Patents

Literature

34results about How to "Temperature close to" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

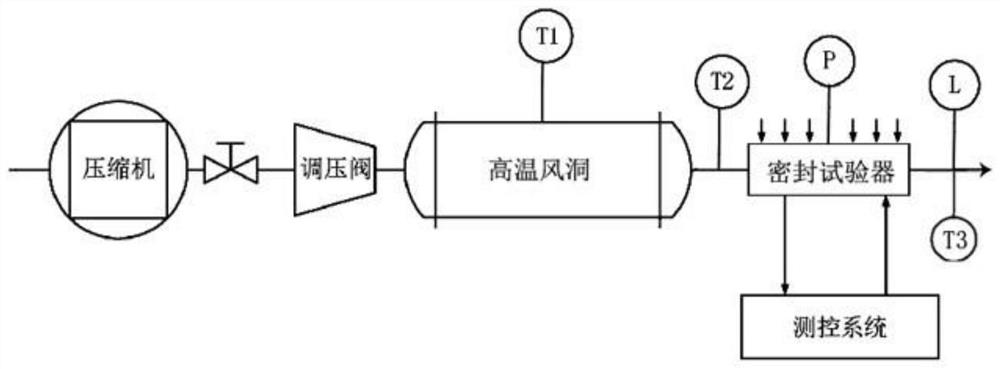

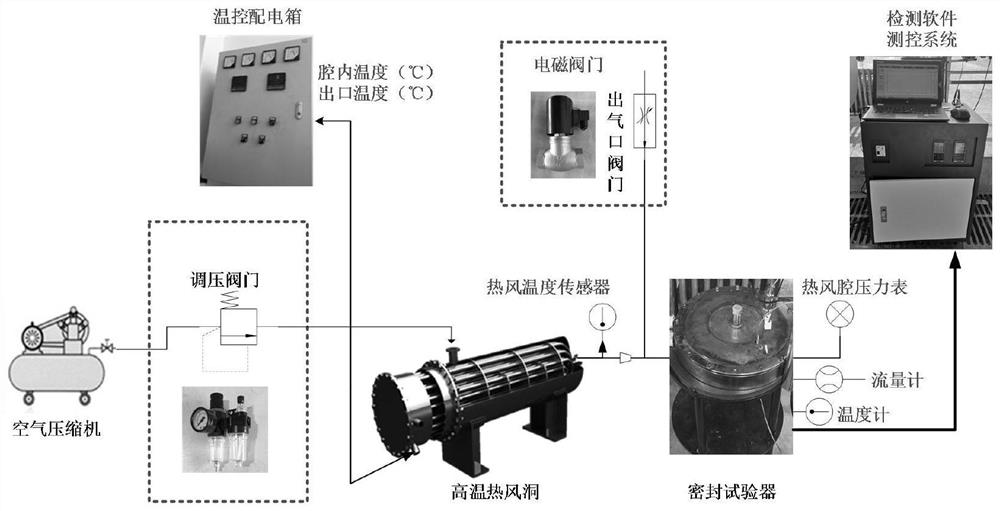

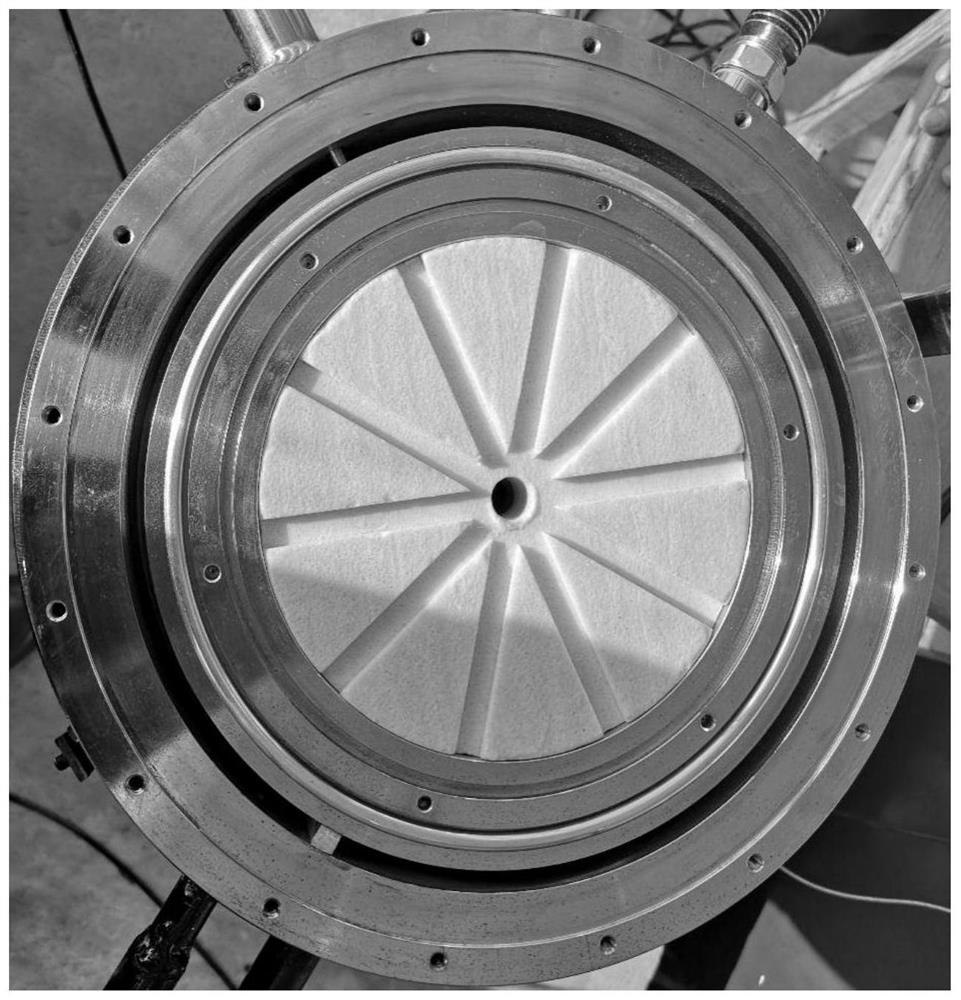

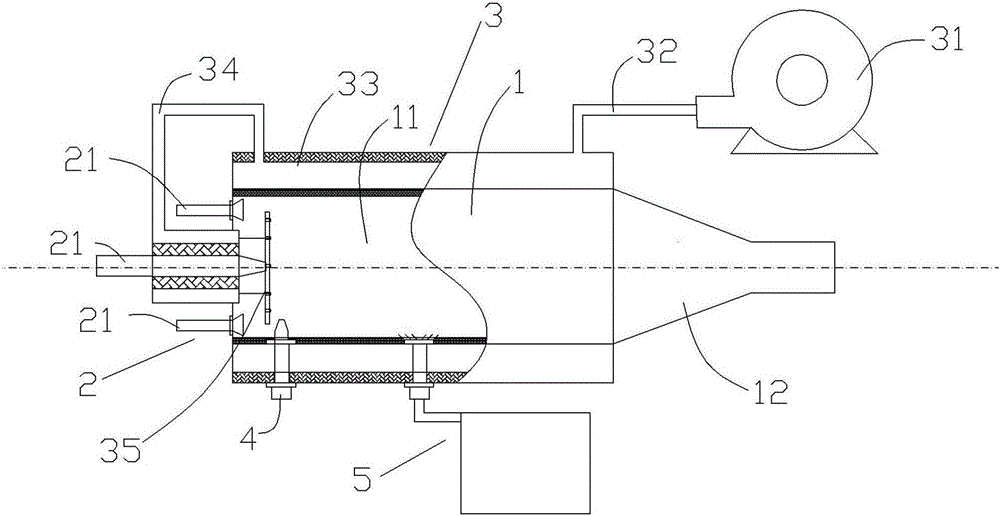

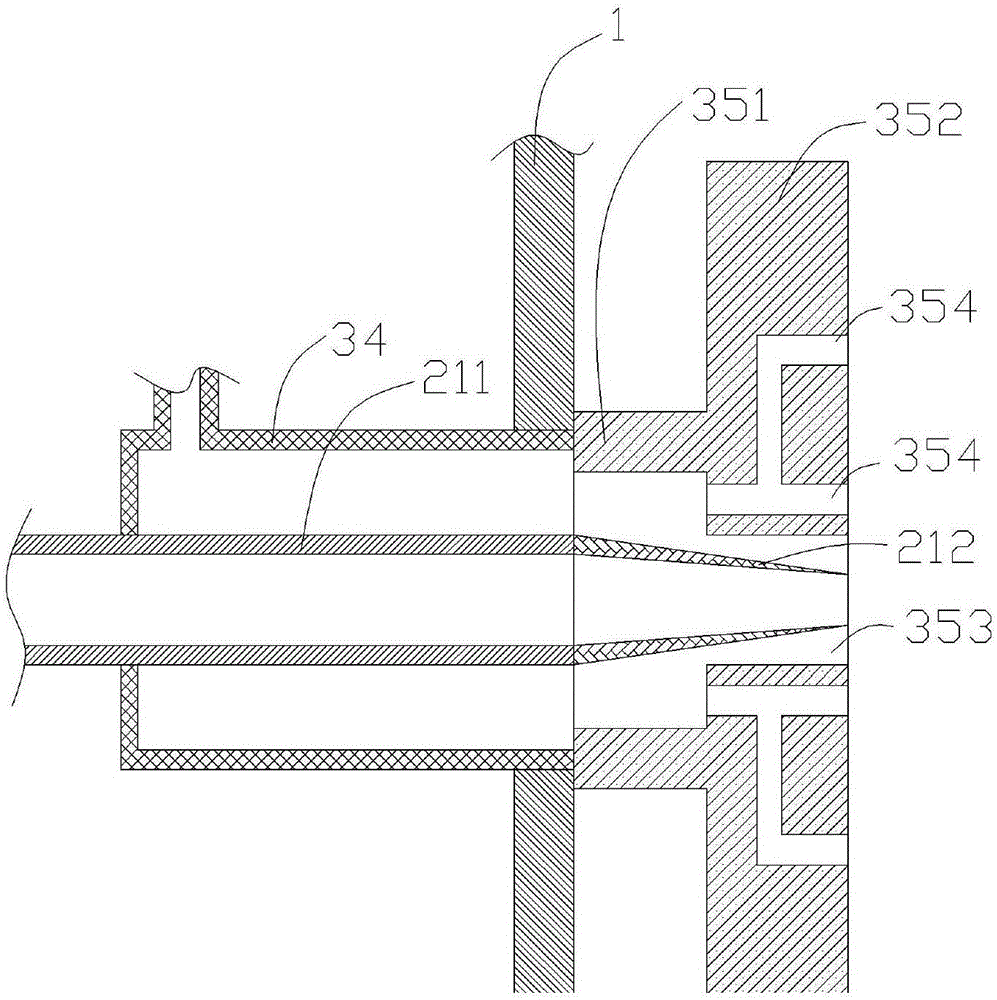

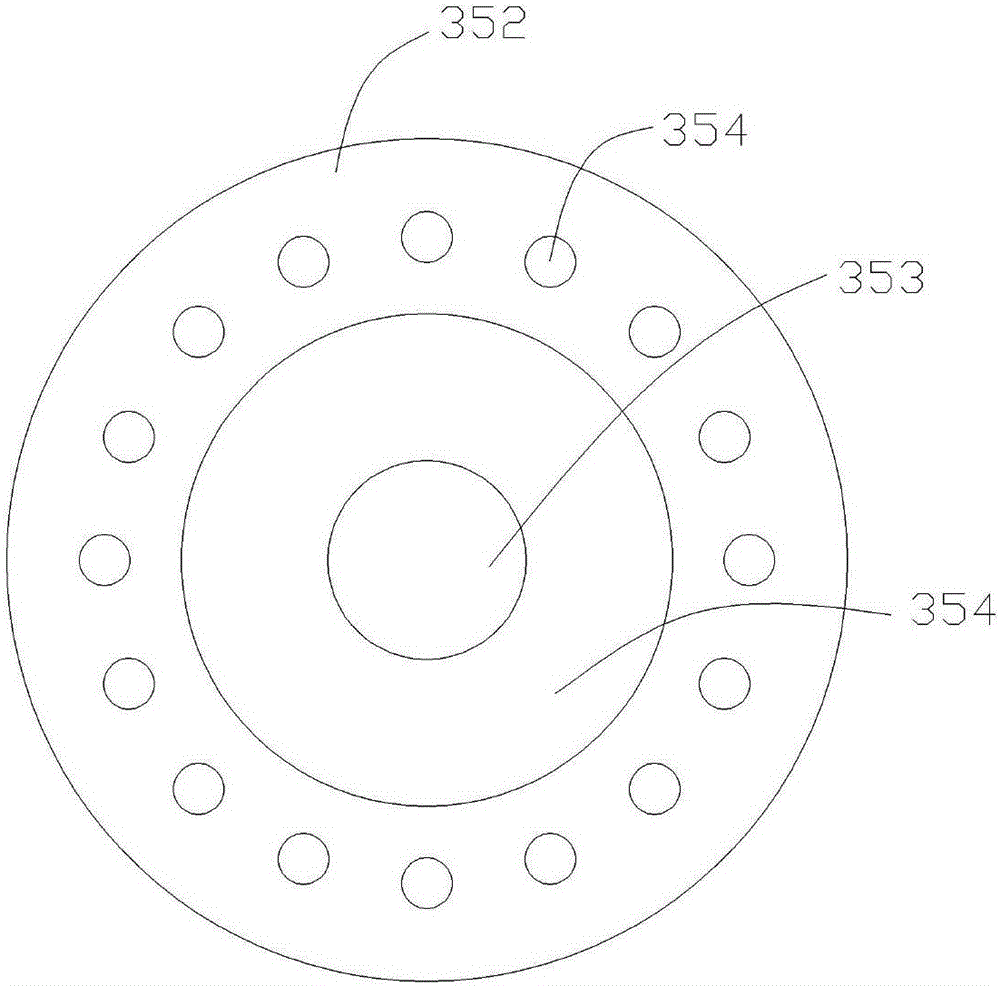

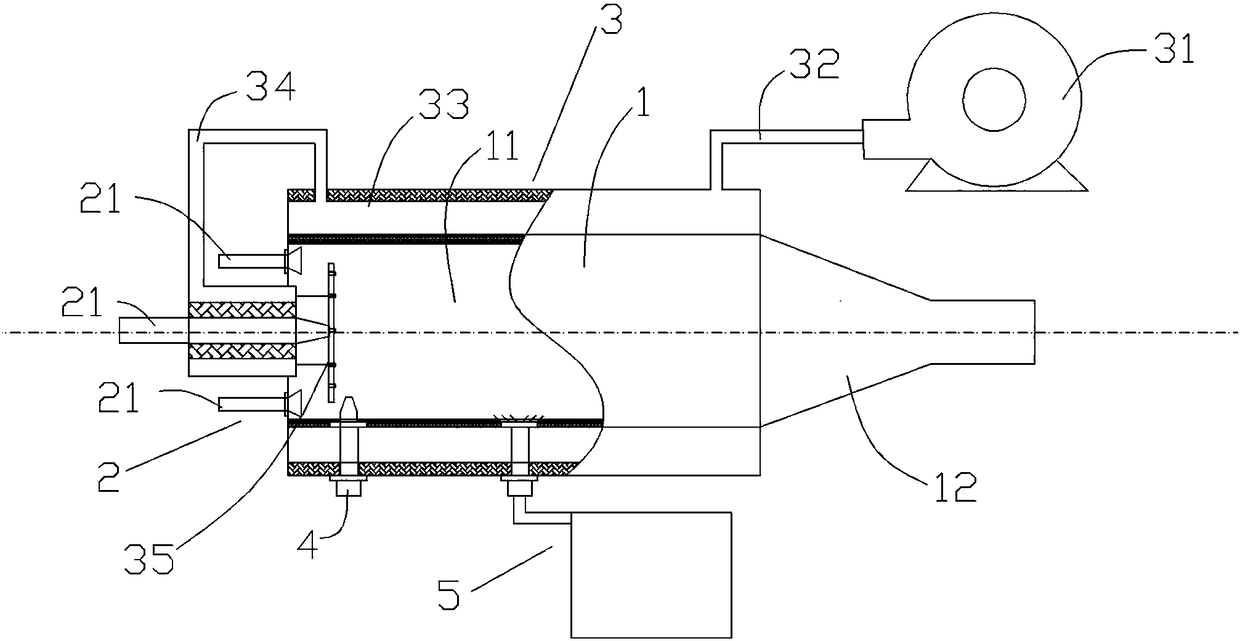

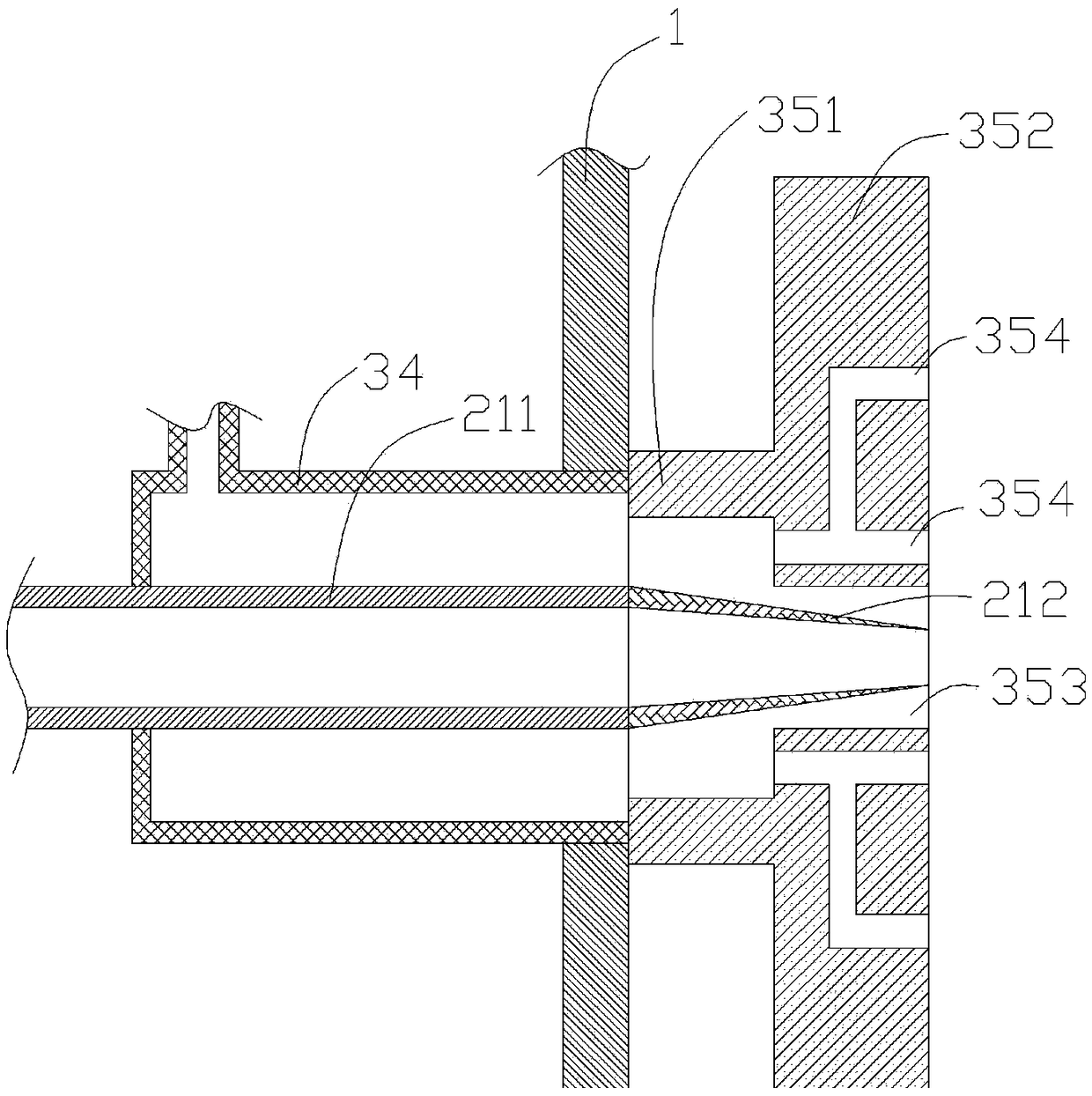

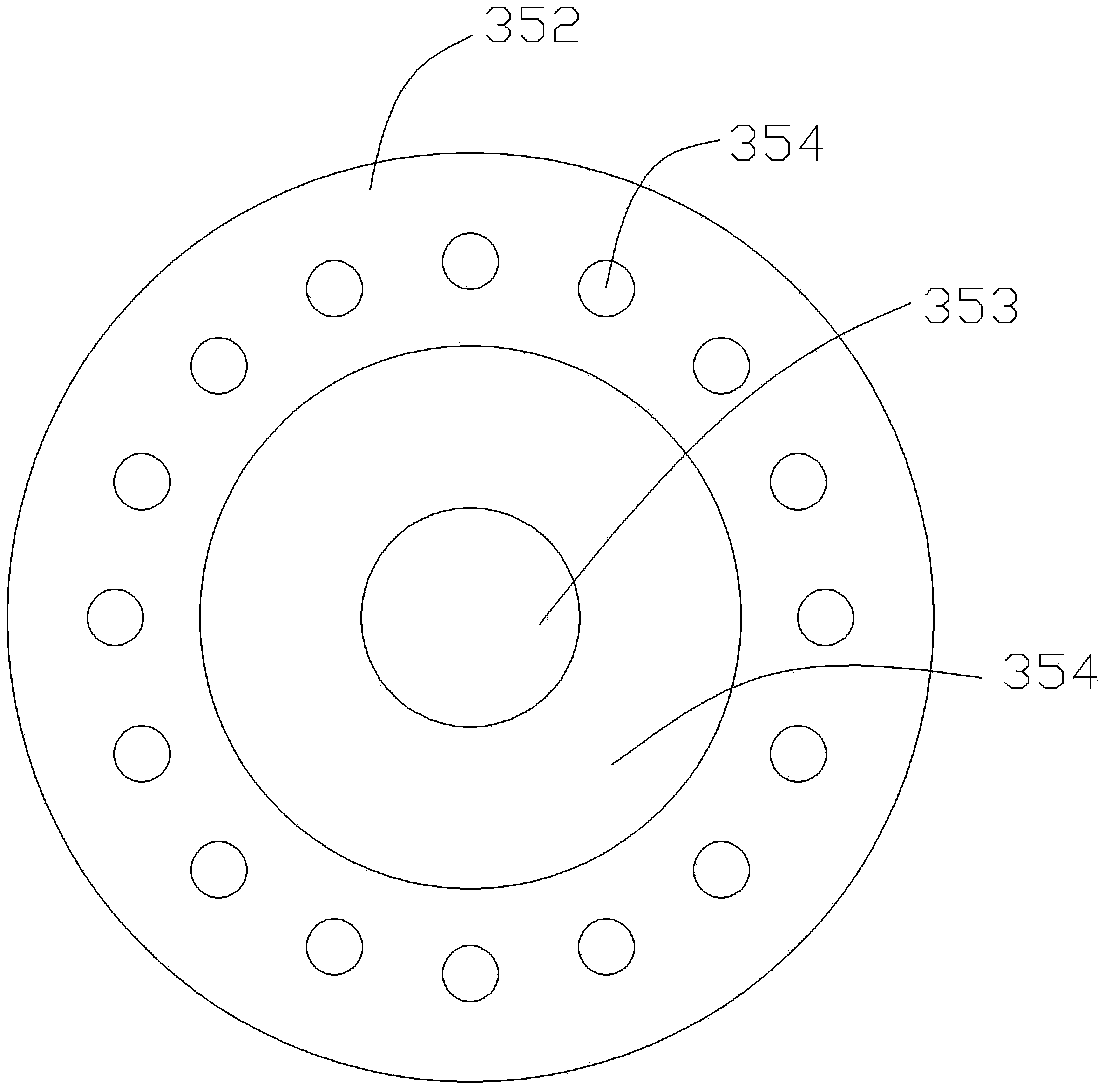

Test system and method for realizing performance simulation test of high-temperature metal sealing ring

ActiveCN112903208AHigh simulationHigh temperature control accuracyMeasurement of fluid loss/gain rateAerodynamic testingFlight vehicleAir compressor

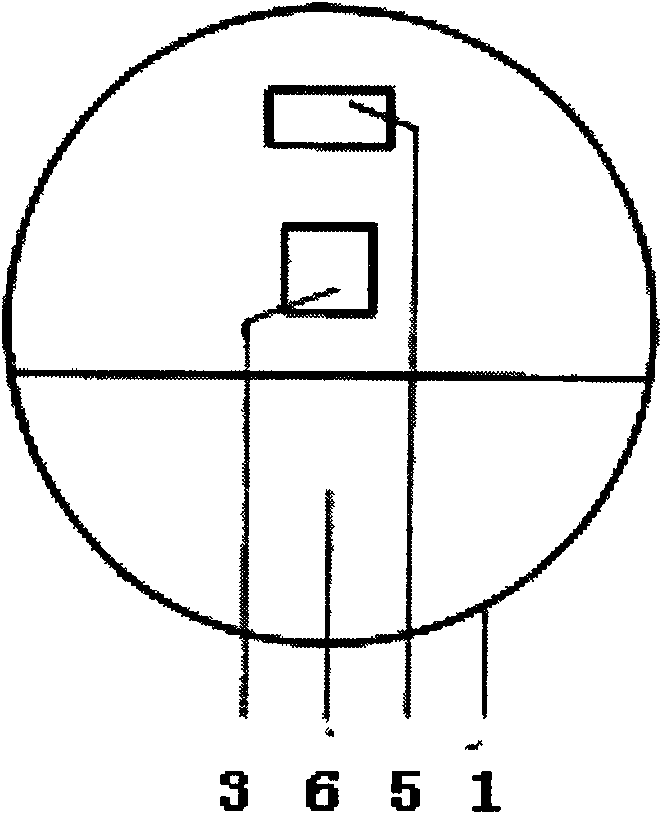

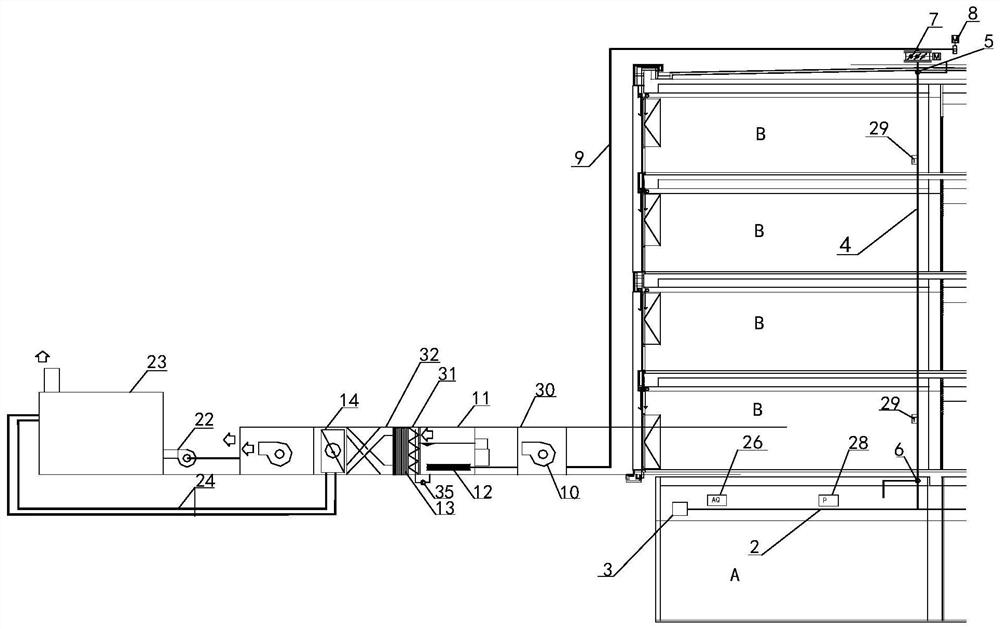

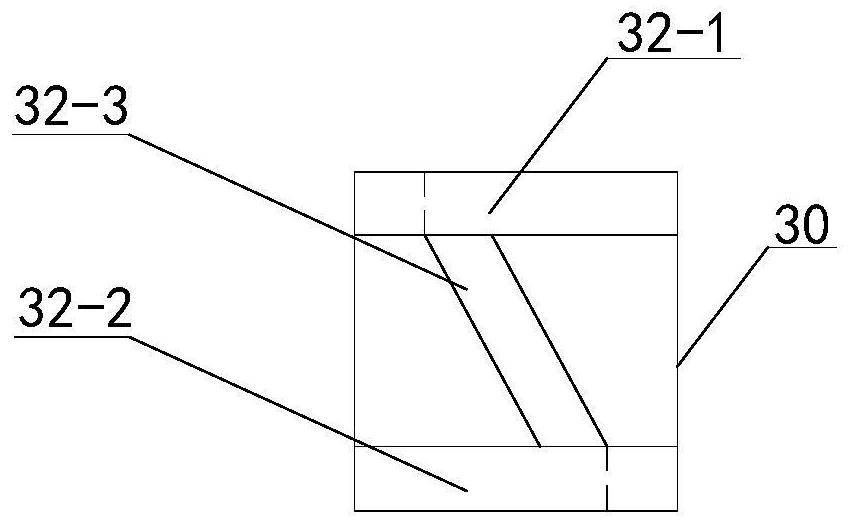

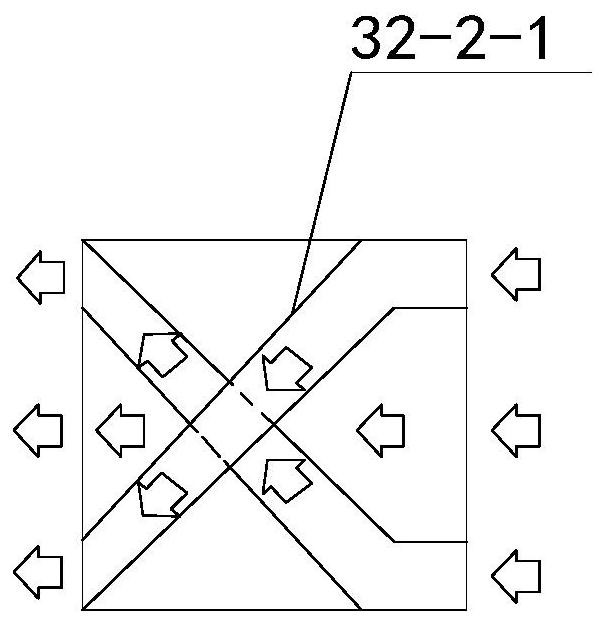

The invention discloses a test system and method for realizing a high-temperature metal sealing ring performance simulation test. The test system is mainly composed of the following parts: an external hot air system (including an air compressor and a high-temperature wind tunnel); a high-temperature sealing tester body; a test piece installed in the body; a measurement box; and a temperature sensor, a pressure gauge, a flow meter and the like that are installed at key positions. On one hand, the design of the test working condition covers the actual operation working condition range; on the other hand, the corresponding relation between the test condition and the actual operation condition needs to be explained. The device is mainly developed and designed for the C-shaped metal sealing ring, and a subsequent high-temperature sealing principle verification test is carried out. According to existing experiment conditions and parameters, sealing airtightness and heat sealing performance tests under actual working conditions are carried out, so that the sealing element performance of an aircraft in a real operation environment is guaranteed.

