Method for assessing remaining service life of rubber sealing ring

A technology of rubber sealing ring and life evaluation, applied in the field of rubber sealing ring, can solve the problems affecting the accuracy of life evaluation of rubber sealing ring, etc., and achieve the effect of good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Evaluation of the remaining storage life of the static seal ring of a missile ejection device that has been stored for 10 years:

[0035] (1) Existing compression set analysis

[0036] By measuring and analyzing the original size of this type of rubber sealing ring, the springback of the section in the direction of compression after disassembly, and its assembly structure and size on the bullet, its original section diameter D 0 =2.5mm, the springback height D of the section in the direction of compression after disassembly 2 = 2.163mm, the compression height D on the bullet 1 = 1.7 mm.

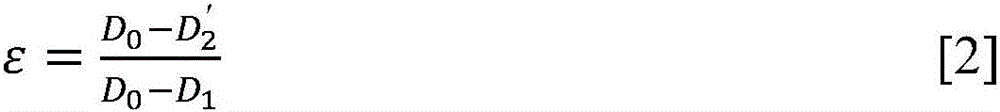

[0037] According to the formula [1], it can be concluded that the compression permanent deformation of the rubber sealing ring after 10 years of bomb storage is:

[0038] ϵ 10 = D 0 - D 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com