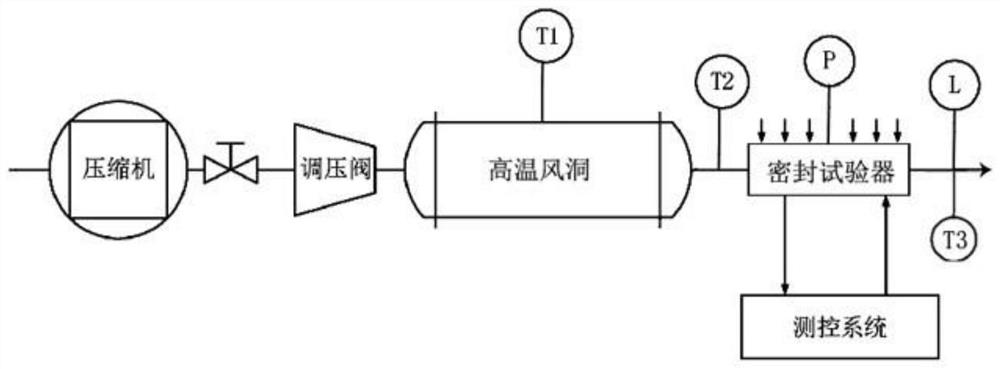

Test system and method for realizing performance simulation test of high-temperature metal sealing ring

A metal sealing ring and test system technology, which is used in machine sealing ring testing, using liquid/vacuum for liquid tightness measurement, control/regulation systems, etc. It can solve the problem of lack of automated test components and relevant parameters. means, can not adjust the parameter test and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

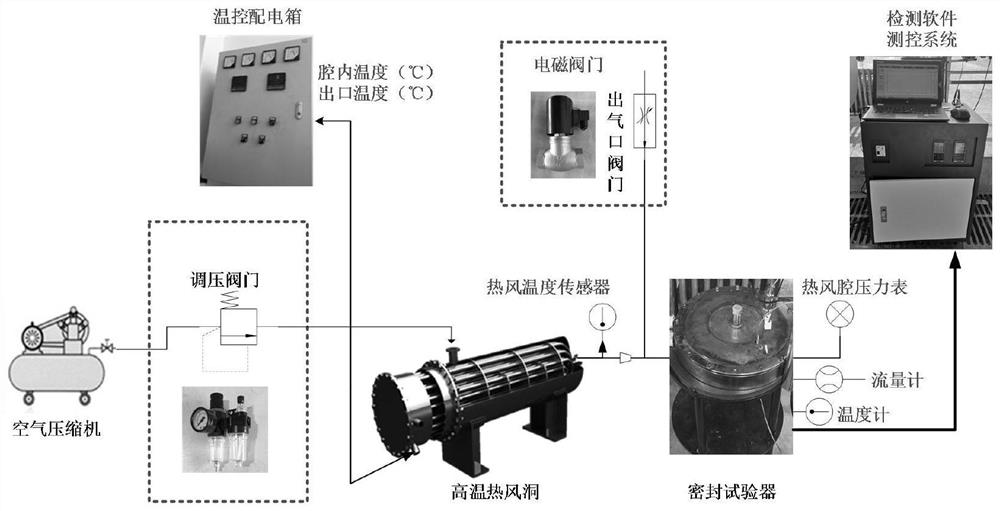

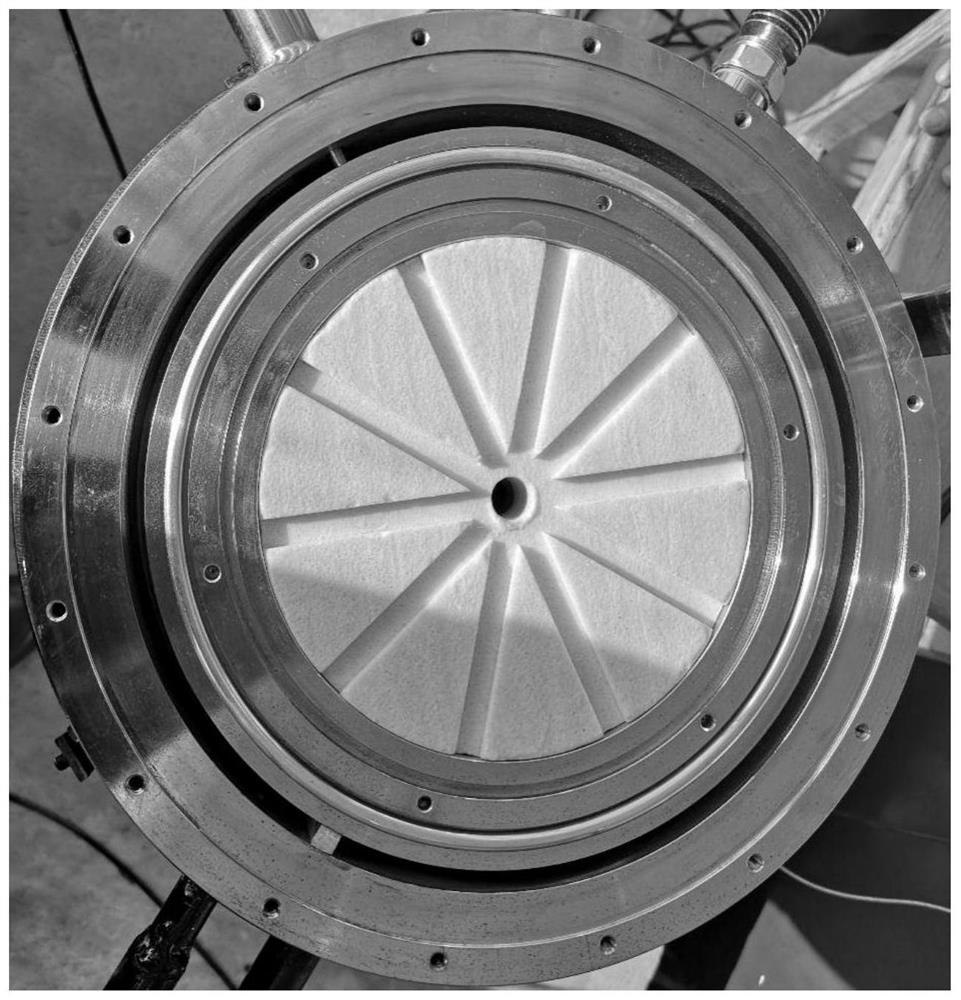

[0032] Embodiment 1: The main structure of the tester body whose compressibility cannot be adjusted is as attached image 3 , 4 shown. The body of this type of tester mainly includes an upper gland, a heating plate, and a base. The base is the foundation of the tester body. Its main functions include forming an airflow path with an external hot air system, and forming a fixed compression ratio of the seal to be tested with the upper cover. , Install various sensors, etc. The base contains two installation positions of the seals to be tested with different diameters and specifications, which can realize the performance test of the seals to be tested with different specifications under various working conditions.

[0033] The heating plate, the external hot air system and various sensors are all connected to the PLC measurement and control system, and the measurement and control software performs unified automatic data collection and control, which reduces the complexity of th...

Embodiment 2

[0035] Embodiment 2: The main structure of the tester body with adjustable compression rate is as attached Figure 5 shown. The main body of this type of tester mainly includes an upper layer gland, a heating plate, an intermediate positioning adjustment block, and a base. The base is the foundation of the tester body. The combination of the cover and the replaceable intermediate positioning adjustment block determines the compression ratio of the seal to be tested, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com