Owner:BEIJING UNIV OF CHEM TECH

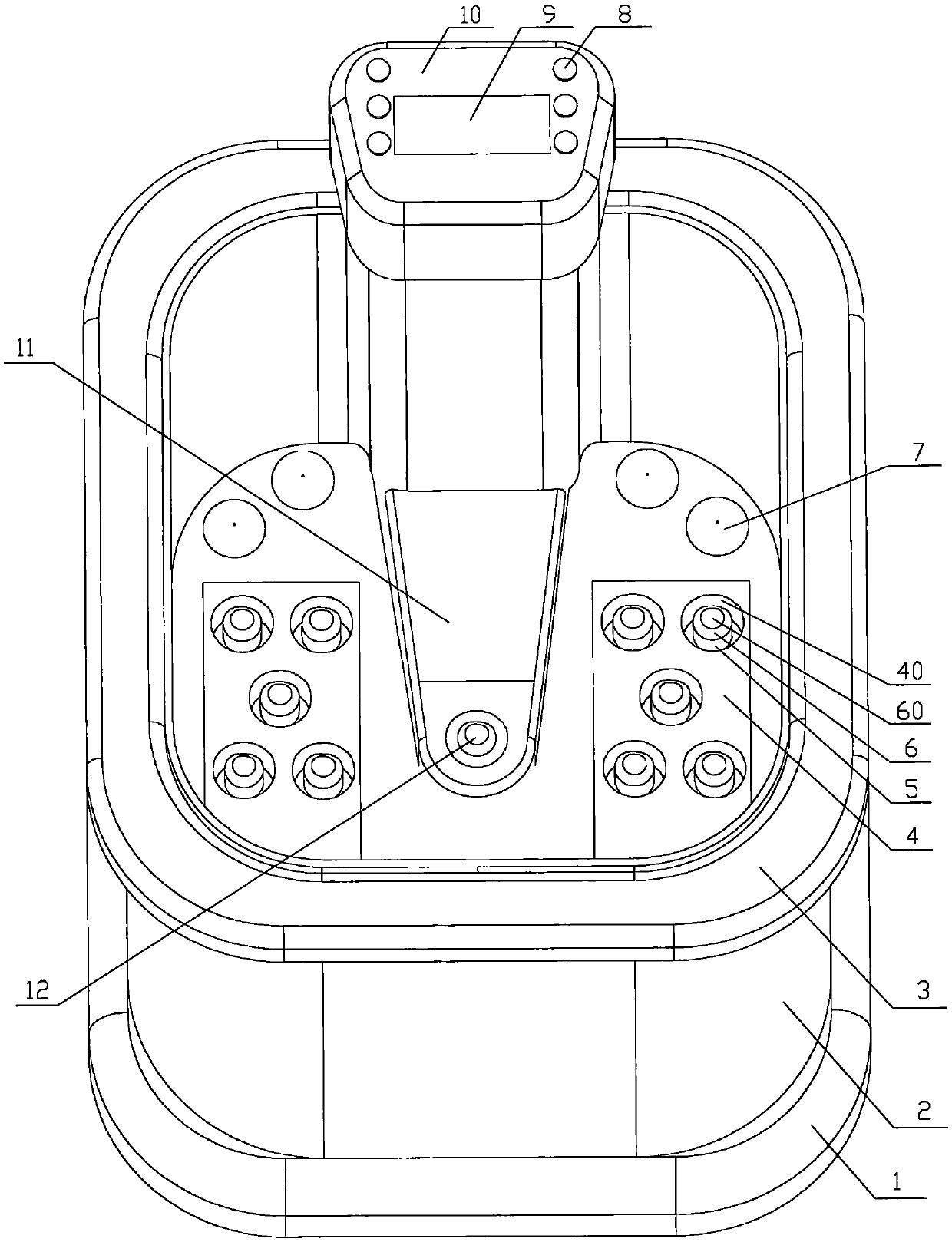

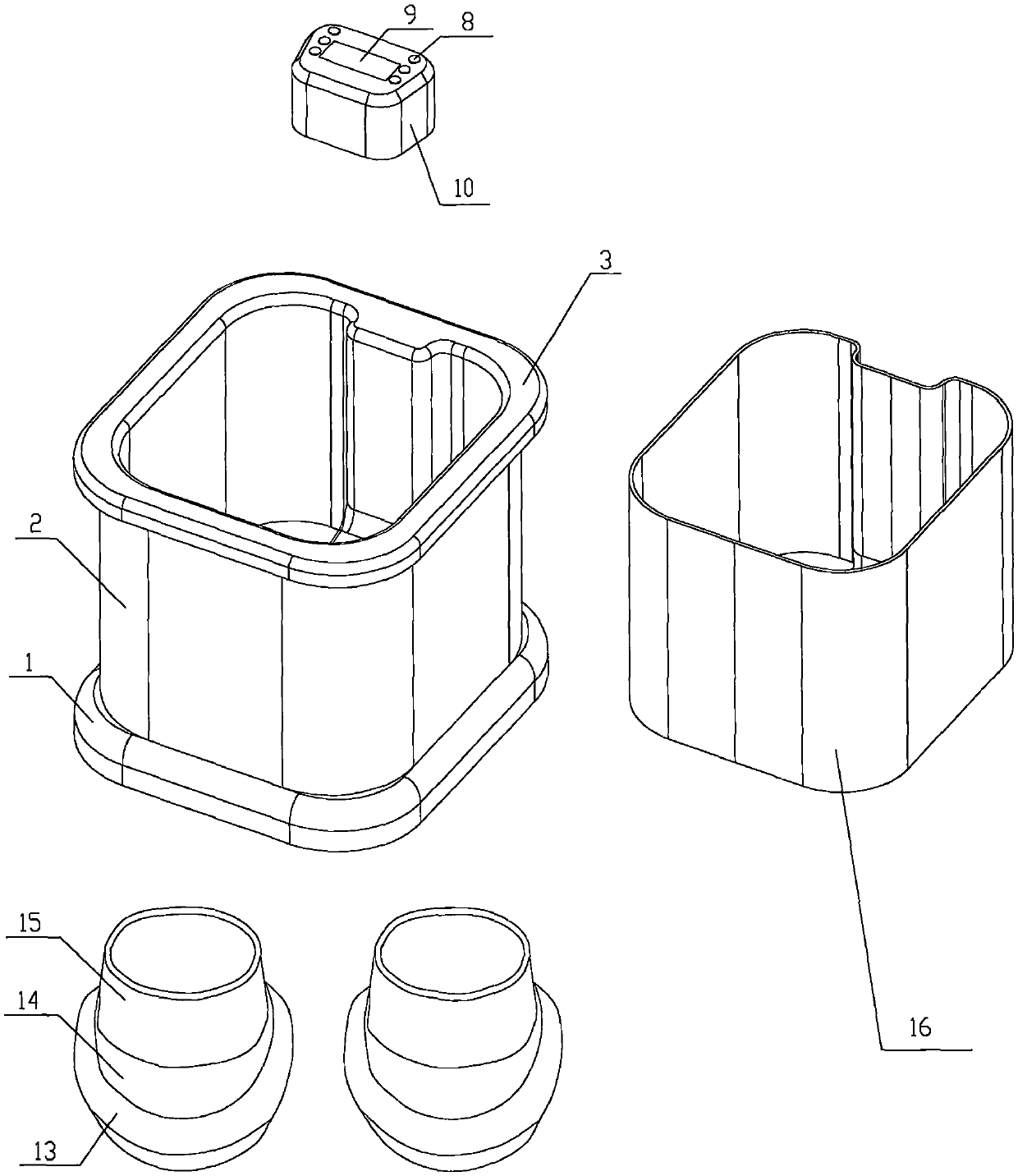

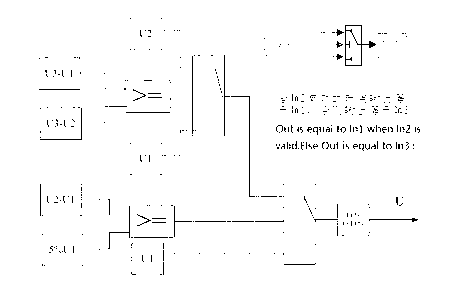

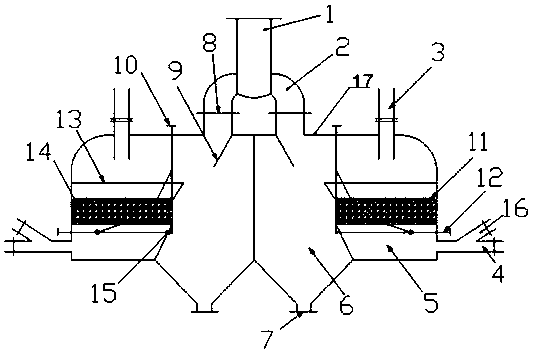

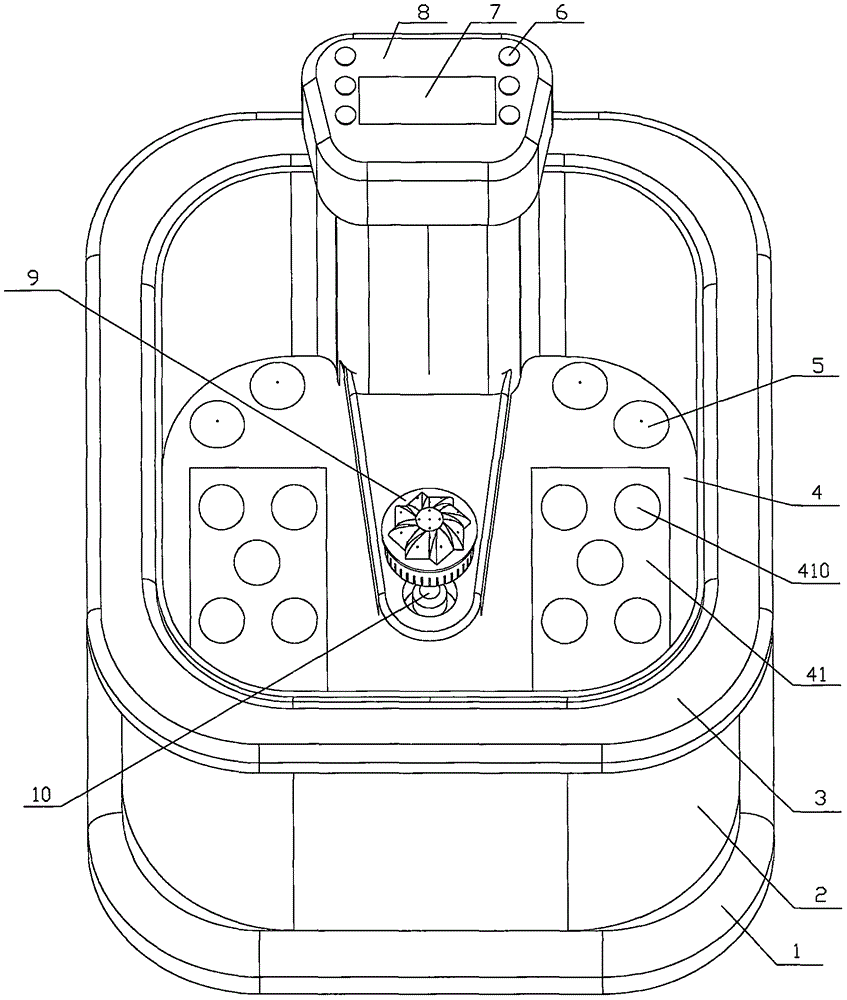

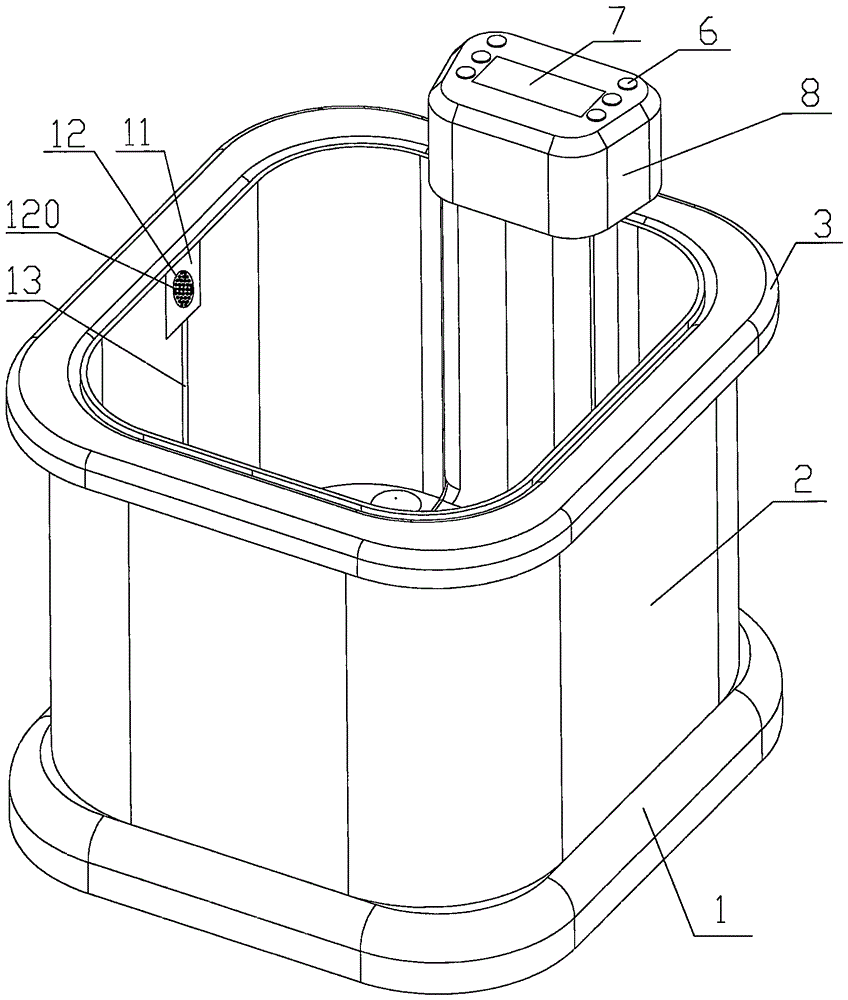

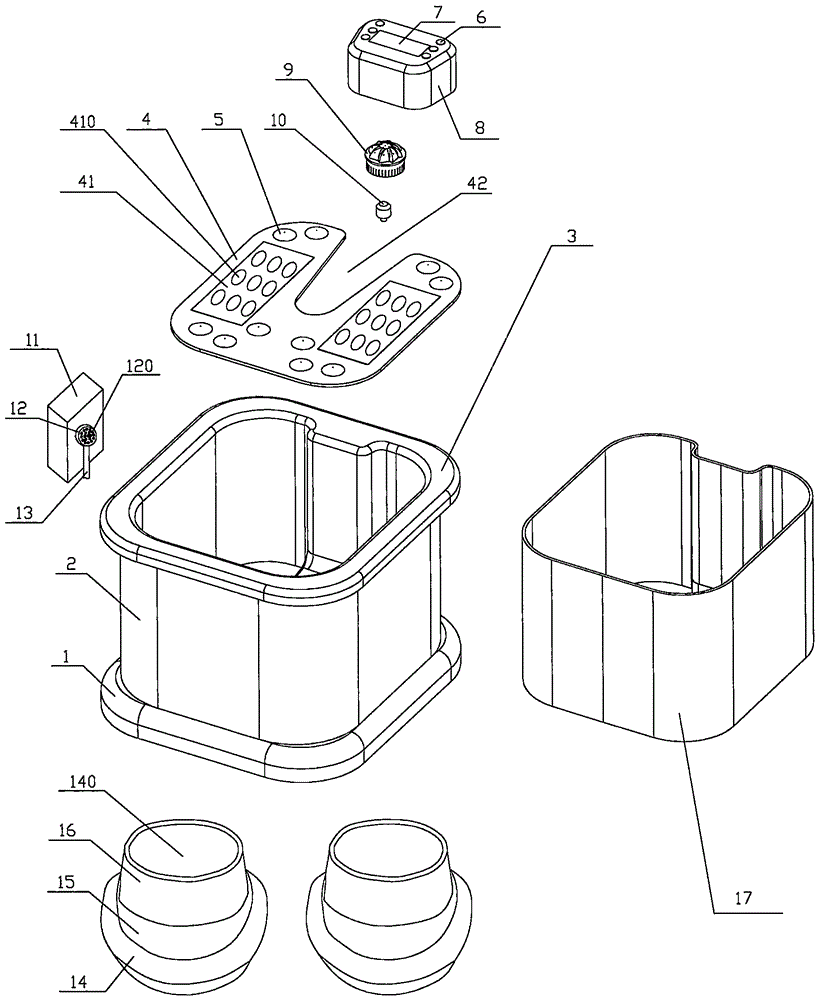

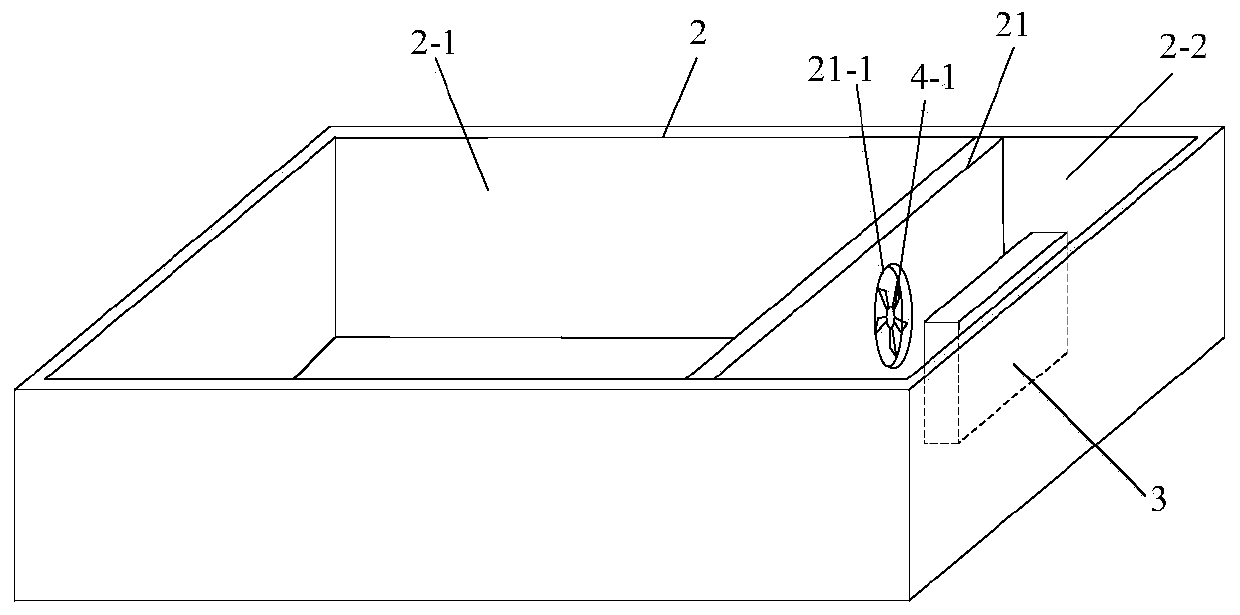

Footbath tub with sole massage function and intelligent control method of footbath tub

ActiveCN105496762APlace stableEasy to carryDevices for pressing relfex pointsBathing devicesTemperature controlMassage

The invention relates to a footbath tub and discloses a footbath tub with a sole massage function and an intelligent control method of the footbath tub. The footbath tub comprises a tub body (2) and footbath devices, the bottom portion of the tub body (2) is filled with footbath liquid, and the footbath devices are fixedly arranged below two soles and eject water to impact sole acupoints. By water ejection for impacting the sole acupoints, automatic sole massaging and rubbing of feet in the footbath tub is realized, and footbath healthcare efficacies are greatly improved; by a temperature control device and a temperature control method, the problem of poor footbath effects caused by local overheating or overcooling in a footbath process is avoided, footbath balance is achieved, a user can experience footbath effects and keep fit in the footbath process, and energy saving and environment friendliness are realized; the footbath tub further has functions of foot drying and sterilization.

