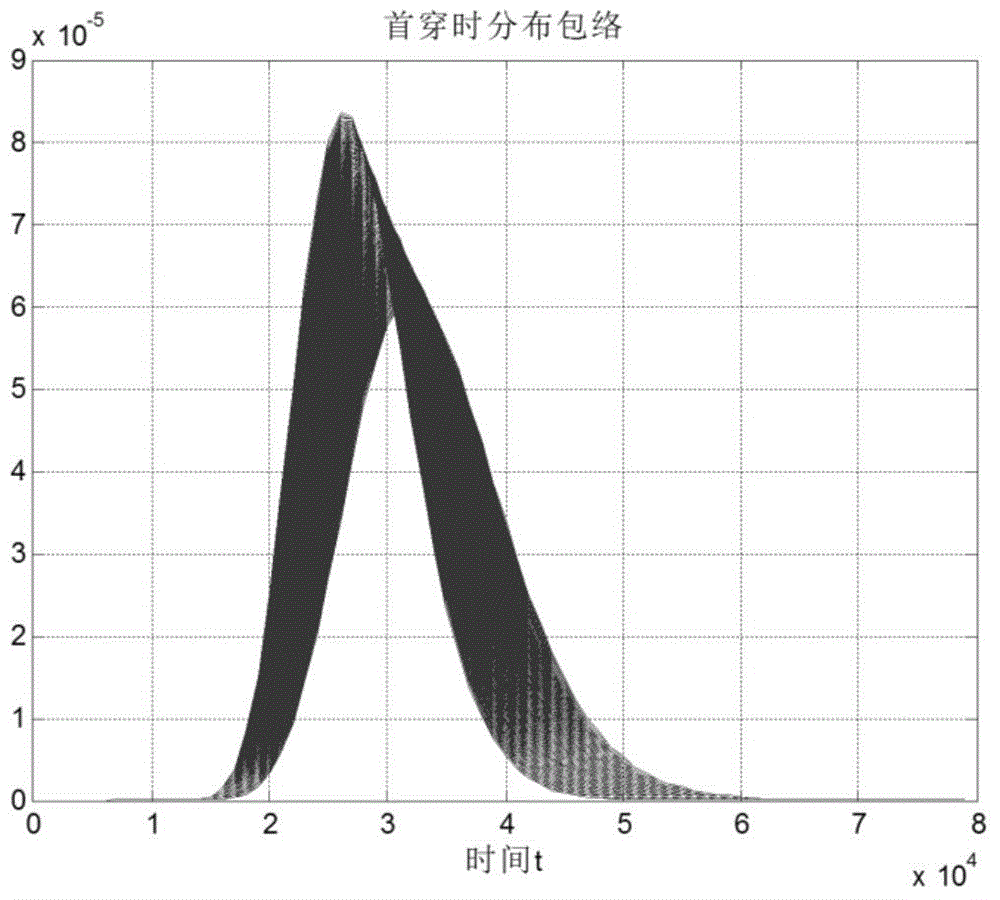

The invention discloses an accelerated degradation test prediction method based on fuzzy theory, which comprises the following steps: collecting test data; performing the analysis of regression aimingat performance degradation data under each stress level; extrapolating the performance degradation rate of the product under a normal stress level; estimating a diffusion coefficient sigma in an excursion Brownian motion with drift by adopting a maximum likelihood estimation method; establishing an accelerated degradation test life and reliability predication model based on the fussy theory; andpredicting the life and the reliability of the product by adopting the fussy life and reliability prediction model. The method firstly introduces the fussy concept into an accelerated degradation testto enable the prediction result of the accelerated degradation test to be more reasonable, avoids the condition of rash routine reliability estimation result through considering the fussiness fuzziness of the performance degradation threshold, solves the problem of failed performance degradation in the engineering reality, and is suitable for the accelerated degradation tests of step stress and progressive stress and unaccelerated performance degradation prediction for the problem of the performance degradation failure.

Owner:BEIHANG UNIV

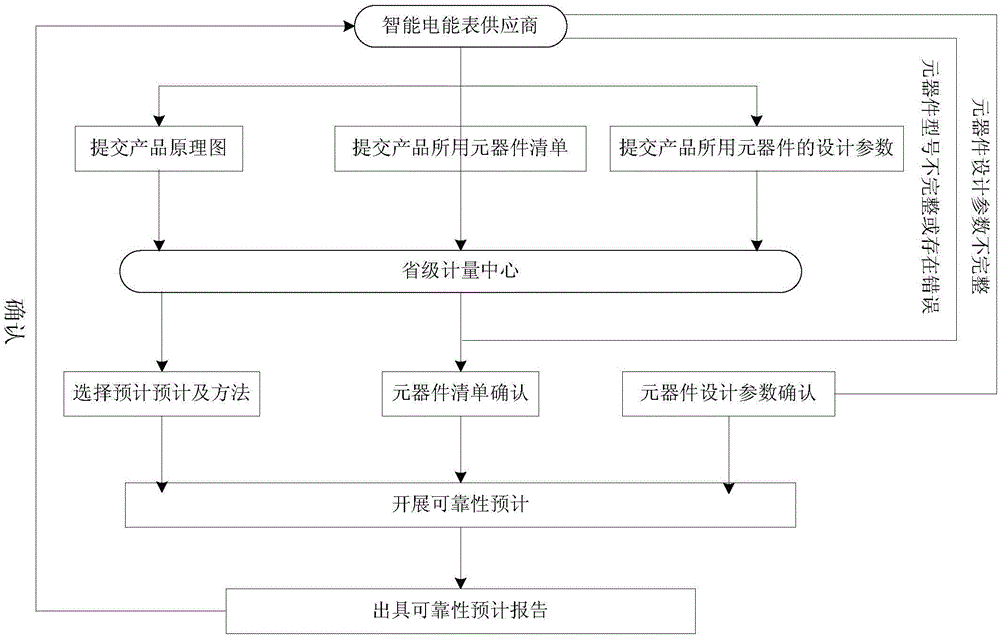

Prediction method for q-precentile life of intelligent meter

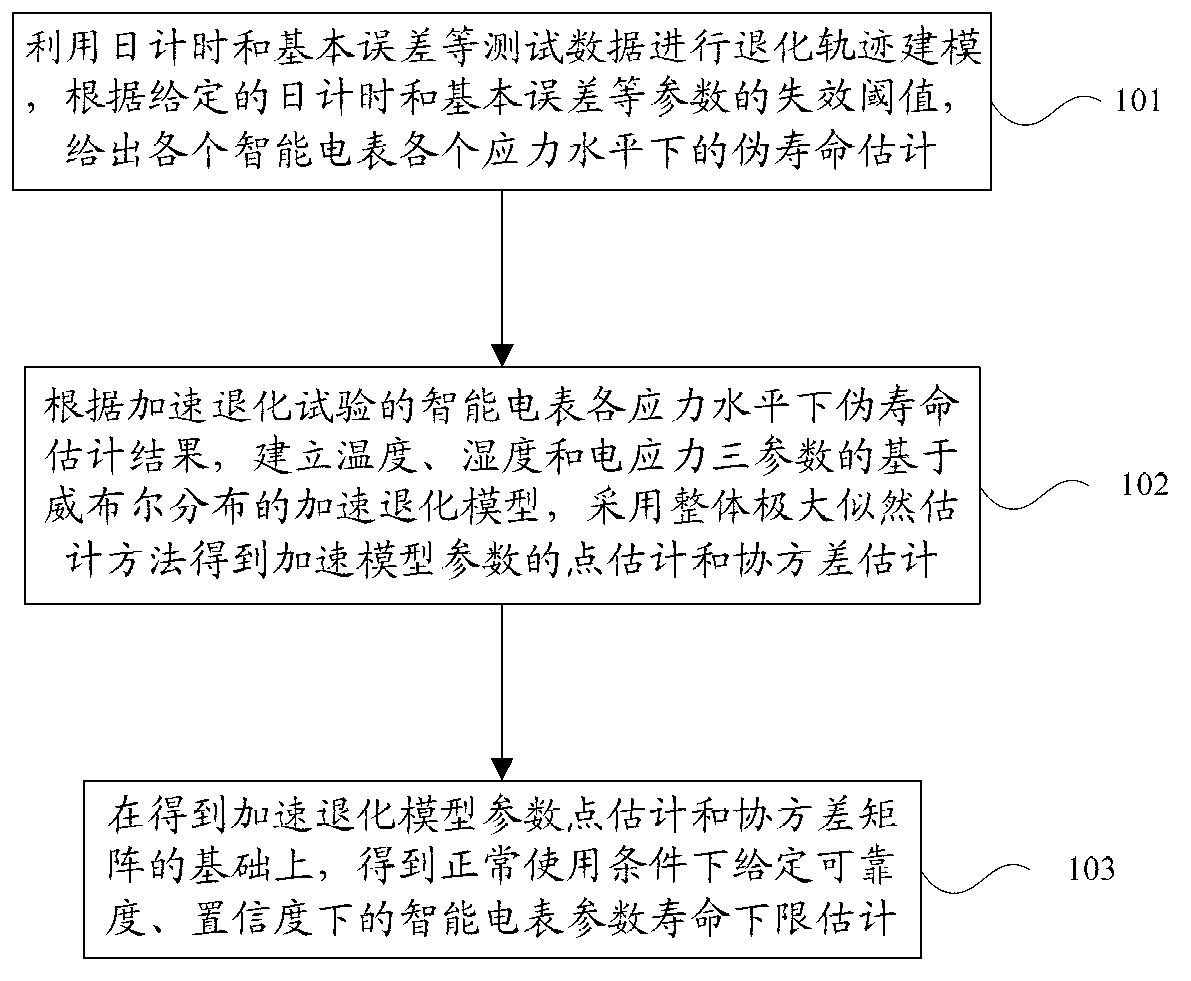

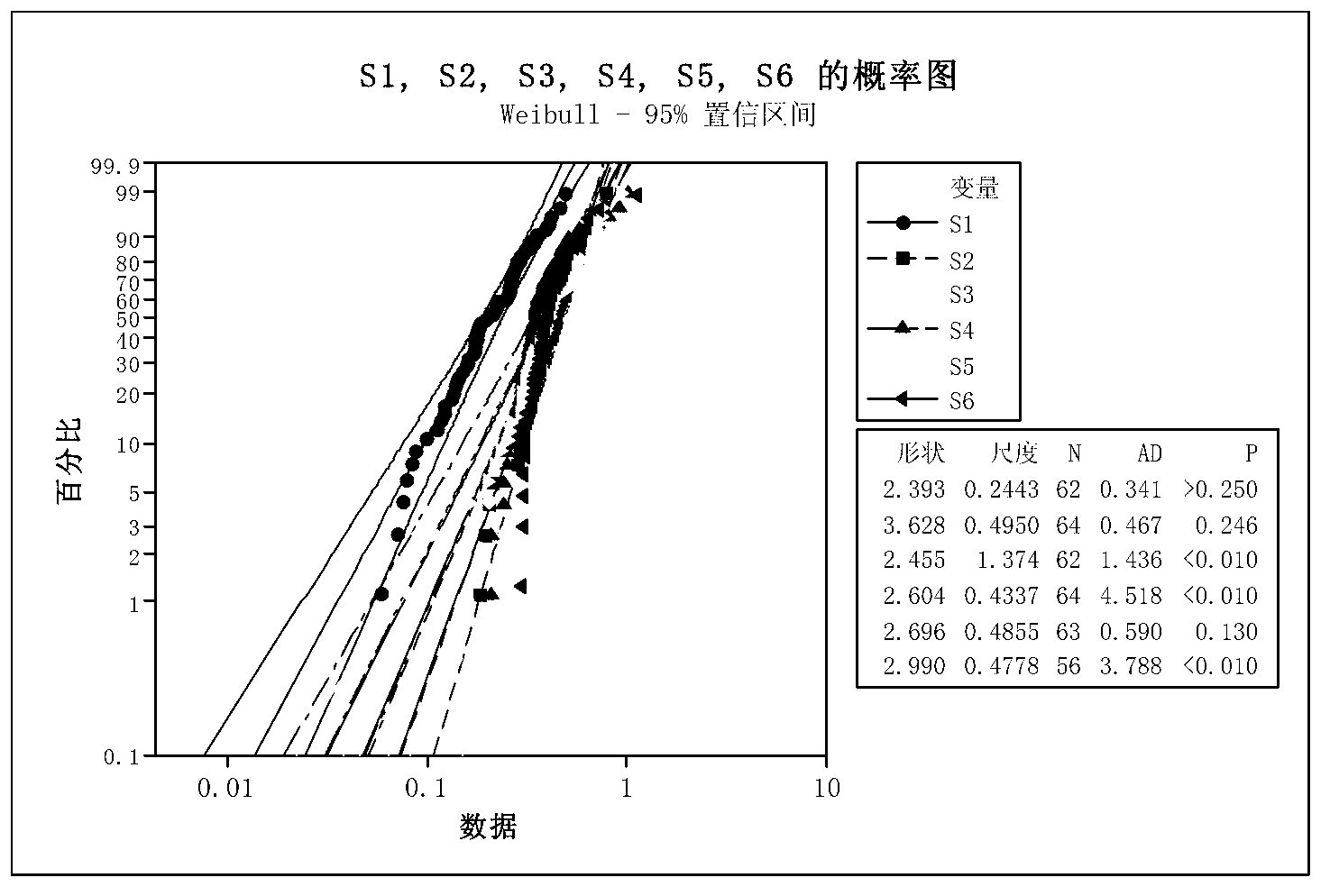

InactiveCN102708306AShorten test timeReduce test costsElectrical measurementsSpecial data processing applicationsAccelerometerModel parameters

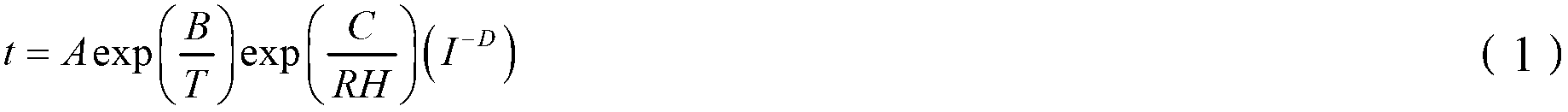

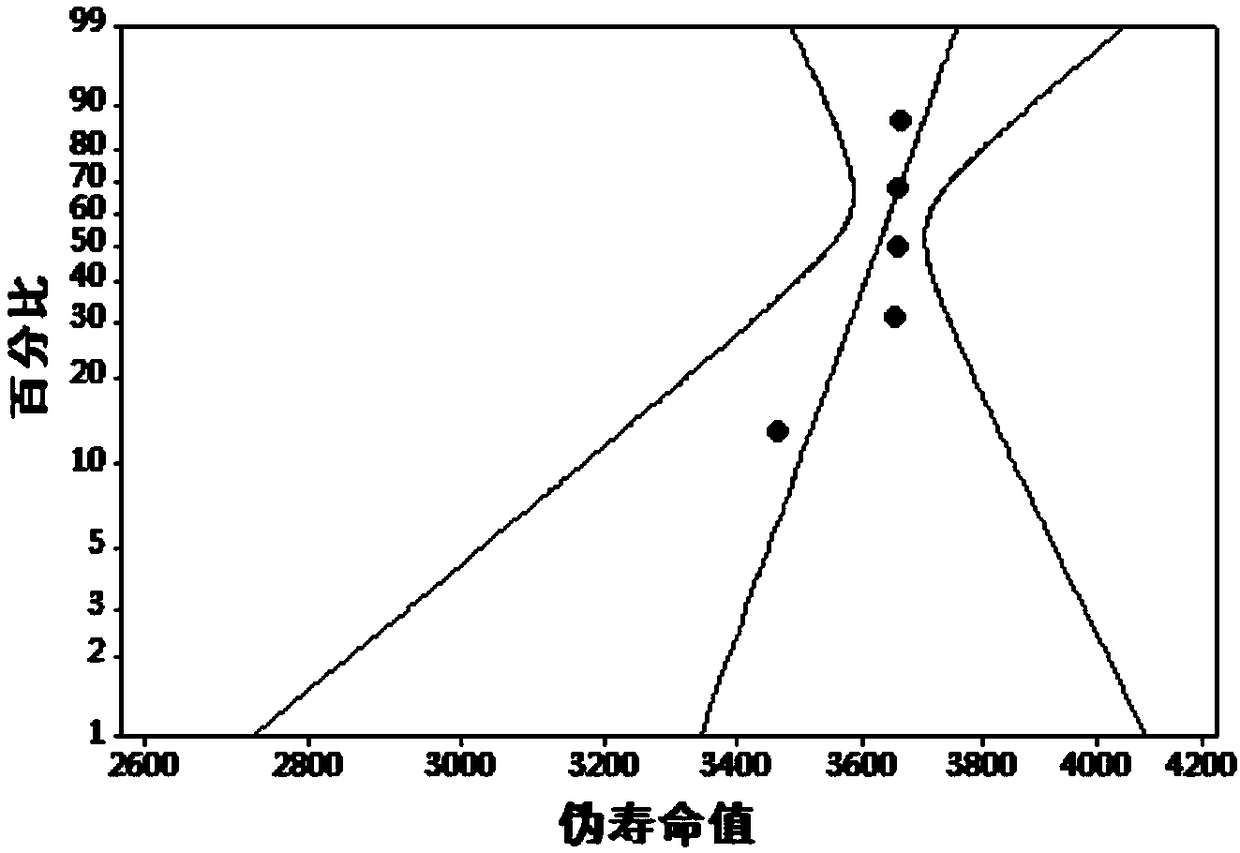

The invention discloses a prediction method for the q-precentile life of an intelligent meter and relates to the technical field of reliability estimation of accelerated degradation data. The method comprises the following steps: performing degradation path modeling according to test data, and obtaining the pseudo life estimation of the intelligent meter under all stress levels according to the failure threshold value of given parameters; building a Weibull distribution-based accelerated degradation model of three parameters, such as temperature, humidity and electrical stress according to the pseudo life estimation results of the intelligent meter under all stress levels of an accelerated degradation test, so as to obtain the point estimation and covariance estimation of the acceleration model; and obtaining the lower estimation of parameter service life of the intelligent meter under a given reliability degree and a given confidence degree in normal use conditions according to the point and covariance matrix of the parameters of the accelerated degradation model. Due to the adoption of the method, the test time is effectively shortened, the test expense is reduced, and the quick and accurate estimation of a stable period of an accelerometer is realized.

Owner:JIBEI ELECTRIC POWER COMPANY LIMITED CENT OF METROLOGY +1

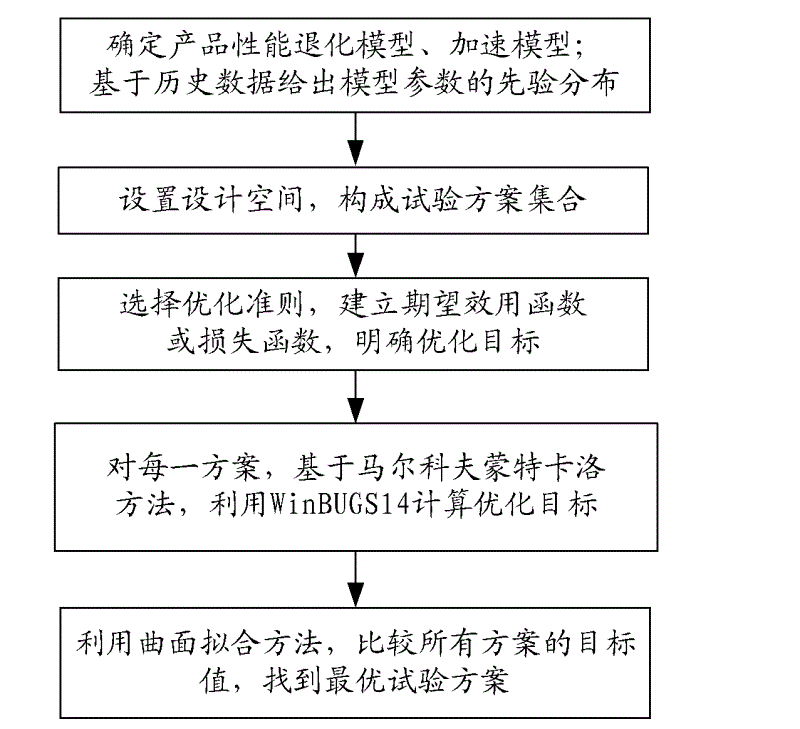

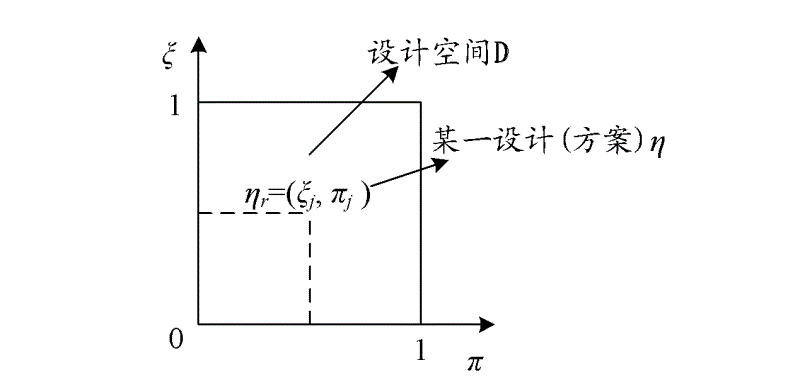

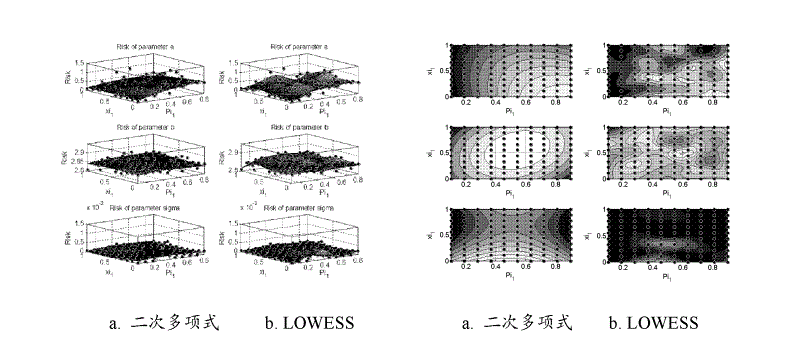

Optimization design method for step stress accelerated degradation test based on Bayesian theory

ActiveCN102622473AAvoid the disadvantage of being prone to large deviationsTaking into account the amount of informationSpecial data processing applicationsAlgorithmOptimal test

The invention discloses an optimization design method for a step stress accelerated degradation test based on a Bayesian theory, and is applied to the technical field of the accelerated degradation test. The optimization design method comprises the steps as follows: firstly, determining product performance degradation and acceleration models, and based on the historical data, giving prior distribution of model parameters; secondly, determining an optimization design space, and forming a test scheme set; thirdly, creating an expected utility function or an expected loss function, determining optimization goals, and based on a Markov Chain Monte Carlo method, determining optimization goal values of designs in the test scheme set; and lastly, finding the optimal test scheme by using a curve fitting method. According to the optimization design method, the shortcoming of high possibility of larger deviation due to the implementation of the traditional (local) test optimization design method when the values of the model parameters are supposed to be known is avoided, and the optimization scheme obtained in the implementation of the test optimization design when the prior distribution of the model parameters is given is more reasonable and more actual.

Owner:BEIHANG UNIV

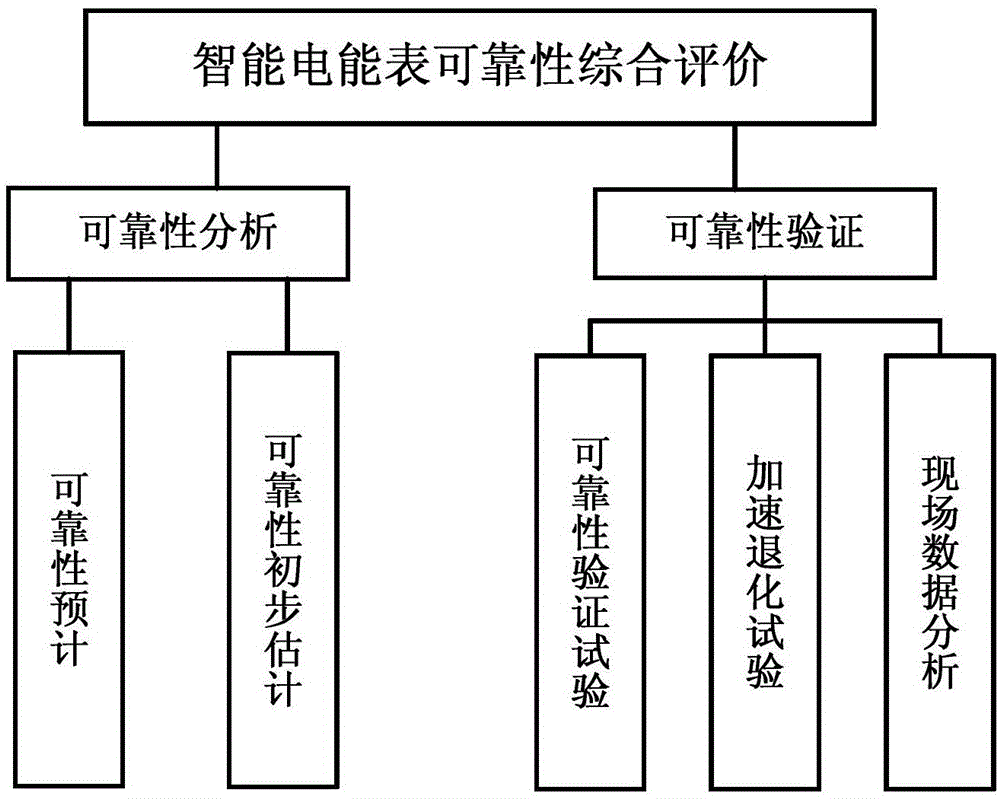

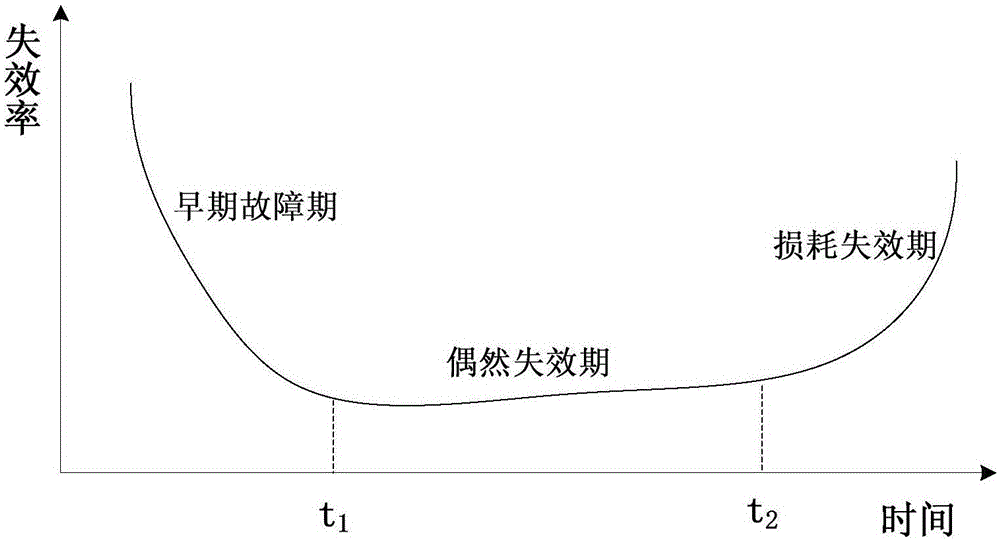

Method of comprehensively estimating reliability of single-phase intelligent electric energy meter

ActiveCN105022019AReduce operation and maintenance costsExtended rotation periodElectrical measurementsFailure rateFull life cycle

The invention discloses a method of comprehensively estimating reliability of a single-phase intelligent electric energy meter in a full life cycle. The reliability level of the intelligent electric energy meter is decided by design research, production, manufacturing, test, detection, operation, maintenance and other steps, and present reliability predication and reliability test are only based on a certain step. According to the method of the invention, reliability estimation on the intelligent electric energy meter is carried out from five aspects: reliability predication, initial reliability estimation, reliability test, accelerated degradation test and field data analysis, the life cycle of the electric energy meter is covered thoroughly, and a quantitative calculation method for determining two important time points for failure rate changes for a position of a dividing point between an early failure period and an accidental failure period and a position of a dividing point between an accidental failure period and a loss failure period on a failure curve.

