Testing method and device for service fatigue performance of hydraulic reciprocating seal

A fatigue performance and test device technology, which is applied in the direction of machine seal ring test, measurement device, and test material strength by applying repeated force/pulsation force, can solve the problem of failure to predict fatigue failure of hydraulic reciprocating seals and obtain seals through tests Fatigue life data, no consideration and other issues, to achieve the effect of overcoming accurate prediction and evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

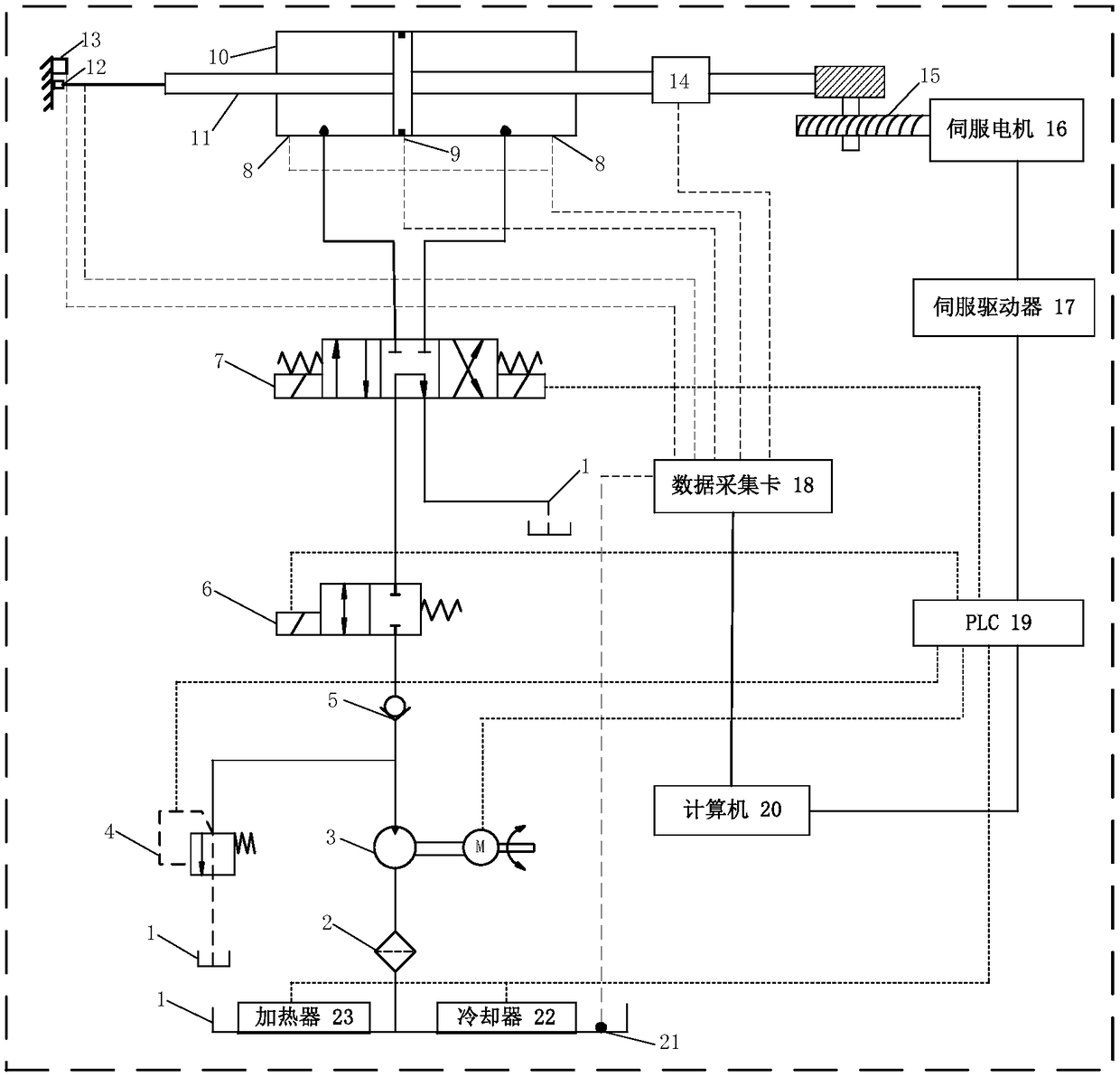

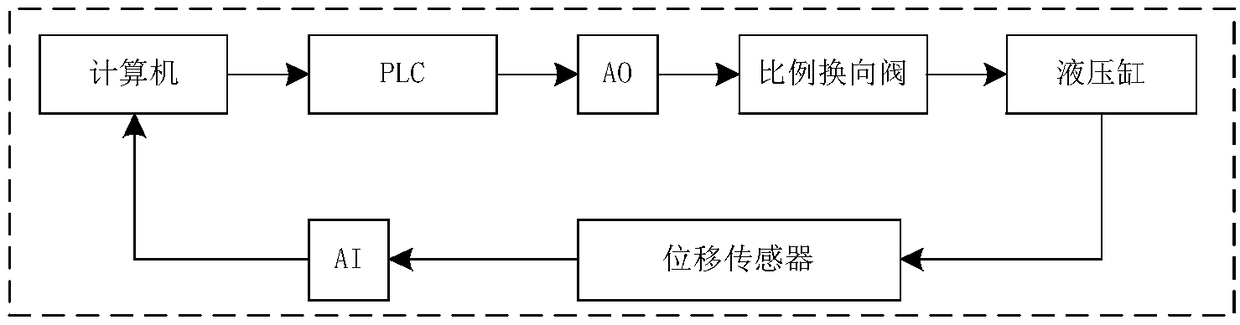

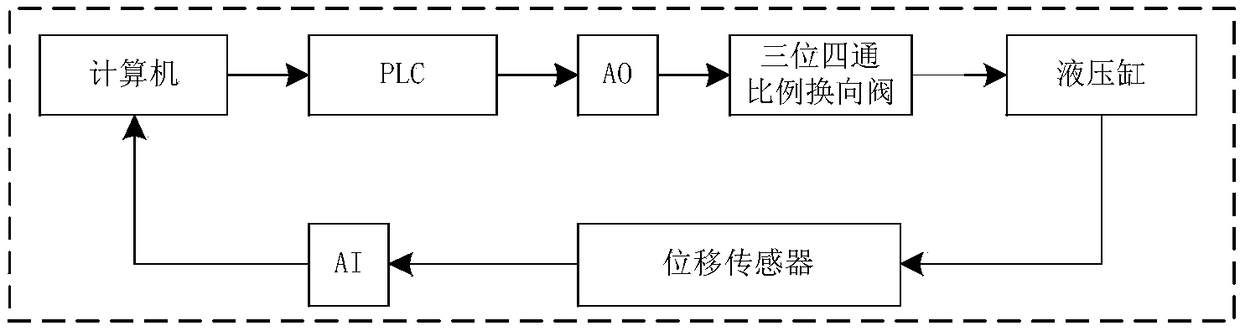

[0042] The service fatigue performance test method of the hydraulic reciprocating seal provided by the present invention is specifically: using the optical fiber grating strain sensor laid on the inner side of the piston guide sleeve to monitor the change of the contact stress at the bottom of the piston seal in real time, and transmit the data to the computer through the data acquisition card 18 20. Use the computer to calculate the fatigue failure probability of the hydraulic cylinder cylinder / piston seal load friction pair system, so as to judge the fatigue failure state of the hydraulic reciprocating seal; use the counter to record the fatigue life of the hydraulic reciprocating seal during service .

[0043] The invention simulates the service environment of the hydraulic reciprocating seal by changing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com