Owner:NINGBO HEALTHOME ELECTRICAL APPLIANCE

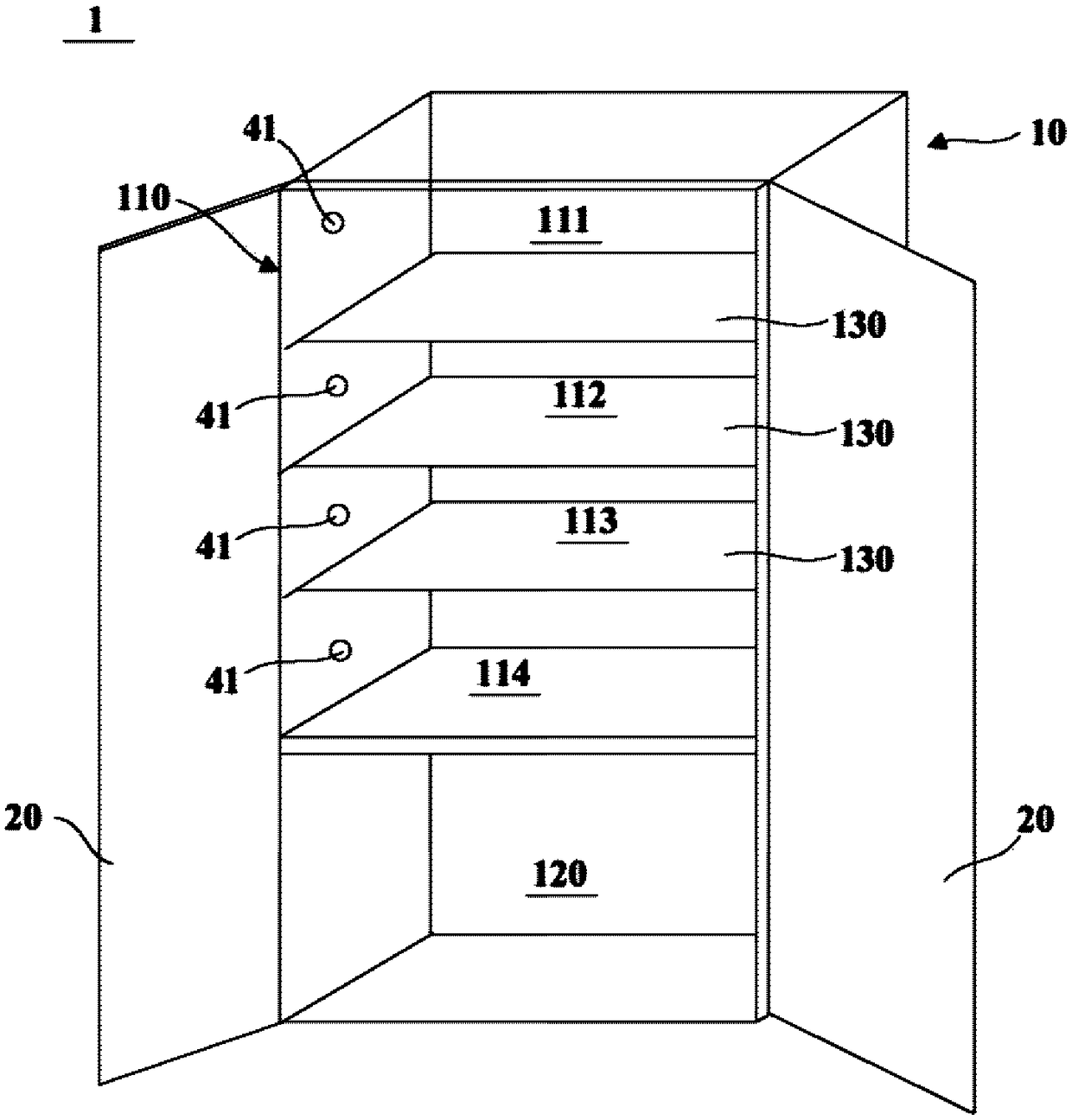

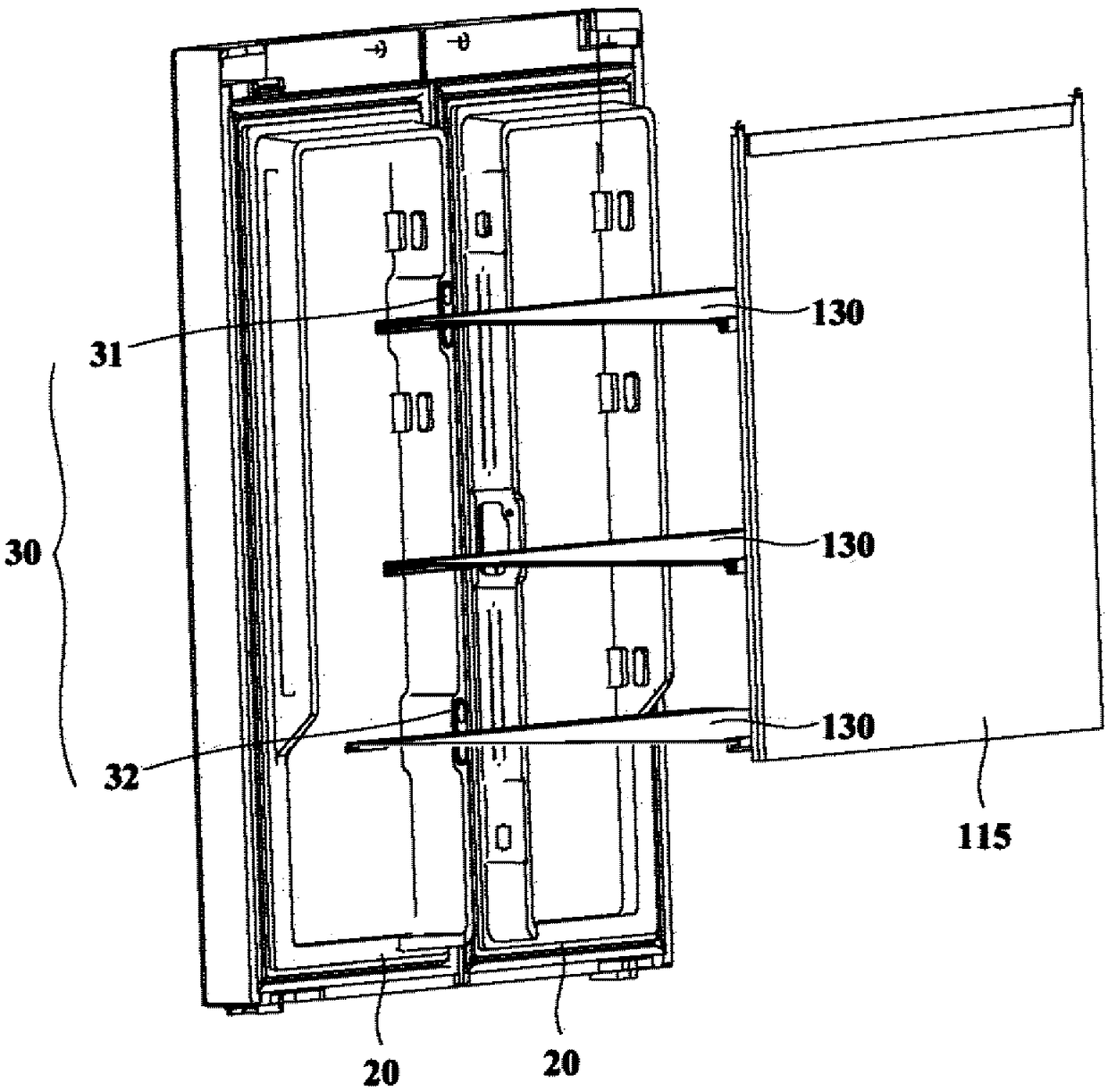

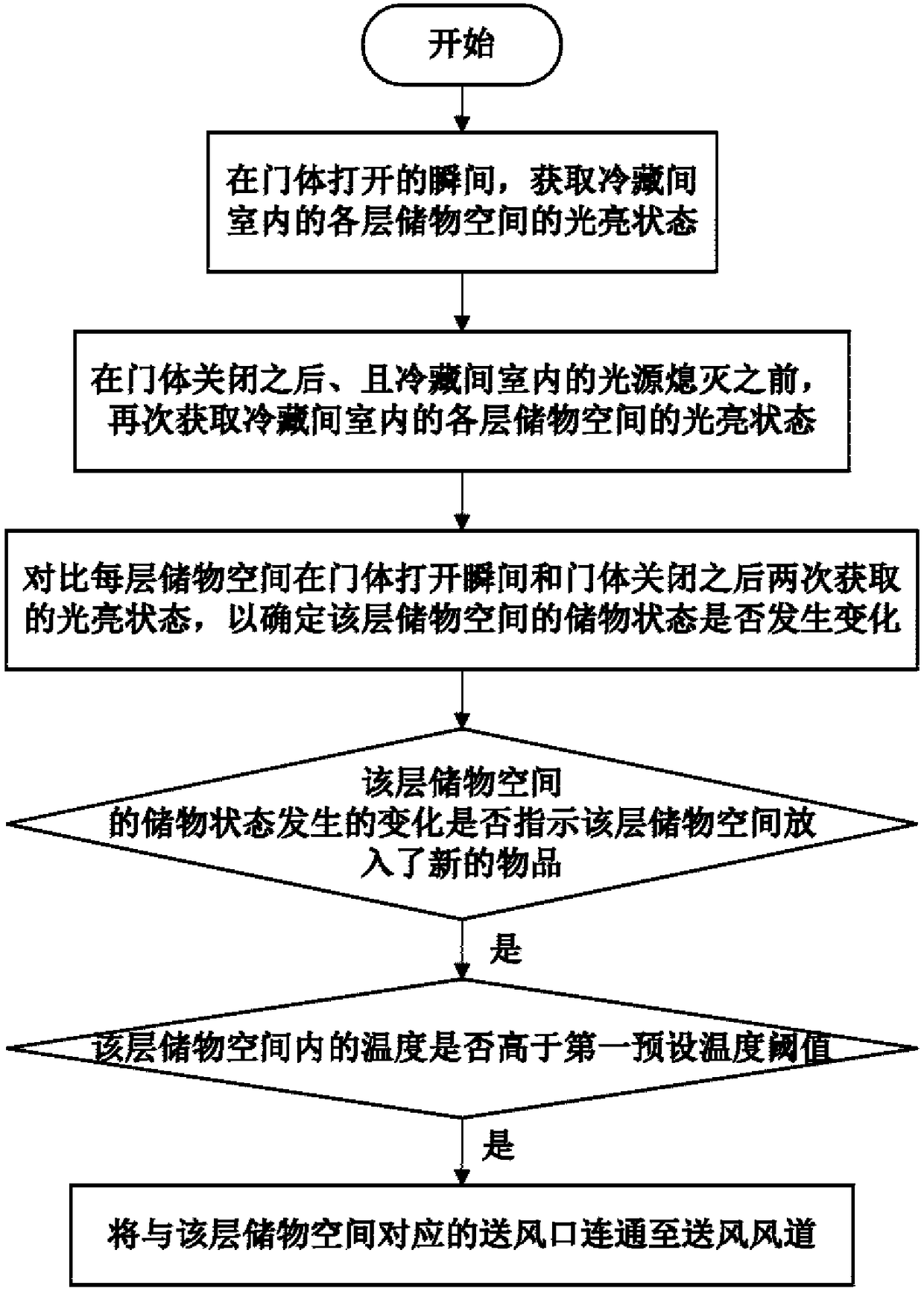

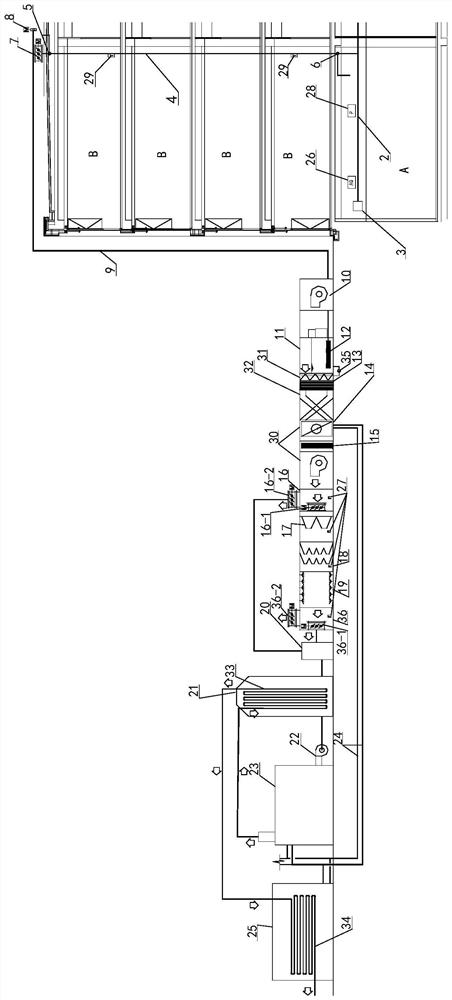

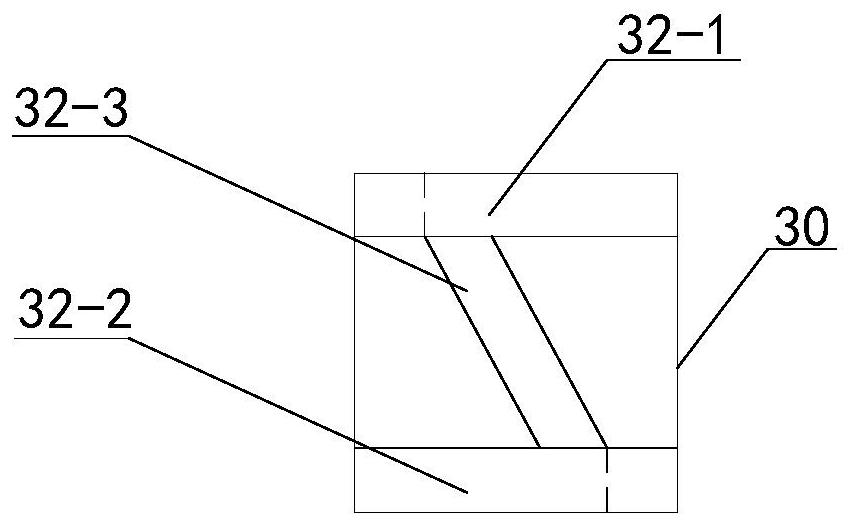

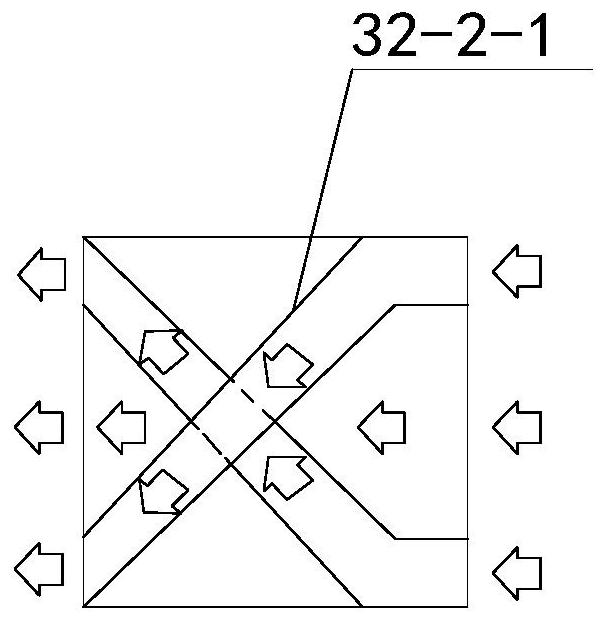

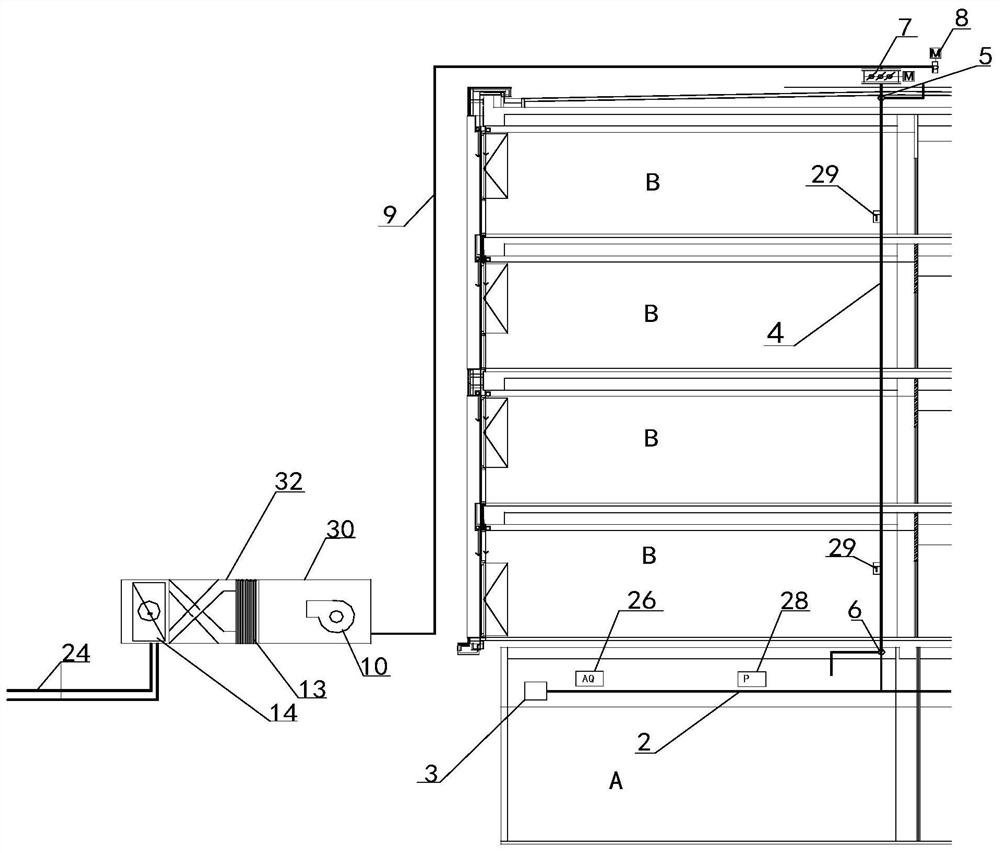

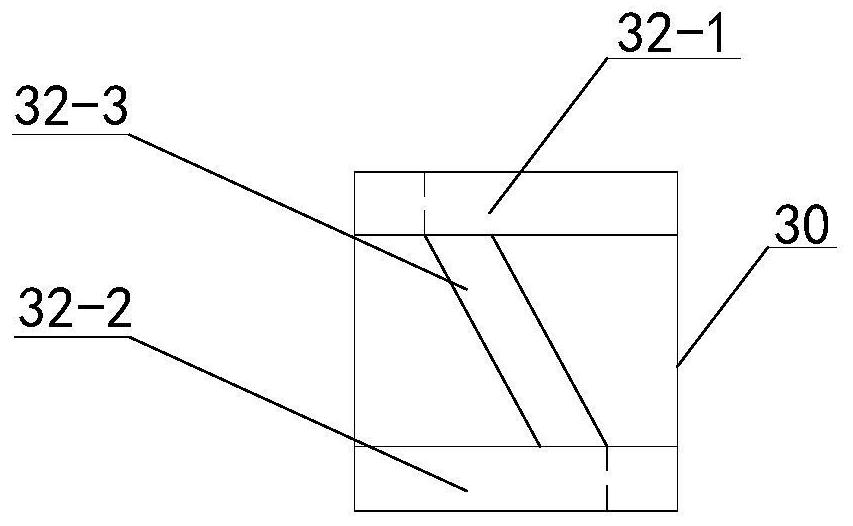

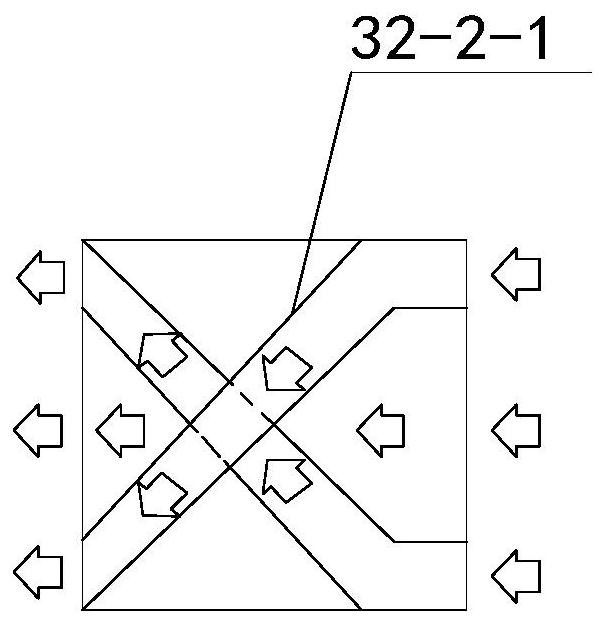

Refrigerating and freezing device and control method thereof

InactiveCN108168189ARealize precise air supplyImprove cooling effectLighting and heating apparatusDomestic refrigeratorsBrightness perceptionEmbedded system

The invention relates to a refrigerating and freezing device and a control method thereof. The control method comprises the steps of: obtaining a brightness state of each-layer storage space in a refrigerating chamber at the moment of opening a door body; obtaining the brightness state of each-layer storage space in the refrigerating chamber again after the door body is closed and before a light source in the refrigerating chamber is turned off; comparing the brightness states obtained twice at the moment of opening the door body and after closing of the door body to determine if a storage state of the storage space is changed; indicating that new objects are placed in the storage space if the storage state of the storage space is changed, and judging if the temperature in the storage space is higher than a first preset temperature threshold or not; and communicating an air supply port corresponding to the storage space to the air supply way if the temperature in the storage space is higher than the first preset temperature threshold. Precise layered air supply is realized; and the refrigerating effect and the refrigerating efficiency are improved.

Owner:HAIER SMART HOME CO LTD

High-pollution building space exhaust disinfection and purification system and method

PendingCN111878927AReduce virus contentImprove disinfection effectDucting arrangementsMechanical apparatusVentilation tubeInsulation layer

The invention provides a high-pollution building space exhaust disinfection and purification system and method. The system comprises a pollution region negative pressure metal ventilation pipe, and any position of the pollution region negative pressure metal ventilation pipe is communicated to the inlet end of a high-resistance ventilation pipeline with a heat insulation and insulation layer. Theoutlet end of the high-resistance ventilation pipeline with the heat insulation and insulation layer is connected to the inlet end of an outdoor negative pressure metal ventilation pipe through an electric backflow prevention valve, and the outlet end of the outdoor negative pressure metal ventilation pipe is connected to an extraction opening of an efficient frequency conversion draught fan. A plurality of virus killing devices are sequentially arranged at the rear end of the efficient variable-frequency draught fan. By means of the system and method, air possibly containing viruses in a high-pollution building space is subjected to high-temperature disinfection and sterilization through an electric heating pipeline, then the air subjected to high-temperature disinfection and sterilization is guided to an outdoor multi-virus disinfection and sterilization device through the negative pressure pipeline to conduct diversified thorough disinfection and sterilization on the introduced air,and the viruses in the air in the high-pollution building space can be thoroughly removed.

Owner:CHINA RAILWAY CONSTR GROUP +1

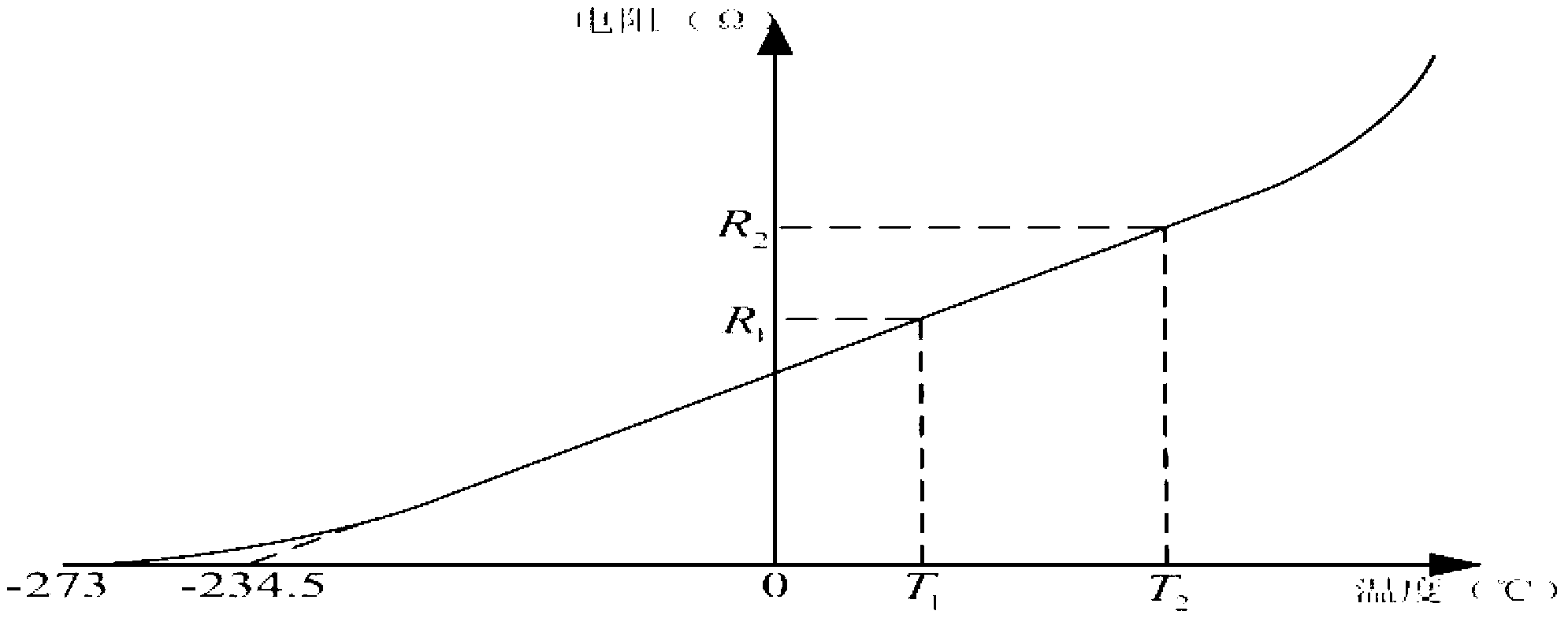

Calculation method of temperature of rotor winding of large-size water-turbine generator set

InactiveCN103267587AAccurate calculationTemperature close toThermometers using electric/magnetic elementsTemperature measurement of moving solidsElectrical resistance and conductanceWater turbine

The invention discloses a calculation method of a temperature of a rotor winding of a large-size water-turbine generator set. The calculation method comprises the following steps: (1) respectively measuring temperatures of a halting state and a no-load state of the rotor winding of a generator and the rotor winding; and calculating to obtain the temperature of the rotor winding and the linear coefficient of a resistor; (2) sampling to obtain real-time sampling values of exciting voltage and exciting current to obtain a resistance value of the rotor winding; and (3) multiplying a real-time resistance value of the rotor winding by the temperatures of the rotor winding and the linear coefficient of the resistor, and subtracting a zero resistance temperature to obtain the temperature of the rotor winding. According to the calculation method disclosed by the invention, the measurement of rotor voltage and rotor current has a filtering function and a fault-tolerant mechanism; and a linear coefficient calculation method of a rotor resistance and a rotor temperature is optimized and the calculation of the resistance value of the rotor winding is closer to an actual value; meanwhile, influence of the slip ring pressure drop and the bus pressure drop on calculation of rotor temperature are considered to enable the calculation of the resistance value of the rotor winding closer to an actual temperature, so that the accuracy of measuring the temperature of a rotor is improved.

