Intelligent controlled sealing gasket

A sealing gasket and gasket technology, applied in engine sealing, machine sealing ring testing, fluid tightness testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

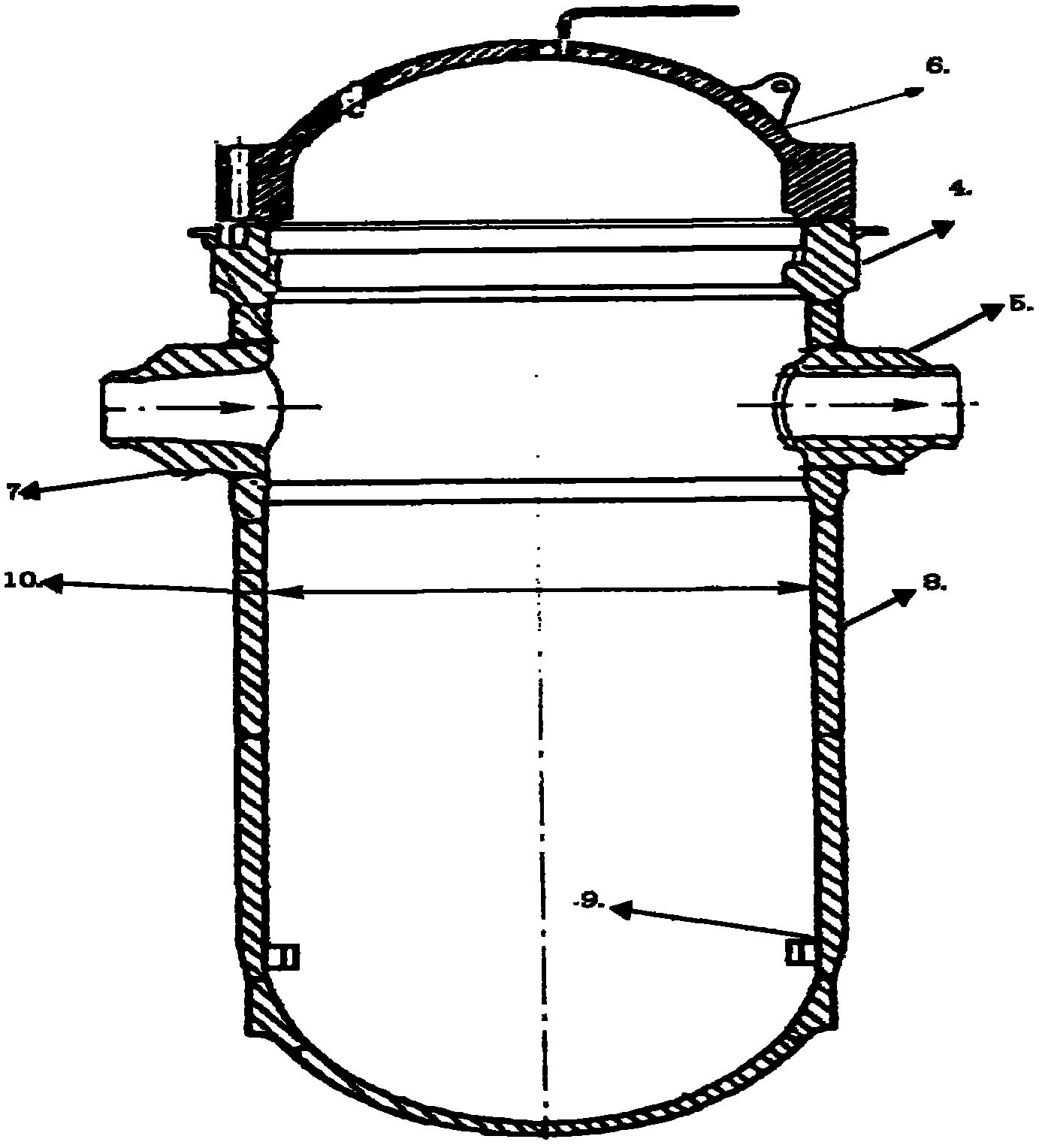

[0013] figure 1 Shown is a pressure vessel for high-temperature, high-pressure coolant. The cylinder 10 consists of a flange 4 with bolt threaded holes, an annular section 8 welded with coolant inlet and outlet nozzles 5, a transition section and a semicircular bottom The head is welded, wherein the top cover 6 is formed into a semicircle by hot pressing of steel plates, bolt holes are drilled on the periphery of the upper flange 4, and a groove for placing the present invention is opened on the supporting surface. When the high-temperature and high-pressure coolant flows in the pressure vessel, part of it flows directly to the outlet of the pressure vessel along the inner wall of the pressure vessel, and is accompanied by changes in temperature and pressure. Since the pressure vessel top cover and cylinder flange are two independently manufactured The components must be assembled together in the pressure vessel and must ensure high sealing performance. The internal pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com