Patents

Literature

346results about "Machine sealing rings testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

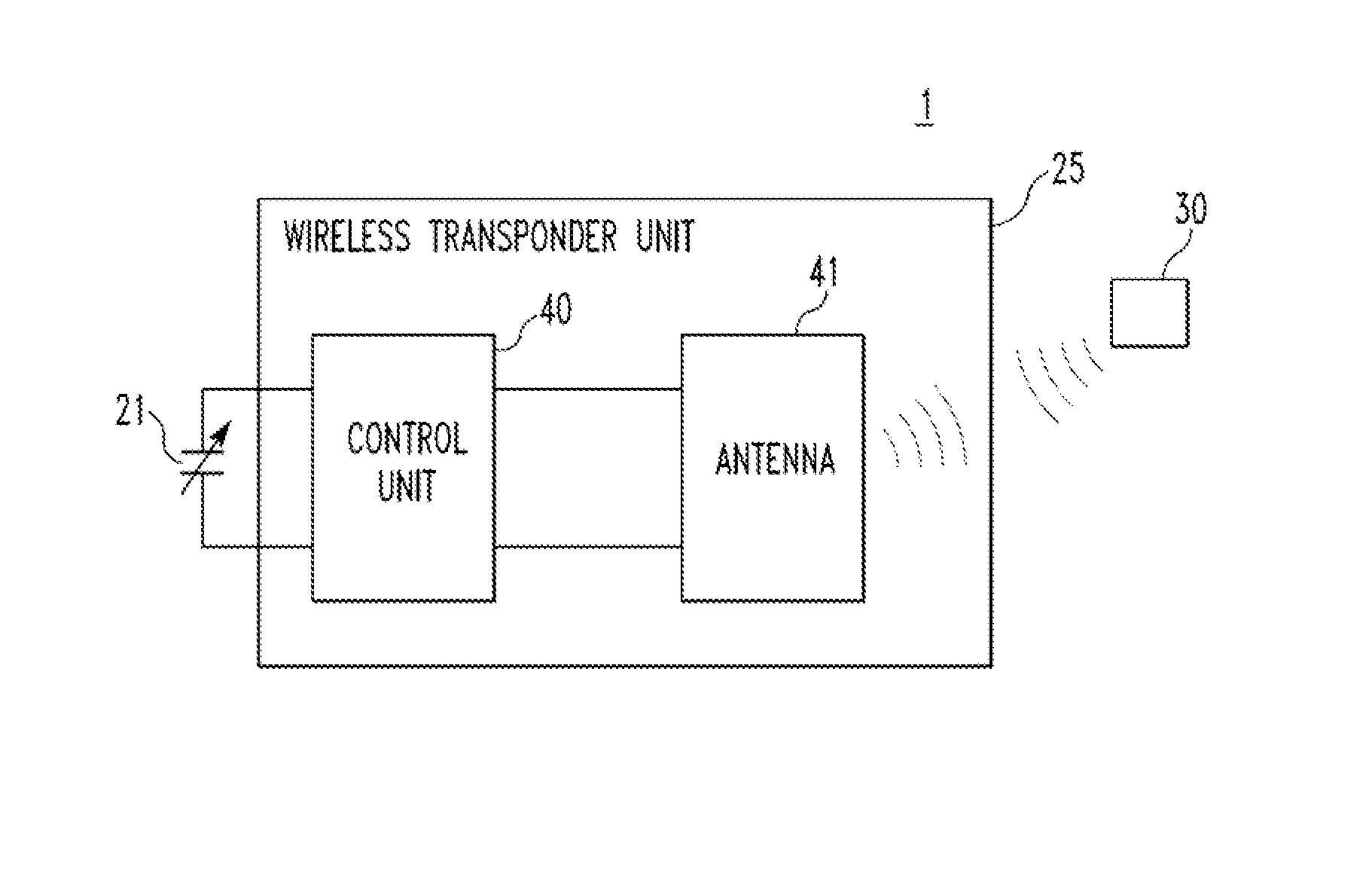

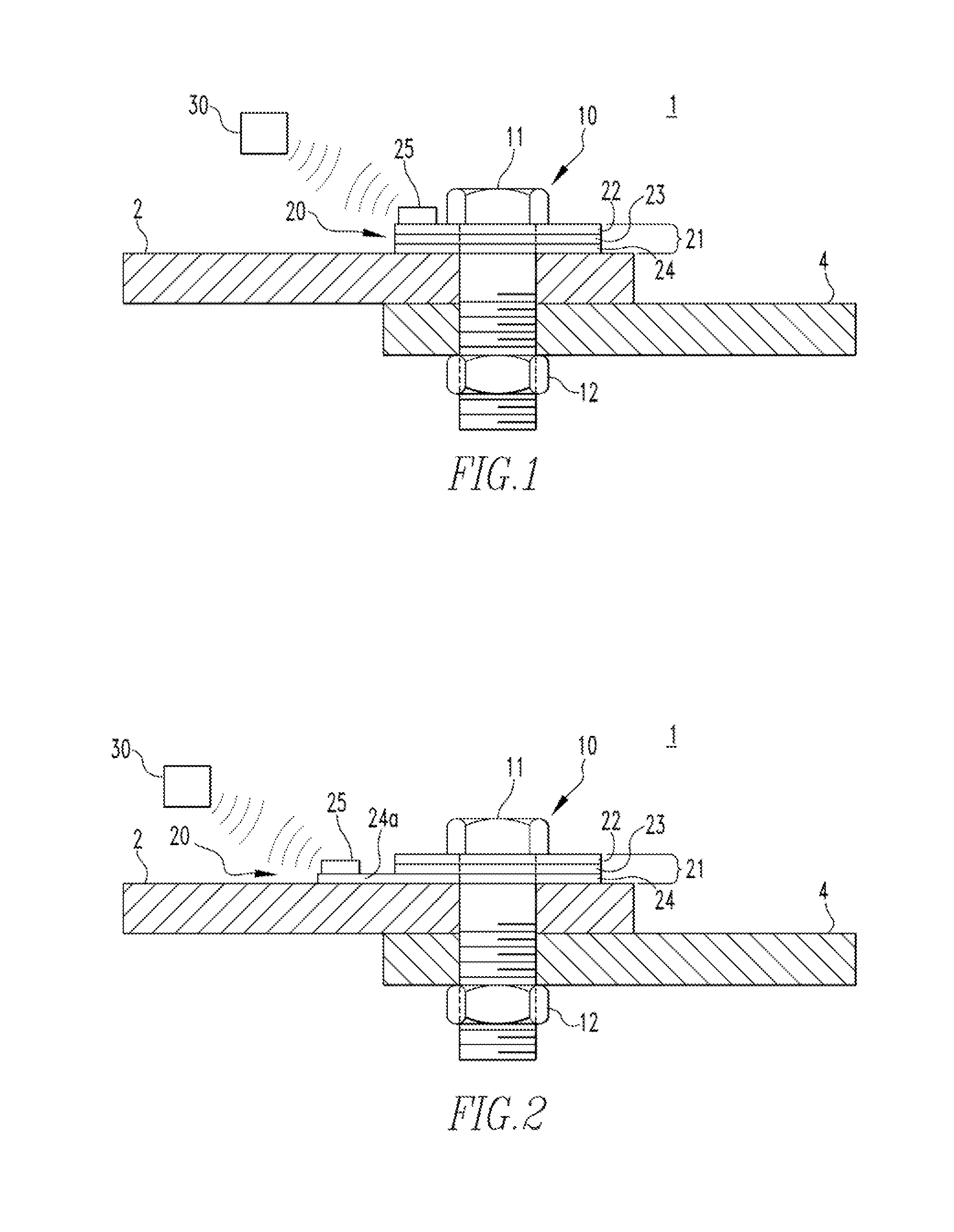

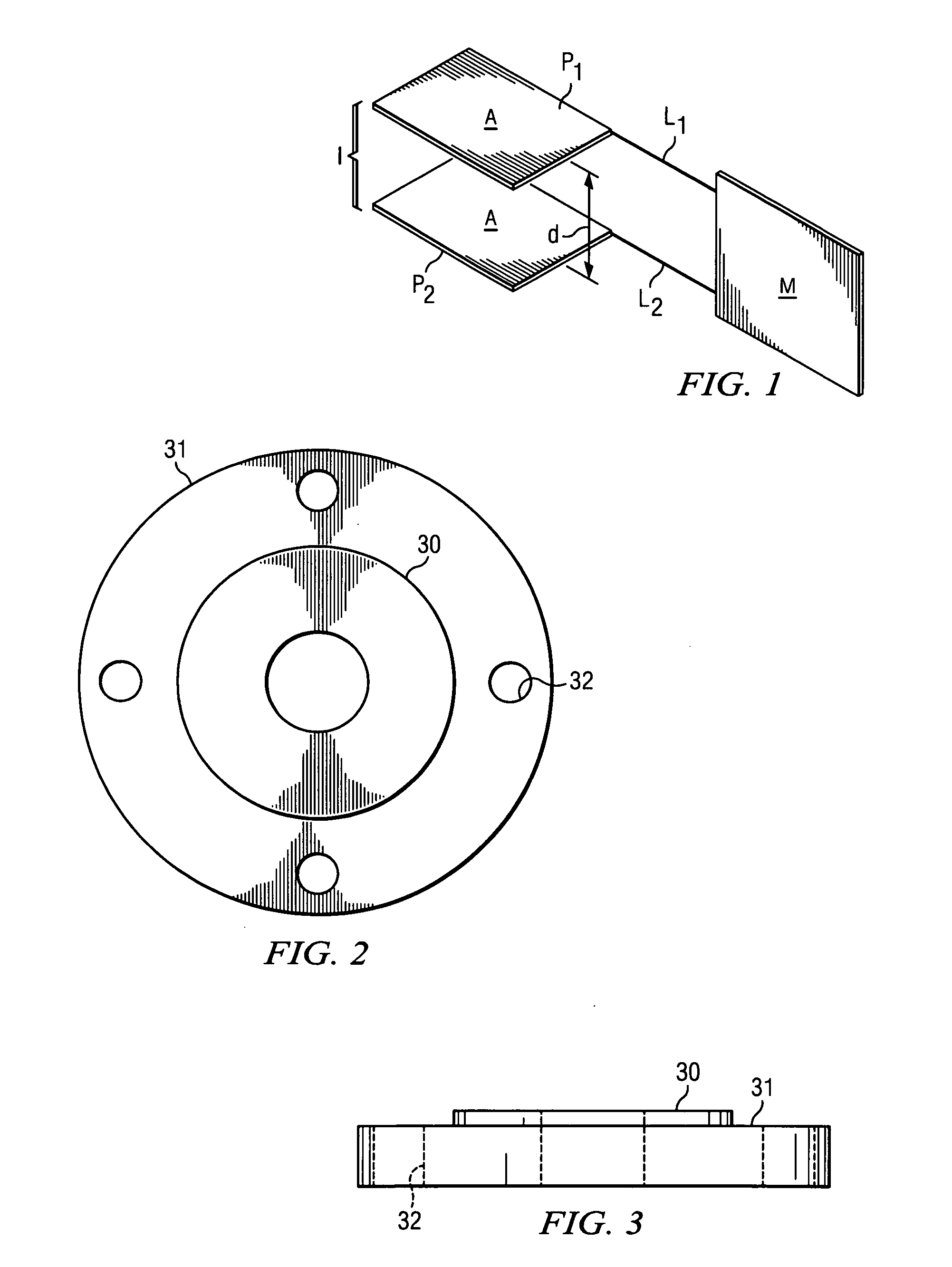

Washer assembly and joint monitoring system employing the same

A washer assembly is for use with a fastener. The washer assembly includes a first conductive portion, a second conductive portion, and an insulating portion disposed between the first conductive portion and the second conductive portion. The first conductive portion, the second conductive portion, and the insulating portion form a variable capacitor having a capacitance based on an amount of force applied thereto by the fastener. A wireless transponder unit includes a control unit electrically connected to the variable capacitor and an antenna electrically connected to the control unit. The control unit is configured to sense the capacitance of the variable capacitor, to generate information representing the capacitance, and to output the information to a wireless reader unit via the antenna.

Owner:EATON INTELLIGENT POWER LTD

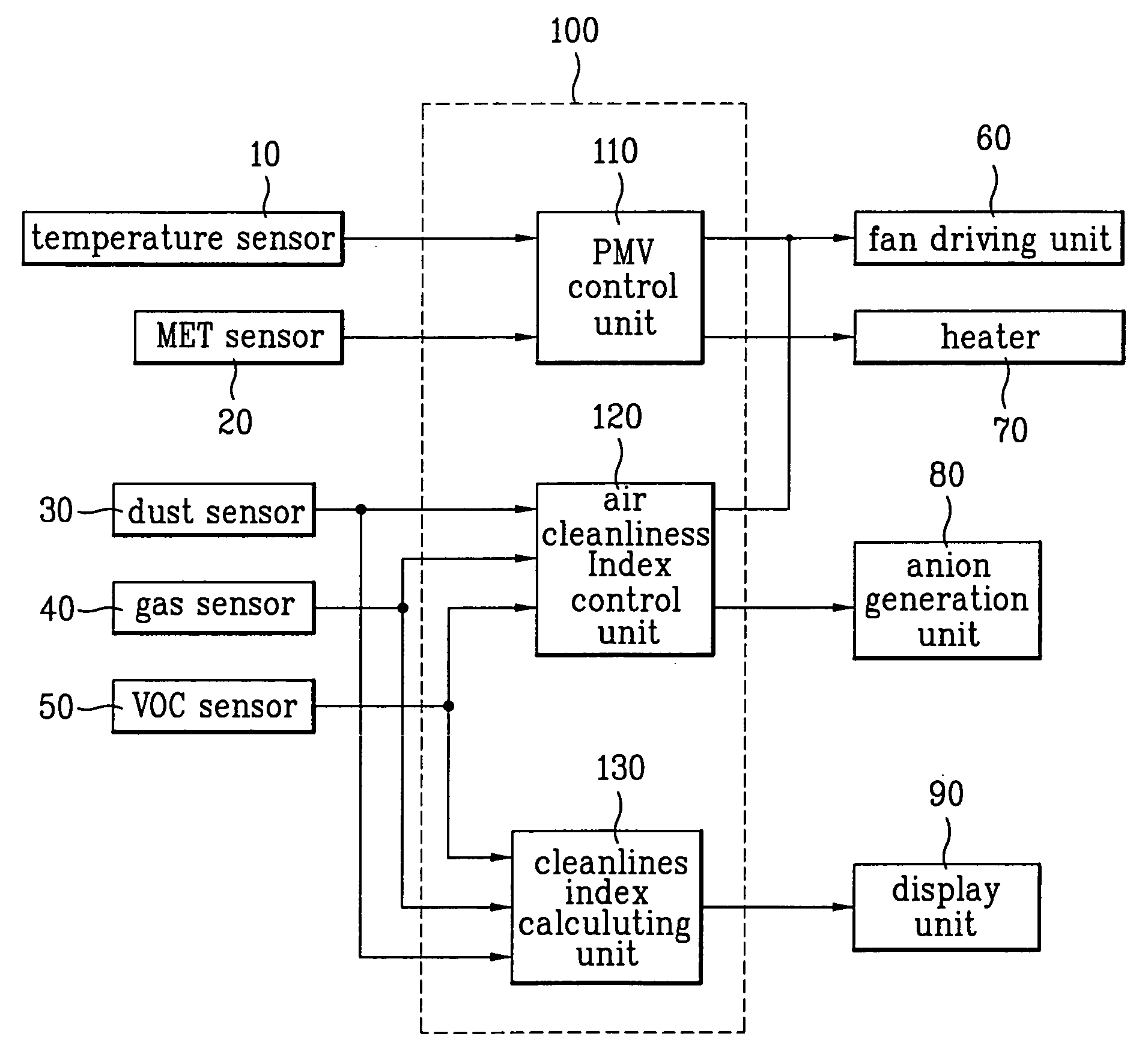

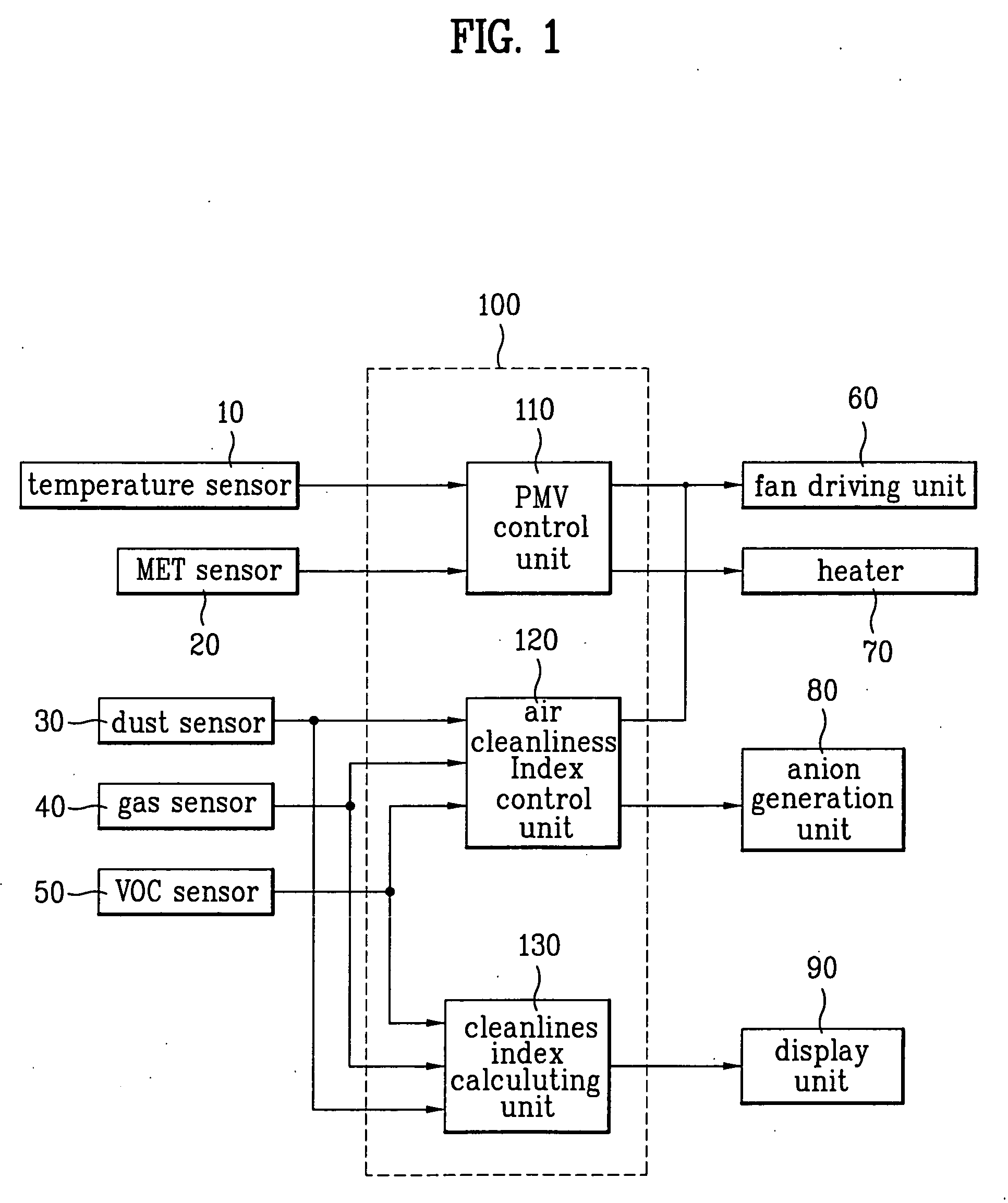

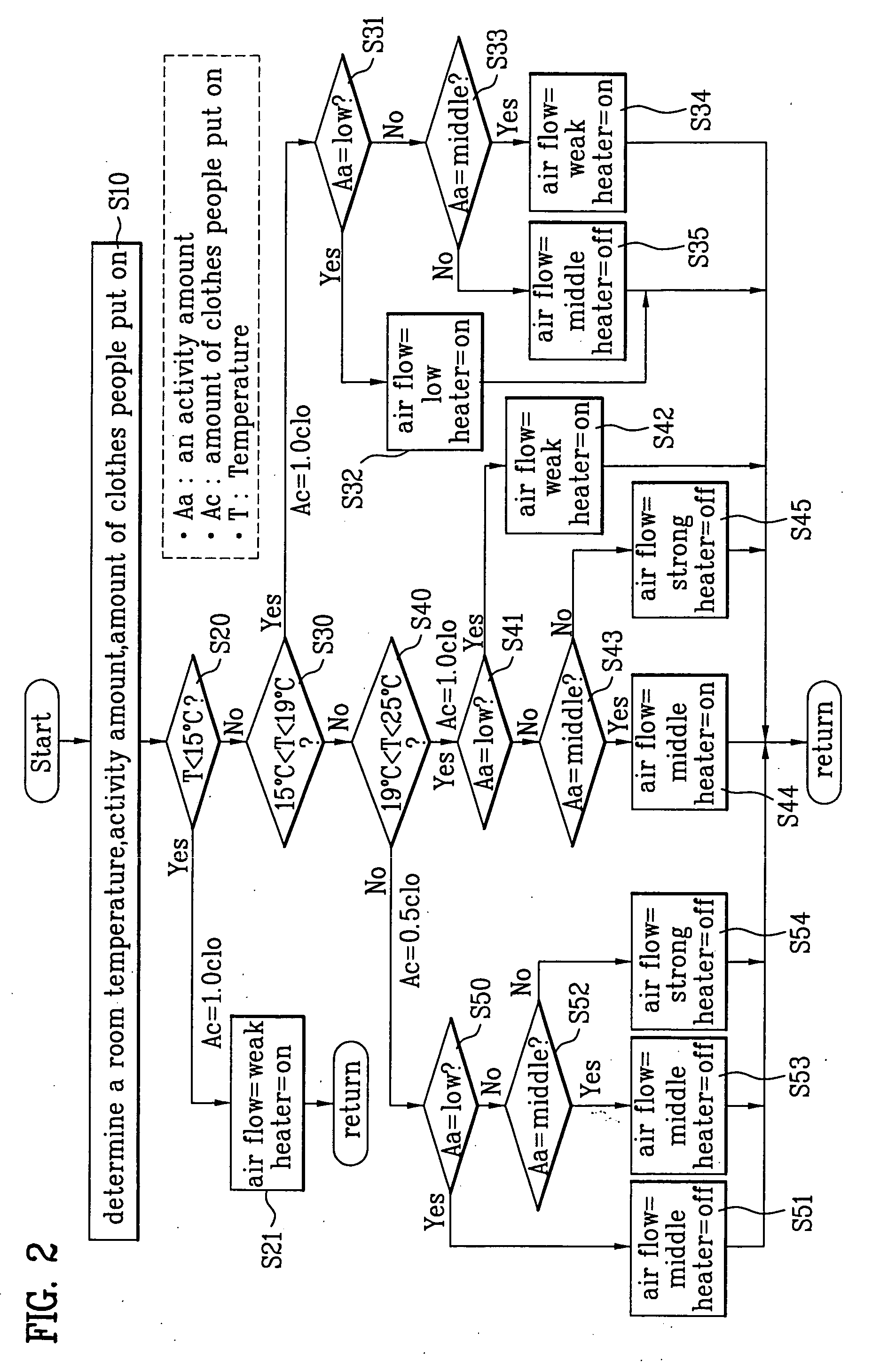

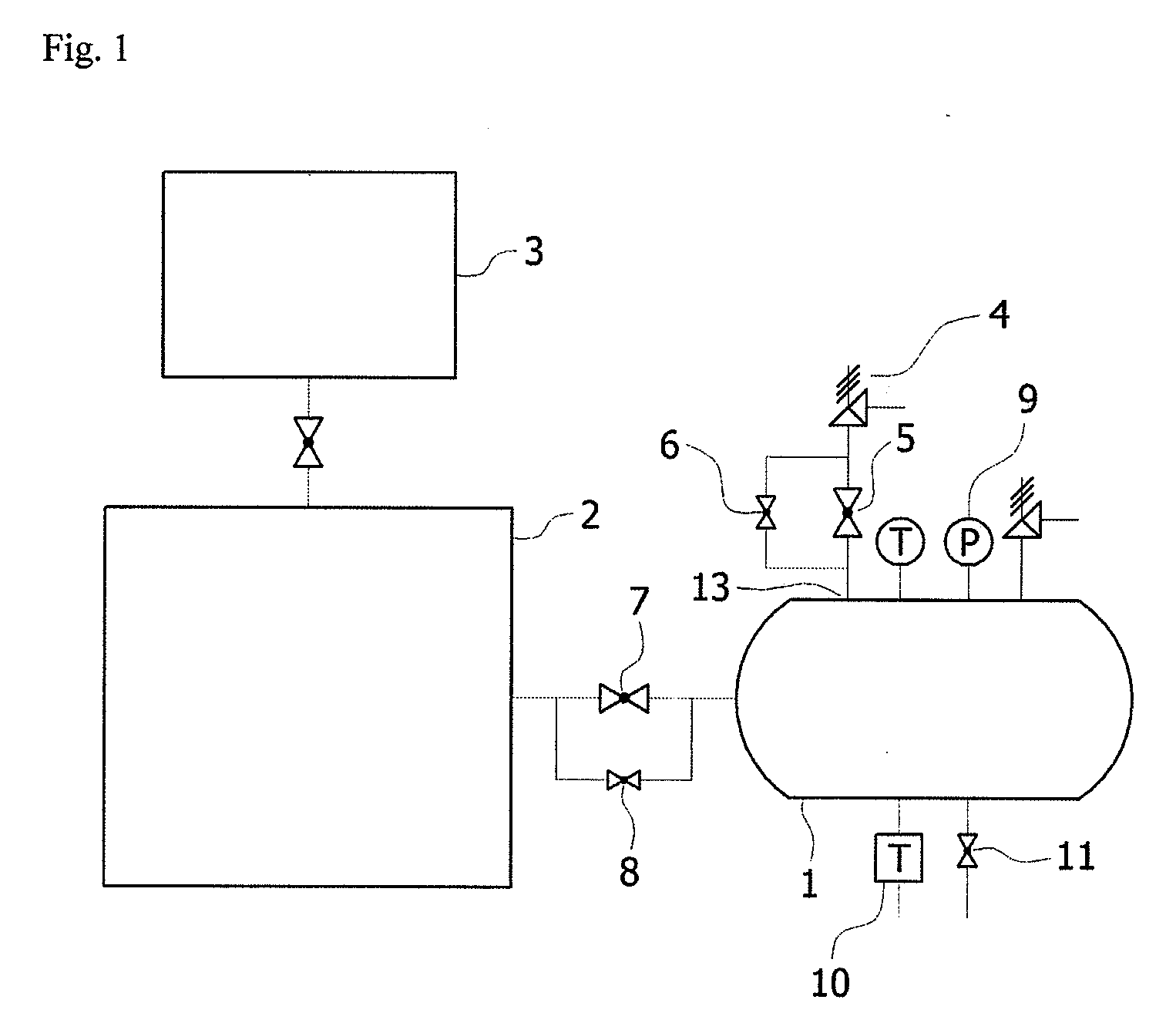

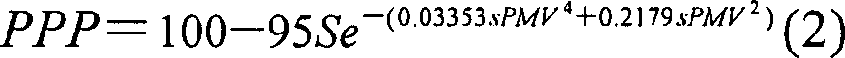

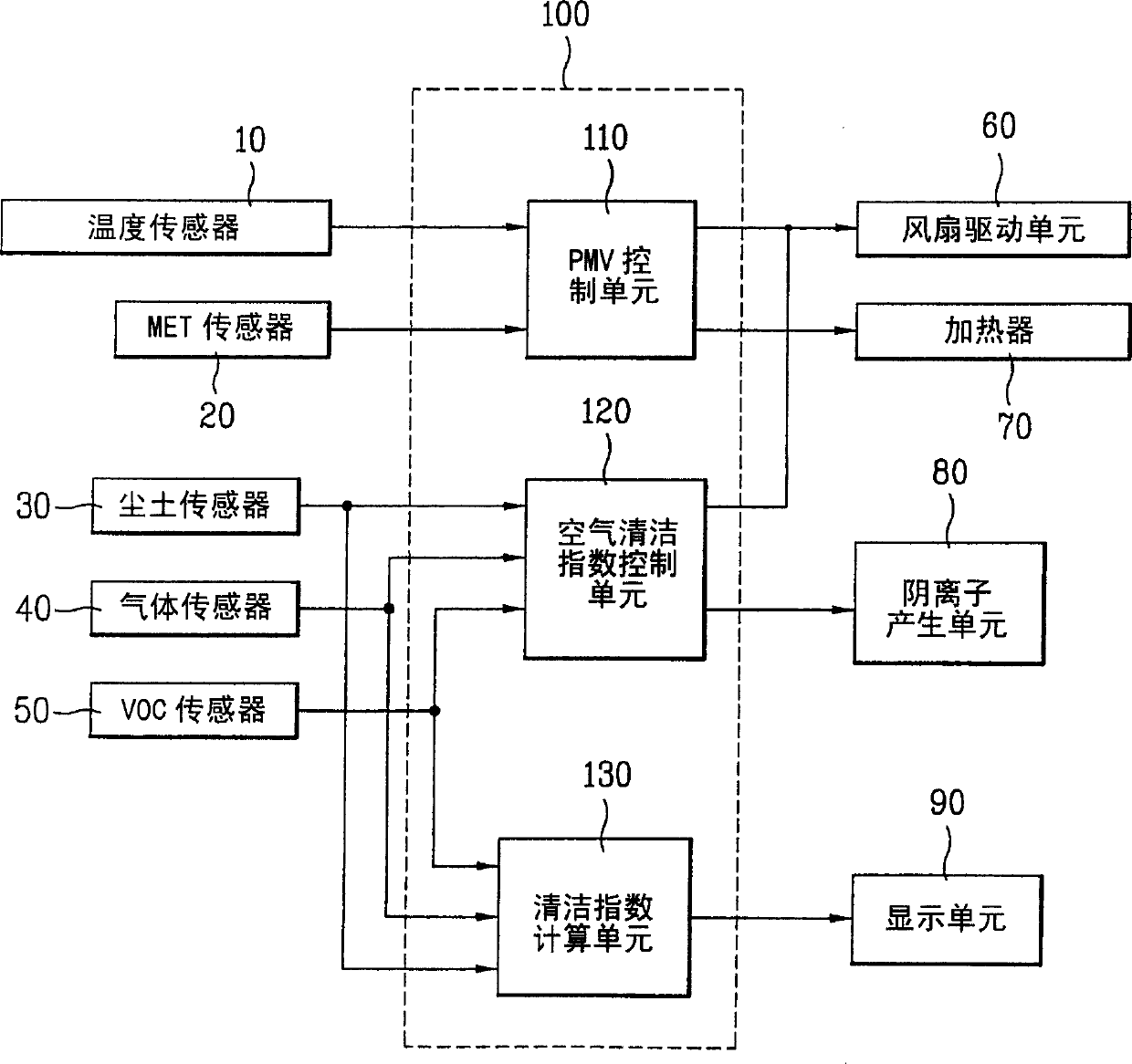

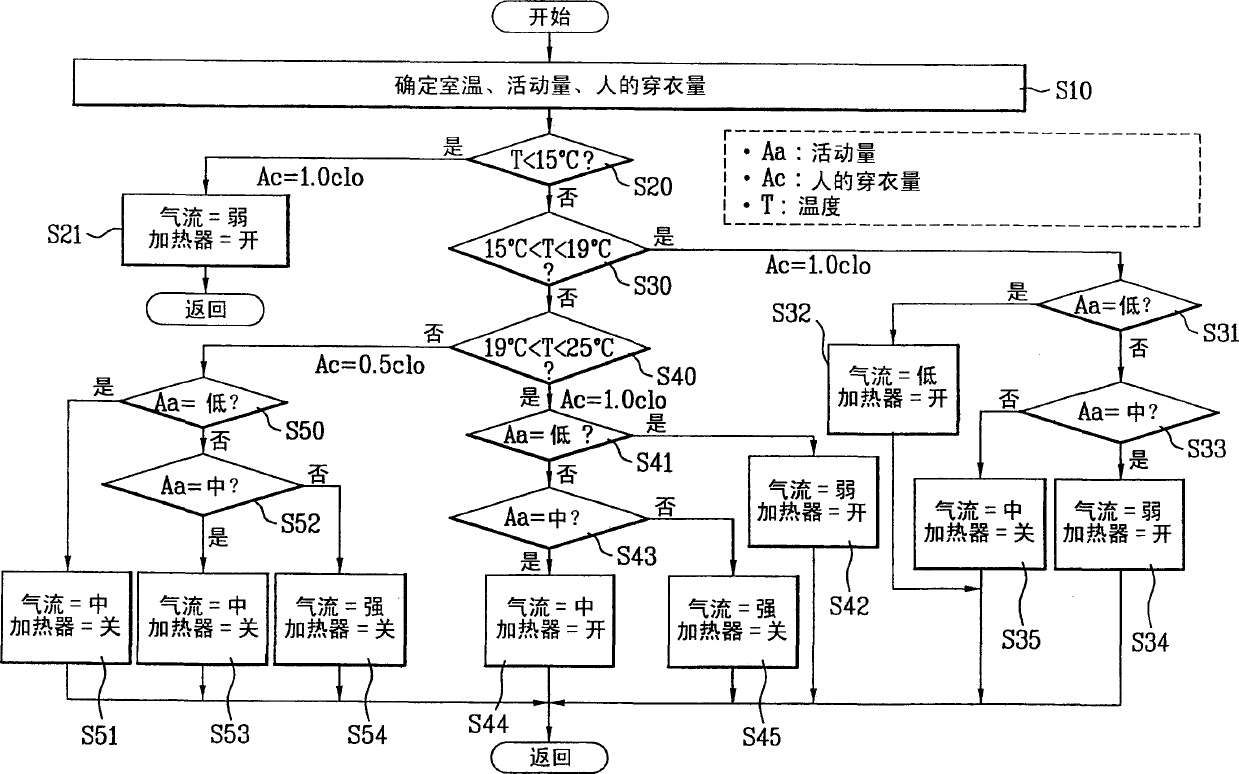

Air conditioning system and method for controlling the same

InactiveUS20050257540A1Optimal sense of comfortImprove satisfactionValve arrangementsLighting and heating apparatusStream flowRoom temperature

Air conditioning system including a temperature sensor for sensing a room temperature, an MET (metabolic) sensor for sensing an activity amount of people in a room, a dust sensor for sensing a dust amount, a gas sensor for sensing an intensity of smell, a VOC (Volatile Organic Compounds) sensor for sensing a compound amount, a fan driving unit for controlling an air flow rate, a heater for raising a room temperature, an anion generating unit for generating anion, and a control unit for controlling the fan driving unit and the heater according to an operation condition preset with reference to a sensed room temperature and the activity amount of people in the room, and controlling the fan driving unit and the anion generating unit according to an operation condition preset with reference to a sensed dust amount, the intensity of smell, and the VOC amount, thereby enhancing comfortability, and performing effective cleaning function, and displaying room cleanliness in real time on a screen, to improve a product reliability.