Owner:NARI TECH CO LTD

Spiral ultra-long cooling loop irradiation device

ActiveCN110853793ASolve the problem of uneven axial temperatureTemperature close toIrradiation devicesOutfallEngineering

The invention discloses a spiral ultra-long cooling loop irradiation device, which is characterized in that an inner-layer annular space is formed between an inner-layer irradiation tank and a middle-layer irradiation tank, and an outer-layer annular space is formed between the middle-layer irradiation tank and an outer-layer irradiation tank; a sample is arranged on a clamping block, and the clamping block is arranged in the inner-layer annular space; an outer-layer cooling pipe and an inner-layer cooling pipe are both wound on the outer wall of the middle-layer irradiation tank; a water outlet of the outer-layer cooling pipe is communicated with the outer-layer annular space at the bottom of the outer-layer irradiation tank; a water outlet of the inner-layer cooling pipe is communicatedwith the bottom of the inner-layer irradiation tank; the inner-layer irradiation tank is communicated with the outer-layer annular space through a one-way valve; a circulating water outlet pipe is arranged at the top of the outer-layer irradiation tank and is communicated with the outer-layer annular space. According to the spiral ultra-long cooling loop irradiation device, the problem that the axial temperature of an irradiation device is not uniform is solved, the inner spiral cooling circulation loop and the outer spiral cooling circulation loop are arranged to control the temperature in the irradiation device, and it is guaranteed that the temperatures of all material samples in the irradiation device are close.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

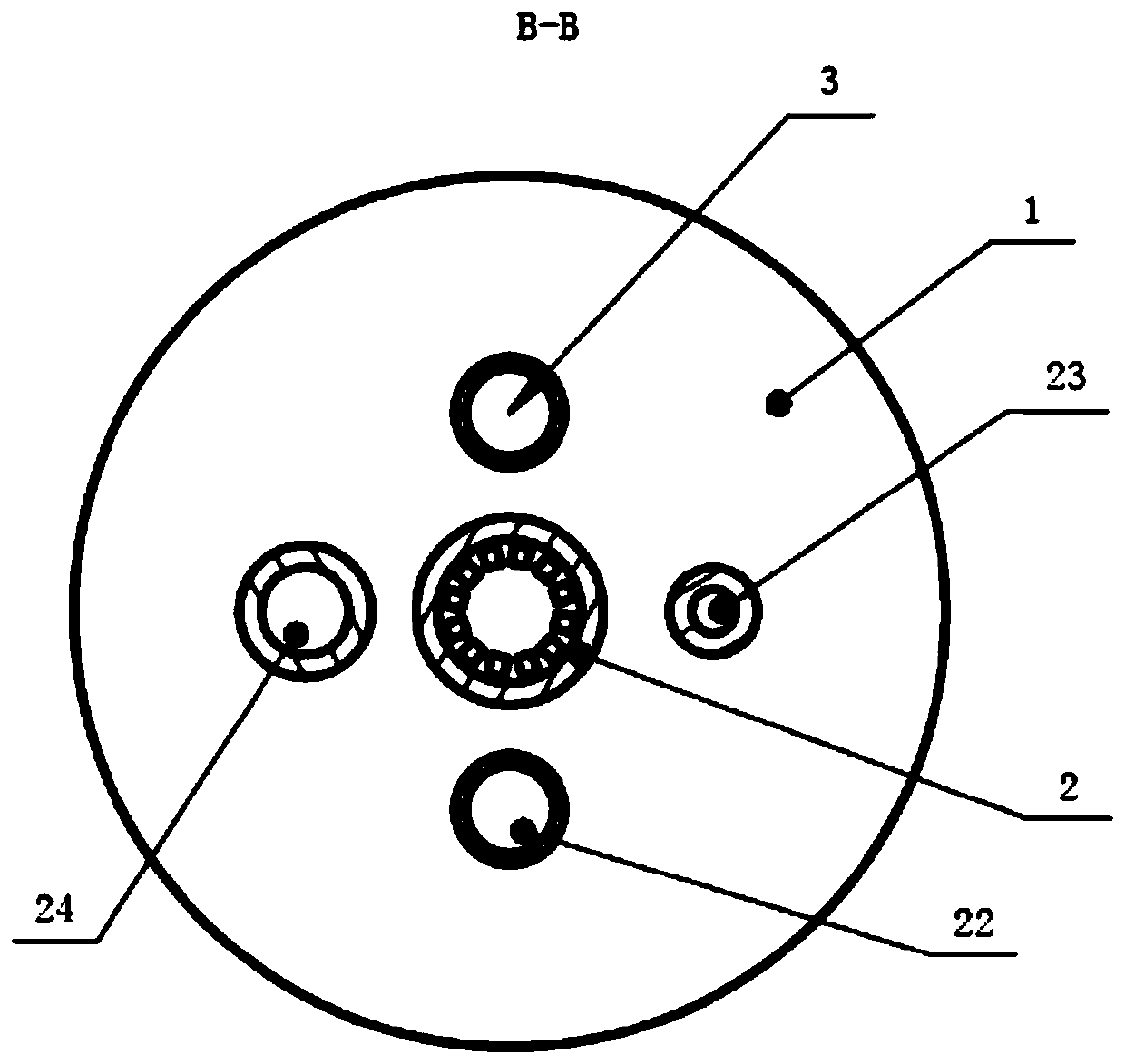

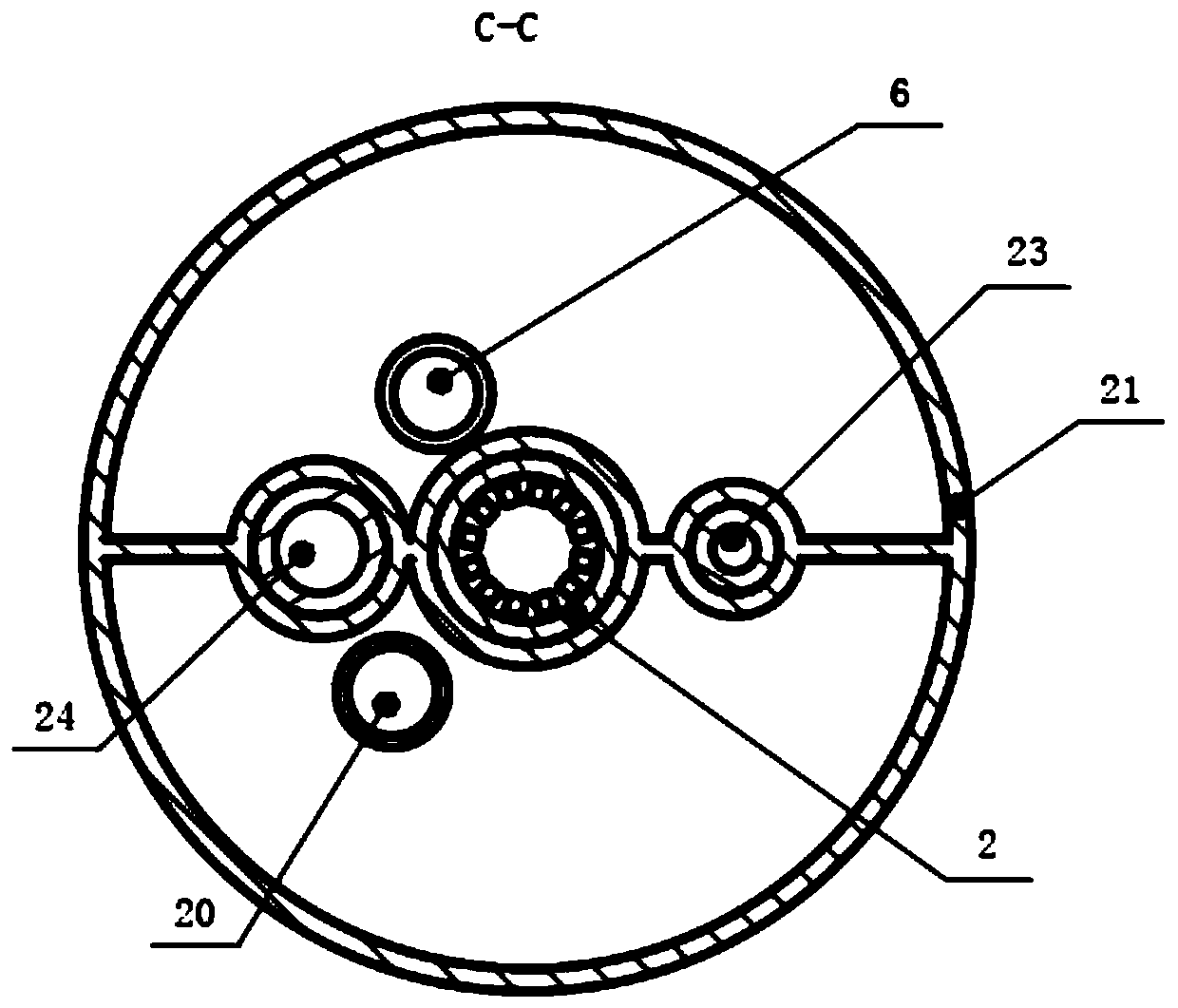

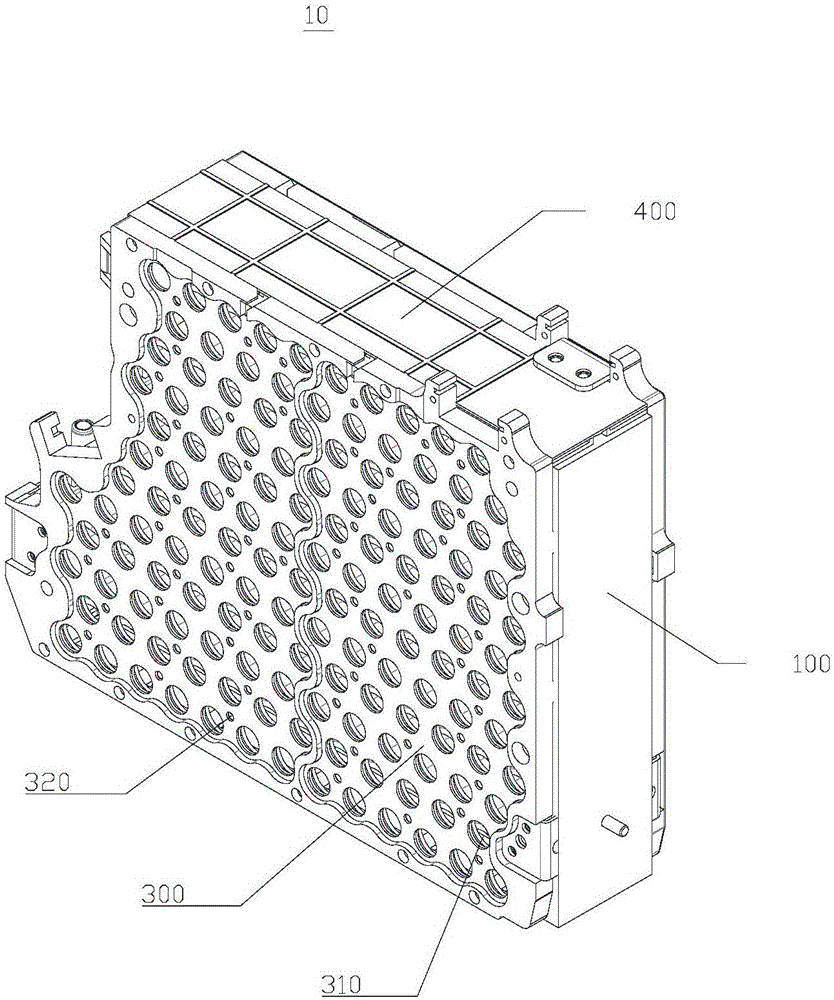

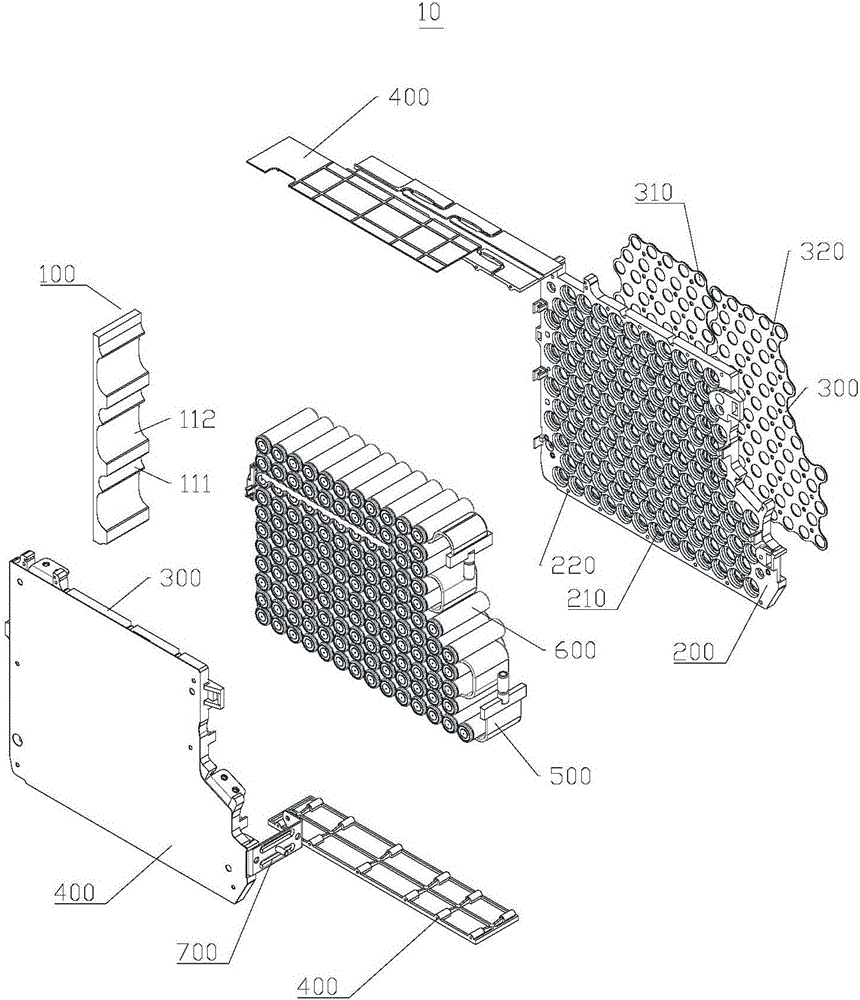

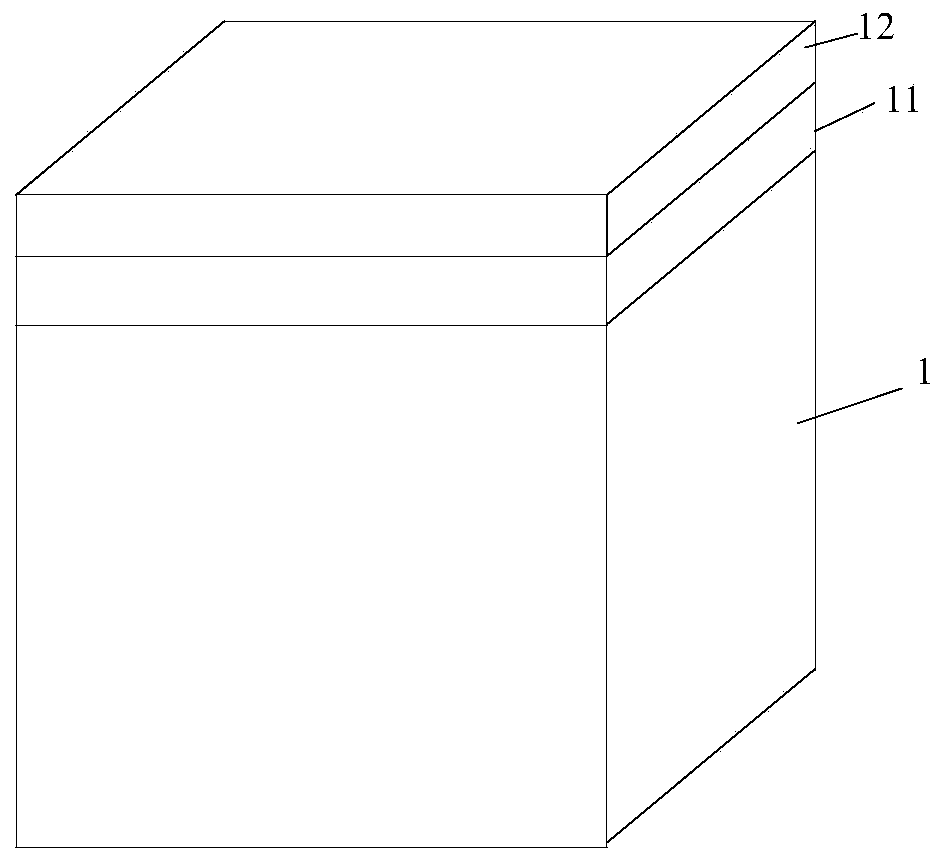

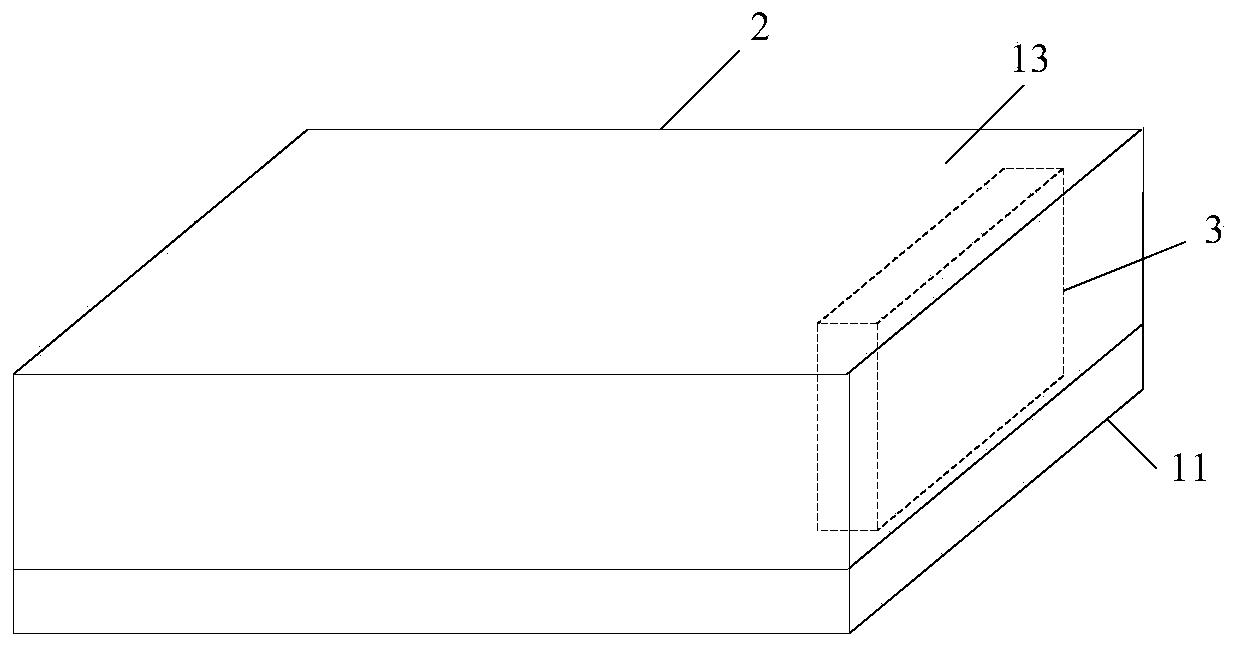

Battery module and temperature equalization structure

PendingCN106785238ATemperature close toSecondary cellsElectrical and Electronics engineeringEqualization

The embodiment of the invention provides a battery module and a temperature equalization structure. The battery module comprises a thermal management device, a plurality of single batteries and a temperature equalization structure, wherein the temperature equalization structure comprises at least one temperature equalization piece which is in contact with the thermal management device and at least one single battery; the temperature equalization piece is used for conducting hot energy and cold energy of the thermal management device to the single batteries. The battery module and the temperature equalization structure can be used for cooling or heating the single batteries which are in contact with the temperature equalization structure, so that the temperatures of the single batteries are approximate to the temperatures of the internal single batteries.

Owner:HUATING HEFEI POWER TECH

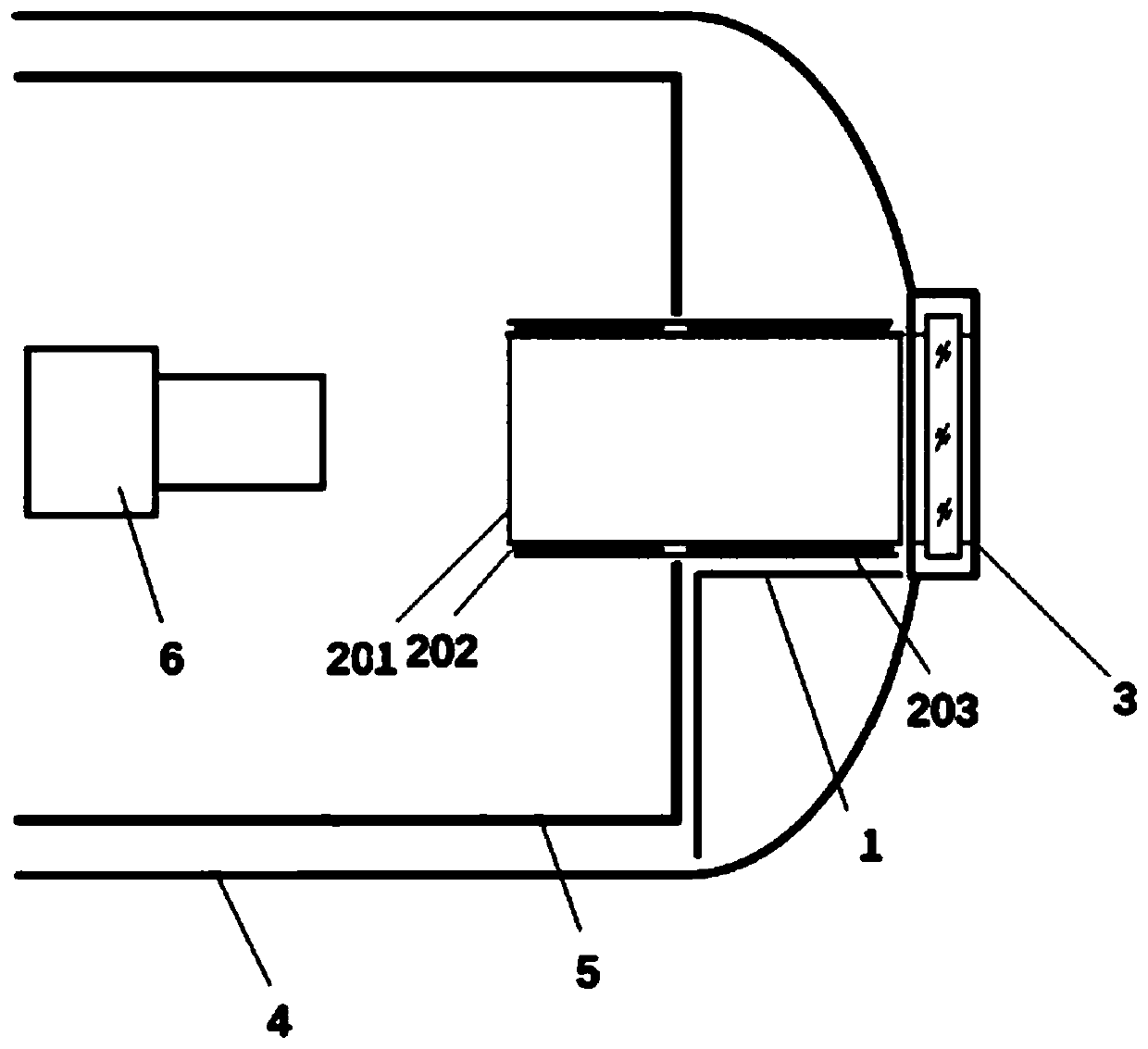

Temperature control device and method for optical window of space environment simulator

PendingCN111405687AEasy temperature controlAvoid temperature effectsCosmonautic condition simulationsOhmic-resistance heatingTemperature controlOptical test

The invention relates to a temperature control device and a temperature control method, in particular to a temperature control device and method for an optical window of a space environment simulator,which are suitable for optical index testing of a space camera ground thermo-optical test. The invention provides the temperature control device and method for an optical window of a space environment simulator to solve the technical problems that an existing temperature control device for the optical window of the space environment simulator is large in size and poor in temperature control effect or a heating film is pasted to influence an optical test result. The device comprises a mounting bracket, a control unit and a cylindrical heating unit, the mounting bracket is arranged at the bottom of the heating unit; the heating unit sequentially comprises a heating cylinder, an electric heating layer and a multi-layer heat insulation assembly from inside to outside. Spaceflight black paintis sprayed on the inner surface of the heating cylinder; the electric heating layer is formed by sticking a thin film type electric heating sheet along the circumferential surface of the outer side ofthe heating cylinder; and the film type electric heating sheets are divided into multiple groups for independent heating along the axial direction of the heating cylinder. According to the method, the device is used for controlling the temperature of the optical window.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

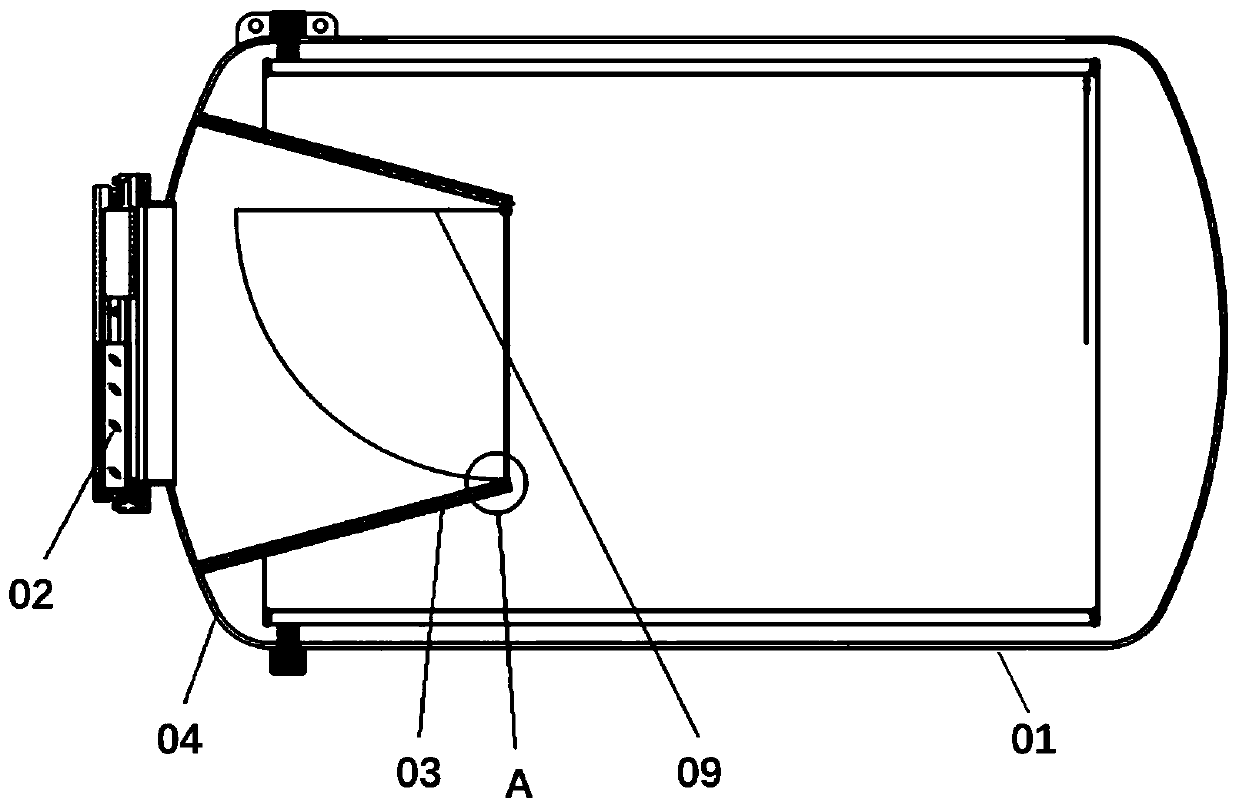

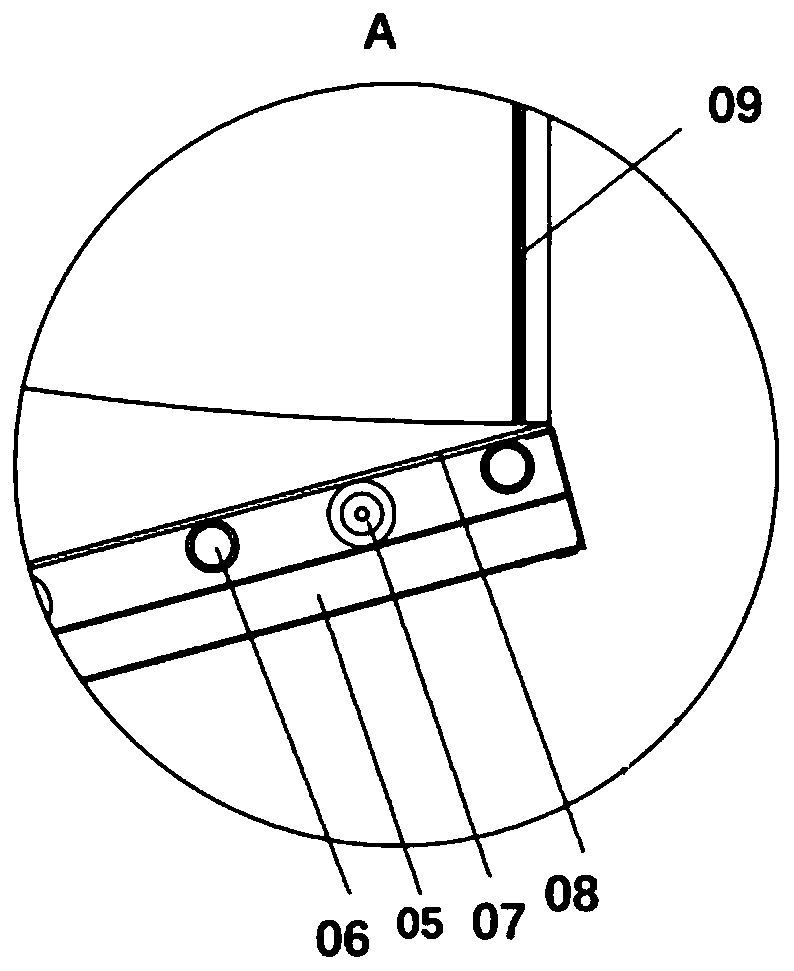

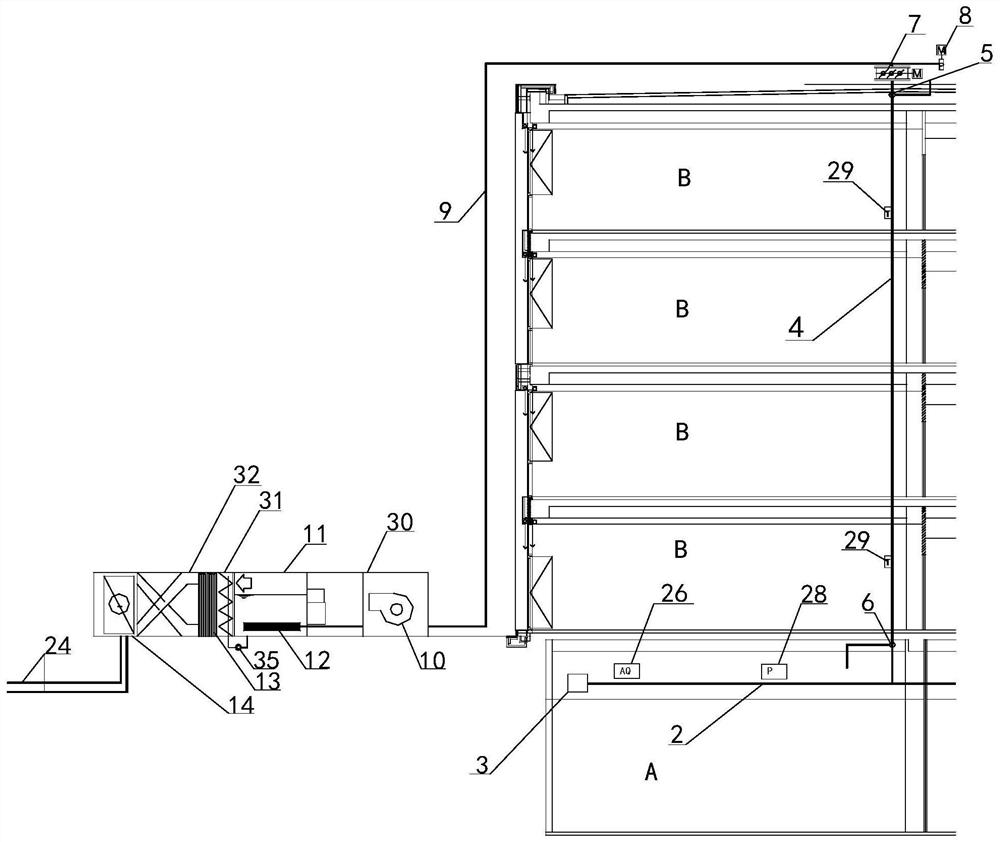

Dust removal device for dust-containing and tar-containing coal gas and dust removal method for dust-containing and tar-containing coal gas