Owner:STATE GRID CORP OF CHINA +2

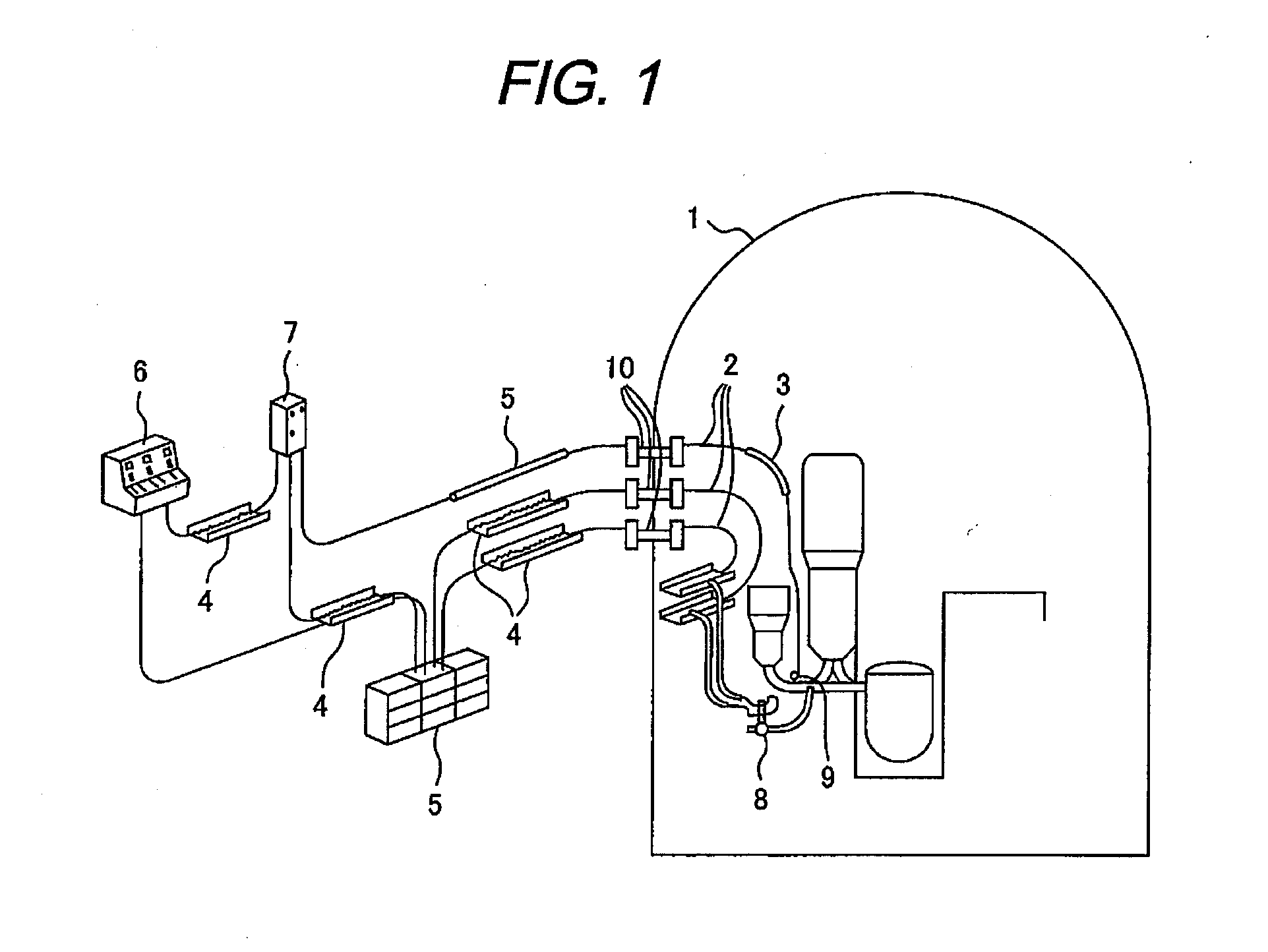

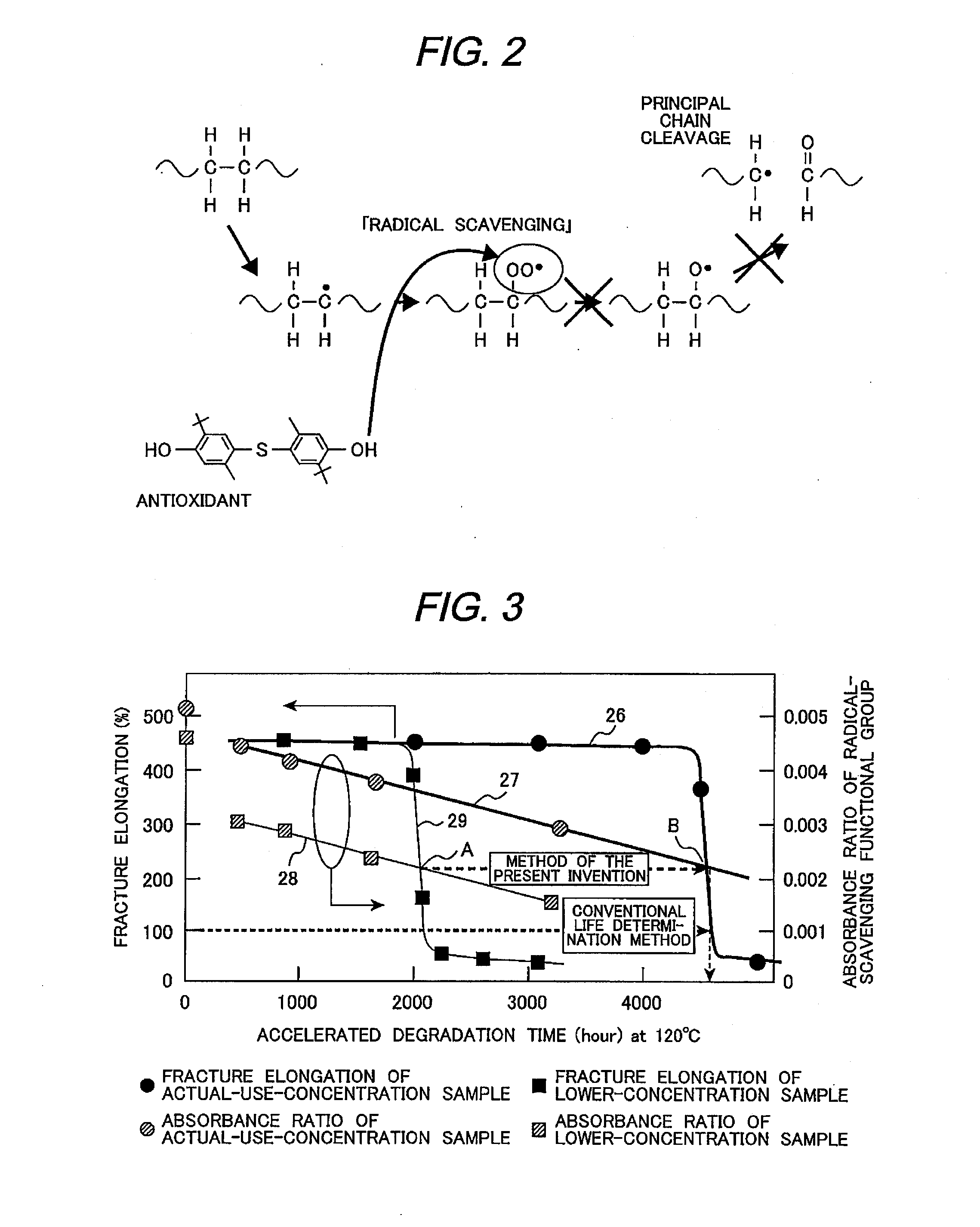

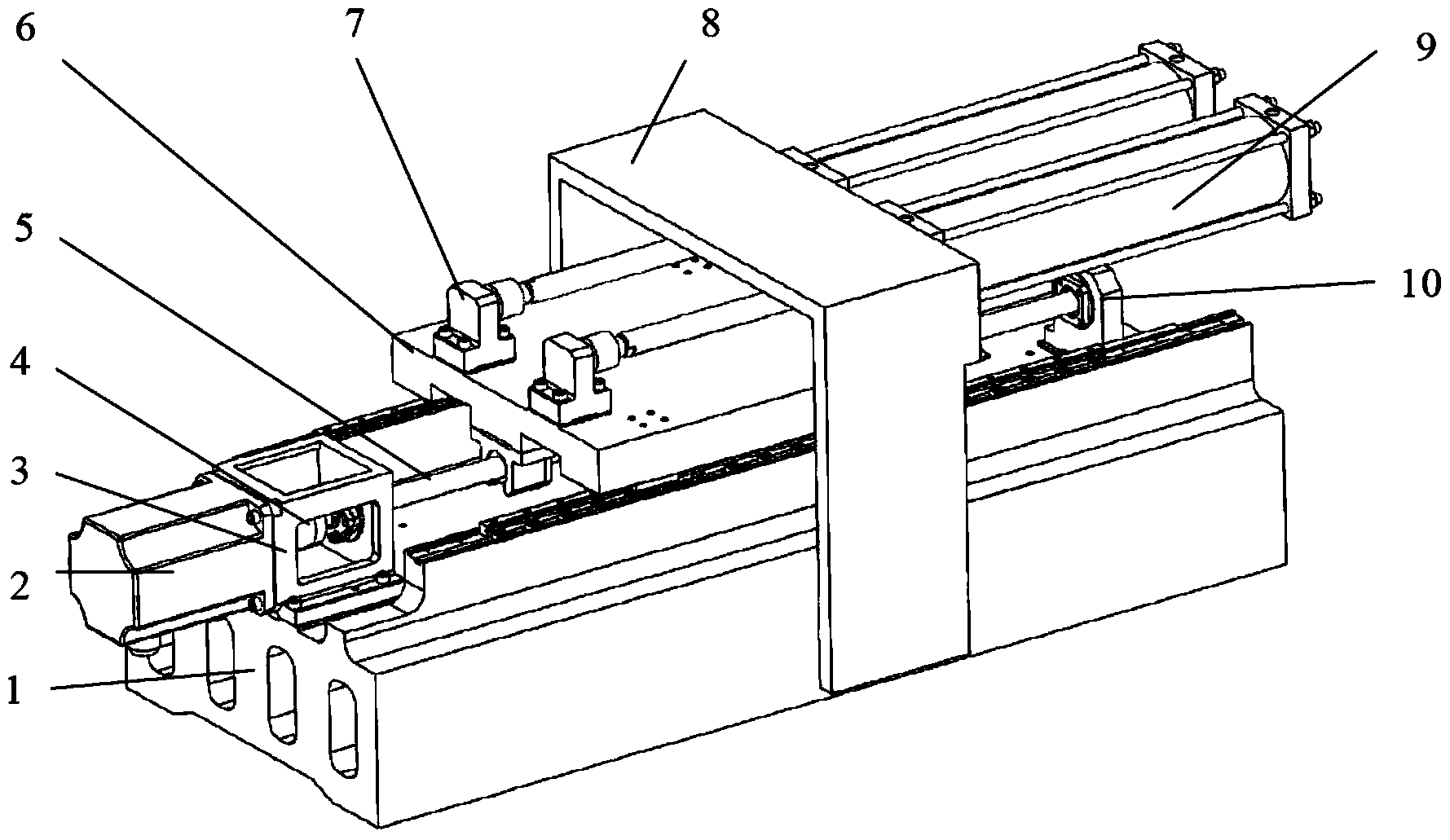

Method for Evaluating Life of Cable Insulating Coating Material

ActiveUS20120213246A1Improve reliabilityImprove securityPlastic/resin/waxes insulatorsWeather/light/corrosion resistanceMethod testAntioxidant

Disclosed is a method for estimating, within a short time, the life of a cable insulating coating material containing an antioxidant in a suitable concentration based on the rate of decrease of the antioxidant and on the critical concentration of the antioxidant at which oxidative degradation rapidly proceeds. The method tests the coating material to examine its life, the coating material including a base polymer, and an antioxidant having a functional group suppressing an oxidative deteriorative reaction of the base polymer. The method includes performing a thermal degradation test on the coating material; determining the degradation levels and degradation rates of the coating material at two or more time points in the thermal degradation test, based on the ratio of the absorbance of the functional group of the antioxidant to the absorbance of the base polymer; and thereby evaluating the life of the coating material.

Owner:HITACHI METALS LTD

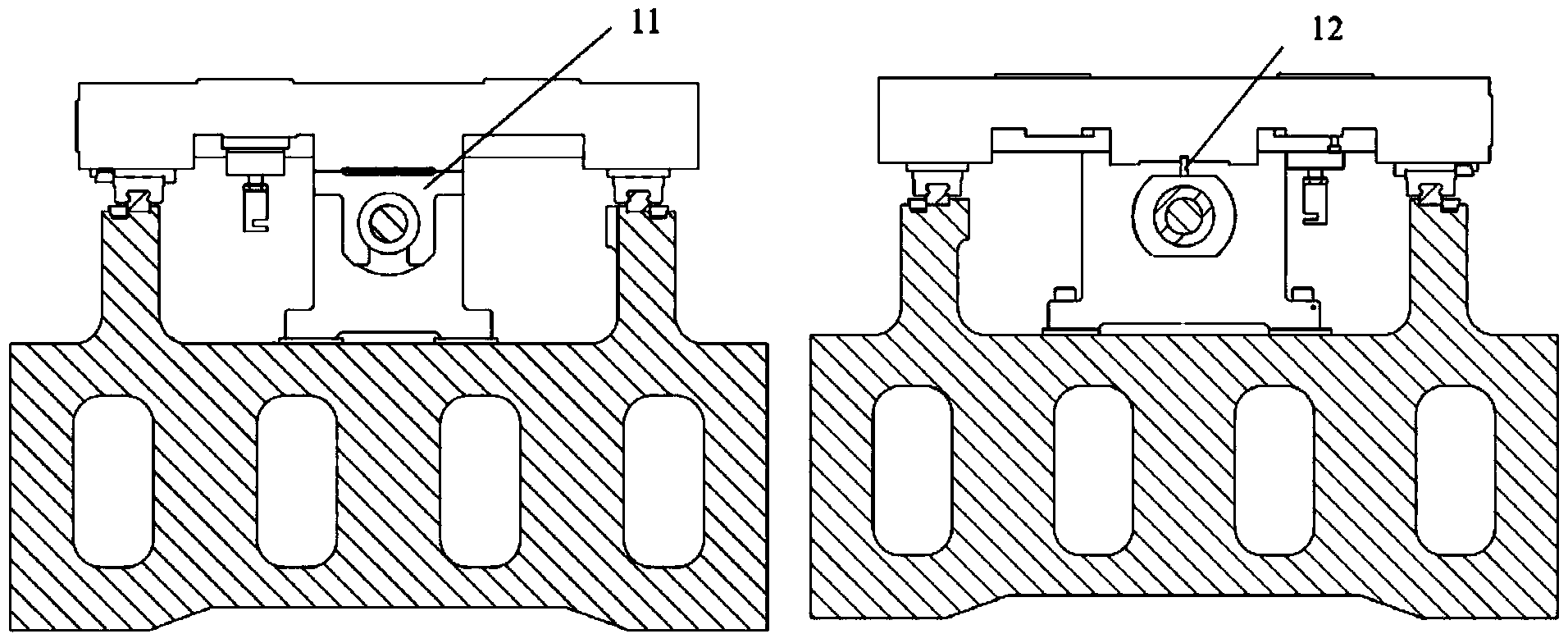

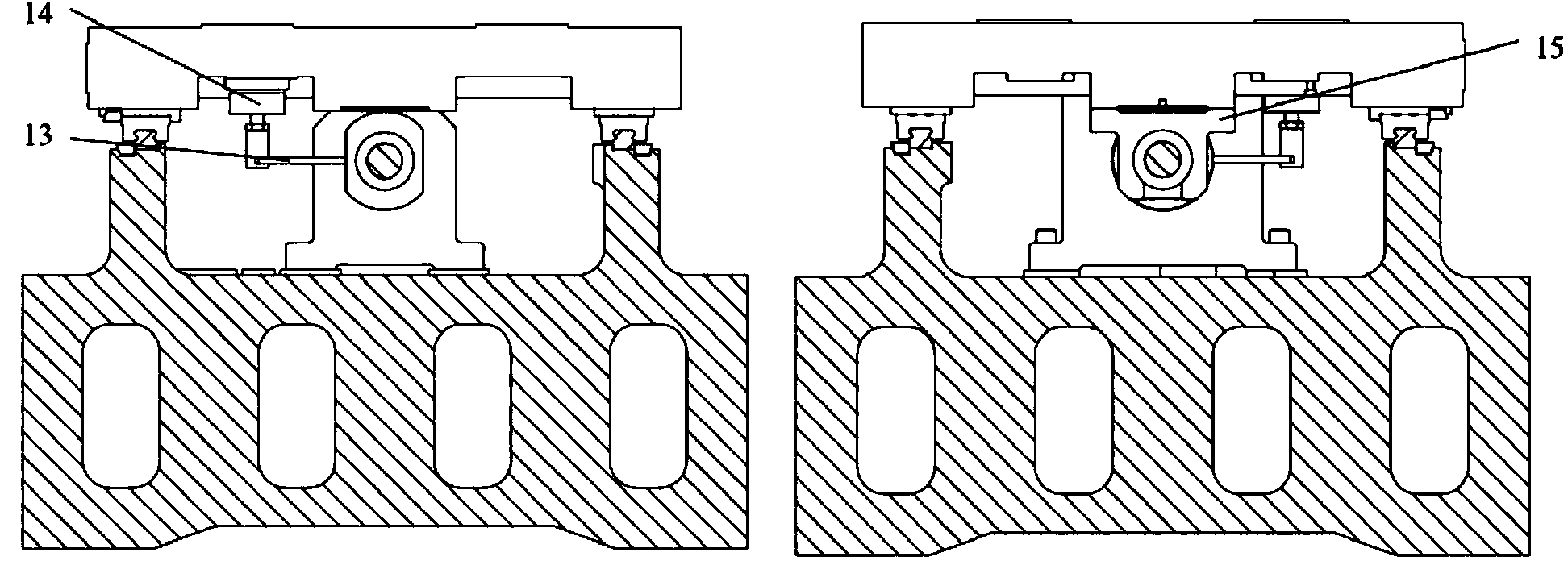

Method and device for testing accelerated degradation of friction moment of ball screw pair

ActiveCN103822784AAccurately reflect the real friction torqueRealize online measurementMachine gearing/transmission testingFriction torqueBall screw

The invention discloses a method and device for testing accelerated degradation of the friction moment of a ball screw pair and belongs to the technical field of detection of ball screw pairs. The ball screw pair is connected with a sliding plate through a replaceable main nut and a replaceable auxiliary nut on the two sides respectively. In the test condition, the ball screw pair drives the sliding plate to reciprocate through the main nut, rotation of the sliding plate is limited by the auxiliary nut through a limiting rod, and load testing is conducted on the sliding plate through a load cylinder. In the testing condition, the ball screw pair drives the sliding plate to reciprocate through the auxiliary nut, the main nut is connected with a pull pressure sensor installed on the sliding plate through a force measurement rod, so that the friction torque between the main nut and a lead screw is obtained accurately. During an accelerated degradation test, axial stepping accelerated loading is conducted on the ball screw pair through the axial load cylinder. Modeling of the friction torque degradation process of the ball screw pair can be achieved through the ball screw pair friction torque data obtained through a short-time acceleration test, and the performance degradation life of the ball screw pair is predicted in a short period of time and with low cost.