Owner:LG ELECTRONICS INC

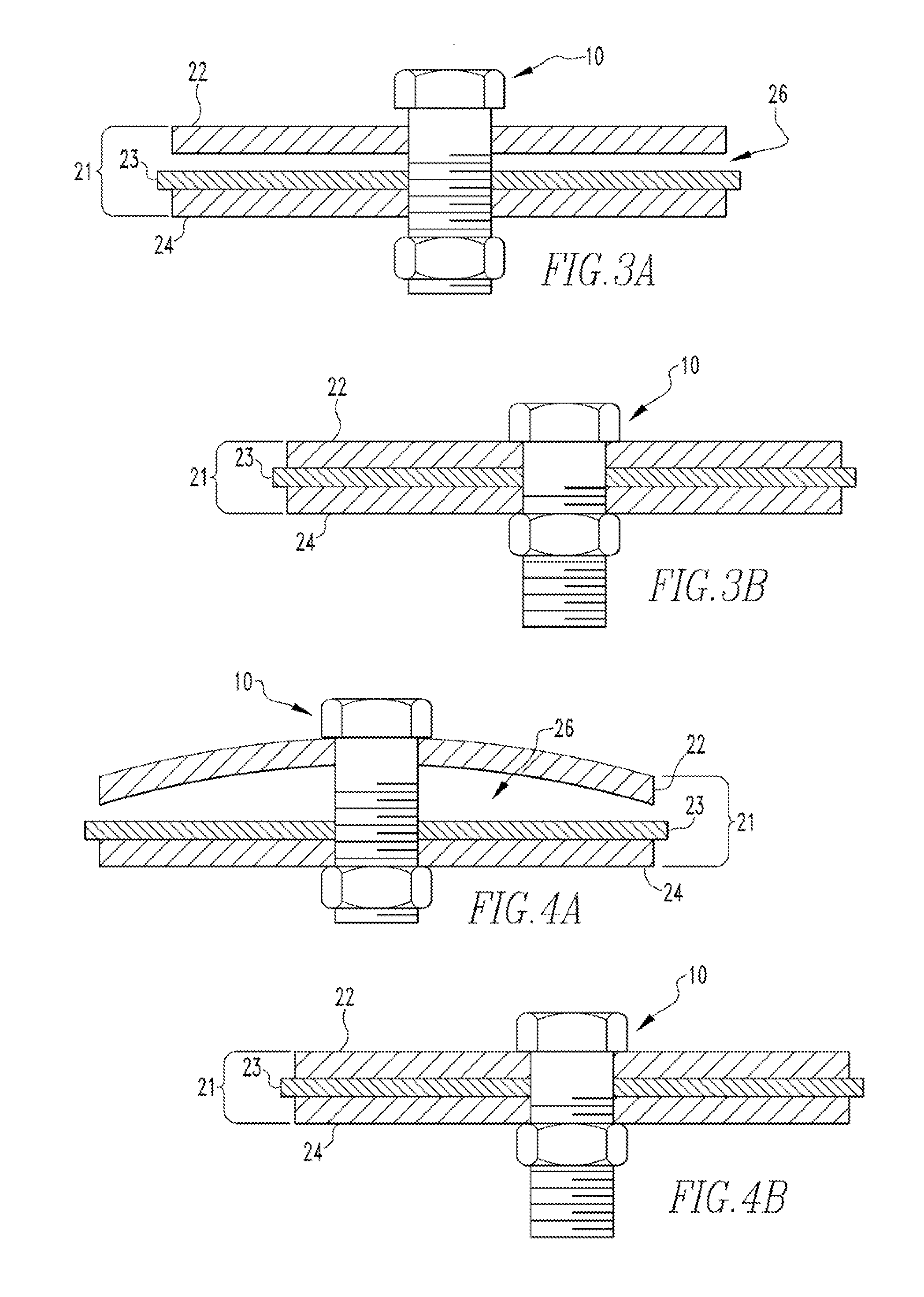

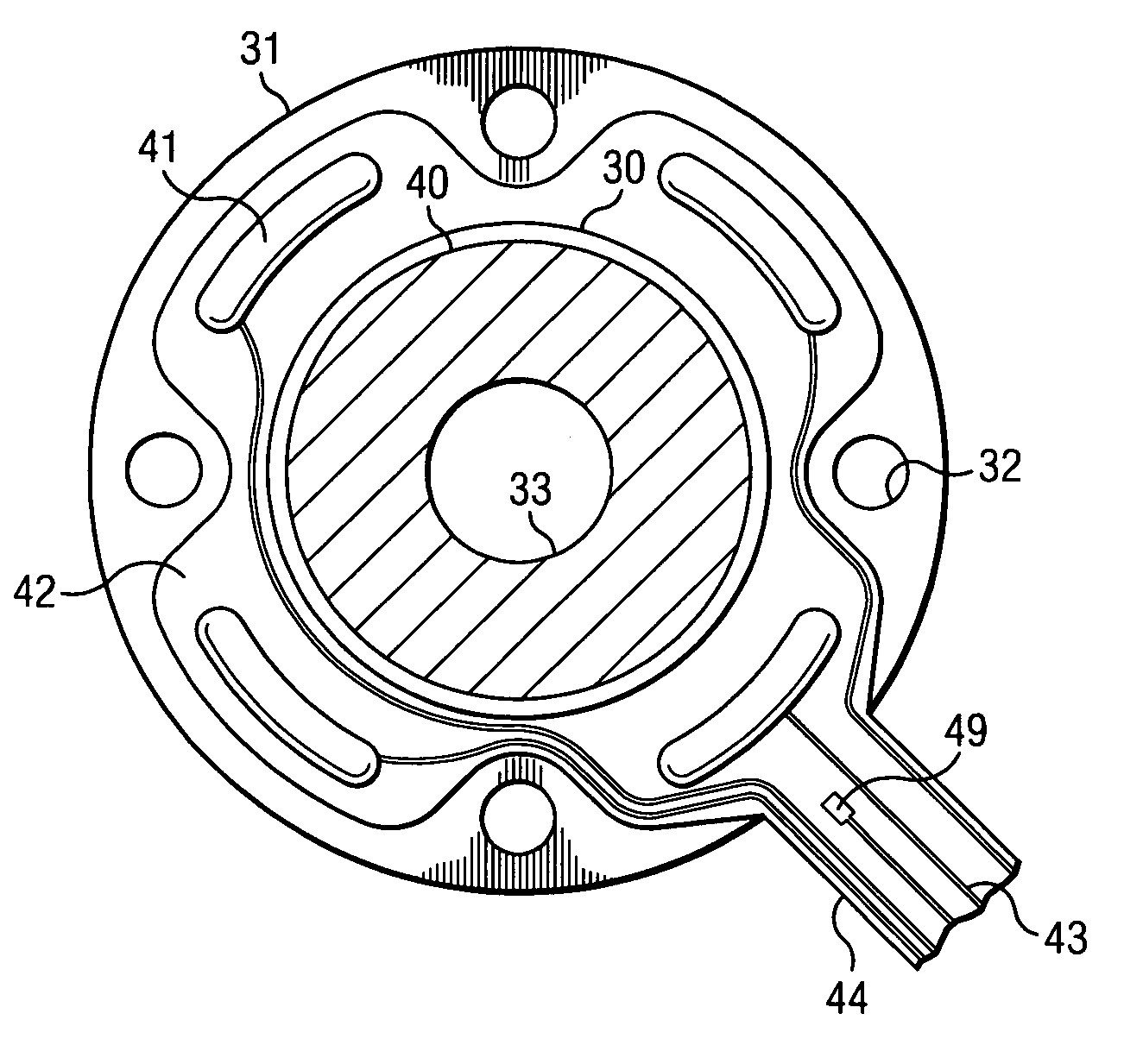

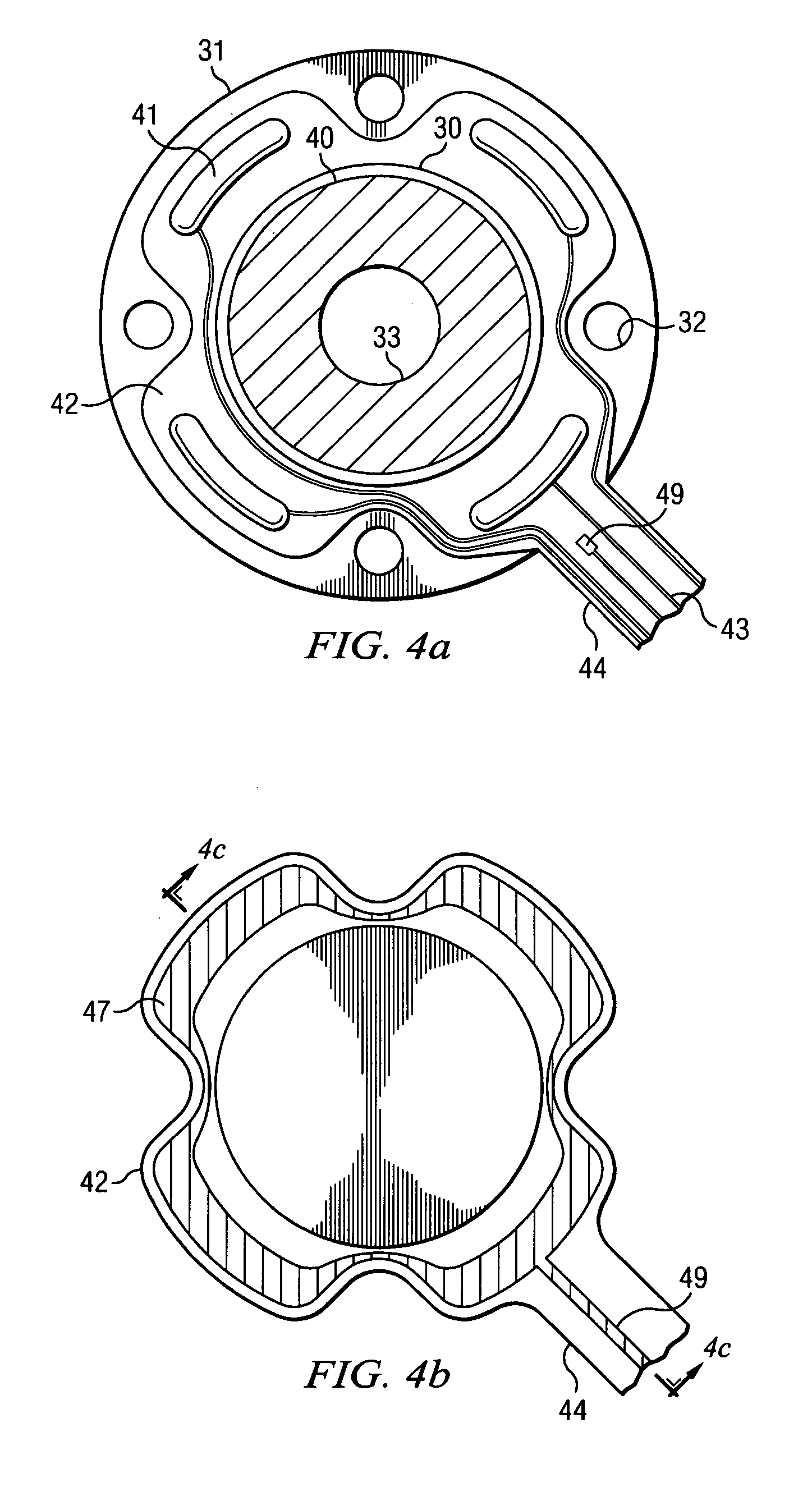

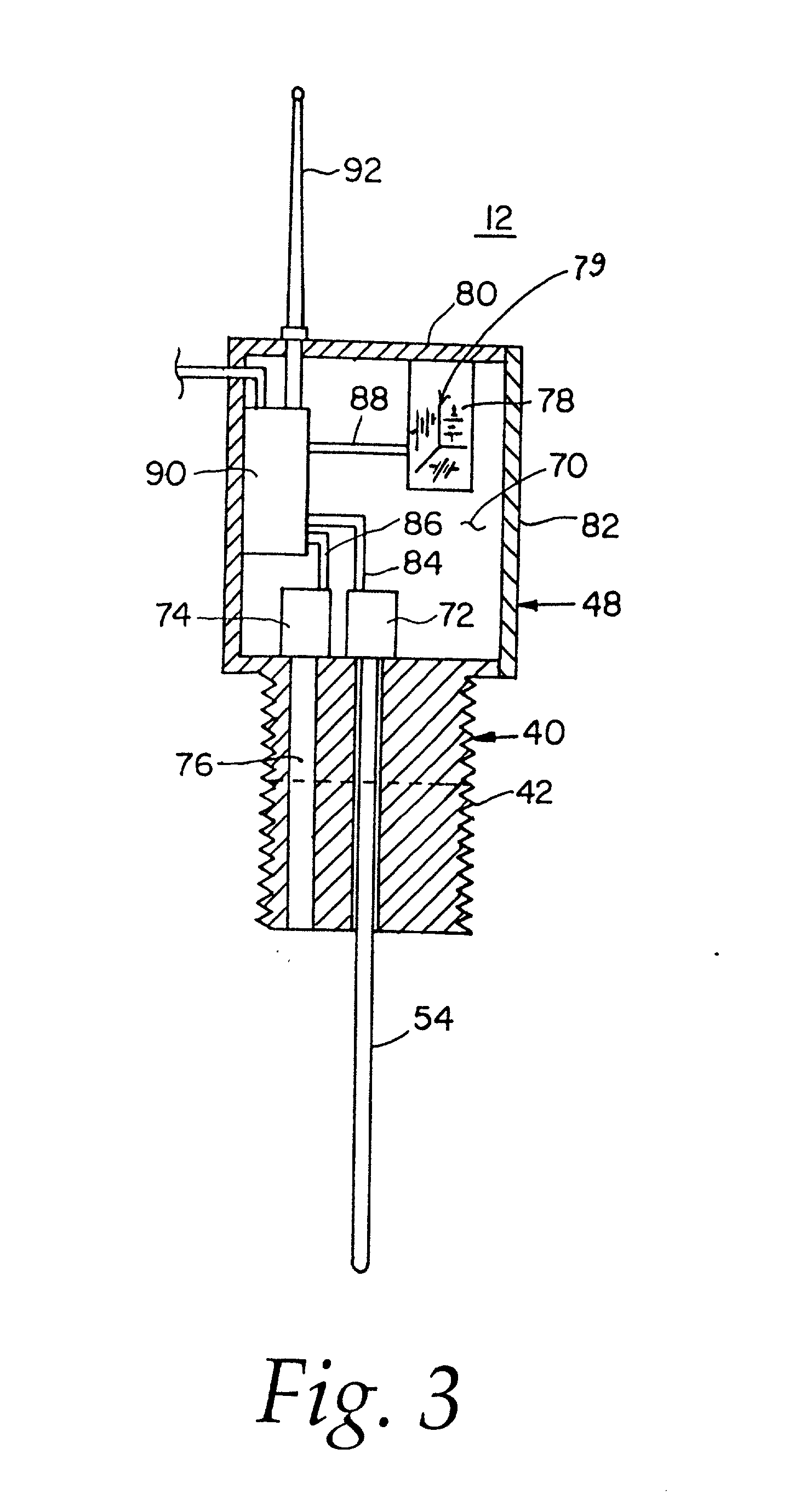

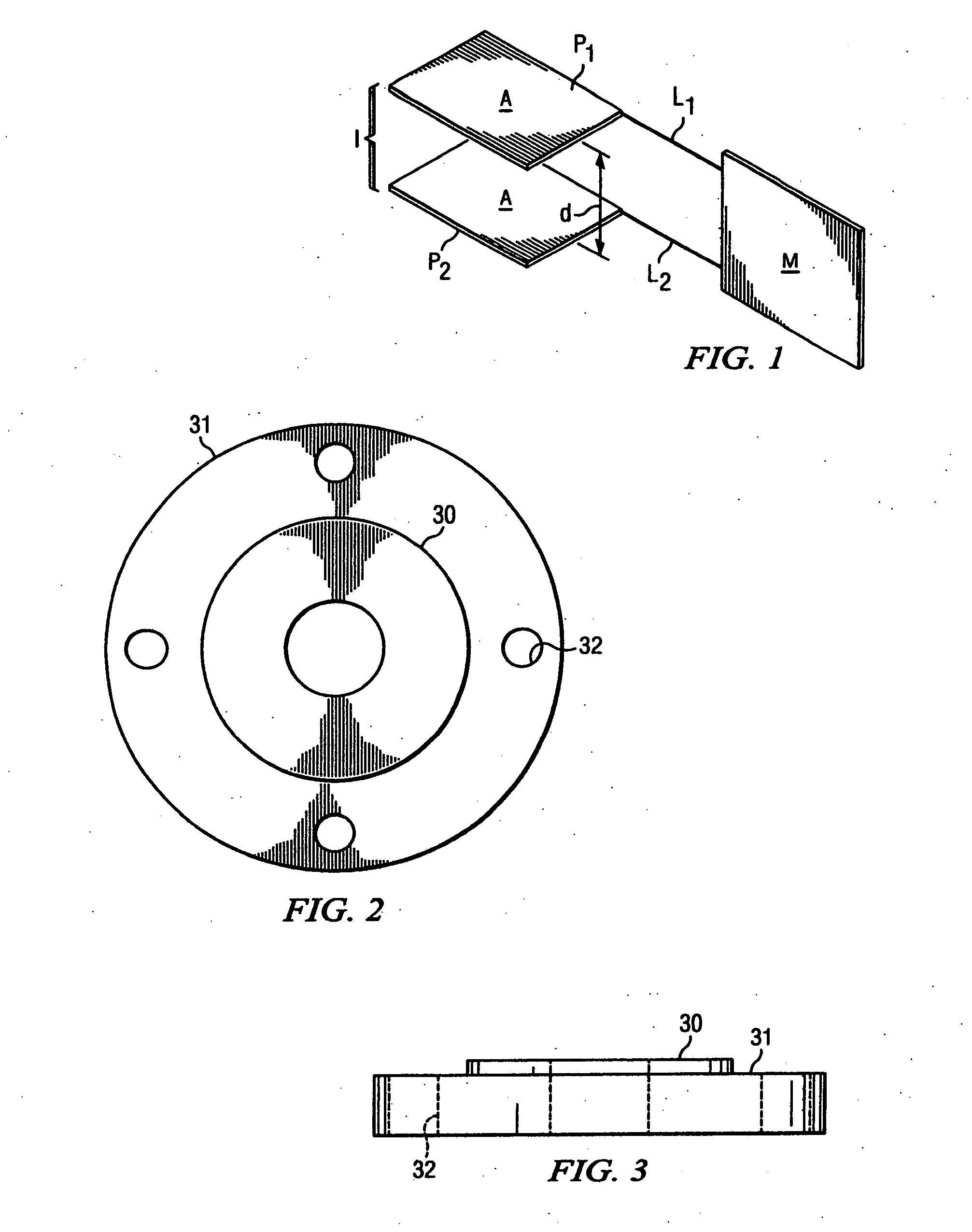

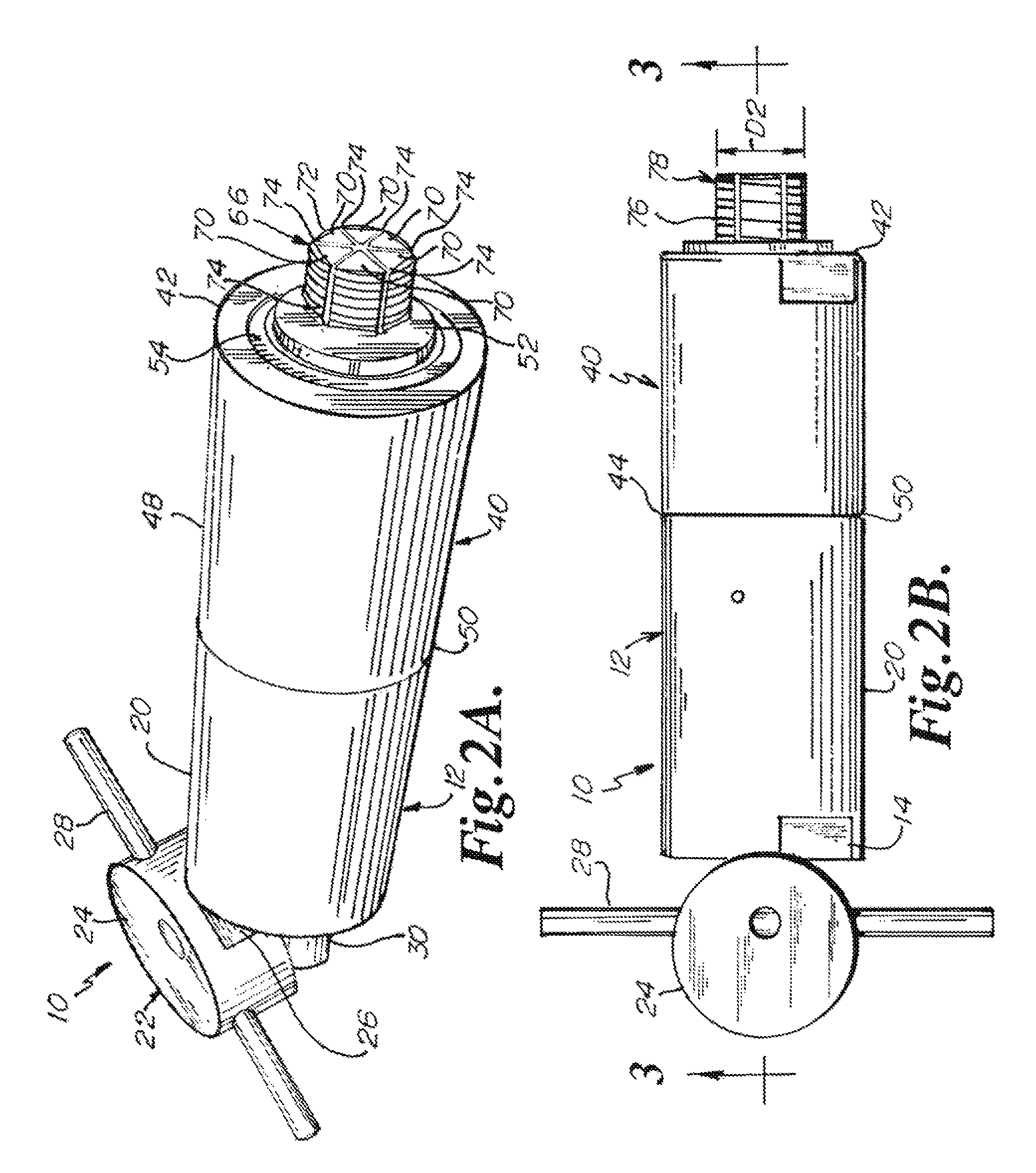

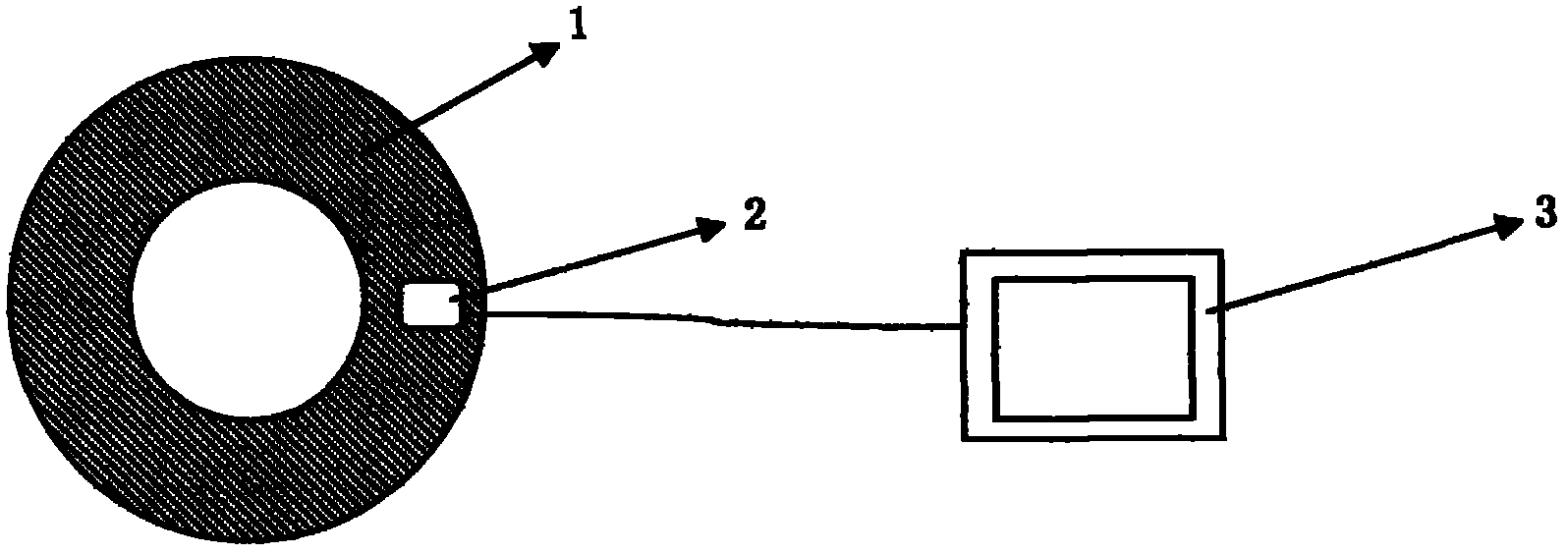

Compressive load sensor by capacitive measurement

InactiveUS20070193361A1Effectively measure parameterMaintain measurement accuracyForce measurementMachine sealing rings testingContinuous measurementElectricity

A thin, flat capacitive load sensor, such as of layered sandwich construction, having a variety of shapes, so as to provide a seal between two or more opposing surfaces. The load sensor includes a thin first and second insulating outer layer between which an inner layer is secured. The inner layer can be formed of dielectric material of a known dielectric constant, with at least one thin electrical conductor to accommodate load sensing disposed against a first face, and another thin electrical conductor to accommodate load sensing disposed against a second face. Electrical conductors connect the thin conductive areas on the first and second faces to the distal end of a tab extending beyond the load or connection measurement area. The distal end of the tab accommodates a connection with electrical measurement apparatus. As the inner layer is compressed, the spacing between the electrically conductive areas on the opposing faces is decreased such that compressive forces can be measured as a function of the changes in capacitance of the sensor. In this manner, proper compression can be achieved by monitoring capacitance during installation. Follow-up sampling or continuous measurement of sensor compression provides early detection prior to failure to allow corrective action.

Owner:DAVIE COFFEY TECH L L C

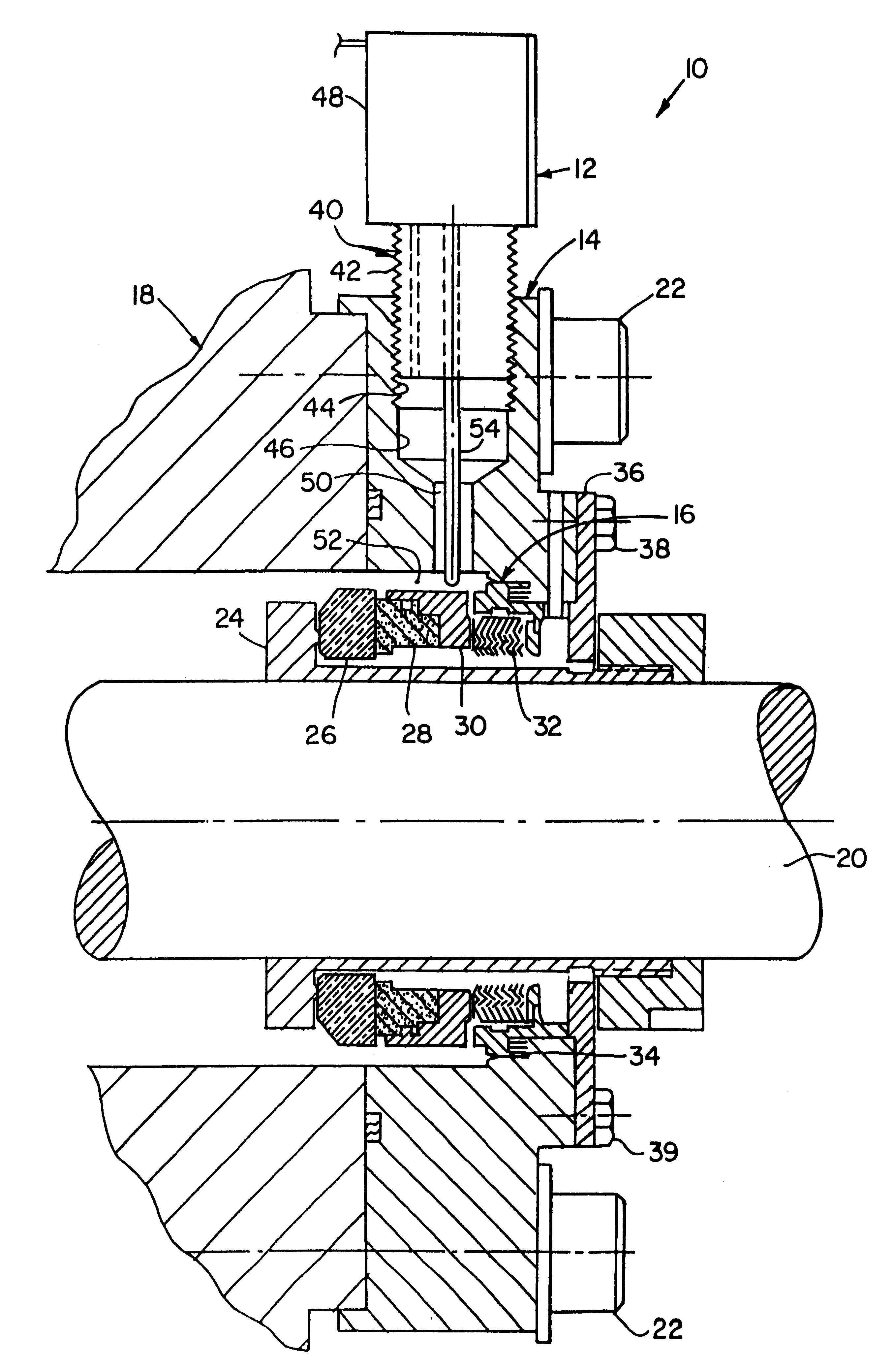

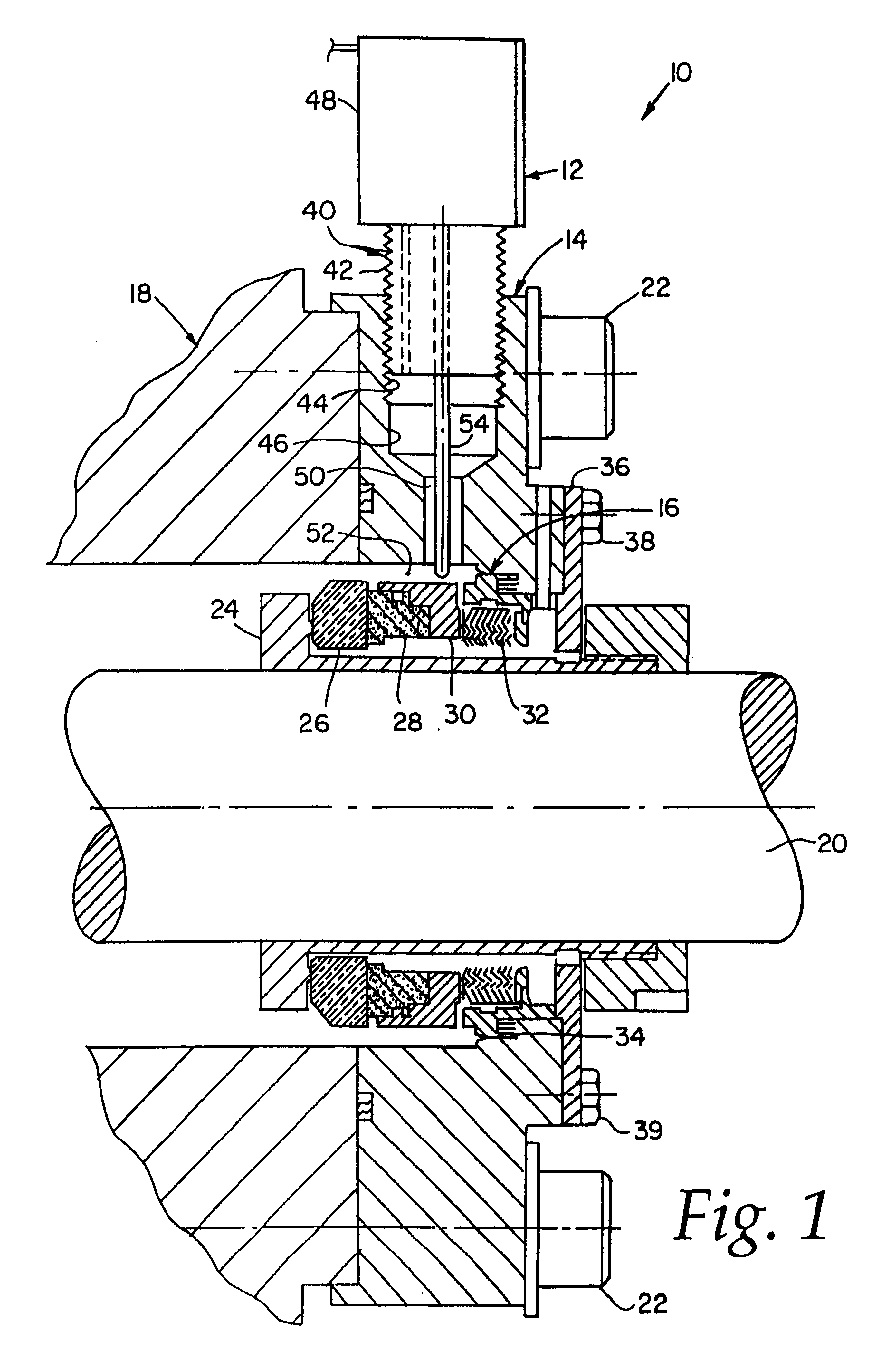

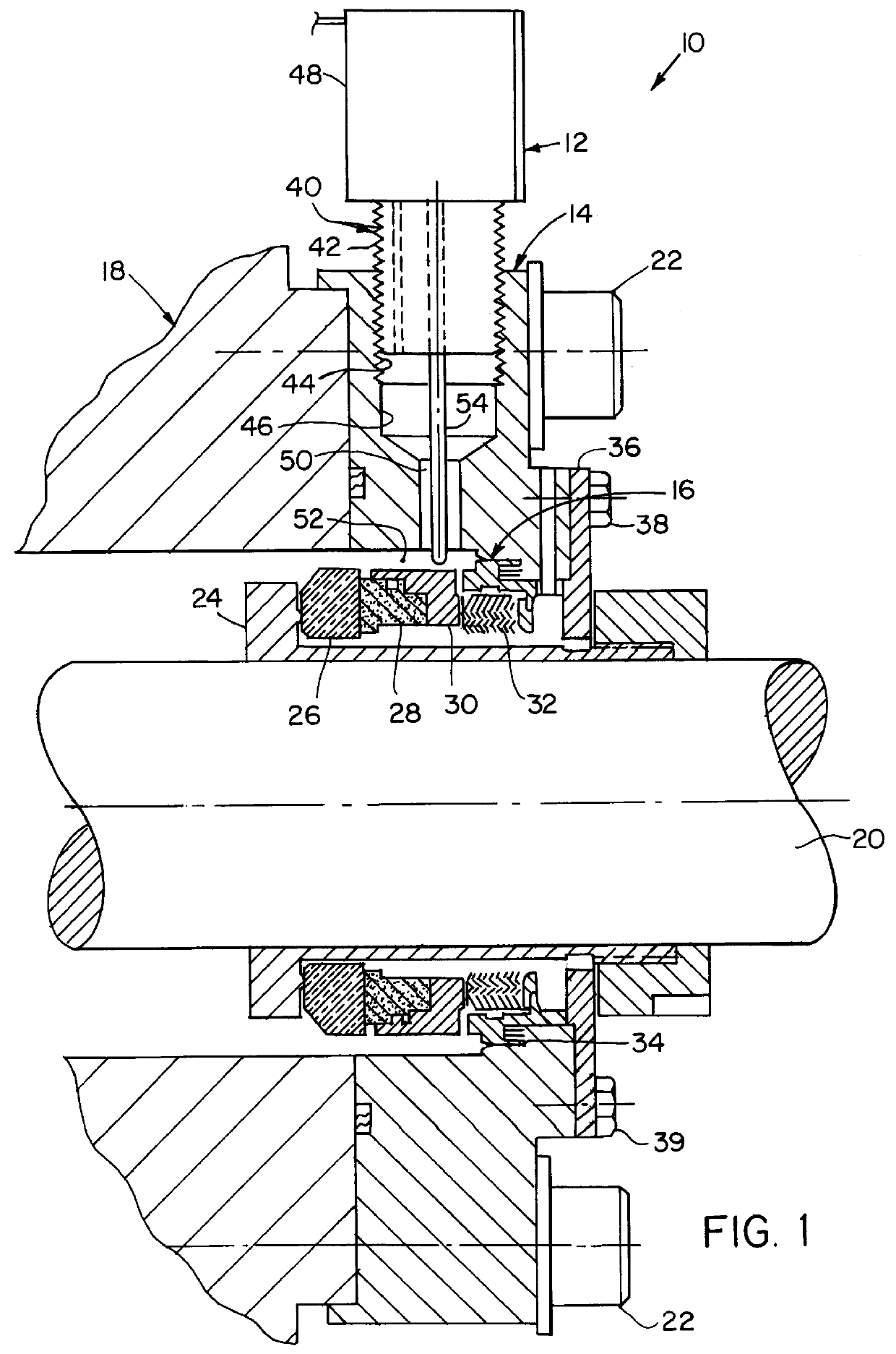

Monitoring seal system

InactiveUS6626436B2Prevent liquid leakageEngine sealsPiston ringsEngineeringElectrical and Electronics engineering

A monitoring seal system comprises a seal housing, a seal assembly, a temperature sensor and a controller. The seal assembly sealingly engages a rotary shaft to prevent fluid leakage between the shaft and the housing. The seal assembly has at least one seal. The seal has a primary ring and a mating ring. The temperature sensor senses the temperature in the vicinity of the seal. The controller determines whether an upset condition has occurred based on at least the temperature in the vicinity of the seal.