ActiveCN111004650AReduce condensationSolve the problem of losing the filtering effectDispersed particle filtrationTransportation and packagingDust controlEnvironmental engineering

The invention discloses a dust removal device for dust-containing and tar-containing coal gas and a dust removal method thereof. The invention relates to a dust removal device, the dust removal deviceat least comprises two dust removal units, and each dust removal unit comprises a shell, an air inlet branch pipe, a material storage dust bin and a filtering device. The storage dust bin is arrangedon one side in the shell; an air inlet cavity is formed in the upper part of the storage dust bin; a filtering device is arranged in the middle of the outer side of the storage dust bin; each filtering device comprises a material flattening rod control rod, a material flattening rod, a discharging rod, a filtering bed and a material baffle plate; the filter bed is arranged in the middle of the outer side of each material storage dust bin, a filter material is laid on a filter screen of the filtering bed, an air purifying chamber is arranged at the lower part of the filtering bed, a discharging rod assembly of a connecting rod structure is arranged in the air purifying chamber, and the material baffle connected with the discharging rod assembly is arranged on the inner side of the filtering bed, the dust removal device effectively solves the problem that the filter material is bonded by tar and loses the filtering effect, and does not influence the positive production of the device andprocess.

Owner:中信重工工程技术有限责任公司

System and method for exhausted air sterilization and aeration and comprehensive heating disinfection of highly-contaminated building space

PendingCN111895550AReduce virus contentImprove disinfection effectDucting arrangementsMechanical apparatusVentilation tubeThermal insulation

The invention provides a system and method for exhausted air sterilization and aeration and comprehensive heating disinfection of a highly-contaminated building space. The system comprises a contaminated area negative pressure metal ventilation pipe, any position thereon communicates with an inlet end of a high-resistance thermal-insulation-layer-carried ventilation pipeline, an outlet end of thehigh-resistance thermal-insulation-layer-carried ventilation pipeline is connected to an inlet end of an outdoor negative pressure metal ventilation pipe through an electric anti-backflow valve, and an outlet end of the outdoor negative pressure metal ventilation pipe is connected with an exhaust port of a high-efficiency variable-frequency fan. Various virus killing devices are sequentially disposed at the rear end of the high-efficiency variable-frequency fan. The system disinfects the air that may contain viruses in the highly-contaminated building space at high temperature through an electric heating pipeline and then guides the air that is disinfected at high temperature to the various outdoor virus killing devices through negative pressure pipelines to diversely and thoroughly disinfect the guided air, thereby thoroughly removing viruses in the air in the highly-contaminated building space.

Owner:CHINA RAILWAY CONSTR GROUP +1

High-contamination exhaust multi-disinfecting-killing system and method

PendingCN111895551AShorten survival timeReduce the risk of residual virusDucting arrangementsMechanical apparatusContamination zoneEnvironmental engineering

The invention provides a high-contamination exhaust multi-disinfecting-killing system and method. The system comprises a contaminated area negative-pressure metal vent pipe, any position on the contaminated area negative-pressure metal vent pipe communicates to the inlet end of a high-resistance tape heat insulating and insulating layer vent pipeline, the outlet end of the high-resistance tape heat insulating and insulating layer vent pipeline is connected to the inlet end of an outdoor negative-pressure metal vent pipe through an electric anti-backflow valve, and the outlet end of the outdoornegative-pressure metal vent pipe is connected to an exhaust port of an efficient variable-frequency fan. Multiple virus disinfecting and killing devices are sequentially arranged at the rear end ofthe efficient variable-frequency fan. Firstly, air probably containing viruses in high-contamination building spaces is disinfected and killed at high temperature through an electric heating pipeline,then the air disinfected and killed at high temperature is exhausted to the outdoor multi-virus disinfecting and killing devices through a negative-pressure pipeline, the introduced air is completelydisinfected and killed diversely, and therefore the viruses in the air of the high-contamination building spaces can be completely removed.

Owner:CHINA RAILWAY CONSTR GROUP +1

Steaming machine and intelligent temperature control method thereof

The invention relates to a steaming machine, and discloses the steaming machine and an intelligent temperature control method thereof.The steaming machine comprises a basin-shaped shell and steaming devices.The steaming devices include the first steaming device fixedly arranged at the bottom of the basin-shaped shell, the second steaming device fixedly arranged at the bottoms of the double feet and the third steaming device fixedly arranged at the upper portion of the basin-shaped shell.According to the steaming machine, the three steaming devices are arranged; the whole-body basis steaming function is provided for a user through the first steaming device arranged at the bottom of the shell; due to the second steaming device below the feet and the third steaming device at the upper portion of the shell, the poor steaming effect caused by local overheating or local overcooling in the steaming process is avoided, balanced whole-body steaming of the body can be achieved, the good steaming effect is achieved, energy is saved, and environment protection is achieved; due to intelligent control over the chemical steam temperature, the user can experience the body building effect and the comfortable steaming effect in the steaming process.

Owner:NINGBO HEALTHOME ELECTRICAL APPLIANCE

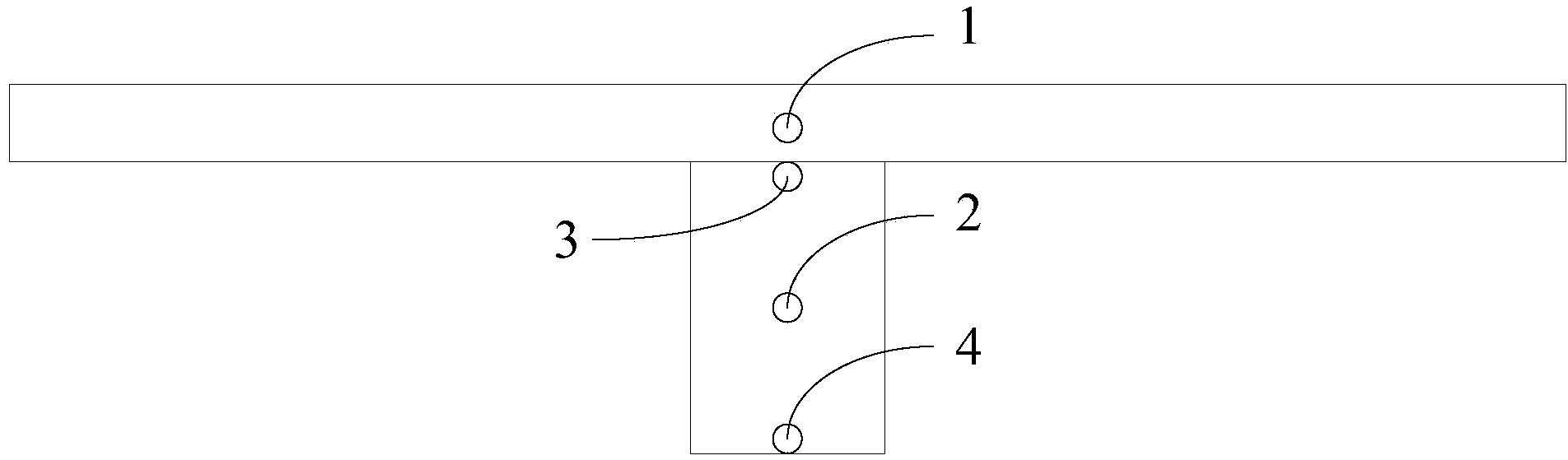

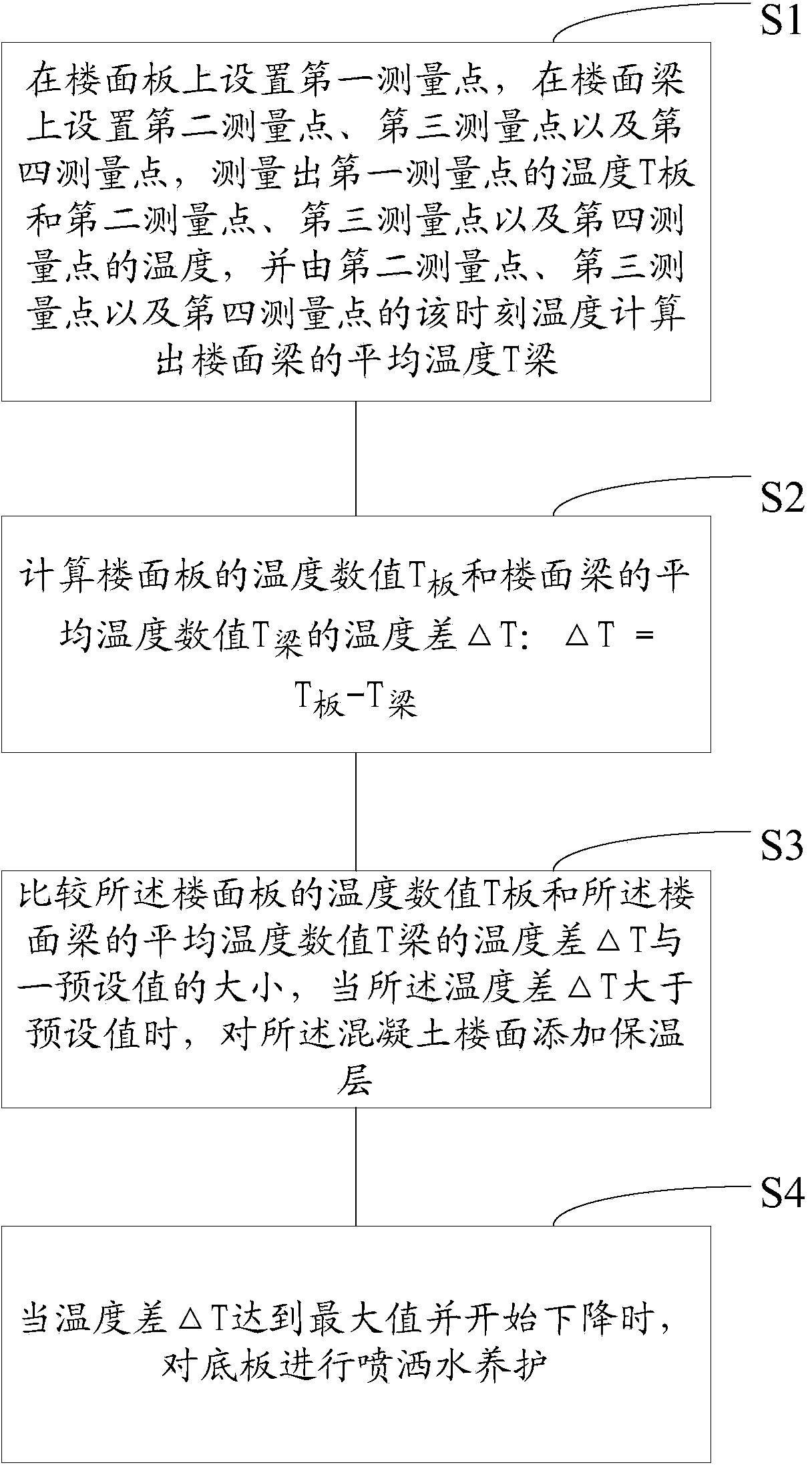

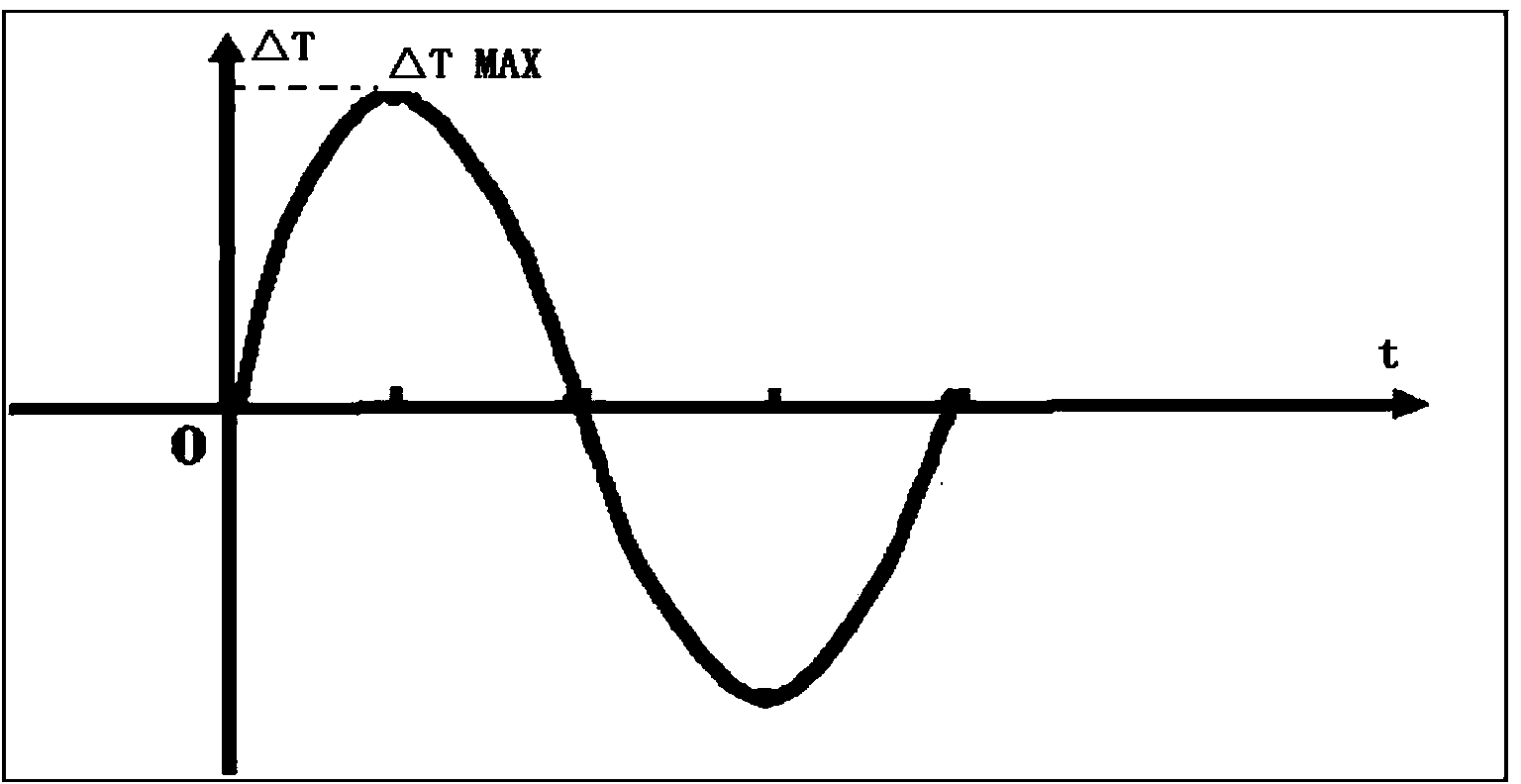

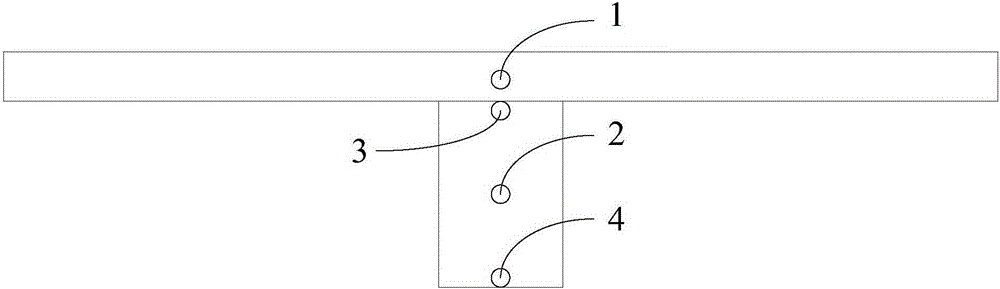

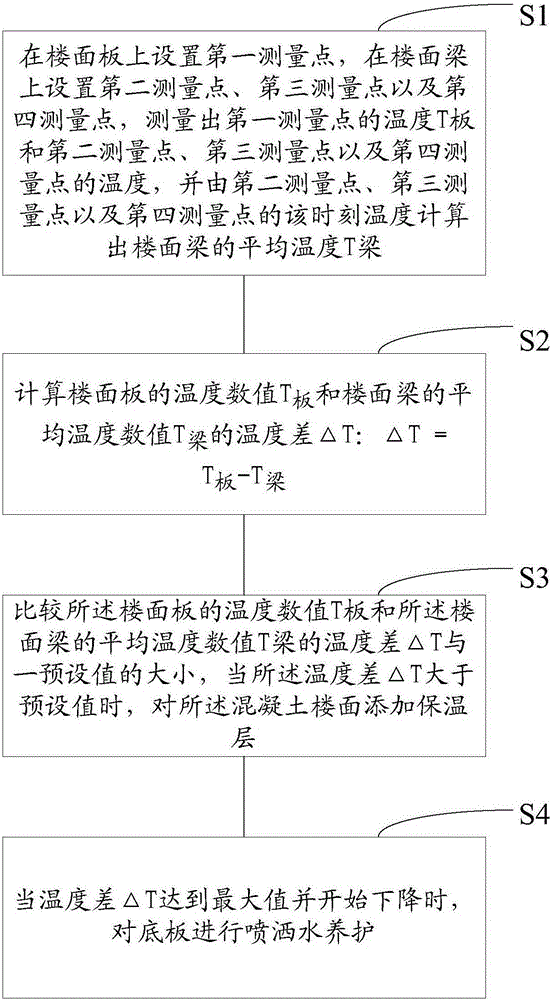

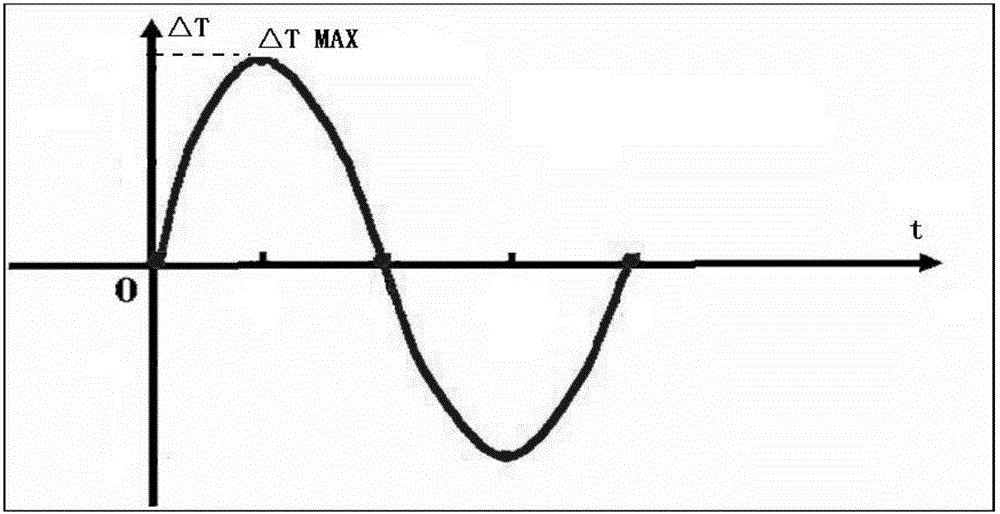

Structure maintenance method and system of concrete floor

ActiveCN103726655AReduce the temperatureTemperature close toBuilding material handlingMeasurement pointTemperature difference

The invention provides a structure maintenance method and system of a concrete floor. The method includes the following steps that firstly, a first temperature sensor located on a first measurement point for monitoring the internal temperature Tboard is arranged on a floorboard; a second temperature sensor, a third temperature sensor and a fourth temperature sensor located on a second measurement point, a third measurement point and a fourth measurement point respectively are arranged on different height layers of a floor beam and used for measuring the average temperature Tbeam of the floor beam; secondly, the temperature difference deltaT between the Tboard and the Tbeam is calculated, wherein deltaT=Tbeam-Tboard; thirdly, when the deltaT is larger than a preset value, a heat preserving layer is additionally arranged for the floor structure; fourthly, when the temperature difference deltaT reaches the largest value and starts to decrease, water is sprinkled onto the floor. The method and system have the advantages that due to the measurement of additionally arranging the heat preserving layer, the temperature difference between the floorboard and the floor beam is reduced, the surface of the concrete floor structure is kept moist by sprinkling water, and finally the floor is efficiently prevented from fracturing in real time.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

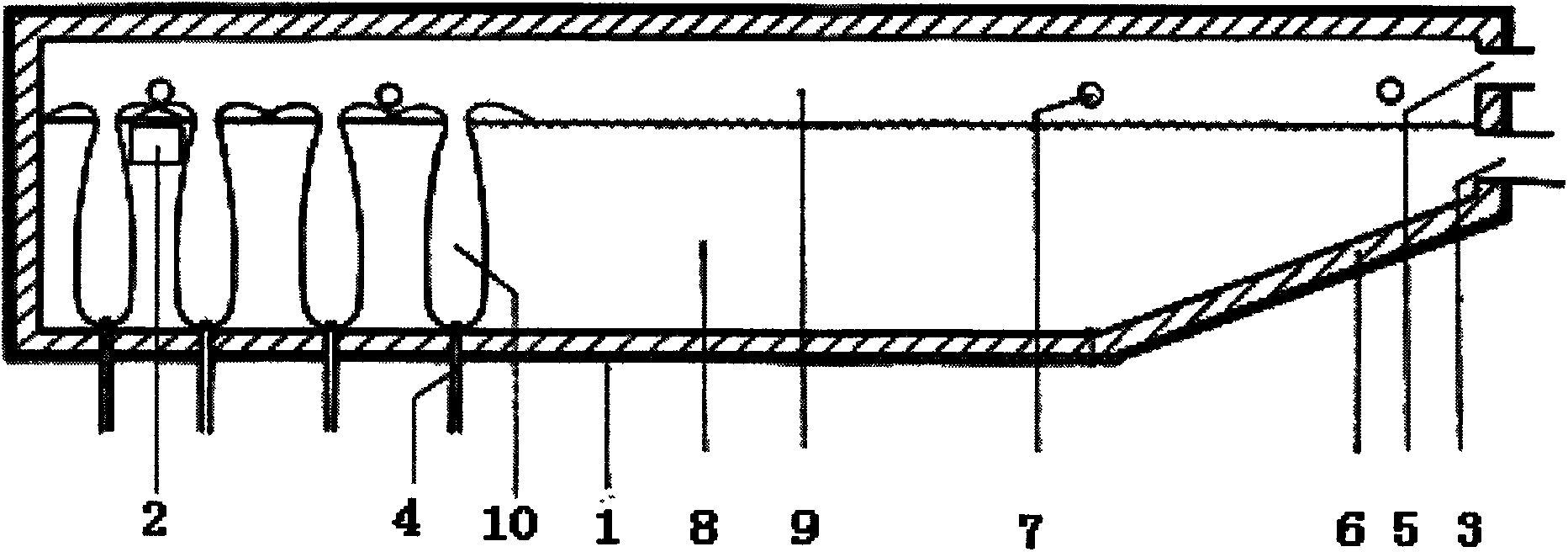

Efficient energy-saving environment-friendly pre-burning burner

The invention discloses an efficient energy-saving environment-friendly pre-burning burner which is simple in structure, higher in heat burning rate of fuel and more energy-saving and environment-friendly. The efficient energy-saving environment-friendly pre-burning burner comprises a pre-burner, an igniter, an air inlet pipe and at least one fuel jetting device, wherein the air inlet pipe and the at least one fuel jetting device are communicated with the pre-burner; and the pre-burner comprises a pre-burning chamber and an air spraying chamber which are communicated, the pre-burning chamber is communicated with all fuel jetting devices and the air inlet pipe, the right end of the air spraying chamber is opened, the air spraying chamber is in a step shape, and the left end of the air spraying chamber is a large end. The ignition end of the igniter is located in the pre-burner, each fuel jetting device comprises a fuel spraying nozzle and an oil supply pipe, each fuel spraying nozzle is located on the side wall of the pre-burner, the fuel spraying nozzles are arranged in the pre-burner, and the left end of each fuel spraying nozzle is communicated with the corresponding oil supply pipe. The efficient energy-saving environment-friendly pre-burning burner further comprises an air blower, a vent pipe and an air bin, the vent pipe is communicated between the air blower and the air bin, the vent pipe is communicated between the air bin and the pre-burner, and the air bin is arranged on the outer wall of the pre-burner.