Owner:江苏启尖丝杠制造有限公司

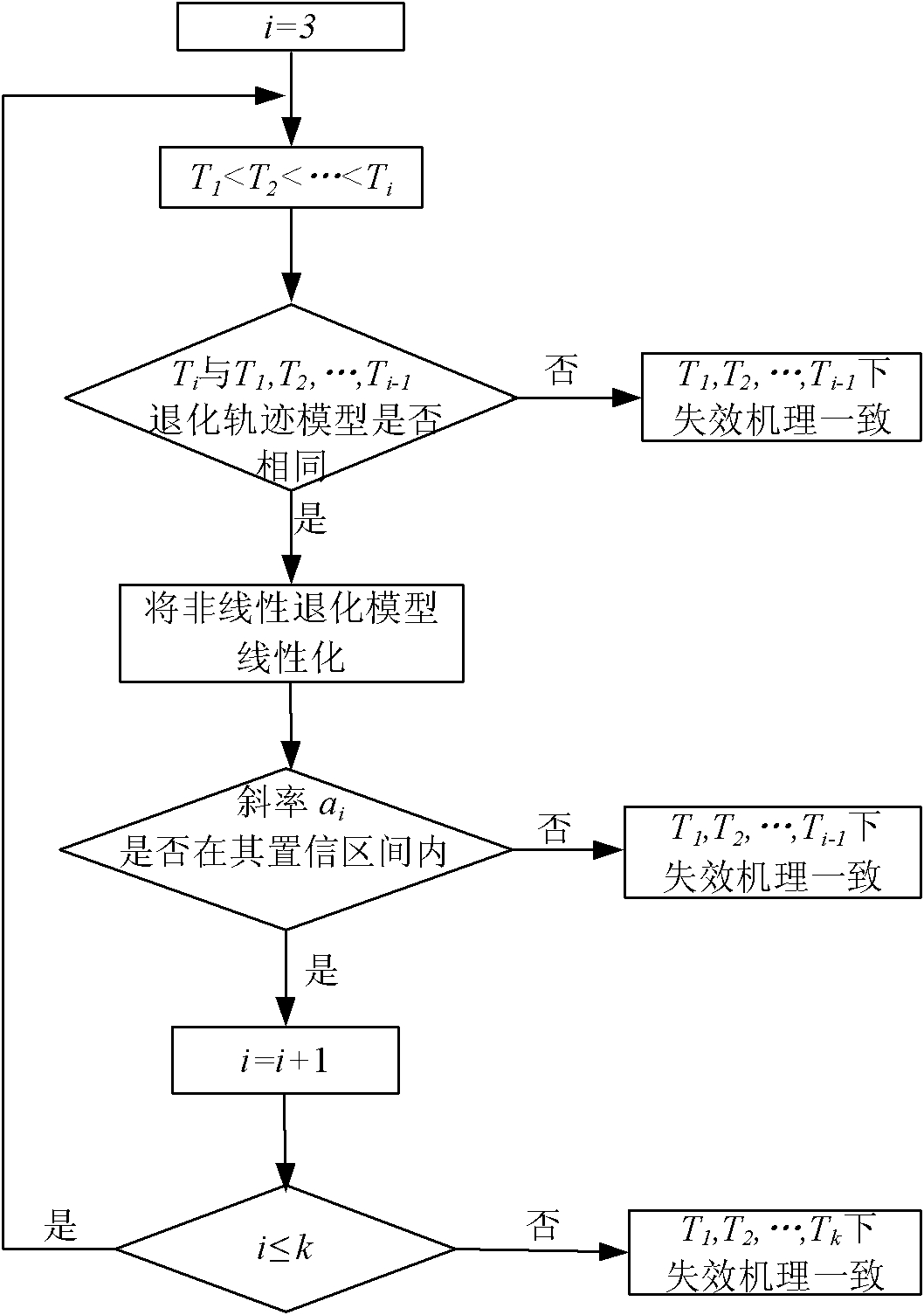

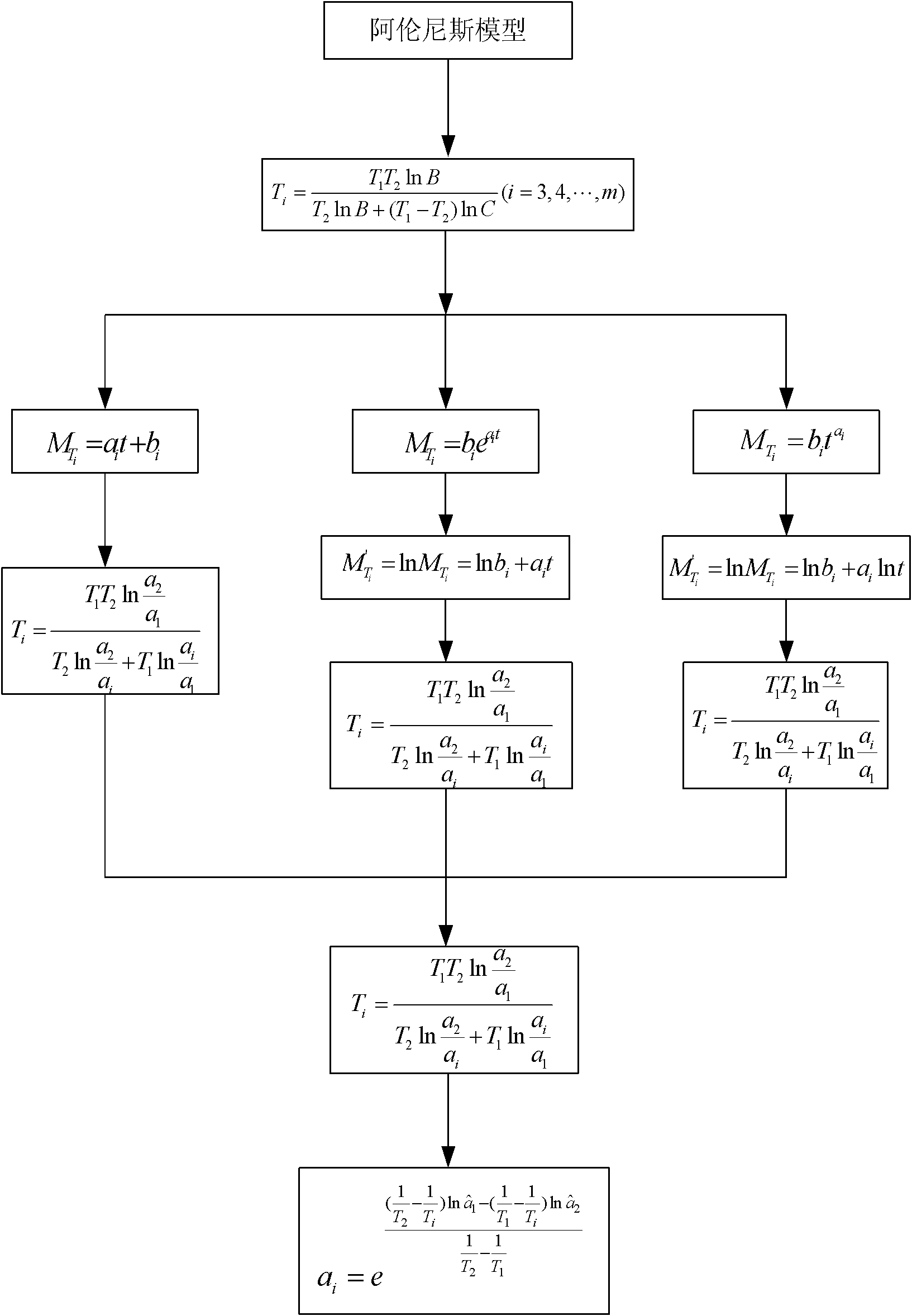

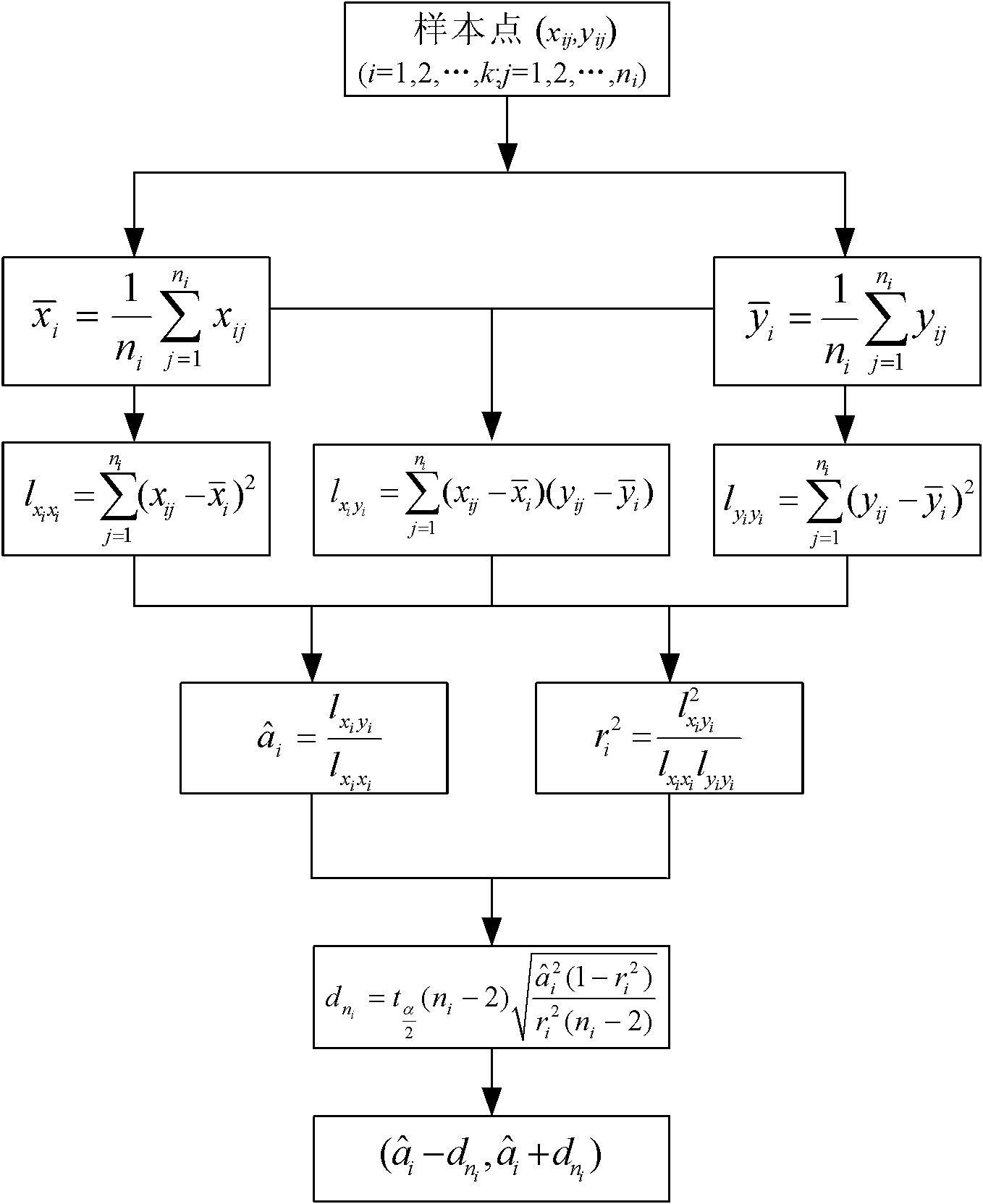

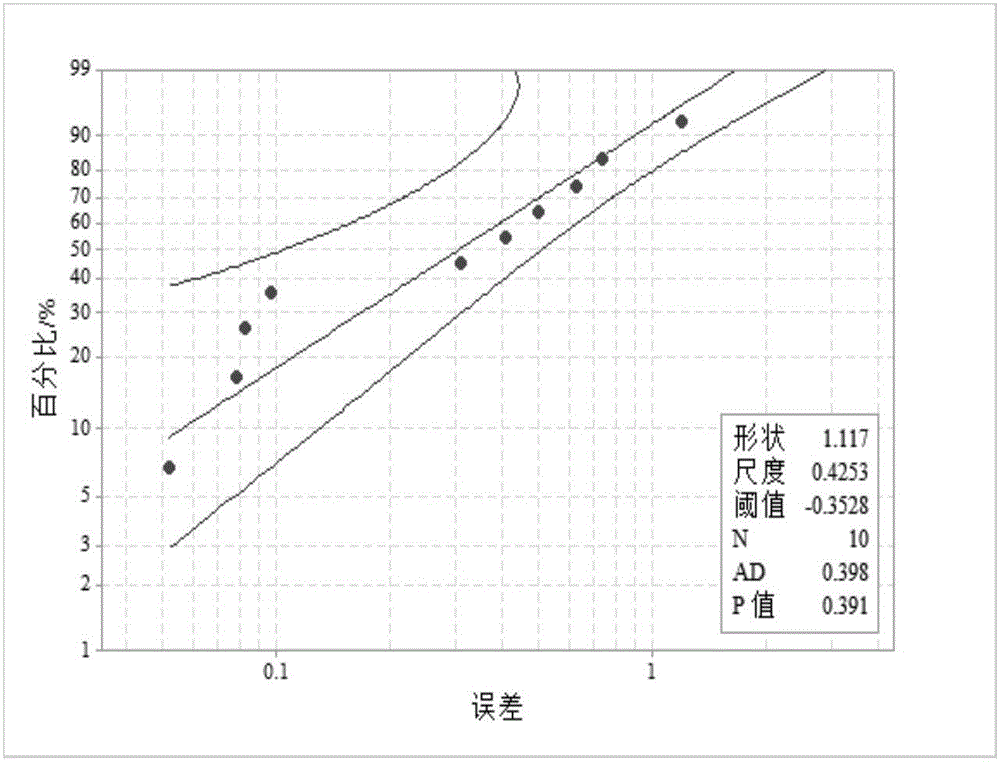

Method for determining consistency boundary of accelerated degradation mechanism based on single parameter

InactiveCN102054104AAccelerated Test SafetyUniform Stress-Slope FormulaSpecial data processing applicationsResearch ObjectConfidence interval

The invention discloses a method for determining consistency boundary of an accelerated degradation mechanism based on a single parameter, comprising the steps of: taking an Arrhenius model which is an accelerated degradation model of an electronic device- as a research object; then combining three common degradation models, including a linear model, an index model and a power model, to deduce a stress-slope formula which ensures that the accelerated mechanism of the electronic device is not changed from a point that the activation energy is not changed; and finally determining a boundary design stress of an electronic device accelerated degradation test according to a slope interval test method of the linear model. Through the invention, the defect that the boundary stress of the accelerated degradation test cannot be determined through a pseudo life distribution parameter homogeneity test method of the electronic device due to the simulation result certainty is successfully overcome, and a mass of samples and funds are saved; when the test level alpha in the slope interval test is 0.1, an obtained slope confidence interval is narrower than a slope confidence interval obtained when alpha is 0.01 or 0.05; and the accelerated degradation test under stress Tm is effectively ensured to be safe under the condition of that the acceleration effect is not influenced.

Owner:BEIHANG UNIV

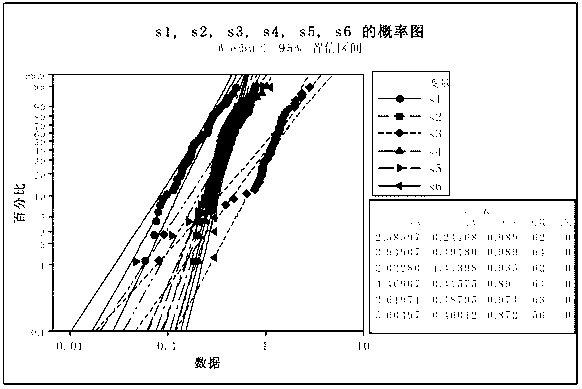

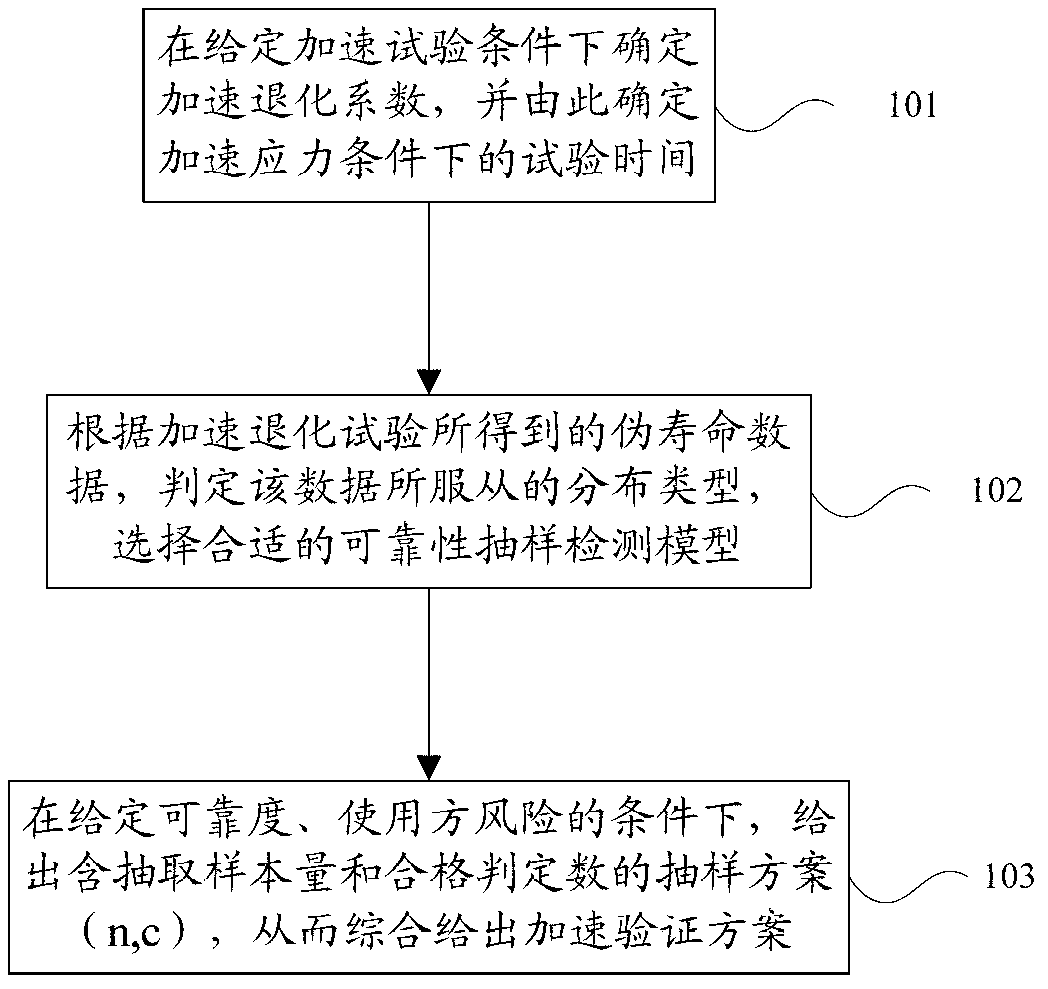

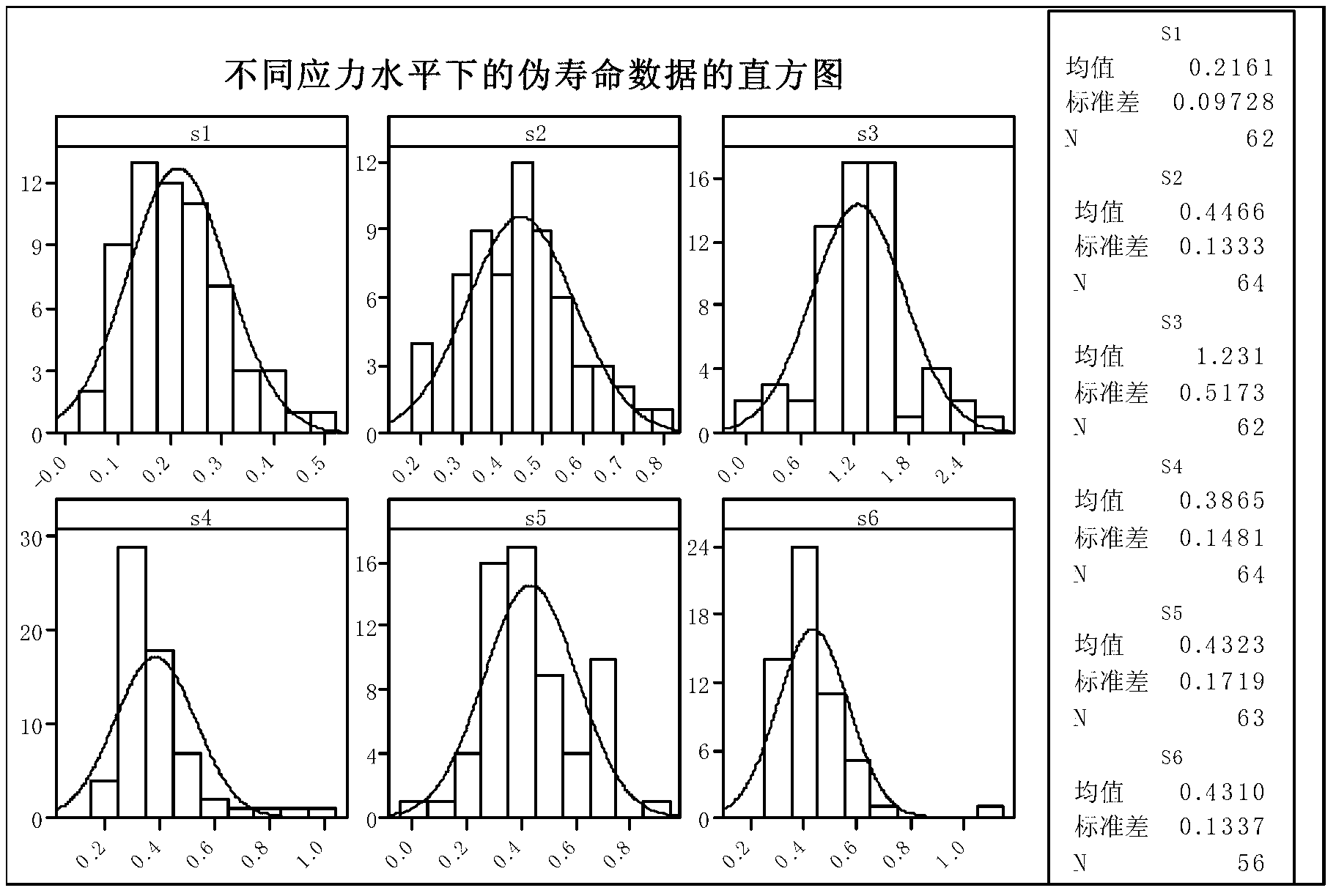

Quick sampling and detecting method for intelligent ammeter

The invention discloses a quick sampling and detecting method for an intelligent ammeter, which belongs to the reliability detection technology of intelligent ammeters. The method comprises the following steps: determining the accelerated degeneration factor under the accelerated test condition, and accordingly determining the test time under the accelerated stress condition; judging the submissive distributional type of false life data obtained in the accelerated degradation test, and selecting an applicable reliability sampling and detecting model; and providing a sampling plan including both the extracted sample size and the acceptance number under the conditions of given reliability and application risk, and accordingly determining an accelerated verification scheme. The invention provides a quick verification scheme for determining whether the reliability of a newly designed, researched and developed intelligent ammeter conforms to the requirement or not, and the false life data obtained in the accelerated degradation test is adopted to achieve one-step sampling inspection on the reliable service life of the intelligent ammeter, so that whether the reliable product service life conforms to the requirement can be quickly verified.

Owner:NORTH CHINA GRID MEASUREMENT CENT

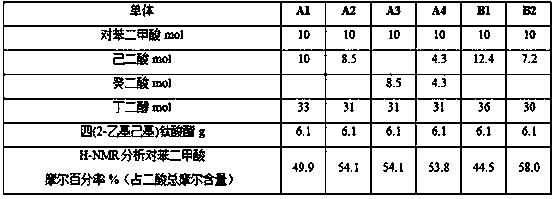

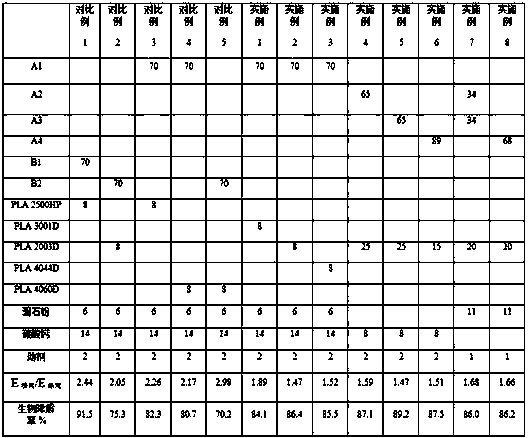

Biodegradable polyester composition and application thereof

The invention discloses a biodegradable polyester composition. The composition is prepared from the following components: (i) 50-94 parts by weight of aliphatic-aromatic copolyester, (ii) 5-30 parts by weight of polylactic acid, and (iii) 0.5-30 parts by weight of an inorganic filler. The composition is prepared by taking the aliphatic-aromatic copolyester having an aromatic carboxylic acid content of 48.5-54.5mol% as matrix resin, and using the polylactic acid having a melting point of 145-170 DEG C as an another phase; furthermore, the inorganic filler is added, so that the prepared biodegradable polyester composition has balanced longitudinal and transverse tearing properties; the polyester composition also has superior biodegradability, and the biodegradation rate of the composition reaches 80% or above in a degradation test process lasting for 12 weeks.

Owner:杨红梅

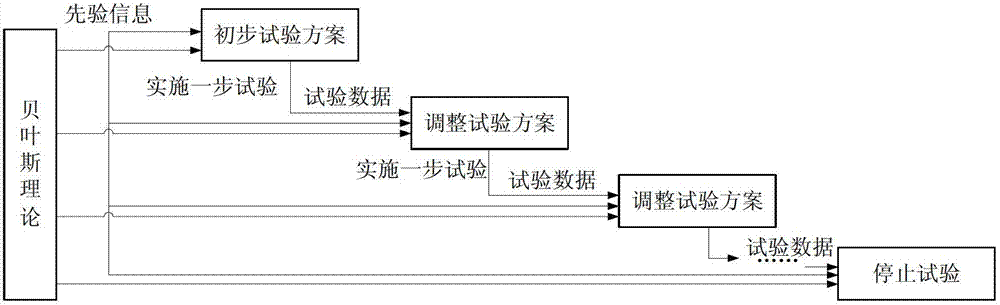

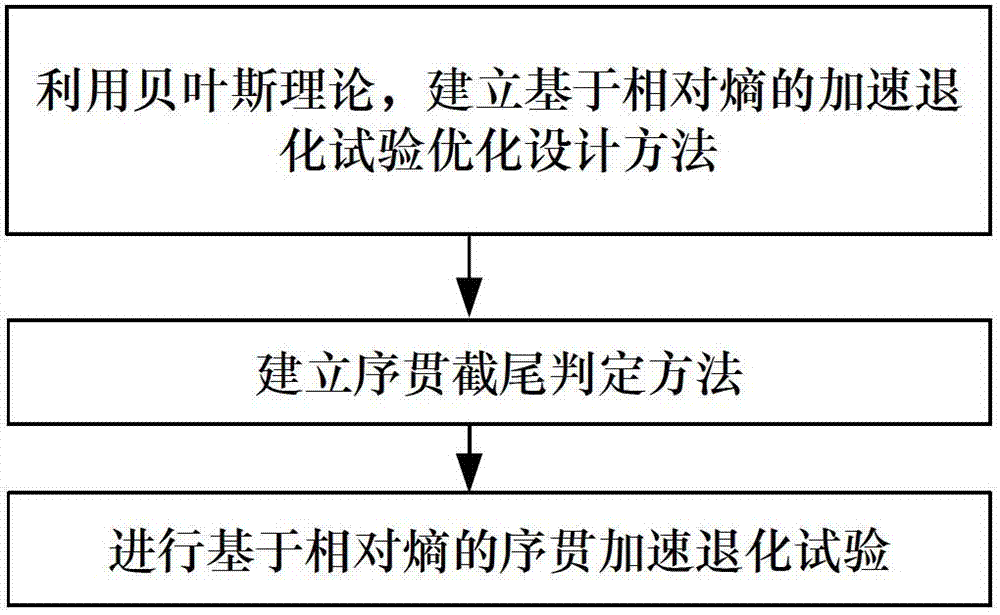

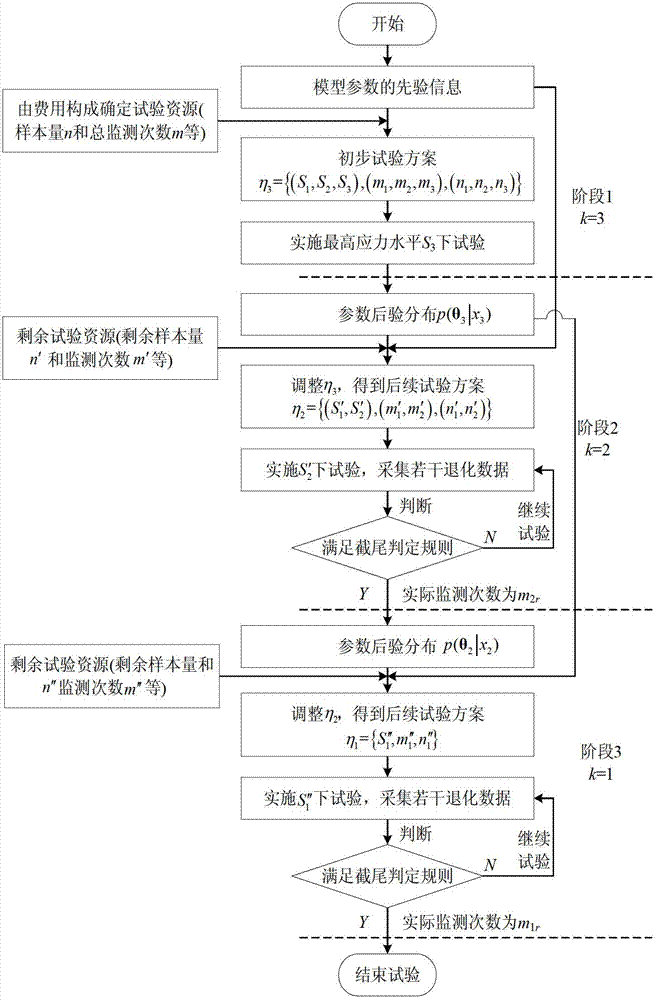

Sequential accelerated degradation test optimal design method based on relative entropy

ActiveCN102779208AReduce Experimental Design ErrorsGreat advantageSpecial data processing applicationsTest designPrior information

The invention discloses a sequential accelerated degradation test optimal design method based on relative entropy, comprising the specific steps of: step 1, utilizing a Bayesian theory to establish an accelerated degradation test optimal design method based on the relative entropy; step 2, establishing a sequential truncation judging method; and step 3, carrying out sequential accelerated degradation test based on the relative entropy. According to the method disclosed by the invention, a 'sequential design' is introduced to an optimal design of the accelerated degradation test for the first time and the sequential accelerated degradation test optimal design method is provided. With the adoption of the 'sequential design', not only can prior information before the test be sufficiently utilized, but also performance degradation information obtained in the test is gradually utilized, and a test design error caused by that the deviation between the prior information and a product real condition is larger is reduced, so that compared with a partial optimal design and Bayesian optimal design of the accelerated degradation test, the sequential accelerated degradation test optimal design method based on the relative entropy has the greater advantage.