Owner:JOHN CRANE INC

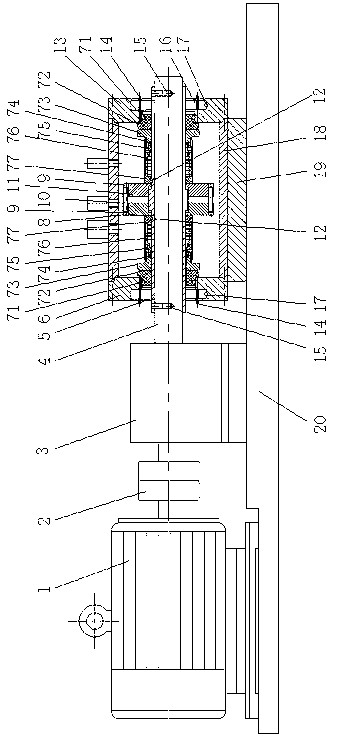

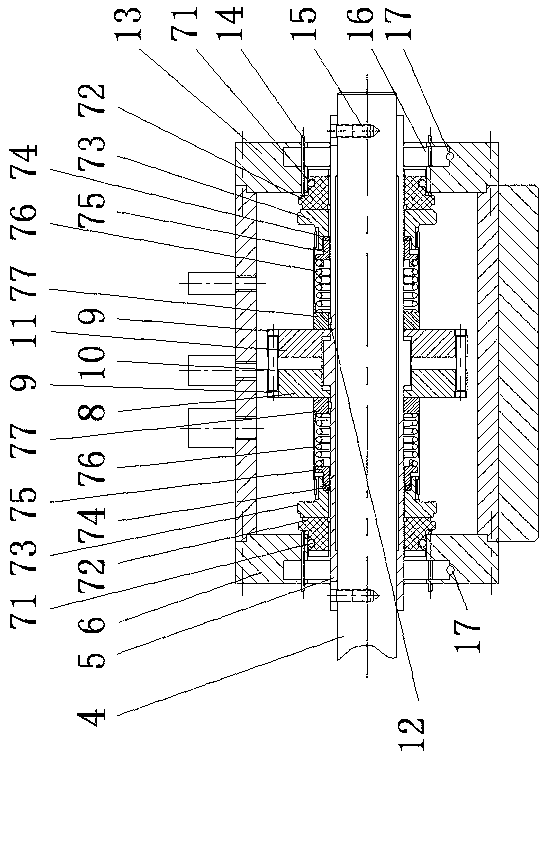

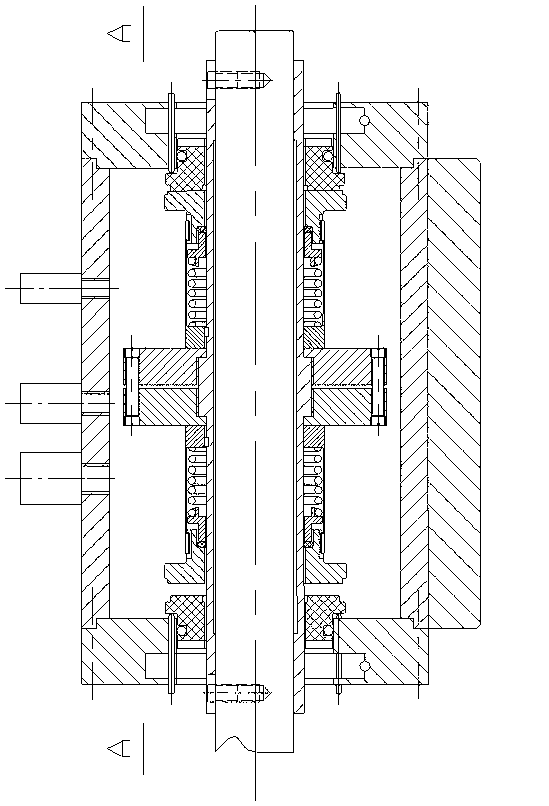

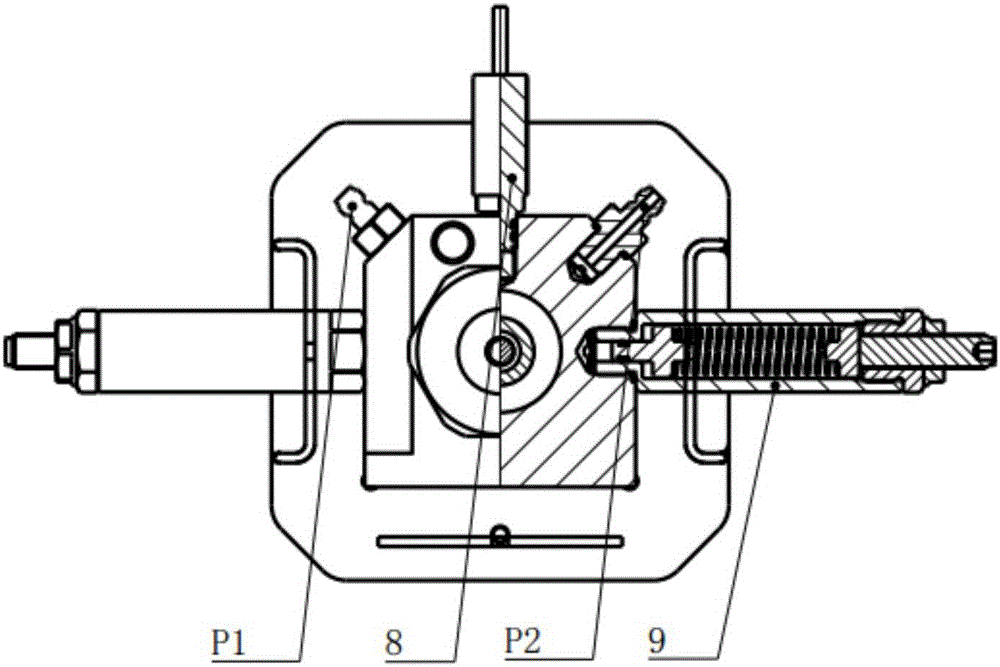

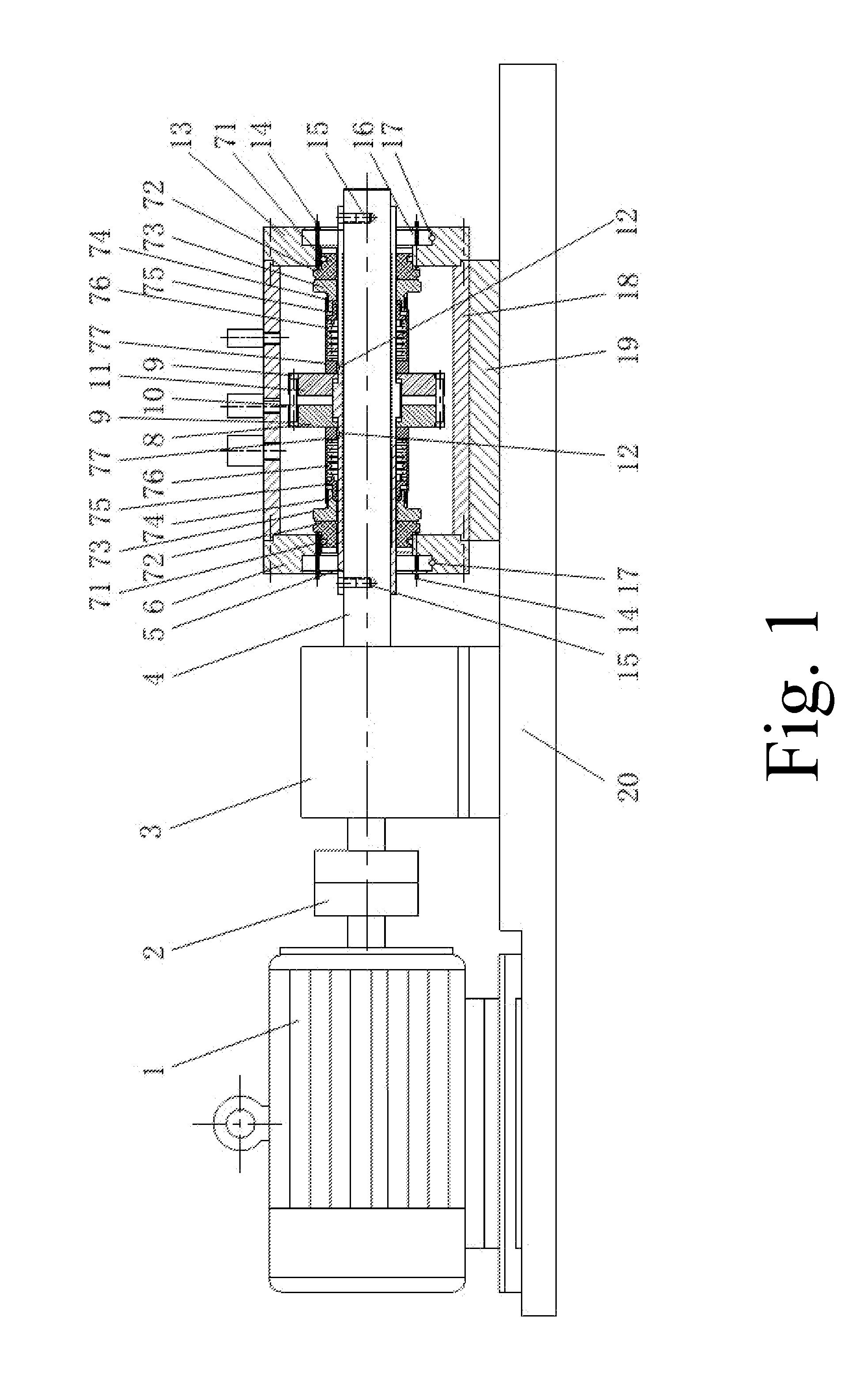

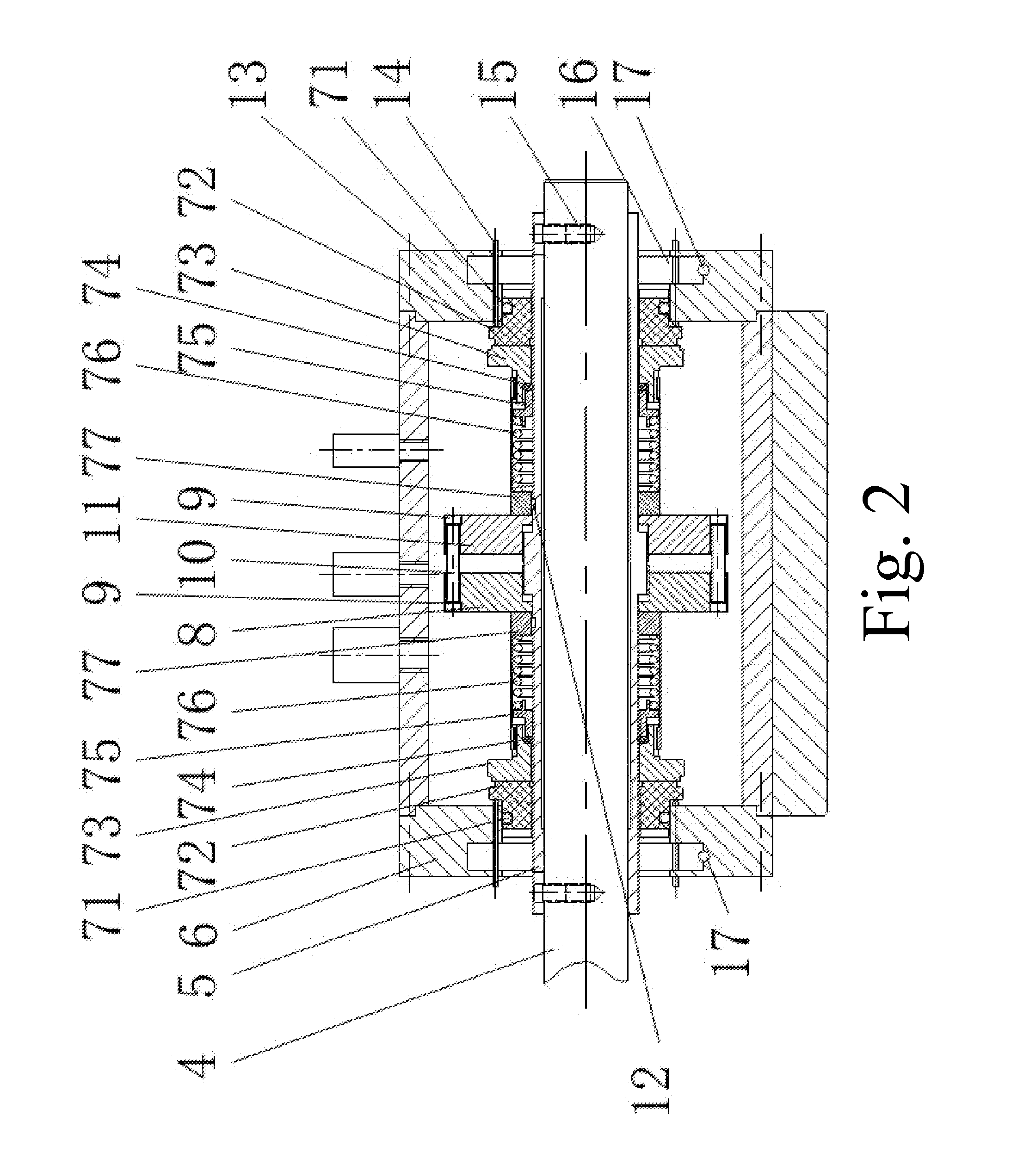

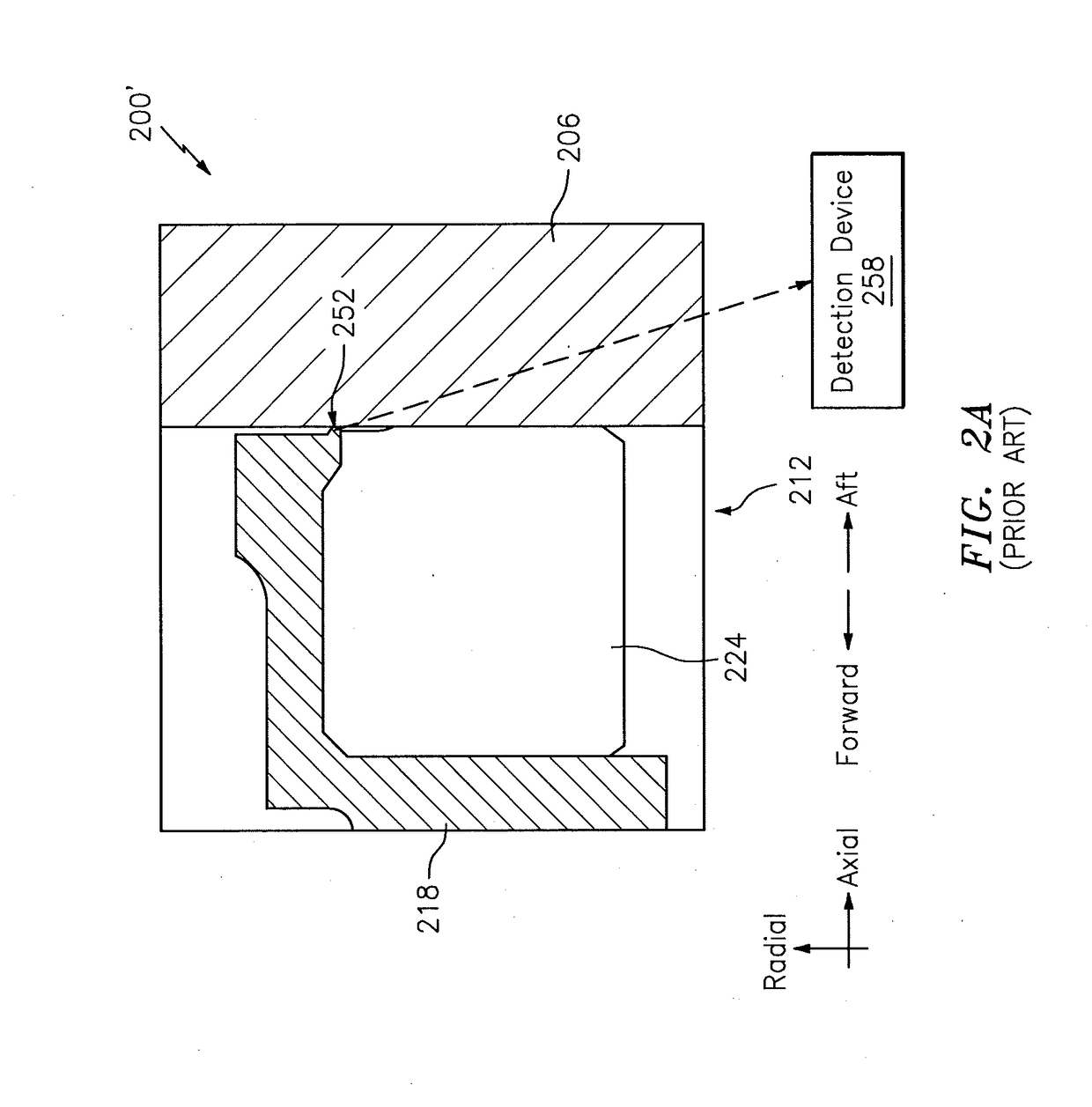

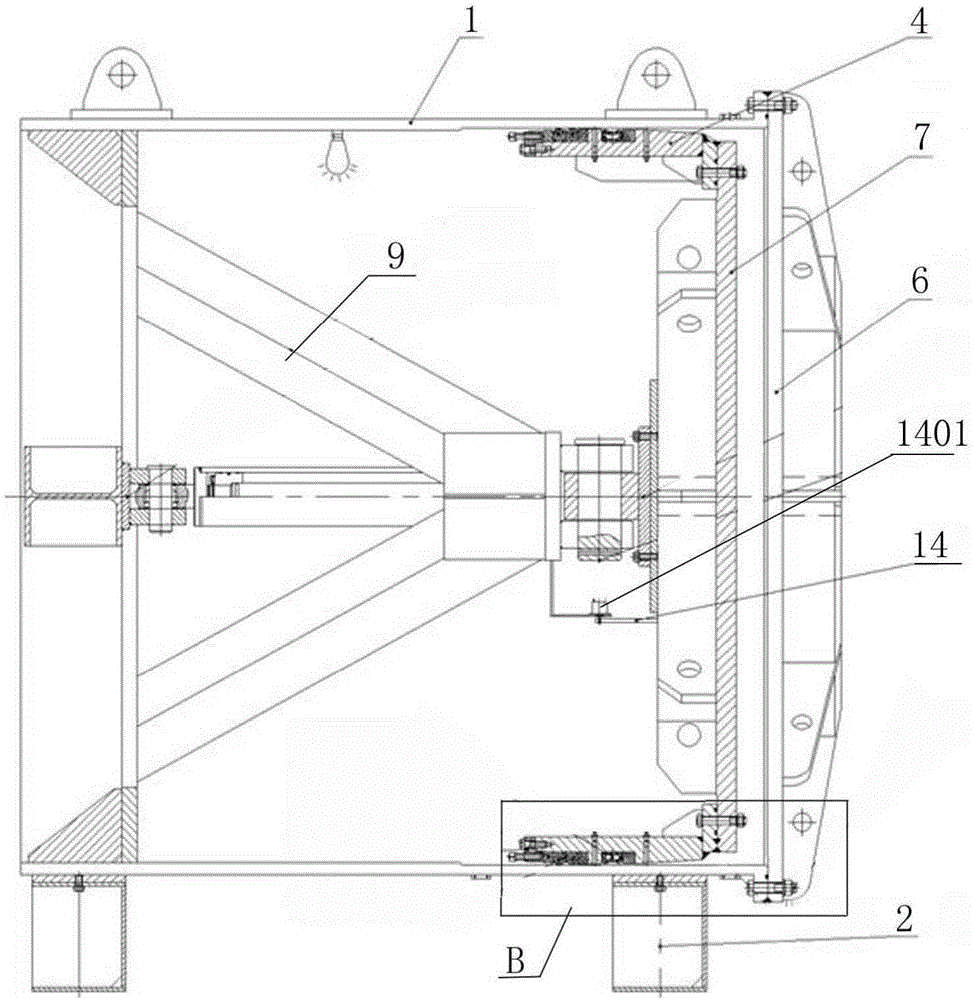

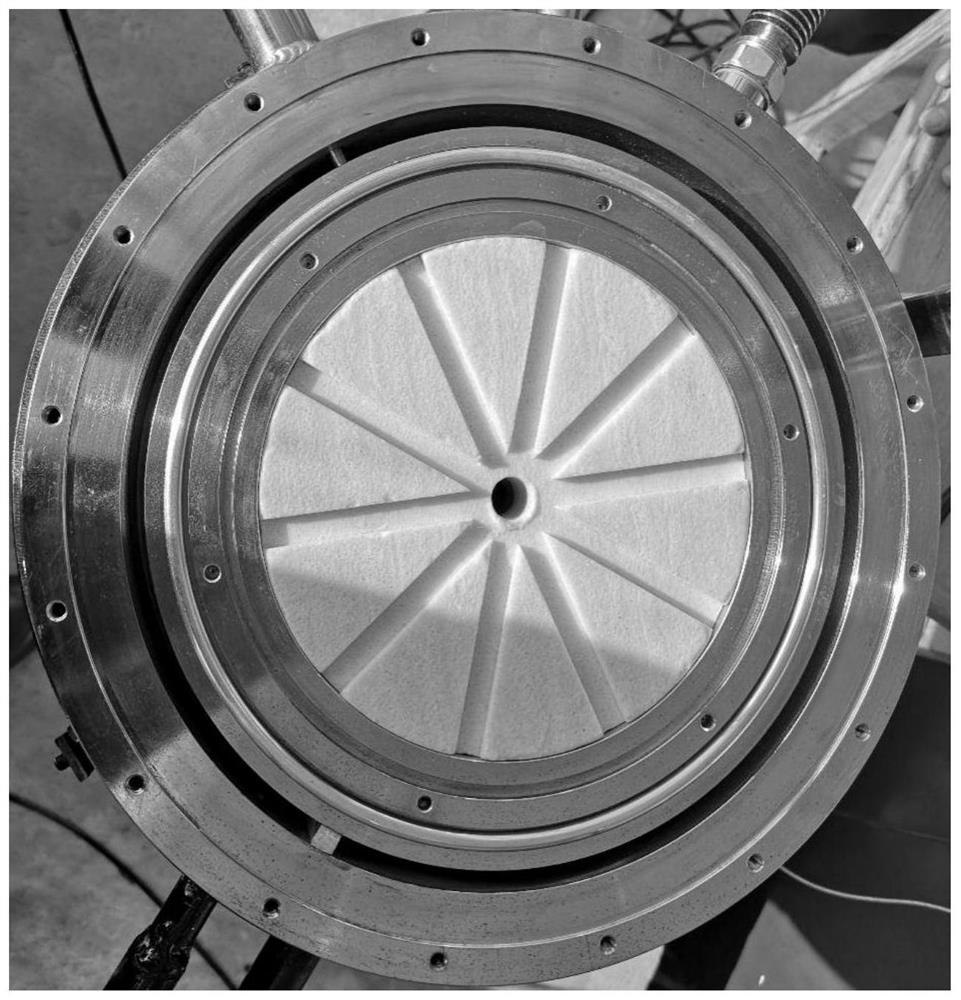

Mechanical seal performance testing device

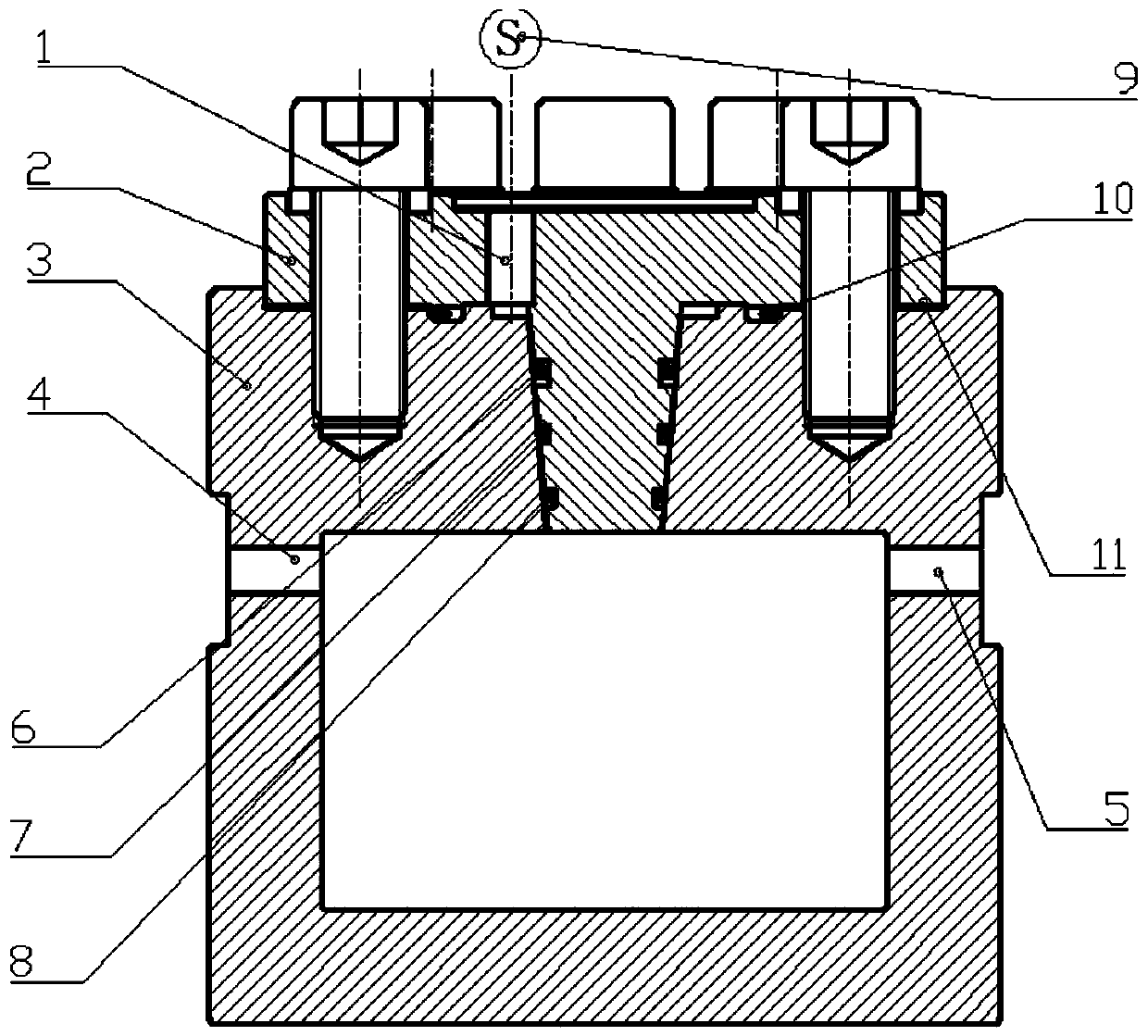

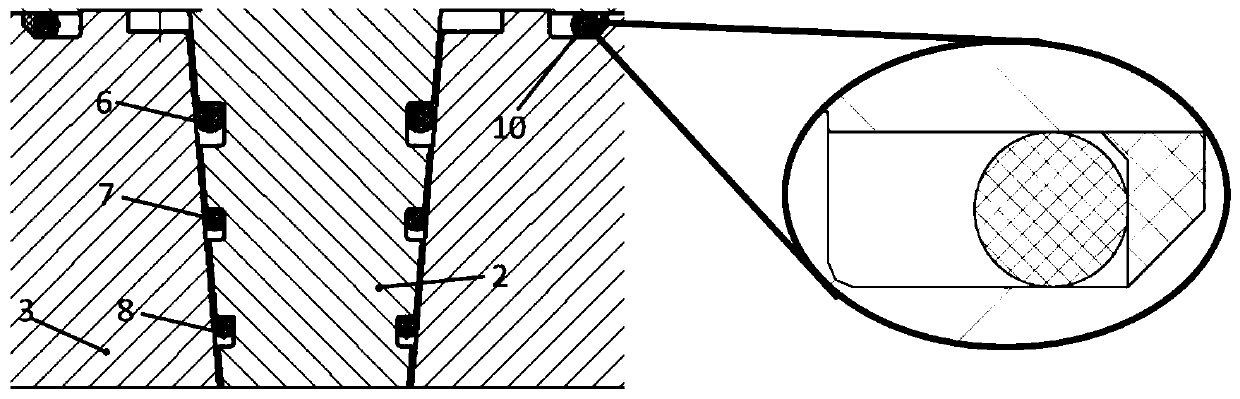

ActiveCN103267613AAvoid axial forceRealize automatic adjustmentMeasurement of fluid loss/gain rateWork measurementFriction torqueAxial force

Provided is a mechanical seal performance testing device. The mechanical seal performance testing device comprises a main shaft, a working cavity with end caps at two ends, and two sets of mechanical seals to be tested. A shaft sleeve and the main shaft are in clearance fit and penetrate through the end caps at the two ends of the working cavity together. U-shaped openings on the same generatrix are arranged in two ends, extending out of the end caps, of the shaft sleeve, and a transmission pin is arranged on a portion, corresponding to the U-shaped openings, of the main shaft; two sections of threads which are equal in thread pitch and opposite in screwing direction are arranged in the middle of the shaft sleeve, and movable ring bases in the two mechanical seals to be tested are arranged on the back sides of two nuts screwed on the threads respectively; the movable ring bases and the shaft sleeve slide in the axial direction and are located and connected in the circumferential direction; a radial force sensor used for measuring end face friction torque indirectly is arranged on the transmission pin, and an axial force sensor used for measuring end face specific pressure is arranged between the back side of a static ring and the end cap of the working cavity; the end cap is provided with an annular ring which is concentric with a center hole, and therefore a leakage cavity used for collecting leakage amount is formed. The mechanical seal performance testing device is suitable for mechanical seal performance tests of various pressure working conditions and various size series, including performance tests of high-pressure and large-diameter mechanical sealing.