Owner:GUANGZHOU YUNENG AMPEREX TECH CO LTD

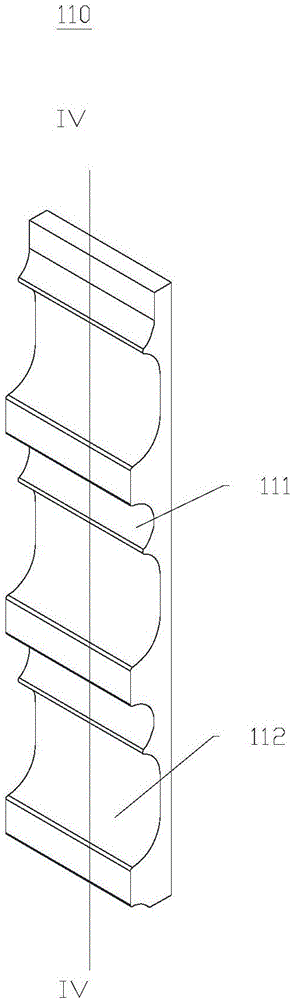

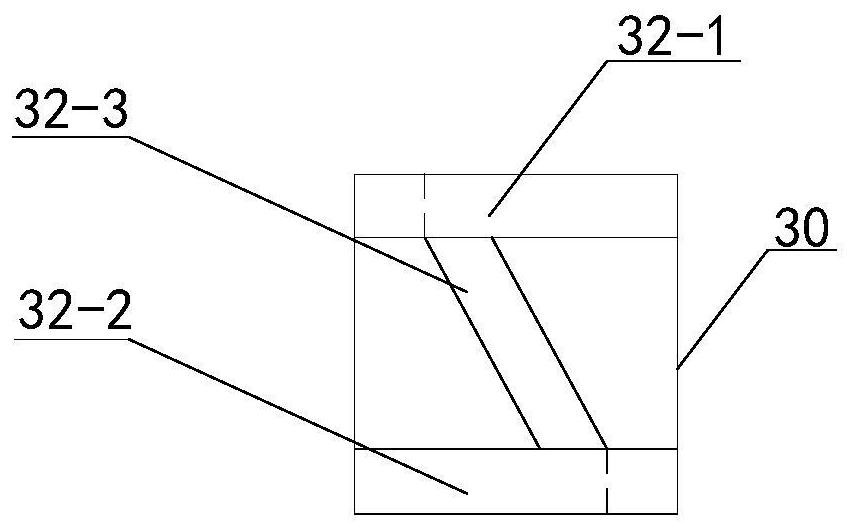

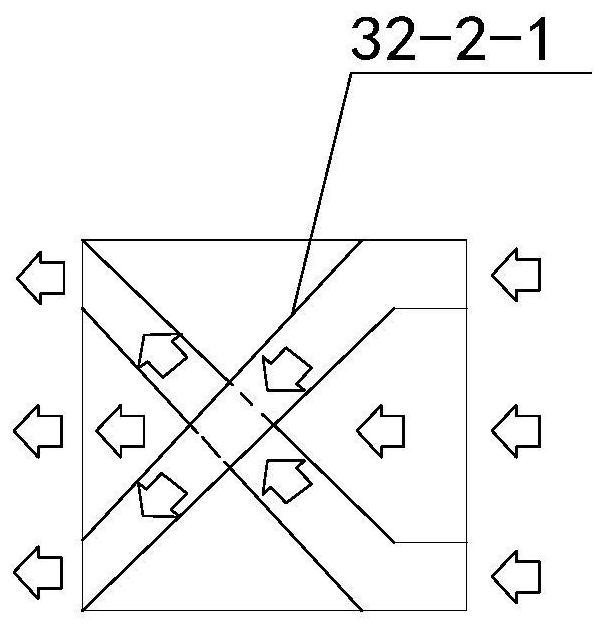

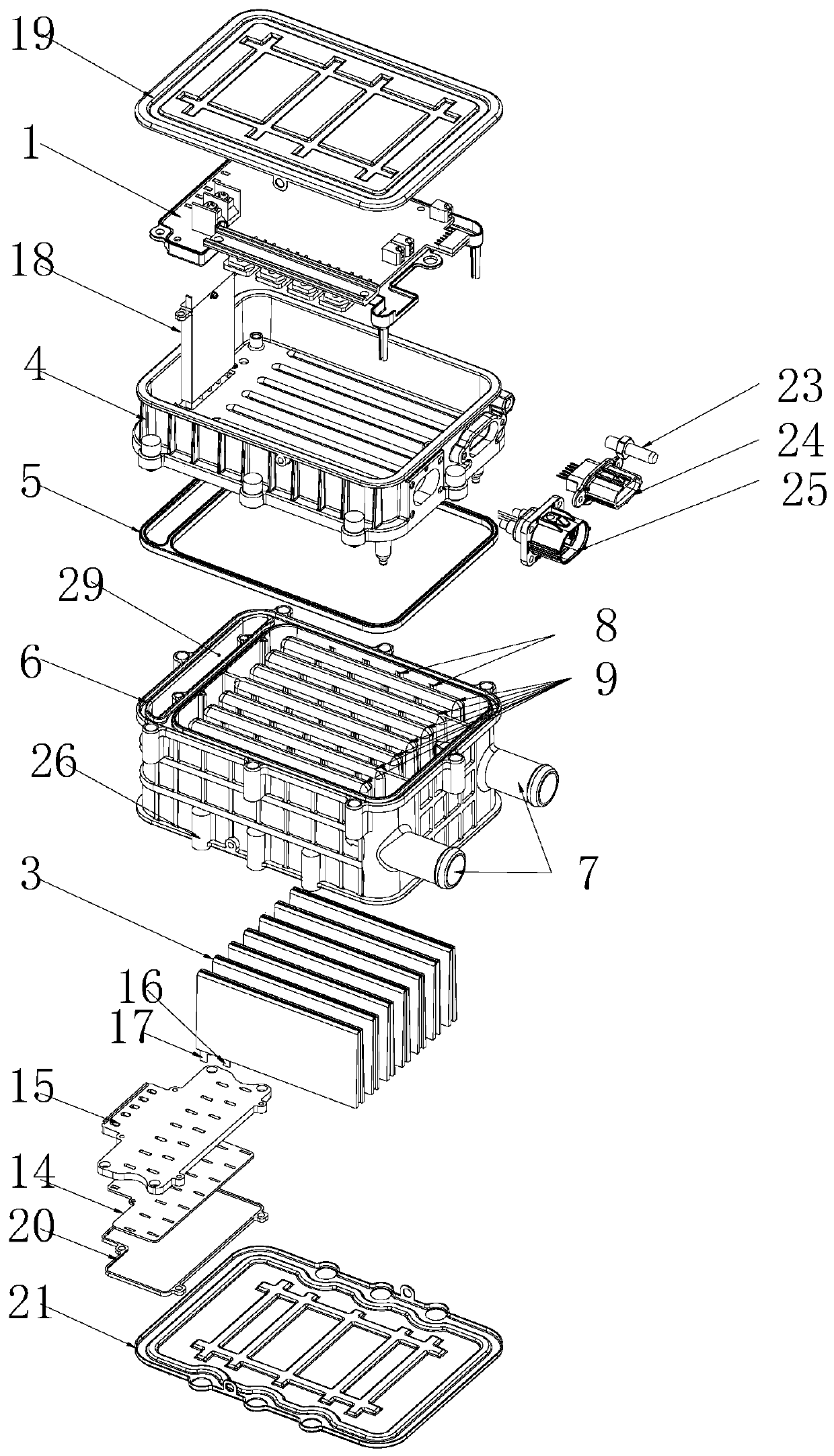

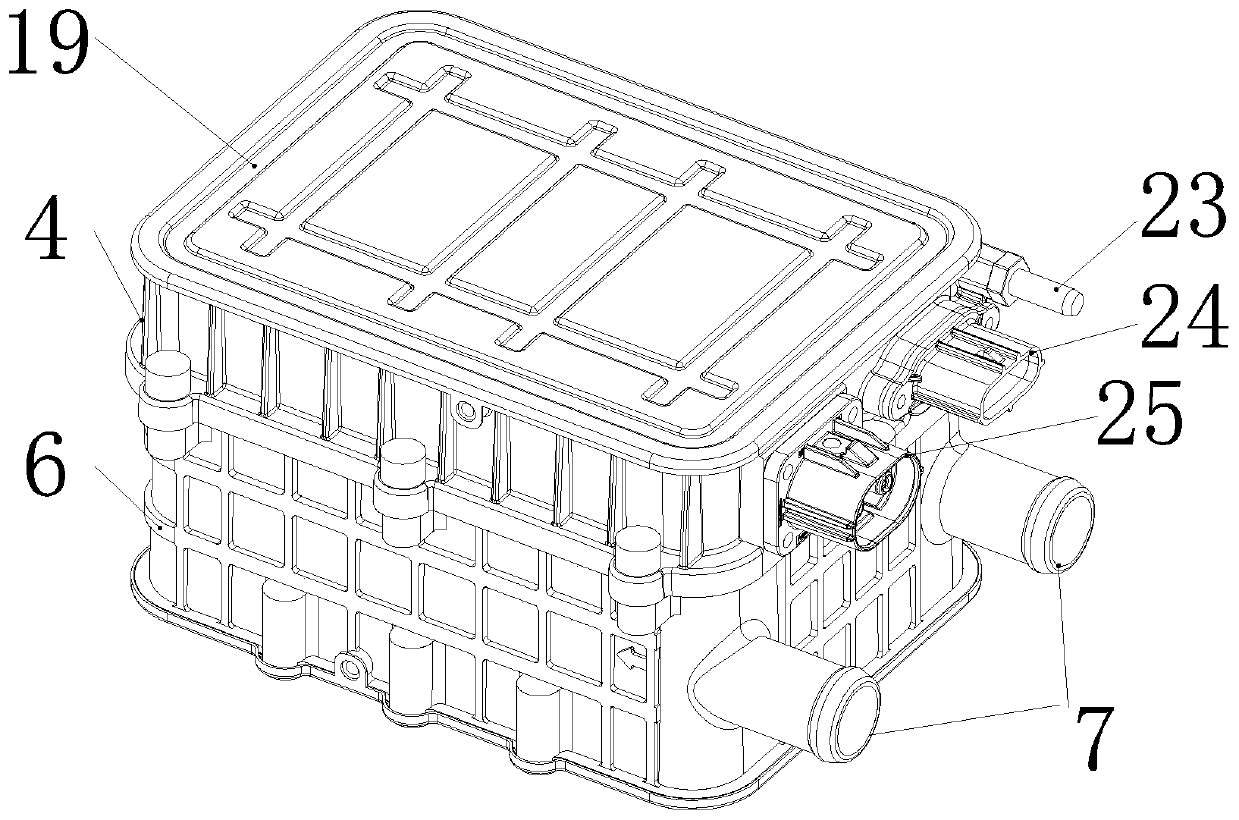

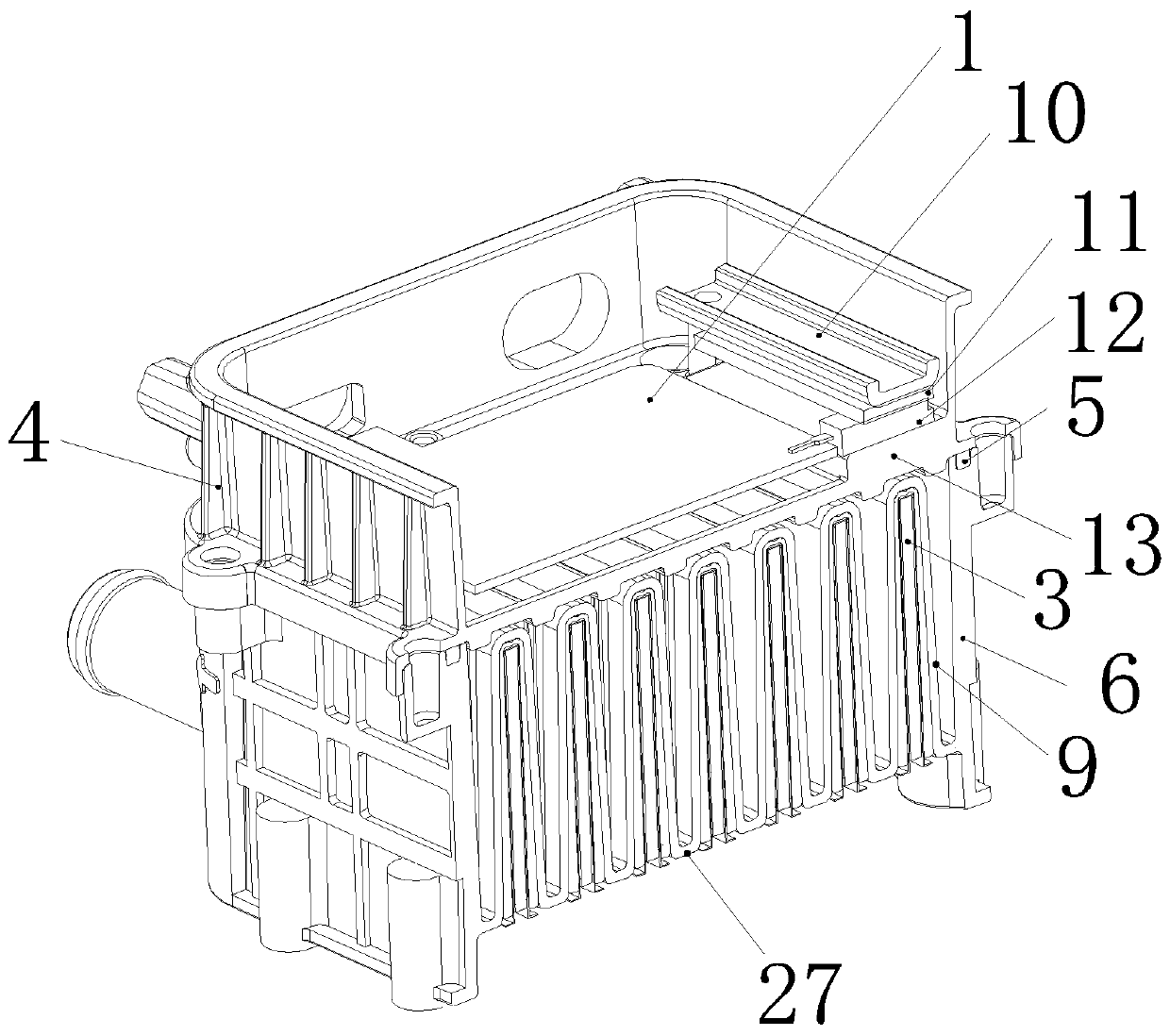

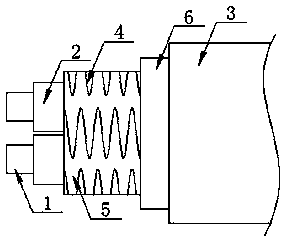

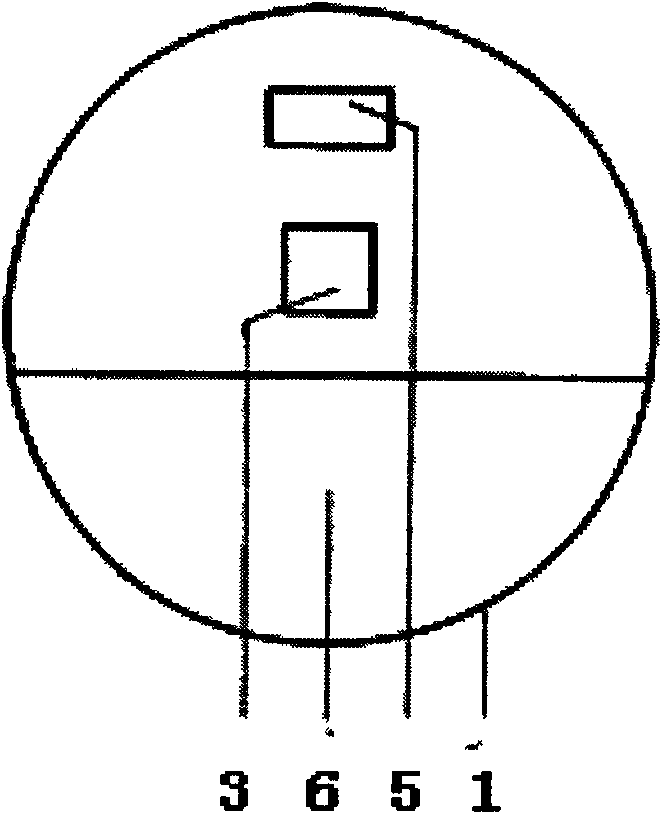

PTC electric heater

PendingCN109729604AIncreased turbulenceChange flow trajectoryHeating element materialsDielectricElectricity

The invention relates to a PTC electric heater, and relates to the technical field of heaters. The PTC electric heater comprises an upper cover, a control box, a dielectric box and a lower cover arranged successively from top to bottom. The upper cover and control box are encircled to form a control cavity, and a control assembly is arranged in the control cavity; the top and bottom of the dielectric box are provided with openings respectively, the middle of the dielectric box is provided with a separator plate, a dielectric cavity is formed between the separator plate and the control box, a heating cavity is formed between the lower cover and the separator plate, and a heating assembly is arranged in the heating cavity; projections arranged side by side are formed in the separator plate towards the dielectric cavity, flow channels are formed between the projections as well as between the sidewall of the dielectric box and the projections, and first ribs are formed on the projections and / or the sidewalls in the two sides of the flow channel. Via simple structural layout, the control assembly is separated from the heating assembly by the dielectric cavity, the first ribs are arranged to increase turbulent flow in the flow channels, a medium flowing in the dielectric cavity takes heat away continuously, and thus, the temperature of the control assembly approaches that of the medium in the dielectric cavity.

