High-pollution exhaust aeration heating combustion disinfection and sterilization system and method

An aeration and disinfection technology, applied in the direction of heating method, ventilation system, heating and ventilation control system, etc., can solve the problems of secondary transmission, lack of disinfection methods, difficulty of new crown virus, etc., and achieve good disinfection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can implement the present invention.

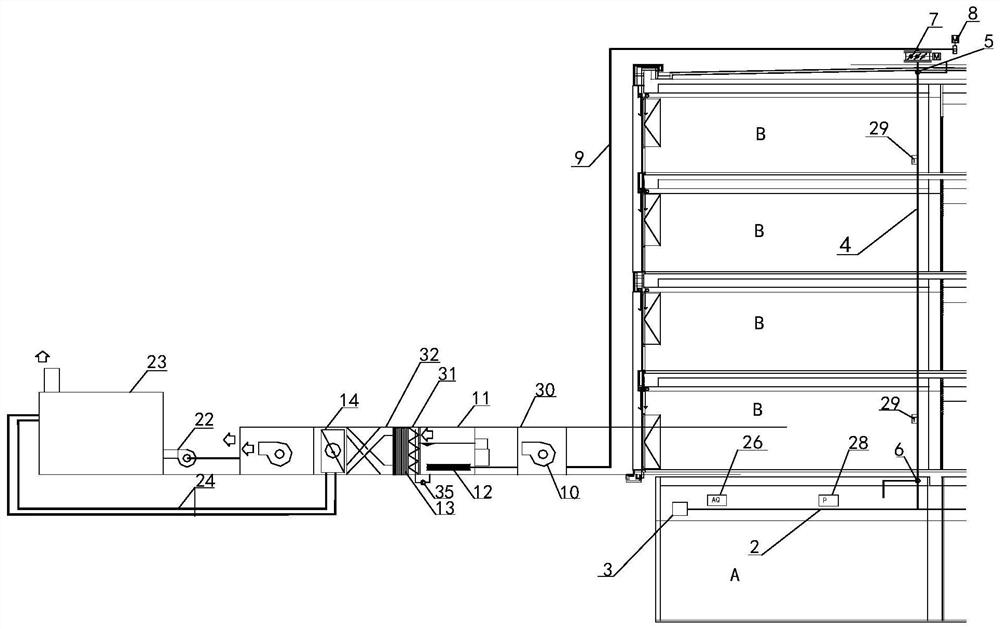

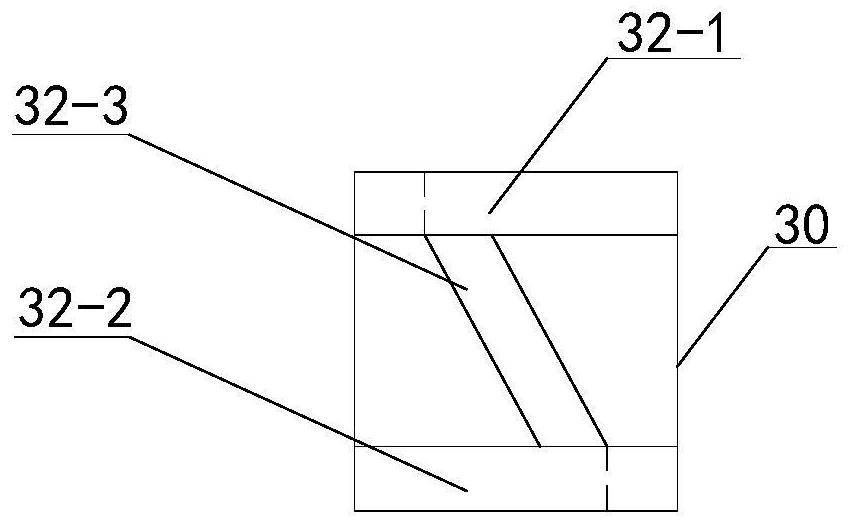

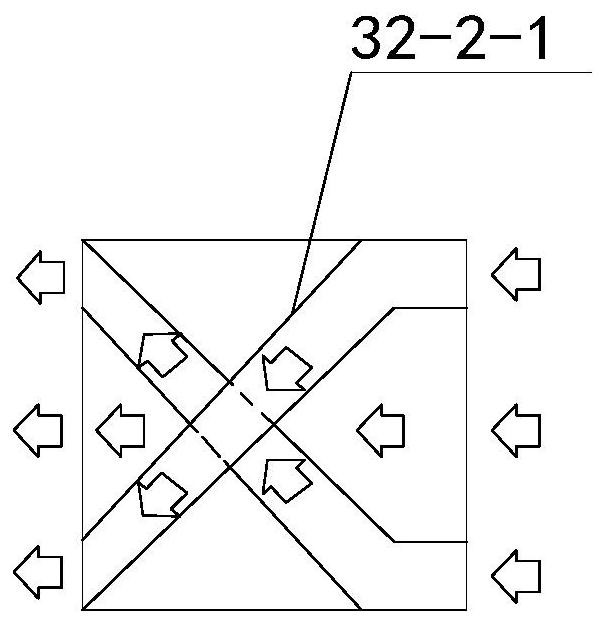

[0038] Such as figure 1 As shown, an embodiment of the high-pollution exhaust air aeration heating combustion disinfecting system of the present invention includes a negative pressure metal ventilation pipe 2 in the polluted area, at least one end of the negative pressure metal ventilation pipe 2 in the polluted area is connected with a primary effect The tuyere 3 of the filter, any position on it is connected to the inlet end of the ventilation duct 4 with a high-resistance insulation layer, and the outlet end of the ventilation duct 4 with a heat-insulation layer is connected to the outdoor negative pressure through an electric anti-backflow valve 7 The inlet end of the metal ventilation pipe 9 and the outlet end of the outdoor negative pressure metal ven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com