Owner:NANJING FORESTRY UNIV

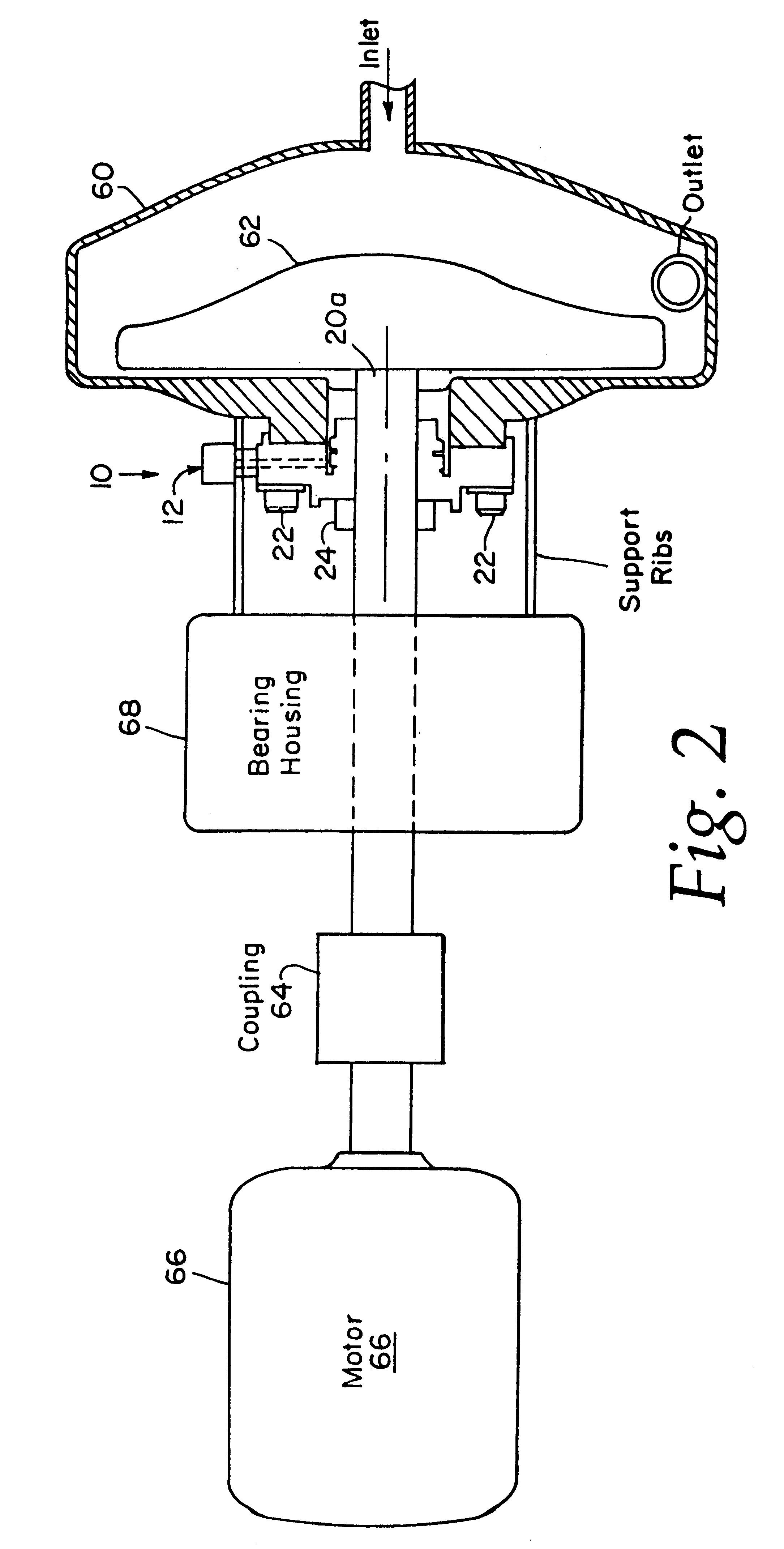

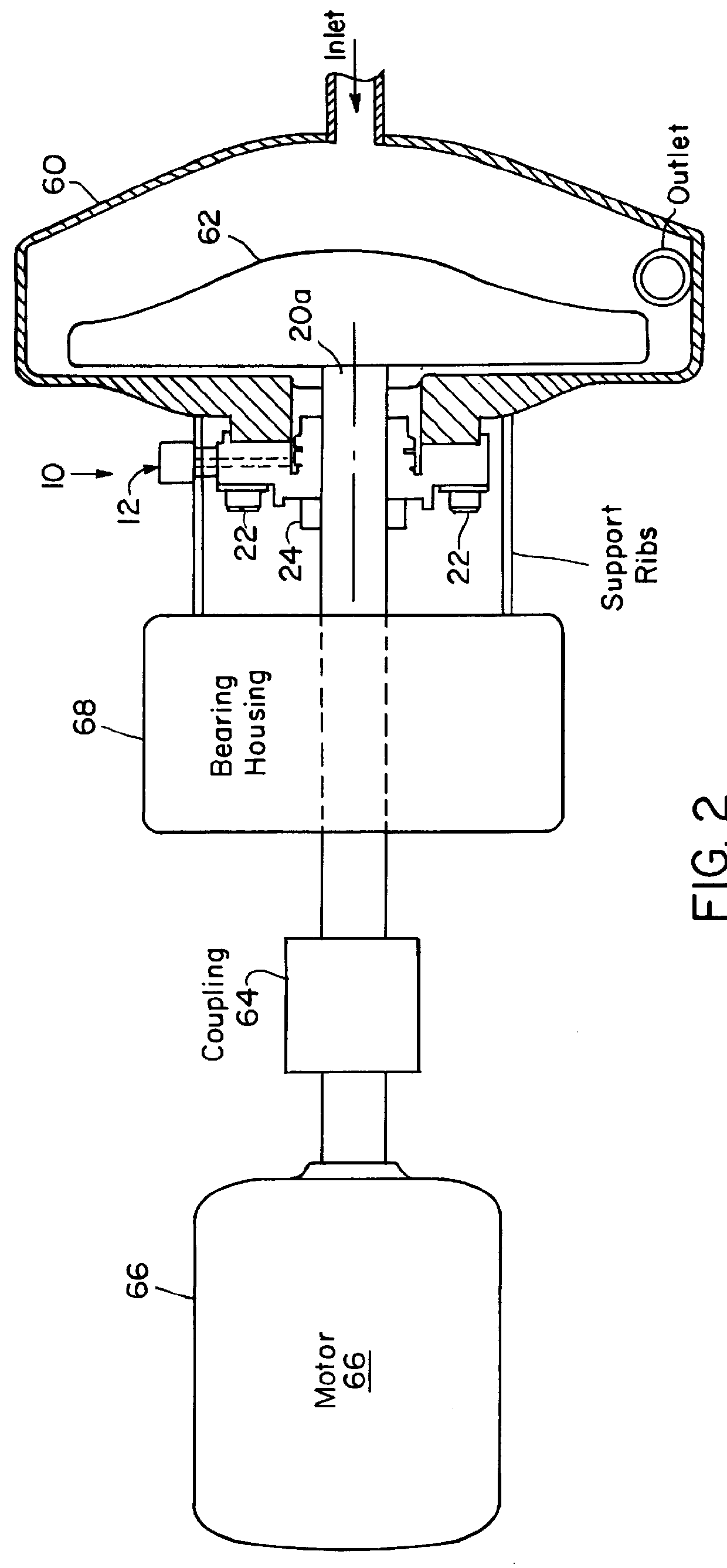

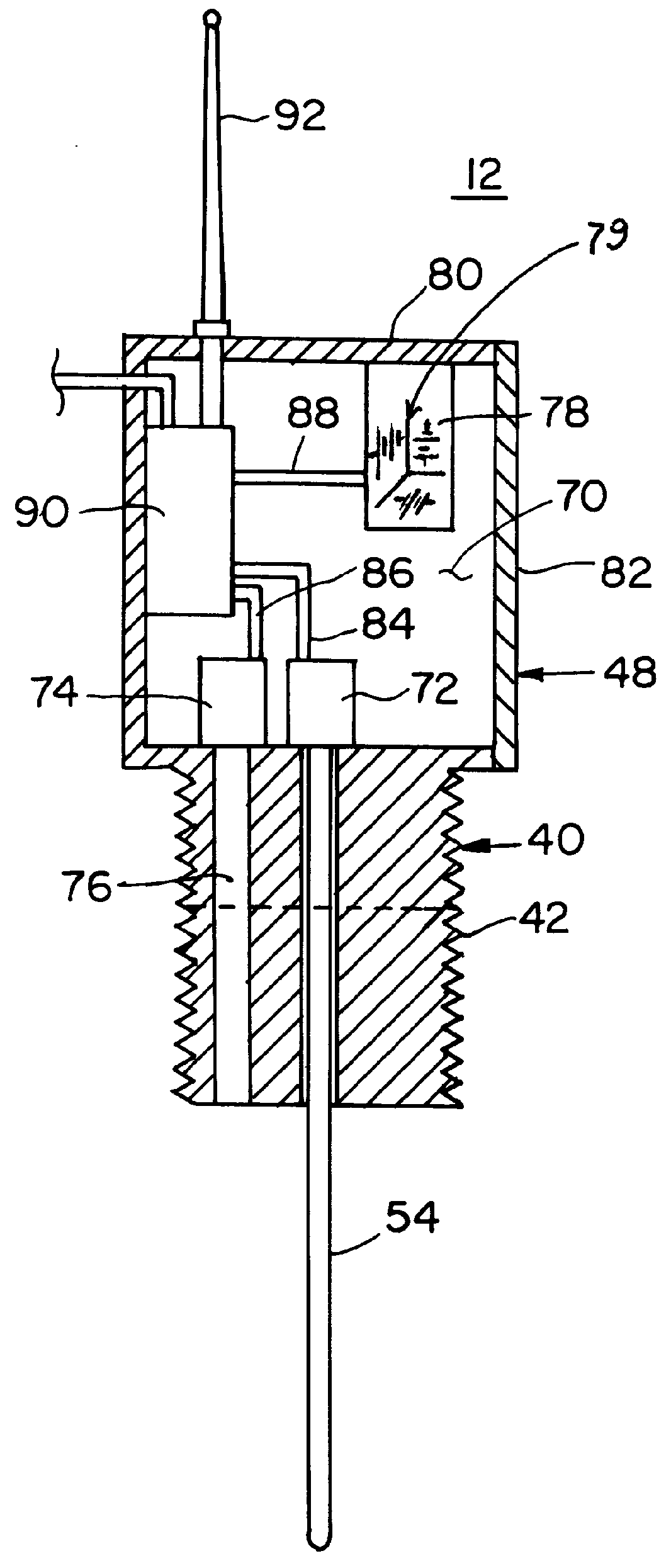

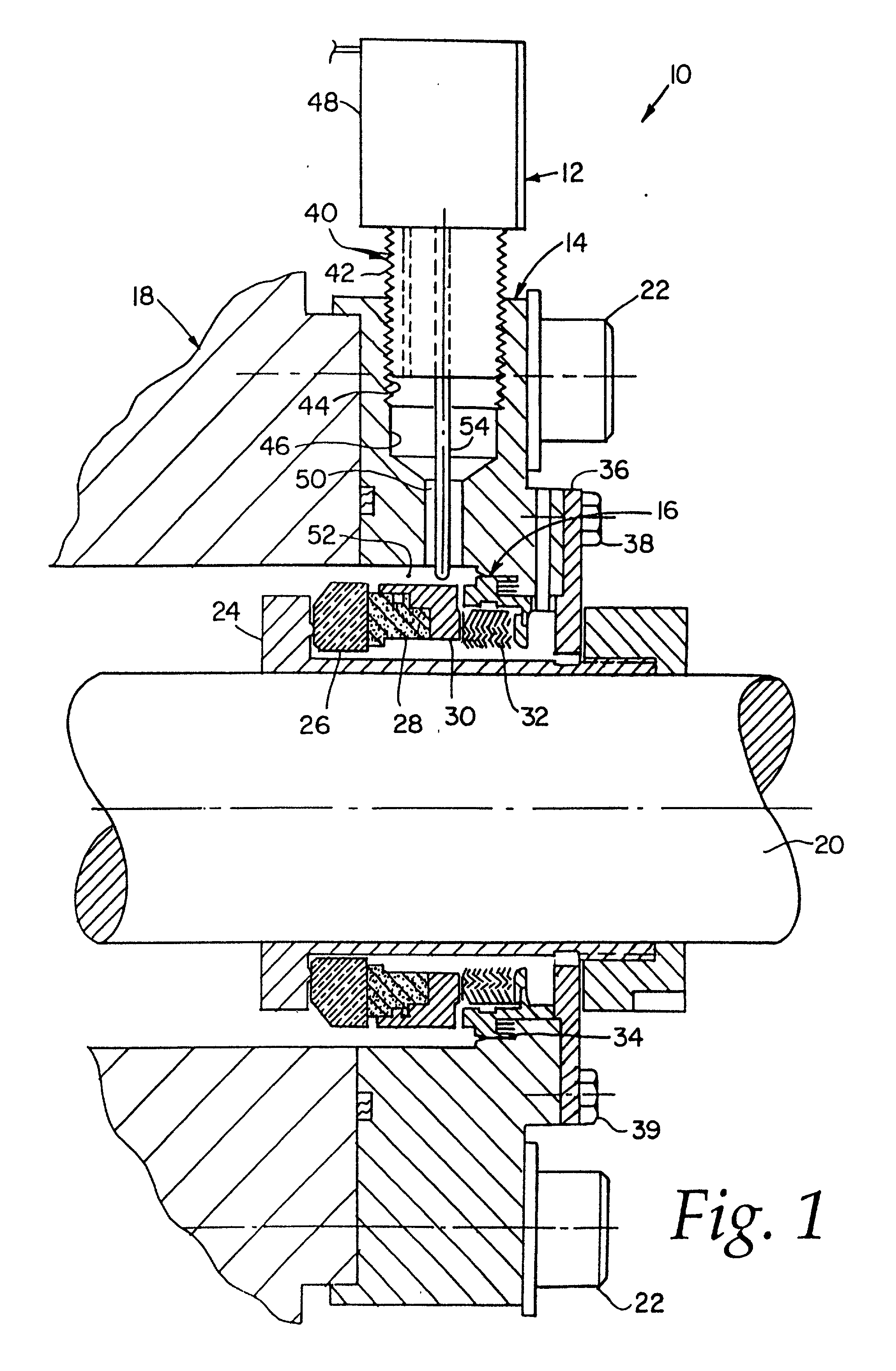

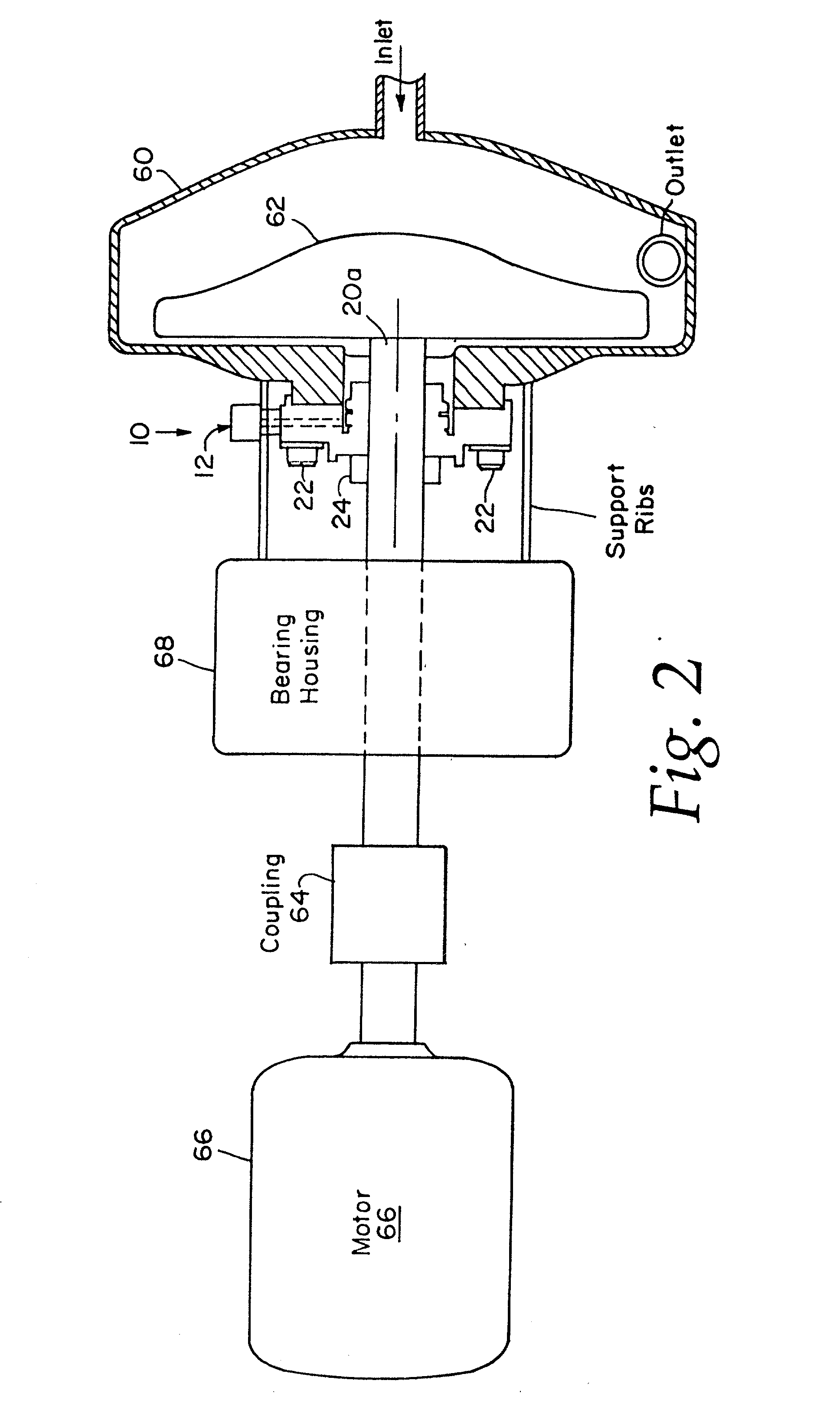

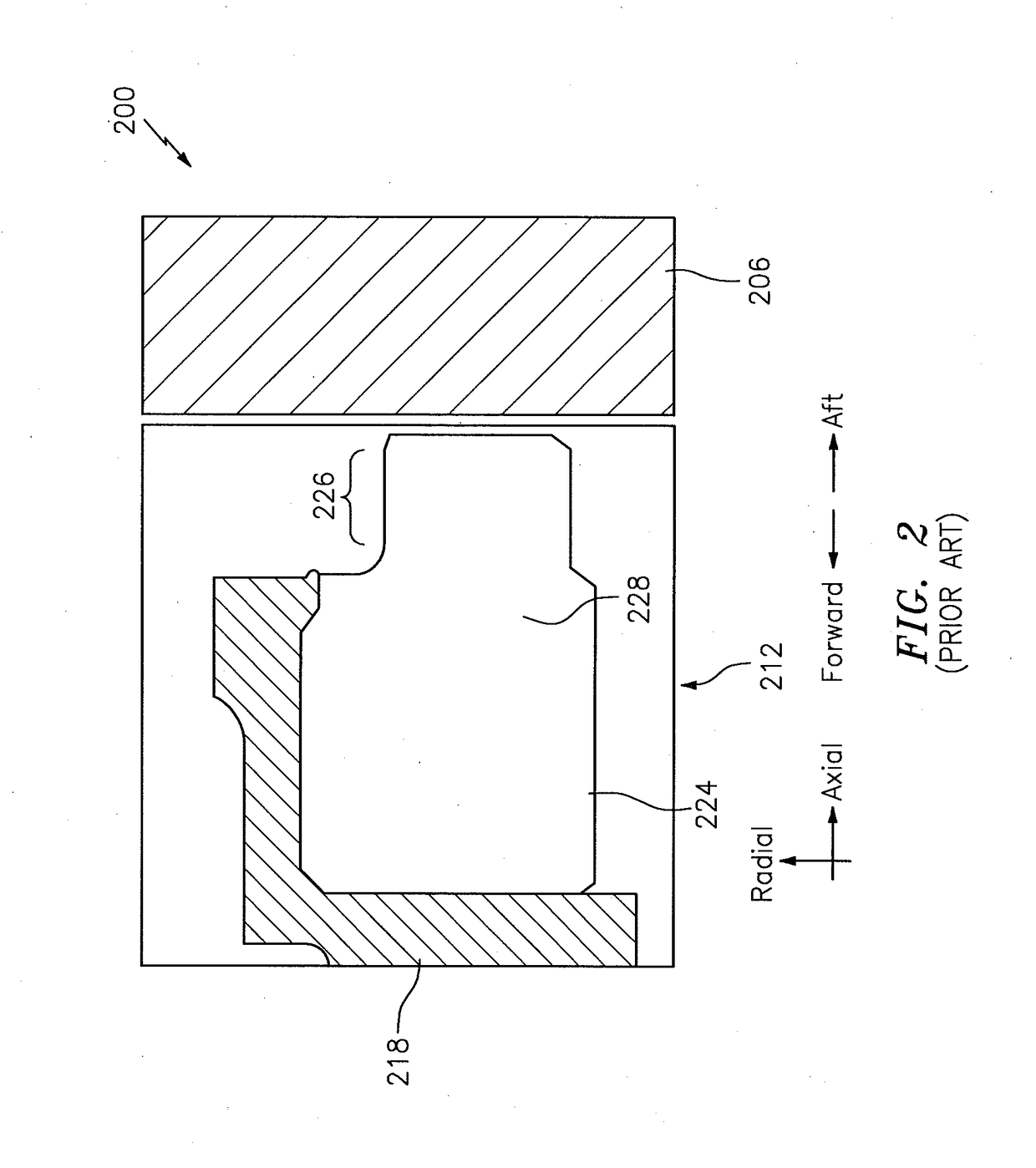

Rotary shaft monitoring seal system

InactiveUS6082737AEasy to installEasy to operateEngine sealsPiston ringsMechanical engineeringFluid leakage

A rotary shaft monitoring seal system includes a seal housing; a seal assembly in the housing for sealingly engaging a rotary shaft to prevent fluid leakage between the shaft and the housing; a monitoring port in the housing; and a detector assembly mounted in the port for sensing conditions in the vicinity of the seal assembly.

Owner:EG&G +1

Monitoring seal system

InactiveUS20010030396A1Prevent liquid leakageEngine sealsPiston ringsElectrical and Electronics engineeringFluid leakage

A monitoring seal system comprises a seal housing, a seal assembly, a temperature sensor and a controller. The seal assembly sealingly engages a rotary shaft to prevent fluid leakage between the shaft and the housing. The seal assembly has at least one seal. The seal has a primary ring and a mating ring. The temperature sensor senses the temperature in the vicinity of the seal. The controller determines whether an upset condition has occurred based on at least the temperature in the vicinity of the seal.

Owner:JOHN CRANE INC

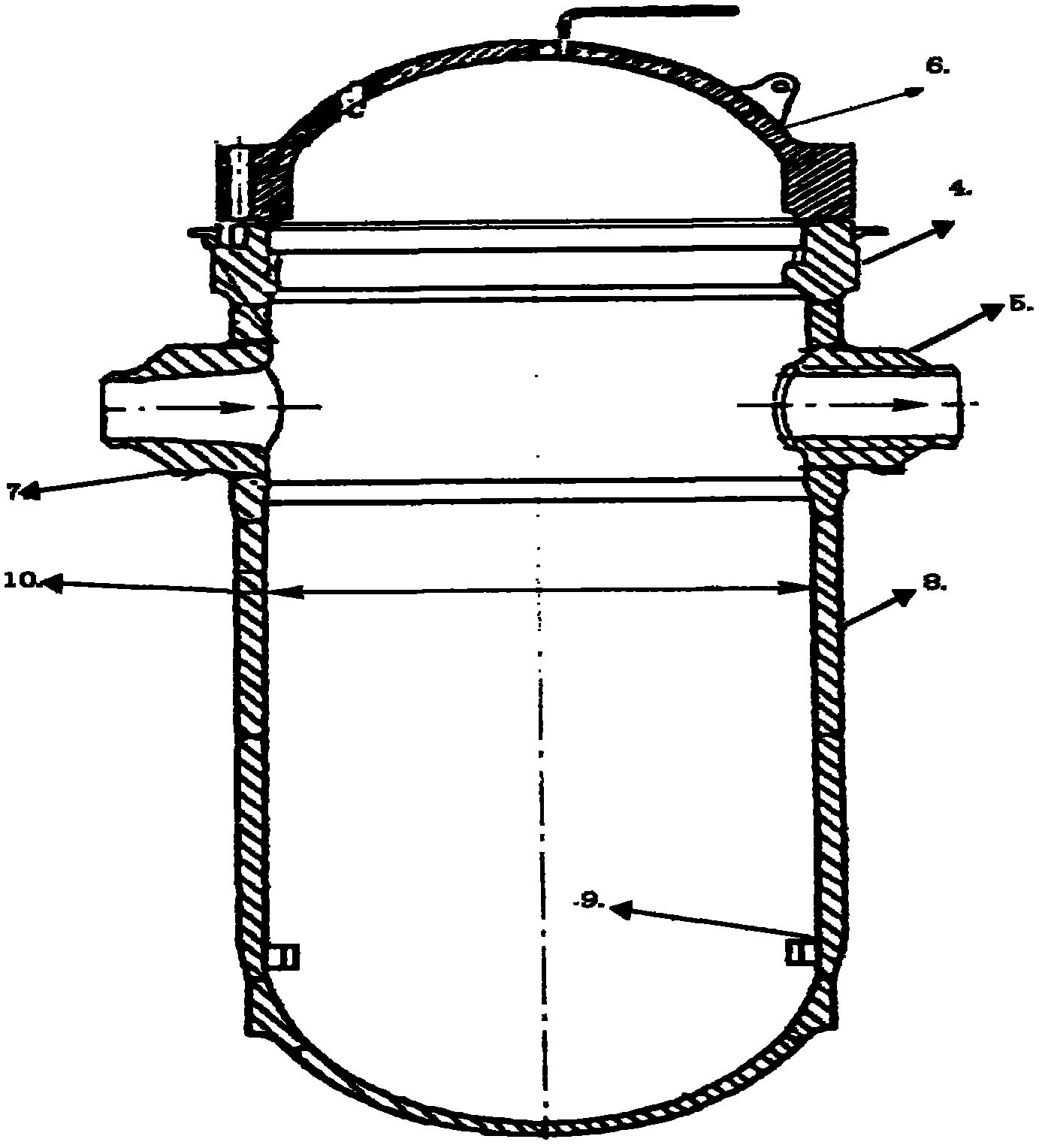

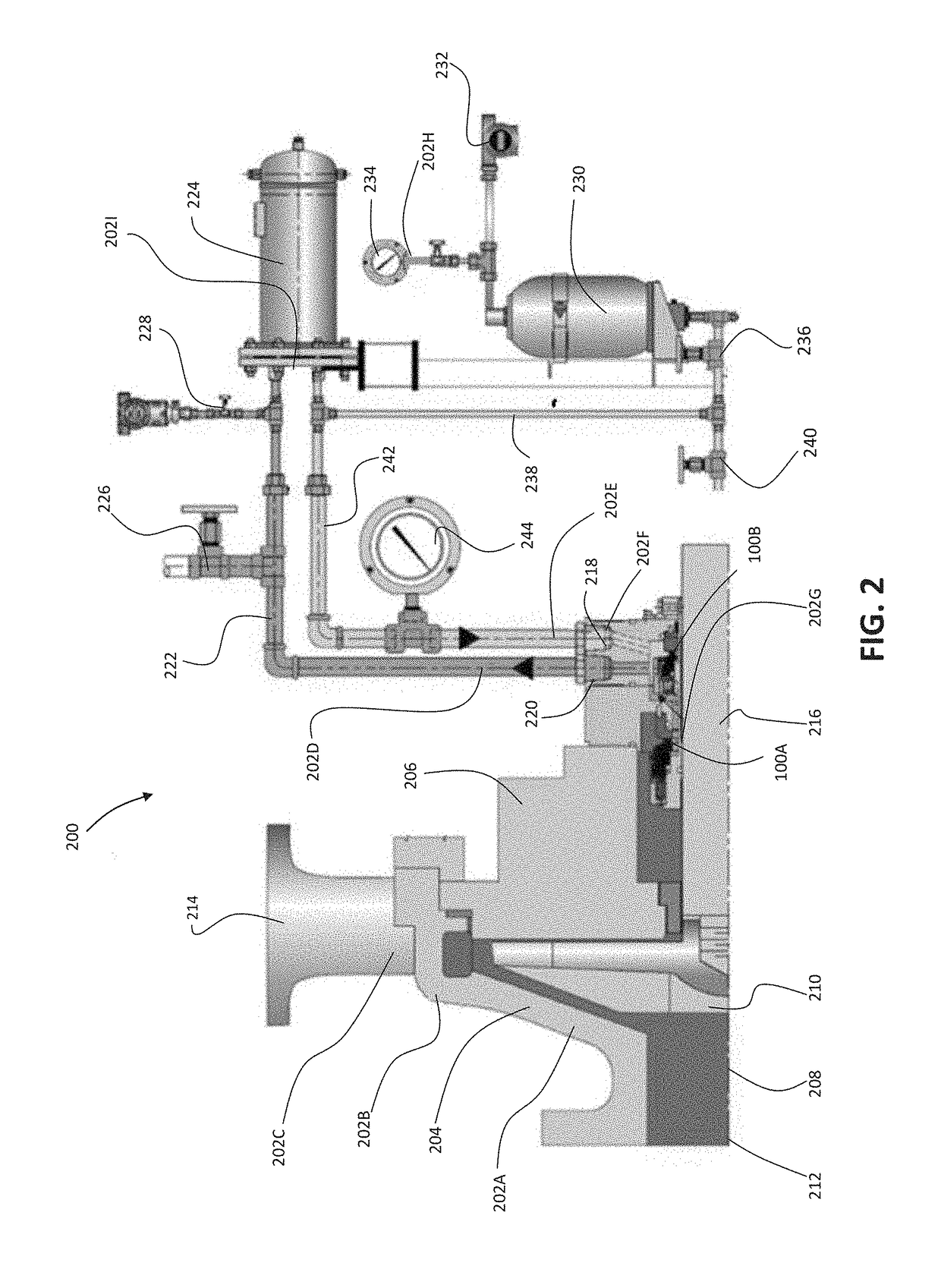

Test apparatus and method for safety valve

InactiveUS20100281954A1Ensure correct executionEasy to produceMeasurement of fluid loss/gain rateMachine valve testingControl flowEngineering

An apparatus and method for testing the performance of a safety valve. The apparatus includes an accumulator including at least one electric heater for heating a predetermined amount of water in the accumulator, and storing steam produced by the electric heater, a test vessel storing the steam supplied from the accumulator, and providing steam at a test pressure to a safety valve, the steam being supplied after controlling flow rate and pressure, a condensing tank storing demineralized water to be supplied to the accumulator, and condensing and collecting the steam discharged from the safety valve, and a water-supply pump supplying the water stored in the condensing tank to the accumulator.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

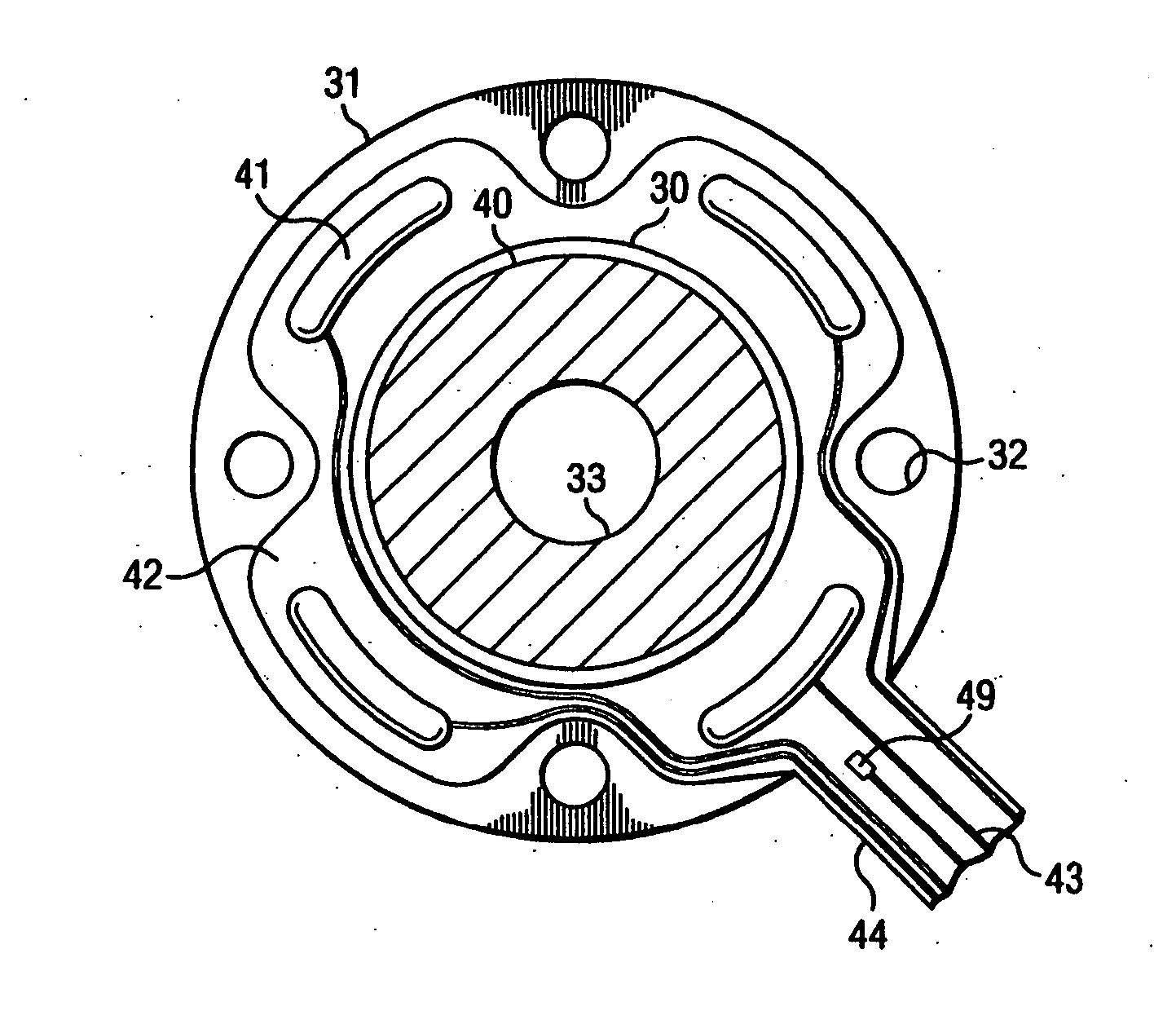

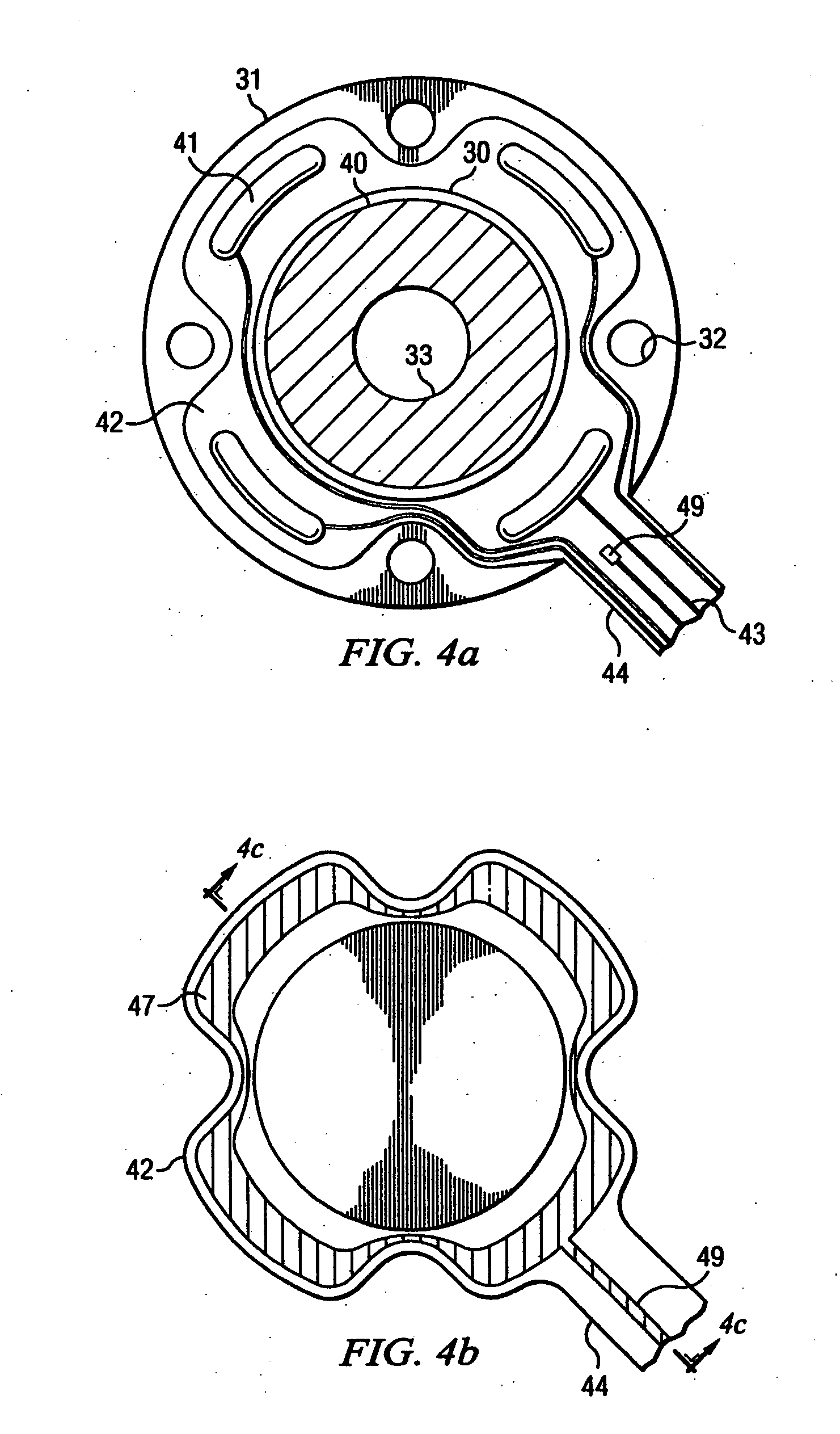

Compressive load sensor by capacitive measurement

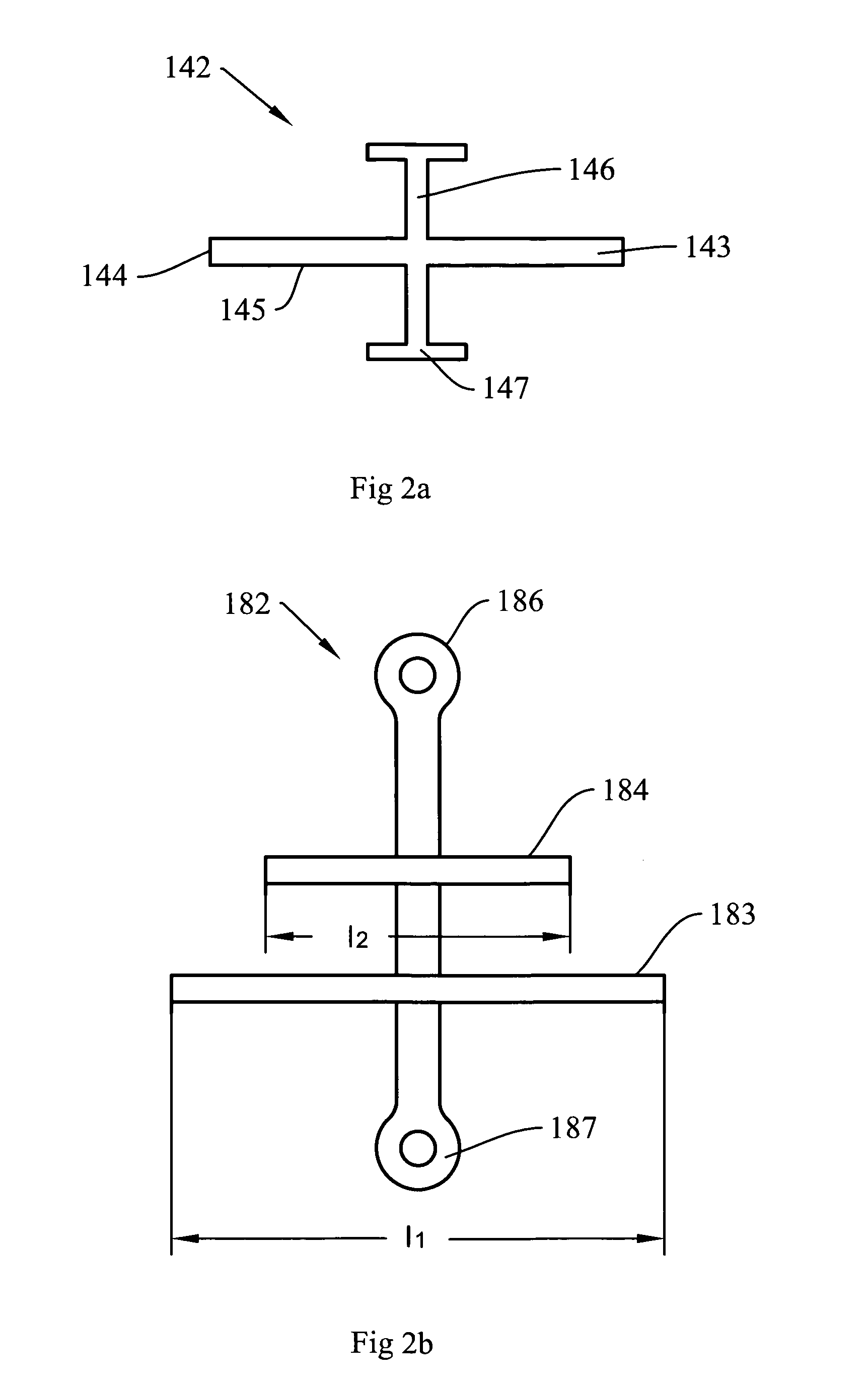

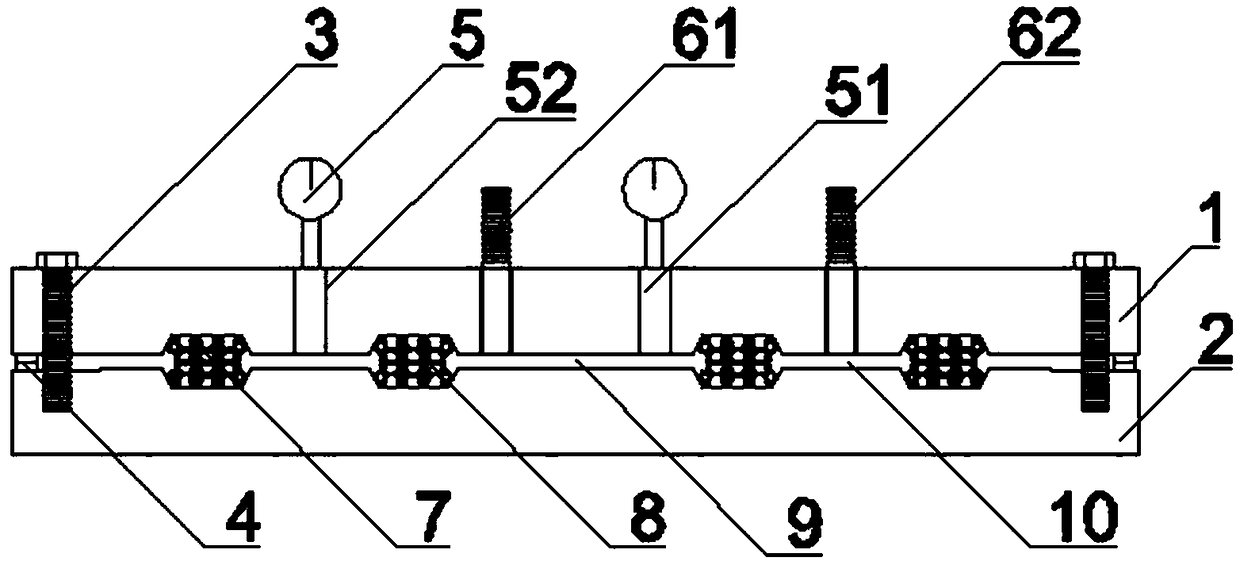

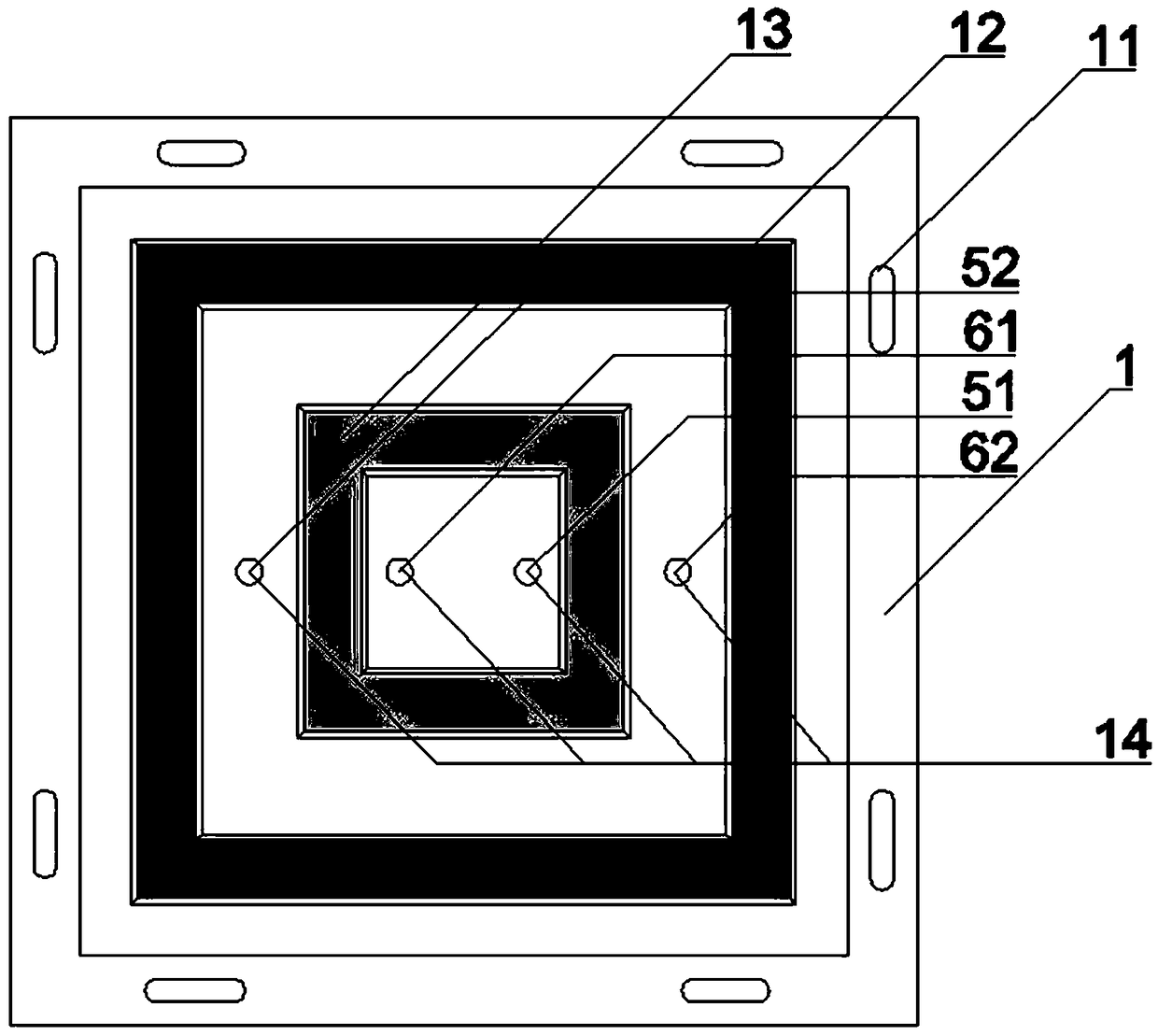

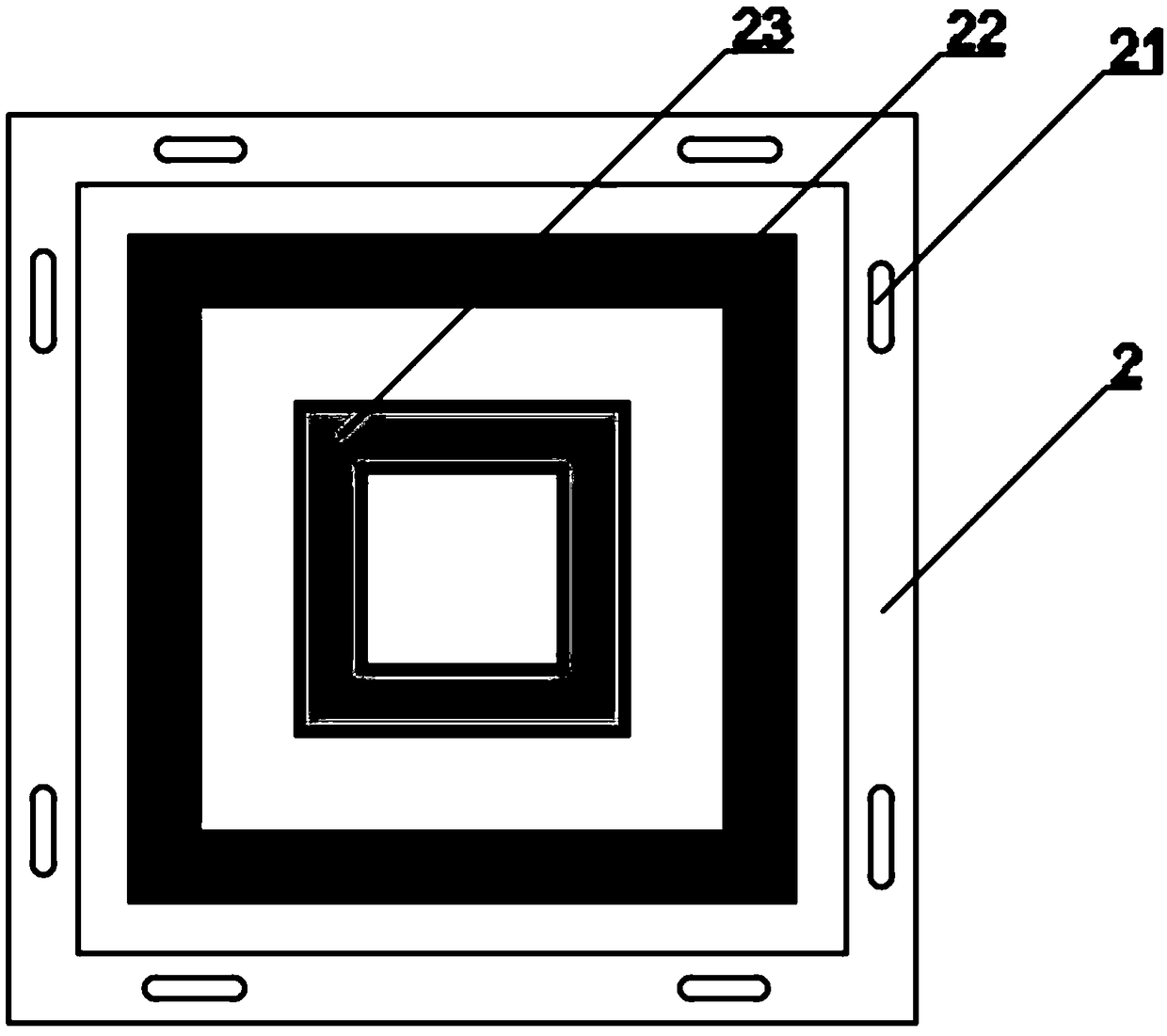

InactiveUS20080041165A1Efficient measurementMaintain measurement accuracyLoad modified fastenersMachine sealing rings testingContinuous measurementElectricity