Owner:BEIHANG UNIV

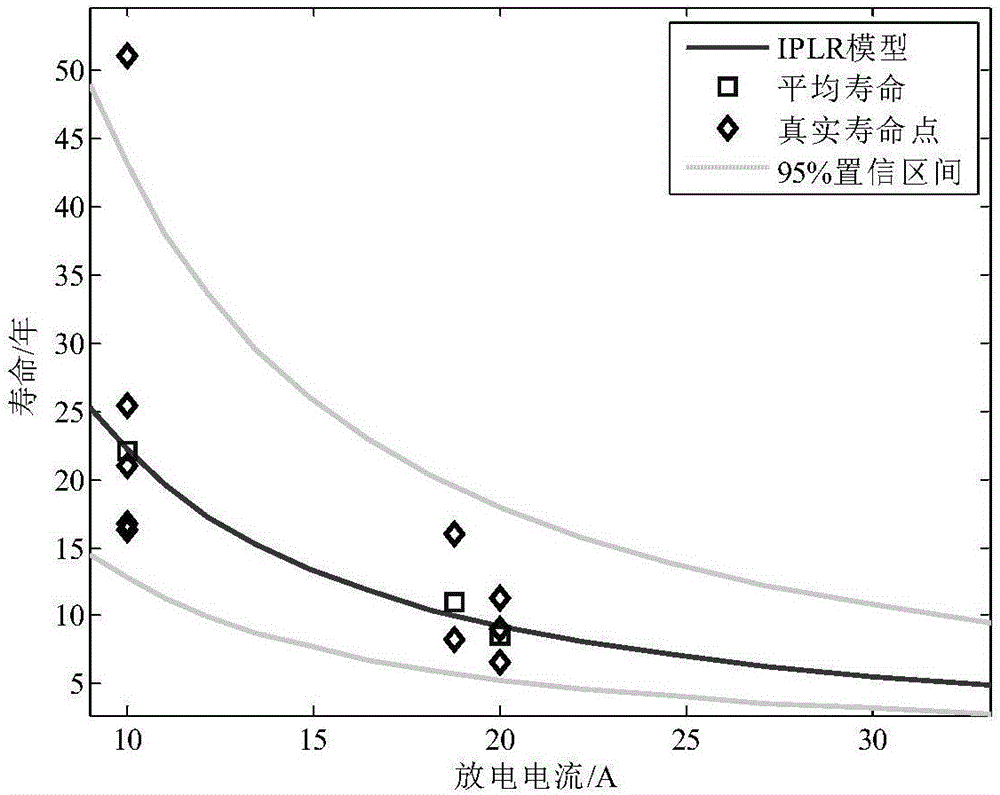

Spatial lithium-ion battery accelerated degradation test time equivalency modeling method

ActiveCN106772080AEffectively explain the feasibilityComprehensive Statistical AnalysisElectrical testingStatistical analysisData modeling

The invention provides a spatial lithium-ion battery accelerated degradation test time equivalency modeling method. For lithium-ion batteries for spatial application, the process of constructing a degradation life test model is described, and an effective accelerated life test model is provided; it is indicated that in spatial lithium-ion battery ground test, operating time under doubled current operating condition (referred to as DDC hereinafter) is about 0.39 times that under actual in-orbit simulated operating condition (referred to as SN hereinafter). Comprehensive statistical analysis is provided for the data for the acceleration test model, data modeling feasibility is characterized clearly, and ineffective work for acceleration modeling for blind application data is avoided. By using various expression modes, life probability density function for each working condition is acquired, life distribution value with acceleration stress being other value is acquired effectively, and lives under different check conditions and acceleration conditions and parameter values under different operating times are acquired quickly.

Owner:HARBIN INST OF TECH

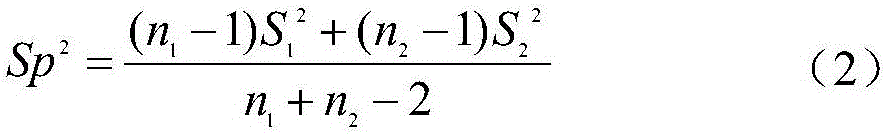

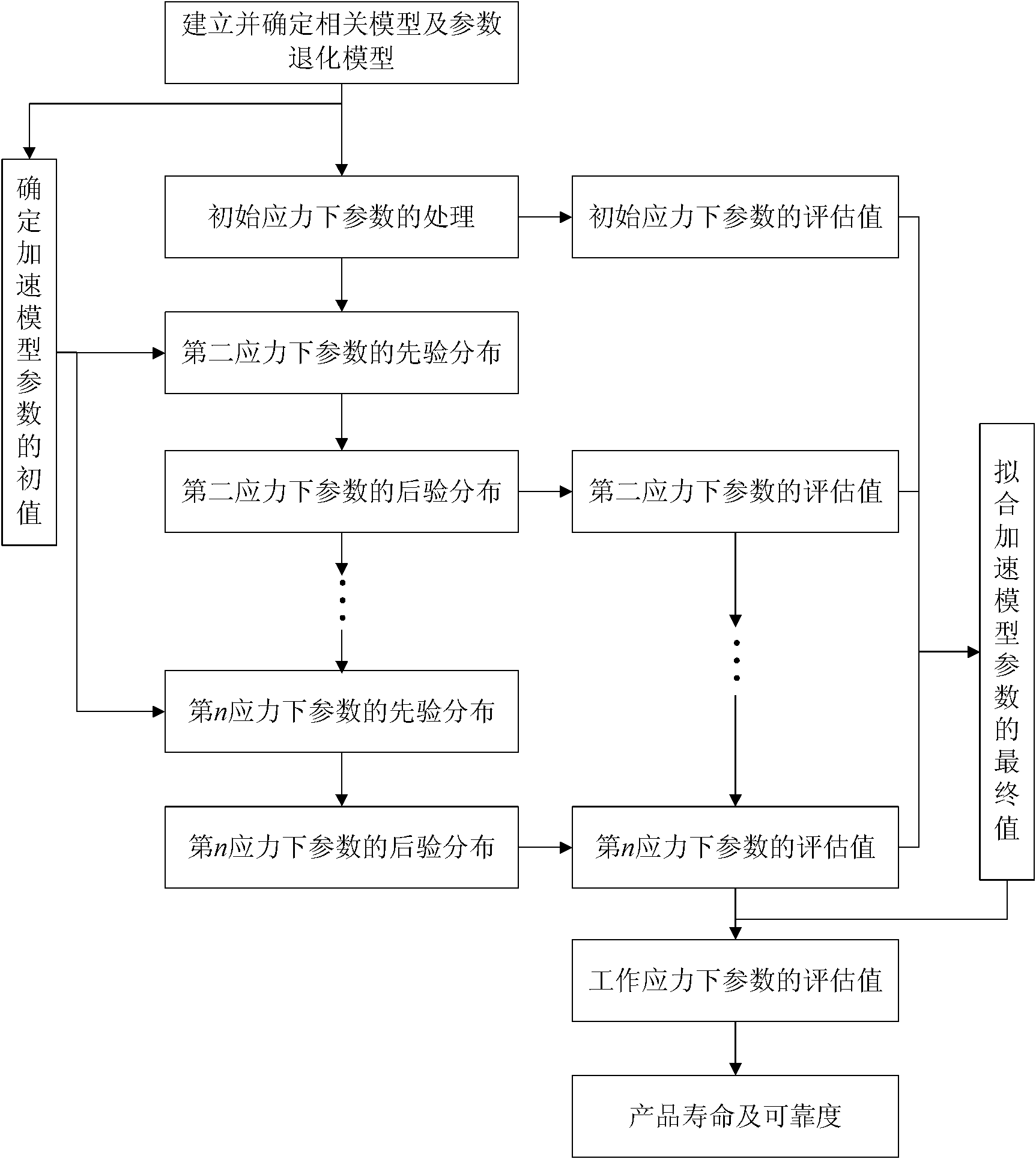

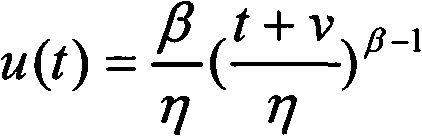

Bayesian appraisal method of accelerated degradation test based on drift Brownian motion model

InactiveCN101976311AImprove evaluation accuracyAvoid error effectsSpecial data processing applicationsTest designStress level

The invention discloses a Bayesian appraisal method of an accelerated degradation test based on a drift Brownian motion model, belonging to the technical filed of life and reliability assessment. The method comprises the following specific steps: 1, creating and determining a relevant model; 2, determining the initial value of acceleration model parameters; 3, building the prior distribution and posterior distribution of the model parameters under various stress levels; 4, fitting the final value of the acceleration model parameters; and 5, appraising product life and reliability. In the invention, the appraisal precision of the acceleration model parameters is improved through determining the initial value of the acceleration model parameters, fitting the final value thereof and other steps, thereby improving the appraisal precision of product life and reliability. Through the method, the following stress level test and appraisal can be guided through existing stress level test information and results, thus optimized test design can be carried out on various stress levels by stages through combing the method with corresponding test optimizing methods.

Owner:BEIHANG UNIV

Method for determining stationary phase of accelerometer based on dual-parameter accelerated degradation data

InactiveCN102253242ADescribe wellRapid assessmentTesting/calibration of speed/acceleration/shock measurement devicesStationary phaseAccelerometer

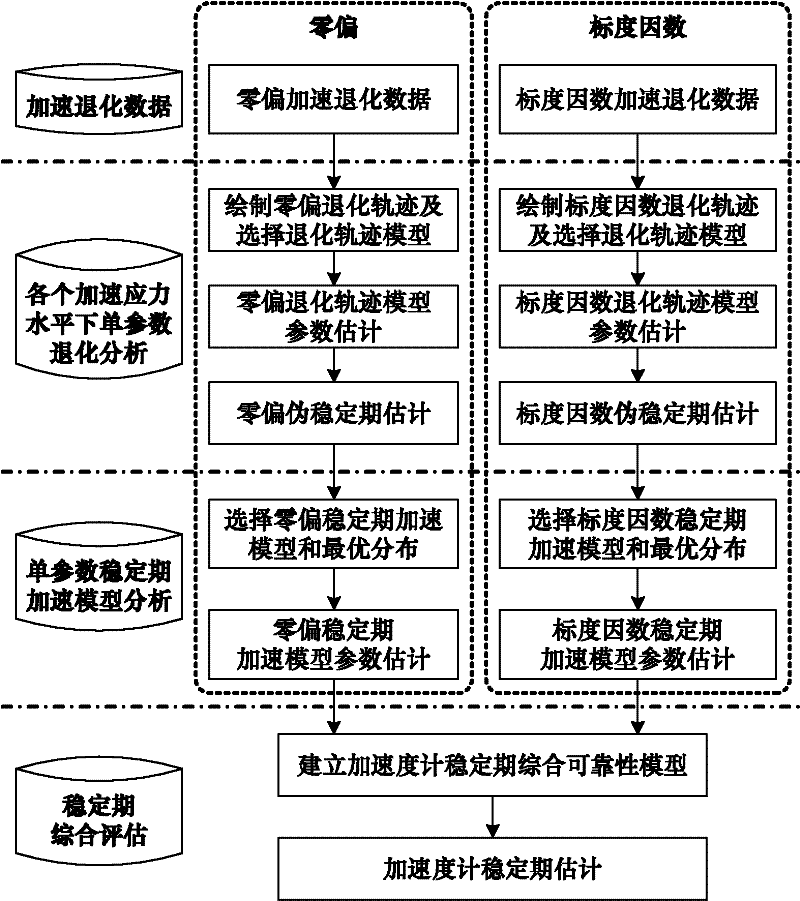

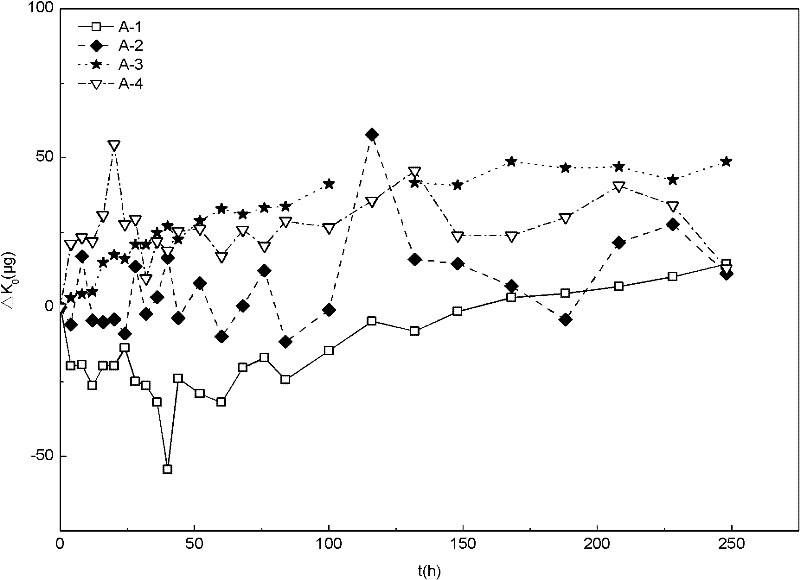

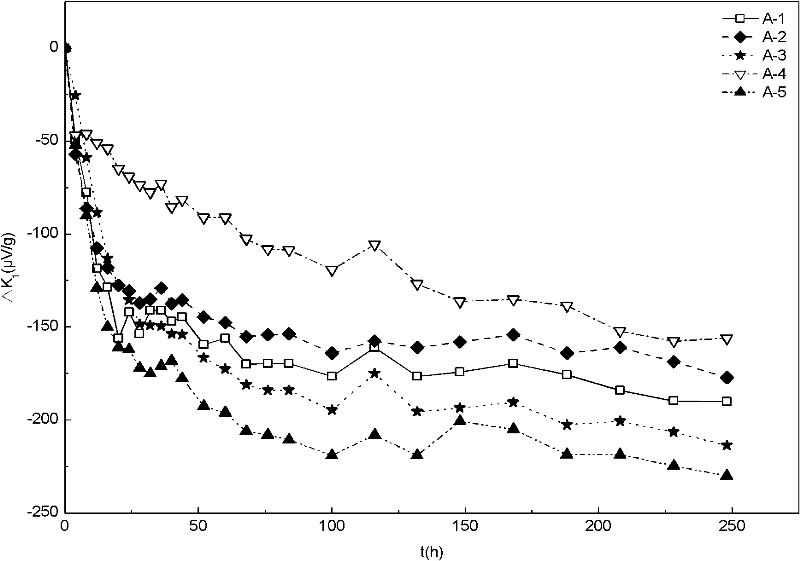

The invention provides a method for determining the stationary phase of an accelerometer based on dual-parameter accelerated degradation data. The method is based on the assumption that the zero deviation and scale factors of the accelerometer degrade commonly and meet a power degradation law, the assumption that a high-temperature accelerated degradation test of the accelerometer meets the consistency condition of a failure mechanism, and the assumption that an accelerated model is an Arrhenius equation. The method comprises the following steps of: 1, establishing a degradation track model of the zero deviation and the scale factors; 2, estimating the pseudo-stationary phase of the zero deviation and the scale factors; 3, establishing a stationary phase accelerated model of the zero deviation and the scale factors; and 4, establishing a comprehensive reliable model of the stationary phase of the accelerometer, and determining the stationary phase of the accelerometer under the reliability. In the method, the influence of the zero-deviation degradation and the scale factors on the stationary phase of the accelerometer is taken into consideration simultaneously, horizontal information among different test temperatures is utilized fully by an integral maximum likelihood estimation process, so that the condition of the stationary phase of the accelerometer can be better describedunder the condition of dual-parameter common degradation, and the estimation accuracy is improved effectively.

Owner:BEIHANG UNIV

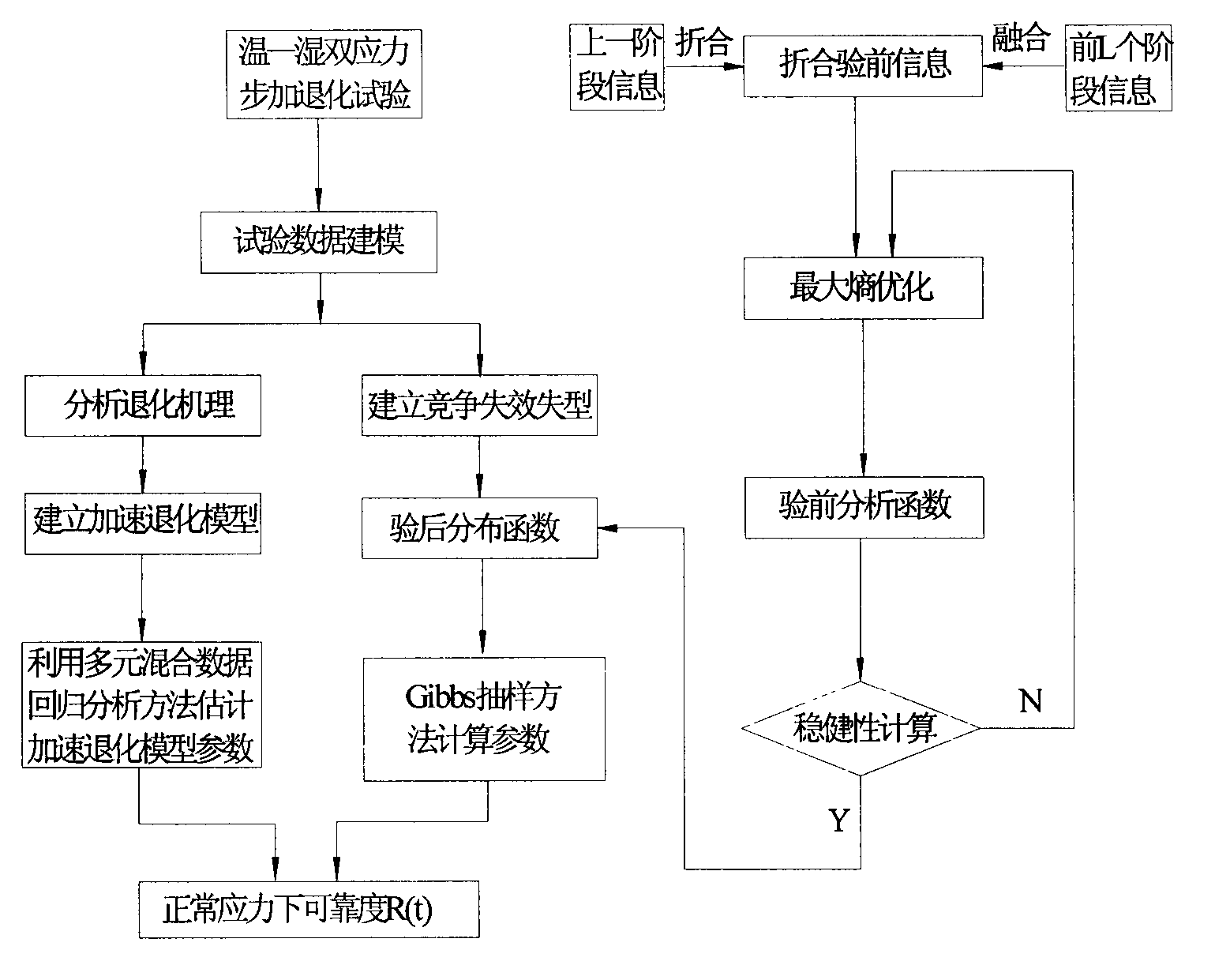

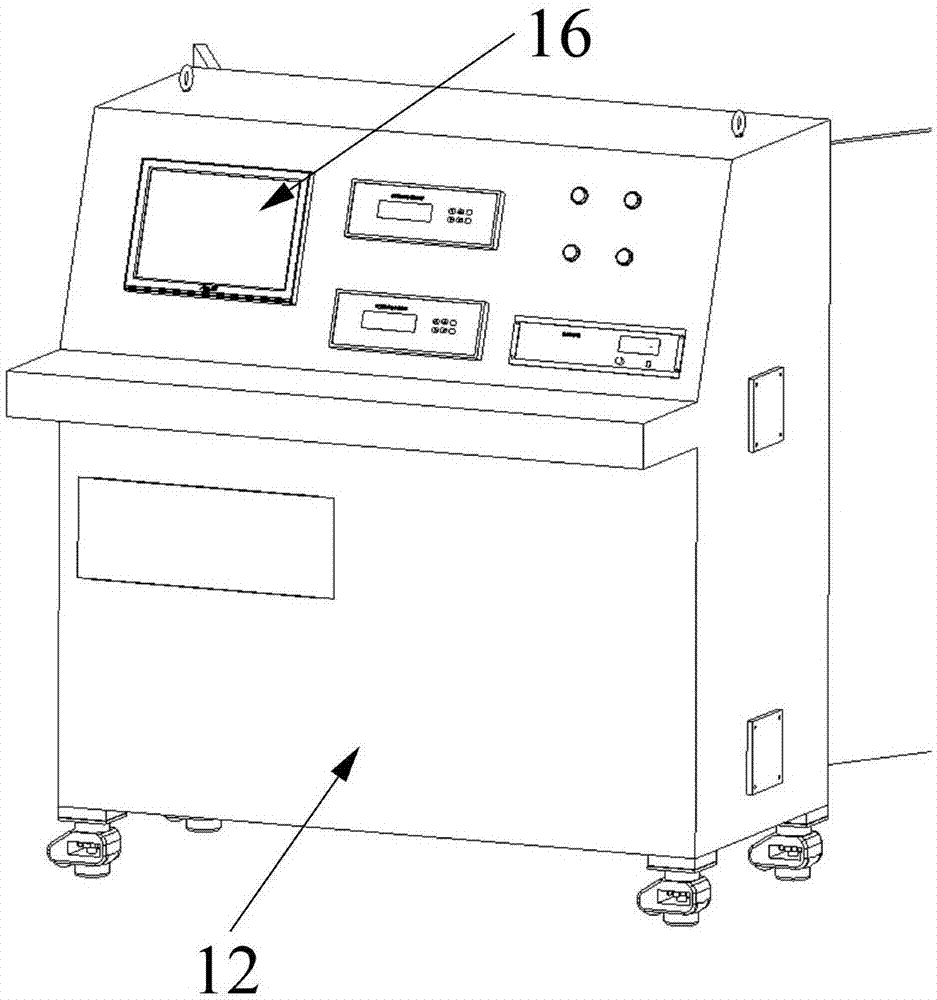

Numerical control system reliability rapid Bayes evaluation system under degradation tests

The invention discloses a numerical control system reliability rapid Bayes evaluation system under degradation tests. According to the failure data small sample characteristic of a high-reliability long-service-life numerical control system, a Bayes evaluation scheme based on the double stress stepping accelerated degradation tests is adopted to achieve rapid secondary acceleration evaluation effects. A double stress acceleration model is established on the basis of a temperature-humidity double stress stepping accelerated service life degradation test scheme; according to the conditions that test data are blended data composed of complete data and censored data, a multiple blended data regression method is adopted to estimate acceleration model parameters; according to the conditions that numerical control system failure modes are not single, a competition failure reliability evaluation model is established; and according to the failure data small sample characteristic, a Bayes method is utilized to solve prior distribution by means of historical information. According to the numerical control system reliability rapid Bayes evaluation system, the model parameters are evaluated by combination with a stepping accelerated test competition failure model, evaluation precision is improved, numerical control system reliability rapid evaluation theories are enriched, and a theory basis is provided for verifying a numerical control system failure mechanism and improving numerical control system reliability.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