Owner:SHENZHEN SHARING ELECTRONICS

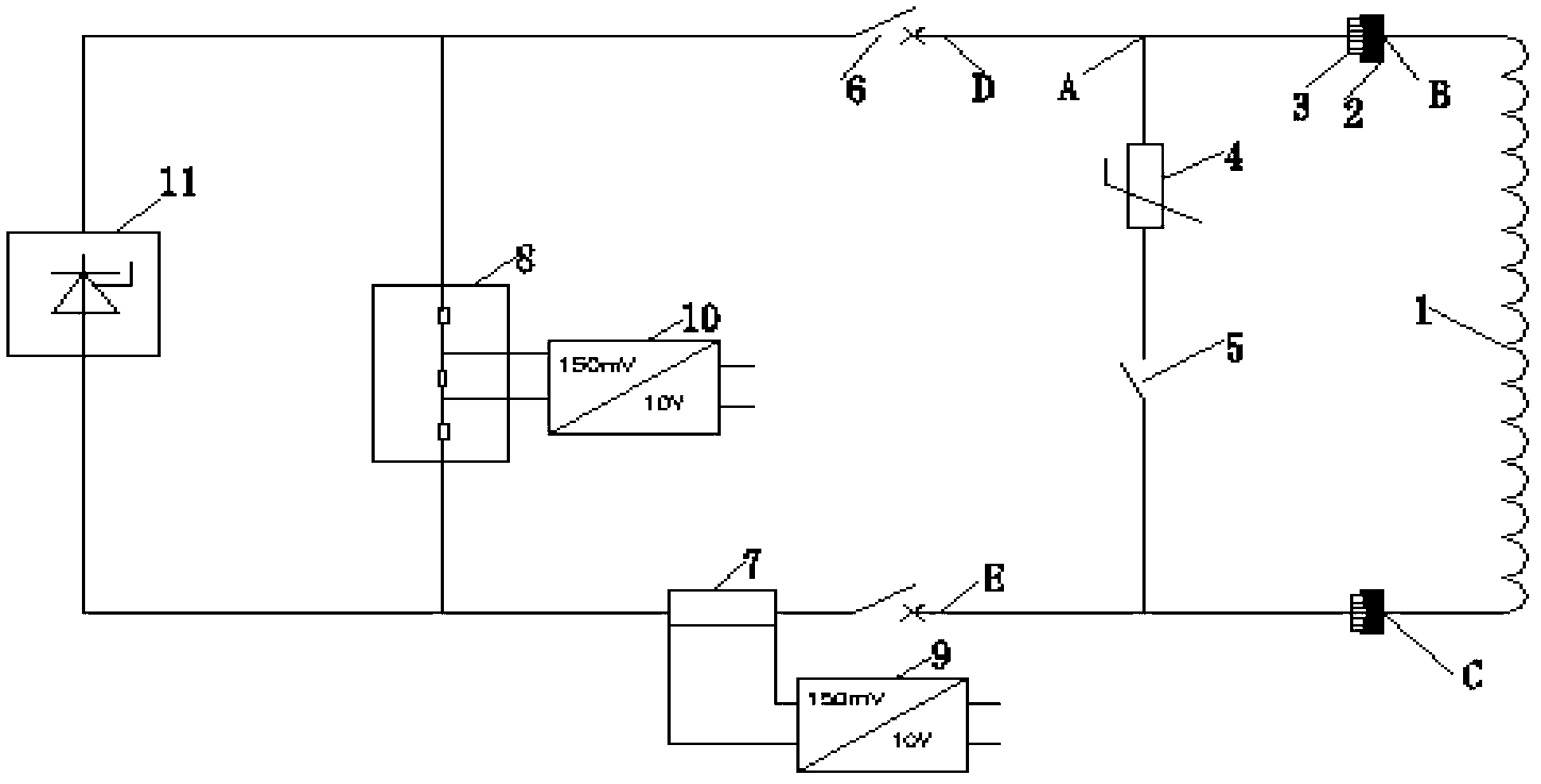

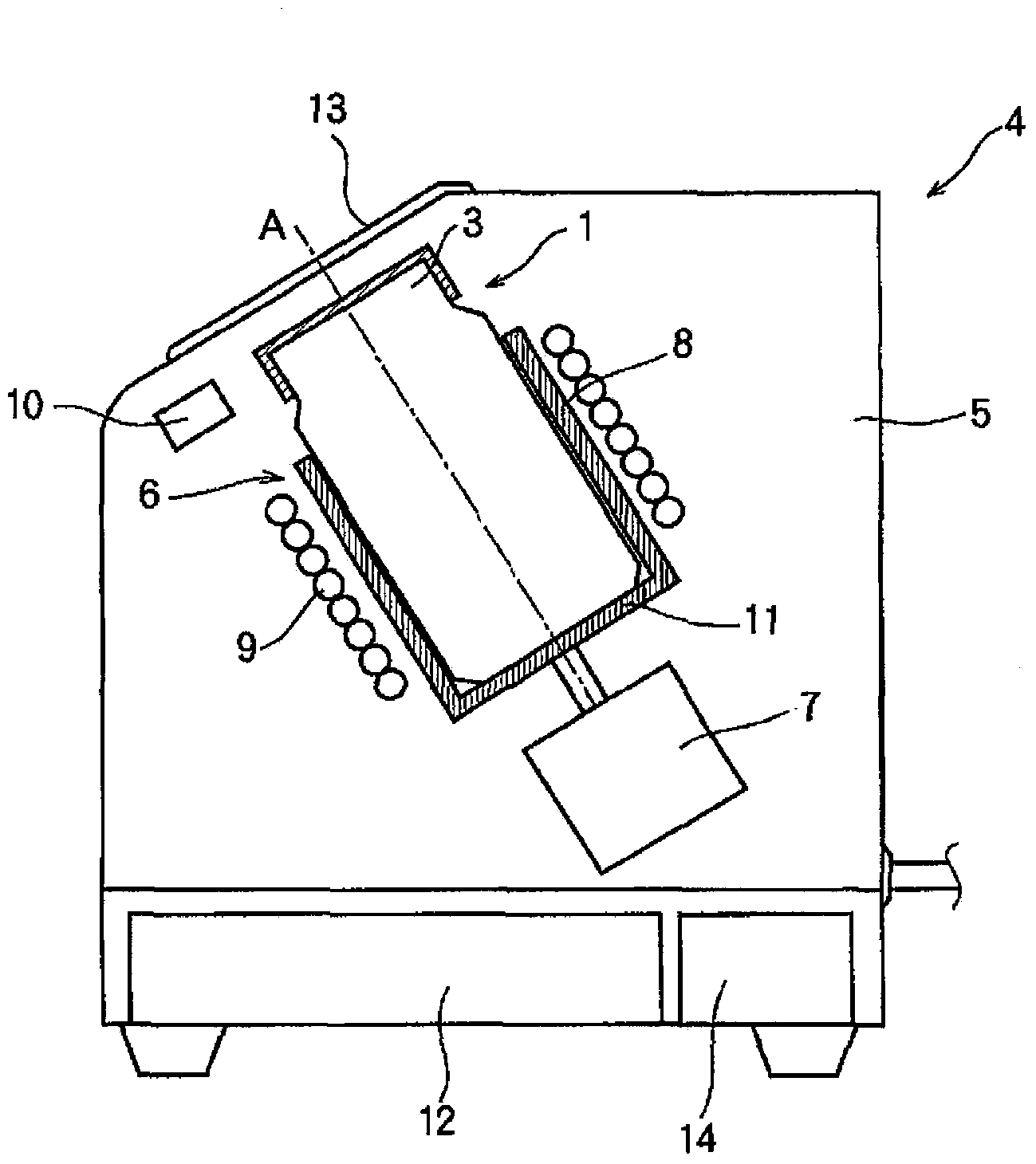

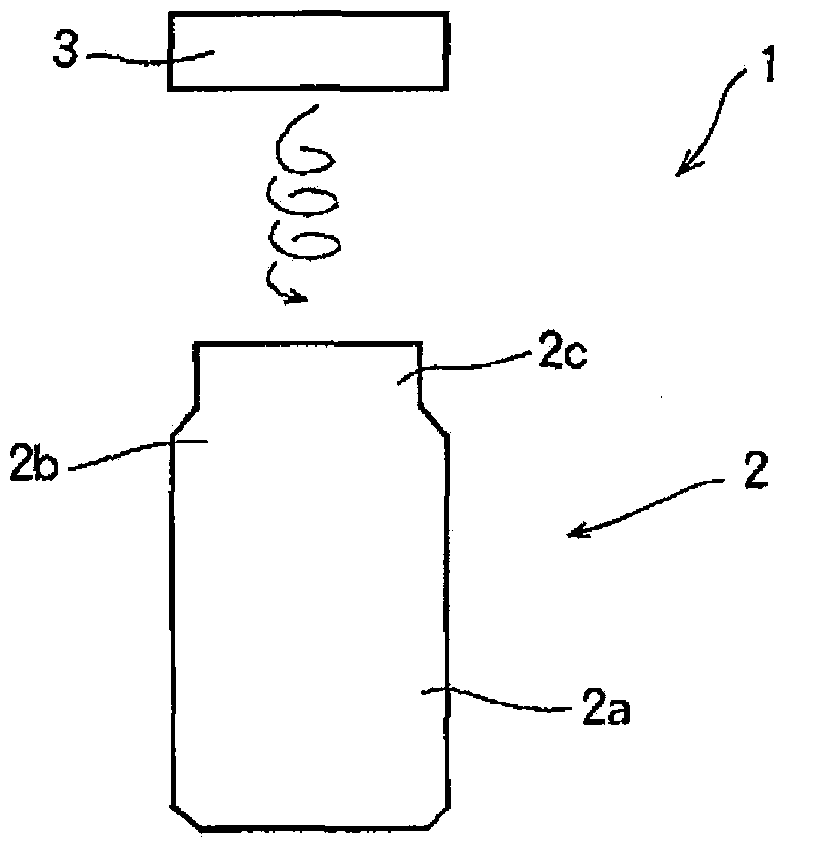

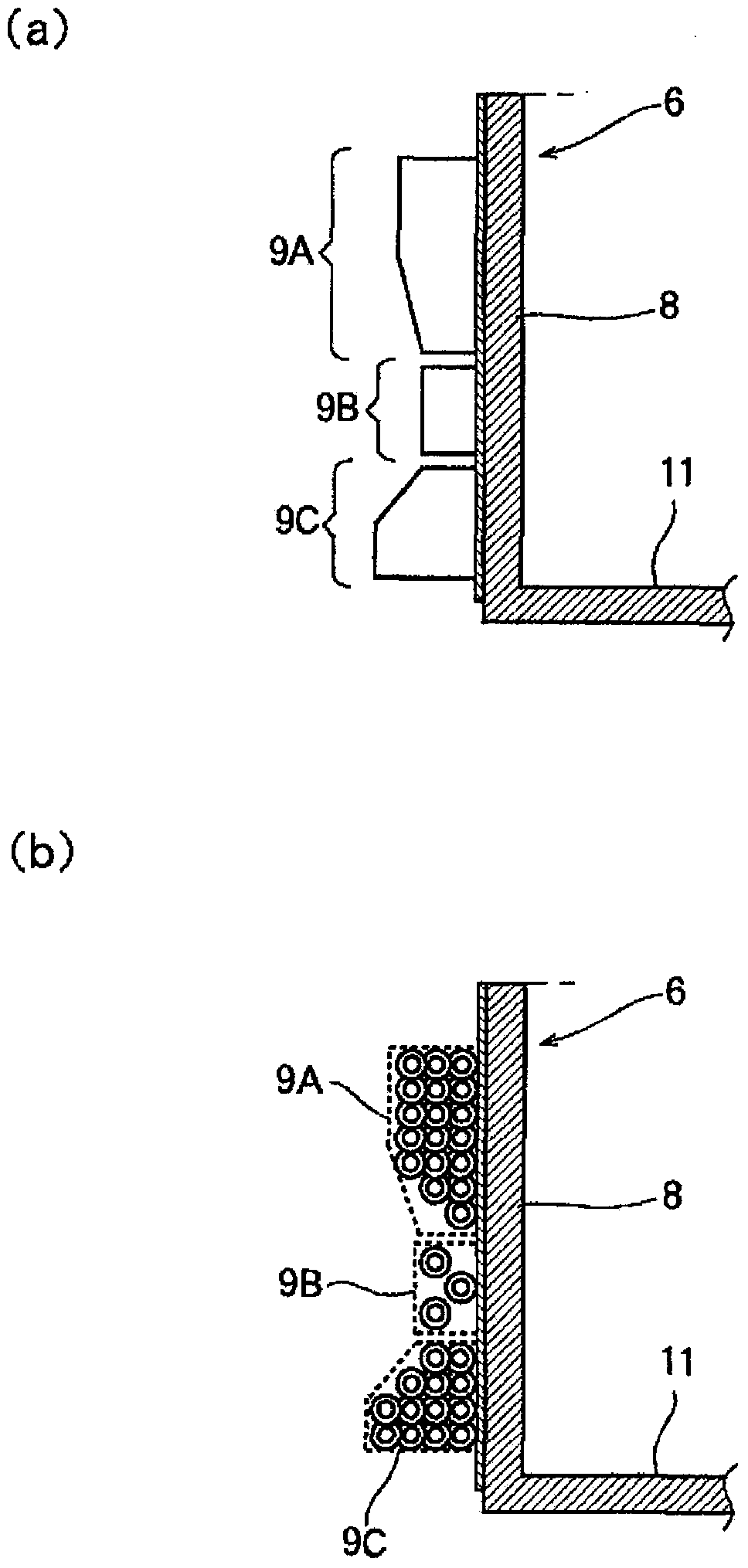

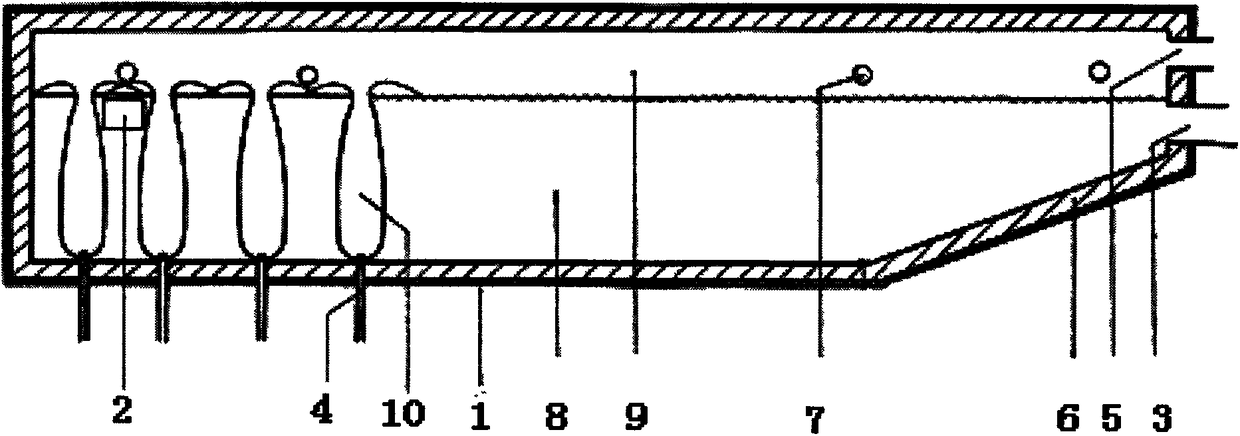

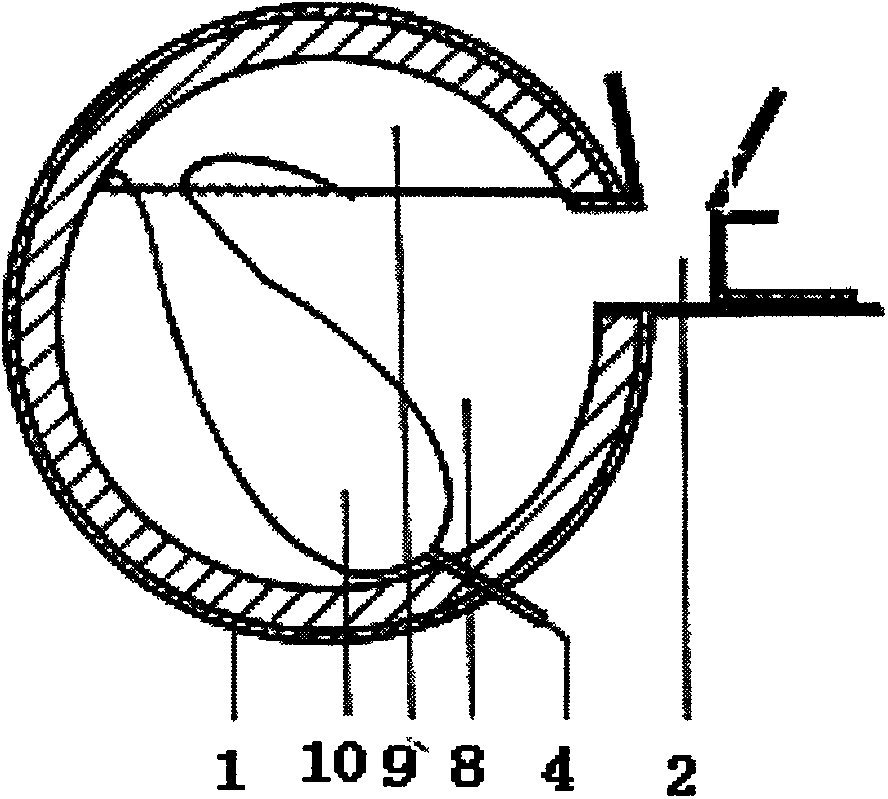

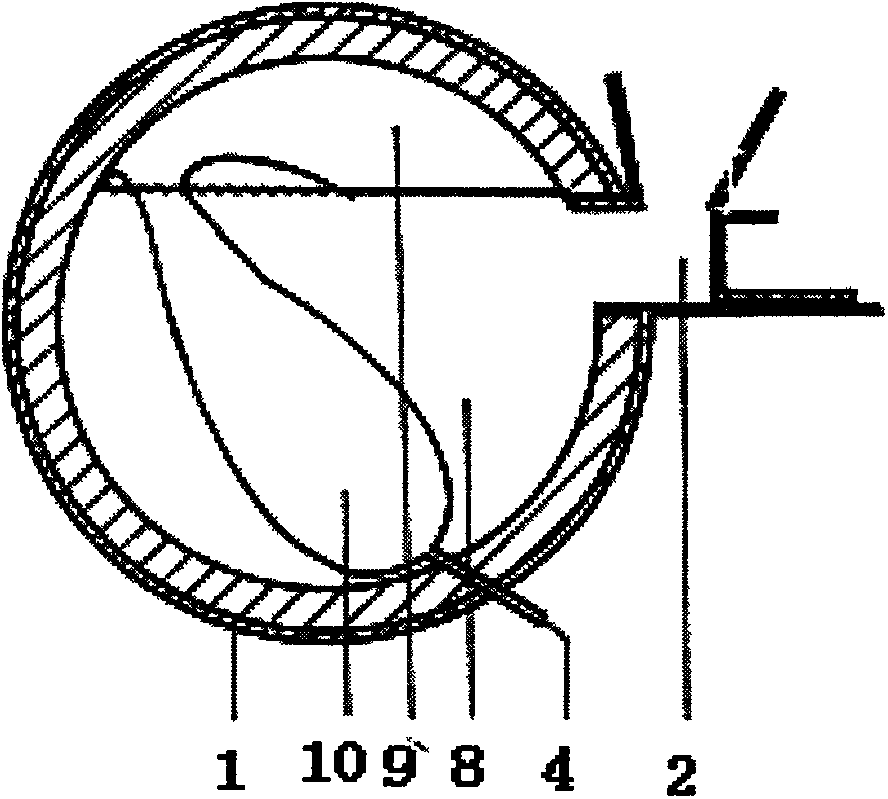

Inductive heating device for beverage can

InactiveCN103562974AHigh precision measurementIncrease inertial forceInduction heatingCoin-freed apparatus detailsBiomedical engineeringMetal

The present invention aims to provide an inductive heating device (4) for a beverage can with which the contents can be heated efficiently and with which the temperature of the contents can be measured precisely. The inductive heating device (4) for a beverage can has a can-holding body (6) that holds a metal beverage can (1) on the neck portion of which a threaded portion is formed, with a cap (3) being wound and tightened onto that threaded portion, and resealing of the beverage can being enabled by the cap (3), and an induction heating coil (9) being arranged at the outer periphery of the can-holding body (6). The can-holding body (6) is constructed such that the metal beverage can (1) is inserted and held with the cap (3) being protruded upward in the axial direction of the metal beverage can (1), and the heating coil (9) is arranged at the outer periphery of the can-holding body (6). The inductive heating device also is equipped with a temperature measurement means (10) that measures the surface temperature of the cap (3) when the metal beverage can (1) is inserted into the can-holding body (6).

Owner:DAIWA CAN

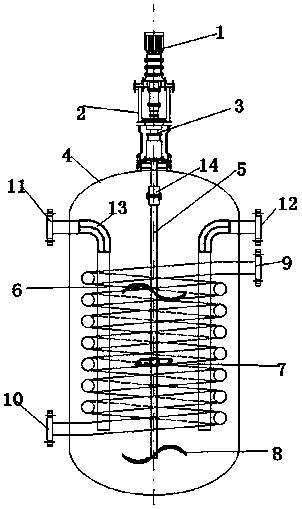

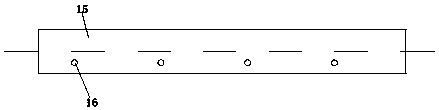

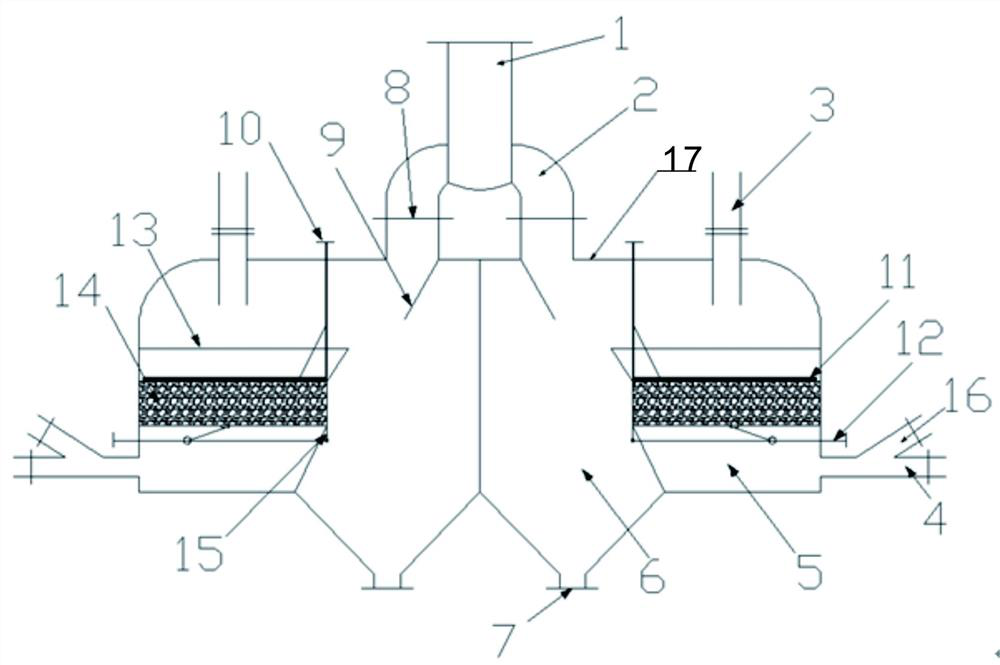

Anti-scaling sufficient mixing reaction kettle capable of continuously reacting

PendingCN108126645ATemperature close toImprove the heating effectProcess control/regulationChemical/physical/physico-chemical stationary reactorsReaction rateReaction temperature

The invention discloses an anti-scaling sufficient mixing reaction kettle capable of continuously reacting. The feed method of the material is changed, the tangential feeding is adopted, feeding components are distributed in the two directions of a reactor, the wall of the reaction kettle and a heating tube are continuously flushed, the feeding temperature is the lowest, the feeding components arebe in direct contact with the heating surface, the heating effect is improved, the temperature of the material in the reaction kettle is much closer to the reaction temperature, the reaction efficiency is improved, various kinds of mixing blades are combined, so that the material does not move in a certain way in the reaction kettle and forms disordered motion, the centrifugal effect is reduced,the particle material or large-gravity material is prevented from being in contact with the heating surface for a long period of time, the scaling of the material is avoided; meanwhile, the mixing ismore sufficient, the reaction efficiency is improved, the scaling is reduced by more than 90% by using the equipment provided by the invention, the temperature is accurately controlled, the material is mixed evenly, and the reaction rate is increased by 5%.

Owner:DANYANG TONGTAI CHEM MACHINERY

A spiral ultra-long cooling circuit irradiation device

ActiveCN110853793BSolve the problem of uneven axial temperatureTemperature close toIrradiation devicesOutfallMechanical engineering

The invention discloses a spiral ultra-long cooling loop irradiation device, which is characterized in that an inner-layer annular space is formed between an inner-layer irradiation tank and a middle-layer irradiation tank, and an outer-layer annular space is formed between the middle-layer irradiation tank and an outer-layer irradiation tank; a sample is arranged on a clamping block, and the clamping block is arranged in the inner-layer annular space; an outer-layer cooling pipe and an inner-layer cooling pipe are both wound on the outer wall of the middle-layer irradiation tank; a water outlet of the outer-layer cooling pipe is communicated with the outer-layer annular space at the bottom of the outer-layer irradiation tank; a water outlet of the inner-layer cooling pipe is communicatedwith the bottom of the inner-layer irradiation tank; the inner-layer irradiation tank is communicated with the outer-layer annular space through a one-way valve; a circulating water outlet pipe is arranged at the top of the outer-layer irradiation tank and is communicated with the outer-layer annular space. According to the spiral ultra-long cooling loop irradiation device, the problem that the axial temperature of an irradiation device is not uniform is solved, the inner spiral cooling circulation loop and the outer spiral cooling circulation loop are arranged to control the temperature in the irradiation device, and it is guaranteed that the temperatures of all material samples in the irradiation device are close.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

A dust removal device and dust removal method for dust-containing and tar-containing gas

ActiveCN111004650BReduce condensationSolve the problem of losing the filtering effectDispersed particle filtrationTransportation and packagingDust controlProcess engineering

Owner:中信重工工程技术有限责任公司

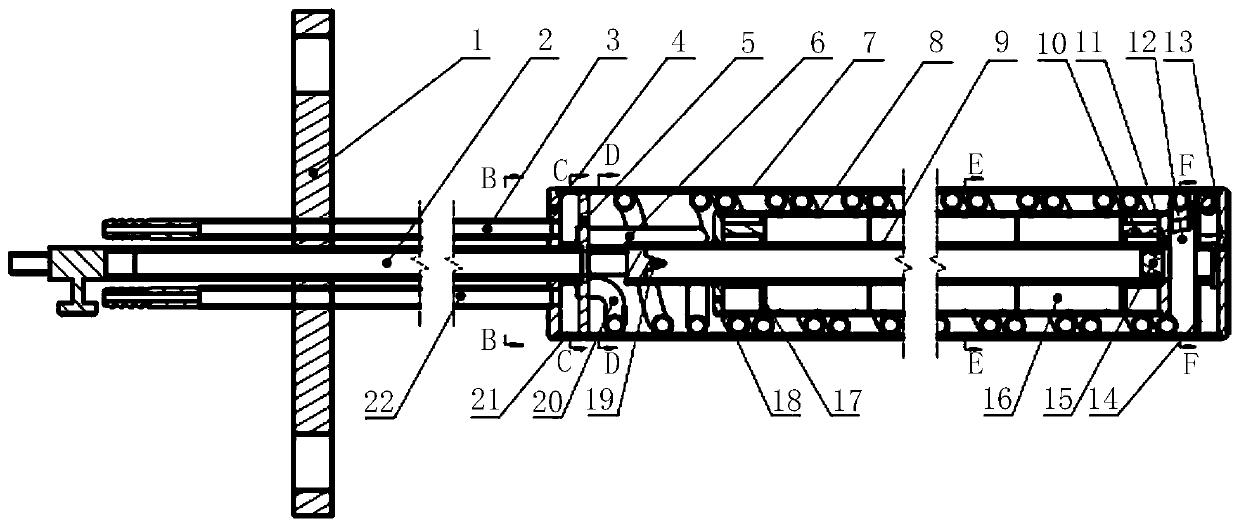

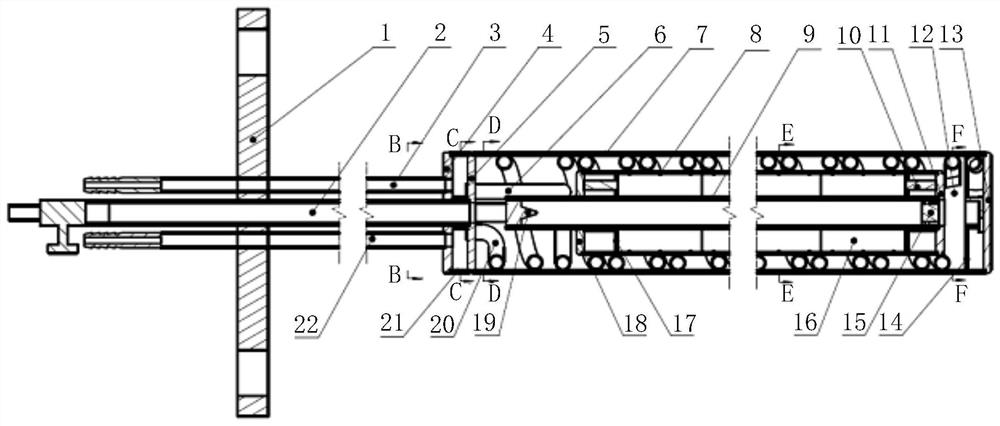

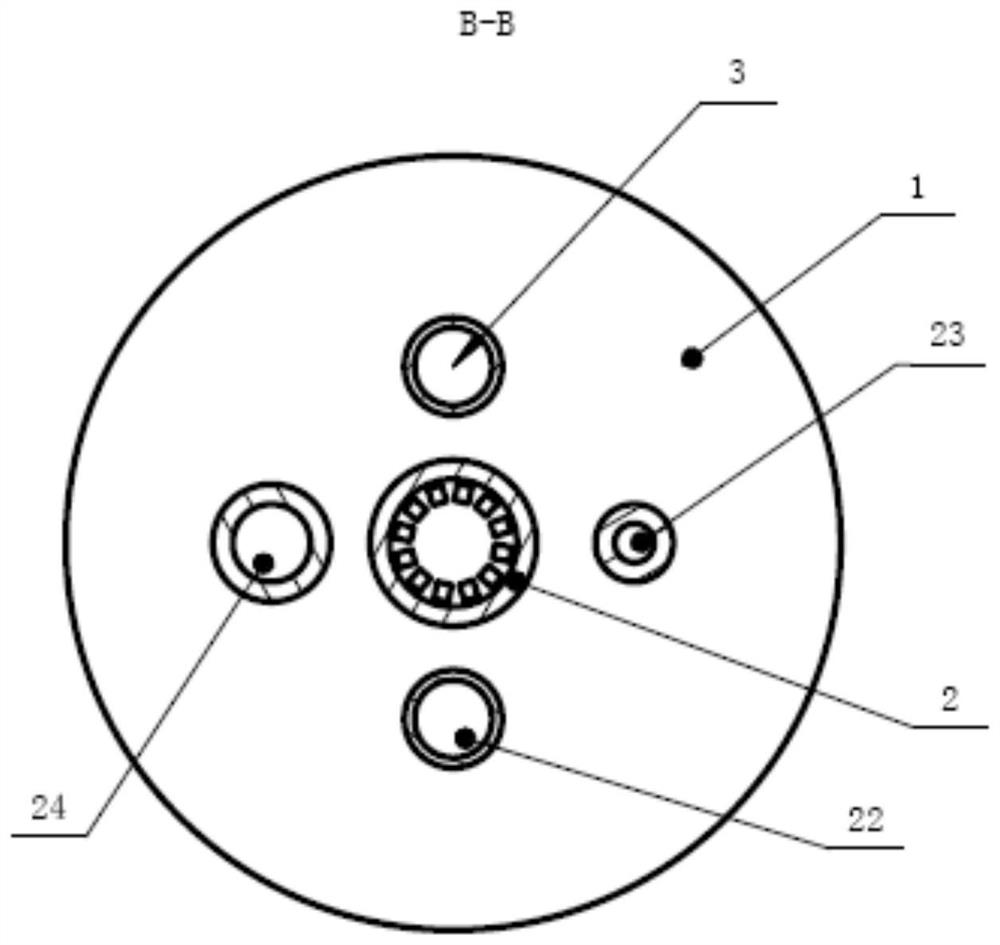

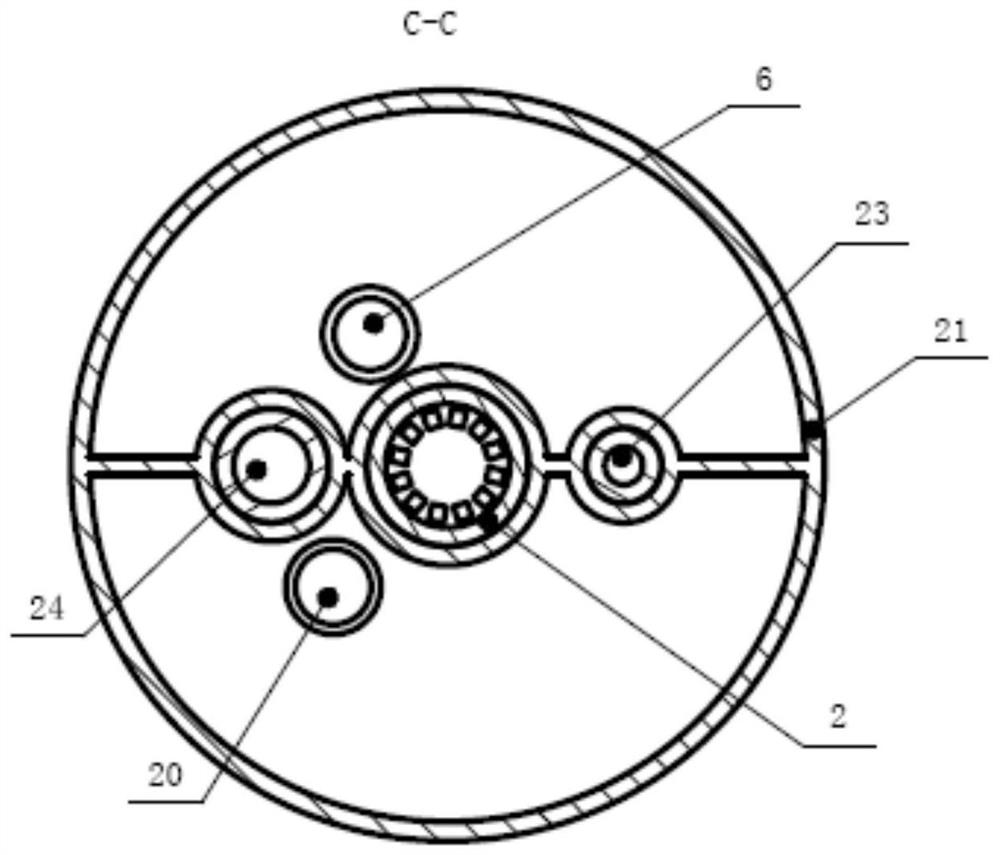

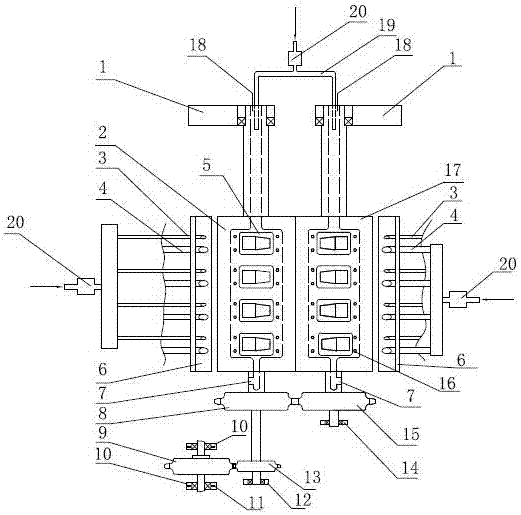

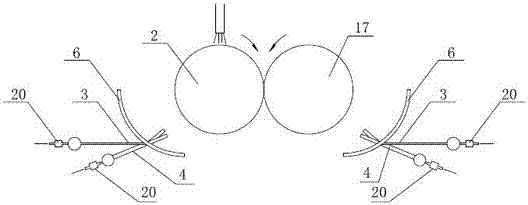

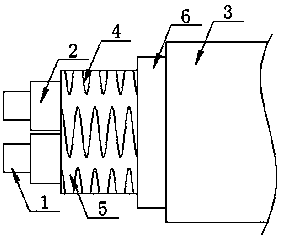

Method and device for forming optical glass

ActiveCN105366920BSmall temperature differenceSave operating timeGlass rolling apparatusGlass productionDrive wheelEngineering

The title of the present invention is a method and device for forming optical glass. The invention belongs to the technical field of optical glass molding. It mainly solves the problems of low optical glass molding efficiency, low yield rate, complicated molding process and large space occupation. Its main features are: it includes active rollers and passive rollers with the same diameter and fixed horizontally on the bearing support; there are installation grooves on the peripheral surfaces of the active and passive rollers, and rolling molds with different mold cavities can be installed in the grooves. ; Both the active and passive rollers are provided with an axial cavity, one end of the cavity is connected with a cold air pipe, and the other end is provided with a ventilation hole; a driving wheel B with the same diameter and the same number of teeth is installed on the fixed shaft of the active and passive rollers 1. Passive wheel B; heating and cooling guide covers for cold air pipes and gas pipes are fixed on both sides of the main and passive rollers. The invention solves the need for continuous molding of small pieces of optical glass, and can improve the molding quality through monitoring and heating and cooling devices. The rolling device is easy to disassemble and facilitates replacement and maintenance.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Horizontal barrel-shaped closed bottom-blown energy-saving glass melting furnace

The invention discloses a horizontal type bucket-shaped closed bottom blowing energy-saving glass furnace, and belongs to glass product manufacturing. The horizontal type bucket-shaped closed bottom blowing energy-saving glass furnace comprises a furnace body, a feeding inlet, a discharging outlet, an oxygen lance, a flue, a bank slope, an observation window, a molten bath and a high-temperature chamber. The horizontal type bucket-shaped closed bottom blowing energy-saving glass furnace is characterized by being formed and supported by a steel structural frame. The horizontal type bucket-shaped closed furnace body is made of lining refractory materials. The large lower part inside the furnace body is the molten bath, and the small upper part inside the furnace body is the high-temperature chamber. The oxygen lance is arranged at the bottom of one end of the furnace body. The feeding inlet is formed in the side wall of the furnace body. The end face of the other end of the furnace body is provided with the discharging outlet and the flue, and the inclined plane bank slope is arranged at the lower portion of the end of the furnace body. The observation window is arranged on the side wall of the high-temperature chamber. Compared with the prior art, the horizontal type bucket-shaped closed bottom blowing energy-saving glass furnace has the advantages of being simple in structure, balanced in stress, safe, reliable, small in size, large in capacity, high in heat efficiency, environmentally friendly, even in ingredient mixing and high in discharging quality, saving energy and the like, and therefore the horizontal type bucket-shaped closed bottom blowing energy-saving glass furnace has the good use and population value.