A thin, flat capacitive load sensor, such as of layered sandwich construction, having a variety of shapes, so as to provide a seal between two or more opposing surfaces. The load sensor includes a thin first and second insulating outer layer between which an inner layer is secured. The inner layer can be formed of dielectric material of a known dielectric constant, with at least one thin electrical conductor to accommodate load sensing disposed against a first face, and another thin electrical conductor to accommodate load sensing disposed against a second face. Electrical conductors connect the thin conductive areas on the first and second faces to the distal end of a tab ending beyond the load or connection measurement area. The distal end of the tab accommodates a connection with electrical measurement apparatus. As the inner layer is compressed, the spacing between the electrically conductive areas on the opposing faces is decreased such that compressive forces can be measured as a function of the changes in capacitance of the sensor. In this manner, proper compression can be achieved by monitoring capacitance during installation. Follow-up sampling or continuous measurement of sensor compression provides early detection prior to failure to allow corrective action.

Owner:COFFEY E MICHAEL +1

Method for assessing remaining service life of rubber sealing ring

InactiveCN106124191AImprove universalityReduced formulaMachine sealing rings testingMaterial testing goodsAccelerated agingCompression set

The invention relates to a method for assessing the remaining service life of a rubber sealing ring. A to-be-assessed object is a rubber sealing ring which is assembled on ammo and other weapons which are stored for some years and has already generated certain compression set. The original radial section height of the to-be-assessed object is known, and the change rule of the compression set generated by the rubber sealing ring in an accelerated aging test is employed for the extrapolation of the change rule of the compression set under the storage temperature, thereby taking an invalid critical value as the basis, and assessing the remaining service life of an old rubber sealing ring.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

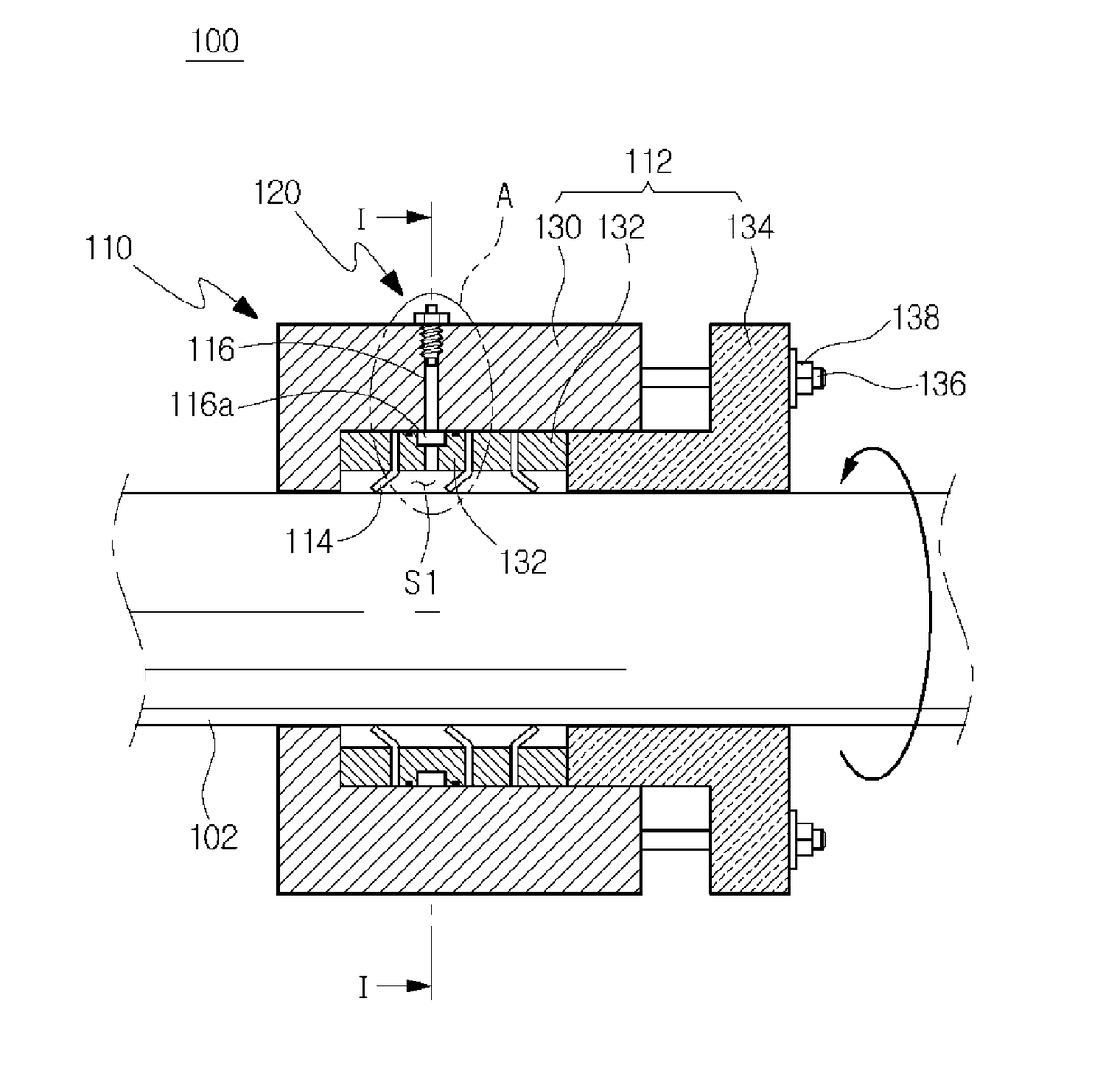

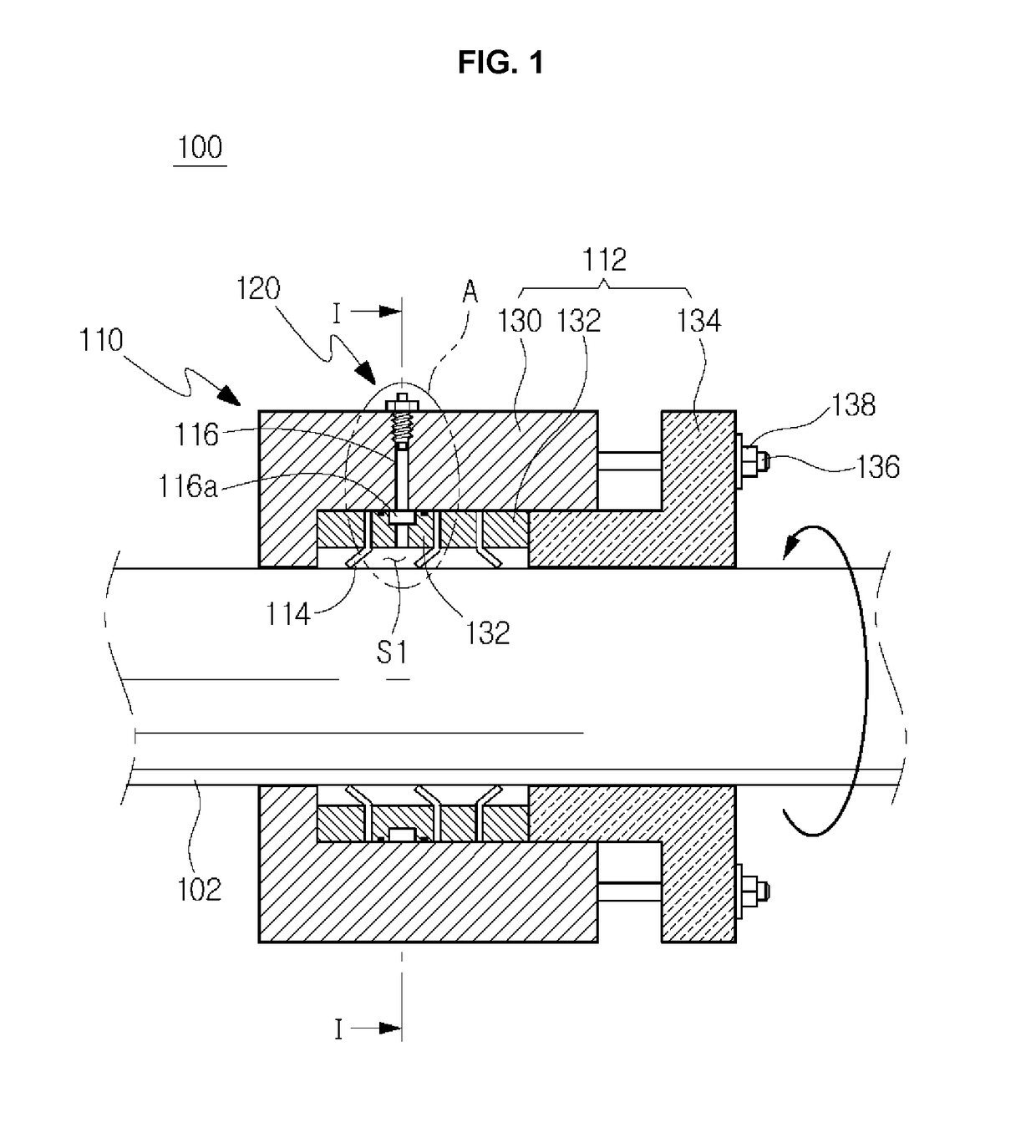

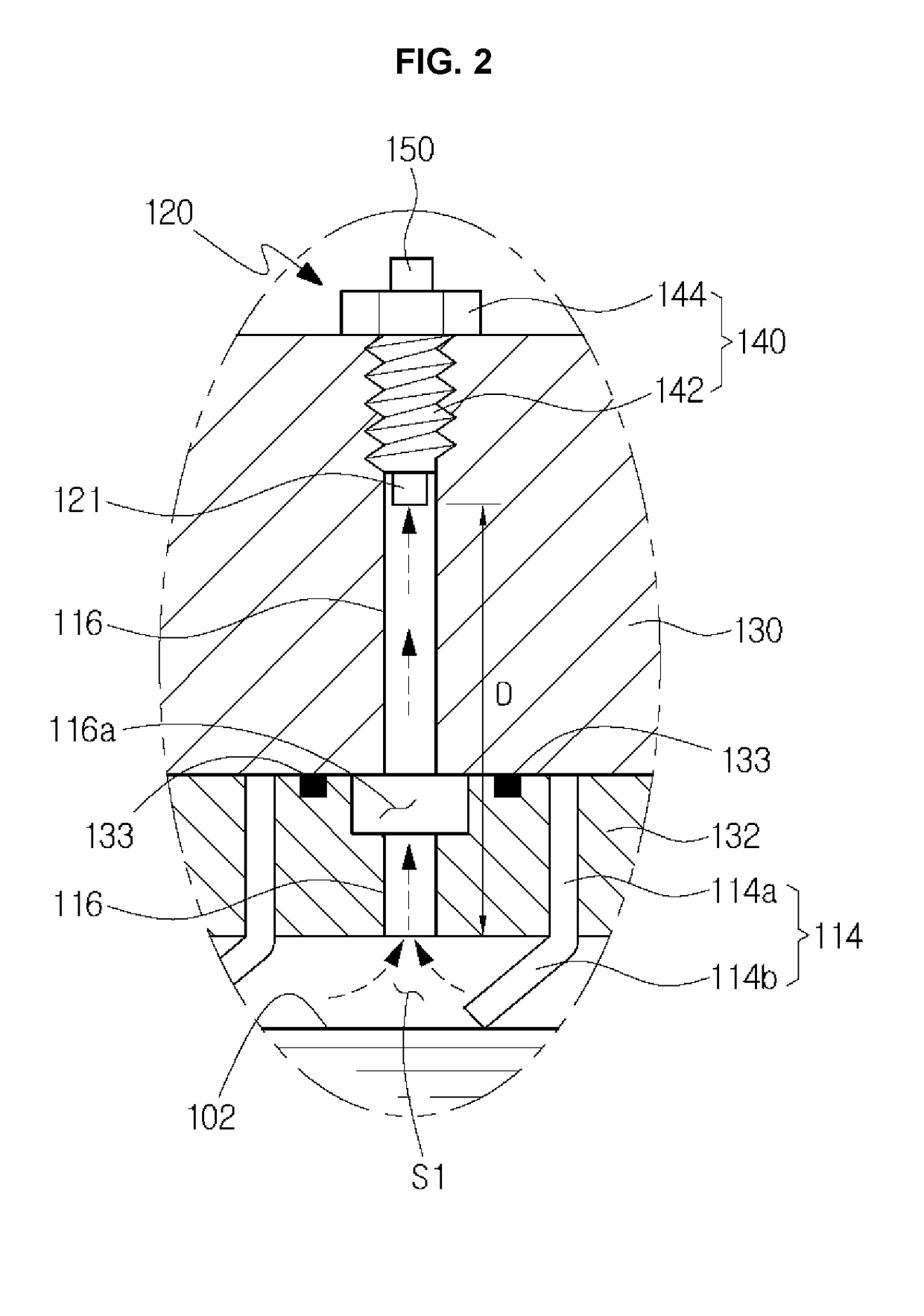

Sealing system having leakage sensing function

ActiveUS20170108399A1Quickly and accurately sense whether sealing memberLeakage accidentDetection of fluid at leakage pointMeasurement of fluid loss/gain rateCommunication unitEngineering

One embodiment of the present invention relates to a sealing system having a leakage sensing function. A leakage sensing unit is arranged in a sealed space which is formed between sealing members of a sealing device body so as to sense, in real time, whether the sealing members are leaking, wherein a sensing value of the leakage sensing unit can be transmitted to the outside by using a communication unit.

Owner:SEALINK

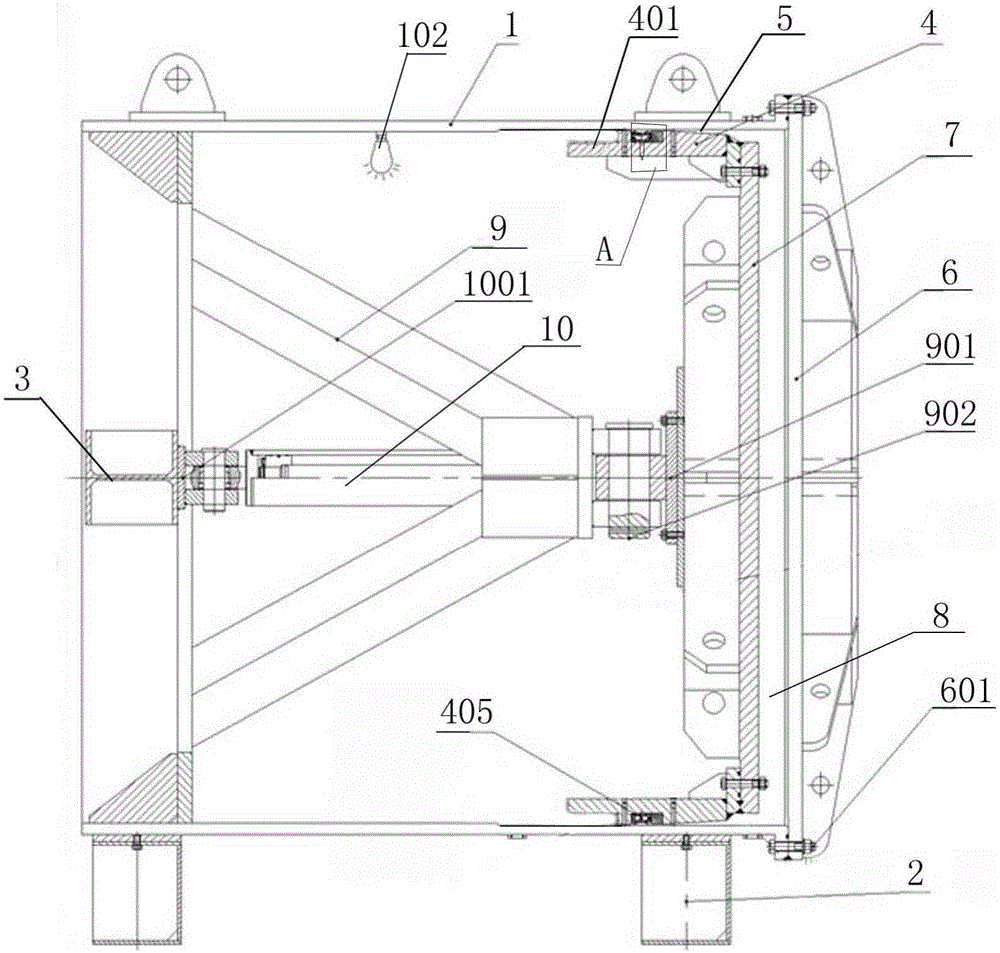

Experimental device and experimental method for rotation dynamic sealing characteristics of sealing ring

ActiveCN106092562AGuaranteed certaintyGuaranteed stabilityMachine sealing rings testingMotor driveExperimental methods

The invention discloses an experimental device and an experimental method for the rotation dynamic sealing characteristics of a sealing ring. The device comprises a support. A torque rotation speed sensor is installed on the support and a sleeve assembly is sleeved on a shaft thereof. The sleeve assembly is fixedly connected with the support. Two Glyd ring mounting parts are arranged in the sleeve assembly at intervals in the axial direction. A sealing ring mounting part is provided between the two Glyd ring mounting parts. After a Glyd ring and a sealing ring are loaded into the Glyd ring mounting parts and the sealing ring mounting part, the shaft can pass through the Glyd ring and the sealing ring to rotate in the Glyd ring and the sealing ring. A containing cavity for the shaft to pass through is arranged inside each of the Glyd ring mounting parts and the sealing ring mounting part respectively inside the sleeve assembly. According to the experimental device for the rotation dynamic sealing characteristics of the sealing ring, a motor driving shaft is rotated inside the sleeve assembly. After a sealing ring is arranged inside a sealing ring mounting part B, the shaft can pass through the sealing ring to rotate in the sealing ring. In this way, the working state of the sealing ring during rotating can be simulated, so that the experiment on the rotation dynamic sealing characteristics of the sealing ring can be conducted.