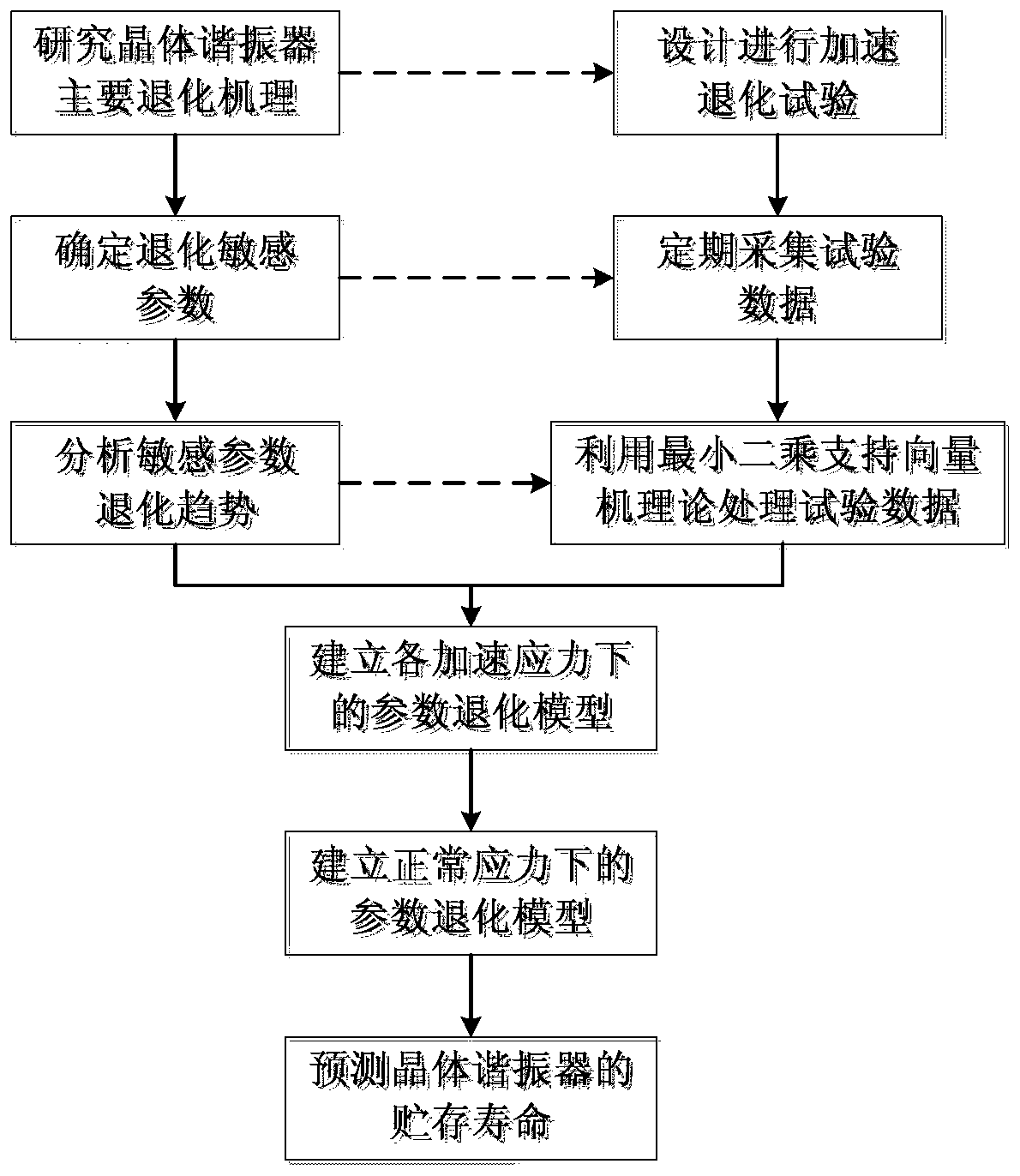

Crystal resonator storage life forecasting method based on least squares support vector machine

The invention relates to a crystal resonator storage life forecasting method based on a least squares support vector machine. The crystal resonator storage life forecasting method based on the least squares support vector machine includes the following four steps that firstly, a degradation mechanism of a crystal resonator is analyzed when the crystal resonator is stored for a long time, influences on parameter variation by the main degradation mechanism are obtained and degradation sensitive parameters of the crystal resonator are determined; secondly, a crystal resonator accelerated storage degradation test is designed and performed, the selected sensitive parameters are measured and test data are collected regularly; thirdly, the theory of the least squares support vector machine is used for processing the test data, and a degradation model of the sensitive parameters is established under different acceleration stress levels; fourthly, a parameter degradation model of the crystal resonator under normal stress is established, failure criteria are determined and the storage life of the crystal resonator is forecast. According to the crystal resonator storage life forecasting method based on the least squares support vector machine, the practical problems of small samples, non-linearity and the like in forecasting the storage life of the crystal resonator are solved, the calculation complexity is relieved, the rate and precision of convergence are improved and high popularization value is achieved.

Owner:BEIHANG UNIV

Step stress acceleration performance degradation reliability analysis method considering measurement error

ActiveCN107885928AIn line with the actual situation of the projectLarge amount of informationDesign optimisation/simulationSpecial data processing applicationsObservational errorGeneralized Wiener process

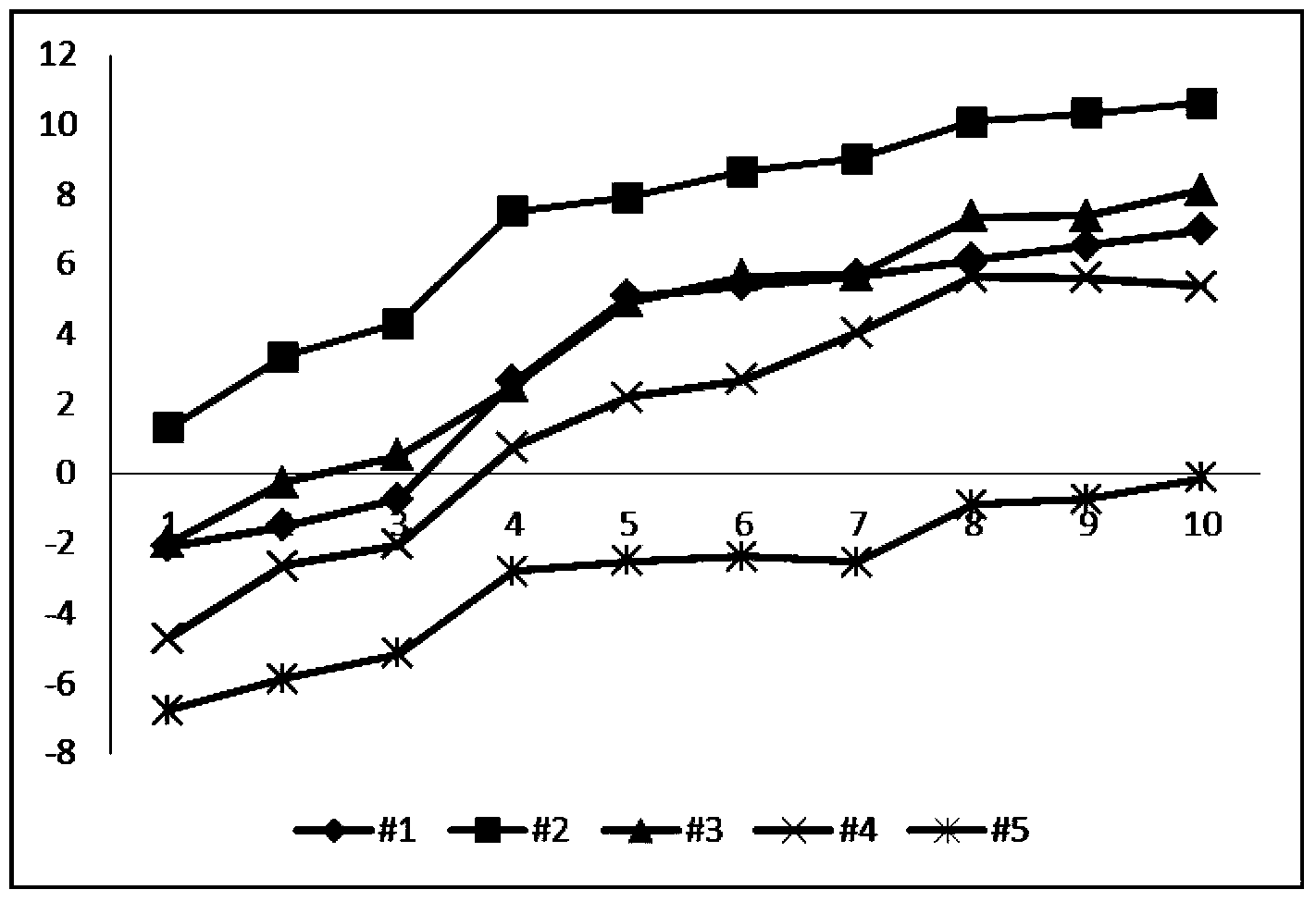

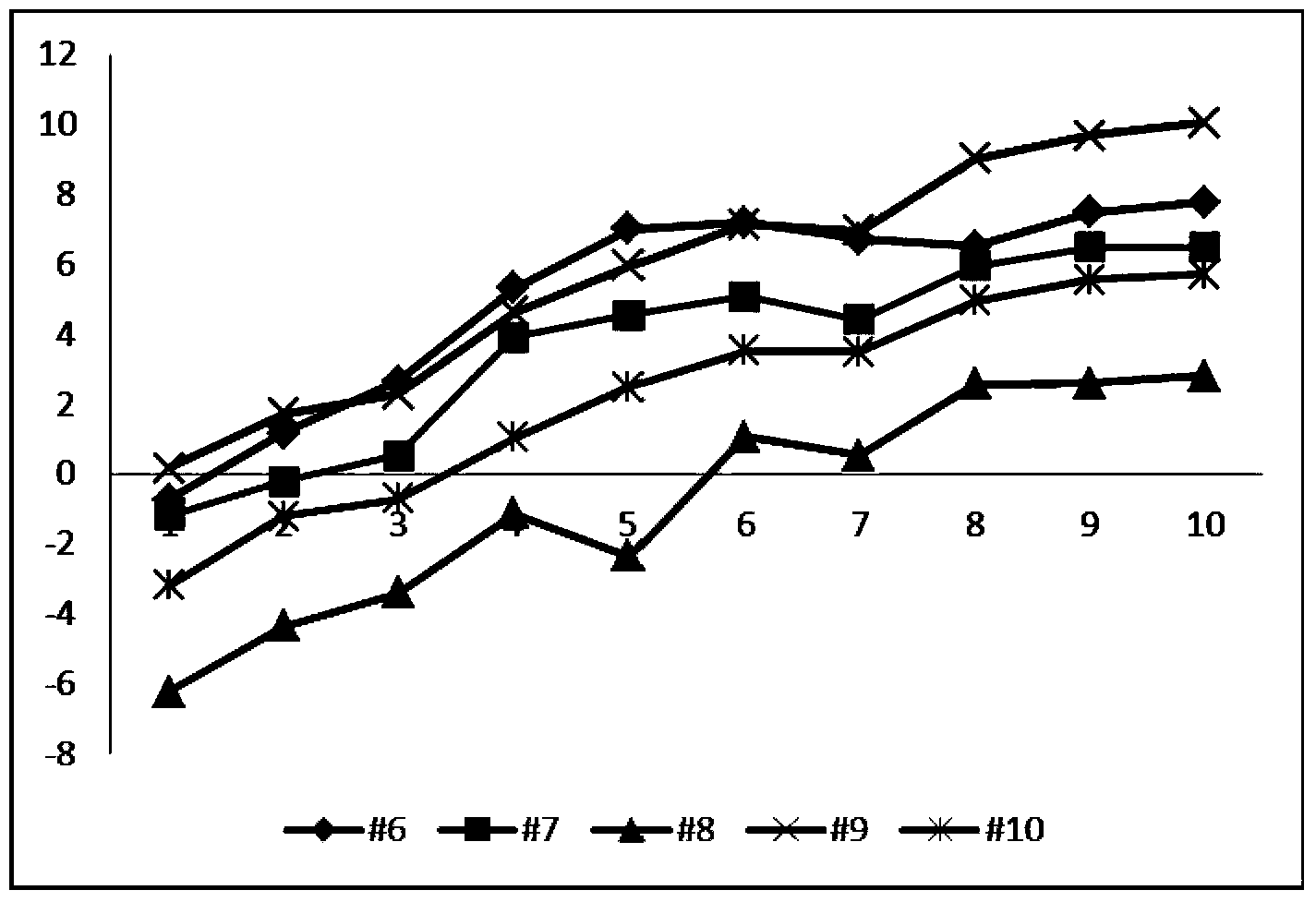

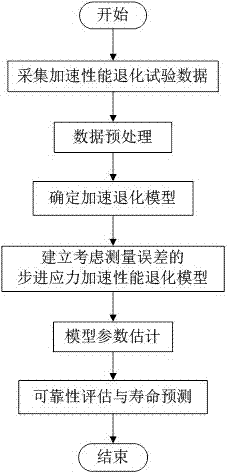

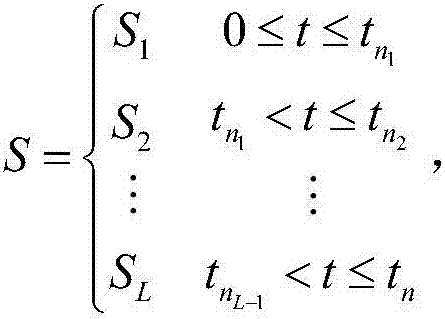

The invention provides a step stress acceleration performance degradation reliability analysis method considering a measurement error. The method comprises the steps that acceleration performance degradation test data of step stress of all samples is collected through an acceleration performance degradation test, and the acceleration performance degradation test data is preprocessed; a performancedegradation process of a product is described based on a generalized Wiener process, an acceleration degradation model is determined, and a step stress acceleration performance degradation model considering the measurement error is established; a likelihood function is utilized to estimate unknown parameters in the step stress acceleration performance degradation model; and reliability assessmentand life prediction are performed on the product. Through the method, the measurement error is introduced into step stress acceleration performance degradation data analysis for the first time, different time-varying characteristics of mean value items and variance items are considered, and the method better conforms to engineering actual conditions; and through sufficient development and utilization of vertical information of the degradation data under different stress levels and horizontal information of different samples, the amount of the information is effectively increased, and reliability assessment precision is improved.

Owner:HENAN UNIV OF SCI & TECH

Accelerated degradation experiment modeling method based on fuzzy theory

ActiveCN104463331AThe result is reasonableHas reference valueFuzzy logic based systemsLogic circuitsStatistical analysisAlgorithm

The invention discloses an accelerated degradation experiment modeling method based on a fuzzy theory. The accelerated degradation experiment modeling method comprises the specific steps of 1 utilizing the fuzzy theory to enable degradation data to be reasonably fuzzified so as to obtain fuzzy degradation data, 2 utilizing fuzzy degradation regression to establish an accelerated degradation test fuzzy linear degradation model and 3 performing model parameter evaluation and reliability degree prediction. According to the established fuzzy linear degradation model, a fuzzy evaluation value of a model parameter is given, and a fuzzy life prediction interval and a fuzzy reliability interval of a product are further given. Compared with a point estimated value given by means of a traditional statistical analysis method, the result obtained by means of the accelerated degradation experiment modeling method is reasonable and has reference value.

Owner:BEIHANG UNIV

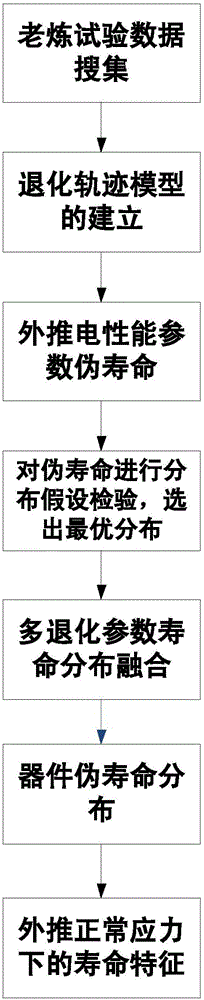

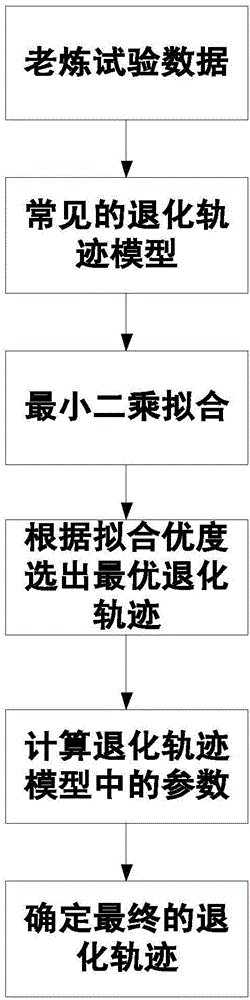

Satellite element service life evaluation method based on aging test data before assembly

The invention relates to a satellite element service life evaluation method based on aging test data before assembly. The method comprises the steps: starting with a failure mode and a failure mechanism in the actual application process of a satellite element through an accelerated degradation test theory model and combining with a space application environment, and building the degradation tracks of all electrical performances in the high-temperature aging test data; calculating the failure pseudo service lives of all electrical parameters through combining with the degradation tracks and failure threshold values of all electrical parameters; calculating the service life distribution of the element under high-temperature strain through the fitting pseudo service life distribution and multi-parameter pseudo service life distribution fusion; and finally carrying out the calculation of the service life of the element under the normal strain through determining an acceleration factor. The method belongs to the technical field of element reliability and service life evaluation.

Owner:BEIHANG UNIV

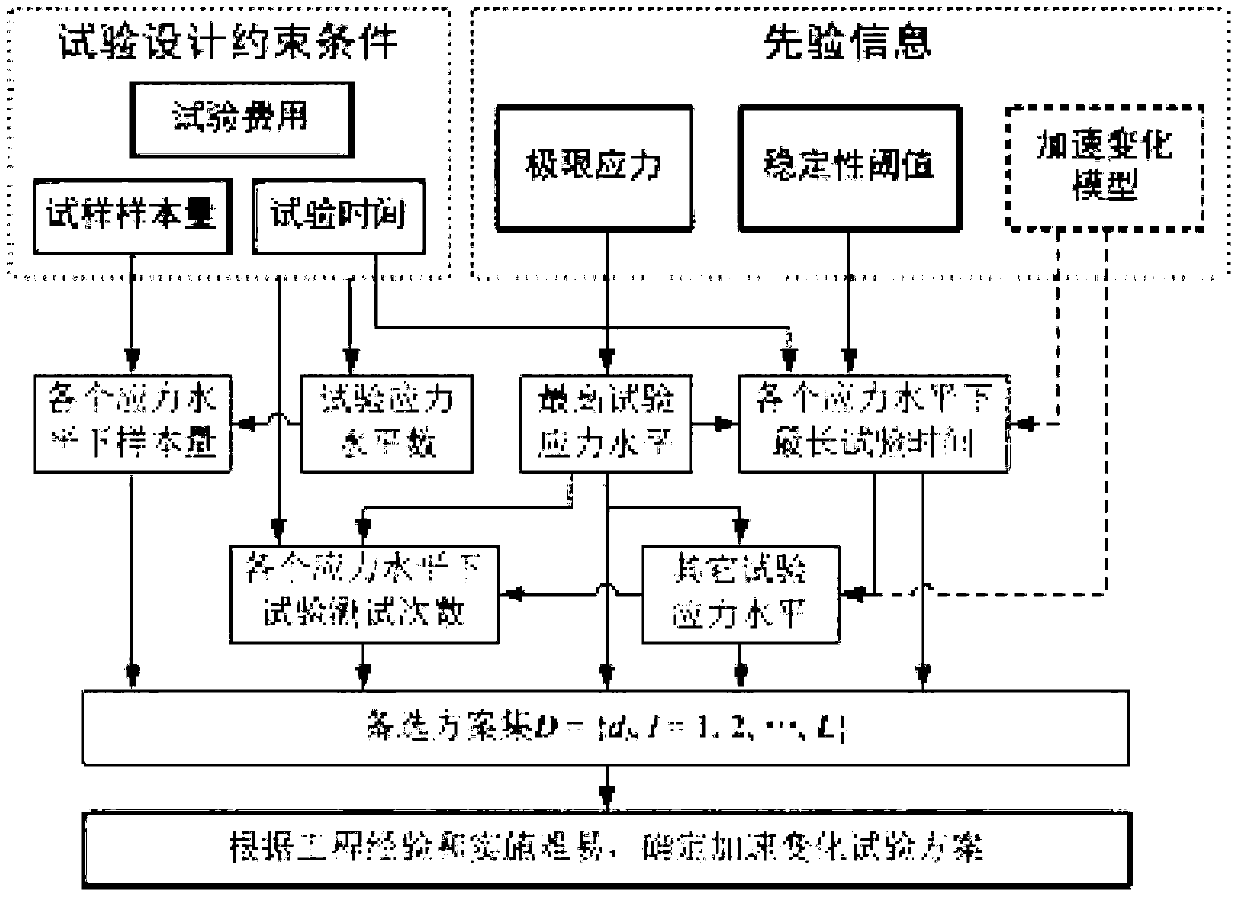

Product accelerated degradation test scheme design method based on engineering experience

A product accelerated degradation test scheme design method based on engineering experience includes the following steps that constraint conditions of conducting test design are determined, wherein the constraint conditions comprise test time, test sample sizes and test expenses, and the test expenses have a whole restraining relationship with the test time, the test sample sizes and test frequency; prior information of an accelerated degradation test is determined, wherein the prior information is obtained according to the engineering experience, design criteria and similar product information and through finite element analysis and product diagnostic test analysis; a design scope of corresponding test design elements is given according to engineering principles and corresponding calculation empirical formulas, wherein the design scope comprises test stress level numbers, stress levels, the test sample sizes, the test time and the test period of the test; corresponding test design alternative schemes are constructed on the basis of the calculation results, and the accelerated degradation test scheme is determined according to the engineering experience and an implement difficulty level.

Owner:BEIHANG UNIV

Electric energy meter life evaluation method based on accelerated degradation test

