Method for determining consistency boundary of accelerated degradation mechanism based on single parameter

A technology to accelerate degradation and determine the method, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of wasting test time and cost, not knowing the failure mechanism, and not being able to obtain the real life information of electronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

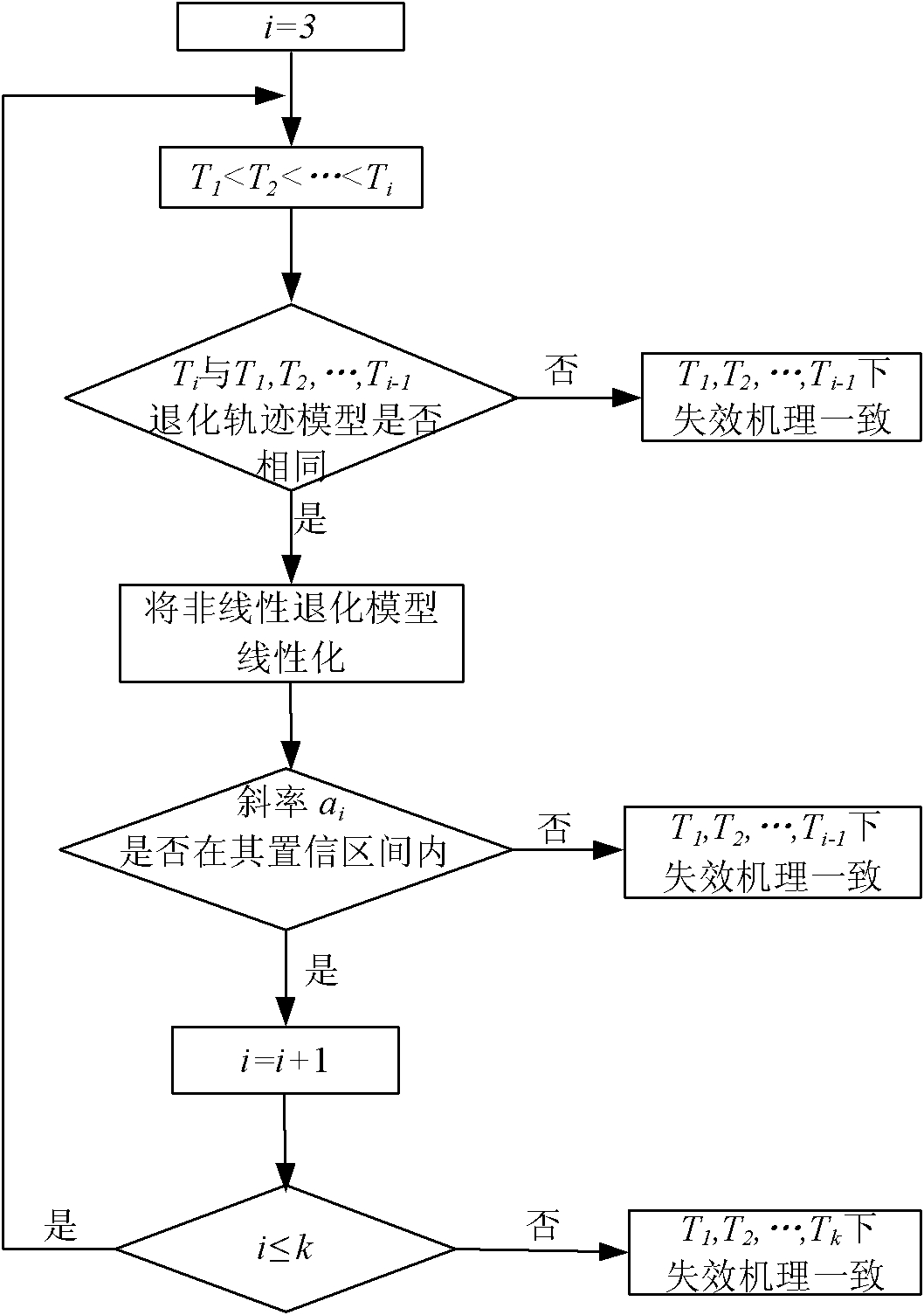

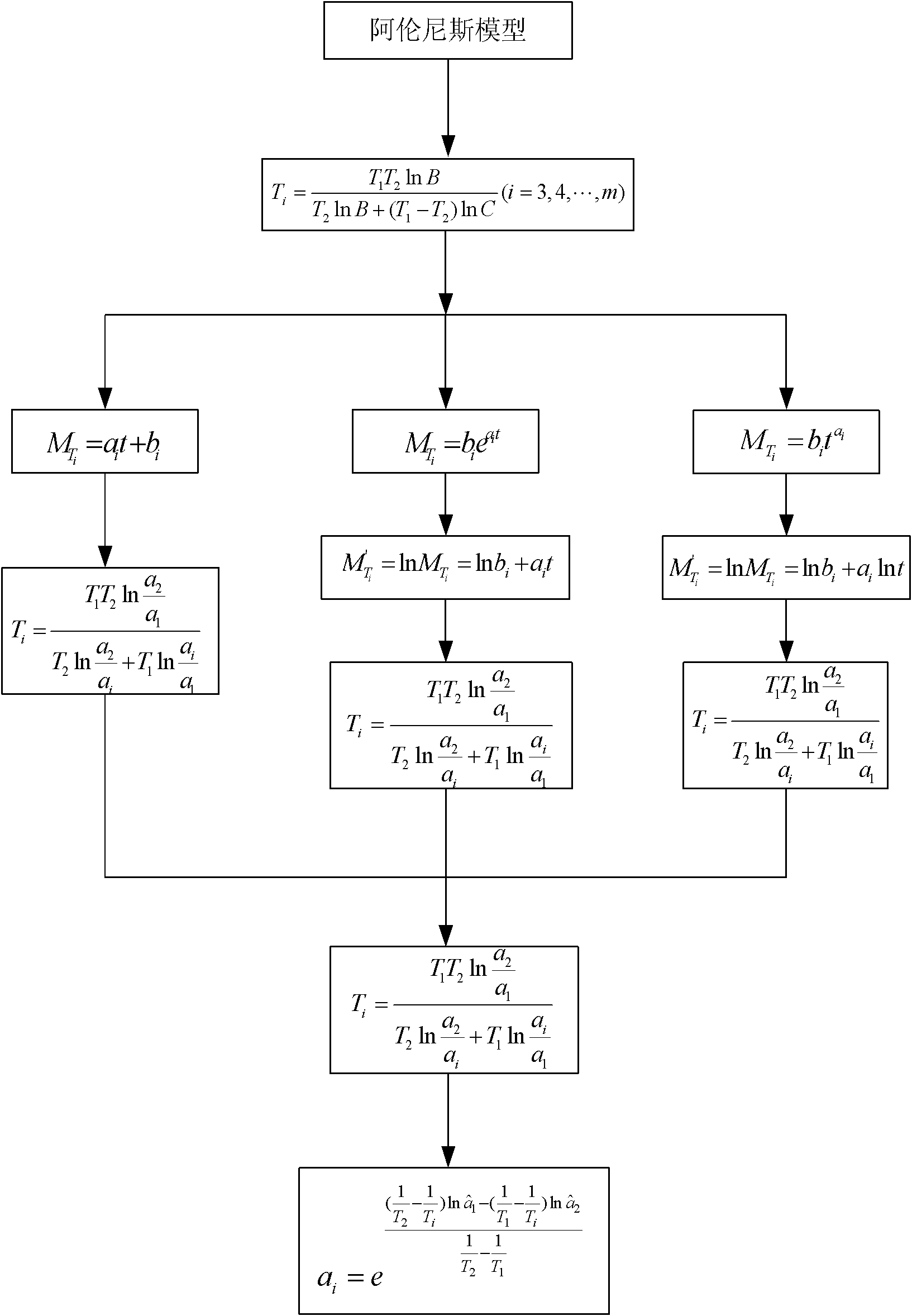

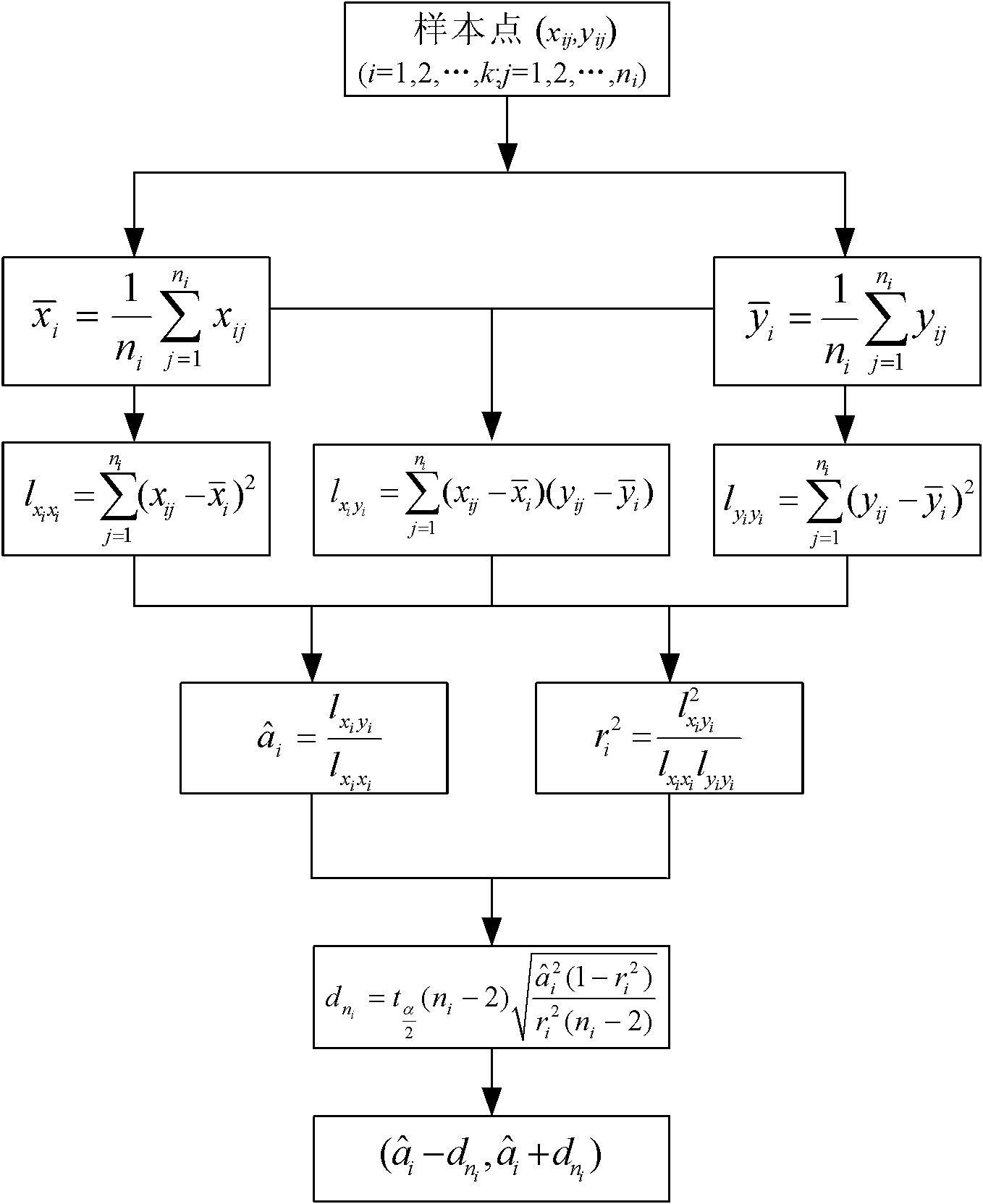

Method used

Image

Examples

Embodiment 1

[0160] Taking the single-parameter scale factor stability accelerated degradation simulation test of a certain type of accelerometer as an example, the method for determining the consistency boundary based on the single-parameter accelerated degradation mechanism is introduced in detail. The specific steps of the method are as follows:

[0161] Step 1. Determine the stress level number k of the accelerated degradation simulation test;

[0162] Take the simulation test stress level number k=6 of this type of accelerometer, and its simulation stress levels are 298K, 333K, 343K, 353K, 363K and 373K respectively;

[0163] Step 2. Collect stress T 1 ,T 2 ,...,T i Simulation test data and data preprocessing of electronic devices;

[0164] The initial i=3, through the Ansys10.0 finite element simulation, the scale factors of this type of accelerometer at 298K, 333K, 343K, 353K, 363K and 373K are obtained respectively with discrete time points (i=1, 2,..., k, j=1, 2,..., n i ) s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com