Owner:OCEAN UNIV OF CHINA

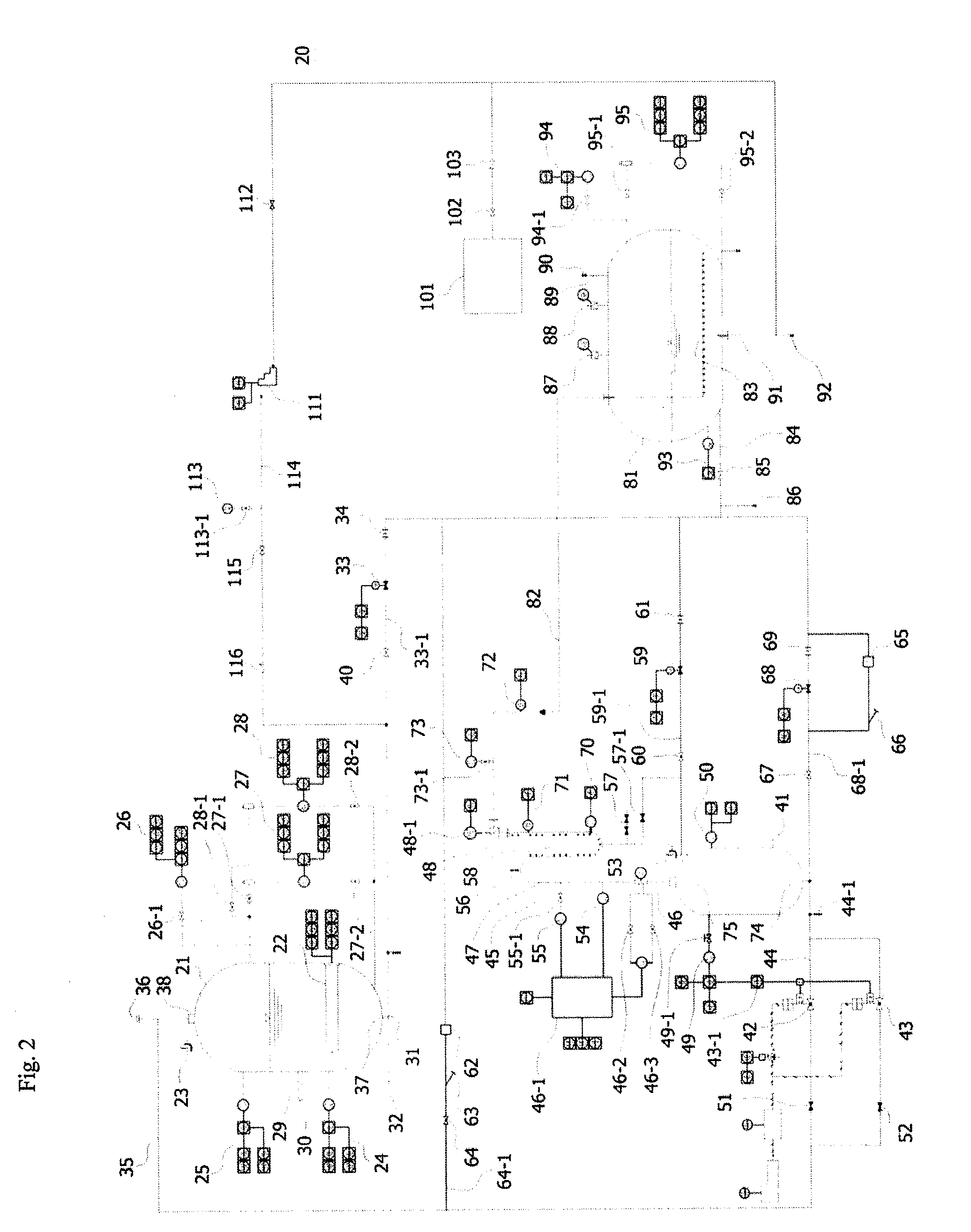

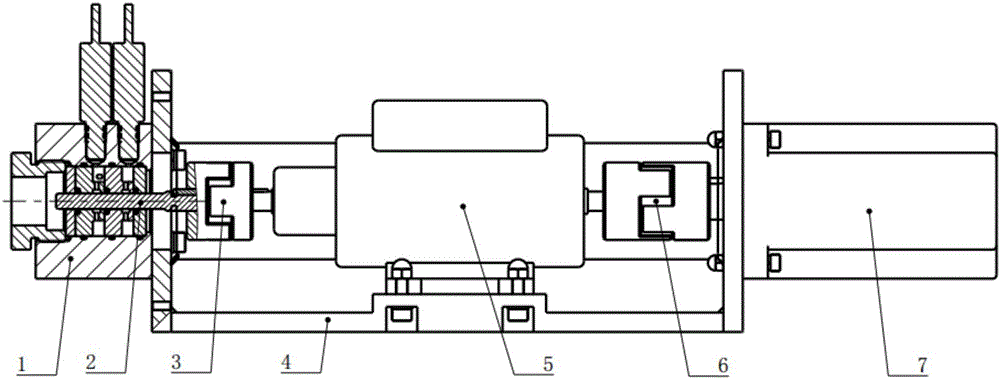

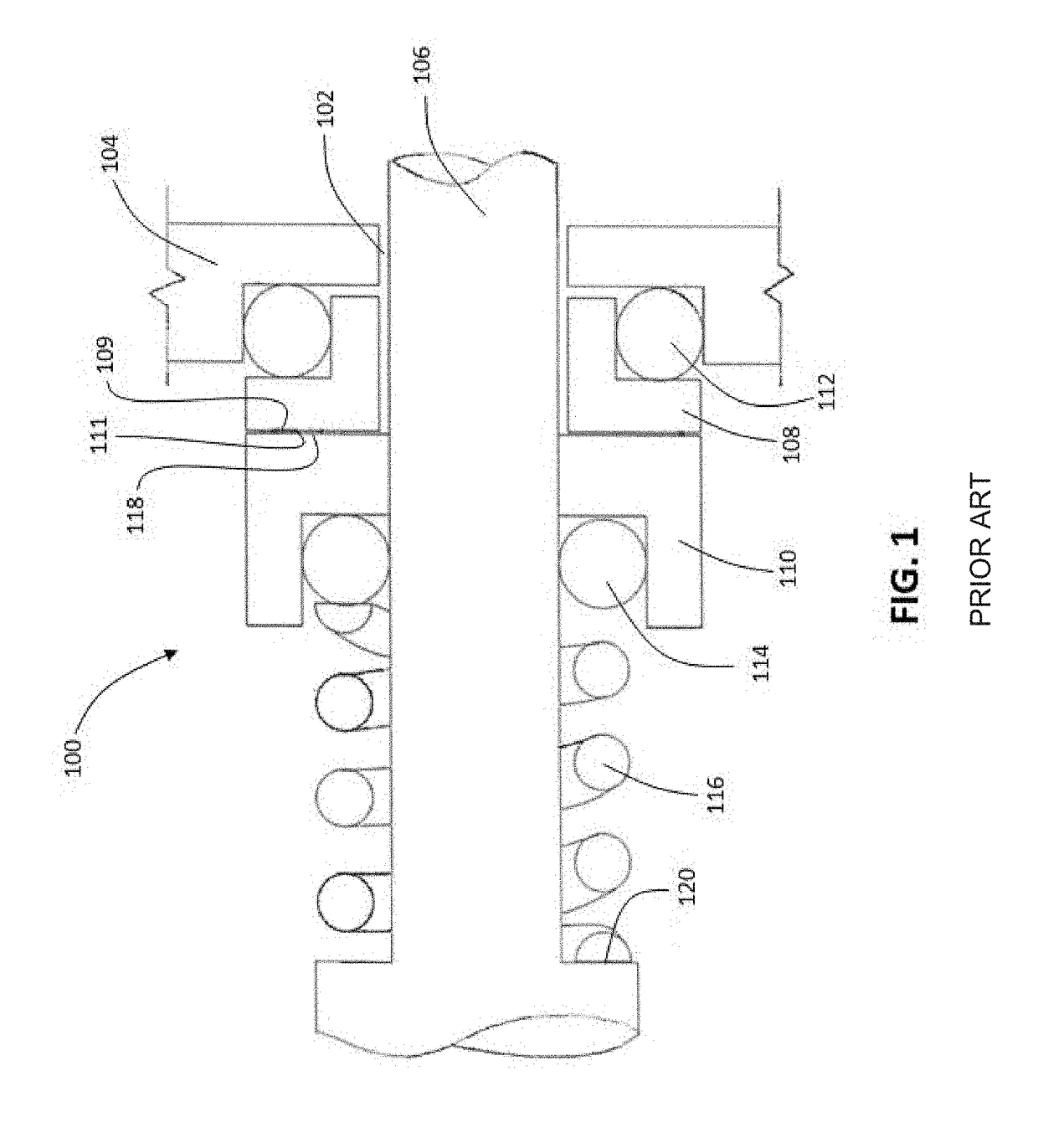

Device for testing mechanical seal performance

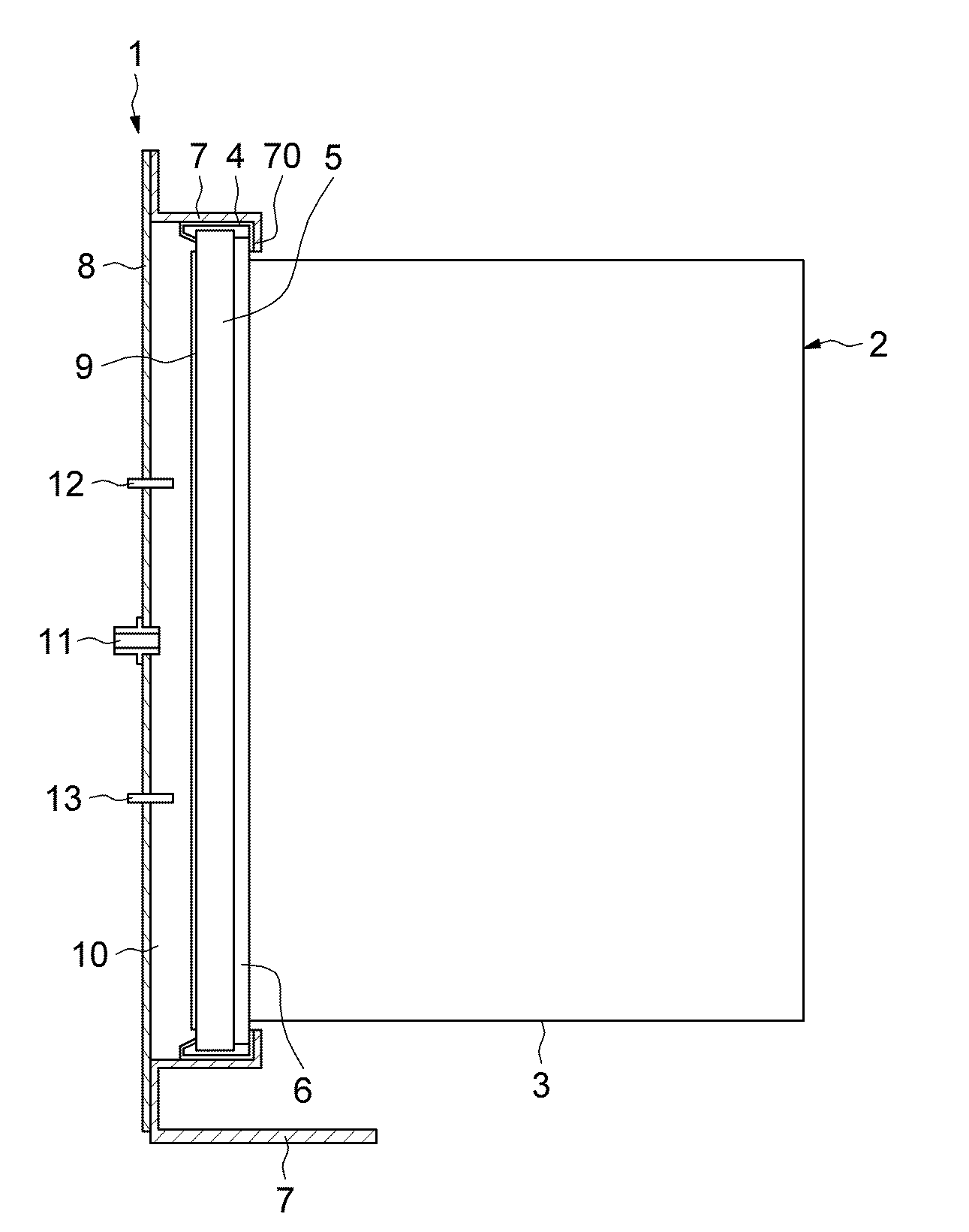

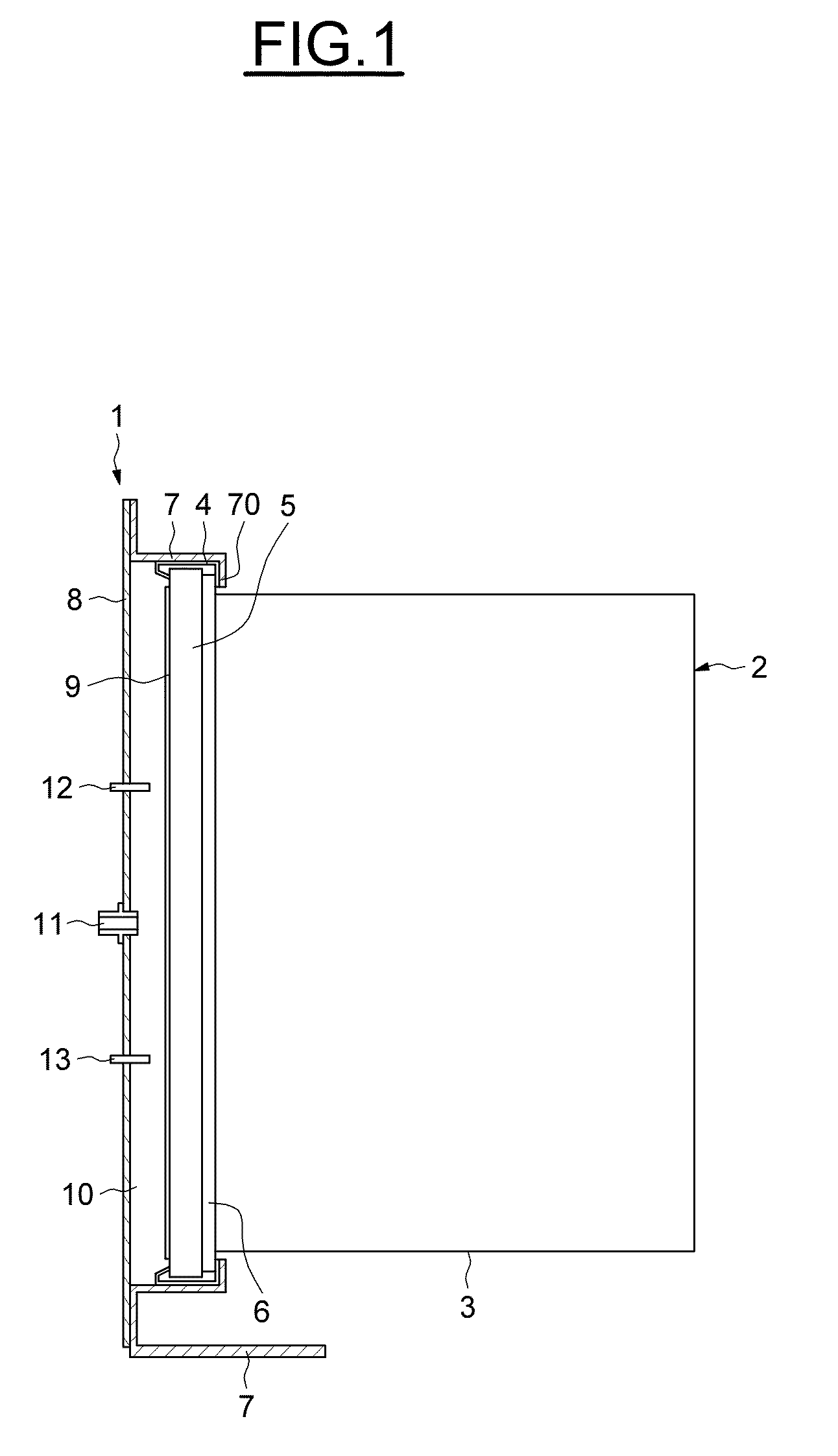

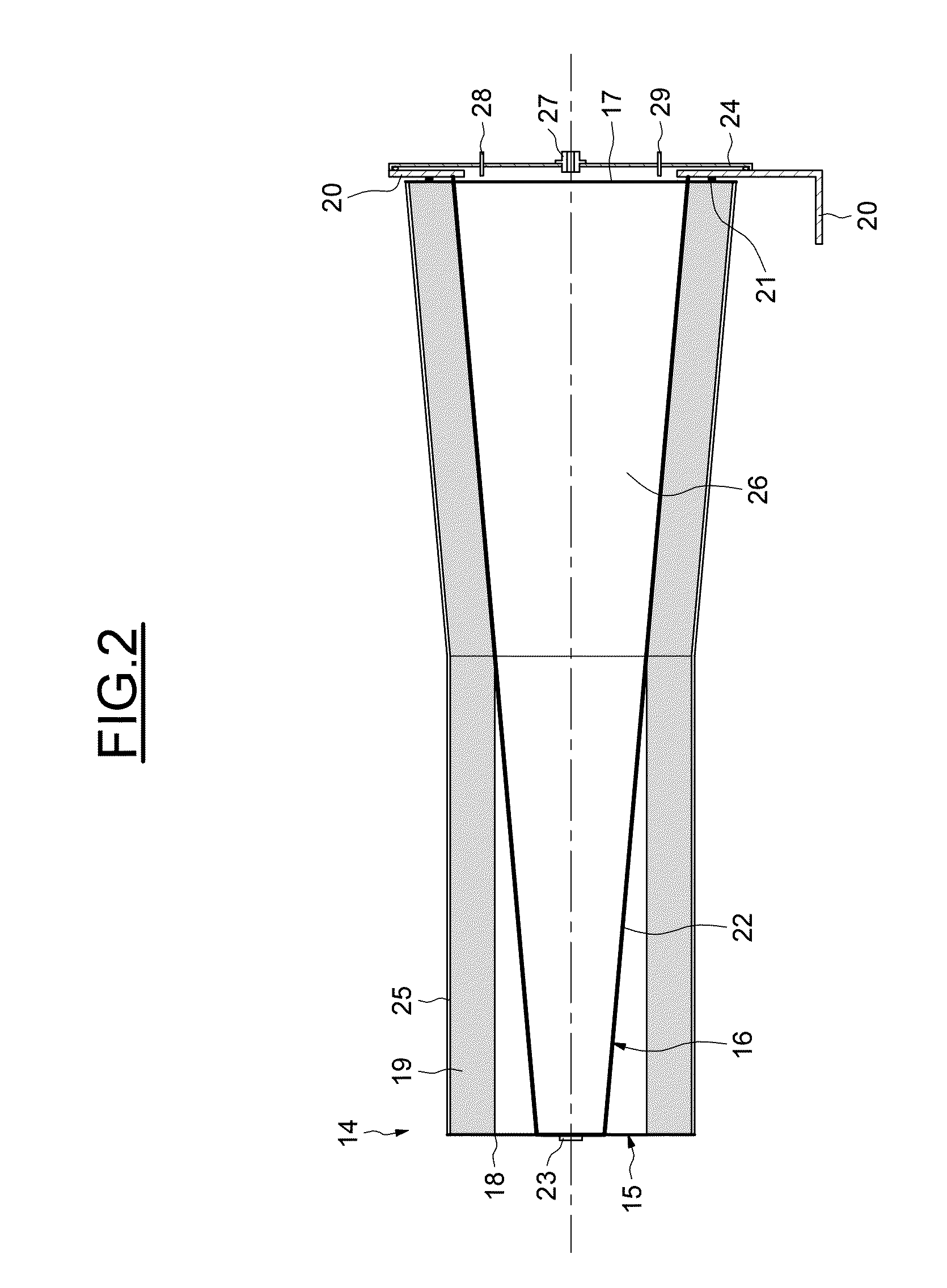

ActiveUS20160146681A1Improving on-site installation workabilityHigh measurement accuracyMeasurement of fluid loss/gain rateWork measurementEngineeringMechanical engineering

A device for testing mechanical seal performance includes a main shaft (4), a working chamber (18) with two end covers (6, 13) respectively located at two ends thereof, and two groups of mechanical seals to be tested (7); wherein a shaft sleeve (5) and the main shaft (4) form a clearance fit and penetrate through the end covers (6, 13) at two ends of the working chamber (18) together; the shaft sleeve (5) extends outside U-shaped openings (23) which are arranged at two ends of the end covers (6, 13) and arranged on the same generatrix; driven pins (15) are arranged on the locations of the main shaft (4) corresponding to the U-shaped openings (23); the middle part of the shaft sleeve (5) is provided with two segments of threads having the same thread pitch and opposite rotating directions.

Owner:NANJING FORESTRY UNIV

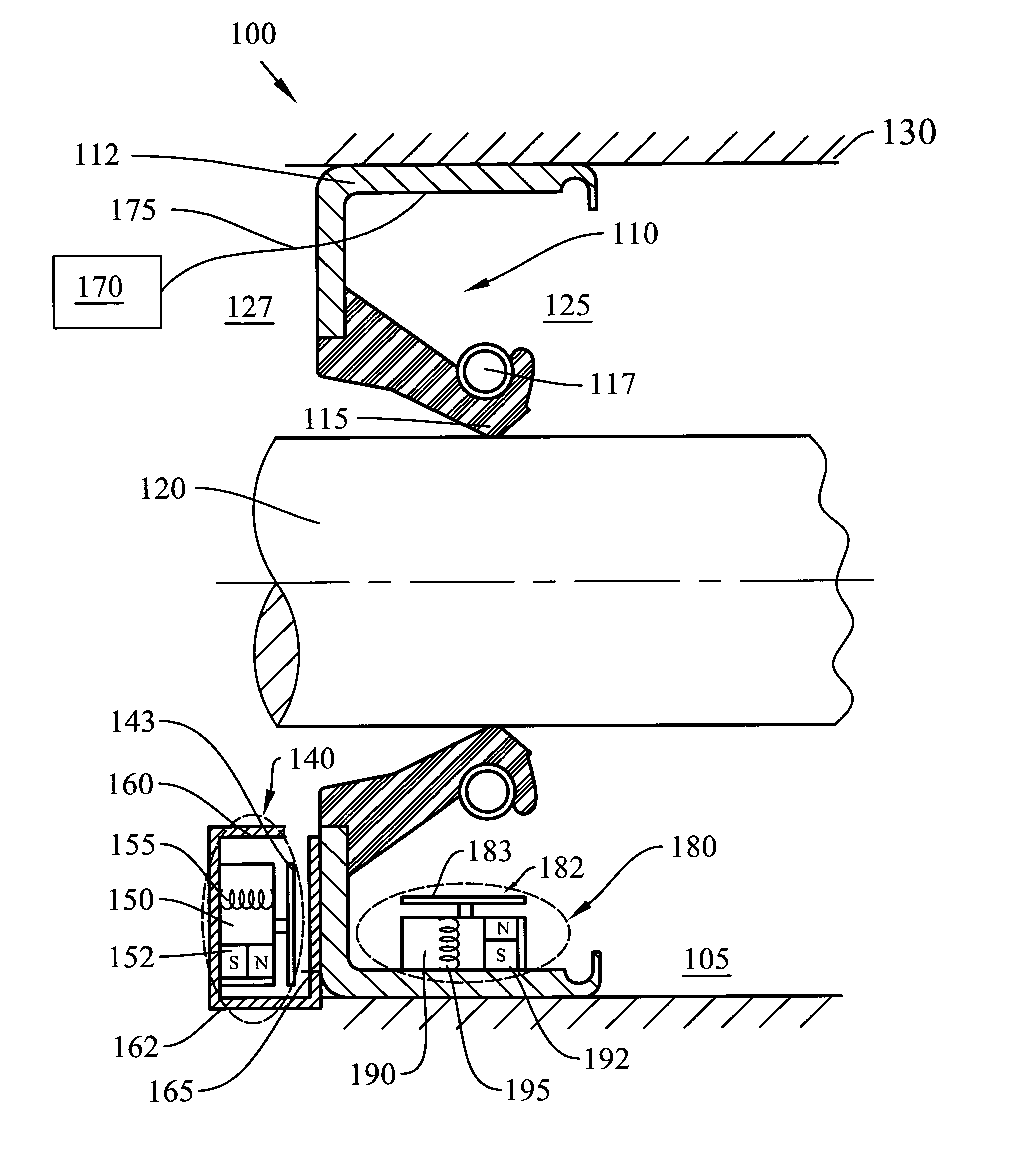

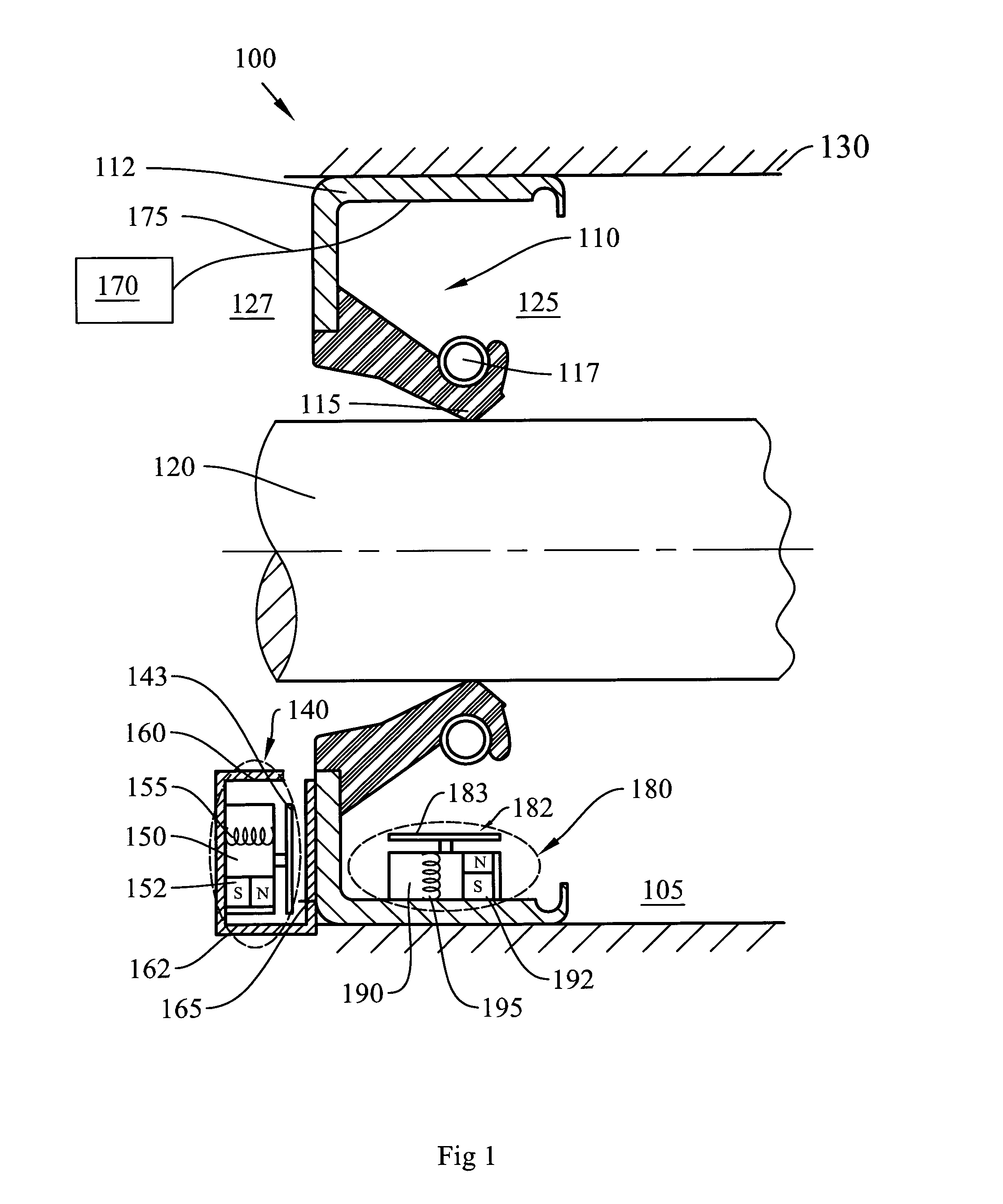

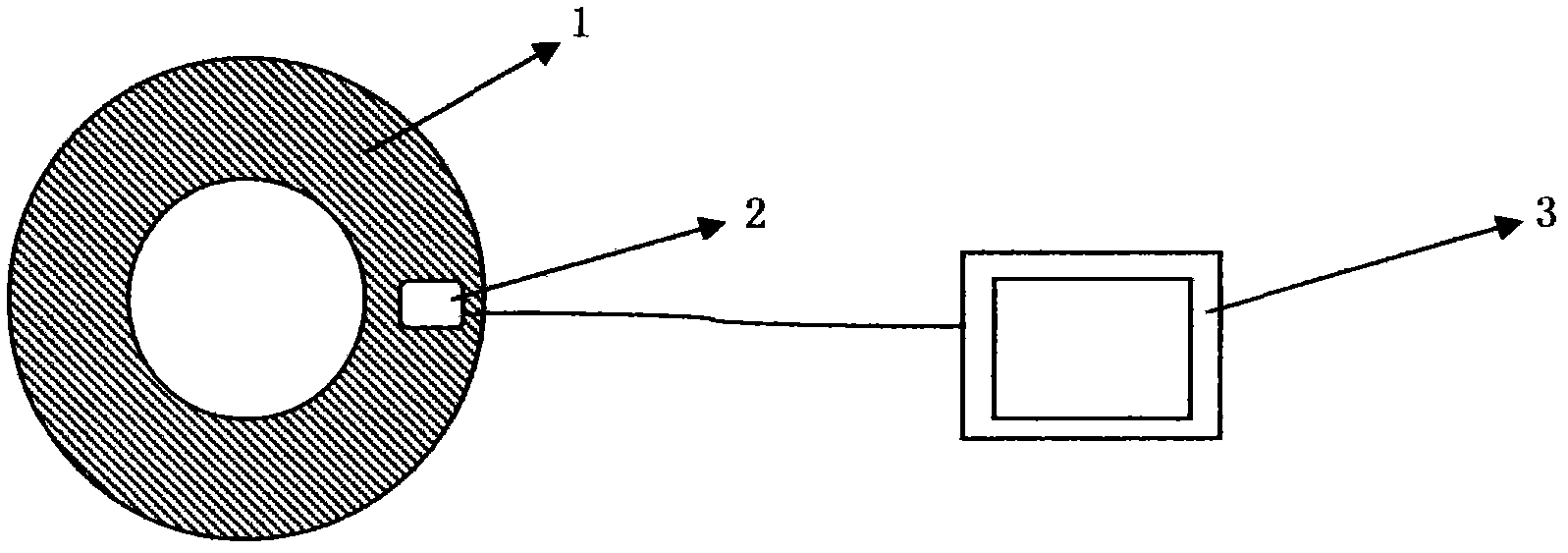

Sensorized Sealing System

ActiveUS20140049008A1Easy to adaptHigh reluctanceDetection of fluid at leakage pointEngine sealsResonanceMagneto elastic

The present invention relates to a sealing system comprising a seal that retains a liquid in a space between two concentrically mounted and relatively rotatable components. According to the invention, the sealing system comprises at least one magneto-elastic resonance sensor for measuring at least one parameter of interest associated with the sealed liquid, based on a detected resonant frequency of the at least one sensor.

Owner:AB SKF

Multi-stage compression rate adjustable static sealing test experiment device

ActiveCN110274735AComprehensive test functionEasy to detectDetection of fluid at leakage pointMachine sealing rings testingPre compressionEngineering

The invention discloses a multi-stage compression rate adjustable static sealing test experiment device. The device comprises a leak detection port, a sealing end cover, an experimental box body, a medium inlet, a medium outlet, a test sealing ring 1, a test sealing ring 2, a test sealing ring 3, a gas sensor, and external seal. The experimental box body is fixed on a workbench, and the sealing end cover is fixedly connected with the experimental box body. A plurality of sealing grooves are arranged at a conical surface of the sealing end cover to achieve a sealing performance test of single channel sealing rings with different outer ring diameters and cross-sectional dimensions, and multi-stage sealing of two-channel and multi-channel O-shaped rings. A gasket between the sealing end cover and the box body is replaced to adjust a distance between the two so as to realize sealing performance detection under different pre-compression ratios.

Owner:TSINGHUA UNIV

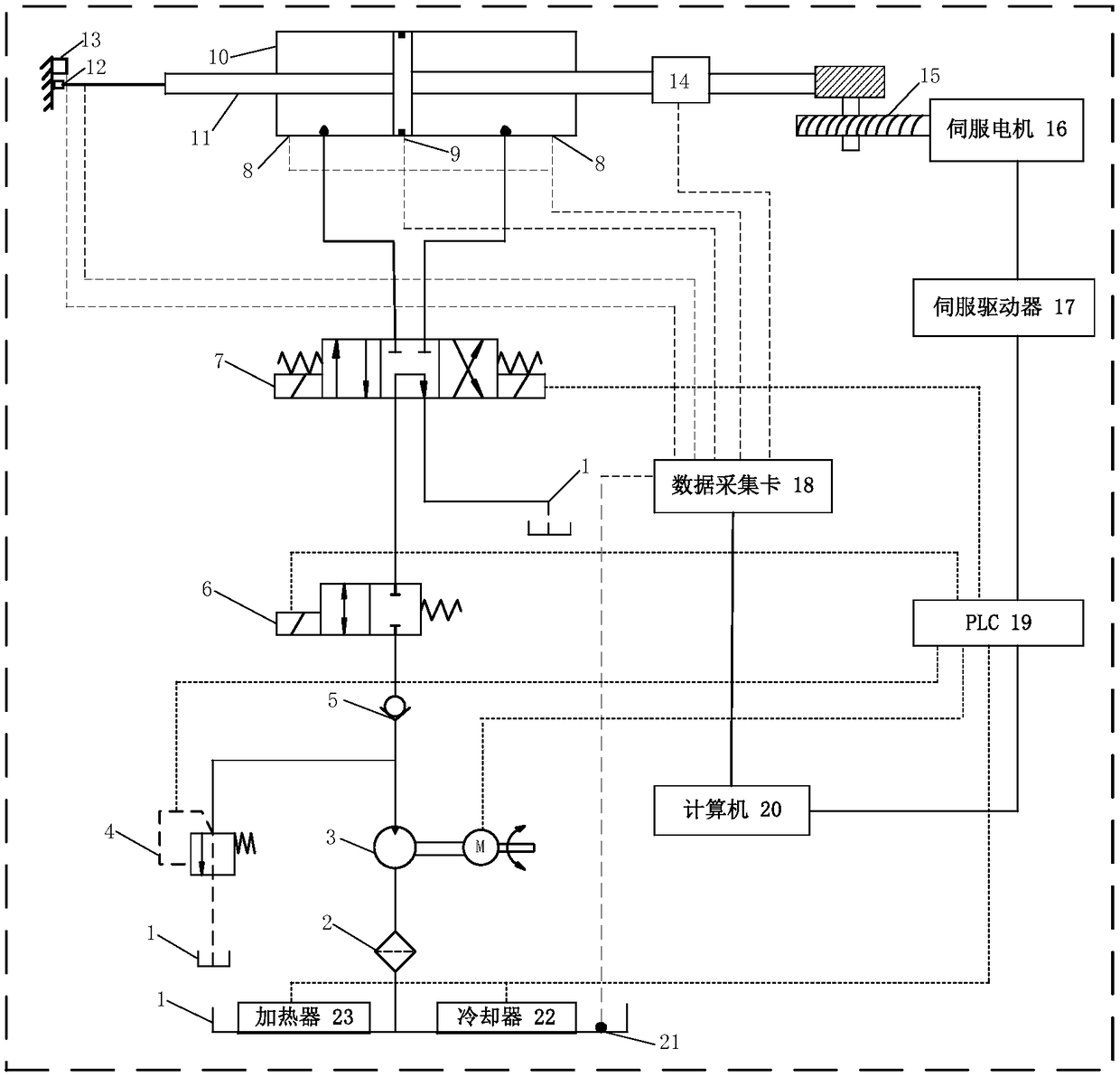

Testing method and device for service fatigue performance of hydraulic reciprocating seal

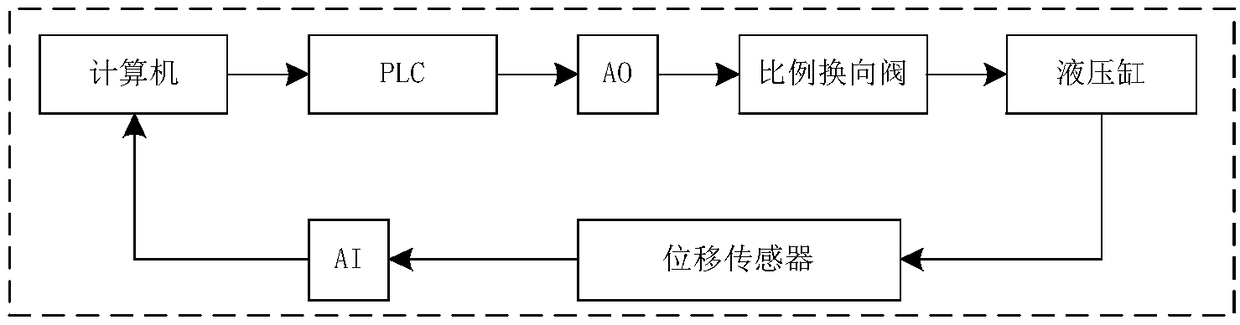

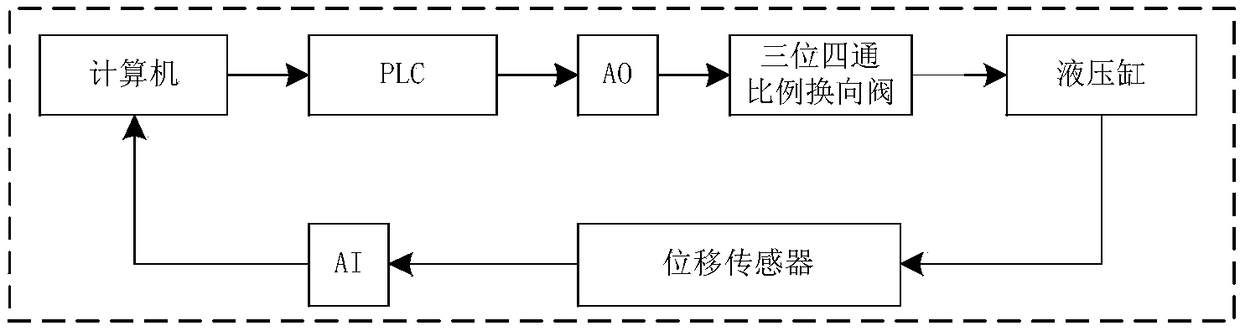

ActiveCN109357960AReal-time monitoring of fatigue statusAccurate Service Fatigue LifeMachine sealing rings testingMaterial strength using repeated/pulsating forcesEngineeringReliability design

The invention relates to a testing method and device for the service fatigue performance of a hydraulic reciprocating seal. A servo motor system provides a variable load for a hydraulic cylinder, a hydraulic system is used to control the reciprocating motion of a test cylinder, and a temperature controlling system is used for the control of the oil temperature, thereby realizing the simulation ofthe actual working condition of the hydraulic reciprocating seal. The contact stress of the hydraulic reciprocating seal is measured by a fiber grating strain sensor laid on the inner side of a pistonguide sleeve to realize the monitoring of the service state of the seal. The analysis and judgment of the fatigue failure state of the hydraulic reciprocating seal are realized by calculating the fatigue failure probability of the hydraulic cylinder / piston seal load friction pairs system. The fatigue life testing result of the hydraulic reciprocating seal under specific service conditions can beobtained through testing, which provides a basis for the reliability design of the hydraulic reciprocating seal.

Owner:WUHAN UNIV OF TECH

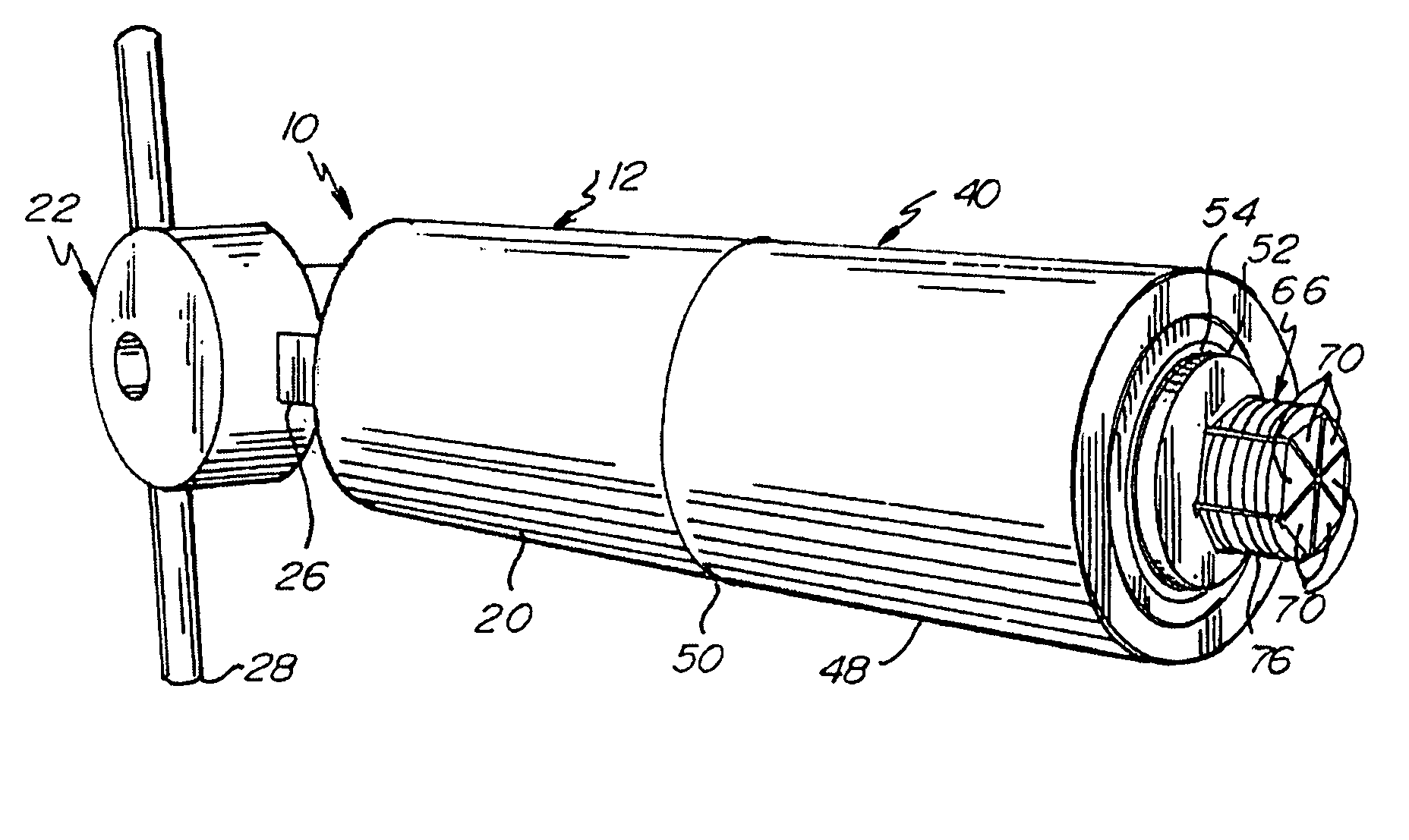

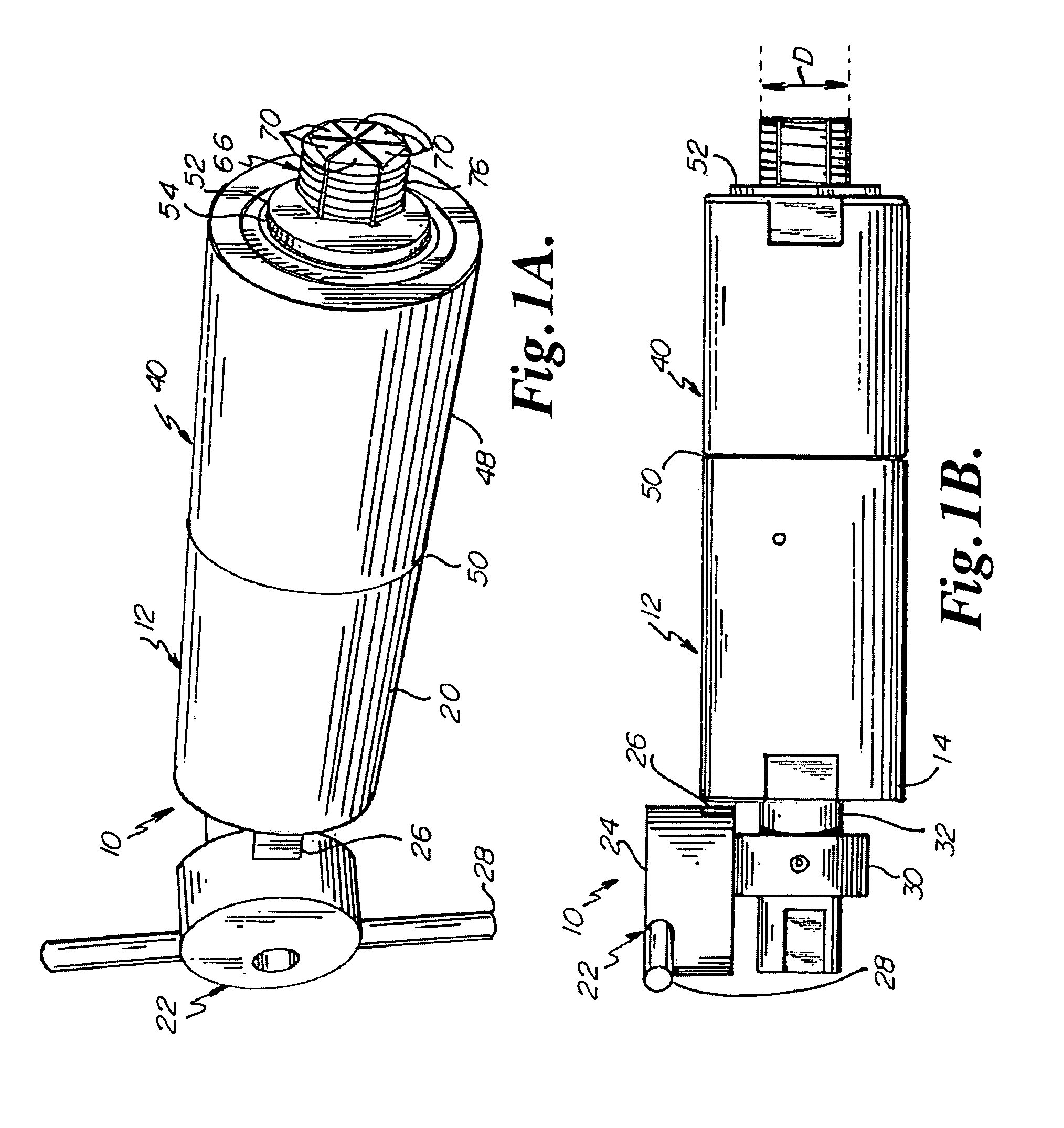

Hydrostatic testing tool and methods of use

ActiveUS7934415B2Quickly unsecuredImprove sealingSleeve/socket jointsDetection of fluid at leakage pointHermetic sealCoupling

A hydrostatic testing tool for testing containers, hoses or the like under high pressures. The testing tool having a coupling that threadably engages a threaded aperture of a test container without having to be rotated into the threaded aperture. The hydrostatic testing tool may be hooked up to a source of pressurized medium and the tool includes a container-engaging head having a plurality of collet segments that each have a threaded surface that can expand radially outward, partially due to the force of the pressurized medium, to engage a threaded aperture of the test container, allowing for the formation of a liquid and / or gas tight seal under high pressures. The testing tool further includes an actuating unit connected to the head that controls the movement of the collet segments with a piston or the like.