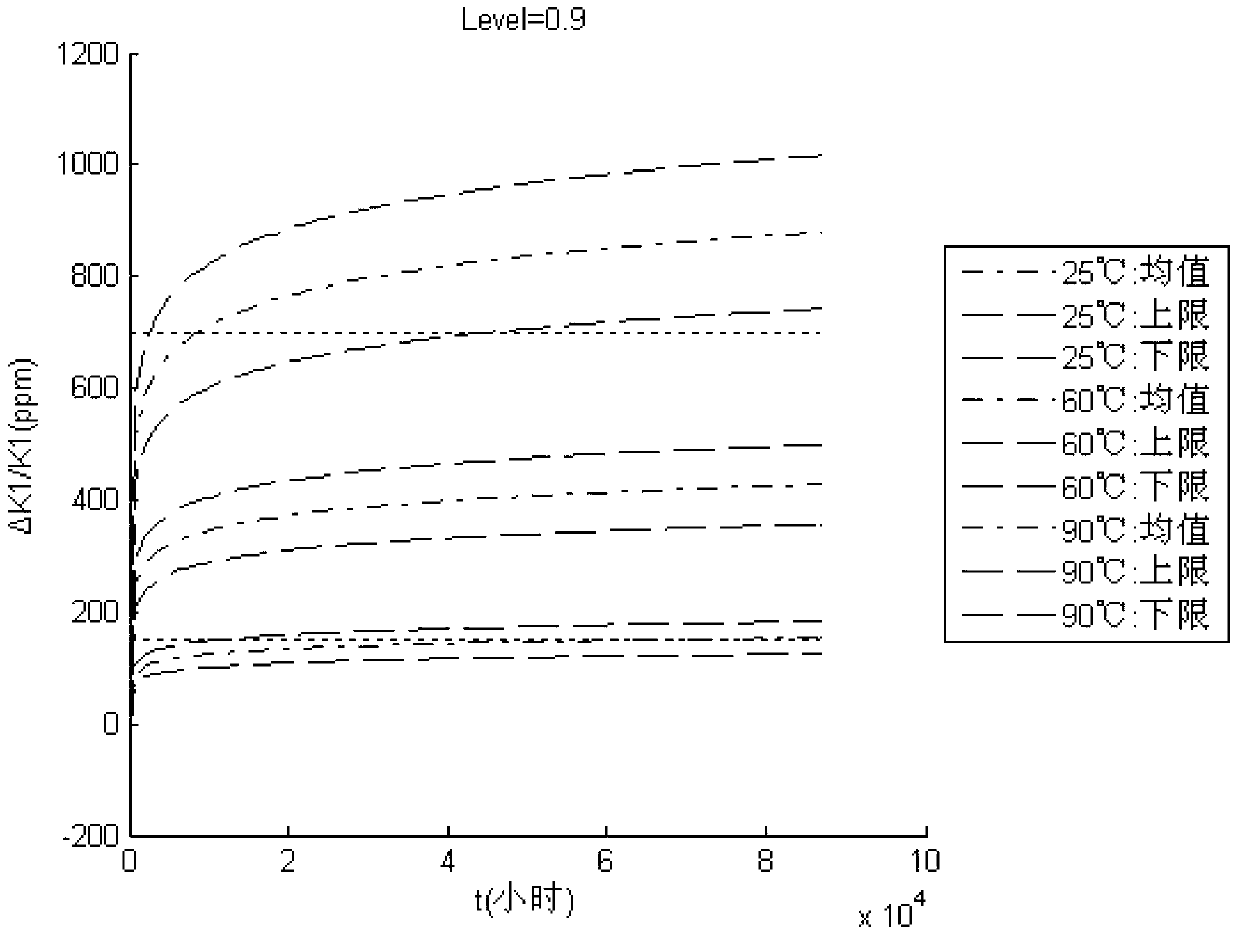

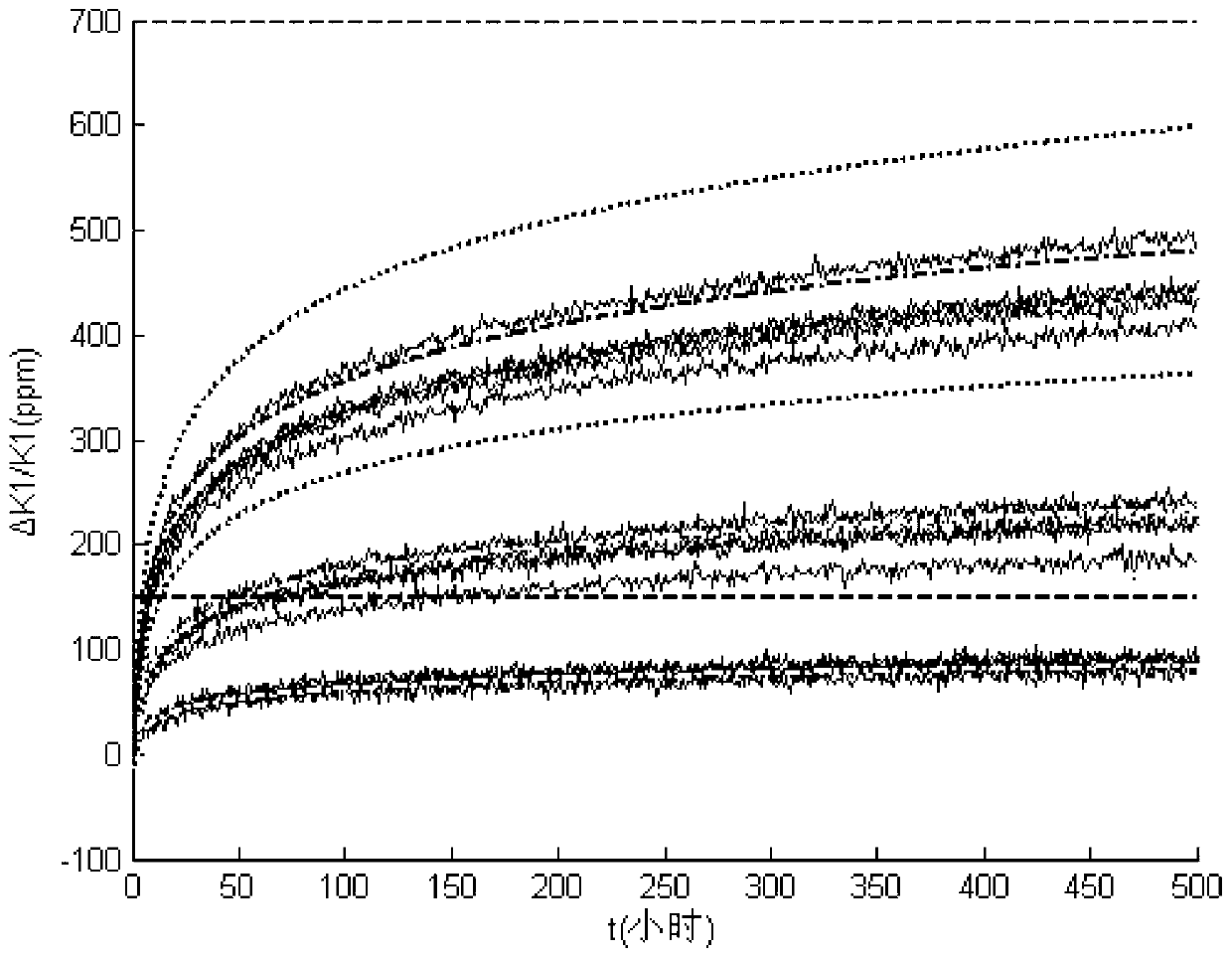

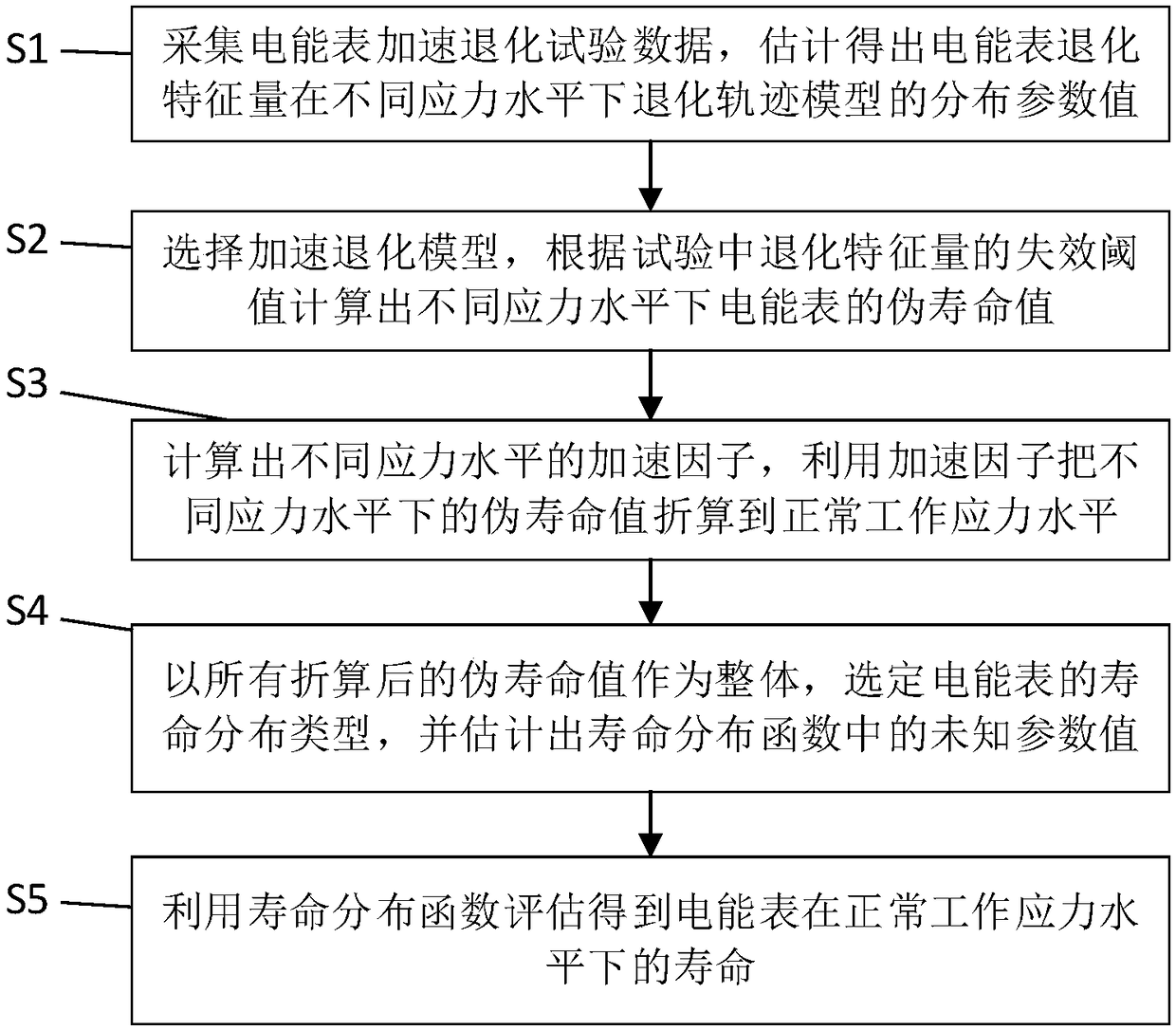

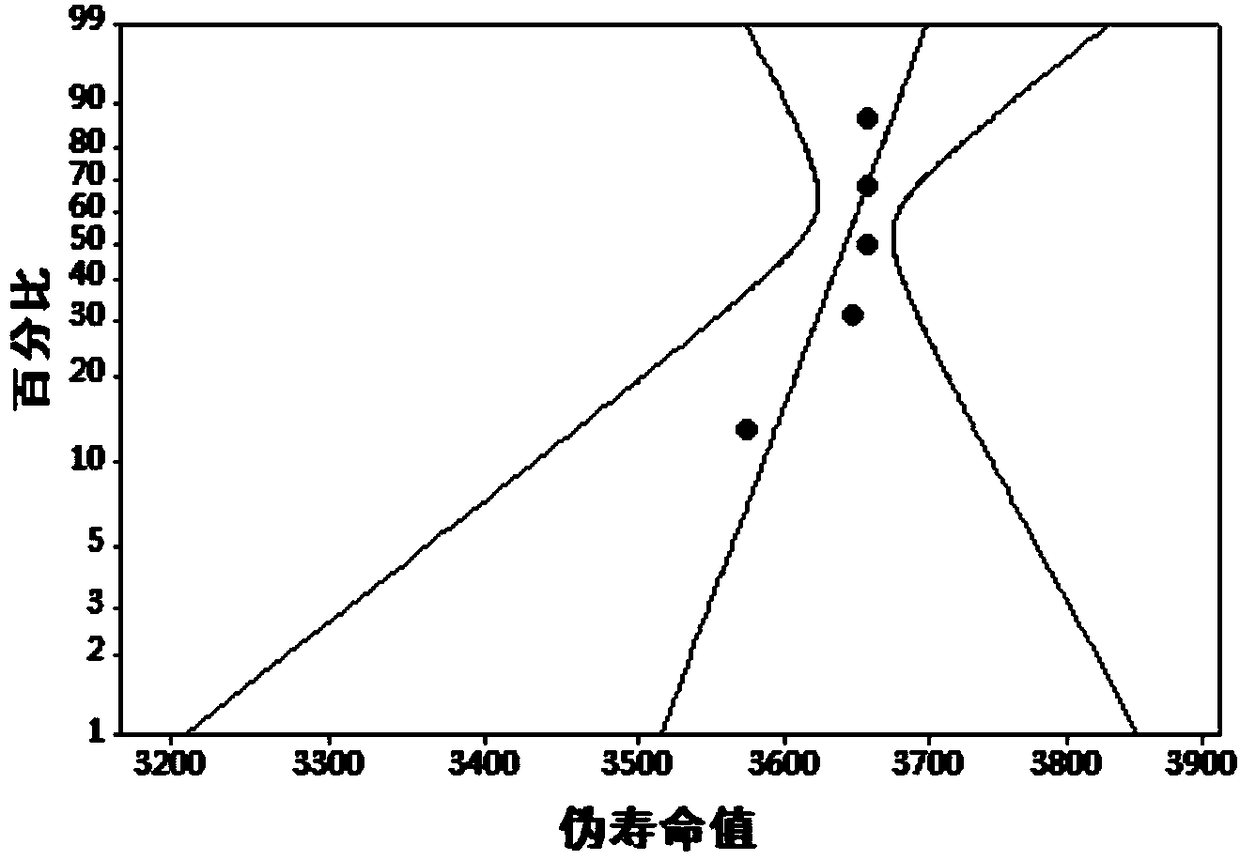

InactiveCN108549047AExact failure conditionReflect failureElectrical measurementsEngineeringLife value

The invention relates to an electric energy meter life evaluation method based on accelerated degradation test. The method comprises the following steps: 1, acquiring electric energy meter accelerateddegradation test data, and estimating the distributed parameter values of a degradation path model of the electric energy meter degradation characteristic quantity under different stress levels; 2, selecting an accelerated degradation model according to the type of acceleration stress, and calculating the false life values of the electric energy meter under different stress levels according to the failure thresholds of the degradation characteristic quantity in the test; 3, calculating acceleration factors corresponding to different stress levels according to the accelerated degradation model, and converting false life values of acceleration factors under different stress levels to the normal work stress level; 4, selecting the life distribution type of an electric energy meter, and estimating the unknown parameter values in a life distribution function; and 5, estimating by utilizing the life distribution function to obtain the life of the electric energy meter under a normal work stress level. Compared with the prior art, the method has the advantages that the life condition of the electric energy meter can be accurately estimated, and more conforms to engineering practice.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

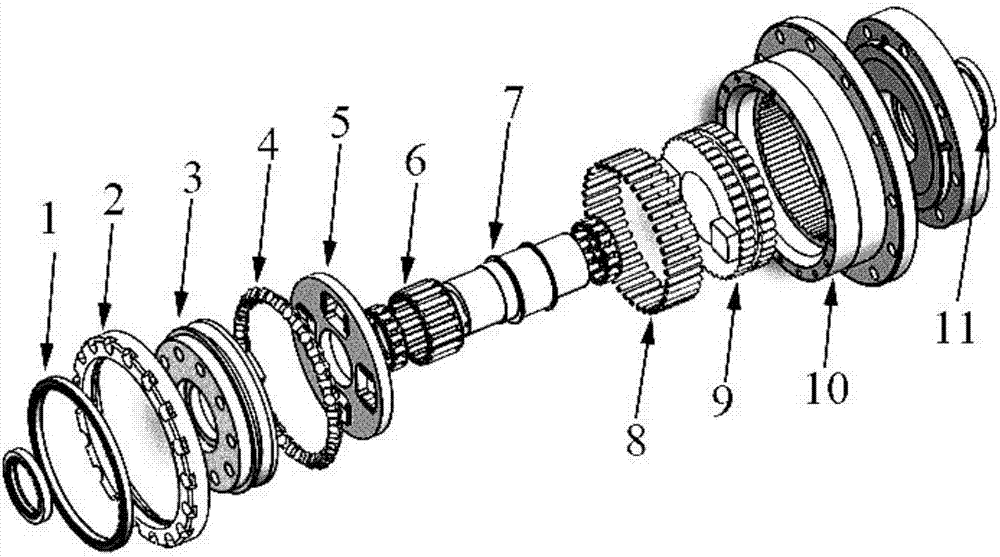

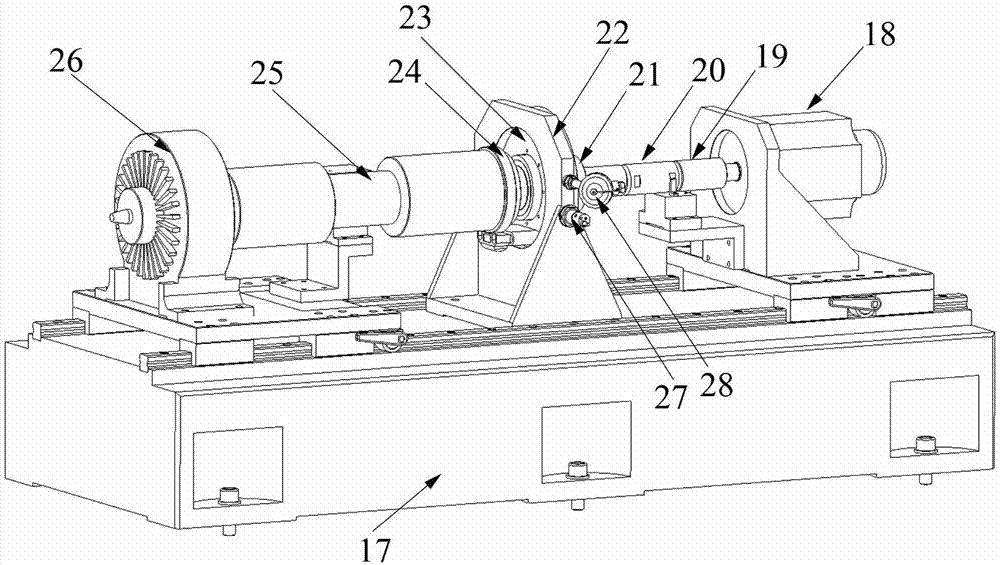

Device and method for testing service life of precision cycloidal speed reducer of robot

PendingCN107991095AEnables accurate assessmentShorten the test cycleMachine gearing/transmission testingEngineeringDegradation test

The invention provides a device and a method for testing the service life of a precision cycloidal speed reducer of a robot. The reducer is subjected to service life prediction and testing by an accelerated degradation test. According to the device and the method for testing the service life of the precision cycloidal speed reducer of the robot, test cycle is greatly shortened by the accelerated degradation test, overall-process state change of the precision cycloidal speed reducer during operating can be reflected by means of continuous monitoring for reducer performance degradation by a sensor, a dynamic loading mode more accords with the actual load state of the reducer of the robot, and accordingly, accurate evaluation for the service life of the precision cycloidal speed reducer can be realized at lower cost.

Owner:安徽哈工湛庐科技装备有限公司

Weibull-distribution-based method for predicting reliable service life of rubber ring

InactiveCN107702905AShorten the timeHigh feasibilityMachine sealing rings testingRubber ringDegradation test

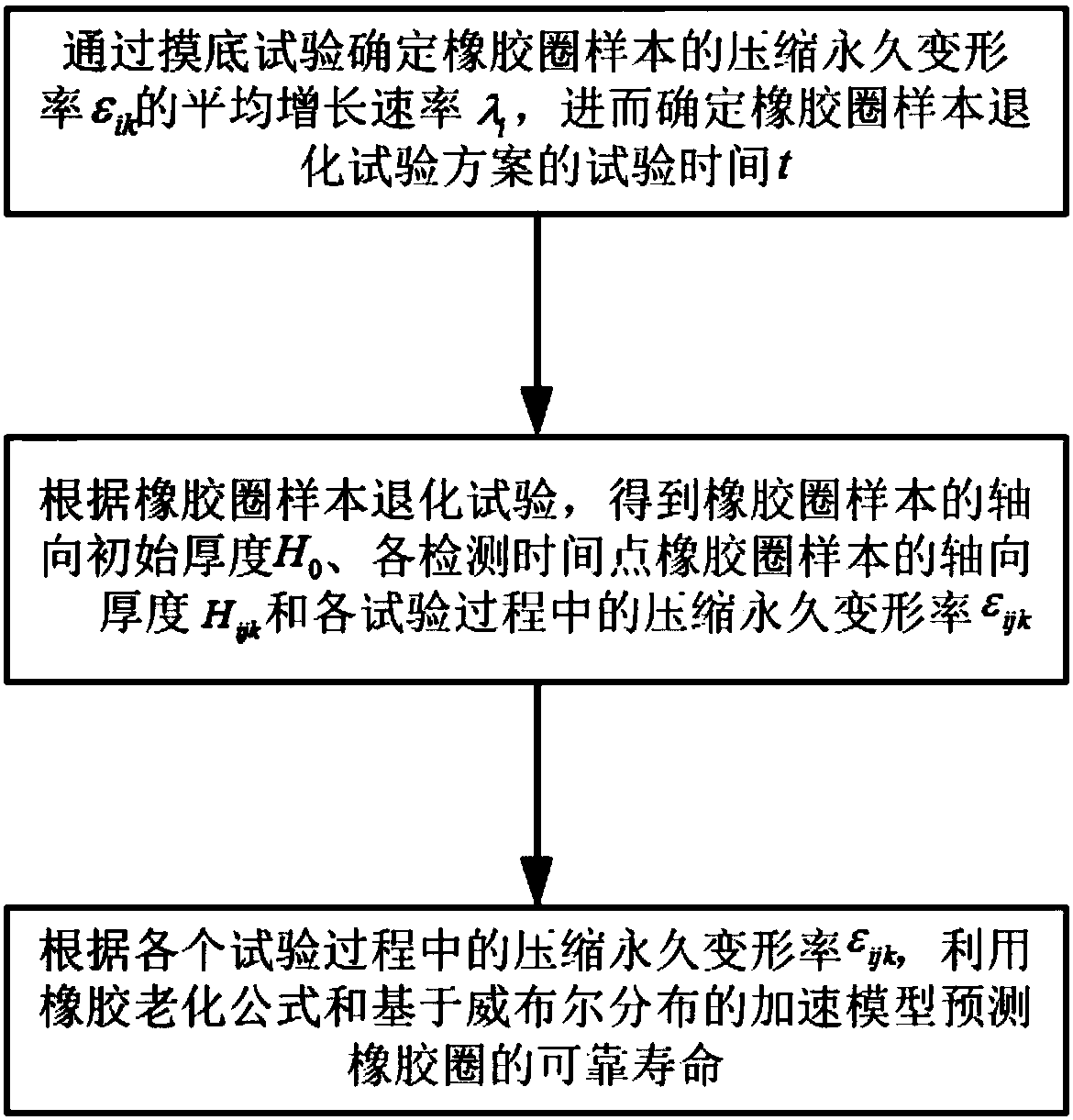

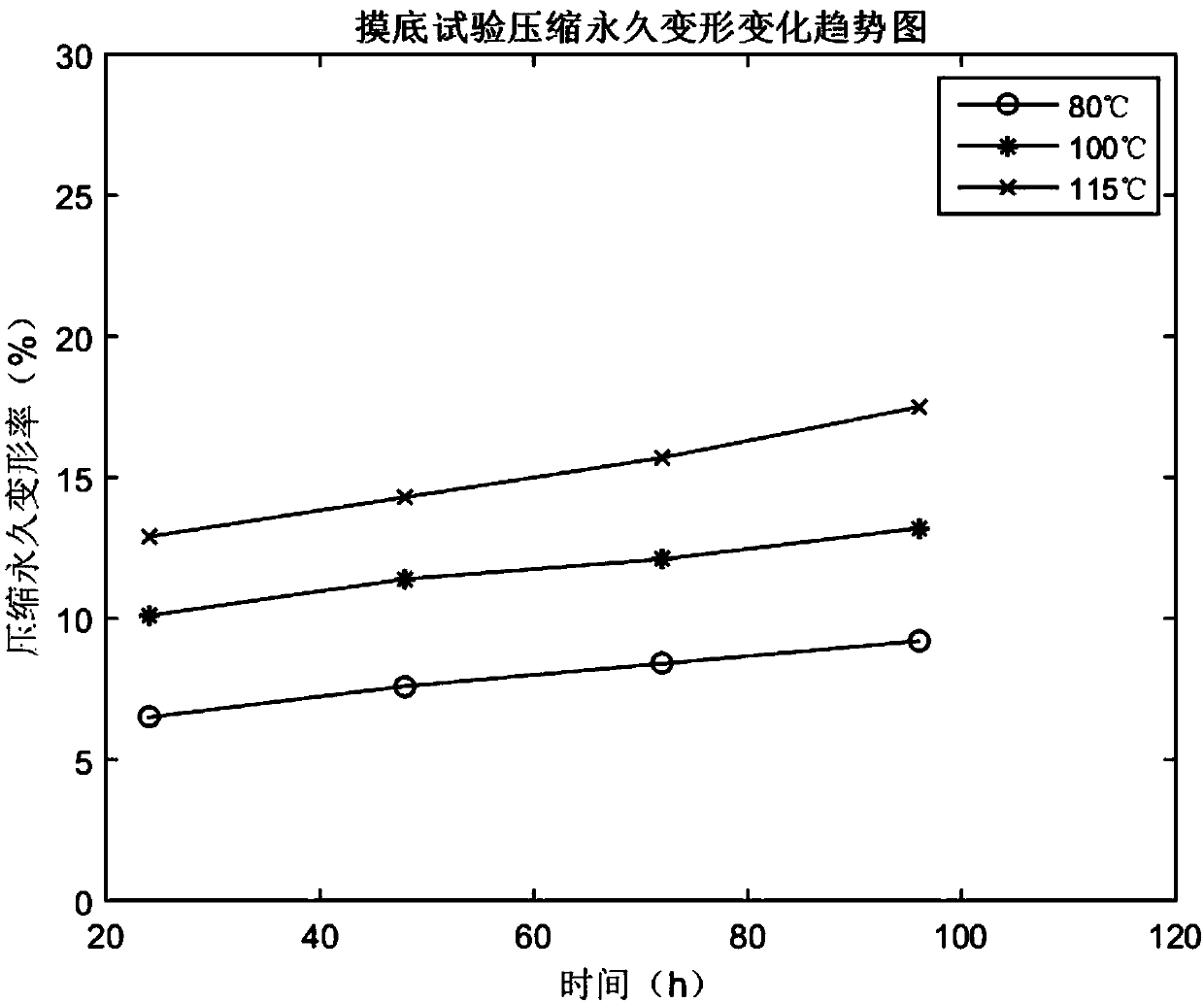

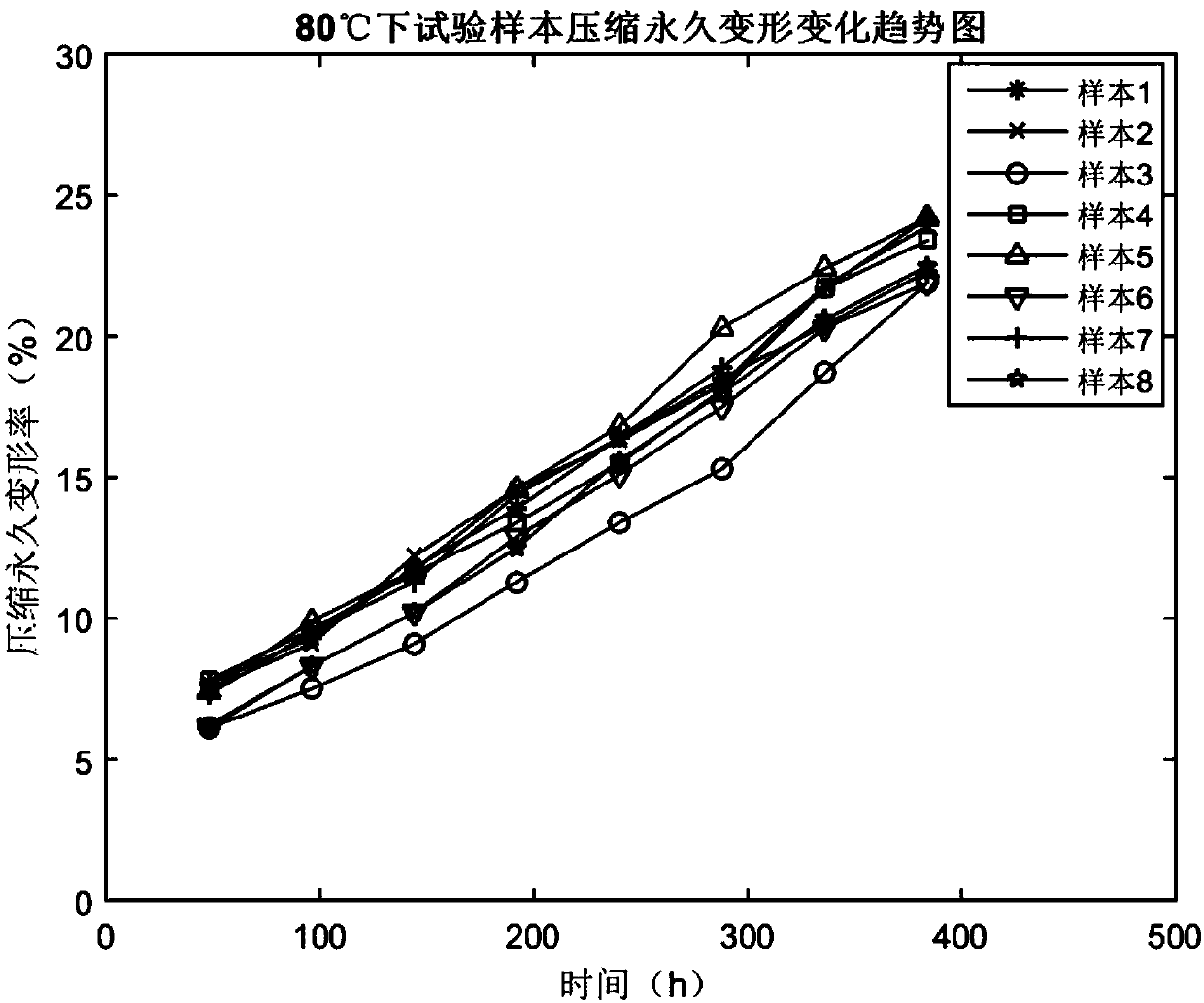

The invention discloses a Weibull-distribution-based method for predicting the reliable service life of a rubber ring. The method includes the following steps: S1, determining an average growth rate lambda i of a permanent compression deformation rate epsilon iK of a rubber ring sample through a diagnostic test and then determining test time t of a rubber ring sample degradation test plan; S2, according to the rubber ring sample degradation test, obtaining an initial axial thickness H0 of the rubber ring sample, an axial thickness HijK of the rubber ring sample at each detection time point, and a permanent compression deformation rate epsilon ijK during each test process; and S3, according to the permanent compression deformation rates epsilon ijK of all test processes, predicting a service life of the rubber ring according to a rubber degradation formula and an acceleration model based on the Weibull distribution and analyzing the reliability of the rubber ring. Compared with the traditional rubber service life prediction method capable of obtaining a single service life prediction value, the method has advantages: a reliable service life value is obtained by using a service lifedistribution function, so that the evaluation result has higher credibility.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