Owner:平湖市金兔实业有限公司

High-pollution exhaust aeration heating combustion disinfection and sterilization system and method

PendingCN111912053AReduce virus contentImprove disinfection effectDucting arrangementsMechanical apparatusVentilation tubeInsulation layer

The invention provides a high-pollution exhaust aeration heating combustion disinfection and sterilization system and method. The system comprises a polluted region negative pressure metal ventilationpipe, wherein any position of the polluted region negative pressure metal ventilation pipe is communicated with an inlet end of a high-resistance belt heat insulation layer ventilation pipeline, an outlet end of the high-resistance belt heat insulation layer ventilation pipeline is connected to an inlet end of an outdoor negative pressure metal ventilation pipe through an electric backflow prevention valve, and an outlet end of the outdoor negative pressure metal ventilation pipe is connected to an extraction opening of a high-efficiency frequency conversion fan; and multi-virus disinfectionand sterilization devices are sequentially arranged at the rear end of the high-efficiency frequency conversion fan. Air possibly containing viruses in a high-pollution building space is subjected tohigh-temperature disinfection and sterilization through an electric heating pipeline, then the air after high-temperature disinfection and sterilization is guided to the outdoor multi-virus disinfection and sterilization devices through negative pressure pipelines for diversified thorough disinfection and sterilization of the introduced air, and the viruses in the air in the high-pollution building space can be thoroughly removed.

Owner:CHINA RAILWAY CONSTR GROUP +1

Temperature control device and etching equipment

ActiveCN111146125AGuaranteed uniformityAvoid Etch Process DefectsSemiconductor/solid-state device manufacturingTemperature controlEngineering

The invention discloses a temperature control device and etching equipment. The device comprises a shell and a heating element arranged in the shell, wherein the shell is of an open structure, the shell is arranged on a top plate of the etching chamber, an opening of the shell faces the top plate, a temperature control cavity is formed between the top plate and the shell, and the heating element is used for heating gas in the temperature control cavity, so the temperature of the top plate of the etching chamber is close to the temperature of etching liquid in the etching chamber. According tothe embodiment of the invention, the gas in the cavity on the top plate of the etching chamber is heated through the heating element, so the top plate is heated, the temperature of the top plate is kept close to the temperature of the etching liquid in the etching chamber, and the volatile gas of the etching liquid is prevented from being condensed into liquid drops when meeting cold on the top plate of the etching chamber, thereby avoiding the etching process defect caused by falling of the liquid drops, guaranteeing the uniformity of an etching substrate, and increasing the yield of products.

Owner:BOE TECH GRP CO LTD +1

An alloy wire evenly distributed heat-generating cable

InactiveCN109068423ATemperature close toOhmic-resistance heating detailsHeating element shapesNickel plateElectrical conductor

The invention discloses an alloy wire uniformly distributed heat-generating cable, comprising two heating conductor cores and an outer sheath wrapped on the outer sides of the two heating conductor cores, each of the heating conductor cores comprises a wire core conductor wire and a wire core insulation sheath wrapped on the outer sides of the wire core conductor wire, uniformly distributed heat alloy wires are arranged in the outer sheath, and the uniformly distributed heat alloy wires are located on the outer sides of the wire core insulation sheath. The wire core conductor wire is a tin-plated copper stranded wire or a nickel-plated copper stranded wire; The wire core insulation sleeve is ethylene Vinyl acetate copolymer material; The outer sheath is made of perfluoroethylene-propylenecopolymer material. The invention provides an alloy wire uniformly distributes heat-generating cable. By arranging a heat-conducting alloy wire between a core insulation sleeve and an outer sheath ofthe heat-generating cable, heat at a high temperature is transferred to a position with low temperature along the length direction of the heat-generating cable through the heat-conducting alloy wire,so that the temperature at each position of the heat-generating cable can be as close as possible.

Owner:WUHU XUHUI ELECTRIC NEW MATERIAL

High-efficiency, energy-saving and environment-friendly pre-combustion burner

The invention discloses an efficient energy-saving environment-friendly pre-burning burner which is simple in structure, higher in heat burning rate of fuel and more energy-saving and environment-friendly. The efficient energy-saving environment-friendly pre-burning burner comprises a pre-burner, an igniter, an air inlet pipe and at least one fuel jetting device, wherein the air inlet pipe and the at least one fuel jetting device are communicated with the pre-burner; and the pre-burner comprises a pre-burning chamber and an air spraying chamber which are communicated, the pre-burning chamber is communicated with all fuel jetting devices and the air inlet pipe, the right end of the air spraying chamber is opened, the air spraying chamber is in a step shape, and the left end of the air spraying chamber is a large end. The ignition end of the igniter is located in the pre-burner, each fuel jetting device comprises a fuel spraying nozzle and an oil supply pipe, each fuel spraying nozzle is located on the side wall of the pre-burner, the fuel spraying nozzles are arranged in the pre-burner, and the left end of each fuel spraying nozzle is communicated with the corresponding oil supply pipe. The efficient energy-saving environment-friendly pre-burning burner further comprises an air blower, a vent pipe and an air bin, the vent pipe is communicated between the air blower and the air bin, the vent pipe is communicated between the air bin and the pre-burner, and the air bin is arranged on the outer wall of the pre-burner.

Owner:GUANGZHOU YUNENG AMPEREX TECH CO LTD

Horizontal type bucket-shaped closed bottom blowing energy-saving glass furnace

The invention discloses a horizontal type bucket-shaped closed bottom blowing energy-saving glass furnace, and belongs to glass product manufacturing. The horizontal type bucket-shaped closed bottom blowing energy-saving glass furnace comprises a furnace body, a feeding inlet, a discharging outlet, an oxygen lance, a flue, a bank slope, an observation window, a molten bath and a high-temperature chamber. The horizontal type bucket-shaped closed bottom blowing energy-saving glass furnace is characterized by being formed and supported by a steel structural frame. The horizontal type bucket-shaped closed furnace body is made of lining refractory materials. The large lower part inside the furnace body is the molten bath, and the small upper part inside the furnace body is the high-temperature chamber. The oxygen lance is arranged at the bottom of one end of the furnace body. The feeding inlet is formed in the side wall of the furnace body. The end face of the other end of the furnace body is provided with the discharging outlet and the flue, and the inclined plane bank slope is arranged at the lower portion of the end of the furnace body. The observation window is arranged on the side wall of the high-temperature chamber. Compared with the prior art, the horizontal type bucket-shaped closed bottom blowing energy-saving glass furnace has the advantages of being simple in structure, balanced in stress, safe, reliable, small in size, large in capacity, high in heat efficiency, environmentally friendly, even in ingredient mixing and high in discharging quality, saving energy and the like, and therefore the horizontal type bucket-shaped closed bottom blowing energy-saving glass furnace has the good use and population value.

Owner:平湖市金兔实业有限公司

A method for manufacture alloy wire heating cable of

A method for manufacture an alloy wire heating cable of includes such step of 1, extruding the insulating sleeve of wire core on the outer side of wire core conductor wire to obtain a heating wire core; 2, combining the two heating cores into one, and extruding a layer of alloy wire inner membrane sleeve on the outside of the two heating wire cores; 3, extruding to produce uniform heat distribution alloy wire, and laying the uniform heat distribution alloy wire on the outer side of the inner film sleeve of the alloy wire; 4, extruding a layer of alloy wire out membrane jacket on the outer sideof the alloy wire inner membrane jacket with uniformly distributed heat alloy wire; 5, extruding a layer of out sheath on that outer side of the outer film sheath of the alloy wire. The invention provides an alloy wire heating cable processing method, which can make the temperature at each position of the heating cable as close as possible.

Owner:WUHU XUHUI ELECTRIC NEW MATERIAL

Structural maintenance method and system for concrete floors

ActiveCN103726655BReduce the temperatureTemperature close toBuilding material handlingInsulation layerStructural engineering

The invention provides a structure maintenance method and system of a concrete floor. The method includes the following steps that firstly, a first temperature sensor located on a first measurement point for monitoring the internal temperature Tboard is arranged on a floorboard; a second temperature sensor, a third temperature sensor and a fourth temperature sensor located on a second measurement point, a third measurement point and a fourth measurement point respectively are arranged on different height layers of a floor beam and used for measuring the average temperature Tbeam of the floor beam; secondly, the temperature difference deltaT between the Tboard and the Tbeam is calculated, wherein deltaT=Tbeam-Tboard; thirdly, when the deltaT is larger than a preset value, a heat preserving layer is additionally arranged for the floor structure; fourthly, when the temperature difference deltaT reaches the largest value and starts to decrease, water is sprinkled onto the floor. The method and system have the advantages that due to the measurement of additionally arranging the heat preserving layer, the temperature difference between the floorboard and the floor beam is reduced, the surface of the concrete floor structure is kept moist by sprinkling water, and finally the floor is efficiently prevented from fracturing in real time.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

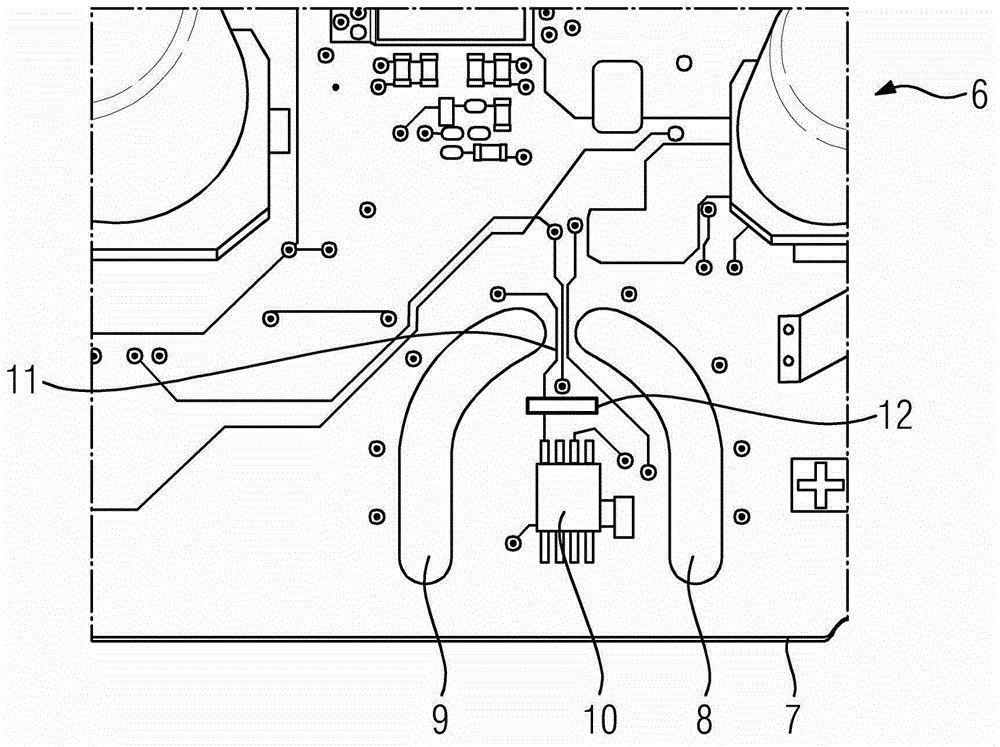

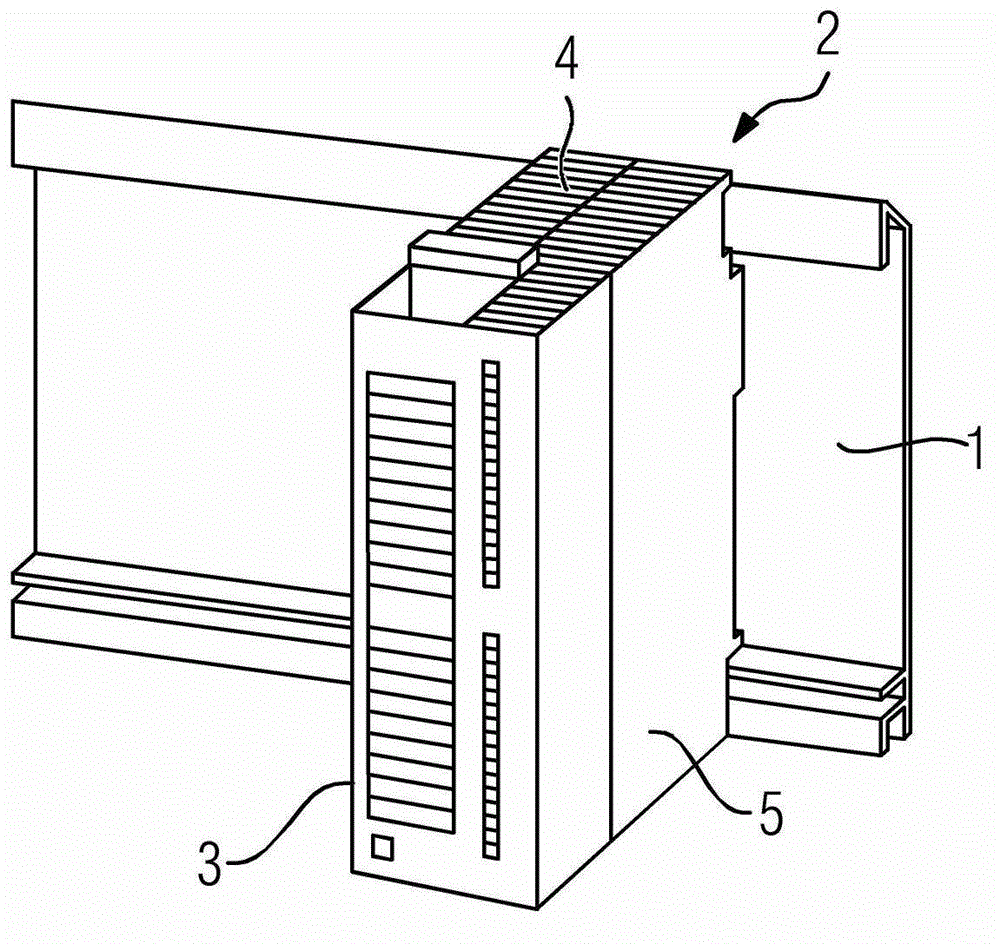

Components for modular automation

InactiveCN103313581BReduce the temperatureTemperature close toPLC for automation/industrial process controlModifications by conduction heat transferModularityEngineering

The component has a strain measurement device (SMD) circuit board (6) arranged parallel to a side wall of a housing capsule. An SMD sensor (10) enables acquisition of temperature of supply air in the housing capsule. The SMD sensor is arranged between recesses (8, 9) of the SMD circuit board and a cooling body (12), where an edge of the sensor is arranged to an air inlet aperture of the housing capsule. The SMD sensor contacts strip conductors (11) between the recesses. The cooling body increases thermal resistance of heat sources of the circuit board.

Owner:SIEMENS AG

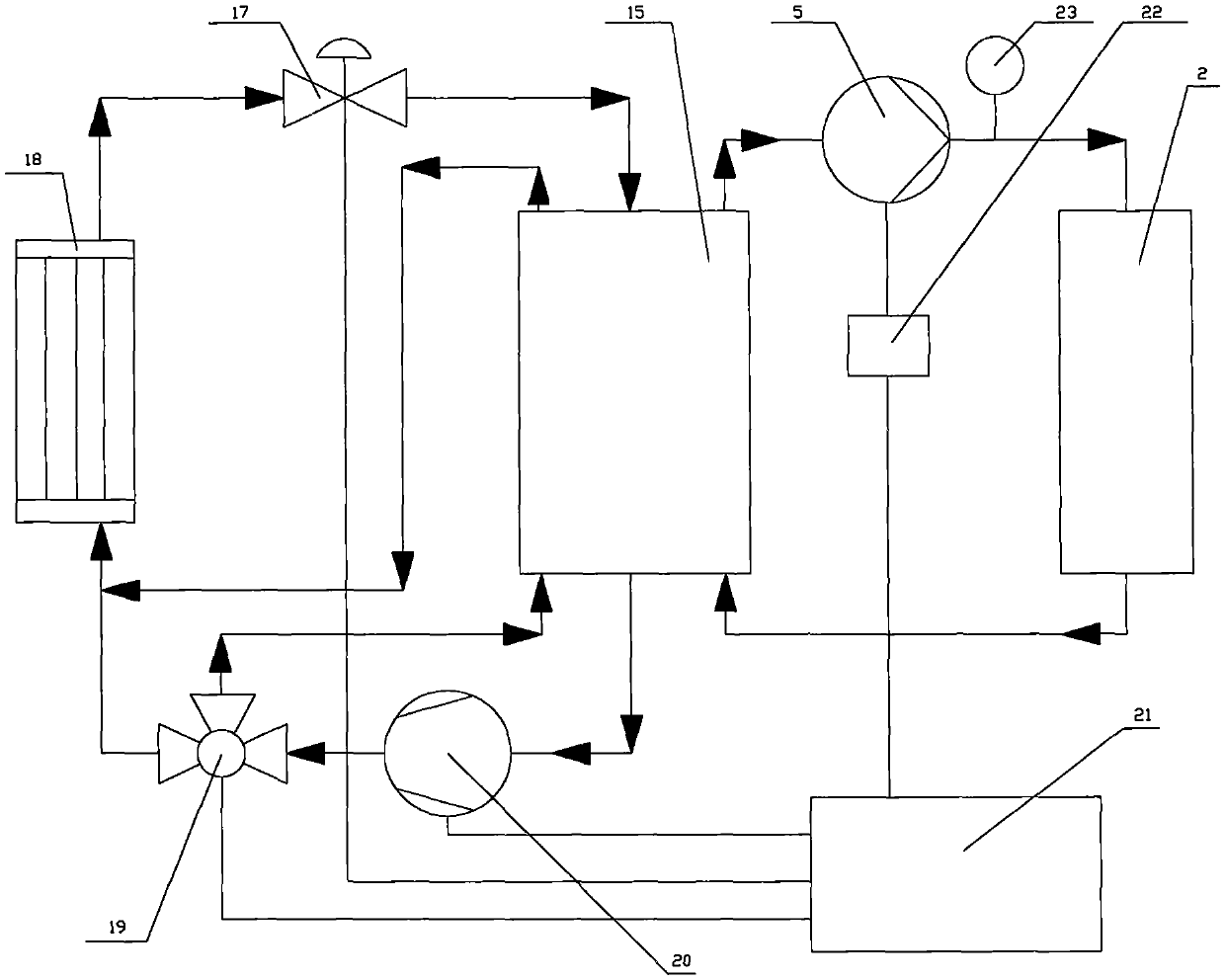

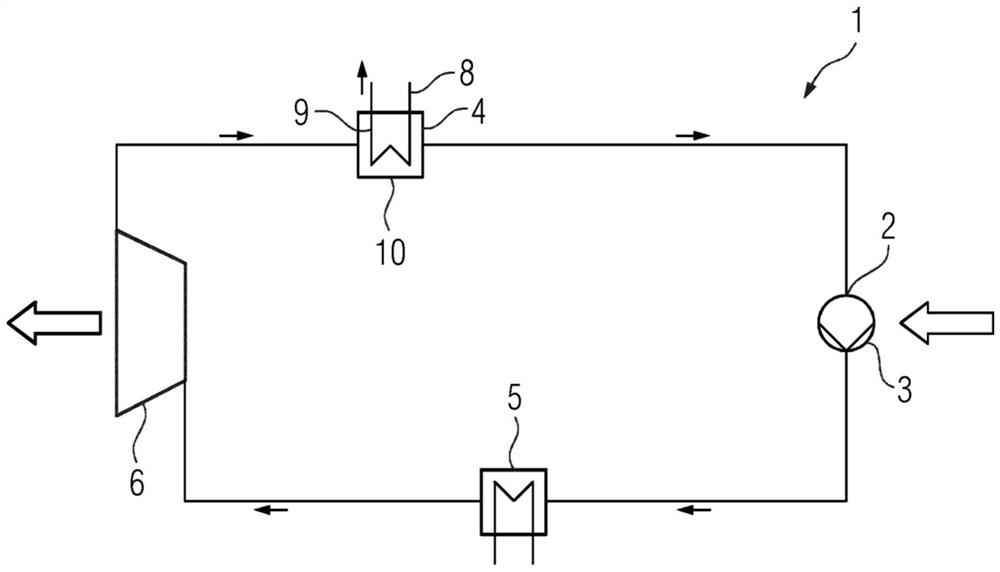

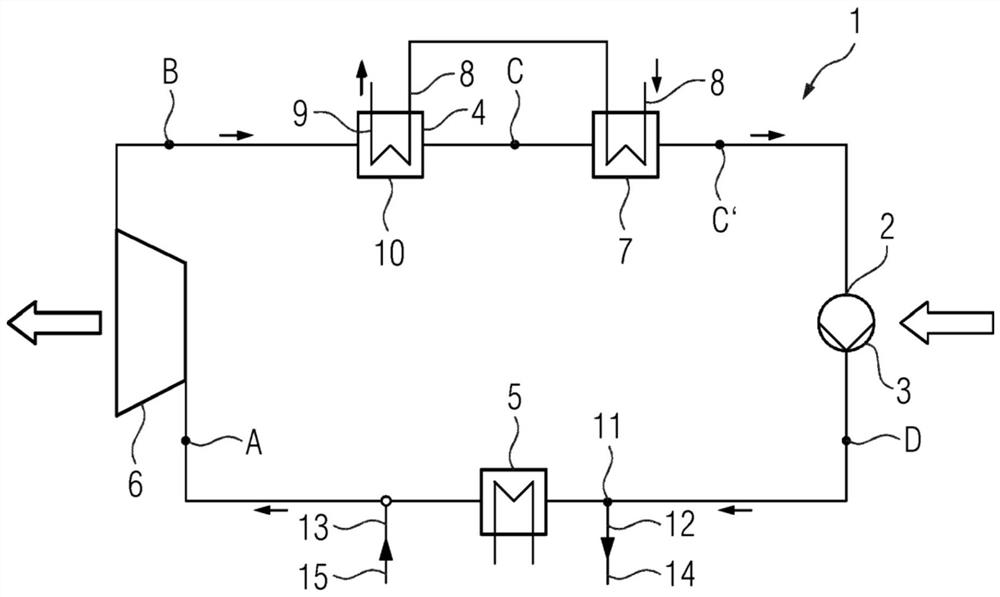

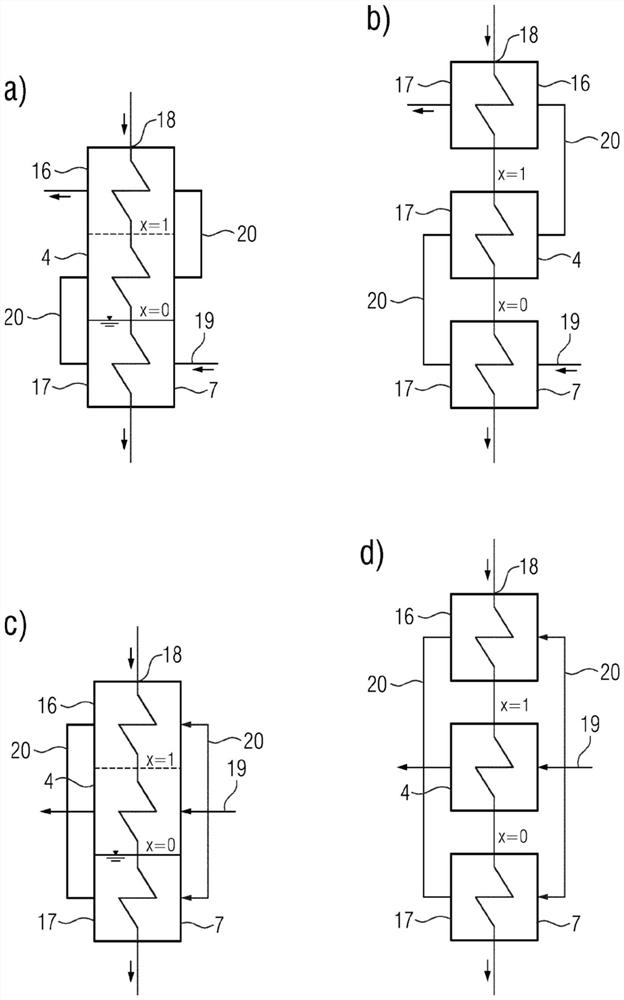

System for converting thermal energy into mechanical energy

PendingCN114127392AHigh densityLow compressibilityGeothermal energy generationSteam/vapor condensersLiquid stateMechanical energy

The invention relates to a system comprising: a pump (3) for conveying a flow medium; an assembly (5) for converting the flow medium from a liquid state to a gaseous state; a fluid machine (6) for converting thermal energy of the flow medium into mechanical energy; a condenser (4) for condensing the gaseous flow medium into a liquid state, a cooling unit (7) for cooling the liquid flow medium being arranged upstream of the pump (3) in order to reduce the compression work.

Owner:SIEMWNS ENERGY GLOBAL GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com