Owner:AIRMO INC

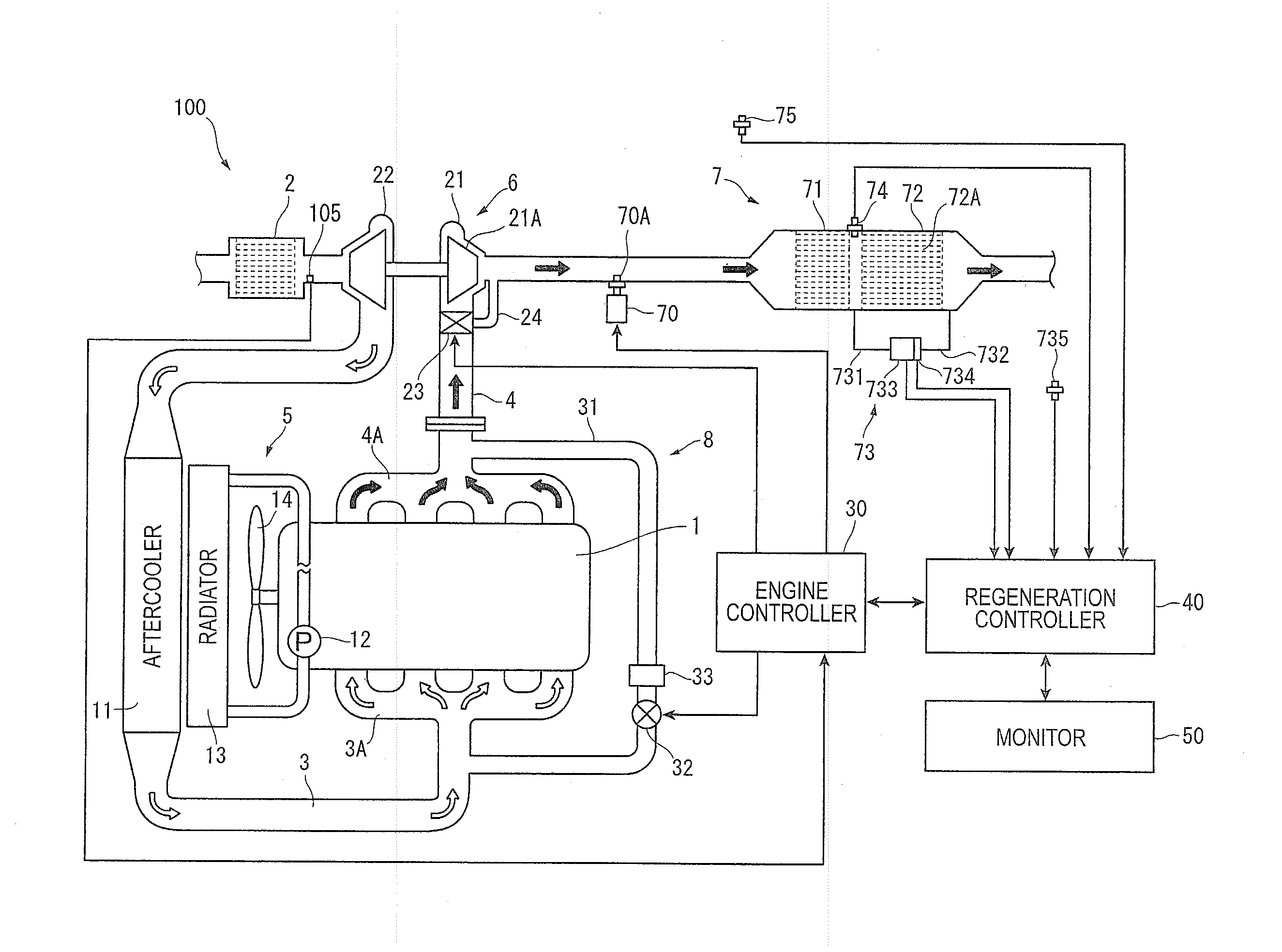

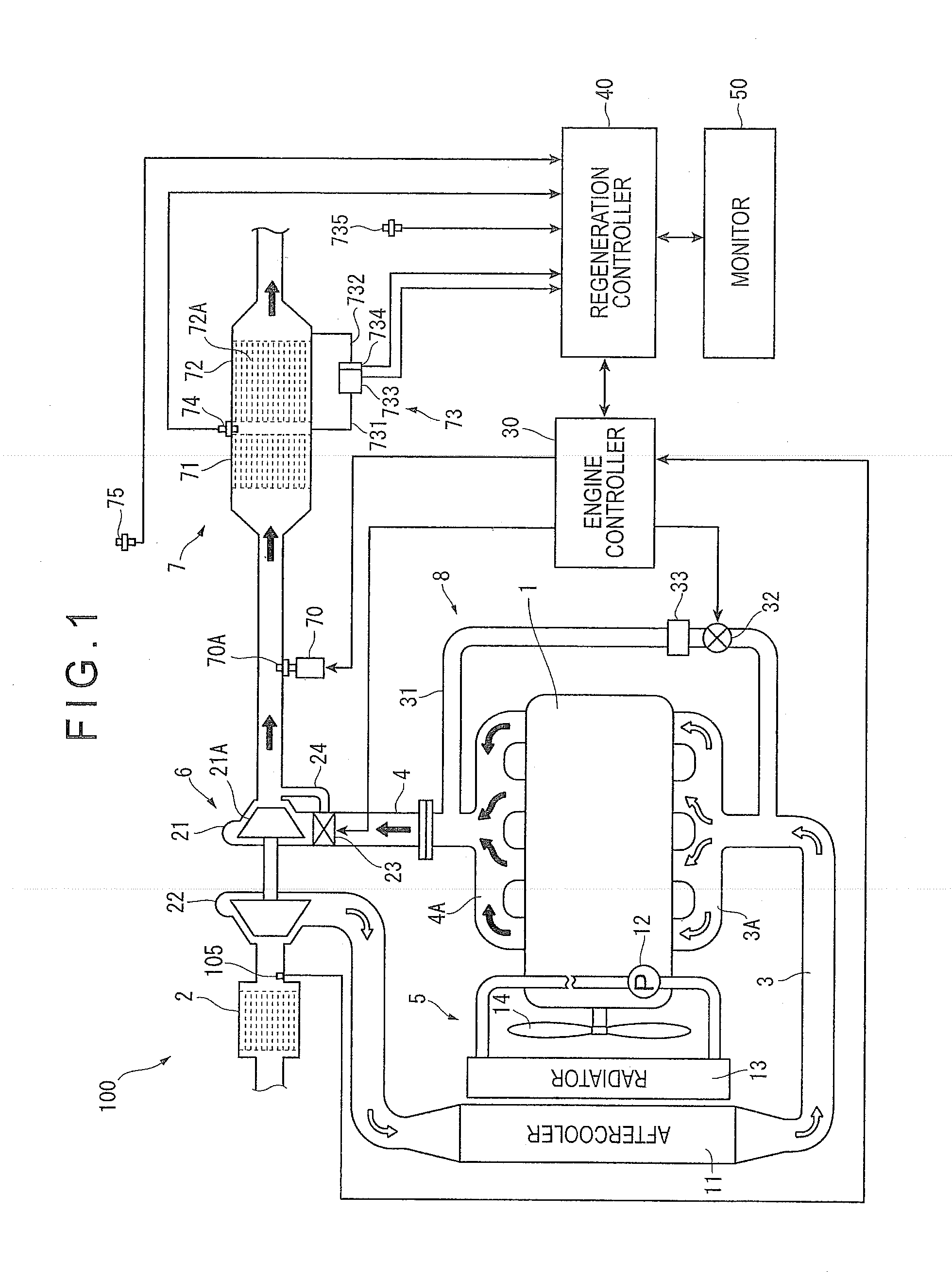

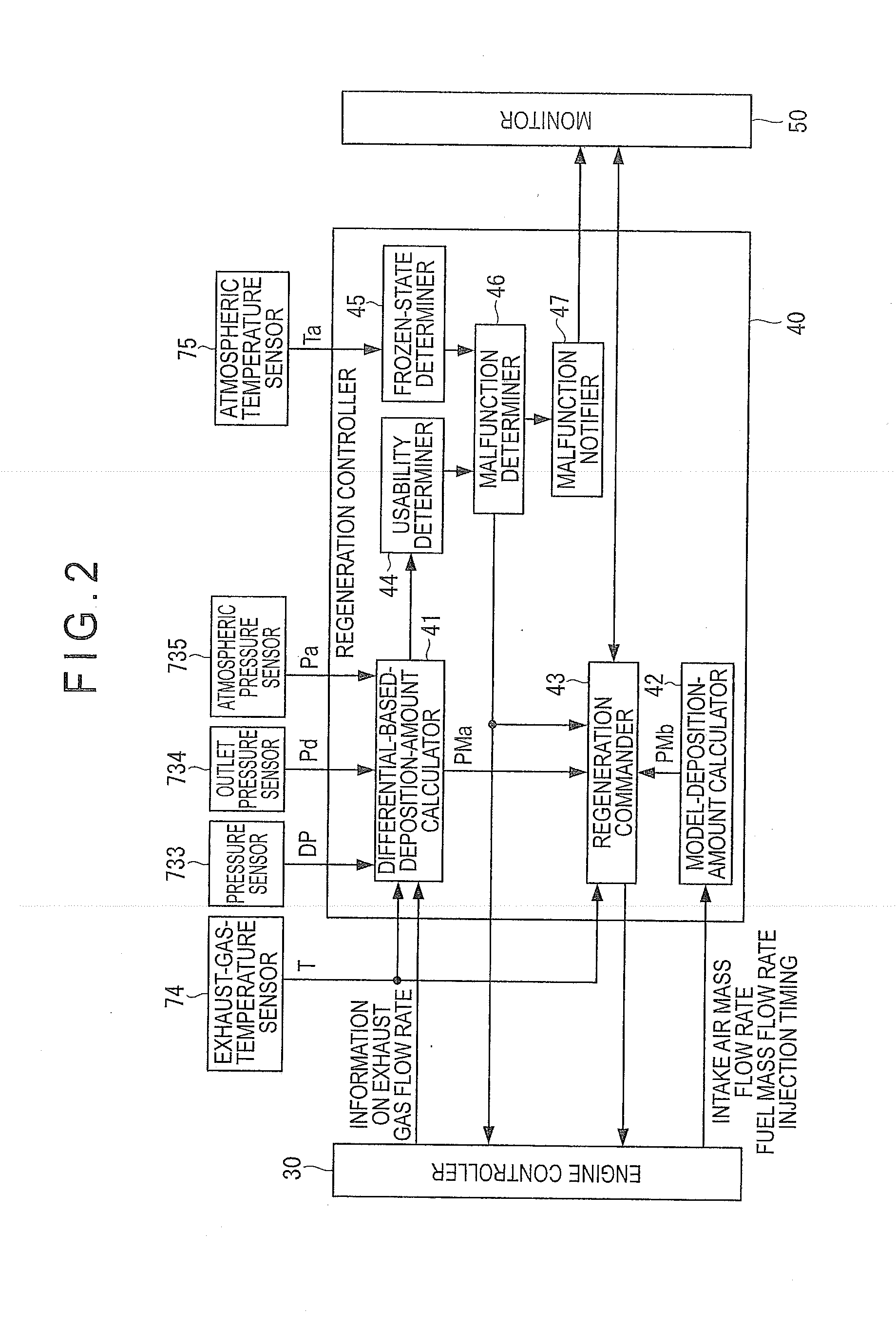

Malfunction-Determining Device for Exhaust Gas Purifying Device and Malfunction-Determining Method for Exhaust Gas Purifying Device

ActiveUS20150240696A1Favorable operation rateIncrease ratingsInternal-combustion engine testingElectrical controlEngineeringUsability

A malfunction-determining device for an exhaust gas purifying device, which includes a filter device and a pressure measuring device, includes a usability determiner being configured to determine whether or not the pressure measuring device is usable based on a pressure measured by the pressure measuring device and an exhaust gas flow rate, a frozen-state determiner being configured to determine whether or not the pressure measuring device is frozen, and a malfunction determiner being configured to determine that the pressure measuring device has a malfunction when the usability determiner determines that the pressure measuring device is unusable and the frozen-state determiner determines that the pressure measuring device is not frozen.

Owner:KOMATSU LTD

Intelligent controlled sealing gasket

InactiveCN102080726AEngine sealsFluid-tightness measurement by detecting dimension changeEngineeringStress relaxation

The invention relates to an intelligent controlled sealing gasket. In the sealing gasket, the temperature, pressure and deformation of the gasket are measured by a sensor, the data is transmitted to a computer by the sensor, and the computer can know important performance parameters such as compressibility, resiliency and ratios of creep relaxation and stress relaxation at any time by analyzing the data, so that the sealing gasket is in the monitoring state at any time to make the conclusion whether the design requirement is met or not, and can predict what kind of leakage states the gasket lies and whether the design requirement still can be met within a period of time in future or not by analysis.

Owner:NINGBO TIANSHENG SEALING PACKING

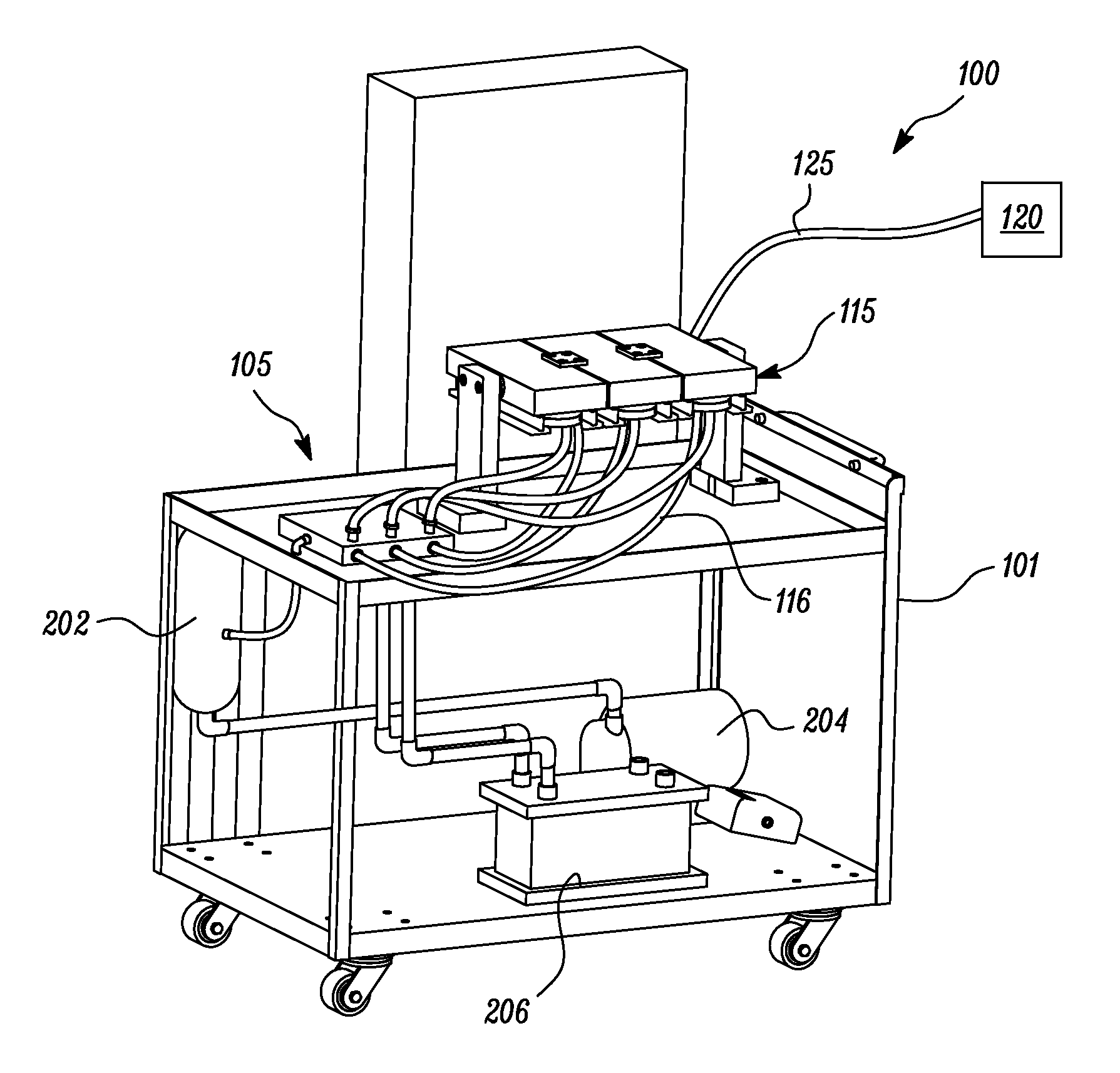

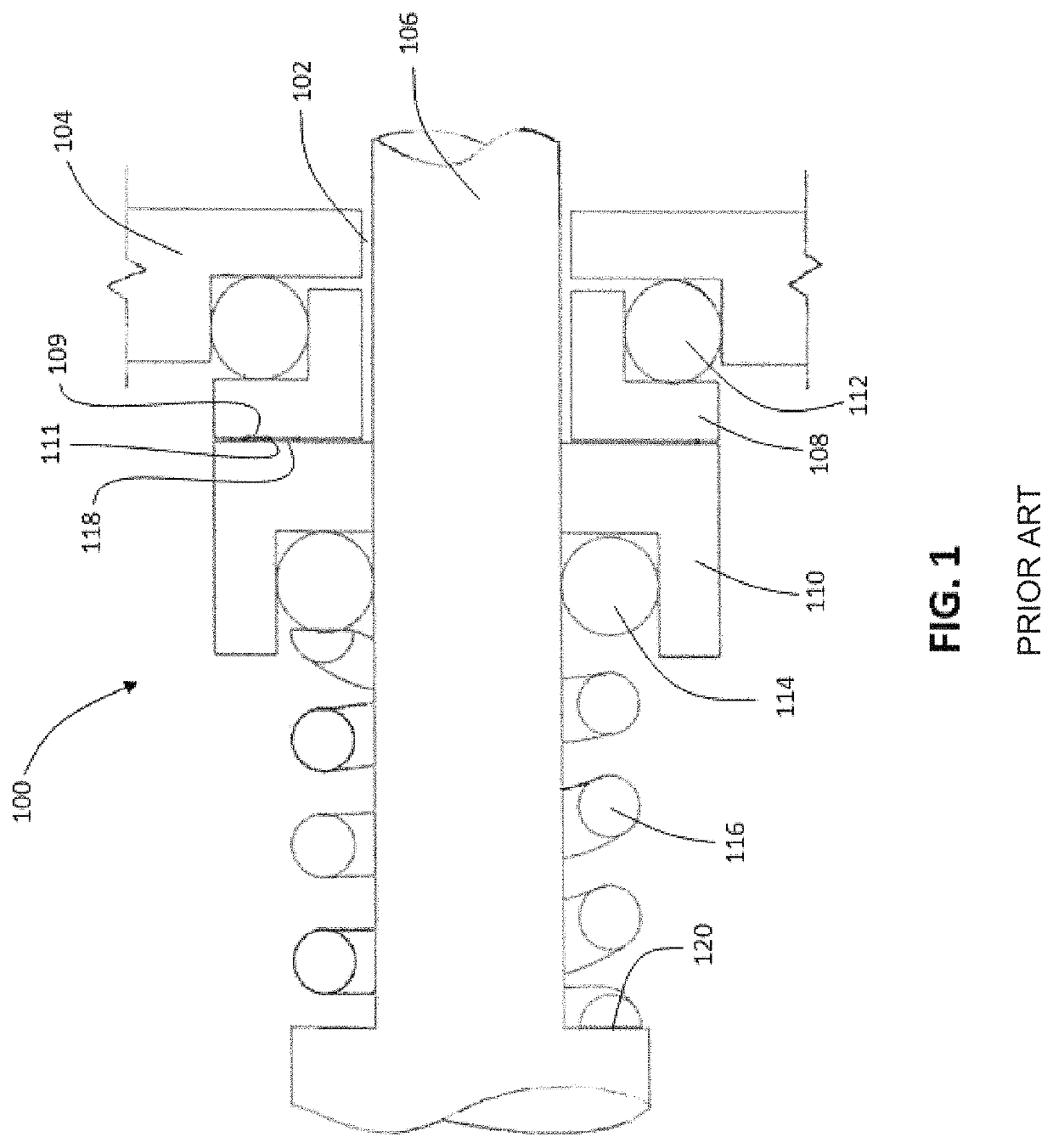

System and method for testing of seal materials

InactiveUS20150233788A1Machine sealing rings testingFluid-tightness measurement using fluid/vacuumEngineering

Owner:CATERPILLAR INC

Air conditioning system and method for controlling the same

Air conditioning system including a temperature sensor for sensing a room temperature, an MET (metabolic) sensor for sensing an activity amount of people in a room, a dust sensor for sensing a dust amount, a gas sensor for sensing an intensity of smell, a VOC (Volatile Organic Compounds) sensor for sensing a compound amount, a fan driving unit for controlling an air flow rate, a heater for raising a room temperature, an anion generating unit for generating anion, and a control unit for controlling the fan driving unit and the heater according to an operation condition preset with reference to a sensed room temperature and the activity amount of people in the room, and controlling the fan driving unit and the anion generating unit according to an operation condition preset with reference to a sensed dust amount, the intensity of smell, and the VOC amount, thereby enhancing comfortability, and performing effective cleaning function, and displaying room cleanliness in real time on a screen, to improve a product reliability.

Owner:LG ELECTRONICS INC

Systems and methods for predictive diagnostics for mechanical systems

ActiveUS20170241955A1Improve reliabilityIncrease speedEngine sealsMeasurement of fluid loss/gain rateEngineeringLogic module

A predictive diagnostics system for monitoring mechanical seals. The system autonomously detects a loss of lubrication within a sliding seal interface of a mechanical seal, the system including a loss of lubrication failure mode logic module configured to monitor data sensed by one or more sensors and diagnose conditions relating to a loss of lubrication within the sliding seal interface, and a plurality of other failure mode logic modules configured to monitor data sensed by the one or more sensors and diagnose conditions relating to specific types of mechanical failures known to occur in mechanical seal systems, the loss of lubrication failure mode logic module configured to determine which of the plurality of other failure mode logic modules are activated during the diagnosis of conditions related to a loss of lubrication within the sliding seal interface.

Owner:JOHN CRANK UK

Shield tunnel segment joint sealing gasket leakage test device

InactiveCN108776011ARealize the test of seam waterproof abilityImplement testMachine sealing rings testingDisplacement controlEngineering

The invention relates to a shield tunnel segment joint sealing gasket leakage test device, so as to carry out leakage test on an elastic sealing washer. The test device comprises an upper sample module and a lower sample module to form a test cavity in mutual buckling by a displacement control unit; the test cavity comprises an inner channel sealing cavity, an inner channel sealing gasket trapezoidal groove, an outer channel sealing cavity and an outer channel sealing gasket trapezoidal groove sequentially from the center to the periphery; the inner channel sealing gasket trapezoidal groove isinternally provided with an inner channel elastic sealing washer; the outer channel sealing gasket trapezoidal groove is internally provided with an outer channel elastic sealing washer; and the upper sample module is provided with multiple measurement loading channels communicated with the test cavity. Compared with the prior art, the shield tunnel segment joint sealing gasket leakage test device has the advantages of real simulation, waterproof arrangement of two channel sealing gaskets, and opening and staggering working condition design.

Owner:TONGJI UNIV

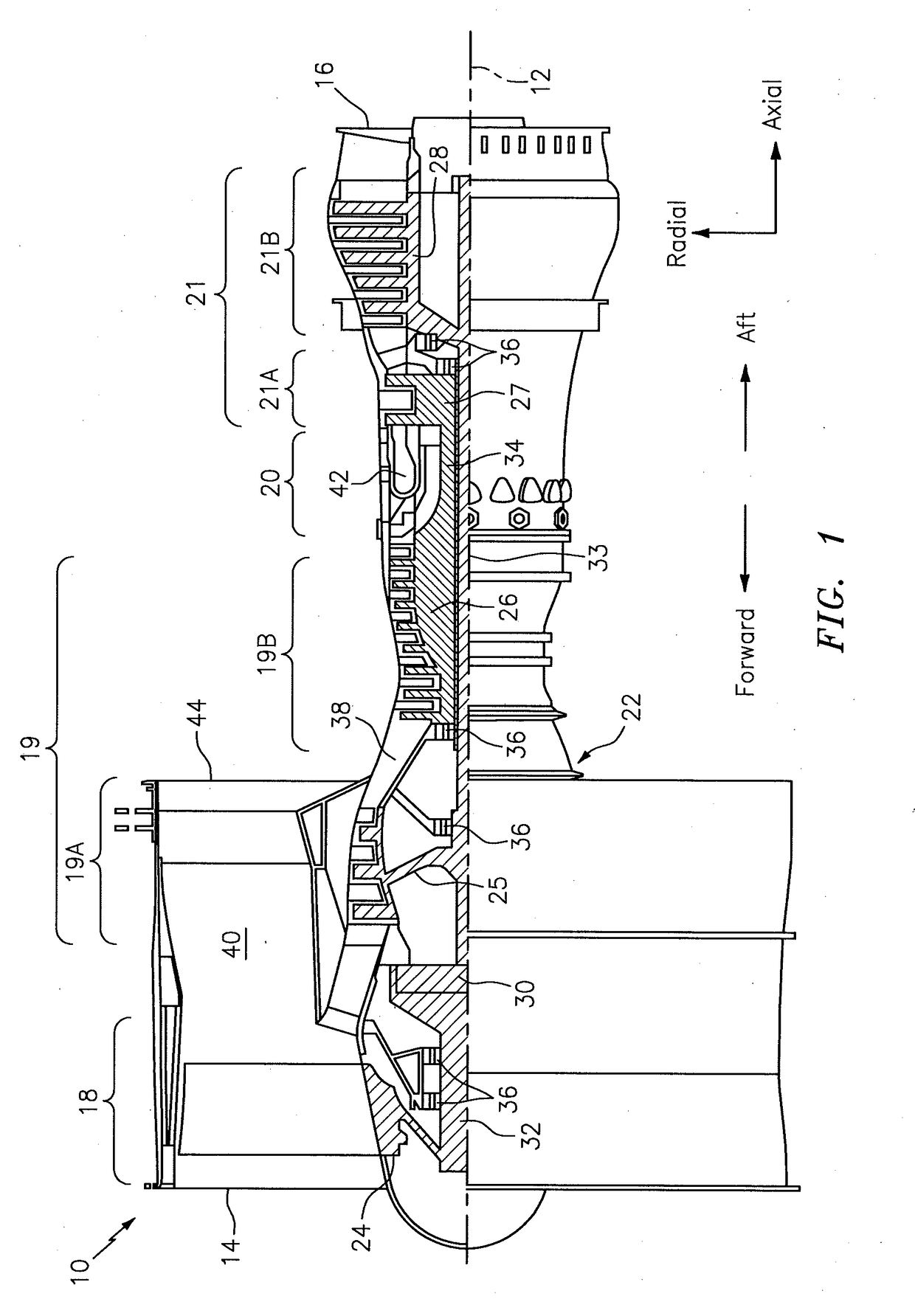

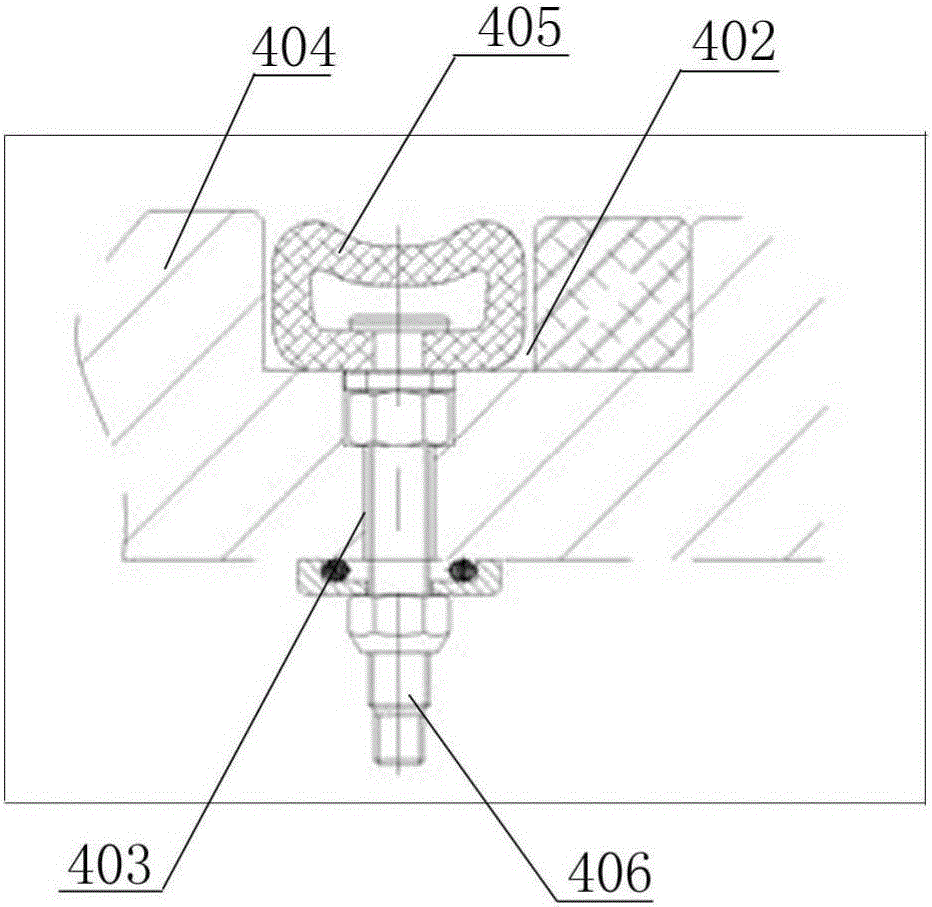

Seal sacrificial wear indicator

Aspects of the disclosure are directed to a system comprising: a rotatable seal runner, a stationary sealing member that includes a base and a nose that extends from the base in an axial direction and interfaces with the seal runner, a carrier that supports the sealing member, and a tab coupled to the carrier, where the tab extends from the carrier in the axial direction towards the seal runner.

Owner:RTX CORP

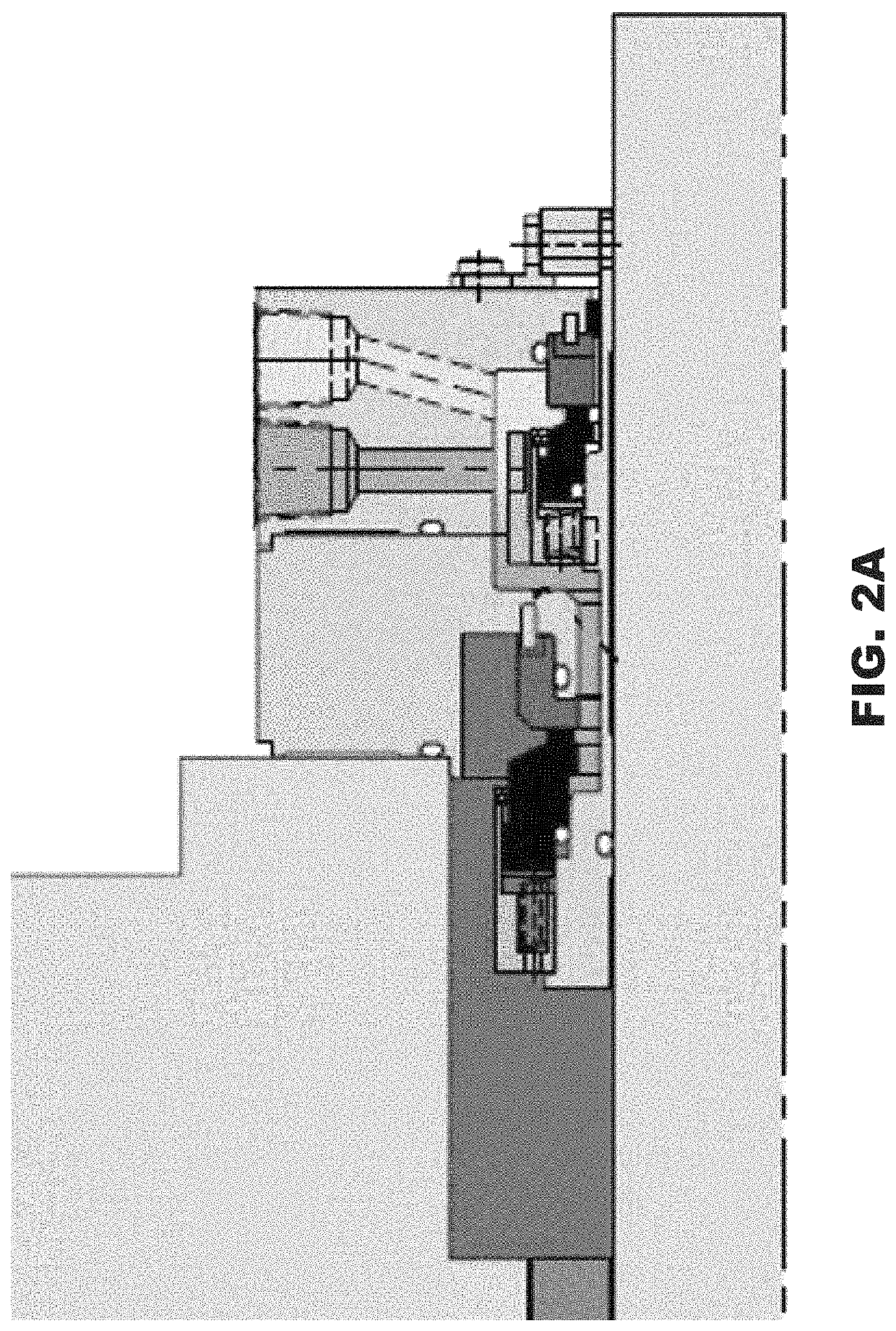

Shield tunneling machine articulation mechanism seal performance test device and test method

ActiveCN106197993ASafe and stable operationReduce construction riskDetection of fluid at leakage pointMachine sealing rings testingEngineeringShield tunneling

The invention discloses a shield tunneling machine articulation mechanism seal performance test device and test method. The test device comprises an outer barrel fixed to an installation rack and an articulation seal ring coaxially arranged in the outer barrel in a sleeved mode, the back end of the articulation seal ring is provided with a step portion for being sleeved with a to-be-tested elastic seal ring, and the middle of the articulation seal ring is provided with an annular groove for being sleeved with a to-be-tested airbag seal ring; the interior of the outer barrel are isolated into a seal cavity through a first baffle and a second baffle, and a force transmission frame for enabling the articulation seal ring to not axially move and hydraulic oil cylinders driving the articulation seal ring to wing are arranged in the outer barrel. By injecting a medium under pressure into the seal cavity and injecting lubricating grease into a gap formed between the outer barrel and the articulation seal ring, real working conditions are simulated, the seal performances of the elastic seal ring and the airbag seal ring are tested, results measured through tests are fed back to research and development of new equipment, a seal scheme achieving the optimal performance is adopted on the new equipment, the reliability of the equipment is enhanced, the equipment construction risk is reduced, and the maintenance cost is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Systems and methods for predictive diagnostics for mechanical systems

ActiveUS10545120B2Improve reliabilityIncrease speedEngine sealsMeasurement of fluid loss/gain rateMedicineControl engineering

A predictive diagnostics system for monitoring mechanical seals. The system autonomously detects a loss of lubrication within a sliding seal interface of a mechanical seal, the system including a loss of lubrication failure mode logic module configured to monitor data sensed by one or more sensors and diagnose conditions relating to a loss of lubrication within the sliding seal interface, and a plurality of other failure mode logic modules configured to monitor data sensed by the one or more sensors and diagnose conditions relating to specific types of mechanical failures known to occur in mechanical seal systems, the loss of lubrication failure mode logic module configured to determine which of the plurality of other failure mode logic modules are activated during the diagnosis of conditions related to a loss of lubrication within the sliding seal interface.

Owner:JOHN CRANK UK

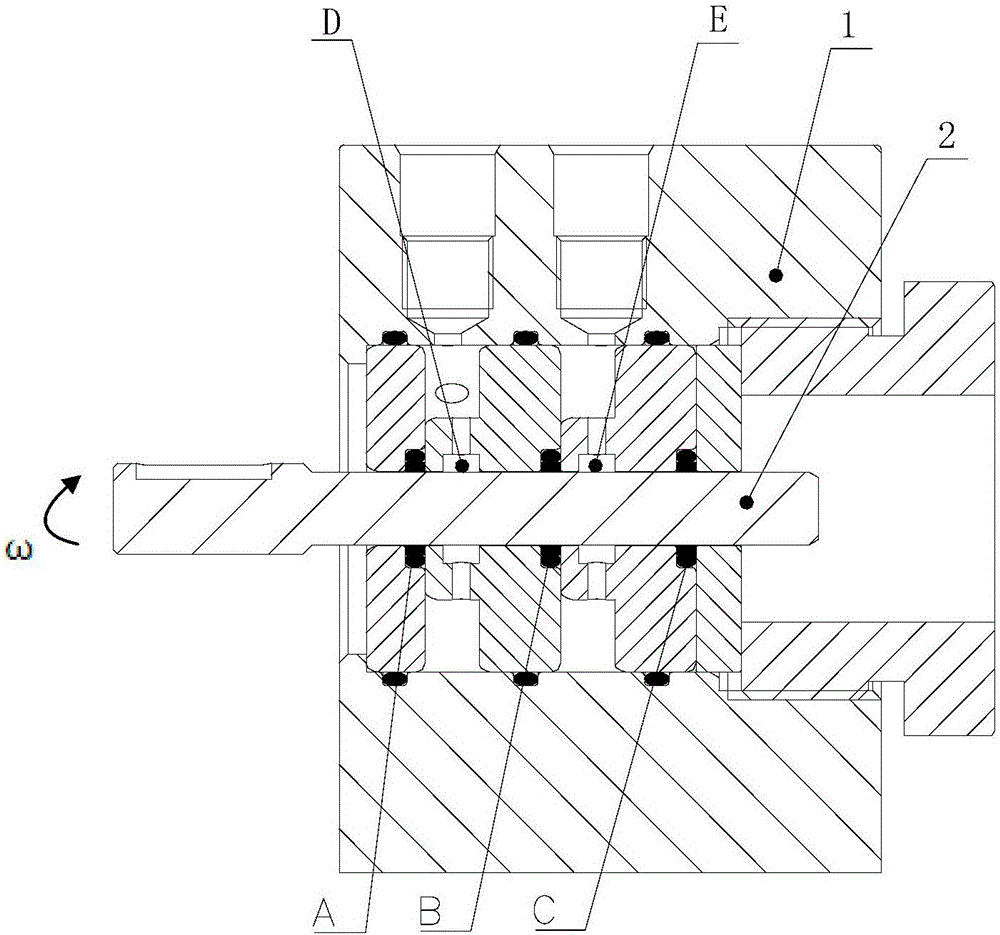

Sealing performance testing machine for sealing ring of bearing

ActiveCN106226059ALight in massCompact structureMachine sealing rings testingFluid-tightness measurement using fluid/vacuumMotor driveEngineering

The invention belongs to the technical field of sealing performance test of bearing sealing rings, and particularly relates to a sealing performance testing machine for a sealing ring of a bearing. The sealing performance testing machine for the sealing ring of the bearing is characterized in that a variable frequency motor drives a belt wheel to rotate; the belt wheel drives a workpiece shaft to rotate through a key joint; the workpiece shaft transfers kinetic energy to a core part tool wheel, so the requirement for a rotating speed needed by the test is met; a tested test sealing ring is mounted between the tool wheel and an outer tool ring; the test sealing ring consists of a sealing lip, a lock ring and a dustproof cover; an entire set of bearing does not need to be used for testing; tool parts simulate the inner and outer rings of the bearing for testing. The sealing performance testing machine for the sealing ring of the bearing is simple and compact in structure, and simple and convenient to operate; multiple types and multiple specifications of products can be detected by means of a tool wheel replacement method, and the machine is multifunctional; the tool wheel is low in weight and convenient to replace, and an entire set of bearing does not need to be used for testing, so the test cost is reduced; the occupation space is small, and the maintenance is convenient; a series of detection for temperature, rotating speed, pressure intensity and the like can be performed on the sealing ring.