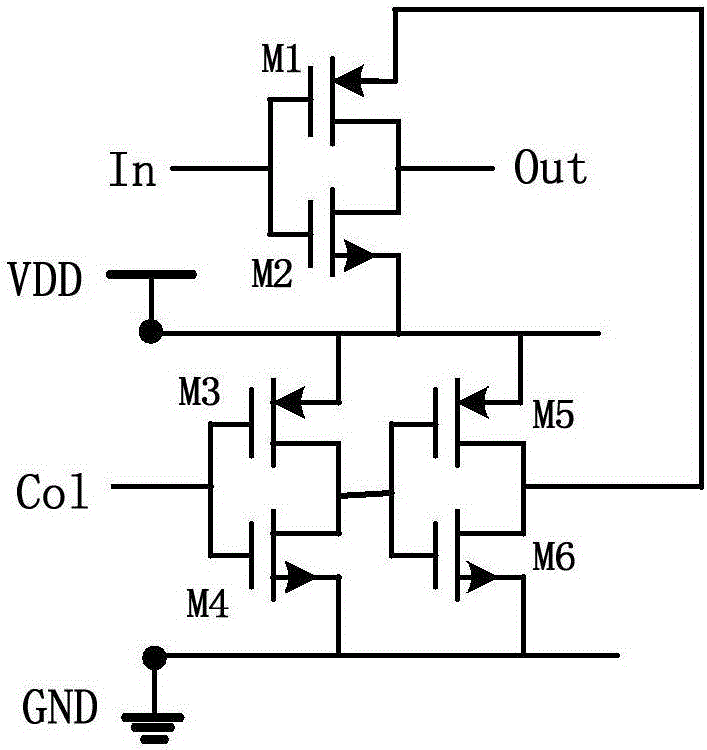

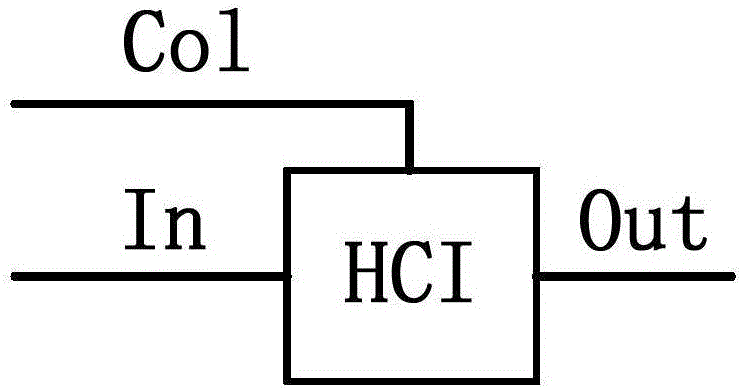

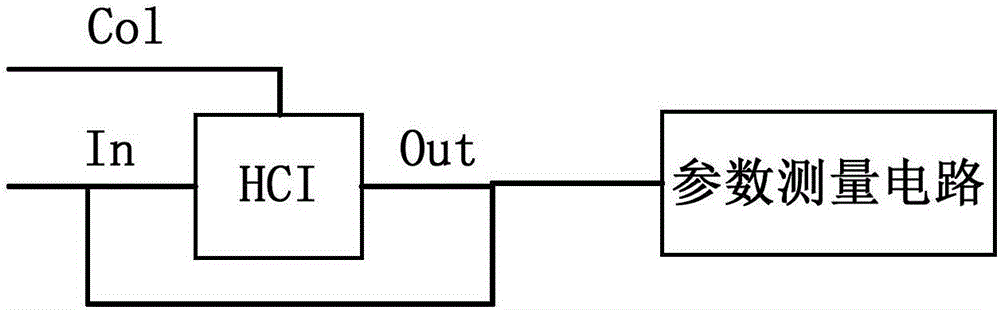

MOS tube parameter degradation circuit, test circuit and early warning circuit

ActiveCN106533406AAccurately respond to the degree of degradationElectronic switchingIndividual semiconductor device testingControl signalEngineering

The invention relates to an MOS tube parameter degradation circuit comprising an NMOS tube and a PMOS tube, wherein the grid of the NMOS tube is connected with the grid of the PMOS tube, and the drain electrode of the NMOS tube is connected with the drain electrode of the PMOS tube; the grid of the PMOS tube is connected with a power supply; the source electrode of the NMOS tube receives a control signal; when the control signal is a high-level signal, a channel of the NMOS tube generates hot carriers; and the grid of the NMOS tube and the grid of the PMOS tube receive input signals, and the drain electrode of the NMOS tube and the drain electrode of the PMOS tube output inverted output signals of the input signals. The MOS tube parameter degradation circuit can improve the accuracy of the output signals. The invention further relates to an MOS tube parameter degradation test circuit capable of improving the accuracy of a test result, another MOS tube parameter degradation test circuit capable of improving the accuracy of the test result, an MOS tube parameter degradation early warning circuit capable of performing accurate early warning and another MOS tube parameter degradation early warning circuit capable of performing accurate early warning.

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

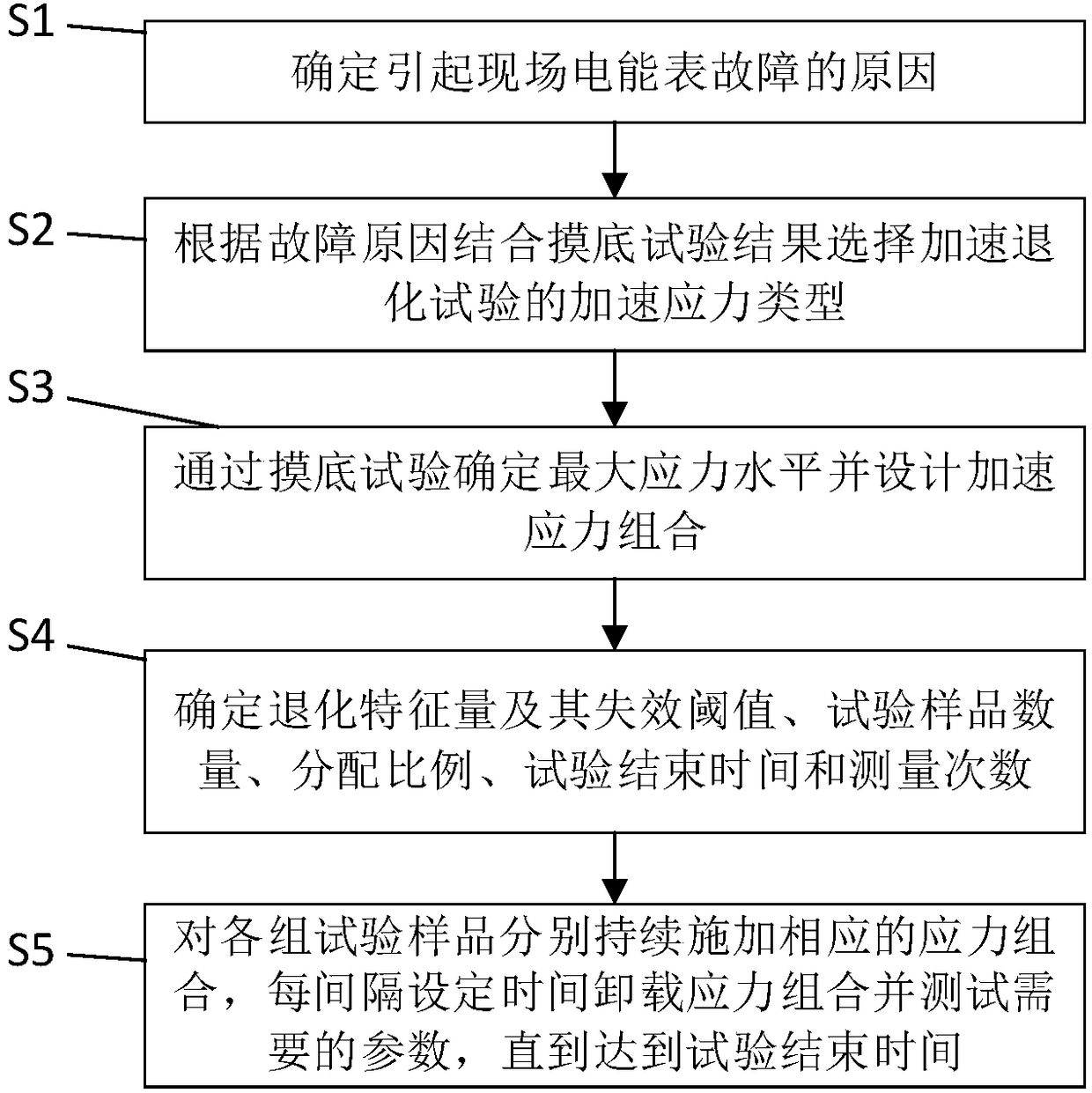

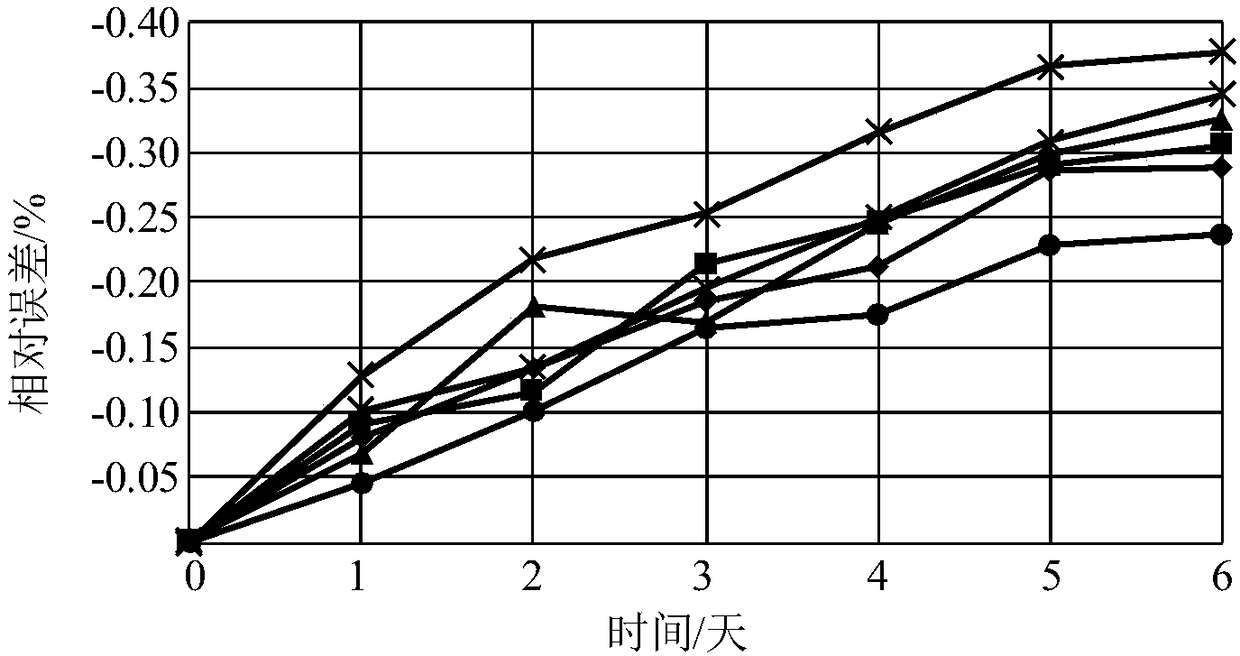

Testing method of accelerated degradation of intelligent electric energy meter

The invention relates to a testing method of accelerated degradation of an intelligent electric energy meter. The method comprises the following steps: S1, determining a fault reason of a field electric energy meter; S2, selecting an accelerated stress type of an accelerated degradation test according to the fault reason determined in the step S1 and a diagnostic test result; S3, determining a maximum stress level through a diagnostic test and designing an accelerated stress combination; S4, determining degradation characteristic quantity, a failure threshold thereof, test sample quantity, distribution ratio, test end time and number of measurements according to requirements; S5, separately continuously applying corresponding stress combinations to all test samples, unloading stress combinations at set intervals, and testing required parameters till the test end time is achieved. Compared with the prior art, the testing method has high feasibility and operability, and is applicable toreliability assessment and analysis on intelligent electric energy meters by electric energy meter manufacturers and electric energy meter quality management departments.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

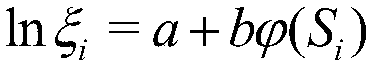

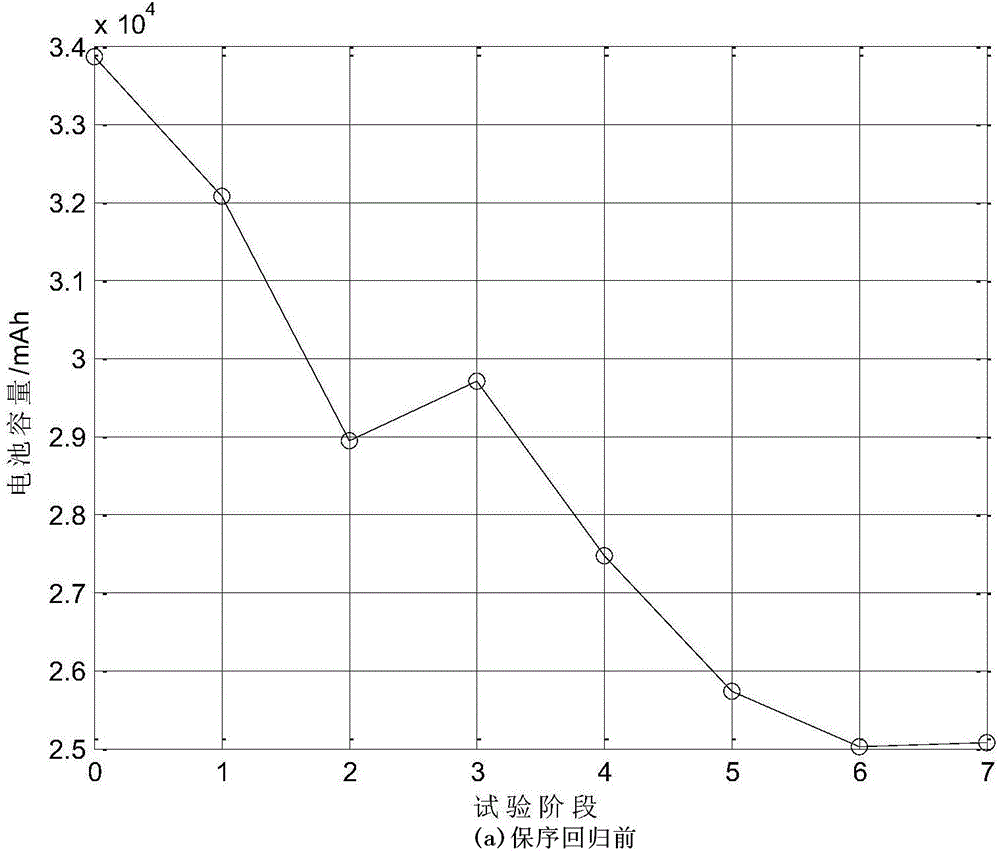

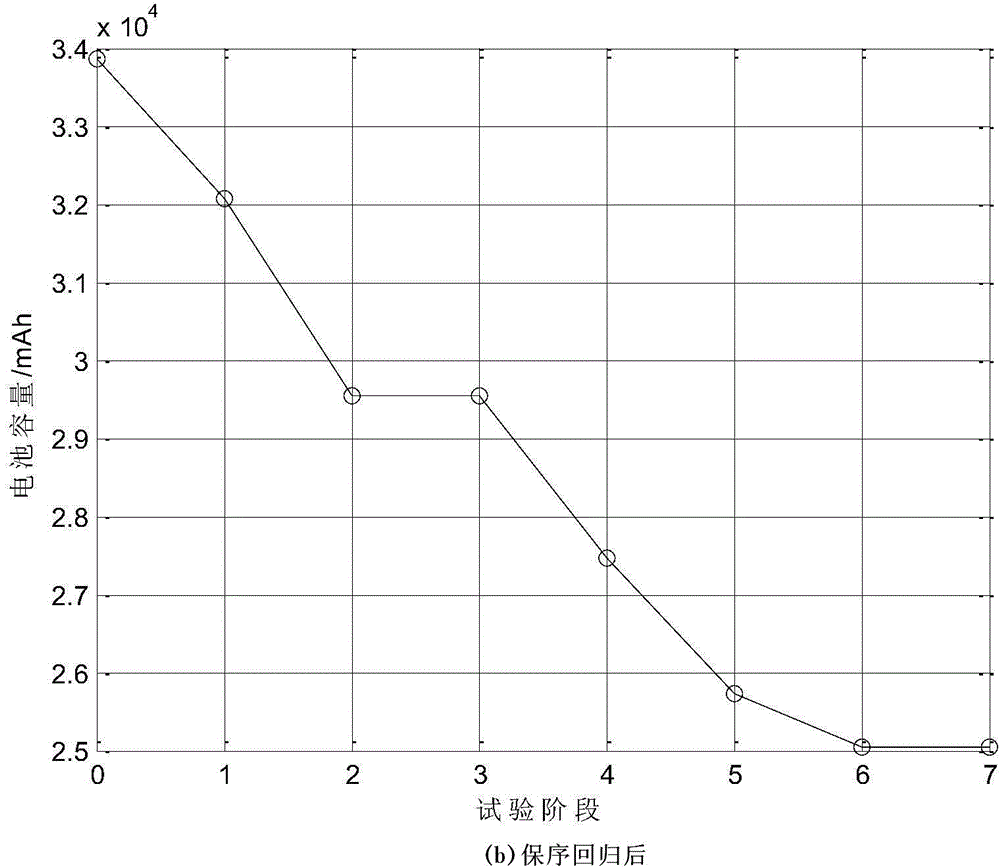

'Upside down' data evaluation method of capacity accelerated degradation test of primary lithium battery

ActiveCN104678312AAvoid Physical Nonlinearity ProblemsGuaranteed correctnessElectrical testingMeasurement pointRoom temperature

An 'upside down' data evaluation method of a capacity accelerated degradation test of a primary lithium battery comprises the following steps: 1, preprocessing data of a battery capacity test, 2, carrying out isotonic regression processing on battery capacity data, 3, correcting a standard deviation of battery capacity at each measurement point by keeping a variation coefficient constant, 4, modeling degradation with a percentile value and estimating an acceleration life under each acceleration stress, and 5, extrapolating a storage life at room temperature with an acceleration model. The purposes of life and reliability evaluation by using 'upside down' data existing in the capacity accelerated degradation test of the primary lithium battery are achieved through the above five steps. The method ensures parameter estimation correctness of a degradation model, and reduces evaluation risks caused by the excessive local standard deviations.

Owner:BEIHANG UNIV

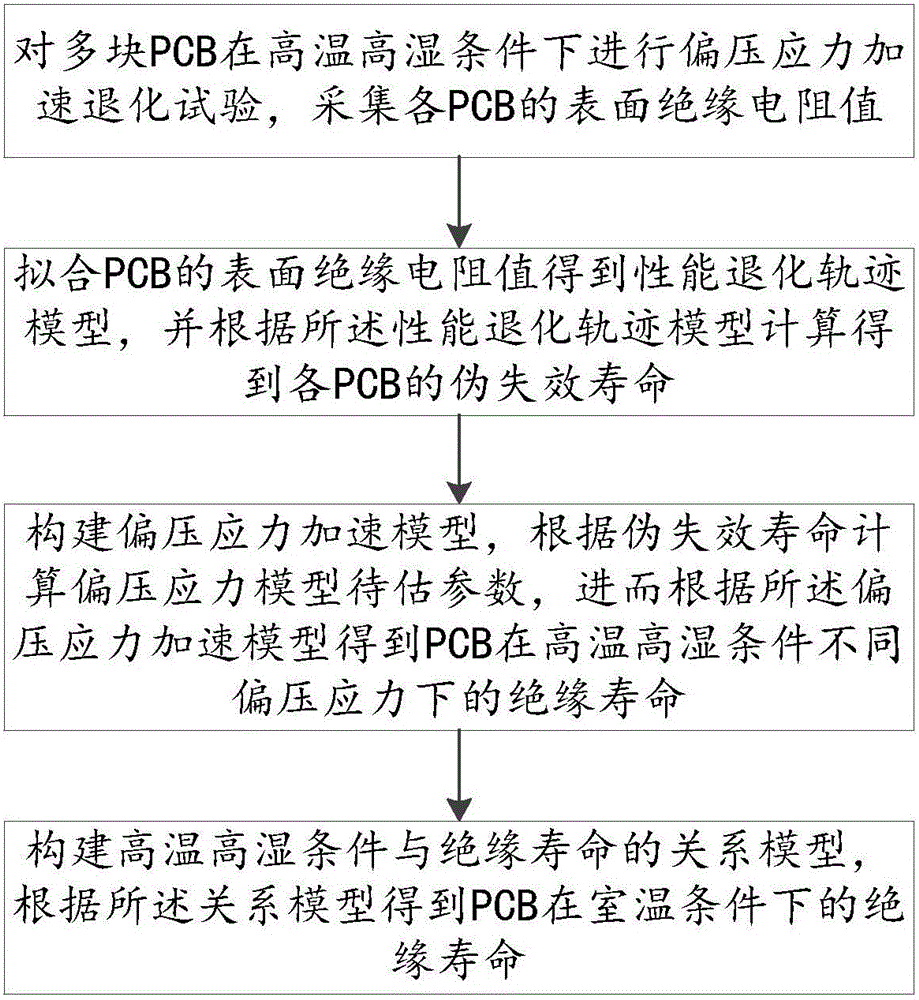

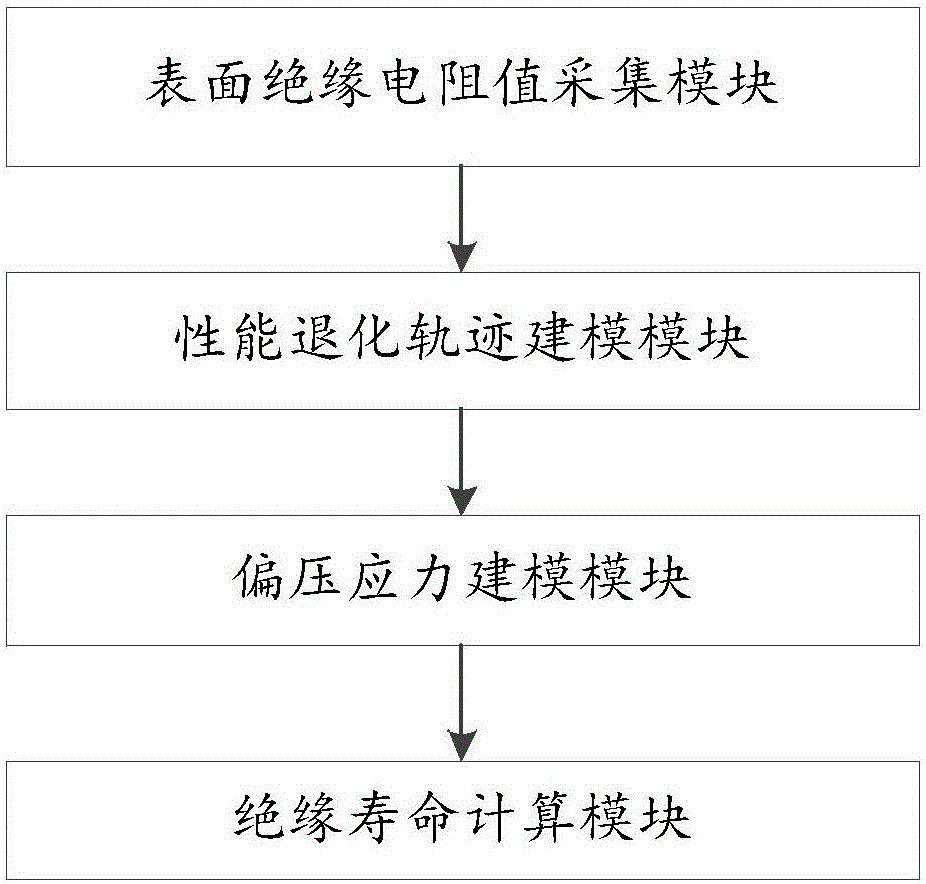

Accelerated degradation test based method and system for rapid prediction of PCB insulation life

InactiveCN105954667ASolve the technical problem of rapid prediction of PCB insulation lifeQuickly get the characteristics of the degraded trajectoryPrinted circuit testingRelational modelPredictive methods

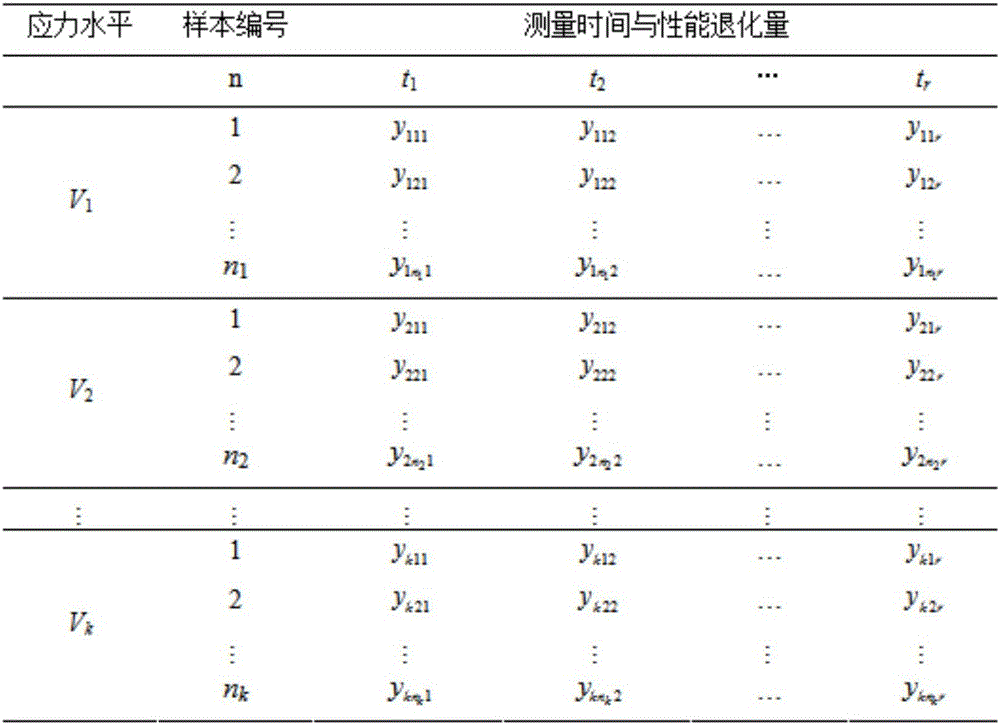

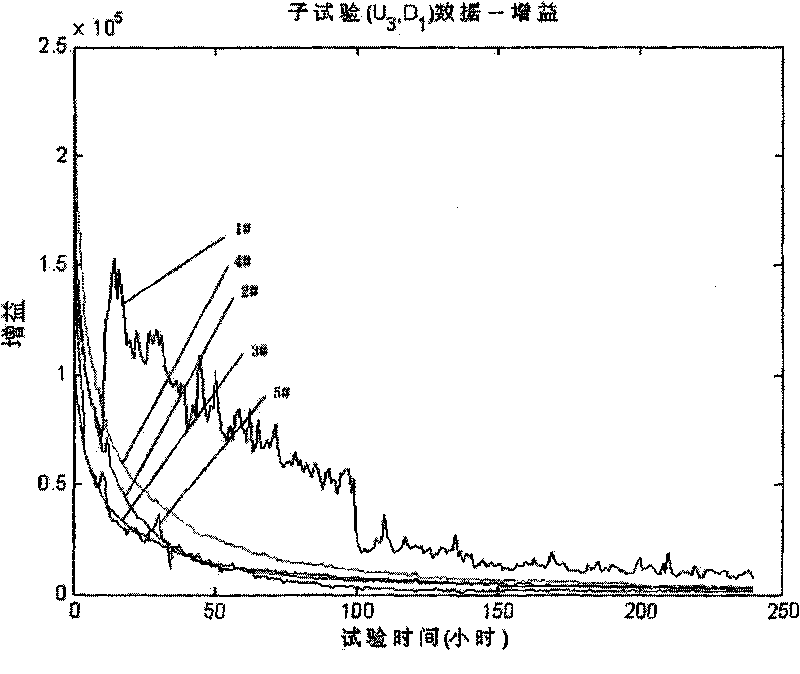

The present invention relates to a method and system for rapid prediction of PCB insulation life based on accelerated degradation tests. The prediction method includes the following steps: step S1, conducting bias stress accelerated degradation tests on multiple PCBs under high temperature and high humidity conditions, collecting various The surface insulation resistance value of the PCB; step S2, fitting the surface insulation resistance value of the PCB to obtain a performance degradation trajectory model, and calculating the pseudo-failure life of each PCB according to the performance degradation trajectory model; step S3, constructing a bias stress acceleration model , calculate the estimated parameters of the bias stress acceleration model according to the pseudo-failure life, and then obtain the insulation life of the PCB under different bias stresses under high temperature and high humidity conditions according to the bias stress acceleration model; step S4, construct the high temperature and high humidity conditions and insulation life A relational model of life, according to the relational model, the insulation life of the PCB at room temperature is obtained. The invention solves the problem of quickly predicting the life of PCB insulation within a limited time by building an acceleration model, and is especially suitable for the technical field of PCB reliability.

Owner:YANTAI UNIV

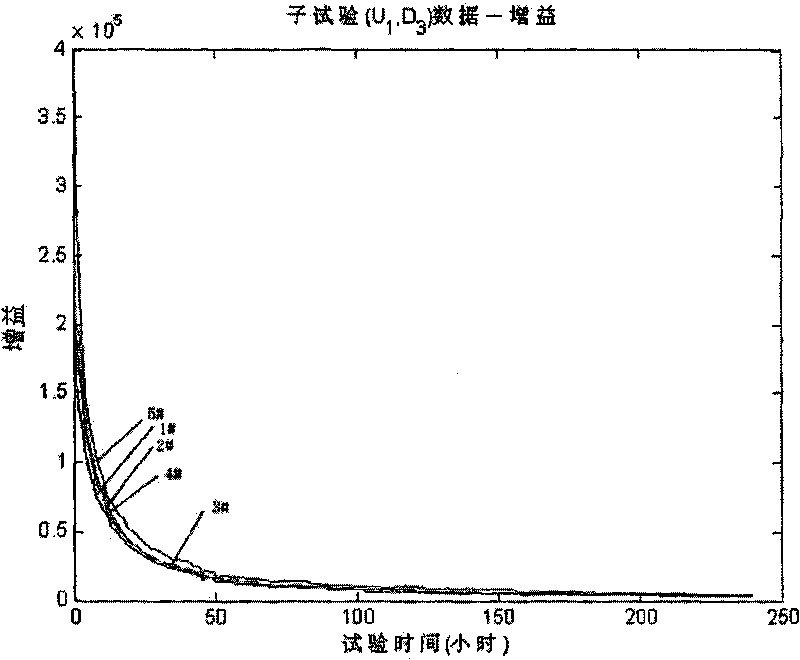

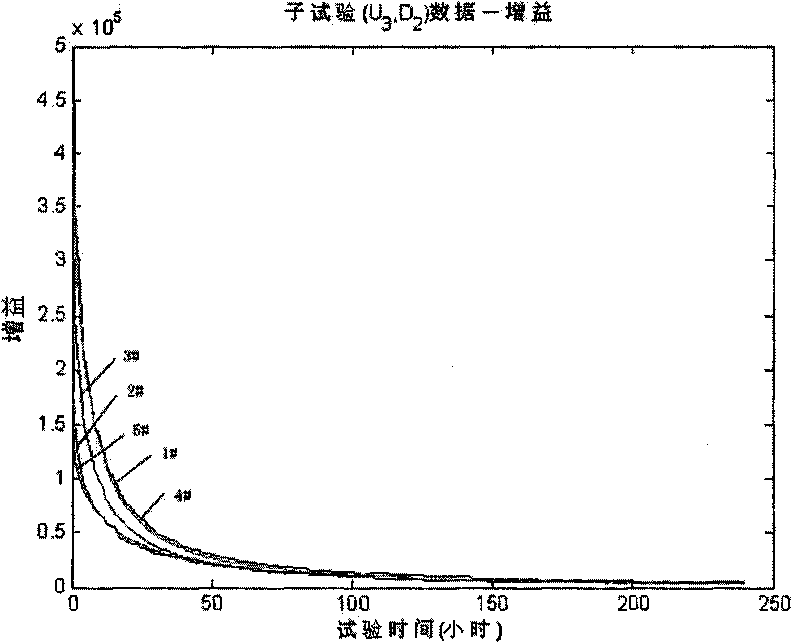

Accelerated degradation test method of multistage separation type dynode electron multiplier

ActiveCN101750622APerformance Degradation Lifetime PredictionRadiation intensity measurementElectron multiplierContinuous monitoring

The invention discloses an accelerated degradation test method of a multistage separation type dynode electron multiplier, which comprises the following steps: 1) placing at least five electron multiplier samples in a sealed container with binding posts, connecting electrodes of the electron multipliers with the corresponding binding posts, pumping the sealed container and maintaining vacuum; 2) respectively imposing at least three groups of incident particle flow strengths and working voltage values with different levels but higher than the normal using level on all the electron multiplier samples; 3) utilizing a milli-ampere current meter for carrying out continuous monitoring on the output current of all the electron multipliers; dividing the output current by the incident particle flow strength, converting into gain data and recording; and 4) utilizing a computer for processing the recorded gain data of the electron multipliers, and obtaining the predicted result of the service life.

Owner:NAT UNIV OF DEFENSE TECH

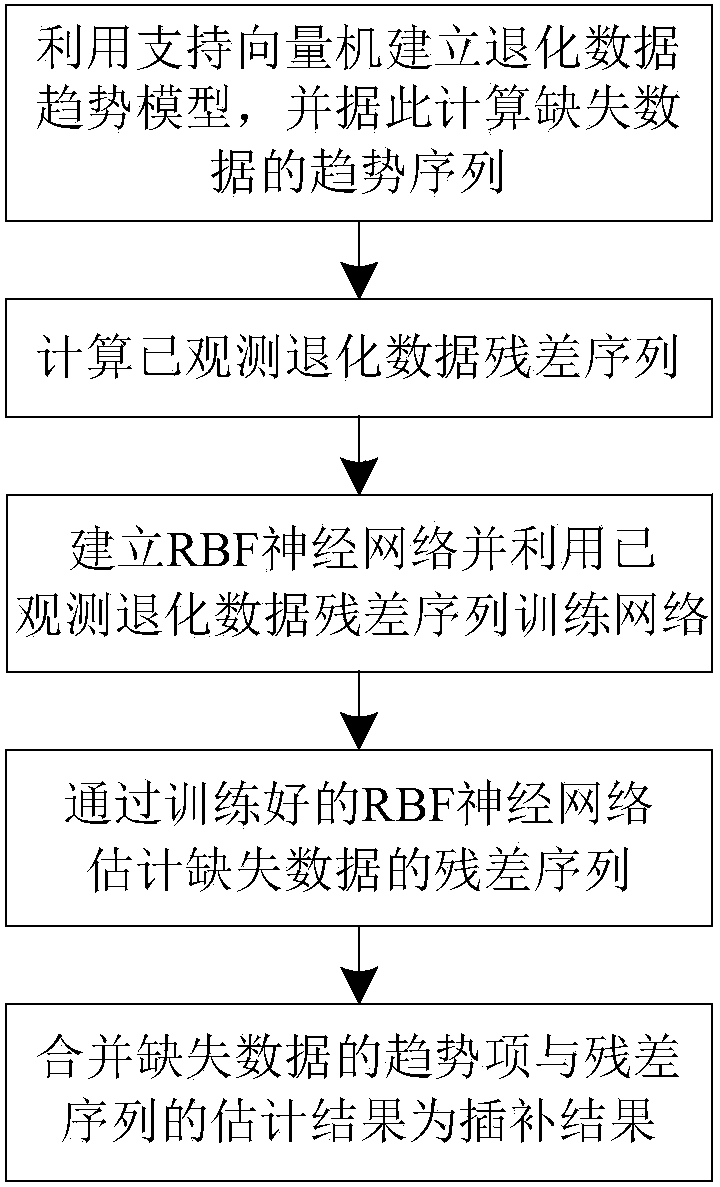

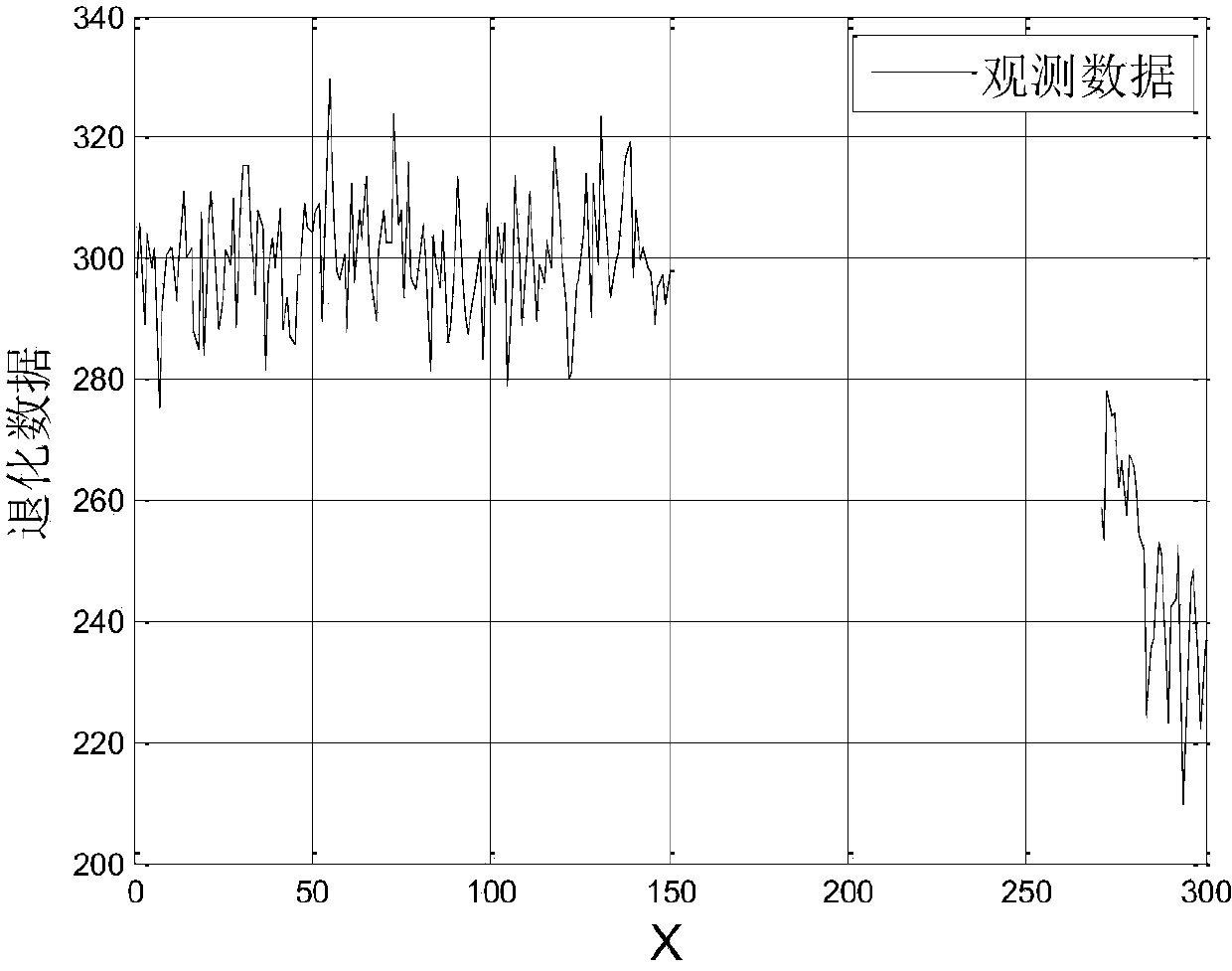

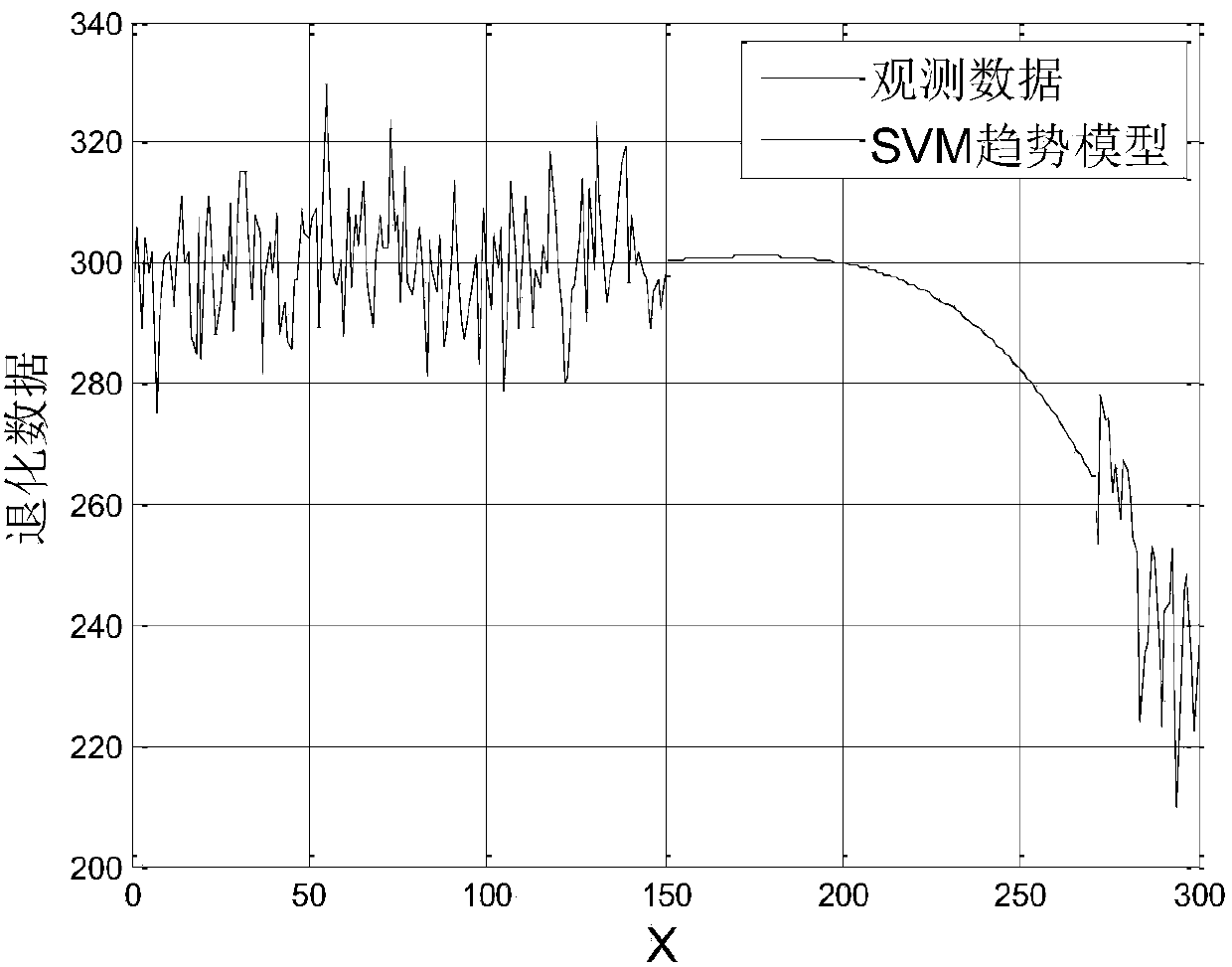

Degradation data missing interpolation method based on support vector machine and RBF neural network

ActiveCN103810392AEasy to useBiological neural network modelsSpecial data processing applicationsMissing dataDegradation test

The invention discloses a degradation data missing interpolation method based on a support vector machine and an RBF neural network. The method includes the following steps that firstly, a degeneration data trend model is established by means of the support vector machine; secondly, residual error sequences of observed degradation data are calculated; thirdly, the RBF neural network is set up, and the network is trained by means of the residual error sequences of the observed degradation data; fourthly, residual error sequences of missing data are estimated through the trained RBF neural network; fifthly, trend terms of the missing data and estimation results of the residual error sequences are merged, so that a degradation data interpolation result is obtained. A support vector machine method and an RBF neural network method are combined to obtain the degradation data missing interpolation method, and the problem of interpolation of performance missing degradation data in an accelerated degradation test is solved.

Owner:BEIHANG UNIV

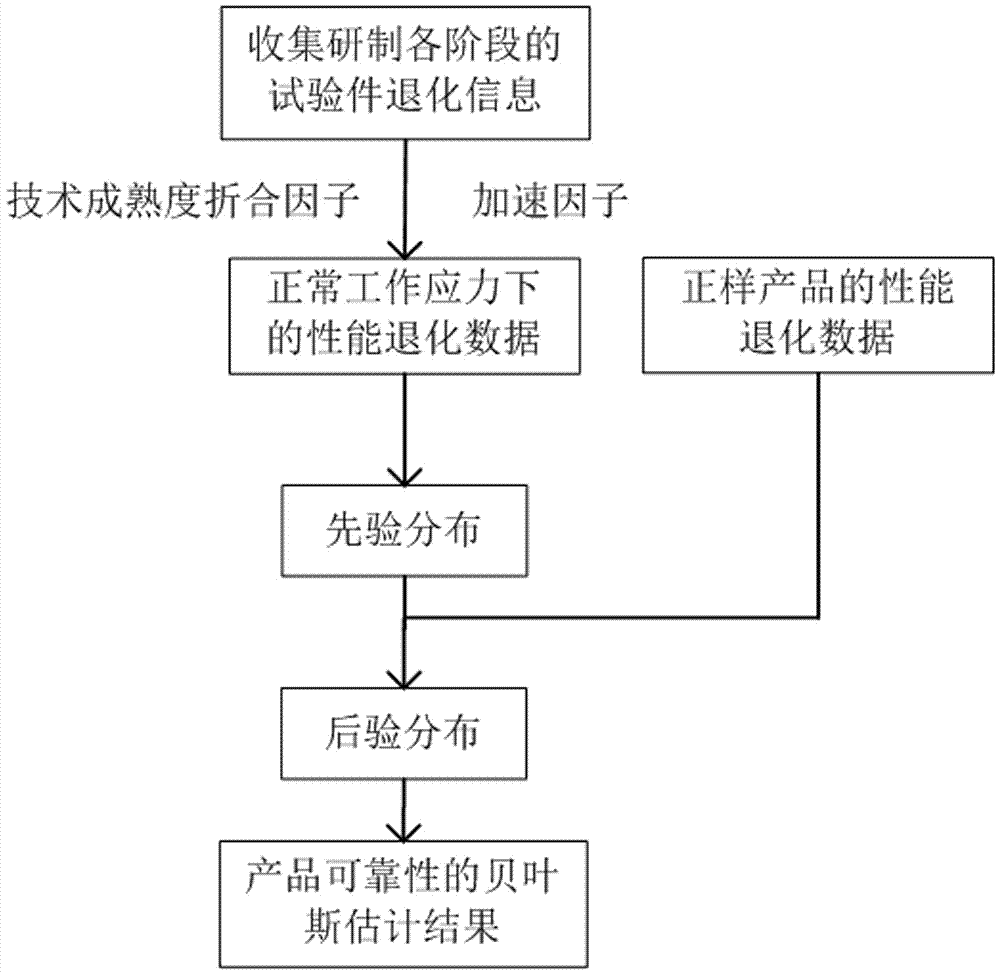

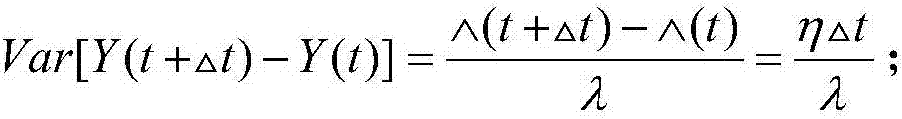

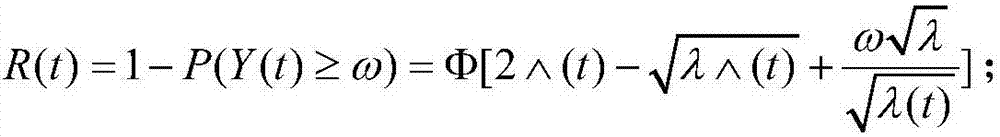

Bayesian reliability evaluation method of performance degradation test based on inverse Gaussian process

ActiveCN107220500AThe reliability assessment results are accurateComprehensive reliability assessment resultsSpecial data processing applicationsInformaticsInverse gaussian processGaussian process

The invention relates to a Bayesian reliability evaluation method of a performance degradation test based on the inverse Gaussian process. The method comprises the steps that S1, a degradation statistical model of the inverse Gaussian process is established, and a reliability function and the mean failure time are determined; S2, performance degradation data of a test piece at each stage of the development of a product is collected; S3, the performance degradation data of the test piece is converted to the performance degradation data of a normal product under a normal working stress and used as the prior information of Bayesian reliability estimation; S4, the performance degradation data of the normal product is used as the posterior information and combined with the prior information, parameters for calculating a reliability function are obtained; S5, the reliability function and the mean failure time are calculated, and Bayesian estimation results of product reliability are obtained. The inverse Gaussian model is adopted to depict the degradation process of the product performance, and data can be better fitted; the performance degradation data of the test piece at each stage of the development is incorporated into the scope of the prior information of Bayesian estimation, and the product Bayesian reliability evaluation results are more accurate and more comprehensive.

Owner:SHANGHAI RADIO EQUIP RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com