Owner:瓦房店轴承集团风电轴承有限责任公司

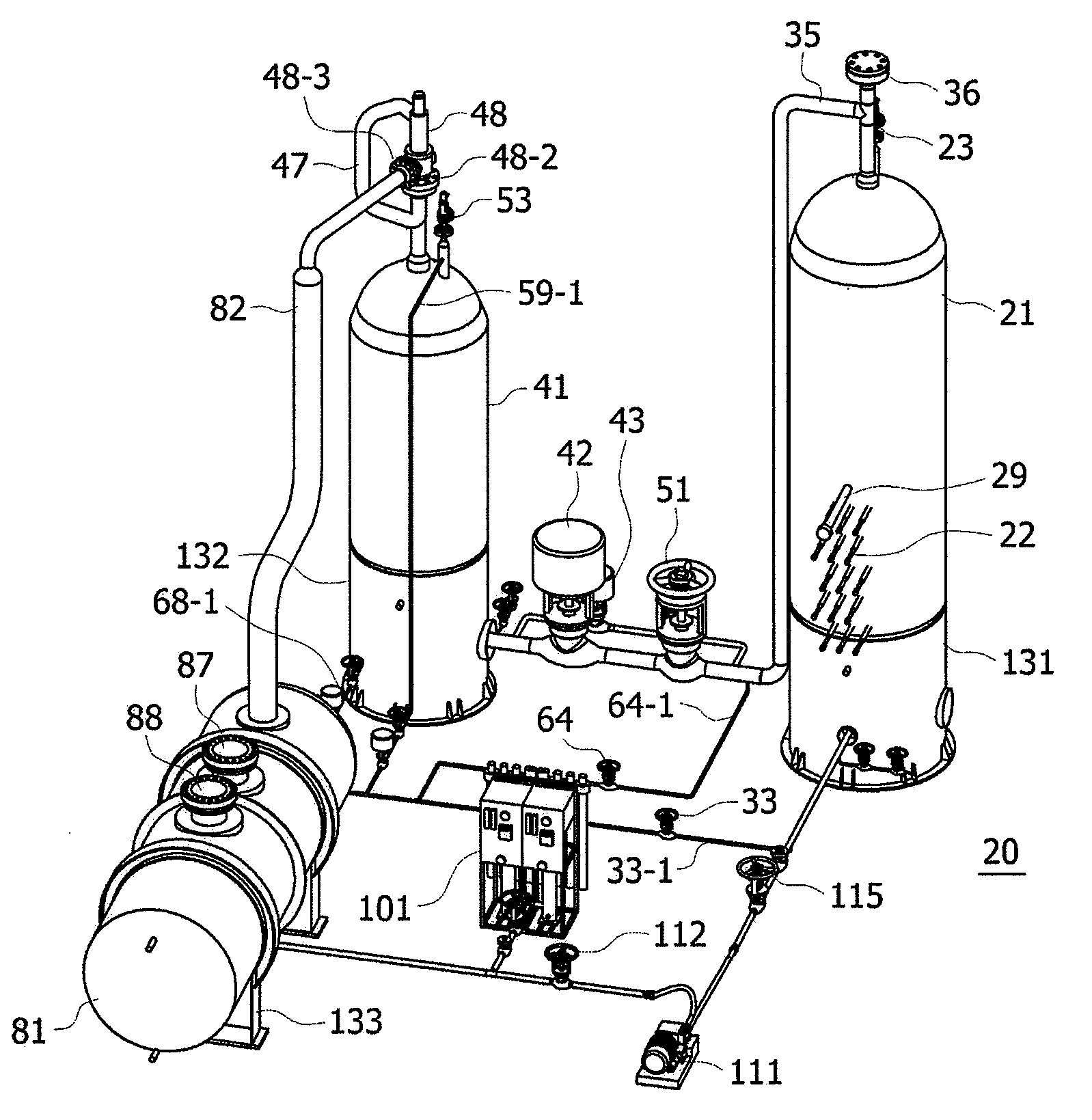

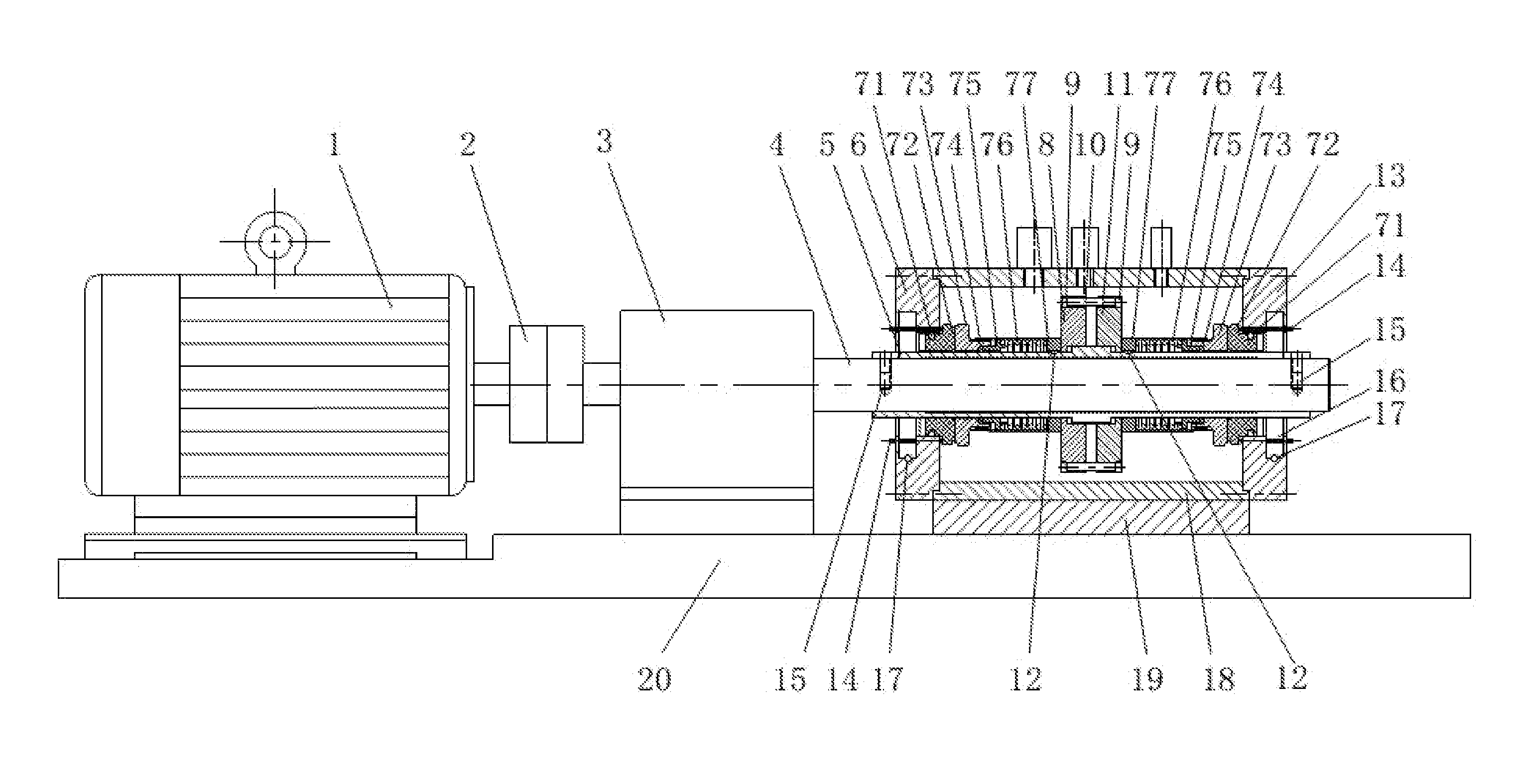

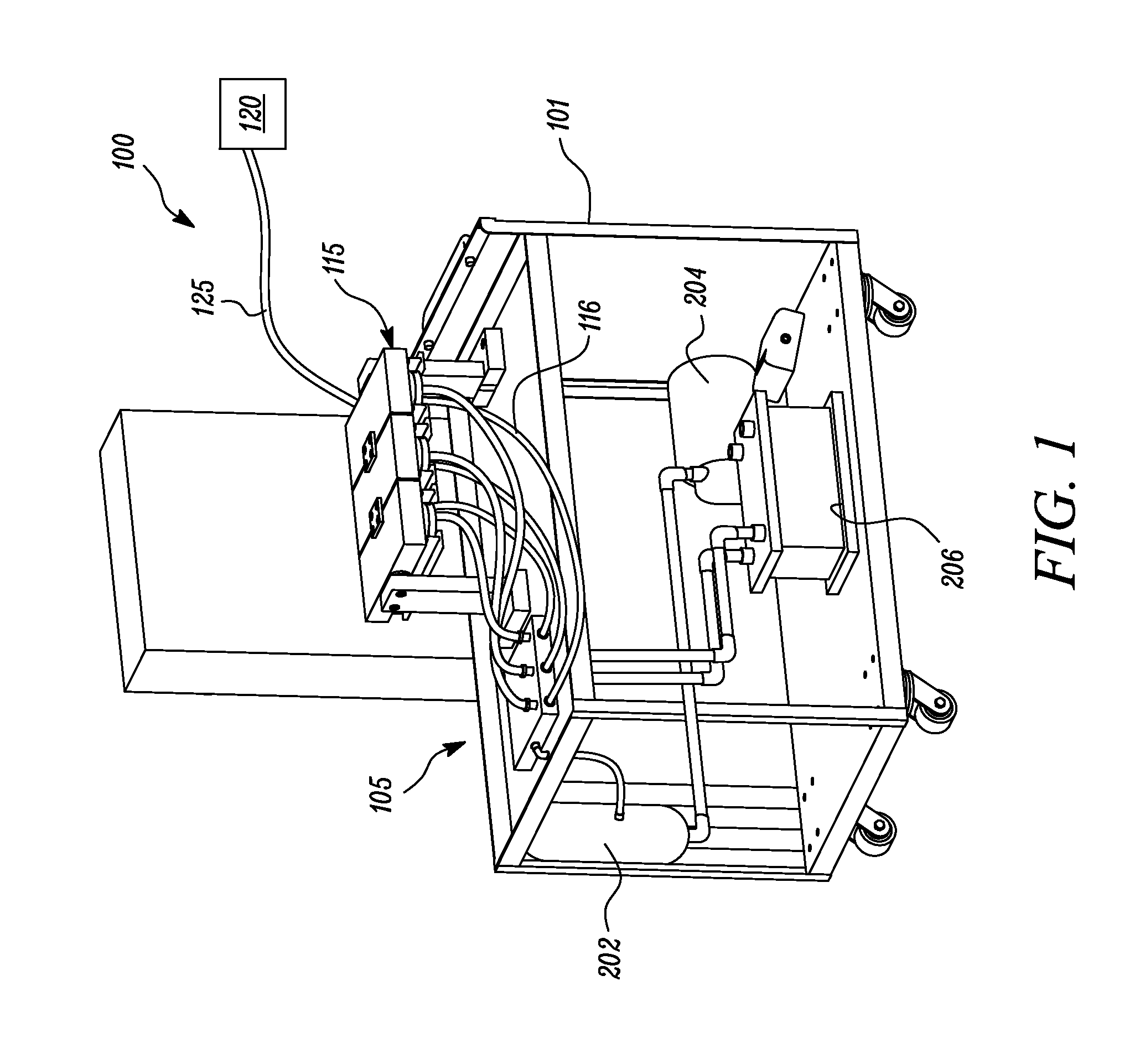

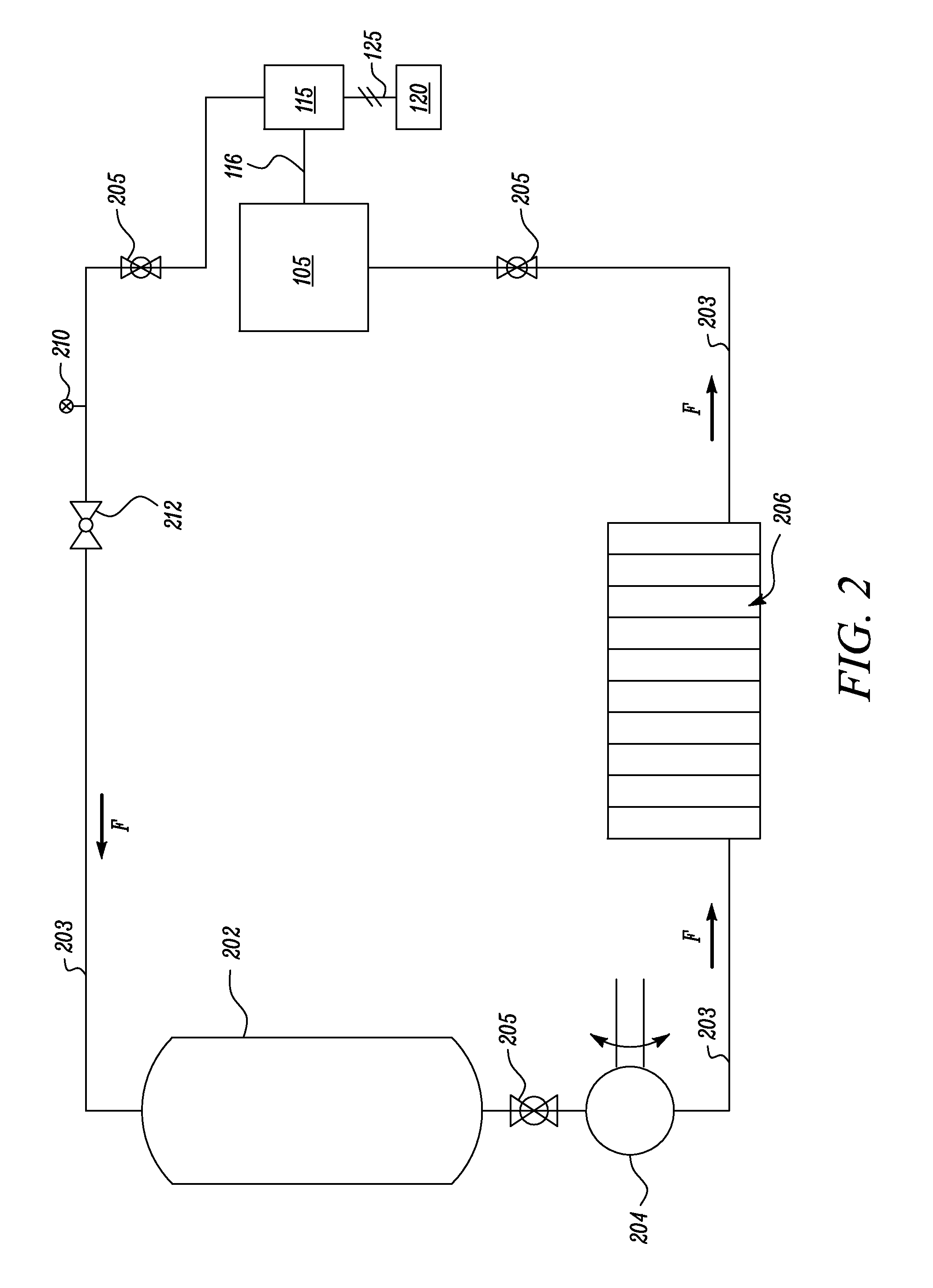

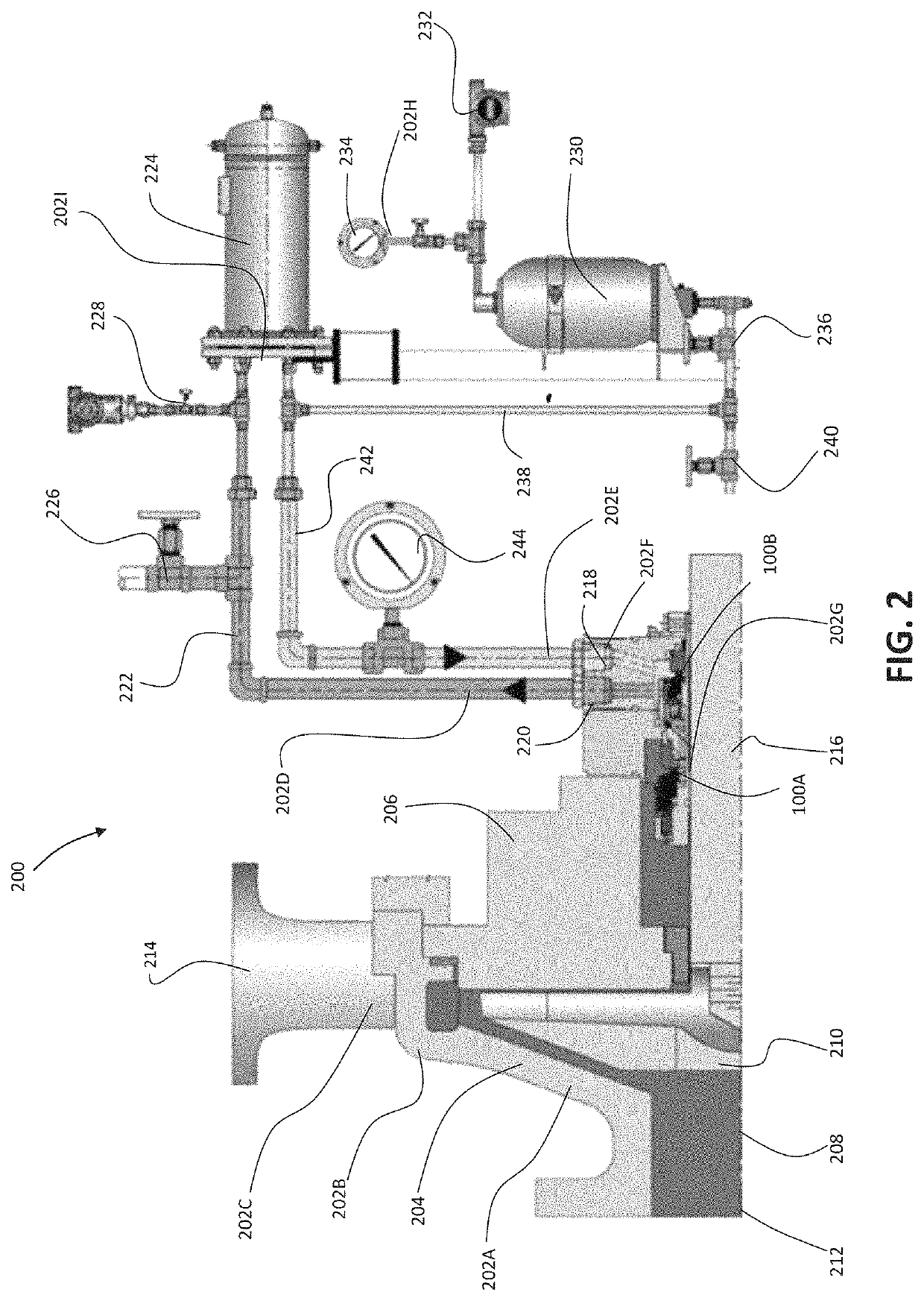

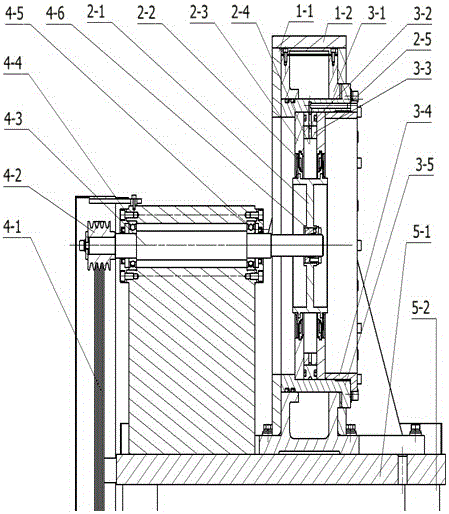

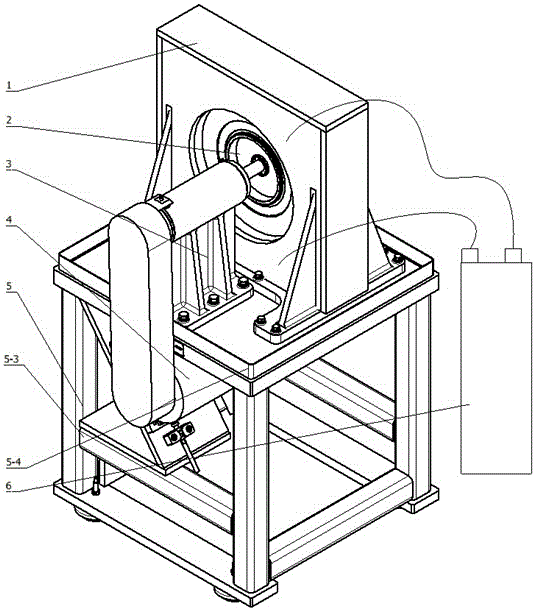

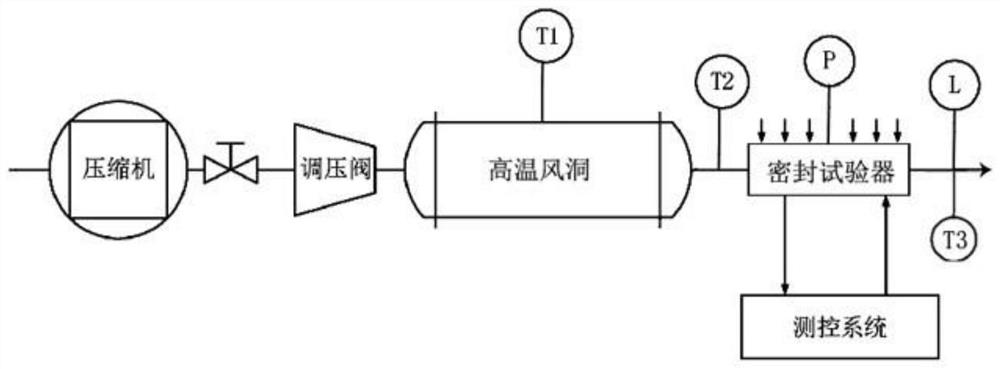

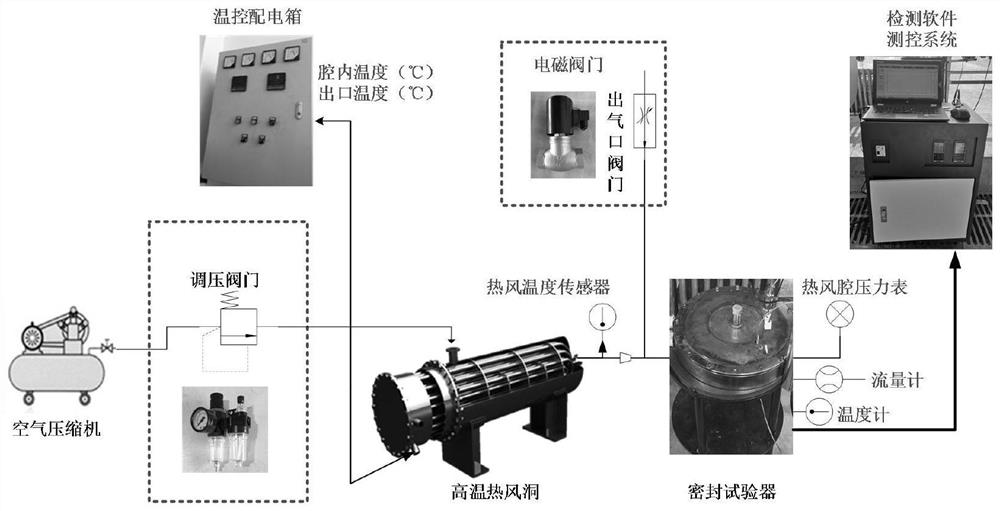

Test system and method for realizing performance simulation test of high-temperature metal sealing ring

ActiveCN112903208AHigh simulationHigh temperature control accuracyMeasurement of fluid loss/gain rateAerodynamic testingFlight vehicleAir compressor

The invention discloses a test system and method for realizing a high-temperature metal sealing ring performance simulation test. The test system is mainly composed of the following parts: an external hot air system (including an air compressor and a high-temperature wind tunnel); a high-temperature sealing tester body; a test piece installed in the body; a measurement box; and a temperature sensor, a pressure gauge, a flow meter and the like that are installed at key positions. On one hand, the design of the test working condition covers the actual operation working condition range; on the other hand, the corresponding relation between the test condition and the actual operation condition needs to be explained. The device is mainly developed and designed for the C-shaped metal sealing ring, and a subsequent high-temperature sealing principle verification test is carried out. According to existing experiment conditions and parameters, sealing airtightness and heat sealing performance tests under actual working conditions are carried out, so that the sealing element performance of an aircraft in a real operation environment is guaranteed.

Owner:BEIJING UNIV OF CHEM TECH

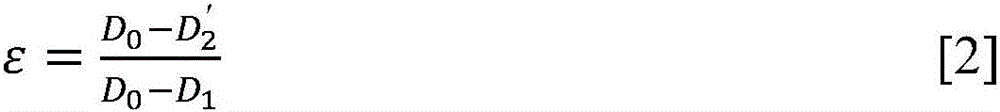

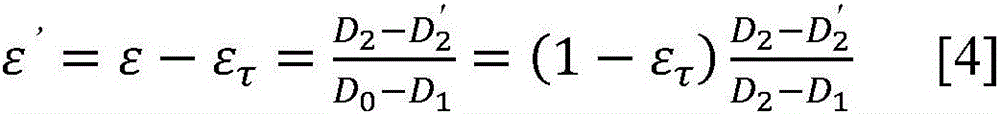

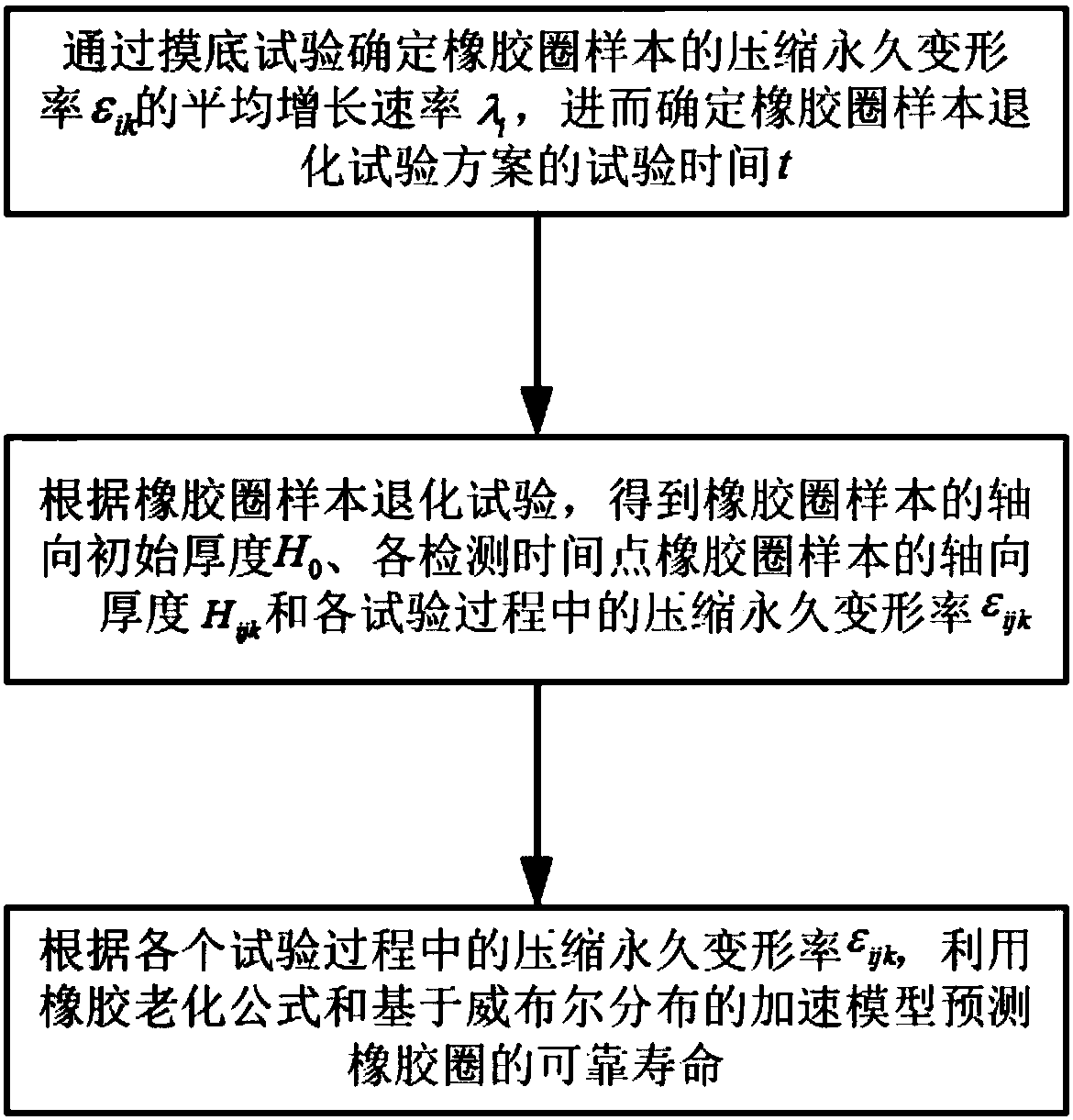

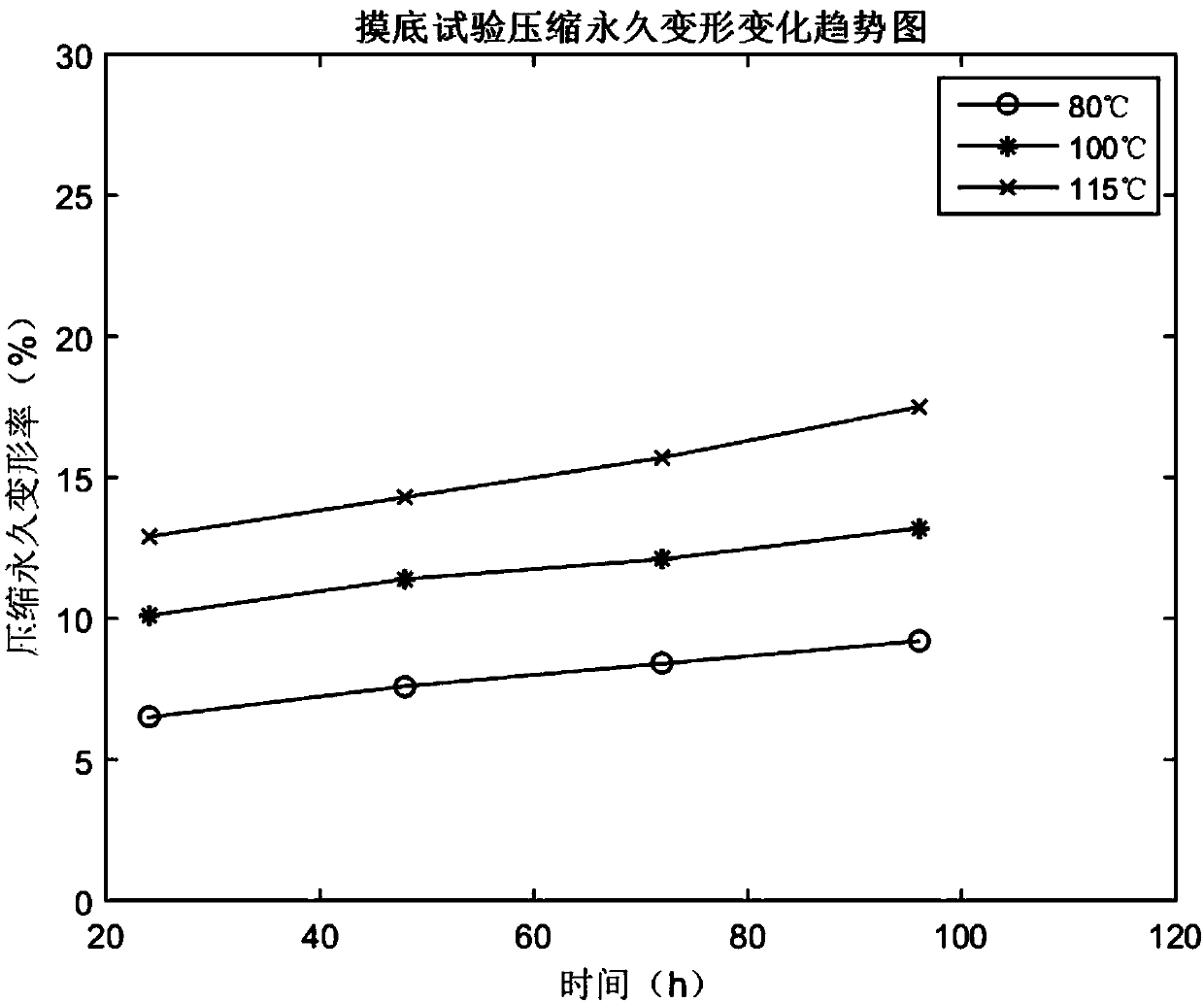

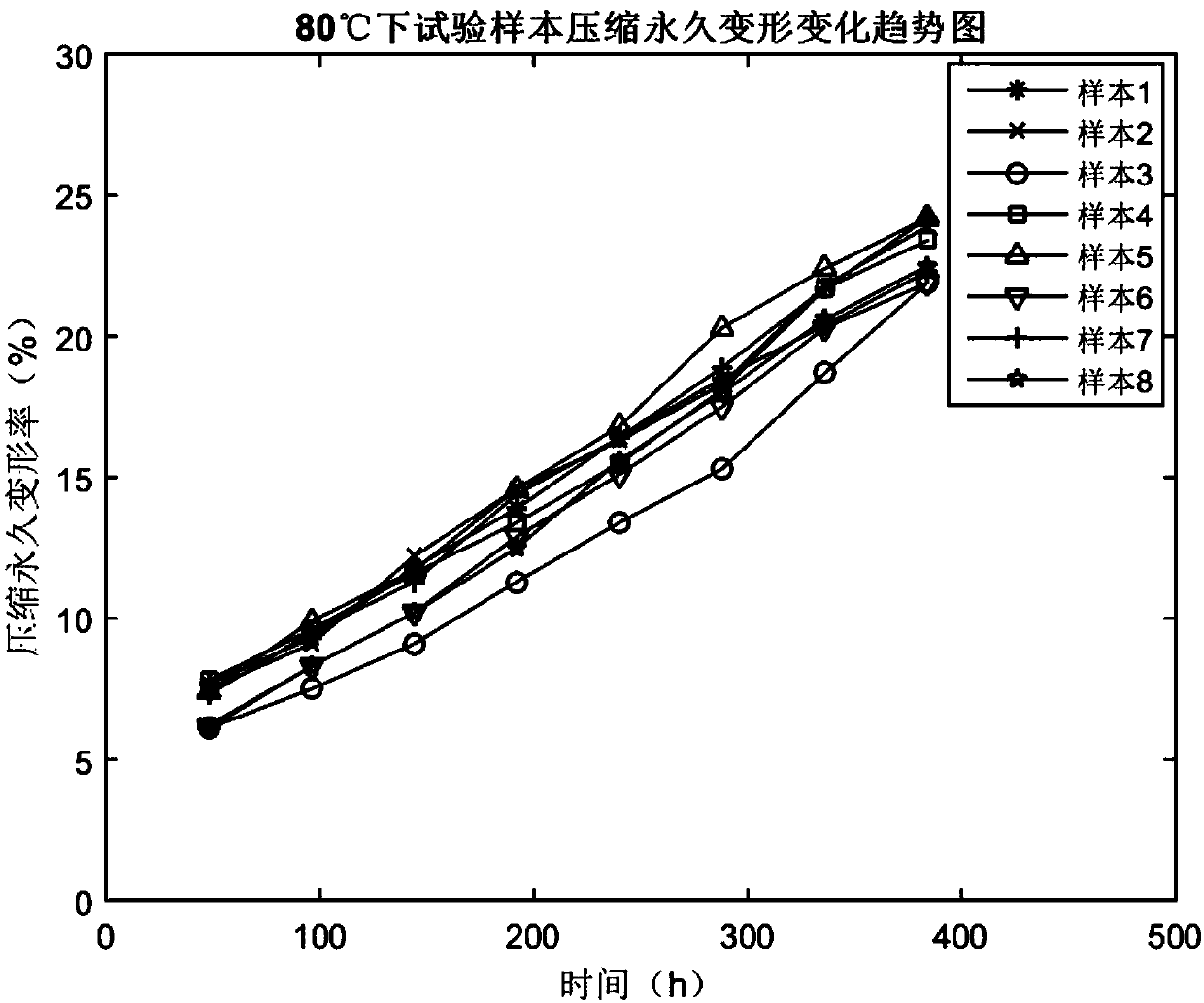

Weibull-distribution-based method for predicting reliable service life of rubber ring

InactiveCN107702905AShorten the timeHigh feasibilityMachine sealing rings testingRubber ringDegradation test

The invention discloses a Weibull-distribution-based method for predicting the reliable service life of a rubber ring. The method includes the following steps: S1, determining an average growth rate lambda i of a permanent compression deformation rate epsilon iK of a rubber ring sample through a diagnostic test and then determining test time t of a rubber ring sample degradation test plan; S2, according to the rubber ring sample degradation test, obtaining an initial axial thickness H0 of the rubber ring sample, an axial thickness HijK of the rubber ring sample at each detection time point, and a permanent compression deformation rate epsilon ijK during each test process; and S3, according to the permanent compression deformation rates epsilon ijK of all test processes, predicting a service life of the rubber ring according to a rubber degradation formula and an acceleration model based on the Weibull distribution and analyzing the reliability of the rubber ring. Compared with the traditional rubber service life prediction method capable of obtaining a single service life prediction value, the method has advantages: a reliable service life value is obtained by using a service lifedistribution function, so that the evaluation result has higher credibility.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Device for measuring impermeability of the sealing means of a filter cartridge and process thereof

ActiveUS20140026643A1Machine sealing rings testingFluid-tightness measurementBiomedical engineeringImpenetrability

A device for measuring permeability of a filter cartridge seal includes a blocking member for blocking an input to the filter cartridge and a housing for tightening the seal. A removable chamber wall is configured to form a sealed chamber with the housing and the blocking member. Pressure in the sealed chamber is varied to test the seal and to detect leaks.

Owner:GENERAL ELECTRIC CO

Popular searches

Level indicators Apparatus for force/torque/work measurement Material capacitance Special data processing applications Efficient regulation technologies Temperature control using digital means Space heating and ventilation safety systems Space heating and ventilation control systems Refrigeration devices Control inputs involving users/components

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com